Page 1

General Description

The DS1870 is a dual-channel bias controller targeted

toward class AB LDMOS RF power-amplifier applications. It uses lookup tables (LUTs) to control 256-position potentiometers based on the amplifier’s

temperature and drain voltage or current (or other

external monitored signal). With its internal temperature

sensor and multichannel A/D converter (ADC), the

DS1870 provides a cost-effective solution that improves

the amplifier’s efficiency by using nonlinear compensation schemes that are not possible with conventional

biasing solutions.

Applications

Cellular Base Stations

Medical Equipment

Industrial Controls

Optical Transceivers

Features

♦ Two-Channel Solution for Programmable RF Bias

Control

♦ The Potentiometer’s Position is Automatically

Updated to Compensate for the Ambient

Temperature and the Drain Voltage or Current

♦ A Five-Channel, 13-Bit ADC Continuously

Monitors the Ambient Temperature, V

CC

, VD, I

D1,

and I

D2

♦ Hi/Lo Alarms for Each ADC Channel can Trigger a

Fault Output

♦ Nonvolatile Memory for the Device Settings,

Lookup Tables, and 32-Bytes of User Memory

♦ I

2

C™-Compatible Serial Interface with Up to Eight

Devices on the Same Serial Bus

♦ Single 5V Power Supply

♦ Small 16-Pin TSSOP Package

♦ -40°C to +95°C Operational Temperature Range

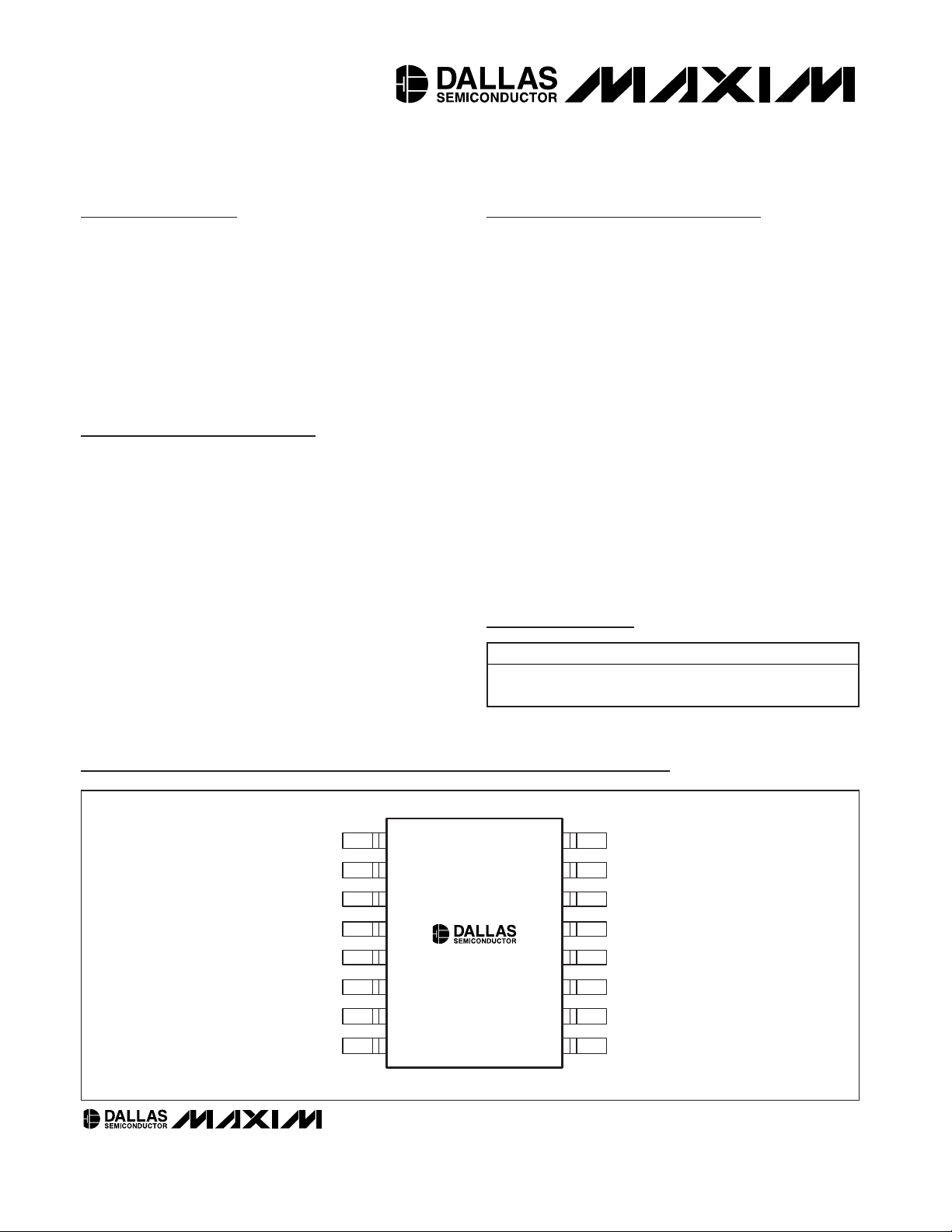

DS1870

LDMOS RF Power-Amplifier Bias

Controller

______________________________________________ Maxim Integrated Products 1

TSSOP (173 mil)

1

2

3

4

5

6

7

89

10

11

12

13

14

15

16L

1

TOP VIEW

W

1

W

2

L

2

I

D1

I

D2

V

D

GND FAULT

A

0

A

1

A

2

SCL

SDA

H

COM

V

CC

DS1870

Pin Configuration

Ordering Information

Rev 1; 5/04

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART TEMP RANGE

PIN-PACKAGE

DS1870E-010 -40°C to +95°C

16 TSSOP

(173 mil)

Typical Operating Circuit appears at end of data sheet.

I

2

C is a trademark of Philips Corp. Purchase of I2C components of Maxim Integrated Products, Inc., or one of its sublicensed Associated Companies, conveys a license under the

Philips I

2

C Patent Rights to use these components in an I2C

system, provided that the system conforms to the I

2

C Standard

Specification as defined by Philips.

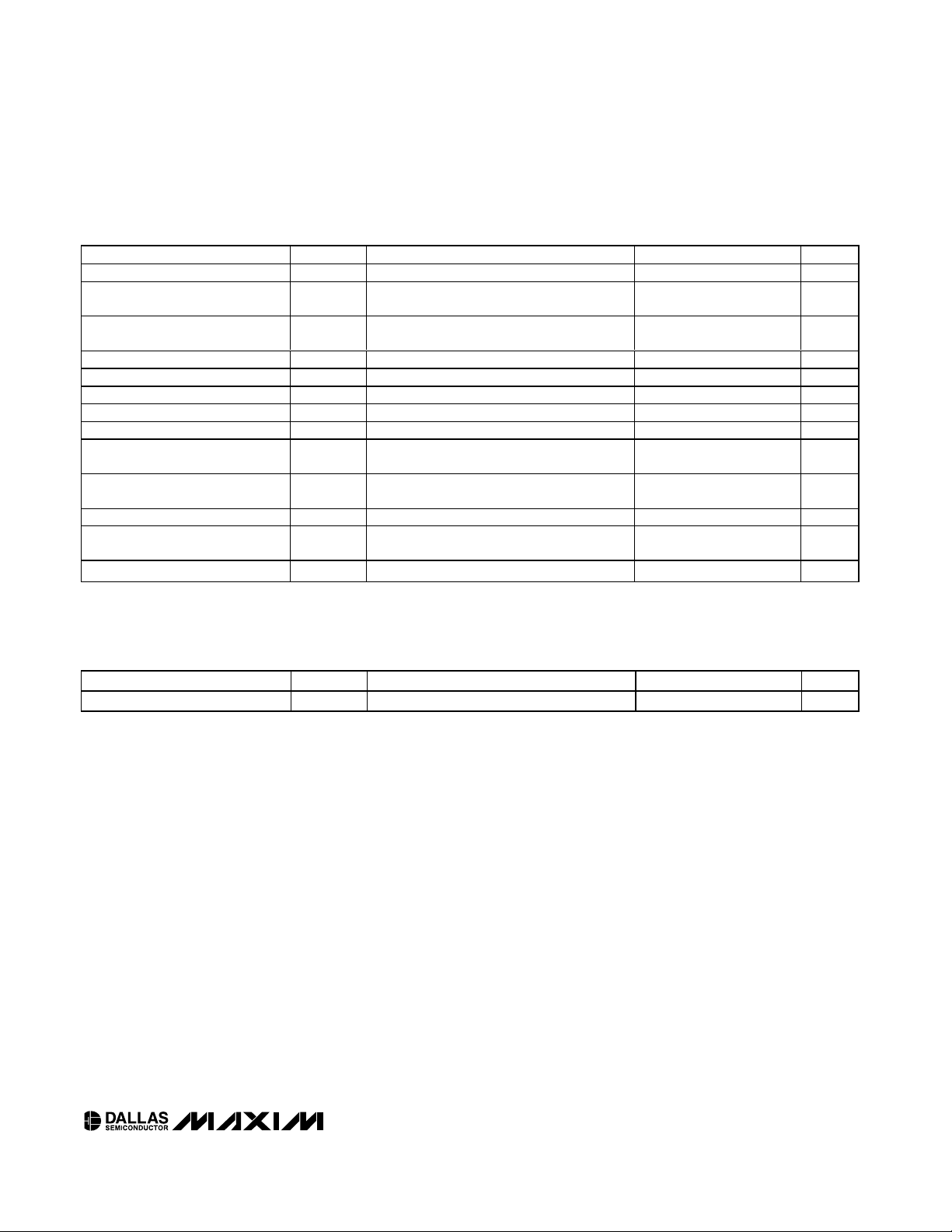

Page 2

DS1870

LDMOS RF Power-Amplifier Bias

Controller

2 _____________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED DC OPERATING CONDITIONS

(TA= -40°C to +95°C)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on VCC, H

COM

, SDA, and SCL Pins Relative to

Ground ...............................................................-0.5V to +6.0V

Voltage Range on A

0

, A1, A2, FAULT, VD, ID1, ID2Relative to

Ground. ...................-0.5V to V

CC

+ 0.5V, not to exceed +6.0V

Voltage Range on L0, L1, W0, and W1 Relative to

Ground .................-0.5V to H

COM

+ 0.5V, not to exceed +6.0V

Operating Temperature Range ...........................-40°C to +95°C

EEPROM Programming Temperature Range .........0°C to +70°C

Storage Temperature Range .............................-55°C to +125°C

Soldering Temperature .......................................See IPC/JEDEC

J-STD-020A Specification

PARAMETER

CONDITIONS

UNITS

Supply Voltage V

CC

(Note 1) 4.5 5.5 V

Input Logic 1

(SDA, SCL, A

2

, A1, A0)

V

IH

0.7 x

V

CC

+

0.3

V

Input Logic 0

(SDA, SCL, A

2

, A1, A0)

V

IL

+0.3 x

V

H

COM

Voltage 4.5 5.5 V

LX and WX Voltage

V

Wiper Current -1 +1 mA

DC ELECTRICAL CHARACTERISTICS

(VCC= +4.5 to 5.5V, TA= -40°C to +95°C.)

PARAMETER

CONDITIONS

Supply Current I

CC

(Note 2) 1 2 mA

Input Leakage I

LI

nA

V

OL1

3mA sink current 0.4 V

Low-Level Output Voltage

(SDA, FAULT)

V

OL2

6mA sink current 0.6 V

I/O Capacitance C

I/O

10 pF

Digital Power-On Reset V

POD

1.0 2.2 V

Analog Power-On Reset V

POA

2.0 2.8 V

SYMBOL

MIN TYP MAX

V

CC

SYMBOL

-0.3

-0.3

MIN TYP MAX UNITS

-200 +200

V

CC

H

COM

+ 0.3

Page 3

DS1870

LDMOS RF Power-Amplifier Bias

Controller

_____________________________________________________________________ 3

ANALOG VOLTAGE-MONITORING CHARACTERISTICS

(VCC= +4.5 to 5.5V, TA = -40°C to +95°C.)

PARAMETER

CONDITIONS

UNITS

VD Monitor FactoryCalibrated FS

Code FFF8h

V

VCC Monitor FactoryCalibrated FS

Code FFF8h

V

ID1 and ID2 Monitor FactoryCalibrated FS

Code FFF8h

V

Resolution

(V

CC

, VD, ID1, ID2)

%FS

Accuracy

(V

CC

, VD, ID1, ID2)

0.5

%FS

Update Rate for

V

CC

, VD, ID1, I

D2

t

frame

50 ms

DIGITAL THERMOMETER CHARACTERISTICS

(VCC= +4.5 to 5.5V, TA= -40°C to +95°C.)

PARAMETER

CONDITIONS

UNITS

Thermometer Error T

ERR

-40°C to 95°C -3 +3 °C

Update Rate t

frame

50 ms

ANALOG POTENTIOMETER CHARACTERISTICS

(VCC= +4.5 to 5.5V, TA= -40°C to +95°C.)

PARAMETER

CONDITIONS

UNITS

Wiper Resistance +25°C

Ω

Potentiometer

End-to-End Resistance

R

POT

+25°C

13

kΩ

Resolution 0.4

%FS

Absolute Linearity (Note 3) -1 +1 LSB

Relative Linearity (Note 4)

LSB

Ratiometric Temperature

Coefficient

5

ppm/°C

End-to-End Temperature

Coefficient

70

ppm/°C

-3dB Cutoff Frequency (Note 5) 1

MHz

Series Resistors from L1, L2 to

GND

R

S

+25°C

kΩ

V

HCOM/VLX

0.6

SYMBOL

SYMBOL

MIN TYP MAX

2.488 2.500 2.513

6.521 6.553 6.587

0.4975 0.5000 0.5025

0.0122

0.25

MIN TYP MAX

SYMBOL

MIN TYP MAX

500 1000

10.0

-0.5 +0.5

15.1 19.5 25.2

0.5975

16.8

0.6025

Page 4

DS1870

LDMOS RF Power-Amplifier Bias

Controller

4 _____________________________________________________________________

LOOKUP TABLE CHARACTERISTICS

(VCC= +4.5 to 5.5V, TA= -40°C to +95°C.)

PARAMETER

CONDITIONS

UNITS

POT1 and POT2 Temp LUT Size

72

Bytes

each

POT1 and POT2 Temp LUT Index

Range

-40

°C

Temp Step 2°C

Temp Hysteresis (Note 6) 1 °C

POT1 and POT2 Drain LUT Size 64

Bytes

each

POT1 and POT2 Drain LUT V

D

Index Range

Hex

POT1 and POT2 Drain LUT V

D

Step

Hex

POT1 and POT2 Drain LUT V

D

Hysteresis

(Note 6)

Hex

POT1 and POT2 Drain LUT I

DX

Index Range

Hex

POT1 and POT2 Drain LUT I

DX

Step

Hex

POT1 and POT2 Drain LUT I

DX

Hysteresis

(Note 6)

Hex

SYMBOL

MIN TYP MAX

+102

8000 FE00

0200

0100

0000 7E00

0200

0100

Page 5

DS1870

LDMOS RF Power-Amplifier Bias

Controller

_____________________________________________________________________ 5

AC ELECTRICAL CHARACTERISTICS

(VCC= +4.5V to 5.5V, TA= -40°C to +95°C, timing referenced to V

IL(MAX)

and V

IH(MIN)

.) (Figure 3)

PARAMETER

CONDITIONS

UNITS

SCL Clock Frequency f

SCL

(Note 7) 0 400 kHz

Bus Free Time Between Stop and

Start Conditions

t

BUF

1.3 µs

Hold Time (Repeated) Start

Condition

0.6 µs

Low Period of SCL t

LOW

1.3 µs

High Period of SCL t

HIGH

0.6 µs

Data Hold Time

0 0.9 µs

Data Setup Time

100 ns

Start Setup Time t

SU:STA

0.6 µs

SDA and SCL Rise Time t

R

(Note 8)

20 +

300 ns

SDA and SCL Fall Time t

F

(Note 8)

20 +

300 ns

Stop Setup Time

0.6 µs

SDA and SCL Capacitive

Loading

C

B

(Note 8) 400 pF

EEPROM Write Time t

W

(Note 9) 10 20 ms

NONVOLATILE MEMORY CHARACTERISTICS

(VCC= +4.5V to 5.5V, TA= 0°C to +70°C.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Writes +70°C (Note 5)

Note 1: All voltages referenced to ground.

Note 2: Supply current is measured with all logic inputs at their inactive state (SDA = SCL = V

CC

) and driven to well-defined logic

levels. All outputs are disconnected.

Note 3: Absolute linearity is the difference of measured value from expected value at the DAC position. Expected value is a

straight line from measured minimum position to measured maximum position.

Note 4: Relative linearity is the deviation of an LSB DAC setting change vs. the expected LSB change. Expected LSB change is

the slope of the straight line from measured minimum position to measured maximum position.

Note 5: This parameter is guaranteed by design.

Note 6: See Figure 1.

Note 7: I

2

C interface timing shown is for fast-mode (400kHz) operation. This device is also backward compatible with I2C stan-

dard-mode timing.

Note 8: C

B

—total capacitance of one bus line in picofarads.

Note 9: EEPROM write begins after a stop condition occurs.

SYMBOL

t

HD:STA

t

HD:DAT

t

SU:DAT

t

SU:STO

MIN TYP MAX

0.1C

B

0.1C

B

50,000

Page 6

DS1870

LDMOS RF Power-Amplifier Bias

Controller

6 _____________________________________________________________________

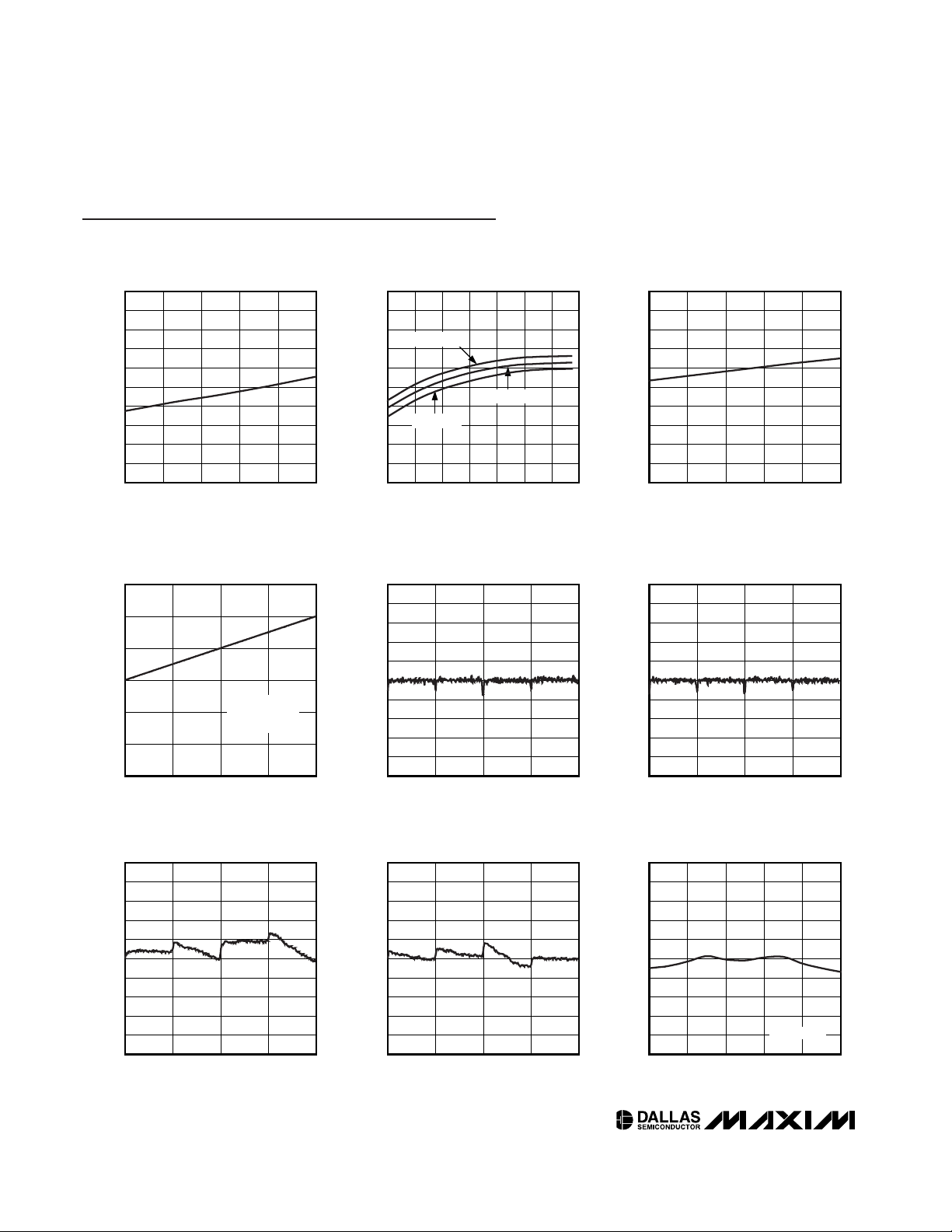

Typical Operating Characteristics

(VCC= +5.0V, TA = +25°C, unless otherwise noted.)

POTENTIOMETER 1 AND 2 OUTPUT VOLTAGE

vs. POSITON

DS1870 toc04

WIPER POSITION (DEC)

WIPER VOLTAGE (V)

19212864

1

2

3

4

5

6

0

0 256

H

COM

= 5V

L1 AND L2

NOT CONNECTED

POTENTIOMETER 1 DIFFERENTIAL

NONLINEARITY vs. WIPER POSITION

DS1870 toc05

WIPER POSITION (DEC)

DIFFERENTIAL NONLINEARITY (LSB)

19212864

-0.20

-0.15

-0.10

-0.05

0

0.05

0.10

0.15

0.20

0.25

-0.25

0256

POTENTIOMETER 2 DIFFERENTIAL

NONLINEARITY vs. WIPER POSITION

DS1870 toc06

WIPER POSITION (DEC)

DIFFERENTIAL NONLINEARITY (LSB)

19212864

-0.20

-0.15

-0.10

-0.05

0

0.05

0.10

0.15

0.20

0.25

-0.25

0 256

POTENTIOMETER 1 INTEGRAL

NONLINEARITY vs. WIPER POSITION

DS1870 toc07

WIPER POSITION (DEC)

INTEGRAL NONLINEARITY (LSB)

19212864

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

-0.5

0 256

POTENTIOMETER 2 INTEGRAL

NONLINEARITY vs. WIPER POSITION

DS1870 toc08

WIPER POSITION (DEC)

INTEGRAL NONLINEARITY (LSB)

19212864

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

-0.5

0256

POTENTIOMETER 1 AND 2

WIPER RESISTANCE vs. WIPER VOLTAGE

DS1870 toc09

WIPER VOLTAGE (V)

WIPER RESISTANCE (Ω)

4321

100

200

300

400

500

600

700

800

900

1000

0

05

H

COM

= 5.0V

SUPPLY CURRENT vs. SUPPLY VOLTAGE

DS1870 toc01

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (mA)

5.35.14.94.7

620

640

660

680

700

720

740

760

780

800

600

4.5 5.5

SUPPLY CURRENT vs. TEMPERATURE

DS1870 toc02

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

806020 400-20

450

500

550

600

650

700

750

800

850

900

400

-40 100

VCC = 5.5V

VCC = 4.5V

VCC = 5.0V

H

COM

CURRENT vs. H

COM

VOLTAGE

DS1870 toc03

H

COM

VOLTAGE (V)

H

COM

CURRENT (mA)

5.35.14.94.7

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0

4.5 5.5

Page 7

DS1870

LDMOS RF Power-Amplifier Bias

Controller

_____________________________________________________________________ 7

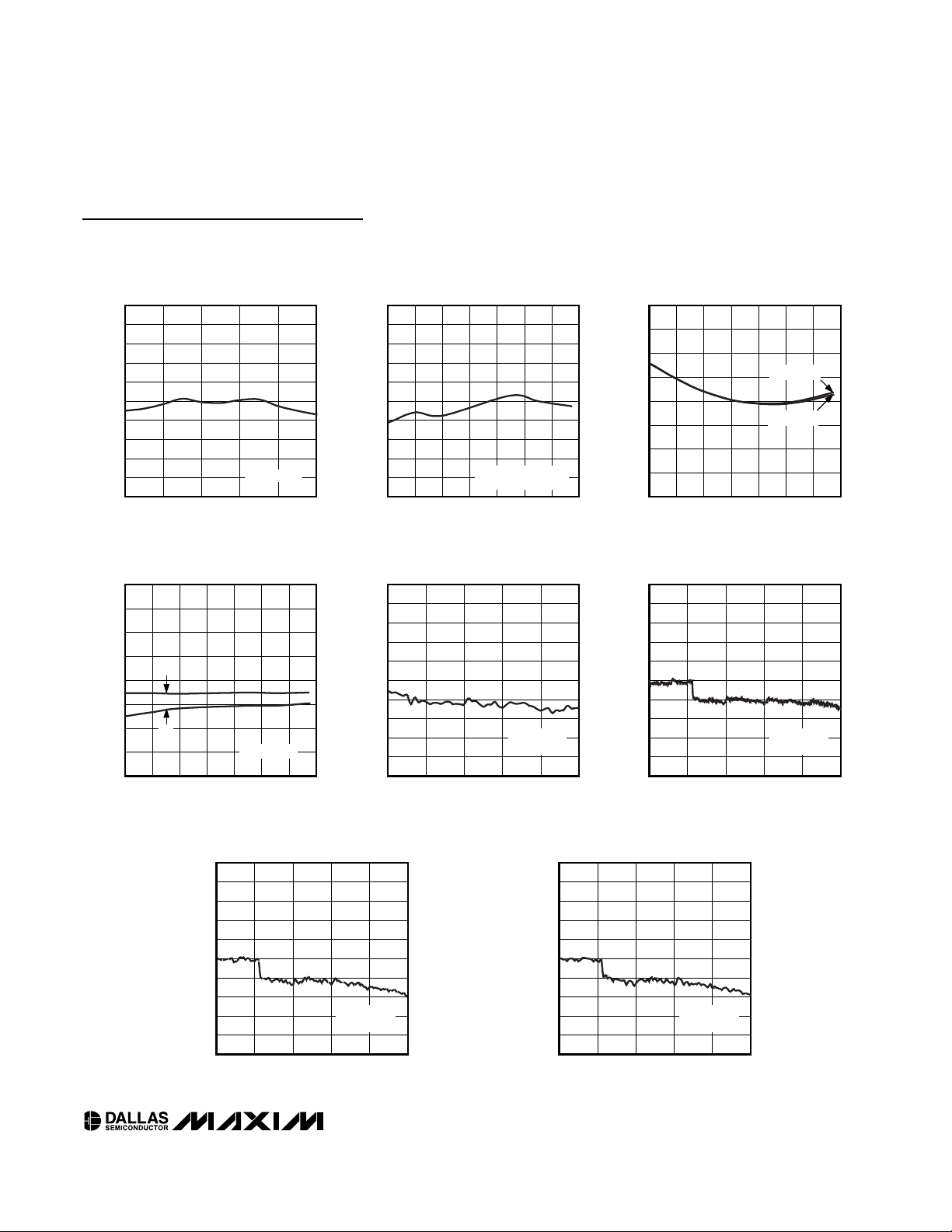

Typical Operating Characteristics (continued)

(VCC= +5.0V, TA = +25°C, unless otherwise noted.)

OUTPUT DRIFT (PPM/C)

-15

-10

-5

0

5

10

15

20

-20

POTENTIOMETER LOW TERMINAL VOLTAGE

vs. TEMPERATURE

DS1870 toc12

TEMPERATURE (°C)

8060-20 0 20 40-40 100

L1

L2

H

COM

= 5.0V

VCC CONVERSION ERROR

vs. SUPPLY VOLTAGE

DS1870 toc13

SUPPLY VOLTAGE (V)

ERROR (% FS)

5.04.54.03.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

-0.5

3.0 5.5

DEFAULT V

CC

CALIBRATION

VD CONVERSION ERROR

vs. INPUT VOLTAGE

DS1870 toc14

INPUT VOLTAGE (V)

ERROR (% FS)

2.01.51.00.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

-0.5

0 2.5

DEFAULT VD

CALIBRATION

ID1 CONVERSION ERROR

vs. INPUT VOLTAGE

DS1870 toc15

INPUT VOLTAGE (V)

ERROR (% FS)

0.40.30.20.1

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

-0.5

0 0.5

DEFAULT ID1

CALIBRATION

ID2 CONVERSION ERROR

vs. INPUT VOLTAGE

DS1870 toc16

INPUT VOLTAGE (V)

ERROR (% FS)

0.40.30.20.1

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

-0.5

0 0.5

DEFAULT ID2

CALIBRATION

POTENTIOMETER 1 AND 2

WIPER RESISTANCE vs. WIPER VOLTAGE

DS1870 toc09

WIPER VOLTAGE (V)

WIPER RESISTANCE (Ω)

4321

100

200

300

400

500

600

700

800

900

1000

0

05

H

COM

= 5.0V

POTENTIOMETER 1 AND 2

WIPER RESISTANCE vs. TEMPERATURE

DS1870 toc10

TEMPERATURE (°C)

RESISTANCE CHANGE FROM 25°C (PPM/C)

806020 400-20

100

200

300

400

500

600

700

800

900

1000

0

-40 100

H

COM

= 5V

WIPER VOLTAGE = 4V

POTENTIOMETER END-TO-END RESISTANCE

vs. TEMPERATURE

DS1870 toc11

TEMPERATURE (°C)

CHANGE FROM RESISTANCE AT 25°C (PPM/C)

8060-20 0 20 40

-150

-100

-50

0

50

100

150

200

-200

-40 100

R

POT2

+ R

S2

R

POT1

+ R

S1

Page 8

DS1870

LDMOS RF Power-Amplifier Bias

Controller

8 _____________________________________________________________________

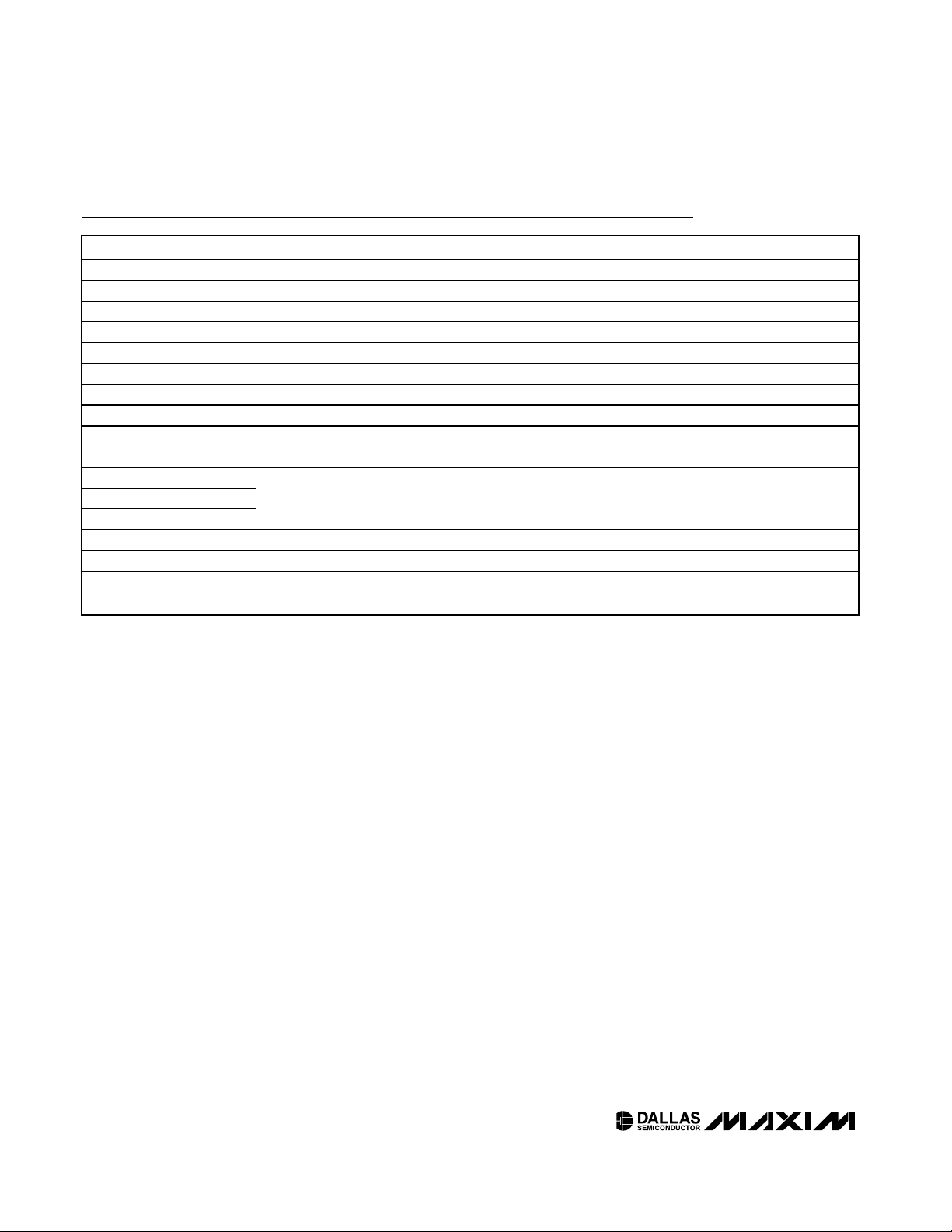

Pin Description

PIN NAME FUNCTION

1L1Potentiometer 1 Low Terminal

2W1Potentiometer 1 Wiper Terminal

3W2Potentiometer 2 Wiper Terminal

4L2Potentiometer 2 Low Terminal

5ID1Drain Current 1 Monitor Input

6ID2Drain Current 2 Monitor Input

7VDDrain Voltage Monitor Input

8 GND Ground

9 FAULT

Fault Output. This open-collector output is active high when one of the enabled alarms is outside its

programmable limit value.

10 A

0

11 A

1

12 A

2

I2C Address Inputs. These inputs determine the slave address of the device. The slave address in

binary is 1010A

2A1A0

.

13 SCL Serial Clock Input. I2C clock input.

14 SDA Serial Data Input/Output. Bidirectional I2C data pin.

15 H

COM

Potentiometer High Terminal. Common to potentiometers 1 and 2.

16 V

CC

Power Input

Page 9

DS1870

LDMOS RF Power-Amplifier Bias

Controller

_____________________________________________________________________ 9

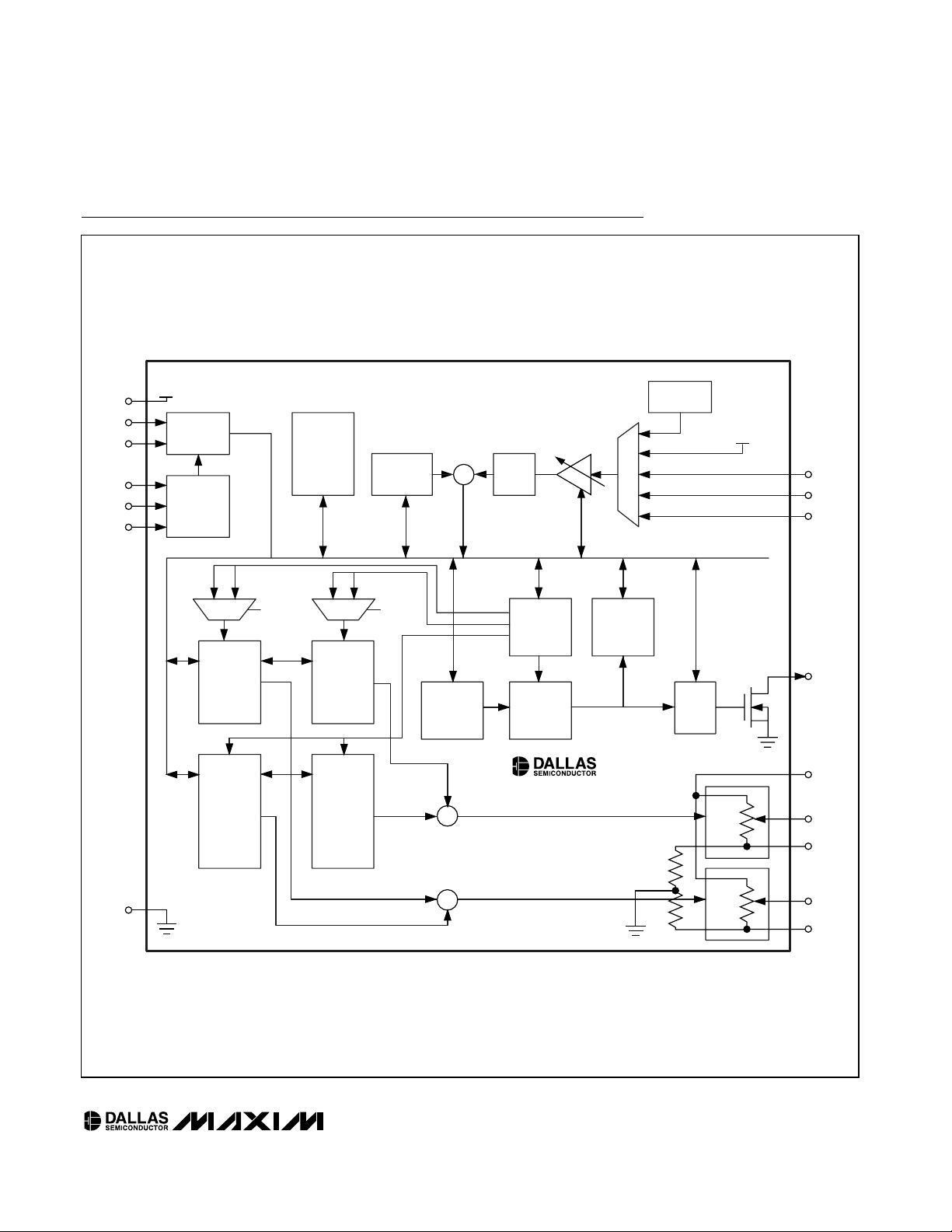

Functional Diagram

∑

∑

+

+

+

+

∑

++

M

U

X

13-BIT

ADC

ON-CHIP

TEMP SENSOR

V

CC

V

D

I

D1

I

D2

ADDRESS

GENERATION

SDA

SCL

A

0

A

1

A

2

I2C DATA BUS

32 BYTES

USER

MEMORY

OFFSET

CALIBRATION

REGISTERS

FAULT

LOAD

INDEX

INDEX

INDEX

INDEX

LOAD

TEMP

POT1

R

POT

POT2

R

POT

H

COM

L

2

W

2

W

1

L

1

POT1

DRAIN

LUT

TABLE 4

(64 BYTES)

POT2

DRAIN

LUT

TABLE 5

(64 BYTES)

LIMIT

COMPARATOR

LIMIT FLAG

REGISTERS

FAULT

MASK

V

CC

V

CC

GND

GAIN

CALIBRATION

REGISTERS

V

D

VD1

VD2

V

D

I

D2

I

D1

POT1

TEMP

LUT

TABLE 2

(72 BYTES)

POT2

TEMP

LUT

TABLE 3

(72 BYTES)

R

S

R

S

I

2

C INTERFACE

CONTROL

HI AND LO

LIMITS FOR

TEMP, V

CC

,

V

D

, ID1, I

D2

MEASURED

VALUES FOR

TEMP, V

CC

,

V

D

, ID0, I

D1

DS1870

Page 10

DS1870

LDMOS RF Power-Amplifier Bias

Controller

10 ____________________________________________________________________

Detailed Description

The DS1870 is a dual-channel LDMOS bias controller.

It is intended to replace traditional bias control solutions that are limited by a constant temperature-coefficient correction. This IC offers lookup table correction

that is programmable as a function of temperature as

well as drain supply voltage or current. The flexibility to

use a nonlinear bias correction improves efficiency significantly. This is a direct consequence of the ability to

lower the bias current, particularly in class AB operation, since the bias correction no longer requires a constant temperature coefficient. In addition, correcting the

bias as a function of drain supply voltage, or drain current in class AB, assists in distortion reduction and gain

management.

Two outputs (W1 and W2), each controlled by a dedicated two-dimensional lookup table as shown in the

functional diagram, drive two LDMOS gates. The two

degrees of freedom are temperature and either drain

supply voltage or drain current. The lookup tables are

programmed during power-amplifier assembly and

test. After calibration, the IC automatically recalls the

proper control setting for each output, based on temperature and drain characteristics.

A 13-bit ADC samples and digitizes the chip temperature, VCC, the drain supply voltage, and two drain currents. These digitized signals are stored in memory

ready to be accessed by the look up table controls.

The digitized values are also compared to alarm

thresholds generating high or low alarm flags. The

FAULT output can be configured to assert high based

any alarm’s assertion, or the alarms can be masked to

prevent unwanted fault assertions. The ADC readings

as well as the alarm flags and fault status are accessible through the I2C-compatible interface.

Voltage/Current Monitor Operation

The DS1870 monitors four voltages (VCC, VD, ID1, and

ID2) plus the temperature in a round-robin fashion using

its 13-bit ADC. The converted voltage values are stored

in memory addresses 62h–69h as 16-bit unsigned

numbers with the ADC result left justified in the register.

The three least significant bits of the ADC result registers

are masked to zero. The round-robin time is specified by

t

frame

in the analog voltage-monitoring characteristics.

The default factory-calibrated values for the voltage

monitors are shown in Table 1.

To calculate the voltage measured from the register

value, first calculate the LSB weight of the 16-bit register that is equal to the full-scale voltage span divided

by 65,528. Next, convert the hexadecimal register

value to decimal and multiply it times the LSB weight.

Example: Using the factory default VCCtrim, what voltage is measured if the V

CC

register value is C347h?

The LSB for V

CC

is equal to (6.553V - 0V) / 65,528 =

100.00µV. C347h is equal to 49,991 decimal, which

yields a supply voltage equal to 49,991 x 100.00µV =

4.999V. Table 2 shows more conversion examples

based on the factory trimmed ADC settings.

By using the internal gain and offset calibration registers, the +FS and -FS signal values shown in Table 1

can be modified to meet customer needs. For more

information on calibration, see the Voltage/Temperature

Monitor Calibration section.

Note: The method shown above for determining the

input voltage level only works when the offset register is

set to zero.

SIGNAL

+FS SIGNAL

+FS

(hex)

-FS

-FS

(hex)

V

CC

6.553V FFF8 0V 0000

V

D

2.5V FFF8 0V 0000

I

D1

0.5V FFF8 0V 0000

I

D2

0.5V FFF8 0V 0000

Table 1. Voltage-Monitor Factory Default

Calibration

SIGNAL

LSB

REGISTER

INPUT

VOLTAGE (V)

V

CC

100.00 8080 3.29

V

CC

100.00 C0F8 4.94

V

D

38.152 C000 1.875

V

D

38.152 8080 1.255

I

D1

7.6303 8000 0.2500

I

D2

7.6303 1328 0.0374

Table 2. Voltage-Monitor Conversion

Examples

SIGNAL

WEIGHT (µV)

VALUE (hex)

Page 11

DS1870

LDMOS RF Power-Amplifier Bias

Controller

____________________________________________________________________ 11

Temperature-Monitor Operation

The internal temperature monitor values are stored as

16-bit 2’s complement numbers at memory addresses

60h to 61h. The round-robin update time (t

frame

) for the

temperature register is the same as the voltage monitors. The factory default calibration values for the temperature monitor are shown in Table 3.

To convert the 2’s complement register value to the

temperature it represents, first convert the 2-byte hexadecimal value to a decimal value as if it is an unsigned

value, then divide the result by 256. Finally, subtract

256 if the result of the division is greater than or equal

to +128. Table 4 shows example converted values.

The offset of the temperature sensor can be adjusted

using the internal calibration registers to account for

differences between the ambient temperature at the

location of the DS1870 and the temperature of the

device it is biasing. When offsets are applied to the

temperature measurement, the value converted will be

off by a fixed value from the DS1870’s ambient temperature. For more information, see the Temperature

Monitor Offset Calibration section.

Potentiometer Operation

Both of the DS1870’s potentiometers are 256 positions

with their high terminals connected to the high common

pin, H

COM

. The low terminals of the potentiometers are

internally shunted to GND by resistors such that the

output voltage is 3V to 5V when H

COM

is connected to

a 5V source. The internal shunt resistors and the potentiometer’s end-to-end resistance feature matching temperature coefficients that prevent the output voltage

from drifting over temperature.

External resistors can be placed from H

COM

to LXand/or

from LXto GND to modify the typical output voltage.

Normal Operation

During normal operation, each potentiometer’s position

is automatically adjusted to the sum of its temperature

and drain LUT values after each round of conversions.

The potentiometer setting is applied after both the base

and offset LUT values are recalled from memory. The

sum of the currently indexed values in the POT1 Temp

LUT (memory table 2) and the POT1 Drain LUT (memory table 4) control potentiometer 1. The sum of the currently indexed values in the POT2 Temp LUT (memory

table 3) and the POT2 Drain LUT (memory table 5) control potentiometer 2. In the event that two table values

are summed and the result is greater than 255 or less

than 0, the potentiometer’s position is set to 255 or 0,

respectively.

SIGNAL

+FS

+FS

(hex)

-FS

-FS

(hex)

Temp

7FF8

8000

Table 3. Internal Temperature-Monitor

Factory Default Calibration

MSB

(bin)

LSB

(bin)

TEMPERATURE

(°C)

01000000 00000000 +64

01000000 00001111 +64.059

01011111 00000000 +95

11110110 00000000 -10

11011000 00000000 -40

Table 4. Temperature Conversion Values

LUT ADDRESS (hex)

CORRESPONDING

TEMPERATURE (°C)

80 ≤ -40°C

81 -38°C

82 -36°C

……

C6 +100°C

C7 ≥ +102°C

Table 5. LUT Addresses for

Corresponding Temperature Values

SIGNAL

+127.97°C

SIGNAL

-128.00°C

Page 12

DS1870

LDMOS RF Power-Amplifier Bias

Controller

12 ____________________________________________________________________

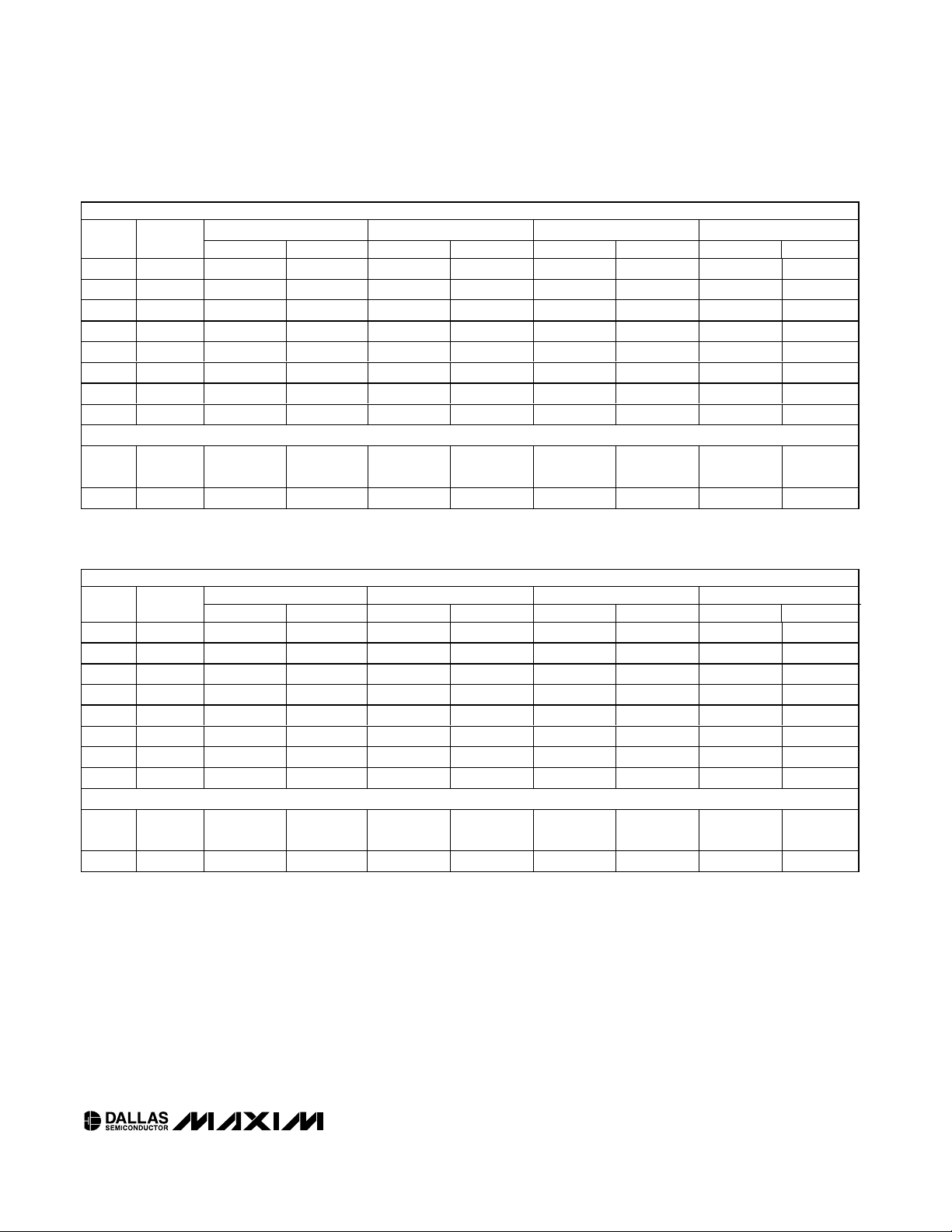

The temperature tables (LUT 2 and LUT 3) are 72 bytes

each. This allows the biasing to be adjusted every 2°C

between -40°C and +102°C. Temperatures less than

-40°C or greater than 102°C use the -40°C or 102°C

values, respectively. The values in the temperature

tables are 8-bit unsigned values (0 to 255 decimal) that

allow the potentiometer to be set to any position as a

function of the temperature. The temperature LUTs

have 1°C hysteresis (Figure 1) to prevent the potentiometer’s position from chattering in the event the temperature remains near a LUT switching point. Table 5

shows how the DS1870 determines the temperature

tables index as a function of temperature.

The drain tables (LUT 4 and LUT5) are 64 bytes each,

and they can be indexed either by the drain voltage or

the drain current corresponding to the potentiometer.

The VD1 control bit determines if the voltage sensed on

VDor ID1adjusts the POT1 Drain LUT, and the VD2

control bit determines if the voltage sensed on VDor

I

D2

controls the POT2 Drain LUT. The VD1 and VD2

control bits are located in register 85h of memory table

1. The drain tables are programmed with an 8-bit

signed value (-128 to +127 decimal) that allow a relative offset from the temperature LUT values determined

by the amplifier’s drain characteristics.

The drain LUTs are indexed either by the upper half of

the V

D

range or the lower half of its corresponding I

DX

range. Table 6 shows how the index is determined

based on the VDor IDXvalues. Hysteresis equal to

0100h is also implemented on the drain monitor

(Figure 1) to ensure that voltages close to a switching

point do not cause the potentiometer position to chatter

between two LUT values. The drain LUT index values are

specified in hexadecimal because the hexadecimal values are applicable regardless of the gain and offset calibration of the DS1870.

Manual Mode

During normal operation, the potentiometer position is

automatically modified once per conversion cycle

based on the ADC results. The DS1870 can either stop

the update function all together by using the B/O_en

bit, or the temperature and drain LUT indexes can be

manually controlled by using the Index_en bit. These

bits are located in the Man DAC register located in

memory table 1, byte AFh. More information about

these bits is in the Register Description section.

Voltage-Monitor Calibration

The DS1870 can scale each analog voltage’s gain and

offset to produce the desired digital result. Each of the

inputs (VCCVD, ID1, ID2) has a unique register for the

gain and offset (in memory table 1) allowing them to be

individually calibrated. Additionally, the DS1870 offers

the ability to provide a temperature offset to allow the

temperature measurement to be compensated to

account for the difference in temperature between the

DS1870 and the device it is biasing.

To scale the gain and offset of the converter for a specific input, you must first know the relationship between

the analog input and the expected digital result. The

input that would produce a digital result of all zeros is

the null value (normally this input is GND). The input

that would produce a digital result of all ones (FFF8h) is

LUT ADDRESS

(hex)

V

D

VALUE

(hex)

IDX VALUE

(hex)

80 ≤ 8000 0000

81 8200 0200

82 8400 0400

…… …

BE FC00 7C00

BF ≥ FE00 ≥ 7E00

Table 6. LUT Addresses for VDor I

DX

Values

9Ah

99h

98h

97h

96h

95h

246 810 12

TEMPERATURE (°C)

MEMORY LOCATION

MEMORY LOCATION

MEMORY LOCATION

9Ah

99h

98h

97h

96h

95h

AA00 AC00 AEOO B000 B200 B400

DRAIN VOLTAGE CONVERSION (HEX)

9Ah

99h

98h

97h

96h

95h

2A00 2C00 2E00 3000 3200 3400

DRAIN CURRENT CONVERSION (HEX)

INCREASING

TEMPERATURE

INCREASING

DRAIN VOLTAGE

INCREASING

DRAIN CURRENT

DECREASING

TEMPERATURE

DECREASING

DRAIN VOLTAGE

DECREASING

DRAIN CURRENT

Figure 1. LUT Hysteresis

Page 13

DS1870

LDMOS RF Power-Amplifier Bias

Controller

____________________________________________________________________ 13

the full-scale (FS) value. The expected FS value is also

found by multiplying an all-ones digital answer by the

LSB weight.

Example: Since the FS digital reading is 65,528 (FFF8

hex) LSBs, if the LSB’s weight is 50µV, then the FS

value is 65,528 x 50µV = 3.2764V.

A binary search is used to calibrate the gain of the converter. This requires forcing two known voltages to the

input pin. It is preferred that one of the forced voltages

is the null input and the other is 90% of FS. Since the

LSB of the least significant bit in the digital reading register is known, the expected digital results can be calculated for both the null input and the 90% of full scale

value.

An explanation of the binary search used to scale the

gain is best served with the following example pseudocode:

/* Assume that the null input is 0.5V */

/* Assume that the requirement for the LSB is 50µV */

FS = 65528 * 50e-6; /*3.2764V */

CNT1 = 0.5 / 50e-6; /* 1000 */

CNT2 = 0.9 X FS / 50e-6; /* 58981.5 */

/* So the null input is 0.5V and 90% of FS is 2.949V */

Set the input’s offset register to zero

gain_result = 0h; /* Working register for gain

calculation */

CLAMP = FFF8h; /* This is the max ADC value*/

For n = 15 down to 0

begin

gain_result = gain_result + 2

n

;

Write gain_result to the input’s

gain register;

Force the 90% FS input (2.949V);

Meas2= ADC result from DS1870;

If Meas2 ≥ CLAMP

Then

gain_result = gain_result - 2

n

;

Else

Force the null input (0.5V)

Meas1 = ADC result from DS1870

If [(Meas2-Meas1)>(CNT2-CNT1)]

Then

gain_result = gain_result - 2

n

;

end;

Write gain_result to the input’s gain

register;

The gain register is now set and the resolution of the

conversion matches the expected LSB. Customers

requiring non-zero null values (e.g., 0.5V) must next

calibrate the input’s offset. If the desired null value is

0V, leave the offset register programmed to 0000h and

skip this step.

To calibrate the offset register, program the gain register with the gain_result value determined above. Next,

force the null input voltage (0.5V for the example) and

read the digital result from the part (Meas1). The offset

value can be calculated using the following formula:

Temperature-Monitor Offset Calibration

The DS1870’s temperature sensor comes precalibrated

and requires no further adjustment by the customer for

proper operation. However, it is possible for customers

to characterize their system and add a fixed offset to

the DS1870’s temperature reading so it is reflective of

another location’s temperature. This is not required for

biasing because the temperature offset can be

accounted for by adjusting the data’s location in the

LUTs, but this feature is available for customers who

see application benefits.

To change the temperature sensor’s offset: write the

temperature offset register to 0000h, measure the

source reference temperature (T

ref

), and read the tem-

perature from the DS1870 (T

DS1870

). Then, the following formula can be used to calculate the value for the

temperature offset register.

Once the value is calculated, write it to the temperature

offset register.

Power-Up and Low-Voltage Operation

During power-up, the device is inactive until V

CC

exceeds the digital power-on-reset voltage (V

POD

). At

this voltage, the digital circuitry, which includes the I2Ccompatible interface, becomes functional. However,

EEPROM-backed registers/settings cannot be internally

read (recalled) until VCCexceeds the analog power-on

reset (V

POA

), at which time the remainder or the device

becomes fully functional. Once V

CC

exceeds V

POA

, the

Rdyb bit in byte 74h is timed to go from a 1 to a 0 and

indicates when ADC conversions begin. If V

CC

ever

dips below V

POA

, the Rdyb bit reads as a 1 again.

Once a device exceeds V

POA

and the EEPROM is

recalled, the values remain active (recalled) until V

CC

falls below V

POD

.

TempOffset T T XOR BB h

ref DS bitwise

=×− + −

()

()

64 275 40

1870

Offset

Meas

= − ×

1

1

4

Page 14

DS1870

LDMOS RF Power-Amplifier Bias

Controller

14 ____________________________________________________________________

As the device powers up, the VCCLO alarm flag

defaults to a 1 until the first VCCADC conversion

occurs and sets or clears the flag accordingly. The

FAULT output is active when VCC< V

POA

.

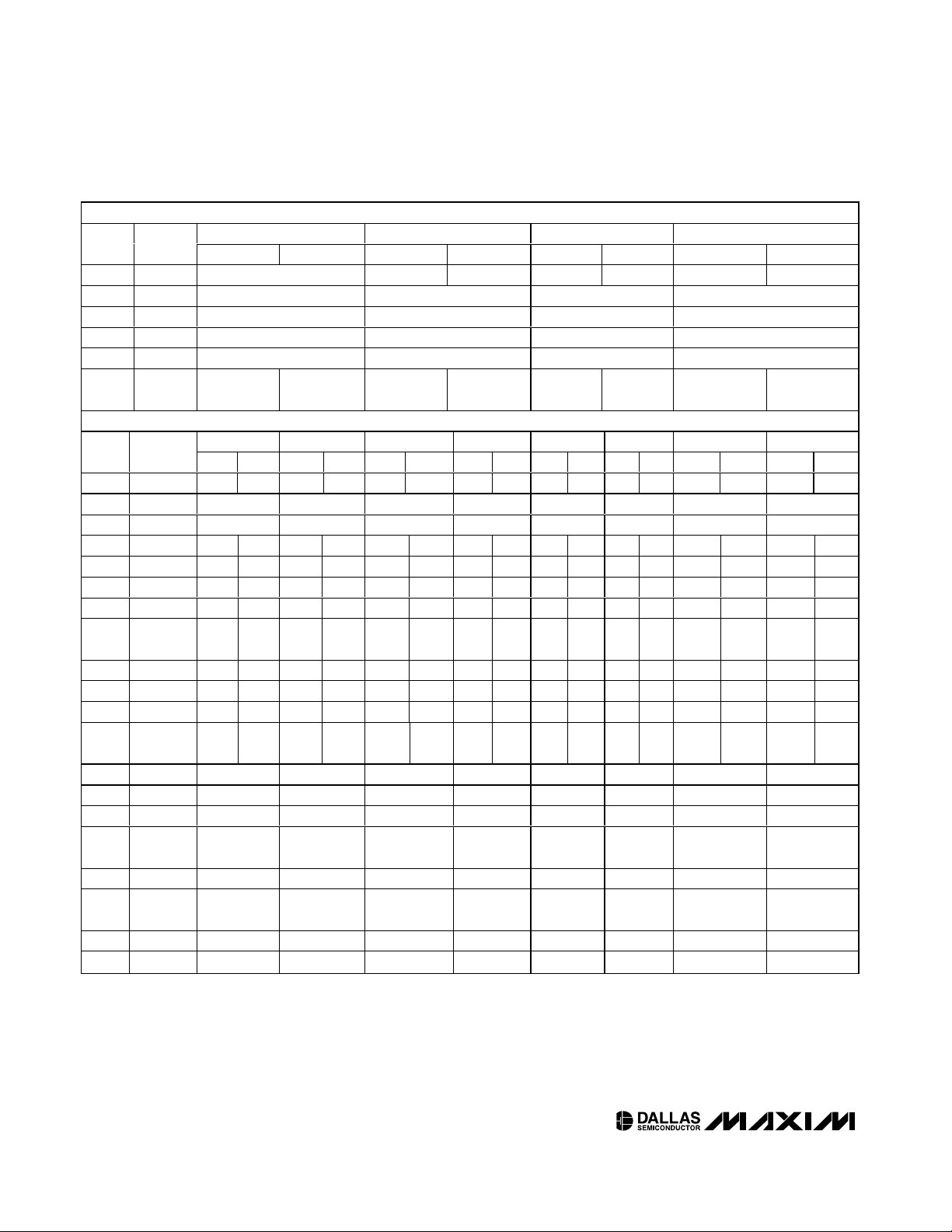

Memory Description

The DS1870 memory map is divided into six sections

that include the lower memory (addresses 00h to 7Fh)

and five memory tables (Figure 2). The memory tables

are addressed by setting the table-select byte (7Fh) to

the desired table number and accessing the upper

memory locations (80h to FFh). The lower memory can

be addressed at any time regardless of the state of the

table-select byte. The lower memory and memory table

1 are used to configure the DS1870 and read the status

of the monitors. The lower memory also contains the 32

bytes of user memory. Memory tables 2 and 3 contain

the base potentiometer positions that are used for biasing based on the reading of the internal temperature

sensor. Memory tables 4 and 5 contain the relative offsets that are added to the base number as a function of

either the drain voltage or the individual drain current

monitors. See the Memory Map for a complete listing of

registers and the Register Description section for

details about each register.

Password Memory Protection

The DS1870 contains a 2-byte password that allows all

of its EE memory to be write protected until the proper

password is entered into the password entry (PWE)

word (address 78h). This allows factory calibration data

for the bias settings, alarm thresholds, and all the other

EEPROM information to be write protected. The password is set by writing to the Password register, which is

the first two bytes of memory table 1.

The factory default value for the password is FFFFh,

which is also the factory default value for PWE on

power-up. This means that parts are unlocked at

power-up when they are first received by customers.

The password should be programmed to a value other

than FFFFh to ensure the calibration data is write protected. The PWE register always reads 0000h regardless of its programmed value.

EEPROM Write Disable

Memory locations 20h to 3Fh and Table 1 locations 80h

to A7h are SRAM-shadowed EEPROM. By default

(SEE = 0) these locations act as ordinary EEPROM. By

setting SEE = 1, these locations begin to function like

SRAM cells, which allow an infinite number of write

cycles without concern of wearing out the EEPROM.

This also eliminates the requirement for the EEPROM

write time. Because changes made with SEE = 1 do not

affect the EEPROM, these changes are not retained

through power cycles. The power-up value is the last

value written with SEE = 0. This function can be used to

limit the number of EEPROM writes during calibration or

to change the monitor thresholds periodically during

normal operation without wearing out the EEPROM. The

SEE bit resides in memory table 1, byte AFh.

Memory Map

The upper part of the memory map is organized into

8-byte or 4-word (2-byte) rows. The beginning address

of the row is shown in the left-most column of the map,

and is equal to the byte 0 or word 0 memory address.

The next byte (Byte 1) is located at the next highest

memory address, and the next word (Word 1) is two

memory addresses greater than the row’s beginning

address. The lower part of the memory map expands

the bytes or the words to show the names of the bits

within the byte/word, or their bit weights (2X) for registers that contain numerical information. Numerical registers that contain an “S” in the most significant bit are

showing sign extension for 2’s complement numbers.

Descriptions of each byte/bit follow in the Register

Description section.

USER MEMORY;

HI/LO ALARM

THRESHOLDS;

ADC RESULTS;

CONFIGURATION

CONFIGURATION

POT1

TEMP

LUT

POT2

TEMP

LUT

POT1

DRAIN

LUT

POT2

DRAIN

LUT

00h

7Fh

80h

AFh

80h

C7h

80h

C7h

80h

BFh

80h

BFh

MAIN MEMORY

TABLE 1 TABLE 2 TABLE 3 TABLE 4 TABLE 5

TABLE-SELECT

BYTE (7Fh)

SEL

SEL SEL

SEL SEL

Figure 2. Memory Organization

Page 15

DS1870

LDMOS RF Power-Amplifier Bias

Controller

____________________________________________________________________ 15

LOWER MEMORY

WORD 0 WORD 1 WORD 2 WORD 3

ROW

(HEX)

ROW

NAME

BYTE 0 BYTE 1 BYTE 2 BYTE 3

BYTE 6

BYTE 7

00

User EE User EE

User EE

User EE

User EE

08

User EE User EE

User EE

User EE

User EE

10

User EE User EE

User EE

User EE

User EE

18

User EE User EE

User EE

User EE

User EE

20

Temp Hi Alarm VCC Hi Alarm VD Hi Alarm ID1 Hi Alarm

28

ID2 Hi Alarm Reserved Reserved Reserved

30

Temp Lo Alarm VCC Lo Alarm VD Lo Alarm ID1 Lo Alarm

38

ID2 Lo Alarm Reserved Reserved Reserved

40

Reserved

48

Reserved

50

Reserved

58

Reserved

60

Temp Value VCC Value VD Value ID1 Value

68

ID2 Value Reserved Reserved Reserved

70 Status

Lo Alarm

Reserved

78

PWE

Tbl Sel

EXPANDED BYTES

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

BYTE

(HEX)

BYTE

NAME

BIT000-1F

User EE EE EE EE EE EE EE EE EE

20

S

2

2

2

-8

22

2

0

24

2

0

26

2

0

28

2

0

30

S

2

2

2

-8

32

2

0

34

2

0

36

2

0

38

2

0

60

S

2

2

2

-8

62

2

0

64 VD Value

2

0

66 ID1 Value

2

0

68 ID2 Value

2

0

70 Hi Alarm Temp Hi VCC Hi VD Hi ID1 Hi ID2 Hi

Reserved

71 Lo Alarm Temp Lo VCC Lo VD Lo ID1 Lo ID2 Lo

Reserved

74 I/O Status

Fault Mint

Rdyb

75

VD Rdy

ID2 Rdy

Reserved

78 PWE 2

15

2

0

7F Tbl Sel 2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

User Row

User Row

User Row

User Row

Threshold

Threshold

Threshold

Threshold

A2D Value

A2D Value

Table Select

0

1

2

3

0

1

2

3

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

0

1

Hi Alarm

Temp Hi Alrm

VCC Hi Alrm 2

VD Hi Alrm 2

ID1 Hi Alrm 2

ID2 Hi Alrm 2

Temp Lo Alrm

VCC Lo Alrm 2

VD Lo Alrm 2

ID1 Lo Alrm 2

ID2 Lo Alrm 2

Temp Value

VCC Value 2

BIT15BIT14BIT13BIT12BIT11BIT10BIT9BIT8BIT7BIT6BIT5BIT4BIT3BIT2BIT

2

2

2

6

2

15

2

15

2

15

2

15

2

2

15

2

15

2

15

2

15

2

2

15

2

15

2

15

2

15

2

5

2

14

13

2

14

13

2

14

13

2

14

13

2

6

5

2

14

13

2

14

13

2

14

13

2

14

13

2

6

5

2

14

13

2

14

13

2

14

13

2

14

13

2

Reserved Reserved Reserved Reserved

A2D Status Temp Rdy VCC Rdy

14

2

13

2

User EE

User EE

User EE

User EE

Reserved Reserved I/O Status A2D Status Reserved

Reserved Reserved Reserved Reserved Reserved

4

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

2

12

11

2

12

12

12

4

12

12

12

12

4

12

12

12

12

2

11

2

2

11

2

2

11

2

2

3

2

11

2

2

11

2

2

11

2

2

11

2

2

3

2

11

2

2

11

2

2

11

2

2

11

2

2

1

2

10

9

2

10

9

2

10

9

2

10

9

2

1

2

10

9

2

10

9

2

10

9

2

10

9

2

1

2

10

9

2

10

9

2

10

9

2

10

9

2

ID1 Rdy

12

11

2

2

10

2

2

BYTE 4 BYTE 5

User EE User EE

User EE User EE

User EE User EE

User EE User EE

0

8

8

8

8

0

8

8

8

8

0

8

8

8

8

282

-1

2

7

2

7

2

7

2

7

2

-1

2

7

2

7

2

7

2

7

2

-1

2

7

2

7

2

7

2

7

2

7

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

9

2-22-32-42-52-62

26252423222

26252423222

26252423222

26252423222

2-22-32-42-52-62

26252423222

26252423222

26252423222

26252423222

2-22-32-42-52-62

26252423222

26252423222

26252423222

26252423222

Reserved Reserved

Reserved Reserved

Reserved

Reserved Reserved

26252423222

1

-7

1

1

1

1

-7

1

1

1

1

-7

1

1

1

1

1

Page 16

DS1870

LDMOS RF Power-Amplifier Bias

Controller

16 ____________________________________________________________________

TABLE 1 ( CONFIGURATION )

WORD 0 WORD 1 WORD 2 WORD 3

ROW

(HEX)

ROW

BYTE 0 BYTE 1 BYTE 2 BYTE 3

BYTE 6 BYTE 7

80

Password

Fault Ena Reserved

88

Reserved Vcc Scale VD Scale ID1 Scale

90

ID2 Scale Reserved Reserved Reserved

98

Reserved Vcc Offset VD Offset ID1 offset

A0

ID2 Offset Reserved Reserved Temp Offset

A8

LUT

T Index

POT2

base

POT2 off Man Dac

EXPANDED BYTES

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

BYTE

(HEX)

BYTE

BIT

0

80

2

3

2

2

2

1

2

0

85

Reserved

VD2 VD1

86

Vcc Ena VD Ena

Reserved Reserved

8A

Vcc

2

3

2

2

2

1

2

0

8C

2

3

2

2

2

1

2

0

8E

2

3

2

2

2

1

2

0

90

2

3

2

2

2

1

2

0

9A

Vcc

Offset

2

5

2

4

2

3

2

2

9C

2

5

2

4

2

3

2

2

9E

ID1

2

5

2

4

2

3

2

2

A0

ID2

2

5

2

4

2

3

2

2

A6

Temp

Offset

2

5

2

-3

2

-4

2

-5

2

-6

A8

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

A9

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

AA

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

AB

POT1

base

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

AC

S262

5

2

4

2

3

2

2

2

1

2

0

AD

POT2

base

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

AE

S262

5

2

4

2

3

2

2

2

1

2

0

AF

Reserved

SEE B/O_en index_en

NAME

Config

Scale

0

Scale

1

Offset

0

Offset

1

Index

NAME

Password 2

LUT Sel Reserved Reserved

Fault Ena Temp Ena

VD Scale 2

ID1 Scale 2

ID2 Scale 2

BIT

BIT14BIT13BIT12BIT11BIT10BIT9BIT8BIT7BIT6BIT5BIT4BIT3BIT2BIT

15

15

15

2

15

15

15

SS2152

VD Offset S S 2

SS2152

SS2152

S282

T Index

O1 Index

O1 Index O2 Index POT1 base POT1 off

14

13

12

11

10

2

2

2

2

2

9

2

Reserved Reserved Reserved

ID1 Ena ID2 Ena Reserved

14

13

12

11

10

2

2

2

2

14

13

2

2

14

2

2

14

2

2

12

2

13

12

2

13

12

2

14

15

14

2

14

14

7

6

2

2

11

2

2

11

2

2

11

2

2

13

2

2

13

2

2

13

2

2

13

2

2

2

9

2

10

9

2

10

9

2

10

9

2

12

11210

2

12

11210

2

12

11210

2

12

11210

2

4

3

2

O2 Index

POT1 off

POT2 off

Man DAC Reserved Reserved

Reserved Reserved

BYTE 4 BYTE 5

LUT Sel

8

2

2726252

4

8

2

2726252

8

2

2726252

8

2

2726252

8

2

2726252

2928272

2928272

2928272

2928272

2

2

21202-12

4

4

4

4

6

6

6

6

-2

1

Page 17

DS1870

LDMOS RF Power-Amplifier Bias

Controller

____________________________________________________________________ 17

TABLE 2 (POT1 TEMP LUT)

WORD 0 WORD 1 WORD 2 WORD 3

ROW

(HEX)

ROW

NAME

BYTE 0 BYTE 1 BYTE 2 BYTE 3 BYTE 4 BYTE 5 BYTE 6 BYTE 7

80 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

88 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

90 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

98 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

A0 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

A8 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

B0 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

B8 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

C0 LUT POT1 POT1 POT1 POT1 POT1 POT1 POT1 POT1

C8

Reserved

D0

Reserved

D8

Reserved

E0

Reserved

E8

Reserved

F0

Reserved

F8

Reserved

EXPANDED BYTES

BYTE

(HEX)

BYTE

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

80-C7

POT1 2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

NAME

Page 18

DS1870

LDMOS RF Power-Amplifier Bias

Controller

18 ____________________________________________________________________

TABLE 3 ( POT2 TEMP LUT)

WORD 0 WORD 1 WORD 2 WORD 3

ROW

(HEX)

ROW

BYTE 0 BYTE 1 BYTE 2 BYTE 3 BYTE 4 BYTE 5 BYTE 6 BYTE 7

80 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

88 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

90 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

98 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

A0 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

A8 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

B0 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

B8 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

C0 LUT POT2 POT2 POT2 POT2 POT2 POT2 POT2 POT2

C8

Reserved

D0

Reserved

D8

Reserved

E0

Reserved

E8

Reserved

F0

Reserved

F8

Reserved

EXPANDED BYTES

BYTE

(HEX)

BYTE

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

80-C7

POT2 2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

NAME

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved Reserved Reserved Reserved

NAME

Page 19

DS1870

LDMOS RF Power-Amplifier Bias

Controller

____________________________________________________________________ 19

TABLE 4 ( POT1 DRAIN LUT)

WORD 0 WORD 1 WORD 2 WORD 3

ROW

(HEX)

ROW

BYTE 0 BYTE 1 BYTE 2 BYTE 3 BYTE 4 BYTE 5 BYTE 6 BYTE 7

80 LUT

POT1 Off

88 LUT

POT1 Off

90 LUT

POT1 Off

98 LUT

POT1 Off

A0 LUT

POT1 Off

A8 LUT

POT1 Off

B0 LUT

POT1 Off

B8 LUT

POT1 Off

EXPANDED BYTES

BYTE

(HEX)

BYTE

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

80-BF

S262

5

2

4

2

3

2

2

2

1

2

0

NAME

POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off

POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off

POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off

POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off

POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off

POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off

POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off

POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off POT1 Off

NAME

POT1 Off

TABLE 5 (POT2 DRAIN LUT)

ROW

(HEX)

ROW

NAME

80 LUT POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off

88 LUT POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off

90 LUT POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off

98 LUT POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off

A0 LUT POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off

A8 LUT POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off

B0 LUT POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off

B8 LUT POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off POT2 Off

BYTE

(HEX)

BYTE

NAME

80-BF POT2 Off S 2

WORD 0 WORD 1 WORD 2 WORD 3

BYTE 0 BYTE 1 BYTE 2 BYTE 3 BYTE 4 BYTE 5 BYTE 6 BYTE 7

EXPANDED BYTES

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

6

5

2

4

2

3

2

2

2

1

2

0

2

Page 20

DS1870

LDMOS RF Power-Amplifier Bias

Controller

20 ____________________________________________________________________

Register Description

The register descriptions are organized by the register’s row address starting with the lower memory, then proceeding through each lookup table in order. The format of the register description is shown below.

TABLE NAME

Name of Row

Name of Byte <Access><Volatility><Power-On/

Factor Default Values> Description

of the byte’s function

a) bit X bit X description

b) bit Y bit Y description

The Access value following each byte’s name defines the read/write access for the register. Possible values are

read-only (R), write-only (W), and read-write (R/W). The Volatility parameter defines if the memory is volatile (V) or

nonvolatile (NV). Some registers correspond to values measured or detected by the DS1870. These parameters are

read-only and listed as NA since their values are indeterminate. Power-On values are the default states of the

volatile register, and the Factory Default values are the values the EEPROM memory is programmed to by the

factory before they are shipped from Dallas Semiconductor.

LOWER MEMORY

User Row

User EE <R/W><NV><00h> NV EEPROM user memory.

Threshold

0

Temp Hi Alarm<R/W><NV><0000h> Temperature measurements above this 2’s complement threshold set its

corresponding alarm bit. Measurements below this threshold clear the alarm bit.

Vcc Hi Alarm <R/W><NV><0000h> Voltage measurements of the VCCinput above this unsigned threshold

set its corresponding alarm bit. Measurements below this threshold clear the alarm bit.

VD Hi Alarm <R/W><NV><0000h> Voltage measurements of the VDinput above this unsigned threshold

set its corresponding alarm bit. Measurements below this threshold clear the alarm bit.

ID1 Hi Alarm <R/W><NV><0000h> Voltage measurements of the I

D1

input above this unsigned threshold set

its corresponding alarm bit. Measurements below this threshold clear the alarm bit.

Threshold

1

ID2 Hi Alarm <R/W><NV><0000h> Voltage measurements of the ID2input above this unsigned threshold set

its corresponding alarm bit. Measurements below this threshold clear the alarm bit.

Threshold

2

Temp Lo Alarm<R/W><NV><0000h> Temperature measurements below this 2’s complement threshold set its

corresponding alarm bit. Measurements above this threshold clear the alarm bit.

Vcc Lo Alarm <R/W><NV><0000h> Voltage measurements of the VCCbelow above this unsigned threshold

set its corresponding alarm bit. Measurements above this threshold clear the alarm bit.

VD Lo Alarm <R/W><NV><0000h> Voltage measurements of the VDinput below this unsigned threshold set

its corresponding alarm bit. Measurements above this threshold clear the alarm bit.

ID1 Lo Alarm <R/W><NV><0000h> Voltage measurements of the ID1input below this unsigned threshold set

its corresponding alarm bit. Measurements above this threshold clear the alarm bit.

Threshold

3

ID1 Lo Alarm <R/W><NV><0000h> Voltage measurements of the ID2input below this unsigned threshold set

its corresponding alarm bit. Measurements above this threshold clear the alarm bit.

Page 21

DS1870

LDMOS RF Power-Amplifier Bias

Controller

____________________________________________________________________ 21

A2D Value

0

Temp Value <R><NA><0000h> The signed 2’s complement direct-to-temperature measurement.

Vcc Value <R><NA><0000h> Unsigned V

CC

voltage measurement.

VD Value <R><NA><0000h> Unsigned VD voltage measurement.

ID1 Value <R><NA><0000h> Unsigned I

D1

voltage measurement.

A2D Value

1

ID2 Value <R><NA><0000h> Unsigned I

D2

voltage measurement.

Status

Hi Alarm <R><NA><00h> High-Alarm Status bits.

a) Temp Hi High-alarm status for temperature measurement.

b) Vcc Hi High-alarm status for VCCmeasurement.

c) VD Hi High-alarm status for VDmeasurement.

d) ID1 Hi High-alarm status for ID1measurement.

e) ID2 HI High-alarm status for I

D2

measurement.

Lo Alarm <R><NA><40h> Low-Alarm Status bits.

a) Temp Lo Low-alarm status for temperature measurement.

b) Vcc Lo Low-alarm status for V

CC

measurement. This bit is set when the VCCsupply is below

the POR trip-point value. It clears itself when a VCCmeasurement is completed and

the value is above the low threshold.

c) VD Lo Low-alarm status for VDmeasurement.

d) ID1 Lo Low-alarm status for ID1measurement.

e) ID2 Lo Low-alarm status for I

D2

measurement.

I/O Status <R><NA><see below> Status of the FAULT pin.

a) Fault Logical value of the FAULT pin. Fault is logic HIGH during power-on.

b) Mint Maskable Interrupt. FAULT is an open-drain output. In case FAULT was pulled low

externally or was missing the external pullup resistor, this bit reflects the logical value

the DS1870 is trying to output on the FAULT pin. If any ‘Hi Alarm’ or ‘Lo Alarm’ is

active and its corresponding ‘Fault Ena’ bit is enabled, or ‘RDBY’ is a 1, then this bit is

active high. Otherwise, this bit is a zero.

c) Rdyb Ready Bar. When the supply is above the power-on-analog (V

POA

) trip point, this bit is

active low. Thus, this bit reads a logic 1 if the supply is below V

POA

or too low to com-

municate over the I2C bus.

A2D Status <R/W><V><00h> Status of completed conversions. At power-on, these bits are cleared and are

set as each conversion is completed. These bits can be cleared so that completion

of new conversions may be verified.

a) Temp Rdy Temperature conversion is ready.

b) Vcc Rdy VCCconversion is ready.

c) VD Rdy VDconversion is ready.

d) ID1 Rdy I

D1

conversion is ready.

e) ID2 Rdy I

D2

conversion is ready.

Page 22

DS1870

LDMOS RF Power-Amplifier Bias

Controller

22 ____________________________________________________________________

PWE

PWE <W><V><FFFFh> Password Entry. Until the correct password is written to this location, the only

memory that can be written are addresses 78h to 7Fh. This includes the PWE and Table_Select

locations. All memory is readable regardless of the PWE value.

TBL Sel <R/W><V><00h> Table Select. The DS1870 contains four tables (1 to 5). Writing a (1 to 5) value

to this register grants access to the corresponding table.

TABLE 1 (CONFIGURATION)

Config

Password <R/W><NV><FFFFh> The PWE value is compared against the value written to this location. All

EEPROM memory is write-protected when PWE does not match thisregister.

LUT Sel <R/W><NV><03h> Selects which inputs are used to control the lookup tables.

a) VD2 A one selects the VDinput to control the drain LUT indexing for POT2 (Table 5). A zero

selects the ID2input.

b) VD1 A one selects the VDinput to control the drain LUT indexing for POT1 (Table 4). A zero

selects the ID1input.

Fault Ena <R/W><NV><00h> Configures the maskable interrupt for the FAULT pin.

a) Temp Ena Temperature measurements, outside the threshold limits, are enabled to create an

active interrupt on the FAULT pin.

b) Vcc Ena VCCmeasurements, outside the threshold limits, are enabled to create an active

interrupt on the FAULT pin.

c) VD Ena VDmeasurements, outside the threshold limits, are enabled to create an active

interrupt on the FAULT pin.

d) ID1 Ena ID1measurements, outside the threshold limits, are enabled to create an active

interrupt on the FAULT pin.

e) ID2 Ena ID2measurements, outside the threshold limits, are enabled to create an active

interrupt on the FAULT pin.

Scale

0

Vcc Scale <R/W><NV><XXXX> Controls the scaling or gain of the VCCmeasurements. The VCCgain is

factory trimmed to 6.5535V FS.

VD Scale <R/W><NV><XXXX> Controls the scaling or gain of the V

D

measurements. The VDgain is

factory trimmed to 2.500V FS.

ID1 Scale <R/W><NV><XXXX> Controls the scaling or gain of the ID1measurements. The ID1gain is

factory trimmed to 0.5V FS.

Scale

1

ID2 Scale <R/W><NV><XXXX> Controls the scaling or gain of the ID2measurements. The ID2gain is

factory trimmed to 0.5V FS.

Offset

0

Vcc Offset <R/W><NV><0000h> Allows for offset control of VCCmeasurement

VD Offset <R/W><NV><0000h> Allows for offset control of V

D

measurement.

ID1 Offset <R/W><NV><0000h> Allows for offset control of I

D1

measurement.

Offset

1

ID2 Offset <R/W><NV><0000h> Allows for offset control of ID2measurement.

Temp Offset <R/W><NV><0000h> Allows for offset control of temperature measurement.

LUT Index

Page 23

DS1870

LDMOS RF Power-Amplifier Bias

Controller

____________________________________________________________________ 23

T Index <R><NA><00h> Holds the calculated index based on the temperature measurement. This

index is used to address LUTs 2 and 3.

O1 Index <R><NA><00h> Holds the calculated index based on the VD or ID1measurement (dependant

on ‘LUT Sel’ byte). This index is used to address LUT 4.

O2 Index <R><NA><00h> Holds the calculated index based on the VD or ID2measurement (dependant

on ‘LUT Sel’ byte). This index is used to address LUT 5.

POT1 base <R><NA><00h> The base value used for POT1 and recalled from Table 2 at the memory

address found in ‘T Index.’ This register is updated at the end of the temperature conversion.

POT1 is not updated with this value until the end of ID2conversion to ensure that both the base

and the offset are known for POT1 and POT2 and they are updated simultaneously.

POT1 off <R><NA><00h> The offset value used for POT1 and recalled from Table 4 at the memory

address found in ‘O1 Index.’ Depending on the value written to ‘LUT Sel’ byte, this register is

updated at the end of the VDor ID1conversion. POT1 is not updated with this value until the end

of ID2conversion to ensure that both the base and the offset are known for POT1 and POT2 and

they are updated simultaneously.

POT2 base <R><NA><00h> The base value used for POT2 and recalled from Table 3 at the memory

address found in ‘T Index.’ This register is updated at the end of the temperature conversion.

POT2 is not updated with this value until the end of ID2conversion to ensure that both the base

and the offset are known for POT1 and POT2 and they are updated simultaneously.

POT2 off <R><NA><00h> The Offset value used for POT2 and recalled from Table 5 at the memory

address found in ‘O2 Index.’ Depending on the value written to ‘LUT Sel’ byte, this register is

updated at the end of the VDor ID2conversion. POT2 is not updated with this value until the end

of ID2conversion to ensure that both the base and the offset are known for POT1 and POT2 and

they are updated simultaneously.

MAN Dac <R/W><NA><03h> Allows user to control either the LUT Index or the base and offset values

used to calculate the potentiometer positions.

a) SEE Shadow EE bar. At power-on this bit is low, which enables EE writes to all shadowed

EE locations. If written to a one, this bit allows for trimming and/or configuring the part

without changing the NV-shadowed EE memory and not having to wait for the EE

cycle time to complete. Writing this bit to a zero does not cause a write from the SRAM

to copy into the EE. Shadow EE locations are addresses 20h to 3Fh and Table 180h

to A7h.

b) B/O_en At power-on this bit is high, which enables auto control of the LUT. If this bit is written

to a zero, then the POT base and offset are writeable by the user and the LUT recalls

are disabled. This allows the user to interactively test their modules by writing the

base and/or offsets for the POTs. The POTs update with the new value at the end of

the write cycle. Thus, all four registers (‘POT1 Base,’ ‘POT1 Off,’ ‘POT2 Base,’ and

‘POT2 OFF’) should be written in the same write cycle. The I2C stop condition is the

end of the write cycle.

c) Index_en At power-on this bit is high, which enables auto control of the LUT. If this bit is cleared

to a zero, then the three index values (‘T index,’ ‘O1 Index,’ and ‘O2 Index’) are writeable by the user and the updates of calculated indexes are disabled. This allows the

user to interactively test their modules by controlling the indexing for the lookup

tables. All three index values should be written in the same write cycle. The recalled

values from the LUTs appear in the base and offset register after each corresponding

conversion (just like it would happen in auto mode). To ensure the recalled base and

offset values from the LUT are updated, the base and offset calculation will not update

the potentiometers until the completion of the next temperature and ID2conversion.

Both pots update at the same time (just like it would happen in auto mode).

Page 24

DS1870

LDMOS RF Power-Amplifier Bias

Controller

24 ____________________________________________________________________

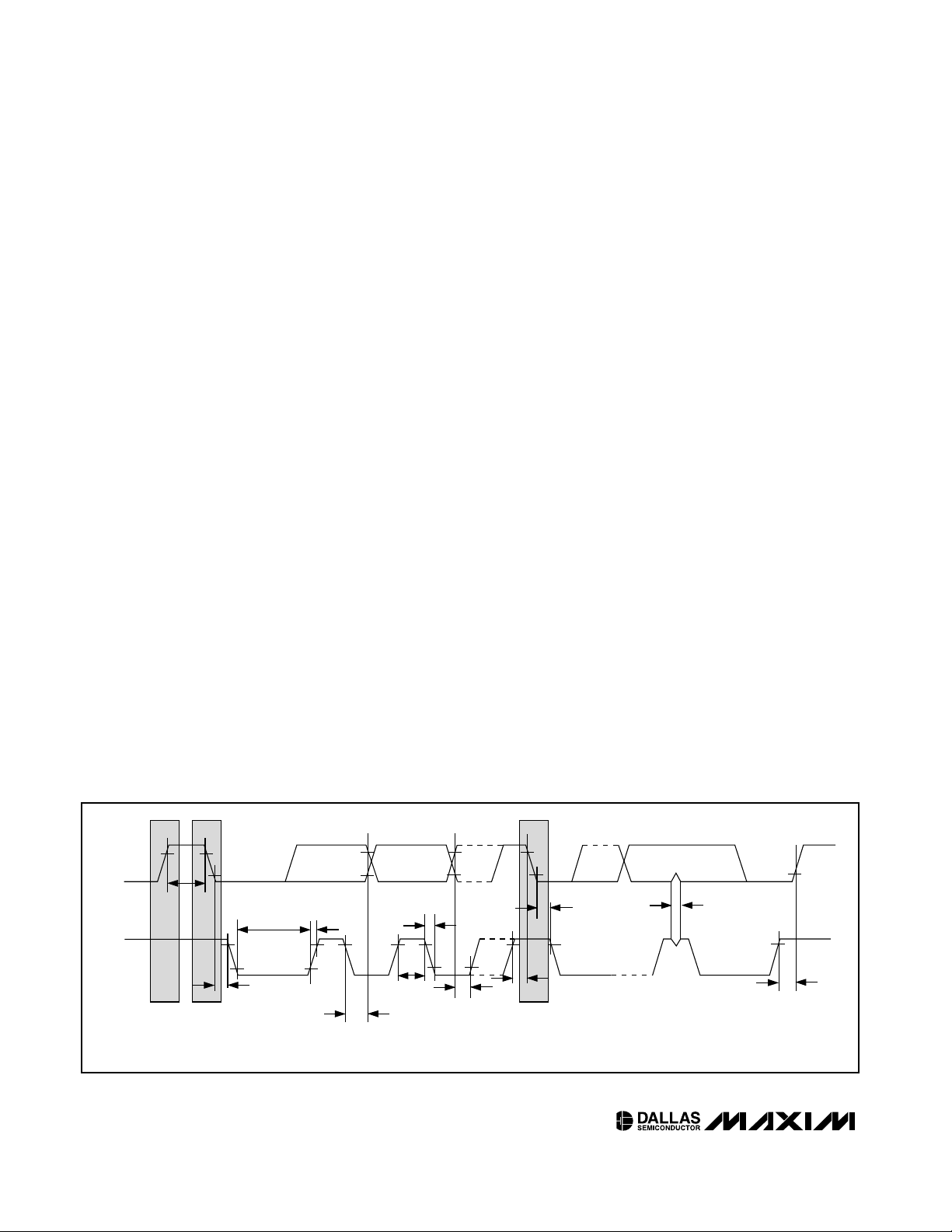

I2C Definitions

The following terminology is commonly used to

describe I2C data transfers.

Master device: The master device controls the slave

devices on the bus. The master device generates SCL

clock pulses, and start and stop conditions.

Slave devices: Slave devices send and receive data at

the master’s request.

Bus idle or not busy: Time between stop and start

conditions when both SDA and SCL are inactive and in

their logic high states. When the bus is idle, it often initiates a low-power mode for slave devices.

Start condition: A start condition is generated by the

master to initiate a new data transfer with a slave.

Transitioning SDA from high to low while SCL remains

high generates a start condition. See the timing diagram for applicable timing.

Stop condition: A stop condition is generated by the

master to end a data transfer with a slave. Transitioning

SDA from low to high while SCL remains high generates a stop condition. See the timing diagram for

applicable timing.

Repeated start condition: The master can use a

repeated start condition at the end of one data transfer

to indicate that it will immediately initiate a new data

transfer following the current one. Repeated starts are

commonly used during read operations to identify a

specific memory address to begin a data transfer. A

repeated start condition is issued identically to a normal start condition. See the timing diagram for applicable timing.

Bit write: Transitions of SDA must occur during the low

state of SCL. The data on SDA must remain valid and

unchanged during the entire high pulse of SCL plus the

SDA

SCL

t

HD:STA

t

LOW

t

HIGH

t

R

t

F

t

BUF

t

HD:DAT

t

SU:DAT

REPEATED

START

t

SU:STA

t

HD:STA

t

SU:STO

t

SP

STOP

NOTE: TIMING IS REFERENCED TO V

IL(MAX)

AND V

IH(MIN)

.

START

Figure 3. I2C Timing Diagram

TABLE 2 (TEMP LUT FOR POT 1)

Bytes 80h–C7h

POT1 <R/W><NV><00h>The unsigned base value for POT1.

TABLE 3 (TEMP LUT FOR POT 2)

Bytes 80h–C7h

POT2 <R/W><NV><00h>The unsigned base value for POT2.

TABLE 4 (DRAIN LUT FOR POT 1)

Bytes 80h–B8h

POT1 Off <R/W><NV><00h>The signed 2’s complement offset value for POT1.

TABLE 5 (DRAIN LUT FOR POT 2)

Bytes 80h–B8h

POT2 Off <R/W><NV><00h>The signed 2’s complement offset value for POT2.

Page 25

DS1870

LDMOS RF Power-Amplifier Bias

Controller

____________________________________________________________________ 25

setup and hold time requirements (Figure 3). Data is

shifted into the device during the rising edge of the SCL.

Bit read: At the end a write operation, the master must

release the SDA bus line for the proper amount of setup

time (Figure 3) before the next rising edge of SCL during a bit read. The device shifts out each bit of data on

SDA at the falling edge of the previous SCL pulse and

the data bit is valid at the rising edge of the current

SCL pulse. Remember that the master generates all

SCL clock pulses, including when it is reading bits from

the slave.

Acknowledgement (ACK and NACK): An acknowledgement (ACK) or not acknowledge (NACK) is always

the 9th bit transmitted during a byte transfer. The

device receiving data (the master during a read or the

slave during a write operation) performs an ACK by

transmitting a zero during the 9th bit. A device performs a NACK by transmitting a one during the 9th bit.

Timing (Figure 3) for the ACK and NACK is identical to

all other bit writes. An ACK is the acknowledgment that

the device is properly receiving data. A NACK is used

to terminate a read sequence or as an indication that

the device is not receiving data.

Byte write: A byte write consists of 8 bits of information

transferred from the master to the slave (most significant bit first) plus a 1-bit acknowledgement from the

slave to the master. The 8 bits transmitted by the master are done according to the bit write definition and the

acknowledgement is read using the bit read definition.

Byte read: A byte read is an 8-bit information transfer

from the slave to the master plus a 1-bit ACK or NACK

from the master to the slave. The 8 bits of information

that are transferred (most significant bit first) from the

slave to the master are read by the master using the bit

read definition above, and the master transmits an ACK

using the bit write definition to receive additional data

bytes. The master must NACK the last byte read to terminated communication so the slave will return control

of SDA to the master.

Slave address byte: Each slave on the I2C bus

responds to a slave addressing byte sent immediately

following a start condition. The slave address byte

(Figure 4) contains the slave address in the most significant 7 bits and the R/W bit in the least significant bit.

The DS1870’s slave address is 1010A2A1A0 (binary),

where A2, A1, and A0are the values of the address

pins. The address pins allow the device to respond to

one of eight possible slave addresses. By writing the