Page 1

www.maxim-ic.com

A

A

A13A

A11A

A9A

A7A6A

A4A

A

A

A

A

A

A

A13A8A9A

A

DS1647/DS1647P

Nonvolatile Timekeeping RAM

FEATURES

§ Integrates NV SRAM, real-time clock,

crystal, power-fail control circuit and lithium

energy source

§ Clock registers are accessed identically to the

static RAM. These registers are resident in

the eight top RAM locations

§ Totally nonvolatile with over 10 years of

operation in the absence of power

§ BCD coded year, month, date, day, hours,

minutes, and seconds with leap year

compensation valid up to 2100

§ Power-fail write protection allows for ±10%

VCC power supply tolerance

§ DS1647 only (DIP Module)

- Standard JEDEC byte-wide 128k x 8

RAM pinout

§ DS1647P only (PowerCap® Module Board)

- Surface mountable package for direct

connection to PowerCap containing

battery and crystal

- Replaceable battery (PowerCap)

- Power-fail output

- Pin-for-pin compatible with other

densities of DS164XP Timekeeping

RAM

ORDERING INFORMATION

DS1647 32-pin DIP module

*DS1647P 34-pin PowerCap Module

Board

*DS9034PCX PowerCap (Required; must

be ordered separately)

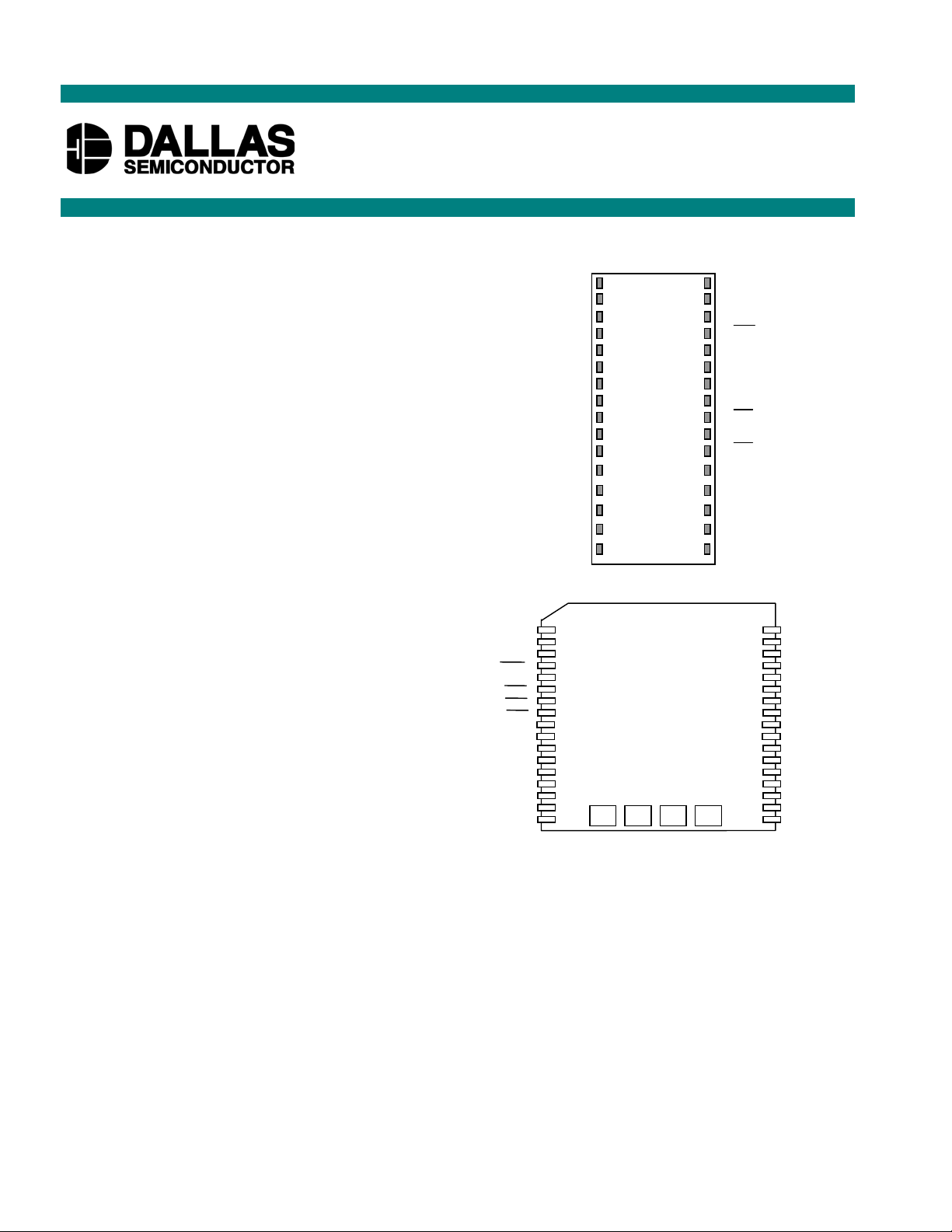

PIN ASSIGNMENT

NC

A15

A16

PFO

V

CC

WE

OE

CE

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

GND

A18

A16

A14

A12

DQ0

DQ1

DQ2

GND

34-Pin PowerCap Module Board

(Uses DS9034PCX PowerCap)

1

2

3

4

A7

5

A6

6

A5

7

A4

8

A3

9

A2

10

A1

11

12

A0

13

14

15

16

32-Pin Encapsulated Package

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

X1 GND V

16

17

BAT

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

X2

V

CC

15

17

WE

11

OE

10

CE

DQ7

DQ6

DQ5

DQ4

DQ3

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

18

17

14

12

10

8

5

3

2

1

0

1 of 11 072401

Page 2

DS1647/DS1647P

PIN DESCRIPTION

A0-A18 - Address Input

CE - Chip Enable

OE - Output Enable

WE - Write Enable

- +5V

V

CC

GND - Ground

DQ0-DQ7 - Data Input/Output

NC - No Connection

PFO - Power-fail Output

(DS1647P only)

X1, X2 - Crystal Connection

V

- Battery Connection

BAT

DESCRIPTION

The DS1647 is a 512k x 8 nonvolatile static RAM with a full-function real-time clock, which are both

accessible in a byte-wide format. The nonvolatile timekeeping RAM is functionally equivalent to any

JEDEC standard 512k x 8 SRAM. The device can also be easily substituted for ROM, EPROM and

EEPROM, providing read/write nonvolatility and the addition of the real-time clock function. The realtime clock information resides in the eight uppermost RAM locations. The RTC registers contain year,

month, date, day, hours, minutes, and seconds data in 24-hour BCD format. Corrections for the day of the

month and leap year are made automatically. The RTC clock registers are double-buffered to avoid access

of incorrect data that can occur during clock update cycles. The double-buffered system also prevents

time loss as the timekeeping countdown continues unabated by access to time register data. The DS1647

also contains its own power-fail circuitry, which deselects the device when the VCC supply is in an out-oftolerance condition. This feature prevents loss of data from unpredictable system operation brought on by

low VCC as errant access and update cycles are avoided.

PACKAGES

The DS1647 is available in two packages: 32-pin DIP and 34-pin PowerCap module. The 32-pin DIP

style module integrates the crystal, lithium energy source, and silicon all in one package. The 34-pin

PowerCap Module Board is designed with contacts for connection to a separate PowerCap (DS9034PCX)

that contains the crystal and battery. This design allows the PowerCap to be mounted on top of the

DS1647P after the completion of the surface mount process. Mounting the PowerCap after the surface

mount process prevents damage to the crystal and battery due to the high temperatures required for solder

reflow. The PowerCap is keyed to prevent reverse insertion. The PowerCap Module Board and PowerCap

are ordered separately and shipped in separate containers. The part number for the PowerCap is

DS9034PCX.

CLOCK OPERATIONS - READING THE CLOCK

While the double-buffered register structure reduces the chance of reading incorrect data, internal updates

to the DS1647 clock registers should be halted before clock data is read to prevent reading of data in

transition. However, halting the internal clock register updating process does not affect clock accuracy.

Updating is halted when a 1 is written into the read bit, the 7th most significant bit in the control register.

As long as 1 remains in that position, updating is halted. After a halt is issued, the registers reflect the

count, that is day, date, and time that was present at the moment the halt command was issued. However,

the internal clock registers of the double-buffered system continue to update so that clock accuracy is not

affected by the access of data. All of the DS1647 registers are updated simultaneously after the clock

status is reset. Updating is within a second after the read bit is written to 0.

2 of 11

Page 3

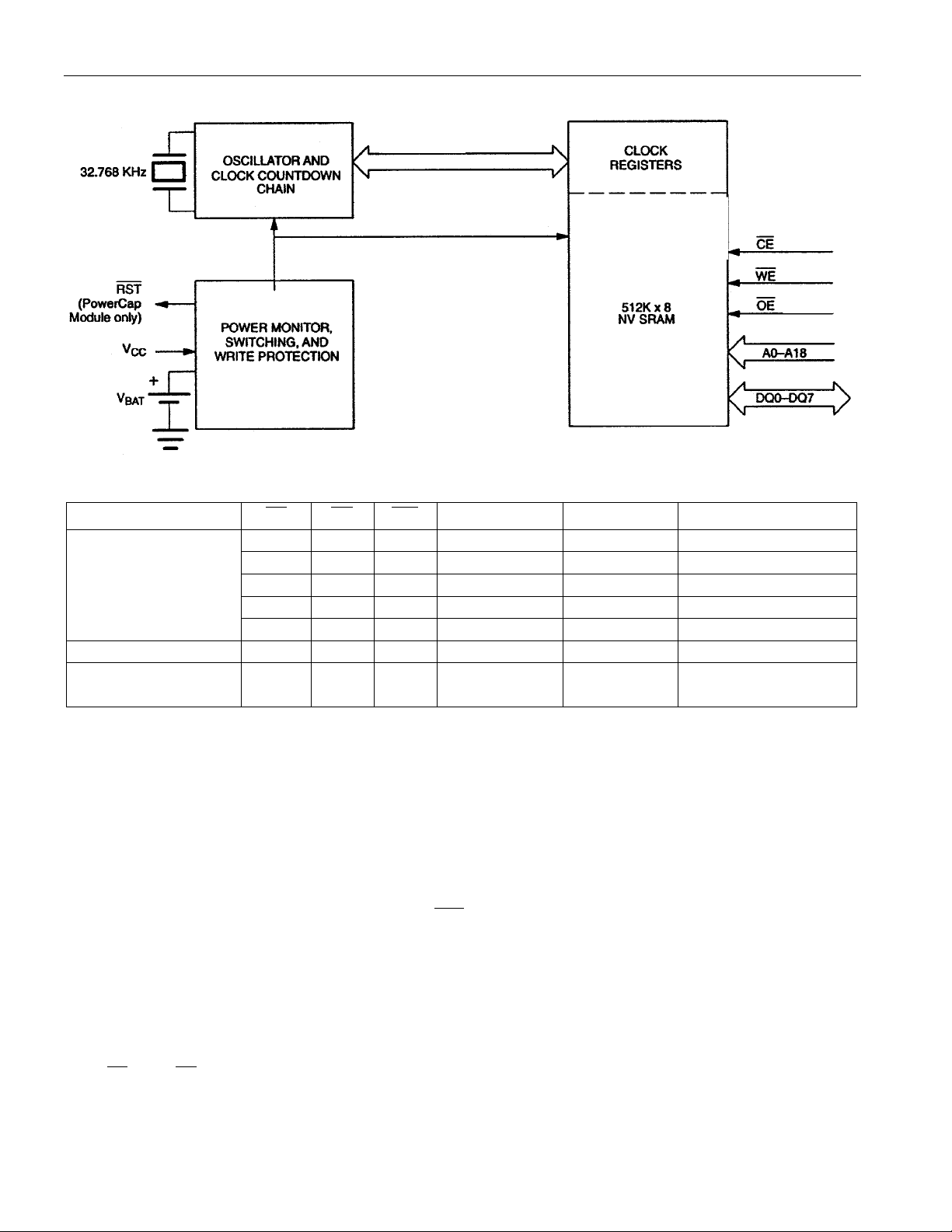

BLOCK DIAGRAM DS1647 Figure 1

TRUTH TABLE DS1647 Table 1

V

CC

5V ± 10%

<4.5V >V

<V

BAT

BAT

CE OE WE

V

IH

X X DESELECT HIGH-Z STANDBY

X X X DESELECT HIGH-Z STANDBY

V

V

V

IL

IL

IL

XVILWRITE DATA IN ACTIVE

V

V

IL

IH

V

V

IH

IH

X X X DESELECT HIGH-Z CMOS STANDBY

X X X DESELECT HIGH-Z DATA RETENTION

DS1647/DS1647P

MODE DQ POWER

READ DATA OUT ACTIVE

READ HIGH-Z ACTIVE

MODE

SETTING THE CLOCK

The MSB Bit, B7, of the control register is the write bit. Setting the write bit to a 1, like the read bit halts

updates to the DS1647 registers. The user can then load them with the correct day, date and time data in

24-hour BCD format. Resetting the write bit to a 0 then transfers those values to the actual clock counters

and allows normal operation to resume.

STOPPING AND STARTING THE CLOCK OSCILLATOR

The clock oscillator may be stopped at any time. To increase the shelf life, the oscillator can be turned off

to minimize current drain from the battery. The OSC bit is the MSB for the second’s registers. Setting it

to a 1 stops the oscillator.

FREQUENCY TEST BIT

Bit 6 of the day byte is the frequency test bit. When the frequency test bit is set to logic 1 and the

oscillator is running, the LSB of the second’s register will toggle at 512 Hz. When the seconds register is

being read, the DQ0 line will toggle at the 512 Hz frequency as long as conditions for access remain valid

CE low, OE low, and address for seconds register remain valid and stable).

(i.e.,

3 of 11

Page 4

DS1647/DS1647P

CLOCK ACCURACY (DIP MODULE)

The DS1647 is guaranteed to keep time accuracy to within ±1 minute per month at 25°C. The RTC is

calibrated at the factory by Dallas Semiconductor using nonvolatile tuning elements, and does not require

additional calibration. For this reason, methods of field clock calibration are not available and not

necessary. Clock accuracy is also effected by the electrical environment and caution should be taken to

place the RTC in the lowest level EMI section of the PCB layout. For additional information please see

application note 58.

CLOCK ACCURACY (POWERCAP MODULE)

The DS1647 and DS9034PCX are each individually tested for accuracy. Once mounted together, the

module will typically keep time accuracy to within ±1.53 minutes per month (35 ppm) at 25°C. Clock

accuracy is also effected by the electrical environment and caution should be taken to place the RTC in

the lowest level EMI section of the PCB layout. For additional information please see application

note 58.

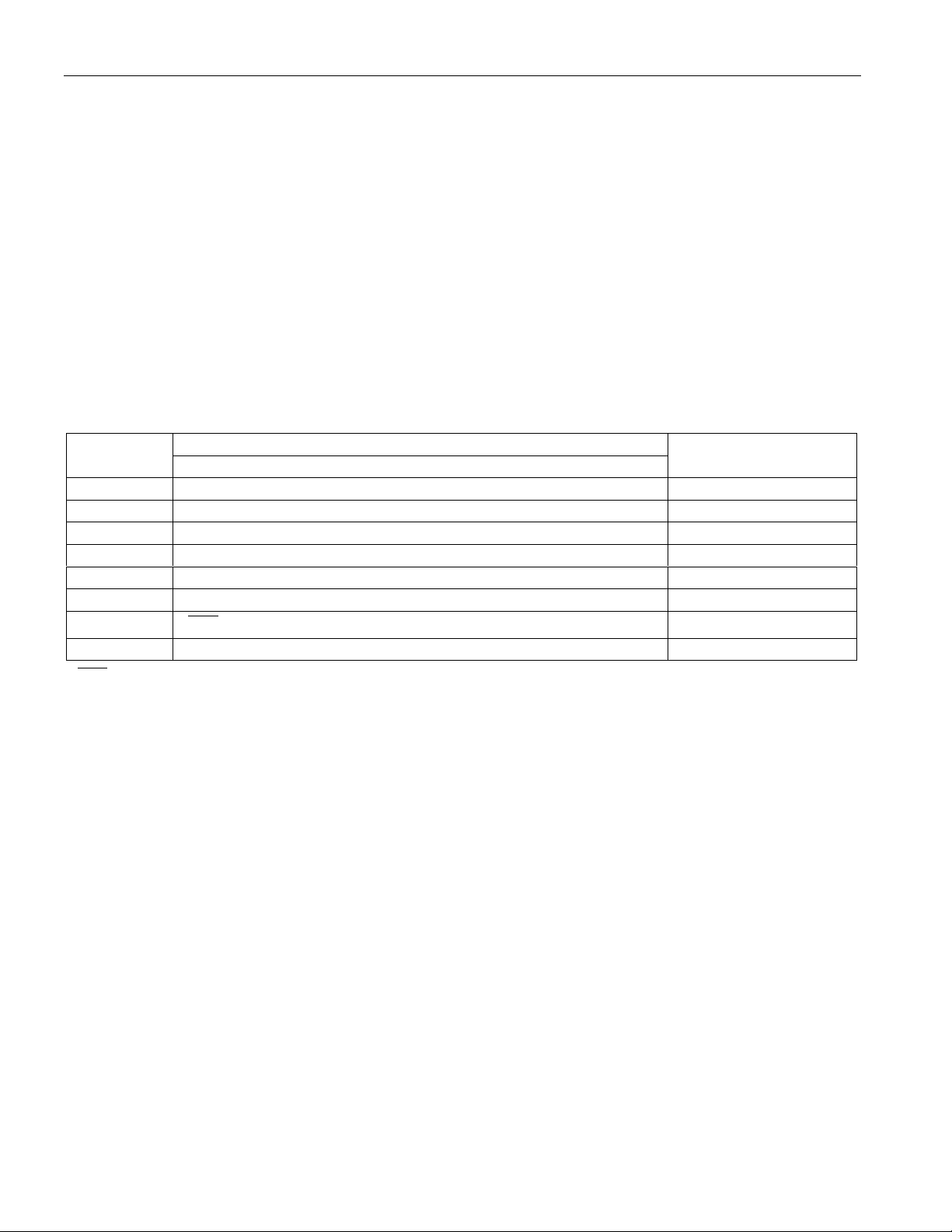

1646 REGISTER MAP - BANK1 Table 2

ADDRESS

B

B

7

6

B

5

7FFFF - - - - - - - - YEAR 00-99

7FFFE X X X - - - - - MONTH 01-12

7FFFD X X - - - - - - DATE 01-31

7FFFC X FT X X X - - - DAY 01-07

7FFFB X X - - - - - - HOUR 00-23

7FFFA X - - - - - - - MINUTES 00-59

7FFF9

OSC

-------

7FFF8WRXXXXXXCONTROLA

DATA

B

4

B

3

B

2

B

1

B

0

FUNCTION

SECONDS 00-59

OSC = STOP BIT

R = READ BIT FT = FREQUENCY TEST

W = WRITE BIT X = UNUSED

NOTE:

All indicated “X” bits are not dedicated to any particular function and can be used as normal RAM bits.

4 of 11

Page 5

DS1647/DS1647P

RETRIEVING DATA FROM RAM OR CLOCK

The DS1647 is in the read mode whenever WE (write enable) is high; CE (chip enable) is low. The

device architecture allows ripple-through access to any of the address locations in the NV SRAM. Valid

data will be available at the DQ pins within tAA after the last address input is stable, providing that the CE

and OE access times and states are satisfied. If CE or OE access times are not met, valid data will be

available at the latter of chip-enable access (t

) or at output enable access time (t

CEA

). The state of the

OEA

data input/output pins (DQ) is controlled by CE and OE . If the outputs are activated before tAA, the data

lines are driven to an intermediate state until tAA. If the address inputs are changed while CE and OE

remain valid, output data will remain valid for output data hold time (tOH) but will then go indeterminate

until the next address access.

WRITING DATA TO RAM OR CLOCK

The DS1647 is in the write mode whenever WE and CE are in their active state. The start of a write is

referenced to the latter occurring high to low transition of WE and CE . The addresses must be held valid

throughout the cycle. CE or WE must return inactive for a minimum of tWR prior to the initiation of

another read or write cycle. Data in must be valid tDS prior to the end of write and remain valid for t

afterward. In a typical application, the OE signal will be high during a write cycle. However, OE can be

active provided that care is taken with the data bus to avoid bus contention. If OE is low prior to WE

transitioning low the data bus can become active with read data defined by the address inputs. A low

transition on WE will then disable the outputs t

after WE goes active.

WEZ

DH

DATA RETENTION MODE

When VCC is within nominal limits (VCC > 4.5 volts) the DS1647 can be accessed as described above with

read or write cycles. However, when VCC is below the power-fail point VPF (point at which write

protection occurs) the internal clock registers and RAM are blocked from access. This is accomplished

internally by inhibiting access via the CE signal. At this time the power-fail output signal ( PFO ) will be

driven active low and will remain active until VCC returns to nominal levels. When VCC falls below the

level of the internal battery supply, power input is switched from the VCC pin to the internal battery and

clock activity, RAM, and clock data are maintained from the battery until VCC is returned to nominal

level.

5 of 11

Page 6

DS1647/DS1647P

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to Ground -0.3V to +7.0V

Storage Temperature -40°C to +85°C

Soldering Temperature 260°C for 10 seconds (DIP Package) (See Note 7)

See IPC/JEDEC Standard J-STD-020A for

Surface Mount Devices

* This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods of time may affect reliability.

OPERATING RANGE

Range Temperature V

Commercial 0°C to +70°C

CC

5V ± 10%

RECOMMENDED DC OPERATING CONDITIONS

(Over the Operating Range)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Voltage V

Logic 1 Voltage All Inputs V

Logic 0 Voltage All Inputs V

CC

IH

IL

4.5 5.0 5.5 V 1

2.2 VCC+0.3 V

-0.3 0.8 V

DC ELECTRICAL CHARACTERISTICS (Over the Operating Range)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Average VCC Power Supply Current I

TTL Standby Current ( CE =VIH)

CMOS Standby Current

I

I

( CE =VCC-0.2V)

Input Leakage Current (any input) I

Output Leakage Current I

Output Logic 1 Voltage

(I

= -1.0 mA)

OUT

Output Logic 0 Voltage

(I

= +2.1 mA)

OUT

V

V

Write Protection Voltage V

CC1

CC2

CC3

IL

OL

OH

OL

PF

3 6 mA 2, 3

2 4.0 mA 2, 3

-1 +1

-1 +1

2.4 V

4.0 4.5 V

85 mA 2, 3

mA

mA

0.4 V

6 of 11

Page 7

DS1647/DS1647P

AC ELECTRICAL CHARACTERISTICS (Over the Operating Range)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Read Cycle Time t

Address Access Time t

CE Access Time

CE Data Off Time

Output Enable Access Time t

Output Enable Data Off Time t

Output Enable to DQ Low-Z t

CE to DQ Low-Z

Output Hold from Address t

Write Cycle Time t

Address Setup Time t

CE Pulse Width

Address Hold from End of Write t

Write Pulse Width t

WE Data Off Time

WE or CE Inactive Time

Data Setup Time t

Data Hold Time High t

RC

AA

t

CEA

t

CEZ

OEA

OEZ

OEL

t

CEL

OH

WC

AS

t

CEW

AH1

t

AH2

WEW

t

WEZ

t

WR

DS

DH1

t

DH2

120 ns

120 ns

120 ns

40 ns

100 ns

40 ns

5ns

5ns

5ns

120 ns

0ns

100 ns

5

30

ns

ns

5

6

75 ns

40 ns

10 ns

85 ns

0

25

ns

ns

5

6

AC TEST CONDITIONS

Input Levels: 0V to 3V

Transition Times: 5 ns

CAPACITANCE (t

= 25°C)

A

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Capacitance on all pins (except DQ) C

Capacitance on DQ pins C

I

DQ

7pF

10 pF

AC ELECTRICAL CHARACTERISTICS

(POWER-UP/DOWN TIMING) (Over the Operating Range)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

CE or WE at V

before Power-Down

IH

VPF (Max) to VPF (Min) VCC Fall Time t

VPF (Min) to VSO VCC Fall Time t

VSO to VPF (Min) VCC Rise Time t

VPF (Min) to VPF (Max) VCC Rise Time t

Power-Up t

Expected Data Retention Time

(Oscillator On)

t

PD

F

FB

RB

R

REC

t

DR

0

300

10

1

0

ms

ms

ms

ms

ms

15 35 ms

10 years 4

7 of 11

Page 8

DS1647 READ CYCLE TIMING

DS1647 WRITE CYCLE TIMING

DS1647/DS1647P

8 of 11

Page 9

POWER-DOWN/POWER-UP TIMING

DS1647/DS1647P

NOTES:

OUTPUT LOAD

1. All voltages are referenced to ground.

2. Typical values are at 25°C and nominal

supplies.

3. Outputs are open.

4. Data retention time is at 25°C and is

calculated from the date code on the device

package. The date code XXYY is the year

followed by the week of the year in which

the device was manufactured. For example,

th

9225 would mean the 25

5. t

6. t

AH1

AH2

, t

are measured from WE going high.

DH1

, t

are measured from CE going high.

DH2

week of 1992.

7. Real-Time Clock Modules (DIP) can be successfully processed through conventional wave-soldering

techniques as long as temperatures as long as temperature exposure to the lithium energy source

contained within does not exceed +85°C. Post-solder cleaning with water washing techniques is

acceptable, provided that ultrasonic vibration is not used.

In addition, for the PowerCap version:

a. Dallas Semiconductor recommends that PowerCap Module bases experience one pass through

solder reflow oriented with the label side up (“live-bug”).

b. Hand soldering and touch-up: Do not touch or apply the soldering iron to leads for more than

3 seconds. To solder, apply flux to the pad, heat the lead frame pad and apply solder. To remove

the part, apply flux, heat the lead frame pad until the solder reflows and use a solder wick to

remove solder.

9 of 11

Page 10

DS1647 32-PIN PACKAGE

PKG 32-PIN

DIM MIN M AX

A IN.

MM

B IN.

MM

C IN.

MM

D IN.

MM

E IN.

MM

F IN.

MM

G IN.

MM

H IN.

MM

J IN.

MM

K IN.

MM

1.680

42.67

0.715

18.16

0.335

8.51

0.075

1.91

0.015

0.38

0.140

3.56

0.090

2.29

0.590

14.99

0.010

0.25

0.015

0.38

1.740

44.20

0.740

18.80

0.365

9.27

0.105

2.67

0.030

0.76

0.180

4.57

0.110

2.79

0.630

16.00

0.018

0.46

0.025

0.64

DS1647/DS1647P

DS1647P

PKG INCHES

DIM MIN NOM MAX

A

B

C

D

E

F

G

0.920 0.925 0.930

0.980 0.985 0.990

- - 0.080

0.052 0.055 0.058

0.048 0.050 0.052

0.015 0.020 0.025

0.025 0.027 0.030

NOTE:

For the PowerCap version:

a. Dallas Semiconductor recommends that PowerCap Module bases experience one pass through

solder reflow oriented with the label side up (“live - bug”).

b. Hand Soldering and touch-up: Do not touch or apply the soldering iron to leads for more than

3 seconds. To solder, apply flux to the pad, heat the lead frame pad and apply solder. To remove

the part, apply flux, heat the lead frame pad until the solder reflows and use a solder wick to

remove solder.

10 of 11

Page 11

DS1647P WITH DS9034PCX ATTACHED

DS1647/DS1647P

PKG INCHES

DIM MIN NOM MAX

A

B

C

D

E

F

G

0.920 0.925 0.930

0.955 0.960 0.965

0.240 0.245 0.250

0.052 0.055 0.058

0.048 0.050 0.052

0.015 0.020 0.025

0.020 0.025 0.030

RECOMMENDED POWERCAP MODULE LAND PATTERN

PKG INCHES

DIM MIN NOM MAX

A

B

C

D

E

- 1.050 -

- 0.826 -

- 0.050 -

- 0.030 -

- 0.112 -

11 of 11

Loading...

Loading...