Page 1

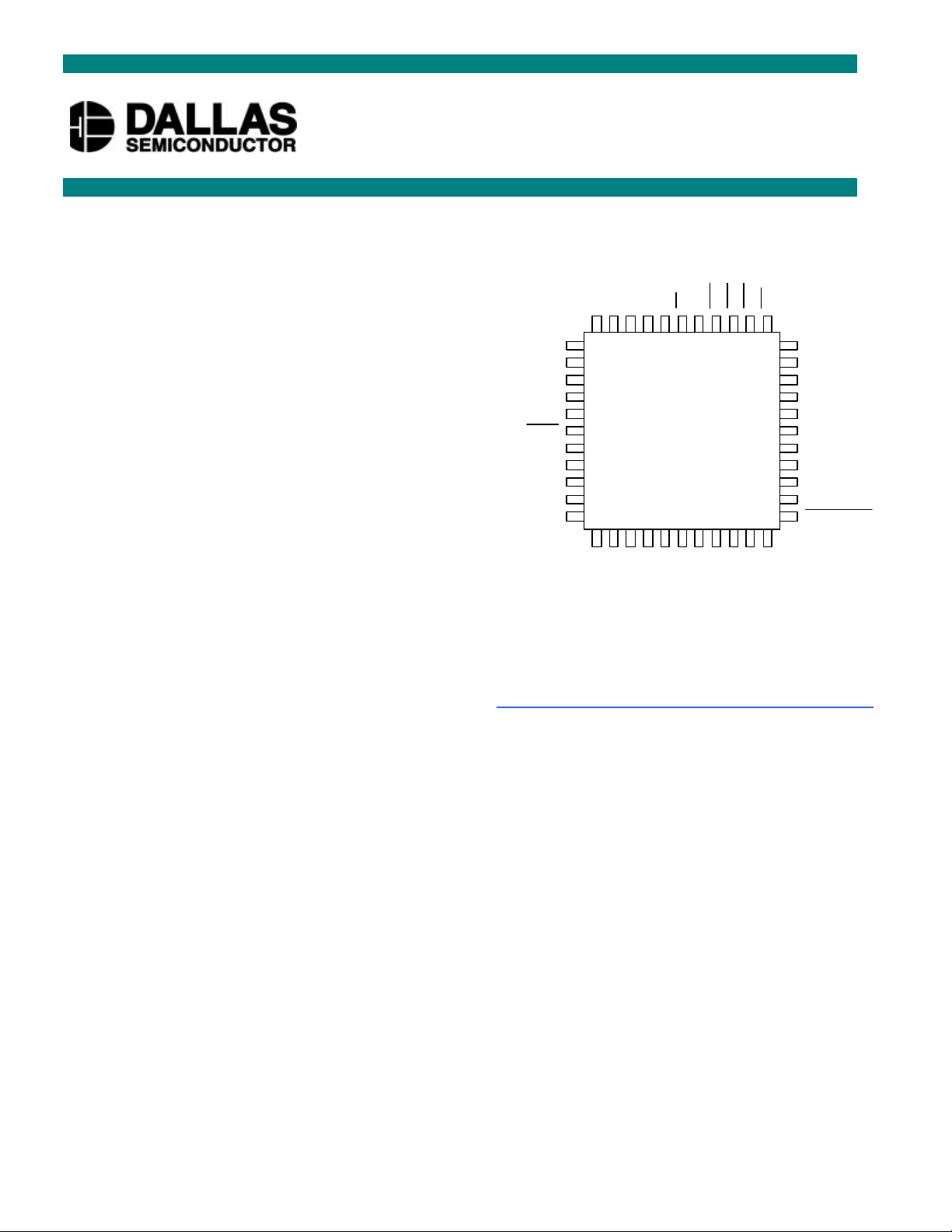

DS1680

www.maxi

m-ic.com

44-

Pin MQFP (10 x 10 x 2mm)

Package dimension information can be found at:

Portable System Controller

with Touch-Screen Control

FEATURES

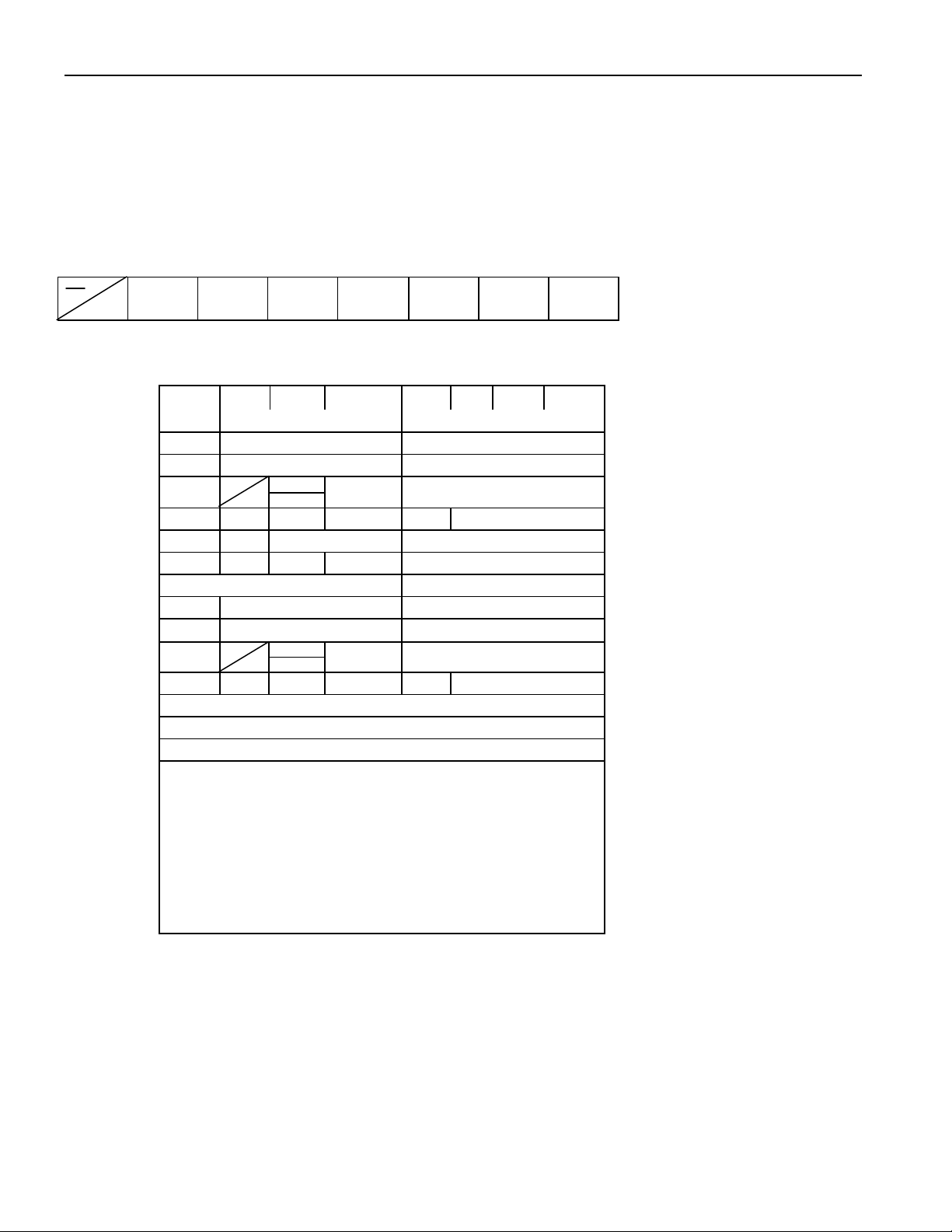

PIN ASSIGNMENT

§ Real-time clock (RTC)

− Counts seconds, minutes, hours, date,

month, day of the week, and year with

leap-year compensation valid up to 2100

− Power control circuitry supports system

power-on from day/time alarm

§ Microprocessor monitor

− Halts microprocessor during power-fail

− Automatically restarts microprocessor

after power failure

− Monitors pushbutton for external

override

− Halts and resets an out of control

microprocessor

§ NV RAM control

− Automatic battery backup and write

protection to external SRAM

§ 1.25V threshold detector for power-fail

V

BAT

X1

X2

AVG

BHE

COEN

OUT_SELECT

CONVERT

PD_RESET

PEN_SELECT

ANSELIN

INT

44

1

12

AVS

I/O

REF

V

V

SCLK

AIN1

AIN0

CCO

CSSTVCCRST

Y-

X+

Y+

AVD

PFO

CEO

X-

PEN_OFF

CEI

34

33

2311

22

OSCIN

PFI

GND

D7

D6

D5

D4

D3

D2

D1

D0

NEW_DATA

warning

§ 10-bit analog-to-digital converter (ADC)

− Monotonic with no missing codes

http://www.maxim-ic.com/TechSupport/DallasPackInfo.htm

§ Four-wire analog resistive touch-screen

interface

ORDERING INFORMATION

DS1680FP-3 3.3V Operation

DS1680FP-5 5.0V Operation

DESCRIPTION

The DS1680 incorporates many functions necessary for low-power portable products, providing an RTC,

NV RAM controller, microprocessor monitor, power-f ail warning, 10-bit ADC, and a touch-screen

controller in one chip.

The RTC provides seconds, minutes, hours, day, date, month, and year information with leap-year

compensation as well as an alarm interrupt. This interrupt works when the DS1680 is powered by the

system power supply or when in battery-backup operation, so the alarm can be used to wake up a system

that is powered down.

1 of 23 110901

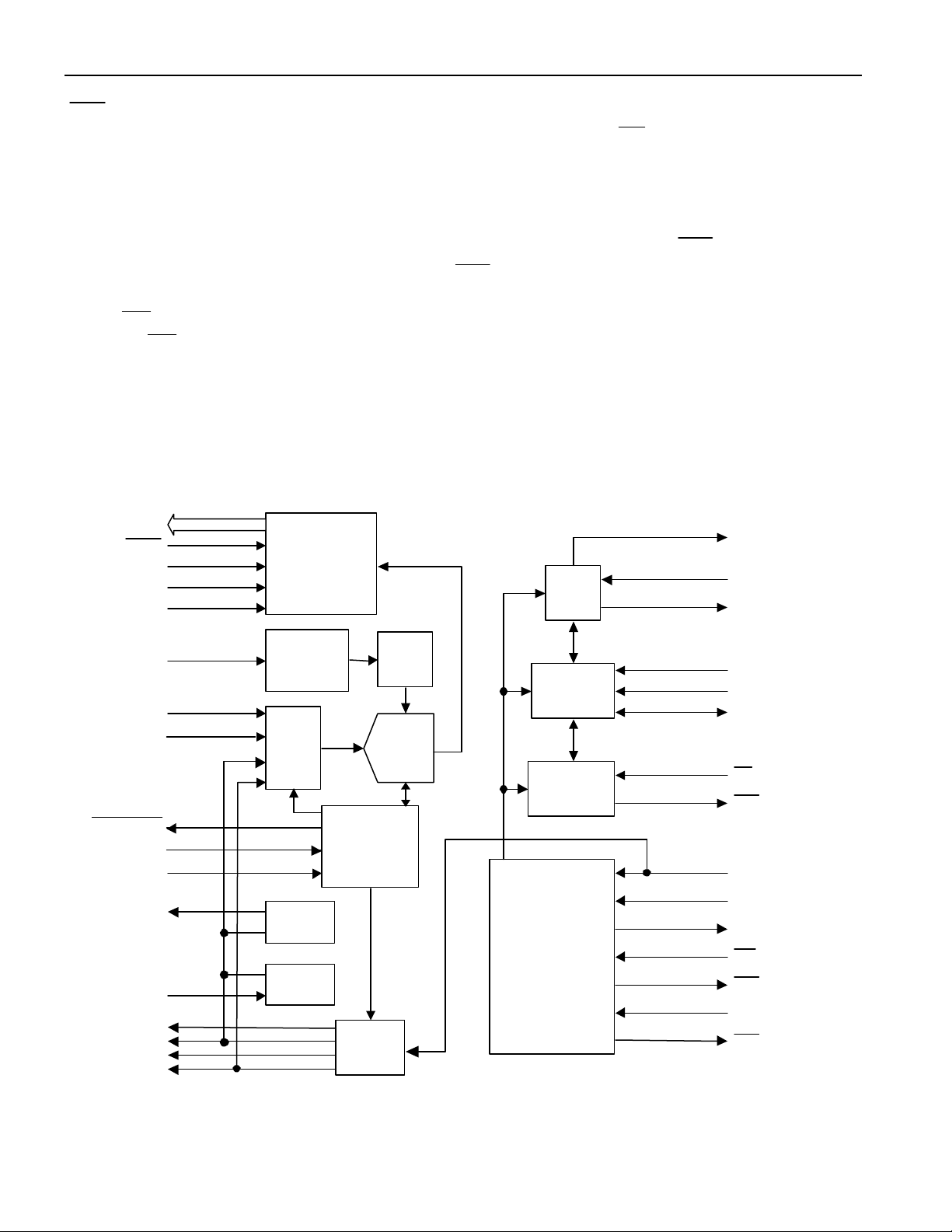

Page 2

DS1680

CLOCK

OSC

CLOCK

GEN

PANEL

DRIVE

CONVERT

CONTROL

10-BIT

ADC

INPUT

MUX

TOUCH

DETECT

POWER

CONTROL

RTC

SERIAL

INTERFACE

WATCHDOG

OUTPUT

MUX

BHE

OUT_SELECT

PEN_SELECT

AIN0

AIN1

COEN

CONVERT

PEN_OFF

PD_RST

D0-D7

OSCIN

X1X2INT

SCLK

CS

I/O

ST

RST

POWER SWITCH,

WRITE PROTECT,

NV CONTROL,

AND

POWER FAIL

WARNING

VCCV

V

CEI

CEO

PFI

PFO

ANSELIN

X+X-Y+Y-NEW_DATA

Automatic backup and write protection of an external SRAM is provided through the V

CCO

and

CEO pins. The backup energy source used to power the RTC is also used to retain RAM data in the

absence of VCC through the V

pin. The chip -enable output to SRAM, CE0 , is controlled during power

CCO

transients to prevent data corruption.

The DS1680’s microprocessor-monitor circuitry provides three basic functions. First, a precision

temperature-compensated reference and comparator circuit monitors the status of VCC. When an out -of-

tolerance condition occurs, an internal power-fail signal is generated that forces RST to the active state.

When VCC returns to an in-tolerance condition, the RST signal is kept in the active state for t

to allow

RPU

the power supply and processor to stabilize. The DS1680 debounces a pushbutton input and guarantees an

active RST pulse width of t

. The third function is a watchdog timer. The DS1680’s internal timer

RST

forces the RST signal to the active state if the strobe input is not driven low prior to watchdog time-out.

The DS1680 also provides a touch-screen controller along with a 10-bit successive approximation ADC.

The ADC is monotonic (no missing codes) and has an internal analog filter to reduce high frequency

noise.

DS1680 BLOCK DIAGRAM Figure 1

2 of 23

BAT

CCO

Page 3

DS1680

SIGNAL DESCRIPTIONS

VCC, GND (Digital Supply and Digital Ground) – DC power to the RTC, watchdog, X and Y drivers,

and power-switching circuitry is provided to the device on these pins.

V

(Backup Power Supply) – Battery input for standard 3V lithium cell or other energy source.

BAT

SCLK (Serial Clock Input) – SCLK is used to synchronize data movement on the serial interface.

I/O (Data Input/Output) – The I/O pin is the bidirectional data pin for the 3-wire interface.

CS (Chip Select) – The chip-select signal must be asserted high during a read or a write for

communication over the 3-wire serial interface.

V

(External SRAM Power Supply Output) – This pin is internally connected to V

CCO

within nominal limits. However, during power-fail V

Switchover occurs when V

drops below V

CC

CCSW

.

is internally connected to the V

CCO

INT (Interrupt Output) – The INT pin is an active-high output of the DS1680 that can be used as an

interrupt input to a microprocessor. The INT output remains high as long as the status bit causing the

interrupt is present and the corresponding interrupt-enable bit is set. The INT pin operates when the

DS1680 is powered by VCC or V

BAT

.

when VCC is

CC

BAT

pin.

CEI (SRAM Chip-Enable Input) – CEI must be driven low to enable the external SRAM.

CEO (SRAM Chip-Enable Output) – Chip-enable output for SRAM.

PFI (Power-Fail Input) – Power-fail comparator input. When PFI is less than 1.25V, PFO goes low;

otherwise PFO remains high. Connect PFI to GND or VCC when not used.

PFO (Power-Fail Output) – Power-fail output goes low and sinks current when PFI is less than 1.25V;

otherwise PFO remains high.

SI (Strobe Input) – The strobe input pin is used in conjunction with the watchdog timer. If the ST pin is

not driven low within the watchdog time period, the RST pin is driven low.

RST (Reset) – The RST pin functions as a microprocessor reset signal. This pin has an internal 47kΩ

pullup resistor.

X1, X2 – Connections for a standard 32.768kHz quartz crystal. For greatest accuracy, the DS1680 must

be used with a crystal that has a specified load capacitance of 6pF. There is no need for external

capacitors or resistors. Note: X1 and X2 are very high-impedance nodes. It is recommended that they and

the crystal be guard-ringed with ground and that high-frequency signals be kept away from the crystal

area. For more information about crystal selection and crystal layout considerations, please consult

Application Note 58, “Crystal Considerations with Dallas Real-Time Clocks.” The DS1680 will not

function without a crystal.

3 of 23

Page 4

DS1680

AVD, AVS (ADC Supply and Ground) – Power supply and ground for the ADC.

AIN0, AIN1 (Analog Inputs) – These pins are the analog inputs for the ADC.

V

(Voltage Reference) – Reference voltage for the ADC.

REF

X+, X- (Resistive Tablet X Plane Dri ver) – Connect to X-terminal of resistive tablet.

Y+, Y- (Resistive Tablet Y Plane Driver) – Connect to Y-terminal of resistive tablet.

CONVERT – Assert to logic 1 to request sample from AIN0 or AIN1. Use with ANSELIN input.

ANSELIN (Analog Select Input ) – Assert to logic 0 to select AIN0. Assert to logic 1 to select AIN1.

Use with CONVERT input.

BHE (Bus High Enable Input) – Drive to logic 1 to select high byte (data bits 2–9). Drive to logic 0 to

select low byte (data bits 0–1). The lower 6 bits will all be zeros when asserted low.

PEN_SELECT (Pen Select Input) – Assert to logic 1 to select X- or Y- data output. Assert to logic 0 to

select AIN0 or AIN1 data output. Use with OUT_SELECT input.

OUT_SELECT (Output Select Input) – Assert to logic 0 to select AIN0 or X- data. Assert to logic 1 to

select AIN1 or Y- data. Use with PEN_SELECT input.

COEN (Chip Output Enable) – The COEN pin must be asserted low to enable the ADC data to be

read on D0–D7.

D0-D7 (Data Bus) – Data output from ADC.

AVG (Data Average Select Pin) – Logic 1 selects data average mode; logic 0 selects raw data mode.

NEW_DATA (New Data Indicator) – A logic 0 pulse indicates that new data packet is available on

D0–D7.

OSCIN (Oscillator Input) – Input for the ADC clock.

PEN_OFF (Pen Detection Output) – Indicates pen not detected. Logic 1 if pen is not detected.

PD_RESET (Power Down/Reset Input) – Assert logic 1 for ≥10ns to reset. Hold at logic 1 for power-

down mode of the analog circuitry.

4 of 23

Page 5

DS1680

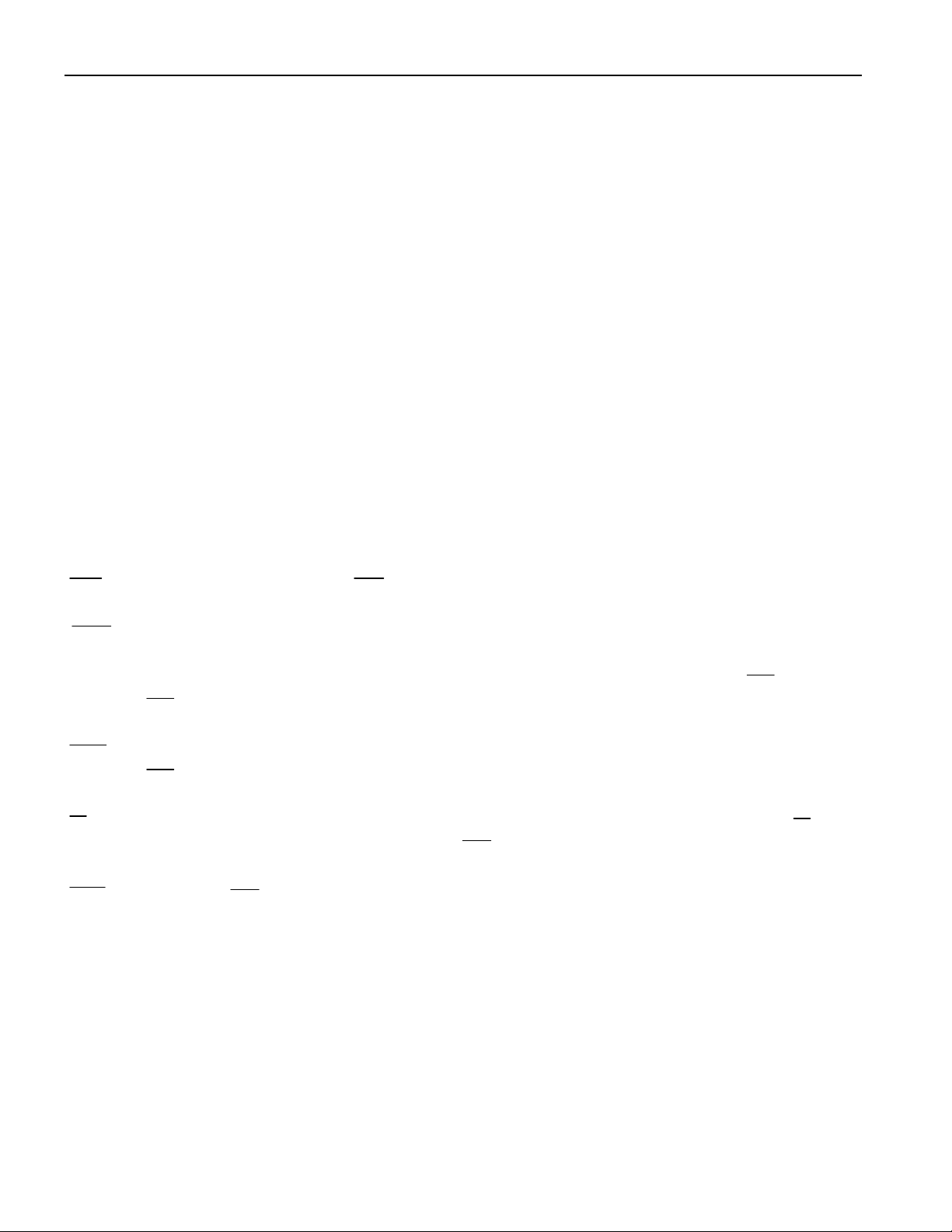

3-WIRE SERIAL INTERFACE

Communication with the RTC and watchdog is accomplished through a simple 3-wire interface

consisting of the chip select (CS), serial clock (SCLK), and input/output (I/O) pins.

All data transfers are initiated by driving the CS input high. The CS input serves two functions. First, CS

turns on the control logic, which allows access to the shift register for the address/command sequence.

Second, the CS signal provides a method of terminating either single byte or multip le byte (burst) data

transfer. A clock cycle is a sequence of a rising edge followed by a falling edge. For data input, data must

be valid during the clock’s rising edge and data bits are output on the clock’s falling edge. If the CS input

goes low, all da ta transfer terminates and the I/O pin goes to a high-impedance state.

Address and data bytes are always shifted LSB first into the I/O pin. Any transaction requires the

address/command byte to specify a read or write to a specific register followed by one or more bytes of

data. The address byte is always the first byte entered after CS is driven high. The most significant bit

(RD /WR) of this byte determines if a read or write will take place. If this bit is 0, one or more read cycles

will occur. If this bit is 1, one or more write cycles will occur.

Data transfers can occur one byte at a time or in multiple-byte burst mode. After CS is driven high an

address is written to the DS1680. After the address, one or more data bytes can be read or written. For a

single byte transfer one byte is read or written and then CS is driven low. Multiple bytes can be read or

written to the DS1680 after the address has been written. Each read or write cycle causes the register

address to automatically increment. Incrementing continues until the device is disabled. After accessing

register 0Dh, the address wraps to 00h.

Data transfer for single-byte transfer and multiple -byte burst transfer is illustrated in Figures 2 and 3.

SINGLE- BYTE DATA TRANSFER Figure 2

MULTIPLE-BYTE BURST TRANSFER Figure 3

5 of 23

Page 6

DS1680

ADDRESS/COMMAND BYTE

Figure 4 shows the command byte for the DS1680. Each data transfer is initiated by a command byte.

Bits 0–6 specify the address of the registers to be accessed. The MSB (bit 7) is the read/write bit. This bit

specifies whether the accessed byte will be read or written. A read operation is selected if bit 7 is a zero

and a write operation is selected if bit 7 is a one. The address map for the DS1680 is shown in Figure 5.

ADDRESS/COMMAND BYTE Figure 4

7 6 5 4 3 2 1 0

RD

WR

A6 A5 A4 A3 A2 A1 A0

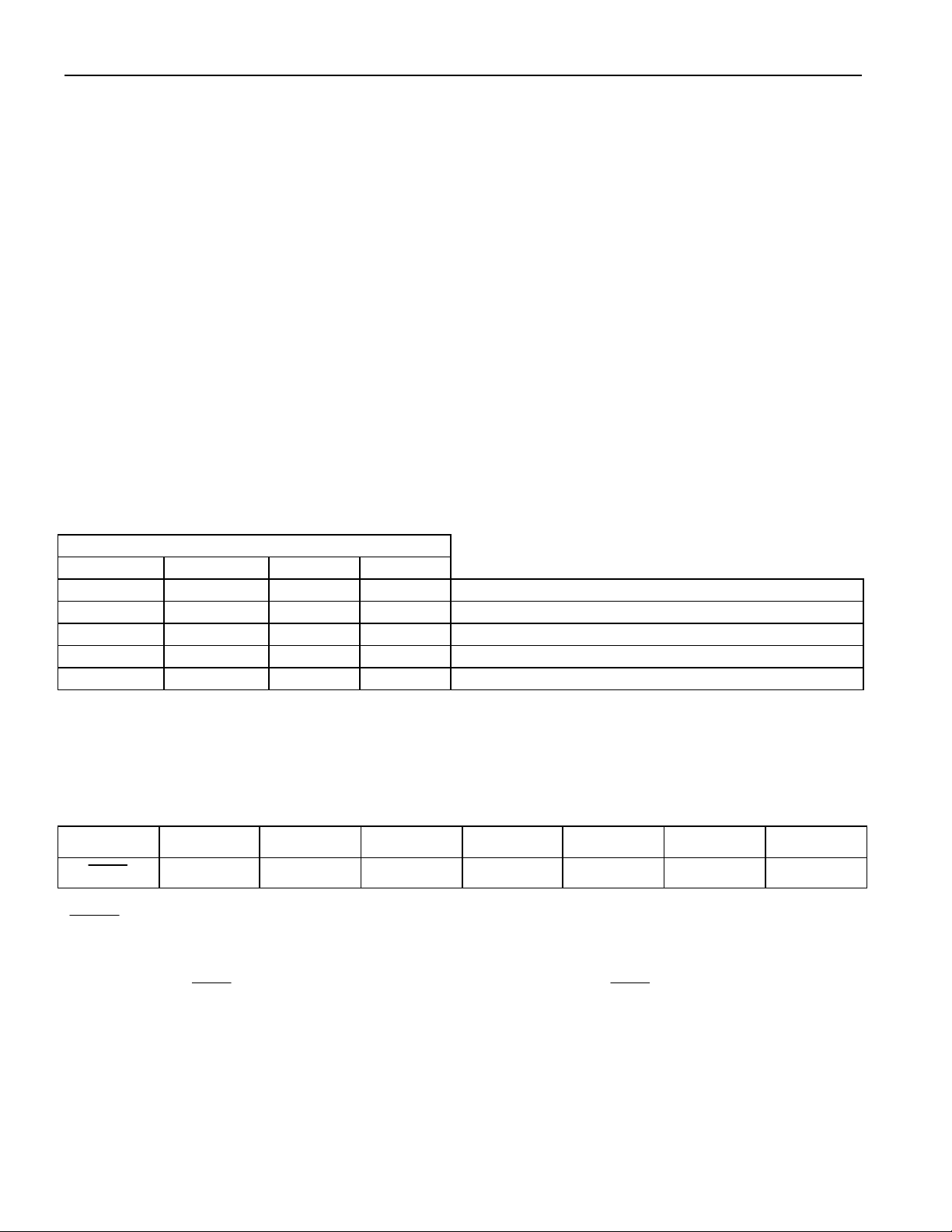

RTC/WATCHDOG ADDRESS MAP Figure 5

BIT7

00 0 10 SECONDS SECONDS

01 0 10 MINUTES MINUTES

02

0

12

24

10 HR

A/P

10 HR HOURS

03 0 0 0 0 0 DAY

04 0 0 10 DATE DATE

05 0 0 0 10 MO.

06 10 YEAR YEAR

07 M 10 SEC ALARM SECONDS ALARM

08 M 10 MIN ALARM MINUTES ALARM

09

M

12

24

10 HR

A/P

10 HR HOUR ALARM

0A M 0 0 0 0 DAY ALARM

0B CONTROL REGISTER

0C STATUS REGISTER

0D WATCHDOG REGISTER

0E

RESERVED

7F

BIT0

MONTH

6 of 23

Page 7

DS1680

CLOCK, CALENDAR, AND ALARM

The time and calendar information is accessed by reading/writing the appropriate register bytes. Note that

some bits are set to zero. These bits will always read zero regardless of how they are written. Also note

that registers 0Eh to 7Fh are reserved. These registers will always read zero regardless of how they are

written. The contents of the time, calendar, and alarm registers are in the binary-coded decimal (BCD)

format.

The DS1680 can run in either 12-hour or 24-hour mode. Bit 6 of the hours register is defined as the 12- or

24-hour mode select bit. When high, the 12-hour mode is selected. In the 12-hour mode, bit 5 is the

AM/PM bit with logic one being PM. In the 24-hour mode, bit 5 is the second 10-hour bit (20–23 hours).

The DS1680 also contains a time-of-day alarm. The alarm registers are located in registers 07h to 0Ah.

Bit 7 of each of the alarm registers are mask bits (Table 1). When all of the mask bits are logic 0, an

alarm will occur once per week when the values stored in time-keeping registers 00h to 03h match the

values stored in the time-of -day alarm registers. An alarm will be generated every day when mask bit of

the day alarm register is set to one. An alarm wil l be generated every hour when the day and hour alarm

mask bits are set to one. Similarly, an alarm will be generated every minute when the day, hour, and

minute alarm mask bits are set to one. When day, hour, minute, and second alarm mask bits are set to one,

an alarm will occur every second.

TIME- OF-DAY ALARM BITS Table 1

ALARM REGISTER MASK BITS (BIT 7)

Seconds Minutes Hours Day

1 1 1 1 Alarm once per second.

0 1 1 1 Alarm when seconds match.

0 0 1 1 Alarm when minutes and seconds match.

0 0 0 1 Alarm when hours, minutes and seconds match.

0 0 0 0 Alarm when day, hours, minutes and seconds match.

SPECIAL PURPOSE REGISTERS

The DS1680 has two additional registers (control register and status register) that control the RTC and

interrupts.

CONTROL REGISTER – 0Bh

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

EOSC

WP SP1 SP0 0 0 0 AIE

EOSC (Enable Oscillator) – This bit, when set to logic 0, will start the oscillator. When this bit is set to

a logic 1, the oscillator is stopped and the DS1680 is placed into a low-power standby mode (I

BAT

) when

in battery-backup mode. When the DS1680 is powered by VCC, the oscillator is always on regardless of

the status of the EOSC bit; however, the RTC is incremented only when EOSC is a logic 0.

SP0 and SP1 (Speed Select) – These bits select the on time of the X- and Y-measurement duty cycle.

The programmable duty cycle section has more detail.

WP (Write Protect) – Before any write operation to the RTC or any other registers, this bit must be logic

0. When high, the write-protect bit prevents a write operation to any register.

7 of 23

Page 8

DS1680

AIE (Alarm Interrupt Enable) – When set to a logic 1, this bit permits the interrupt request flag (IRQF)

bit in the status register to assert INT. When the AIE bit is set to logic 0, the IRQF bit does not initiate the

INT signal.

STATUS REGISTER – 0Ch

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0 LOBAT 0 0 0 0 0 IRQF

LOBAT (Low Battery Flag) – This bit reflects the status of the backup power source connected to the

V

pin. When V

BAT

is greater than 2.5V, LOBAT is set to a logic 0. When V

BAT

is less than 2.3V,

BAT

LOBAT is set to a logic 1.

IRQF (Interrupt Request Flag) – A logic 1 in the interrupt request flag bit indicates that the current

time has matched the time of day alarm registers. If the AIE bit is also a logic 1, the INT pin will go high.

IRQF is cleared by reading or writing to any of the alarm registers.

POWER-UP/POWER-DOWN CONSIDERATIONS

When VCC is applied to the DS1680 and reaches a level greater than V

becomes fully accessible after t

VCC drops below V

, the device is switched over to the V

CCSW

(250ms typical). Before t

RPU

elapses, some inputs are disabled. When

RPU

supply.

BAT

During power-up, when VCC returns to an in-tolerance condition, the RST pin is kept in the active state

for 250ms (typical) to allow the power supply and microprocessor to stabilize.

(trip point), the device

CCTP

NONVOLATILE SRAM CONTROL LER

The DS1680 provides automatic backup and write protection for an external SRAM. This function is

provided by gating the chip-enable signal and by providing a constant power supply through the V

CCO

pin.

The DS1680 nonvolatizes the external SRAM by write-protecting the SRAM and by providing a backup

power supply in the absence of VCC. When V

falls below V

CC

, access to the external SRAM is

CCTP

prohibited by forcing CE0 high regardless of the level of CEI . Upon power-up, access is prohibited until

the end of t

RPU

.

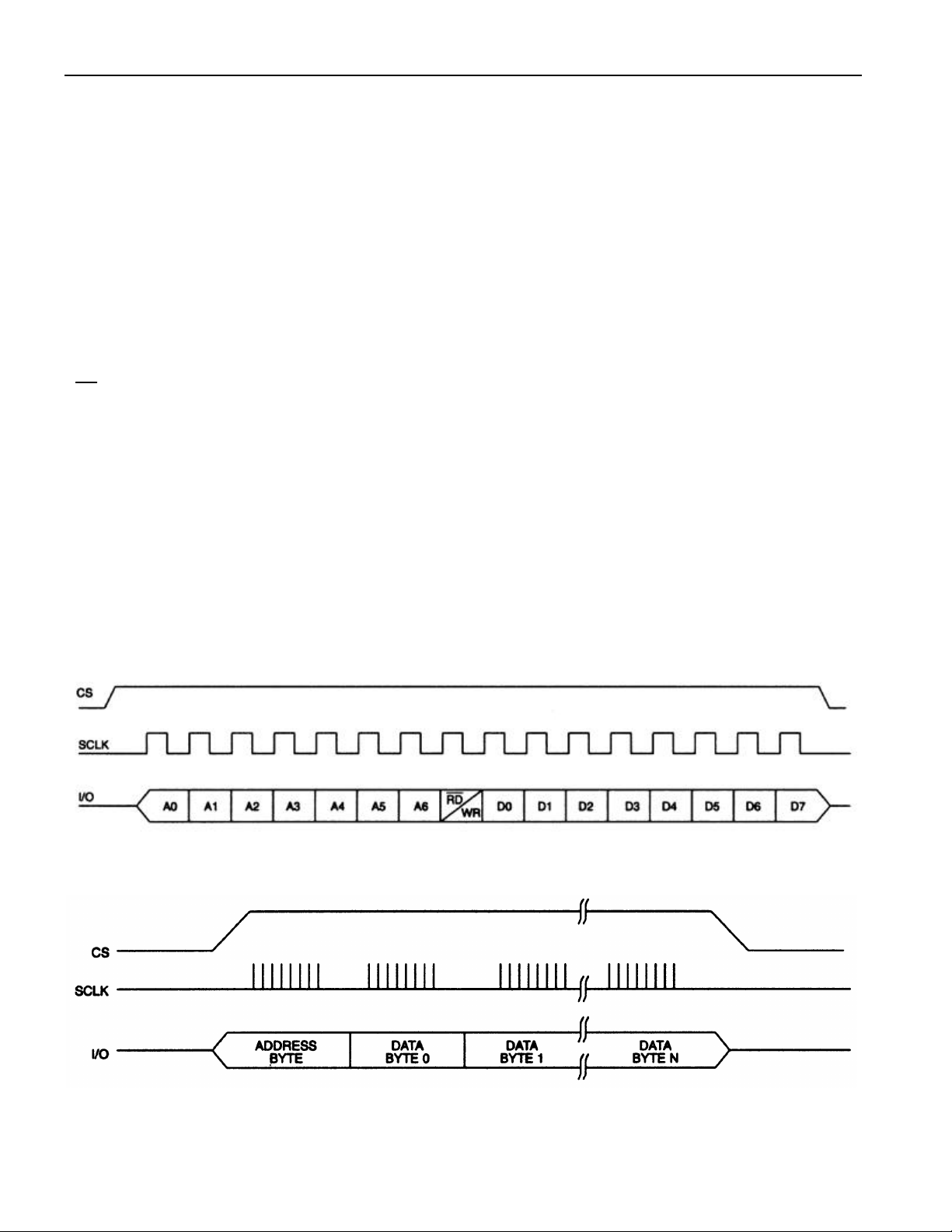

POWER-FAIL COMPARATOR

The PFI input is connected to an internal reference. If PFI is less than 1.25V, PFO goes low. The powerfail comparator can be used as an undervoltage detector to signal an impending power supply failure.

PFO can be used as a µP interrupt input to prepare for power-down. For battery conservation, the

comparator is turned off and PFO is held low when in battery-backup mode.

ADDING HYSTERESIS TO THE POWER -FAIL COMPARATOR

Hysteresis adds a noise margin to the power-fail comparator and prevents PFO from oscillating when

VIN is near the power-fail comparator trip point. Figure 6 shows how to add hysteresis to the power-fail

comparator. Select the ratio of R1 and R2 such that PFI sees 1.25V when VIN falls to the desired trip

point (VTRIP). Resistors R2 and R3 adds hysteresis. R3 will typically be an order of magnitude greater

than R1 or R2. R3 should be chosen so it does not load down the PFO pin. Capacitor C1 adds noise

filtering and has a value of typically 1.0µF (See Figure 6 for a schematic diagram and equations.)

8 of 23

Page 9

DS1680

POWER-FAIL COMPARATOR Figure 6

+5V

V

CC

R1

VIN

PFI

V

TRIP

C1

= 1.25

R2 R3

R1 + R2

R2

VI – 1.25

R1

+

to µP

V

= 1.25 /

H

5 - 1.25

R3

DS1680

PFO

GND

R2||R3

R1 + R2||R3

1.25

=

R2

9 of 23

Page 10

DS1680

MICROPROCESSOR MONITOR

The DS1680 monitors three vital conditions for a microprocessor: power supply, software execution, and

external override.

First, a precision temperature-compensated reference and comparator circuit monitors the status of VCC.

When an out-of -tolerance condition occurs, an internal power-fail signal is generated that forces the RST

pin to the active state, thus warning a processor-based system of impending power failure. When VCC

returns to an in-tolerance condition upon power-up, the reset signal is kept in the active state for t

RST

to

allow the power supply and microprocessor to stabilize. Note, however, that if the EOSC bit is set to a

logic 1 (to disable the oscillator during battery-backup mode), the RST signal will be kept in an active

state for t

plus the start-up time of the oscillator.

RST

The second monitoring function is pushbutton reset control. The DS1680 provides for a pushbutton

switch to be connected to the RST output pin. When the DS1680 is not in a reset cycle, it continuously

monitors the RST signal for a low-going edge. If an edge is detected, the DS1680 will debounce the

switch by pulling the RST line low. After the internal timer has expired, the DS1680 will continue to

monitor the RST line. If the line is still low, the DS1680 will continue to monitor the line looking for a

rising edge. Upon detecting release, the DS1680 will force the RST line low and hold it low for t

RST

.

The third microprocessor monitoring function provided by the DS1680 is a watchdog timer. The

watchdog timer function forces RST to the active state when the ST input is not stimulated within the

predetermined time period. The time period is set by the time delay (TD) bits in the watchdog register.

The time delay can be set to 250ms, 500ms, or 1000ms. If TD0 and TD1 are both set to zero, the

watchdog timer is disabled. When enabled, the watchdog timer starts timing out from the set time period

as soon as RST is inactive. The default setting is for the watchdog timer to be enabled with 1000ms time

delay. If a high-to-low transition occurs on the ST input pin prior to time-out, the watchdog timer is reset

and begins to time-out again. If the watchdog timer is allowed to time-out, the RST signal is driven to the

active state for t

. The ST input can be derived from microprocessor address signals, data signals,

RST

and/or control signals. To guarantee that the watchdog timer does not time-out, a high-to-low transition

must occur at or less than the minimum period.

WATCHDOG REGISTER – 0Dh

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0 0 0 0 0 0 TD1 TD0

WATCHDOG TIME-OUT BITS Table 2

TD1 TD0 WATCHDOG TIME-OUT

0 0 Watchdog Disabled

0 1 250ms

1 0 500ms

1 1 1000ms

10 of 23

Page 11

DS1680

RESISTIVE TOUCH SCREEN (4-WIRE)

Resistive touch screens consist of two resistive plates that are separated by a small gap. Each plate has an

electrode at each end; when the screen is touched the pressure forces the two plates to come in contact at

the exact position of the touch. To get the x-coordinate position, the DS1680 will drive the X-plane

resistive film (via X+ and X-) and sense the voltage picked up by the Y-plane resistive film (via Y+ and

Y-). Next, to get the y-coordinate position, the DS1680 will drive the Y- plane resistive film and sense the

voltage picked up by the X-plane resistive film.

ANALOG-TO-DIGITAL CONVERTER (ADC)

The DS1680 provides a 10-bit ADC. Two multiplexed analog inputs are provided through the AIN0 and

AIN1 pins along with two other inputs on the X- and Y- pins. The ADC is monotonic (no missing codes)

and uses a successive approximation tec hnique to convert the analog signal into a digital code.

An analog-to-digital conversion is the process of assigning a digital code to an analog input voltage. This

code represents the input value as a fraction of the full-scale voltage (FSV) range. The FSV range is then

divided by the ADC into 1024 codes (10 bits), and is bound by an upper limit equal to the reference

voltage and the lower limit, which is ground.

On-chip circuitry detects if the pen is in contact with the digitizer tablet. The pen-detection status is

indicated on pin (PEN_OFF) and can be used by the system for signaling end -of-stroke for handwriting

recognition software purposes. If no pen is detected, PEN_OFF will be pulled to logic 1 and no

coordinate data will be made available. PEN_OFF at logic 0 indicates that a pen is detected on the

digitizer tablet and its coordinate position will be made available on D0–D7. The NEW_DATA pin

pulses low to indicate when a new coordinate data pair is available.

When the AVG pin is set to logic 0, the data at pins D0 –D7 will indicate the most recent sample of the

ADC. Setting the AVG pin to logic 1 invokes the data averaging mode. In this mode, the data output on

D0–D7 will indicate the rolling average of the four most recent samples of the ADC.

The DS1680 continuously monitors the CONVERT and ANSELIN signals; on the internal clock’s rising

edge (state cycle), the corresponding AIN0 or AIN1 conversion is requested. The conversion request

must be completed before T0 (Figure 7c) in order for AIN0 and/or AIN1 to be sampled and converted in

the present conversion cycle; otherwise AIN0 and/or AIN1 will be sampled and converted in the next

conversion cycle. The logic level of the ANSELIN input will determine whether a sample is taken from

the AIN0 or AIN1 input. Table 3 lists the specific analog input that is selected by this signal. Figure 8

shows the required timing associated with CONVERT and ANSELIN. If the state of ANSELIN changes

while CONVERT is at logic 1 and you meet the timing requirements of figure 8, both AIN0 and AIN1

conversions are requested. If the ANSELIN does not change states while CONVERT is at

logic 1, only AIN0 or AIN1 conversion is requested. If a pen is detected during a conversion request, then

X and Y will be sampled and converted pr ior to the AIN0 and/or AIN1 conversion. The AIN0 and AIN1

conversion result is output on the D0 –D7 as defined in the Parallel Interface section.

ANALOG INPUT SELECTION Table 3

ANSELIN ANALOG INPUT

0 AINO

1 AIN1

11 of 23

Page 12

DS1680

PROGRAMMABLE DUTY CYCLE

The current required to take an X or Y measurement is V

V

= 5V, the current required is 20mA. The average current is the current during the measurement,

AVD

multiplied by the ratio of the time the drivers are on, to the power of total sample time. In order to

minimize the average current, the on-time should be limited to the minimum time required for the tablet

RC delay.

Experimental data suggests that a typical RC time constant is between 4µs and 5µs for a resistive touch

screen. In order to achieve 10-bit resolution, the settling time must be eight time constants. This creates a

requirement of a minimum of 80 µs on-time total, 40µs for each X and Y measurement.

To provide both low power and high sample rate, the on-time for the X- and Y-measurement duty cycle is

programmable. Bits 4 and 5 (SP0 and SP1) of the control register (0Bh) select the on-time of four

different frequency ranges. The frequencies given are the maximum frequency for that timing range,

which will not violate the 40µs-per-measurement requirement.

SP1 SP0 FREQUENCY RANGE (MHz)

AVERAGE

CURRENT (A)

0* 0* 2.0 870µ 543 5

0 1 2.8 1.217m 760 7

1 0 4.0 1.739m 1086 10

1 1 5.0 2.261m 1359 13

*This is the default setting

Average current is the current required for the measurement, averaged out over the entire sample. This

average current is only related to the measurement phase when the drivers are on. The average current

will be drawn from the VCC supply. There is also current associated with the pen-detection phase, the

ADC, and the control logic.

The number of cycles indicated is the number of on-time state cycles. One state cycle is 16 main clock

cycles. If the frequency range is 2.0MHz, the state frequency is 2MHz/16 = 125kHz. There are 230 state

cycles in one complete sample. The number of cycles can be used to calculate the settling time and the

sample rate.

Example 1:

Frequency Range : 2.0MHz

Input Clock Frequency : 1.8432MHz

tsettle = (1 / 1.8432e6) x 16 x 5 = 43.4µs

Iavg = (10 / 230) x 20mA = 870µA

Sample Rate = 1.8432e6 / (16 x 230) = 501 samples/sec

Example 2:

Frequency Range : 2.8MHz

Input Clock Frequency : 1.8432MHz

tsettle = (1 / 1.8432e6) x 16 x 7 = 60.8µs

Iavg = (14 / 230) / x 20mA = 1.217mA

Sample Rate = 1.8432e6 / (16 x 230) = 501 samples/sec

/ RD. In the case of RD = 250O and

AVD

SAMPLES/SEC NO. OF

CYCLES

12 of 23

Page 13

DS1680

CONVERSION TIMING Figure 7a

Pen Down

PEN_OFF

X - Y

Measure

PD A0 A1X Y

A0 - A1

Measure

PD PDPDPDPD X XXX Y Y YY A0A0 A1A1

A1A0PDPD PDPD

NEW_DATA

AVG = 0 (Disabled)

NEW_DATA

AVG = 1 (Enabled)

X to Y MEASUREMENT Figure 7b

115 state cycles

30 28-3610-18 13-5 21

1001 00

PD

11

X-drivers

on

13-5

111001 00

Y-drivers

on

30

PD

1 State Cycle = 16 Main Clock Cycles

AIN0 to AIN1 MEASUREMENT Figure 7c

115 state cycles

30 20618 6 35 30

PD A0

PDA1

1 State Cycle = 16 Main Clock Cycles

T

0

13 of 23

Page 14

DS1680

CONVERT AND ANSELIN TIMING Figure 8

must be at least

2 state cycles

CONVERT

AIN0 conversion requested

ANSELIN = 0

must be at least 4 state cycles

CONVERT

both AIN0 and AIN1 conversion requested

ANSELIN

CONVERT

ANSELIN = 1

must be at least

2 state cycles

must be at least

2 state cycles

must be at least

2 state cycles

AIN1 conversion requested

14 of 23

Page 15

DS1680

PARALLEL INTERFACE

The ADC output is available on the data bus at pins D0–D7. A logic 0 on COEN will enable data onto the

data bus so that the DS1680 can be used in parallel with other devices. PEN_SELECT and

OUT_SELECT are used to decode which analog output (X-, Y-, AIN0, or AIN1) is outp ut on the data bus

when COEN is asserted low. Since the device offers 10-bit resolution, the BHE pin is used to decode the

10 bits of data on the data bus. A logic 1 on BHE will enable data bits B2 –B9. A logic 0 will enable data

bits B0–B1 along with the six LSBs = 0. The status pin ( NEW_DATA ) pulses low to indicate that new

coordinate or conversion is available. The output can be read while NEW_DATA is low or after it has

gone high. Output selection and parallel data format is shown below.

OUTPUT SELECTION Table 4

PEN_SELECT OUT_SELECT ANALOG OUTPUT

0 0 AIN0

0 1 AIN1

1 0 X1 1 Y-

PARALLEL DATA FORMAT

MSB LSB

High Byte BHE = 1 B9 B8 B7 B6 B5 B4 B3 B2

Low Byte BHE = 0 B1 B0 0 0 0 0 0 0

POWER MANAGEMENT (ADC AND PEN-INPUT PROCESSOR)

The DS1680 analog circuitry can be placed into a low-power mode by asserting and holding the

PD_RESET pin at logic 1. Normal operation will resume when PD_RESET is returned to logic 0.

To further conserve power, the pen-detection circuitry will automatically switch the analog circuitry to

power-down mode whenever there is no pen input detected for more than three seconds. Normal

operation will automatically resume when any one of the following three events occur: pen down is

detected, the CONVERT signal is activated, or chip is reset (PD_RESET pulled to logic 1 and then

returned to logic 0).

15 of 23

Page 16

DS1680

ABSOLUTE MAXIMUM RATINGS*

Voltage Range on Any Pin Relative to Ground -0.3V to +7.0V

Operating Temperature Range 0°C to +70°C

Storage Temperature Range -55°C to +125°C

Soldering Temperature Range See J-STD-020A Specification

*This is a stress rating only and functional operation of the device at these or any other conditions beyond

those indicated in the operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods of time can affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (0°C to +70°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Digital Power Supply Voltage

3.3V Operation

Digital Power Supply Voltage

5V Operation

Input Logic 1 VIH 2.0

V

CC, VAVD,

V

REF

V

CC, VAVD,

V

REF

2.97 3.3 3.63 V

4.5 5.0 5.5 V

VCC + 0.3

V

Input Logic 0 VIL -0.3 +0.8 V

Battery Voltage V

2.5 3.7 V

BAT

DC ELECTRICAL CHARACTERISTICS (0°C to +70°C; VCC = 5.0V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Leakage ILI -1 +1

CS Leakage ILO 260

Logic 1 Output (I

Logic 0 Output (I

Active Supply Current (No Pen Detect) I

Active Supply Current (Pen Detected) I

Standby Current I

Oscillator Current I

Battery Current (Oscillator Off) I

= -0.4mA) VOH 2.4 V 1

OUT

= 1.5mA) VOL 0.4 V 2

OUT

200 500 µA 3

CCA

5 mA 19

CCPD

175 300

CCS

300 500 nA 17

OSC

100 nA 18

BAT

Internal RST Pullup Resistor RP 25 47 87

VCC Trip Point V

VCC Switchover V

4.15 4.33 4.50 V

CCTP

2.67 2.78 V 12, 20

CCSW

µA

µA

µA

kΩ

Pushbutton Detect PBDV 0.8 2.0 V

Pushbutton Release PBRD 0.3 0.8 V

Output Voltage V

V

Output Current (Source = VCC) I

CCO

V

Output Current (Source = V

CCO

BAT)

I

PFI Input Threshold V

PFI Input Leakage I

PFO Output Voltage, I

= -0.4mA

OH

VOH

CCO

CCO1

CCO2

PFI

PFI

VCC - 0.3

V 11

150 mA 13

150

µA

1.15 1.25 1.35 V

-25 25 nA

VCC - 1.5

V

7

4

14

PFO Output Voltage, I

= 1.5mA

OL

VOL 0.4 V

16 of 23

Page 17

DS1680

DC ELECTRICAL CHARACTERISTICS (0°C to +70°C; VCC = 3.3V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Leakage ILI -1 +1

CS Leakage ILO 170

Logic 1 Output (I

Logic 0 Output (I

Active Supply Current (No Pen Detect) I

Active Supply Current (Pen Detected) I

Standby Current I

Oscillator Current I

Battery Current (Oscillator Off) I

= -0.4mA) VOH 2.4 V 1

OUT

= 1.5mA) VOL 0.4 V 2

OUT

115 300 µA 3

CCA

3 mA 19

CCPD

110 200

CCS

300 500 nA 17

OSC

100 nA 18

BAT

Internal RST Pullup Resistor RP 25 47 87

VCC Trip Point V

VCC Switchover V

2.75 2.86 2.97 V

CCTP

2.67 2.78 V 12, 20

CCSW

µA

µA

µA

kΩ

7

4

Pushbutton Detect PBDV 0.8 2.0 V

Pushbutton Release PBRD 0.3 0.8 V

Output Voltage V

V

Output Current (Source = VCC) I

CCO

V

Output Current (Source = V

CCO

BAT)

I

PFI Input Threshold V

PFI Input Leakage I

PFO Output Voltage, I

PFO Output Voltage, I

= -0.4mA

OH

=1.5mA

OL

VCC-0.3

CCO

80 mA 13

CCO1

100

CCO2

1.15 1.25 1.35 V

PFI

-25 25 nA

PFI

VOH VCC-1.5

V 11

µA

V

VOL 0.4 V

14

CAPACITANCE (TA = +25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance CI 10 pF

I/O Capacitance C

15 pF

I/O

Crystal Capacitance CX 6 pF

3-WIRE INTERFACE CHARACTERISTICS (0°C to +70 °C; VCC = 5.0V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Data to Clock Setup tDC 50 ns 8

CLK to Data Hold t

CLK to Data Delay t

70 ns 8

CDH

200 ns 8, 9, 10

CDD

CLK to Low Time tCL 250 ns 8

CLK to High Time tCH 250 ns 8

CLK Frequency t

2.0 MHz 8

CLK

CLK Rise and Fall tR, tF 500 ns

CS to CLK Setup tCC 1

CLK to CS Hold t

CS Inactive Time t

CS to I/O High-Z t

250 ns 8

CCH

1

CWH

70 ns 8

CDZ

µs

µs

8

8

17 of 23

Page 18

DS1680

3-WIRE INTERFACE CHARACTERISTICS (0°C to +70 °C; VCC = 3.3V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Data to Clock Setup tDC 150 ns 8

CLK to Data Hold t

CLK to Data Delay t

CLK to Low Time tCL 750 ns 8

CLK to High Time tCH 750 ns 8

CLK Frequency t

CLK Rise and Fall tR, tF 1500 ns

CS to CLK Setup tCC 3

CLK to CS Hold t

CS Inactive Time t

CS to I/O High-Z t

ADC CHARACTERISTICS (0°C to +70°C; VCC, V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Resistance of Digitizer Film RD 250 600 1000 Ω

210 ns 8

CDH

600 ns 8, 9, 10

CDD

0.667 MHz 8

CLK

µs

750 ns 8

CCH

3

CWH

210 ns 8

CDZ

AVD

µs

= 5.0V ± 10%)

8

8

Resistance of On-Chip Driver R

Parasitic Capacitance Between X-

and Y-Plates of Digitizer

Ladder Resistance R

ADC Active Current I

ADC Standby Current I

Reference Current I

12 25 Ω

DRIVER

CXY 5 10 nF

8 25 60 kΩ

REF

450 650 µA 5

AVDA

120 200 µA 6

AVDS

200 650 µA

REF

Input Leakage (AIN0, AIN1) ILI 10 nA

Analog Input Capacitance CIN 10 15 pF

Resolution 10 Bits

Differential Nonlinearity EDL ±0.5 ±1.0 LSB

Integral Nonlinearity EIL ±0.5 ±1.0 LSB

Offset Error EOS ±1.0 ±1.5 LSB

Gain Error EG ±0.25 ±1.0 %

ADC Clock Frequency F

Multiplexer Selector Path

Propagation Delay

5.0 MHz

OSCIN

t

60 ns

MUX

COEN Falling Edge to Data Bus

Driven

COEN Rising Edge to Data Bus

High-Z

18 of 23

t

40 ns

OEA

t

40 ns

OEZ

Page 19

DS1680

ADC CHARACTERISTICS (0°C to +70°C; VCC, V

= 3.3V ± 10%)

AVD

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Resistance of Digitizer Film RD 250 600 1000 Ω

Resistance of On-Chip Driver R

Parasitic Capacitance Between Xand Y-Plates of Digitizer

Ladder Resistance R

ADC Active Current I

ADC Standby Current I

Reference Current I

15 30 Ω

DRIVER

CXY 5 10 nF

8 25 60 kΩ

REF

320 450 µA 5

AVDA

50 150 µA 6

AVDS

150 550 µA

REF

Input Leakage (AIN0, AIN1) ILI 10 nA

Analog Input Capacitance CIN 10 15 pF

Resolution 10 Bits

Differential Nonlinearity EDL ±0.5 ±1.0 LSB

Integral Nonlinearity EIL ±0.5 ±1.0 LSB

Offset Error EOS ±1.0 ±1.5 LSB

Gain Error EG ±0.25 ±1.0 %

ADC Clock Frequency F

Multiplexer Selector Path

Propagation Delay

COEN Falling Edge to Data Bus

Driven

COEN Rising Edge to Data Bus

High-Z

2.5 MHz

OSCIN

t

120 ns

MUX

t

80 ns

OEA

t

80 ns

OEZ

POWER-FAIL AND RESET CHARACTERISTICS

(0°C to +70 °C; VCC = 5.0V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

t

PFI Low to PFO Low

PFI High to PFO High

VCC Detect to RST (VCC Falling)

VCC Detect to RST (VCC Rising)

Reset Active Time t

Pushbutton Debounce PBDB 250 ms 15

ST Pulse Width

Chip-Enable Propagation Delay to

External SRAM

V

CCTP(MAX)

to V

CCSW(MIN)

Fall Time tFB 200 µs 20

100 ns

PFD

t

100 ns

PFU

t

100 ns

RPD

t

250 ms 15,16

RPU

250 ms 15

RST

tST 20 ns

t

8 15 ns

CED

19 of 23

Page 20

DS1680

t

t

t

t

t

t

t

t

t

POWER-FAIL AND RESET CHARACTERISTICS

(0ºC to +70ºC; VCC = 3.3V ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

t

PFI Low to PFO Low

PFI High to PFO High

VCC Detect to RST (VCC Falling)

VCC Detect to RST (VCC Rising)

Reset Active Time t

200 ns

PFD

t

200 ns

PFU

t

200 ns

RPD

t

250 ms 15, 16

RPU

250 ms 15

RST

Pushbutton Debounce PBDB 250 ms 15

ST Pulse Width

Chip-Enable Propagation Delay to

tST 40 ns

t

8 15 ns

CED

External SRAM

V

CCTP(MAX)

to V

CCSW(MIN)

Fall Time tFB 50 µs 20

PARALLEL INTERFACE OUTPUT TIMING Figure 9

COEN

PEN_SELECT

OUT_SELECT

BHE

D0 - D7

OEA

X,

HIGH

MUX

X,

LOW

MUX

MUX

Y,

HIGHY,LOW

MUX

AIN0,

HIGH

MUX

AIN0,

LOW

MUX

AIN1,

LOW

OEZ

MUX

AIN1,

LOW

20 of 23

Page 21

DS1680

3-WIRE TIMING DIAGRAM: READ DATA Figure 10

3-WIRE TIMING DIAGRAM: WRITE DATA Figure 11

PUSHBUTTON RESET Figure 12

21 of 23

Page 22

DS1680

VCC POWER -UP Figure 13

VCC POWER -DOWN Figure 14

POWER-FAIL WARNING Figure 15

22 of 23

Page 23

DS1680

NOTES:

1. Logic 1 voltages are specified at VCC = 3.3V or 5.0V, VOH = VCC for capacitive loads. Exclude RST

pin.

2. Logic 0 voltages are specified at VCC = 3.3 or 5.0V, VOL = GND for capacitive loads.

3. I

4. I

5. I

6. I

7. CS has a 40kΩ pulldown resistor to ground.

8. Measured at VIH = 2.0V or VIL = 0.8V and 10ns maximum rise and fall time.

9. Measured at VOH = 2.4V or VOL = 0.4V.

10. Load capacitance = 25pF.

11. I

12. V

13. Current from VCC input pin to V

14. Current from V

15. Timebase is generated by the crystal oscillator. Accuracy of this time period is based on the 32kHz

16. If the EOSC bit in the control register is set to a logic 1, t

17. VCC = 0V, V

18. VCC = 0V, V

19. I

20. Under certain slew rate conditions, VSW can be as low as 1.8V.

is specified with outputs open, CS set to a logic 1, SCLK = 500kHz, oscillator enabled, ADC

CCA

disabled, and no pen detected.

is specified with CS, V

CCS

is specified with ADC enabled.

AVDA

is specified with ADC disabled.

AVDS

= 100 mA, VCC > V

CCO

switchover from VCC to V

CCO

BAT

CCTP

input pin to V

open and I/O, SCLK at logic 0, ADC disabled, and no pen detected.

CCO

.

occurs when VCC drops below the lower of V

BAT

output pin.

CCO

output pin.

CCO

CCSW

and V

BAT

.

crystal that is used. A typical crystal with a specified load capacitance of 6pF will provide accuracy

within ±100ppm over the 0°C to +70°C temperature range. For greater accuracy, see the DS32kHz

data sheet.

is equal to 250ms plus the start-up time

RPU

of the crystal oscillator.

= 0V, V

AVD

= 0V, V

AVD

is specified with outputs open, CS set to a logic 1, SCLK = 500kHz, oscillator enabled, ADC

CCPD

= 3.7V. and oscillator enabled. Measured without RAM connected.

BAT

= 3.7V, and oscillator disabled. Measured without RAM connected.

BAT

enabled, and pen detected.

23 of 23

Loading...

Loading...