Page 1

r

www.maxim-ic.com

DS1678

Real-Time Event Recorde

FEATURES

§ Real-time clock (RTC)/calendar in binary-

coded decimal (BCD) format counts seconds,

minutes, hours, date, month, day of the week,

and year with leap-year compensation and is

year 2000-compliant

§ Logs up to 1025 consecutive events in read-

only nonvolatile (NV) memory

§ The event trigger is user-programmable and

can be triggered by the falling edge, rising

edge, or rising and falling edges of the

INT pin

§ Event count register provides data on the

number of events that have been logged in the

current event logging mission

§ Programmable real-time clock alarm

§ 32-byte, battery-backed, NV RAM for data

storage

§ Two-wire serial interface allows for a simple

connection to your system

§ Three resolution options are available to trade

off accuracy versus maximum time between

events

§ Underwriters Laboratory (UL) recognized

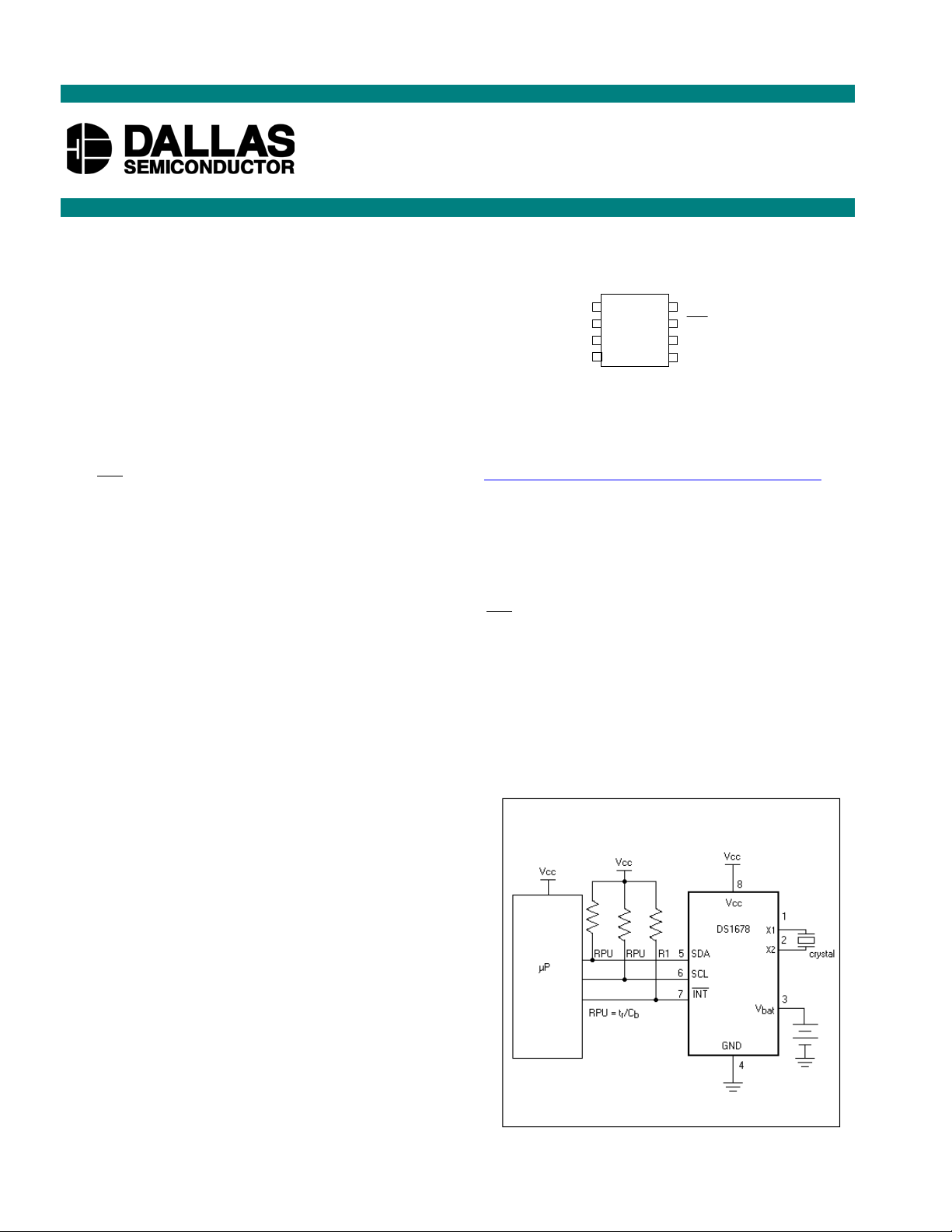

PIN ASSIGNMENT

1

X1

2

X2

3

V

BAT

GND

4

8-Pin DIP (300-mil)

8-Pin SOIC (208-mil)

Package dimension information can be found at:

http://www.maxim-ic.com/TechSupport/PackInfo.htm

Vcc

8

7

INT

6

SCL

5

SDA

PIN DESCRIPTION

V

BAT

X1 - Crystal Input

X2 - Crystal Output

INT - Interrupt Input/Output

GND - Ground

SDA - 2-wire Input/Output

SCL - 2-wire Clock Input

V

CC

- Battery Supply

- +5V Supply

TYPICAL OPERATING CIRCUIT

ORDERING INFORMATION

DS1678 8-Pin DIP (300-mil)

DS1678S 8-Pin SOIC (208-mil)

1 of 26 100101

Page 2

DS1678

DESCRIPTION

The DS1678 Real-Time Clock Event Recorder records the time and date of a non-periodic, asynchronous

event each time the INT pin is activated. The device records the seconds, minutes, hours, date, day of the

week, month, year, and century when the first event occurs. Subsequent events trigger the recording of

the 16-bit elapsed time counter (ETC) into the 2048 bytes of event log memory. This allows for up to

1025 events to be logged.

The event count register contains the total number of events that have been logged in the current eventlogging mission. The event count register also allows the user to determine if the data in the event log

memory has rolled over.

Three resolution options allow users to maximize the event log resolution while providing an adequate

maximum time between events without using extra memory locations based on the specific

characteristics of the event being logged. The seconds resolution provides the time of an event down to

the second while allowing up to 18.2 hours between events without using extra memory locations. The

minutes resolution provides the time of an event down to the minute while allowing up to 45.5 days

between events without using extra memory locations. The hours resolution provides the time of an event

down to the hour in which it occurred, while allowing up to 7.5 years between events without using extra

memory locations. Based on the expected frequency of events, the correct setting can be easily selected

to maximize the resolution and memory utilization.

The event can be triggered in three different ways depending on how the user programs the trigger select

(TRx) bits in the control register. The event can be triggered by a falling edge on the INT pin only, a

rising edge only, or it can be triggered by rising and falling edges. Triggering with both the rising and

falling edges allows for monitoring when something is turned on/off and how long it is in either state.

The RTC provides seconds, minutes, hours, day, date, month, and year information with leap-year

compensation, year 2000-compliance, and also provides an alarm interrupt. The 2-wire interface allows

the RTC to function as a stand alone RTC in the system.

The programmable alarm trip points in the RTC will allow a flag to be set in the control register when the

specified time in the alarm trip point register is reached. The flag is readable via the 2-wire interface

during an event logging mission or, when the DS1678 is not in a mission, the

INT pin will become an

output and generate an alarm interrupt if the value in the RTC equals the value in the RTC alarm register

and the duration interval select (DISx) bits are both set to zeros.

The DS1678 operates as a slave device on the 2-wire serial bus. Access is obtained by implementing a

START condition and providing a device identification code followed by a register address. All data is

transferred to and from the DS1678 most significant bit (MSB) first. The address counter will

automatically increment so that subsequent registers can be accessed sequentially until a STOP condition

is executed. When V

falls below 1.25 x V

CC

the device automatically write protects itself, terminates

BAT

any access in progress and resets the device address counter. Inputs to the device via the 2-wire bus will

not be recognized at this time to prevent erroneous data from being written to the device from an out of

tolerance system. When VCC falls below V

the device switches into a low-current battery backup

BAT

mode. Upon power-up, the device switches from battery power to VCC when VCC is greater than

+ 0.2V and recognizes inputs from the system when VCC is greater than 1.25 x V

V

BAT

by releasing

BAT

control of the write protection on the 2-wire bus.

2 of 26

Page 3

DS1678

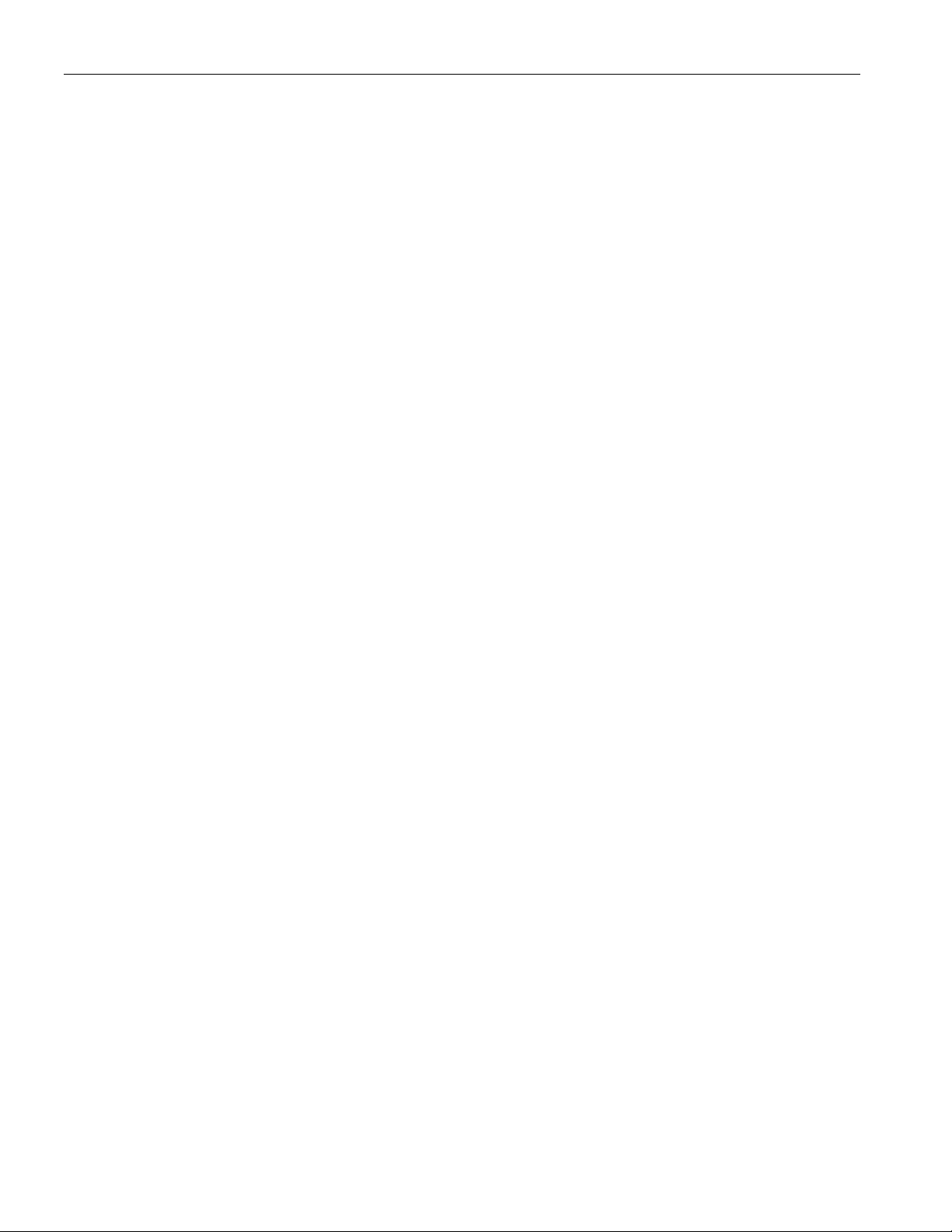

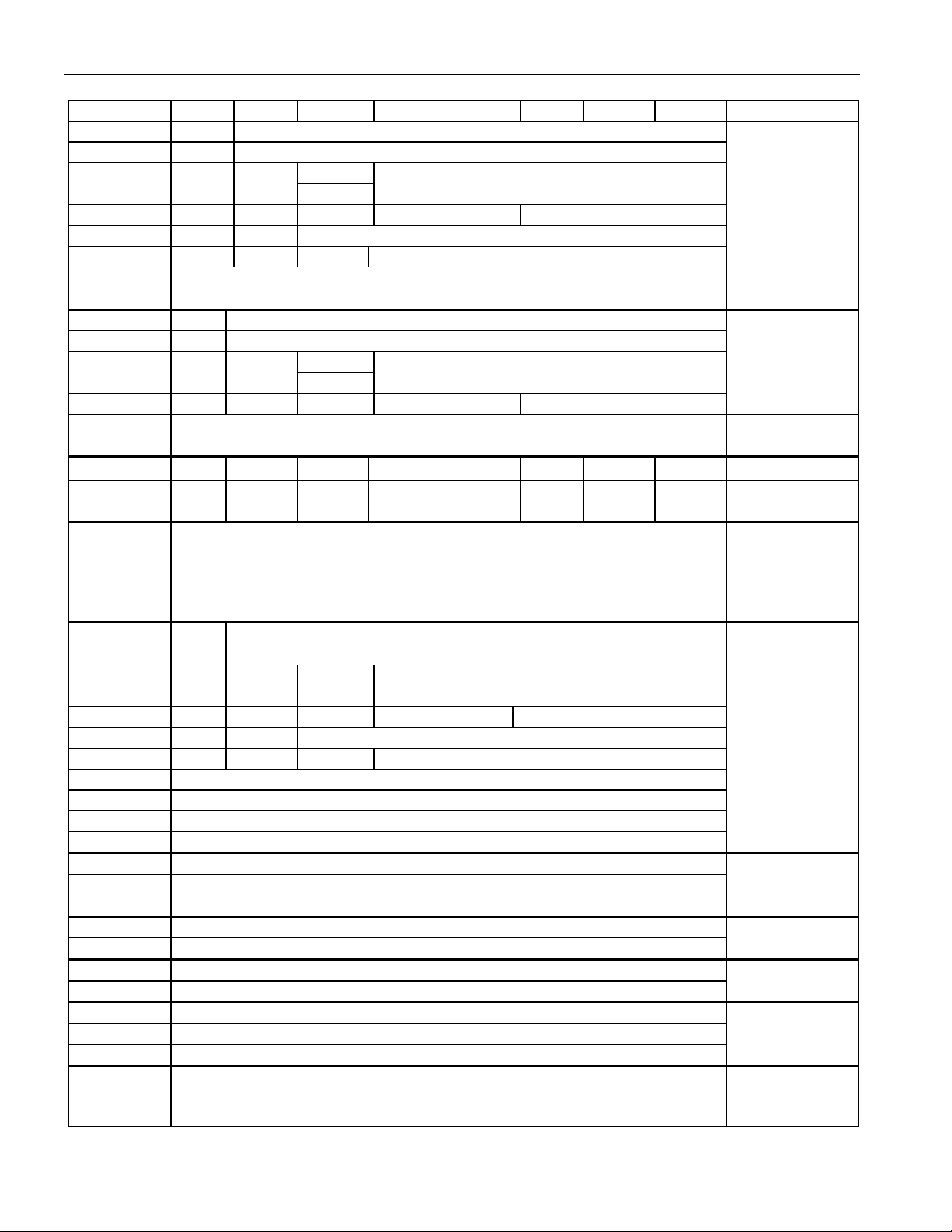

The block diagram in Figure 1 shows the main elements of the RTC event recorder. The device has four

major components: 1) 64-bit RTC and control block, 2) 32-byte user NV RAM, 3) 2048 bytes of event

log memory (1024 events), and 4) 2-wire serial interface.

3 of 26

Page 4

DS1678 BLOCK DIAGRAM Figure 1

A

R

2

C

T

A

R

32.768 kHz

DS1678

INT

SCL

SDA

V

C

V

BA

GND

X

OSCILLATOR

ND DIVIDE

CONTROL

LOGIC

2-WIRE SERIAL

INTERFACE

POWER

CONTROL

X1

DDRESS

REGISTE

RTC

USER

RAM

DATA LOG

RAM PORT

DATA LOG

NV SRAM

SIGNAL DESCRIPTIONS

The following paragraphs describe the function of each pin.

VCC – VCC is a +5V input supply. Communication with the DS1678 can take place only when VCC is

connected to a +5V supply.

– Battery input for standard lithium cell or other energy source. All functions of the DS1678 with

V

BAT

the exception of the serial interface circuitry are powered by V

powered by VCC when VCC > V

. If a battery or other energy source is not used, V

BAT

connected directly to ground. UL recognized to ensure against reverse charging current when used in

conjunction with a lithium battery.

See “Conditions of Acceptability” at http://www.maxim-ic.com/TechSupport/QA/ntrl.htm.

GND – Ground.

SCL (2-Wire Serial Clock Input) – The SCL pin is the serial clock input for the 2-wire synchronous

communications channel. The SCL pin is an open drain input, which requires an external pull-up resistor.

SDA (2-Wire Input/Output) – The SDA pin is the data input/output (I/O) signal for the 2-wire

synchronous communications channel. The SDA pin is an open drain I/O, which requires an external

pull-up resistor.

when VCC < V

BAT

. All functions are

BAT

should be

BAT

4 of 26

Page 5

DS1678

INT (Interrupt Input/Output) – The INT pin is an I/O that will be activated by an external device to

signify an event has occurred and should be logged. Once the pin is activated, the event will be recorded

in the event log memory and the event counter register will be incremented by one.

The INT pin can be activated in three different ways depending on how the user programs the TRx bits.

The event can be triggered by a falling edge on the INT pin only, a rising edge only, or it can be

triggered by both the rising and falling edges. By logging both the rising and falling edges as events, the

time when something is turned on and turned off can be determined and the amount of time that the

external system was in either state.

This assumes that the external system always starts logging data in a known state. For example, if a light

switch is being monitored and the switch is always in the off position before a mission is started, the first

event would be turning the lights on. The next event would have to be to turn the lights off. The time

between the events would be the amount of time the lights were in the on state. The time from turning the

lights off until the next event, which would be to turn the lights back on again, would be the amount of

time the lights were off.

The INT pin can also be used as an output when the DS1678 is not in an event logging mission. The INT

pin will become an output and generate an alarm interrupt if the DISx bits are both set to zero and the

RTC reaches the preset value in the alarm register. The INT output remains low as long as the status bit

causing the interrupt is present and the DISx bits are both set to zero.

The INT pin is an open-drain input/output with a weak internal pull-down resistor to prevent the pin

from floating if the signal connected to the pin is tri-stated. Without the resistor, the input would float

and potentially log phantom events. With the pull-down resistor, the pin can be transitioned to a low state

causing an event to be recorded if the INT pin was being held high by an outside signal that becomes tristated.

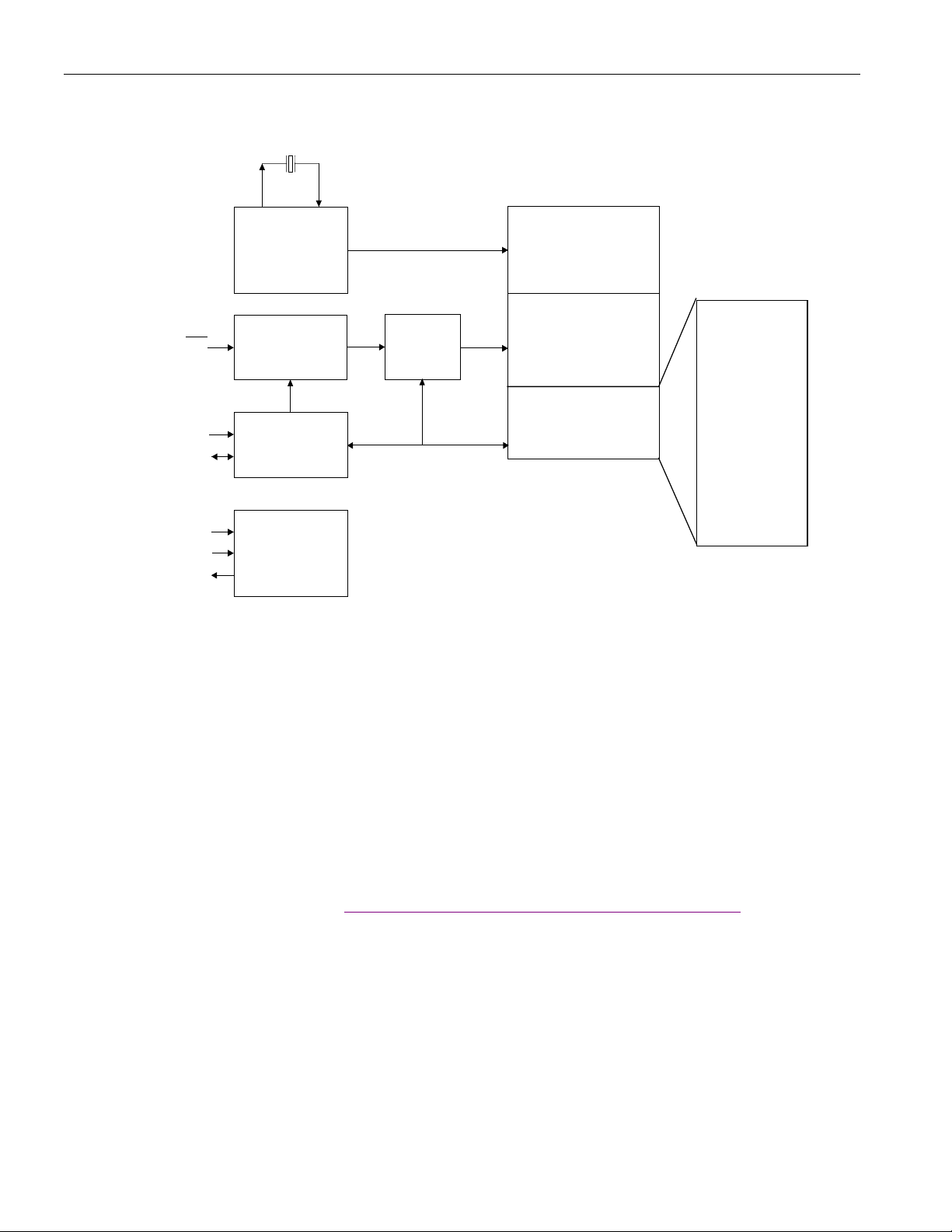

X1, X2 – Connections for a standard 32.768kHz quartz crystal, Daiwa part number DT-26S or

equivalent. For greatest accuracy, the DS1678 must be used with a crystal that has a specified load

capacitance of 12.5pF. There is no need for external capacitors or resistors. Note: X1 and X2 are very

high impedance nodes. It is recommended that they and the crystal be guard-ringed with ground and that

high frequency signals be kept away from the crystal area. For more information on crystal selection and

crystal layout considerations, please consult Application Note 58, “Crystal Considerations with Dallas

Real-Time Clocks.”

RECOMMENDED LAYOUT FOR CRYSTAL

5 of 26

Page 6

DS1678

CLOCK ACCURACY

The accuracy of the clock is dependent upon the accuracy of the crystal and the accuracy of the match

between the capacitive load of the oscillator circuit and the capacitive load for which the crystal was

trimmed. Additional error will be added by crystal frequency drift caused by temperature shifts.

External circuit noise coupled into the oscillator circuit may result in the clock running fast. See

Application Note 58, “Crystal Considerations with Dallas Real-Time Clocks” for detailed information.

MEMORY

The memory map in Figure 2a shows the general organization of the DS1678. As can be seen in the

figure, the device memory is in one contiguous segment with a data port to access the event log memory.

Since the 2-wire bus only has the capability to use one byte addressing, the DS1678 utilizes the data port

to access the 2048 bytes of event log memory. The address that the next data will be written to is stored

in the address pointer registers LSB (3Fh) and MSB (40h). These will be helpful in recovering all of the

data if a rollover occurs. The address pointer will point to the oldest event in the memory after a rollover.

This is the memory location in event log memory that would be over written by the next event. Read the

data from this point to the end of the memory and the start time stamp, including the 2-byte ETC from

last event. Working backward from the value in the start time stamp, subtract the value in the ETC from

last event to get the time the last event in the memory occurred. Then subtract the values in each of the

2-byte memory locations for elapsed time between events in order to recover the time the previous event

occurred.

The value in the ETC register LSB (3Dh) and MSB (3Eh) is the value in the actual ETC. This is the time

from the last event recorded until logging was stopped. Since a new event has not occurred, this data has

not been stored in the event memory yet.

The data port is made up of three bytes. The first byte (41h) is the event log memory address LSB, the

second byte (42h) is the event log memory address MSB, and the third byte (43h) is the event log

memory data byte. To access data via the data port, the LSB of the event log memory address is written

into 41h, the main memory address pointer will automatically increment to 42h where the event log

memory address MSB data will be written. The next transfer will indicate a read command with a 1 in

the R/

W bit of the 2-wire address byte. The data from the event log memory location corresponding to

the address written into main memory locations 41h and 42h will be available in location 43h to be read.

Any address greater than 43h will read back 00h and will not be able to be written. For address above

43h, the address pointer will increment until it reaches FFh then rollover to 00h.

The event log memory address pointer in main memory locations 41h and 42h will be auto-incremented

to the next higher event log memory address, while the pointer for the main memory will remain at

location 43h. This will allow the event log memory to be read continuously without having to write the

next desired event log memory location prior to each data read. The even address locations in the event

log memory will correspond to the LSB of the elapsed time between events and the odd memory

locations will correspond to the MSB of the elapsed time between events. For more information about

how the data is stored in the event log memory, see Figure 2b.

When the event log memory address pointer gets to the last address location (07FFh), the automatic

incrementing will stop. A new starting address will then have to be written into the event log memory

pointer bytes (41h & 42h) in order to begin reading additional data. The event log memory addresses that

can be put into the pointer (41h & 42h) are 0000h to 07FFh. The five MSB of the address are ignored.

6 of 26

Page 7

DS1678

Entering a value greater than 07FFh will result in the address location associated with the value of the

lowest 11 bits of the address.

The RTC and control registers (See Figure 2a for more detail.) are located in the main memory between

addresses 00h and 0Fh. The user NV RAM resides in locations 10h through 2Fh. The event logging

memory data port is located at locations 41h, 42h, and 43h. Memory locations 44h and up are reserved

for future extensions and will read 00h.

The end user can write only to the RTC and control registers and the user NV RAM. The rest of the

memory map is read-only from the end user’s perspective. During an event log mission, all of the

memory is read only. A write will terminate the mission. If there is an event being recorded when the

mission is terminated, the event will finish being recorded before the mission will be stopped and the

values in the MIP and ME bits will not change to 0’s until the mission has completed.

During an event log mission, memory locations 30h and above are not accessible to the user to avoid data

collisions from a user read and an event being logged at the same time. If the user tries to read a location

with an address greater than 2Fh during a mission, the value returned will be 00h.

7 of 26

Page 8

DS1678 RTC AND CONTROL PAGE Figure 2a

ADDRESS BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 FUNCTION

00 0 10 SECONDS SECONDS

01 0 10 MINUTES MINUTES

02

03 0 0 0 0 0 DAY OF WEEK

04 0 0 10 DATE DATE

05 0 0 0 10 MO MONTH

06 10 YEAR YEAR

07 10 CENTURY CENTURY

08 MS 10 SECONDS ALARM SECONDS ALARM

09 MM 10 MINUTES ALARM MINUTES ALARM

0A MH 12/24

0B MD 0 0 0 0 DAY-OF-WEEK ALARM

0C

0D

0E ME CLR DIS1 DIS0 RO TR1 TR0 COE Control

0F 0

10

11

12

↓

2F

30 0 10 SECONDS SECONDS

31 0 10 MINUTES MINUTES

32

33 0 0 0 0 0 DAY-OF-WEEK

34 0 0 10 DATE DATE

35 0 0 0 10 MO MONTH

36 10 YEAR YEAR

37 10 CENTURY CENTURY

38 Event 0 Elapsed Time from last Event Counter LSB

39 Event 0 Elapsed Time from last Event Counter MSB

3A Low byte

3B Medium Byte

3C High Byte

3D Low Byte

3E High Byte

3F Low Address Byte

40 High Address Byte

41 Low Address Byte

42 High Address Byte

43 Data Byte

44

↓

FF

0 12/24

MEM

CLR

0 12/24

AM/PM

10 HR

AM/PM

10 HR

MIP CM LOBAT ROF 0 ALMF

AM/PM

10 HR

10 HR

10 HR HOUR ALARM

(reads 00h) Reserved

Byte 1

Byte 2

Byte 3

↓

Byte 32

10 HR

(reads 00h) Reserved

HOUR

RTC

RTC

Alarm

Status

User-

Programmable

NV Memory

HOURS

Time Stamp

And

Elapsed Time

Counter

Event Count

Elapsed Time

Counter (ETC)

Address

Pointer

Data Log

RAM

Port

DS1678

8 of 26

Page 9

DS1678

DS1678 EVENT ELAPSED TIME DURATION Figure 2b

ADDRESS REGISTER

0000 Event 1 Elapsed Time from Last Event Counter LSB

0001 Event 1 Elapsed Time from Last Event Counter MSB

0002 Event 2 Elapsed Time from Last Event Counter LSB

0003 Event 2 Elapsed Time from Last Event Counter MSB

0004

¯

07FB

07FC Event 1023 Elapsed Time from Last Event Counter LSB

07FD Event 1023 Elapsed Time from Last Event Counter MSB

07FE Event 1024 Elapsed Time from Last Event Counter LSB

07FF Event 1024 Elapsed Time from Last Event Counter MSB

¯

EVENT LOGGING

When the DS1678 event logging function is enabled, the device is said to be on an “event log mission”

until the event logging is stopped.

An event can be triggered one of three ways depending on the settings of the TRx bits in the control

register. With TR0 bit set to a 1 and TR1 bit set to a 0, the INT signal will be activated on the falling

edge of the input signal. With the TR0 bit set to a 0 and the TR1 bit set to a 1, the INT pin will be

activated on the rising edge of the input signal. With both TR0 and TR1 bits set to 1, the INT pin will be

activated on both the falling and rising edges to allow for the measurement of on/off type events and their

duration’s. If TR0 and TR1 are both set to 0, nothing will happen when the INT pin is toggled and a

mission will not start. This is an illegal state and the mission will not start without a valid value in the

TRx bits prior to attempting to start the mission.

During an event log mission, every time the INT pin is activated, the elapsed time from the last event is

written to the event log memory pages. These memory pages are accessible through the data port in the

main memory. To access data via the data port, the LSB of the address location in the event log memory

is written into 41h, the main memory address pointer will automatically increment to 42h where the

event log memory address MSB data will be written. The data from the event log memory location

corresponding to the address written into main memory locations 41h and 42h will be available in

location 43h to be read. The event log data is located at addresses 0000h to 07FFh in the event log

memory. The LSB of the first event duration is written to address location 0000h. The MSB of the first

event duration is written to address location 0001h. The LSB of the second event is written to address

location 0002h. The MSB of the second event duration is written to address location 0003h (see figure

2b for more details). Likewise, the address is incremented with each additional event duration. A total of

2048 registers have been reserved for event log data, which will allow 1024 events to be logged.

A event log mission can be initiated via two different methods (See Figure 7); by a host writing a 1 to the

MIP bit of the status register over the serial interface which automatically sets the mission enable bit in

the control register to a 1 or by activating the INT input when the mission enable bit in the control

register is set to a one. The elapsed time between events recorded during an event log mission is equal to

the value written to the event logger memory multiplied by one second, minute, or hour depending on

which one of the three is selected in the DISx bits of the control register. Writing a 0 to the MIP bit in the

Status register completes the mission and automatically writes a 0 to the ME bit in the control register

9 of 26

Page 10

DS1678

once any events that are being recorded have completed. The value in the MIP and ME bits will remain a

1 until the mission has completed, even if they are written to a 0. Upon initiation of an event log mission

by either method, the DS1678 will set the Mission-in-Progress (MIP) bit in the Control register to a one.

It should be noted that the MEM CLR bit of the Status register must be a one in order to start an event

log mission. This means that the Event Log memory, the Event Count, Elapsed Time Counter, Address

Pointer, and Start Time Stamp registers are cleared of data (all zero’s) so that an end user can not turn the

logger on and off to avoid recording events. Once the mission is stopped, the memory must be cleared in

order to start a new mission.

The time at which the first event log sample is measured is dependent upon the way the mission is

started. The first way to start a mission is with a delayed start by writing a 1 to the ME bit. The ME bit

will only be able to be written to a 1 if the MEM CLR bit is set to a 1. The mission will have a delayed

start until the first event occurs by activating the

to a one and the

INT pin is activated, the MIP bit in the status register is set to a one, the current

INT pin. If the mission starts because the ME bit is set

time/date is written to the start time stamp register, the event 0 elapsed time from last event bytes in the

time/date stamp are both written with zeros, the event count register will be incremented and the elapsed

time counter will start incrementing based on the settings in the DISx bits of the control register.

Subsequent events will be logged as the duration of time from the previous event by writing the contents

of the ETC into the event log memory when that subsequent event is triggered by the INT pin being

activated.

The second way to start a mission is write a 1 to the MIP bit of the status register over the 2-wire

interface, which will automatically write a 1 to the ME bit of the control register. This start mission

command will be ignored and no action taken if the MEM CLR bit is not set to a 1. When the MIP bit is

written to a 1 and the ME bit is set to a 1, the mission is started by loading the current time/date into the

start time stamp, the event 0 elapsed time from last event bytes in the time/date stamp are both written

with zeros, the event count register will be incremented and the elapsed time counter will start

incrementing based on the settings in the DISx bits of the control register. The first event will then be

logged as the duration of time since the start time. All subsequent events will then be logged as the

duration of time since the previous event.

The user has two options for dealing with the potential occurrence of a data overrun (i.e., more than 1024

total event logs in the event log memory) (See Figure 8). The first option is to enable the rollover feature

of the DS1678. This is accomplished by setting the rollover bit (bit 3 of the control register) to 1. When

the rollover feature is enabled, new data is written over previous data, starting with the start time stamp

register as if a new mission is starting.

The one difference with a time/date stamp from a rollover compared to a new mission start is that the two

bytes after the time/date stamp, event 0 elapsed time from last event, will have the elapsed time since

event 1024 of the event log memory. This is to allow the user to recover the information recorded prior to

the rollover. At the start of a mission, the value in these two bytes will be all zeros since there was no

previous event to have an elapsed time from.

The next event will have its elapsed time since the new time/date stamp recorded in event log memory

locations 0000h and 0001h as before. For example, if the event log memory has been completely filled

(i.e., 1024 event logs have been recorded in the event log memory) the next event will cause a new

time/date stamp to be written to the start time stamp register and the elapsed time since event 1024

10 of 26

Page 11

DS1678

written to the two event 0 elapsed time from last event registers, the subsequent event log will be written

to address locations 0000h and 0001h, and the address pointer will be incremented with each successive

data sample. When this rollover occurs, the roll over flag (ROF) in the control register will be set to one

to indicate that the memory has rolled over at least one time.

The second option for dealing with data overrun is to simply stop the recording of events after the event

log memory has been completely used. In other words, the DS1678 will stop recording event logs after

event 1025. More precisely, when the address pointer is incremented from 07FFh to 0000h after the last

memory byte is filled with a log, the DS1678 will stop recording events. This feature is enabled by

setting the Rollover bit to 0. The device will still continue monitoring the INT pin and the event counter

will continue to increment when the INT pin is activated even though the event log memory has been

filled.

It should be noted that during an event log mission, a time stamp for the first event is recorded, but is not

included for each subsequent event. However, the time of acquisition for any event is easily determined

by considering the start time, the value in the event counter register, ROF, and the address of the

particular data sample in the event log memory.

If no rollover has occurred in the event log memory (ROF = 0), the sample time associated with any

particular data point can be calculated by multiplying the sum of the elapsed time between the events up

to that event by one second, minute, or hour depending on which resolution is selected in the DISx bits of

the control register, and adding this elapsed time to the value in the start time stamp register.

If the rollover feature has been enabled, the user can determine if rollover has occurred by reading the

value in the events counter register or the ROF. The event counter register counts the total number of

events that have been acquired. If this value is greater than 0400h (decimal 1025) then the user knows

that rollover has occurred. If rollover has occurred, the user needs to determine how many times rollover

occurred in determining the sample time for any particular data sample. The address pointer will be

pointing to the oldest data in the event log memory and if the memory has rolled over at least one time,

the roll over flag will be set to 1.

As a safety measure, the DS1678 has been designed such that the end user cannot write to the event log

memory. This prevents the falsification of event log data by writing values to event log registers.

CLOCK, CALENDAR, AND ALARM

The time and calendar information is accessed by reading/writing the appropriate register bytes. Note

that some bits are set to zero. These bits will always read zero regardless of how they are written. The

contents of the time, calendar, and alarm registers are in the BCD format and are year 2000-compliant.

The DS1678 can run in either 12-hour or 24-hour mode. Bit 6 of the hour’s register is defined as the 12or 24-hour mode select bit. When high, the 12-hour mode is selected. In the 12-hour mode, bit 5 is the

AM/PM bit with logic one being PM. In the 24-hour mode, bit 5 is the second 10-hour bit (20–23 hours).

11 of 26

Page 12

DS1678

TIME-OF-DAY ALARM BITS Table 1

ALARM REGISTER MASK BITS (bit 7)

SECONDS

(MS)

1 1 1 1 ALARM ONCE PER SECOND

0 1 1 1 ALARM WHEN SECONDS MATCH

0 0 1 1 ALARM WHEN MINUTES AND SECONDS

0 0 0 1 ALARM WHEN HOURS, MINUTES, AND

0 0 0 0 ALARM WHEN DAY, HOURS, MINUTES, AND

The DS1678 also contains a time-of-day alarm. The alarm registers are located in registers 08h to 0Bh.

Bit 7 of each of the alarm registers are mask bits (See Table 1). When all of the mask bits are logic 0, an

alarm will occur once per week when the values stored in timekeeping registers 00h to 03h match the

values stored in the time-of-day alarm registers. An alarm will be generated every day when mask bit of

the day alarm register is set to 1. An alarm will be generated every hour when the day and hour alarm

mask bits are set to 1. Similarly, an alarm will be generated every minute when the day, hour, and minute

alarm mask bits are set to 1. When day, hour, minute, and seconds alarm mask bits are set to 1, an alarm

will occur every second.

MINUTES

(MM)

HOURS

(MH)

DAYS

(MD)

MATCH

SECONDS MATCH

SECONDS MATCH

As a security measure to prevent unauthorized tampering, writing to any memory location or changing

any value in the RTC and control registers will stop a event log mission and clear the MIP bit to a 0.

SPECIAL PURPOSE REGISTERS

The following description defines the operation of the special function registers of the DS1678.

CONTROL REGISTER

MSB LSB

ME CLR DIS1 DIS0 RO TR1 TR0 COE

ME - Mission Enable – This bit enables the device to begin a mission. The ME bit can not be written to

a 1 unless the MEM CLR bit in the Status register is a 1, signifying that the memory and registers have

been cleared. With the ME bit set to a one, the device will wait for the first event to occur ( INT is

activated). Once that first event occurs, the time/date stamp will be recorded in the start time stamp

register, the event 0 elapsed time from last event bytes are both written with zeros, the event count

register will be incremented, and the elapsed time count will begin incrementing to be ready with the

duration of time from the first event until the next event.

When the ME bit is set to logic 0, the DS1678 will wait until a 1 is written to the MIP bit via the 2-wire

interface to start the mission. When the MIP bit is written to a 1, the ME bit will be set to a one, the

current time/date will be recorded in the start time stamp, the event 0 elapsed time from last event bytes

are both written with zeros, the event count register will be incremented, and the elapsed time count will

begin incrementing to be ready with the duration of time from the start until the first event.

The ME bit is automatically written to a 0 whenever a mission is stopped.

12 of 26

Page 13

DS1678

CLR - Clear Enable – This bit enables the memory to be cleared. When this bit is set to a one and the

clear memory (CM) bit in the status register is subsequently written to a 1, the event log memory, event

count, and start time stamp registers are all cleared to zeros. Following the writing of a 1 to the ME bit,

the CLR bit is also cleared to zero. If the clear enable bit is set, but a command other than writing a 1 to

the clear memory bit is issued next, the CLR bit is cleared to a zero and the contents of the event log,

start time stamp, and event counter register are unchanged.

DIS1, DIS0 - Duration Interval Select [0-1] – These bits select the amount of time between increments

of the elapsed time counter that is used to determine the amount of time between events. After the first

event is recorded, all subsequent events are recorded as the elapsed time since the previous event. When

a subsequent event occurs, the ETC value is stored in the event log memory.

In order to obtain the maximum accuracy of the event logger, the smallest possible resolution of the ETC

should be selected. The expected maximum time between events must also be taken into account in order

to get the full 1025 events logged because when the ETC count reaches 65535 increments, if the next

event has not occurred by that point in time, FFh will be written into the memory, the ETC will roll over

to 00h and continue to count until the next event occurs or FFh is reached again. Whenever FFh is

reached by the ETC, it will store that value in event log memory, reset to 00h, continue counting, and the

memory address pointer will increment to the next memory location. When ever an FFh appears in the

memory, the next two bytes of data will be part of the elapsed time for the same event, even if the value

in the next two bytes of memory are 00h which means that an event occurred at time increment FFh. In

order to recover the total elapsed time between events when a FFh is in the Event Log Memory; simply

add the contents of the next two bytes to the FFh. If the next two bytes are 00h indicating that the event

occurred at FFh, by adding the 00h in the next two bytes, you will end up with FFh. If the next two bytes

are 01h, you will get 100h when the data is added to FFh. This will represent the total elapsed time since

the previous event. The event counter will not be incremented when the ETC rolls over since a new event

has not occurred.

The ETC will be incremented as the selected single seconds, minutes, or hours byte of the RTC

increments to prevent time losses from short duration events. Since the time base in the RTC continues to

run, even when the ETC is cleared to prepare for a new event, and the ETC is incremented every time the

selected byte in the RTC increments, the actual time resolution will not be lost even when events occur

more frequently than the minimum time resolution selected. If an event occurs half way between

increments of the ETC, then the first increment of the next event will occur when the seconds, minutes or

hours register increments next, thus preserving the correct time to the resolution selected in the DISx bits.

The user can select one of the settings in Table 2.

When the Alarm Interrupt Output is to be used, the DISx bits should be set to zeros, which will disable

the ETC and the rest of the event logger circuitry to conserve battery life. An event-logging mission can

not be started if the DISx bits are both set to zero. This will enable the Alarm Flag to generate an Alarm

Interrupt via the

INT output pin.

With the DIS0 bit set to a one and the DIS1 bit set to zero, the ETC will increment every time the single

seconds byte in the RTC is incremented. This will give the maximum resolution between events, but

since the counter is limited to only 16 bit and will roll over to the next two memory bytes when it reaches

the maximum value, the largest interval between events that can be accurately measured without using

additional memory space and reducing the total number of events able to be logged is 65,535 seconds or

about 18.2 hours. If the maximum time between events could be greater than 18.2 hours, you should

consider using one of the courser resolutions to conserve memory.

13 of 26

Page 14

DS1678

With the DIS0 bit set to a zero and the DIS1 bit set to a one, the ETC will increment every time the

single minutes byte in the RTC is incremented. This will give a medium resolution between events, but

will increase the largest possible interval between events that can be accurately measured without using

additional memory space and reducing the total number of events able to be logged to 65,535 minutes or

about 45.5 days. If the maximum time between events could be greater than 45.5 days, you should

consider using one of the courser resolutions to conserve memory.

With both of the DISx bits set to a one, the ETC will increment every time the single hours byte in the

RTC is incremented. This will give the lowest resolution between events, but will increase the largest

possible interval between events that can be accurately measured without using additional memory space

and reducing the total number of events able to be logged to 65,535 hours or about 7.5 years.

In the event that a second event occurs before the ETC is able to increment for the first time, all zeros

will be logged in the event log memory and the ETC will be reset. If this occurs, the time base will

remain correct since it is based on the separate RTC incrementing, but the exact time of the event will be

no more accurate than the size of the time increment that is chosen. For this reason, it is recommended to

use the finest resolution possible for your logging to minimize the errors. If the normal duration between

events is several days or months, then a few minutes or an hour may not be significant to your data

accuracy.

As an example, an event occurs after 28h hours which causes the ETC to be reset. The ETC is set to

increment on the hour, but the next event happens after 45 minutes. The value recorded in the event log

memory is 00h, the event counter is incremented, and the ETC is cleared to begin counting for the next

event. That next event happens 20 minutes later, but the value in the ETC is 01h because the RTC

incremented the ETC on the hour, which was 15 minutes after the last event was recorded in the event

log memory. We now know that in the course of about an hour three events took place. If this is normal,

then we should have chosen a finer resolution, but this does sometimes happen, even when events are

normally spread widely apart. We did not loose any data in our example because we know in which hour

the events took place and when we chose the resolution, we decided that knowing which hour was

accurate enough for our needs. The RTC maintained the correct time base, even though the ETC was

cleared before it was incremented even once for the second event in our example. The third event

incremented after only 15 minutes, but, relative to the first event in our example, this was correct because

the second event occurred after 45 minutes, and the third event was incremented after an additional

15 minutes, which makes one hour.

DURATION INTERVAL SELECT BITS Table 2

DIS1 DIS0 ELAPSED TIME COUNT

RESOLUTION

0 0 Alarm Interrupt Output Enabled

0 1 The Counter will Increment Every Second 18.2 Hours

1 0 The Counter will Increment Every Minute 45.5 Days

1 1 The Counter will Increment Every Hour 7.5 Years

RO - Roll-Over – This bit determines whether the datalog function of the DS1678 rolls over or stops

writing data to the event log memory if the event log memory is completely filled. If RO is set to a 1, the

event log memory will “roll over” after all 2048 bytes in the event log memory have been used. In other

words, after the 1024th event recorded in the event log memory, the following sample will have the full

time/date stamp information written to the start time stamp register and the contents of the ETC written to

the 2-byte following the start time stamp (event 0 elapsed time from last event) and the next sample will

have the duration of time from the new start time stamp value written to event log memory address

14 of 26

MAX. TIME BETWEEN

EVENTS

Page 15

DS1678

locations 0000h and 0001h, overwriting the original data. Likewise, subsequent samples will increment

through the event log registers, overwriting their data.

The event 0 elapsed time from last event bytes will have the elapsed time since the last event in the event

log memory. This is to allow the user to recover the information prior to the rollover. At the start of a

mission, the value in these 2 bytes will be all zeros since there was no previous event from which to have

an elapsed time.

If RO is set to a 0, no further event logs will be written to the event log memory after all event log

memory registers have been filled. Events, however, will continue to be recognized and the Event Count

register will be incremented for each event. Likewise, the RTC alarm flag will also continue to function.

TR1, TR0 - Trigger Select [1,0] – This bit selects the edge(s) that will activate the INT pin to cause an

event to be logged. An event can be triggered one of three ways depending on the settings of the TRx bits

in the control register. With TR0 bit set to a 1 and TR1 bit set to a 0, the

the falling edge of the input signal. With the TR0 bit set to a 0 and the TR1 bit set to a 1, the

INT signal will be activated on

INT pin will

be activated on the rising edge of the input signal.

With both TR0 and TR1 bits set to 1, the INT pin will be activated by both the rising and falling edges to

allow for the measurement of on/off type events and their durations. If TR0 and TR1 are both set to 0,

nothing will happen when the INT pin is toggled and a mission will not start. This is an illegal state and

the mission will not start without a valid value in the TRx bits prior to attempting to start the mission.

TRIGGER SELECT BITS Table 3

TR1 TR0 EDGE(S) USED TO TRIGGER AN EVENT

0 0 Nothing, Illegal State

0 1 Falling Edge

1 0 Rising Edge

1 1 Both Rising and Falling Edges

COE - Clock Oscillator Enable – This bit allows the clock oscillator to be shut off to save power. The

RTC will no longer keep time when the oscillator is shut off, but the information stored in the device

memory will be maintained. An event log mission can not start with COE set to zero and the RTC must

be reset to the correct value after the oscillator is restarted and prior to starting a mission in order to

obtain good data. A clear memory can also not be executed without the oscillator running. When VCC >

V

, the oscillator will automatically start, no matter what the value in the COE bit to allow proper

BAT

communications. This is a way to preserve the data longer in battery mode once a mission has been

completed in order to increase the battery life and thus the data integrity lifetime.

STATUS REGISTER

MSB LSB

0MEM CLRMIP CMLOBATROF 0 ALMF

MEM CLR - Memory Cleared – This bit indicates that the event log memory, event count, and start

time stamp registers are all cleared to zero. MEM CLR is cleared to zero when an event log mission is

started (i.e., MIP = 1).

15 of 26

Page 16

DS1678

MIP - Mission in Progress – This bit indicates the sampling status of the DS1678. If MIP is logic 1, the

device is currently on a “mission” in which it is operating in the event logging mode. The MIP bit is

changed to logic 1 immediately following the activation of the INT pin if the ME bit of the control

register contains a 1. In order to immediately start an event logging mission via the 2-wire bus, a 1 can be

written into the MIP bit and a 1 will automatically be written into the ME bit of the control register.

If MIP is logic 0, the DS1678 is not currently in event logging mode. The MIP bit transitions from logic 1

to logic 0 whenever event logging is stopped. Event logging is stopped when the DS1678 is cleared by

writing to the clear enable and memory clear bits or when any memory location including the RTC or

control registers are written to during a mission. The MIP bit can also be written to logic 0 by the end user

to stop event logging via the 2-wire bus. By writing a 0 to the MIP bit and stopping the mission, a 0 is

automatically written to the ME bit of the control register. It cannot, however, be written to logic 1 to start

a mission unless the MEM CLR bit is a 1 to signify that the memory has been cleared.

CM - Clear Memory – This bit will trigger the memory to be cleared if the CLR clear enable and COE

clock oscillator enable bits in the control register are set to a 1. This will cause the event log memory,

event count, and start time stamp registers to all be cleared to zeros. Once the memory has been cleared,

the CLR enable bit and the CM bits will be set to zeros and the MEM CLR bit will be set to a 1 to allow a

new mission to begin. Clearing the memory is a two-write process to reduce the risk of accidentally

erasing the memory. The CLR bit must be set to a 1 before the CM bit can be written to a 1. During the

clear memory operation the DS1678 should not be accessed for 500µs while the memory is erased. The

MEM CLR bit should read a 1 before trying to access the cleared memory or registers.

LOBAT - Low Battery Flag – This bit reflects the status of the backup power source connected to the

V

pin. A logic 1 for this bit indicates an exhausted lithium energy source.

BAT

ROF - Roll Over Flag – This bit will be set to a one if the RO bit of the control register is set to a one,

the last data log memory location has been filled and a new event has occurred, which will cause the

time/date stamp to be over written. If RO is set to a 0 (roll over is disabled), the last data log memory

location has been filled and an new event has occurred, ROF will be set to a 1 to indicate that more events

have occurred than the number of available memory locations. The event counter will continue to record

events, even after the event log memory is full. The ROF is cleared by the clear memory command.

ALMF - Alarm Flag – A logic 1 in the alarm flag bit indicates that the current time has matched the

time-of-day alarm registers. If at the same time, the DISx bits are both logic 0’s, the

INT pin will go low

to issue an alarm interrupt. ALMF is a read only bit and is cleared by accessing any of the Alarm register

bytes either with a read or a write. Writing any memory location during a mission will stop the mission. A

mission can not be started when the DISx bits are both set to 0.

EVENT COUNTER

This 3-byte register set provides the number of events that have been logged during the current data

logging operation (also known as a “mission”). The contents of this register can be used by software to

point to the most recent data sample in the event log memory. The data in these registers are cleared when

the event log memory is cleared. The event counter is not incremented when the ETC reaches FFh and

rolls over to the next 16 bits of memory.

ADDRESS POINTER REGISTER

The address pointer register always contains the address that the next data LSB will be written to in the

event log memory. The address pointer registers are located in the main memory map at LSB (3Fh) and

16 of 26

Page 17

DS1678

MSB (40h). These will be helpful in recovering all of the data if a rollover occurs. The address pointer

will point to the oldest event in the memory after a rollover. This is the memory location that would be

over written by the next event. Read the data from this point to the end of the memory and the start time

stamp including the 2-byte ETC from last event in order to recover all of the data in the correct order.

GLITCH CONTROL CIRCUIT

The DS1678 has a built-in glitch control circuit to filter noise on the INT pin from triggering false events.

A minimum of one internal clock cycle (0.122ms) up to a maximum of two internal clock cycles

(0.245ms) are required to recognize a transition on the input as an event. An event then requires an

additional six to eight internal clock cycles (0.752ms to 0.977ms) to be processed and recorded into

memory. This means that the minimum event occurrence that can be recognized by the DS1678 requires

seven to 10 internal clock cycles (0.854ms to 1.22ms). Failure to ensure this timing will cause the event

to be ignored. Thus, it is recommended that you design with the maximum timing specs.

The INT pin has a weak internal pull-down resistor to prevent the pin from floating if the signal

connected to the pin is tri-stated. Without the resistor, the input would float and potentially log phantom

events. With the pull-down resistor, the pin can be transitioned to a low state causing an event to be

recorded if the INT pin was being held high by an outside signal that becomes tri-stated.

SECURITY

The DS1678 provides several measures to insure data integrity for the end user. These security measures

are intended to prevent third-party intermediaries from tampering with the data that has been stored in the

event log memory.

As a first security measure, the event log memory is read-only from the perspective of the end user. The

DS1678 can write the data into these memory banks, but the end user cannot write data to individual

registers. This prevents an unscrupulous intermediary from writing false data to the DS1678. The end

user, however, can clear the contents of the event log memory. A new mission can not be started unless

the MEM CLR bit has been set to a 1 to indicate that the memory and registers are cleared.

As a second security measure, changing any value in the memory including the RTC and control registers

will stop event logging and clear the MIP and ME bits. The MEM CLR bit must be set to 1 so that the

memory and registers are cleared before a new event log mission can begin.

POWER CYCLING

When VCC falls below 1.25 x V

progress and resets the device address counter. Inputs to the device via the 2-wire bus will not be

recognized at this time to prevent erroneous data from being written to the device from an out of tolerance

system. When V

falls below V

CC

power-up, the device switches from battery power to VCC when VCC is greater than V

recognizes inputs from the system when V

protection on the 2-wire bus.

the device automatically write protects itself, terminates any access in

BAT

the device switches into a low-current battery backup mode. Upon

BAT

+ 0.2V and

BAT

is greater than 1.25 x V

CC

by releasing control of the write

BAT

2-WIRE SERIAL DATA BUS

The DS1678 supports a bi-directional, 2-wire bus and data transmission protocol. A device that sends

data onto the bus is defined as a transmitter, and a device receiving data as a receiver. The device that

controls the message is called a “master.” The devices that are controlled by the master are “slaves.” The

bus must be controlled by a master device that generates the serial clock (SCL), controls the bus access,

17 of 26

Page 18

DS1678

and generates the START and STOP conditions. The DS1678 operates as a slave on the 2-wire bus.

Connections to the bus are made via the open-drain I/O lines SDA and SCL.

The following bus protocol has been defined (See Figure 3):

§ Data transfer may be initiated only when the bus is not busy.

§ During data transfer, the data line must remain stable whenever the clock line is HIGH. Changes in

the data line while the clock line is high will be interpreted as control signals.

Accordingly, the following bus conditions have been defined:

Bus not busy: Both data and clock lines remain HIGH.

Start data transfer: A change in the state of the data line, from HIGH to LOW, while the clock is HIGH,

defines a START condition.

Stop data transfer: A change in the state of the data line, from LOW to HIGH, while the clock line is

HIGH, defines the STOP condition.

Data valid: The state of the data line represents valid data when, after a START condition, the data line

is stable for the duration of the HIGH period of the clock signal. The data on the line must be changed

during the LOW period of the clock signal. There is one clock pulse per bit of data.

Each data transfer is initiated with a START condition and terminated with a STOP condition. The

number of data bytes transferred between START and STOP conditions is not limited, and is determined

by the master device. The information is transferred byte-wise and each receiver acknowledges with a

ninth bit. Within the bus specifications a regular mode (100kHz clock rate) and a fast mode (400kHz

clock rate) are defined. The DS1678 works in both modes.

Acknowledge: Each receiving device, when addressed, is obliged to generate an acknowledge after the

reception of each byte. The master device must generate an extra clock pulse which is associated with this

acknowledge bit.

A device that acknowledges must pull down the SDA line during the acknowledge clock pulse in such a

way that the SDA line is stable LOW during the HIGH period of the acknowledge related clock pulse. Of

course, setup and hold times must be taken into account. A master must signal an end of data to the slave

by not generating an acknowledge bit on the last byte that has been clocked out of the slave. In this case,

the slave must leave the data line HIGH to enable the master to generate the STOP condition.

18 of 26

Page 19

DS1678

Figure 4 details how data transfer is accomplished on the 2-wire bus. Depending upon the state of the

R/ W bit, two types of data transfer are possible:

1. Data transfer from a master transmitter to a slave receiver. The first byte transmitted by the

master is the slave address. Next follows a number of data bytes. The slave returns an acknowledge

bit after each received byte.

2. Data transfer from a slave transmitter to a master receiver. The first byte (the slave address) is

transmitted by the master. The slave then returns an acknowledge bit. Next follows a number of data

bytes transmitted by the slave to the master. The master returns an acknowledge bit after all received

bytes other than the last byte. At the end of the last received byte, a “not acknowledge” is returned.

The master device generates all of the serial clock pulses and the START and STOP conditions. A

transfer is ended with a STOP condition or with a repeated START condition. Since a repeated START

condition is also the beginning of the next serial transfer, the bus will not be released.

The DS1678 may operate in the following two modes:

1. Slave receiver mode (DS1678 write mode): Serial data and clock are received through SDA and

SCL. After each byte is received, the receiver transmits an acknowledge bit. START and STOP

conditions are recognized as the beginning and end of a serial transfer. The slave address byte is the

first byte received after the start condition is generated by the master. The address byte contains the 7-

bit DS1678 address, which is 1001010, followed by the direction bit (R/ W ), which is 0. The second

byte from the master is the register address. This sets the register pointer. If the write is being done to

set the register pointer, a STOP or repeated START may then be sent by the master. Otherwise, the

master then transmits each byte of data, with the DS1678 acknowledging each byte received. The

master will generate a stop condition to terminate the data write (See Figure 4).

2.

Slave transmitter mode (DS1678 read mode): The first byte is received and handled as in the slave

receiver mode. However, in this mode, the direction bit will indicate that the transfer direction is

reversed. Serial data is transmitted on SDA by the DS1678 while the serial clock is input on SCL. The

slave address byte is the first byte received after the start condition is generated by the master. The

address byte contains the 7-bit DS1678 address, which is 1001010, followed by the direction bit

(R/

W ), which is 1. After receiving a valid slave address byte and direction bit, the DS1678 generates

an acknowledge on the SDA line. The DS1678 begins to transmit data on each SCL pulse starting

with the register address pointed to by the register pointer. As the master reads each byte, it must

generate an acknowledge. The DS1678 must receive a “not acknowledge” on the last byte to end a

read (See Figure 4).

19 of 26

Page 20

DS1678

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground -0.3V to +6V

Operating Temperature -40°C to +85°C

Storage Temperature -55°C to +125°C

Soldering Temperature See J-STD-020A specification

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (-40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Power Supply Voltage V

Input Logic 1 V

Input Logic 0 V

Battery Voltage V

CC

IH

IL

BAT

4.5 5.0 5.5 V

2.2 VCC + 0.3 V

-0.3 +0.8 V

2.6 3.5 V

DC ELECTRICAL CHARACTERISTICS (-40°C to +85°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Leakage I

Logic 0 Output

I

= 4mA

OL

V

LI

OL

-1 +1

0.4 V

mA

Output Current 0.4V

Active Supply Current I

Battery Standby Current

CCA

I

OSC

12mA

300 500 nA

(Oscillator On)

Battery Standby Current

I

BAT

50 150 nA

(Oscillator Off)

Power-Fail Voltage V

PF

1.216 x V

BAT

1.25 x V

BAT

1.284 x V

BAT

V6

AC ELECTRICAL CHARACTERISTICS (-40°C to 85°C, VCC= 2.6V to 5.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

Crystal Capacitance C

Minimum Signal Width t

Minimum Event Rate t

GLITCH

EVENT

I

X

10 pF

12.5 pF

0.122 0.245 ms

0.854 1.22 ms

20 of 26

Page 21

DS1678

AC ELECTRICAL CHARACTERISTICS (-40°C to +85°C, VCC = 4.5V to 5.5V)

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS NOTES

SCL Clock Frequency f

Bus Free Time

t

Between a STOP and

START Condition

Hold Time (Repeated)

t

hd:sta

START Condition.

LOW Period of SCL t

HIGH Period of SCL t

Set-Up Time for a

high

t

su:sta

Repeated START

Data Hold Time t

Data Set-up Time t

hd:dat

su:dat

Rise Time of Both

SDA and SCL Signals

Fall Time of Both

SDA and SCL Signals

Set-up Time for STOP t

Capacitive Load for

su:sto

C

Each Bus Line

Input Capacitance C

scl

buf

low

t

r

t

f

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

Fast Mode

Standard Mode

b

i

100 400

100

1.3

4.7

0.6

4.0

1.3

4.7

0.6

4.0

0.6

4.7

0

0

100

250

20 +

0.1C

20 +

0.1C

b

b

300

1000

300

300

0.6

4.0

400 pF 4

5pF

kHz

µs

µs 1

µs

µs

µs

0.9 µs 2

ns 3

ns 4

ns 4

µs

DATA TRANSFER ON 2-WIRE SERIAL BUS Figure 3

SDA

SCL

START

CONDITION

MSB

12 6789

slave address

R/W

direction

bit

acknowledgement

signal from receiver

12 89

ACK ACK

21 of 26

3 - 8

repeated if more bytes

are transferred

acknowledgement

signal from receiver

STOP CONDITION

OR

REPEATED

START CONDITION

Page 22

2-WIRE SERIAL COMMUNICATION WITH DS1678 Figure 4

S

Write to Memory Address Pointer

SCL

A2

SDA

0W1S 1 0 A1 A000 A A P

1

A3A4A5A6A7

DS1678

Device Address Byte Memory Address ByteStart

DS16 78

ACK

Write to Memory Location (Single Byte)

SCL

SDA

1S 1 0 A1 A000 A

Device Address Byte Mem ory Address ByteStart

1

0W

DS16 78

ACK

Read Single Byte from C urrent Memory Address Pointer Location

SCL

SDA

1S 1 1000 Rd A N P

Device Address Byte Da ta B yteStart

DS16 78

ACK

Read Mu ltip le Bytes from C urrent Memory Ad dress Pointer Location

SCL

SDA

1S 1 10 D000 Rd A A

Start

Device Address Byte Most Significant

DS16 78

ACK

Da ta B yte

Read Single Byte from New Mem ory Address Po inter Location

SCL

SDA

1S 1 000 A A

Device Address Byte Memory Address ByteStart

10W 0

DS16 78

ACK

SCL

NP

SDA

D7

D1D2D3D4D5D6 D0

DS1678

Stop

ACK

A2A3A4A5A6A7

A2A3A4A5A6A7

A

DS1678

ACK

D1D2D3D4D5D6D70 D0

NACK

D1D2D3D4D5D6D7 NP

Master

ACK

A1 A0

DS16 78

ACK

Data Byte

StopMaster

Least Significant

Data Byte

1R 1 1000 Rd A

Repeated

Start

Device Address

Byte

D1D2D3D4D5D6D7

D1D2D3D4D5D6D70 D0

D0

DS1678

ACK

NACK

AP

Stop

StopMaster

DS16 78

ACK

Data Byte StopMaster

NACK

2-WIRE COMMUNICATION TIMING DIAGRAM Figure 5

SDA

t

BUF

t

HD:STA

TART

SCL

STOP

START

t

t

HD:STA

LOW

t

R

t

HD:DAT

t

HIGH

t

F

t

t

SU:DAT

SU:STA

REPEATED

t

SU:STO

22 of 26

Page 23

EVENT RECOGNITION TIMING DIAGRAM Figure 6a

Good Events

t

EVENT

t

/INT

GLITCH

Transition Point

DS1678

Event 1

Event 2

Bad Event 1

t

/INT

GLITCH

Transition Point

Bad Event 2

t

/INT

Event 1

Event 2

EVENT

Transition Point

is missed

EVENT RECOGNITION TIMING DIAGRAM Figure 6b

Good Events

t

EVENT

t

/INT

GLITCH

Transition Point

Bad Event 1

/INT

Bad Event 2

/INT

Event 1 Event 2

t

GLITCH

Event 1

Event 2

is missed

Transition Point

t

EVENT

Transition Point

23 of 26

Page 24

START MISSION FLOW CHART Figure 7

y

DS1678

Start via

Computer

Mem Clr =1

yes

Write a 1 to

the MIP bit

The ME bit is

Automatically

Written to a 1

Time/Date Stamp

is Written

no

Clear

Memory

Start via

External Event

Mem Clr =1

yes

Write a 1 to

the ME bit.

MIP = 0

INT Input

Activated

yes

no

no

Clear

Memory

Continue to

Monitor Input

ETC Starts

Incrementing

EC is

Incremented

INT Input

Activated

yes

Record Event in

Event Memory

ETC is

Cleared

no

Continue to

Monitor Input

MIP Automaticall

Written to a 1

Time/Date Stamp is

Written

ETC Starts

Incrementing.

EC is

Incremented

INT Input

Activated

yes

Record Event in

Event Memory

no

Continue to

Monitor Input

ETC is

Cleared

24 of 26

Page 25

ROLL OVER FLOW CHART Figure 8

y

EC is

Incremented

DS1678

INT Input

Activated

Memor

Full

Rollover

Enable = 1

yes

yes

yes

no

no

no

Continue to

Monitor Input

Record Event in

Event Memory

ETC Written to Event 0

and

Time/Date Stamp

is Written

ETC is

Cleared

25 of 26

Page 26

DS1678

NOTES:

1. After this period, the first clock pulse is generated.

2.

A device must initially provide a hold time of at least 300ns for the SDA signal in order to bridge the

undefined region of the falling edge of SCL. The maximum t

not stretch the LOW period (t

3.

A fast mode device can be used in a standard mode system, but the requirement t

) of the SCL signal.

low

then be met. This will automatically be the case if the device does not stretch the LOW period of the

SCL signal. If such a device does stretch the LOW period of the SCL signal, it must output the next

data bit to the SDA line t

4.

C

– Total capacitance of one bus line in pF.

B

5.

t

and tF are measured with a 1.7kΩ pull-up resistor, 200pF pull-up capacitor, 1.7kΩ pull-down

R

r MAX

+ t

= 1000 + 250 = 1250ns before the SCL line is released.

su:dat

resistor and 5pF pull-down capacitor.

6.

V

measures at V

pf

BAT

= 3.0V.

has only to be met if the device does

hd:dat

> 250ns must

su:dat

26 of 26

Loading...

Loading...