Page 1

AMS0805WAH

CATALOG No.:

2008.03

AMS0805WAH

Motion Sensor Data Sheet

Ver. 1.3

Advanced Material on Technolog y

Page 2

AMS0805WAH

MOTION SENSOR

Overview

Motion sensor is a 6-axis module consisting of 3-axis magnetic sensor and 3-axis

accelerometer. It allows highly accurate motion detection with geomagnetic direction and tilting

data. AMS0805WAH is a world’s smallest class of motion sensor module with embedded uCom.

Moreover, our exclusive embedded calibration algorithm, iRAC, eliminates the need for initial

manual calibrations. It also enables users to access to reliable motion data virtually anywhere.

Therefore, motion sensor is suitable for deployment in hand-held devices, where diverse

movements are constantly expected, in order to acquire accurate positioning and direction data.

Features

● a 3-axis accelerometer, a 3-axis magnetic sensor

● an internal micro-processor

● Built-in software (for auto-calibration)

● Serial interface: IIC, SPI

● Size: 7 X 9 X 1.2 (mm)

● iRAC (Intelligent Real time Automatic Calibration)

- Automatic offset compensation

- Automatic temperature compensation

- Automatic sensitivity calibration

- Automatic calibration for magnetic field disturbance

● Maximum sampling rate : 30Hz

● Low power: less than 9 mA in active

less than 20 uA in all power down mode

Applications

● Personal Navigation in mobile phone

● Calorie counter

● Constellation seeking device

● Robot motion control

● 3-D presenter

● Game controller

2

Page 3

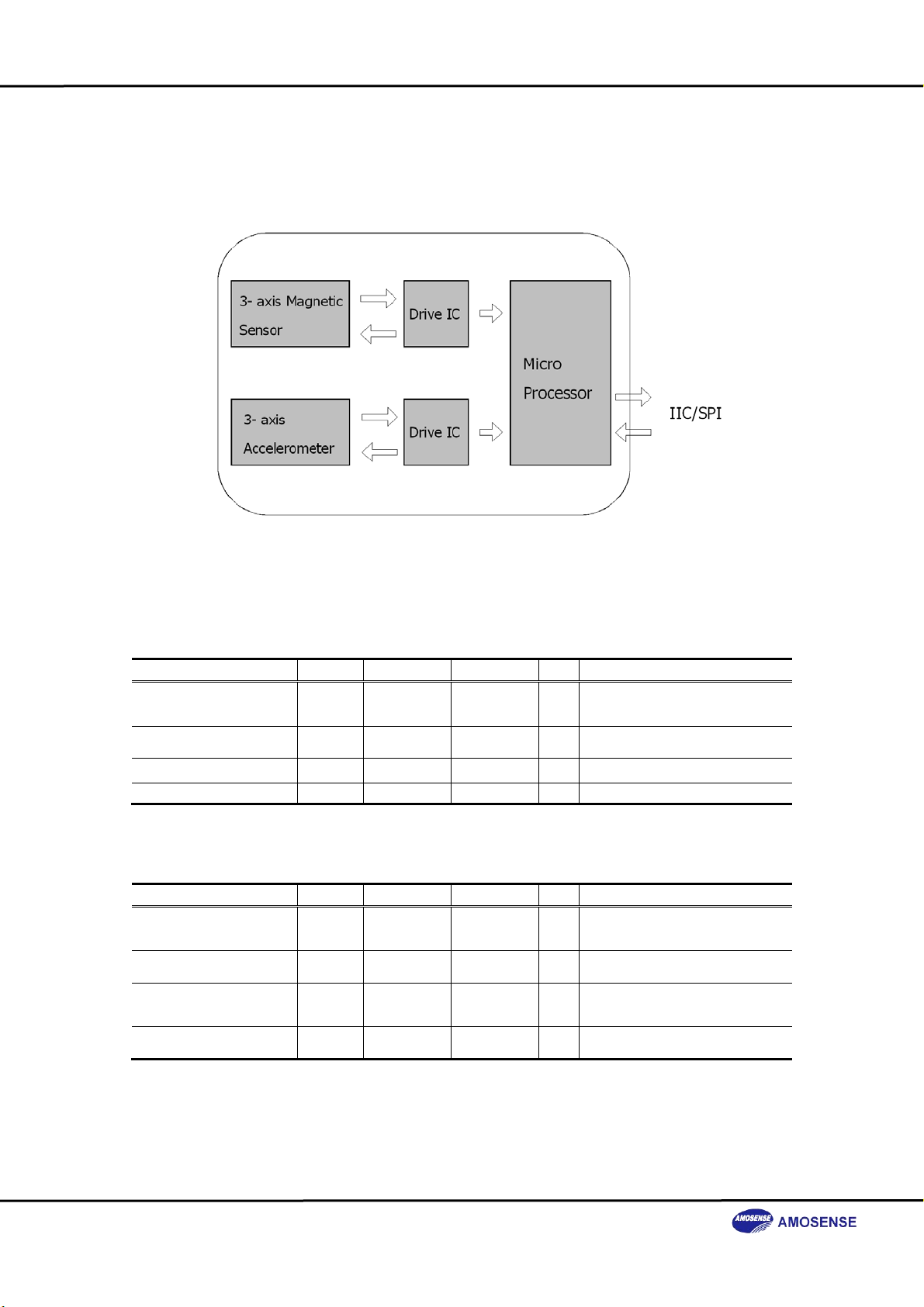

Functional Block Diagram

Absolute Maximum Ratings

Item Symbol Min. Max. Unit Description

DC Supply Voltage

(DVDD,DVDDIO,AVDD)

Storage Temperature

Range

Mechanical Shock - - + 4,600 g

ESD - - + 2,000 V

- - 0.3 + 4 V

- - 55 + 125 ℃

AMS0805WAH

MOTION SENSOR

Recommended Operating Conditions

Item Symbol Min. Max. Unit Description

Operating DVDD Supply

Voltage Range

Operating AVDD Supply

Voltage Range

Operating DVDDIO

Supply Voltage Range

Operating Temperature

Range

- + 2.7 + 3.4 V

- + 2.7 + 3.4 V

- + 1.8 + 3.4 V

- - 20 + 85 ℃

3

Page 4

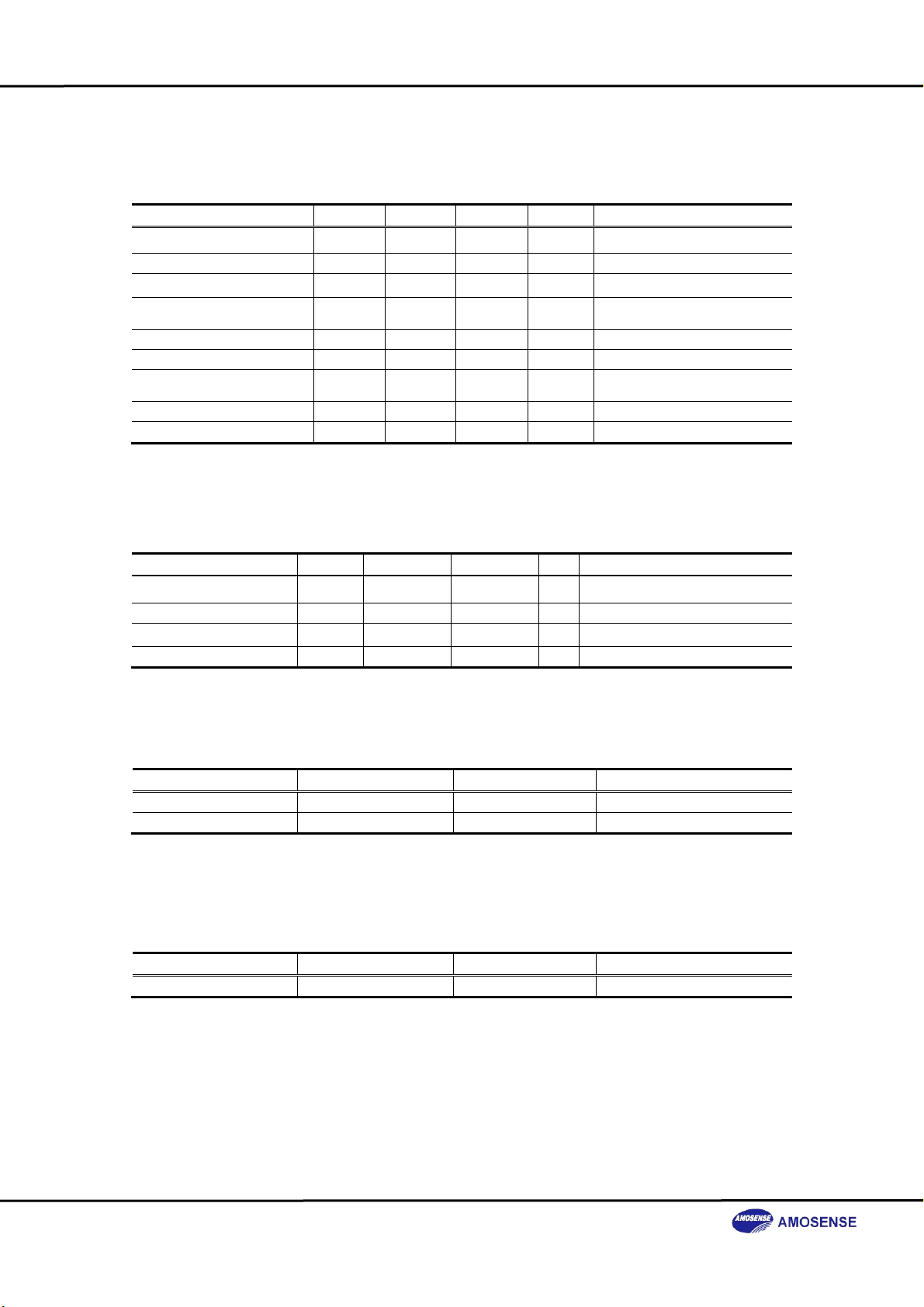

Compass Specifications

Item Min. Typ. Max. Unit Description

Azimuth accuracy - 5 - + 5 degree

Azimuth range 0 - 359 degree

Azimuth resolution - 1 - degree

Flux density measurement

range

Maximum sampling rate - - 30 Hz

Power consumption - - 27 mW Power down : 60 uW(@ 3.0 V)

Roll/pitch compensation

range

Roll/pitch resolution - 1 - degree

Roll/pitch accuracy - 5 - + 5 degree

- 1,000 - + 1,000 μT

- 89 - + 89 degree

DC characteristics

At. DVDD & DVDDIO = 2.7~3.4V Ta= -20 ~85℃℃

Item Symbol Min. Max. Unit Description

Input high voltage 1 VIH1 0.7 x DVDD DVDD + 0.6 V All Digital I/O Port except RESET

Input high voltage 2 VIH2 0.9 x DVDD DVDD + 0.6 V /RESET(Schmitt input)

Input low voltage 1 VIL1 -0.5 0.3 x DVDD V All Digital I/O Port except RESET

Input low voltage 2 VIL2 -0.5 0.3 x DVDD V /RESET(Schmitt input)

IIC characteristics

At. DVDDIO = 2.7~3.4V Ta= -20 ~85℃℃

Parameter Max. Units Description

Clock Frequency 400 kHz SCL

Sink Current 2 mA SDA, SCL

AMS0805WAH

MOTION SENSOR

SPI characteristics

At. DVDDIO = 2.7~3.4V Ta= -20 ~85℃℃

Parameter Max. Units Description

Clock Frequency 1 MHz SCK

4

Page 5

A

A

A

A

A

A

A

Pin Descriptions

● Serial Interface

Pin name Pin No. Pin type Initial Function

NC / /SS 3 DI

NC / MOSI 2 DI

SDA / MISO 1 DIO / DO

SCL / SCK 4 DI - Clock.

IIC / SPI 7 DI - L : SPI, H : IIC

3-states

H

3-states

H

Z

H

● Power

Pin name Pin No. Pin type Function

DVDD 12,18 PWR Digital power supply

DVDDIO 13 PWR Digital I/O power supply (See page )

DVSS 5,14,22 PWR GND for digital.

VDD 8 PWR

VSS 10 PWR GND for analog.

● NC for only Testing

Pin name Pin No. Function

NC 9,11,15,16 For only test

● Etc

Pin name Pin No. Pin type Initial Function

/RESET 6 DSI H Reset pin, active "L", Schmitt input.

/WAKE_UP 17 DI H Wake up signal : active "L"

X-

xis Accelerometer analog output.

AXOUT 19 AO -

AYOUT 21 AO -

AZOUT 20 AO -

External capacitor must be connected for stable signal

( 100nF )

xis Accelerometer analog output.

YExternal capacitor must be connected for stable signal

( 100nF )

xis Accelerometer analog output.

ZExternal capacitor must be connected for stable signal

( 100nF )

Note

DI: Digital input DO: Digital output

DSI: Digital Schmitt input AO: Analog output

DIO: Digital bi-directional PWR: Power

IIC mode: NC.

SPI mode: Slave - Selection pin.

IIC mode: NC.

SPI mode: Master-Output, Slave-Input.

IIC mode: SD

SPI mode: Master-Input, Slave-Output.

nalog power supply.

AMS0805WAH

MOTION SENSOR

5

Page 6

AMS0805WAH

MOTION SENSOR

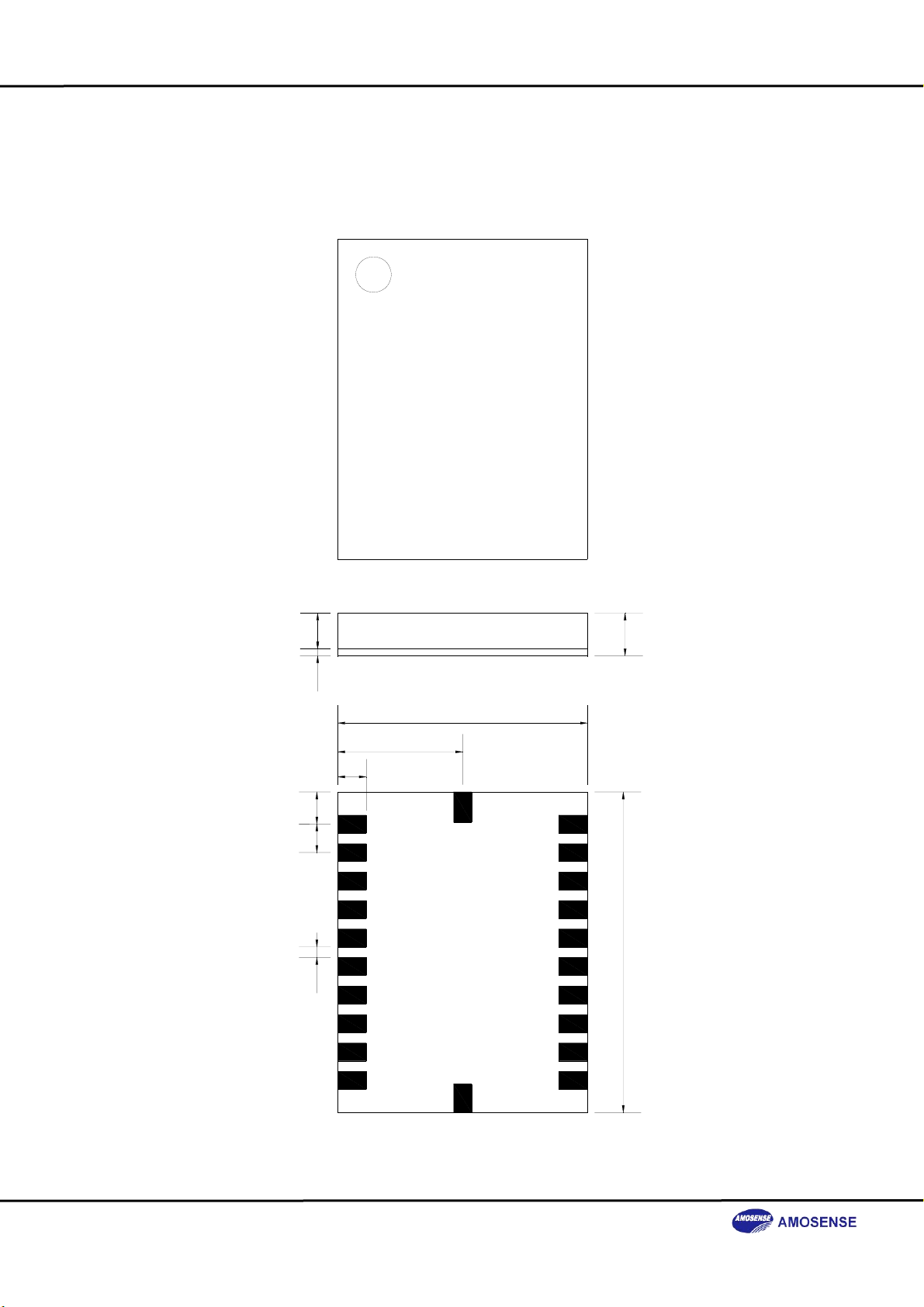

Package Information (unit: mm)

DVSS

22

SDA/MISO

NC/MOSI

NC//SS

SCL/SCK

DVSS

/RESET

IIC/SPI

AVDD

NC

AVSS

1

2

3

4

5

6

7

8

9

10

Top view

11

NC

21

20

19

18

17

16

15

14

13

12

AY OUT

AZ OUT

AX OUT

DVDD

/WAKE_UP

NC

NC

DVSS

DVDDIO

DVDD

1

0,2

0,8

Side view

3,5

1,2

7

0,90,80,3

21

22

1

Bottom view

9

12

10

11

6

Page 7

AMS0805WAH

MOTION SENSOR

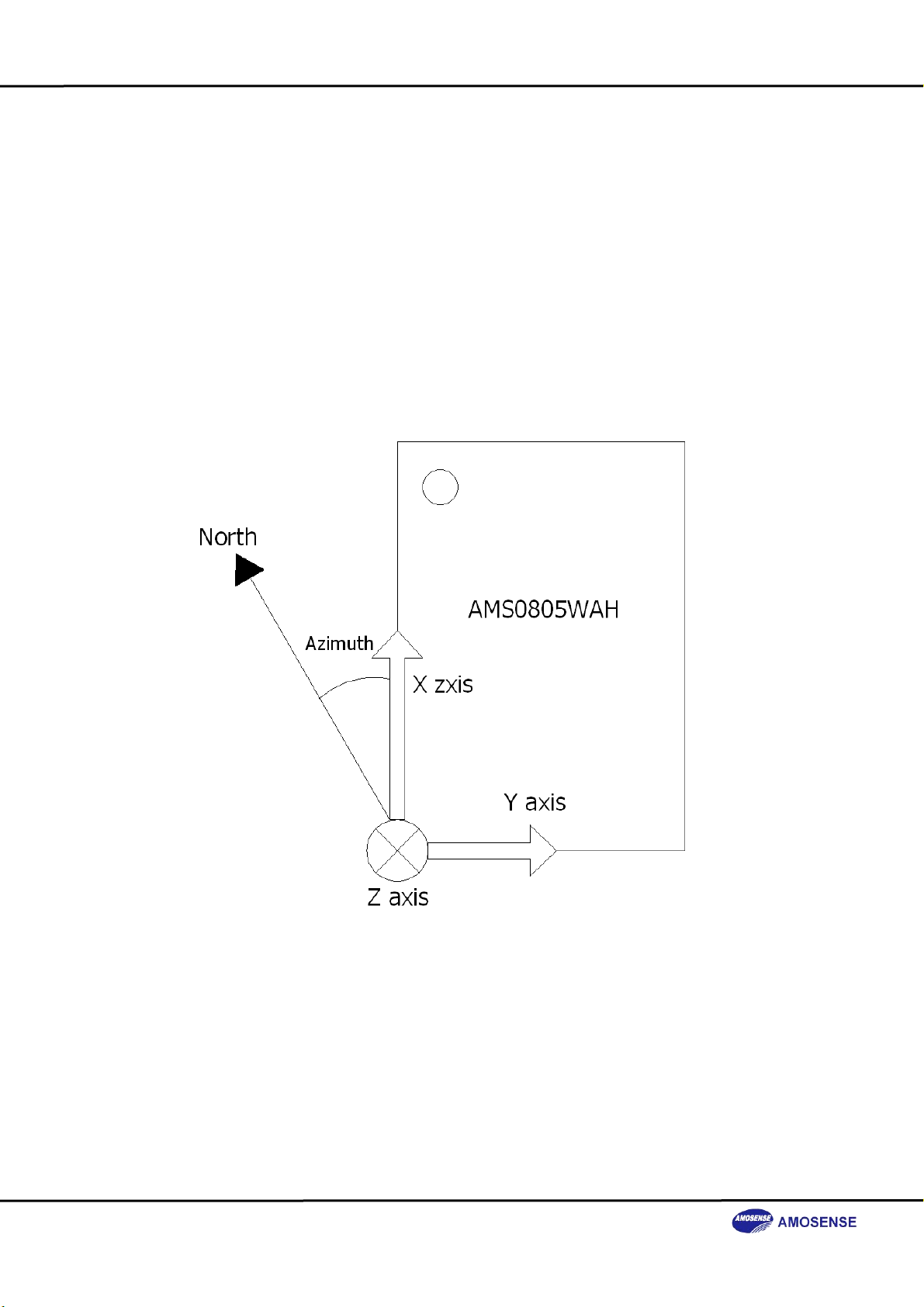

A P P E N D I X

Coordinate system

Basically, the

right thumb into the positive rotation axis and curl your fingers into the forward rotational direction.

right-hand rule

is used for determining the sign of a rotation: point your

7

Page 8

AMS0805WAH

MOTION SENSOR

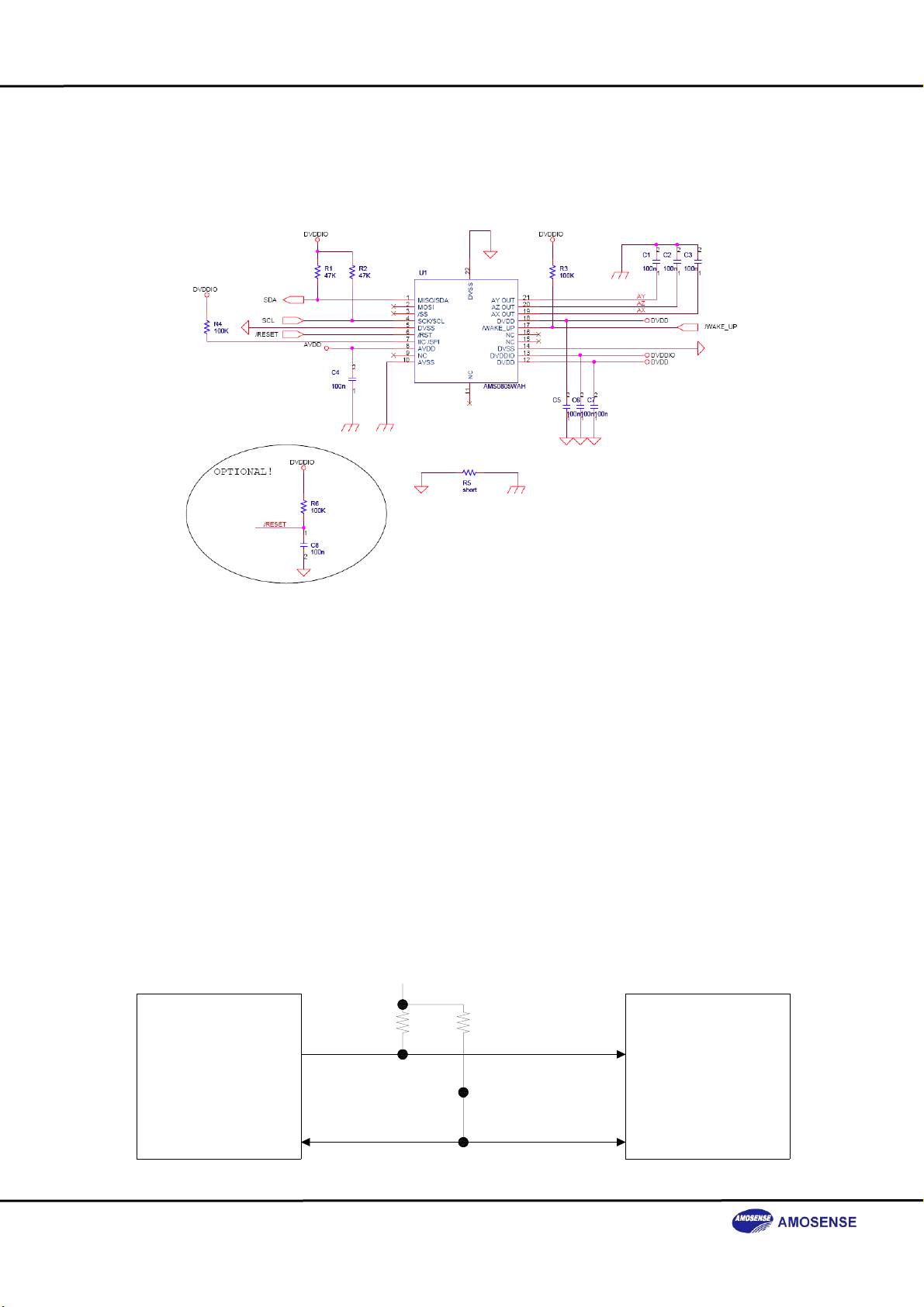

Typical Connection ( IIC default )

IIC Serial Peripheral Interface

IIC is suited for typical micro-controller. It is designed to easily connect any µcom to IIC

compliant slave. The 2 required lines on the slave side are the clock (SCL) signal and the data

(SDA) signal.

Typical Operating Circuit

● Typical Connection

VDD

Master Controller

(MCU)

IIC

Serial

I/F

SCL

SDA

8

SCL

Slave Device

SDA

Page 9

AMS0805WAH

MOTION SENSOR

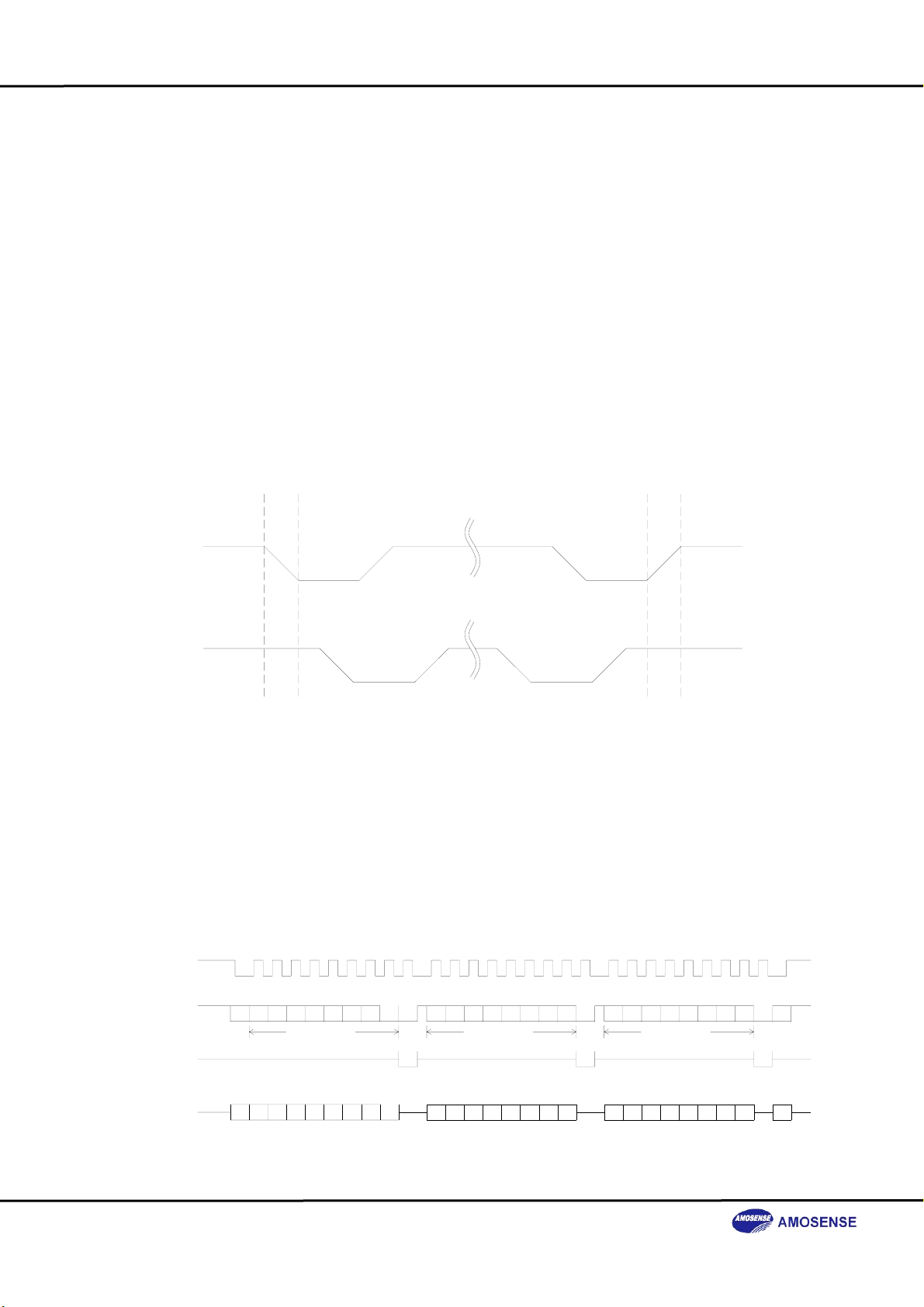

Protocol

● Transaction Rules

Each data transferred on the SDA is accompanied by a pulse on the clock signal. The

data on the SDA must be stable when the clock is high. The only exception is for generating start

and stop. The master initiates and terminates a data transmission.

Start condition

Stop condition

SDA

SCL

acknowledgement. It starts by a start condition and ends by a stop condition. The first byte is the

Slave Address, the second is the Register Address and the third is the Data Byte. The LSB of the

Slave Code byte is the R/W indicator.

MASTER Transmit & SLAVE Receive

SCL

SDA

SDA SLAVE

SDA MASTER

: To start reading/writing operation, it is necessary to generate a start condition by

switching the SDA input from high level to low level when the SCL input is high

level.

: To stop reading/writing operation, it is necessary to generate stop condition by

switching the SDA input from low level to high level when the SCL input is high

level. When the stop condition is generated, the operation is stopped, the data

is processed and the system enters in standby mode.

Start

Stop

● Single-Byte Write Sequence

The Single Byte Write Sequence is composed of 3 bytes of 9 bits, the 9

0

0S65

1

MSB LSB MSB LSB MSB LSB

10100XW0S6

00XWA

1

Slave address

765

AAA

3

4

Command

5

4321076

21

0A

7P

th

bit being the

3

4

21

Data

5

432107P

0A

9

Page 10

● Single-Word Read Sequence

There is no Single-Byte Read Sequence, so that "DEV_ID" and "REVNUM" should be

read at word length if it would be read. In this case, upper byte of the word is "zero" and the valid

data is in lower byte. Only Word read sequence is provided as following:

MASTER Transmit & SLAVE Receive

SCL

SDA

SDA MASTER

MASTER Receive & SLAVE Transmit

SCL

SDA

SDA SLAVE

SDA MASTER

Here, Command means Register Address actually.

0

0S65

1

MSB LSB MSB LSB

1

1010 0XRA

0S6

MSB LSB MSB LSB MSB LSB

1010 0XR0S P

00XWA

1

Slave address

0

00XW0S65

1

Slave address

AMS0805WAH

MOTION SENSOR

7P

AASDA SLAVE

76

A

6

3

4

Write Data

3

4

5

43210A

Data H

5

4321076

0A

21

07P

21

5

7P

5

AA

TO MASTER Transmit

43210A

Data

432107

10

Page 11

AMS0805WAH

MOTION SENSOR

● Slave & Register address

The 7bit field is slave code field. The last bit on the SDA is Read/Write bit.

● Slave address field

Bit NAME Value Description

Bit[7...0] Slave address

01010000(=0x50)

01010001(=0x51)

● Register Field

Bit NAME Range Description

Bit[7...0] Register address 0x01 ~ 0x34 Internal register address

Write Sequence

Read Sequence

11

Page 12

AMS0805WAH

MOTION SENSOR

Typical Connection ( SPI [OPTION] )

SPI Serial Peripheral Interface (Original SPI)

The Serial Peripheral Interface (SPI) is a 4-wire Clock Synchronous Serial Interface. It

is designed to easily connect any CPU to SPI compliant slaves using only 3 lines plus one chip

select line per slave. Few slaves can be connected on the CPU SPI. The 4 required lines on the

slave side for the SPI are MISO, MOSI, SCK signal and /SS signal.

● Typical Operating Circuit

- Typical Connection with one Slave

Master Controller

(MCU)

SPI

Serial I/F

/CS

SCK

MOSI

MISO

12

/SS

SCK

Slave Device 1

MOSI

MISO

Page 13

AMS0805WAH

MOTION SENSOR

- Typical Connection with two Slaves

/CS

Master Controller

(MCU)

SPI

Serial I/F

SCK

MOSI

MISO

/SS

SCK

Slave Device 1

MOSI

MISO

/SS

SCK

Slave Device 2

MOSI

MISO

Protocol

The data format is MSB in first and LSB in last.

● Single Byte Write Sequence

/SS

SCK

MOSI

MISO

76543

MSB LSB MSB LSB

Commend & Register Byte

21

0

76543

● Single Byte Read Sequence

/SS

SCK

MOSI

MISO 7 6 5

76543

MSB LSB

Commend & Register Byte

21

0

MSB LSB

13

Data Byte

4

Data Byte

21

3

21

0

0

Page 14

AMS0805WAH

MOTION SENSOR

● Multi Byte Read Sequence

/SS

SCK

MOSI

MISO

76543

MSB LSB

Commend & Register Byte

21

0

76543210

MSB LSB

Data Byte 1

(Adress)

76543210

MSB LSB

Data Byte 2

(Address + 1)

14

Page 15

Register Table

Register Symbol R/W Explanation

01(h) DEV_ID R Device ID

02(h) REVNUM R Revision Number

03(h) MAG_STATUS R Big Magnetic Field Status Flag

14(h) POWER W Power Down Mode

20(h) AZIMUTH_H R MSB of AZIMUTH

21(h) AZIMUTH_L R LSB of AZIMUTH

22(h) MAG_XH R MSB of Magnetic Sensor X axis

23(h) MAG_XL R LSB of Magnetic Sensor X axis

24(h) MAG_YH R MSB of Magnetic Sensor Y axis

25(h) MAG_YL R LSB of Magnetic Sensor Y axis

26(h) MAG_ZH R MSB of Magnetic Sensor Z axis

27(h) MAG_ZL R LSB of Magnetic Sensor Z axis

28(h) CAL_XH R MSB of slope compensated X axis

29(h) CAL_XL R LSB of slope compensated X axis

2A(h) CAL_YH R MSB of slope compensated Y axis

2B(h) CAL_YL R LSB of slope compensated Y axis

2C(h) ACC_XH R MSB of Accelerometer X axis

2D(h) ACC_XL R LSB of Accelerometer X axis

2E(h) ACC_YH R MSB of Accelerometer Y axis

2F(h) ACC_YL R LSB of Accelerometer Y axis

30(h) ACC_ZH R MSB of Accelerometer Z axis

31(h) ACC_ZL R LSB of Accelerometer Z axis

32(h) PITCH_H R MSB of PITCH angle

33(h) PITCH_L R LSB of PITCH angle

34(h) ROLL_H R MSB of ROLL angle

35(h) ROLL_L R LSB of ROLL angle

AA(h) CAL_ACC W Accelerometer Offset Calibration Mode ( See page 22~26 )

AMS0805WAH

MOTION SENSOR

15

Page 16

AMS0805WAH

MOTION SENSOR

Register Descriptions

01(h) "DEV_ID" Device ID Register

Device ID 04H

02(h) "REVNUM" Revision number Register

Revision number 20H

03(h) "MAG_ALARM" External Big Magnetic Field Status Flag

- No External Big Magnetic Field condition 00H

- External Big Magnetic Field condition 01H

z This register is operated over than 0.4gauss external magnetic field distortion.

(In this condition, the Azimuth of AMS0805WAH may be directed wrong,

You need to calibration AMS0805WAH)

14(h) "AMS_POWER" Power Management Register

Registers Descriptions

00h(W)

01h(W)

ACTIVE : ALL POWER ON

(Magnetic sensor ON, Accelerometer ON, MICOM ON)

POWER DOWN: ALL POWER OFF

(Magnetic sensor OFF, Accelerometer OFF, MICOM OFF)

02(h) POWER SAVE: Magnetic sensor OFF, Accelerometer ON, MICOM ON

20(h) ~ 21(h) "AZIMUTH"

- Direction of AMS0805WAH

- Data range: 0 ~ 360

- Resolution: 1 degree

22(h) ~ 23(h) "MAG_X"

- X axis Magnetic flux density value

24(h) ~ 25(h) "MAG_Y"

- Y axis Magnetic flux density value

26(h) ~ 27(h) "MAG_Z"

- Z axis Magnetic flux density value

16

Page 17

AMS0805WAH

MOTION SENSOR

28(h) ~ 29(h) "CAL_X"

- Slope compensated X axis Magnetic flux density value

2A(h) ~ 2B(h) "CAL_Y"

- Slope compensated Y axis Magnetic flux density value

2C(h) ~ 2D(h) "ACC_X"

- X axis Acceleration value

- Data range: - 2,048 ~ 2,047

- Resolution: 1 counts = 0.01225m/s

2E(h) ~ 2F(h) "ACC_Y"

- X axis Acceleration value

- Data range: -2,048 ~ 2,047

- Resolution: 1 counts = 0.01225m/s

30(h) ~ 31(h) "ACC_Z"

- X axis Acceleration value

- Data range: -2,048 ~ 2,047

- Resolution: 1 counts = 0.01225m/s

32(h) ~ 34(h) "PITCH"

- Pitch angle of AMS0805WAH

- Data range: - 89 ~+ 89

- Resolution: 1 degree

34(h) ~ 35(h) "ROLL"

- Roll angle of AMS0805WAH

- Data range: - 89 ~+ 89

- Resolution: 1 degree

AA(h) "CAL_ACC"

- Accelerometer Offset Calibration Mode

- See page 22 ~ 26

2

2

2

17

Page 18

AMS0805WAH

MOTION SENSOR

18

Page 19

AMS0805WAH

MOTION SENSOR

Communication specification and software applications (IIC)

Communication mode : IIC serial interface.

Communication speed : Maximum 400 kHz(Fast mode)

Operation is not guaranteed for exceeding this speed.

SLAVE ADDRESSS A COMMAND A P

Pulse width

More than 2.5us

More than 50us

W

Interval time

Interval time

More than 50us

SLAVE ADDRESSS A DataH A DataL A PR

From master to slave

From slave to master

Interval time

More than 50us

A : acknowledge(SDA LOW)

Ā : not acknowledge(SDA HIGH)

S : start condition

P : stop condition

Interval time

More than 50us

Interval time

More than 50us

...S

19

Page 20

AMS0805WAH

MOTION SENSOR

Communication specification and software applications (SPI)

Communication mode : SPI serial interface.

Communication speed : Maximum 1.5 MHz

Operation is not guaranteed for exceeding this speed.

20

Page 21

AMS0805WAH

MOTION SENSOR

Wake-up from power down mode

we serve two type of wake-up functions(using /WAKE_UP signal [ for SPI ] or using IIC communication at Address match [ for IIC ] )

● Using /WAKE_UP signal

21

Page 22

AMS0805WAH

MOTION SENSOR

● Using IIC communication

22

Page 23

AMS0805WAH Accelerometer Offset Calibration Mode Manual

The accelerometer’s offset can be changed a little value, because of big shock, very high

temperature by soldering etc. For the more precision azimuth and tilt, we need to calibrate

accelerometer’s offset. AMS0805WAH supports ACC offset calibration mode. It is that you can

calibrate accelerometer’s offset in this mode.

The calibration sequence is below.

- Put AMS0805WAH(or product) on a table.

Î Maintain stable condition before starting the CAL ACC offset mode.

- Start the Accelerometer Offset Calibration Mode

Î If host transmits ‘0xAA’ and ‘0x55’ continuously, AMS0805WAH is started the

Accelerometer Offset Calibration Mode.

- Completely and slowly rotate AMS0805WAH on the table.

Î Don’t shake and give any tilt when AMS0805WAH is in the Accelerometer Offset

Calibration Mode.

- Exit ACC offset mode

Î If host transmit ‘0xAA’ and ‘0x55’ continuously again, AMS0805WAH is saved offset

values and exit the Accelerometer Offset Calibration Mode,

AMS0805WAH

MOTION SENSOR

23

Page 24

AMS0805WAH

MOTION SENSOR

Interval time

More than 50us

0x50S A 0xAA A 0x55 A P

Interval time

More than 50us

START the ACC offset CAL mode

Interval time

More than 50us

... P

0x50S A 0xAA A 0x55 A P ...S

Completely & slowly

Rotates AMS0805WAH

on a table.

...S

Go back to Normal mode

within 50ms

Interval time

More than 50us

Save offset values & Exit the ACC offset CAL mode

ACC offset CAL mode

IIC communication protocol

From master to slave

From slave to master

A : acknowledge(SDA LOW)

Ā : not acknowledge(SDA HIGH)

S : start condition

P : stop condition

24

Page 25

AMS0805WAH

MOTION SENSOR

Interval time

More than 50us

/SS

Completely & slowly

SCK

Rotates AMS0805WAH

on a table.

MOSI

0xAA 0x55

START the ACC offset CAL mode

/SS

SCK

MOSI

Save offset values & Exit the ACC offset CAL mode

ACC offset CAL mode

SPI communication protocol

...

Go back to Normal mode

within 50ms

Interval time

More than 50us

0xAA 0x55 ...

From master to slave

25

Page 26

AMS0805WAH

MOTION SENSOR

AMS0805WAH

Table

AMS0805WAH

e

l

ab

T

θ

Although the table has some tilt, you can calibrate accelerometer’s offset.

Note : Don’t shake and give any tilt when AMS0805WAH is in the ACC offset CAL mode.

26

Page 27

AMS0805WAH

MOTION SENSOR

Data format in the ACC offset CAL mode.

In the calibration-mode, registers are below

20(h) ~ 21(h) "ACC_X"

- X axis Acceleration value

- Data range: 0 ~ 4,095

22(h) ~ 23(h) "ACC_Y"

- Y axis Acceleration value

- Data range: 0 ~ 4,095

24(h) ~ 25(h) "ACC_Z"

- Z axis Acceleration value

- Data range: 0 ~ 4,095

26(h) ~ 27(h) "Maximum ACC_X"

- Maximum X axis Acceleration value in the calibration mode

- Data range: 0 ~ 4,095

28(h) ~ 29(h) "Minimum ACC_X"

- Minimum X axis Acceleration value in the calibration mode

- Data range: 0 ~ 4,095

2A(h) ~ 2B(h) "Maximum ACC_Y"

- Maximum Y axis Acceleration value in the calibration mode

- Data range: 0 ~ 4,095

2C(h) ~ 2D(h) "Minimum ACC_Y"

- Minimum Y axis Acceleration value in the calibration mode

- Data range: 0 ~ 4,095

2E(h) ~ 2F(h) "Maximum ACC_Z"

- Maximum Z axis Acceleration value in the calibration mode

- Data range: 0 ~ 4,095

30(h) ~ 31(h) "Minimum ACC_Z"

- Minimum Z axis Acceleration value in the calibration mode

- Data range: 0 ~ 4,095

27

Page 28

AMS0805WAH

MOTION SENSOR

IMPORTANT NOTICE

*Specifications are subject to change without prior notification

AMOSENSE CO., LTD. ---- ----------------------------------------AGENT-----------------------------------

17-2, Jamwon-Dong, Seocho-Gu,

Seoul, 137-902, Korea

Tel : +82-2-540-3850

Fax : +82-2-517-7183

All rights reserved © 2007 Advanced Material on Te chn olo gy

28

Loading...

Loading...