Page 1

www.maxim-ic.com

NT

www.maxim-ic.com

DS1339

Serial Real-Time Clock

FEATURES

§ Real-time clock (RTC) counts seconds,

minutes, hours, day, date, month, and year

with leap-year compensation valid up to 2100

§ 2-wire serial interface

§ Two time-of-day alarms

§ Programmable square-wave output

§ Oscillator stop flag

§ Automatic power-fail detect and switch

circuitry

§ Trickle charge capability

ORDERING INFORMATION

PART

DS1339U-2 8 µSOP 1339 ##-2

DS1339U-3 8 µSOP 1339 ##-3

DS1339U-33 8 µSOP 1339 ##-33

## = second line, revision code

2 = 2.0V, V

3 = 3.0V, V

33 = 3.3V, V

±10%

CC

±10%

CC

CC

±10%

PIN-

PACKAGE

TOP MARK

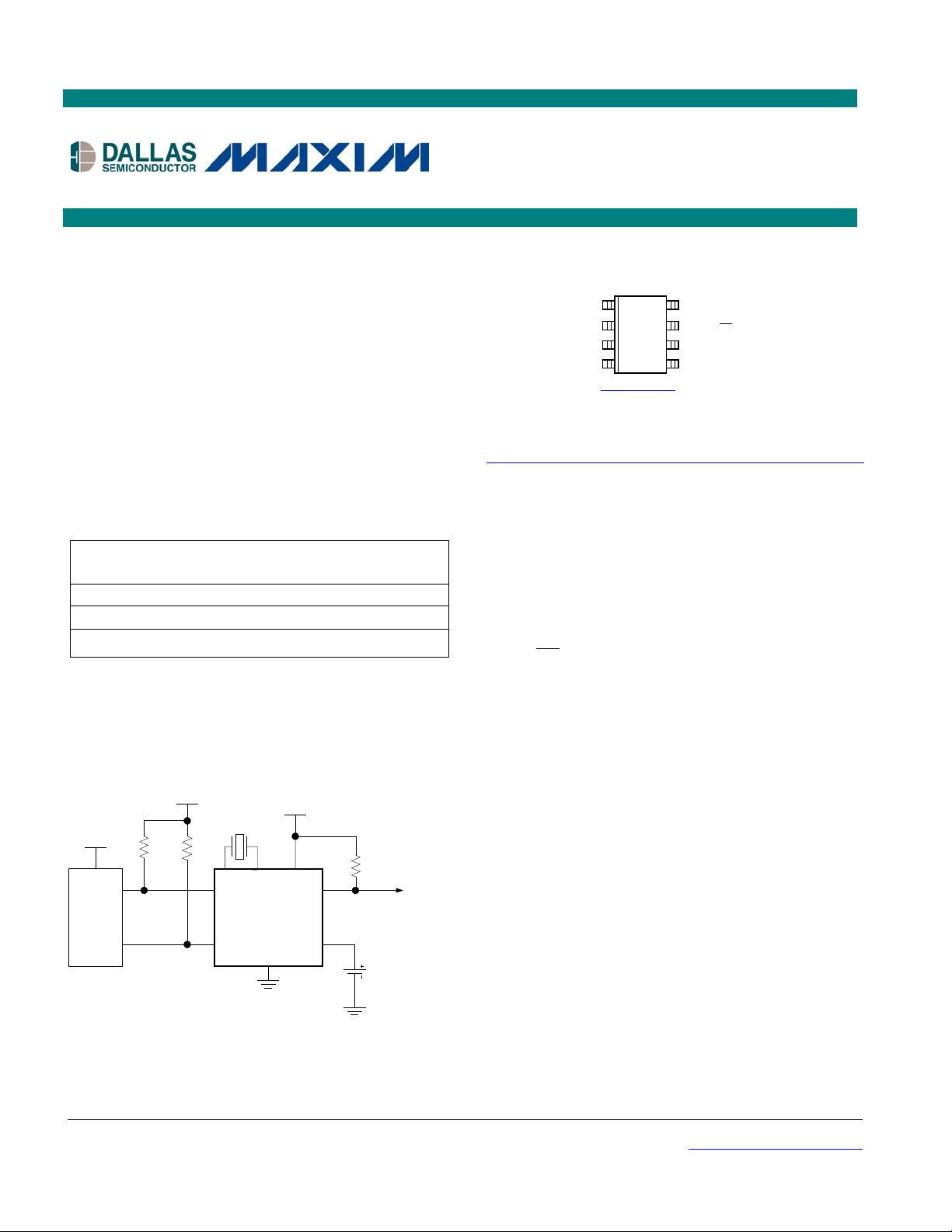

TYPICAL OPERATING CIRCUIT

VCC

CPU

RPU RPU

VCC

CRYSTAL

12

6

SCL

5

SDA

X2X1

SQW /INT

DS1339

VBACKUP

GND

4

VCC

VCC

8

7

i

3

PIN ASSIGNMENT (Top View)

X1

X2

V

BACKUP

GND

8-Pin mSOP

Package Dimension Information

http://www.maxim-ic.com/TechSupport/DallasPackInfo.htm

V

CC

SQW/

SCL

SDA

I

PIN DESCRIPTION

V

CC

X1, X2 - 32.768kHz Crystal Connection

GND - Ground

SDA - Serial Data

SCL - Serial Clock

V

BACKUP

- Secondary Power Supply

SQW/ INT - Square-Wave/Interrupt Output

- Power Supply

APPLICATIONS

§ Handhelds (GPS, POS Terminal)

§ Consumer Electronics (Set-Top Box, Digital

Recording, Network Appliance)

§ Office Equipment (Fax/Printer, Copier)

§ Medical (Glucometer, Medicine Dispenser)

§ Telecommunications (Router, Switcher,

Server)

§ Other (Utility Meter, Vending Machine,

Thermostat, Modem)

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, click here: http://www.maxim-ic.com/errata.

1 of 18 072302

Page 2

DS1339

DESCRIPTION

The DS1339 serial real-time clock is a low-power clock/date device with two programmable time-of-day

alarms and a programmable square-wave output. Address and data are transferred serially by a 2-wire

bidirectional bus. The clock/date provides seconds, minutes, hours, day, date, month, and year

information. The date at the end of the month is automatically adjusted for months with fewer than 31

days, including corrections for leap year. The clock operates in either the 24-hour or 12-hour format with

AM/PM indicator. The DS1339 has a built-in power-sense circuit that detects power failures and

automatically switches to the backup supply.

OPERATION

The DS1339 operates as a slave device on the serial bus. Access is obtained by implementing a START

condition and providing a device identification code followed by data. Subsequent registers can be

accessed sequentially until a STOP condition is executed. The device is fully accessible and data can be

written and read when VCC is greater than VPF. However, when VCC falls below VPF, the internal clock

registers are blocked from any access. If VPF is less than V

to V

BACKUP

VCC to V

when VCC drops below VPF. If VPF is greater than V

BACKUP

when VCC drops below V

BACKUP

. The registers are maintained from the V

BACKUP

, the device power is switched from V

BACKUP

, the device power is switched from

BACKUP

CC

source

until VCC is returned to nominal levels. The block diagram in Figure 1 shows the main elements of the

serial real-time clock.

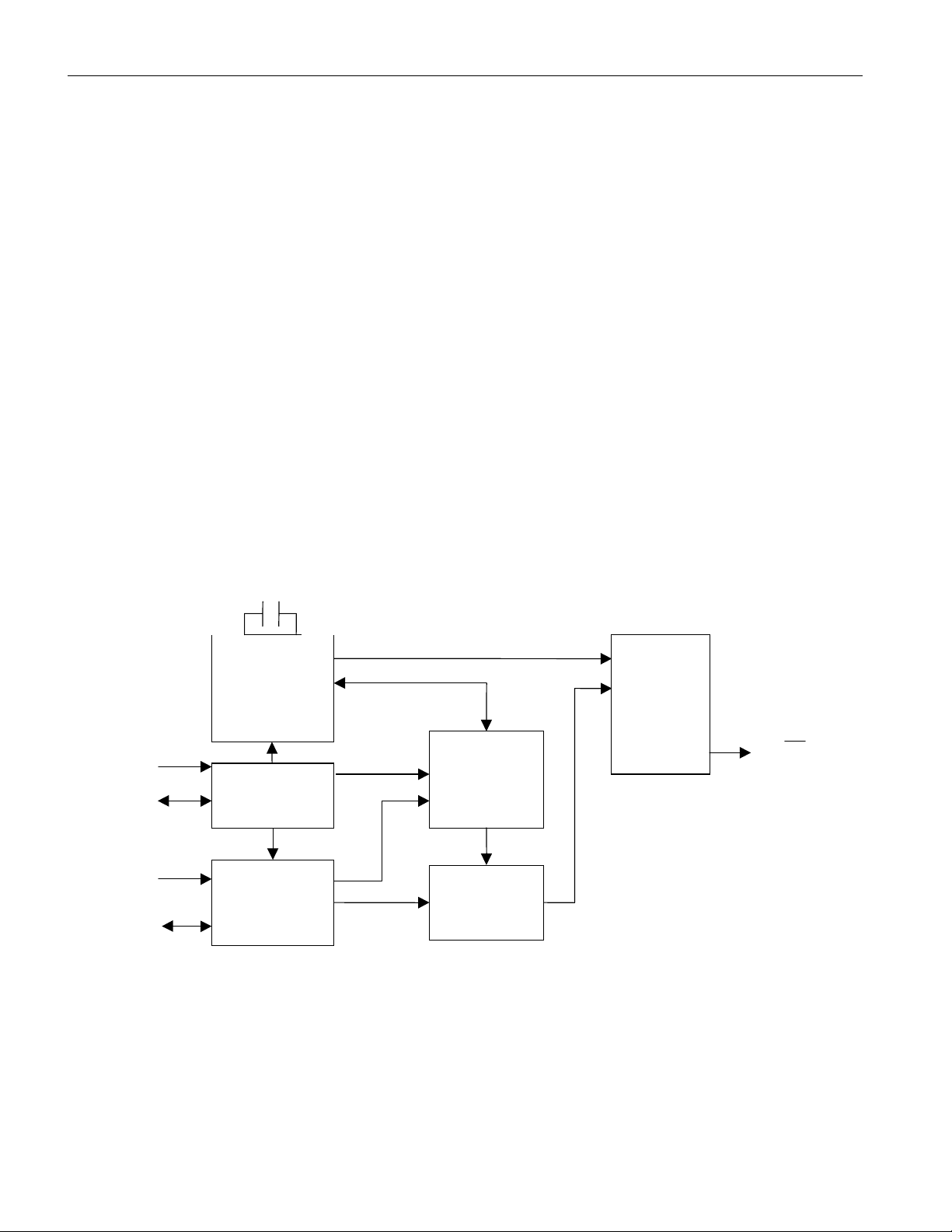

Figure 1. BLOCK DIAGRAM

X1 X2

V

BACKUP

V

CC

SCL

SDA

OSCILLATOR

AND

DIVIDER

POWER

CONTROL

SERIAL BUS

INTERFACE

CONTROL

LOGIC

ADDRESS

REGISTER

TIMEKEEPING,

CONTROL,

AND

TRICKLE

CHARGE

REGISTERS

SQW

/

INT

2 of 18

Page 3

DS1339

SIGNAL DESCRIPTIONS

VCC, GND – DC power is provided to the device on these pins.

SCL (Serial Clock Input) – SCL is used to synchronize data movement on the serial interface.

SDA (Serial Data Input/Output) – SDA is the input/output pin for the 2-wire serial interface. The SDA

pin is an open-drain output and requires an external pullup resistor.

V

BACKUP

(Secondary Supply Input) – Connection for a secondary power supply. Supply voltage must

be held between 1.3V and 3.7V for proper operation. This pin can be connected to a primary cell such as

a lithium button cell. Additionally, this pin can be connected to a rechargeable cell or a super cap when

used with the trickle charge feature.

SQW/ INT (Square-Wave/Interrupt Output) – Programmable square-wave or interrupt-output signal.

The SQW/ INT pin is an open-drain output and requires an external pullup resistor.

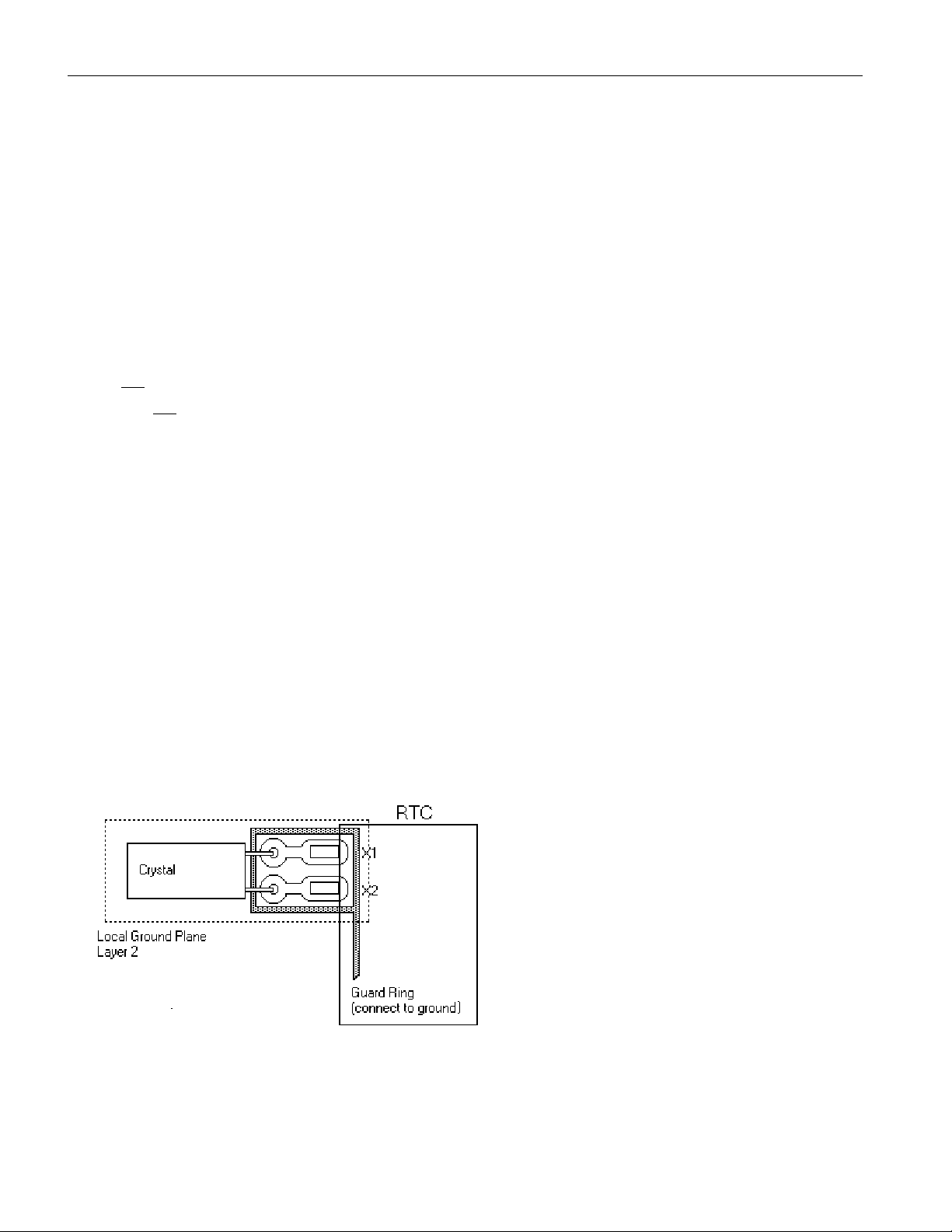

X1, X2 – These signals are connections for a standard 32.768kHz quartz crystal. The internal oscillator

circuitry is designed for operation with a crystal having a specified load capacitance (CL) of 6pF.

For more information about crystal selection and crystal layout considerations, refer to Application Note

58 “Crystal Considerations with Dallas Real-Time Clocks.”

The DS1339 can also be driven by an external 32.768kHz oscillator. In this configuration, the X1 pin is

connected to the external oscillator signal and the X2 pin is floated.

The oscillator is controlled by an enable bit in the control register. Oscillator startup times are highly

dependent upon crystal characteristics, PC board leakage, and layout. High ESR and excessive capacitive

loads are the major contributors to long startup times. A circuit using a crystal with the recommended

characteristics and proper layout usually starts within one second.

TYPICAL PC BOARD LAYOUT FOR CRYSTAL

3 of 18

Page 4

DS1339

CLOCK ACCURACY

The accuracy of the clock is dependent upon the accuracy of the crystal and the accuracy of the match

between the capacitive load of the oscillator circuit and the capacitive load for which the crystal was

trimmed. Additional error is added by crystal frequency drift caused by temperature shifts. External

circuit noise coupled into the oscillator circuit can result in the clock running fast. Refer to Application

Note 58 “Crystal Considerations with Dallas Real-Time Clocks” for detailed information.

ADDRESS MAP

The address map for the registers of the DS1339 is shown in Figure 2. During a multibyte access, when

the address pointer reaches the end of the register space (10h), it wraps around to location 00h. On a 2wire START, STOP, or address pointer incrementing to location 00h, the current time is transferred to a

second set of registers. The time information is read from these secondary registers, while the clock can

continue to run. This eliminates the need to re-read the registers in case of an update of the main registers

during a read.

4 of 18

Page 5

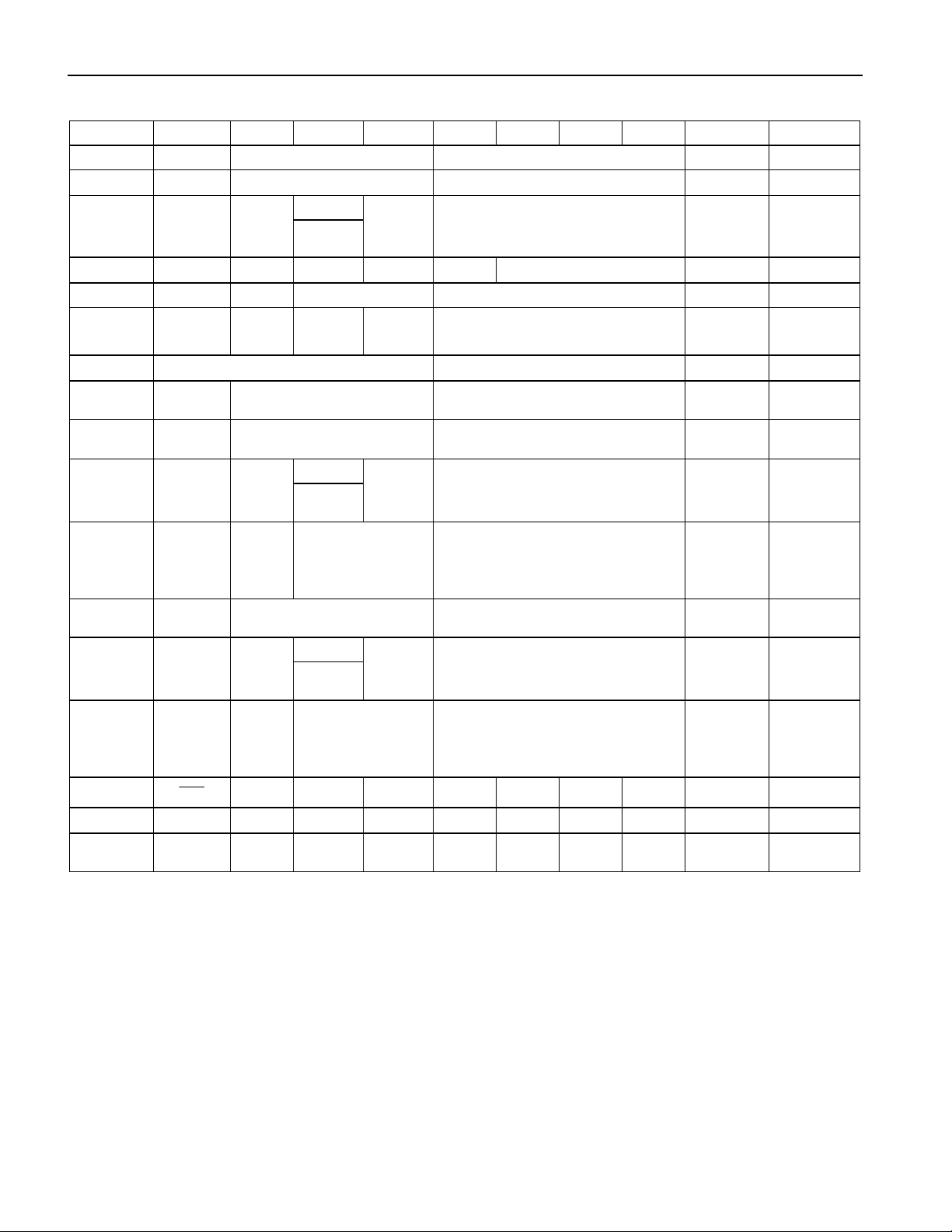

Figure 2. DS1339 TIMEKEEPER REGISTERS

ADDRESS BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0 FUNCTION RANGE

00H 0 10 SECONDS SECONDS Seconds 00–59

01H 0 10 MINUTES MINUTES Minutes 00–59

02H 0 12/24

AM/PM

10HR HOUR Hours

10HR

1–12 +

AM/PM

00–23

03H 0 0 0 0 0 DAY Day 1–7

04H 0 0 10 DATE DATE Date 00–31

05H CENTURY 0 0 10 MO MONTH

Month/

Century

01–12 +

Century

06H 10 YEAR YEAR Year 00–99

07H A1M1 10 SECONDS SECONDS

08H A1M2 10 MINUTES MINUTES

AM/PM

09H A1M3 12/24

10HR HOUR

10HR

Alarm 1

Seconds

Alarm 1

Minutes

Alarm 1

Hours

00–59

00–59

1–12 +

AM/PM

00-23

Alarm 1

0AH A1M4 DY/DT 10 DATE

DAY

DATE

Day

Alarm 1

1–7

1–31

Date

0BH A2M2 10 MINUTES MINUTES

AM/PM

0CH A2M3 12/24

10HR HOUR

10HR

Alarm 2

Minutes

Alarm 2

Hours

00–59

1–12 +

AM/PM

00–23

Alarm 2

0DH A2M4 DY/DT 10 DATE

DAY

DATE

Day

Alarm 2

1–7

1–31

Date

DS1339

0EH

EOSC

0 BBSQI RS2 RS1 INTCN A2IE A1IE Control —

0FH OSF 0 0 0 0 0 A2F A1F Status —

10H TCS3 TCS2 TCS1 TCS0 DS1 DS0 ROUT1 ROUT0

Trickle

Charge

Note: Unless otherwise specified, the registers’ state are not defined when power is first applied or VCC and V

falls below the V

BACKUP

5 of 18

—

BACKUP

min.

Page 6

DS1339

TIME AND DATE OPERATION

The time and date information is obtained by reading the appropriate register bytes. The real-time clock

registers are illustrated in Figure 2. The time and date are set or initialized by writing the appropriate

register bytes. The contents of the time and date registers are in the binary coded decimal (BCD) format.

The DS1339 can be run in either 12-hour or 24-hour mode. Bit 6 of the hours register is defined as the

12-hour or 24-hour mode-select bit. When high, the 12-hour mode is selected. In the 12-hour mode, bit 5

is the AM/PM bit with logic high being PM. In the 24-hour mode, bit 5 is the second 10-hour bit (20–23

hours). All hours values, including the alarms, must be re-entered whenever the 12/24-hour mode bit is

changed. The century bit (bit 7 of the month register) is toggled when the years register overflows from

99 to 00. The day-of-week register increments at midnight. Values that correspond to the day of week are

user-defined, but must be sequential (i.e., if 1 equals Sunday, then 2 equals Monday, and so on). Illogical

time and date entries result in undefined operation.

When reading or writing the time and date registers, secondary (user) buffers are used to prevent errors

when the internal registers update. When reading the time and date registers, the user buffers are

synchronized to the internal registers on any START or STOP, and when the address pointer rolls over to

0. The countdown chain is reset whenever the seconds register is written. Write transfers occur on the

acknowledge pulse from the device. To avoid rollover issues, once the countdown chain is reset, the

remaining time and date registers must be written within one second. The 1Hz square-wave output, if

enabled, transitions high 500ms after the seconds data transfer, provided the oscillator is already running.

ALARMS

The DS1339 contains two time-of-day/date alarms. Alarm 1 can be set by writing to registers 07h to 0Ah.

Alarm 2 can be set by writing to registers 0Bh to 0Dh. The alarms can be programmed (by the alarm

enable and INTCN bits of the control register) to activate the SQW/ INT output on an alarm match

condition. Bit 7 of each of the time-of-day/date alarm registers are mask bits (Figure 3). When all of the

mask bits for each alarm are logic 0, an alarm only occurs when the values in the timekeeping registers

00h–06h match the values stored in the time-of-day/date alarm registers. The alarms can also be

programmed to repeat every second, minute, hour, day, or date. Figure 3 shows the possible settings.

Configurations not listed in the table result in illogical operation.

The DY/DT bits (bit 6 of the alarm day/date registers) control whether the alarm value stored in bits 0 to

5 of that register reflects the day of the week or the date of the month. If DY/DT is written to a logic 0,

the alarm is the result of a match with date of the month. If DY/DT is written to a logic 1, the alarm is the

result of a match with day of the week.

When the RTC register values match alarm register settings, the corresponding alarm flag (A1F or A2F)

bit is set to logic 1. If the corresponding alarm interrupt enable (A1IE or A2IE) is also set to logic 1 and

the INTCN bit is set to logic 1, the alarm condition activates the SQW/

INT signal.

6 of 18

Page 7

Figure 3. ALARM MASK BITS

ALARM 1 REGISTER MASK BITS

DY/DT

A1M4 A1M3 A1M2 A1M1

X 1 1 1 1 Alarm once per second

X 1 1 1 0 Alarm when seconds match

X 1 1 0 0 Alarm when minutes and seconds match

X 1 0 0 0 Alarm when hours, minutes, and seconds match

0 0 0 0 0 Alarm when date, hours, minutes, and seconds match

1 0 0 0 0 Alarm when day, hours, minutes, and seconds match

ALARM 2 REGISTER MASK BITS

DY/DT

A2M4 A2M3 A2M2

X 1 1 1 Alarm once per minute (00 second of every minute)

X 1 1 0 Alarm when minutes match

X 1 0 0 Alarm when hours and minutes match

0 0 0 0 Alarm when date, hours, and minutes match

1 0 0 0 Alarm when day, hours, and minutes match

(BIT 7)

(BIT 7)

ALARM RATE

ALARM RATE

DS1339

SPECIAL PURPOSE REGISTERS

The DS1339 has two additional registers (control and status) that control the RTC, alarms, and squarewave output.

CONTROL REGISTER (0Eh)

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

EOSC

EOSC (Enable Oscillator) – This bit when set to logic 0 starts the oscillator. When this bit is set to a

logic 1, the oscillator is stopped. This bit is enabled (logic 0) when power is first applied.

BBSQI (Battery-Backed Square-Wave and Interrupt Enable) – This bit when set to a logic 1 enables

the square-wave or interrupt output when V

pin. When BBSQI is a logic 0, the SQW/ INT pin goes high impedance when VCC falls below the powerfail trip point. This bit is disabled (logic 0) when power is first applied.

RS2 and RS1 (Rate Select) – These bits control the frequency of the square-wave output when the

square wave has been enabled. Figure 4 shows the square-wave frequencies that can be selected with the

RS bits. These bits are both set to logic 1 (32kHz) when power is first applied.

0 BBSQI RS2 RS1 INTCN A2IE A1IE

is absent and the DS1339 is being powered by the V

CC

BACKUP

7 of 18

Page 8

Figure 4. SQUARE-WAVE OUTPUT FREQUENCY

RS2 RS1

SQUARE-WAVE OUTPUT

FREQUENCY

DS1339

0 0 1Hz

0 1 4.096kHz

1 0 8.192kHz

1 1 32.768kHz

INTCN (Interrupt Control) – This bit controls the relationship between the two alarms and the interrupt

output pins. When the INTCN bit is set to logic 1, a match between the timekeeping registers and the

Alarm 1 or Alarm 2 registers activate the SQW/INT pin (provided that the alarms are enabled).When the

INTCN bit is set to logic 0, a square wave is output on the SQW/ INT pin. This bit is set to logic 0 when

power is first applied.

A1IE (Alarm 1 Interrupt Enable) – When set to logic 1, this bit permits the A1F bit in the status

register to assert SQW/ INT (when INTCN = 1). When the A1IE bit is set to logic 0 or INTCN is set to

logic 0, the A1F bit does not initiate the an interrupt signal. The A1IE bit is disabled (logic 0) when

power is first applied.

A2IE (Alarm 2 Interrupt Enable) – When set to a logic 1, this bit permits the A2F bit in the status

register to assert SQW/ INT (when INTCN = 1). When the A2IE bit is set to logic 0 or INTCN is set to

logic 0, the A2F bit does not initiate an interrupt signal. The A2IE bit is disabled (logic 0) when power is

first applied.

STATUS REGISTER (0Fh)

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

OSF 0 0 0 0 0 A2F A1F

OSF (Oscillator Stop Flag) – A logic 1 in this bit indicates that the oscillator either is stopped or was

stopped for some period of time and can be used to judge the validity of the clock and date data. This bit

is edge-triggered and set to logic 1 anytime the oscillator stops. The following are examples of conditions

that can cause the OSF bit to be set:

1) The first time power is applied.

2) The voltage present on both VCC and V

BACKUP

3) The EOSC bit is turned off.

4) External influences on the crystal (e.g., noise, leakage, etc.).

This bit remains at logic 1 until written to logic 0. This bit can only be writte n to a logic 0. Attempting to

write to logic 1 leaves the value unchanged.

A1F (Alarm 1 Flag) – A logic 1 in the A1F bit indicates that the time matched the Alarm 1 registers. If

are insufficient to support oscillation.

the A1IE bit is a logic 1 and the INTCN bit is set to a logic 1, the SQW/ INT pin is also be asserted. A1F

8 of 18

Page 9

DS1339

is cleared when written to logic 0. This bit can only be written to logic 0. Attempting to write to logic 1

leaves the value unchanged.

A2F (Alarm 2 Flag) – A logic 1 in the A2F bit indicates that the time matched the Alarm 2 registers. If

the A2IE bit is a logic 1 and the INTCN bit is set to a logic 1, the SQW/ INT pin is also asserted. A2F is

cleared when written to logic 0. This bit can only be written to logic 0. Attempting to write to logic 1

leaves the value unchanged.

TRICKLE CHARGE REGISTER (10h)

The simplified schematic of Figure 6 shows the basic components of the trickle charger. The tricklecharge select (TCS) bits (bits 4–7) control the selection of the trickle charger. In order to prevent

accidental enabling, only a pattern on 1010 enables the trickle charger. All other patterns disable the

trickle charger. The trickle charger is disabled when power is first applied. The diode select (DS) bits

(bits 2 and 3) select whether or not a diode is connected between VCC and V

0, 1) select the value of the resistor connected between VCC and V

BACKUP

. Bit values are shown in Figure

BACKUP

. The ROUT bits (bits

5.

Figure 5. TRICKLE CHARGE REGISTER (10h) BIT VALUES

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

TCS3 TCS2 TCS1 TCS0 DS1 DS0 ROUT1 ROUT0

FUNCTION

XXXX0 0 X XDisabled

XXXX1 1 X XDisabled

XXXXXX 0 0Disabled

101001 0 1

101010 0 1

101001 1 0

101010 1 0

101001 1 1

101010 1 1

No diode, 250W resistor

One diode, 250W resistor

No diode, 2kW resistor

One diode, 2kW resistor

No diode, 4kW resistor

One diode, 4kW resistor

The user determines diode and resistor selection according to the maximum current desired for battery or

super cap charging. The maximum charging current can be calculated as illustrated in the following

example:

Assume that a system power supply of 3.3V is applied to V

and a super cap is connected to V

CC

BACKUP

Also assume that the trickle charger has been enabled with a diode and resistor R2 between VCC and

V

BACKUP

. The maximum current I

would, therefore, be calculated as follows:

MAX

.

I

= (3.3V - diode drop) / R2 » (3.3V - 0.7V) / 2kW » 1.3mA

MAX

As the super cap or battery charges, the voltage drop between VCC and V

the charge current decreases.

9 of 18

BACKUP

decreases and, therefore,

Page 10

Figure 6. PROGRAMMABLE TRICKLE CHARGE

DS1339

V

CC

NOTE: ONLY 1010 ENABLES CHARGER

1 OF 16 SELECT

1 OF 2

SELECT

1 OF 3

SELECT

TCS3 TCS2 TCS1 TCS0 DS1 DS0 ROUT1 ROUT0

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

TRICKLE CHARGE REGISTER

R1

250W

R2

2kW

R3

4kW

TCS

= TRICKLE CHARGE SELECT

0-3

= DIODE SELECT

DS

0-1

ROUT

= RESISTOR SELECT

0-1

V

BACKUP

10 of 18

Page 11

DS1339

2-WIRE SERIAL DATA BUS

The DS1339 supports a bidirectional 2-wire bus and data transmission protocol. A device that sends data

onto the bus is defined as a transmitter and a device receiving data as a receiver. The device that controls

the message is called a master. The devices that are controlled by the master are referred to as slaves. The

bus must be controlled by a master device that generates the serial clock (SCL), controls the bus access,

and generates the START and STOP conditions. The DS1339 operates as a slave on the 2-wire bus.

Connections to the bus are made by the open-drain I/O lines SDA and SCL.

The following bus protocol has been defined (Figure 7):

§ Data transfer can be initiated only when the bus is not busy.

§ During data transfer, the data line must remain stable whenever the clock line is HIGH. Changes in

the data line while the clock line is HIGH are interpreted as control signals.

Accordingly, the following bus conditions have been defined:

Bus Not Busy: Both data and clock lines remain HIGH.

Start Data Transfer: A change in the state of the data line, from HIGH to LOW, while the clock is

HIGH, defines a START condition.

Stop Data Transfer: A change in the state of the data line, from LOW to HIGH, while the clock line is

HIGH, defines the STOP condition.

Data Valid: The state of the data line represents valid data when, after a START condition, the data line

is stable for the duration of the HIGH period of the clock signal. The data on the line must be changed

during the LOW period of the clock signal. There is one clock pulse per bit of data.

Each data transfer is initiated with a START condition and terminated with a STOP condition. The

number of data bytes transferred between START and STOP conditions is not limited and is determined

by the master device. The information is transferred byte-wise and each receiver acknowledges with a

ninth bit.

Acknowledge: Each receiving device, when addressed, is obliged to generate an acknowledge after the

reception of each byte. The master device must generate an extra clock pulse that is associated with this

acknowledge bit.

A device that acknowledges must pull down the SDA line during the acknowledge clock pulse in such a

way that the SDA line is stable LOW during the HIGH period of the acknowledge-related clock pulse. Of

course, setup and hold times must be taken into account. A master must signal an end of data to the slave

by not generating an acknowledge bit on the last byte that has been clocked out of the slave. In this case,

the slave must leave the data line HIGH to enable the master to generate the STOP condition.

11 of 18

Page 12

DS1339

Figure 7. DATA TRANSFER ON 2-WIRE SERIAL BUS

Depending upon the state of the R/ W bit, two types of data transfer are possible:

1) Data Transfer from a Master Transmitter to a Slave Receiver. The first byte transmitted by the

master is the slave address. Next follows a number of data bytes. The slave returns an acknowledge

bit after each received byte. Data is transferred with the most significant bit (MSB) first.

2) Data Transfer from a Slave Transmitter to a Master Receiver. The first byte (the slave address) is

transmitted by the master. The slave then returns an acknowledge bit. This is followed by the slave

transmitting a number of data bytes. The master returns an acknowledge bit after all received bytes

other than the last byte. At the end of the last received byte, a “not acknowledge” is returned. The

master device generates all of the serial clock pulses and the START and STOP conditions. A transfer

is ended with a STOP condition or with a repeated START condition. Since a repeated START

condition is also the beginning of the next serial transfer, the bus is not released. Data is transferred

with the MSB first.

12 of 18

Page 13

DS1339

The DS1339 can operate in the following two modes:

1) Slave Receiver Mode (Write Mode): Serial data and clock are received through SDA and SCL.

After each byte is received an acknowledge bit is transmitted. START and STOP conditions are

recognized as the beginning and end of a serial transfer. Address recognition is performed by

hardware after reception of the slave address and direction bit (Figure 8). The slave address byte is

the first byte received after the START condition is generated by the master. The slave address byte

contains the 7-bit DS1339 address, which is 1101000, followed by the direction bit (R/ W ), which, for

a write, is a 0. After receiving and decoding the slave address byte, the slave outputs an acknowledge

on the SDA line. After the DS1339 acknowledges the slave address + write bit, the master transmits a

register address to the DS1339. This sets the register pointer on the DS1339, with the DS1339

acknowledging the transfer. The master can then transmit zero or more bytes of data, with the

DS1339 acknowledging each byte received. The address pointer increments after each byte is

transferred. The master generates a STOP condition to terminate the data write.

2) Slave Transmitter Mode (Read Mode): The first byte is received and handled as in the slave

receiver mode. However, in this mode, the direction bit indicates that the transfer direction is

reversed. Serial data is transmitted on SDA by the DS1339 while the serial clock is input on SCL.

START and STOP conditions are recognized as the beginning and end of a serial transfer (Figure 9).

The slave address byte is the first byte received after the START condition is generated by the

master. The slave address byte contains the 7-bit DS1339 address, which is 1101000, followed by the

direction bit (R/ W ), which, for a read, is a 1. After receiving and decoding the slave address byte the

slave outputs an acknowledge on the SDA line. The DS1339 then begins to transmit data starting with

the register address pointed to by the register pointer. If the register pointer is not written to before the

initiation of a read mode, the first address that is read is the last one stored in the register pointer. The

address pointer is incremented after each byte is transferred. The DS1339 must receive a “not

acknowledge” to end a read.

Figure 8. DATA WRITE: SLAVE RECEIVER MODE

Figure 9. DATA READ: SLAVE TRANSMITTER MODE

13 of 18

Page 14

DS1339

ABSOLUTE MAXIMUM RATINGS*

Voltage Range on Any Pin Relative to Ground -0.3V to +6.0V

Operating Temperature Range -40°C to +85°C

Storage Temperature Range -55°C to +125°C

Soldering Temperature Range See IPC/JEDEC J-STD-020A

*This is a stress rating only and functional operation of the device at these or any other conditions beyond those indicated in the operation

sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time can affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (T

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Voltage, DS1339-2 V

Supply Voltage, DS1339-3 V

Supply Voltage, DS1339-33 V

Backup Supply Voltage V

BACKUP

Logic 1 V

Logic 0 V

Power-Fail Voltage, DS1339-2 V

Power-Fail Voltage, DS1339-3 V

Power-Fail Voltage, DS1339-33 V

CC

CC

CC

IH

IL

PF

PF

PF

1.8 2.0 2.2 V

2.7 3.0 3.3 V

2.97 3.3 3.63 V

1.3 3.0 3.7 V

0.7 V

CC

-0.5 0.3 V

1.58 1.70 1.80 V

2.45 2.59 2.70 V

2.70 2.85 2.97 V

DC ELECTRICAL CHARACTERISTICS

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Leakage I

I/O Leakage I

Logic 0 Out VOL = 0.4V, VCC > V

Min (-3, -33), VCC ≥ 2.0V (-2)

Logic 0 Out VOL = 0.2 (VCC)

1.8V < VCC < 2.0V (DS1339-2)

Logic 0 Out VOL - 0.2 (VCC)

1.3V < VCC < 1.8V (DS1339-2)

VCC Active Current I

Vcc Standby Current I

Trickle Charge Resistor Register

10h = A5h, VCC = Typ, V

BACKUP

Trickle Charge Resistor Register

10h = A6h, VCC = Typ, V

BACKUP

Trickle Charge Resistor Register

10h = A7h, VCC = Typ, V

V

BACKUP

Leakage Current I

BACKUP

CC

= 0V

= 0V

= 0V

(VCC = MIN to MAX, TA = -40°C to +85°C) (Note 12)

LI

LO

I

OL

I

OL

I

OL

CCA

CCS

80 150

R1 250

R2 2000

R3 4000

BKLKG

25 100 nA

= -40°C to +85°C) (Note 12)

A

VCC + 0.5 V

CC

1

1

V

mA

mA

1

2

3mA2

3mA2

250 µA 2

450

mA

mA

3

4

DC ELECTRICAL CHARACTERISTICS (V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

V

BACKUP

V

BACKUP

V

BACKUP

Current EOSC = 0, SQW Off

Current EOSC = 0, SQW On

Current EOSC = 1

I

BKOSC

I

BKSQW

I

BKDR

14 of 18

= 0V, TA = -40°C to +85°C) (Note 12)

CC

400 700 nA 10

600 1000 nA 10

10 100 nA 10

Page 15

DS1339

CRYSTAL SPECIFICATIONS*

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Nominal Frequency F

O

32.768 kHz

Series Resistance ESR 45 k

Load Capacitance C

*The crystal, traces, and crystal input pins should be isolated from RF generating signals. Refer to Application Note 58 “Crystal Considerations

for Dallas Real-Time Clocks” for additional specifications.

L

6pF

CHIP AND PACKAGE INFORMATION

TRANSISTOR COUNT: 10,950

PROCESS: CMOS

THERMAL RESISTANCE, TYP, µsop: qJA, +207°C/W, qJC +40°C/W

15 of 18

Page 16

DS1339

AC ELECTRICAL CHARACTERISTICS

(VCC = MIN to MAX, TA = -40°C to +85°C) (Note 12)

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS NOTES

SCL Clock

Frequency

Bus Free Time

Between a STOP

and START

Condition

(Repeated) START

Condition

LOW Period of

SCL Clock

HIGH Period of

SCL Clock

Setup Time for a

Repeated START

Condition

f

SCL

t

BUF

t

HD:STA

t

LOW

t

HIGH

t

SU:STA

Fast Mode 100 400

Standard Mode 100

Fast Mode 1.3

Standard Mode 4.7

Fast Mode 0.6Hold Time

Standard Mode 4.0

Fast Mode 1.3

Standard Mode 4.7

Fast Mode 0.6

Standard Mode 4.0

Fast Mode 0.6

Standard Mode 4.7

kHz

ms

ms

ms

ms

ms

5

Data Hold Time t

Data Setup Time t

HD:DAT

SU:DAT

SDA and SCL

Signals

SDA and SCL

Signals

Setup Time for

STOP Condition

t

SU:STO

Capacitive Load for

Each Bus Line

I/O Capacitance C

C

Fast Mode 0 0.9

ms

6, 7

Standard Mode 0

Fast Mode 100

ns 9

Standard Mode 250

Fast Mode 300Rise Time of Both

t

R

Standard Mode

20 + 0.1C

B

ns 8

1000

Fast ModeFall Time of Both

t

F

20 + 0.1C

B

300 ns 8

Standard Mode

Fast Mode 0.6

ms

Standard Mode 4.0

400 pF 8

I/O

B

10 pF

Oscillator Stop Flag

(OSF) Delay

t

OSF

100 ms 11

16 of 18

Page 17

Figure 10. TIMING DIAGRAM

DS1339

Figure 11. POWER-UP/DOWN TIMING

V

CC

V

PF(max)

V

PF(min)

t

VCCF

INPUTS

OUTPUTS

RECOGNIZED RECOGNIZED

VALID

DON'T CARE

HIGH-Z

t

VCCR

t

REC

VALID

17 of 18

Page 18

DS1339

POWER-UP DOWN CHARACTERISTICS (T

= -40°C to +85°C) (Note 12)

A

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Recovery at Power-up t

VCC Fall Time; V

VCC Rise Time; V

PF(MAX)

PF(MIN)

to V

to V

PF(MIN)

PF(MAX)

REC

t

VCCF

t

VCCR

300

0

2ms13

ms

ms

Warning: Under no circumstances are negative undershoots, of any amplitude, allowed when the device

is in backup-battery mode.

NOTES:

1) SCL only.

2) SDA, and SQW/INT .

3) I

4) Specified with 2-wire bus inactive, VIL = 0.0V, VIH = VCC, trickle charge disabled.

5) After this period, the first clock pulse is generated.

6) A device must internally provide a hold time of at least 300ns for the SDA signal (referred to the

7) The maximum t

8) CB: Total capacitance of one bus line in pF.

9) A fast-mode device can be used in a standard-mode system, but the requirement t

10) Using recommended crystal on X1 and X2.

11) The parameter t

12) Limits at -40°C are guaranteed by design and are not production tested.

13) This delay applies only if the oscillator is running. If the oscillator is disabled or stopped, no power-

: SCL at fSC max, VIL = 0.0V, VIH = VCC, trickle charge disabled.

CCA

V

of the SCL signal) in order to bridge the undefined region of the falling edge of SCL.

IHMIN

has only to be met if the device does not stretch the LOW period (t

HD:DAT

LOW

) of the

SCL signal.

³ to 250ns

SU:DAT

must then be met. This is automatically the case if the device does not stretch the LOW period of the

SCL signal. If such a device does stretch the LOW period of the SCL signal, it must output the next

data bit to the SDA line t

is the period of time the oscillator must be stopped in order for the OSF flag to be

OSF

RMAX + tSU:DAT

set over the voltage range of 0V V

= 1000 + 250 = 1250ns before the SCL line is released.

CC

V

and 1.3V V

CCMAX

BACKUP

3.7V.

up delay occurs.

18 of 18

Loading...

Loading...