Page 1

General Description

The DS1875 controls and monitors all functions for burstmode transmitters, APD receivers, and video receivers.

It also includes a power-supply controller for APD bias

generation, and provides all SFF-8472 diagnostic and

monitoring functionality. The combined solution of the

DS1875 and the MAX3643 laser driver provides APC

loop, modulation current control, and eye safety functionality. Ten ADC channels monitor V

CC

, temperature

(both internal signals), and eight external monitor inputs

(MON1–MON8) that can be used to meet transmitter,

digital receiver, video receiver, and APD receiver-signal

monitoring requirements. Four total DAC outputs are

available. A PWM controller with feedback and compensation pins can be used to generate the bias for an APD

or as a step-down converter. Five I/O pins allow additional monitoring and configuration.

Applications

BPON, GPON, or EPON Optical Triplexers

SFF, SFP, and SFP+ Transceiver Modules

APD Controller

Features

♦ Meets All PON Burst-Timing Requirements for

Burst-Mode Operation

♦ Laser Bias Controlled by APC Loop and

Temperature Lookup Table (LUT)

♦ Laser Modulation Controlled by Temperature LUT

♦ Six Total DACs: Four External, Two Internal

♦ Two 8-Bit DACs, One of Which is Optionally

Controlled by MON4 Voltage

♦ Internal 8-Bit DAC Controlled by a Temperature-

Indexed LUT

♦ PWM Controller

♦ Boost or Buck Mode

♦ Boost Mode: Uses Optional External

Components, Up to 90V Bias Generation

♦ 131kHz, 262kHz, 525kHz, or 1050kHz Selectable-

Switching Frequency

♦ APD Overcurrent Protection Using Optional Fast

Shutdown

♦ 10 Analog Monitor Channels: Temperature, V

CC

,

Eight Monitors

♦ Internal, Factory-Calibrated Temperature Sensor

♦ RSSI with 29dB Electrical Dynamic

♦ Five I/O Pins for Additional Control and

Monitoring Functions, Four of Which are Either

Digital I/O or Analog Monitors

♦ Comprehensive Fault-Measurement System with

Maskable Laser Shutdown Capability

♦ Two-Level Password Access to Protect

Calibration Data

♦ 120 Bytes of Password-1 Protected Memory

♦ 128 Bytes of Password-2 Protected Memory in

Main Device Address

♦ 256 Additional Bytes Located at A0h Slave

Address

♦ I

2

C-Compatible Interface for Calibration and

Monitoring

♦ 2.85V to 3.9V Operating Voltage Range

♦ -40°C to +95°C Operating Temperature Range

♦ 38-Pin TQFN (5mm x 7mm) Package

DS1875

________________________________________________________________

Maxim Integrated Products

1

×

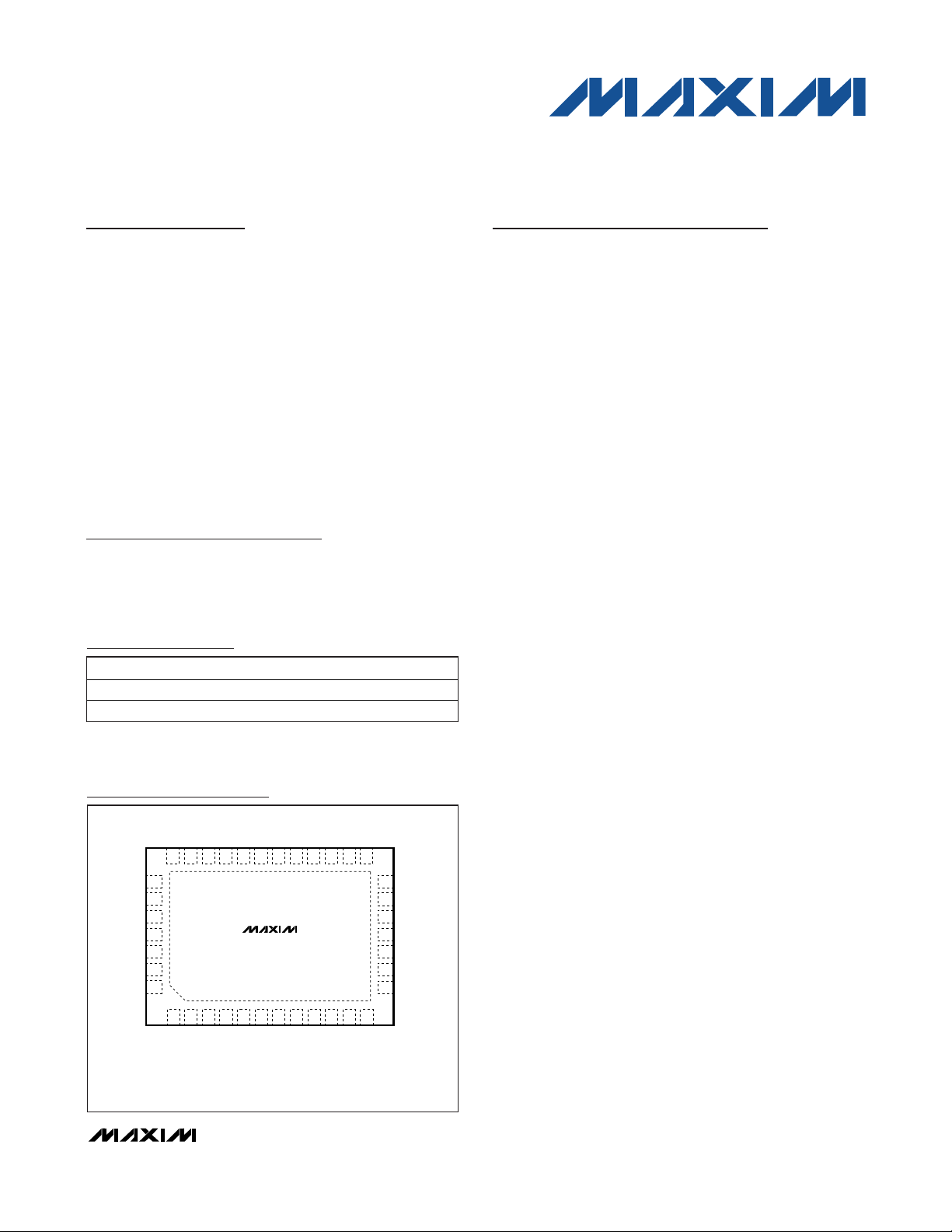

Pin Configuration

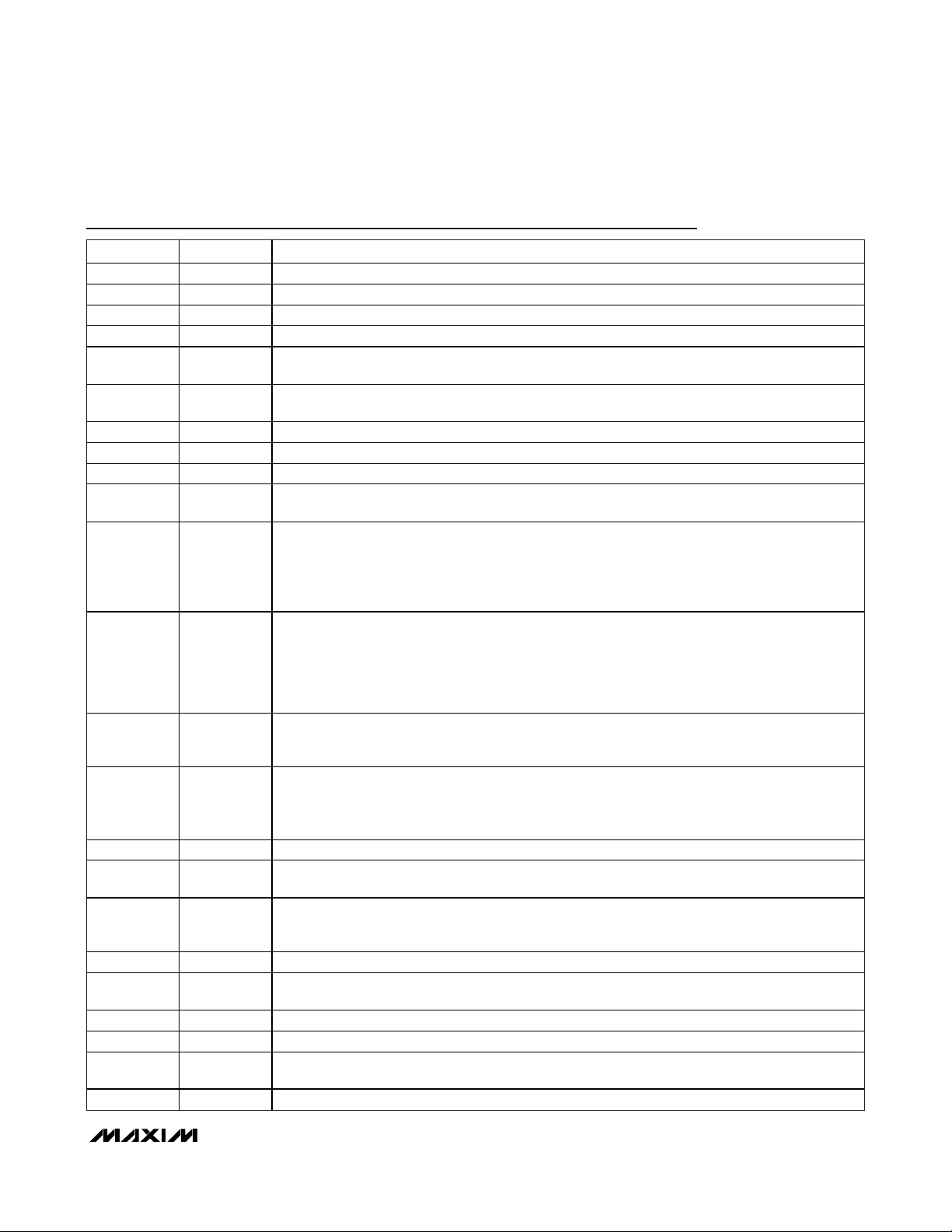

Ordering Information

Rev 1; 10/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead-free/RoHS-compliant package.

T&R = Tape and reel.

*

EP = Exposed pad.

PON Triplexer and SFP Controller

PART TEMP RANGE PIN-PACKAGE

DS1875T+ -40°C to +95°C 38 TQFN-EP*

DS1875T+T&R -40°C to +95°C 38 TQFN-EP*

TOP VIEW

GND

GND

SW

V

N.C.

N.C.

N.C.

CC

V

31 30 29 28 27 26 25 24 23 22 21 20

32

33

34

35

CC

36

37

38

+

123456789101112

BEN

*EXPOSED PAD.

BMD

SDA

MOD

COMP

SCL

TX-F

(5mm

M4DAC

FB

BIAS

DS1875

N.C.

N.C.

FETG

TQFN

7mm × 0.8mm)

GND

TX-D

DAC1

CC

V

MON3P

GND

MON3N

*EP

N.C.

N.C.

LOSI

19

18

17

16

15

14

13

MON4

MON2

MON1

MON8/D3

MON7/D2

MON6/D1

MON5/D0

Page 2

DS1875

2 _______________________________________________________________________________________

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

AC Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Characteristics (DAC1 and M4DAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Analog Input Characteristics (BMD, TXP HI, TXP LO, HBIAS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Analog Output Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PWM Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Timing Characteristics (Control Loop and Quick Trip) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Analog Voltage Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Digital Thermometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Nonvolatile Memory Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

I

2

C Timing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Typical Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Typical Operating Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Detailed Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Bias Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Autodetect Bias Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Open-Loop Bias Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Closed-Loop Bias Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

DC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Modulation Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

BIAS and MOD Output During Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

BIAS and MOD Output as a Function of Transmit Disable (TX-D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

APC and Quick-Trip Shared Comparator Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Monitors and Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Power-On Analog (POA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Quick-Trip Monitors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

MON3 Quick Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

ADC Monitors and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

ADC Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Right-Shifting ADC Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Transmit Fault (TX-F) Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Safety Shutdown (FETG) Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Determining Alarm Causes Using the I

2

C Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

TABLE OF CONTENTS

PON Triplexer and SFP Controller

Page 3

DS1875

_______________________________________________________________________________________ 3

Die Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Low-Voltage Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Enhanced RSSI Monitoring (Dual Range Functionality) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

PWM Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Inductor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Stability and Compensation Component Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

DAC1 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

M4DAC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Digital I/O Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

I

2

C Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

I2C Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

I2C Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Memory Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Shadowed EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Lower Memory Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 00h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 01h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 02h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 03h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 04h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Table 05h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Table 06h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 07h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 08h Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Auxiliary A0h Memory Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Lower Memory Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Table 00h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Table 01h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Table 02h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Table 03h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Table 04h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Table 05h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Table 06h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Table 07h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Table 08h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

TABLE OF CONTENTS (continued)

PON Triplexer and SFP Controller

Page 4

DS1875

PON Triplexer and SFP Controller

4 _______________________________________________________________________________________

Auxiliary Memory A0h Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Package Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

TABLE OF CONTENTS (continued)

Figure 1. Power-Up Timing (BEN is a Long Burst) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 2. TX-D Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 3. APC Loop and Quick-Trip Sample Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 4. M3QT Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 5. ADC Timing with EN5TO8B = 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 6. ADC Timing with EN5TO8B = 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 7. TX-F Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 8. FETG/Output Disable Timing (Fault Condition Detected) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 9. SEE Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 10. RSSI Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 11. PWM Controller Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 12. PWM Controller Typical APD Bias Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 13. PWM Controller Voltage Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 14. PWM Controller Current-Sink Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 15. I

2

C Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 16. Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Table 1. DS1875 Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table 2. Update Rate Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Table 3. ADC Default Monitor Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Table 4. TX-F as a Function of TX-D and Alarm Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Table 5. FETG, MOD, and BIAS Outputs as a Function of TX-D and Alarm Sources . . . . . . . . . . . . . . . . . . . . . . . . .22

Table 6. MON3 Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Table 7. MON3 Hysteresis Threshold Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

LIST OF FIGURES

LIST OF TABLES

Page 5

DS1875

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on MON1–MON8,

BEN, BMD, and TX-D Pins

Relative to Ground .................................-0.5V to (V

CC

+ 0.5V)*

Voltage Range on V

CC

, SDA, SCL,

D0–D3, and TX-F Pins Relative to Ground...............-0.5V to 6V

Operating Temperature Range ...........................-40°C to +95°C

Programming Temperature Range .........................0°C to +85°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature...........................Refer to the IPC/JEDEC

J-STD-020 Specification.

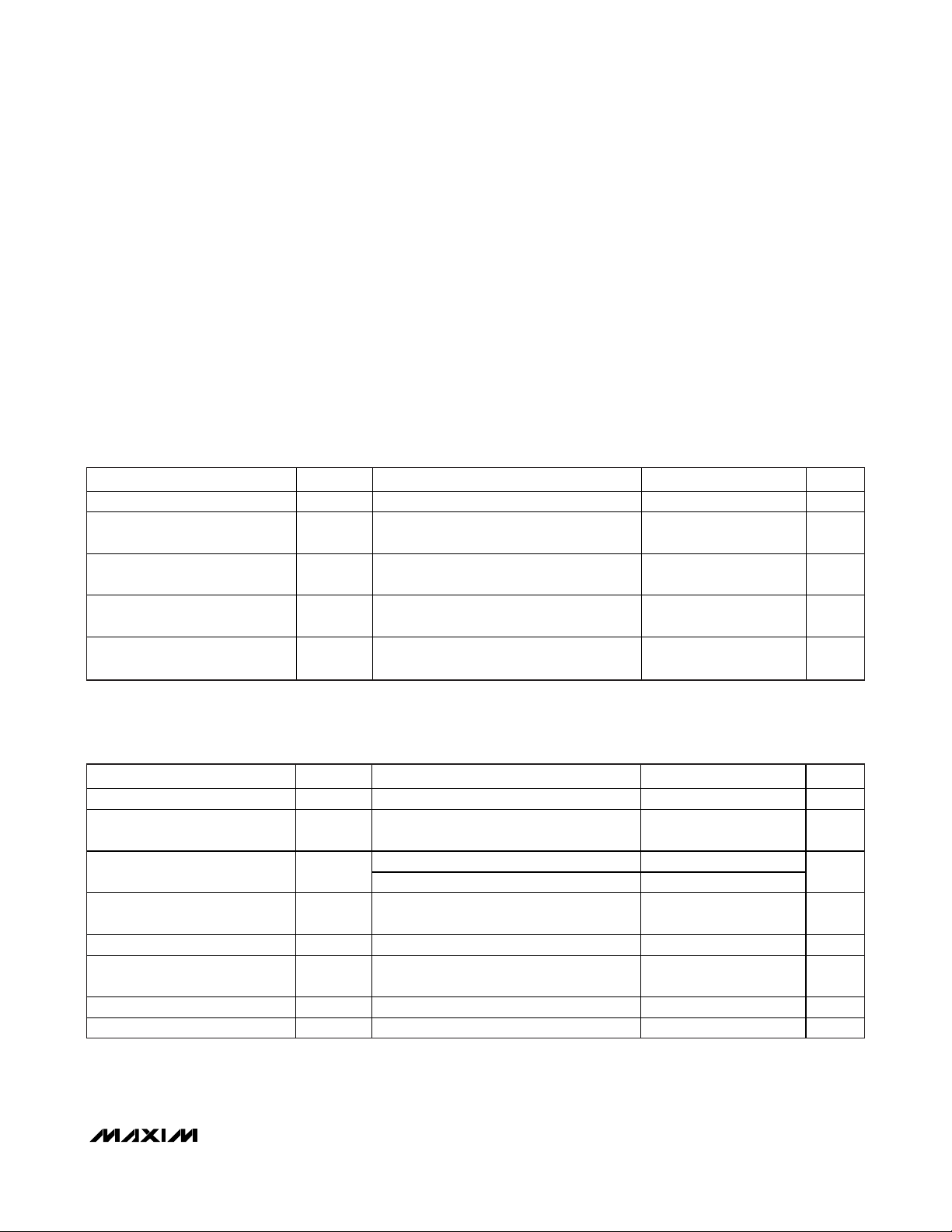

AC ELECTRICAL CHARACTERISTICS

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

*

Subject to not exceeding +6V.

RECOMMENDED OPERATING CONDITIONS

(TA= -40°C to +95°C, unless otherwise noted.)

ABSOLUTE MAXIMUM RATINGS

PON Triplexer and SFP Controller

_______________________________________________________________________________________ 5

Main Supply Voltage VCC (Note 1) +2.85 +3.9 V

High-Level Input Voltage

(SDA, SCL, BEN)

Low-Leve l Input Voltage

(SDA, SCL, BEN)

High-Level Input Voltage

(TX-D, LOSI, D0, D1, D2, D3)

Low-Leve l Input Voltage

(TX-D, LOSI, D0, D1, D2, D3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

IH:1

V

-0.3

IL:1

V

2.0

IH:2

V

-0.3 +0.8 V

IL:2

0.7 x

V

CC

V

CC

0.3

0.3 x

V

CC

V

CC

0.3

+

V

V

+

V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Current ICC (Notes 1, 2) 5.5 10 mA

Output Leakage

(SDA, TX-F, D0, D1, D2, D3)

Low-Leve l Output Voltage

(SDA, TX-F, FETG, D0, D1, D2, D3)

High-Level Output Voltage

(FETG)

FETG Before Recall (Note 3) 10 100 nA

Input Leakage Current

(SCL, BEN, TX-D, LOSI)

Digital Power-On Reset POD 1.0 2.2 V

Analog Power-On Reset POA 2.1 2.75 V

I

(Note 2) 1 μA

LO

V

V

I

OH

LI:1

IOL = 4mA 0.4

OL

IOL = 6mA 0.6

V

-

IOH = 4mA

1 μA

CC

0.4

V

V

Page 6

DS1875

PON Triplexer and SFP Controller

6 _______________________________________________________________________________________

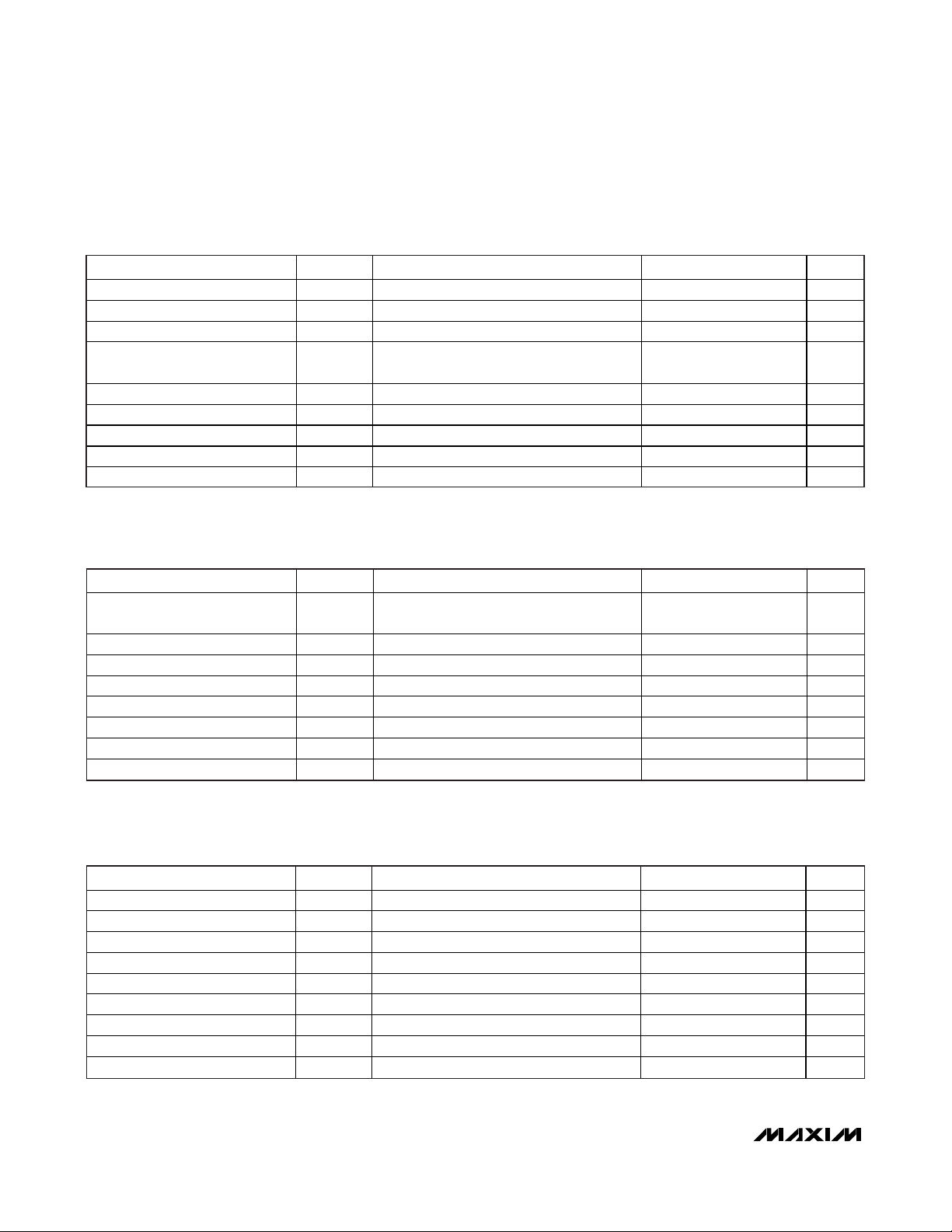

ANALOG OUTPUT CHARACTERISTICS

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

ANALOG INPUT CHARACTERISTICS (BMD, TXP HI, TXP LO, HBIAS)

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

ELECTRICAL CHARACTERISTICS (DAC1 AND M4DAC)

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

DAC Output Range 2.5 V

DAC Output Resolution 8 Bits

DAC Output Integral Nonlinearity -1 +1 LSB

DAC Output Differential

Nonlinearity

DAC Error TA = +25°C -1.25 +1.25 %FS

DAC Temperature Drift -2 +2 %FS

DAC Offset -12 +12 mV

Max imum Load -500 +500 μA

Maximum Load Capacitance 250 pF

BMD, TXP HI, TXP LO Full-Scale

Voltage

HBIAS Full-Scale Voltage (Note 5) 1.25 V

BMD Input Resistance 35 50 65 k

Resolution 8 Bits

Error TA = +25°C (Note 6) ±2 %FS

Integral Nonlinearity -1 +1 LSB

Differentia l Nonl inearit y -1 +1 LSB

Temperature Drift -2.5 +2.5 %FS

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

-1 +1 LSB

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

(Note 4) 2.5 V

V

APC

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

BIAS Current I

I

Shutdown Current I

BIAS

Voltage at I

MOD Full-Scale Voltage V

MOD Output Impedance (Note 7) 3 k

V

Error TA = +25°C (Note 8) -1.25 +1.25 %FS

MOD

V

Integral Nonlinearity -1 +1 LSB

MOD

V

Differentia l Nonl inearit y -1 +1 LSB

MOD

V

Temperature Drift -2 +2 %FS

MOD

0.7 1.2 1.4 V

BIAS

(Note 1) 1.2 mA

BIAS

BIAS:OFF

10 100 nA

(Note 5) 1.25 V

MOD

Page 7

DS1875

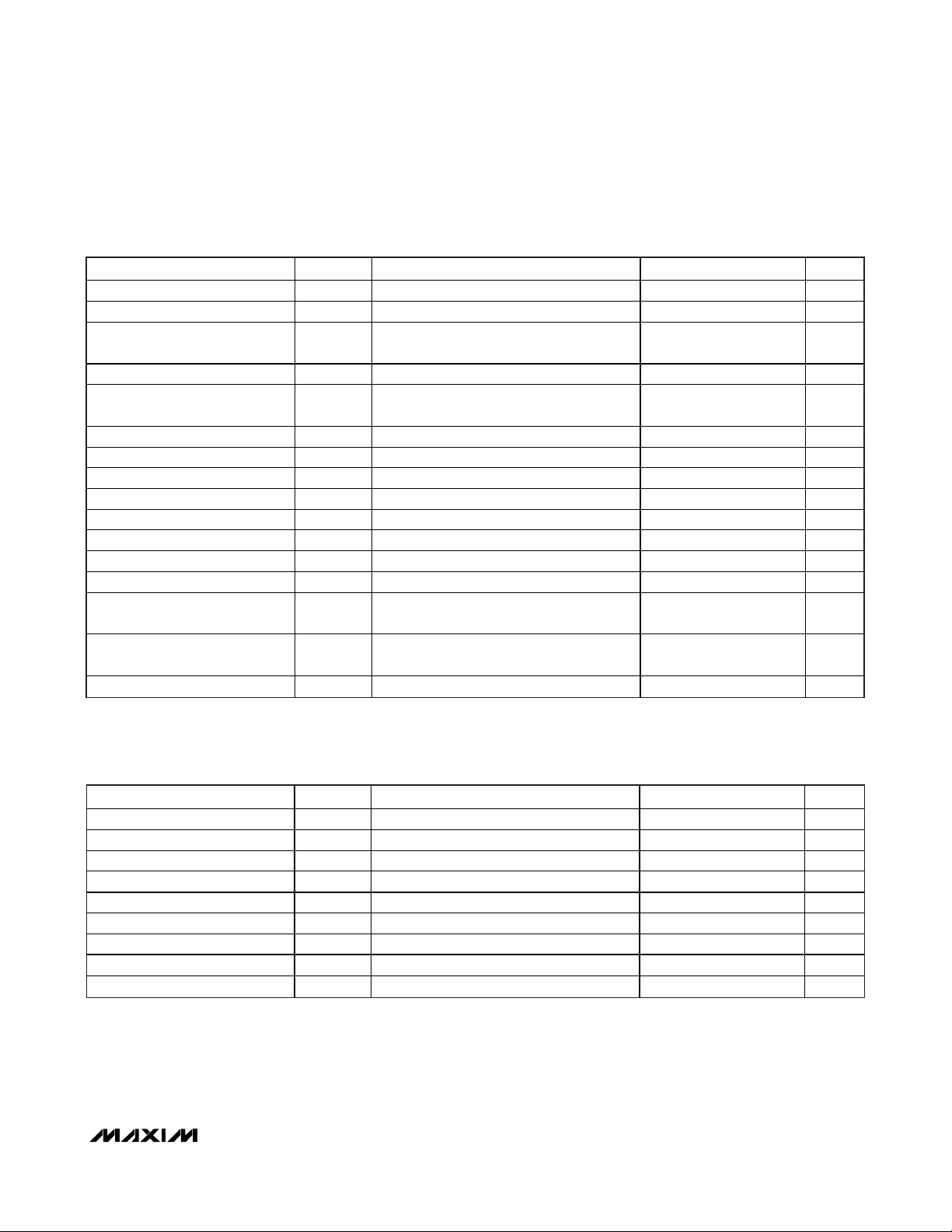

TIMING CHARACTERISTICS (CONTROL LOOP AND QUICK TRIP)

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

PWM CHARACTERISTICS

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

PON Triplexer and SFP Controller

_______________________________________________________________________________________ 7

PWM-DAC Full-Scale Voltage V

PWM-DAC Resolution 8 Bit s

V

PWM-DAC

Error

V

PWM-DAC

V

PWM-DAC

Nonlinearity

V

PWM-DAC

SW Output Impedance 20

SW Frequency Error f

SW Dut y C ycle D

Error-Amplifier Source Current -10 μA

Error-Amplifier Sink Current +10 μA

COMP High-Voltage Clamp 2.1 V

COMP Low-Voltage Clamp 0.8 V

Error-Amplifier

Transconductance

Error-Amplifier Output

Impedance

FB Pin Capacitance 5 pF

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

PWM-DAC

Full-Scale Voltage

Integral Nonlinearity -1 1 LSB

Differential

Temperature Drift -2 +2 %FS

1.25 V

T

-1 1 LSB

SWER

MAX

G

M

260 M

R

EA

= +25°C 1.25 %

A

(Note 9) -5 +7 %

89 90 91 %

425 μS

First BMD Sample Following BEN t

Remaining Updates During BEN t

BEN High Time t

BEN Low Time t

Output-Enable Time Following POA t

BIAS and MOD Turn-Off Delay t

BIAS and MOD Turn-On Delay tON 5 μs

FETG Turn-On Delay t

FETG Turn-Off Delay t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

(Note 10)

FIRST

(Note 10)

UPDATE

BEN:HIGH

BEN:LOW

FETG:ON

FETG:OFF

400 ns

96 ns

10 ms

INIT

5 μs

OFF

5 μs

5 μs

Page 8

DS1875

PON Triplexer and SFP Controller

8 _______________________________________________________________________________________

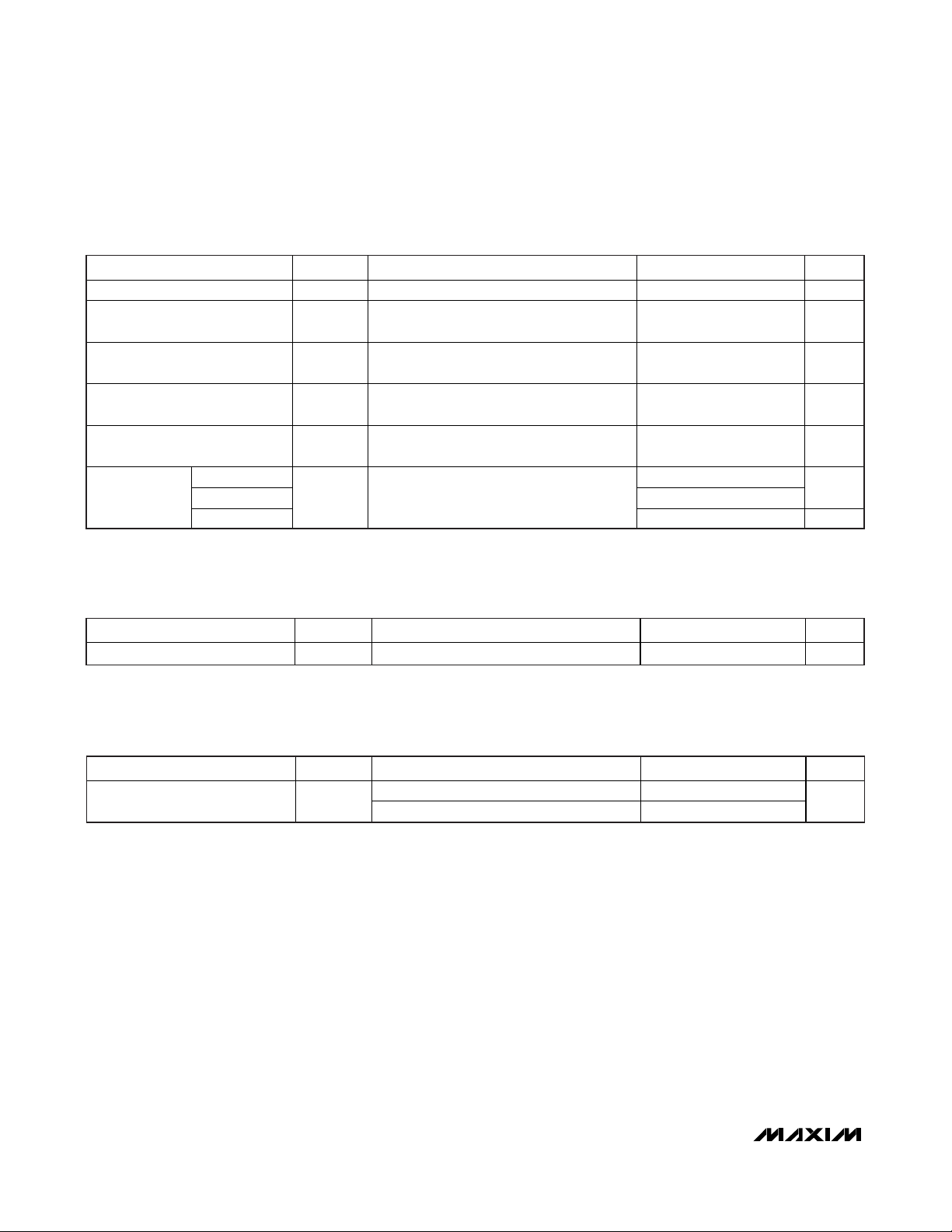

NONVOLATILE MEMORY CHARACTERISTICS

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

DIGITAL THERMOMETER

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

ANALOG VOLTAGE MONITORING

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ADC Re solution 13 Bits

Input/Supply Accuracy

(MON1–MON8, V

Update Rate for Temp,

MON1–MON4, and V

Update Rate for MON5–MON8 t

Input/Supply Offset

(MON1–MON8, V

Factor y Setting

)

CC

CC

)

CC

MON1–MON8 2.5

V

CC

MON3 Fine

Thermometer Error T

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ACC At factory sett ing 0.25 0.50 %FS

t

FRAME:1

FRAME:2

78 95 ms

Bit EN5TO8B is enabled in Table 02h,

Regi ster 89h

V

(Note 11) 0 5 LSB

OS

Ful l sca le s are user programmable

-40°C to +95°C ±3.0 °C

ERR

156 190 ms

6.5536

312.5 μV

V

EEPROM Write Cycles

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

At +85°C (Note 11) 50,000

At +25°C (Note 11) 200,000

Page 9

DS1875

Note 1: All voltages are referenced to ground. Current into IC is positive, and current out of the IC is negative.

Note 2: Digital inputs are at rail. FETG is disconnected. SDA = SCL = V

CC

. SW, DAC1, and M4DAC are not loaded.

Note 3: See the

Safety Shutdown (FETG) Output

section for details.

Note 4: Eight ranges allow the full scale to change from 625mV to 2.5V.

Note 5: Eight ranges allow the full scale to change from 312.5mV to 1.25V.

Note 6: This specification applies to the expected full-scale value for the selected range. See the COMP RANGING register

description for available full-scale ranges.

Note 7: The output impedance of the DS1875 is proportional to its scale setting. For instance, if using the 1/2 scale, the output

impedance would be approximately 1.56kΩ.

Note 8: This specification applies to the expected full-scale value for the selected range. See the MOD RANGING register

description for available full-scale ranges.

Note 9: The switching frequency is selectable between four values: 131.25kHz, 262.5kHz, 525kHz, and 1050kHz.

Note 10: See the

APC and Quick-Trip Shared Comparator Timing

section for details.

Note 11: Guaranteed by design.

Note 12: I

2

C interface timing shown is for fast-mode (400kHz) operation. This device is also backward compatible with I2C stan-

dard mode.

Note 13: C

B

—Total capacitance of one bus line in pF.

Note 14: EEPROM write begins after a STOP condition occurs.

I2C TIMING SPECIFICATIONS

(VCC= +2.85V to +3.9V, TA= -40°C to +95°C, timing referenced to V

IL(MAX)

and V

IH(MIN)

.) (See Figure 15.)

PON Triplexer and SFP Controller

_______________________________________________________________________________________ 9

SCL Clock Frequency f

Cloc k Pulse-Width Low t

Cloc k Pulse-Width High t

Bus-Free Time Between STOP

and START Condition

START Hold Time t

START Setup Time t

Data in Hold Time t

Data in Setup Time t

Capacitive Load for Each Bus Line CB 400 pF

Rise Time of Both SDA and SCL

Signals

Fal l Time of Both SDA and SCL

Signals

STOP Setup Time t

EEPROM Write Time tW (Note 14) 20 ms

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

(Note 12) 0 400 kH z

SCL

1.3 μs

LOW

0.6 μs

HIGH

t

1.3 μs

BUF

0.6 μs

HD: STA

0.6 μs

SU:STA

0 0.9 μs

HD:DAT

100 ns

SU:DAT

t

(Note 13)

R

t

(Note 13)

F

0.6 μs

SU:STO

20 +

0.1C

20 +

0.1C

300 ns

B

300 ns

B

Page 10

DS1875

PON Triplexer and SFP Controller

10 ______________________________________________________________________________________

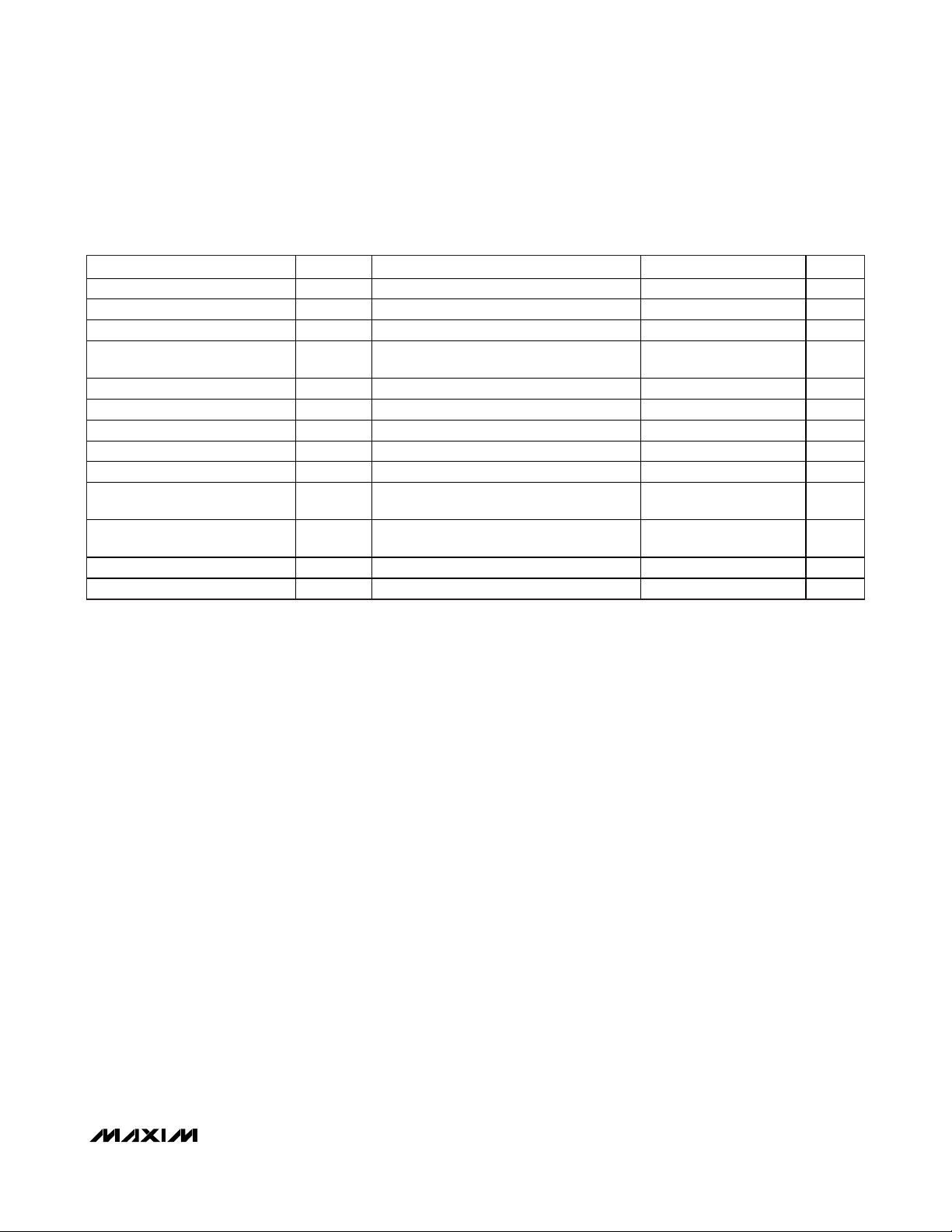

Typical Operating Characteristics

(VCC= +2.85V to +3.9V, TA= +25°C, unless otherwise noted.)

9.0

SDA = SCL = V

8.5

8.0

7.5

7.0

6.5

6.0

SUPPLY CURRENT (mA)

5.5

5.0

4.5

2.85

SUPPLY CURRENT vs. TEMPERATURE

V

CC

SW = 525kHz

SW = 262.5kHz

-40

(mA)

CC

I

8.8

8.6

8.4

8.2

8.0

7.8

7.6

7.4

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

CC

+95°C

+25°C

-40°C

VCC (V)

= 5V, NO BIAS CURRENT

SW = 1050kHz

SW = 131.25kHz

TEMPERATURE (°C)

SUPPLY CURRENT

vs. TEMPERATURE

9.0

SDA = SCL = V

DS1875 toc01

3.853.35

8.5

8.0

7.5

7.0

6.5

6.0

SUPPLY CURRENT (mA)

5.5

5.0

4.5

-40

CC

VCC = 3.9V

VCC = 2.85V

TEMPERATURE (°C)

DS1875 toc02

806020 400-20

DAC1 AND M4DAC DNL

1.0

DS1875 toc04

806040200-20

0.8

0.6

0.4

0.2

0

-0.2

-0.4

DAC1 AND M4DAC DNL (LSB)

-0.6

-0.8

-1.0

0

DAC1 AND M4DAC POSITION (DEC)

DS1875 toc05

25020015010050

SUPPLY CURRENT vs. TEMPERATURE

V

= 3.3V, NO BIAS CURRENT

CC

SW = 1050kHz

SW = 525kHz

SW = 262.5kHz

SW = 131.25kHz

-40

TEMPERATURE (°C)

(mA)

CC

I

7.4

7.3

7.2

7.1

7.0

6.9

6.8

6.7

6.6

6.5

6.4

DAC1 AND M4DAC INL

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

DAC1 AND M4DAC INL (LSB)

-0.6

-0.8

-1.0

0

DAC1 AND M4DAC POSITION (DEC)

DS1875 toc03

806020 400-20

DS1875 toc06

25020015010050

DAC1 AND M4DAC OFFSET vs. V

0.05

TA = -40°C TO +95°C

0.04

LOAD = -0.5mA TO +0.5mA

0.03

0.02

0.01

0

-0.01

-0.02

DAC1 AND M4DAC OFFSET (mV)

-0.03

-0.04

-0.05

2.85

VCC (V)

DAC1 AND M4DAC OFFSET VARIATION

CC

3.853.653.453.253.05

0.0010

0.0008

DS1875 toc07

0.0006

0.0004

0.0002

0

-0.0002

-0.0004

DAC1 AND M4DAC OFFSET (mV)

-0.0006

-0.0008

-0.0010

-0.5 0.5

vs. LOAD CURRENT

VCC = 2.85V

VCC = 3.6V

VCC = 3.9V

LOAD CURRENT (mA)

1.259

DS1875 toc08

1.257

1.255

1.253

1.251

1.249

DAC1 AND M4DAC OUTPUT (V)

1.247

0.30.1-0.1-0.3

1.245

DAC1 AND M4DAC OUTPUT

vs. LOAD CURRENT

OUTPUT WITHOUT OFFSET

VCC = 2.85V

VCC = 3.9V

-0.5 0.5

LOAD CURRENT (mA)

DS1875 toc09

0.30.1-0.3 -0.1

Page 11

DS1875

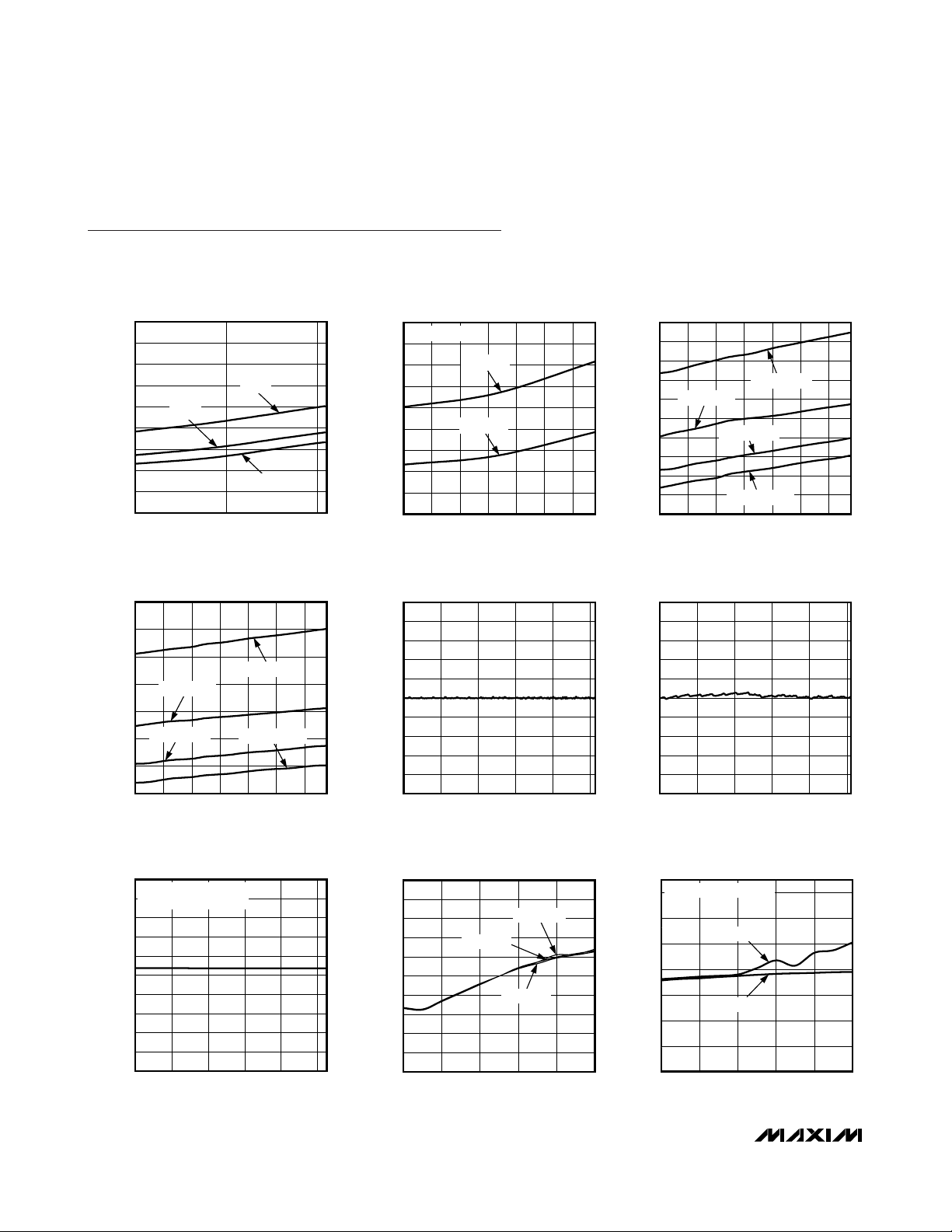

Typical Operating Characteristics (continued)

(VCC= +2.85V to +3.9V, TA= +25°C, unless otherwise noted.)

CALCULATED AND DESIRED % CHANGE

IN V

MOD

vs. MOD RANGING

DS1875 toc10

MOD RANGING VALUE (DEC)

CHANGE IN V

MOD

(%)

007006004 005002 003001

10

20

30

40

50

60

70

80

90

100

0

000

CALCULATED

VALUE

DESIRED

VALUE

DESIRED AND CALCULATED CHANGE

IN V

BMD

vs. COMP RANGING

DS1875 toc11

COMP RANGING (DEC)

CHANGE IN V

BMD

(%)

111110100 101010 011001

10

20

30

40

50

60

70

80

90

100

0

000

CALCULATED

VALUE

DESIRED

VALUE

MON1 TO MON8 INL

DS1875 toc12

MON1 TO MON8 INPUT VOLTAGE (V)

MON1 TO MON8 INL (LSB)

2.01.51.00.5

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0 2.5

USING FACTORY-PROGRAMMED

FULL-SCALE VALUE OF 2.5V

MON1 TO MON8 DNL

DS1875 toc13

MON1 TO MON8 INPUT VOLTAGE (V)

MON1 TO MON8 DNL (LSB)

2.01.51.00.5

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0 2.5

USING FACTORY-PROGRAMMED

FULL-SCALE VALUE OF 2.5V

V

BMD

INL vs. APC INDEX

DS1875 toc14

APC INDEX (DEC)

V

BMD

INL (LSB)

25020015010050

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0

V

MOD

INL vs. MOD INDEX

DS1875 toc15

MOD INDEX (DEC)

V

MOD

INL (LSB)

25020015010050

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0

FB VOLTAGE vs. TEMPERATURE

PWM DAC = FFh

DS1875 toc16

TEMPERATURE (°C)

V

OUT

(V)

806040200-20

1.245

1.250

1.255

1.260

1.240

-40

V

OUT

vs. V

CC

VIN = 3.3V

DS1875 toc17

VCC (V)

V

OUT

(V)

3.853.35

75.2

75.4

75.6

75.8

76.0

76.2

76.4

76.6

76.8

77.0

75.0

2.85

DUTY-CYCLE LIMIT vs. TEMPERATURE

DS1875 toc18

TEMPERATURE (°C)

V

OUT

(V)

8060-20 0 20 40

89.25

89.50

89.75

90.00

90.25

90.50

90.75

91.00

89.00

-40

SW FREQUENCY

525kHz

262.5kHz

131.25kHZ

1050kHz

PON Triplexer and SFP Controller

______________________________________________________________________________________

11

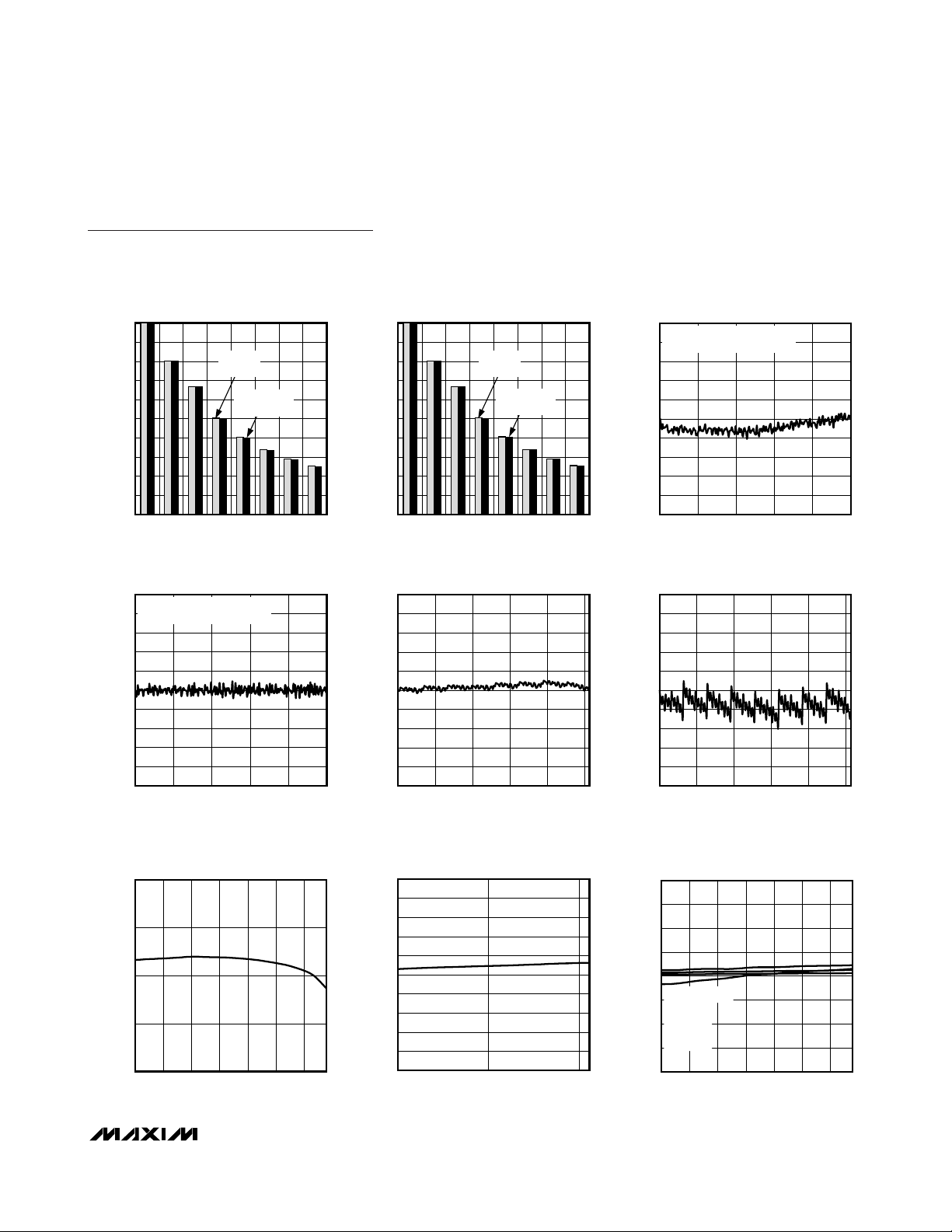

Page 12

DS1875

PON Triplexer and SFP Controller

12 ______________________________________________________________________________________

μ

Typical Operating Characteristics (continued)

(VCC= +2.85V to +3.9V, TA= +25°C, unless otherwise noted.)

1.00

0.75

0.50

0.25

0

DAC DNL (LSB)

-0.25

-0.50

-0.75

-1.00

0 256

PWM DAC DNL

DAC SETTING (DEC)

1.00

0.75

0.50

0.25

0

DAC INL (LSB)

-0.25

-0.50

-0.75

-1.00

0 256

PWM DAC CHANGING FROM 00h TO 80h

20V/div

0V

200mV/div

0V

200mV/div

0V

R

COMP

V

FB

COMP

22419232 64 96 128 160

M3QT DAC INL

DAC SETTING (dec)

= 24.3kΩ, C

OUT

DUTY CYCLE

DS1875 toc19

5ms/div

1.00

PWM DAC INL

0.75

0.50

0.25

0

DAC INL (LSB)

-0.25

-0.50

-0.75

-1.00

0 256

DAC SETTING (DEC)

DS1875 toc22

22419232 64 96 128 160

= 220nF

COMP

DS1875 toc24

10%/div

0%

1V/div

10mA/div

0mA

5V/div

50V/div

100mA/div

0mA

100mV/div

1.00

0.75

DS1875 toc20

0.50

0.25

0

DAC DNL (LSB)

-0.25

-0.50

-0.75

-1.00

22419232 64 96 128 160

0 256

DAC SETTING (DEC)

SW CURRENT INTO BSS123 FET

M3QT DAC DNL

FREQUENCY = 1050kHz 50% DUTY CYCLE

SW

0V

SW

CURRENT

100ns/div

DS1875 toc23

SWITCHING WAVEFORMS

V

0V

0V

0V

= 3.3V, V

IN

V

OUT

RIPPLE (AC-COUPLED)

OUT

C2 = 0.1

INDUCTOR

VOLTAGE

INDUCTOR

CURRENT

~ 90V, I

2μs/div

OUT

F

~ 1.25mA,

DS1875 toc25

SW

DS1875 toc21

22419232 64 96 128 160

Page 13

DS1875

PON Triplexer and SFP Controller

______________________________________________________________________________________ 13

Pin Description

PIN NAME FUNCTION

1 BEN Burst-Enable Input. Triggers the samp les for the APC and quick-trip monitors.

2 SDA I2C Serial-Data Input/Output

3 SCL I2C Serial-Clock Input

4 TX-F Transm it-Fault Output

5, 7, 11, 20,

36, 37, 38

6 FETG

8 TX-D Transmit-Disable Input. Disables analog outputs.

9, 31, 35 VCC Power-Supply Input (2.85V to 3.9V)

10, 24, 32, 33 GND Ground Connection

12 LOSI

13 MON5/D0

14, 15, 16

17, 18, 19

21, 22

23 DAC1 8-Bit DAC Output. Driven either by I2C interface or temperature-indexed LUT.

25 M4DAC

26 FB

27 BIAS Bias-Current Output. This 13-bit current output generates the bias current reference for the MAX3643.

28 MOD

29 COMP Compensation for Error Amplifier in PWM Controller

30 BMD Back Mon itor Diode Input (Feedback Voltage, Transmit Power Mon itor)

34 SW

— EP Exposed Pad

N.C. No Connection

FET Gate Output. Signals an external n-channel or p-channel MOSFET to enable/disable the

laser’s current.

Loss-of-Signal Input. Open-collector buffer for external loss-of-signal input. This input is

accessible in the statu s regi ster through the I

External Monitor Input 5 or Digita l I/O 0. This signal i s the open-collector output driver for IN. It

can also be control led by the MUX0 and OUT0 bit s. The voltage level of this pin can be read at

IN0. In analog input mode, the voltage at this pin is digitized by the internal 13-bit analog-todigital converter and can be read through the I

assigned to interrupt the processor based on the ADC result.

External Monitor Inputs 6, 7, and 8 or Digital I/O 1, 2, and 3. In digital mode, these open-collector

MON6/D1,

MON7/D2,

MON8/D3

MON1,

MON2,

MON4

MON3N,

MON3P

outputs are controlled by the OUTx bits, and their voltage level s can be read at the INx bits. In

analog input mode, the voltages at these pins are digitized by the internal 13-bit analog-to-digital

converter and can be read through the I

to interrupt the processor based on the ADC result. D2 i s configurable a s a quick-trip output for

MON3.

External Monitor Input 1, 2, and 4. The voltage at these pins is digitized by the internal 13-bit

analog-to-digital converter and can be read through the I

can be ass igned to interrupt the processor based on the ADC result.

External Monitor Input 3. This is a differentia l input that is digitized by the internal 13-bit ADC

and can be read through the I

the processor based on the ADC result. When used as a s ingle-ended input, connect MON3N to

ground.

8-Bit DAC Output for Generating Analog Voltage. Can be controlled by a LUT indexed by the

voltage applied to MON4.

Converter Feedback. Input to error amplifier. The other input to the error amplifier is an 8-bit DAC.

The DAC can be driven by a temperature-indexed LUT. The output of the error amplifier is the

input of the comparator used to create the PWM signal.

Modulation Output Voltage. This 8-bit vo ltage output has eight full-scale ranges from 1.25V to

0.3125V. This pin is connected to the MAX3643’s VMSET input to control the modulation current.

PWM Output. This is typically the switching node of a PWM converter. In conjunction with FB, a

boost converter, buck converter, or analog 8-bit output can be created.

2

C interface.

2

C interface. Alarm and warning values can be

2

C interface. Alarm and warning values can be assigned

2

C interface. Alarm and warning values

2

C interface. Alarm and warning values can be assigned to interrupt

Page 14

DS1875

PON Triplexer and SFP Controller

14 ______________________________________________________________________________________

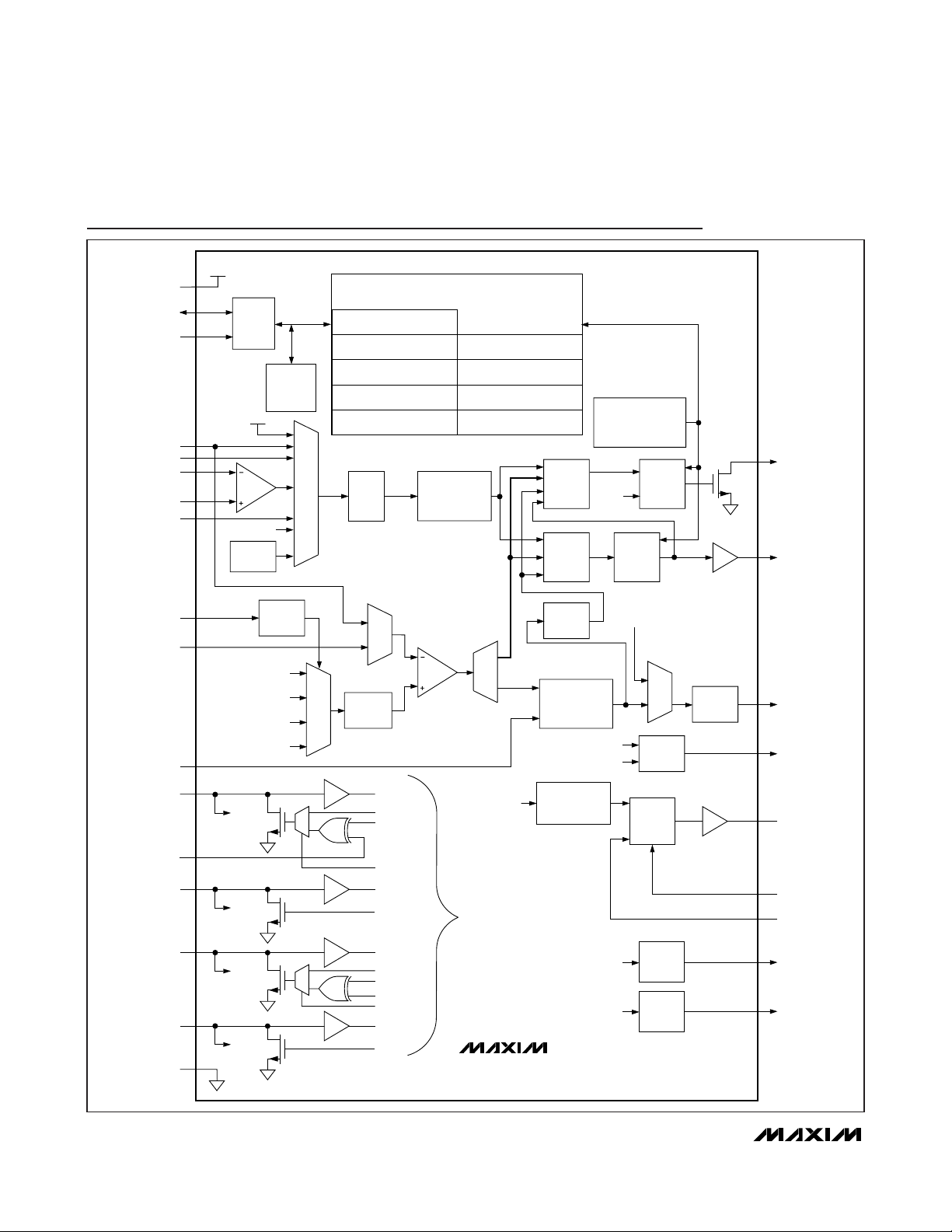

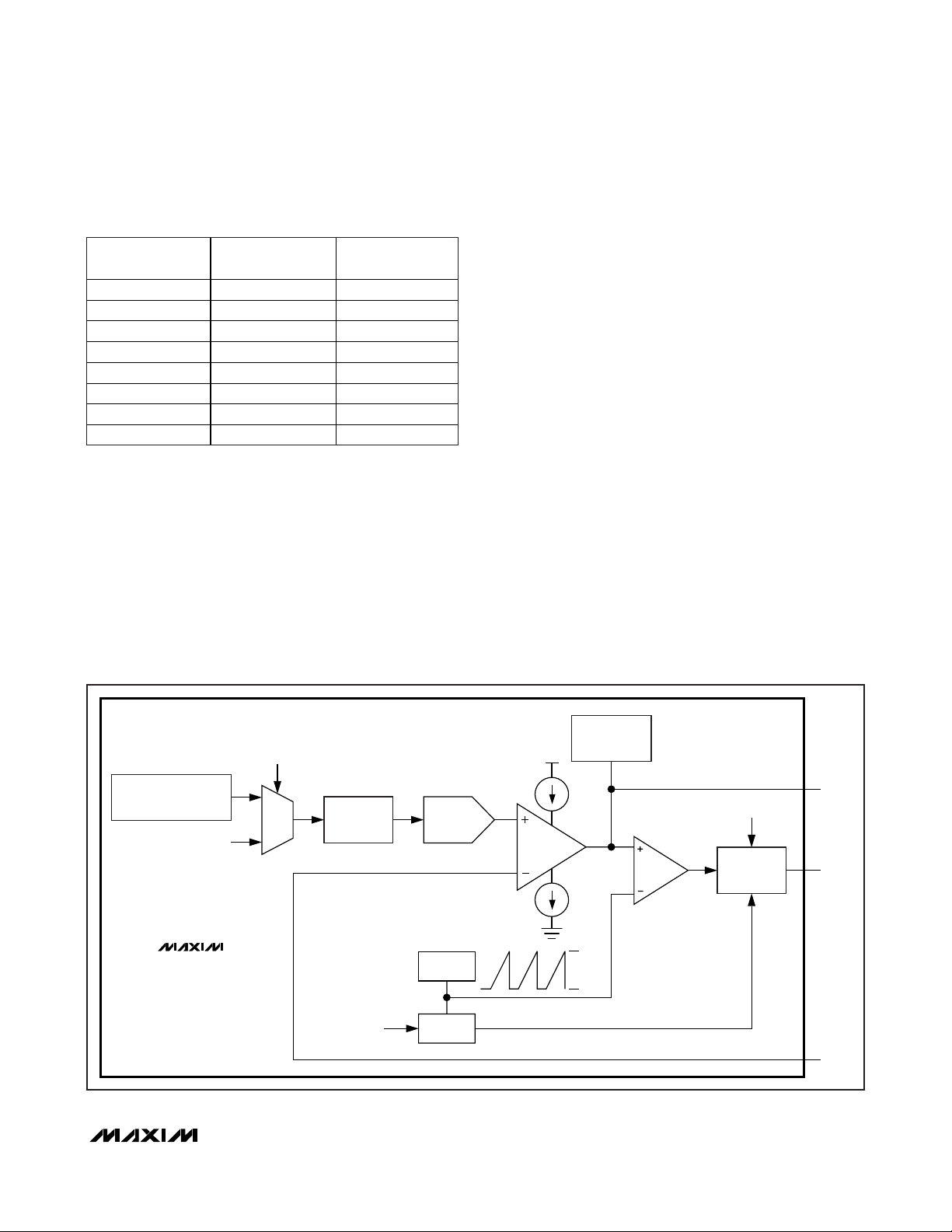

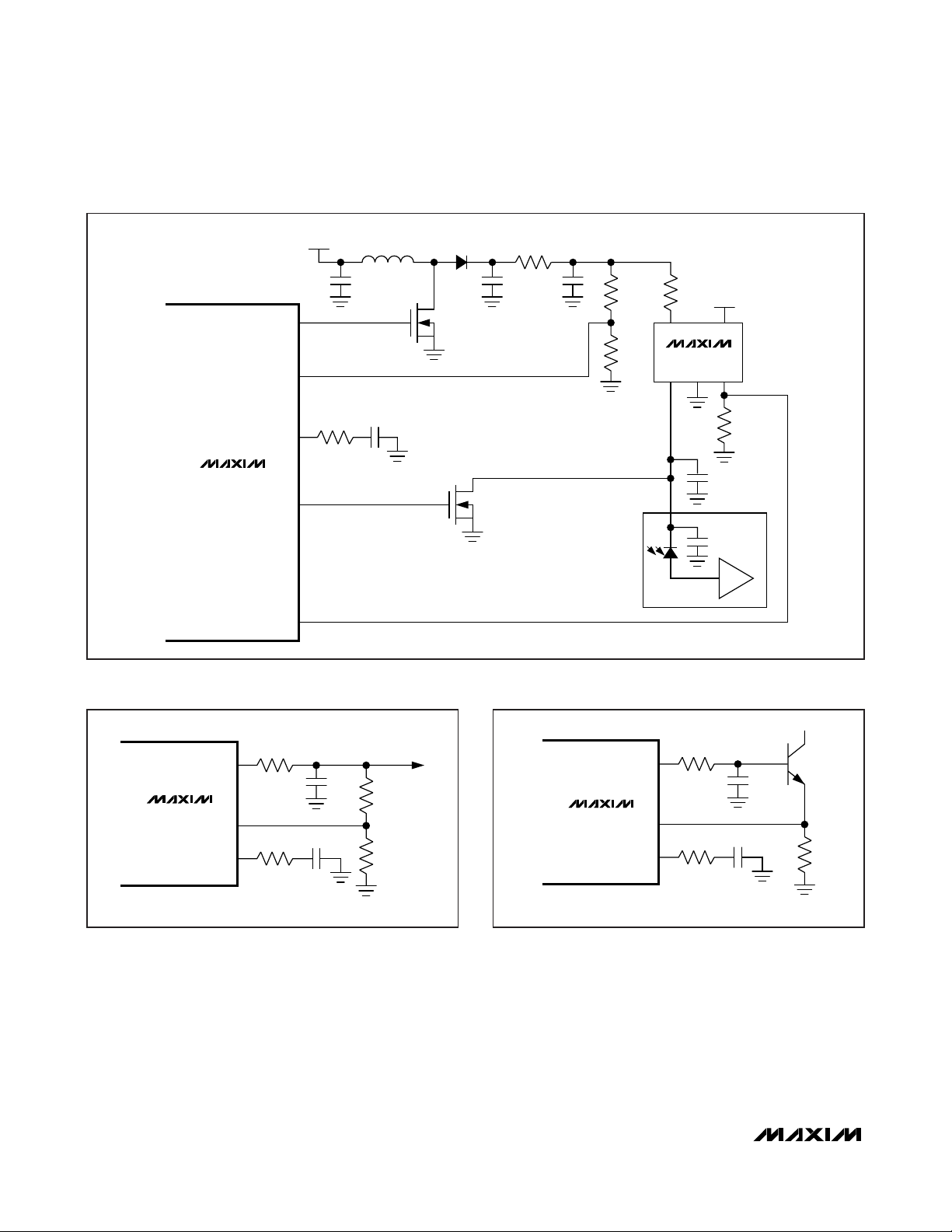

Block Diagram

V

CC

SDA

SCL

MON1

MON2

MON3N

MON3P

MON4

BEN

BMD

TX-D

MON5/D0

V

CC

2

C

I

INTERFACE

256 BYTES AT

V

CC

MON[5:8]

TEMP

SENSOR

SAMPLE

CONTROL

HBIAS

QUICK-TRIP LIMIT

HTXP

QUICK-TRIP LIMIT

LTXP

QUICK-TRIP LIMIT

APC SET POINT FROM

TRACKING-ERROR TABLE

MON5

EEPROM

A0h SLAVE

ADDRESS

DS1865 MEMORY ORGANIZATION

ADDITIONAL MONITORS

USER MEMORY, ALARM TRAP

CONFIGURATION AND CALIBRATION

13-BIT

ANALOG MUX

DAC WITH

MUX

SCALING

TTL

0

1

TTL

TABLE 00h (EEPROM)

TABLE 01h (EEPROM)

TABLE 02h (EEPROM)

TABLE 03h (EEPROM)

USER MEMORY

TABLE 04h (EEPROM)

MODULATION LUT

ADC

MUX

8-BIT

LOS STATUS/

D0 IN

D0 OUT

INV0

MAIN MEMORY

EEPROM/SRAM

ALARM/WARNING COMPARISONS

DIGITAL LIMIT

COMPARATOR FOR

ADC RESULTS

LUT CAN BE INDEXED BY

ADC CONFIGURATION/RESULTS

SYSTEM STATUS BITS

TABLE 05h (EEPROM)

ADC TE LUT

TABLE 06h (EEPROM)

M4DAC LUT

TABLE 07h (EEPROM)

PWM LUT

TABLE 08h (EEPROM)

BIAS OL LUT

INTERRUPT

INTERRUPT

BIAS MAX

QUICK TRIP

MUX

TABLE 07h

PWM VOLTAGE

TEMP SENSOR

MASK

MASK

DIGITAL

APC

INTEGRATOR

8-BIT

PWM-DAC

SRAM RESET

LATCH

ENABLE

TX-D INPUT

MOD LUT

POWER-ON ANALOG

> V

V

CC

POA

NONMASKABLE

INTERRUPT

INTERRUPT

LATCH

INTERRUPT

LATCH

TABLE 08h

BIAS OL LUT

TEMP INDEXED

MUX

8-BIT

DAC WITH

SCALING

PWM

13-BIT

DAC

TX-F

FETG

BIAS

MOD

SW

LOSI

MON6/D1

MON7/D2

MON8/D3

GND

MON6

MON7

MON8

TTL

TTL

0

1

TTL

TTL

MUX0

D1 IN

D1 OUT

D2 IN

D2 OUT

INV M3QT

M3QT

MUX2

D3 IN

D3 OUT

I2C CONTROL

DS1875

M4DAC LUT INDEXED BY MON4

TABLE 06h

2

C CONTROL

I

M4DAC

8-BIT, 2.5V

FULL SCALE

DAC1

8-BIT, 2.5V

FULL SCALE

COMP

FB

M4DAC

DAC1

Page 15

DS1875

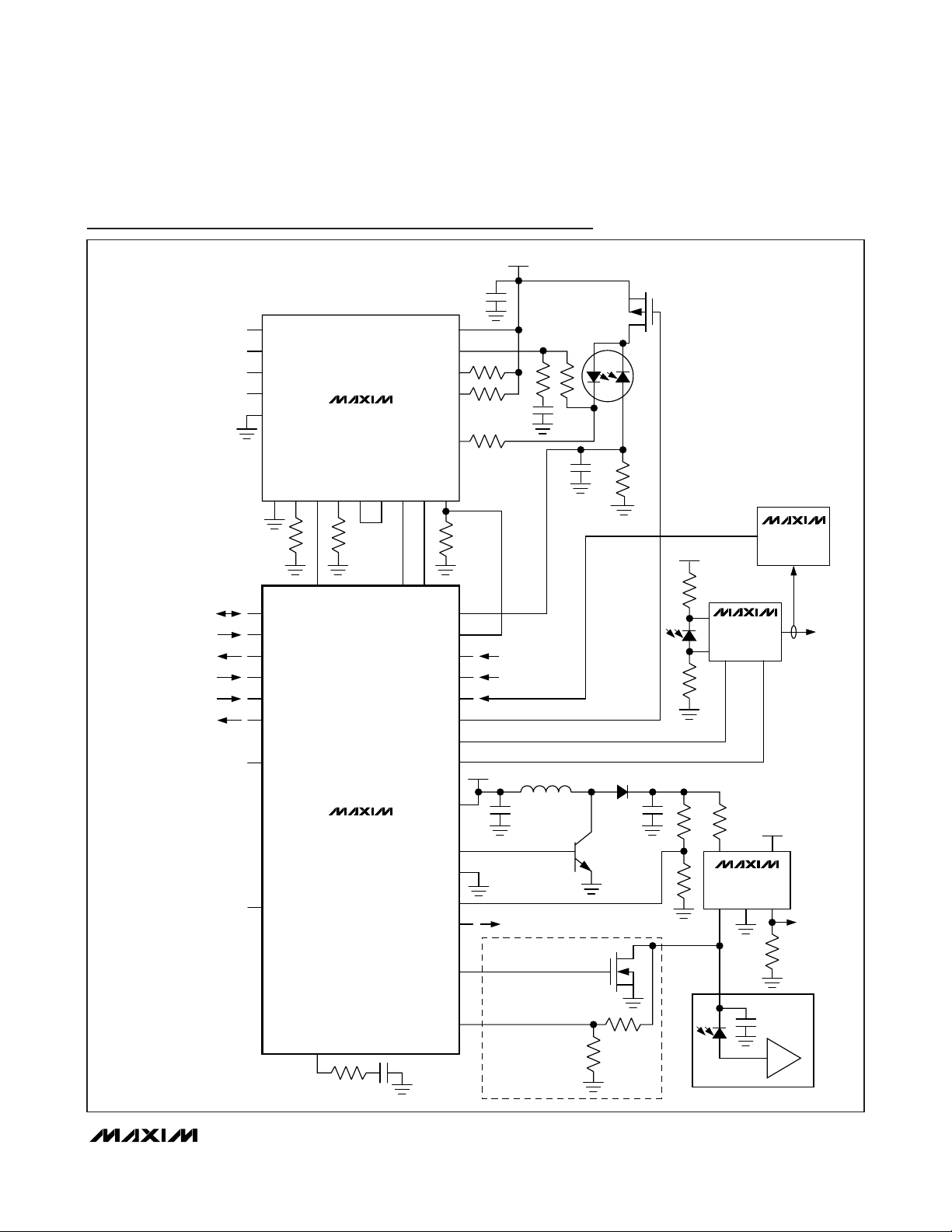

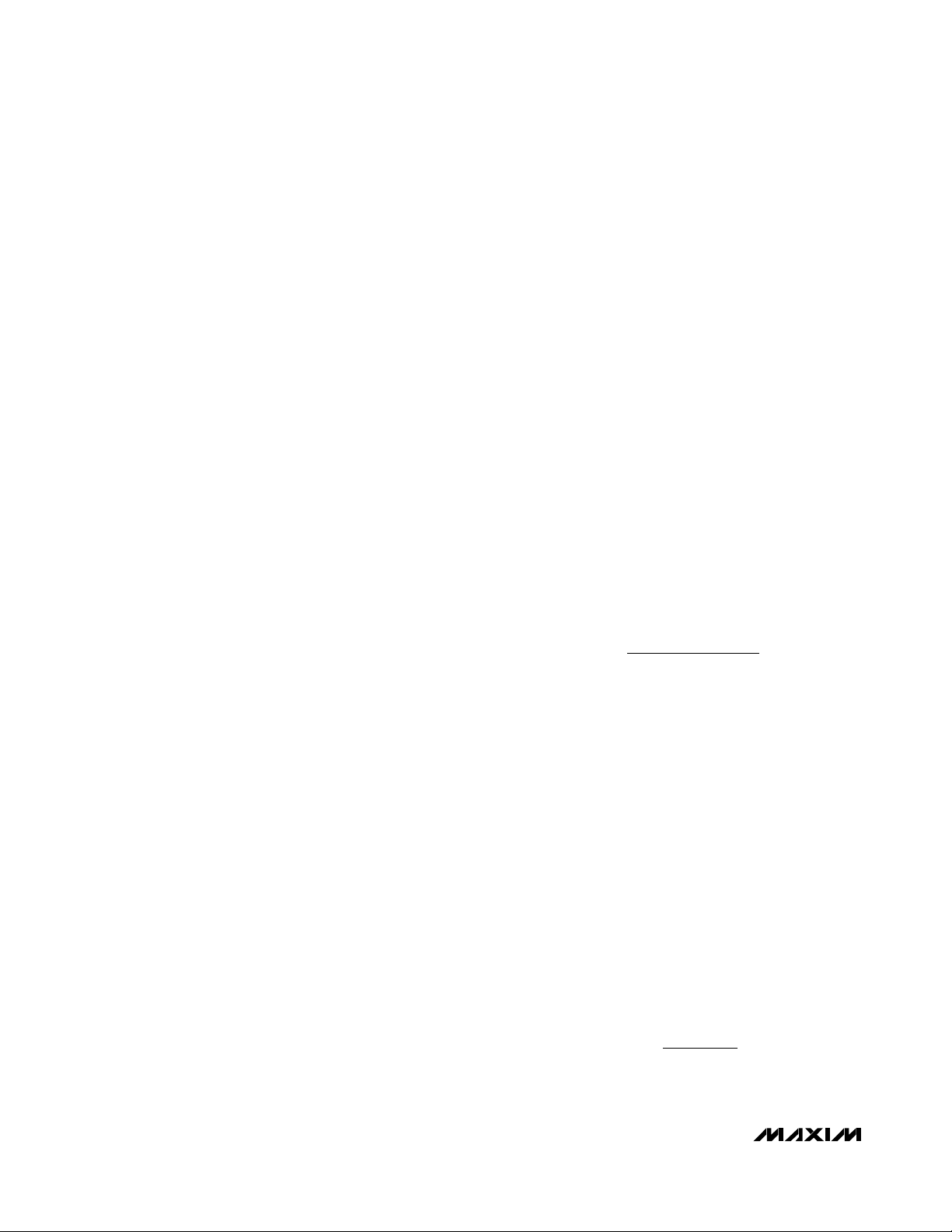

Typical Operating Circuit

PON Triplexer and SFP Controller

______________________________________________________________________________________ 15

I2C COMMUNICATION

FAULT OUTPUT

DISABLE INPUT

RECEIVER LOS

OPEN-DRAIN LOS OUTPUT

ADDITIONAL DIGITAL I/O

IN+

IN-

BEN+

BEN-

DIS

IMAX

GND

VMSET

MOD BIAS BEN

SDA

SCL

TX-F

TX-D

LOSI

D0

D3

MAX3643

MODSET

VREF

VBSET

BIASSET

M4DAC

V

CC

OUT+

OUT-

BIAS-

BIAS+

BENOUT

BCMON

BMD

MON1

MON2

MON3

MON4

FETG

D1

3.3V

3.3V

TRANSMIT POWER

RECEIVE POWER

CATV RF POWER

CATV SHUTDOWN CONTROL

MAX4003

MAX3654

FTTH CATV

TIA

RF DETECTOR

CATV

12V

GAIN CONTROL

ADDITIONAL MONITORS

MON[5:7]

COMP

DS1875

V

SW

GND

DAC1

MON8

CC

FB

APD OVERLOAD QUICK TRIP

D2

APD VOLTAGE MONITOR

VOLTAGE REFERENCE

OPTIONAL

R

AGC

MAX4007

CURRENT MONITOR

APD

3.3V

RECEIVE

POWER

(CURRENT)

ROSA

TIA

Page 16

DS1875

PON Triplexer and SFP Controller

16 ______________________________________________________________________________________

Detailed Description

The DS1875 integrates the control and monitoring functionality required to implement a PON system using

Maxim’s MAX3643 compact burst-mode laser driver.

The compact laser-driver solution offers a considerable

cost benefit by integrating control and monitoring features in the low-power CMOS process, while leaving

only the high-speed portions to the laser driver. Key

components of the DS1875 are shown in the

Block

Diagram

and described in subsequent sections. Table

1 contains a list of acronyms used in this data sheet.

Bias Control

Bias current is controlled by an APC loop. The APC

loop uses digital techniques to overcome the difficulties

associated with controlling burst-mode systems.

Autodetect Bias Control

This is the default mode of operation. In autodetect bias

control, transmit burst length is monitored. A “short

burst” is declared when the burst is shorter than

expected based on the sample rate setting in Table

02h, Register 88h. In the case that 32 consecutive short

bursts are transmitted, the integrator is disabled and

the BIAS DAC is loaded from the BIAS LUT (Table 08h).

Any single burst of adequate burst length re-enables

the APC integrator.

Open-Loop Bias Control

Open-loop control is configured by setting FBOL in

Table 02h, Register C7h. In this mode, the BIAS LUT

(Table 08h) is directly loaded to the BIAS DAC output.

The BIAS LUT can be programmed in 2°C increments

over the 40°C to +102°C range. It is left-shifted so that

the LUT value is loaded to either the DAC MSB or the

DAC MSB-1 (Bit BOLFS, Table 02h, Register 89h).

Closed-Loop Bias Control

The closed-loop control requires a burst length long

enough to satisfy the sample rate settings in Table 02h,

Register 88h (APC_SR[3:0]). Closed-loop control is

configured by setting FBCL in Table 02h, Register C7h.

In this mode, the APC integrator is enabled, which controls the BIAS DAC.

The APC loop begins by loading the value from the

BIAS LUT (Table 08h) indexed by the present temperature conversion. The feedback for the APC loop is the

monitor diode (BMD) current, which is converted to a

voltage using an external resistor. The feedback voltage is compared to an 8-bit scaleable voltage reference, which determines the APC set point of the

system. Scaling of the reference voltage accommodates the wide range in photodiode sensitivities. This

allows the application to take full advantage of the APC

reference’s resolution.

The DS1875 has an LUT to allow the APC set point to

change as a function of temperature to compensate for

TE. The TE LUT (Table 05h) has 36 entries that determine the APC setting in 4°C windows between -40°C to

+100°C. Ranging of the APC DAC is possible by programming a single byte in Table 02h, Register 8Dh.

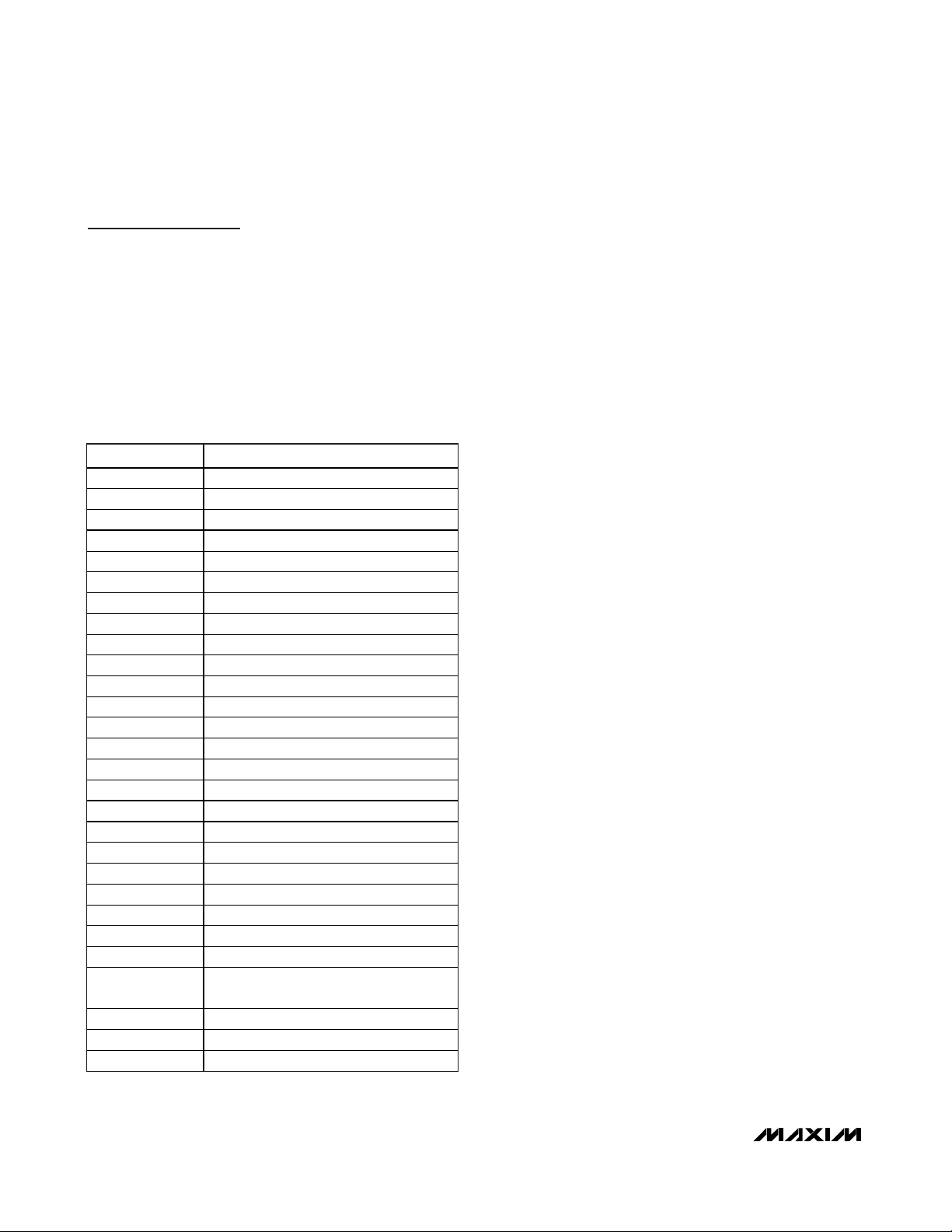

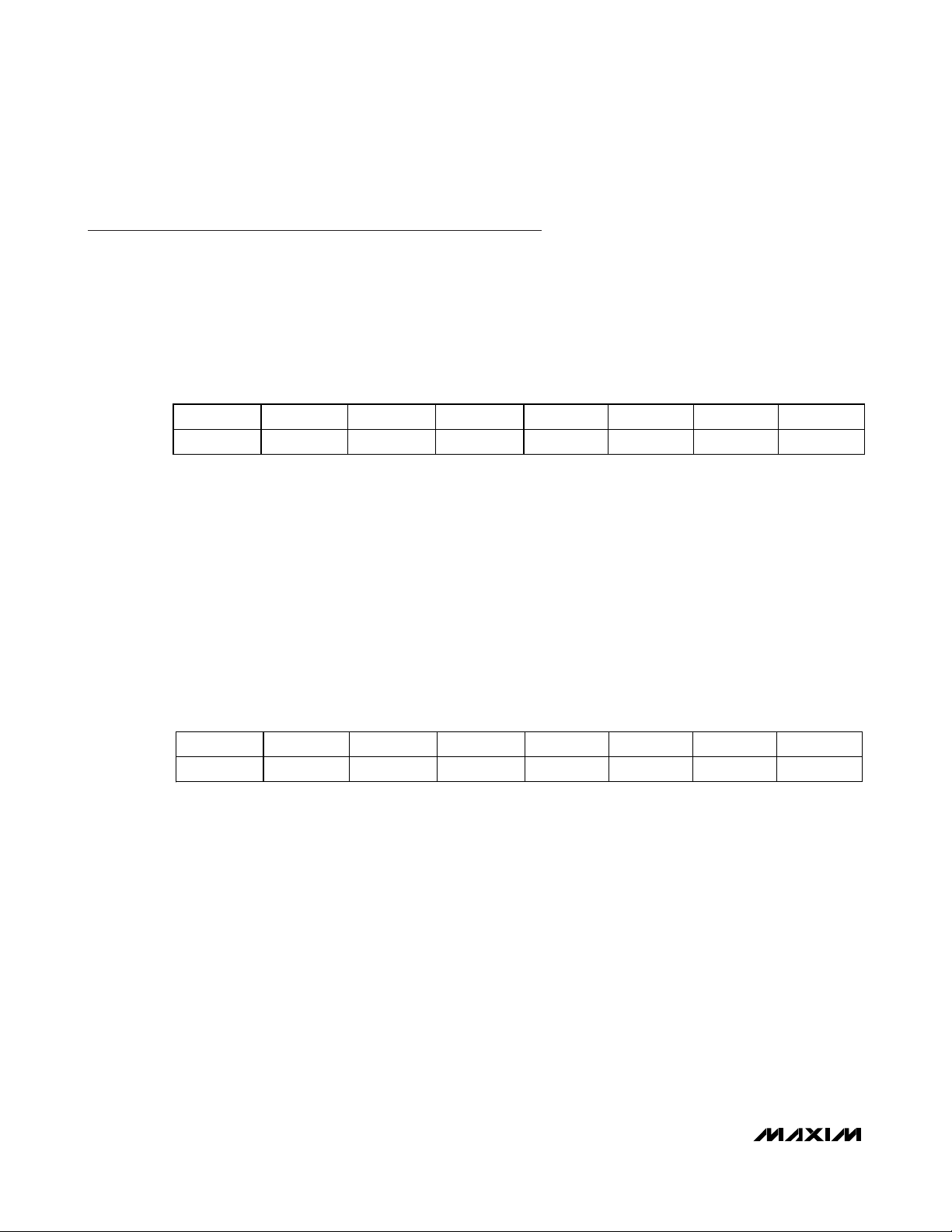

Table 1. DS1875 Acronyms

ACRONYM DEFINITION

10GEPON 10-Gigabit Ethernet PON

ADC Analog-to-Digital Converter

AGC Automatic Gain Control

APC Automatic Power Control

APD Avalanche Photodiode

BM Burst Mode

BPON Broadband PON

CATV Cable Televis ion

EPON Ethernet PON

ER Extinction Ratio

DAC Digital-to-Analog Converter

FTTH Fiber-to-the-Home

FTTX Fiber-to-the-X

GEPON Gigabit Ethernet PON

GPON Gigabit PON

LOS Loss of Signal

LUT Lookup Table

TE Track ing Error

TIA Transimpedance Amplif ier

ROSA Receiver Optical Subassembly

RSSI Receive Signal Strength Indicator

PON Passive Optical Network

PWM Pulse-Width Modulation

SFF Small Form Factor

SFF-8472

SFP Small Form Factor Pluggable

SFP+ Enhanced SFP

TOSA Transmit Optical Subassembly

Document Defining Register Map of

SFPs and SFFs

Page 17

DS1875

DC Operation

When using autodetect mode or closed-loop mode,

BEN should be equal to VCCor long burst. In open-loop

mode, BEN should be ground or any burst length.

Modulation Control

The MOD output is an 8-bit scaleable voltage output

that interfaces with the MAX3643’s VMSET input. An

external resistor to ground from the MAX3643’s

MODSET pin sets the maximum current that the voltage

at the VMSET input can produce for a given output

range. This resistor value should be chosen to produce

the maximum modulation current the laser type requires

over temperature. Then the MOD output’s scaling is

used to calibrate the full-scale (FS) modulation output

to a particular laser’s requirements. This allows the

application to take full advantage of the MOD output’s

resolution. The modulation LUT can be programmed in

2°C increments over the -40°C to +102°C range.

Ranging of the MOD DAC is possible by programming

a single byte in Table 02h, Register 8Bh.

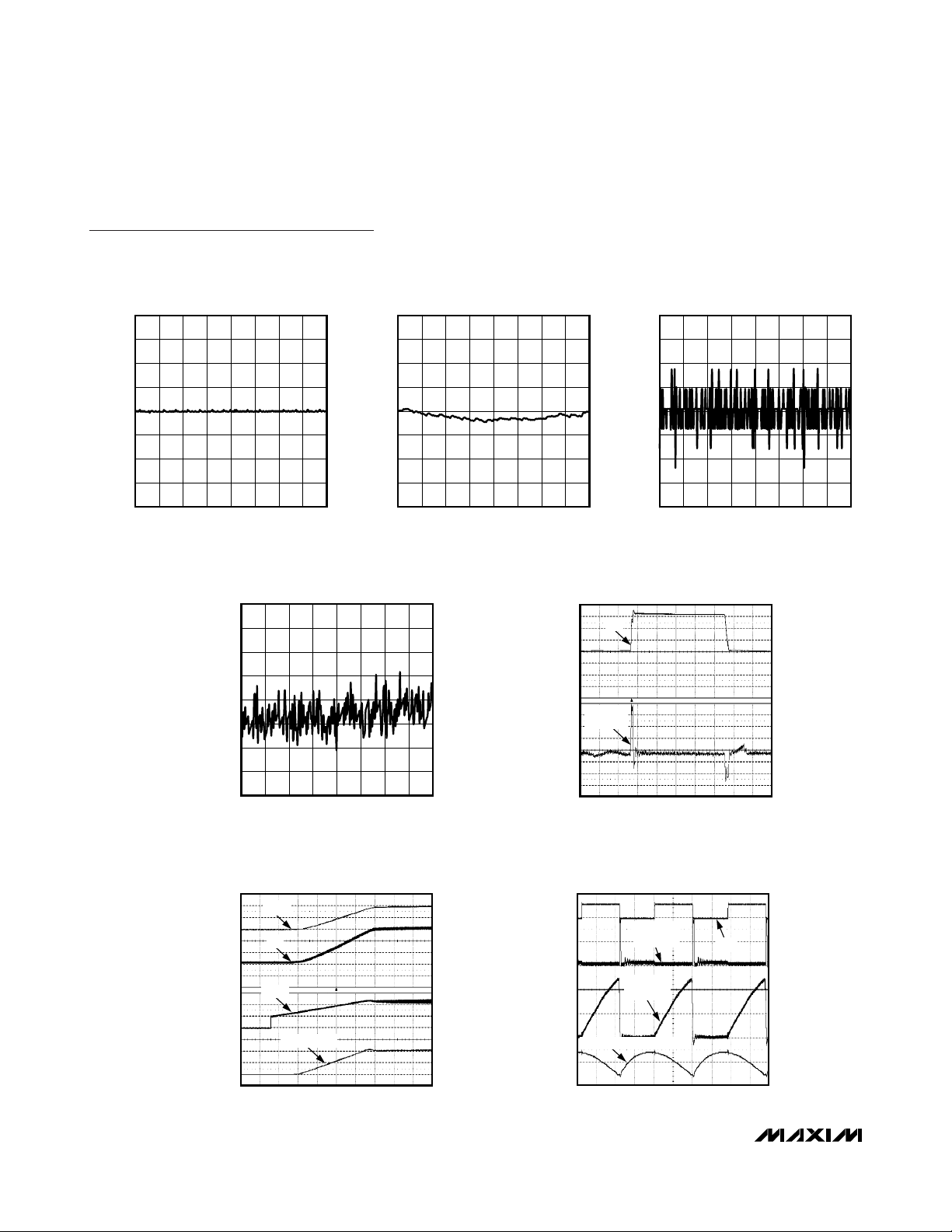

BIAS and MOD Output During Power-Up

On power-up the modulation and bias outputs remain off

until VCCis above V

POA

, a temperature conversion has

been completed, and, if the VCCADC alarm is enabled,

a V

CC

conversion above the customer-defined VCClow

alarm level must clear the VCClow alarm (t

INIT

). Once all

these conditions (t

INIT

) are satisfied, the MOD output is

enabled with the value determined by the temperature

conversion and the modulation LUT (Table 04h).

When the MOD output is enabled, the BIAS output is

turned on to a value equal to the temperature-indexed

value in the BIAS LUT (Table 08h). Next, the APC integrator is enabled, and single LSB steps are taken to

tightly control the average power.

If a fault is detected and TX-D is toggled to re-enable

the outputs, the DS1875 powers up following a similar

sequence to an initial power-up. The only difference is

that the DS1875 already determined the present temperature, so the t

INIT

time is not required for the

DS1875 to recall the APC and MOD set points from

EEPROM.

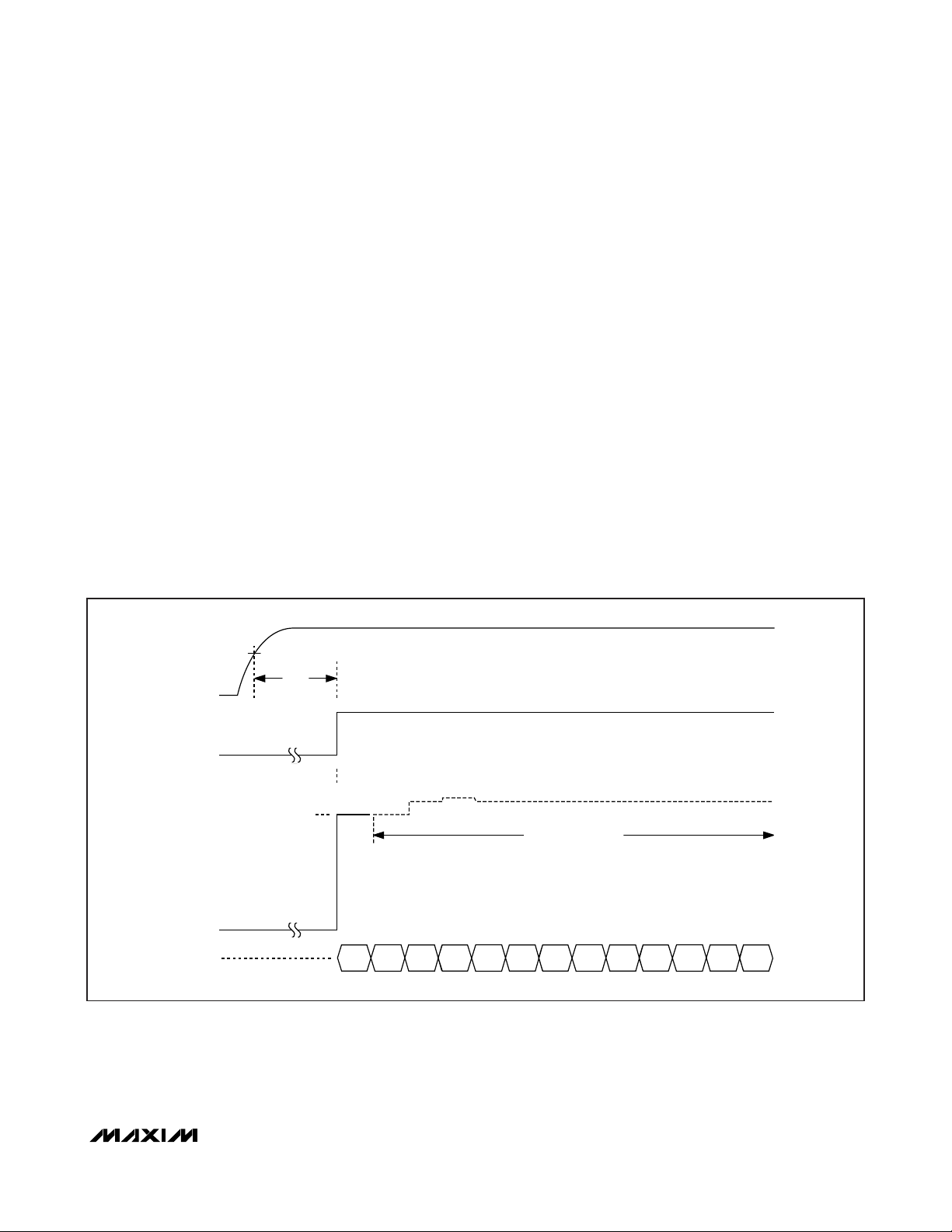

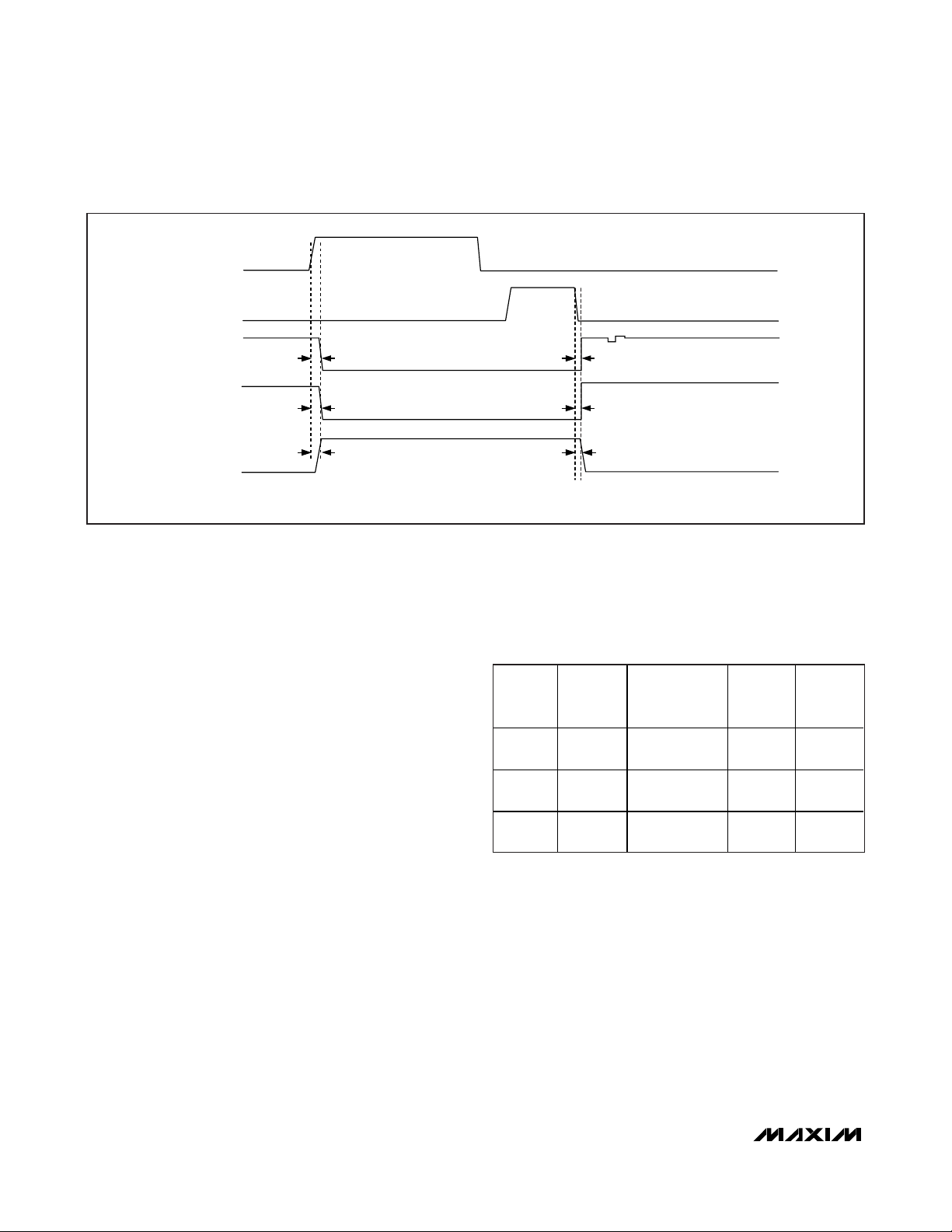

Figure 1. Power-Up Timing (BEN is a Long Burst)

PON Triplexer and SFP Controller

______________________________________________________________________________________ 17

V

V

CC

POA

t

INIT

V

MOD

BIAS LUT

VALUE

I

BIAS

BIAS

SAMPLE

12345678910111213

APC INTEGRATOR ON

Page 18

DS1875

PON Triplexer and SFP Controller

18 ______________________________________________________________________________________

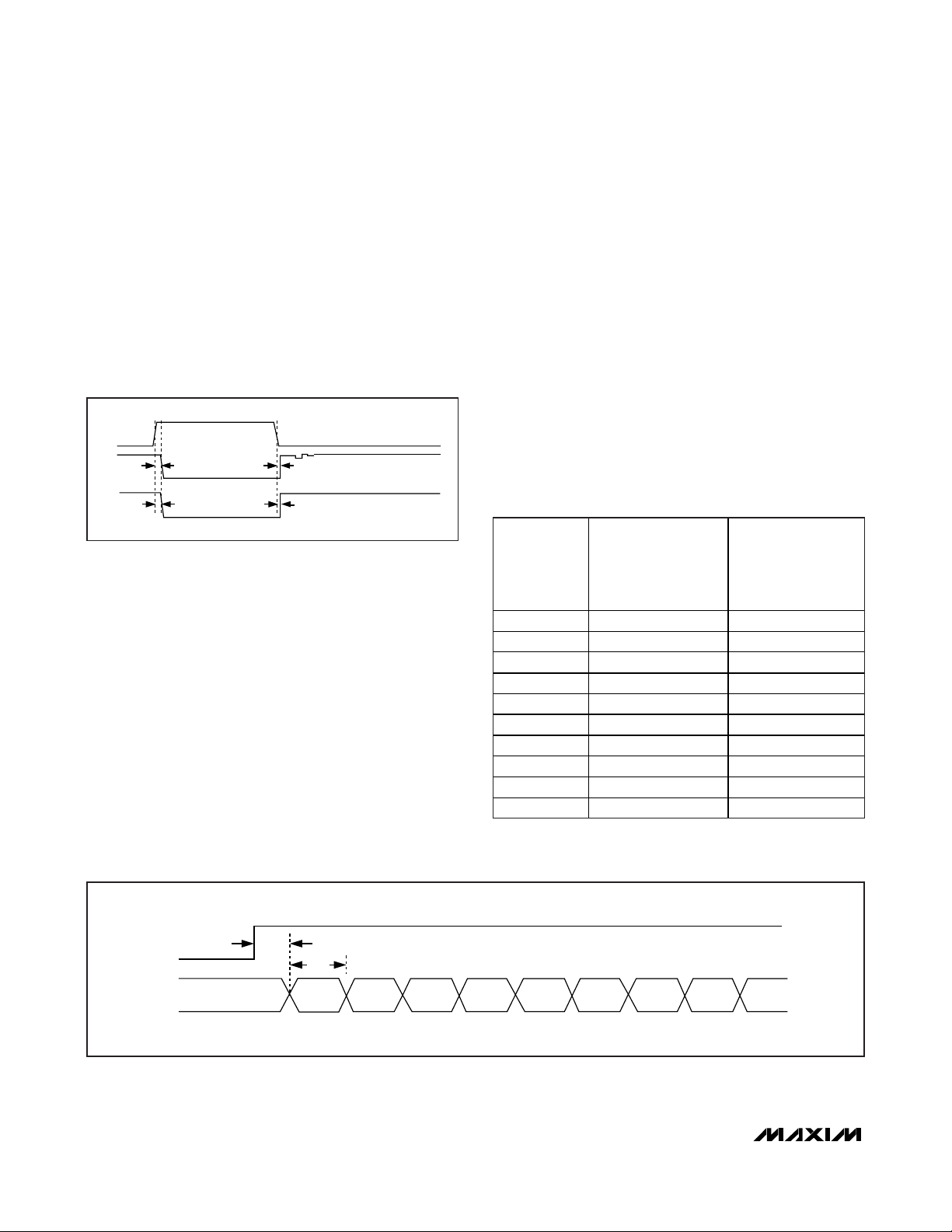

BIAS and MOD Output as a Function of

Transmit Disable (TX-D)

If the TX-D pin is asserted (logic 1) during normal operation, the outputs are disabled within t

OFF

. When TX-D

is deasserted (logic 0), the DS1875 turns on the MOD

output with the value associated with the present temperature and initializes the BIAS using the same search

algorithm used at startup. When asserted, the SOFT

TX-D bit (Lower Memory, Register 6Eh) offers a software control identical to the TX-D pin (see Figure 2).

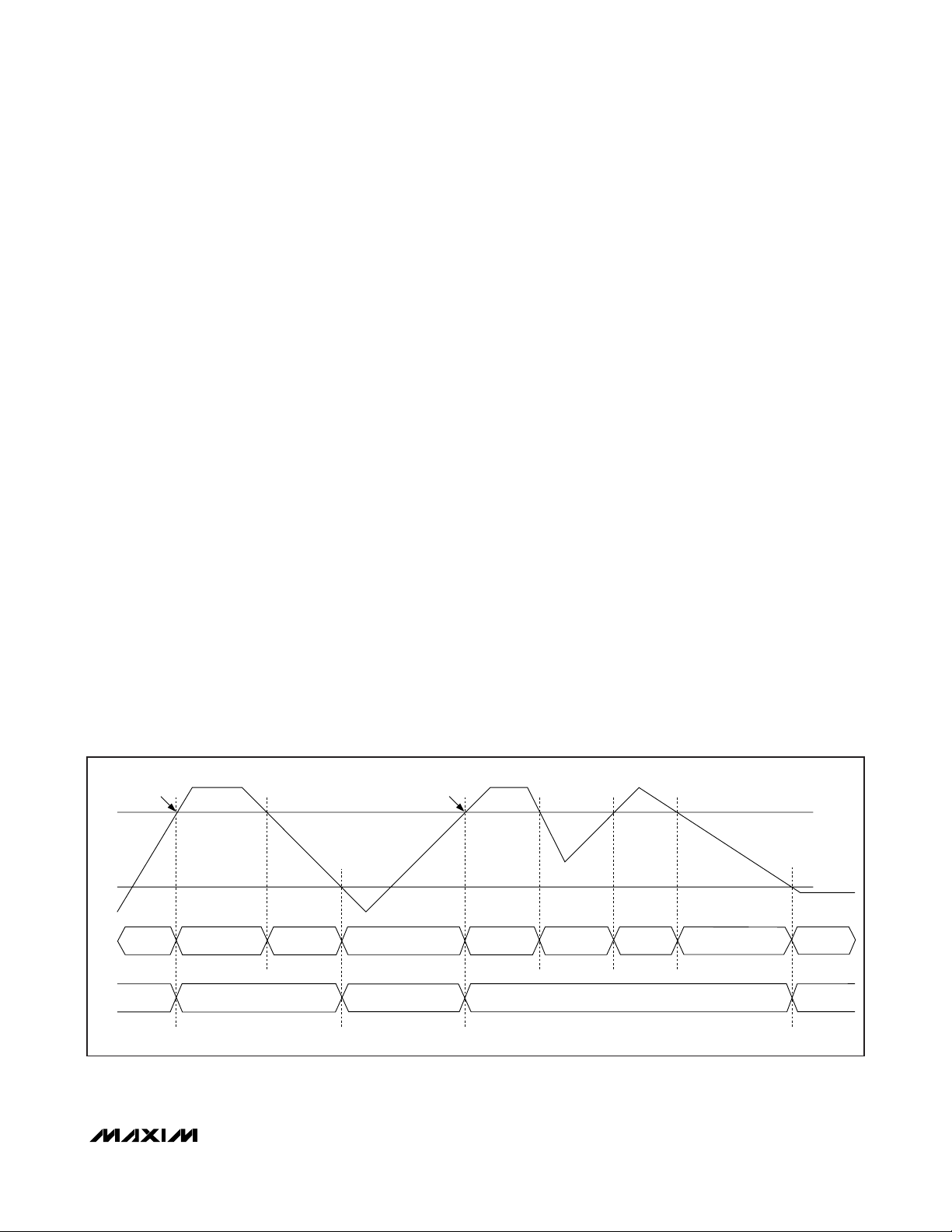

APC and Quick-Trip Shared Comparator

Timing

As shown in Figure 3, the DS1875’s input comparator is

shared between the APC control loop and the three

quick-trip alarms (TXP HI, TXP LO, and BIAS HI). The

comparator polls the alarms in a multiplexed sequence.

Six of every eight comparator readings are used for

APC loop-bias current control. The other two updates

are used to check the HTXP/LTXP (monitor diode voltage) and the HBIAS (MON1) signals against the internal APC and BIAS reference. If the last APC

comparison was higher than the APC set point, it

makes an HTXP comparison, and if it is lower, it makes

an LTXP comparison. Depending on the results of the

comparison, the corresponding alarms and warnings

(TXP HI, TXP LO) are asserted or deasserted.

The DS1875 has a programmable comparator sample

time based on an internally generated clock to facilitate

a wide variety of external filtering options suitable for

burst-mode transmitters. The rising edge of BEN triggers the sample to occur, and the Update Rate register

(Table 02h, Register 88h) determines the sampling time.

The first sample occurs (t

FIRST

) after the rising edge of

BEN. The internal clock is asynchronous to BEN, causing a ±50ns uncertainty regarding when the first sample

will occur following BEN. After the first sample occurs,

subsequent samples occur on a regular interval, t

REP

.

Table 2 shows the sample rate options available.

Updates to the TXP HI and TXP LO quick-trip alarms do

not occur during the BEN low time. The BIAS HI quick

trip can be sampled during the burst-low time. Any

*

All codes greater than 1001b (1010b to 1111b) use the

maximum sample time of code 1001b.

Figure 3. APC Loop and Quick-Trip Sample Timing

Table 2. Update Rate Timing

Figure 2. TX-D Timing

TX-D

I

BIAS

V

MOD

t

OFF

t

OFF

t

ON

t

ON

MINIMUM TIME

FROM BEN TO

APC_SR[3:0]

0000b 350 800

0001b 550 1200

0010b 750 1600

0011b 950 2000

0100b 1350 2800

0101b 1550 3200

0110b 1750 3600

0111b 2150 4400

1000b 2950 6000

1001b* 3150 6400

FIRST SAMPLE

(t

) ±50ns

FIRST

(ns)

REPEATED

SAMPLE PERIOD

FOLLOWING FIRST

SAMPLE (t

(ns)

REP

)

t

BEN

APC QUICK-TRIP

SAMPLE TIMES

FIRST

t

REP

APC

SAMPLE

APC

SAMPLE

APC

SAMPLE

APC

SAMPLE

APC

SAMPLE

APC

SAMPLE

HTXP/LTXP

SAMPLE

HBIAS

SAMPLE

APC

SAMPLE

Page 19

DS1875

quick-trip alarm that is detected by default remains

active until a subsequent comparator sample shows the

condition no longer exists. A second bias-current monitor (BIAS MAX) compares the DS1875’s BIAS DAC’s

code to a digital value stored in the MAX BIAS register.

This comparison is made at every bias-current update

to ensure that a high bias current is quickly detected.

Monitors and Fault Detection

Monitors

Monitoring functions on the DS1875 include a power-on

analog (POA) VCCcomparison, five quick-trip comparators, and ADC channels. This monitoring combined

with the interrupt masks determine if the DS1875 shuts

down its outputs and triggers the TX-F and FETG outputs. All the monitoring levels and interrupt masks are

user programmable with the exception of POA, which

trips at a fixed range and is nonmaskable for safety

reasons.

Power-On Analog (POA)

POA holds the DS1875 in reset until VCCis at a suitable

level (VCC> V

POA

) for the part to accurately measure

with its ADC and compare analog signals with its quicktrip monitors. Because VCCcannot be measured by the

ADC when VCCis less than V

POA

, POA also asserts the

VCClow alarm, which is cleared by a VCCADC conversion greater than the customer-programmable VCClow

ADC limit. This allows a programmable limit to ensure

that the head room requirements of the transceiver are

satisfied during slow power-up. The TX-F and FETG

outputs do not latch until there is a conversion above

the VCClow limit. The POA alarm is nonmaskable. The

TX-F and FETG outputs are asserted when VCCis

below V

POA

. See the

Low-Voltage Operation

section for

more information.

Five Quick-Trip Monitors and Alarms

Five quick-trip monitors are provided to detect potential

laser safety issues. These monitor:

1) High Bias Current (HBIAS)

2) Low Transmit Power (LTXP)

3) High Transmit Power (HTXP)

4) Max Output Current (BIAS MAX)

5) MON3 Quick Trip (M3QT)

The high- and low-transmit power quick-trip registers

(HTXP and LTXP) set the thresholds used to compare

against the BMD voltage to determine if the transmit

power is within specification. The HBIAS quick trip compares the MON1 input (generally from the MAX3643

bias monitor output) against its threshold setting to

determine if the present bias current is above specifica-

tion. The BIAS MAX quick trip is a digital comparison

that determines if the BIAS DAC indicates that the bias

current is above specification. I

BIAS

is not allowed to

exceed the value set in the MAX BIAS register. When

the DS1875 detects that the bias is at the limit, it sets

the BIAS MAX status bit and clamps the bias current at

the MAX BIAS level. In the closed-loop mode, if the

recalled value from the BIAS LUT is greater than MAX

BIAS then, the update is not done and I

BIAS

reverts to

the previous I

BIAS

value. The quick trips are routed to

the TX-F and FETG outputs through interrupt masks to

allow combinations of these alarms to be used to trigger

these outputs. When FETG is triggered, the DS1875 also

disables the MOD and BIAS outputs. See the

BIAS and

MOD Output During Power-Up

section for details.

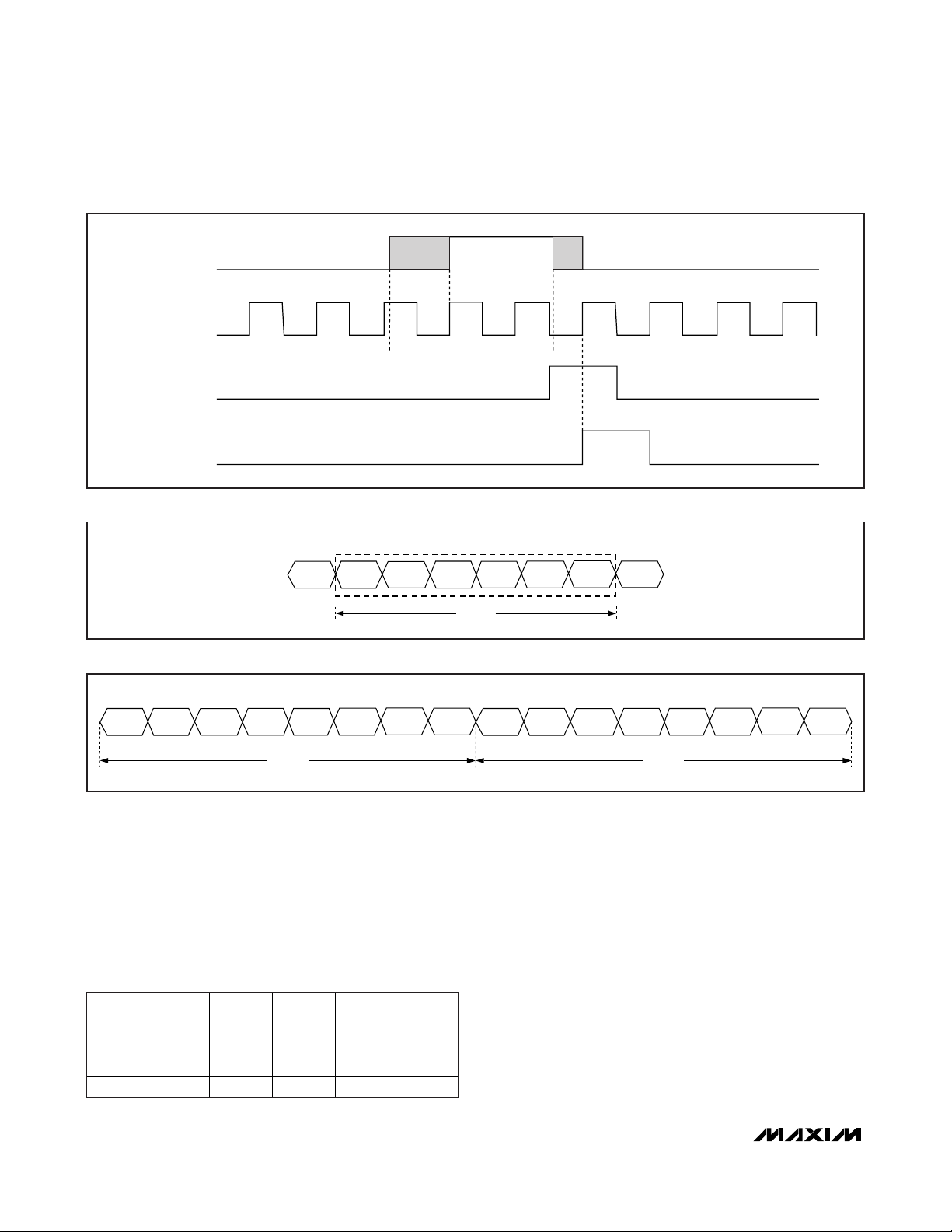

MON3 Quick Trip

One additional quick trip is used to protect the APD

from overcurrent. MON3P is used to monitor the current

through the APD. When MON3P exceeds a threshold

set by the M3QT DAC register (Table 02h, Register

C3h), the PWM is shut down by blocking SW pulses.

The MON3 comparison is single-ended referenced to

ground. In the case where MON3 is used differentially

and not referenced to ground, this must be considered

when setting the MON3 quick-trip threshold.

Additionally, the D2 pin can be driven either high or low

as determined by INV M3QT and MUX M3QT bits in

Lower Memory, Register 79h. An external switch controlled by pin D2 may be used to clamp the converter’s

output when MON3 quick trip occurs. This external

switch discharges the output voltage much faster than

allowing the load to discharge the rail. The MON3

quick-trip alarm can be latched by enabling M3QT LEN

in Table 02h, Register 89h. The latch is reset by setting

M3QT RESET in Lower Memory, Register 78h. A soft

quick trip is performed by setting SOFT M3QT in Lower

Memory, Register 78h (see Figure 4).

ADC Monitors and Alarms

The ADC monitors six channels that measure temperature (internal temp sensor), VCC, and MON1–MON4

using an analog multiplexer to measure them round

robin with a single ADC. Each channel has a customerprogrammable full-scale range and offset value that is

factory programmed to default value (see Table 3).

Additionally, MON1–MON4 can right-shift results by up

to 7 bits before the results are compared to alarm

thresholds or read over the I2C bus. This allows customers with specified ADC ranges to calibrate the ADC

full scale to a factor of 1/2ntheir specified range to

measure small signals. The DS1875 can then right-shift

the results by n bits to maintain the bit weight of their

specification.

PON Triplexer and SFP Controller

______________________________________________________________________________________ 19

Page 20

DS1875

PON Triplexer and SFP Controller

20 ______________________________________________________________________________________

The ADC results (after right-shifting, if used) are compared to high and low alarm and warning thresholds

after each conversion. The alarm values can be used to

trigger the TX-F or FETG outputs. These ADC thresholds

are user programmable through the I2C interface, as

well as masking registers that can be used to prevent

the alarms from triggering the TX-F and FETG outputs.

ADC Timing

There are 10 analog channels that are digitized in a

sequential fashion. The MON5–MON8 channels are

sampled depending on the state of the EN5TO8B bit in

Table 02h, Register 89h. If the bit is programmed to

logic 0, the ADC cycles through temperature, VCC, and

MON1–MON4 (Figure 5). If the bit is programmed to

logic 1, all 10 channels are digitized, including channels MON5–MON8 (Figure 6). In this mode (EN5TO8B

= 0), each of MON5–MON8 is sampled on alternate

cycles, as shown in Figure 5. The total time required to

convert one set of channels is the sequential ADC

cycle time, t

FRAME1

or t

FRAME2

(see Figure 6).

Table 3. ADC Default Monitor Ranges

Figure 6. ADC Timing with EN5TO8B = 1

Figure 5. ADC Timing with EN5TO8B = 0

Figure 4. M3QT Timing

TRIP CONDITION

mCLK

(525kHz)

CAPTURE ALARM

M3QT ALARM

(UNLATCHED)

ONE ADC CYCLE

MON4

TEMP

V

CC

MON1

V

CC

MON2 MON3 MON4

t

FRAME2

MON5 MON6TEMP V

SIGNAL

+FS

SIGNAL

Temperature (°C) 127.996 7FFF -128 8000

VCC (V) 6.5528 FFF8 0 0000

MON1–MON8 (V) 2.4997 FFF8 0 0000

+FS

HEX

-FS

SIGNAL

-FS

HEX

MON1 MON2 MON3 MON4 TEMP

t

FRAME1

MON1

CC

MON2 MON3 MON4

t

FRAME2

MON7 MON8TEMP

Page 21

DS1875

Right-Shifting ADC Result

If the weighting of the ADC digital reading must conform to a predetermined full-scale value defined by a

standard’s specification, then right-shifting can be used

to adjust the predetermined full-scale analog measurement range while maintaining the weighting of the ADC

results. The DS1875’s range is wide enough to cover all

requirements; when the maximum input value is ≤ 1/2

the FS value, right-shifting can be used to obtain

greater accuracy. For instance, the maximum voltage

might be 1/8th the specified predetermined full-scale

value, so only 1/8th the converter’s range is used. An

alternative is to calibrate the ADC’s full-scale range to

1/8th the readable predetermined full-scale value and

use a right-shift value of 3. With this implementation, the

resolution of the measurement is increased by a factor

of 8, and because the result is digitally divided by 8 by

right-shifting, the bit weight of the measurement still

meets the standard’s specification (i.e., SFF-8472).

The right-shift operation on the ADC result is carried out

based on the contents of RIGHT SHIFT1/0 registers

(Table 02h, Registers 8Eh–8Fh). Four analog channels,

MON1–MON4, have 3 bits each allocated to set the

number of right-shifts. Up to seven right-shift operations

are allowed and are executed as a part of every conversion before the results are compared to the high and

low alarm levels, or loaded into their corresponding

measurement registers (Table 01h, Registers

62h–6Bh). This is true during the setup of internal calibration as well as during subsequent data conversions.

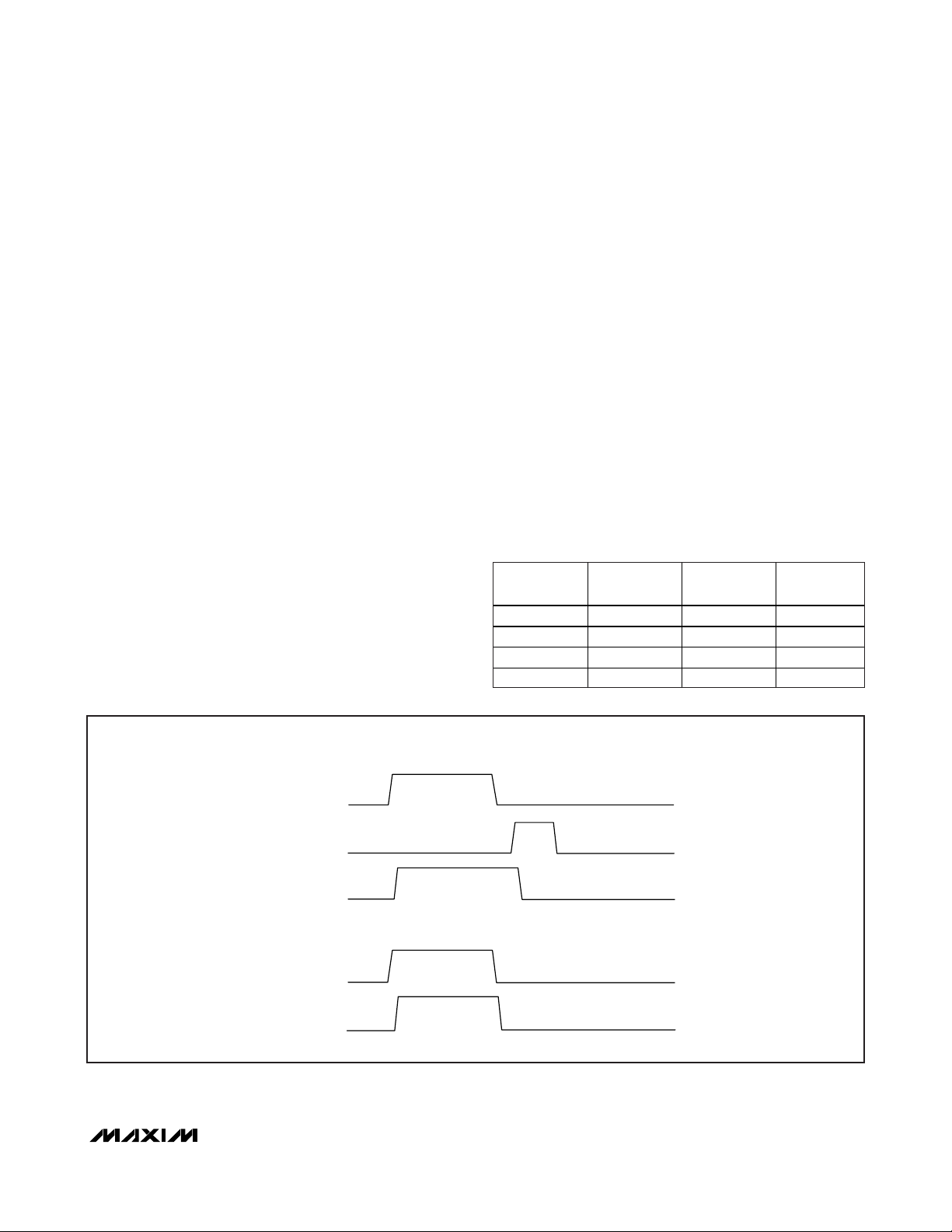

Transmit Fault (TX-F) Output

The TX-F output has masking registers for the ADC

alarms and the QT alarms to select which comparisons

cause it to assert. In addition, the FETG alarm is selectable through the TX-F mask to cause TX-F to assert. All

alarms, with the exception of FETG, only cause TX-F to

remain active while the alarm condition persists.

However, the TX-F latch bit can enable the TX-F output

to remain active until it is cleared by the TX-F reset bit,

TX-D, SOFT TX-D, or by power cycling the part. If the

FETG output is configured to trigger TX-F, it indicates

that the DS1875 is in shutdown and requires TX-D,

SOFT TX-D, or cycling power to reset. Only enabled

alarms activate TX-F (see Figure 7). Table 4 shows

TX-F as a function of TX-D and the alarm sources.

Table 4. TX-F as a Function of TX-D and

Alarm Sources

Figure 7. TX-F Timing

PON Triplexer and SFP Controller

______________________________________________________________________________________ 21

VCC > V

POA

No X X 1

Yes 0 0 0

Yes 0 1 1

Yes 1 X 0

TX-D

NONMASKED

TX-F ALARM

TX-F

TX-F LATCHED OPERATION

DETECTION OF

TX-F FAULT

TX-D OR

TX-F RESET

TX-F

TX-F NONLATCHED OPERATION

DETECTION OF

TX-F FAULT

TX-F

Page 22

DS1875

PON Triplexer and SFP Controller

22 ______________________________________________________________________________________

Safety Shutdown (FETG) Output

The FETG output has masking registers (separate from

TX-F) for the ADC alarms and the QT alarms to select

which comparisons cause it to assert. Unlike TX-F, the

FETG output is always latched. Its output polarity is

programmable to allow an external nMOS or pMOS to

open during alarms to shut off the laser-diode current.

If the FETG output triggers, indicating that the DS1875

is in shutdown, it requires TX-D, SOFT TX-D, or cycling

power to be reset. Under all conditions, when the analog outputs are reinitialized after being disabled, all the

alarms with the exception of the VCClow ADC alarm

are cleared. The VCClow alarm must remain active to

prevent the output from attempting to operate when

inadequate VCCexists to operate the laser driver. Once

adequate VCCis present to clear the VCClow alarm,

the outputs are enabled following the same sequence

as the power-up sequence.

As previously mentioned, the FETG is an output used to

disable the laser current through a series nMOS or

pMOS. This requires that the FETG output can sink or

source current. Because the DS1875 does not know if it

should sink or source current before VCCexceeds

V

POA

, which triggers the EE recall, this output is high

impedance when VCCis below V

POA

(see the

Low-

Voltage Operation

section for details and diagram). The

application circuit should use a pullup or pulldown

resistor on this pin that pulls FETG to the alarm/shutdown state (high for a pMOS, low for a nMOS). Once

VCCis above V

POA

, the DS1875 pulls the FETG output

to the state determined by the FETG DIR bit (Table 02h,

Register 89h). Set FETG DIR to 0 if an nMOS is used

and 1 if a pMOS is used.

Determining Alarm Causes Using the I2C

Interface

To determine the cause of the TX-F or FETG alarm, the

system processor can read the DS1875’s alarm trap bytes

(ATB) through the I2C interface (Table 01h, Registers

F8h–FBh). The ATB has a bit for each alarm. Any time an

alarm occurs, regardless of the mask bit’s state, the

DS1875 sets the corresponding bit in the ATB. Active ATB

bits remain set until written to 0s through the I2C interface.

On power-up, the ATB is 0s until alarms dictate otherwise.

FETG causes additional alarms that make it difficult to

determine the root cause of the problem. Therefore, no

updates are made to the ATB when FETG occurs.

Figure 8. FETG/Output Disable Timing (Fault Condition Detected)

Table 5. FETG, MOD, and BIAS Outputs

as a Function of TX-D and Alarm Sources

DETECTION OF

FETG FAULT

TX-D

I

BIAS

V

MOD

FETG*

*FETG DIR = 0

t

OFF

t

OFF

t

FETG:ON

t

ON

t

ON

t

FETG:OFF

VCC >

V

POA

Yes 0 0

Yes 0 1

Yes 1 X

TX-D

NONMASKED

FETG ALARM

FETG

FETG

DIR

FETG

DIR

FETG

DIR

MOD AND

BIAS

OUTPUTS

Enabled

Disabled

Disabled

Page 23

DS1875

Die Identification

The DS1875 has an ID hard-coded to its die. Two registers (Table 02h, Registers 86h–87h) are assigned for

this feature. Byte 86h reads 75h to identify the part as

the DS1875; byte 87h reads the die revision.

Low-Voltage Operation

The DS1875 contains two power-on reset (POR) levels.

The lower level is a digital POR (V

POD

) and the higher

level is an analog POR (V

POA

). At startup, before the

supply voltage rises above V

POA

, the outputs are disabled (FETG and BIAS outputs are high impedance,

MOD is low), all SRAM locations are low (including

shadowed EEPROM (SEE)), and all analog circuitry is

disabled. When VCCreaches V

POA

, the SEE is

recalled, and the analog circuitry is enabled. While V

CC

remains above V

POA

, the device is in its normal operating state, and it responds based on its nonvolatile configuration. If during operation VCCfalls below V

POA

but

is still above V

POD

, the SRAM retains the SEE settings

from the first SEE recall, but the device analog is shut

down and the outputs are disabled. FETG is driven to

its alarm state defined by the FETG DIR bit (Table 02h,

Register 89h). If the supply voltage recovers back

above V

POA

, the device immediately resumes normal

functioning. When the supply voltage falls below V

POD

,

the device SRAM is placed in its default state and

another SEE recall is required to reload the nonvolatile

settings. The EEPROM recall occurs the next time V

CC

exceeds V

POA

. Figure 9 shows the sequence of events

as the voltage varies.

Any time V

CC

is above V

POD

, the I2C interface can be

used to determine if VCCis below the V

POA

level. This

is accomplished by checking the RDYB bit in the status

(Lower Memory, Register 6Eh) byte. RDYB is set when

VCCis below V

POA

. When VCCrises above V

POA

,

RDYB is timed (within 500µs) to go to 0, at which point

the part is fully functional.

For all device addresses sourced from EEPROM (Table

02h, Register 8Ch), the default device address is A2h

until VCCexceeds V

POA

, allowing the device address

to be recalled from the EEPROM.

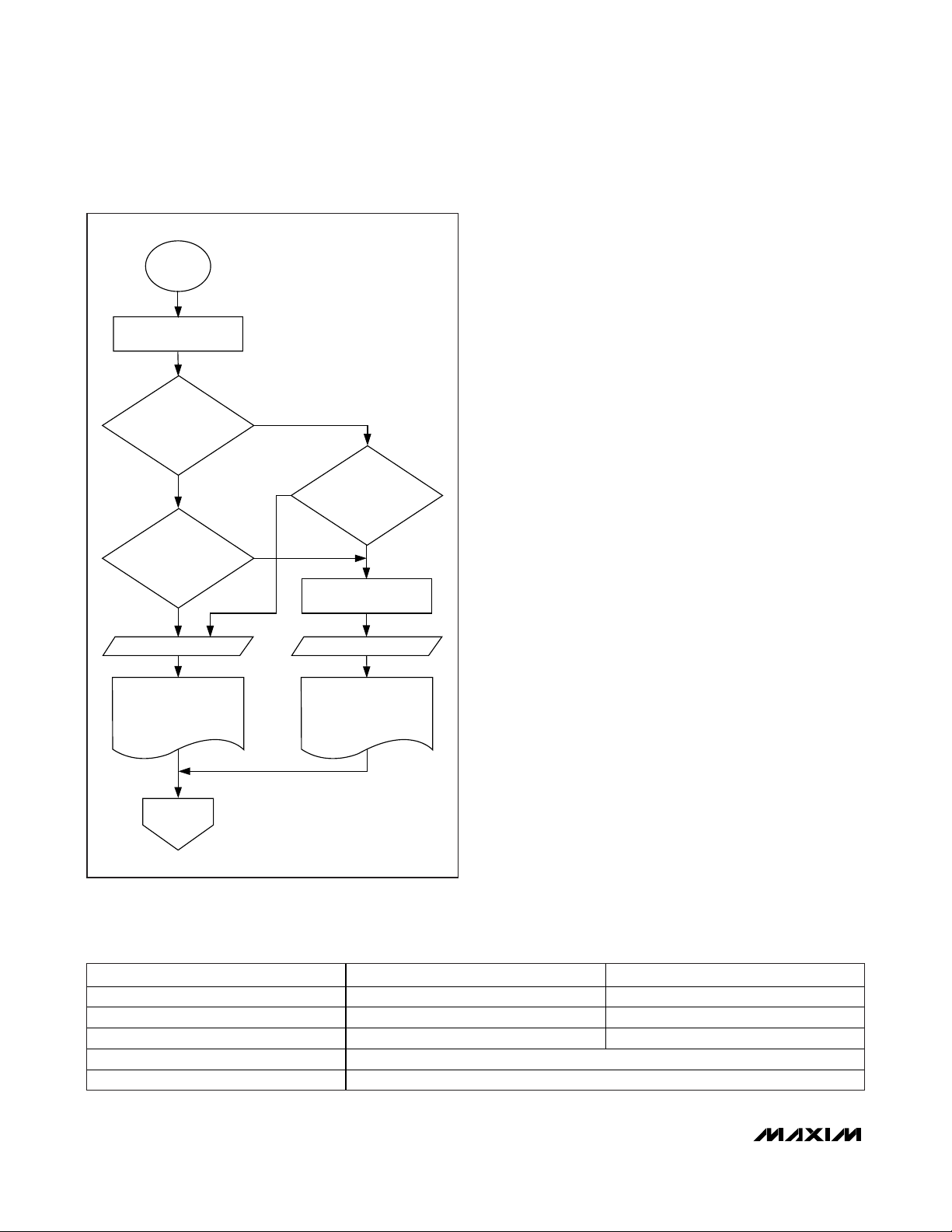

Enhanced RSSI Monitoring (Dual Range

Functionality)

The DS1875 offers a new feature to improve the accuracy and range of MON3, which is most commonly

used for monitoring RSSI. This feature enables rightshifting (along with its gain and offset settings) when

the input signal is below a set threshold (within the

range that benefits using right-shifting) and then automatically disables right-shifting (recalling different gain

and offset settings) when the input signal exceeds the

threshold. Also, to prevent “chattering,” hysteresis prevents excessive switching between modes in addition

to ensuring that continuity is maintained. Dual range

operation is enabled by default (factory programmed in

EEPROM). However, it can easily be disabled through

the RSSI_FF and RSSI_FC bits. When dual range operation is disabled, MON3 operates identically to the

other MON channels, although featuring a differential

input.

Figure 9. SEE Timing

PON Triplexer and SFP Controller

______________________________________________________________________________________ 23

SEE RECALL SEE RECALL

V

POA

V

CC

V

POD

HIGH

FETG

IMPEDANCE

PRECHARGED

SEE

TO 0

HIGH

IMPEDANCE

PRECHARGED

TO 0

RECALLED

VALUE

DRIVEN TO

FETG DIR

NORMAL

OPERATION

NORMAL

OPERATION

DRIVEN TO

FETG DIR

OPERATION

RECALLED

VALUE

NORMAL

DRIVEN TO

FETG DIR

HIGH

IMPEDANCE

PRECHARGED

TO 0

Page 24

DS1875

24 ______________________________________________________________________________________

Dual-range functionality consists of two modes of operation: fine mode and coarse mode. Each mode is calibrated for a unique transfer function, hence the term, dual

range. Table 6 highlights the registers related to MON3.

Fine mode is equivalent to the other MON channels. Fine

mode is calibrated using the gain, offset, and right-shifting registers at locations shown in Table 6 and is ideal

for relatively small analog input voltages. Coarse mode is

automatically switched to when the input exceeds the

threshold (to be discussed in a subsequent paragraph).

Coarse mode is calibrated using different gain and offset

registers, but lacks right-shifting (since coarse mode is

only used on large input signals). The gain and offset

registers for coarse mode are also shown in Table 6.

With the use of right-shifting, the fine mode full scale is

programmed to (1/2N)th the coarse mode full scale. The

DS1875 will now autorange to choose the range that

gives the best resolution for the measurement. To eliminate chatter, 6.25% of hysteresis is applied when the

input resides at the boundary of the two ranges. See

Figure 10. Additional information for each of the registers

can be found in the

Memory Map

section.

Dual range operation is transparent to the end user. The

results of MON3 analog-to-digital conversions are still