Page 1

DS1720

PRELIMINARY

DS1720

Econo – Digital Thermometer and

Thermostat

FEATURES

• Requires no external components

• Supply voltage range covers from 2.7V to 5.5V

• Measures temperatures from –55°C to +125°C in

0.5°C increments. Fahrenheit equivalent is –67°F to

+257°F in 0.9°F increments

• Temperature is read as a 9–bit value

• Converts temperature to digital word in 1 second

(max)

• Thermostatic settings are user–definable and non–

volatile

• Data is read from/written via a 3–wire serial interface

(CLK, DQ, RST

)

• Applications include thermostatic controls, industrial

systems, consumer products, thermometers, or any

thermally sensitive system

• 8–pin SOIC (208 mil) package

PIN ASSIGNMENT

1

DQ

CLK/CONV

RST

GND

DS1720S 8–PIN SOIC (208 MIL)

See Mech Drawings Section

8

V

2

3

4

DD

7

T

HIGH

6

T

LOW

5

T

COM

PIN DESCRIPTION

DQ – 3–Wire Input/Output

CLK/CONV

RST – 3–Wire Reset Input

GND – Ground

T

HIGH

T

LOW

T

COM

V

DD

– 3–Wire Clock Input and

Stand–alone

Convert Input

– High Temperature Trigger

– Low Temperature Trigger

– High/Low Combination Trigger

– Power Supply Voltage (3V – 5V)

DESCRIPTION

The DS1720 Digital Thermometer and Thermostat provides 9–bit temperature readings which indicate the

temperature of the device. With three thermal alarm outputs, the DS1720 can also act as a thermostat. T

driven high if the DS1720’s temperature is greater than

or equal to a user–defined temperature TH. T

driven high if the DS1720’s temperature is less than or

equal to a user–defined temperature TL. T

COM

HIGH

is

LOW

is driven

high when the temperature exceeds TH and stays high

until the temperature falls below that of TL.

User–defined temperature settings are stored in non–

is

volatile memory, so parts can be programmed prior to

insertion in a system, as well as used in stand–alone

applications without a CPU. Temperature settings and

temperature readings are all communicated to/from the

DS1720 over a simple 3–wire interface.

030598 1/12

Page 2

DS1720

OPERATION–MEASURING TEMPERATURE

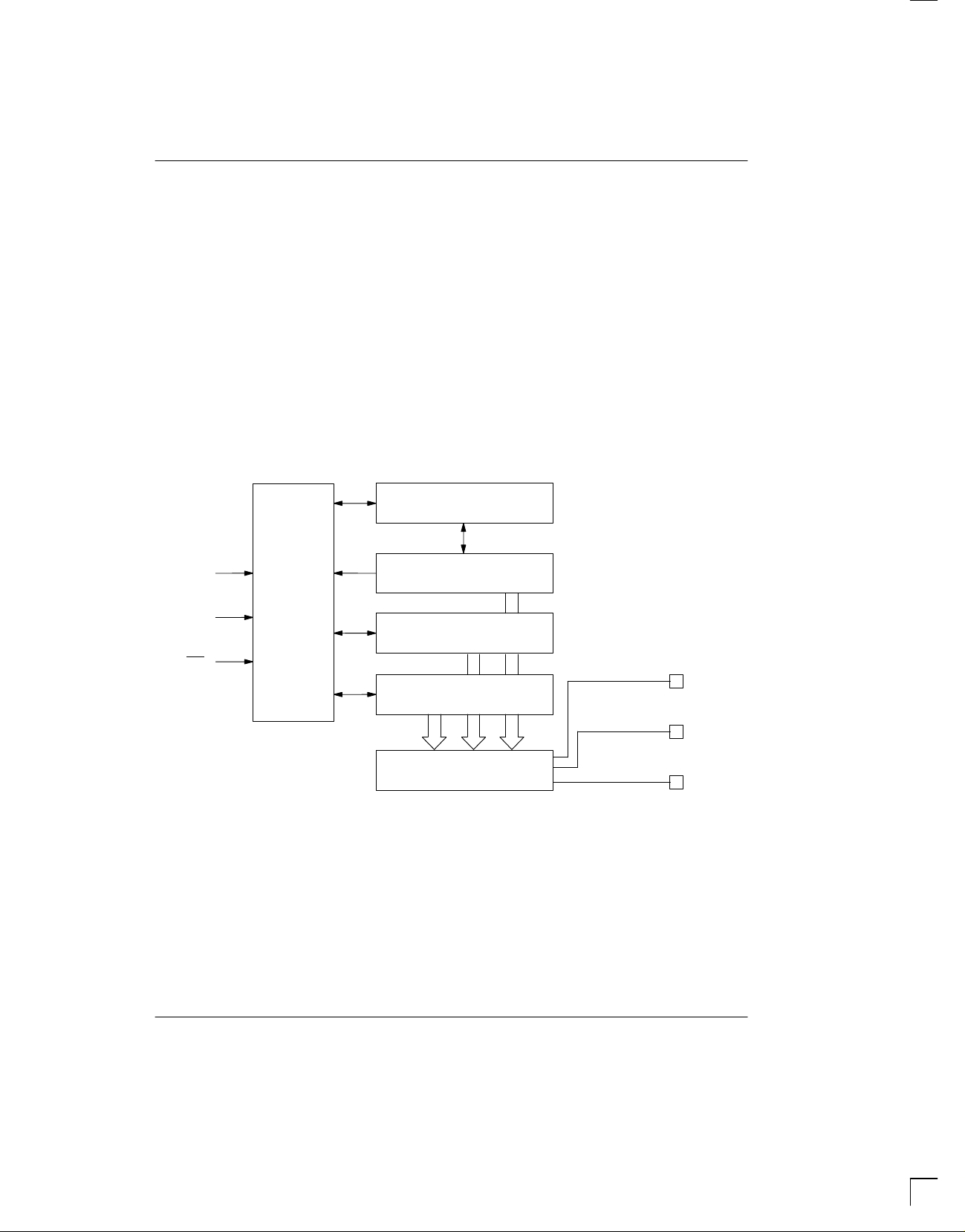

A block diagram of the DS1720 is shown in Figure 1.

The DS1720 measures temperatures through the use of

an on–board proprietary temperature measurement

technique. A block diagram of the temperature measurement circuitry is shown in Figure 2.

The DS1720 measures temperature by counting the

number of clock cycles that an oscillator with a low temperature coefficient goes through during a gate period

determined by a high temperature coefficient oscillator .

The counter is preset with a base count that corresponds to –55°C. If the counter reaches zero before the

gate period is over, the temperature register, which is

also preset to the –55°C value, is incremented, indicating that the temperature is higher than –55°C.

DS1720 FUNCTIONAL BLOCK DIAGRAM Figure 1

STATUS REGISTER AND

CONTROL LOGIC

CLK

DQ

ADDRESS

AND

RESET

TEMPERATURE SENSOR

HIGH TEMP TRIGGER, TH

At the same time, the counter is then preset with a value

determined by the slope accumulator circuitry . This circuitry is needed to compensate for the parabolic behavior of the oscillators over temperature. The counter is

then clocked again until it reaches zero. If the gate

period is still not finished, then this process repeats.

The slope accumulator is used to compensate for the

nonlinear behavior of the oscillators over temperature,

yielding a high resolution temperature measurement.

This is done by changing the number of counts necessary for the counter to go through for each incremental

degree in temperature. T o obtain the desired resolution,

therefore, both the value of the counter and the number

of counts per degree C (the value of the slope accumulator) at a given temperature must be known.

RST

030598 2/12

LOW TEMP TRIGGER, TL

DIGITAL COMPARATOR/LOGIC

T

T

T

HIGH

LOW

COM

Page 3

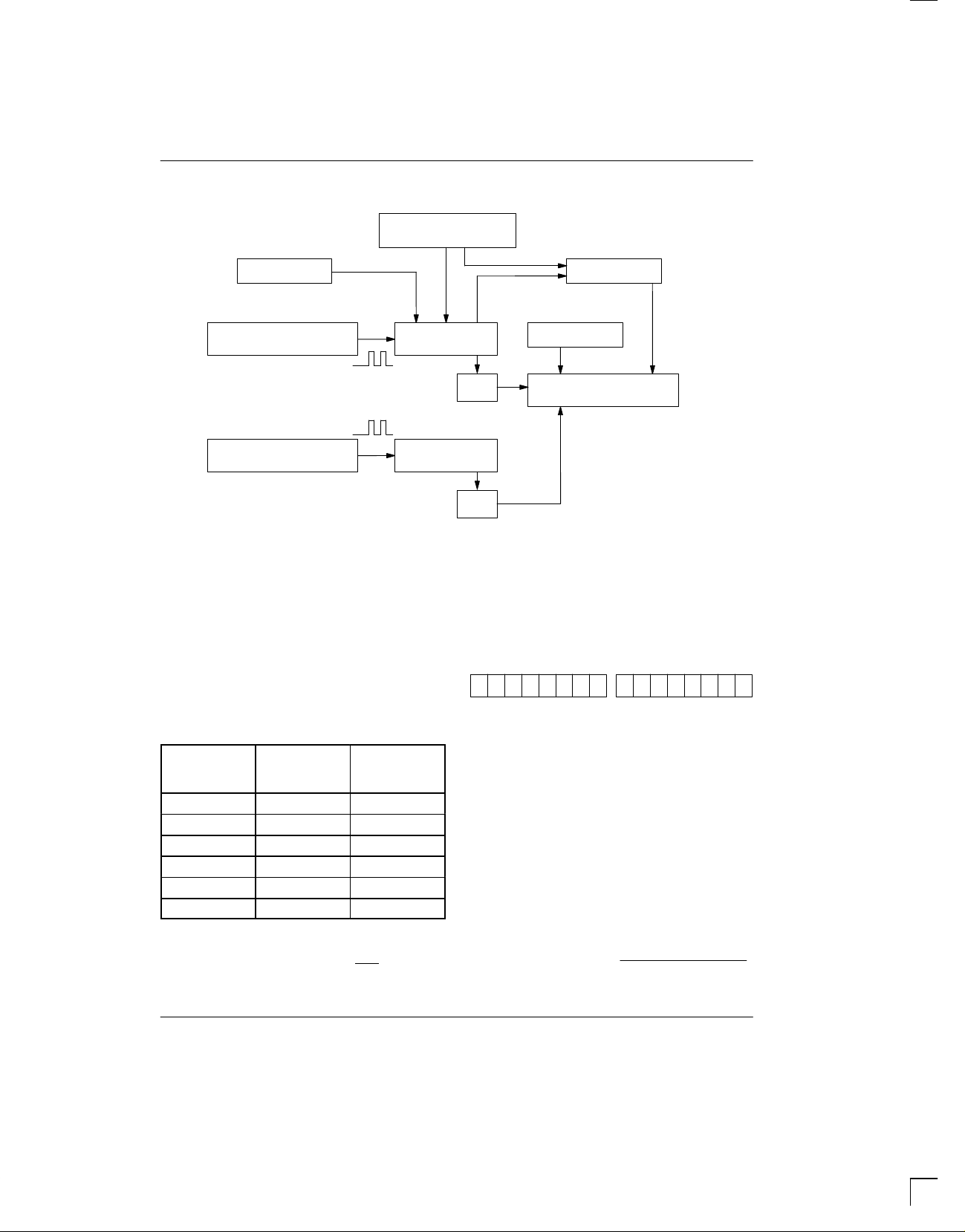

TEMPERATURE MEASURING CIRCUITRY Figure 2

SLOPE ACCUMULATOR

DS1720

PRESET

LOW TEMPERATURE

COEFFICIENT OSCILLATOR

HIGH TEMPERATURE

COEFFICIENT OSCILLATOR

COUNTER

COUNTER

This calculation is done inside the DS1720 to provide

0.5°C resolution. The temperature reading is provided

in a 9–bit, two’s complement reading by issuing a READ

TEMPERATURE command. Table 1 describes the

exact relationship of output data to measured temperature. The data is transmitted serially through the 3–wire

serial interface, LSB first. The DS1720 can measure

temperature over the range of –55°C to +125°C in 0.5°C

increments. For Fahrenheit usage, a lookup table or conversion factor must be used.

COMPARE

PRESET

INC

=0

STOP

=0

TEMPERATURE REGISTER

SET/CLEAR

LSB

9th (MSB) bit), or as two transfers of 8–bit words, with

the most significant 7 bits being ignored or set to zero,

as illustrated in T able 1. After the MSB, the DS1720 will

output 0s.

Note that temperature is represented in the DS1720 in

terms of a

MSB LSB

XXXXXXX1 11 0 01 11 0

1

/2°C LSB, yielding the following 9–bit format:

TEMPERATURE/DATA RELATIONSHIPS

T able 1

DIGITAL

OUTPUT

TEMP

(Binary)

+85°C 0 10101010 00AA

+25°C 0 00110010 0032h

1

+

°C 0 00000001 0001h

/2

+0°C 0 00000000 0000h

–1/2°C 1 11111111 01FFh

–25°C 1 11001110 01CEh

Since data is transmitted over the 3–wire bus LSB first,

temperature data can be written to/read from the

DS1720 as either a 9–bit word (taking RST low after the

DIGITAL

OUTPUT

(Hex)

T = –25°C

Higher resolutions may be obtained by reading the temperature, and truncating the 0.5°C bit (the LSB) from the

read value. This value is TEMP_READ. The value left in

the counter may then be read by issuing a READ

COUNTER command. This value is the count remaining (COUNT_REMAIN) after the gate period has

ceased. By loading the value of the slope accumulator

into the count register (using the READ SLOPE command), this value may then be read, yielding the number

of counts per degree C (COUNT_PER_C) at that temperature. The actual temperature may be then be calculated by the user using the following:

TEMPERATURE = TEMP_READ – 0.25

(COUNT_PER_C – COUNT_REMAIN)

COUNT_PER_C

030598 3/12

Page 4

DS1720

DETAILED PIN DESCRIPTION Table 2

PIN SYMBOL DESCRIPTION

1 DQ Data Input/Output pin for 3–wire communication port.

2 CLK/CONV Clock input pin for 3–wire communication port. When the DS1720 is used in a

3 RST Reset input pin for 3–wire communication port.

4 GND Ground pin.

5 T

6 T

7 T

8 V

COM

LOW

HIGH

DD

stand–alone application with no 3–wire port, this pin can be used as a convert pin.

Temperature conversion will begin on the falling edge of CONV

.

High/Low Combination Trigger. Goes high when temperature exceeds TH; will

reset to low when temperature falls below TL.

Low Temperature Trigger. Goes high when temperature falls below TL.

High Temperature Trigger. Goes high when temperature exceeds TH.

Supply Voltage. 2.7V – 5.5V input power pin.

OPERATION–THERMOSTAT CONTROLS

Three thermally triggered outputs, T

T

, are provided to allow the DS1720 to be used as a

COM

thermostat, as shown in Figure 3. When the DS1720’s

temperature meets or exceeds the value stored in the

high temperature trip register, the output T

becomes active (high) and remains active until the

DS1720’s measured temperature becomes less than

the stored value in the high temperature register, TH.

The T

output can be used to indicate that a high

HIGH

temperature tolerance boundary has been met or

exceeded, or as part of a closed loop system can be

used to activate a cooling system and to deactivate it

when the system temperature returns to tolerance.

The T

output functions similarly to the T

LOW

When the DS1720’s measured temperature equals or

HIGH

, T

HIGH

LOW

output.

, and

HIGH

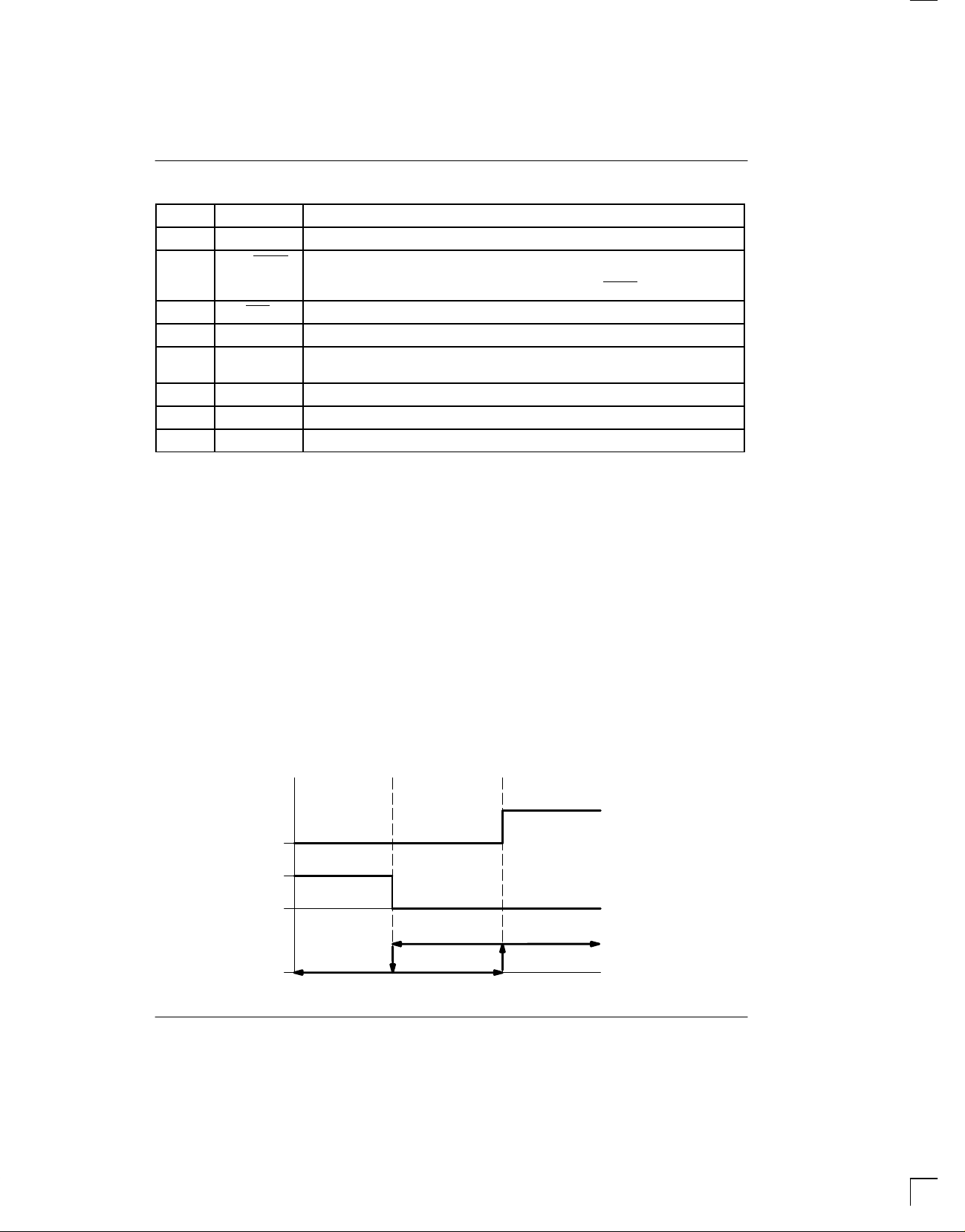

THERMOSTAT OUTPUT OPERATION Figure 3

T

HIGH

T

LOW

falls below the value stored in the low temperature register, the T

output becomes active. T

LOW

LOW

remains

active until the DS1720’s temperature becomes greater

than the value stored in the low temperature register,

TL. The T

output can be used to indicate that a low

LOW

temperature tolerance boundary has been met or

exceeded, or as part of a closed loop system, can be

used to activate a heating system and to deactivate it

when the system temperature returns to tolerance.

The T

output goes high when the measured tem-

COM

perature meets or exceeds TH, and will stay high until

the temperature equals or falls below TL. In this way,

any amount of hysteresis can be obtained.

030598 4/12

T

COM

TL TH

T (°C)

Page 5

DS1720

OPERATION AND CONTROL

The DS1720 must have temperature settings resident in

the TH and TL registers for thermostatic operation. A

configuration/status register is also used to determine

the method of operation that the DS1720 will use in a

particular application, as well as indicating the status of

the temperature conversion operation. The configuration register is defined as follows:

CONFIGURATION/STATUS REGISTER

DONE THF TLF NVB 1 0 CPU 1SHOT

where

DONE = Conversion Done bit. 1=conversion com-

plete, 0=conversion in progress.

THF = Temperature High Flag. This bit will be set

to 1 when the temperature is greater than

or equal to the value of TH. It will remain 1

until reset by writing 0 into this location or

by removing power from the device. This

feature provides a method of determining

if the DS1720 has ever been subjected to

temperatures above TH while power has

been applied.

TLF = Temperature Low Flag. This bit will be set

to 1 when the temperature is less than or

equal to the value of TL. It will remain 1

until reset by writing 0 into this location or

by removing power from the device. This

feature provides a method of determining

if the DS1720 has ever been subjected to

temperatures below TL while power has

been applied.

NVB = Nonvolatile Memory Busy Flag. 1=write to

CPU = CPU use bit. If CPU=0, the CLK/CONV

1SHOT = One–Shot Mode. If 1SHOT is 1, the

2

an E

memory cell in progress. 0=nonvolatile memory is not busy. A copy to E

may take up to 10 ms.

pin acts as a conversion start control,

when RST is low. If CPU is 1, the DS1720

will be used with a CPU communicating to

it over the 3–wire port, and the operation

of the CLK/CONV

pin is as a normal clock

in concert with DQ and RST. This bit is

stored in nonvolatile E2 memory, capable

of at least 50,000 writes. The DS1720 is

shipped with CPU=0.

DS1720 will perform one temperature

conversion upon reception of the Start

Convert T protocol. If 1SHOT is 0, the

DS1720 will continuously perform temperature conversion. This bit is stored in

nonvolatile E

2

memory, capable of at least

50,000 writes. The DS1720 is shipped

with 1SHOT=0.

For typical thermostat operation, the DS1720 will operate in continuous mode. However, for applications

where only one reading is needed at certain times, and

to conserve power, the one–shot mode may be used.

Note that the thermostat outputs (T

HIGH

will remain in the state they were in after the last valid

temperature conversion cycle when operating in one–

shot mode.

OPERATION IN STAND–ALONE MODE

In applications where the DS1720 is used as a simple

thermostat, no CPU is required. Since the temperature

limits are nonvolatile, the DS1720 can be programmed

prior to insertion in the system. In order to facilitate

operation without a CPU, the CLK/CONV

be used to initiate conversions. Note that the CPU bit

must be set to 0 in the configuration register to use this

mode of operation. Whether CPU=0 or 1, the 3–wire

port is active. Setting CPU=1 disables the stand–alone

mode.

To use the CLK/CONV

pin to initiate conversions, RST

must be low and CLK/CONV must be high. If CLK/

CONV is driven low and then brought high in less than

10 ms, one temperature conversion will be performed

and then the DS1720 will return to an idle state. If CLK/

is driven low and remains low, continuous con-

CONV

versions will take place until CLK/CONV is brought high

again. With the CPU bit set to 0, the CLK/CONV will

override the 1–shot bit if it is equal to 1. This means that

2

even if the part is set for one–shot mode, driving CLK/

low will initiate conversions.

CONV

3–WIRE COMMUNICATIONS

The 3–wire bus is comprised of three signals. These are

the RST (reset) signal, the CLK (clock) signal, and the

DQ (data) signal. All data transfers are initiated by driving the RST

nates communication. (See Figures 4 and 5). A clock

cycle is a sequence of a falling edge followed by a rising

edge. For data inputs, the data must be valid during the

rising edge of a clock cycle. Data bits are output on the

input high. Driving the RST input low termi-

, T

, T

LOW

COM

pin (pin 2) can

)

030598 5/12

Page 6

DS1720

falling edge of the clock, and remain valid through the

rising edge.

When reading data from the DS1720, the DQ pin goes

to a high impedance state while the clock is high. T aking

RST

low will terminate any communication and cause

the DQ pin to go to a high impedance state.

Data over the 3–wire interface is communicated LSB

first. The command set for the 3–wire interface as

shown in Table 3 is as follows; only these protocols

should be written to the DS1720, as writing other protocols to the device may result in permanent damage to

the part.

Read Temperature [AAh]

This command reads the contents of the register which

contains the last temperature conversion result. The

next nine clock cycles will output the contents of this register.

Write TH [01h]

This command writes to the TH (HIGH TEMPERATURE) register. After issuing this command, the next

nine clock cycles clock in the 9–bit temperature limit

which will set the threshold for operation of the T

output.

HIGH

Write TL [02h]

This command writes to the TL (LOW TEMPERATURE) register. After issuing this command, the next

nine clock cycles clock in the 9–bit temperature limit

which will set the threshold for operation of the T

output.

LOW

Read TH [A1h]

This command reads the value of the TH (HIGH TEMPERATURE) register. After issuing this command, the

next nine clock cycles clock out the 9–bit temperature

limit which sets the threshold for operation of the T

output.

HIGH

Read TL [A2h]

This command reads the value of the TL (LOW TEMPERATURE) register. After issuing this command, the

next nine clock cycles clock out the 9–bit temperature

limit which sets the threshold for operation of the T

output.

LOW

Read Counter [A0h]

This command reads the value of the counter byte. The

next nine clock cycles will output the contents of this

register.

Read Slope [A9h]

This command reads the value of the slope counter byte

from the DS1720. The next nine clock cycles will output

the contents of this register.

Start Convert T [EEh]

This command begins a temperature conversion. No

further data is required. In one–shot mode, the temperature conversion will be performed and then the DS1720

will remain idle. In continuous mode, this command will

initiate continuous conversions.

Stop Convert T [22h]

This command stops temperature conversion. No further data is required. This command may be used to halt

a DS1720 in continuous conversion mode. After issuing

this command, the current temperature measurement

will be completed, and then the DS1720 will remain idle

until a Start Convert T is issued to resume continuous

operation.

Write Config [0Ch]

This command writes to the configuration register. After

issuing this command, the next eight clock cycles clock

in the value of the configuration register.

Read Config [ACh]

This command reads the value in the configuration register. After issuing this command, the next eight clock

cycles output the value of the configuration register.

030598 6/12

Page 7

DS1720 COMMAND SET Table 3

3–WIRE BUS

DATA AFTER

ISSUING

INSTRUCTION DESCRIPTION PROTOCOL

TEMPERATURE CONVERSION COMMANDS

Read Temperature Reads last converted temperature

AAh <read data>

value from temperature register

Read Counter Reads value of count remaining from

A0h <read data>

counter

Read Slope Reads value of the slope accumulator A9h <read data>

Start Convert T Initiates temperature conversion EEh Idle 1

Stop Convert T Halts temperature conversion 22h Idle 1

THERMOSTAT COMMANDS

Write TH Writes high temperature limit value into

01h <write data> 2

TH register

Write TL Writes low temperature limit value into

02h <write data> 2

TL register

Read TH Reads stored value of high tempera-

A1h <read data> 2

ture limit from TH register

Read TL Reads stored value of low temperature

A2h <read data> 2

limit from TL register

Write Config Writes configuration data to configura-

0Ch <write data> 2

tion register

Read Config Reads configuration data from configu-

ACh <read data> 2

ration register

PROTOCOL

DS1720

NOTES

NOTES:

1. In continuous conversion mode, a Stop Convert T command will halt continuous conversion. T o restart, the Start

Convert T command must be issued. In one–shot mode, a Start Convert T command must be issued for every

temperature reading desired.

2

2. Writing to the E

should be requested for at least 10 ms.

typically requires 10 ms at room temperature. After issuing a write command, no further writes

030598 7/12

Page 8

DS1720

FUNCTION EXAMPLE

Example: CPU sets up DS1720 for continuous conversion and thermostatic function.

CPU MODE

TX RX 0Ch CPU issues Write Config command

TX RX 00h CPU sets DS1720 up for continuous conversion

TX RX Toggle RST CPU issues Reset to DS1720

TX RX 01h CPU issues Write TH command

TX RX 0050h CPU sends data for TH limit of +40°C

TX RX Toggle RST CPU issues Reset to DS1720

TX RX 02h CPU issues Write TL command

TX RX 0014h CPU sends data for TL limit of +10°C

TX RX Toggle RST CPU issues Reset to DS1720

TX RX A1h CPU issues Read TH command

RX TX 0050h DS1720 sends back stored value of TH for CPU

TX RX Toggle RST CPU issues Reset to DS1720

TX RX A2h CPU issues Read TL command

RX TX 0014h DS1720 sends back stored value of TL for CPU

TX RX Toggle RST CPU issues Reset to DS1720

TX RX EEh CPU issues Start Convert T command

TX RX Toggle RST CPU issues Reset to DS1720

DS1720 MODE

(3–WIRE)

DATA (LSB FIRST) COMMENTS

to verify

to verify

030598 8/12

Page 9

READ DATA TRANSFER Figure 4

DS1720

RST

t

CC

CLK

t

CDH

DQ

t

DC

017

WRITE DATA TRANSFER Figure 5

RST

t

CLK

DQ

CC

t

DC

017

t

CDH

t

CL

PROTOCOL

t

R

t

CH

t

CCH

t

CDD

LSB

DATA

t

DC

LSB

DATA

t

DCH

t

F

MSB

DATA

t

CCH

t

CDZ

MSB

DATA

t

CWH

t

RDZ

PROTOCOL

NOTE: tCL, tCH, tR, and tF apply to both read and write data transfer.

RELATED APPLICATION NOTES

The following Application Notes can be applied to the

DS1720. These notes can be obtained from the Dallas

Semiconductor “Application Note Book”, via our website at http:\\www.dalsemi.com/, or through our faxback

service at (972) 371–4441.

Application Note 67

in T emperature Control Applications”

: “Applying and Using the DS1620

Application Note 85

: “Interfacing the DS1620 to the Mo-

torola SPI Bus”

Application Note 105

: “High Resolution Temperature

Measurement with Dallas Direct–to–Digital Temperature Sensors”

Sample DS1720 subroutines that can be used in conjunction with AN105 can be downloaded from the website or our Anonymous FTP Site.

030598 9/12

Page 10

DS1720

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground –0.5V to +7.0V

Operating Temperature –55°C to +125°C

Storage Temperature –55°C to +125°C

Soldering Temperature 260°C for 10 seconds

* This is a stress rating only and functional operation of the device at these or any other conditions above those

indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods of time may affect reliability.

The Dallas Semiconductor DS1720 is built to the highest quality standards and manufactured for long term reliability.

All Dallas Semiconductor devices are made using the same quality materials and manufacturing methods. However,

the DS1720 is not exposed to environmental stresses, such as burn–in, that some industrial applications require. For

specific reliability information on this product, please contact the factory in Dallas at (972) 371–4448.

RECOMMENDED DC OPERATING CONDITIONS

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply V

Logic 1 V

Logic 0 V

DD

IH

IL

2.7 5.5 V 1

2.0 VCC+0.3 V 1

–0.3 +0.6 V 1

DC ELECTRICAL CHARACTERISTICS (–55°C to +125°C; VDD=2.7V to 5.5V)

PARAMETER SYMBOL CONDITION MIN MAX UNITS NOTES

Thermometer Error T

Logic 0 Output V

Logic 1 Output V

Input Resistance R

Active Supply Current I

Standby Supply Current I

STBY

ERR

OL

OH

I

CC

0°C to 85°C ±2.5 °C 10, 11

–55°C to

+125°C

See Typical Curve

0.4 V 3

2.4 V 2

RST to GND

DQ,CLK to V

DD

2

2

MΩ

MΩ

0°C to +70°C 1 mA 4, 5

0°C to +70°C 1 µA 4, 5

SINGLE CONVERT TIMING DIAGRAM (STAND–ALONE MODE)

CONV

t

CNV

030598 10/12

Page 11

DS1720

AC ELECTRICAL CHARACTERISTICS (–55°C to +125°C; VDD=2.7V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Temperature Conversion Time T

Data to CLK Setup t

CLK to Data Hold t

CLK to Data Delay t

CLK Low Time t

CLK High Time t

CLK Frequency f

DC

CDH

CDD

CL

CH

CLK

CLK Rise and Fall tR, t

RST to CLK Setup t

CLK to RST Hold t

RST Inactive Time t

CLK High to I/O High–Z t

RST Low to I/O High–Z t

Convert Pulse Width t

NV Write Cycle Time t

CC

CCH

CWH

CDZ

RDZ

CNV

WR

TC

35 ns 6

40 ns 6

285 ns 6

285 ns 6

DC 1.75 MHz 6

F

100 ns 6

40 ns 6

125 ns 6, 9

250 ns 500 ms

400 1000 ms

100 ns 6, 7, 8

500 ns

50 ns 6

50 ns 6

10 50 ms 12

AC ELECTRICAL CHARACTERISTICS (–55°C to +125°C; VDD=2.7V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

I/O Capacitance C

I

I/O

5 pF

10 pF

NOTES:

1. All voltages are referenced to ground.

2. Logic one voltages are specified at a source current of 1 mA.

3. Logic zero voltages are specified at a sink current of 4 mA.

specified with DQ pin open and CLK pin at VDD.

4. I

CC

specified with VCC at 3.3V and RST=GND.

5. I

CC

6. Measured at V

7. Measured at V

8. Load capacitance = 50 pF.

9. t

must be 10 ms minimum following any write command that involves the E2 memory.

CWH

10.See typical curve for specification limits outside 0°C to 85°C range.

11.Thermometer error reflects temperature accuracy as tested during calibration.

12.Writing to the nonvolatile memory should only take place in the 0°C to 70°C temperature range.

= 2.0V or VIL = 0.6V.

IH

= 2.4V or VOL = 0.4V.

OH

030598 11/12

Page 12

DS1720

DS1720 TYPICAL THERMOMETER ERROR

DS1720 TYPICAL THERMOMETER ERROR

4

3

UPPER SPEC

LIMIT

–55 –25 –10 5 20 45 60 75 90 100

THERMOMETER ERROR (C)

2

1

–1

–2

–3

–4

–5

–6

AMBIENT TEMPERATURE (C)

TYPICAL ERROR

LOWER SPEC

LIMIT

125

030598 12/12

Loading...

Loading...