Page 1

DS1315

PRELIMINARY

DS1315

Phantom Time Chip

FEATURES

• Real time clock keeps track of hundredths of seconds,

seconds, minutes, hours, days, date of the month,

months, and years

• Adjusts for months with fewer than 31 days

• Automatic leap year correction valid up to 2100

• No address space required to communicate with RTC

• Provides nonvolatile controller functions for battery

backup of SRAM

• Supports redundant battery attachment for high–reli-

ability applications

• Full ±10% V

operating range

CC

• +3.3 volt or +5 volt operation

• Industrial (–45°C to +85°C) operating temperature

ranges available

• Drop in replacement for DS1215

ORDERING INFORMATION

DS1315XX–XX

33–3.3 volt operation

5–5 volt operation

blank–commercial temp range

N–industrial temp range

blank–16–pin DIP

S–16–pin SOIC

E–20–pin TSSOP

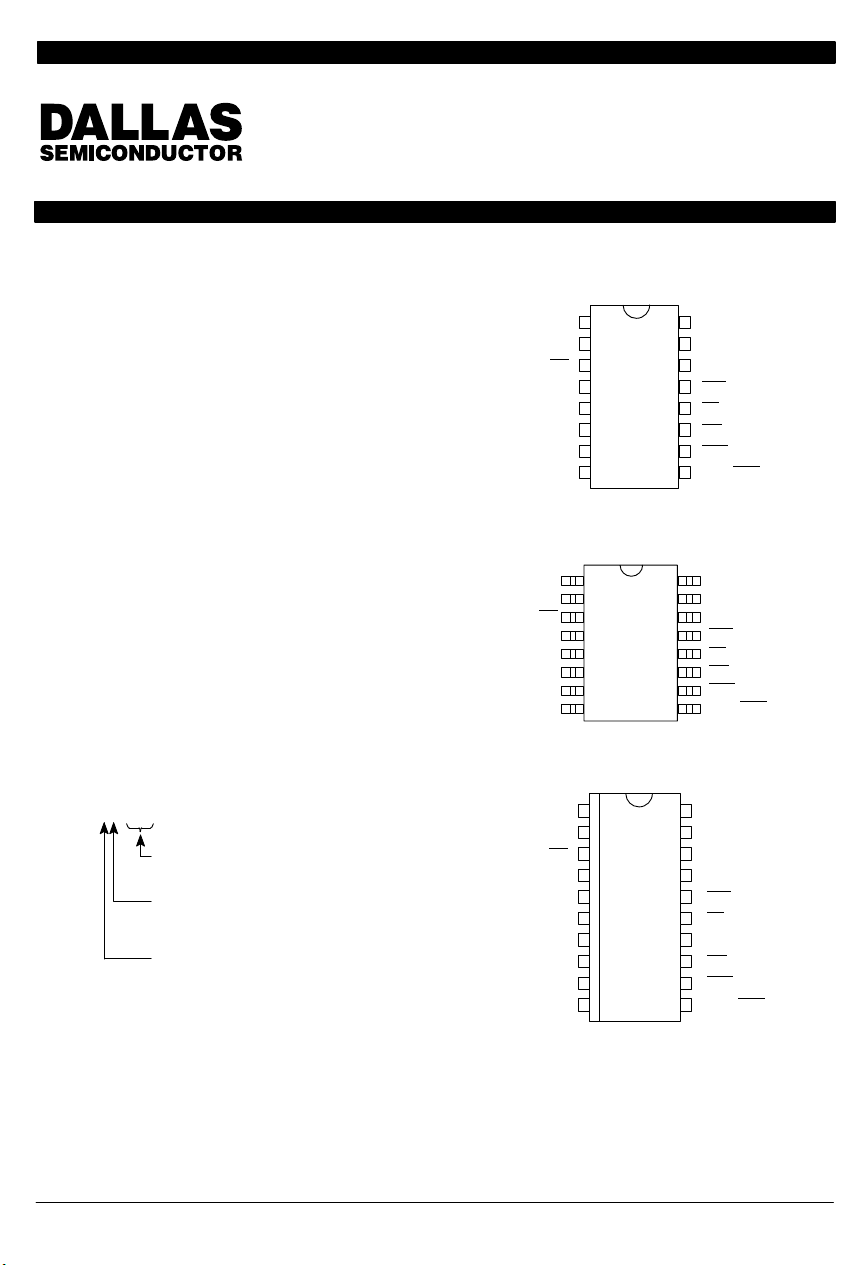

PIN ASSIGNMENT

X1

X2

WE

BAT1

GND

D

Q

GND

16–PIN DIP (300 MIL)

X1

X2

WE

BAT1

GND

D

Q

GND

16–PIN SOIC (300 MIL)

X1

X2

WE

NC

BAT1

GND

NC

D

Q

GND

1

16

2

15

3

14

4

13

5

12

6

11

7

10

8

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

1

2

3

4

5

6

7

8

9

10

20–PIN TSSOP

9

20

19

18

17

16

15

14

13

12

11

9

V

CCI

V

CCO

BAT2

RST

OE

CEI

CEO

ROM/RAM

V

CCI

V

CCO

BAT2

RST

OE

CEI

CEO

ROM/RAM

V

CCI

V

CCO

BAT2

NC

RST

OE

NC

CEI

CEO

ROM/RAM

Copyright 1995 by Dallas Semiconductor Corporation.

All Rights Reserved. For important information regarding

patents and other intellectual property rights, please refer to

Dallas Semiconductor data books.

041697 1/22

Page 2

DS1315

PIN DESCRIPTION

X1, X2 – 32.768 KHz Crystal Connection

WE – Write Enable

BAT1 – Battery 1 Input

GND – Ground

D – Data Input

Q – Data Output

ROM/RAM

– ROM/RAM Mode Select

CEO – Chip Enable Output

CEI – Chip Enable Input

OE

– Output Enable

RST – Reset

BAT2 – Battery 2 Input

V

V

CCO

CCI

– Switched Supply Output

– Power Supply Input

DESCRIPTION

The DS1315 Phantom Time Chip is a combination of a

CMOS timekeeper and a nonvolatile memory controller.

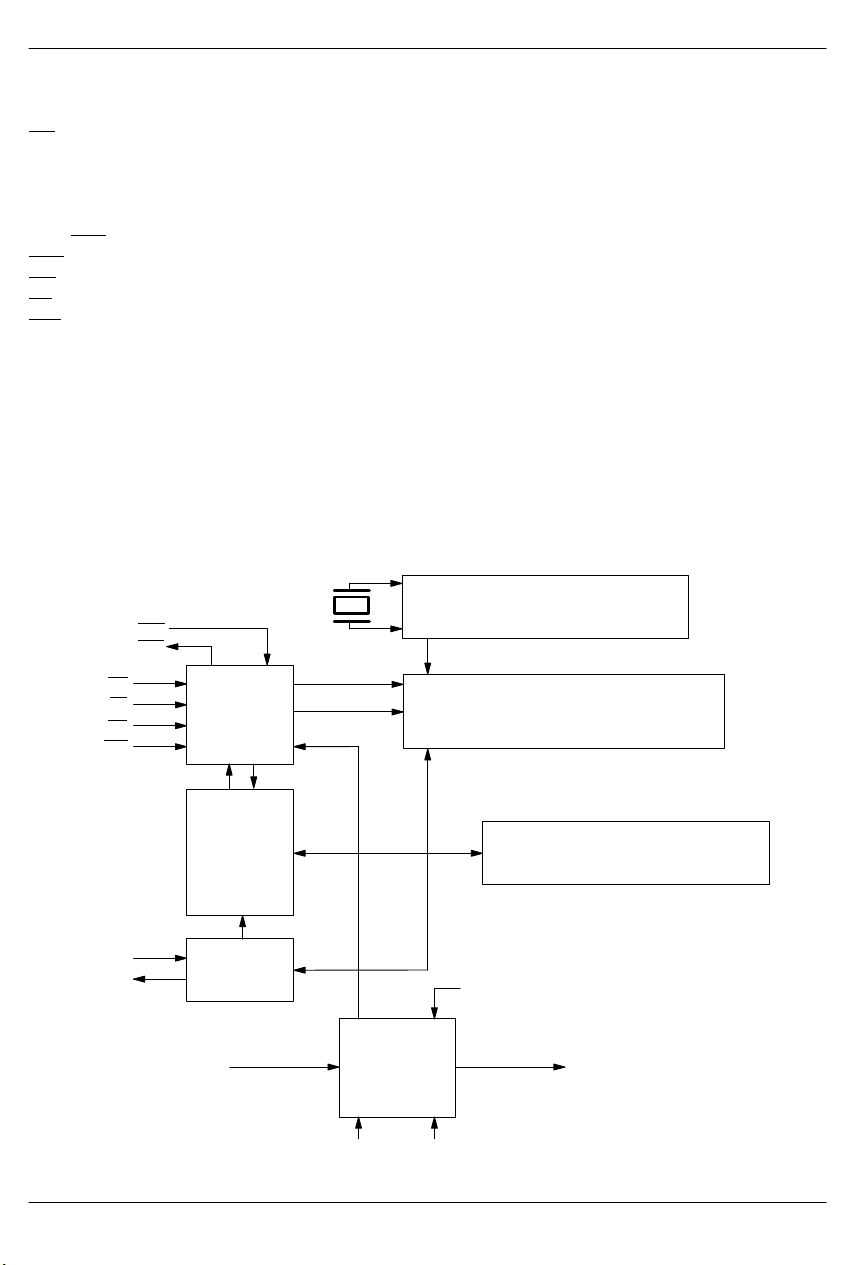

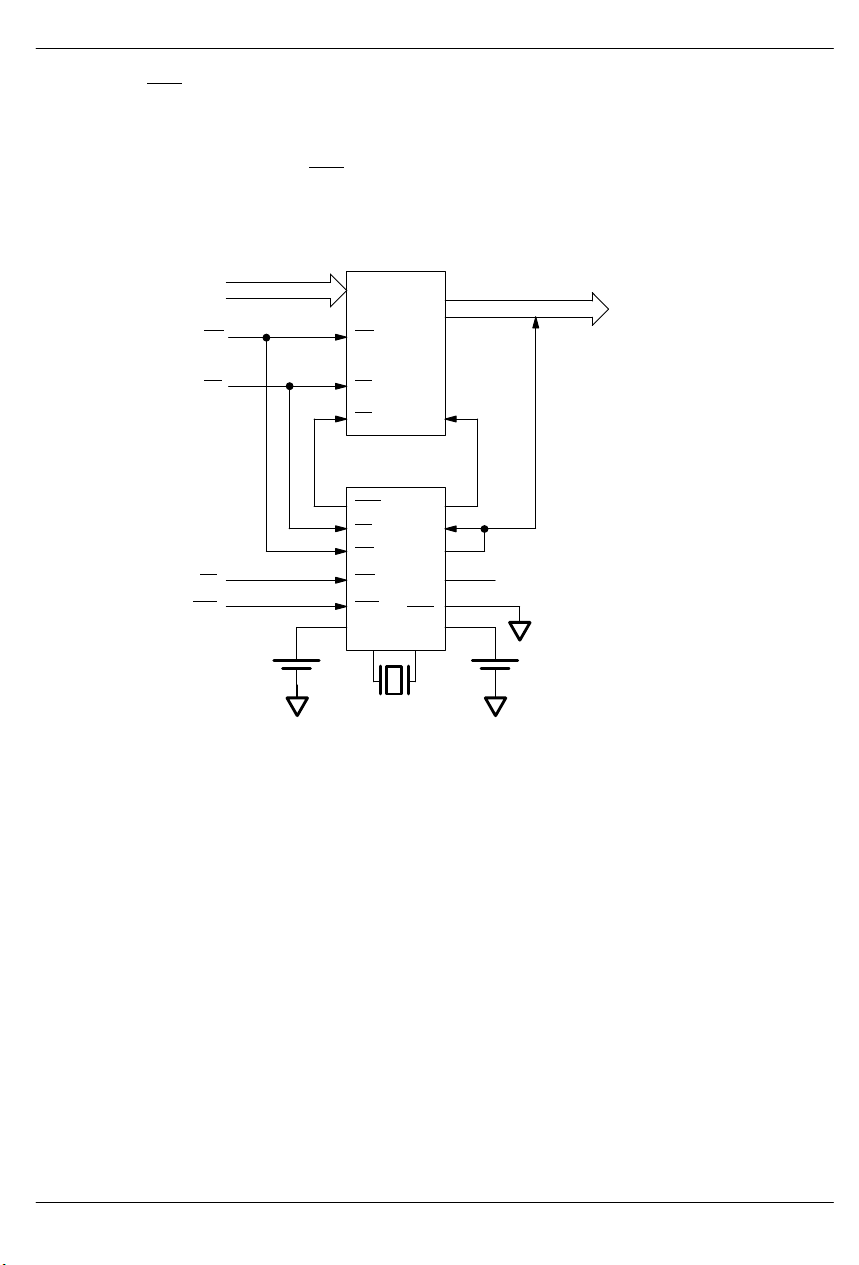

TIMING BLOCK DIAGRAM Figure 1

32.768 KHz

ROM/RAM

CEO

CEI

OE

WE

RST

CONTROL

LOGIC

POWER–FAIL

READ

WRITE

X

1

X

2

In the absence of power, an external battery maintains

the timekeeping operation and provides power for a

CMOS static RAM. The watch keeps track of hundredths of seconds, seconds, minutes, hours, day, date,

month, and year information. The last day of the month

is automatically adjusted for months with less than

31 days, including leap year correction. The watch operates in one of two formats: a 12–hour mode with an

AM/PM indicator or a 24–hour mode. The nonvolatile

controller supplies all the necessary support circuitry to

convert a CMOS RAM to a nonvolatile memory. The

DS1315 can be interfaced with either RAM or ROM

without leaving gaps in memory .

OPERATION

The block diagram of Figure 1 illustrates the main elements of the Time Chip. The following paragraphs

describe the signals and functions.

CLOCK/CALENDAR LOGIC

UPDATE

TIMEKEEPING REGISTER

041697 2/22

ACCESS

ENABLE

SEQUENCE

DETECTOR

D

Q

I/O BUFFERS

V

CCI

DATA

POWER–FAIL

DETECT

LOGIC

BAT

1

BAT

INTERNAL V

2

COMPARISON REGISTER

CC

V

CCO

Page 3

DS1315

Communication with the Time Chip is established by

pattern recognition of a serial bit stream of 64 bits which

must be matched by executing 64 consecutive write

cycles containing the proper data on data in (D). All

accesses which occur prior to recognition of the 64–bit

pattern are directed to memory via the chip enable output pin (CEO

).

After recognition is established, the next 64 read or write

cycles either extract or update data in the Time Chip and

CEO

remains high during this time, disabling the con-

nected memory.

Data transfer to and from the timekeeping function is

accomplished with a serial bit stream under control of

chip enable input (CEI

), output enable (OE), and write

enable (WE). Initially , a read cycle using the CEI and OE

control of the Time Chip starts the pattern recognition

sequence by moving pointer to the first bit of the 64–bit

comparison register. Next, 64 consecutive write cycles

are executed using the CEI

and WE control of the Time

Chip. These 64 write cycles are used only to gain

access to the Time Chip.

When the first write cycle is executed, it is compared to

bit 1 of the 64–bit comparison register. If a match is

found, the pointer increments to the next location of the

comparison register and awaits the next write cycle. If a

match is not found, the pointer does not advance and all

subsequent write cycles are ignored. If a read cycle occurs at any time during pattern recognition, the present

sequence is aborted and the comparison register pointer is reset. Pattern recognition continues for a total of 64

write cycles as described above until all the bits in the

comparison register have been matched. (This bit pattern is shown in Figure 2). With a correct match for

64 bits, the Time Chip is enabled and data transfer to or

from the timekeeping registers may proceed. The next

64 cycles will cause the Time Chip to either receive data

on D, or transmit data on Q, depending on the level of

OE

pin or the WE pin. Cycles to other locations outside

the memory block can be interleaved with CEI

cycles

without interrupting the pattern recognition sequence or

data transfer sequence to the Time Chip.

A standard 32,768 KHz quartz crystal can be directly

connected to the DS1315 via pins 1 and 2 (X1, X2). The

crystal selected for use should have a specified load capacitance (C

) of 6 pF . For more information on crystal

L

selection and crystal layout considerations, please consult Application Note 58, “Crystal Considerations with

Dallas Real Time Clocks”.

041697 3/22

Page 4

DS1315

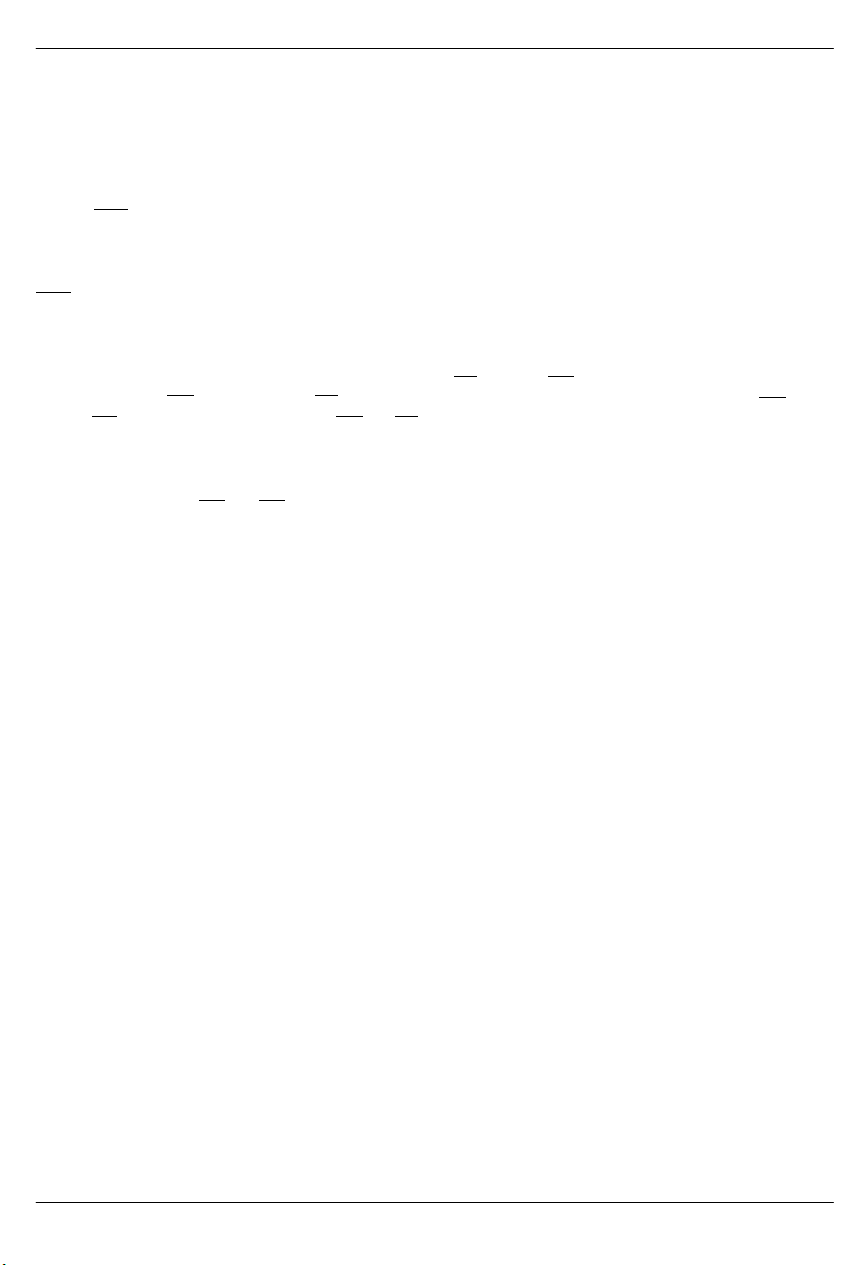

TIME CHIP COMPARISON REGISTER DEFINITION Figure 2

76543210

BYTE 0

BYTE 1

BYTE 2

BYTE 3

BYTE 4

BYTE 5

BYTE 6

11000101

00111010

10100011

01011100

11000101

00111010

10100011

C5

3A

A3

5C

C5

3A

A3

BYTE 7

01011100

5C

NOTE:

The pattern recognition in Hex is C5, 3A, A3, 5C, C5, 3A, A3, 5C. The odds of this pattern being accidentally duplicated

and causing inadvertent entry to the Phantom Time Chip are less than 1 in 10

NONVOLATILE CONTROLLER OPERATION

The operation of the nonvolatile controller circuits within

the Time Chip is determined by the level of the

ROM/RAM select pin. When ROM/RAM is connected to

ground, the controller is set in the RAM mode and performs the circuit functions required to make CMOS RAM

and the timekeeping function nonvolatile. A switch is

provided to direct power from the battery inputs or V

to V

with a maximum voltage drop of 0.3 volts. The

CCO

V

output pin is used to supply uninterrupted power

CCO

to CMOS SRAM. The DS1315 also performs redundant

battery control for high reliability. On power–fail, the battery with the highest voltage is automatically switched to

. If only one battery is used in the system, the un-

V

CCO

The DS1315 safeguards the Time Chip and RAM data

by power–fail detection and write protection. Power–fail

detection occurs when V

by an internal bandgap reference. The DS1315 constantly monitors the V

than VPF, power–fail circuitry forces the chip enable output (CEO

write protection. During nominal supply conditions,

CCI

) to V

CEO will track CEI with a maximum propagation delay

of 5 ns. Internally, the DS1315 aborts any data transfer

in progress without changing any of the Time Chip registers and prevents future access until V

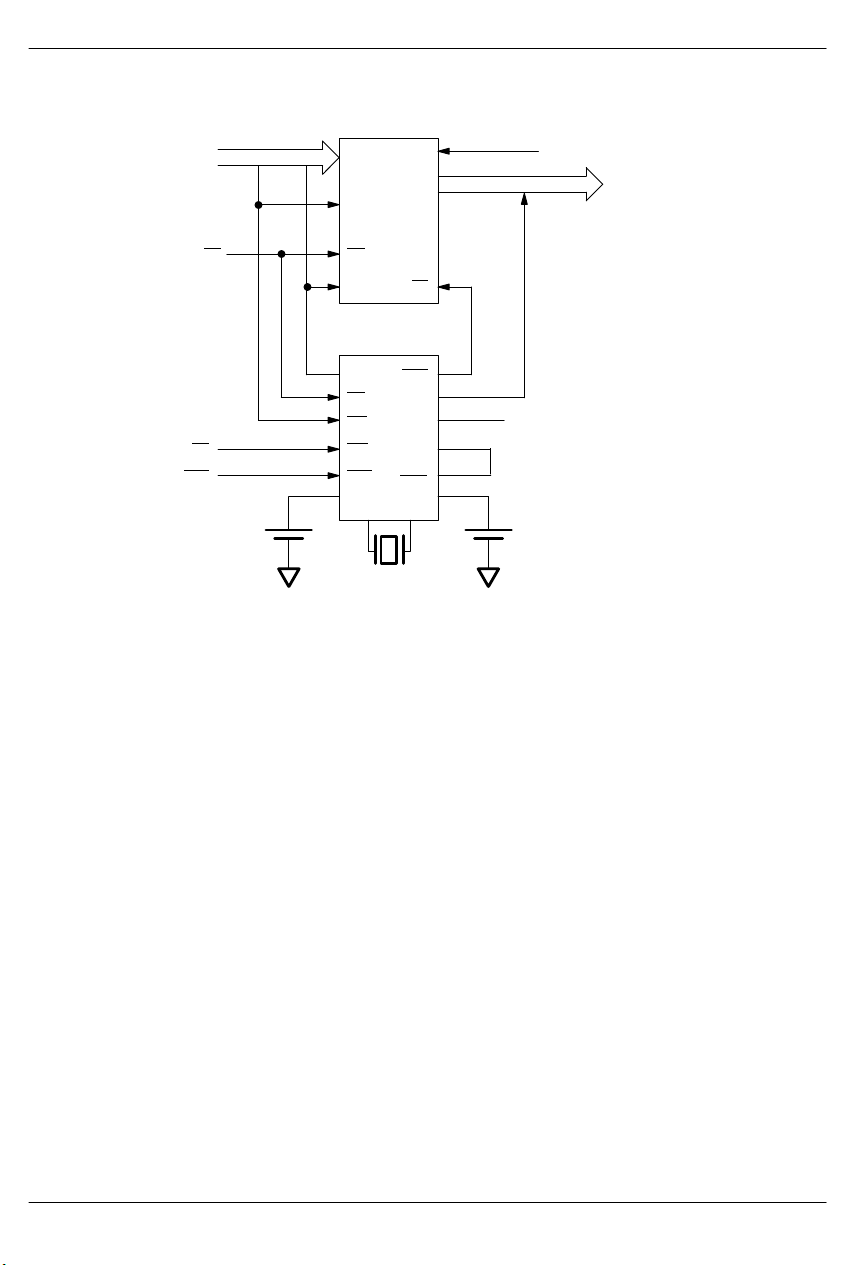

A typical RAM/Time Chip interface is illustrated in

Figure 3.

used battery input should be connected to ground.

041697 4/22

CCI

19

.

falls below VPF which is set

CCI

supply pin. When V

CCI

or V

–0.2 volts for external RAM

BAT

CCI

exceeds VPF.

CCI

is less

Page 5

DS1315

When the ROM/RAM pin is connected to V

CCO

, the controller is set in the ROM mode. Since ROM is a read–

only device that retains data in the absence of power,

battery backup and write protection is not required. As a

result, the chip enable logic will force CEO

low when

DS1315 TO RAM/TIME CHIP INTERFACE Figure 3

CMOS STATIC RAM

A0 – AN

WE

OE

CE

RST

BAT

1

A0 – AN

DATA I/O

WE

OE

CE

V

CC

DS1315

CEO

V

CCO

OE

WE

CEI

RST

BAT

X

12

32.768 KHz

D

Q

V

CCI

ROM/

RAM

BAT

1

2

X

1

2

power fails. However, the Time Chip does retain the

same internal nonvolatility and write protection as described in the RAM mode. A typical ROM/Time Chip interface is illustrated in Figure 4.

D0 – D7

V

CC

++

BAT

2

041697 5/22

Page 6

DS1315

ROM/TIME CHIP INTERFACE Figure 4

A0 – AN

ROM

A1, A3 – AN

DATA I/O

A2

V

CC

V

CC

D0 – D7

OE

A0

DS1315

D

OE

WE

CEI

RST

BAT

1

X

1

32.768 KHz

CE

RST

OE

BAT

1

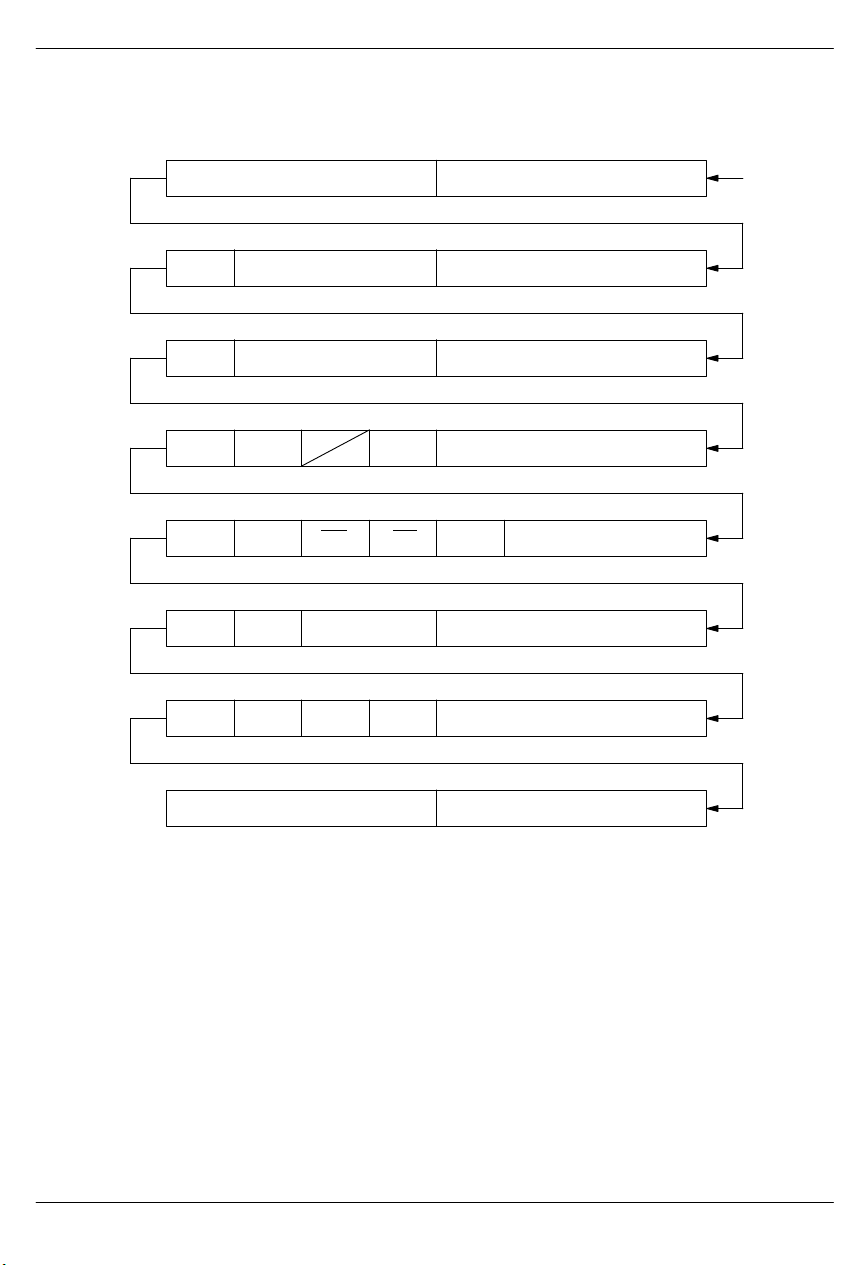

TIME CHIP REGISTER INFORMATION

Time Chip information is contained in eight registers of

8 bits, each of which is sequentially accessed one bit at

a time after the 64–bit pattern recognition sequence has

been completed. When updating the Time Chip registers, each must be handled in groups of 8 bits. Writing

and reading individual bits within a register could produce erroneous results. These read/write registers are

defined in Figure 5.

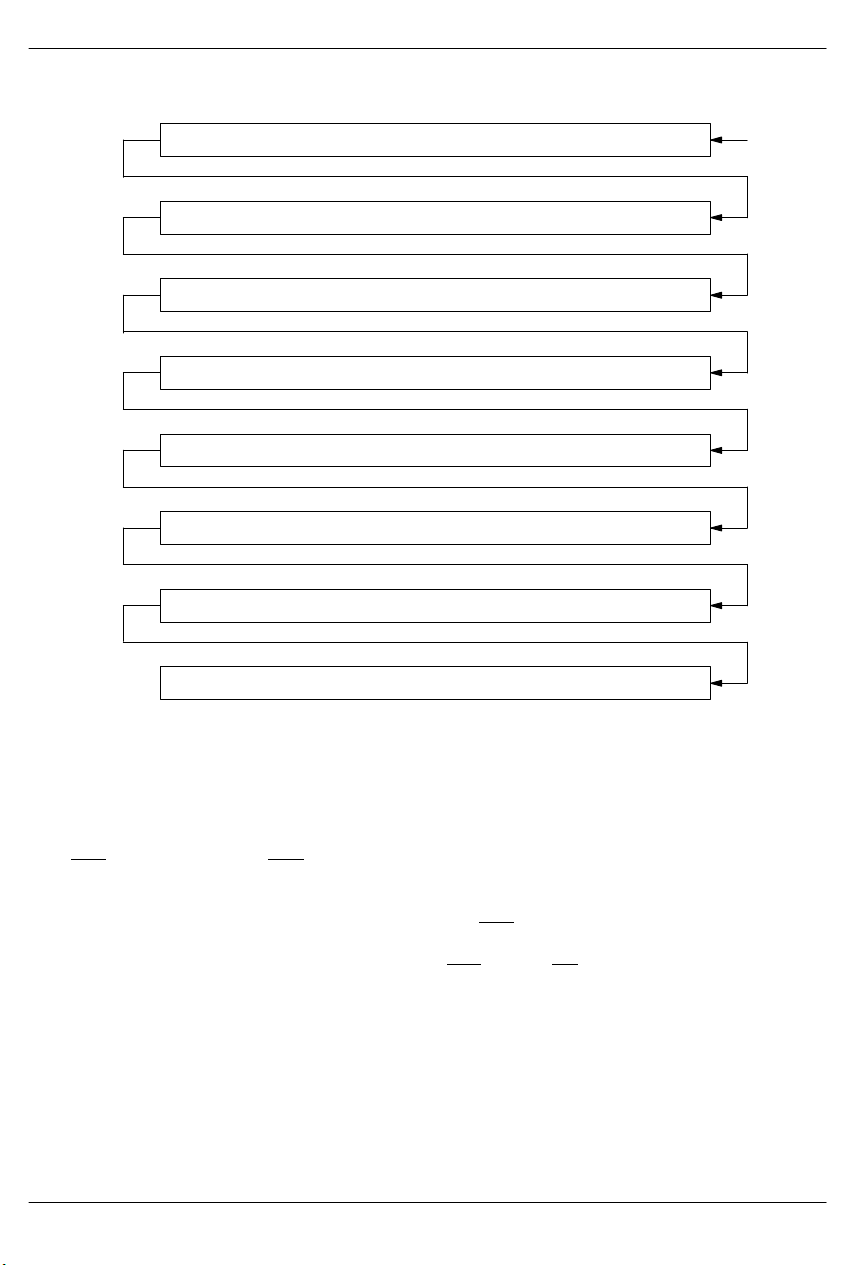

Data contained in the Time Chip registers is in binary

coded decimal format (BCD). Reading and writing the

registers is always accomplished by stepping though all

eight registers, starting with bit 0 of register 0 and ending

with bit 7 of register 7.

CE

CEO

Q

V

CCI

V

CCO

ROM/

RAM

BAT

2

X

2

V

CC

++

BAT

2

with logic high being PM. In the 24–hour mode, bit 5 is

the second 10–hour bit (20–23 hours).

OSCILLATOR AND RESET BITS

Bits 4 and 5 of the day register are used to control the

reset and oscillator functions. Bit 4 controls the reset pin

input. When the reset bit is set to logic 1, the reset input

pin is ignored. When the reset bit is set to logic 0, a low

input on the reset pin will cause the Time Chip to abort

data transfer without changing data in the timekeeping

registers. Reset operates independently of all other inputs. Bit 5 controls the oscillator. When set to logic 0, the

oscillator turns on and the real time clock/calendar

begins to increment.

AM–PM/12/24 MODE

Bit 7 of the hours register is defined as the 12– or

24–hour mode select bit. When high, the 12–hour mode

is selected. In the 12–hour mode, bit 5 is the AM/PM bit

041697 6/22

ZERO BITS

Registers 1, 2, 3, 4, 5, and 6 contain one or more bits that

will always read logic 0. When writing these locations,

either a logic 1 or 0 is acceptable.

Page 7

TIME CHIP REGISTER DEFINITION Figure 5

REGISTER

7654 3210

0

0.1 SEC

0.01 SEC

RANGE

(BCD)

00–99

DS1315

1

2

3

4

5

6

7

0

0

12/24 0

00 0

00

0 0 0 10 MONTH

10 SEC SECONDS

10 MIN MINUTES

10

OSC RST

10 YEAR YEAR

HR

A/P

10 DATE DATE

MONTH

HOUR

DAY

00–59

00–59

01–12

00–23

01–07

01–31

01–12

00–99

041697 7/22

Page 8

DS1315

ABSOLUTE MAXIMUM RATINGS*

Voltage on any Pin Relative to Ground –0.3V to +7.0V

Operating T emperature, commercial range 0°C to 70°C

Operating T emperature, industrial range –45°C to +85°C

Storage Temperature –55°C to +125°C

Soldering Temperature 260°C for 10 seconds

* This is a stress rating only and functional operation of the device at these or any other conditions above those

indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS (0°C to 70°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Power Supply Voltage 5 Volt

Operation

Power Supply Voltage 3.3 Volt

Operation

Input Logic 1 V

Input Logic 0 V

Battery Voltage V

BAT1

or V

BAT2

V

V

V

CC

V

CC

IH

BAT1

BAT2

4.5 5.0 5.5 V 1

3.0 3.3 3.6 V 1

2.2 V

IL

–0.3 +0.6 V 1

,

2.5 3.7 V

+ 0.3 V 1

CC

DC OPERATING ELECTRICAL CHARACTERISTICS (0°C to 70°C; VCC = 5.0 ± 10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Average VCC Power Supply

Current

VCC Power Supply Current,

= V

(V

CCO

CCI

–0.3)

TTL Standby Current (CEI = VIH) I

CMOS Standby Current

= V

(CEI

CCI

–0.2)

Input Leakage Current (any input) I

Output Leakage Current (any

output)

Output Logic 1 Voltage

= –1.0 mA)

(I

OUT

Output Logic 0 Voltage

= 4.0 mA)

(I

OUT

Power–Fail Trip Point V

Battery Switch Voltage V

I

CC1

I

CC01

CC2

I

CC3

I

V

V

IL

OL

OH

OL

PF

SW

5 mA 6

150 mA 7

3 mA 6

1 mA 6

–1 +1 µA 10

–1 +1 µA

2.4 V 2

0.4 V 2

4.25 4.5 V

V

,

BAT1

V

BAT2

13

041697 8/22

Page 9

DS1315

DC POWER DOWN ELECTRICAL CHARACTERISTICS (0°C to 70°C; VCC < 4.5V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

CEO Output Voltage V

V

BAT1

or V

Battery Current I

BAT2

Battery Backup Current

= V

@ V

CCO

BAT

–0.2V

CEO

BAT

I

CCO2

V

or V

CCI

–0.2

–0.2

BAT1,2

V 8

0.5 µA 6

10 µA 9

AC ELECTRICAL OPERATING CHARACTERISTICS

ROM/RAM

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Read Cycle Time t

CEI Access Time t

OE Access Time t

CEI to Output Low Z t

OE to Output Low Z t

CEI to Output High Z t

OE to Output High Z t

Read Recovery t

Write Cycle t

Write Pulse Width t

Write Recovery t

Data Setup t

Data Hold Time t

CEI Pulse Width t

OE Pulse Width t

RST Pulse Width t

CEI Propagation Delay t

CEI High to Power–Fail t

= GND (0°C to 70°C; VCC = 5.0 ± 10%)

RC

CO

OE

COE

OEE

OD

ODO

RR

WC

WP

WR

DS

DH

CW

OW

RST

PD

PF

65 ns

55 ns

55 ns

5 ns

5 ns

25 ns

25 ns

10 ns

65 ns

55 ns

10 ns 4

30 ns 5

0 ns 5

60 ns

55 ns

65 ns

5 ns 2, 3, 11

0 ns 11

041697 9/22

Page 10

DS1315

AC ELECTRICAL OPERATING CHARACTERISTICS

ROM/RAM

= V

CCO

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Read Cycle Time t

CEI Access Time t

OE Access Time t

CEI to Output Low Z t

OE to Output Low Z t

CEI to Output High Z t

OE to Output High Z t

Address Setup Time t

Address Hold Time t

Read Recovery t

Write Cycle t

CEI Pulse Width t

OE Pulse Width t

Write Recovery t

Data Setup t

Data Hold Time t

RST Pulse Width t

CEI Propagation Delay t

CEI High to Power–Fail t

RC

CO

OE

COE

OEE

OD

ODO

AS

AH

RR

WC

CW

OW

WR

DS

DH

RST

PD

PF

65 ns

5 ns

5 ns

5 ns

5 ns

10 ns

65 ns

55 ns

55 ns

10 ns 4

30 ns 5

0 ns 5

65 ns

(0°C to 70°C; VCC = 5.0 ± 10%)

55 ns

55 ns

25 ns

25 ns

5 ns 2, 3, 11

0 ns 11

3.3 VOLT DEVICE OPERATING RANGE CHARACTERISTICS

DC OPERATING ELECTRICAL CHARACTERISTICS (0°C to 70°C; V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Average VCC Power Supply

Current

Average VCC Power Supply

= V

Current, (V

CCO

CCI

–0.3)

TTL Standby Current (CEI = VIH) I

CMOS Standby Current

= V

(CEI

CCI

–0.2)

Input Leakage Current (any input) I

Output Leakage Current (any

output)

041697 10/22

I

CC1

I

CC01

CC2

I

CC3

I

LO

3 mA 6

100 mA 7

2 mA 6

1 mA 6

IL

–1 +1 µA

–1 +1 µA

= 3.3 ± 10%)

CC

Page 11

DS1315

DC OPERATING ELECTRICAL CHARACTERISTICS (cont’d) (0°C to 70°C; VCC = 3.3 ±10%)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Output Logic 1 Voltage

= 0.4 mA)

(I

OUT

Output Logic 0 Voltage

= 1.6 mA)

(I

OUT

Power–Fail Trip Point V

Battery Switch Voltage V

V

OH

V

OL

PF

SW

2.4 V 2

0.4 V 2

2.8 3.0 V

V

,

BAT1

V

BAT2

13

DC POWER DOWN ELECTRICAL CHARACTERISTICS (0°C to 70°C; VCC < 2.7V)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

V

or

CCI

CEO Output Voltage V

V

BAT1

or V

Battery Current I

BAT2

Battery Backup Current

V

@ V

CCO =

BAT

–0.2

CEO

BAT

I

CCO2

V

BAT1,2

–0.2

V 8

0.3 µA 6

10 µA 9

041697 11/22

Page 12

DS1315

AC ELECTRICAL OPERATING CHARACTERISTICS

ROM/RAM

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Read Cycle Time t

CEI Access Time t

OE Access Time t

CEI to Output Low Z t

OE to Output Low Z t

CEI to Output High Z t

OE to Output High Z t

Read Recovery t

Write Cycle t

Write Pulse Width t

Write Recovery t

Data Setup t

Data Hold Time t

CEI Pulse Width t

OE Pulse Width t

RST Pulse Width t

CEI Propagation Delay t

CEI High to Power–Fail t

= GND (0°C to 70°C; VCC = 3.3 ± 10%)

RC

CO

OE

COE

OEE

OD

ODO

RR

WC

WP

WR

DS

DH

CW

OW

RST

PD

PF

120 ns

100 ns

100 ns

5 ns

5 ns

40 ns

40 ns

20 ns

120 ns

100 ns

20 ns 4

45 ns 5

0 ns 5

105 ns

100 ns

120 ns

10 ns 2, 3, 12

0 ns 12

041697 12/22

Page 13

DS1315

AC ELECTRICAL OPERATING CHARACTERISTICS

ROM/RAM

= V

CCO

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Read Cycle Time t

CEI Access Time t

OE Access Time t

CEI to Output Low Z t

OE to Output Low Z t

CEI to Output High Z t

OE to Output High Z t

Address Setup Time t

Address Hold Time t

Read Recovery t

Write Cycle t

CEI Pulse Width t

OE Pulse Width t

Write Recovery t

Data Setup t

Data Hold Time t

RST Pulse Width t

CEI Propagation Delay t

RC

CO

OE

COE

OEE

OD

ODO

AS

AH

RR

WC

CW

OW

WR

DS

DH

RST

PD

120 ns

5 ns

5 ns

10 ns

10 ns

20 ns

120 ns

100 ns

100 ns

20 ns 4

45 ns 5

0 ns 5

120 ns

(0°C to 70°C; VCC = 3.3 ± 10%)

100 ns

100 ns

40 ns

40 ns

5 ns 2, 3, 12

CAPACITANCE (tA = 25°C)

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Capacitance C

Output Capacitance C

IN

OUT

10 pF

10 pF

041697 13/22

Page 14

DS1315

TIMING DIAGRAM: READ CYCLE TO TIME CHIP ROM/RAM = GND Figure 6

WE

= V

IH

t

CEI

OE

RC

t

CO

t

CW

t

OE

t

OW

t

OEE

t

COE

t

t

ODO

RR

t

OD

Q

OUTPUT DATA VALID

TIMING DIAGRAM: WRITE CYCLE TO TIME CHIP ROM/RAM = GND Figure 7

OE

= V

IH

t

WE

t

WP

WC

t

WR

041697 14/22

CEI

D

t

CW

t

DS

DATA IN STABLE

t

WR

t

DH

t

DH

Page 15

DS1315

TIMING DIAGRAM: READ CYCLE TO TIME CHIP ROM/RAM = V

t

RC

t

CO

CEI

OE

WE

t

t

AS

AS

t

OEE

t

COE

Q

t

CW

t

t

OE

t

OW

RC

t

AH

OUTPUT DATA VALID

TIMING DIAGRAM: WRITE CYCLE TO TIME CHIP ROM/RAM = V

t

WC

t

CW

CEI

CCO

CCO

Figure 8

t

RR

t

OD

t

RR

t

ODO

t

AH

Figure 9

t

WR

OE

WE

t

t

WC

t

OW

t

AS

t

AS

t

DS

t

DS

D

DATA IN STABLE

t

t

WR

t

AH

AH

t

DH

DH

041697 15/22

Page 16

DS1315

TIMING DIAGRAM: RESET PULSE Figure 10

t

RST

RST

5V DEVICE POWER–UP POWER–DOWN CHARACTERISTICS,

ROM/RAM

= V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Recovery Time at

Power–Up

VCC Slew Rate Power–

Down

VCC Slew Rate Power–

Down

VCC Slew Rate Power–

UP

CEI High to Power–Fail t

OR GND (0°C to 70°C)

CCO

t

REC

VCC>4.5

4.0 ≤ V

4.5

t

3.0 ≤ V

4.0

4.5 ≤ V

4.0

t

FB

t

PF

F

≤

CC

300 mS 11

10 mS 11

≤

CC

R

≤

CC

0 mS 11

2 mS 11

0 mS 11

5V DEVICE POWER–UP CONDITION Figure 1 1

CEI

t

REC

4.5V

4.25V

041697 16/22

ROM/RAM = GND

= V

ROM/RAM

CCO

4.0V

V

CCI

BAT - 0.2V

CEO

CEO

t

R

t

CE

V

IL

t

PD

t

CE

Page 17

5V DEVICE POWER–DOWN CONDITION Figure 12

t

CEI

CE

DS1315

t

PF

V

- 0.2V

BAT

4.25V

t

F

4.0V

V

BAT1,2

t

FB

ROM/RAM = GND

= V

ROM/RAM

CCO

CEO

CEO

V

CCI

t

PD

t

CE

4.5V

3.3V DEVICE POWER–UP POWER–DOWN CHARACTERISTICS,

ROM/RAM

= V

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Recovery Time at

Power–Up

VCC Slew Rate Power–

Down

VCC Slew Rate Power–

UP

CEI High to Power–Fail t

OR GND (0°C to 70°C)

CCO

t

VCC>3

2.9 ≤ V

3 ≤ V

REC

t

F

t

R

CC

PF

CC

≤ 2.9

≤ 3

300 ms 12

0 ms 12

0 ms 12

2 ms 12

041697 17/22

Page 18

DS1315

3.3V DEVICE POWER–UP CONDITION Figure 13

CEI

t

REC

t

CE

V

IL

2.7V

2.6V

2.5V

V

CCI

t

R

BAT - 0.2V

CCO

CEO

CEO

ROM/RAM = GND

= V

ROM/RAM

3.3V DEVICE POWER–DOWN CONDITION Figure 14

t

CE

t

PD

t

CE

ROM/RAM = GND

CEI

CEO

t

PD

t

CE

t

PF

V

- 0.2V

BAT

ROM/RAM

041697 18/22

= V

CCO

CEO

V

CCI

2.7V

2.6V

2.5V

t

F

Page 19

NOTES:

1. All voltages are referenced to ground.

2. Measured with load shown in Figure 15.

3. Input pulse rise and fall times equal 10 ns.

is a function of the latter occurring edge of WE or CE in RAM mode, or OE or CE in ROM mode.

4. t

WR

5. t

DH

and t

are functions of the first occurring edge of WE or CE in RAM mode, or OE or CE in ROM mode.

DS

6. Measured without RAM connected.

7. I

8. Applies to CEO

9. I

10.Applies to all input pins except RST

is the maximum average load current the DS1315 can supply to external memory.

CC01

with the ROM/RAM pin grounded. When the ROM/RAM pin is connected to V

to a low level as V

is the maximum average load current that the DS1315 can supply to memory in the battery backup mode.

CC02

falls below V

CCI

.

BAT

. RST is pulled internally to V

CCI

.

11.See Figures 11 and 12.

12.See Figures 13 and 14.

is determined by the larger of V

13.V

SW

BAT1

and V

BAT2

.

OUTPUT LOAD Figure 15

, CEO will go

CCO

DS1315

680

V

CCI

1.1K

50 pF

041697 19/22

Page 20

DS1315

DS1315 TIME CHIP 16–PIN DIP

B D

1

A

C

F

K

E

G

J

H

16–PINPKG

DIM MIN MAX

A IN. 0.740 0.780

MM

B IN. 0.240 0.260

MM

C IN. 0.120 0.140

MM

D IN. 0.300 0.325

MM

E IN. 0.015 0.040

MM

F IN. 0.110 0.140

MM

G IN. 0.090 0.110

MM

H IN. 0.300 0.370

MM

J IN. 0.008 0.012

MM

K IN. 0.015 0.021

MM

041697 20/22

Page 21

DS1315 TIME CHIP 16–PIN SOIC

GK

B

1

A

C

DS1315

H

F

E

PKG 16–PIN

DIM MIN MAX

A IN.MM0.402

B IN.MM0.290

C IN.MM0.089

E IN.MM0.004

F IN.MM0.094

G IN.

MM

H INMM0.398

J INMM0.009

K IN.MM0.013

L INMM0.016

PHI 0° 8°

10.21

7.37

2.26

0.102

2.38

0.050 BSC

1.27 BSC

10.11

0.229

0.33

0.40

0.412

10.46

0.300

7.65

0.095

2.41

0.012

0.30

0.105

2.68

0.416

10.57

0.013

0.33

0.019

0.48

0.040

1.02

phi

J

L

041697 21/22

Page 22

DS1315

DS1315 TIME CHIP 20–PIN TSSOP

D

n

B

e1

DIM MIN MAX

A MM – 1.10

A1 MM 0.05 –

A2 MM 0.75 1.05

C MM 0.09 0.18

L MM 0.50 0.70

e1 MM 0.65 BSC

B MM 0.18 0.30

D MM 6.40 6.90

E MM 4.40 NOM

G MM 0.25 REF

H MM 6.25 6.55

phi 0° 8°

56–G2010–000

E

H

SEE DETAIL A

c

A2

A1

L

DETAIL A

phi

G

A

041697 22/22

Loading...

Loading...