Page 1

DS1800

PRODUCT PREVIEW

DS1800

Dual Inverting Log Gain/Attenuator

FEATURES

• Ultra–low power consumption

• Operates from 3V or 5V supplies

• Two digitally controlled, 128–position potentiometers

including mute

• Logarithmic Gain Characteristics

• Zero–crossing detection circuitry eliminates noise

caused by discrete wiper position changes

• Two Control Interfaces

– 3–wire serial CPU control

– Push–button control

• 20–pin DIP (300 Mil), 20–pin SOIC (300 Mil), and

20–pin (173 Mil) TSSOP packaging available

• Operating Temperature:

– Commercial: 0°C to 70°C

– Industrial: –40°C to 85°C

• Software and hardware mute

• Resistance Available: 53KΩ

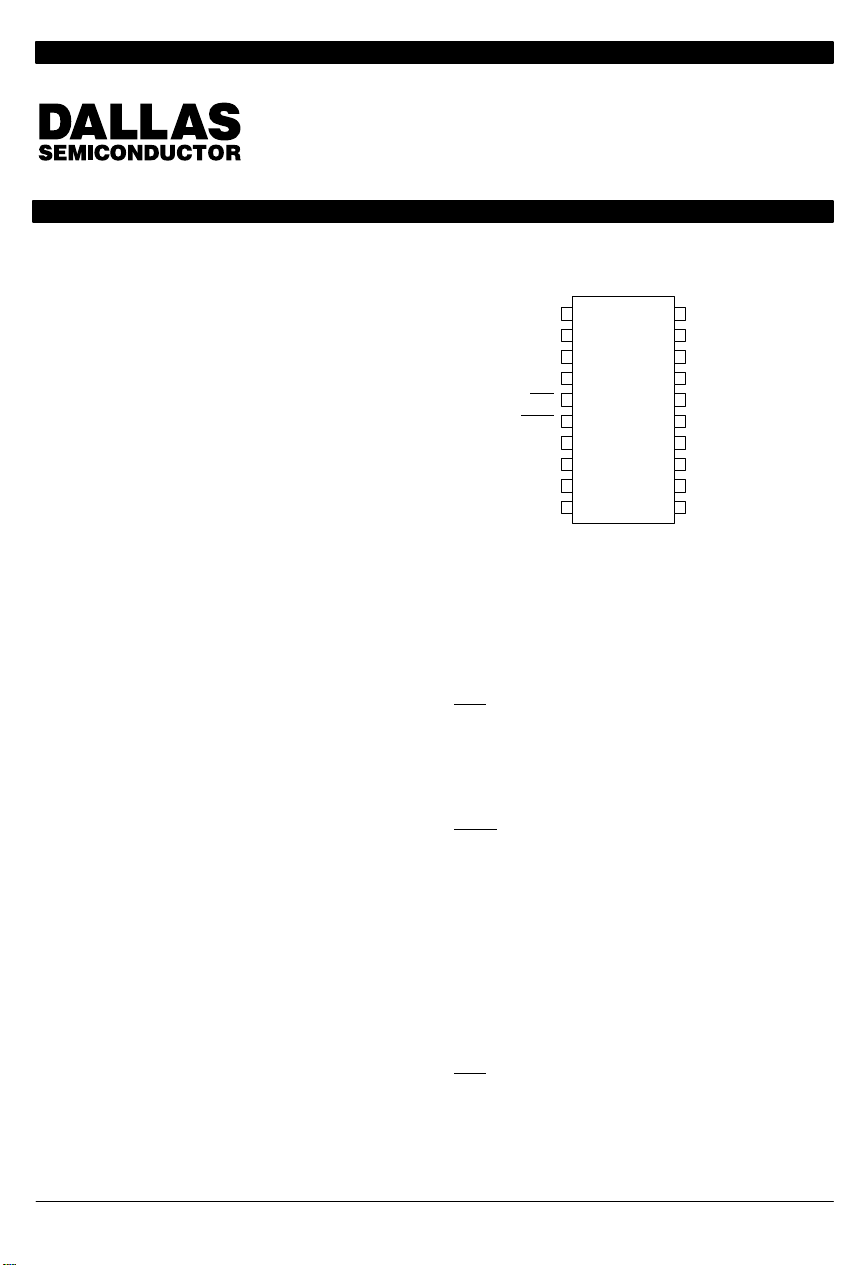

PIN ASSIGNMENT

GND

1

C

2

OUT

3

CLK

4

D

5

RST

ZCEN

MODE

OUT0

6

7

8

W0

9

10

IN0

20–PIN DIP (300 MIL)

20–PIN SOIC (300 MIL)

20–PIN TSSOP

20

V

CC

19

P1G

18

P1A

17

P0G

16

P0A

15

MUTE

14

AGND

13

IN1

12

OUT1

11

W1

PIN DESCRIPTION

OUT0,OUT1 – Low–end of resistor

IN0, IN1 – High–end of resistor

W0,W1 – Wiper Terminal

V

CC

RST – Serial Port Reset Input

CLK – Serial Port Clock Input

D – Serial Port Data Input

C

OUT

P0G,P1G – Gain Input Pot Controls

P0A,P1A – Attenuation Input Pot Controls

ZCEN – Zero–Crossing Detect Input

MUTE – Hardware Mute Control Input

AGND – Analog Ground

GND – Ground

– 3V or 5V Power Supply Input

– Cascade Data Output

DESCRIPTION

The DS1800 is a dual audio–taper potentiometer

designed specifically for use in the feedback path of the

inverting configuration of an operational amplifier (see

Figure 2). In this configuration, the DS1800 provides a

relationship of –20log(RF/RI) giving a gain/attenu-

V

O/VI

ation range covering +20 dB to –63 dB. Each potentiometer has a total of 129 positions including mute. The

DS1800 provides five areas of resolution which include

0.25 dB per step from +20 dB to +3 dB, 0.5 dB per step

from +3 dB to –12 dB, 1 dB from –12 dB to –27 dB, and

Copyright 1995 by Dallas Semiconductor Corporation.

All Rights Reserved. For important information regarding

patents and other intellectual property rights, please refer to

Dallas Semiconductor data books.

from –27 dB to –47 dB; 2 dB per step, and from –47 dB to

–63 dB; 4 dB per step. The mute position provides 100

dB of attenuation.

The DS1800 has two control interfaces (see Figure 1).

The first is a 3–wire serial CPU interface consisting of

RST

, CLK, and D. The second interface is a contact–

closure interface, allowing easy push–button control

without the need for external debounce or timing circuitry. The device also provides for software muting (via

072095 1/13

Page 2

DS1800

CPU) or hardware muting (MUTE control input). The

hardware mute is a toggle type which returns the wiper

positions to their prior states. Additional information on

CPU and push–button control is described under the

section entitled “OPERATION”.

The DS1800 is available in 20–pin DIPs, SOICs, and

TSSOPs. One standard resistance grade of 53KΩ is

available for the device.

OPERATION

The DS1800 provides two 129–position 45KΩ potentiometers. These potentiometers are specifically

designed to operate in the configuration shown in Figure

2. Under this configuration the V0/VI relationship provides the gain/attenuation function of –20log(R

F/RI

over a range of +20 dB to –63 dB. This function is illustrated in Figure 3 as a graph of gain/attenuation versus

position. Figure 4 provides the relationship between R

and RI as a function of position.

The DS1800 has a total of 129 positions including a

mute position. Five areas of resolution are provided

over the gain/attenuation range and are illustrated in

Figure 3. From position 0 to position 68, a resolution of

0.25 dB per step is attained covering a gain/attenuation

range of +20 dB to +3 dB. From position 68 to position

98, 0.5 dB per step of resolution is attained covering +3

dB to –12 dB of gain/attenuation. Positions 98 to 113

have 1 dB per step resolution and cover a gain/attenuation range of –12 to –27 dB. Positions 113 to 123 provide 2 dB per step and cover a gain/attenuation range of

–27 dB to –47 dB. Positions 123 to 127 provide 4 dB per

step and cover a gain/attenuation range of –47 dB to 63

dB. Position 128 is the mute position and typically provides 100 dB of attenuation.

PIN DESCRIPTIONS

The DS1800 has a total of 20 pins which provide various

functions for the device. This section provides a

description of each pin’s operation.

V

– Power Supply Voltage Input. The DS1800 will

CC

support 3V or 5V power supply operation.

GND – Ground. The DS1800 has two ground pins. The

GND supports the digital ground for the device.

AGND – Analog Ground. The DS1800 has two ground

pins. The AGND supports analog ground for the device.

IN0, IN1 – Input terminals for the two respective potentiometers as shown in Figure 2. These terminals should

be connected to the analog signal,VI, to provide the

gain/attenuation characteristics stated. These terminals are referenced as INx in the Figure 2 drawing.

OUT0, OUT1 – Analog Outputs. These pins should be

connected to the output terminal of the operational

amplifier as shown in Figure 2. These inputs are referenced as OUTx in the Figure 2 drawing.

W0, W1 – Wiper T erminals. The wiper terminals of each

pot are connected to the inverting terminal of the operational amplifier. The position of the wiper terminal is

selected either through CPU control or push–button

control.

)

P0A, P1A – Attenuation Push–button Inputs. These

push–button inputs are used to control wiper position of

F

the part . Activity on these inputs will cause the position

of the wiper to move towards the OUT0, and OUT1 terminals, respectively .

P0G, P1G – Gain Push–button Inputs. These push–

button inputs control wiper position and are used to

move the position of the wiper towards the IN0 and IN1

terminals, respectively .

RST

– Serial Port Reset. The RST input deactivates the

3–wire serial interface. This input is active when in the

low–state. All 3–wire communications must take place

when this input is in a high state.

CLK – Serial Clock Input. The CLK input is the positive–

edge clock signal input used for 3–wire timing synchronization.

D – Serial Data Input. The D input is used to input serial

data for wiper position changes.

C

– Serial Cascade Output. The C

OUT

OUT

signal used to read the contents of the current settings

of the wiper positions. As data is clocked into the D

input, data corresponding to the wipers are shifted out of

OUT

pin.

the C

MODE – Push–button Debounce Control. The MODE

pin is used to choose between a fast and slow mode of

push–button debouncing. When in a high state, push–

button debounce is slow. When in a low–state, push–

is an output

072095 2/13

Page 3

DS1800

button debounce is faster. These timing differences are

discussed in the section entitled “Push–button Interface Control”. The state of this pin is determined only at

device power–up.

POWER–UP CONDITIONS

The position of the wipers of the DS1800 on power up

are internally set to position 127, which is the last position before mute. The user then has the responsibility of

changing the wiper position to the desired attenuation/

gain levels.

Additionally , the serial port is stable and active within 10

microseconds. The contact closure control interface

inputs are active after 50 ms.

INTERFACE CONTROL OPTIONS

Control of the DS1800 is provided via two types of interface ports. A 3–wire CPU control interface allows the

exact wiper positions of the potentiometers to be written

using two 8–bit words. A cascade output, C

OUT

, is provided when controlling multiple devices via one CPU or

when reading the wiper positions of each potentiometer .

The second interface is a contact closure interface that

allows push–buttons to control movement of the wiper

positions. Under push–button control no external

debounce or timing circuitry is needed. A block diagram

of the DS1800 is shown in Figure 1.

3–WIRE SERIAL INTERFACE CONTROL

CPU control of the DS1800 is accomplished using the

3–Wire serial port of the device. This interface drives an

internal control logic unit. Direct wiper positioning is

accomplished by using this port which consist of three

input signals: RST, CLK, and D.

The RST

port write operations. The CLK terminal is an input that

provides synchronization for data I/O. Data is input bit

by bit via the D input signal pin.

The 3–Wire serial timing diagrams are provided in Figure 5. Serial port operation or activity begins with the

transition of the RST

state. Once activated, data is clocked into the part on

the low to high transition of the CLK signal input. Data

input via the D terminal is transferred in order of the

control signal is used to enable 3–wire serial

signal from a low–state to a high–

desired potentiometer–0 wiper value, followed by the

potentiometer–1 wiper position value.

Two 8–bit values are used to store wiper position for

each potentiometer during powered conditions. These

8–bit values are written to a 16–bit I/O shift register. A

detailed diagram of the 16–bit I/O shift register is shown

in Figure 6.

Bits 0 through 7 are reserved for the positioning of

wiper–0 while bits 8 through 15 are reserved for control

of wiper–1. Bits 0 through 6 are used for actual wiper

positioning of potentiometer–0. Bit 7 is used to mute

potentiometer–0. If this bit is set to a “1”, the potentiometer–0 wiper will be connected to the OUT0 end of the

resistor array regardless of the settings of bits 0 through

6.

Bits 8 through 15 are used for positioning the wiper of

potentiometer–1. Bits 8 through 14 control wiper position on the resistor array. Bit 15 is used for muting potentiometer–1. Bit 15, like bit 7, when set to “1” will mute

potentiometer 1, regardless of the settings of bits 8

through 14.

Data is transmitted LSB first starting with bit–0. A complete transmission of 16 bits of data is required to insure

proper setting of each potentiometer’s wiper. An incomplete transmission may result in undesired wiper settings.

Once the 16 bits of information has been transmitted

and the RST

signal input transitions to a low–state, the

new wiper positions are loaded into the part.

PUSH–BUTTON INTERFACE CONTROL

The DS1800 can be configured to operate from contact

closure or push–button inputs. The push–button inputs

consist of signals P0A, P0G, P1A, P1G and MUTE.

P0A and P0G allow attenuation and gain control of the

input signal to potentiometer–0, while P1A and P1G

provide the same control for potentiometer–1. The

MUTE input provides a toggle control for muting the

potentiometers via pushbutton.

The P0A and P1A control inputs, based on the recommended circuit configuration, are used to attenuate the

incoming signal by moving the wiper position towards

the OUTx terminals. The P0G and P1G control inputs

072095 3/13

Page 4

DS1800

provide the opposite function; positioning the wiper(s)

closer to the INx terminals, thus providing gain.

Each of these control inputs are internally pulled–up via

a 50KΩ resistance. Additionally, these inputs require no

external components for debouncing or timing which

are provided internal to the part.

Contact closure is defined as the transition from a high

level to a low level on these input terminals. The

DS1800 interprets input pulse widths as the means of

controlling wiper movement. A single pulse input over

the PxA or PxG input terminals will cause the wiper to

move one position. A transition from high to low on

these inputs is considered the beginning of pulse activity or contact closure. The DS1800 has two timing

modes for controlling the speed at which pushbuttons

will operate. These modes are termed fast mode operation and slow mode operation.

In slow mode operation, a single pulse is defined as

being greater than 1 ms but lasting no longer than 0.8

seconds. Correspondingly, in fast mode operation, a

single pulse is defined as being greater than 50 µs but

lasting no longer than 0.8 second.

Repetitive pulsed inputs can be used to step through

each resistive position of the device in a relatively fast

manner. The timing requirements for repetitive pulsed

inputs is that pulses must be separated by a minimum

time of 1 ms for slow mode operation and 50 µs for fast

mode operation.

Pulse inputs lasting longer than 0.8 seconds will cause

the wiper to move one position every 25 ms seconds

after the initial 0.8 second hold time. This is true regardless of the mode input. The total time required to transcend the entire potentiometer using a continuous input

pulse is given by the following formula:

0.8(seconds) + 127 x 25 ms = 3.975(seconds)

SLOW MODE AND FAST MODE OPERATION

Pushbutton operation, as mentioned. can be operated

at two distinct speeds or modes; fast and slow. The

mode or speed of pushbutton debounce is determined

at device power–up by the state of the MODE pin. When

MODE powers to a high–state, pushbutton debounce

timing will operate at the slow mode rate. When powered and in the low–state, debounce timing operates at

the fast rate. Timing specifications for pushbutton

operation can be found in the AC Electrical Specification

Table for pushbutton operation. Timing diagrams for

push–button operation can be found in Figure 7.

ZERO CROSSING DETECTION

The DS1800 provides a zero–crossing detection capability when using the 3–Wire serial interface. Zero–

crossing detection provides a means for minimizing

unwanted audible noise that may result from sizable discrete wiper transitions when using the part in audio

applications. The zero crossing detect feature allows

independent wiper changes only when the two terminals of the potentiometer(s) have equal potentials and

within a 50 ms time window from the fall of the RST

signal. If at 50 ms the DS1800 has not detected a zero

crossing, the wiper position of the potentiometer(s) will

change regardless of the state of the input signal. Zero–

crossing detection is activated when the ZCEN input is

in a low–state. When high, the ZCEN

input deactivates

both the 50 ms time requirement and zero–detection

crossing.

Zero crossing detection is also available when using the

part in push–button operation. When a push–button is

activated, the part will change wiper position during the

first detected zero–crossing or at the end of a 50 ms time

window.

When operating in push–button operation with a continuous input pulse, the wiper position will change once

during the initial 0.8 second time period. This change is

dictated by a detected zero–crossing or 50 ms time window. Subsequent changes when operating with a continuous input pulse occur on 25 ms time intervals and

are dependent on zero crossings or 50 ms time–outs.

MUTE CONTROL

The DS1800 provides a mute control feature which can

be accessed by the user through hardware or software.

Hardware control of the device is achieved through the

MUTE input pin. This pin is internally pulled up through

a 50K resistor and functions like the PxG and PxA pushbutton controls. When this input is driven low, the wiper

outputs of both potentiometers will be internally connected to the OUTx terminal of their respective potentiometers. This input performs as a toggle input, with the

first activity on this pin connecting the wiper terminals to

the OUTx terminals (position 128) of the potentiometer.

The next input activity on this pin will return the wiper

position to the previous state before muting occurred.

072095 4/13

Page 5

DS1800

Also, if operating in push–button mode, MUTE will be

deactivated if an input is received over any push–button

input. This input, like the push–button inputs, is internally debounced and requires no external circuitry.

When the device powers up, the first activity on the mute

pin will move the wipers to position 128 or the OUTx end

of the potentiometer(s).

Software muting was discussed in the 3–wire serial control section. Bits 7 and 15 are reserved for muting each

respective potentiometer. If these bits have value “1”,

the wiper positions of the pot will be transferred to the

mute position. Unlike hardware mute control, software

muting allows the user individual control of each potentiometer. Additionally, the software mute requires that

the complete wiper position setting be rewritten to

establish a non muted position. Note that bits 7 and 15

of the I/O shift register must have value “0” to release the

software mute position.

CASCADE OPERATION

A feature of the DS1800 is the ability to control multiple

devices from a single processor. Multiple DS1800’s can

be linked or daisy chained as shown in Figure 8. As a

data bit is entered into the I/O shift register of the

DS1800, a data bit will appear at the C

maximum delay of 50 nanoseconds.

output after a

OUT

The C

output of the DS1800 can be used to drive the

OUT

D input of another DS1800. When connecting multiple

devices, the total number of bits sent is always 16 times

the number of DS1800’s is the daisy chain.

An optional feedback resistor can be placed between

the C

terminal of the last device and the D input of

OUT

the first DS1800, thus allowing the controlling processor

to circularly clock data through the daisy chain. The

value of the feedback or isolation resistor should be in

the range from 2K to 20KΩ.

When reading data via the C

pin and the isolation

OUT

resistor, the D input is left floating by the reading device.

When RST is driven high, bit–0 is present on the C

OUT

pin, which is fed back to the D pin through the isolation

resistor. When the CLK input transitions low to high,

bit–0 is loaded into the first position of the I/O shift register and bit 1 becomes present on C

and D of the next

OUT

device. After 16 bits (or 16 times the number of

DS1800s in the daisy chain), the data has shifted completely around and back to its original position. When

transitions to the low state to end data transfer, the

RST

value (the same as before the read occurred is loaded

into the wiper–0 and wiper–1 registers.

072095 5/13

Page 6

DS1800

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground –1.0V to +7.0V

Operating Temperature 0°C to 70°C; commercial

–40°C to +85°C; industrial

Storage Temperature –55°C to 125°C

Soldering Temperature 260°C for 10 seconds

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time may af fect reliability.

RECOMMENDED DC OPERATING CONDITIONS (–40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Voltage V

Input Logic 1 V

Input Logic 0 V

CC

IH

IL

2.7 5.5 V 1

2.0 VCC+0.5 V 1, 2

–0.5 +0.8 V 1, 2

Analog Ground AGND GND–0.5 GND+0.5 14

Resistor Inputs L,H,W GND–0.5 GND+0.5 V 1

DC ELECTRICAL CHARACTERISTICS (–40°C to +85°C; VCC=2.7V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Current I

Input Leakage I

Wiper Resistance R

Wiper Current I

Logic 1 Output Current @ 2.4V I

Logic 0 Output Current @ 0.4V I

Standby Current: 3 Volts

I

5 Volts

Power Up Time t

CC

LI

W

W

OH

OL

STBY

PU

–1 +1 µA

400 1000 Ω

–1 mA

12

20

50 ms 8

2000 µA 10

1 mA

4 mA

40

µA

µA

12

072095 6/13

Page 7

DS1800

ANALOG RESISTOR CHARACTERISTICS (–40°C to +85°C; VCC=2.7V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Total Resistance 53 KΩ

End–to–End Resistor Tolerance –20 +20 %

Absolute Tolerance –0.5

–1.0

Tap–to–Tap Tolerance –0.5 +0.5 dB 7

Interchannel Matching –0.25

–0.5

–3 dB Cutoff Frequency f

cutoff

1 MHz 13

T emperature Coef ficient 650 ppm/°C

Total Harmonic Distortion

=1Vrms, 20 Hz to 20 KHz,

(V

IN

Tap=0 dB)

Output Noise (20 Hz to 20 KHz,

THD 0.002 % 13

2.2 µVrms 13

Grounded Input, Tap=0 dB)

Digital Feedthrough (20 Hz to 20

–90 dB 13

KHz, Tap=0 dB)

Interchannel Isolation (1 KHz,

–100 dB 13

Tap=0 dB)

Mute Control Active MUTE –100 dB

+0.5

+1.0

+0.25

+0.5

dB

dB

dB

dB

9

6

CAPACITANCE (–40°C to +85°C; VCC=2.7V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

Output Capacitance C

IN

OUT

5 pF

7 pF

072095 7/13

Page 8

DS1800

AC ELECTRICAL CHARACTERISTICS (–40°C to +85°C; VCC=2.7V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

CLK Frequency f

Width of CLK Pulse t

Data Setup Time t

Data Hold Time t

Propagation Delay Time

Low to High Level

CLK

CH

DC

CDH

t

PLH

DC 10 MHz

50 ns

30 ns

10 ns

50 ns

High to Low Level

RST High to Clock Input High t

RST Low from Clock Input High t

CLK Rise Time t

RST Inactive t

CC

HLT

CB

BLT

50 ns

50 ns

50 ns

200 ns

AC ELECTRICAL CHARACTERISTICS

PUSHBUTTON INPUTS (–40°C to +85°C; V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Single Pulse Input

Slow Mode

Fast Mode

Repetitive Input Pulse High Time

Slow Mode

Fast Mode

Continuous Input Pulse t

t

CPW

t

HPW

CCP

1

800 ms

50

1

800 ms

50

0.8 DC s 3, 5, 11

=2.7V to 5.5V)

CC

µs

µs

3, 5, 11

3, 5, 11

NOTES:

1. All voltages are referenced to ground

2. Valid for V

3. Both PxA and PxG inputs are internally pulled up with a 50KΩ resistance.

4. Capacitance values apply at 25°C.

5. Input pulse width is the minimum time required for an input to cause an increment or decrement of wiper position. If the PxA or PxG inputs are held active for longer than 0.8 seconds, subsequent increments or decrements will occur at intervals of 25 ms. Timing tolerances for pushbutton control are specified at 35%.

6. Inter–Channel Matching is used to determine the relative voltage difference in dB between the same position

on each potentiometer. The DS1800 is specified for ±0.25 dB inter channel matching from position 0 to position 112 (+20 dB to –27 dB) and ±0.5 dB from position 113 to position 127.

7. Tap–to–Tap tolerance is used to determine the change in voltage between successive tap positions. The

DS1800 is specified for ±0.5 dB tap–to–tap tolerance. From position 0 to position 112 (+20 dB to –27 dB).

From position 113 to position 127, the DS1800 is specified for ± 1 dB tap–to–tap tolerance.

072095 8/13

= 5V only.

CC

Page 9

DS1800

8. Power–up time is the time for all push–button inputs to be stable and active once power has reached a valid

level, 2.7V min.

9. Absolute tolerance is used to determine wiper voltage versus expected wiper voltage as determined by wiper

position. The DS1800 is bounded by a ±0.5 dB absolute tolerance from position 0 to position 112 and ±1 dB

tolerance from position 113 to position 127.

10.Maximum current specifications are based on clock rate, active zero–crossing detection, and push–button

activation.

11. Valid for V

=3V or 5V.

CC

12.Standby current levels apply when all inputs are driven to appropriate supply levels.

13.These parameters are characterized and not 100% tested.

14.See Figure 9.

DS1800 BLOCK DIAGRAM Figure 1

IN1 OUT0 IN1 OUT1

POTENTIOMETER–0 POTENTIOMETER–1

POS–0 POS–128 POS–0 POS–128

129–TO–1 MULTIPLEXER 129–TO–1 MULTIPLEXER

W0 W1

RST

CLK

D

3–WIRE SERIAL

INTERFACE

WIPER–0 (8–BIT REGISTER) WIPER–1 (8–BIT REGISTER)

B0 B7 B8 B15

CONTROL

LOGIC

UNIT

P0G

P0A

PUSHBUTTON CONTROL

INPUTS

P1G

P1A

COUT

MODE

072095 9/13

Page 10

DS1800

RECOMMENDED CIRCUIT CONFIGURATION Figure 2

DS1800

V

I

R

R

I

F

Wx

OUTxINx

–

+

V

/2

CC

VO/VI GAIN/ATTENUATION VS. POSITION RELATIONSHIP Figure 3

GAIN/ATTENUATION VERSUS POSITION

V

O

GAIN (dB)

072095 10/13

POSITION

Page 11

RF/RI RELATIONSHIP VS. POSITION Figure 4

RF, RI VERSUS POSITION

RESISTANCE (ohms)

POSITION

DS1800

3–WIRE SERIAL TIMING DIAGRAM Figure 5

C

RST

CLK

OUT

t

CC

t

DC

D

FIRST DATA BIT

t

PLH

t

CDH

t

CH

SECOND DATA BIT

•••

•••

•••

t

RLT

t

HLT

072095 11/13

Page 12

DS1800

16–BIT I/O SHIFT REGISTER Figure 6

WIPER–1

POSITION VALUE

15 14 13 12 11 10 9 8 7 6543210

WIPER–0

POSITION VALUE

CONTACT CLOSURE TIMING DIAGRAMS Figure 7

(a) Single Pulse Inputs

t

CPW

V

IH

V

IL

(b) Repetitive Pulse Inputs

t

CPW

V

IH

V

IL

t

HPW

(c) Continuous Pulse Inputs

V

IH

V

IL

CASCADING OPERATION Figure 8

072095 12/13

DD DC

DS1800

C

OUT

#1

t

CCP

C

DS1800

#2

OUT

2K–20KΩ

(ISOLATION RESISTOR)

DS1800

#n

OUT

Page 13

DS1800

DIGITAL OUTPUT LOAD Figure 9

D.U.T.

680Ω

INTERNAL GROUND CONNECTIONS Figure 10

AGND GND

5V

1.1 KΩ

50 pF

100Ω (TYPICAL)

NOTE: GND and AGND must be tied to the same voltage level.

072095 13/13

Loading...

Loading...