Page 1

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

4k×8 bit electrically erasable PROM

BR24L32-W / BR24L32F-W / BR24L32FJ-W

BR24L32FV-W

The BR24L32-W series is 2-wire (I2C BUS type) serial EEPROMs which are electrically programmable.

2

C BUS is a registered trademark of Philips.

I

∗

Applications

z

General purpose

Features

z

1) 4k registers × 8 bits serial architecture.

2) Single power supply (1.8V to 5.5V).

3) T wo w ire seri al in terfa ce.

4) Automatic erase.

5) 32byte Page Write Mode.

6) Low power consumption.

Write

Read (5V) : 0.2mA (Typ.)

Standby (5V) : 0.1µA (Typ .)

7) DATA security

Write protect feature (WP pin).

Inhibit to WRITE at low V

8) Small package - - - DIP8 / SOP8 / SSOP-B8 pin

9) High reliability EEPROM with Double-Cell structure.

10) High reliability fine pattern CMOS technology.

11) Endurance : 1,000,000 erase / write cycles

12) Data retent ion : 40 y ears

13) Filtered inputs in SCL,SDA for noise suppression.

14) Initial data FFh in all address.

(5V) : 1.5 mA (Typ.)

CC

.

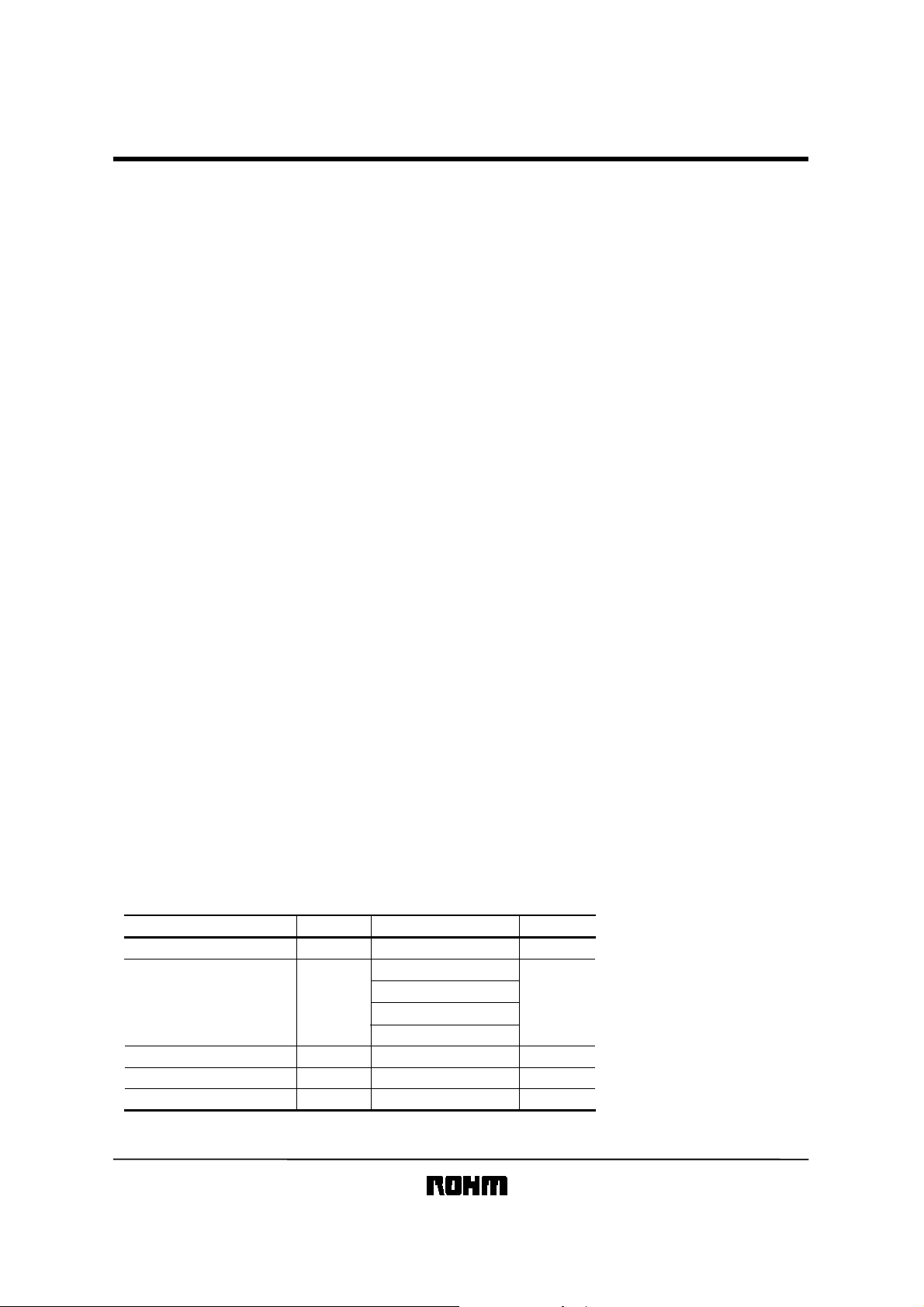

Absolute maximum ratings

z

Parameter Symbol Limits Unit

Supply voltage −0.3 to +6.5 V

Power dissipation mW

Storage temperature

Operating temperature

Terminal voltage

∗1 Degradation is done at 8.0mW/°C for operation above 25°C.

∗2,3 Degradation is done at 4.5mW/°C for operation above 25°C.

∗4 Degradation is done at 3.0mW/°C for operation above 25°C.

(T a=25°C)

CC

V

Pd

Tstg

Topr

−

800(DIP8)

450(SOP8)

450(SOP-J8)

300(SSOP-B8)

−65 to +125

−40 to +85

−0.3 to VCC+0.3

∗1

∗2

∗3

∗4

°C

°C

V

1/25

Page 2

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

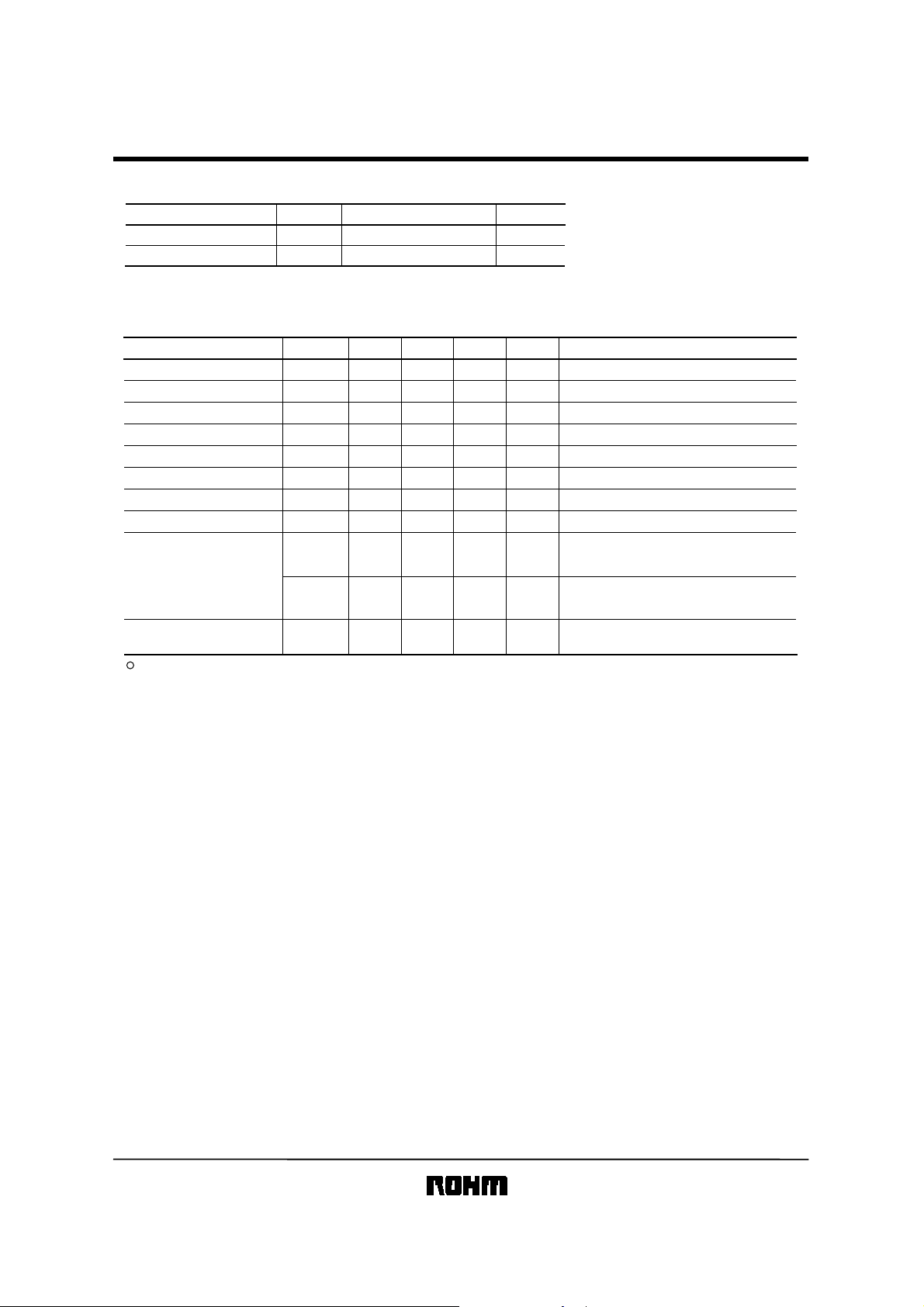

Recommende d operat ing condi tions

z

Parameter Symbol Limits Unit

Supply voltage

Input voltage V

CC

V

IN

(Ta=25°C)

1.8 to 5.5

0 to V

V

CC

V

DC operating ch aract eristi cs

z

(Unless otherwise specified T a=−40 to 85°C, V

Parameter Symbol Min. Typ. Max. Unit Conditions

0.7V

"HIGH" input volatge 1

"LOW" input volatge 1

"HIGH" input volatge 2

"LOW" input volatge 2

"LOW" output volatge 1

"LOW" output volatge 2

Input leakage current I

Output leakage current I

IH1

V

V

IL1

V

IH2

V

IL2

OL1

V

OL2

V

LI

LO

I

CC1

−−

0.8V

−−

−−

−−

−1

−1 −

−

Operating current

I

CC2

Standby current I

This product is not designed for protection against radioactive rays.

SB

−

−

CC

−−

CC

−−

−

−

−

−

0.3V

CC

0.2V

CC

0.4 V

0.2 V

1 µA

1 µA

3.0 mA

0.5 mA

2.0

CC

1.8 to 5.5V)

=

<

V

V

V

V

<

2.5V V

=

<

2.5V V

=

1.8V V

=<=

<

1.8V V

=

CC

CC

CC

CC

=

<

=

<

<

=

5.5V

5.5V

2.5V

2.5V

IOL=3.0mA, 2.5V V

I

OL

=0.7mA, 1.8V V

VIN=0V to V

OUT

=0V to V

V

CC

=5.5V, f

V

SCL

Byte Write, Page Write

CC

=5.5V, f

V

Random Read, Current Read,

Sequential Read

CC

V

µA

A0,A1,A2=GND, WP=GND

SCL

=5.5V, SDA,SCL=VCC,

<

<

CC

5.5V, (SDA)

=

=

<

<

CC

5.5V, (SDA)

=

=

CC

CC

=400kHz, tWR=5ms,

=400kHz

2/25

Page 3

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

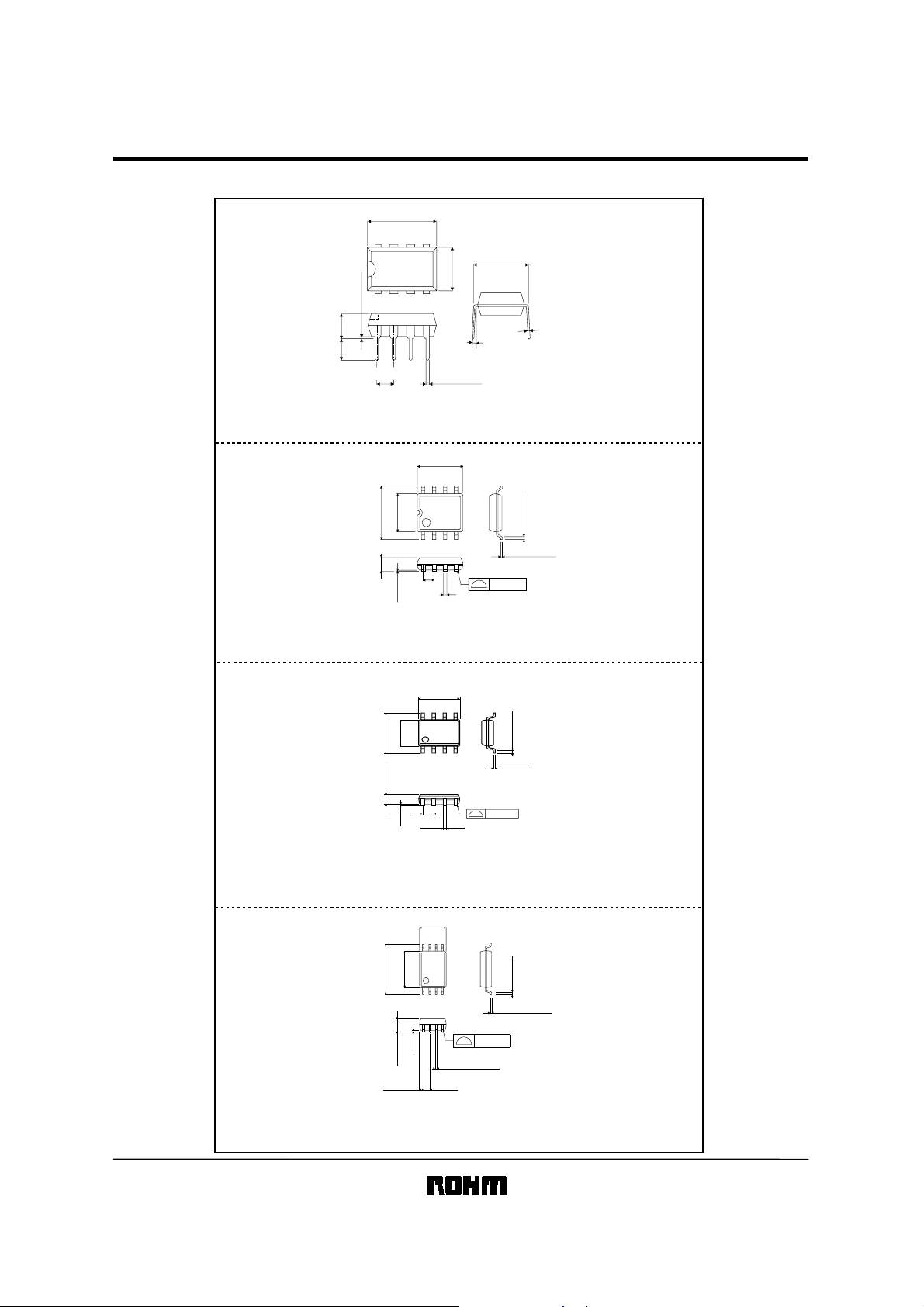

Dimension

z

9.3±0.3

85

7.62

14

0.51Min.

0.3

±

3.4

0.2

±

2.54

3.2

Fig.1(a) PHYSICAL DIMENSION (Units : mm) DIP8 (BR24L32-W)

6.5±0.3

0.3±0.1

0° ~ 15°

0.5±0.1

5.0±0.2

85

4.4±0.2

6.2±0.3

1.5±0.1

0.11

Fig.1(b) PHYSICAL DIMENSION (Units : mm) SOP8 (BR24L32F-W)

41

1.27

0.4±0.1

0.3Min.

0.15±0.1

0.1

4.9±0.2

85

76

3.9±0.2

6.0±0.3

1.375±0.1

0.175

Fig.1(c) PHYSICAL DIMENSION (Units : mm) SOP-J8 (BR24L32FJ-W)

4123

1.27

0.42±0.1

0.45Min.

0.2±0.1

0.1

3.0±0.2

548

0.2

±

4.4

6.4±0.3

1

0.1

1.15±0.1

(0.52)

Fig.1(d) PHYSICAL DIMENSION (Units : mm) SSOP-B8 (BR24L32FV-W)

0.22±0.1

0.65

0.3Min.

0.15±0.1

0.1

3/25

Page 4

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

Block diagra m

z

1

A0

32kbit EEPROM array

VCC8

GND 4

Pin configur ation

z

A1 2

A2 3

12bit

Address

decoder

12bits

Slave word

address register

STOPSTART

Control logic

High voltage generator Vcc level detect

Fig.2 BLOCK DIAGRAM

V

CC

WP

SCLA2SDA

BR24L32-W

BR24L32F-W

BR24L32FJ-W

BR24L32FV-W

8bit

Data

WP7

register

6 SCL

ACK

SDA5

5678

Pin name

z

Pin name

V

CC

GND

A0, A1, A2

SCL

SDA

WP

∗ An open drain output requires a pull-up resistor.

I / O

−

−

IN

IN

IN / OUT

IN

Power supply

Ground (0V)

Slave address set

Serial clock input

Slave and word address,

serial data input, serial data output

Write protect input

1234

A0

A1

GND

Fig.3 PIN LAYOUT

Function

∗

4/25

Page 5

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

AC operatin g ch aract eris tics

z

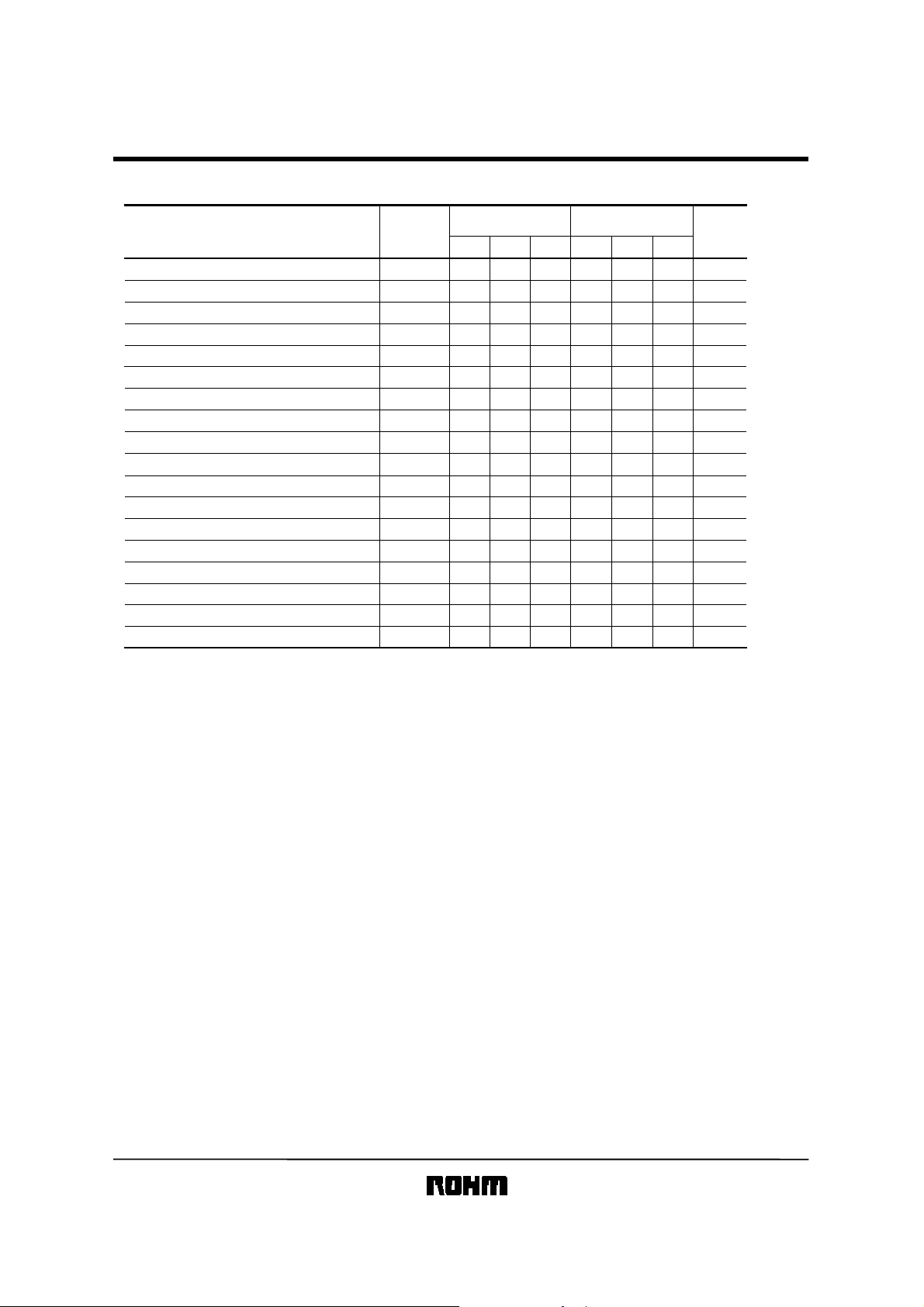

Parameter Symbol

Clock frequency

Data clock "HIGH" period

Data clock "LOW" period tLOW

SDA and SCL rise time

SDA and SCL fall time tF

Start condition hold time

Start condition setup time

Input data hold time

Input data setup time

Output data delay time

Output data hold time

Stop condition setup time

Bus free time

Write cycle time

Noise spike width (SDA and SCL)

WP hold time

WP setup time

WP high period

∗ Not 100% tested.

(Unless otherwise specified T a=−40 to 85°C, V

∗

∗

tHD:STA

tSU:STA

tHD:DAT

tSU:DAT

tSU:STO

tHIGH:WP

CC

1.8 to 5.5V)

=

Fast-mode

2.5V Vcc 5.5V

Min.

fSCL kHz

tHIGH

tR

tPD

tDH

tBUF

tWR

tI

tHD:WP

tSU:WP

−

0.6

1.2

−

−

0.6

0.6

0

100

0.1

0.1

0.6

1.2

−

−

0

0.1

1.0

<

=<=

Max.

Typ.

400

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−−

−−

−

−

0.3

0.3

−

−

−

−

0.9

−

−

−

5

0.1

−

Standard-mode

<

1.8V Vcc 5.5V

Min.

−

4.0

4.7

−

−

4.0

4.7

0

250

0.2

0.2

4.7

4.7

−

−

0

0.1

1.0

<

=

=

Typ.

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−−

−−

Max.

100

−

−

1.0

0.3

−

−

−

−

3.5

−

−

−µs

5

0.1

−

Unit

µs

µs

µs

µs

µs

µs

ns

ns

µs

µs

µs

ms

µs

ns

µs

µs

5/25

Page 6

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

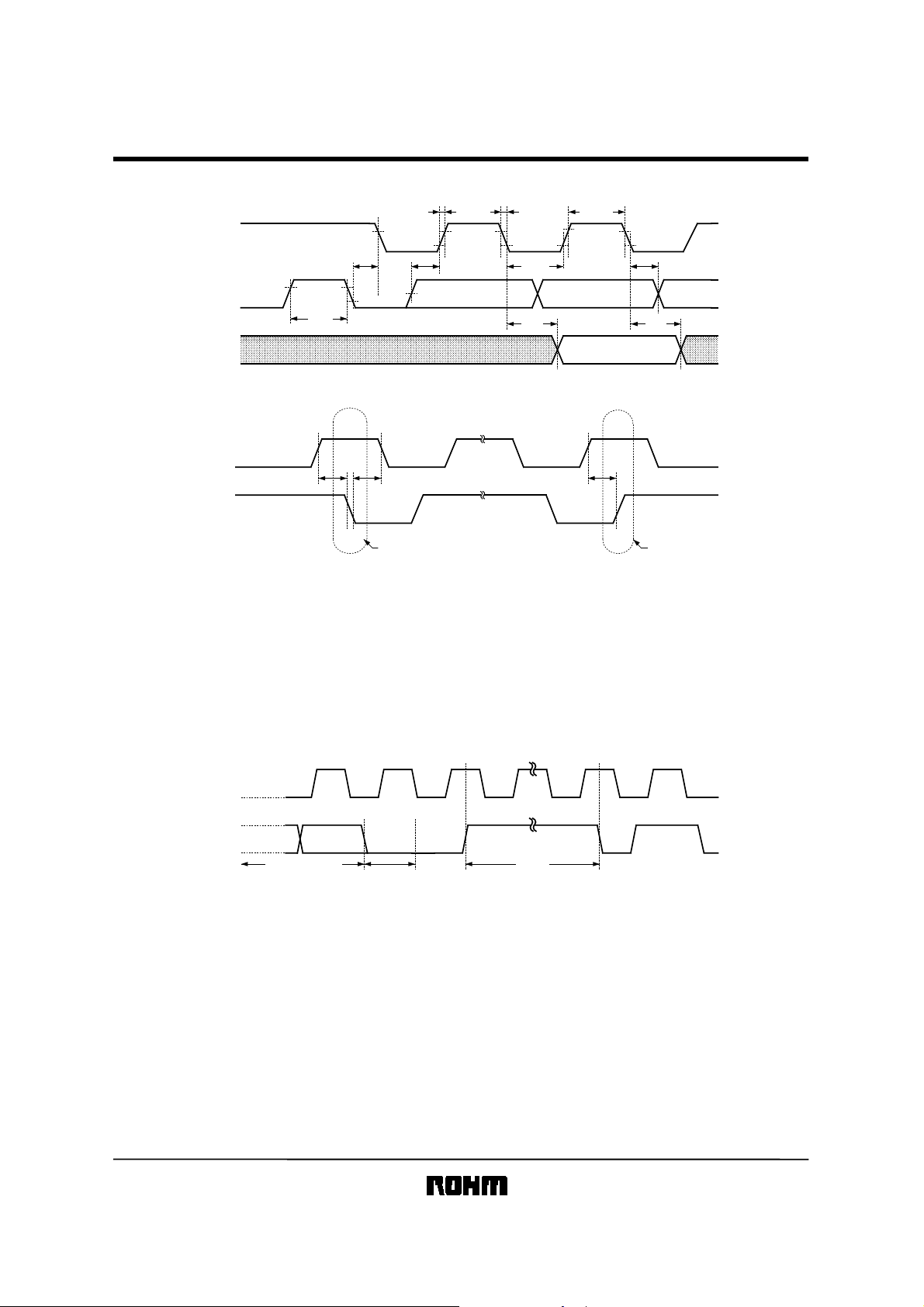

Synchronous d ata timin g

z

t

HIGH

t

DH

SCL

SDA

(IN)

SDA

(OUT)

t

R

t

HD :

STA t

t

BUF

tSU : DAT tHD : DAT

t

F

t

LOW

PD

SCL

SDA

START BIT STOP BIT

Fig.4 SYNCHRONOUS DATA TIMING

SDA data is latched into the chip at the rising edge of SCL clock.

•

Output data toggles at the falling edge of SCL clock.

•

Write cy cle timing

z

SCL

SDA

WRITE DATA (n)

ACKD0

tSU : STOtHD : STAtSU : STA

t

WR

START CONDITIONSTOP CONDITION

Fig.5 WRITE CYCLE TIMING

6/25

Page 7

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

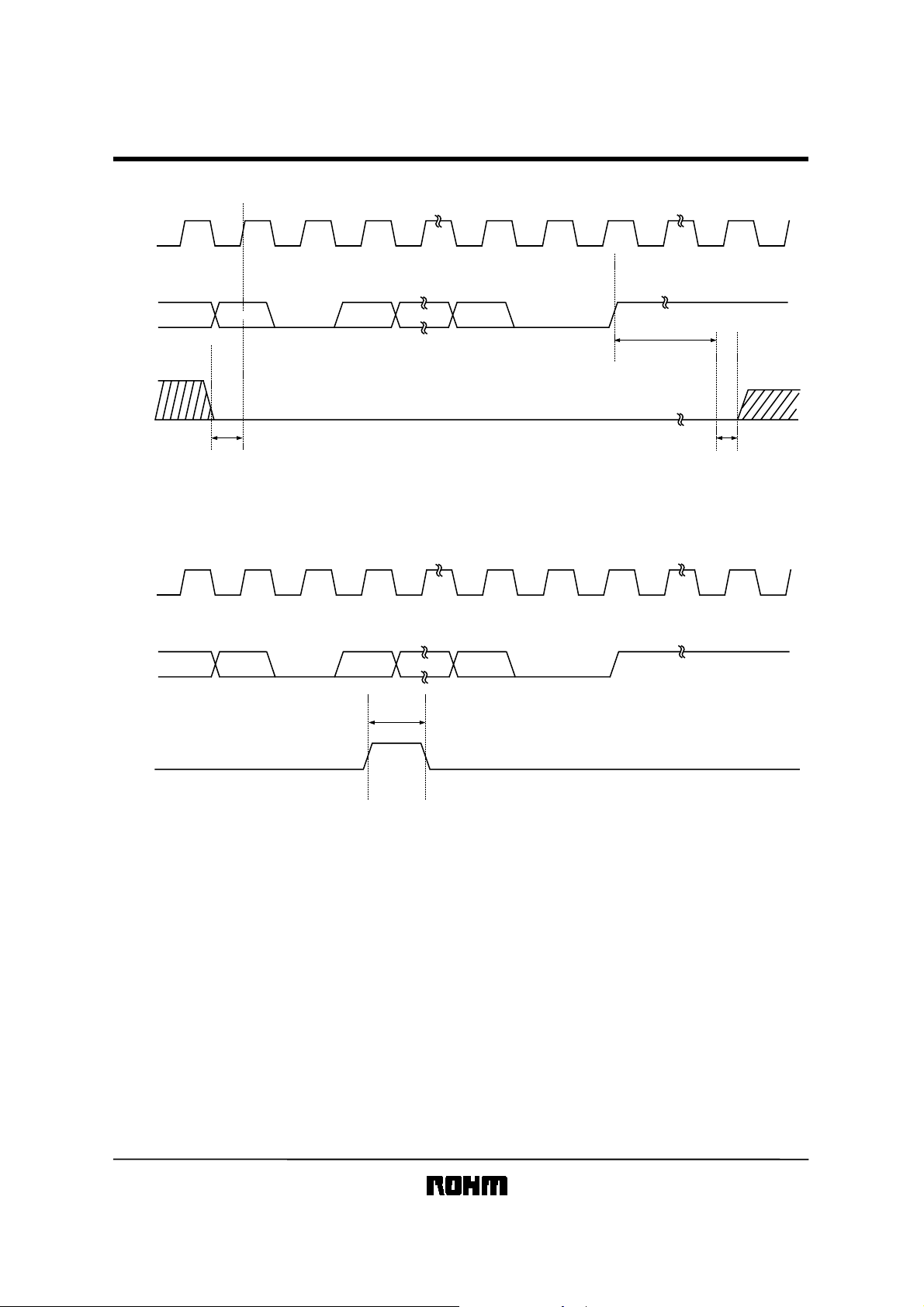

WP timing

z

SCL

DATA (n)DATA (1)

SDA

WP

SCL

SDA

WP

D1

t

SU : WP

D0

ACKACK

t

WR

STOP BIT

t

HD : WP

Fig.6(a) WP TIMING OF THE WRITE OPERATION

DATA (n)DATA (1)

D1

D0

t

HIGH : WP

ACKACK

Fig.6(b) WP TIMING OF THE WRITE CANCEL OPERATION

•For the WRITE operation, WP must be “LOW” during the period of time from the rising edge of the clock which takes in

D0 of first byte until the end of t

WR

. ( See Fig. 6 (a) )

During this period, WRITE operation is canceled by setting WP “HIGH”. ( See Fig.6 (b) )

•In the case of setting WP “HIGH” during t

WR

, WRITE operation is stopped in the middle and the data of accessing

address is not guaranteed. Please write correct data again in the case.

7/25

Page 8

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

Device oper ation

z

1) Start condition (Recognition of start bit)

• All commands are proceeded by the start condition, which is a HIGH to LOW transition of SDA when SCL is HIGH.

• The device continuously monitors the SDA and SCL lines for the start condition and will not respond to any command

until this condition has been met. (See Fig.4 SYNCHRONOUS DATA TIMING)

2) Stop condition (Recognition of stop bit)

• All communications must be terminated by a stop condition, which is a LOW to HIGH transition of SDA when SCL is

HIGH. (Se e Fig.4 SY NCHRONOUS D AT A TIM ING)

3) Notice about write command

• In the case that stop condition is not executed in WRITE mode, transferred data will not be written in a memory.

4) Device addressing

• Following a START condition, the master output the slave address to be accessed.

• The most sig nifica nt four bi ts of th e slave ad dress ar e the “de vice ty pe ident ifier”, f or thi s devic e it is fixe d as “1010” .

• The next three bit (device address) identify the specified device on the bus.

The device address is defined by the state of A0, A1 and A2 input pins. This IC works only when the device address

inputted from SDA pin correspond to the state of A0, A1 and A2 input pins. Using this address scheme, up to eight

devices may be connected to the bus. The last bit of the stream (R/W - - - READ / WRITE) determines the operation

to the performed.

• The last bit of the stream (R/W - - - READ / WRITE) determines the operation to be performed. When set to “1”, a read

operation is selected ; when set to “0”, a write operation is selected.

R / W set to “0” - - - - - - WRITE (including word address input of Random Read)

R / W set to “1” - - - - - - READ

5) Write protect (WP)

When WP pin set to V

When WP pin set to GND (L level), enable to write 4,096 words (all address).

Either control this pin or connect to GND (or V

A2 A1 A01010 R / W

CC

(H level), write protect is set for 4,096 words (all address).

CC

). It is inhibited from being left unconnected.

8/25

Page 9

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

6) Acknow ledg e

• Acknowledge is a software convention used to indicate successful data transfers.

The transmitter device will release the bus after transmitting eight bits.

(When inputting the slave address in the write or read operation, transmitter is µ-COM. When outputting the data in

the r ead oper atio n, it is t his devi ce.)

• During the ninth clock cycle, the receiver will pull the SDA line LOW to Acknowledge that the eight bits of data has

been received.

(When inputting the slave address in the write or read operation, receiver is this device. When outputting the data in

the read operation, it is µ-COM.)

• The device will respond with an Acknowledge after recognition of a START condition and its slave address (8bit).

• In the WRITE mode, the device will respond with an Acknowledge, after the receipt of each subsequent 8-bit word

(word address and write data).

• In the READ mode, the device will transmit eight bit of data, release the SDA line, and monitor the line for an

Acknowledge.

• If an Acknowledge is detected, and no STOP condition is generated by the master, the device will continue to transmit

the data. If an Acknowledge is not detected, the device will terminate further data transmissions and await a STOP

condition before returning to the standby mode. (See Fig.7 ACKNOWLEDGE RESPONSE FROM RECEIVER)

START CONDITION

(START BIT)

SCL

(From µ−COM)

SDA

(µ−COM

OUTPUT DATA)

SDA

(IC OUTPUT DATA)

189

Acknowledge Signal

(ACK Signal)

Fig.7 ACKNOWLEDGE RESPONSE FROM RECEIVER

9/25

Page 10

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

Byte write

z

W

R

I

T

E

A0A1A2

R

/

W

1st WORD

ADDRESS

∗∗∗∗

A

C

K

2nd WORD

ADDRESS

WA

11

A

C

K

Fig.8 BYTE WRITE CYCLE TIMING

WA

DATA

D7

0

A

C

K

D0

A

C

K

∗Don't care

SDA

LINE

WP

S

T

A

R

T

SLAVE

ADDRESS

10 01

• By using this command, the data is programmed into the indicated word address.

• When the master generates a STOP condition, the device begins the internal write cycle to the nonvolatile memory

array.

Page write

z

S

T

O

P

W

R

I

T

E

A0A1A2

R

/

W

1st WORD

ADDRESS (n)

∗∗∗∗

A

C

K

2nd WORD

ADDRESS (n)

WA

11

A

C

K

Fig.9 PAGE WRITE CYCLE TIMING

WA

0

DATA (n)

D7

A

C

K

D0

A

C

K

DATA (n+31)

D0

∗Don't care

SDA

LINE

WP

S

T

A

R

T

SLAVE

ADDRESS

10 01

• This device is capable of thirty-two byte Page Write operation.

• When two or more byte data are inputted, the five low order address bits are internally incremented by one after the

receipt of each word. The seven higher order bits of the address (WA11 to WA5) remain constant.

• If the master transmits more than thirty-two words, prior to generating the STOP condition, the address counter will

“roll over”, and the previous transmitted data will be overwritten.

S

T

O

P

A

C

K

10/25

Page 11

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

Current read

z

S

T

A

R

T

SLAVE

ADDRESS

R

E

A

D

DATA

S

T

O

P

SDA

LINE

11

00

A2 A1 A0

Fig.10 CURRENT READ CYCLE TIMING

D7 D0

R

A

/

C

W

K

A

C

K

• In case that the p revi ous o perat ion is Ra ndom or C urren t Rea d (w hich incl udes S eque ntia l Rea d r espect ively ), t he

internal address counter is increased by one from the last accessed address (n).

Thus Current Read outputs the data of the next word address (n+1).

If the last command is Byte or Page Write, the internal address counter stays at the last address (n).

Thus Current Read outputs the data of the word address (n).

• If an Acknowledge is detected, and no STOP condition is generated by the master (µ-COM), the device will continue

to transmit the data. [ It can transmit all data (32kbit 4096word)

]

• If an Acknowledge is not detected, the device will terminate further data transmissions and await a STOP condition

before returning to the standby mode.

Note) If an Acknowledge is detected with “Low” level, not “High” level, command will become Sequential Read.

So the device transmits the next data, Read is not terminated. In the case of terminating Read, input

Acknowledge with “High” always, then input stop condition.

Random read

z

S

T

A

R

T

SLAVE

ADDRESS

W

R

I

T

E

1st WORD

ADDRESS(n)

2nd WORD

ADDRESS(n)

S

T

A

R

T

SLAVE

ADDRESS

R

E

A

D

DATA(n)

S

T

O

P

SDA

LINE

110 0 A2A1A0 A2A1A0

R

A

/

C

W

K

WA

∗∗∗∗

11

A

C

K

Fig.11 RANDOM READ CYCLE TIMING

WA

0

A

C

K

110 0 D7 D0

A

R

C

/

K

W

∗Don't care

A

C

K

• Random read operation allows the master to access any memory location indicated word address.

• If an Acknowledge is detected, and no STOP condition is generated by the master (µ-COM), the device will continue

to transmit the data. [ It can transmit all data (32kbit 4096word)

]

• If an Acknowledge is not detected, the device will terminate further data transmissions and await a STOP condition

before returning to the standby mode.

Note) If an Acknowledge is detected with “Low” level, not “High” level, command will become Sequential Read.

So the device transmits the next data, Read is not terminated. In the case of terminating Read, input

Acknowledge with “High” always, then input stop condition.

11/25

Page 12

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

Sequential r ead

z

S

T

A

R

T

SLAVE

ADDRESS

R

E

A

D

DATA(n)

DATA(n+x)

S

T

O

P

SDA

LINE

1100A2

A1 A0

D7 D7D0 D0

A

R

C

/

K

W

Fig.12 SEQUENTIAL READ CYCLE TIMING

(Current Read)

A

C

K

A

C

K

A

C

K

• If an Acknowledge is detected, and no STOP condition is generated by the master (µ-COM), the device will continue

to transmit the data. [ It can transmit all data (32kbit 4096word)

]

• If an Acknowledge is not detected, the device will terminate further data transmissions and await a STOP condition

before returning to the standby mode.

• The Sequential Read operation can be performed with both Current Read and Random Read.

Note) If an Acknowledge is detected with “Low” level, not “High” level, command will become Sequential Read.

So the device transmits the next data, Read is not terminated. In the case of terminating Read, input

Acknowledge with “High” always, then input stop condition.

12/25

Page 13

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

Application

z

1) WP effe ctive ti ming

WP is fixed to “H” or “L” usually. But in case of controlling WP to cancel the write command, please pay attention to

[ WP effective timing ] as follows.

During write command input, write command is canceled by controlling WP “H” within the WP cancellation effective

period.

The period from the start condition to the rising edge of the clock which take in D0 of the data (the first byte of the data

for Page Write) is the cancellation invalid period. WP input is don’t care during the period. Setup time for rising edge of

the SCL which takes in D0 must be more than 100ns.

The period from the rising edge of SCL which takes in D0 to the end of internal write cycle (t

effective period. In case of setting WP to “H” during t

WR

, WRITE operation is stopped in the middle and the data of

accessing address is not guaranteed, so that write correct data again please.

It is not necessary waiting t

WR

(5msmax.) after stopping command by WP, because the device is stand by state.

· The rising edge of the clock

which take in D0

WR

) is the cancellation

SDA

WP

S

T

A

ADDRESS

R

T

SCL

SDA D1 D0 ACK

AN ENLARGEMENT

A

SLAVE

WORD

C

ADDRESS

K

L

WP cancellation invalid period WP cancellation effective period

C

SCL

SDA D0 ACK

AN ENLARGEMENT

A

K

L

A

C

K

L

No data will be written

A

C

DATAD7 D6 D5 D4 D3 D2 D1 D0

K

L

A

C

K

L

S

T

O

P

Stop of the write

· The rising edge

of SDA

tWR

operation

Data is not

guaranteed

Fig.13 WP EFFECTIVE TIMING

13/25

Page 14

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

2) Software reset

Please execute software reset in case that the device is an unexpected state after power up and / or the command

input need to be reset.

There are som e kinds of softwar e reset. Here we show thr ee types o f examp le as fol lows.

During dummy clock, please release SDA bus (tied to V

During that time, the device may pull the SDA line LOW for Acknowledge or outputting or read data.

If the master controls the SDA line HIGH, it will conflict with the device output LOW then it makes a current overload.

It may cause instantaneous power down and may damage the device.

DUMMY CLOCK × 14 START × 2

CC

by pull up resistor).

SCL

SDA

SDA

12 1413

Fig.14-(a) DUMMY CLOCK × 14 + START + START

START START

Fig.14-(b) START+ DUMMY CLOCK × 9 + START

123 789SCL

DUMMY CLOCK × 9

12 89SCL

START × 9

COMMAND

COMMAND

COMMAND

COMMAND

COMMAND

SDA

COMMAND starts with start condition.

∗

COMMAND

Fig.14-(c) START × 9

14/25

Page 15

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

3) Acknowledge polling

Since the device ignore all input commands during the internal write cycle, no ACK will be returned.

When the master send the next command after the write command, if the device returns the ACK, it means that the

program is completed. If no ACK id returned, it means that the device is still busy.

By using Acknowledge polling, the waiting time is minimized less than t

In case of operating Write or Current Read right after Write, first, send the slave address (R / W is “HIGH” or “LOW”

respectively). After the device returns the ACK, continue word address input or data output respectively.

THE FIRST WRITE COMMAND

WR

5ms.

=

During the internal write cycle,

no ACK will be returned.

(ACK=HIGH)

• • •

S

T

A

R

T

WRITE COMMAND

S

T

A

ADDRESS

R

T

SLAVE

t

WR

S

T

O

P

A

C

K

H

S

T

SLAVE

A

ADDRESS

R

T

S

T

SLAVE

A

ADDRESS

R

T

A

C

K

H

THE SECOND WRITE COMMAND

A

C

WORD

K

ADDRESS

L

S

T

SLAVE

A

ADDRESS

R

T

t

WR

A

C

K

L

DATA

A

C

• • •

K

H

A

S

C

T

K

O

L

P

After the internal write cycle

is completed ACK will be returned

(ACK=LOW). Then input next

Word Address and data.

Fig.15 SUCCESSIVE WRITE OPERATION BY ACKNOWLEDGE POLLING

15/25

Page 16

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

4) Command ca ncell ation by start a nd stop c onditi on

During a command input, it is canceled by the successive inputs of start condition and stop condition. (Fig.4)

But during ACK or data output, the device may output the SDA line LOW. In such cases, operation of start and stop

condition is impossible, so that the reset can’t work. Execute the software reset in the cases. (See Page14)

Operating the command cancel by start and stop condition during the command of Random Read or Sequential Read

or Current Read, internal address counter is not confirmed.

Therefore operation of Current Read after this in not valid. Operate a Random Read in this case.

SCL

SDA

Fig.16 COMMAND CANCELLATION BY START AND STOP CONDITION

DURING THE INPUT OF SLAVE ADDRESS

1100

START

CONDITION

STOP

CONDITION

16/25

Page 17

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

5) Notes for power supply

CC

V

rises through the low voltage region in which internal circuit of IC and the controller are unstable, so that device

may not work pr operly due to an in compl ete rese t of int ernal circ uit.

T o pr event th is, the d evice h as the fea ture of P.O.R. and L V

In the case of power up, keep the following conditions to ensure functions of P.O.R and L V

(1) It is necessary to be “SDA=‘H’ ” and “SCL=’L’ or ‘H’ ”.

(2) Follow the recommended conditions of tR, t

CC

V

0

VCC rising wave from

OFF

, Vbot for the function of P.O.R. durning power up.

t

R

t

OFF

(3) Prevent SDA and SCL from being “Hi-Z”.

In case that condition 1. and / or 2. cannot be met, take following actions.

A) Unable to keep co ndition 1. (SDA is “LO W” duri ng power u p.)

Control SDA, SC L to be “HIGH” a s figur e below .

→

CC

Vbot

.

Recommended conditions of t

t

R

Below 10ms

Below 100ms

t

OFF

Above 10ms

Above 10ms

CC

R

, t

OFF

Below 0.3V

Below 0.2V

.

, Vbot

Vbot

V

CC

SCL

SDA

After VCC becomes stable

a) SCL="H" and SDA="L"

B) Unable to keep condition 2.

After power becomes stable, execute software reset. (See Page14 )

→

C) Unable to keep condition 1 and 2.

Follow the instruction A first, then the instruction B.

→

CC

circuit

• LV

CC

LV

circuit inhibit write operation at low voltage, and prevent an inadvertent write. Below the LVCC voltage

(Typ.=1.2V), write operation is inhibited.

t

LOW

After VCC becomes stable

t

DH

t

SU:DAT

b) SCL="L" and SDA="L"

t

SU:DAT

17/25

Page 18

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

6) I / O circuit

• Pull up resister of SDA pin

The pull up resister is needed because SDA is NMOS open drain. Decide the value of this resister (R

by considering V

If large R

IL

, IL characteristics of a controller which control the device and VOH, IOL charact erist ics of t he dev ice.

PU

is chosen, clock frequency need to be slow. In case of small RPU, the operating current increases.

PU

) properly,

• Maximum of R

PU

Maximum of RPU is determined by following factor.

c SDA rise time determined by R

PU

and the capacitance of bus line (C

BUS

) must be less than TR.

And the other timing must keep the conditions of AC spec.

d When SDA bus is HIGH, the voltage A of SDA bus determined by a total input leak (I

connected to the bus and RPU must be enough higher than input HIGH level of a controller and the device,

including noise margin 0.2VCC.

VCC − ILRPU − 0.2VCC V

0.8VCC − V

<

RPU

=

Examples : When V

According to

R

PU

<

IH

=

IH

IL

CC

=3V IL=10µA VIH=0.7V

2

0.8×3−0.7×3

<

=

10×10

<

300 [kΩ]

=

MICRO

COMPUTER

R

PU

IL IL

CC

−6

THE CAPACITANCE OF

BUS LINE (C

L

) of the all dev ices

BR24LXX

A

SDA PIN

BUS)

18/25

Page 19

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

• The mini mum v alu e R

PU

The minimum value of RPU is determined by following factors.

c Meet the condition that V

VCC − V

OL

<

I

OL

=

R

PU

VCC − V

<

RPU

OLMAX

d V

recommended noise margin (0.1VCC).

Examples : V

=

(=0.4V) must be l ower tha n the inp ut LO W level of th e contro ller and the EEPROM includi ng

V

OL

I

OL

<

OLMAX

VIL − 0.1V

=

CC

=3V, VOL=0.4V, IOL=3mA, the VIL of the controller and the EEPROM is VIL=0.3V

According to

and

OLMAX

CC

1

0.4V , I

=

RPU

OL

V

V

IL

OLMAX

3mA when the device output low on SDA line.

=

3−0.4

<

−3

=

3×10

<

867 [Ω]

=

=0.4[V]

=0.3×3

=0.9[V]

CC

so that condition is met

2

• Pull up r esis ter o f SC L pin

In the case that SCL is controlled by CMOS output, the pull up resister of SCL is not needed.

But in the case that there is a timing at which SCL is Hi-Z, connect SCL to V

CC

with pull u p resist er .

Several ∼ several dozen kΩ is recommended as a pull up resister, which is considered with the driving ability of the

output port of the controller.

7) Connections of A0, A1, A2, WP pin

• Connections of device address pin (A0, A1, A2)

The state of device address PIN are compared with the device address send by the master, then one of the devices

which are connected to the identical bus is selected. Pull up or down these pins, or connect them to V

CC

or GND .

Pins which is not used as device address (N.C. PIN) may be either HIGH, LOW, and Hi-Z.

The type of the device which have N.C. PIN BR24L16 / F / FJ / FV / FVM-W A0, A1, A2

BR24L08 / F / FJ / FV / FVM-W A0, A1

BR24L04 / F / FJ / FV / FVM-W A0

• Connections of WP pin

The WP input allows or inhibits write operations. When WP is HIGH, only READ is available and WRITE to any

address is inhibited. Both Read and Write are available when WP is LOW.

In the case that the device is used as a ROM, it is recommended that WP is pulled up or connected to V

CC

.

In the case that both READ and WRITE are operated, WP pin must be pulled down or connected to GND or

controlled.

19/25

Page 20

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

8) Notes for n oise on V

CC

• About by pass c apac itor

Noise and surges on power line may cause the abnormal function. It is recommended that the bypass capacitors

(0.1µF) are attached on the V

CC

and GND l ine besi de t he d evice.

The attachment of bypass capacitors on the board near by connector is also recommended.

PRINT BASE

IC

GND V

CC

capacitor 10 to 100µF

capacitor 0.01 to 0.1µF

9) The notice about the connection of controller

• About R

S

The open drain interface is recommended for SDA port in I2C BUS. But, in th e case that Tr i-stat e CMOS interf ace is

applied to SDA, insert a series resister R

S

between SDA pin of the device and a pull up resister RPU. It limits the

current from PM OS of contro ller to NMOS of EEPROM.

S

R

also protect s SDA pin fr om surg es. Ther efore, RS is able to be used though SDA port is open drain.

SCL

SDA

CONTROLLER EEPROM

"H" OUTPUT OF

CONTROLLER

The "H" output of controller

and the "L" output of EEPROM may cause

current overload to SDA line.

R

PU

R

S

SDA PIN

ACK

"L" OUTPUT OF

EEPROM

20/25

Page 21

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

• The maximum value of R

S

The maximum value of RS is dete rmined by f ollow in g fac tors.

c SDA rise time determined by R

And the other timing m ust also keep th e condi tions of the AC tim ing.

PU

and the capacitance of bus line (C

d When the device outputs LOW on SDA line, the voltage of the bus A determined by R

BUS

) of SDA must be less than tR.

PU

lower than the inputs LOW level of the controller, including recommended noise margin (0.1V

(VCC−VOL) × R

RPU+R

RS × R

Examples : When V

According to

RS × 20×10

S

OL

+0.1VCC V

+ V

S

VIL−VOL−0.1V

<

=

1.1VCC−V

CC

=3V, VIL=0.3VCC, VOL=0.4V, RPU=20kΩ

CC

IL

<

IL

=

PU

2

0.3×3−0.4−0.1×3

<

=

1.1×3−0.3×3

<

1.67 [kΩ]

=

V

CC

A

R

PU

R

S

3

V

OL

and RS must b e

CC

).

• The minimum value of R

CAPACITANCE OF

BUS LINE (C

V

IL

CONTROLLER EEPROM

S

BUS

)

The minimum value of RS is determined by the current overload due to the conflict on the bus.

The current overload may cause noise on the power line and instantaneous power down.

The followin g condit ions m ust be met , where Ι is the maximum permissible current.

The maximum permissible current depends on V

CC

line impedance and so on. It need to be less than 10mA for

EEPROM.

V

CC

<

Ι

=

R

S

V

CC

<

RS

=

Ι

"H" OUTPUT

R

PU

R

MAXIMUM

CURRENT

S

"L" OUTPUT

R

Ι

Examples : When V

<

S

=

10×10

<

300 [Ω]

=

CC

=3V, Ι=10mA

3

−3

CONTROLLER EEPROM

21/25

Page 22

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

10) The special character DATA

The followin g charac teri stic data a re typ. value.

6

5

(V)

IH

4

3

SPEC

2

H INPUT VOLTAGE : V

1

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.17 High input voltage VIH

(A0,A1,A2,SCL,SDA,WP)

1

0.8

0.6

0.4

0.2

L OUTPUT VOLTAGE : VOL (V)

0

01 34 65

L OUTPUT CURRENT : IOL (mA)

SPEC

Ta=85°C

2

Ta=25°C

Ta=85°C

Ta=−40°C

Ta=25°C

Ta=−40°C

6

5

(V)

IL

4

Ta=85°C

3

Ta=−40°C

Ta=25°C

2

L INPUT VOLTAGE : V

1

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.18 Low input voltage VIL

(A0,A1,A2,SCL,SDA,WP)

1.2

1

0.8

0.6

0.4

INPUT LEAK CURRENT : ILI (µA)

0.2

0

01 34 65

SUPPLY VOLTAGE : VCC (V)

SPEC

2

SPEC

Ta=85°C

Ta=25°C

Ta=−40°C

1

0.8

0.6

0.4

SPEC

0.2

L OUTPUT VOLTAGE : VOL (V)

0

01 34 65

Ta=85°C

2

L OUTPUT CURRENT : IOL (mA)

Fig.19 Low output voltage VOL−I

(VCC=1.8V)

1.2

SPEC

1

0.8

0.6

0.4

0.2

OUTPUT LEAK CURRENT : ILO (µA)

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Ta=25°C

Ta=−40°C

Ta=85°C

Ta=25°C

Ta=−40°C

OL

Fig.20 Low output voltage VOL−I

(VCC=2.5V)

3.5

(mA)

3

1

CC

f

SCL

=400kHz

2.5

DATA=AAh

2

1.5

AT WRITING : I

1

0.5

CURRENT CONSUMPTION

0

01 34 65

Ta=25°C

Ta=85°C

Ta=−40°C

2

SUPPLY VOLTAGE : VCC (V)

Fig.23 Write operating current

CC

1 (f

I

SPEC

SCL

=400kHz)

OL

Fig.21 Input leakage current ILI

0.6

(mA)

2

0.5

CC

f

SCL

0.4

DATA=AAh

0.3

AT READING : I

0.2

0.1

CURRENT CONSUMPTION

0

01 34 65

Fig.24 Read operating current

(A0,A1,A2,SCL,WP)

SPEC

=400kHz

Ta=85°C

Ta=−40°C

2

SUPPLY VOLTAGE : VCC (V)

CC

2 (f

SCL

=400kHz)

I

Ta=25°C

Fig.22 Output leakage current

LO

(SDA)

I

3.5

3

(mA)

1

CC

f

SCL

=100kHz

2.5

DATA=AAh

2

1.5

AT WRITING : I

1

0.5

CURRENT CONSUMPTION

0

01 34 65

Ta=25°C

Ta=85°C

Ta=−40°C

2

SUPPLY VOLTAGE : VCC (V)

Fig.25 Write operating current

CC

1 (f

SCL

I

SPEC

=100kHz)

22/25

Page 23

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

0.6

(mA)

0.5

2

CC

f

SCL

=100kHz

0.4

DATA=AAh

0.3

AT READING : I

0.2

Ta=85°C

0.1

CURRENT CONSUMPTION

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.26 Read operating current

CC

2 (f

SCL

I

5

4

(µs)

HIGH

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

3

2

Ta=−40°C

Ta=25°C

1

Ta=85°C

DATA CLK H TIME : t

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

SPEC

=100kHz)

SPEC2

SPEC1

Ta=25°C

Ta=−40°C

2.5

2

(µA)

SB

1.5

1

0.5

STANDBY CURRENT : I

0

01 34 65

Ta=85°C

2

SUPPLY VOLTAGE : VCC (V)

Fig.27 Standby current I

5

SPEC2

4

(µs)

SPEC1 : FAST-MODE

LOW

SPEC2 : STANDARD-MODE

3

2

Ta=85°C

Ta=25°C

1

DATA CLK L TIME : t

Ta=−40°C

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

SPEC

SPEC1

Ta=25°C

Ta=−40°C

SB

10000

1000

(kHz)

SCL

100

SPEC2

10

SCL FREQUENCY : f

1

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.28 Clock frequency f

5

(µs)

HD:STA

4

3

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

SPEC2

2

Ta=−40°C

1

Ta=25°C

Ta=85°C

0

START CONDITION HOLD TIME : t

01 34 65

SUPPLY VOLTAGE : VCC (V)

SPEC1

2

Ta=85°C

Ta=25°C

Ta=−40°C

SPEC1

SCL

Fig.29 Data clock "H" period t

6

(µs)

SU:STA

5

4

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

SPEC2

3

2

Ta=−40°C

1

Ta=25°C

Ta=85°C

0

01 34 65

START CONDITION SET UP TIME : t

SUPPLY VOLTAGE : VCC (V)

SPEC1

2

Fig.32 Start condition setup time

SU:STA

t

HIGH

50

(ns)

0

HD:DAT

−50

−100

−150

INPUT DATA HOLD TIME : t

−200

01 34 65

Fig.30 Data clock "L" period t

SPEC1,2

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

Ta=85°C

Ta=25°C

Ta=−40°C

2

SUPPLY VOLTAGE : VCC (V)

Fig.33 Input data hold time

HD:DAT

(HIGH)

t

LOW

Fig.31 Start condition hold time

50

(ns)

0

SPEC1 : FAST-MODE

HD:DAT

SPEC2 : STANDARD-MODE

−50

−100

−150

Ta=25°C

INPUT DATA HOLD TIME : t

−200

01 34 65

HD:STA

t

SPEC1,2

Ta=85°C

Ta=−40°C

2

SUPPLY VOLTAGE : VCC (V)

Fig.34 Input data hold time

HD:DAT

(LOW)

t

23/25

Page 24

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

300

(ns)

SPEC1 : FAST-MODE

200

SU:DAT

SPEC2 : STANDARD-MODE

100

0

Ta=85°C

Ta=25°C

−100

INPUT DATA SET UP TIME : t

−200

Ta=−40°C

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.35 Input data setup time

SU:DAT

(HIGH)

t

4

(µs)

PD

3

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

2

Ta=−40°C

Ta=25°C

Ta=85°C

1

SPEC2

SPEC1

OUTPUT DATA DELAY TIME : t

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

SPEC2

SPEC2

SPEC1

SPEC1

300

(ns)

SPEC1 : FAST-MODE

200

SU:DAT

SPEC2 : STANDARD-MODE

100

0

Ta=25°C

−100

INPUT DATA SET UP TIME : t

−200

01 34 65

SUPPLY VOLTAGE : VCC (V)

Ta=85°C

Ta=−40°C

2

Fig.36 Input data setup time

SU:DAT

(LOW)

t

4

(µs)

DH

3

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

2

Ta=85°C

Ta=25°C

Ta=−40°C

1

SPEC2

OUTPUT DATA HOLD TIME : t

SPEC1

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

SPEC2

SPEC2

SPEC1

SPEC1

4

(µs)

PD

3

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

2

Ta=85°C

Ta=25°C

Ta=−40°C

1

SPEC2

SPEC1

OUTPUT DATA DELAY TIME : t

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.37 Output data delay time

PD

0

t

4

(µs)

DH

3

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

2

Ta=−40°C

Ta=25°C

Ta=85°C

1

SPEC2

SPEC1

OUTPUT DATA HOLD TIME : t

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

SPEC2

SPEC1

SPEC2

SPEC1

Fig.38 Output data delay time

PD

1

t

5

(µs)

SU:STO

4

3

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

SPEC2

2

Ta=85°C

1

Ta=25°C

Ta=−40°C

0

STOP CONDITION SET UP TIME : t

01 34 65

SUPPLY VOLTAGE : VCC (V)

SPEC1

2

Fig.41 Stop condition setup time

SU:STO

t

Fig.39 Output data hold time

DH

0

t

5

(µs)

4

BUF

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

3

2

Ta=−40°C

1

Ta=25°C

BUS OPEN TIME

Ta=85°C

BEFORE TRANSMISSION : t

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.42 BUS free time t

SPEC2

SPEC1

BUF

Fig.40 Output data hold time

DH

1

t

(ms)

WR

6

5

4

3

SPEC1,2

Ta=−40°C

Ta=85°C

2

1

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

0

01 34 65

INTERNAL WRITING CYCLE TIME : t

2

SUPPLY VOLTAGE : VCC (V)

Fig.43 Write cycle time t

Ta=25°C

WR

24/25

Page 25

BR24L32-W / BR24L32F-W / BR24L32FJ-W / BR24L32FV-W

Memory ICs

0.6

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

0.5

0.4

(SCL H) (µs)

I

Ta=25°C

0.3

0.2

EFFECTIVE TIME : t

0.1

NOISE REDUCTION

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.44 Noise spike width

I (SCL H)

t

0.6

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

0.5

0.4

(SDA L) (µs)

I

0.3

Ta=25°C

0.2

EFFECTIVE TIME : t

0.1

NOISE REDUCTION

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Ta=−40°C

Ta=85°C

SPEC1,2

Ta=−40°C

Ta=85°C

SPEC1,2

0.6

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

0.5

0.4

(SCL L) (µs)

I

0.3

0.2

Ta=25°C

EFFECTIVE TIME : t

0.1

NOISE REDUCTION

0

01 34 65

SUPPLY VOLTAGE : VCC (V)

Ta=−40°C

Ta=85°C

2

Fig.45 Noise spike width

I (SCL L)

t

0.2

(µs)

0

SPEC1 : FAST-MODE

SU:WP

SPEC2 : STANDARD-MODE

−0.2

−0.4

WP SET UP TIME : t

Ta=25°C

−0.6

01 34 65

SPEC1,2

Ta=85°C

2

SUPPLY VOLTAGE : VCC (V)

SPEC1,2

Ta=−40°C

0.6

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

0.5

0.4

(SDA H) (µs)

I

Ta=25°C

0.3

0.2

EFFECTIVE TIME : t

0.1

NOISE REDUCTION

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

Fig.46 Noise spike width

I (SDA H)

t

1.2

(µs)

1

HIGH:WP

0.8

SPEC1 : FAST-MODE

SPEC2 : STANDARD-MODE

0.6

0.4

0.2

WP EFFECTIVE TIME : t

0

01 34 65

2

SUPPLY VOLTAGE : VCC (V)

SPEC1,2

Ta=−40°C

Ta=85°C

SPEC1,2

Ta=−40°C

Ta=25°C

Ta=85°C

Fig.47 Noise spike width

I (SDA L)

t

Fig.48 WP setup time t

SU:WP

Fig.49 WP high period t

HIGH:WP

25/25

Loading...

Loading...