Page 1

www.maxim-ic.com

DS1305

Serial Alarm Real-Time Clock

FEATURES

§ Real-time clock (RTC) counts seconds,

minutes, hours, date of the month, month,

day of the week, and year with leap-year

compensation valid up to 2100

§ 96-byte, battery-backed NV RAM for data

storage

§ Two time-of-day alarms, programmable on

combination of seconds, minutes, hours, and

day of the week

§ Serial interface supports Motorola SPI

(serial peripheral interface) serial data ports

or standard 3-wire interface

§ Burst mode for reading/writing successive

addresses in clock/RAM

§ Dual-power supply pins for primary and

backup power supplies

§ Optional trickle charge output to backup

supply

§ 2.0V to 5.5V operation

§ Optional industrial temperature range:

-40°C to +85°C

§ Available in space-efficient, 20-pin TSSOP

package

§ Underwriters Laboratory (UL) recognized

™

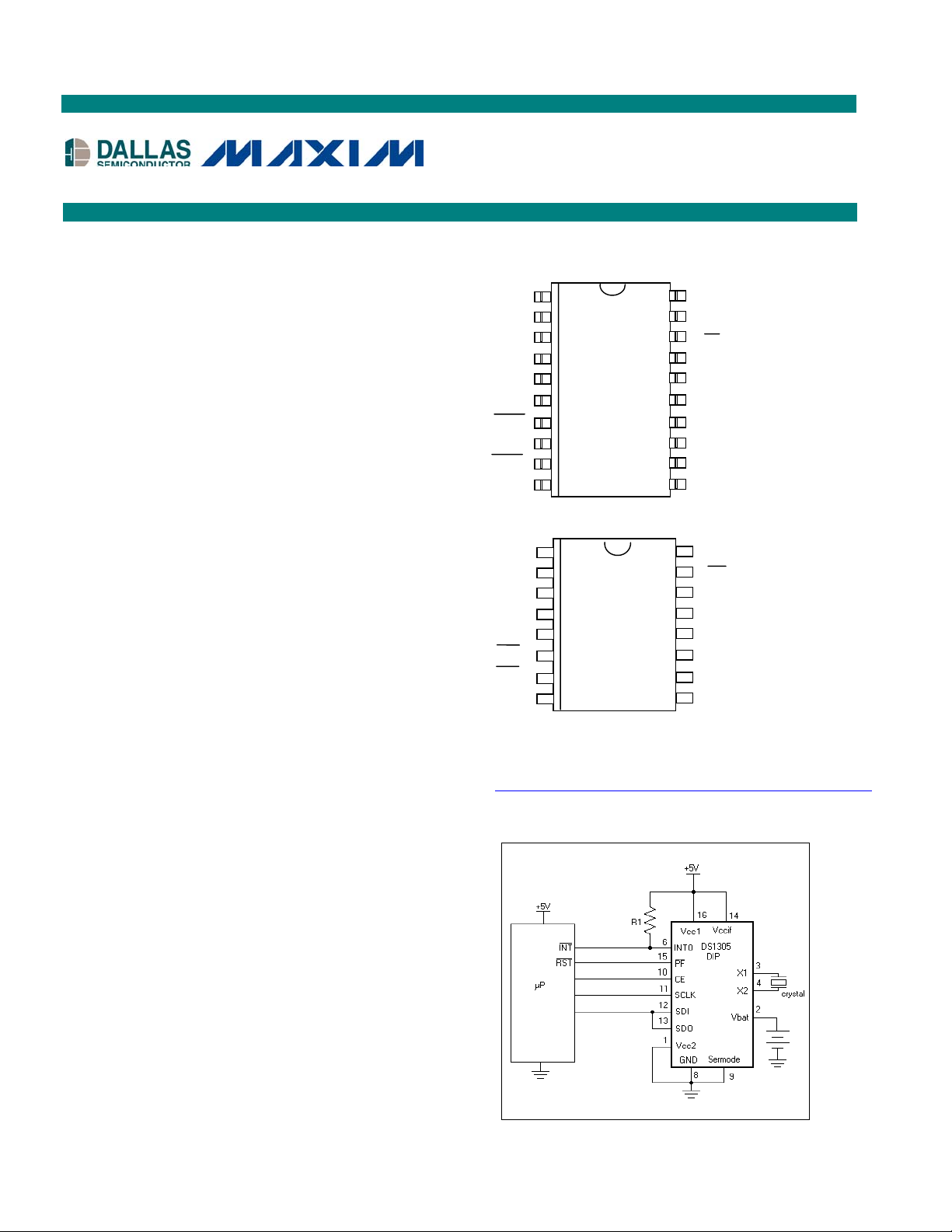

PIN ASSIGNMENT

V

CC2

V

BAT

X1 3 18 PF

NC 4 17 V

X2 5 16 SD0

NC 6 15 SDI

INT0 7 14 SCLK

NC 8 13 NC

INT1 9 12 CE

GND 10 11 SERMODE

DS1305 20-Pin TSSOP (4.4mm)

V

CC2

V

BAT

X1 3 14 V

X2 4 13 SDO

NC 5 12 SDI

INT0 6 11 SCLK

INT1 7 10 CE

GND 8 9 SERMODE

DS1305 16-Pin DIP (300mil)

Package dimension information can be found at:

http://www.maxim-ic.com/TechSupport/DallasPackInfo.htm

120V

219NC

1 16 V

215PF

CC1

CCIF

CC1

CCIF

ORDERING INFORMATION

DS1305 16-Pin DIP (300mil)

DS1305N 16-Pin DIP (Industrial)

DS1305E 20-Pin TSSOP (173mil)

DS1305EN 20-Pin TSSOP (Industrial)

SPI is a trademark of Motorola, Inc.

TYPICAL OPERATING CIRCUIT

1 of 20 061202

Page 2

DS1305

PIN DESCRIPTION

V

CC1

V

- Backup Power Supply

CC2

V

- +3V Battery Input

BAT

V

- Interface Logic Power-Supply Input

CCIF

GND - Ground

X1, X2 - 32,768kHz Crystal Connection

INT0 - Interrupt 0 Output

INT1 - Interrupt 1 Output

SDI - Serial Data In

SDO - Serial Data Out

CE - Chip Enable

SCLK - Serial Clock

SERMODE - Serial Interface Mode

PF - Power-Fail Output

- Primary Power Supply

DESCRIPTION

The DS1305 serial alarm real-time clock provides a full binary coded decimal (BCD) clock calendar that

is accessed by a simple serial interface. The clock/calendar provides seconds, minutes, hours, day, date,

month, and year information. The end of the month date is automatically adjusted for months with fewer

than 31 days, including corrections for leap year. The clock operates in either the 24-hour or 12-hour

format with AM/PM indicator. In addition, 96 bytes of NV RAM are provided for data storage.

An interface logic power-supply input pin (V

) allows the DS1305 to drive SDO and PF pins to a level

CCIF

that is compatible with the interface logic. This allows an easy interface to 3V logic in mixed supply

systems.

The DS1305 offers dual-power supplies as well as a battery input pin. The dual power supplies support a

programmable trickle charge circuit that allows a rechargeable energy source (such as a super cap or

rechargeable battery) to be used for a backup supply. The V

pin allows the device to be backed up by

BAT

a non-rechargeable battery. The DS1305 is fully operational from 2.0V to 5.5V.

Two programmable time-of-day alarms are provided by the DS1305. Each alarm can generate an

interrupt on a programmable combination of seconds, minutes, hours, and day. “Don’t care” states can be

inserted into one or more fields if it is desired for them to be ignored for the alarm condition. The time-ofday alarms can be programmed to assert two different interrupt outputs or to assert one common interrupt

output. Both interrupt outputs operate when the device is powered by V

CC1

CC2

, or V

BAT

.

, V

The DS1305 supports a direct interface to SPI serial data ports or standard 3-wire interface. A

straightforward address and data format is implemented in which data transfers can occur 1 byte at a time

or in multiple-byte-burst mode.

2 of 20

Page 3

DS1305

OPERATION

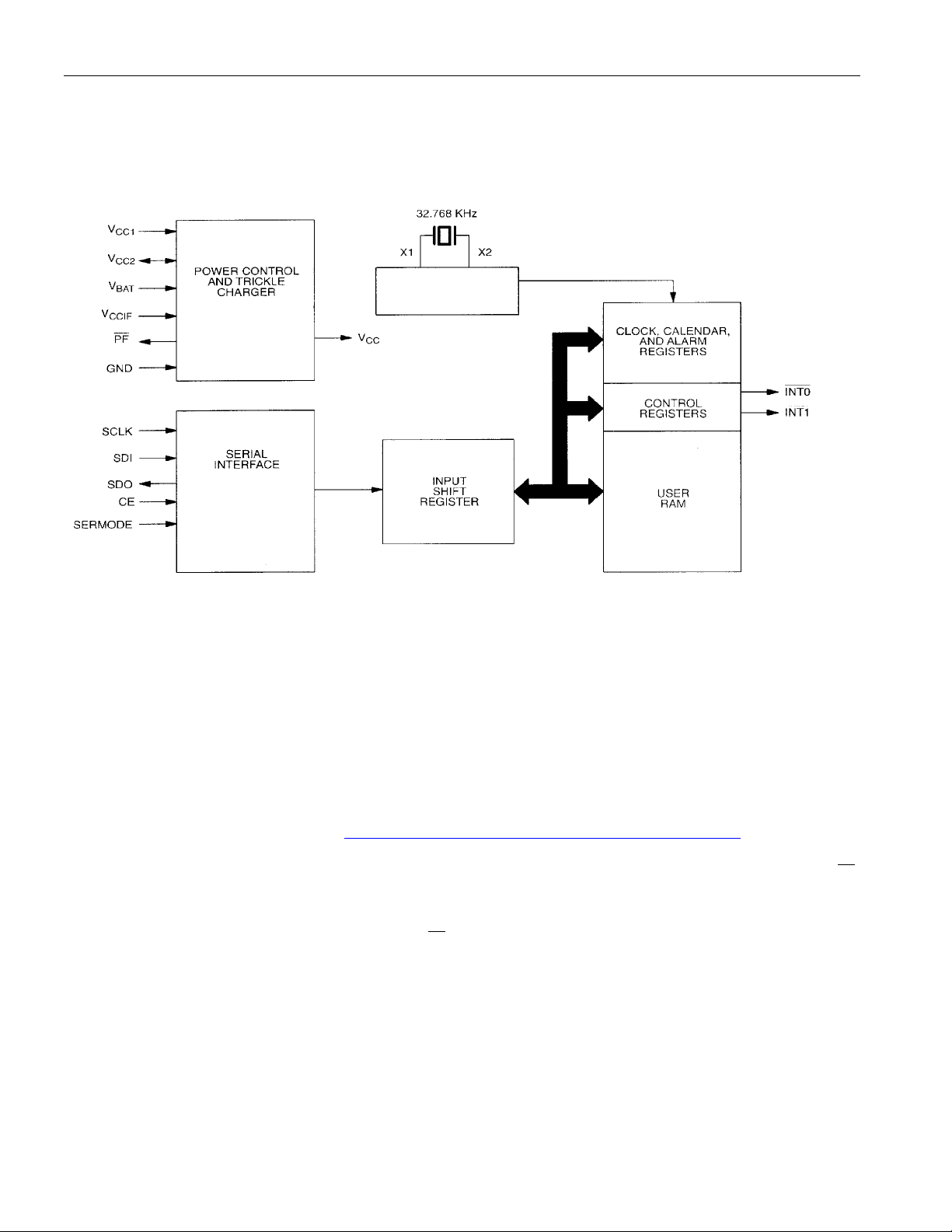

The block diagram in Figure 1 shows the main elements of the serial alarm RTC. The following

paragraphs describe the function of each pin.

Figure 1. BLOCK DIAGRAM

OSCILLATOR AND

COUNTDOWN CHAIN

1Hz

SIGNAL DESCRIPTIONS

V

– DC power is provided to the device on this pin. V

CC1

V

– This is the secondary power supply pin. In systems using the trickle charger, the rechargeable

CC2

energy source is connected to this pin.

is the primary power supply.

CC1

V

– Battery input for any standard 3V lithium cell or other energy source. UL recognized to ensure

BAT

against reverse charging current when used in conjunction with a lithium battery.

See “Conditions of Acceptability” at http://www.maxim-ic.com/TechSupport/QA/ntrl.htm.

V

(Interface Logic Power-Supply Input) – The V

CCIF

pin allows the DS1305 to drive SDO and PF

CCIF

output pins to a level that is compatible with the interface logic, thus allowing an easy interface to 3V

logic in mixed supply systems. This pin is physically connected to the source connection of the p-channel

transistors in the output buffers of the SDO and

PF pins.

SERMODE (Serial Interface Mode Input) – The SERMODE pin offers the flexibility to choose

between two serial interface modes. When connected to GND, standard 3-wire communication is

selected. When connected to VCC, SPI communication is selected.

SCLK (Serial Clock Input) – SCLK is used to synchronize data movement on the serial interface for

either the SPI or 3-wire interface.

3 of 20

Page 4

DS1305

SDI (Serial Data Input) – When SPI communication is selected, the SDI pin is the serial data input for

the SPI bus. When 3-wire communication is selected, this pin must be tied to the SDO pin (the SDI and

SDO pins function as a single I/O pin when tied together).

SDO (Serial Data Output) – When SPI communication is selected, the SDO pin is the serial data output

for the SPI bus. When 3-wire communication is selected, this pin must be tied to the SDI pin (the SDI and

SDO pins function as a single I/O pin when tied together).

CE (Chip Enable) – The chip enable signal must be asserted high during a read or a write for both 3wire and SPI communication. This pin has an internal 55k pulldown resistor (typical).

INT0 (Interrupt 0 Output) – The INT0 pin is an active low output of the DS1305 that can be used as an

interrupt input to a processor. The INT0 pin can be programmed to be asserted by only Alarm 0 or can be

programmed to be asserted by either Alarm 0 or Alarm 1. The

INT0 pin remains low as long as the status

bit causing the interrupt is present and the corresponding interrupt enable bit is set. The

when the DS1305 is powered by V

CC1

, V

CC2

, or V

. The INT0 pin is an open drain output and requires

BAT

INT0 pin operates

an external pullup resistor.

INT1 (Interrupt 1 Output) – The INT1 pin is an active-low output of the DS1305 that can be used as an

interrupt input to a processor. The INT1 pin can be programmed to be asserted by Alarm 1 only. The

INT1 pin remains low as long as the status bit causing the interrupt is present and the corresponding

interrupt enable bit is set. The INT1 pin operates when the DS1305 is powered by V

CC1

, V

CC2

, or V

BAT

The INT1 pin is an open-drain output and requires an external pullup resistor.

Both INT0 and INT1are open-drain outputs. The two interrupts and the internal clock continue to run

regardless of the level of VCC (as long as a power source is present).

PF (Power-Fail Output) – The PF pin is used to indicate loss of the primary power supply (V

When V

is less than V

CC1

or is less than V

CC2

, the PF pin is driven low.

BAT

CC1

X1, X2 – Connections for a standard 32.768kHz quartz crystal. The internal oscillator is designed for

operation with a crystal having a specified load capacitance of 6pF. For more information on crystal

selection and crystal layout considerations, refer to Application Note 58, “Crystal Considerations with

Dallas Real-Time Clocks.” The DS1305 can also be driven by an external 32.768kHz oscillator. In this

configuration, the X1 pin is connected to the external oscillator signal and the X2 pin is floated.

.

).

4 of 20

Page 5

DS1305

RECOMMENDED LAYOUT FOR CRYSTAL

CLOCK ACCURACY

The accuracy of the clock is dependent upon the accuracy of the crystal and the accuracy of the match

between the capacitive load of the oscillator circuit and the capacitive load for which the crystal was

trimmed. Additional error is added by crystal frequency drift caused by temperature shifts. External

circuit noise coupled into the oscillator circuit can result in the clock running fast. Refer to Application

Note 58, “Crystal Considerations with Dallas Real-Time Clocks” for detailed information.

CLOCK, CALENDAR, AND ALARM

The time and calendar information is obtained by reading the appropriate register bytes. The RTC

registers and user RAM are illustrated in Figure 2. The time, calendar, and alarm are set or initialized by

writing the appropriate register bytes. Note that some bits are set to 0. These bits always read 0 regardless

of how they are written. Also note that registers 12h to 1Fh (read) and registers 92h to 9Fh are reserved.

These registers always read 0 regardless of how they are written. The contents of the time, calendar, and

alarm registers are in the BCD format.

Except where otherwise noted, the initial power on state of all registers is not defined. Therefore, it is

important to enable the oscillator (EOSC = 0) and disable write protect (WP = 0) during initial

configuration.

WRITING TO THE CLOCK REGISTERS

The internal time and date registers continue to increment during write operations. However, the

countdown chain is reset when the seconds register is written. Writing the time and date registers within

one second after writing the seconds register ensures consistent data.

Terminating a write before the last bit is sent aborts the write for that byte.

READING FROM THE CLOCK REGISTERS

Buffers are used to copy the time and date register at the beginning of a read. When reading in burst

mode, the user copy is static while the internal registers continue to increment.

5 of 20

Page 6

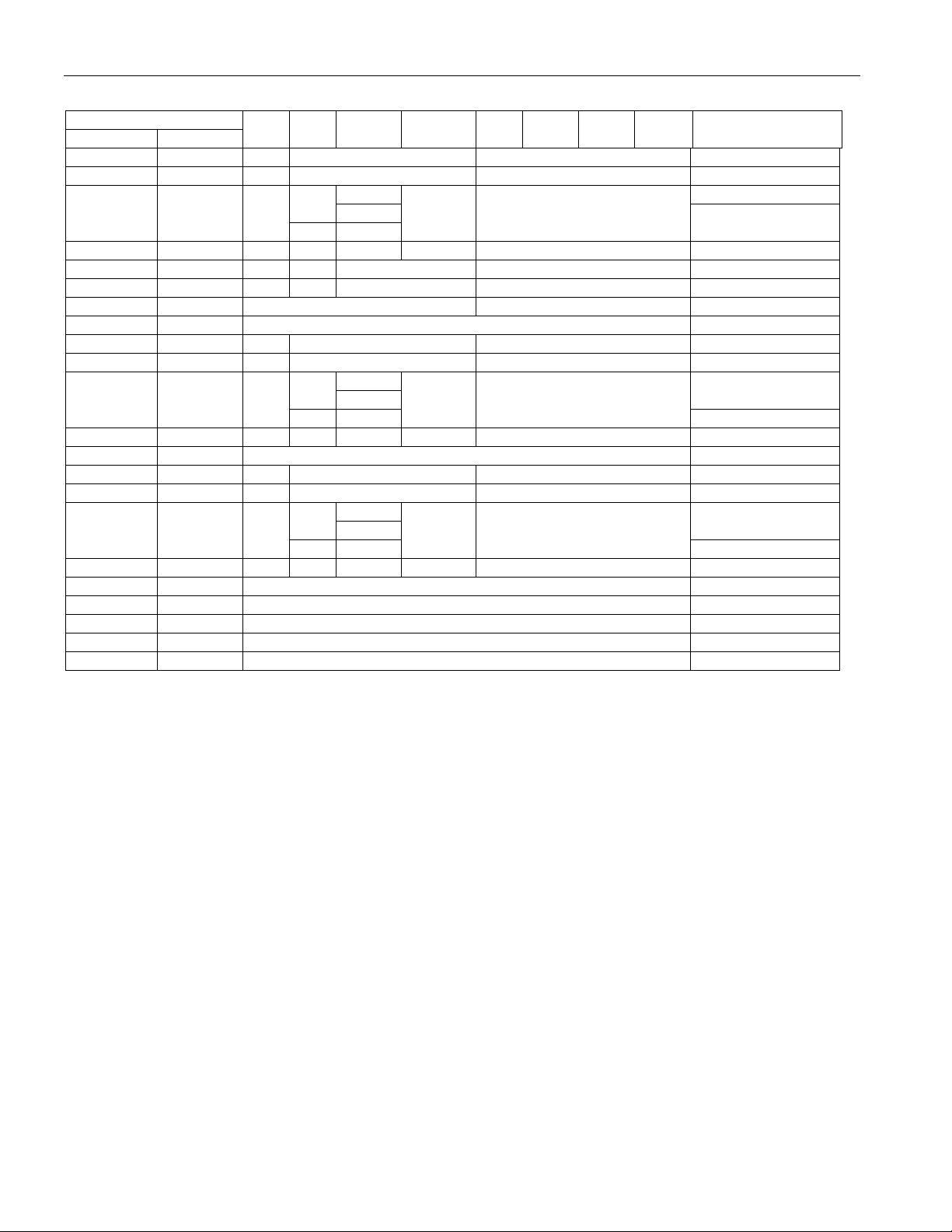

Figure 2. RTC REGISTERS AND ADDRESS MAP

DS1305

HEX ADDRESS

READ WRITE

00H 80H 0 10-SEC SEC 00–59

01H 81H 0 10-MIN MIN 00–59

02H 82H 0

03H 83H 0 0 0 0 DAY 1–7

04H 84H 0 0 10-DATE DATE 1–31

05H 85H 0 0 10-MONTH MONTH 01–12

06H 86H 10 YEAR YEAR 00–99

——

07H 87H M 10-SEC ALARM SEC ALARM 00–59

08H 88H M 10-MIN ALARM MIN ALARM 00–59

09H 89H M

0AH 8AH M 0 0 0 DAY ALARM 01–07

——

0BH 8BH M 10-SEC ALARM SEC ALARM 00–59

0CH 8CH M 10-MIN ALARM MIN ALARM 00–59

0DH 8DH M

0EH 8EH M 0 0 0 DAY ALARM 01–07

0FH 8FH CONTROL REGISTER —

10H 90H STATUS REGISTER —

11H 91H TRICKLE CHARGER REGISTER —

12–1FH 92–9FH RESERVED —

20–7FH A0–FFH 96 BYTES USER RAM 00–FF

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0 RANGE

12

24 10

12

24 10

12

24 10

P 01–12 + P/A

A

P

A

P

A

10-HR HOURS

ALARM 0

10 HR HOUR ALARM

ALARM 1

10 HR HOUR ALARM

00–23

—

01–12 + P/A

00–23

—

01–12 + P/A

00–23

Note: Range for alarm registers does not include mask’m’ bits.

The DS1305 can be run in either 12-hour or 24-hour mode. Bit 6 of the hours register is defined as the

12- or 24-hour mode select bit. When high, the 12-hour mode is selected. In the 12-hour mode, bit 5 is the

AM/PM bit with logic high being PM. In the 24-hour mode, bit 5 is the second 10-hour bit (20 to 23

hours).

The DS1305 contains two time-of-day alarms. Time-of-day Alarm 0 can be set by writing to registers 87h

to 8Ah. Time-of-day Alarm 1 can be set by writing to registers 8Bh to 8Eh. The alarms can be

programmed (by the INTCN bit of the control register) to operate in two different modes; each alarm can

drive its own separate interrupt output or both alarms can drive a common interrupt output. Bit 7 of each

of the time-of-day alarm registers are mask bits (Table 1). When all of the mask bits are logic 0, a timeof-day alarm only occurs once per week when the values stored in timekeeping registers 00h to 03h

match the values stored in the time-of-day alarm registers. An alarm is generated every day when bit 7 of

the day alarm register is set to a logic 1. An alarm is generated every hour when bit 7 of the day and hour

alarm registers is set to a logic 1. Similarly, an alarm is generated every minute when bit 7 of the day,

hour, and minute alarm registers is set to a logic 1. When bit 7 of the day, hour, minute, and seconds

alarm registers is set to a logic 1, alarm occurs every second.

6 of 20

Page 7

DS1305

During each clock update, the RTC compares the Alarm 0 and Alarm 1 registers with the corresponding

clock registers. When a match occurs, the corresponding alarm flag bit in the status register is set to a 1. If

the corresponding alarm interrupt enable bit is enabled, an interrupt output is activated.

Table 1. TIME-OF-DAY ALARM MASK BITS

ALARM REGISTER MASK BITS (BIT 7)

SECONDS MINUTES HOURS DAYS

1 1 1 1 Alarm once per second

0 1 1 1 Alarm when seconds match

0 0 1 1 Alarm when minutes and seconds match

0 0 0 1 Alarm hours, minutes, and seconds match

0 0 0 0 Alarm day, hours, minutes and seconds match

FUNCTION

SPECIAL PURPOSE REGISTERS

The DS1305 has three additional registers (control register, status register, and trickle charger register)

that control the RTC, interrupts, and trickle charger.

CONTROL REGISTER (READ 0FH, WRITE 8FH)

BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

EOSC

EOSC (Enable Oscillator) – This bit when set to logic 0 startS the oscillator. When this bit is set to a

logic 1, the oscillator is stopped and the DS1305 is placed into a low-power standby mode with a current

drain of less than 100nA when power is supplied by V

defined.

WP 0 0 0 INTCN AIE1 AIEO

BAT

or V

. The initial power-on state is not

CC2

WP (Write Protect) – Before any write operation to the clock or RAM, this bit must be logic 0. When

high, the write protect bit prevents a write operation to any register, including bits 0, 1, 2, and 7 of the

control register. Upon initial power-up, the state of the WP bit is undefined. Therefore, the WP bit should

be cleared before attempting to write to the device.

INTCN (Interrupt Control) – This bit controls the relationship between the two time-of-day alarms and

the interrupt output pins. When the INTCN bit is set to a logic 1, a match between the timekeeping

registers and the Alarm 0 registers activates the INT0 pin (provided that the alarm is enabled) and a

match between the timekeeping registers and the Alarm 1 registers activate the INT1 pin (provided that

the alarm is enabled). When the INTCN bit is set to a logic 0, a match between the timekeeping registers

and either Alarm 0 or Alarm 1 activate the

INT0 pin (provided that the alarms are enabled). INT1 has no

function when INTCN is set to a logic 0.

AIE0 (Alarm Interrupt Enable 0) – When set to a logic 1, this bit permits the interrupt 0 request flag

(IRQF0) bit in the status register to assert

not initiate the

INT0 signal.

INT0 . When the AIE0 bit is set to logic 0, the IRQF0 bit does

AIE1 (Alarm Interrupt Enable 1) – When set to a logic 1, this bit permits the interrupt 1 request flag

(IRQF1) bit in the status register to assert

INT1 (when INTCN = 1) or to assert INT0 (when INTCN = 0).

When the AIE1 bit is set to logic 0, the IRQF1 bit does not initiate an interrupt signal.

7 of 20

Page 8

DS1305

STATUS REGISTER (READ 10H)

BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

000000IRQF1IRQF0

IRQF0 (Interrupt 0 Request Flag) – A logic 1 in the interrupt request flag bit indicates that the current

time has matched the Alarm 0 registers. If the AIE0 bit is also a logic 1, the INT0 pin goes low. IRQF0 is

cleared when the address pointer goes to any of the Alarm 0 registers during a read or write.

IRQF1 (Interrupt 1 Request Flag) – A logic 1 in the interrupt request flag bit indicates that the current

time has matched the Alarm 1 registers. This flag can be used to generate an interrupt on either

INT1 depending on the status of the INTCN bit in the control register. If the INTCN bit is set to a logic 1

INT0 or

and IRQF1 is at a logic 1 (and AIE1 bit is also a logic 1), the INT1 pin goes low. If the INTCN bit is set

to a logic 0 and IRQF1 is at a logic 1 (and AIE1 bit is also a logic 1), the

INT0 pin goes low. IRQF1 is

cleared when the address pointer goes to any of the Alarm 1 registers during a read or write.

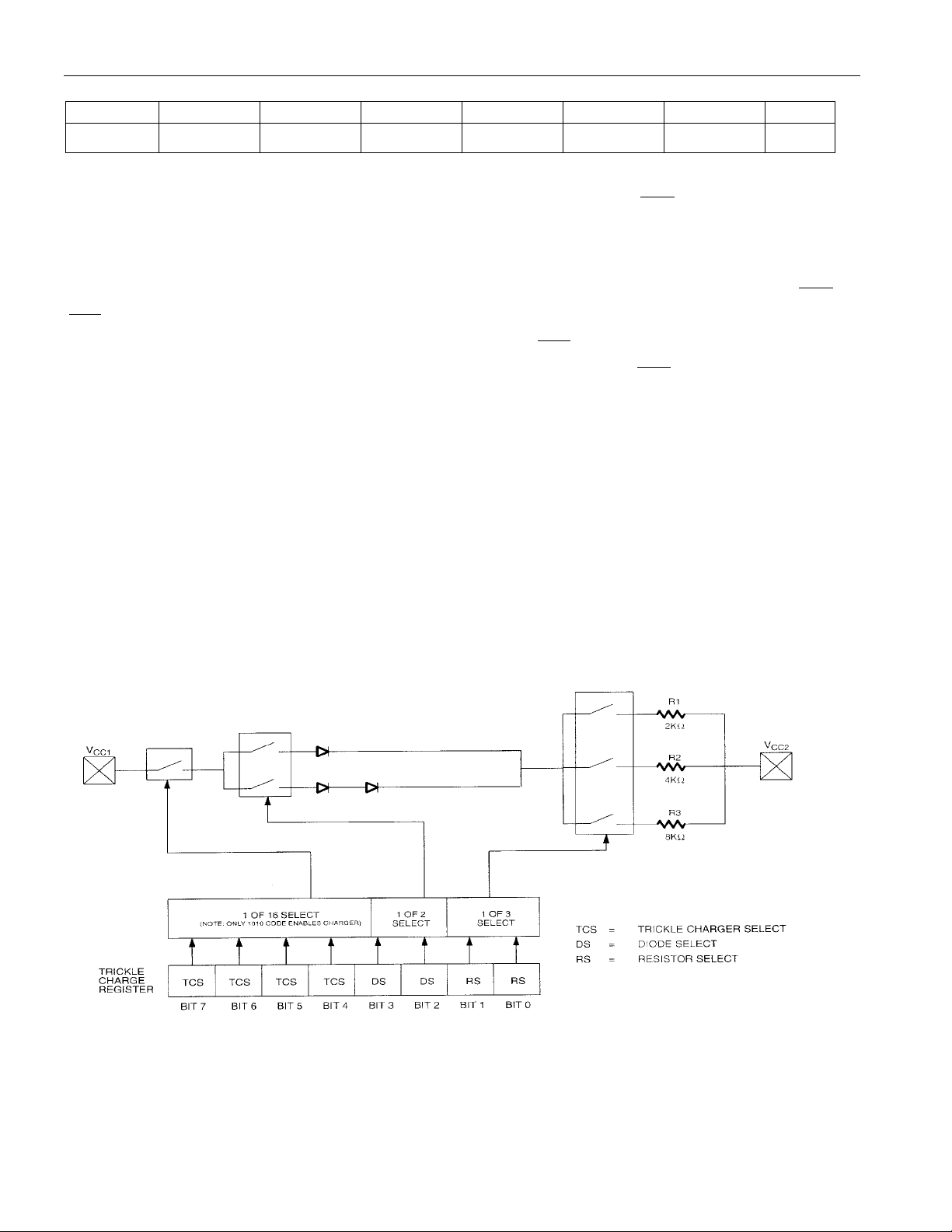

TRICKLE CHARGE REGISTER (READ 11H, WRITE 91H)

This register controls the trickle charge characteristics of the DS1305. The simplified schematic of Figure

3 shows the basic components of the trickle charger. The trickle-charge select (TCS) bits (bits 4–7)

control the selection of the trickle charger. To prevent accidental enabling, only a pattern of 1010 enables

the trickle charger. All other patterns disable the trickle charger. On the initial application of power, the

DS1305 powers up with the trickle charger disabled. The diode select (DS) bits (bits 2–3) select whether

one diode or two diodes are connected between V

resistor that is connected between V

CC1

and V

CC2

CC1

and V

. The resistor select (RS) bits select the

CC2

. The resistor and diodes are selected by the RS and DS

bits, as shown in Table 2.

Figure 3. PROGRAMMABLE TRICKLE CHARGER

8 of 20

Page 9

Table 2. TRICKLE CHARGER RESISTOR AND DIODE SELECT

DS1305

TCS

Bit 7

X X XXXX0 0 Disabled

X X XX0 0 XX Disabled

X X XX1 1 XX Disabled

1 0 100101 1 Diode, 2kΩ

1 0 100110 1 Diode, 4kΩ

1 0 100111 1 Diode, 8kΩ

1 0 101001 2 Diodes, 2kΩ

1 0 101010 2 Diodes, 4kΩ

1 0 101011 2 Diodes, 8kΩ

TCS

Bit 6

TCS

Bit 5

TCS

Bit 4DSBit 3DSBit 2RSBit 1RSBit 0

FUNCTION

The user determines diode and resistor selection according to the maximum current desired for battery or

super cap charging. The maximum charging current can be calculated as illustrated in the following

example. Assume that a system power supply of 5V is applied to V

V

. Also assume that the trickle charger has been enabled with 1 diode and resister R1 between V

CC2

and V

. The maximum current I

CC2

would, therefore, be calculated as follows:

MAX

and a super cap is connected to

CC1

CC1

I

= (5.0V - diode drop) / R1 » (5.0V - 0.7V) / 2kW » 2.2mA

MAX

As the super cap charges, the voltage drop between V

CC1

and V

decreases and, therefore, the charge

CC2

current decreases.

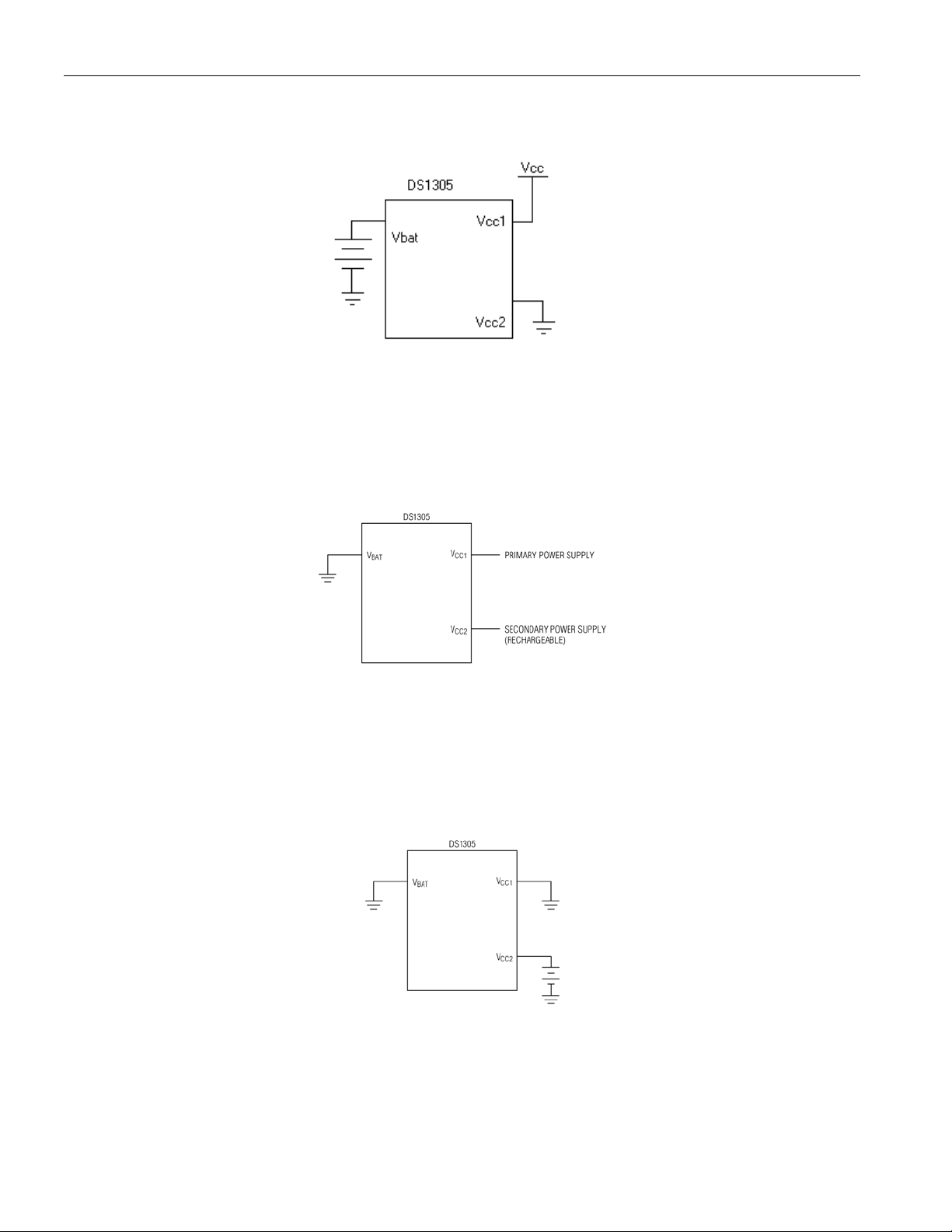

POWER CONTROL

Power is provided through the V

are illustrated in Figure 4. Configuration 1 shows the DS1305 being backed up by a nonrechargeable

energy source such as a lithium battery. In this configuration, the system power supply is connected to

and V

V

CC1

accessible when V

is grounded. The DS1305 is write-protected if V

CC2

is greater than V

CC1

Configuration 2 illustrates the DS1305 being backed up by a rechargeable energy source. In this case, the

pin is grounded, V

V

BAT

is connected to the primary power supply, and V

CC1

secondary supply (the rechargeable energy source). The DS1305 operates from the larger of V

V

V

CC2

CC2

. When V

, V

powers the DS1305. The DS1305 does not write-protect itself in this configuration.

CC2

is greater than V

CC1

Configuration 3 shows the DS1305 in battery operate mode where the device is powered only by a single

battery. In this case, the V

CC1

and V

CC1

CC2

, V

BAT

, and V

CC2

+ 0.2V.

BAT

+ 0.2V (typical), V

pins. Three different power-supply configurations

BAT

is less than V

CC1

powers the DS1305. When V

CC1

BAT

CC2

pins are grounded and the battery is connected to the V

. The DS1305 is fully

is connected to the

or

CC1

is less than

CC1

pin.

CC2

Only these three configurations are allowed. Unused supply pins must be grounded.

9 of 20

Page 10

Figure 4. POWER SUPPLY CONFIGURATIONS

Configuration 1: Backup Supply is a Nonrechargeable Lithium Battery

V

CCTP

Note: Device is write-protected if VCC < V

Configuration 2: Backup Supply is a Rechargeable Battery or Super Capacitor

CCTP

.

DS1305

Note: Device does not provide automatic write protection.

Configuration 3: Battery Operate Mode

10 of 20

Page 11

DS1305

SERIAL INTERFACE

The DS1305 offers the flexibility to choose between two serial interface modes. The DS1305 can

communicate with the SPI interface or with a standard 3-wire interface. The interface method used is

determined by the SERMODE pin. When this pin is connected to VCC, SPI communication is selected.

When this pin is connected to ground, standard 3-wire communication is selected.

SERIAL PERIPHERAL INTERFACE (SPI)

The serial peripheral interface (SPI) is a synchronous bus for address and data transfer, and is used when

interfacing with the SPI bus on specific Motorola microcontrollers such as the 68HC05C4 and the

68HC11A8. The SPI mode of serial communication is selected by tying the SERMODE pin to VCC. Four

pins are used for the SPI. The four pins are the SDO (serial data out), SDI (serial data in), CE (chip

enable), and SCLK (serial clock). The DS1305 is the slave device in an SPI application, with the

microcontroller being the master.

The SDI and SDO pins are the serial data input and output pins for the DS1305, respectively. The CE

input is used to initiate and terminate a data transfer. The SCLK pin is used to synchronize data

movement between the master (microcontroller) and the slave (DS1305) devices.

The shift clock (SCLK), which is generated by the microcontroller, is active only during address and data

transfer to any device on the SPI bus. The inactive clock polarity is programmable in some

microcontrollers. The DS1305 determines the clock polarity by sampling SCLK when CE becomes

active. Therefore, either SCLK polarity can be accommodated. Input data (SDI) is latched on the internal

strobe edge and output data (SDO) is shifted out on the shift edge (Figure 5). There is one clock for each

bit transferred. Address and data bits are transferred in groups of eight.

11 of 20

Page 12

DS1305

Figure 5. SERIAL CLOCK AS A FUNCTION OF MICROCONTROLLER CLOCK

POLARITY (CPOL)

CE

CPOL = 1

SCLK

SHIFT DATA OUT (READ)

CPOL = 0

SCLK

SHIFT DATA OUT (READ)

DATA LATCH (WRITE)

DATA LATCH (WRITE)

1) CPHA bit polarity (if applicable) may need to be set accordingly.

2) CPOL is a bit that is set in the microcontroller’s control register.

3) SDO remains at high-Z until 8 bits of data are ready to be shifted out during a read.

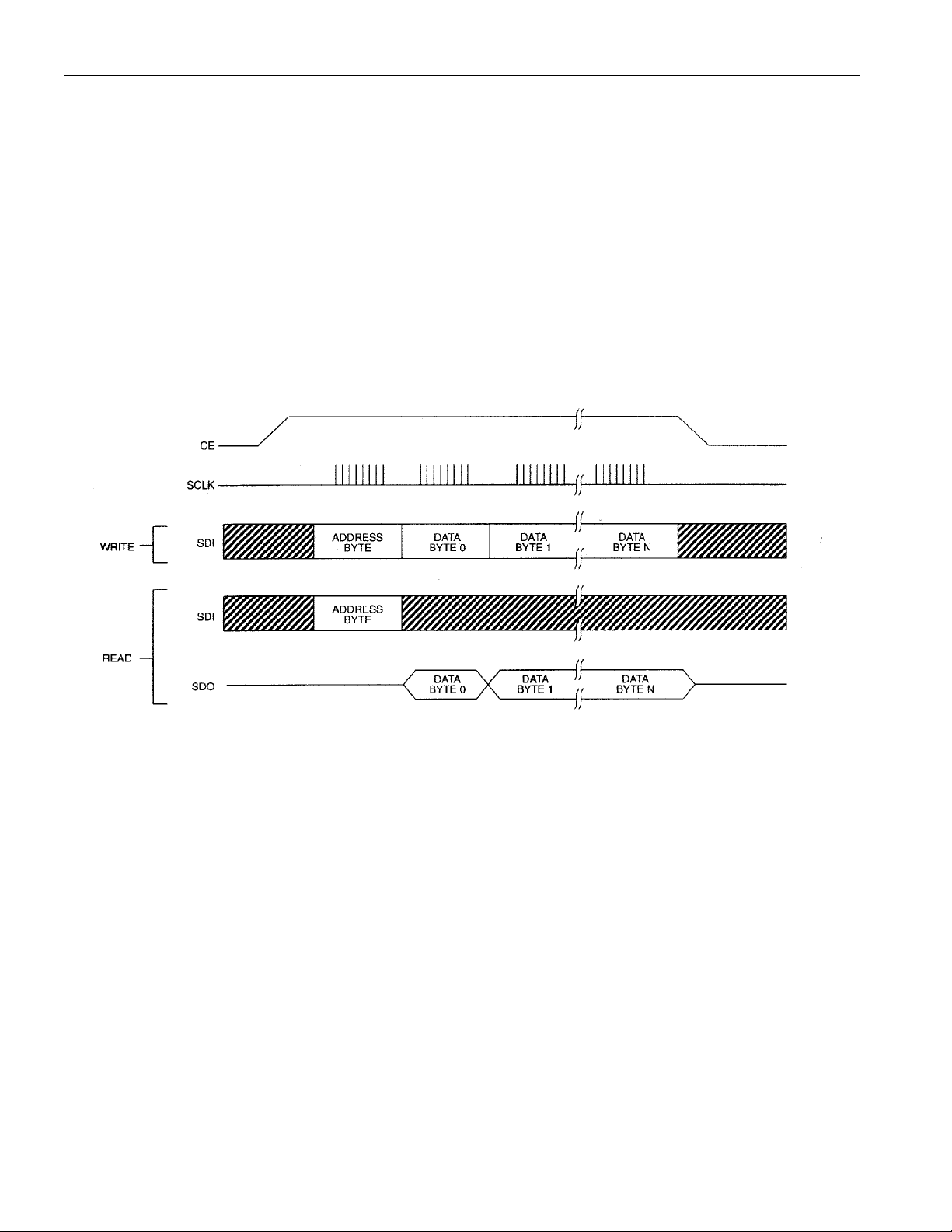

ADDRESS AND DATA BYTES

Address and data bytes are shifted MSB first into the serial data input (SDI) and out of the serial data

output (SDO). Any transfer requires the address of the byte to specify a write or read to either a RTC or

RAM location, followed by one or more bytes of data. Data is transferred out of the SDO for a read

operation and into the SDI for a write operation (Figures 6 and 7).

Figure 6. SPI SINGLE-BYTE WRITE

Figure 7. SPI SINGLE-BYTE READ

*SCLK can be either polarity.

12 of 20

Page 13

DS1305

The address byte is always the first byte entered after CE is driven high. The most significant bit (A7) of

this byte determines if a read or write takes place. If A7 is 0, one or more read cycles occur. If A7 is 1,

one or more write cycles occur.

Data transfers can occur one byte at a time or in multiple-byte burst mode. After CE is driven high an

address is written to the DS1305. After the address, one or more data bytes can be written or read. For a

single-byte transfer, one byte is read or written and then CE is driven low. For a multiple-byte transfer,

however, multiple bytes can be read or written to the DS1305 after the address has been written. Each

read or write cycle causes the RTC register or RAM address to automatically increment. Incrementing

continues until the device is disabled. When the RTC is selected, the address wraps to 00h after

incrementing to 1Fh (during a read) and wraps to 80h after incrementing to 9Fh (during a write). When

the RAM is selected, the address wraps to 20h after incrementing to 7Fh (during a read) and wraps to

A0h after incrementing to FFh (during a write).

Figure 8. SPI MULTIPLE-BYTE BURST TRANSFER

READING AND WRITING IN BURST MODE

Burst mode is similar to a single-byte read or write, except that CE is kept high and additional SCLK

cycles are sent until the end of the burst. The clock registers and the user RAM can be read or written in

burst mode. When accessing the clock registers in burst mode, the address pointer wraps around after

reaching 1Fh (9Fh for writes). When accessing the user RAM in burst mode, the address pointer wraps

around after reaching 7Fh (FFh for writes).

13 of 20

Page 14

DS1305

A

3-WIRE INTERFACE

The 3-wire interface mode operates similarly to the SPI mode. However, in 3-wire mode there is one I/O

instead of separate data in and data out signals. The 3-wire interface consists of the I/O (SDI and SDO

pins tied together), CE, and SCLK pins. In 3-wire mode, each byte is shifted in LSB first unlike SPI mode

where each byte is shifted in MSB first.

As is the case with the SPI mode, an address byte is written to the device followed by a single data byte

or multiple data bytes. Figure 9 illustrates a read and write cycle. In 3-wire mode, data is input on the

rising edge of SCLK and output on the falling edge of SCLK.

Figure 9. 3-WIRE SINGLE-BYTE TRANSFER

Single-Byte Read

CE

SCLK

I/O*

0 A1 A2 A3 A4 A5 A6 0

Single-Byte Write

CE

SCLK

I/O*

In burst mode, CE

*I/O is SDI and SDO tied together.

is kept high and additional SCLK cycles are sent until the end of the burst.

D0 D1 D2 D3 D4 D5 D6 D7

14 of 20

Page 15

DS1305

ABSOLUTE MAXIMUM RATINGS*

Voltage Range on Any Pin Relative to Ground -0.5V to +7.0V

Storage Temperature Range -55°C to +125°C

Soldering Temperature Range See IPC/JEDEC J-STD-020A

*This is a stress rating only and functional operation of the device at these or any other conditions beyond

those indicated in the operation sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods of time can affect reliability.

OPERATING RANGE

RANGE TEMP. RANGE V

Commercial 0°C to +70°C 2.0 to 5.5 V

CC

(V)

CC1

or V

CC2

Industrial -40°C to +85°C 2.0 to 5.5 V

CC1

or V

CC2

RECOMMENDED DC OPERATING CONDITIONS Over the operating range*

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Supply Voltage

V

, V

CC1

CC2

V

Logic 1 Input V

Logic 0 Input V

V

Battery Voltage V

BAT

V

Supply Voltage V

CCIF

*Unless otherwise specified.

CC1

, V

IH

IL

BAT

CCIF

CC2

VCC = 2.0V +0.3

VCC = 5V

2.0 5.5 V 7

2.0 VCC + 0.3 V

-0.3

V

+0.8

2.0 5.5 V

2.0 5.5 V 11

15 of 20

Page 16

DS1305

DC ELECTRICAL CHARACTERISTICS Over the operating range*

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Input Leakage I

Output Leakage I

Logic 0 Output IOL= 1.5mA

I

= 4.0mA

OL

Logic 1 Output IOH = -0.4mA

I

V

Active Supply Current I

CC1

V

Timekeeping Current

CC1

(Osc on)

V

Standby Current

CC1

(Osc off)

V

Active Supply

CC2

Current

V

Timekeeping Current

CC2

= -1.0mA

OH

I

I

I

I

(Osc on)

V

Standby Current

CC2

I

(Osc off)

Battery Timekeeping Current I

Battery Standby Current I

VCC Trip Point V

Trickle Charge Resistors

Trickle Charge Diode

Voltage Drop

LI

LO

V

OL

V

OH

CC1A

CC1T

CC1S

CC2A

CC2T

CC2S

BAT

BATS

CCTP

R1

R2

R3

V

TD

VCC = 2.0V 0.4

VCC = 5V 0.4

V

= 2.0V 1.6

CCIF

V

= 5V 2.4

CCIF

V

= 2.0V 0.425

CC1

V

= 5V 1.28

CC1

V

= 2.0V 25.3

CC1

V

= 5V 81

CC1

V

= 2.0V 25

CC1

V

= 5V 80

CC1

V

= 2.0V 0.4

CC2

V

= 5V 1.2

CC2

V

= 2.0V 0.3

CC2

V

= 5V 1

CC2

V

= 2.0V 200

CC2

V

= 5V 200

CC2

V

= 3V 400 nA 10, 12

BAT

V

= 3V 200 nA 10, 12

BAT

-100 +500 µA

-1 1 µA

V

+

V

- 50

BAT

BAT

200

2

4

8

0.7 V

V

V

mA 2, 8

µA 1, 8, 12

µA 6, 8, 12

mA 2, 9

µA 1, 9, 12

nA 6, 9, 12

mV

kW

*Unless otherwise specified.

CAPACITANCE (TA = +25°C)

PARAMETER SYMBOL CONDITION TYP MAX UNITS NOTES

Input Capacitance C

Output Capacitance C

Crystal Capacitance C

I

O

X

16 of 20

10 pF

15 pF

6pF

Page 17

DS1305

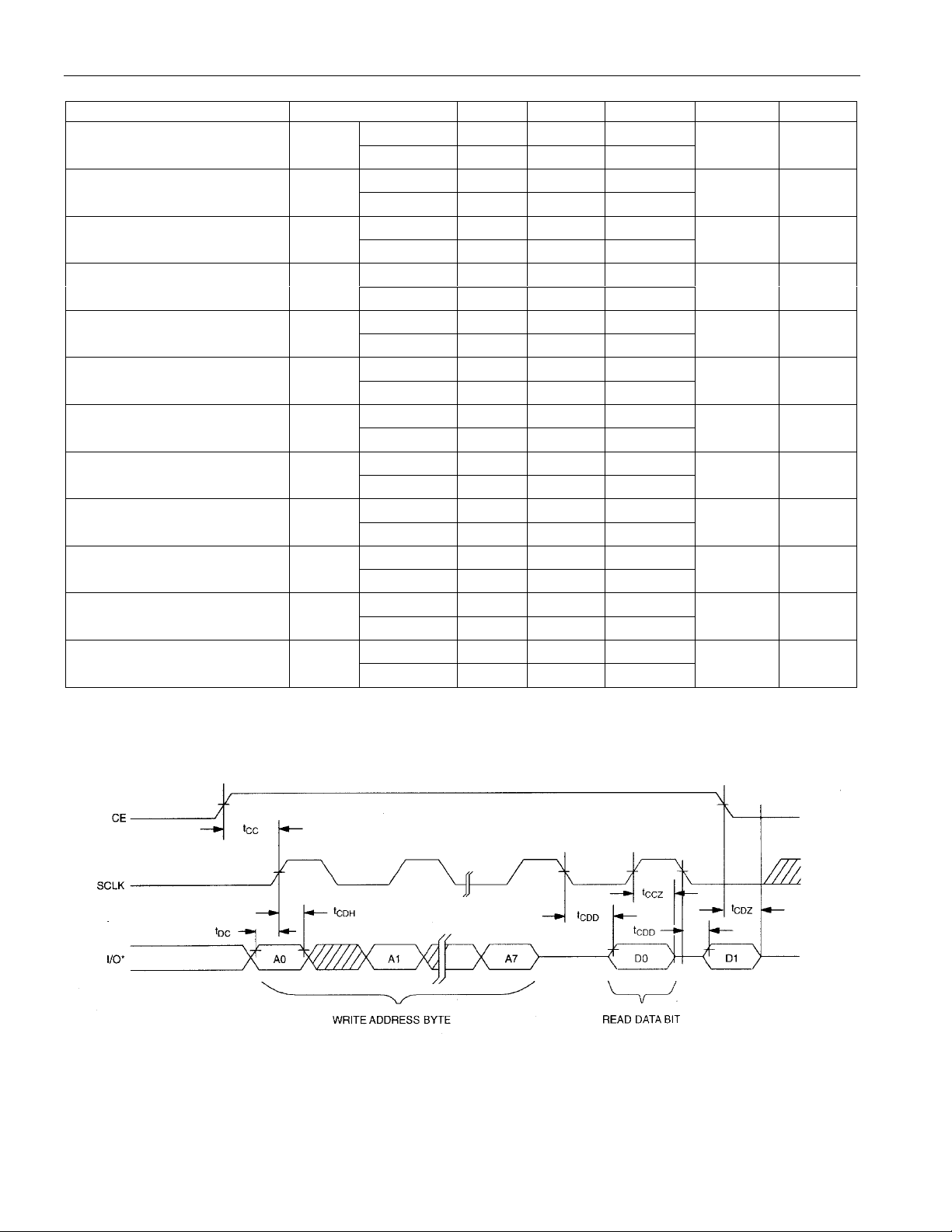

3-WIRE AC ELECTRICAL CHARACTERISTICS Over the operating range*

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Data to CLK Setup t

CLK to Data Hold t

CLK to Data Delay t

CLK Low Time t

CLK High Time t

CLK Frequency t

CLK Rise and Fall t

CE to CLK Setup t

CLK to CE Hold t

CE Inactive Time t

CE to Output High-Z t

SCLK to Output High-Z t

DC

CDH

CDD

CL

CH

CLK

R, tF

CC

CCH

CWH

CDZ

CCZ

VCC = 2.0V 200

VCC = 5V 50

VCC = 2.0V 280

VCC = 5V 70

VCC = 2.0V 800

VCC = 5V 200

VCC = 2.0V 1000

VCC = 5V 250

VCC = 2.0V 1000

VCC = 5V 250

VCC = 2.0V 0.6

VCC = 5V DC 2.0

VCC = 2.0V 2000

VCC = 5V 500

VCC = 2.0V 4

VCC = 5V 1

VCC = 2.0V 240

VCC = 5V 60

VCC = 2.0V 4

VCC = 5V 1

VCC = 2.0V 280

VCC = 5V 70

VCC = 2.0V 280

VCC = 5V 70

ns 3,4

ns 3,4

ns 3,4,5

ns 4

ns 4

MHz 4

ns

µs4

ns 4

µs4

ns 3,4

ns 3,4

*Unless otherwise specified.

Figure 10. TIMING DIAGRAM: 3-WIRE READ DATA TRANSFER

17 of 20

Page 18

DS1305

Figure 11. TIMING DIAGRAM: 3-WIRE WRITE DATA TRANSFER

SPI AC ELECTRICAL CHARACTERISTICS Over the operating range*

PARAMETER SYMBOL MIN TYP MAX UNITS NOTES

Data to CLK Setup t

CLK to Data Hold t

CLK to Data Delay t

CLK Low Time t

CLK High Time t

CLK Frequency t

CLK Rise and Fall t

CE to CLK Setup t

CLK to CE Hold t

CE Inactive Time t

CE to Output High-Z t

DC

CDH

CDD

CL

CH

CLK

R, tF

CC

CCH

CWH

CDZ

VCC = 2.0V 200

VCC = 5V 50

VCC = 2.0V 280

VCC = 5V 70

VCC = 2.0V 800

VCC = 5V 200

VCC = 2.0V 1000

VCC = 5V 250

VCC = 2.0V 1000

VCC = 5V 250

VCC = 2.0V 0.6

VCC = 5V DC 2.0

VCC = 2.0V 2000

VCC = 5V 500

VCC = 2.0V 4

VCC = 5V 1

VCC = 2.0V 240

VCC = 5V 60

VCC = 2.0V 4

VCC = 5V 1

VCC = 2.0V 280

VCC = 5V 70

ns 5,6

ns 5,6

ns 5,6,7

ns 6

ns 6

MHz 6

ns

µs6

ns 6

µs6

ns 5,6

*Unless otherwise specified.

18 of 20

Page 19

Figure 12. TIMING DIAGRAM: SPI READ DATA TRANSFER

Figure 13. TIMING DIAGRAM: SPI WRITE DATA TRANSFER

DS1305

19 of 20

Page 20

NOTES:

DS1305

1) I

2) I

CC1T

CC1A

and I

and I

are specified with CE set to a logic 0 and EOSC bit = 0 (oscillator enabled).

CC2T

are specified with CE = VCC, SCLK=2MHz at VCC = 5V; SCLK = 500kHz

CC2A

at VCC = 2.0V, VIL = 0V, VIH = VCC, and EOSC bit = 0 (oscillator enabled).

3) Measured at VIH = 2.0V or VIL = 0.8V and 10ms maximum rise and fall time.

4) Measured with 50pF load.

5) Measured at VOH = 2.4V or VOL = 0.4V.

6) I

CC1S

and I

are specified with CE set to a logic 0. The EOSC bit must be set to logic 1 (oscillator

CC2S

disabled).

7) VCC = V

8) V

9) V

10) V

11) V

CC2

CC1

CC1

CCIF

= 0V.

= 0V.

< V

, when V

CC1

BAT.

CC1

> V

+ 0.2V (typical); VCC = V

CC2

must be less than or equal to the largest of V

CC1

, V

CC2

CC2

, and V

, when V

BAT

CC2

.

> V

12) Using a crystal on X1 and X2, rated for 6pF load.

CC1

.

20 of 20

Loading...

Loading...