Page 1

19-4998; Rev 0; 10/09

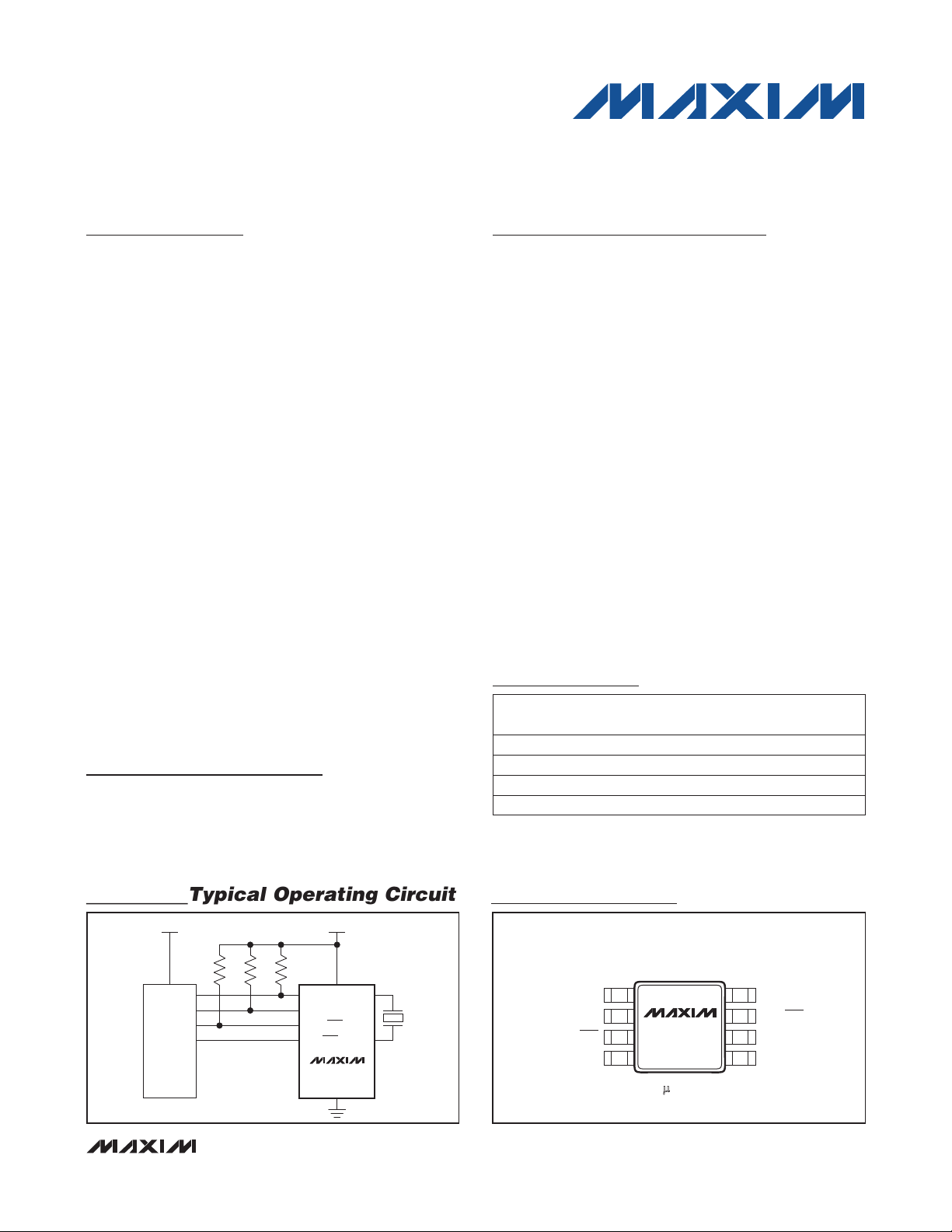

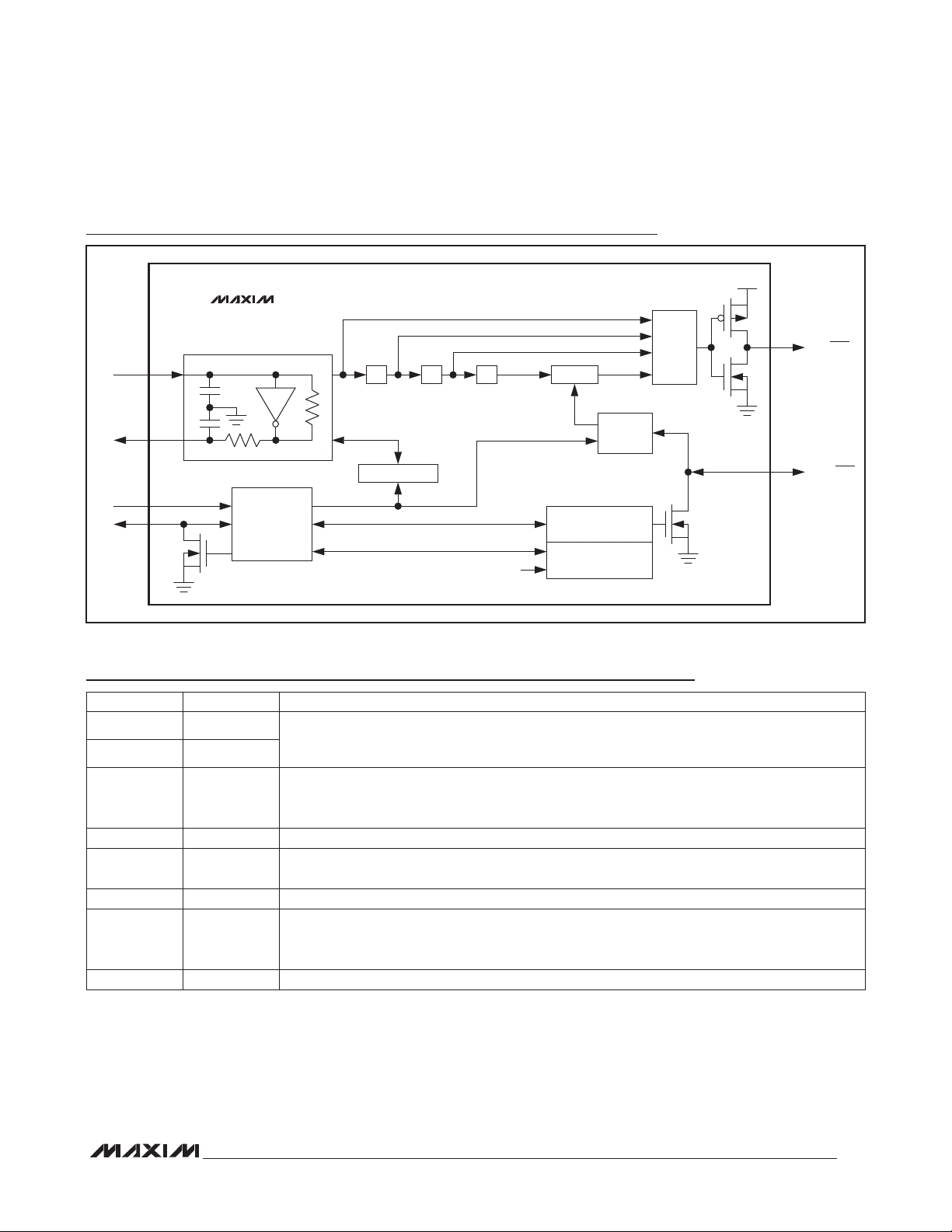

Typical Operating Circuit

Low-Current I2C RTCs for High-ESR Crystals

General Description

The DS1341/DS1342 low-current real-time clocks (RTCs)

are timekeeping devices that provide an extremely low

standby current, which permits longer life from a power

supply. The DS1341/DS1342 support high-ESR crystals,

which broaden the pool of usable crystals for the devices.

The DS1341 uses a 6pF crystal, while the DS1342 uses a

12.5pF crystal. These devices are accessed through an

I2C serial interface. Other features include two time-of-day

alarms, two interrupt outputs, a programmable squarewave output, and a serial bus timeout mechanism.

The clock/calendar provides seconds, minutes, hours,

day, date, month, and year information. The date at the

end of the month is automatically adjusted for months

with fewer than 31 days, including corrections for leap

year. The clock operates in either 24hr or 12hr format

with an AM/PM indicator.

The DS1341/DS1342 also include an input for synchronization. When a reference clock (e.g., 60Hz power line or

GPS 1PPS) is present at the CLKIN pin and the enable

external clock input bit (ECLK) is set to 1, the DS1341/

DS1342 RTCs are frequency-locked to the external clock

and the clock accuracy is determined by the external

source. In case of external clock failure, the clock is

switched to the crystal oscillator.

The devices are available in a lead(Pb)-free/RoHScompliant, 8-pin FSOP package. The devices support a

-40NC to +85NC extended temperature range.

Applications

Medical

Point of Sale (POS)

Telematics

Portable Instruments

Portable Audio

Automotive

Features

S Low Timekeeping Current of 250nA (typ)

S Compatible with Crystal ESR Up to 80kI

S Use Crystals with C

= 6pF (DS1341) or

L

CL = 12.5pF (DS1342)

S +1.8V to +5.5V Operating Voltage Range

S Maintain Time Down to +1.15V (typ)

S Fast (400kHz) I

S Bus Timeout for Lockup-Free Operation

S RTC Counts Seconds, Minutes, Hours, Day, Date,

2

C Interface

Month, and Year with Leap Year Compensation

Valid Through 2099

S External Clock Source for Synchronization Clock

Reference (e.g., 32kHz, 50Hz/60Hz Power Line,

GPS 1PPS)

S Two Time-of-Day Alarms with Two Interrupt

Outputs

S Programmable Square-Wave Output

S Industrial Temperature Range

S Small, 8-Pin µSOP Package

Ordering Information

PART TEMP RANGE

DS1341U+

DS1341U+T&R

DS1342U+*

DS1342U+T&R*

+Denotes a lead(Pb)-free/RoHS-compliant package.

T&R = Tape and reel.

*Future product—contact factory for availability.

-40NC to +85NC 8 FSOP

-40NC to +85NC 8 FSOP

-40NC to +85NC 8 FSOP

-40NC to +85NC 8 FSOP

PINPACKAGE

OSC

CL (pF)

6

6

12.5

12.5

DS1341/DS1342

V

CC

R

R

R

PU

CPU

_______________________________________________________________ Maxim Integrated Products 1

PU

PU

V

CC

V

CC

SCL

SDA

CLKIN/INTA

SQW/INTBX1X2

DS1341/DS1342

GND

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

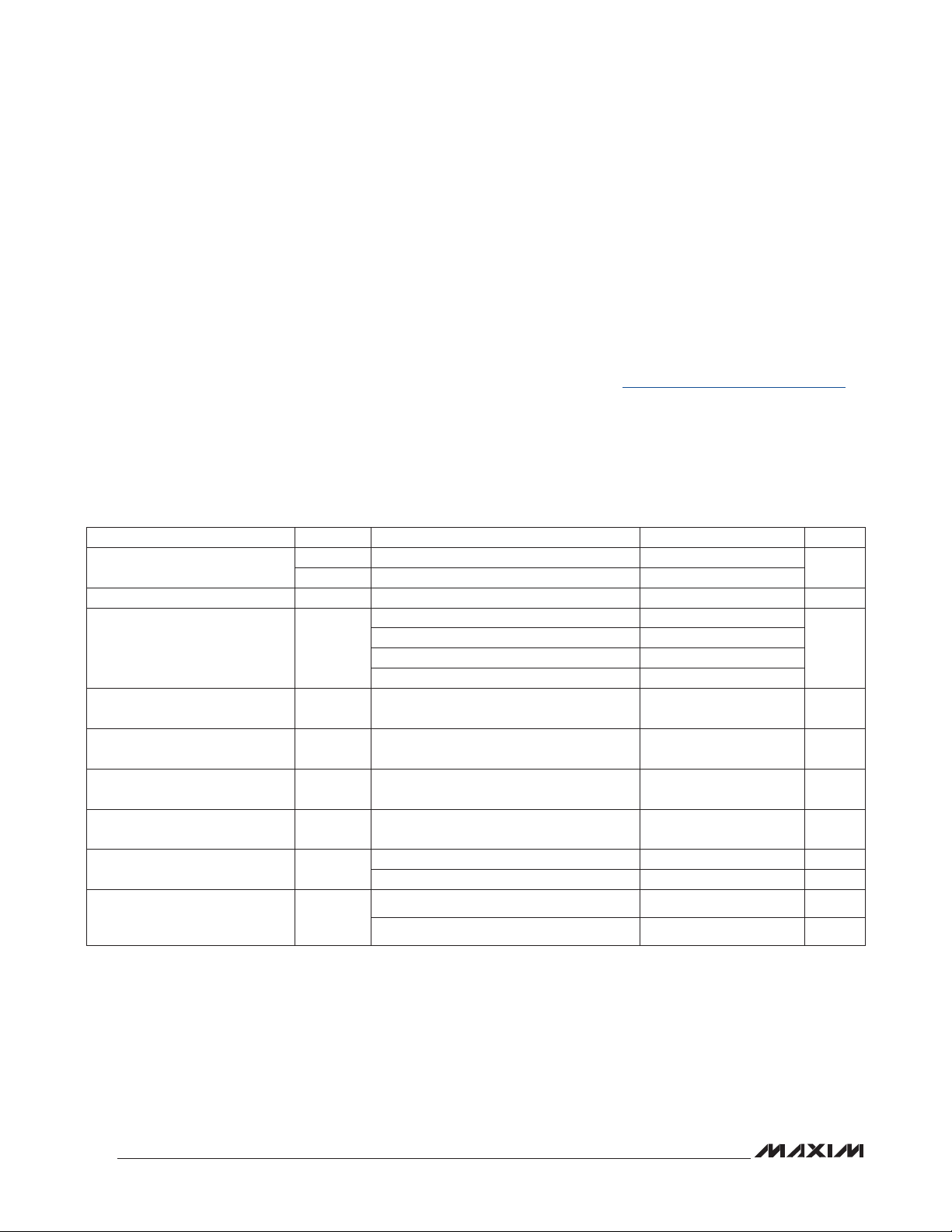

Pin Configuration

TOP VIEW

+

1 8 V

X1

2 7 SQW/INTBX2

DS1341

DS1342

µSOP

CC

SCLCLKIN/INTA 3 6

SDAGND 4 5

Page 2

Low-Current I2C RTCs for High-ESR Crystals

ABSOLUTE MAXIMUM RATINGS

Voltage Range on Any Pin Relative to Ground ....-0.3V to +6.0V

Operating Temperature Range .......................... -40NC to +85NC

Junction-to-Ambient Thermal

Resistance (BJA) (Note 1) ........................................ +221NC/W

Junction-to-Case Thermal

Resistance (BJC) (Note 1) ......................................... +39NC/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Junction Temperature Maximum .....................................+150NC

Storage Temperature Range ............................ -55NC to +125NC

Soldering Temperature .........................Refer to the IPC/JEDEC

J-STD-020 Specification.

DS1341/DS1342

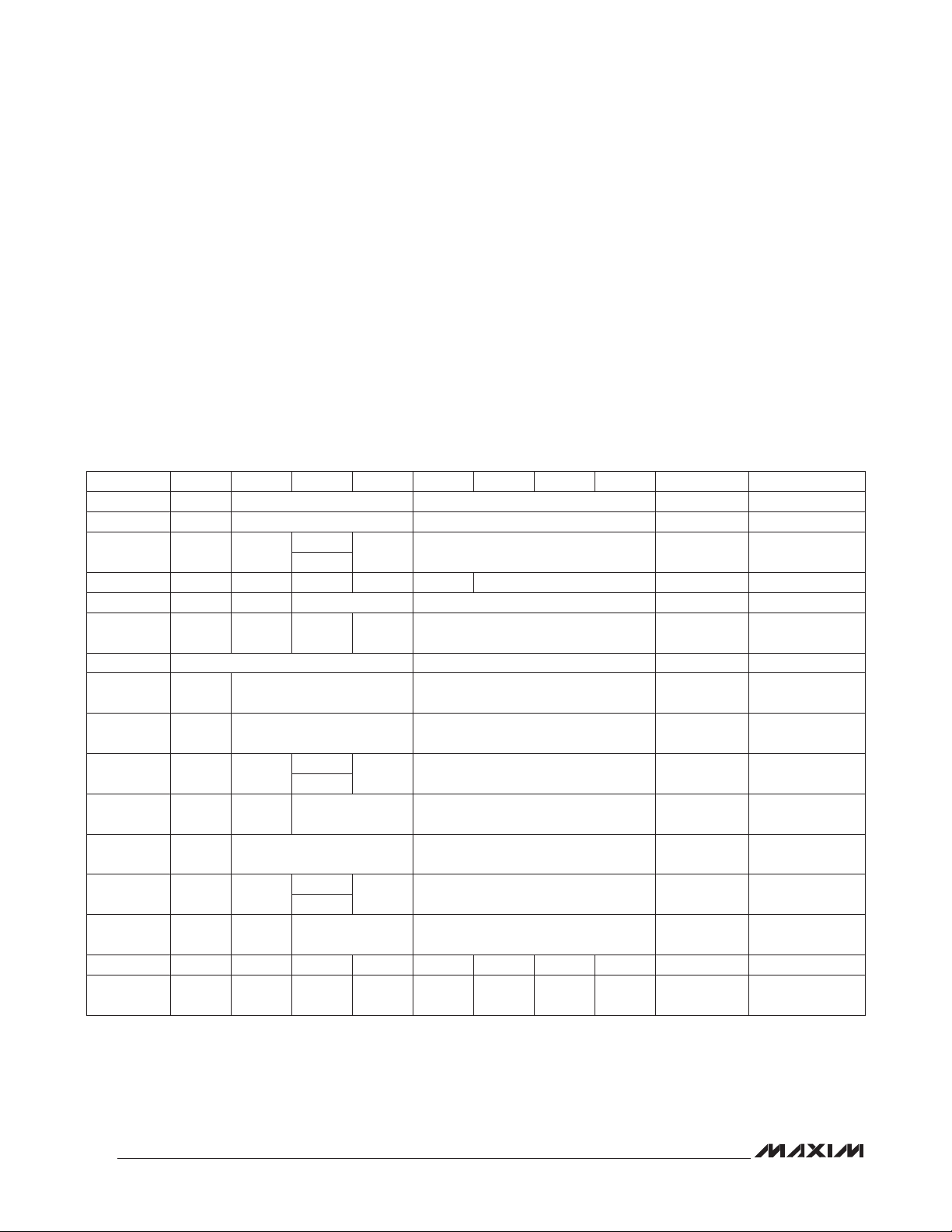

DC ELECTRICAL CHARACTERISTICS

(VCC = +1.8V to +5.5V, TA = -40NC to +85NC, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Operating Voltage Range

Minimum Timekeeping Voltage V

Timekeeping Current: DS1341

CLKIN = GND or CLKIN = VCC

(Note 4)

Logic 1 Input V

Logic 0 Input V

Input Leakage

(SCL, CLKIN/INTA)

Output Leakage

(CLKIN/INTA, SQW/INTB)

Output Logic 1

VOH = +1.0V (SQW /INTB)

Output Logic 0

VOL = +0.4V (SDA, CLKIN/INTA,

SQW/INTB)

V

CCTMIN

I

V

CCT

CCT

I

I

I

OH

I

OL

CC

LI

O

Full operation (Note 3) 1.8 5.5

Timekeeping (Notes 3, 4) 1.3 5.5

TA = +25NC (Notes 3, 4)

VCC = +3.0V, EGFIL = 0, DOSF = 1 220 500

VCC = +5.5V 250 600

VCC = +3.0V, EGFIL = 1, DOSF = 0 280 560

VCC = +5.5V 320 700

(Note 2)

IH

(Note 2) -0.3

IL

ECLK = 1, VIN = 0V to V

ECLK = A1IE = A2IE = 0 -1.0 +1.0

VCC R 1.8V, INTCN = 0

VCC R 1.3V, INTCN = 0

VCC R 1.8V

VCC R 1.3V (Note 5)

CC

0.7 x

V

CC

-0.1 +0.1

-3.0 mA

-250

3.0 mA

250

1.15 1.3 V

VCC +

0.3

0.3 x

V

CC

V

nA

V

V

FA

FA

FA

FA

2

Page 3

Low-Current I2C RTCs for High-ESR Crystals

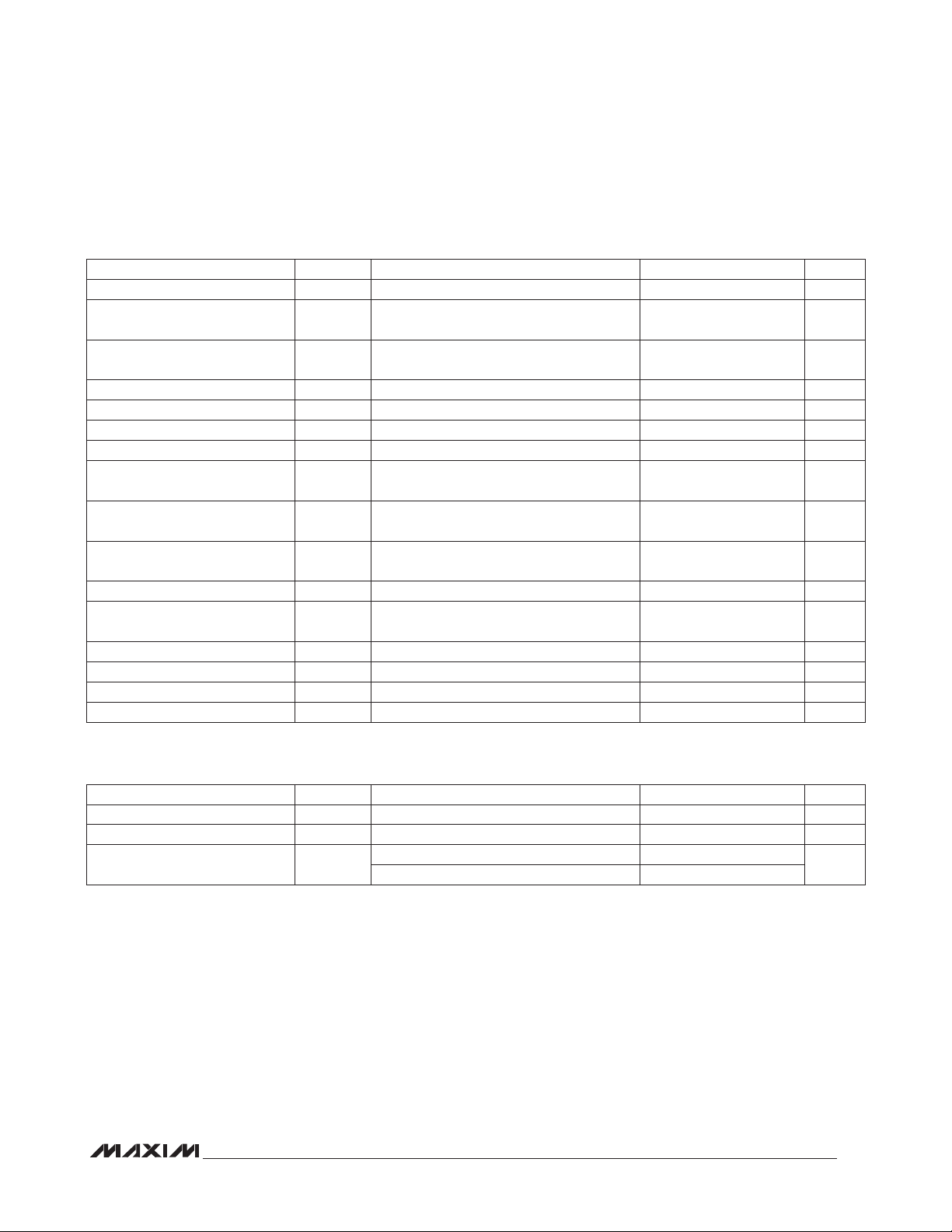

AC ELECTRICAL CHARACTERISTICS

(VCC = +1.8V to +5.5V, TA = -40NC to +85NC, unless otherwise noted.) (Note 2, Figure 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time (Repeated) START

Condition

Low Period of SCL Clock t

High Period of SCL Clock t

Data Hold Time t

Data Setup Time t

Setup Time for a Repeated

START Condition

Rise Time of Both SDA and SCL

Signals

Fall Time for Both SDA and SCL

Signals

Setup Time for STOP Condition t

Capacitive Load for Each Bus

Line

I/O Capacitance C

SCL Spike Suppression t

Oscillator Stop Flag (OSF) Delay t

Timeout Interval t

t

HD:STA

HD:DAT

SU:DAT

t

SU:STA

SU:STO

TIMEOUT

SCL

t

BUF

LOW

HIGH

t

t

C

I/O

SP

OSF

(Note 6) 400 kHz

(Note 7) 0.6

(Notes 8, 9) 0 0.9

(Note 10) 100 ns

(Note 11)

R

(Note 11)

F

(Note 11) 400 pF

B

(Note 12) 25 100 ms

(Note 13) 25 35 ms

1.3

1.3

0.6

0.6

20 +

0.1C

20 +

0.1C

0.6

B

B

10 pF

30 ns

DS1341/DS1342

Fs

Fs

Fs

Fs

Fs

Fs

300 ns

300 ns

Fs

CRYSTAL PARAMETERS

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Nominal Frequency f

Series Resistance ESR 35 80

Load Capacitance C

Note 2: Limits at -40NC are guaranteed by design and not production tested.

Note 3: Voltage referenced to ground.

Note 4: Specified with I2C bus inactive. Oscillator operational, INTCN = 1, ECLK = 0.

Note 5: Applies to CLKIN/INTA and SQW/INTB only.

Note 6: The minimum SCL clock frequency is limited by the bus timeout feature, which resets the serial bus interface if SCL is

held low for t

Note 7: After this period, the first clock pulse is generated.

Note 8: A device must internally provide a hold time of at least 300ns for the SDA signal (referred to the V

nal) to bridge the undefined region of the falling edge of SCL.

Note 9: The maximum t

Note 10: A fast-mode device can be used in a standard-mode system, but the requirement t

met. This is automatically the case if the device does not stretch the low period of the SCL signal. If such a device does

stretch the low period of the SCL signal, it must output the next data bit to the SDA line t

1250ns before the SCL line is released.

TIMEOUT

.

need only be met if the device does not stretch the low period (t

HD:DAT

O

DS1341 6

L

DS1342 12.5

SU:DAT

32.768 kHz

of the SCL sig-

IHMIN

) of the SCL signal.

LOW

R to 250ns must then be

RMAX

+ t

= 1000 + 250 =

SU:DAT

kI

pF

3

Page 4

Low-Current I2C RTCs for High-ESR Crystals

Note 11: CB is the total capacitance of one bus line, including all connected devices, in pF.

Note 12: The parameter t

range of 2.4V P VCC P V

Note 13: The DS1341/DS1342 can detect any single SCL clock held low longer than t

in reset state and can receive a new START condition when SCL is held low for at least t

detects this condition, the SDA output is released. The oscillator must be running for this function to work.

SDA

t

DS1341/DS1342

SCL

NOTE: TIMING IS REFERENCED TO V

BUF

t

HD:STA

STOP START REPEATED

is the period of time the oscillator must be stopped for the OSF flag to be set over the voltage

OSF

CCMAX

.

TIMEOUTMIN

. The devices’ I2C interface is

TIMEOUTMAX

ILMAX

t

LOW

AND V

IHMIN

t

F

t

t

R

t

HD:DAT

.

HIGH

t

SU:DAT

START

t

SU:STA

t

HD:STA

t

SP

. Once the device

t

SU:STO

Figure 1. Data Transfer on I2C Serial Bus

4

Page 5

Low-Current I2C RTCs for High-ESR Crystals

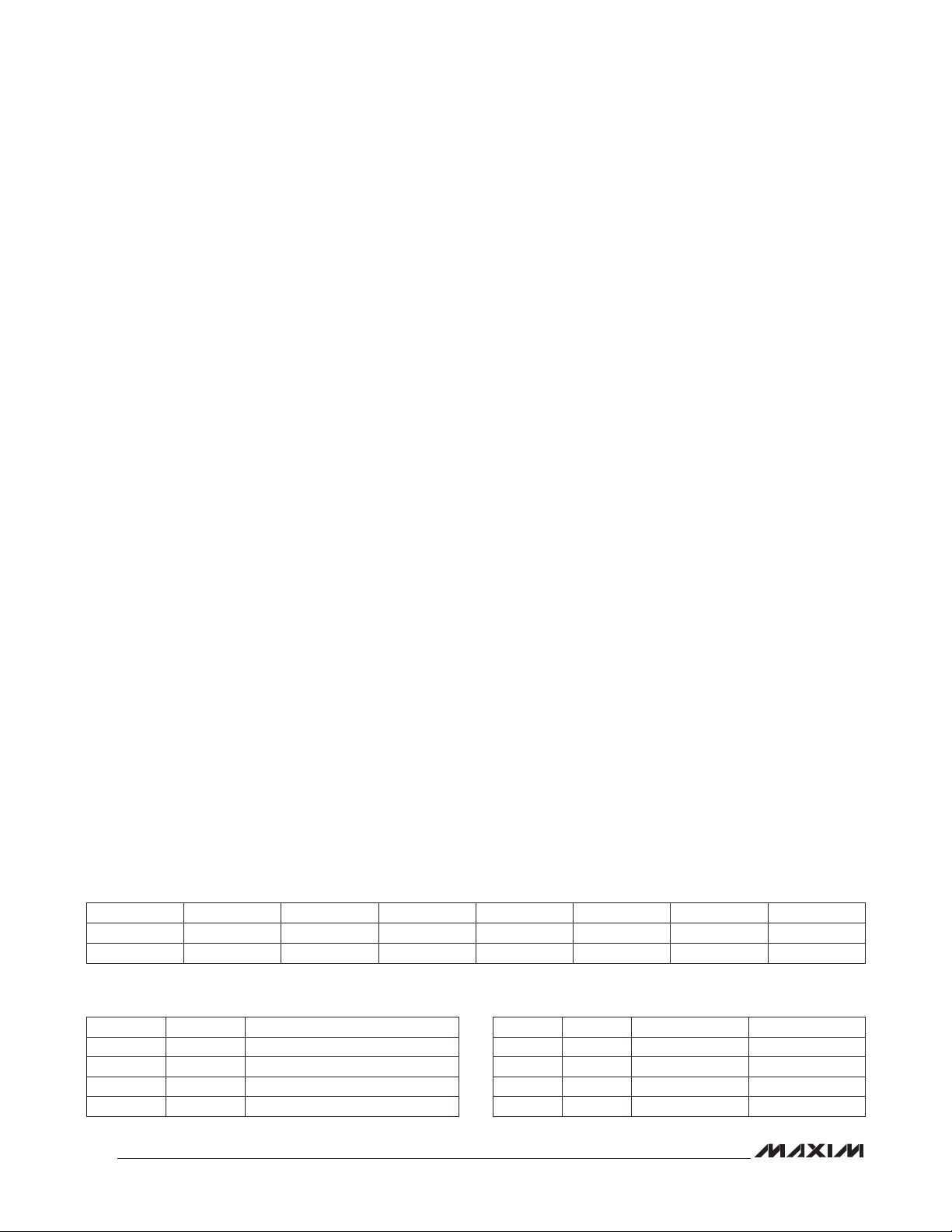

Functional Diagram

V

CC

DS1341/DS1342

32.768kHz

8.192kHz

4.096kHz

/4 /32 EXTSYNC

CONTROL LOGIC

/2

128Hz OSC-1Hz

OSC-1Hz

EXT-1Hz

ALARM AND

CONTROL REGISTERS

CLOCK AND

CALENDAR REGISTERS

DIVIDER

MUX/

BUFFER

P

SQW/INTB

N

CLKIN/INTA

N

SCL

SDA

DS1341/DS1342

X1

X2

SERIAL BUS

INTERFACE AND

ADDRESS

N

REGISTER

Pin Description

PIN NAME FUNCTION

1 X1

2 X2

3

CLKIN/INTA

4 GND Ground

5 SDA

6 SCL Serial-Clock Input. SCL is used to synchronize data movement on the serial interface.

7

8 V

SQW/INTB

CC

Connections for a Standard 32.768kHz Quartz Crystal. The internal oscillator circuitry is

designed for operation with a crystal having a specified load capacitance (CL) of 6pF (DS1341)

or 12.5pF (DS1342).

Clock Input/Active-Low Interrupt Output. This I/O pin is used to output an alarm interrupt or

accept an external clock input to drive the RTC counter. In the output mode, this is an open

drain and requires an external pullup resistor. If not used, connect this pin to ground.

Serial-Data Input/Output. SDA is the input/output pin for the I2C serial interface. The SDA pin is

open drain and requires an external pullup resistor.

Square-Wave/Active-Low Interrupt Output. This pin is used to output a programmable square

wave or an alarm interrupt signal. This is a CMOS push-pull output and does not require an

external pullup resistor. If not used, this pin can be left unconnected.

DC Power Input. This pin should be decoupled using a 0.01FF or 0.1FF capacitor.

5

Page 6

Low-Current I2C RTCs for High-ESR Crystals

Detailed Description

The DS1341/DS1342 low-current RTCs are timekeeping

devices that consume an extremely low timekeeping current, which permits longer life from a power supply. The

clock/calendar provides seconds, minutes, hours, day,

date, month, and year information. The date at the end of

the month is automatically adjusted for months with fewer

than 31 days, including corrections for leap year through

2099. The clock operates in either a 24hr or 12hr format

with an AM/PM indicator.

The DS1341/DS1342 use an external 32.768kHz crystal. The oscillator circuit does not require any external

resistors or capacitors to operate. The devices support

DS1341/DS1342

a high-ESR crystal, which broadens the pool of usable

crystals for the device. The DS1342 uses a 12.5pF crystal. The DS1341 uses a 6pF crystal, which decreases

oscillator current draw, but is less commonly available

than the 12.5pF crystals.

The DS1341/DS1342 also accept an external clock

reference for synchronization. The external clock can

be a 32.768kHz, 50Hz, 60Hz, or 1Hz source. When the

enable oscillator bit (EOSC) is a 0, the DS1341/DS1342

use the oscillator for timekeeping. If the enable external

clock input bit (ECLK) is set to 1, the time base derived

from the oscillator is compared to the 1Hz signal that is

derived from the CLKIN signal. The conditioned signal

drives the RTC time and date counters. If the oscillator

is disabled and the CLKIN signal is absent, the time and

date values remain static, provided that VCC remains at

a valid level.

When the external clock is lost or when the frequency

differs more than Q0.8% from the crystal frequency, the

signal derived from the crystal oscillator drives the RTC

counter.

When ECLK is set to 0, the RTC counter is always driven

with the signal derived from the crystal oscillator. When

the EOSC bit is a 1 and the external clock source is

selected, the RTC counter is always clocked by the signal from the CLKIN pin.

Address and data are transferred serially through an I2C

serial interface. Other features include two time-of-day

alarms, two interrupts, a programmable square-wave

output, and a bus timeout mechanism that resets the I2C

bus if it remains inactive for a minimum of t

TIMEOUT

The DS1341/DS1342 are available in a lead(Pb)-free/

RoHS-compliant, 8-pin FSOP package. Both devices

support a -40NC to +85NC extended temperature range.

Oscillator Circuit

The DS1341/DS1342 use an external 32.768kHz crystal. The oscillator circuit does not require any external

resistors or capacitors to operate. The DS1341 includes

integrated capacitive loading for a 6pF CL crystal, and

the DS1342 includes integrated capacitive loading for a

12.5pF CL crystal. See the Crystal Parameters table for

the external crystal parameters. The Functional Diagram

shows a simplified schematic of the oscillator circuit. The

startup time is usually less than 1 second when using a

crystal with the specified characteristics.

Clock Accuracy

When running from the internal oscillator, the accuracy of

the clock is dependent upon the accuracy of the crystal

and the accuracy of the match between the capacitive

load of the oscillator circuit and the capacitive load for

which the crystal was trimmed. Additional error is added

by crystal frequency drift caused by temperature shifts.

External circuit noise coupled into the oscillator circuit

can result in the clock running fast. Figure 2 shows a

typical PCB layout for isolation of the crystal and oscillator from noise. Refer to Application Note 58: Crystal

Considerations with Dallas Real-Time Clocks for detailed

information.

LOCAL GROUND PLANE (LAYER 2)

X1

CRYSTAL

X2

GND

.

NOTE: AVOID ROUTING SIGNALS IN THE CROSSHATCHED AREA (UPPER LEFT-HAND

QUADRANT) OF THE PACKAGE UNLESS THERE IS A GROUND PLANE BETWEEN THE

SIGNAL LINE AND THE PACKAGE.

Figure 2. Layout Example

6

Page 7

Low-Current I2C RTCs for High-ESR Crystals

External Synchronization

When an external clock reference is used, the input

from CLKIN/INTA is divided down to 1Hz by the divisor selected by the CLKSEL[2:1] bits. The 1Hz from the

divider (Ext-1Hz, see the Functional Diagram) is used to

correct the 1Hz that is derived from the 32.768kHz oscillator (Osc-1Hz). As Osc-1Hz drifts in relation to Ext-1Hz,

Osc-1Hz is digitally adjusted.

As shown in the Functional Diagram, the three highest frequencies driving the SQW/INTB pin are derived

from the uncorrected oscillator, while the 1Hz output is

derived from the adjusted Osc-1Hz signal.

Conceptually, the circuit can be thought of as two 1Hz

signals, one derived from the internal oscillator and the

other derived from the external reference clock, with the

oscillator-derived 1Hz signal being locked to the 1Hz

signal derived from the external reference clock. The

edges of the 1Hz signals do not need to be aligned with

OSC-1Hz

FROM OSCILLATOR

each other. While the external clock source is present

DS1341/DS1342

and within tolerance, the Ext-1Hz and Osc-1Hz maintain

their existing lock, regardless of their edge alignment,

with periodic correction of the Osc-1Hz signal. If the

external signal is lost and then regained sometime later,

the signals relock with whatever new alignment exists

(see Figure 3).

The Ext-1Hz is used by the device as long as it is within

tolerance, which is about 0.8% of Osc-1Hz. While Ext1Hz is within tolerance, the skew between the two signals could shift until a change of approximately 7.8ms

accumulates, after which the Osc-1Hz signal is adjusted

(see Figure 4). The adjustment is accomplished by digitally adjusting the 32kHz oscillator divider chain.

If the difference between Ext-1Hz and Osc-1Hz is greater

than approximately 0.8%, Osc-1Hz runs unadjusted (see

Figure 3) and the loss of signal (LOS) is set, provided the

ECLK bit is set.

SKEW SKEW

FROM EXTERNAL REFERENCE

Figure 3. Loss and Reacquisition of External Reference Clock

FROM EXTERNAL REFERENCE

EXT-1Hz

BREAK IN EXTERNAL REFERENCE SIGNAL

OSC-1Hz

FROM OSCILLATOR

CURRENT LOCK SHIFTED BACK TO CURRENT LOCKDRIFT AFTER N CYCLES

EXT-1Hz

Figure 4. Drift and Adjustment of Internal 1Hz to External Reference Clock

7

Page 8

Low-Current I2C RTCs for High-ESR Crystals

Register Map

Table 1 shows the map for the DS1341/DS1342 registers. During a multibyte access, if the address pointer

reaches the end of the register space (0Fh), it wraps

around to location 00h. On either an I2C START or

address pointer incrementing to location 00h, the current

time is transferred to a second set of registers. The time

information is read from these secondary registers while

the clock continues to run. This eliminates the need to

reread the registers in case the main registers update

during a read.

Table 1. Register Map

DS1341/DS1342

ADDRESS BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 FUNCTION RANGE

00h 0 10 Seconds Seconds Seconds 00–59

01h 0 10 Minutes Minutes Minutes 00–59

02h 0

03h 0 0 0 0 0 Day Day 1–7

04h 0 0 10 Date Date Date 01–31

05h CENT 0 0 10 MO Month

06h 10 Year Year Year 00–99

07h A1M1 10 Seconds Seconds

08h A1M2 10 Minutes Minutes

09h A1M3

0Ah A1M4

0Bh A2M2 10 Minutes Minutes

0Ch A2M3

0Dh A2M4

0Eh

0Fh OSF DOSF LOS CLKSEL2 CLKSEL1 ECLK A2F A1F

Note: Bits listed as 0 always read back as 0 and cannot be written to a 1.

EOSC

12/24

12/24

DY/DT

12/24

DY/DT

AM/PM

10hr

AM/PM

10hr

AM/PM

10hr

0 EGFIL RS2 RS1 INTCN A2IE A1IE Control —

10hr Hour Hours

10hr Hour

10 Date

10hr Hour

10 Date

The I2C interface is guaranteed to operate when VCC is

between 1.8V and 5.5V and the EOSC bit is 0. The I2C

interface is accessible whenever VCC is at a valid level.

To prevent invalid device operation, the I2C interface

should not be accessed when VCC is below +1.8V.

If a microcontroller connected to the DS1341/DS1342

resets during I2C communications, it is possible that the

microcontroller and the DS1341/DS1342 could become

unsynchronized. When the microcontroller resets, the

DS1341/DS1342 I2C interface can be placed into a

Month/

Century

Alarm 1

Seconds

Alarm 1

Minutes

Alarm 1

Hours

Day,

Date

Day,

Date

Alarm 1 Day,

Alarm 1 Date

Alarm 2

Minutes

Alarm 2

Hours

Alarm 2 Day,

Alarm 2 Date

Control/

Status

I2C Interface

1–12+AM/PM

01–12 + Century

1–12 + AM/PM

1–12 + AM/PM

00–23

00–59

00–59

00–23

1–7

1–31

00–59

00–23

1–7

1–31

—

8

Page 9

Low-Current I2C RTCs for High-ESR Crystals

known state by holding SCL low for t

limits the minimum frequency at which the I2C interface

can be operated. If data is being written to the device

when the interface timeout is exceeded, prior to the

acknowledge, the incomplete byte of data is not written.

TIMEOUT

. Doing so

Clock and Calendar (00h–06h)

The time and calendar information is obtained by reading the appropriate register bytes. The RTC registers are

illustrated in Table 1. The time and calendar are set or

initialized by writing the appropriate register bytes. The

contents of the time and calendar registers are in the

binary-coded decimal (BCD) format. The Day register

increments at midnight and rolls over from 7 to 1. Values

that correspond to the day-of-week are user-defined

but must be sequential (i.e., if 1 equals Sunday, then 2

equals Monday, and so on). The CENT bit in the Month

register toggles when the Years register rolls over from

99 to 00. Illogical time and date entries result in an undefined operation.

The DS1341/DS1342 can be run in either 12hr or 24hr

mode. Bit 6 of the Hours register is defined as the 12hr

or 24hr mode select bit. When high, the 12hr mode is

selected. In the 12hr mode, bit 5 is the AM/PM bit, with

a content of 1 being PM. In the 24hr mode, bit 5 is the

second bit of the 10hr field. The century bit (bit 7 of the

DS1341/DS1342

Month register) is toggled when the Years register increments from 99 to 00. On a power-on reset (POR), the

time and date are set to 00:00:00 00/01/01 and the Day

register is set to 01.

Alarms (07h–0Dh)

The DS1341/DS1342 contain two time-of-day/date

alarms. Alarm 1 can be set by writing to registers 07h–

0Ah. Alarm 2 can be set by writing to registers 0Bh–0Dh.

The alarms can be programmed to activate the CLKIN/

INTA or SQW/INTB outputs (see Table 5) on an alarm

match condition. Bit 7 of each of the time of day/date

alarm registers are mask bits. When all the mask bits for

each alarm are 0, an alarm only occurs when the values

in the timekeeping registers 00h–06h match the values

stored in the time of day/date alarm registers. The alarms

can also be programmed to repeat every second, minute, hour, day, or date. Tables 2 and 3 show the possible

alarm settings. Configurations not listed in the tables

result in illogical operation. POR values are undefined.

The DY/DT bits (bit 6 of the alarm day/date registers)

control whether the alarm value stored in bits 0 to 5 of

that register reflects the day of the week or the date of

the month. If DY/DT is written to 0, the alarm is the result

Table 2. Alarm 1 Mask Bits

DY/DT

X 1 1 1 1 Alarm once per second.

X 1 1 1 0 Alarm when seconds match.

X 1 1 0 0 Alarm when minutes and seconds match.

X 1 0 0 0 Alarm when hours, minutes, and seconds match.

0 0 0 0 0 Alarm when date, hours, minutes, and seconds match.

1 0 0 0 0 Alarm when day, hours, minutes, and seconds match.

X = Don’t care.

ALARM 1 MASK BITS (BIT 7)

A1M4 A1M3 A1M2 A1M1

ALARM RATE

Table 3. Alarm 2 Mask Bits

DY/DT

X 1 1 1 Alarm once per minute (00 second of every minute).

X 1 1 0 Alarm when minutes match.

X 1 0 0 Alarm when hours and minutes match.

0 0 0 0 Alarm when date, hours, and minutes match.

1 0 0 0 Alarm when day, hours, and minutes match.

X = Don’t care.

ALARM 2 MASK BITS (BIT 7)

A2M4 A2M3 A2M2

ALARM RATE

9

Page 10

Low-Current I2C RTCs for High-ESR Crystals

of a match with date of the month. If DY/DT is written to

1, the alarm is the result of a match with day of the week.

When the RTC register values match alarm register settings, the corresponding alarm flag bit (A1F or A2F) is

set to 1 in the Control/Status register. If the corresponding alarm interrupt enable bit (A1IE or A2IE) is also set

to 1 in the Control register, the alarm condition activates

the output(s) defined by the ECLK and INTCN bits (see

Table 5).

Control Register (0Eh)

Bit 7: Enable Oscillator (EOSC). When the EOSC bit

is 0, the oscillator is enabled. When this bit is a 1, the

oscillator is disabled. This bit is cleared (0) when power

DS1341/DS1342

is first applied.

Bit 6: No Function

Bit 5: Enable Glitch Filter (EGFIL). When the EGFIL bit

is 1, the 5Fs glitch filter at the output of the crystal oscillator is enabled. The glitch filter is disabled when this bit

is 0. Disabling the glitch filter is useful in reducing power

consumption. This bit is cleared (0) when power is first

applied.

Bits 4 and 3: Rate Select (RS[2:1]). These bits control the frequency of the square-wave output when the

square wave has been enabled. Table 4 shows the

square-wave frequencies that can be selected with the

RS bits. These bits are both set to 1 (32.768kHz) when

power is first applied.

The 32.768kHz oscillator is the source of all square-wave

output frequencies. Frequencies above 1Hz are not conditioned by CLKIN. The 1Hz output is the 32.768kHz oscillator frequency, divided down to 1Hz and conditioned by

CLKIN, provided that the CLKIN frequency differs by no

more than Q0.8% from the crystal frequency. Cycle-tocycle jitter of the 1Hz square wave can be up to 2ms.

Bit 2: Interrupt Control (INTCN). This bit controls the

relationship between the two alarms and the interrupt

output pins. When the INTCN bit is 0, a square wave is

output on the SQW/INTB pin, and the state of the ECLK

bit determines the function of the CLKIN/INTA pin (see

Table 5). When the INTCN bit is 1 and the ECLK bit is a

0, a match between the timekeeping registers and the

alarm 1 registers activates the CLKIN/INTA pin (provided

that the alarm is enabled) and a match between the

timekeeping registers and the alarm 2 registers activates

the SQW/INTB pin (provided that the alarm is enabled).

When the INTCN bit is 1 and the ECLK bit is a 1, a match

between the timekeeping registers and the alarm 1

registers or a match between the timekeeping registers

and the alarm 2 registers activates the SQW/INTB pin

(provided that the alarm is enabled). This bit is cleared

(0) when power is first applied.

Bit 1: Alarm 2 Interrupt Enable (A2IE). When the A2IE

bit is 0, the alarm 2 interrupt function is disabled. When

the A2IE bit is 1, the alarm 2 interrupt function is enabled

and is routed to an output, based upon the steering

defined by the INTCN and ECLK bits, as noted in Table

5. Regardless of the state of A2IE, a match between

the timekeeping registers and the alarm 2 registers

(0Bh–0Dh) sets the alarm 2 flag bit (A2F). This bit is

cleared (0) when power is first applied.

Bit 0: Alarm 1 Interrupt Enable (A1IE). When the A1IE

bit is 0, the alarm 1 interrupt function is disabled. When

the A1IE bit is 1, the alarm 1 interrupt function is enabled

and is routed to an output, based upon the steering

defined by the INTCN and ECLK bits, as noted in Table

5. Regardless of the state of A1IE, a match between the

timekeeping registers and the alarm 1 registers (07h–

0Ah) sets the alarm 1 flag bit (A1F). This bit is cleared (0)

when power is first applied.

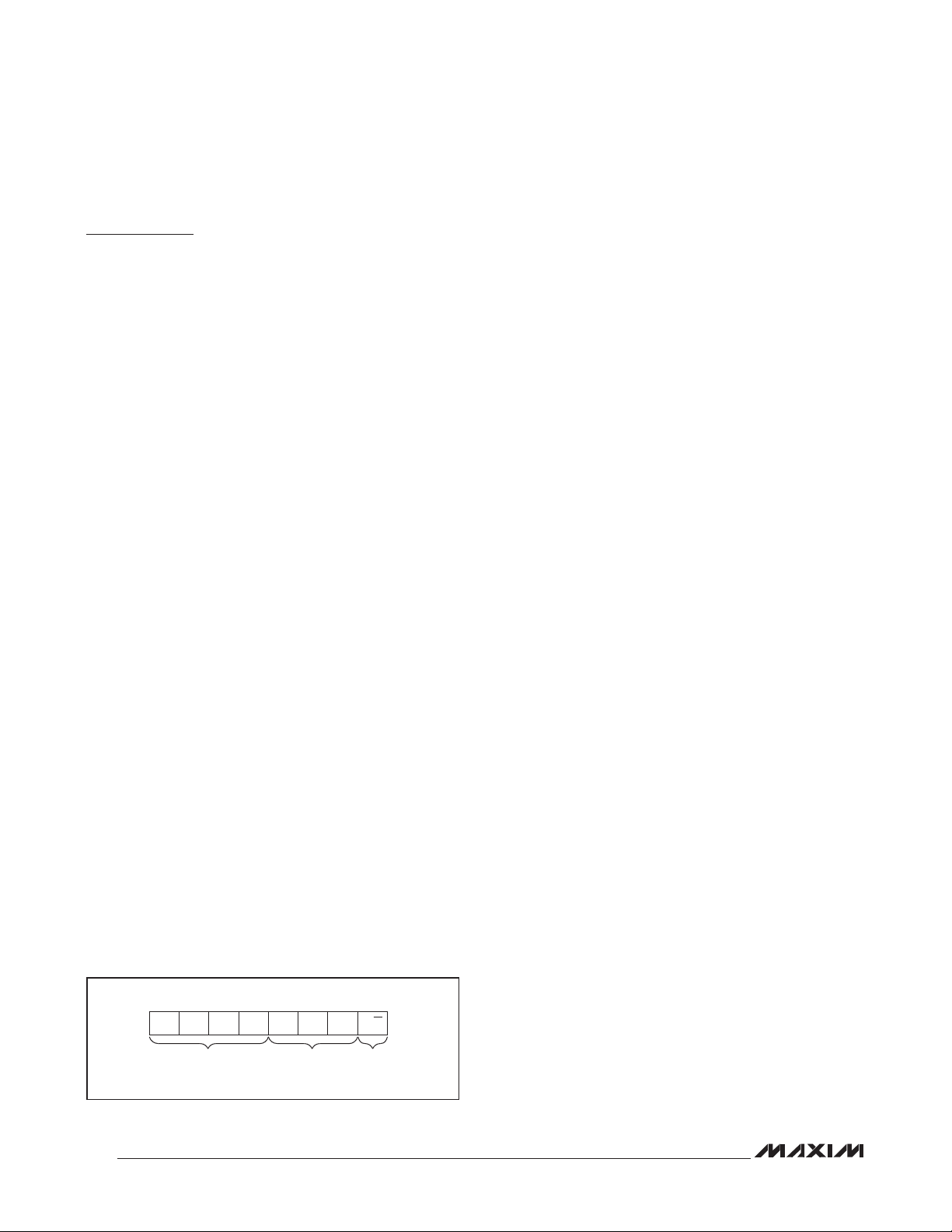

Control Register Bitmap (0Eh)

BIT 7

EOSC

0 0 0 1 1 0 0 0

BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0 EGFIL RS2 RS1 INTCN A2IE A1IE

Table 4. SQW/INTB Output Settings Table 5. Interrupt Output Routing

RS2 RS1

0 0 1Hz

0 1 4.098kHz

1 0 8.192kHz

1 1 32.768kHz

10

SQW/INTB

INTCN ECLK

0 0 A1F + A2F SQW

0 1 CLKIN Input SQW

1 0 A1F A2F

1 1 CLKIN Input A1F + A2F

CLKIN/INTA SQW/INTB

Page 11

Low-Current I2C RTCs for High-ESR Crystals

Control/Status Register Bitmap (0Fh)

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

OSF DOSF LOS CLKSEL2 CLKSEL1 ECLK A2F A1F

1 0 1 0 0 0 X X

Control/Status Register (0Fh)

Bit 7: Oscillator Stop Flag (OSF). If the OSF bit is a 1,

that indicates the oscillator has stopped or was stopped

for some period of time, and could be used to judge

the validity of the clock and calendar data. This bit is

edge triggered and is set to 1 when the internal circuitry

senses the oscillator has transitioned from a normal run

state to a STOP condition. The following are examples of

conditions that can cause the OSF bit to be set:

1) Power is applied for the first time.

2) The voltage present on VCC is insufficient to support

oscillation.

3) The EOSC bit is turned off.

4) There are external influences on the crystal (e.g.,

noise, leakage, etc.).

This bit remains at 1 until written to 0. Attempting to write

OSF to 1 leaves the value unchanged.

Bit 6: Disable Oscillator Stop Flag (DOSF). This bit,

when set to 1, disables the sensing of the oscillator

conditions that would set the OSF bit. OSF remains

at 0 regardless of what happens to the oscillator.

This bit is cleared (0) when power is first applied.

Disabling the oscillator sensing is useful in reducing

power consumption.

Bit 5: Loss of Signal (LOS). This status bit indicates the

state of the CLKIN pin. The bit is set to 1 when the RTC

counter is no longer conditioned by the external clock.

This happens when ECLK = 0, or when the clock signal

at CLKIN stops toggling, or when the CLKIN frequency

differs more than Q0.8% from the selected input frequency. This bit remains at 1 until written to 0. Attempting

to write LOS to 1 leaves the value unchanged. Clearing

the LOS flag when the CLKIN frequency is invalid inhibits

subsequent detections of the input frequency deviation.

Bits 4 and 3: Select Clock Source (CLKSEL[2:1]).

These two register bits select the clock source to drive

the RTC counter. Table 6 lists the input frequencies that

can be selected. Upon power-up, the bits are cleared to

0 and the 1Hz rate is selected.

Table 6. Input Frequency Options

CLKSEL2 CLKSEL1

0 0 1Hz Input

0 1 50Hz Input

1 0 60Hz Input

1 1 32.768kHz Input

Bit 2: Enable External Clock Input (ECLK). This bit

controls the direction of the CLKIN/INTA pin (see Table

5). When the ECLK bit is 1, the CLKIN/INTA pin is an

input, with the expected input rate defined by the state

of CLKSEL2 and CLKSEL1 (see Table 6).

When the ECLK bit is 0, the CLKIN/INTA pin is an

interrupt output (see Table 5). If the INTCN bit is 0,

CLKIN/INTA contains the status of A1F (provided that

the A1IE bit is 1) or A2F (provided that the A2IE bit is 1).

If the INTCN bit is 1, CLKIN/INTA contains the status of

A1F (provided that the A1IE bit is 1).

This bit is set to 0 when power is first applied.

Bit 1: Alarm 2 Flag (A2F). A 1 in the alarm 2 flag bit

indicates that the time matched the alarm 2 registers.

This flag can be used to generate an interrupt on either

CLKIN/INTA or SQW/INTB depending on the status of

the INTCN bit in the Control register. If the INTCN bit is

set to 0 and A2F bit is a 1 (and A2IE bit is also 1), the

CLKIN/INTA pin goes low. If the INTCN bit is set to 1 and

A2F bit is 1 (and A2IE bit is also 1), the SQW/INTB pin

goes low. The A2F bit is cleared when written to 0. This

bit can only be written to 0. Attempting to write this bit to

1 leaves the value unchanged.

Bit 0: Alarm 1 Flag (A1F). A 1 in the alarm 1 flag bit

indicates that the time matched the alarm 1 registers. If

the A1IE bit is also 1, the CLKIN/INTA pin goes low. A1F

is cleared when written to 0. This bit can only be written

to 0. Attempting to write this bit to 1 leaves the value

unchanged.

DS1341/DS1342

CLKIN/INTA

11

Page 12

Low-Current I2C RTCs for High-ESR Crystals

I2C Serial Port Operation

I2C Slave Address

The DS1341/DS1342s’ slave address byte is D0h. The

first byte sent to the device includes the device identifier,

device address, and the R/W bit (Figure 5). The device

address sent by the I2C master must match the address

assigned to the device.

I2C Definitions

The following terminology is commonly used to describe

I2C data transfers.

Master Device: The master device controls the slave

devices on the bus. The master device generates

DS1341/DS1342

SCL clock pulses and START and STOP conditions.

Slave Devices: Slave devices send and receive data

at the master’s request.

Bus Idle or Not Busy: Time between STOP and

START conditions when both SDA and SCL are

inactive and in their logic-high states. When the bus

is idle, it often initiates a low-power mode for slave

devices.

START Condition: A START condition is generated

by the master to initiate a new data transfer with a

slave. Transitioning SDA from high to low while SCL

remains high generates a START condition. See

Figure 1 for applicable timing.

STOP Condition: A STOP condition is generated

by the master to end a data transfer with a slave.

Transitioning SDA from low to high while SCL remains

high generates a STOP condition. See Figure 1 for

applicable timing.

Repeated START Condition: The master can use

a repeated START condition at the end of one data

transfer to indicate that it immediately initiates a new

data transfer following the current one. Repeated

STARTs are commonly used during read operations

to identify a specific memory address to begin a data

transfer. A repeated START condition is issued identically to a normal START condition. See Figure 1 for

applicable timing.

MSB

1 1 10 R/W000

DEVICE

IDENTIFIER

Figure 5. Slave Address Byte

DEVICE

ADDRESS

LSB

READ/

WRITE BIT

Bit Write: Transitions of SDA must occur during

the low state of SCL. The data on SDA must remain

valid and unchanged during the entire high pulse of

SCL plus the setup and hold time requirements (see

Figure 1). Data is shifted into the device during the

rising edge of the SCL.

Bit Read: At the end of a write operation, the master

must release the SDA bus line for the proper amount

of setup time (see Figure 1) before the next rising

edge of SCL during a bit read. The device shifts out

each bit of data on SDA at the falling edge of the

previous SCL pulse and the data bit is valid at the

rising edge of the current SCL pulse. Remember that

the master generates all SCL clock pulses including

when it is reading bits from the slave.

Acknowledge (ACK and NACK): An acknowledge

(ACK) or not acknowledge (NACK) is always the

ninth bit transmitted during a byte transfer. The

device receiving data (the master during a read or

the slave during a write operation) performs an ACK

by transmitting a 0 during the ninth bit. A device performs a NACK by transmitting a 1 during the ninth bit.

Timing for the ACK and NACK is identical to all other

bit writes. An ACK is the acknowledgment that the

device is properly receiving data. A NACK is used to

terminate a read sequence or as an indication that the

device is not receiving data.

Byte Write: A byte write consists of 8 bits of information transferred from the master to the slave (most

significant bit first) plus a 1-bit acknowledgment from

the slave to the master. The 8 bits transmitted by the

master are done according to the bit write definition

and the acknowledgment is read using the bit read

definition.

Byte Read: A byte read is an 8-bit information transfer

from the slave to the master plus a 1-bit ACK or NACK

from the master to the slave. The 8 bits of information

that are transferred (most significant bit first) from the

slave to the master are read by the master using the

bit read definition, and the master transmits an ACK

using the bit write definition to receive additional data

bytes. The master must NACK the last byte read to

terminate communication so the slave returns control

of SDA to the master.

Slave Address Byte: Each slave on the I2C bus

responds to a slave address byte sent immediately

following a START condition. The slave address byte

contains the slave address in the most significant 7

bits and the R/W bit in the least significant bit. The

12

Page 13

Low-Current I2C RTCs for High-ESR Crystals

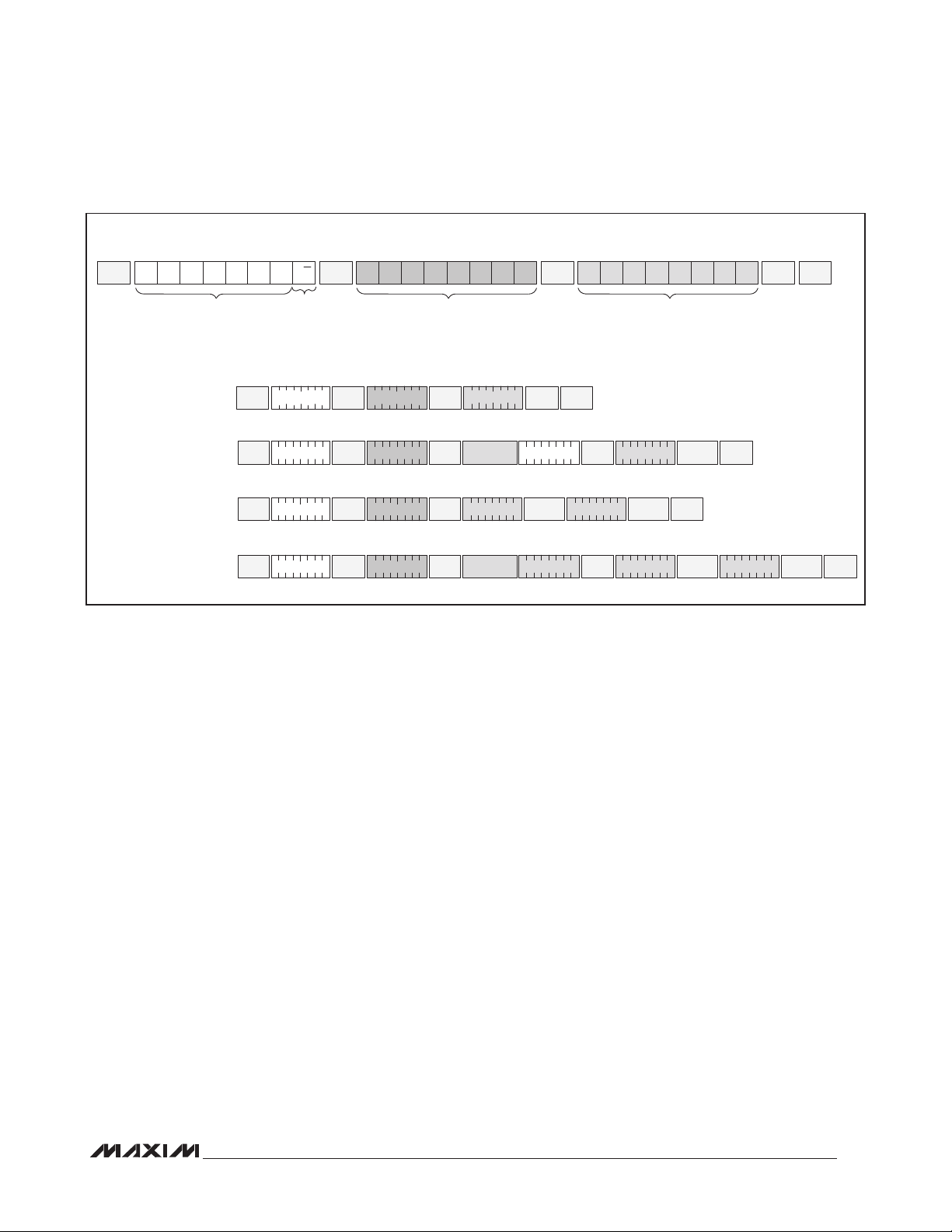

2

C WRITE TRANSACTION

TYPICAL I

MSB LSB MSB LSB MSB LSB

START

1 1 0 1 0 0 0

R/W

SLAVE

b7 b6 b5 b4 b3 b2 b1 b0

ACK

SLAVE

b7 b6 b5 b4 b3 b2 b1 b0

ACK

SLAVE

ACK

DS1341/DS1342

STOP

READ/

WRITE

D0h 0Eh

1 1 0 1 0 0 0 0 0 0 0 0 1 1 1 0

SLAVE

ACK

D0h

SLAVE

ACK

D0h 04h

SLAVE

ACK

D0h 0Ch

SLAVE

ACK

0Eh

2

EXAMPLE I

C TRANSACTIONS

A)

SINGLE BYTE WRITE

-WRITE CONTROL REGISTER

TO 18h

B)

SINGLE BYTE READ

-READ CONTROL REGISTER

C)

MULTIBYTE WRITE

-WRITE DATE REGISTER

TO "02" AND MONTH

REGISTER TO "11"

D)

MULTIBYTE READ

-READ ALARM 2 HOURS

AND DATE VALUES

SLAVE

ADDRESS

START

START

START 1 1 0 1 0 0 0 0 0 0 0 0 0 1 0 0

START 1 1 0 1 0 0 0 0 0 0 0 0 1 1 0 0

Figure 6. I2C Transactions

DS1341/DS1342s’ slave address is D0h and cannot

be modified by the user. When the R/W bit is 0 (such

as in D0h), the master is indicating it writes data to the

slave. If R/W = 1 (D1h in this case), the master is indicating it wants to read from the slave. If an incorrect

slave address is written, the DS1341/DS1342 assume

the master is communicating with another I2C device

and ignore the communication until the next START

condition is sent.

Memory Address: During an I2C write operation, the

master must transmit a memory address to identify

the memory location where the slave is to store the

data. The memory address is always the second byte

transmitted during a write operation following the

slave address byte.

I2C Communication

See Figure 6 for an I2C communication example.

Writing a Single Byte to a Slave: The master must

generate a START condition, write the slave address

byte (R/W = 0), write the memory address, write

the byte of data, and generate a STOP condition.

Remember the master must read the slave’s acknowledgment during all byte write operations.

REGISTER ADDRESS

SLAVE

0 0 0 1 1 0 0 0

ACK

SLAVE

ACK

SLAVE

0 0 0 0 0 0 1 0

ACK

SLAVE

ACK

DATA

18h

SLAVE

STOP

ACK

REPEATED

START

02h

REPEATED

START

D1h

D1h

SLAVE

ACK

11h

0 0 0 1 0 0 0 1

SLAVE

ACK

1 1 0 1 0 0 0 1

SLAVE

ACK

1 1 0 1 0 0 0 1 VALUE

DATA

VALUE

SLAVE

ACK

DATA

MASTER

NACK

STOP

MASTER

STOP1 1 0 1 0 0 0 0 0 0 0 0 1 1 1 0

DATA

ACK

Writing Multiple Bytes to a Slave: To write multiple

bytes to a slave, the master generates a START condition, writes the slave address byte (R/W = 0), writes

the starting memory address, writes multiple data

bytes, and generates a STOP condition.

Reading a Single Byte from a Slave: Unlike the write

operation that uses the specified memory address

byte to define where the data is to be written, the read

operation occurs at the present value of the memory

address counter. To read a single byte from the slave,

the master generates a START condition, writes the

slave address byte with R/W = 1, reads the data byte

with a NACK to indicate the end of the transfer, and

generates a STOP condition. However, since requiring the master to keep track of the memory address

counter is impractical, use the method for manipulating the address counter for reads.

Manipulating the Address Counter for Reads: A

dummy write cycle can be used to force the address

counter to a particular value. To do this the master generates a START condition, writes the slave

address byte (R/W = 0), writes the memory address

where it desires to read, generates a repeated START

condition, writes the slave address byte (R/W = 1),

MASTER

NACK

STOPVALUE

13

Page 14

Low-Current I2C RTCs for High-ESR Crystals

reads data with ACK or NACK as applicable, and

generates a STOP condition. See Figure 6 for a read

example using the repeated START condition to

specify the starting memory location.

Reading Multiple Bytes from a Slave: The read

operation can be used to read multiple bytes with a

single transfer. When reading bytes from the slave,

the master simply ACKs the data byte if it desires to

read another byte before terminating the transaction.

After the master reads the last byte it must NACK to

indicate the end of the transfer and then it generates

a STOP condition.

Bus Timeout

DS1341/DS1342

To avoid an unintended I2C interface timeout, SCL

should not be held low longer than t

I2C interface is in the reset state and can receive a

new START condition when SCL is held low for at least

t

TIMEOUTMAX

SDA is released and allowed to be pulled high by the

external pullup resistor. For the timeout function to work,

the oscillator must be enabled and running.

. When the device detects this condition,

TIMEOUTMIN

. The

Applications Information

Power-Supply Decoupling

To achieve the best results when using the DS1341/

DS1342, decouple the VCC power supply with a 0.01FF

and/or 0.1FF capacitor. Use a high-quality, ceramic, surface-mount capacitor if possible. Surface-mount compo-

nents minimize lead inductance, which improves performance, and ceramic capacitors tend to have adequate

high-frequency response for decoupling applications.

Using Open-Drain Outputs

The CLKIN/INTA output is open drain and, therefore,

requires an external pullup resistor to realize a logic-high

output level.

SDA and SCL Pullup Resistors

SDA is an open-drain output and requires an external

pullup resistor to realize a logic-high level.

Because the DS1341/DS1342 do not use clock cycle

stretching, a master using either an open-drain output

with a pullup resistor or CMOS output driver (push-pull)

could be used for SCL.

Chip Information

SUBSTRATE CONNECTED TO GROUND

Package Information

For the latest package outline information and land patterns, go to www.maxim-ic.com/packages. Note that

a “+”, “#”, or “-” in the package code indicates RoHS

status only. Package drawings may show a different suffix character, but the drawing pertains to the package

regardless of RoHS status.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

8 FSOP

U8+1

21-0036

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time.

14 Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

©

2009 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...