Page 1

Features

• High-performance, Low-power AVR

• RISC Architecture

– 118 Powerful Instructions – Most Single Clock Cycle Execution

– 32 x 8 General Purpose Working Registers

– Fully Static Operation

– Up to 16 MIPS Throughput at 16 MHz

• Data and Non-volatile Program Memory

– 2K Bytes of In-System Programmable Program Memory Flash

Endurance: 1,000 Write/Erase Cycles

– 128 Bytes of In-System Programmable EEPROM

Endurance: 100,000 Write/Erase Cycles

– 128 Bytes Internal SRAM

– Programming Lock for Flash Program and EEPROM Data Security

• Peripheral Features

– 8-bit Timer/Counter with Separate Prescaler

– 8-bit High-speed Timer with Separate Prescaler

2 High Frequency PWM Outputs with Separate Output Compare Registers

Non-overlapping Inverted PWM Output Pins

– Universal Serial Interface with Start Condition Detector

– 10-bit ADC

11 Single Ended Channels

8 Differential ADC Channels

7 Differential ADC Channel Pairs with Programmable Gain (1x, 20x)

– On-chip Analog Comparator

– External Interrupt

– Pin Change Interrupt on 11 Pins

– Programmable Watchdog Timer with Separate On-chip Oscillator

• Special Microcontroller Features

– Low Power Idle, Noise Reduction, and Power-down Modes

– Power-on Reset and Programmable Brown-out Detection

– External and Internal Interrupt Sources

– In-System Programmable via SPI Port

– Internal Calibrated RC Oscillator

• I/O and Packages

– 20-lead PDIP/SOIC: 16 Programmable I/O Lines

• Operating Voltages

– 2.7V - 5.5V for ATtiny26L

– 4.5V - 5.5V for ATtiny26

• Speed Grades

– 0 - 8 MHz for ATtiny26L

– 0 - 16 MHz for ATtiny26

®

8-bit Microcontroller

8-bit

Microcontroller

with 2K Bytes

Flash

ATtiny26

ATtiny26L

Preliminary

Rev. 1477B–AVR–04/02

1

Page 2

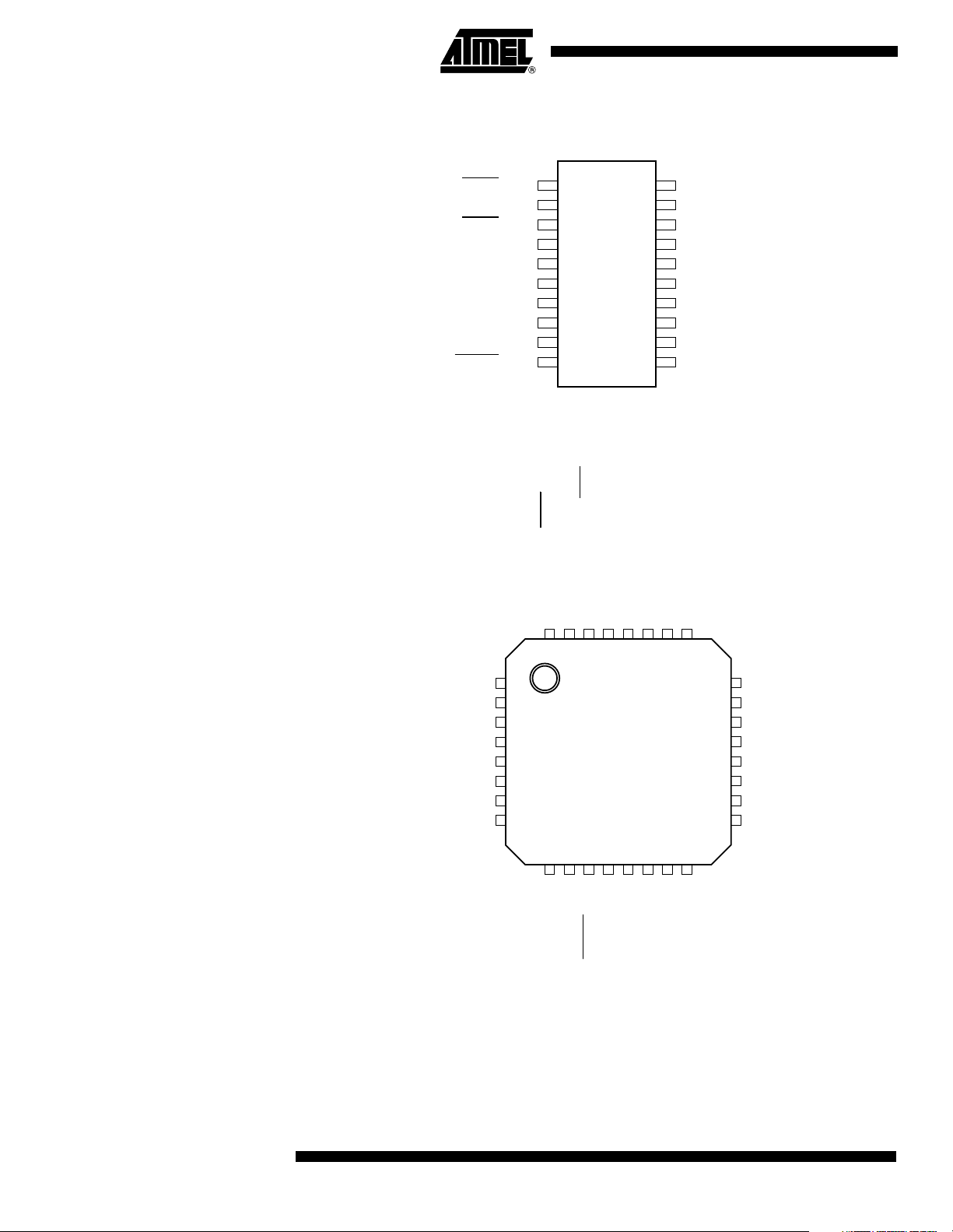

Pin Configuration

PDIP/SOIC/SSOP

(MOSI/DI/SDA/OC1A) PB0

(MISO/DO/OC1A) PB1

(SCK/SCL/OC1B) PB2

(OC1B) PB3

VCC

GND

(ADC7/XTAL1) PB4

(ADC8/XTAL2) PB5

(ADC9/INT0/T0) PB6

(ADC10/RESET) PB7

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

MLF Top View

PB2 (SCK/SCL/OC1B)

PB1 (MISO/DO/OC1A)

PB0 (MOSI/DI/SDA/OC1A)

NCNCNC

PA0 (ADC0)

PA0 (ADC0)

PA1 (ADC1)

PA2 (ADC2)

PA3 (AREF)

GND

AVCC

PA4 (ADC3)

PA5 (ADC4)

PA6 (ADC5/AIN0)

PA7 (ADC6/AIN1)

PA1 (ADC1)

NC

(OC1B) PB3

NC

VCC

GND

NC

(ADC7/XTAL1) PB4

(ADC8/XTAL2) PB5

32313029282726

1

2

3

4

5

6

7

8

9

10111213141516

NC

(ADC9/INT0/T0) PB6

NC

(ADC6/AIN1) PA7

(ADC10/RESET) PB7

25

NC

24

PA2 (ADC2)

23

PA3 (AREF)

22

GND

21

NC

20

NC

19

AVCC

18

PA4 (ADC3)

17

NC

(ADC4) PA5

(ADC5/AIN0) PA6

Disclaimer Typical values contained in this data sheet are based on simulations and characteriza-

tion of other AVR microcontrollers manufactured on the same process technology. Min

and Max values will be available after the device is characterized.

2

ATtiny26(L)

1477B–AVR–04/02

Page 3

ATtiny26(L)

Description The ATtiny26/L is a low-power CMOS 8-bit microcontroller based on the AVR enhanced

RISC architecture. By executing powerful instructions in a single clock cycle, the

ATtiny26/L achieves throughputs approaching 1 MIPS per MHz allowing the system

designer to optimize power consumption versus processing speed.

The AVR core combines a rich instruction set with 32 general purpose working registers.

All the 32 registers are directly connected to the Arithmetic Logic Unit (ALU), allowing

two independent registers to be accessed in one single instruction executed in one clock

cycle. The resulting architecture is more code efficient while achieving throughputs up to

ten times faster than conventional CISC microcontrollers. The ATtiny26/L has a high

precision ADC with up to 11 single ended channels and 8 differential channels. Seven

differential channels have an optional gain of 20x. Four out of the seven differential

channels, which have the optional gain, can be used at the same time. The ATtiny26/L

also has a high frequency 8-bit PWM module with two independent outputs. Two of the

PWM outputs have inverted non-overlapping output pins ideal for synchronous rectification. The Universal Serial Interface of the ATtiny26/L allows efficient software

implementation of TWI (Two-wire Serial Interface) or SM-bus interface. These features

allow for highly integrated battery charger and lighting ballast applications, low-end thermostats, and firedetectors, among other applications.

The ATtiny26/L provides 2K bytes of Flash, 128 bytes EEPROM, 128 bytes SRAM, up

to 16 general purpose I/O lines, 32 general purpose working registers, two 8-bit

Timer/Counters, one with PWM outputs, internal and external Oscillators, internal and

external interrupts, programmable Watchdog Timer, 11-channel, 10-bit Analog to Digital

Converter with two differential voltage input gain stages, and four software selectable

power saving modes. The Idle mode stops the CPU while allowing the Timer/Counters

and interrupt system to continue functioning. The ATtiny26/L also has a dedicated ADC

Noise Reduction mode for reducing the noise in ADC conversion. In this sleep mode,

only the ADC is functioning. The Power-down mode saves the register contents but

freezes the oscillators, disabling all other chip functions until the next interrupt or hardware reset. The Standby mode is the same as the Power-down mode, but external

oscillators are enabled. The wakeup or interrupt on pin change features enable the

ATtiny26/L to be highly responsive to external events, still featuring the lowest power

consumption while in the Power-down mode.

1477B–AVR–04/02

The device is manufactured using Atmel’s high density non-volatile memory technology.

By combining an enhanced RISC 8-bit CPU with Flash on a monolithic chip, the

ATtiny26/L is a powerful microcontroller that provides a highly flexible and cost effective

solution to many embedded control applications.

The ATtiny26/L AVR is supported with a full suite of program and system development

tools including: Macro assemblers, program debugger/simulators, In-circuit emulators,

and evaluation kits.

3

Page 4

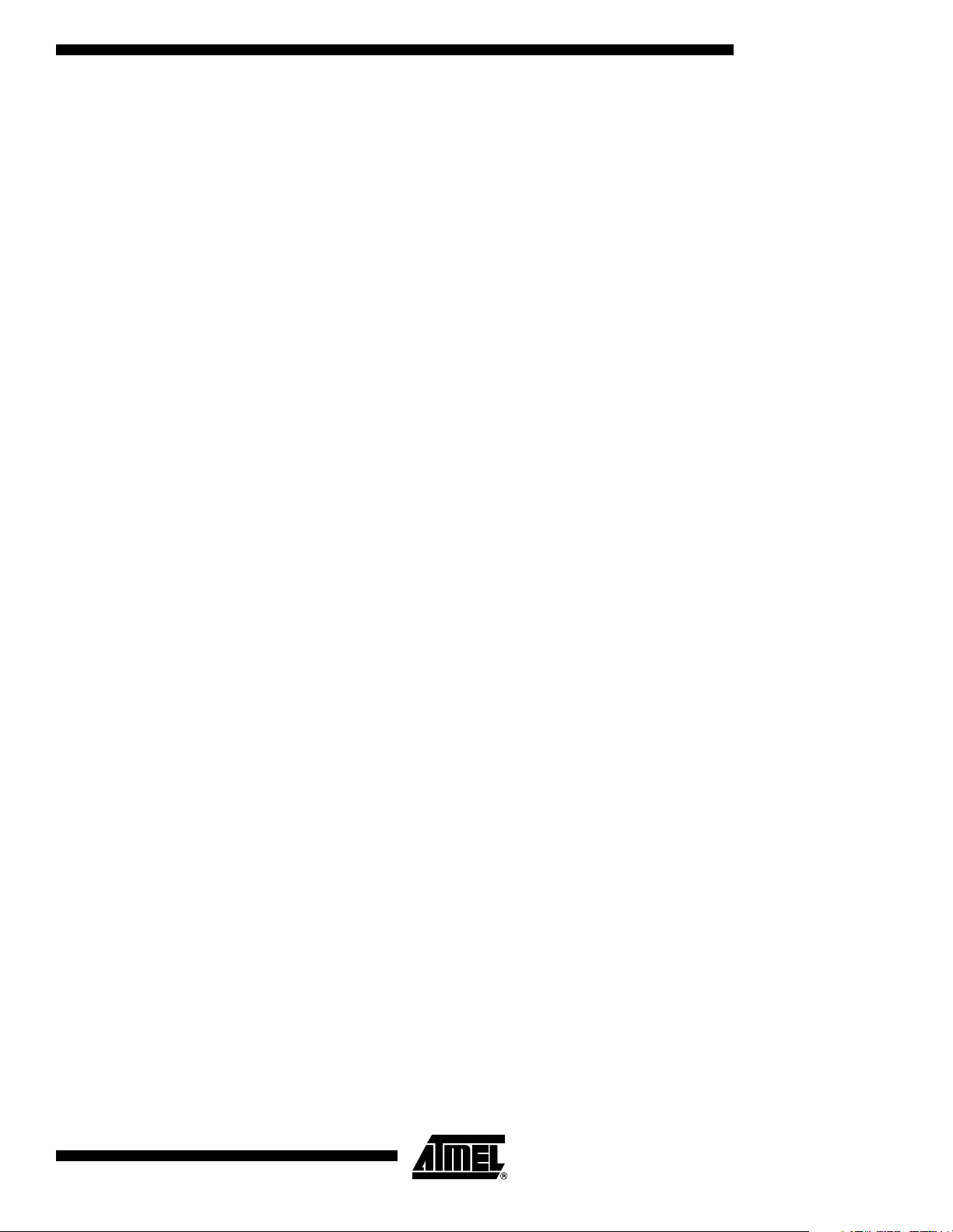

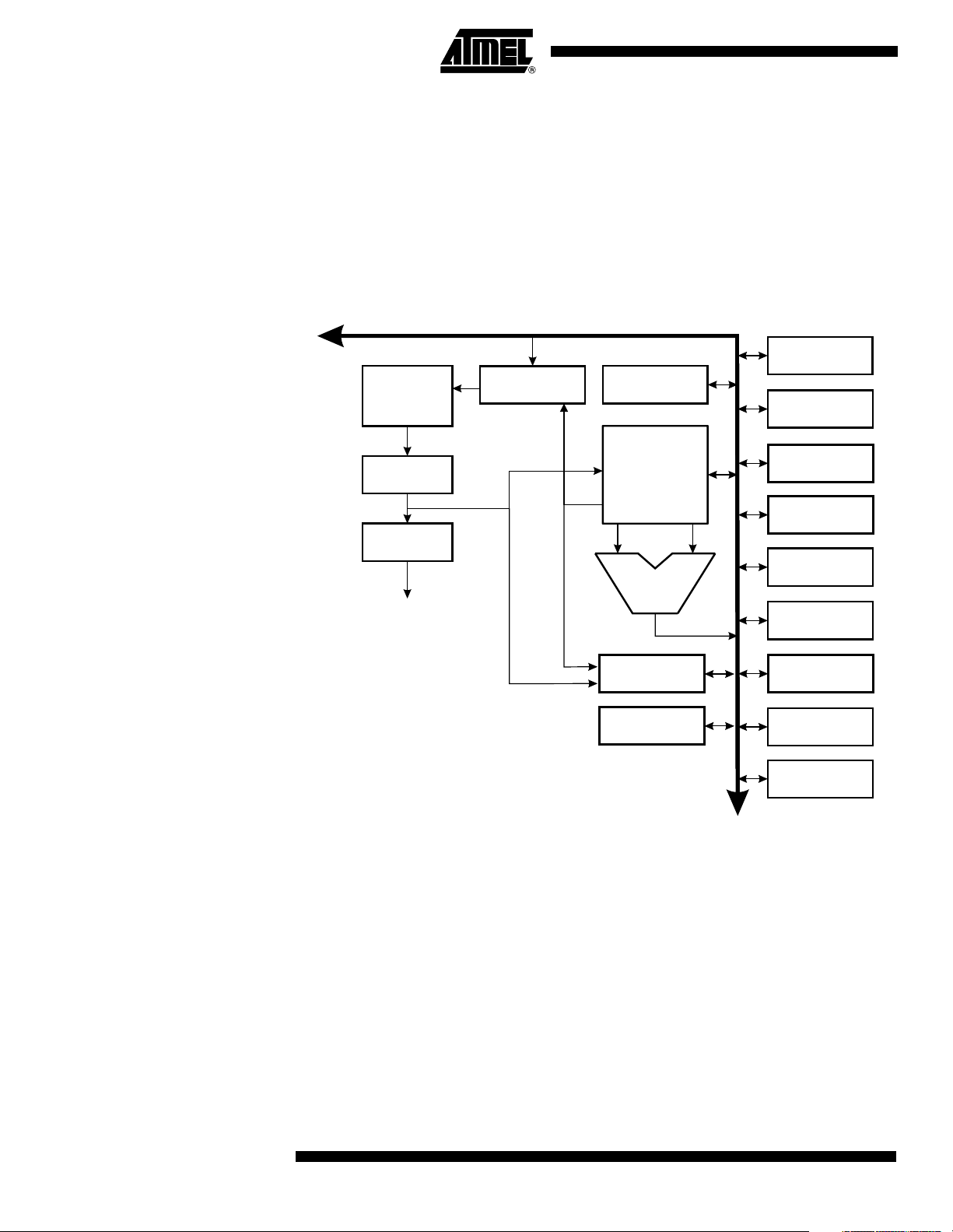

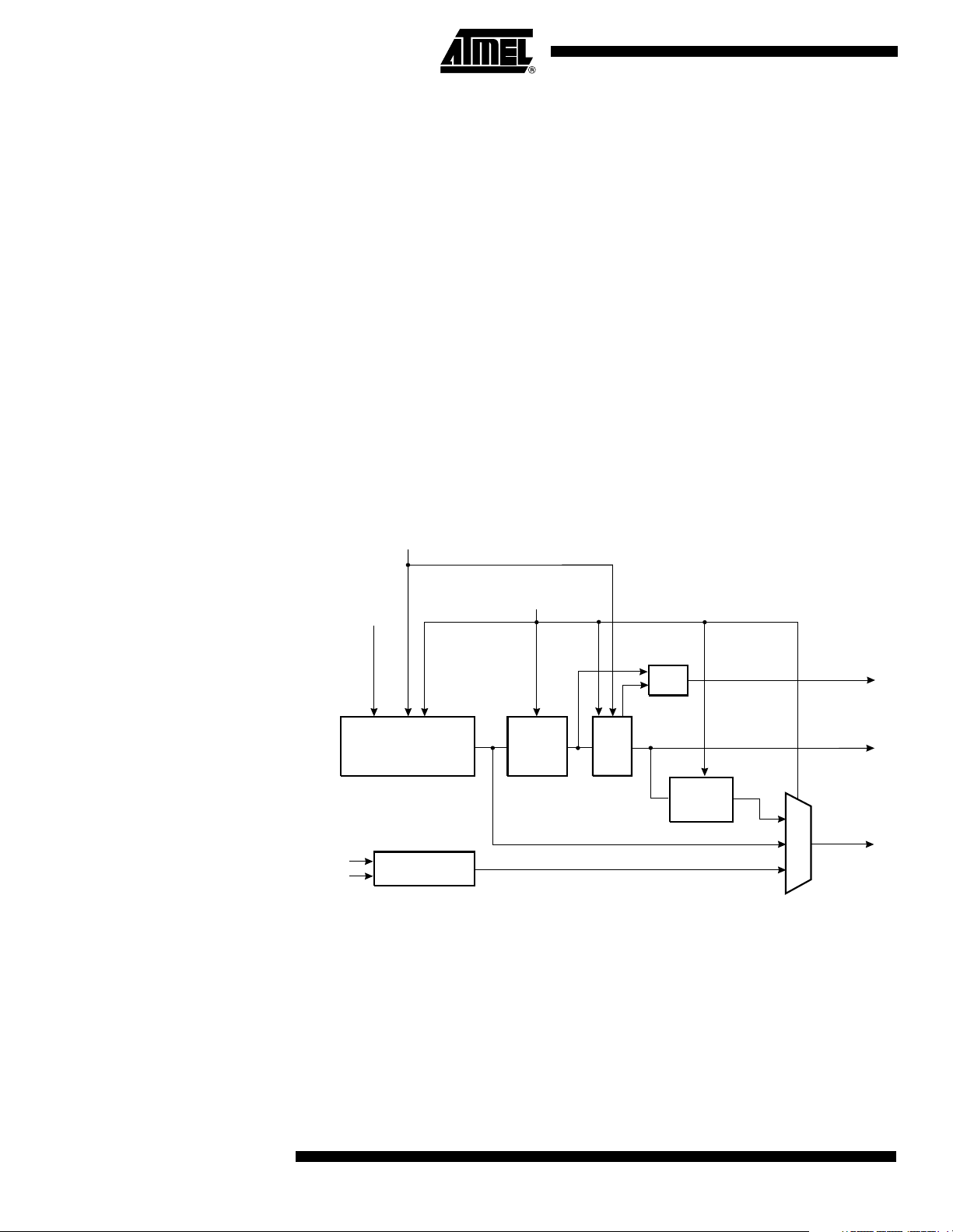

Block Diagram Figure 1. The ATtiny26/L Block Diagram

VCC

GND

AVCC

PROGRAM

COUNTER

PROGRAM

FLASH

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

PROGRAMMING

LOGIC

STACK

POINTER

SRAM

GENERAL

PURPOSE

REGISTERS

X

Y

Z

ALU

STATUS

REGISTER

ISP INTERFACE

8-BIT DATA BUS

INTERNAL

OSCILLATOR

WATCHDOG

TIMER

MCU CONTROL

REGISTER

MCU STATUS

REGISTER

TIMER/

COUNTER0

TIMER/

COUNTER1

UNIVERSAL

SERIAL

INTERFACE

INTERRUPT

UNIT

EEPROM

INTERNAL

CALIBRATED

OSCILLATOR

TIMING AND

CONTROL

OSCILLATORS

+

-

DATA REGISTER

PORT A

ANALOG

COMPARATOR

DATA DIR.

REG.PORT A

PORT A DRIVERS

PA0-PA7

ADC

DATA REGISTER

PORT B

PORT B DRIVERS

PB0-PB7

DATA DIR.

REG.PORT B

4

ATtiny26(L)

1477B–AVR–04/02

Page 5

ATtiny26(L)

Pin Descriptions

VCC Digital supply voltage pin.

GND Digital ground pin.

AVCC AVCC is the supply voltage pin for Port A and the A/D Converter (ADC). It should be

externally connected to V

connected to V

ADC.

Port A (PA7..PA0) Port A is an 8-bit general purpose I/O port. PA7..PA0 are all I/O pins that can provide

internal pull-ups (selected for each bit). Port A has alternate functions as analog inputs

for the ADC and analog comparator and pin change interrupt as described in “Alternate

Port Functions” on page 95.

Port B (PB7..PB0) Port B is an 8-bit general purpose I/O port. PB6..0 are all I/O pins that can provide inter-

nal pull-ups (selected for each bit). PB7 is an I/O pin if not used as the reset. To use pin

PB7 as an I/O pin, instead of RESET pin, program (“0”) RSTDISBL Fuse. Port B has

alternate functions for the ADC, clocking, timer counters, USI, SPI programming, and

pin change interrupt as described in “Alternate Port Functions” on page 95.

through a low-pass filter. See page 77 for details on operating of the

CC

, even if the ADC is not used. If the ADC is used, it should be

CC

An External Reset is generated by a low level on the PB7/RESET

longer than 50 ns will generate a reset, even if the clock is not running. Shorter pulses

are not guaranteed to generate a reset.

XTAL1 Input to the inverting oscillator amplifier and input to the internal clock operating circuit.

XTAL2 Output from the inverting oscillator amplifier.

pin. Reset pulses

1477B–AVR–04/02

5

Page 6

Architectural Overview

The fast-access Register File concept contains 32 x 8-bit general purpose working registers with a single clock cycle access time. This means that during one single clock

cycle, one ALU (Arithmetic Logic Unit) operation is executed. Two operands are output

from the Register File, the operation is executed, and the result is stored back in the

Register File – in one clock cycle.

Six of the 32 registers can be used as 16-bit pointers for indirect memory access. These

pointers are called the X-, Y-, and Z-pointers, and they can address the Register File

and the Flash program memory.

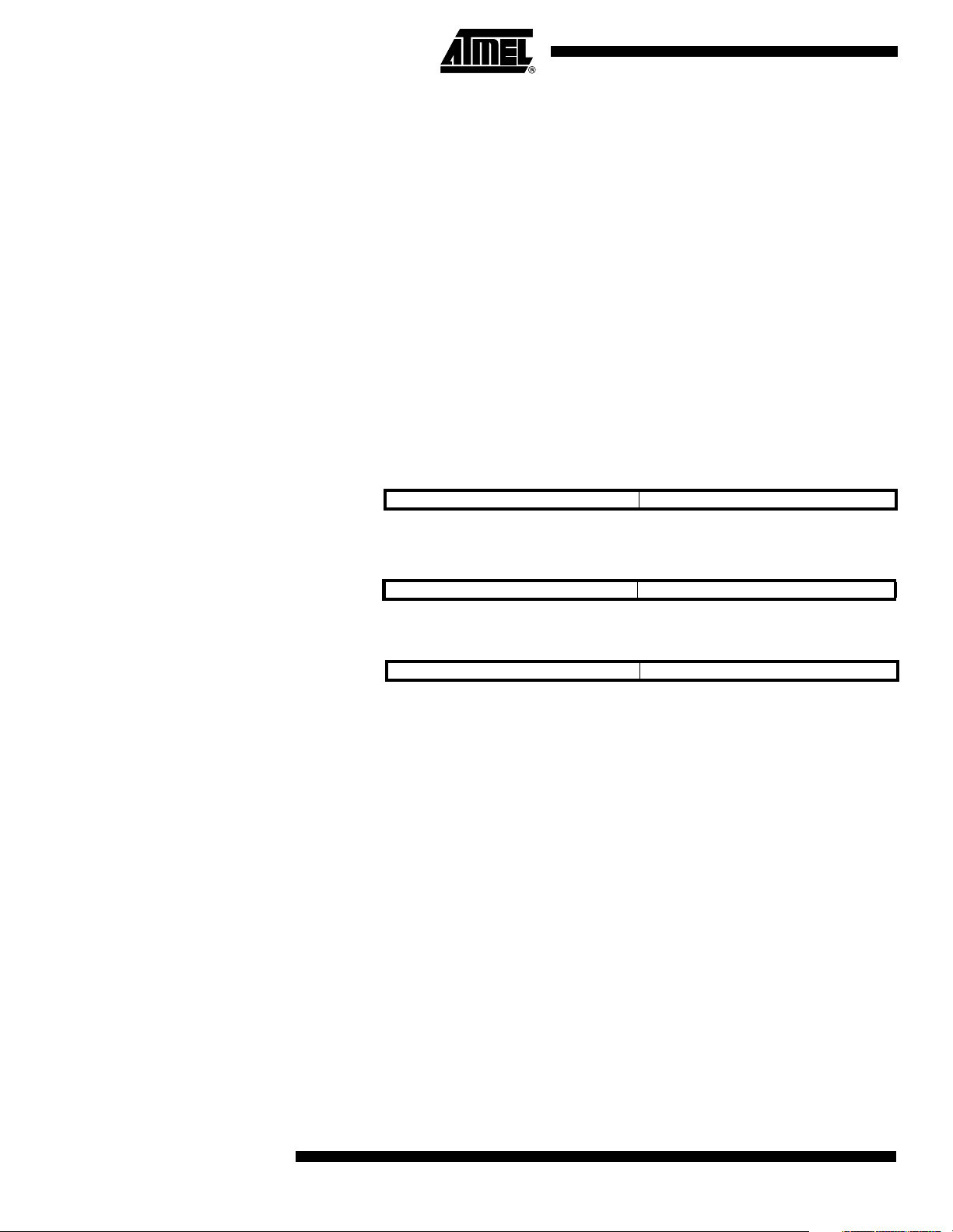

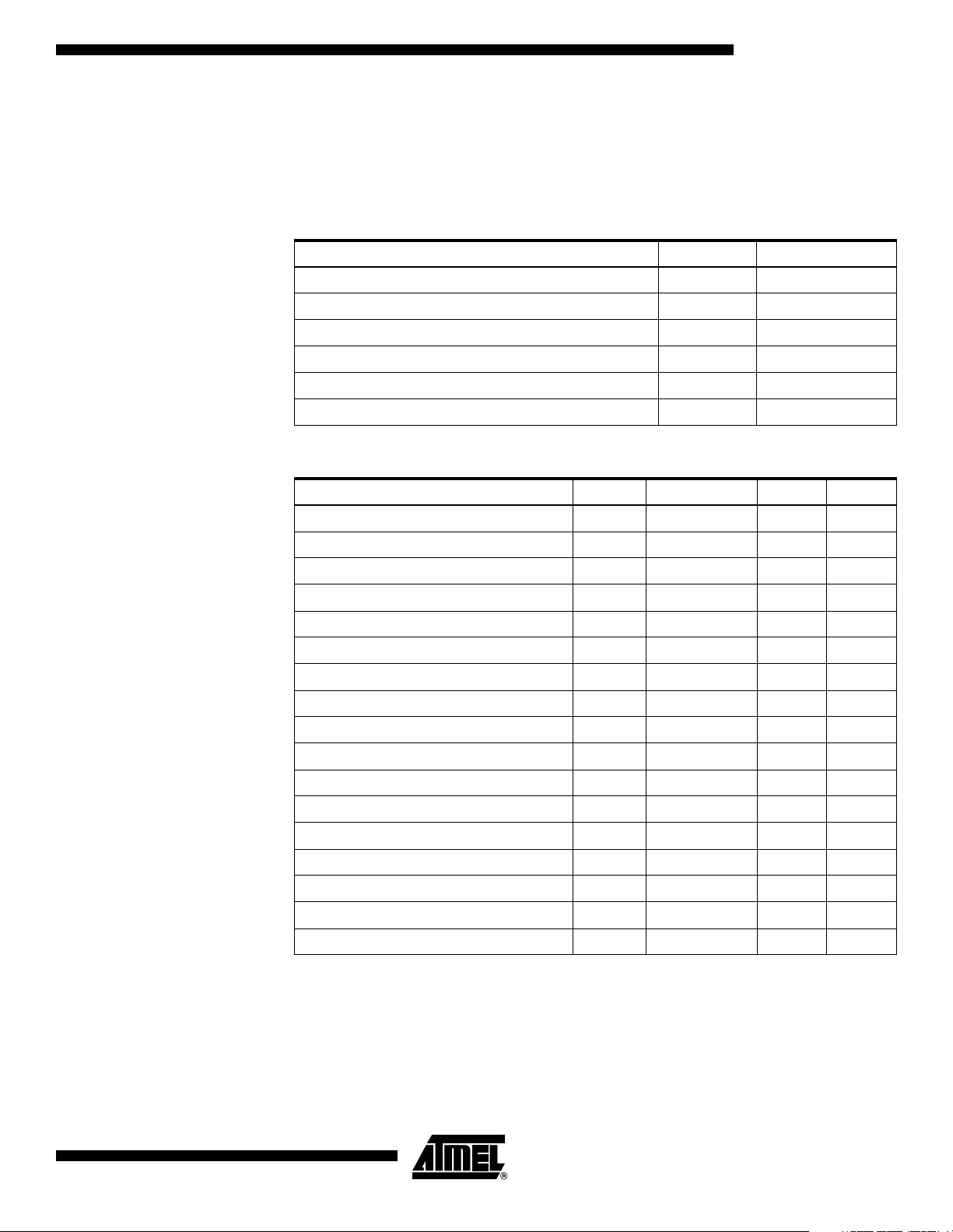

Figure 2. The ATtiny26/L AVR Enhanced RISC Architecture

8-bit Data Bus

Control

Registers

Interrupt

Unit

1024 x 16

Program

FLASH

Program

Counter

Status

and Test

Instruction

Register

Instruction

Decoder

Control Lines

Direct Addressing

Indirect Addressing

32 x 8

General

Purpose

Registers

ALU

128 x 8

SRAM

128 byte

EEPROM

Universal

Serial Interface

ISP Unit

2 x 8-bit

Timer/Counter

Watchdog

Timer

ADC

Analog

Comparator

I/O Lines

The ALU supports arithmetic and logic functions between registers or between a constant and a register. Single register operations are also executed in the ALU. Figure 2

shows the ATtiny26/L AVR Enhanced RISC microcontroller architecture. In addition to

the register operation, the conventional memory addressing modes can be used on the

Register File as well. This is enabled by the fact that the Register File is assigned the 32

lowermost Data Space addresses ($00 - $1F), allowing them to be accessed as though

they were ordinary memory locations.

The I/O memory space contains 64 addresses for CPU peripheral functions as Control

Registers, Timer/Counters, A/D Converters, and other I/O functions. The I/O Memory

can be accessed directly, or as the Data Space locations following those of the Register

File, $20 - $5F.

The AVR uses a Harvard architecture concept with separate memories and buses for

program and data memories. The program memory is accessed with a two stage

6

ATtiny26(L)

1477B–AVR–04/02

Page 7

ATtiny26(L)

pipelining. While one instruction is being executed, the next instruction is pre-fetched

from the program memory. This concept enables instructions to be executed in every

clock cycle. The program memory is In-System programmable Flash memory.

With the relative jump and relative call instructions, the whole address space is directly

accessed. All AVR instructions have a single 16-bit word format, meaning that every

program memory address contains a single 16-bit instruction.

During interrupts and subroutine calls, the return address program counter (PC) is

stored on the Stack. The Stack is effectively allocated in the general data SRAM, and

consequently the stack size is only limited by the total SRAM size and the usage of the

SRAM. All user programs must initialize the SP in the reset routine (before subroutines

or interrupts are executed). The 8-bit Stack Pointer SP is read/write accessible in the I/O

space. For programs written in C, the stack size must be declared in the linker file. Refer

to the C user guide for more information.

The 128 bytes data SRAM can be easily accessed through the five different addressing

modes supported in the AVR architecture.

The memory spaces in the AVR architecture are all linear and regular memory maps.

The I/O memory space contains 64 addresses for CPU peripheral functions as Control

Registers, Timer/Counters, and other I/O functions. The memory spaces in the AVR

architecture are all linear and regular memory maps.

General Purpose Register File

A flexible interrupt module has its control registers in the I/O space with an additional

Global Interrupt Enable bit in the Status Register. All the different interrupts have a separate Interrupt Vector in the Interrupt Vector table at the beginning of the program

memory. The different interrupts have priority in accordance with their Interrupt Vector

position. The lower the Interrupt Vector address, the higher the priority.

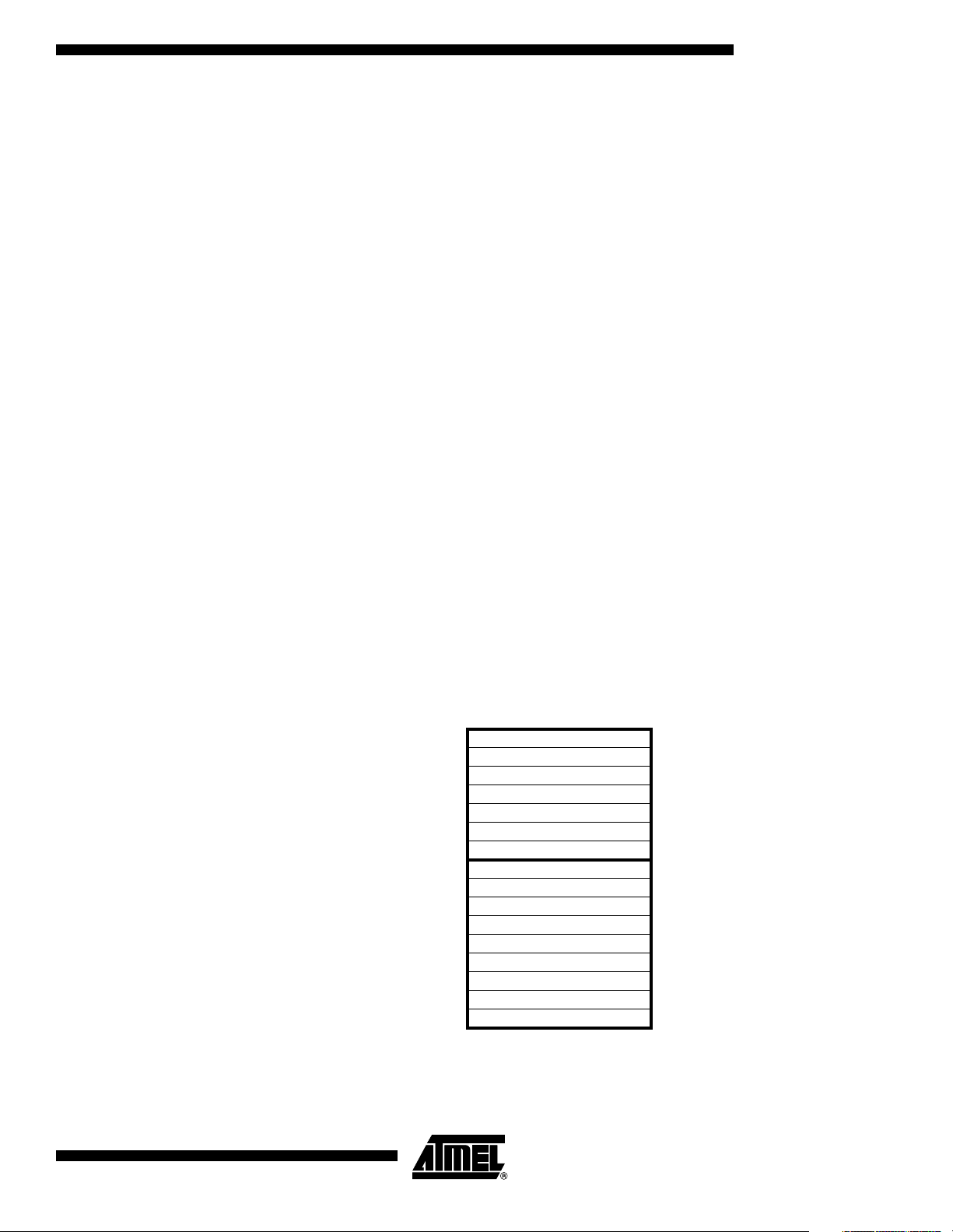

Figure 3 shows the structure of the 32 general purpose working registers in the CPU.

Figure 3. AVR CPU General Purpose Working Registers

7 0 Addr.

R0 $00

R1 $01

R2 $02

…

R13 $0D

General R14 $0E

Purpose R15 $0F

Working R16 $10

Registers R17 $11

…

R26 $1A X-register Low Byte

R27 $1B X-register High Byte

R28 $1C Y-register Low Byte

R29 $1D Y-register High Byte

R30 $1E Z-register Low Byte

R31 $1F Z-register High Byte

1477B–AVR–04/02

7

Page 8

All of the register operating instructions in the instruction set have direct and single cycle

access to all registers. The only exceptions are the five constant arithmetic and logic

instructions SBCI, SUBI, CPI, ANDI, and ORI between a constant and a register, and

the LDI instruction for load immediate constant data. These instructions apply to the

second half of the registers in the Register File – R16..R31. The general SBC, SUB, CP,

AND, and OR, and all other operations between two registers or on a single register

apply to the entire Register File.

As shown in Figure 3, each register is also assigned a data memory address, mapping

them directly into the first 32 locations of the user Data Space. Although not being physically implemented as SRAM locations, this memory organization provides flexibility in

access of the registers, as the X-, Y-, and Z-registers can be set to index any register in

the file.

X-register, Y-register, and Zregister

ALU – Arithmetic Logic Unit

The registers R26..R31 have some added functions to their general purpose usage.

These registers are address pointers for indirect addressing of the Data Space. The

three indirect address registers X, Y, and Z are defined as:

Figure 4. X-, Y-, and Z-register

15 0

X-register 7 0 7 0

R27 ($1B) R26 ($1A)

15 0

Y-register 7 0 7 0

R29 ($1D) R28 ($1C)

15 0

Z-register 7 0 7 0

R31 ($1F) R30 ($1E)

In the different addressing modes, these address registers have functions as fixed displacement, automatic increment and decrement (see the descriptions for the different

instructions).

The high-performance AVR ALU operates in direct connection with all 32 general purpose working registers. Within a single clock cycle, ALU operations between registers in

the Register File are executed. The ALU operations are divided into three main categories – Arithmetic, Logical, and Bit-functions.

8

ATtiny26(L)

1477B–AVR–04/02

Page 9

ATtiny26(L)

In-System Programmable Flash Program Memory

The ATtiny26/L contains 2K bytes On-chip In-System Programmable Flash memory for

program storage. Since all instructions are 16- or 32-bit words, the Flash is organized as

1K x 16. The Flash memory has an endurance of at least 1,000 write/erase cycles. The

ATtiny26/L Program Counter – PC – is 10 bits wide, thus addressing the 1024 program

memory addresses, see “Memory Programming” on page 106 for a detailed description

on Flash data downloading. See “Program and Data Addressing Modes” on page 10 for

the different program memory addressing modes.

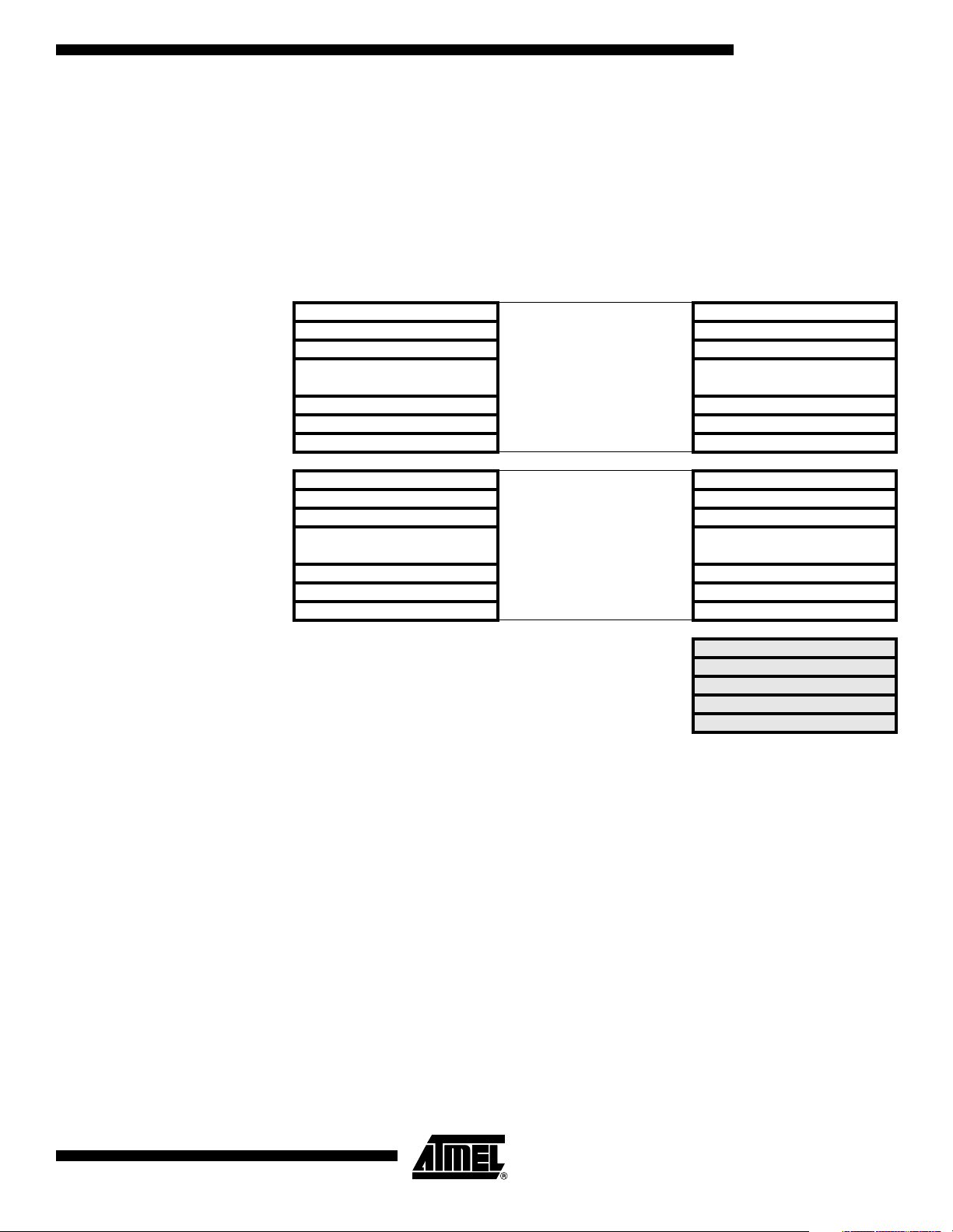

Figure 5. SRAM Organization

Register File Data Address Space

R0 $0000

R1 $0001

R2 $0002

... ...

R29 $001D

R30 $001E

R31 $001F

I/O Registers

$00 $0020

$01 $0021

$02 $0022

… …

$3D $005D

$3E $005E

$3F $005F

Internal SRAM

SRAM Data Memory Figure 5 above shows how the ATtiny26/L SRAM Memory is organized.

The lower 224 Data Memory locations address the Register File, the I/O Memory and

the internal data SRAM. The first 96 locations address the Register File and I/O Memory, and the next 128 locations address the internal data SRAM.

The five different addressing modes for the data memory cover: Direct, Indirect with Displacement, Indirect, Indirect with Pre-decrement, and Indirect with Post-increment. In

the Register File, registers R26 to R31 feature the indirect addressing pointer registers.

The direct addressing reaches the entire data space. The Indirect with Displacement

mode features a 63 address locations reach from the base address given by the Y- or Zregister.

When using register indirect addressing modes with automatic pre-decrement and postincrement, the address registers X, Y, and Z are decremented and incremented.

$0060

$0061

...

$00DE

$00DF

1477B–AVR–04/02

The 32 general purpose working registers, 64 I/O Registers and the 128 bytes of internal data SRAM in the ATtiny26/L are all accessible through all these addressing modes.

See the next section for a detailed description of the different addressing modes.

9

Page 10

Program and Data Addressing Modes

The ATtiny26/L AVR Enhanced RISC microcontroller supports powerful and efficient

addressing modes for access to the Flash program memory, SRAM, Register File, and

I/O Data memory. This section describes the different addressing modes supported by

the AVR architecture. In the figures, OP means the operation code part of the instruction

word. To simplify, not all figures show the exact location of the addressing bits.

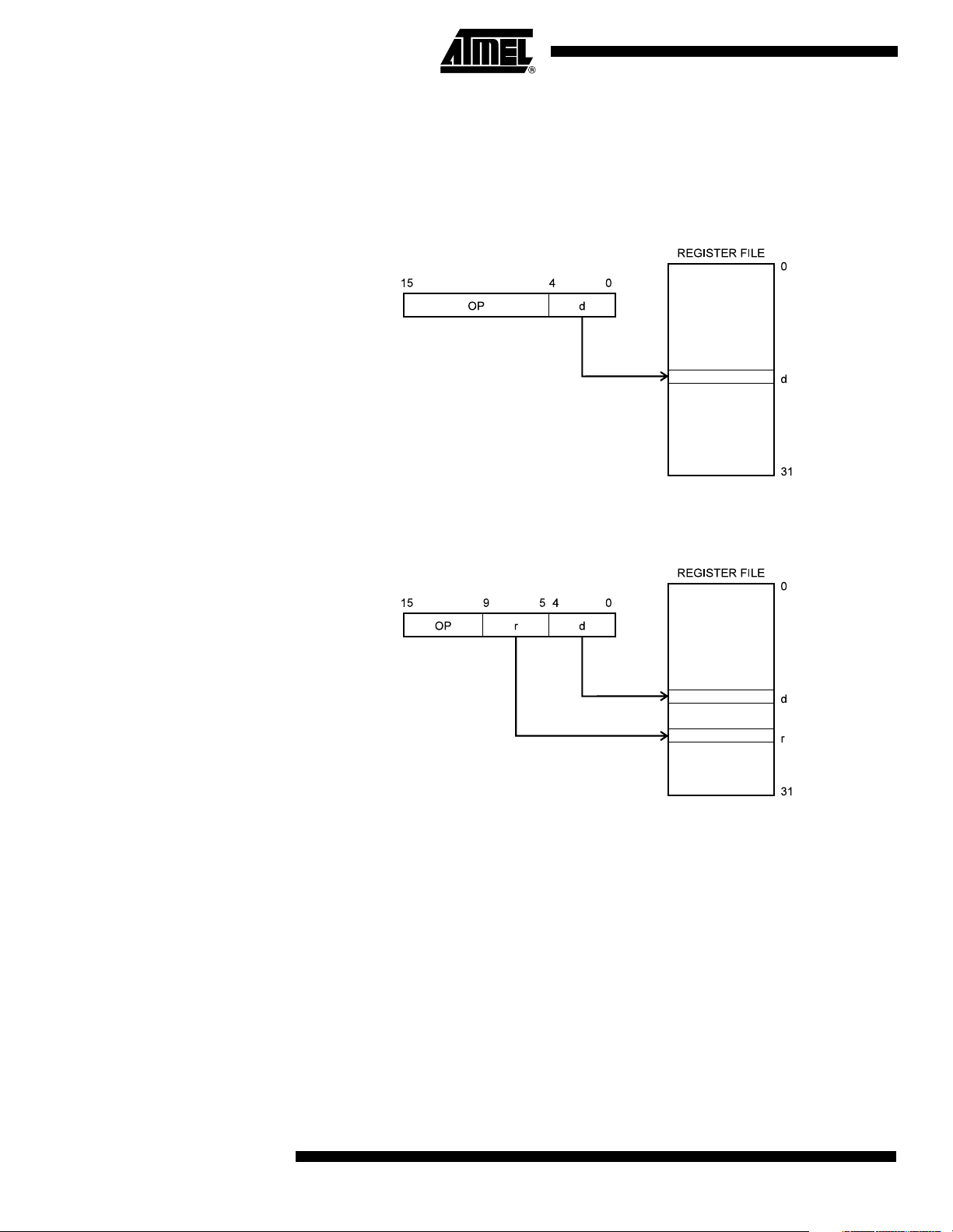

Register Direct, Single Register Rd

Register Direct, Two Registers Rd and Rr

Figure 6. Direct Single Register Addressing

The operand is contained in register d (Rd).

Figure 7. Direct Register Addressing, Two Registers

10

Operands are contained in register r (Rr) and d (Rd). The result is stored in register d

(Rd).

ATtiny26(L)

1477B–AVR–04/02

Page 11

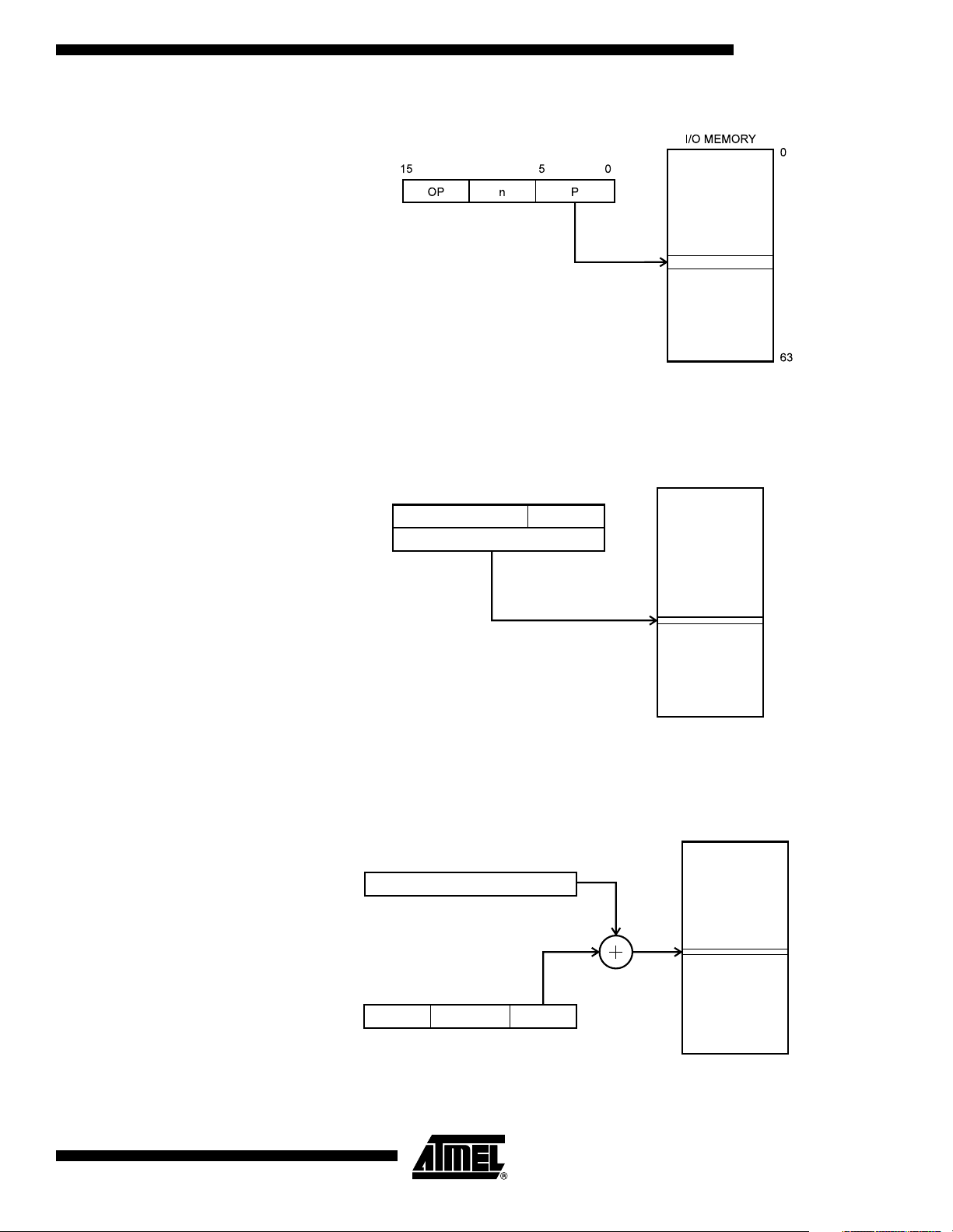

I/O Direct Figure 8. I/O Direct Addressing

Operand address is contained in 6 bits of the instruction word. n is the destination or

source register address.

Data Direct Figure 9. Direct Data Addressing

31

OP Rr/Rd

15 0

20 19

16 LSBs

16

ATtiny26(L)

Data Space

$0000

Data Indirect with Displacement

1477B–AVR–04/02

$00DF

A 16-bit Data Address is contained in the 16 LSBs of a two-word instruction. Rd/Rr

specify the destination or source register.

Figure 10. Data Indirect with Displacement

15

Y OR Z - REGISTER

15

OP an

Data Space

0

05610

$0000

$00DF

11

Page 12

Operand address is the result of the Y- or Z-register contents added to the address contained in 6 bits of the instruction word.

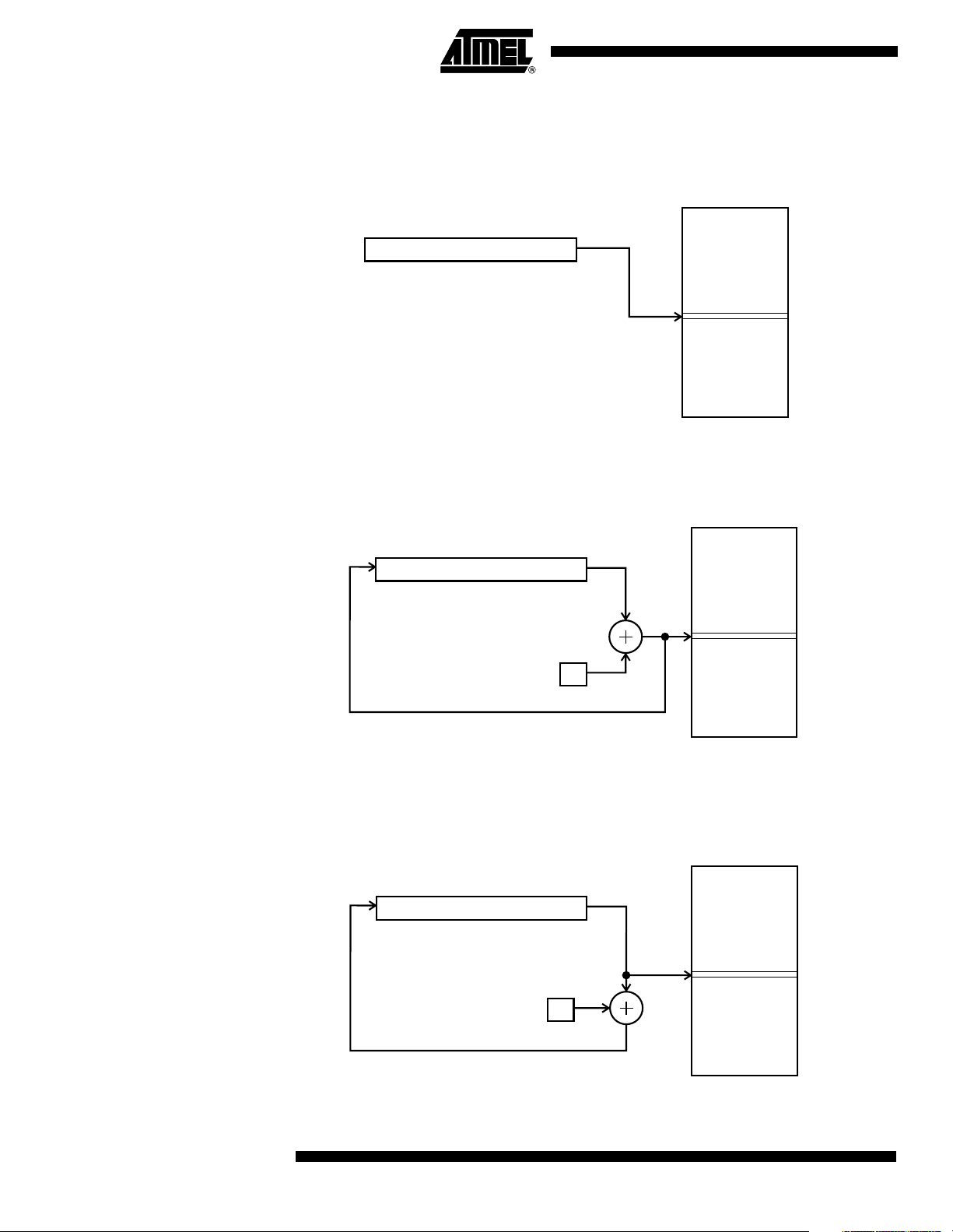

Data Indirect Figure 11. Data Indirect Addressing

X-, Y-, OR Z-REGISTER

Operand address is the contents of the X-, Y-, or the Z-register.

Data Space

$0000

015

$00DF

Data Indirect with Predecrement

Data Indirect with Postincrement

Figure 12. Data Indirect Addressing with Pre-decrement

Data Space

$0000

015

X-, Y-, OR Z-REGISTER

-1

$00DF

The X-, Y-, or Z-register is decremented before the operation. Operand address is the

decremented contents of the X-, Y-, or Z-register.

Figure 13. Data Indirect Addressing with Post-increment

Data Space

$0000

015

X-, Y-, OR Z-REGISTER

12

1

$00DF

ATtiny26(L)

1477B–AVR–04/02

Page 13

ATtiny26(L)

The X-, Y-, or Z-register is incremented after the operation. Operand address is the content of the X-, Y-, or Z-register prior to incrementing.

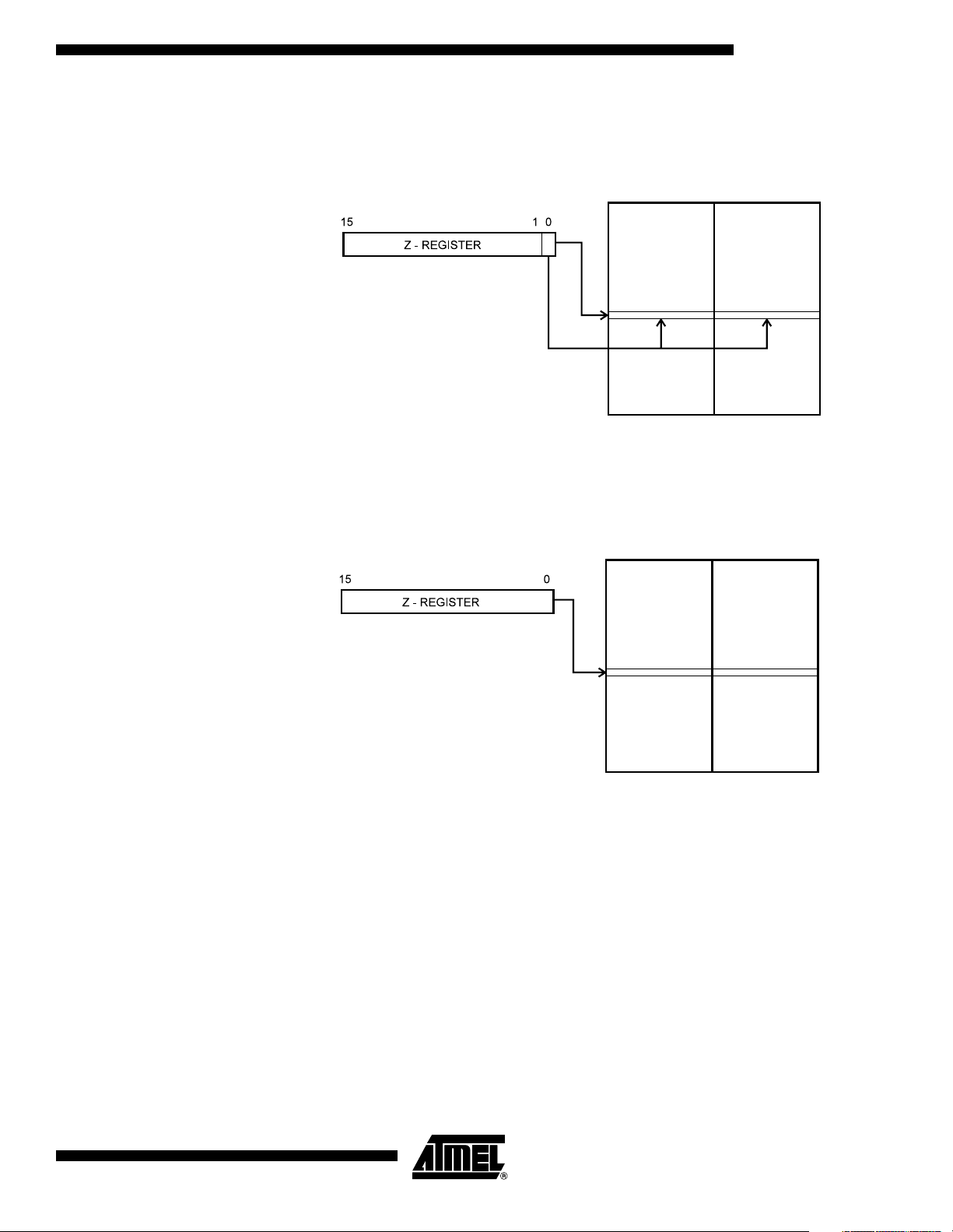

Constant Addressing Using the LPM Instruction

Indirect Program Addressing, IJMP and ICALL

Figure 14. Code Memory Constant Addressing

PROGRAM MEMORY

$000

$3FF

Constant byte address is specified by the Z-register contents. The 15 MSBs select word

address (0 - 1K), the LSB selects low byte if cleared (LSB = 0) or high byte if set

(LSB = 1).

Figure 15. Indirect Program Memory Addressing

PROGRAM MEMORY

$000

1477B–AVR–04/02

$3FF

Program execution continues at address contained by the Z-register (i.e., the PC is

loaded with the contents of the Z-register).

13

Page 14

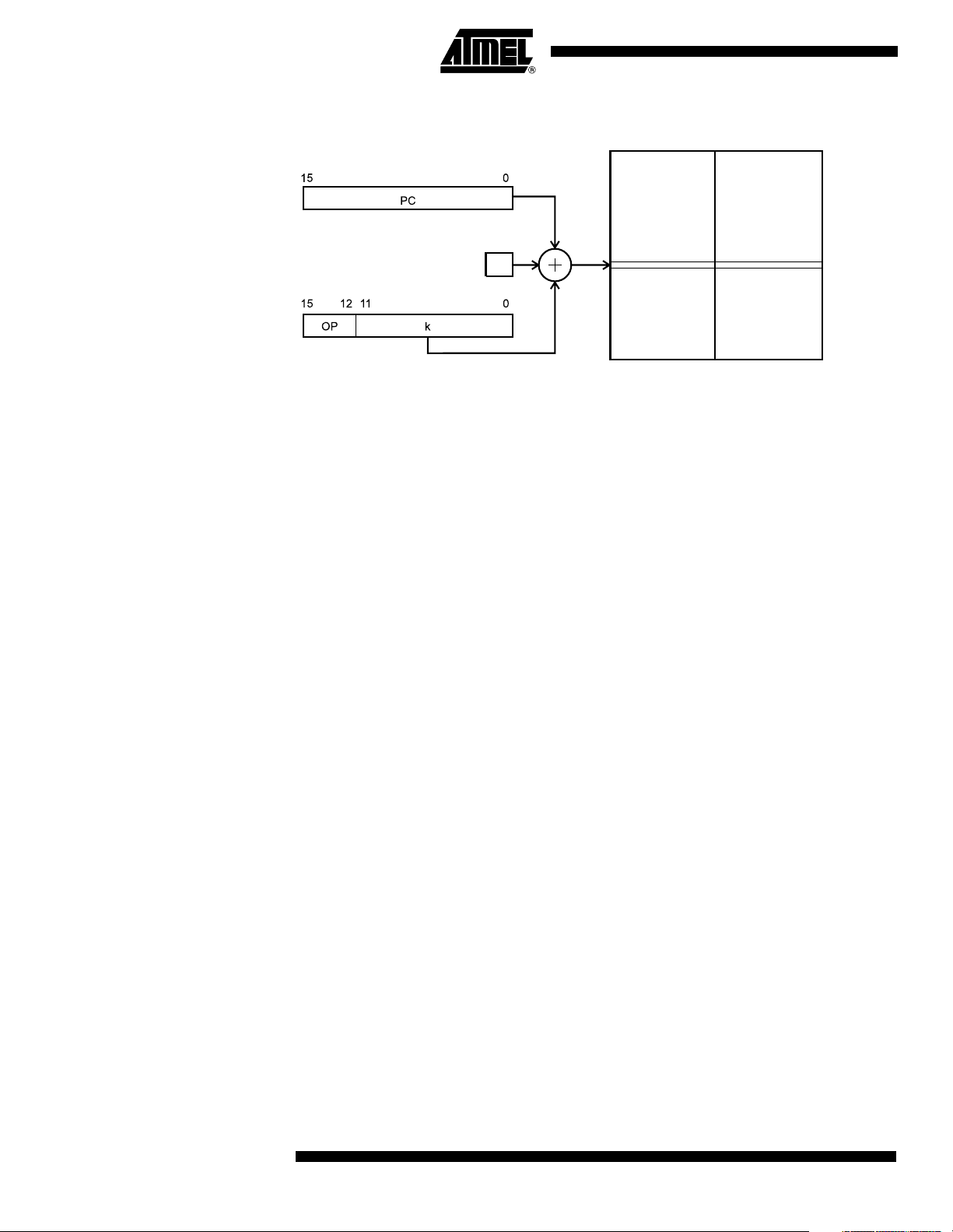

Relative Program Addressing, RJMP and RCALL

Figure 16. Relative Program Memory Addressing

+1

PROGRAM MEMORY

$000

$3FF

Program execution continues at address PC + k + 1. The relative address k is from

-2048 to 2047.

EEPROM Data Memory The ATtiny26/L contains 128 bytes of data EEPROM memory. It is organized as a sepa-

rate data space, in which single bytes can be read and written. The EEPROM has an

endurance of at least 100,000 write/erase cycles per location. The access between the

EEPROM and the CPU is described on “EEPROM Read/Write Access” on page 60

specifying the EEPROM Address Registers, the EEPROM Data Register, and the

EEPROM Control Register.

For the programming of the EEPROM See “Memory Programming” on page 106.

14

ATtiny26(L)

1477B–AVR–04/02

Page 15

ATtiny26(L)

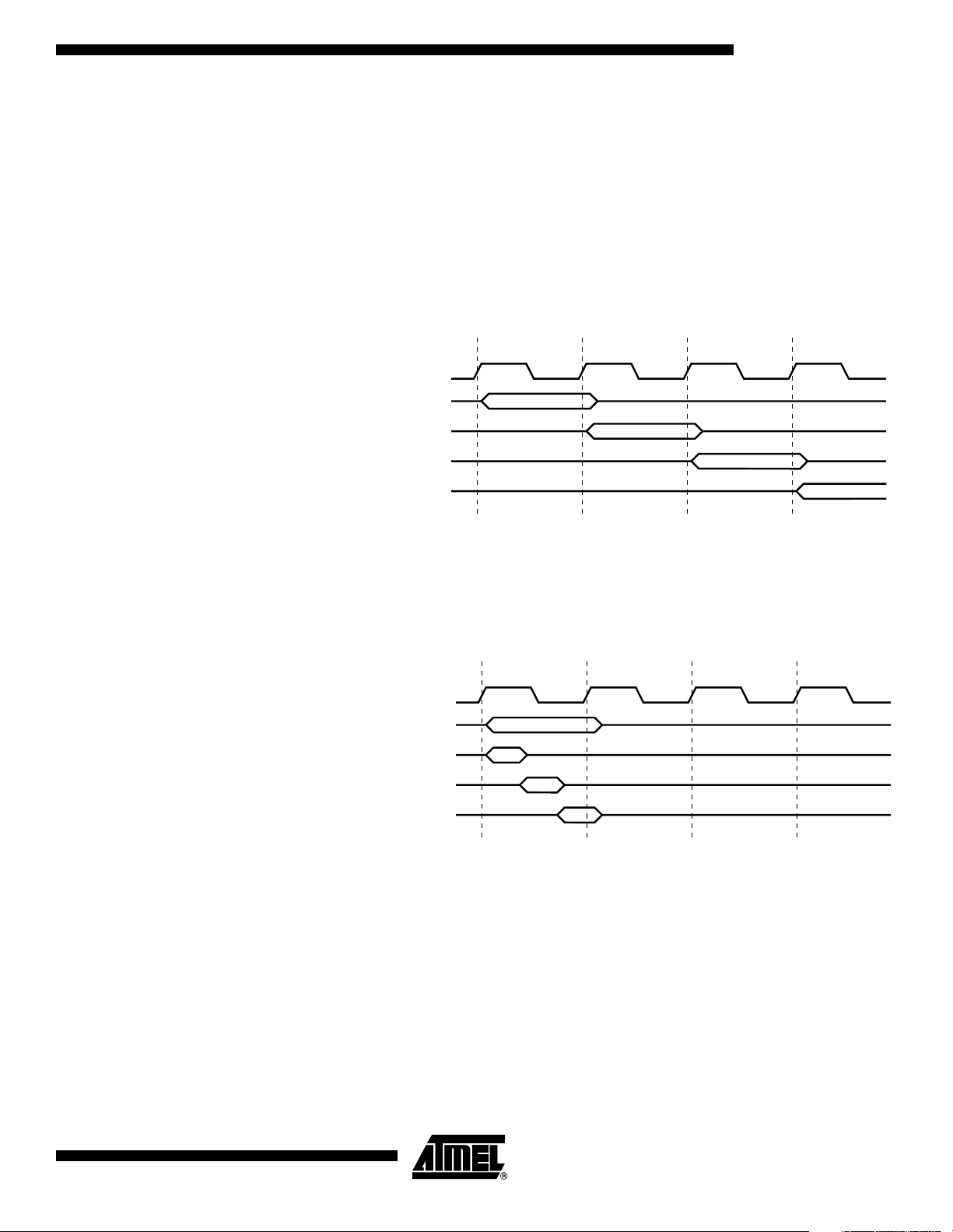

Memory Access Times and Instruction Execution Timing

This section describes the general access timing concepts for instruction execution and

internal memory access.

The AVR CPU is driven by the System Clock Ø, directly generated from the external

clock crystal for the chip. No internal clock division is used.

Figure 17 shows the parallel instruction fetches and instruction executions enabled by

the Harvard architecture and the fast-access Register File concept. This is the basic

pipelining concept to obtain up to 1 MIPS per MHz with the corresponding unique results

for functions per cost, functions per clocks, and functions per power-unit.

Figure 17. The Parallel Instruction Fetches and Instruction Executions

T1 T2 T3 T4

System Clock Ø

1st Instruction Fetch

1st Instruction Execute

2nd Instruction Fetch

2nd Instruction Execute

3rd Instruction Fetch

3rd Instruction Execute

4th Instruction Fetch

Figure 18 shows the internal timing concept for the Register File. In a single clock cycle

an ALU operation using two register operands is executed, and the result is stored back

to the destination register.

Figure 18. Single Cycle ALU Operation

T1 T2 T3 T4

System Clock Ø

Total Execution Time

Register Operands Fetch

ALU Operation Execute

Result Write Back

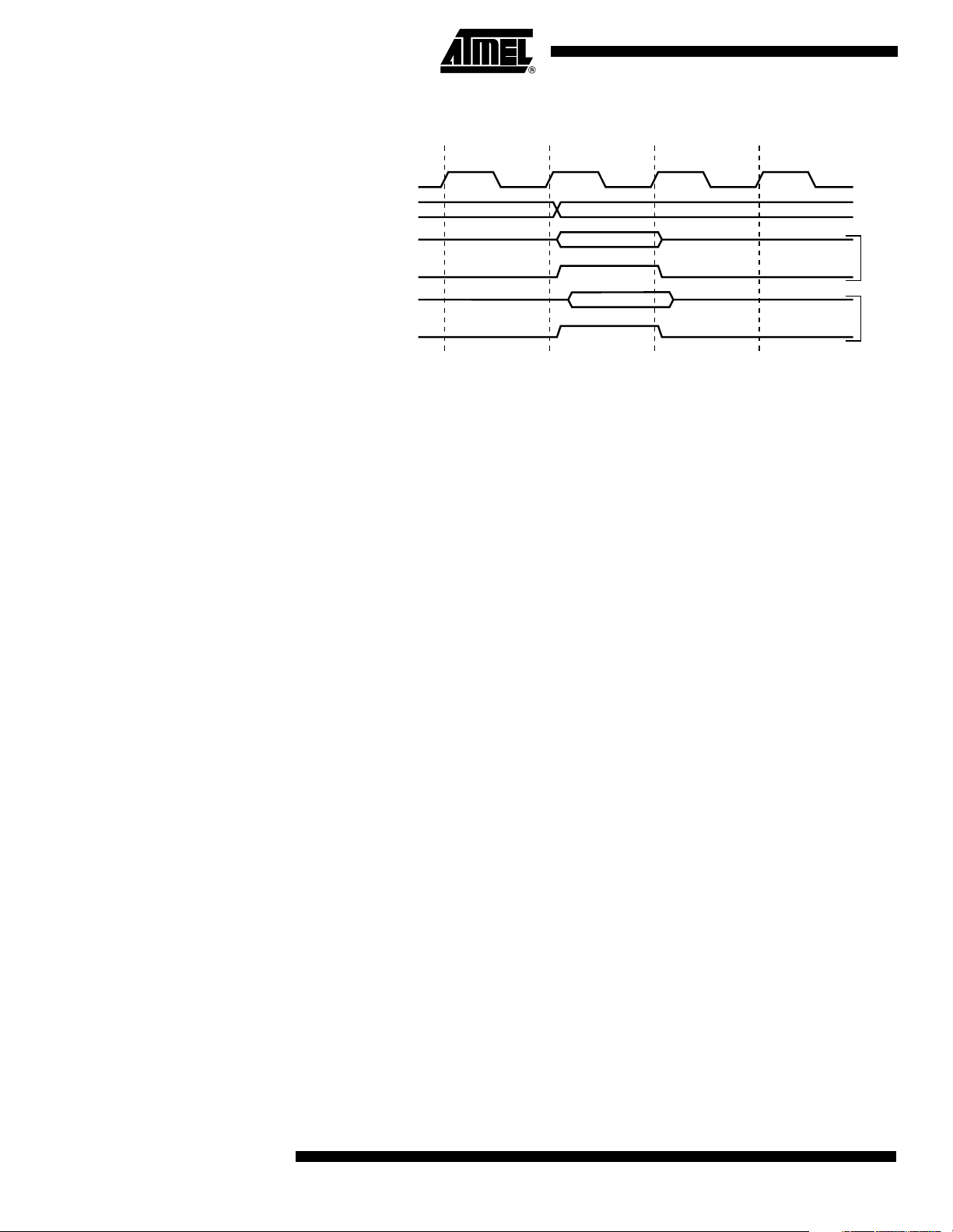

The internal data SRAM access is performed in two System Clock cycles as described

in Figure 19.

1477B–AVR–04/02

15

Page 16

Figure 19. On-chip Data SRAM Access Cycles

T1 T2 T3 T4

System Clock Ø

Address

Data

WR

Data

RD

Prev. Address

Address

Write

Read

16

ATtiny26(L)

1477B–AVR–04/02

Page 17

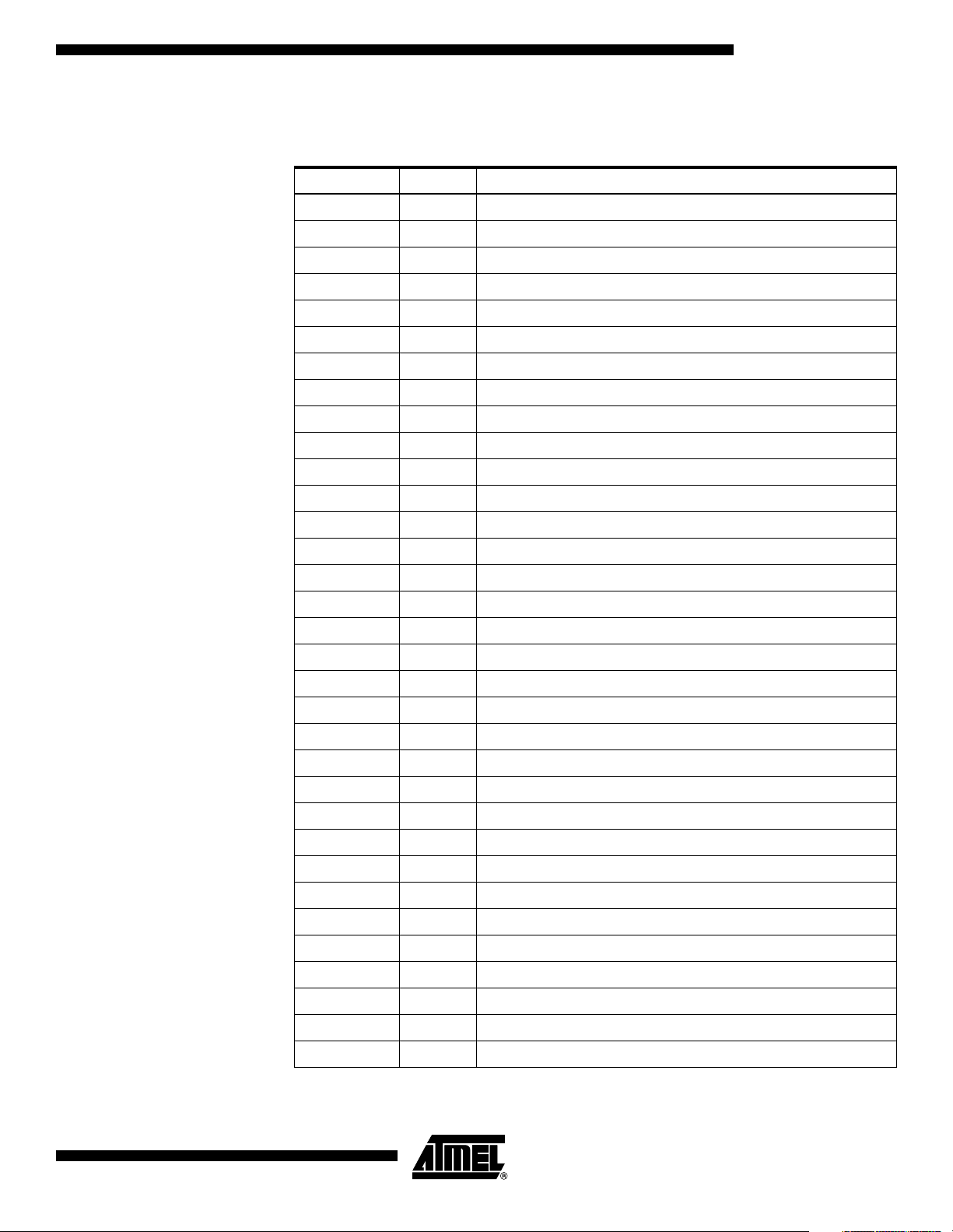

I/O Memory The I/O space definition of the ATtiny26/L is shown in Table 1

ATtiny26(L)

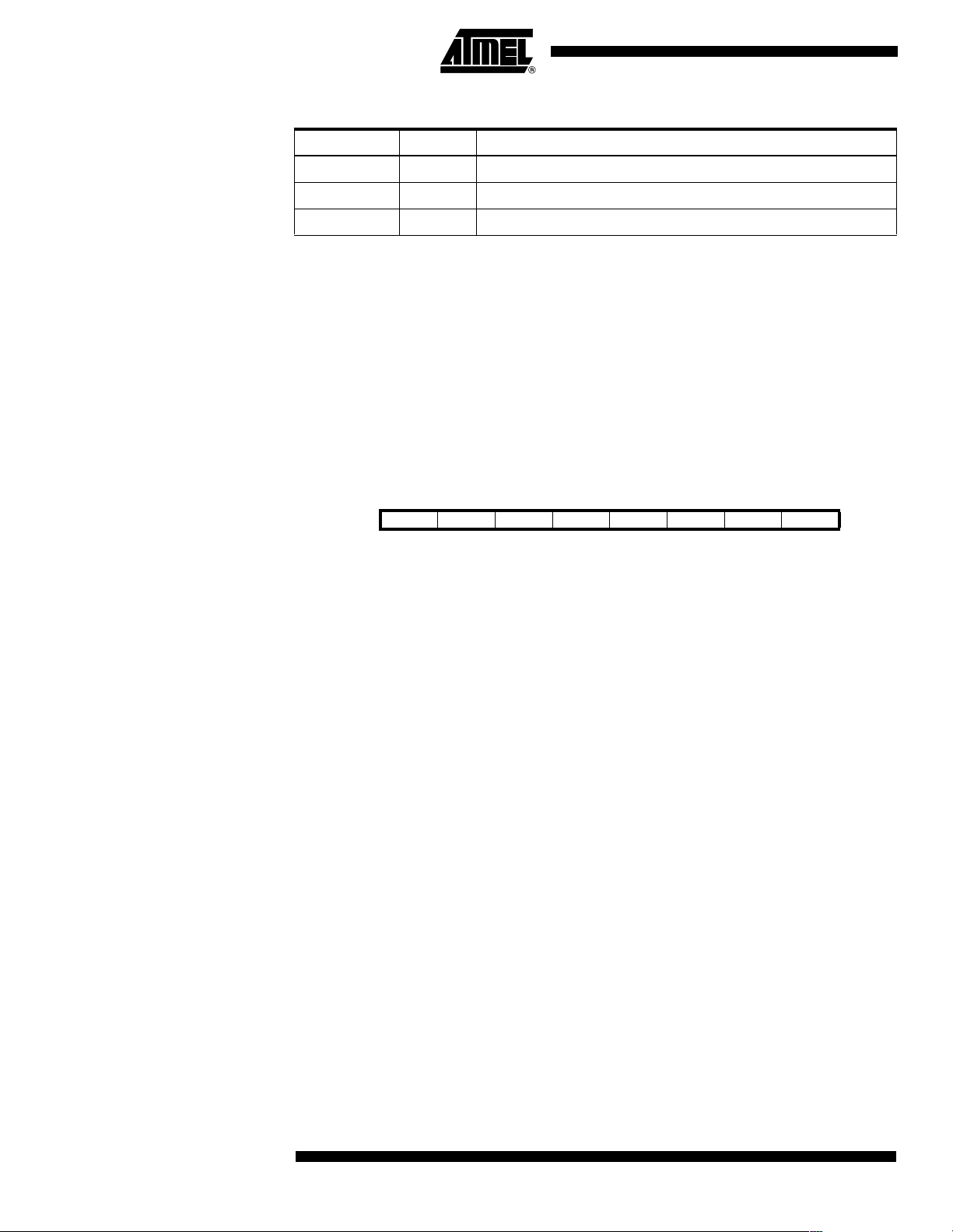

Table 1. ATtiny26/L I/O Space

Address Hex Name Function

$3F ($5F) SREG Status Register

$3D ($5D) SP Stack Pointer

$3B ($5B) GIMSK General Interrupt Mask Register

$3A ($5A) GIFR General Interrupt Flag Register

$39 ($59) TIMSK Timer/Counter Interrupt Mask Register

$38 ($58) TIFR Timer/Counter Interrupt Flag Register

$35 ($55) MCUCR MCU Control Register

$34 ($54) MCUSR MCU Status Register

$33 ($53) TCCR0 Timer/Counter0 Control Register

$32 ($52) TCNT0 Timer/Counter0 (8-bit)

$31 ($51) OSCCAL Oscillator Calibration Register

$30 ($50) TCCR1A Timer/Counter1 Control Register A

$2F ($4F) TCCR1B Timer/Counter1 Control Register B

$2E ($4E) TCNT1 Timer/Counter1 (8-bit)

$2D ($4D) OCR1A Timer/Counter1 Output Compare Register A

$2C ($4C) OCR1B Timer/Counter1 Output Compare Register B

(1)

$2B ($4B) OCR1C Timer/Counter1 Output Compare Register C

$29 ($29) PLLCSR PLL Control and Status Register

$21 ($41) WDTCR Watchdog Timer Control Register

$1E ($3E) EEAR EEPROM Address Register

$1D ($3D) EEDR EEPROM Data Register

$1C ($3C) EECR EEPROM Control Register

$1B ($3B) PORTA Data Register, Port A

$1A ($3A) DDRA Data Direction Register, Port A

$19 ($39) PINA Input Pins, Port A

$18 ($38) PORTB Data Register, Port B

$17 ($37) DDRB Data Direction Register, Port B

$16 ($36) PINB Input Pins, Port B

$0F ($2F) USIDR Universal Serial Interface Data Register

$0E ($2E) USISR Universal Serial Interface Status Register

$0D ($2D) USICR Universal Serial Interface Control Register

$08 ($28) ACSR Analog Comparator Control and Status Register

$07 ($27) ADMUX ADC Multiplexer Select Register

1477B–AVR–04/02

17

Page 18

Table 1. ATtiny26/L I/O Space

Address Hex Name Function

$06($26) ADCSR ADC Control and Status Register

$05($25) ADCH ADC Data Register High

$04($24) ADCL ADC Data Register Low

Note: 1. Reserved and unused locations are not shown in the table.

(1)

(Continued)

All ATtiny26/L I/O and peripheral registers are placed in the I/O space. The I/O locations

are accessed by the IN and OUT instructions transferring data between the 32 general

purpose working registers and the I/O space. I/O Registers within the address range

$00 - $1F are directly bit-accessible using the SBI and CBI instructions. In these registers, the value of single bits can be checked by using the SBIS and SBIC instructions.

Refer to the instruction set chapter for more details. For compatibility with future

devices, reserved bits should be written zero if accessed. Reserved I/O memory

addresses should never be written.

The I/O and peripheral control registers are explained in the following sections.

Status Register – SREG The AVR Status Register – SREG – at I/O space location $3F is defined as:

Bit 76543210

$3F ($5F) I T H S V N Z C SREG

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value00000000

• Bit 7 – I: Global Interrupt Enable

The Global Interrupt Enable bit must be set (one) for the interrupts to be enabled. The

individual interrupt enable control is then performed in the Interrupt Mask Registers –

GIMSK and TIMSK. If the Global Interrupt Enable Register is cleared (zero), none of the

interrupts are enabled independent of the GIMSK and TIMSK values. The I-bit is cleared

by hardware after an interrupt has occurred, and is set by the RETI instruction to enable

subsequent interrupts. The I-bit can also be set and cleared by the application with the

SEI and CLI instructions, as described in the instruction set reference.

• Bit 6 – T: Bit Copy Storage

The Bit Copy instructions BLD (Bit LoaD) and BST (Bit STore) use the T-bit as source

and destination for the operated bit. A bit from a register in the Register File can be copied into T by the BST instruction, and a bit in T can be copied into a bit in a register in the

Register File by the BLD instruction.

• Bit 5 – H: Half Carry Flag

The Half Carry Flag H indicates a Half Carry in some arithmetic operations. See the

Instruction Set Description for detailed information.

• Bit 4 – S: Sign Bit, S = N

⊕ V

The S-bit is always an exclusive or between the Negative Flag N and the Two’s Complement Overflow Flag V. See the Instruction Set Description for detailed information.

18

• Bit 3 – V: Two’s Complement Overflow Flag

The Two’s Complement Overflow Flag V supports two’s complement arithmetics. See

the Instruction Set Description for detailed information.

ATtiny26(L)

1477B–AVR–04/02

Page 19

ATtiny26(L)

• Bit 2 – N: Negative Flag

The Negative Flag N indicates a negative result after the different arithmetic and logic

operations. See the Instruction Set Description for detailed information.

• Bit 1 – Z: Zero Flag

The Zero Flag Z indicates a zero result after the different arithmetic and logic operations. See the Instruction Set Description for detailed information.

• Bit 0 – C: Carry Flag

The Carry Flag C indicates a carry in an arithmetic or logic operation. See the Instruction

Set Description for detailed information.

Stack Pointer – SP The ATtiny26/L Stack Pointer is implemented as an 8-bit register in the I/O space loca-

tion $3D ($5D). As the ATtiny26/L data memory has 224 ($E0) locations, eight bits are

used.

Bit 76543210

$3D ($5D) SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0 SP

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value00000000

The Stack Pointer points to the data SRAM stack area where the Subroutine and Interrupt Stacks are located. This Stack space in the data SRAM must be defined by the

program before any subroutine calls are executed or interrupts are enabled. The Stack

Pointer must be set to point above $60. The Stack Pointer is decremented by one when

data is pushed onto the Stack with the PUSH instruction, and it is decremented by two

when an address is pushed onto the Stack with subroutine calls and interrupts. The

Stack Pointer is incremented by one when data is popped from the Stack with the POP

instruction, and it is incremented by two when an address is popped from the Stack with

return from subroutine RET or return from interrupt RETI.

1477B–AVR–04/02

19

Page 20

Reset and Interrupt Handling

The ATtiny26/L provides eleven interrupt sources. These interrupts and the separate

Reset Vector, each have a separate program vector in the program memory space. All

the interrupts are assigned individual enable bits which must be set (one) together with

the I-bit in the Status Register in order to enable the interrupt.

The lowest addresses in the program memory space are automatically defined as the

Reset and Interrupt vectors. The complete list of vectors is shown in Table 2. The list

also determines the priority levels of the different interrupts. The lower the address the

higher is the priority level. RESET has the highest priority, and next is INT0 – the External Interrupt Request 0 etc.

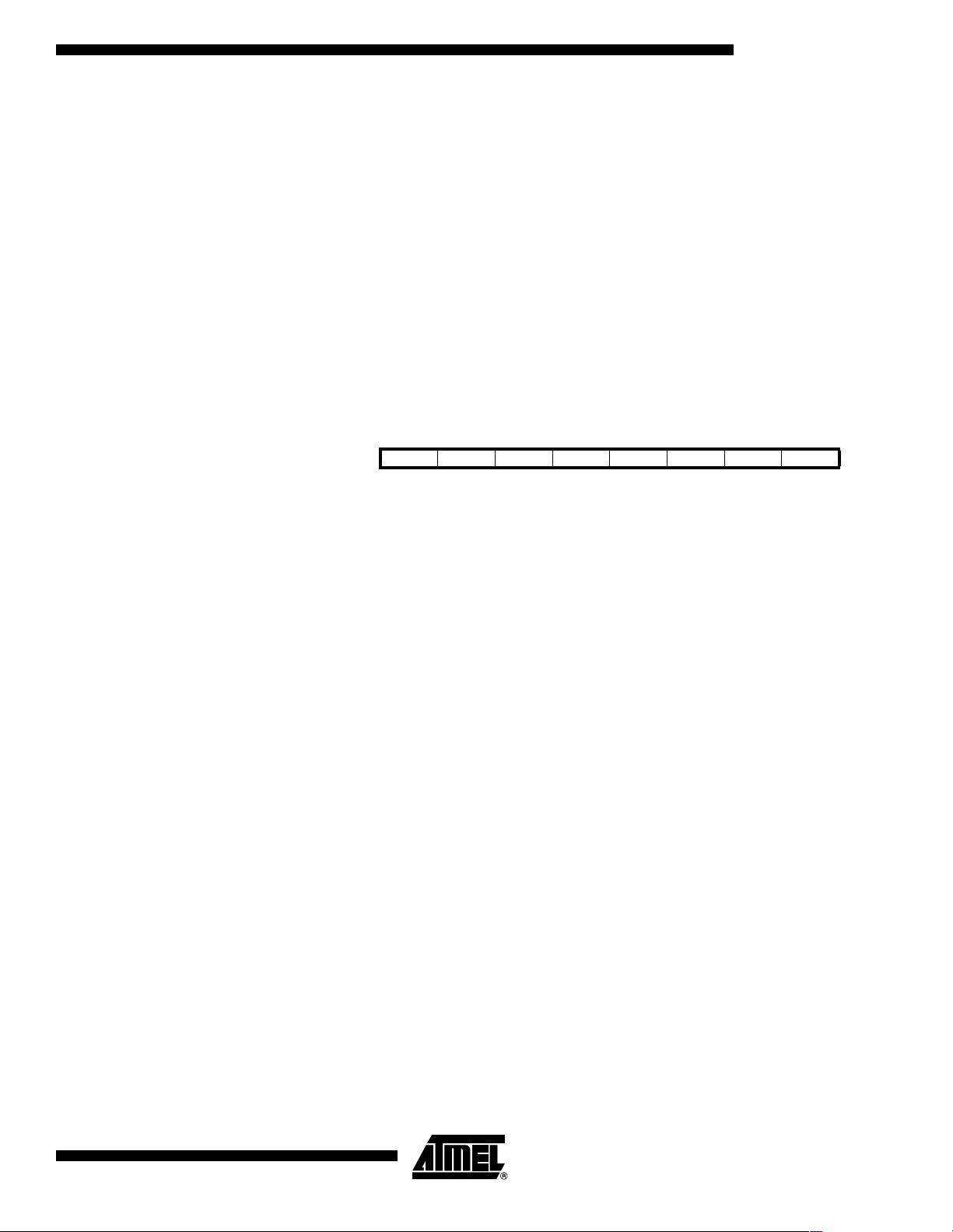

Table 2. Reset and Interrupt Vectors

Vector No Program Address Source Interrupt Definition

1 $000 RESET Hardware Pin and Watchdog Reset

2 $001 INT0 External Interrupt Request 0

3 $002 I/O Pins Pin Change Interrupt

4 $003 TIMER1, CMPA Timer/Counter1 Compare Match 1A

5 $004 TIMER1, CMPB Timer/Counter1 Compare Match 1B

6 $005 TIMER1, OVF1 Timer/Counter1 Overflow

7 $006 TIMER0, OVF0 Timer/Counter0 Overflow

8 $007 USI_STRT USI Start

9 $008 USI_OVF USI Overflow

A $009 EE_RDY EEPROM Ready

B $00A ANA_COMP Analog Comparator

C $00B ADC ADC Conversion Complete

The most typical and general program setup for the Reset and Interrupt Vector

Addresses are:

Address Labels Code Comments

$000 rjmp RESET ; Reset handler

$001 rjmp EXT_INT0 ; IRQ0 handler

$002 rjmp PIN_CHANGE ; Pin change handler

$003 rjmp TIM1_CMP1A ; Timer1 compare match 1A

$004 rjmp TIM1_CMP1B ; Timer1 compare match 1B

$005 rjmp TIM1_OVF ; Timer1 overflow handler

$006 rjmp TIM0_OVF ; Timer0 overflow handler

$007 rjmp USI_STRT ; USI Start handler

$008 rjmp USI_OVF ; USI Overflow handler

$009 rjmp EE_RDY ; EEPROM Ready handler

$00A rjmp ANA_COMP ; Analog Comparator handler

$00B rjmp ADC ; ADC Conversion Handler

;

$009 RESET: ldi r16, RAMEND ; Main program start

$00A out SP, r16

$00B sei

… … … …

20

ATtiny26(L)

1477B–AVR–04/02

Page 21

Reset Sources The ATtiny26/L provides four sources of reset:

• Power-on Reset. The MCU is reset when the supply voltage is below the Power-on

Reset threshold (V

POT

).

• External Reset. To use the PB7/RESET pin as an External Reset, instead of I/O pin,

unprogram (“1”) the RSTDISBL Fuse. The MCU is reset when a low level is present

on the RESET

pin for more than 50 ns.

• Watchdog Reset. The MCU is reset when the Watchdog timer period expires and

the Watchdog is enabled.

• Brown-out Reset. The MCU is reset when the supply voltage V

Brown-out Reset threshold (V

BOT

).

During reset, all I/O Registers are then set to their initial values, and the program starts

execution from address $000. The instruction placed in address $000 must be an RJMP

– Relative Jump – instruction to the reset handling routine. If the program never enables

an interrupt source, the interrupt vectors are not used, and regular program code can be

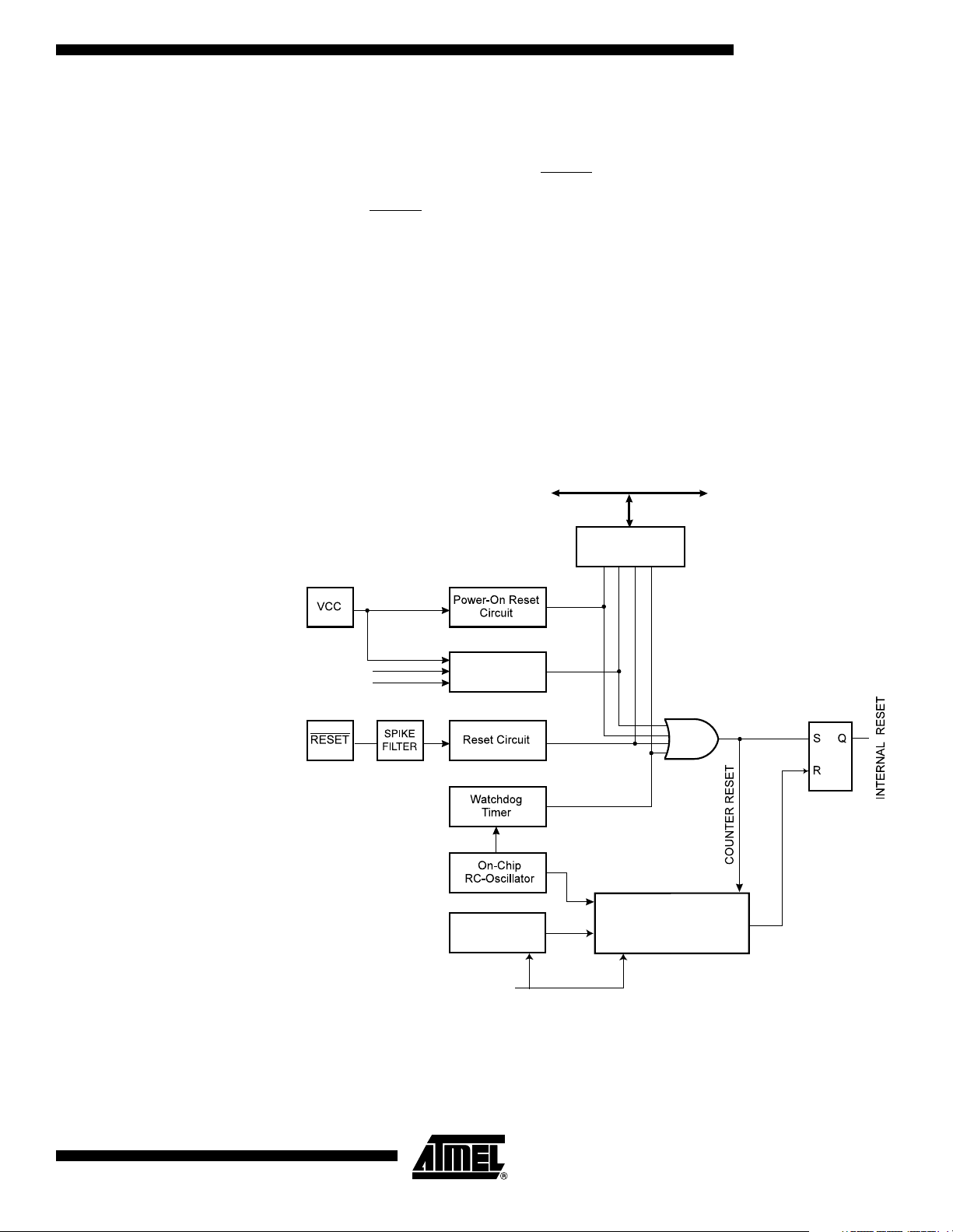

placed at these locations. Figure 20 shows the reset logic for the ATtiny26/L. Table 3

shows the timing and electrical parameters of the reset circuitry for ATtiny26/L.

Figure 20. Reset Logic for the ATtiny26/L

DATA BU S

ATtiny26(L)

is below the

CC

BODEN

BODLEVEL

Brown-Out

Reset Circuit

Clock

Generator

CKSEL[3:0]

MCU Status

Register (MCUSR)

BORF

PORF

CK

WDRF

EXTRF

Delay Counters

TIMEOUT

1477B–AVR–04/02

21

Page 22

0

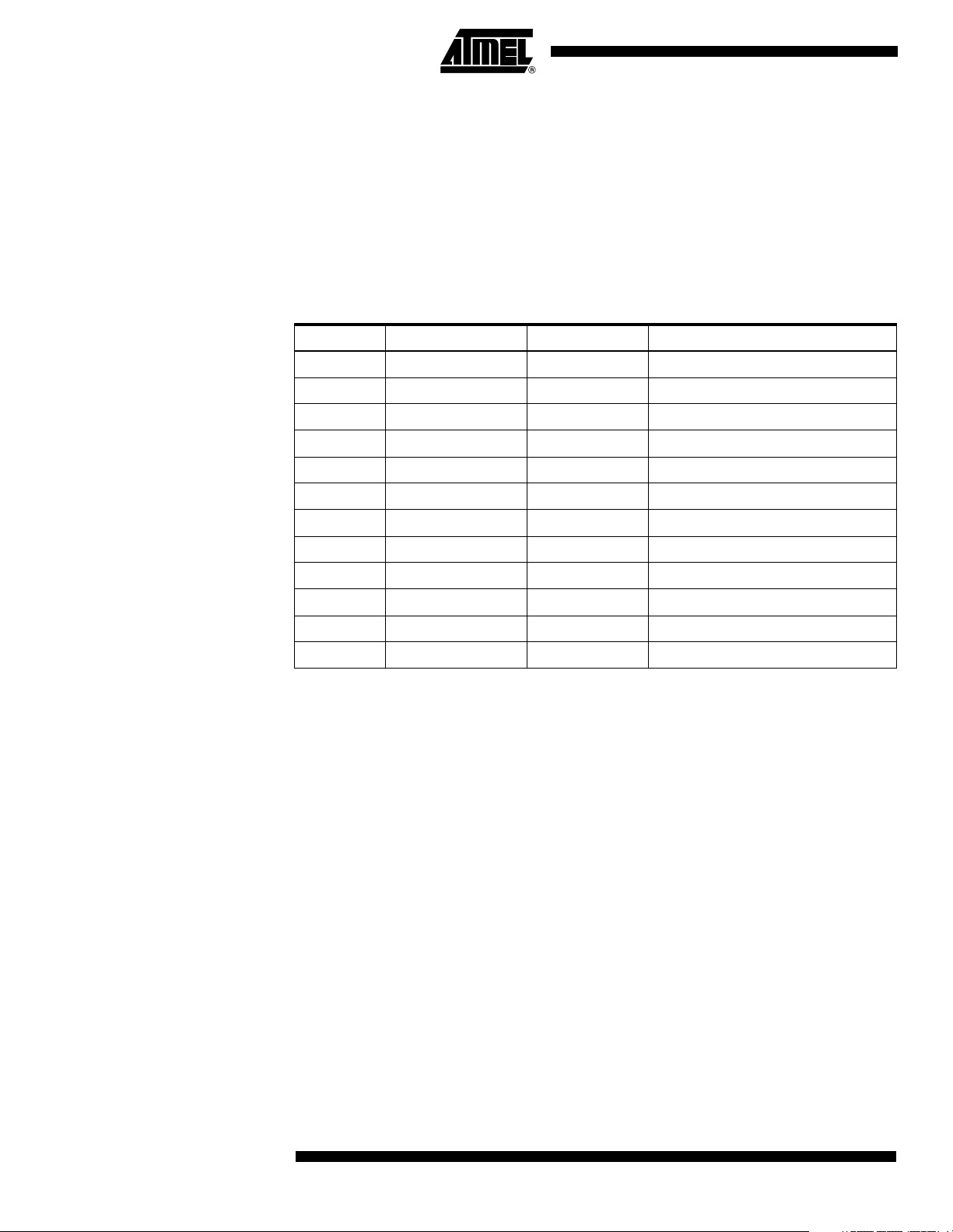

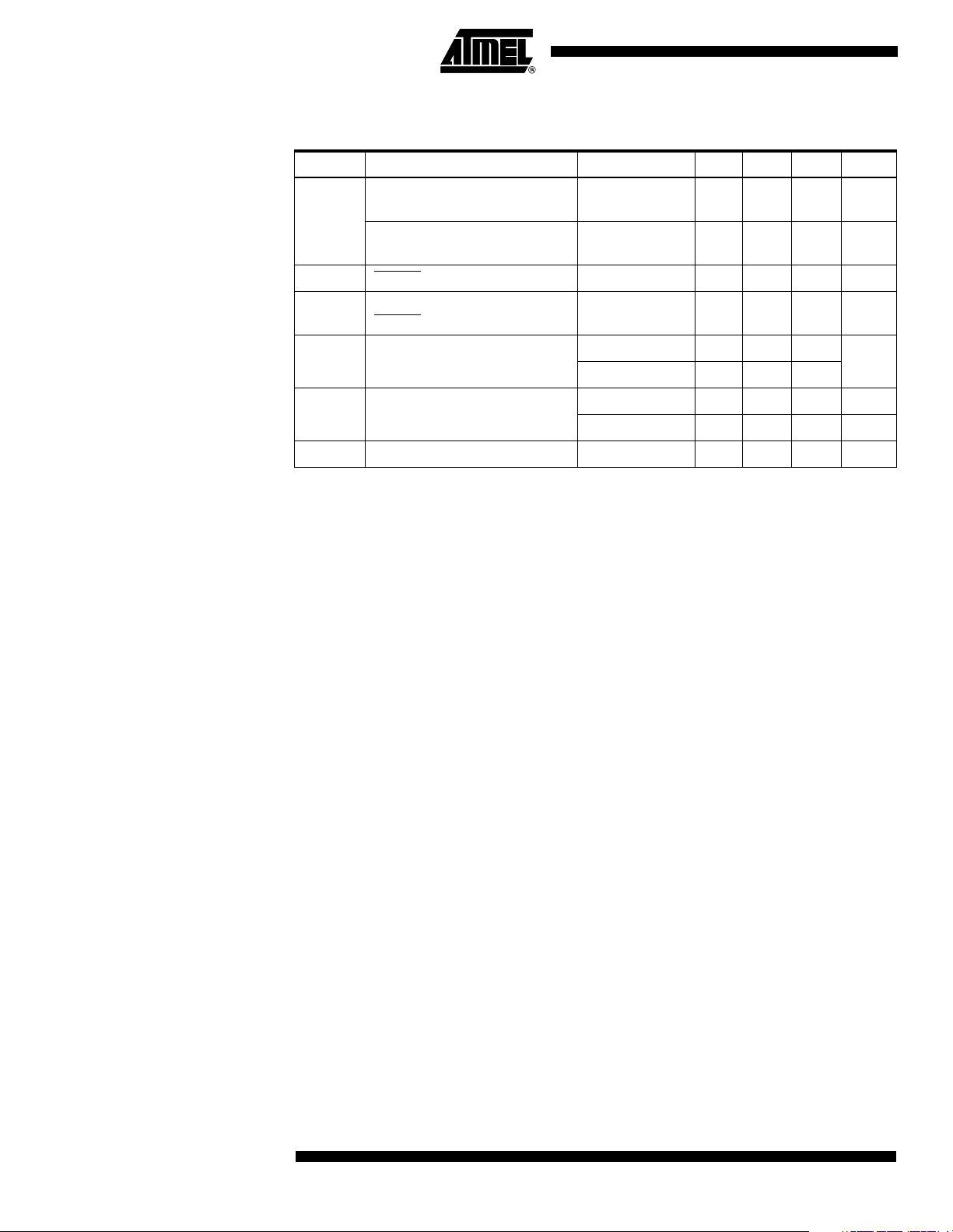

Table 3. Reset Characteristics

Symbol Parameter Condition Min Typ Max Units

V

POT

Power-on Reset Threshold

Voltage (rising)

Power-on Reset Threshold

Voltage (falling)

(1)

1.4 2.3 V

1.3 2.3 V

V

RST

t

RST

V

BOT

t

BOD

V

HYST

Notes: 1. The Power-on Reset will not work unless the supply voltage has been below V

RESET Pin Threshold Voltage 0.1 0.9 V

Minimum pulse width on

RESET

Brown-out Reset Threshold

Vol ta ge

Pin

(2)

Minimum low voltage period for

Brown-out Detection

BODLEVEL = 1 2.5 2.7 3.2

BODLEVEL = 0 3.7 4.0 4.2

BODLEVEL = 1 2 µs

BODLEVEL = 0 2 µs

50 ns

CC

V

Brown-out Detector hysteresis 130 mV

POT

(falling)

2. V

may be below nominal minimum operating voltage for some devices. For

BOT

devices where this is the case, the device is tested down to V

CC

= V

during the

BOT

production test. This guarantees that a Brown-out Reset will occur before V

CC

drops

to a voltage where correct operation of the microcontroller is no longer guaranteed.

The test is performed using BODLEVEL=1 for ATtiny26L and BODLEVEL=0 for

ATtiny26. BODLEVEL=1 is not applicable for ATtiny26.

See start-up times from reset from “System Clock and Clock Options” on page 25.

When the CPU wakes up from Power-down, only the clock counting part of the start-up

time is used. The Watchdog Oscillator is used for timing the real-time part of the start-up

time.

Power-on Reset A Power-on Reset (POR) pulse is generated by an On-chip Detection circuit. The detec-

tion level is defined in Table 3 The POR is activated whenever V

is below the

CC

detection level. The POR circuit can be used to trigger the Start-up Reset, as well as

detect a failure in supply voltage.

22

ATtiny26(L)

The Power-on Reset (POR) circuit ensures that the device is reset from Power-on.

Reaching the Power-on Reset threshold voltage invokes a delay counter, which determines the delay, for which the device is kept in RESET after V

rise. The time-out

CC

period of the delay counter can be defined by the user through the CKSEL Fuses. The

different selections for the delay period are presented in “System Clock and Clock

Options” on page 25. The RESET signal is activated again, without any delay, when the

decreases below detection level.

V

CC

1477B–AVR–04/02

Page 23

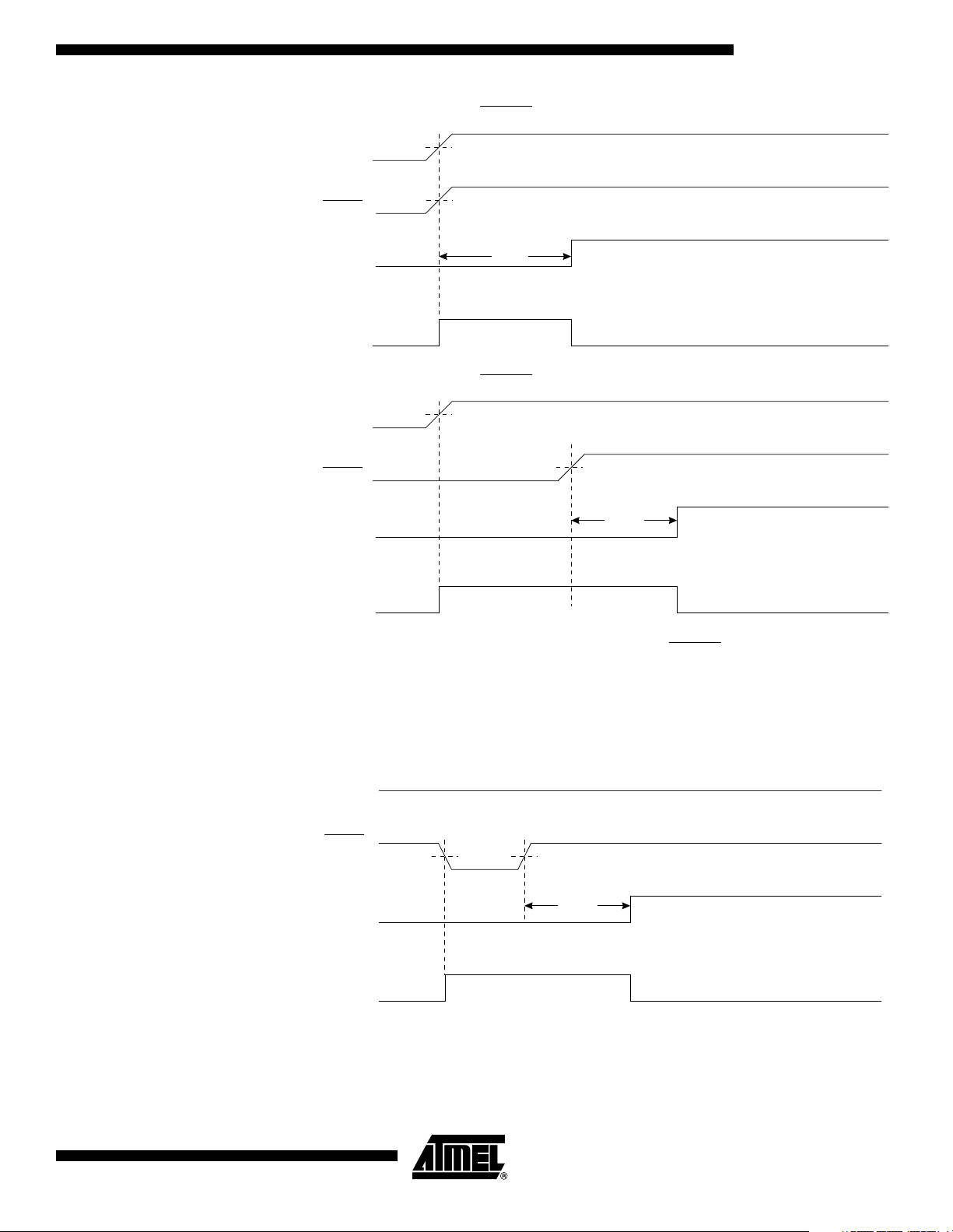

Figure 21. MCU Start-up, RESET Tied to VCC

V

VCC

RESET

TIME-OUT

INTERNAL

RESET

POT

V

RST

t

TOUT

Figure 22. MCU Start-up, RESET Controlled Externally

V

VCC

RESET

POT

V

RST

ATtiny26(L)

t

TIME-OUT

INTERNAL

RESET

TOUT

External Reset An External Reset is generated by a low level on the RESET

than 500 ns will generate a reset, even if the clock is not running. Shorter pulses are not

guaranteed to generate a reset. When the applied signal reaches the Reset Threshold

Voltage – V

period t

TOUT

– on its positive edge, the delay timer starts the MCU after the Time-out

RST

has expired.

Figure 23. External Reset During Operation

VCC

RESET

TIME-OUT

V

RST

t

TOUT

pin. Reset pulses longer

1477B–AVR–04/02

INTERNAL

RESET

23

Page 24

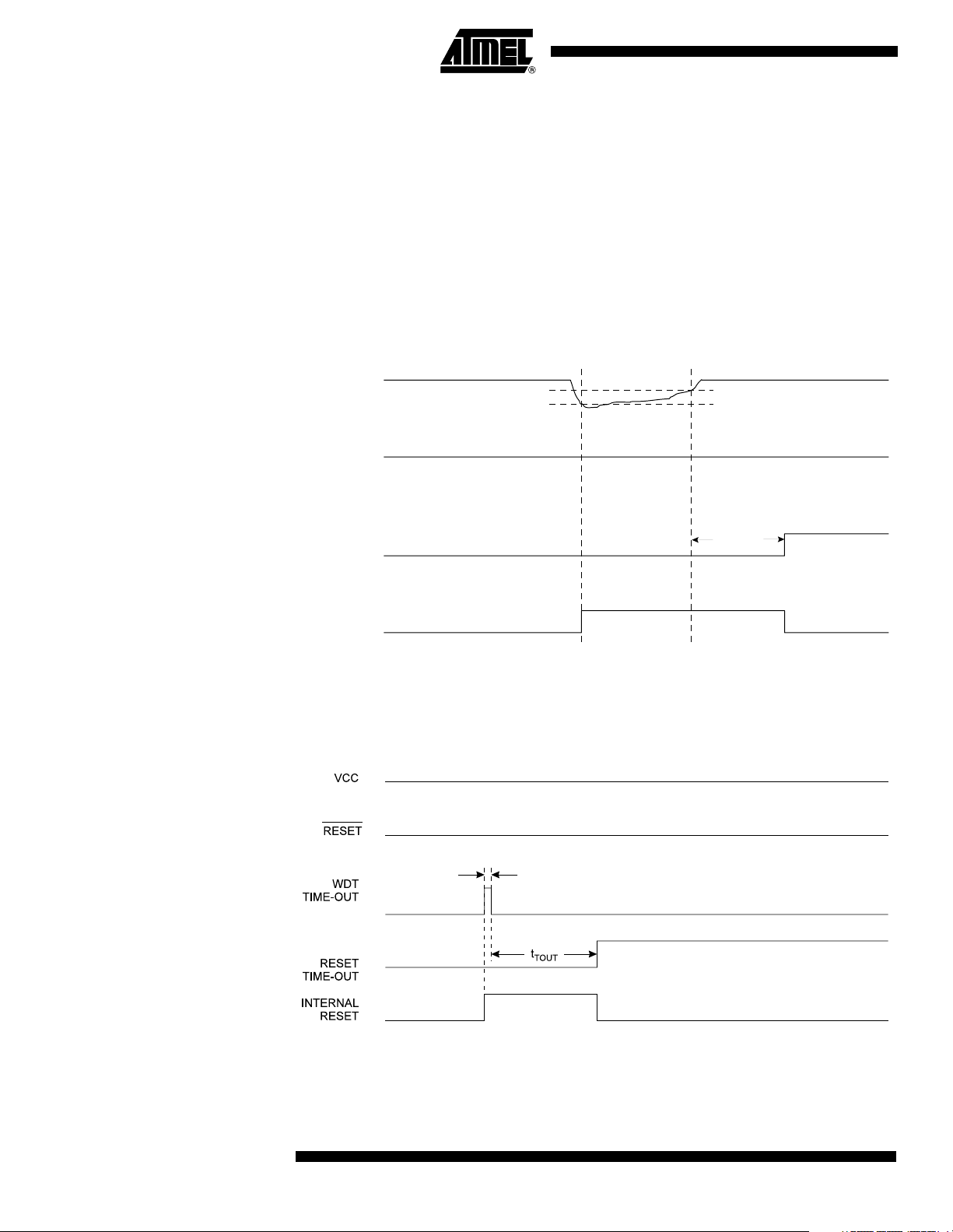

Brown-out Detection ATtiny26/L has an On-chip Brown-out Detection (BOD) circuit for monitoring the V

level during the operation. The BOD circuit can be enabled/disabled by the fuse

BODEN. When the BOD is enabled (BODEN programmed), and V

the trigger level, the Brown-out Reset is immediately activated. When V

decreases below

CC

increases

CC

above the trigger level, the Brown-out Reset is deactivated after a delay. The delay is

defined by the user in the same way as the delay of POR signal, in Table 2. The trigger

level for the BOD can be selected by the fuse BODLEVEL to be 2.7V (BODLEVEL

unprogrammed), or 4.0V (BODLEVEL programmed). The trigger level has a hysteresis

of 50 mV to ensure spike free Brown-out Detection.

CC

The BOD circuit will only detect a drop in V

for longer than t

given in Table 3.

BOD

if the voltage stays below the trigger level

CC

Figure 24. Brown-out Reset During Operation

V

CC

V

BOT-

V

BOT+

RESET

t

TIME-OUT

TOUT

INTERNAL

RESET

Watchdog Reset When the Watchdog times out, it will generate a short reset pulse of one CK cycle dura-

tion. On the falling edge of this pulse, the delay timer starts counting the Time-out period

. Refer to page 58 for details on operation of the Watchdog.

t

TOUT

24

Figure 25. Watchdog Time-out

1 CK Cycle

ATtiny26(L)

1477B–AVR–04/02

Page 25

System Clock and Clock Options

ATtiny26(L)

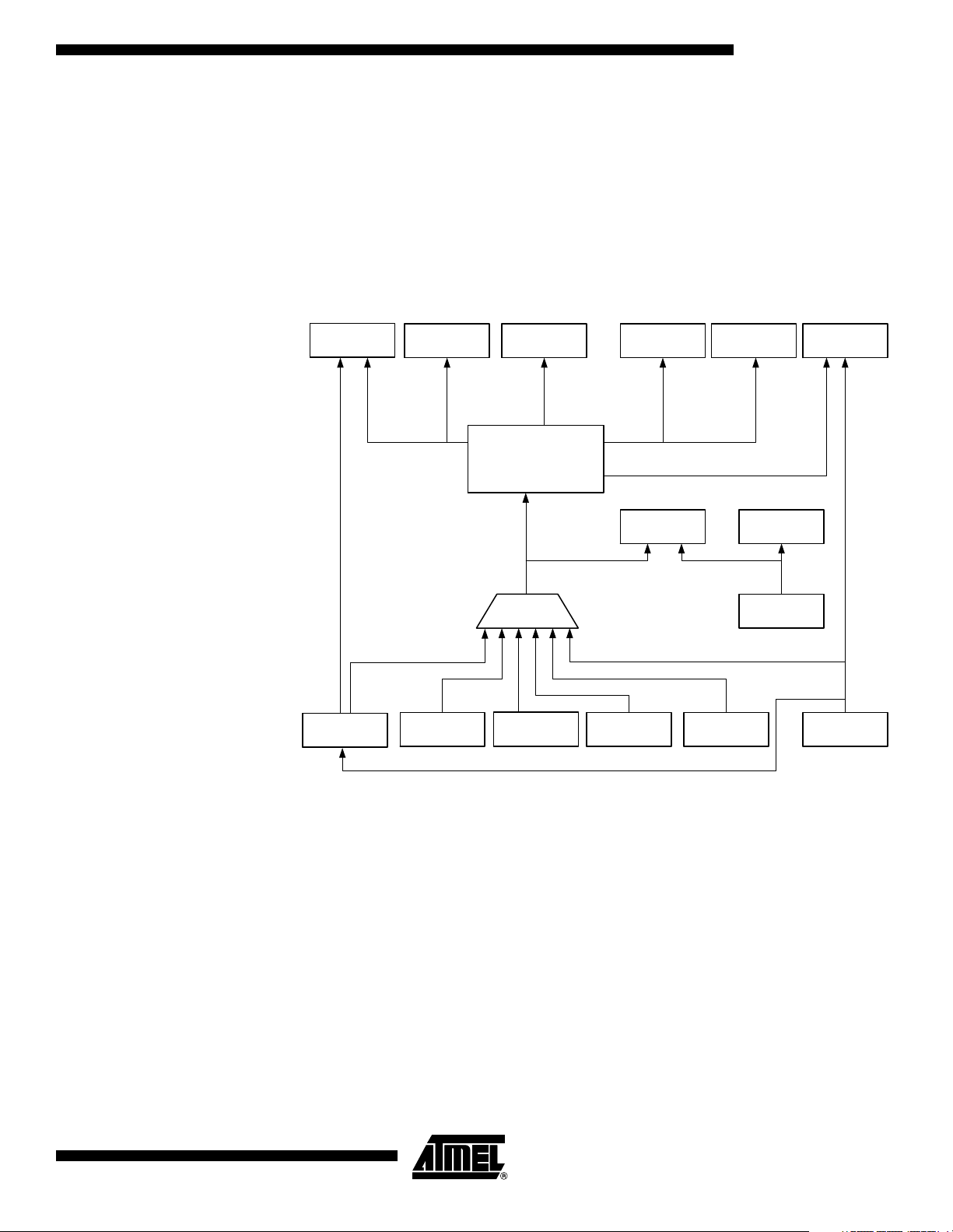

Clock Systems and their Distribution

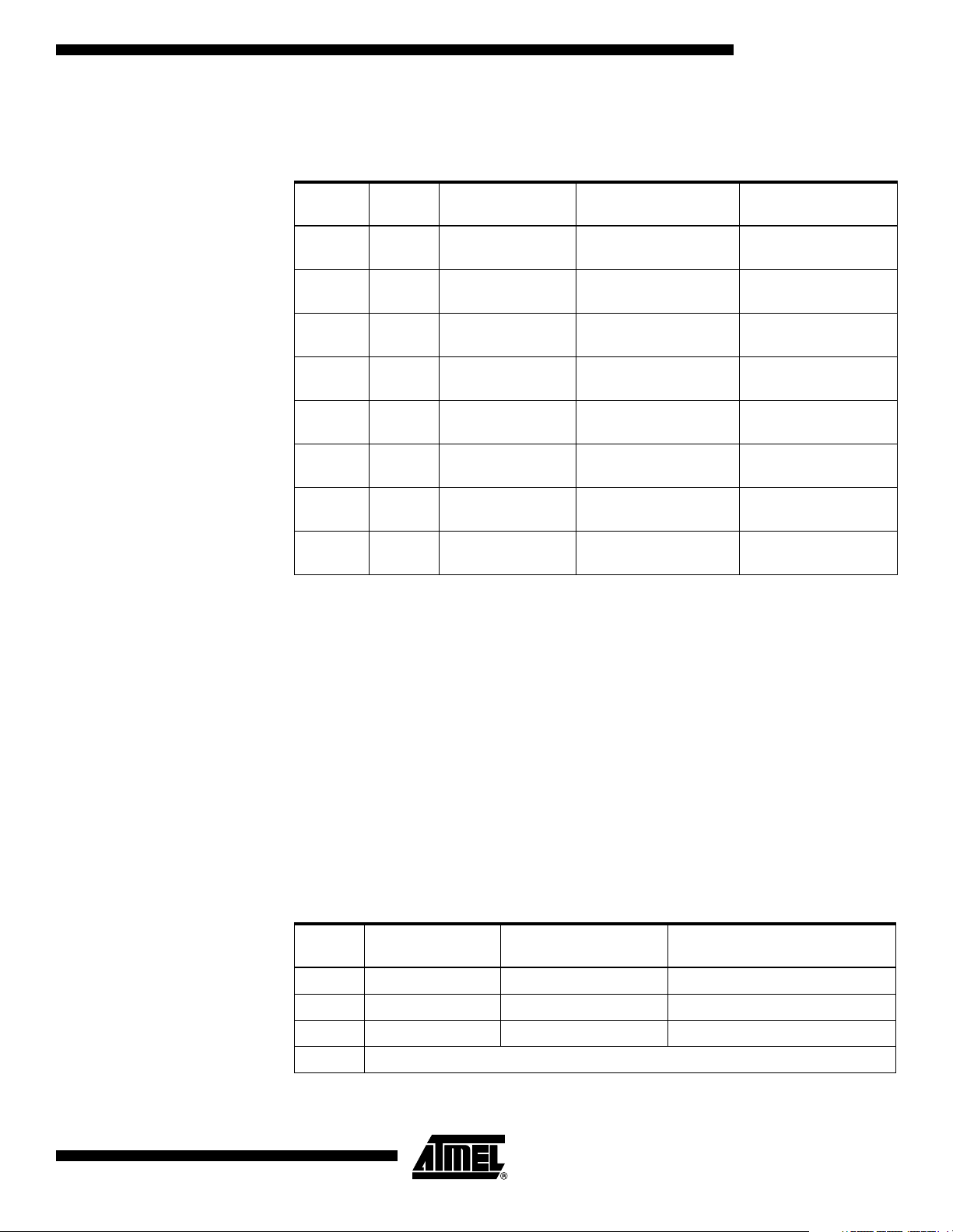

Figure 26 presents the principal clock systems in the AVR and their distribution. All of

the clocks need not be active at a given time. In order to reduce power consumption, the

clocks to modules not being used can be halted by using different sleep modes, as

described in “Power Management and Sleep Modes” on page 41. The clock systems

are detailed below.

Figure 26. Clock Distribution

Timer/Counter1

General I/O

modules

clk

I/O

ADC CPU Core RAM

clk

ADC

AVR Clock

Control Unit

Clock

Multiplexer

Source clock

clk

CPU

clk

FLASH

Reset Logic

Watchdog Timer

Watchdog clock

Watchdog

Oscillator

Flash and

EEPROM

CPU Clock – clk

I/O Clock – clk

I/O

Flash Clock – clk

ADC Clock – clk

CPU

FLASH

ADC

clk

clk

PCK

PLL

PLL

External RC

Oscillator

External clock

Crystal

Oscillator

Low-Frequency

Crystal Oscillator

Calibrated RC

Oscillator

The CPU clock is routed to parts of the system concerned with operation of the AVR

core. Examples of such modules are the General Purpose Register File, the Status Register and the data memory holding the Stack Pointer. Halting the CPU clock inhibits the

core from performing general operations and calculations.

The I/O clock is used by the majority of the I/O modules, like Timer/Counters, and USI.

The I/O clock is also used by the External Interrupt module, but note that some external

interrupts are detected by asynchronous logic, allowing such interrupts to be detected

even if the I/O clock is halted.

The Flash clock controls operation of the Flash interface. The Flash clock is usually

active simultaneously with the CPU clock.

The ADC is provided with a dedicated clock domain. This allows halting the CPU and

I/O clocks in order to reduce noise generated by digital circuitry. This gives more accurate ADC conversion results.

1477B–AVR–04/02

25

Page 26

Internal PLL for Fast

Peripheral Clock Generation –

clk

PCK

The internal PLL in ATtiny26/L generates a clock frequency that is 64x multiplied from

nominally 1 MHz input. The source of the 1 MHz PLL input clock is the output of the

internal RC Oscillator which is automatically divided down to 1 MHz, if needed. See the

Figure 27 on page 26. When the PLL reference frequency is the nominal 1 MHz, the fast

peripheral clock is 64 MHz. The fast peripheral clock, or a clock prescaled from that, can

be selected as the clock source for Timer/Counter1.

The PLL is locked on the RC Oscillator and adjusting the RC Oscillator via OSCCAL

Register will adjust the fast peripheral clock at the same time. However, even if the possibly divided RC Oscillator is taken to a higher frequency than 1 MHz, the fast peripheral

clock frequency saturates at 70 MHz (worst case) and remains oscillating at the maximum frequency. It should be noted that the PLL in this case is not locked any more with

the RC Oscillator clock.

Therefore it is recommended not to take the OSCCAL adjustments to a higher frequency than 1 MHz in order to keep the PLL in the correct operating range. The internal

PLL is enabled only when the PLLE bit in the register PLLCSR is set or the PLLCK Fuse

is programmed (“0”). The bit PLOCK from the register PLLCSR is set when PLL is

locked.

Both internal 1 MHz RC Oscillator and PLL are switched off in Power-down and Standby

sleep modes.

Figure 27. PCK Clocking System

PLLE

RC OSCILLATOR

XTAL1

XTAL2

OSCCAL

1

2

4

8 MHz

OSCILLATORS

PLLCK &

CKSEL

FUSES

DIVIDE

TO 1 MHz

PLL

64x

Lock

Detector

PLOCK

PCK

DIVIDE

BY 4

CK

26

ATtiny26(L)

1477B–AVR–04/02

Page 27

ATtiny26(L)

Clock Sources The device has the following clock source options, selectable by Flash Fuse bits as

shown below on Table 4. The clock from the selected source is input to the AVR clock

generator, and routed to the appropriate modules.The use of pins PB5 (XTAL2), and

PB4 (XTAL1) as I/O pins is limited depending on clock settings, as shown below in

Table 5.

Table 4. Device Clocking Options Select

Device Clocking Option PLLCK CKSEL3..0

External Crystal/Ceramic Resonator 1 1111 - 1010

External Low-frequency Crystal 1 1001

External RC Oscillator 1 1000 - 0101

Calibrated Internal RC Oscillator 1 0100 - 0001

External Clock 1 0000

PLL Clock 0 0001

Table 5. PB5, and PB4 Functionality vs. Device Clocking Options

Device Clocking Option PLLCK CKSEL [3:0] PB4 PB5

External Clock 1 0000 XTAL1 I/O

Internal RC Oscillator 1 0001 I/O I/O

Internal RC Oscillator 1 0010 I/O I/O

Internal RC Oscillator 1 0011 I/O I/O

Internal RC Oscillator 1 0100 I/O I/O

External RC Oscillator 1 0101 XTAL1 I/O

External RC Oscillator 1 0110 XTAL1 I/O

External RC Oscillator 1 0111 XTAL1 I/O

External RC Oscillator 1 1000 XTAL1 I/O

External Low-frequency Oscillator 1 1001 XTAL1 XTAL2

External Crystal/Resonator Oscillator 1 1010 XTAL1 XTAL2

External Crystal/Resonator Oscillator 1 1011 XTAL1 XTAL2

External Crystal/Resonator Oscillator 1 1100 XTAL1 XTAL2

External Crystal/Resonator Oscillator 1 1101 XTAL1 XTAL2

External Crystal/Resonator Oscillator 1 1110 XTAL1 XTAL2

(1)

1477B–AVR–04/02

External Crystal/Resonator Oscillator 1 1111 XTAL1 XTAL2

PLL 0 0001 I/O I/O

Note: 1. For all fuses “1” means unprogrammed while “0” means programmed.

The various choices for each clocking option is given in the following sections. When the

CPU wakes up from Power-down, the selected clock source is used to time the start-up,

ensuring stable oscillator operation before instruction execution starts. When the CPU

starts from Reset, there is as an additional delay allowing the power to reach a stable

level before commencing normal operation. The Watchdog Oscillator is used for timing

this real-time part of the start-up time. The number of WDT Oscillator cycles used for

27

Page 28

each time-out is shown in Table 6. The frequency of the Watchdog Oscillator is voltage

dependent as shown in the Electrical Characteristics section. The device is shipped with

PLLCK = “1”, CKSEL = “0001”, and SUT = “10” (1 MHz Internal RC Oscillator, slowly rising power).

Table 6. Number of Watchdog Oscillator Cycles

Typ Time-out (VCC = 5.0V) Typ Time-out (VCC = 3.0V) Number of Cycles

4.1 ms 4.3 ms 4K (4,096)

65 ms 69 ms 64K (65,536)

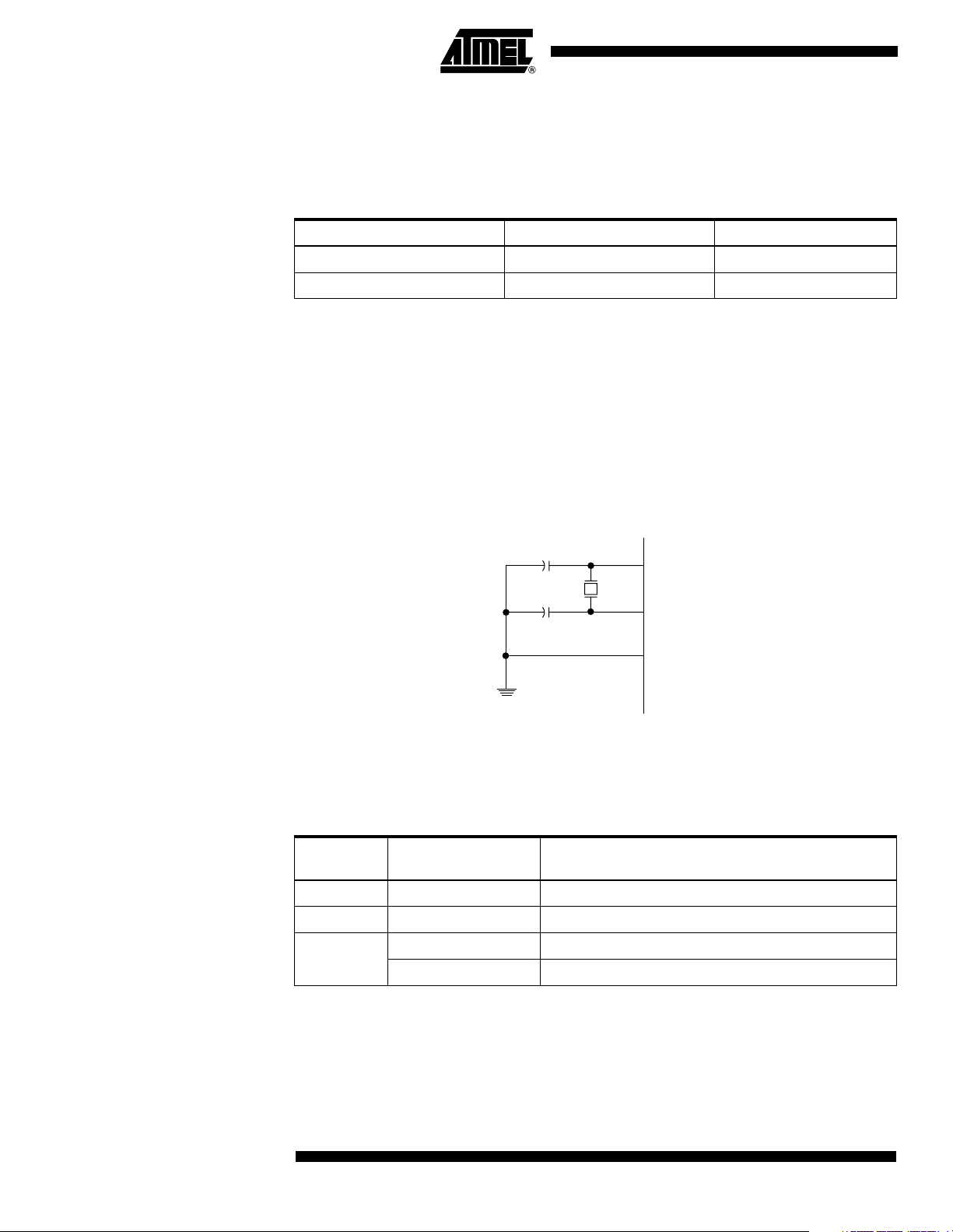

Crystal Oscillator XTAL1 and XTAL2 are input and output, respectively, of an inverting amplifier which can

be configured for use as an On-chip Oscillator, as shown in Figure 28. Either a quartz

crystal or a ceramic resonator may be used. The maximum frequency for resonators is

12 MHz. The CKOPT Fuse should always be unprogrammed when using this clock

option. C1 and C2 should always be equal. The optimal value of the capacitors depends

on the crystal or resonator in use, the amount of stray capacitance, and the electromagnetic noise of the environment. Some initial guidelines for choosing capacitors for use

with crystals are given in Table 7. For ceramic resonators, the capacitor values given by

the manufacturer should be used.

Figure 28. Crystal Oscillator Connections

C2

C1

XTAL2

XTAL1

GND

The Oscillator can operate in three different modes, each optimized for a specific frequency range. The operating mode is selected by the fuses CKSEL3..1 as shown in

Table 7.

Table 7. Crystal Oscillator Operating Modes

Frequency

CKSEL3..1

(2)

101

110 0.9 - 3.0 12 - 22

111

Notes: 1. The frequency ranges are preliminary values. Actual values are TBD.

2. This option should not be used with crystals, only with ceramic resonators.

(1)

Range

(MHz)

0.4 - 0.9 –

3.0 - 16 12 - 22

16 - 12 - 15

Recommended Range for Capacitors C1 and

C2 for Use with Crystals (pF)

28

ATtiny26(L)

1477B–AVR–04/02

Page 29

ATtiny26(L)

The CKSEL0 Fuse together with the SUT1..0 Fuses select the start-up times as shown

in Table 8.

Table 8. Start-up Times for the Crystal Oscillator Clock Selection

Start-up Time

CKSEL0 SUT1..0

0 00 258 CK

0 01 258 CK

010 1K CK

011 1K CK

100 1K CK

1 01 16K CK – Crystal Oscillator,

1 10 16K CK 4.1 ms Crystal Oscillator, fast

1 11 16K CK 65 ms Crystal Oscillator,

Notes: 1. These options should only be used when not operating close to the maximum fre-

quency of the device, and only if frequency stability at start-up is not important for the

application.

2. These options are intended for use with ceramic resonators and will ensure frequency stability at start-up. They can also be used with crystals when not operating

close to the maximum frequency of the device, and if frequency stability at start-up is

not important for the application.

from Power-down

(1)

(1)

(2)

(2)

(2)

Additional Delay from

Reset (VCC = 5.0V)

4.1 ms Ceramic resonator,

65 ms Ceramic resonator,

– Ceramic resonator,

4.1 ms Ceramic resonator,

65 ms Ceramic resonator,

Recommended

Usage

fast rising power

slowly rising power

BOD enabled

fast rising power

slowly rising power

BOD enabled

rising power

slowly rising power

Low-frequency Crystal Oscillator

1477B–AVR–04/02

To use a 32.768 kHz watch crystal as the clock source for the device, the Low-frequency Crystal Oscillator must be selected by setting the PLLCK to “1” and CKSEL

Fuses to “1001”. The crystal should be connected as shown in Figure 28. By programming the CKOPT Fuse, the user can enable internal capacitors on XTAL1 and XTAL2,

thereby removing the need for external capacitors. The internal capacitors have a nominal value of 36 pF.

When this oscillator is selected, start-up times are determined by the SUT Fuses as

shown in Table 9.

Table 9. Start-up Times for the Low-frequency Crystal Oscillator Clock Selection

Start-up Time

SUT1..0

00 1K CK

01 1K CK

10 32K CK 65 ms Stable frequency at start-up

11 Reserved

Note: 1. These options should only be used if frequency stability at start-up is not important for

from Power-down

(1)

(1)

the application.

Additional Delay from

Reset (VCC = 5.0V) Recommended Usage

4.1 ms Fast rising power or BOD enabled

65 ms Slowly rising power

29

Page 30

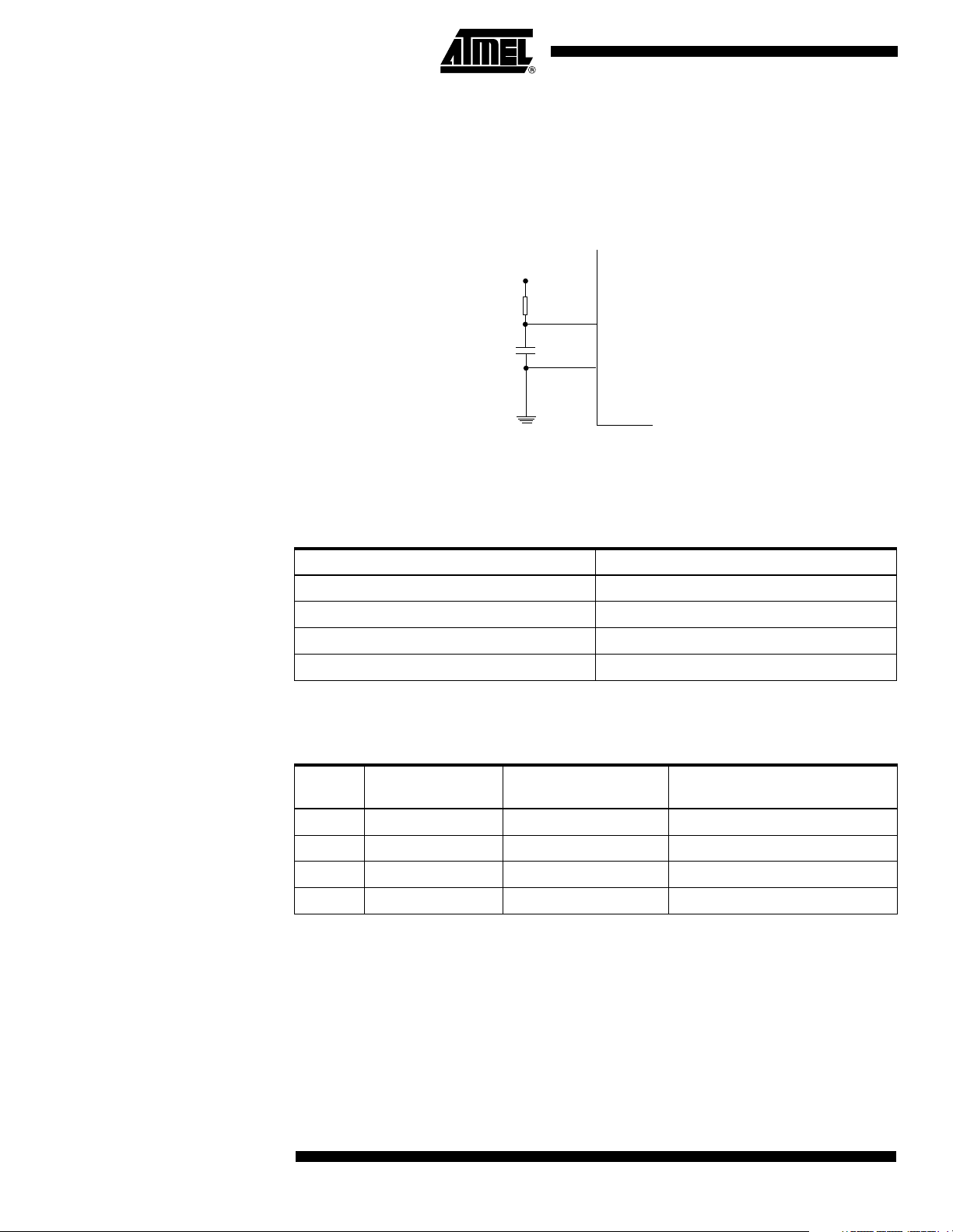

External RC Oscillator For timing insensitive applications, the external RC configuration shown in Figure 29

can be used. The frequency is roughly estimated by the equation f = 1/(3RC). C should

be at least 22 pF. By programming the CKOPT Fuse, the user can enable an internal

36 pF capacitor between XTAL1 and GND, thereby removing the need for an external

capacitor.

Figure 29. External RC Configuration

V

CC

PB5 (XTAL2)

R

XTAL1

C

GND

The oscillator can operate in four different modes, each optimized for a specific frequency range. The operating mode is selected by the fuses CKSEL3..0 as shown in

Table 10.

Table 10. External RC Oscillator Operating Modes

CKSEL3..0 Frequency Range (MHz)

0101 - 0.9

0110 0.9 - 3.0

0111 3.0 - 8.0

1000 8.0 - 12.0

When this oscillator is selected, start-up times are determined by the SUT Fuses as

shown in Table 11.

Table 11. Start-up Times for the External RC Oscillator Clock Selection

30

ATtiny26(L)

Start-up Time

SUT1..0

00 18 CK – BOD enabled

01 18 CK 4.1 ms Fast rising power

10 18 CK 65 ms Slowly rising power

11 6 CK

Notes: 1. This option should not be used when operating close to the maximum frequency of

from Power-down

(1)

the device.

Additional Delay from

Reset (VCC = 5.0V) Recommended Usage

4.1 ms Fast rising power or BOD enabled

1477B–AVR–04/02

Page 31

ATtiny26(L)

Calibrated Internal RC Oscillator

The calibrated internal RC Oscillator provides a fixed 1.0, 2.0, 4.0, or 8.0 MHz clock. All

frequencies are nominal values at 5V and 25

°C. This clock may be selected as the sys-

tem clock by programming the CKSEL Fuses as shown in Table 12. If selected, it will

operate with no external components. The CKOPT Fuse should always be unprogrammed when using this clock option. During Reset, hardware loads the calibration

byte into the OSCCAL Register and thereby automatically calibrates the RC Oscillator.

When this oscillator is used as the chip clock, the Watchdog Oscillator will still be used

for the Watchdog Timer and for the reset time-out. For more information on the pre-programmed calibration value, see the section “Calibration Byte” on page 108.

Table 12. Internal Calibrated RC Oscillator Operating Modes

CKSEL3..0 Nominal Frequency (MHz)

(1)

0001

0010 2.0

0011 4.0

0100 8.0

Note: 1. The device is shipped with this option selected.

1.0

When this oscillator is selected, start-up times are determined by the SUT Fuses as

shown in Table 13. PB4 (XTAL1) and PB5 (XTAL2) can be used as general I/O ports.

Table 13. Start-up Times for the Internal Calibrated RC Oscillator Clock Selection

Oscillator Calibration Register – OSCCAL

Start-up Time from

SUT1..0

00 6 CK – BOD enabled

01 6 CK 4.1 ms Fast rising power

(1)

10

11 Reserved

Note: 1. The device is shipped with this option selected.

Bit 76543210

$31 ($51) CAL7 CAL6 CAL5 CAL4 CAL3 CAL2 CAL1 CAL0 OSCCAL

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value Device Specific Calibration Value

Power-down

6 CK 65 ms Slowly rising power

Additional Delay from

Reset (VCC = 5.0V) Recommended Usage

• Bits 7..0 – CAL7..0: Oscillator Calibration Value

Writing the calibration byte to this address will trim the internal oscillator to remove process variations from the oscillator frequency. During Reset, the 1 MHz calibration value

which is located in the signature row high byte (address 0x00) is automatically loaded

into the OSCCAL Register. If the internal RC is used at other frequencies, the calibration

value must be loaded manually. This can be done by first reading the signature row by a

programmer, and then store the calibration values in the Flash or EEPROM. Then the

value can be read by software and loaded into the OSCCAl Register. When OSCCAL is

zero, the lowest available frequency is chosen. Writing non-zero values to this register

will increase the frequency of the internal oscillator. Writing $FF to the register gives the

highest available frequency. The calibrated Oscillator is used to time EEPROM and

Flash access. If EEPROM or Flash is written, do not calibrate to more than 10% above

the nominal frequency. Otherwise, the EEPROM or Flash write may fail. Note that the

1477B–AVR–04/02

31

Page 32

oscillator is intended for calibration to 1.0, 2.0, 4.0, or 8.0 MHz. Tuning to other values is

not guaranteed, as indicated in Table 14.

Table 14. Internal RC Oscillator Frequency Range.

Min Frequency in Percentage of

OSCCAL Value

$00 50% 100%

$7F 75% 150%

$FF 100% 200%

Nominal Frequency

Max Frequency in Percentage of

Nominal Frequency

External Clock To drive the device from an external clock source, XTAL1 should be driven as shown in

Figure 30. To run the device on an external clock, the CKSEL Fuses must be programmed to “0000” and PLLCK to “1”. By programming the CKOPT Fuse, the user can

enable an internal 36 pF capacitor between XTAL1 and GND.

Figure 30. External Clock Drive Configuration

PB5 (XTAL2)

EXTERNAL

CLOCK

SIGNAL

XTAL1

GND

32

ATtiny26(L)

When this clock source is selected, start-up times are determined by the SUT Fuses as

shown in Table 15.

Table 15. Start-up Times for the External Clock Selection

Start-up Time from

SUT1..0

00 6 CK – BOD enabled

01 6 CK 4.1 ms Fast rising power

10 6 CK 65 ms Slowly rising power

11 Reserved

Power-down

Additional Delay from

Reset (VCC = 5.0V) Recommended Usage

1477B–AVR–04/02

Page 33

ATtiny26(L)

High Frequency PLL Clock –

PLL

CLK

MCU Status Register – MCUSR

There is an internal PLL that provides nominally 64 MHz clock rate locked to the RC

Oscillator for the use of the Peripheral Timer/Counter1 and for the system clock source.

When selected as a system clock source, by programming (“0”) the fuse PLLCK, it is

divided by four. When this option is used, the CKSEL3..0 must be set to “0001”. This

clocking option can be used only when operating between 4.5 - 5.5V. When using this

clock option, start-up times are determined by the SUT Fuses as shown in Table 16.

See also “PCK Clocking System” on page 26.

Table 16. Start-up Times for the PLLCK

Start-up Time from

SUT1..0

00 1K CK – BOD enabled

01 1K CK 4.1 ms Fast rising power

10 1K CK 65 ms Slowly rising power

11 16K CK – Slowly rising power

Bit 76543210

$34 ($54) ––––WDRF BORF EXTRF PORF MCUSR

Read/Write R R R R R/W R/W R/W R/W

Initial Value 0 0 0 0 See Bit Description

Power-down

Additional Delay from

Reset (VCC = 5.0V) Recommended Usage

• Bit 7..4 – Res: Reserved Bits

These bits are reserved bits in the ATtiny26/L and always read as zero.

• Bit 3 – WDRF: Watchdog Reset Flag

This bit is set (one) if a Watchdog Reset occurs. The bit is reset (zero) by a Power-on

Reset, or by writing a logic zero to the flag.

• Bit 2 – BORF: Brown-out Reset Flag

This bit is set (one) if a Brown-out Reset occurs. The bit is reset (zero) by a Power-on

Reset, or by writing a logic zero to the flag.

• Bit 1 – EXTRF: External Reset Flag

This bit is set (one) if an External Reset occurs. The bit is reset (zero) by a Power-on

Reset, or by writing a logic zero to the flag.

• Bit 0 – PORF: Power-on Reset Flag

This bit is set (one) if a Power-on Reset occurs. The bit is reset (zero) by writing a logic

zero to the flag.

To make use of the reset flags to identify a reset condition, the user should read and

then reset (zero) the MCUSR as early as possible in the program. If the register is

cleared before another reset occurs, the source of the reset can be found by examining

the reset flags.

1477B–AVR–04/02

33

Page 34

Interrupt Handling The ATtiny26/L has two 8-bit Interrupt Mask Control Registers; GIMSK – General Inter-

rupt Mask Register and TIMSK – Timer/Counter Interrupt Mask Register.

When an interrupt occurs, the Global Interrupt Enable I-bit is cleared (zero) and all interrupts are disabled. The user software can set (one) the I-bit to enable nested interrupts.

The I-bit is set (one) when a Return from Interrupt instruction – RETI – is executed.

When the Program Counter is vectored to the actual Interrupt Vector in order to execute

the interrupt handling routine, hardware clears the corresponding flag that generated the

interrupt. Some of the interrupt flags can also be cleared by writing a logic one to the flag

bit position(s) to be cleared.

If an interrupt condition occurs when the corresponding interrupt enable bit is cleared

(zero), the interrupt flag will be set and remembered until the interrupt is enabled, or the

flag is cleared by software.

If one or more interrupt conditions occur when the Global Interrupt Enable bit is cleared

(zero), the corresponding interrupt flag(s) will be set and remembered until the Global

Interrupt Enable bit is set (one), and will be executed by order of priority.

Note that external level interrupt does not have a flag, and will only be remembered for

as long as the interrupt condition is active.

Note that the Status Register is not automatically stored when entering an interrupt routine and restored when returning from an interrupt routine. This must be handled by

software.

Interrupt Response Time The interrupt execution response for all the enabled AVR interrupts is four clock cycles

minimum. After the four clock cycles the program vector address for the actual interrupt

handling routine is executed. During this four clock cycle period, the Program Counter

(10 bits) is pushed onto the Stack. The vector is a relative jump to the interrupt routine,

and this jump takes two clock cycles. If an interrupt occurs during execution of a multicycle instruction, this instruction is completed before the interrupt is served.

General Interrupt Mask Register – GIMSK

A return from an interrupt handling routine takes four clock cycles. During these four

clock cycles, the Program Counter (10 bits) is popped back from the Stack. When AVR

exits from an interrupt, it will always return to the main program and execute one more

instruction before any pending interrupt is served. Note that the Status Register – SREG

– is not handled by the AVR hardware, neither for interrupts nor for subroutines. For the

routines requiring a storage of the SREG, this must be performed by user software.

Bit 76543210

$3B ($5B) – INT0 PCIE1 PCIE0 ––––GIMSK

Read/Write R R/W R/W R/W R R R R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – Res: Reserved Bit

This bit is a reserved bit in the ATtiny26/L and always reads as zero.

• Bit 6 – INT0: External Interrupt Request 0 Enable

When the INT0 bit is set (one) and the I-bit in the Status Register (SREG) is set (one),

the external pin interrupt is enabled. The Interrupt Sense Control0 bits 1/0 (ISC01 and

ISC00) in the MCU general Control Register (MCUCR) define whether the external

interrupt is activated on rising or falling edge, on pin change, or low level of the INT0 pin.

Activity on the pin will cause an interrupt request even if INT0 is configured as an output.

34

ATtiny26(L)

1477B–AVR–04/02

Page 35

ATtiny26(L)

The corresponding interrupt of External Interrupt Request 0 is executed from program

memory address $001. See also “External Interrupt” on page 38.

• Bit 5 – PCIE1: Pin Change Interrupt Enable1

When the PCIE1 bit is set (one) and the I-bit in the Status Register (SREG) is set (one),

the interrupt pin change is enabled on analog pins PB[7:4], PA[7:6] and PA[3]. Unless

the alternate function masks out the interrupt, any change on the pin mentioned before

will cause an interrupt. The corresponding interrupt of Pin Change Interrupt Request is

executed from program memory address $002. See also “Pin Change Interrupt” on

page 38.

• Bit 4– PCIE0: Pin Change Interrupt Enable0

When the PCIE0 bit is set (one) and the I-bit in the Status Register (SREG) is set (one),

the interrupt pin change is enabled on digital pins PB[3:0]. Unless the alternate function

masks out the interrupt, any change on the pin mentioned before will cause an interrupt.

The corresponding interrupt of Pin Change Interrupt Request is executed from program

memory address $002. See also “Pin Change Interrupt” on page 38.

• Bits 3..0 – Res: Reserved Bits

These bits are reserved bits in the ATtiny26/L and always read as zero.

General Interrupt Flag Register – GIFR

Bit 76543210

$3A ($5A) – INTF0 PCIF –––––GIFR

Read/Write R R/W R/W R R R R R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – Res: Reserved Bit

This bit is a reserved bit in the ATtiny26/L and always reads as zero.

• Bit 6 – INTF0: External Interrupt Flag0

When an event on the INT0 pin triggers an interrupt request, INTF0 becomes set (one).

If the I-bit in SREG and the INT0 bit in GIMSK are set (one), the MCU will jump to the

Interrupt Vector at address $001. The flag is cleared when the interrupt routine is executed. Alternatively, the flag can be cleared by writing a logical one to it. The flag is

always cleared when INT0 is configured as level interrupt.

• Bit 5 – PCIF: Pin Change Interrupt Flag

When an event on pins PB[7:0], PA[7:6], or PA[3] triggers an interrupt request, PCIF

becomes set (one). PCIE1 enables interrupt from analog pins PB[7:4], PA[7:6], and

PA[3]. PCIE0 enables interrupt on digital pins PB[3:0]. Note that pin change interrupt

enable bits PCIE1 and PCIE0 also mask the flag if they are not set. For example, if

PCIE0 is cleared, a pin change on PB[3:0] does not set PCIF. If an alternate function is

enabled on a pin, PCIF is masked from that individual pin. If the I-bit in SREG and the

PCIE bit in GIMSK are set (one), the MCU will jump to the Interrupt Vector at address

$002. The flag is cleared when the interrupt routine is executed. Alternatively, the flag

can be cleared by writing a logical one to it. See also “Pin Change Interrupt” on page 38.

1477B–AVR–04/02

• Bits 4..0 – Res: Reserved Bits

These bits are reserved bits in the ATtiny26/L and always read as zero.

35

Page 36

Timer/Counter Interrupt Mask Register – TIMSK

Bit 76543210

$39 ($59) – OCIE1A OCIE1B ––TOIE1 TOIE0 – TIMSK

Read/Write R R/W R/W R R R/W R/W R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – Res: Reserved Bit

This bit is a reserved bit in the ATtiny26/L and always reads as zero.

• Bit 6 – OCIE1A: Timer/Counter1 Output Compare Interrupt Enable

When the OCIE1A bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter1 compare match A, interrupt is enabled. The corresponding interrupt at

vector $003 is executed if a compare match A occurs. The Compare Flag in

Timer/Counter1 is set (one) in the Timer/Counter Interrupt Flag Register.

• Bit 5 – OCIE1B: Timer/Counter1 Output Compare Interrupt Enable

When the OCIE1B bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter1 compare match B, interrupt is enabled. The corresponding interrupt at

vector $004 is executed if a compare match B occurs. The Compare Flag in

Timer/Counter1 is set (one) in the Timer/Counter Interrupt Flag Register.

• Bit 4..3 – Res: Reserved Bits

These bits are reserved bits in the ATtiny26/L and always read as zero.

• Bit 2 – TOIE1: Timer/Counter1 Overflow Interrupt Enable

When the TOIE1 bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter1 Overflow interrupt is enabled. The corresponding interrupt (at vector

$005) is executed if an overflow in Timer/Counter1 occurs. The Overflow Flag (Timer1)

is set (one) in the Timer/Counter Interrupt Flag Register – TIFR.

• Bit 1 – TOIE0: Timer/Counter0 Overflow Interrupt Enable

When the TOIE0 bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter0 Overflow interrupt is enabled. The corresponding interrupt (at vector

$006) is executed if an overflow in Timer/Counter0 occurs. The Overflow Flag (Timer0)

is set (one) in the Timer/Counter Interrupt Flag Register – TIFR.

• Bit 0 – Res: Reserved Bit

This bit is a reserved bit in the ATtiny26/L and always reads as zero.

36

ATtiny26(L)

1477B–AVR–04/02

Page 37

ATtiny26(L)

Timer/Counter Interrupt Flag Register – TIFR

Bit 7 6 5 4 3 2 1 0

$38 ($58) – OCF1A OCF1B ––TOV1 TOV0 – TIFR

Read/Write R R/W R/W R R R/W R/W R

Initial Value 0 0 0 0 0 0 0 0

• Bit 7 – Res: Reserved Bit

This bit is a reserved bit in the ATtiny26/L and always reads as zero.

• Bit 6 – OCF1A: Output Compare Flag 1A

The OCF1A bit is set (one) when compare match occurs between Timer/Counter1 and

the data value in OCR1A – Output Compare Register 1A. OCF1A is cleared by hardware when executing the corresponding interrupt handling vector. Alternatively, OCF1A

is cleared, after synchronization clock cycle, by writing a logic one to the flag. When the

I-bit in SREG, OCIE1A, and OCF1A are set (one), the Timer/Counter1 A Compare

Match interrupt is executed.

• Bit 5 – OCF1B: Output Compare Flag 1B

The OCF1B bit is set (one) when compare match occurs between Timer/Counter1 and

the data value in OCR1B – Output Compare Register 1A. OCF1B is cleared by hardware when executing the corresponding interrupt handling vector. Alternatively, OCF1B

is cleared, after synchronization clock cycle, by writing a logic one to the flag. When the

I-bit in SREG, OCIE1B, and OCF1B are set (one), the Timer/Counter1 B Compare

Match interrupt is executed.

• Bits 4..3 – Res: Reserved Bits

These bits are reserved bits in the ATtiny26/L and always read as zero.

• Bit 2 – TOV1: Timer/Counter1 Overflow Flag

The bit TOV1 is set (one) when an overflow occurs in Timer/Counter1. TOV1 is cleared

by hardware when executing the corresponding interrupt handling vector. Alternatively,

TOV1 is cleared, after synchronization clock cycle, by writing a logical one to the flag.

When the SREG I-bit, and TOIE1 (Timer/Counter1 Overflow Interrupt Enable), and

TOV1 are set (one), the Timer/Counter1 Overflow interrupt is executed.

• Bit 1 – TOV0: Timer/Counter0 Overflow Flag

The bit TOV0 is set (one) when an overflow occurs in Timer/Counter0. TOV0 is cleared

by hardware when executing the corresponding interrupt handling vector. Alternatively,

TOV0 is cleared by writing a logical one to the flag. When the SREG I-bit, and TOIE0

(Timer/Counter0 Overflow Interrupt Enable), and TOV0 are set (one), the

Timer/Counter0 Overflow interrupt is executed.

• Bit 0 – Res: Reserved Bit

This bit is a reserved bit in the ATtiny26/L and always reads as zero.

1477B–AVR–04/02

37

Page 38

External Interrupt The External Interrupt is triggered by the INT0 pin. Observe that, if enabled, the interrupt

will trigger even if the INT0 pin is configured as an output. This feature provides a way of

generating a software interrupt. The External Interrupt can be triggered by a falling or

rising edge, a pin change, or a low level. This is set up as indicated in the specification

for the MCU Control Register – MCUCR. When the External Interrupt is enabled and is

configured as level triggered, the interrupt will trigger as long as the pin is held low.

Pin Change Interrupt The pin change interrupt is triggered by any change on any I/O pin of Port B and pins

PA3, PA6, and PA7, if the interrupt is enabled and alternate function of the pin does not

mask out the interrupt. The bit PCIE1 in GIMSK enables interrupt from pins PB[7:4],

PA[7:6], and PA[3]. PCIE0 enables interrupt on digital pins PB[3:0].

The pin change interrupt is different from other interrupts in two ways. First, pin change

interrupt enable bits PCIE1 and PCIE0 also mask the flag if they are not set. The normal

operation on most interrupts is that the flag is always active and only the execution of

the interrupt is masked by the interrupt enable.

Secondly, please note that pin change interrupt is disabled for any pin that is configured

as an alternate function. For example, no pin change interrupt is generated from pins

that are configured as AREF, AIN0 or AIN1, OC1A, OC1A

XTAL2 in a fuse selected clock option, Timer0 clocking, or RESET

, OC1B, OC1B, XTAL1, or

function. See Table

17 for alternate functions which mask the pin change interrupt and how the function is

enabled. For example pin change interrupt on the PB0 is disabled when USI Two-wire

mode or USI Three-wire mode or Timer/Counter1 inverted output compare is enabled.

If the interrupt is enabled, the interrupt will trigger even if the changing pin is configured

as an output. This feature provides a way of generating a software interrupt. Also

observe that the pin change interrupt will trigger even if the pin activity triggers another

interrupt, for example the external interrupt. This implies that one external event might

cause several interrupts.

The value of the programmed fuse is “0” and unprogrammed is “1”. Each of the lines

enables the alternate function so “or” function of the lines enables the function.

Table 17. Alternative Functions

Control Register[Bit Name] which

Pin Alternate Function

PA3 AREF ADMUX[REFS0] 1

PA6 Analog Comparator ACSR[ACD] 0

PA7 Analog Comparator ACSR[ACD] 0

PB0 USI Two-wire mode

USI Three-wire mode

TC1 compare/PWM

PB1 USI Three-wire mode

TC1 compare/PWM

PB2 USI Two-wire mode

USI Three-wire mode

TC1 compare/PWM

PB3 TC1 compare/PWM TCCR1A[COM1B1]

set the Alternate Function

USICR[USIWM1]

USICR[USIWM1,USIWM0]

TCCR1A[COM1A1,COM1A0,PWM1A]

USICR[USIWM1,USIWM0]

TCCR1A[COM1A1]

TCCR1A[COM1A0]

USICR[USIWM1]

USICR[USIWM1,USIWM0]

TCCR1A[COM1B1,COM1B0,PWM1B]

TCCR1A[COM1B0]

(1)

Bit or Fuse

Val ue

1

01

011

01

1

1

1

01

011

1

1

(2)

38

ATtiny26(L)

1477B–AVR–04/02

Page 39

Table 17. Alternative Functions (Continued)

ATtiny26(L)

MCU Control Register – MCUCR

Control Register[Bit Name] which

Pin Alternate Function

PB4 XTAL1, clock source FUSE[PLLCK,CKSEL]

PB5 XTAL2, clock source FUSE[PLLCK,CKSEL] 11001-11111

PB6 External interrupt

TC0 clock

PB7 RESET RSTDISBL FUSE 1

Notes: 1. Each line represents a bit or fuse combination which enables the function.

2. A fuse value of “0” is programmed, “1” is unprogrammed.

set the Alternate Function

FUSE[PLLCK,CKSEL]

GIMSK[INT0],MCUCR[ISC01,ISC01]

TCCR0[CS02,CS01]

(1)

Bit or Fuse

Val ue

10000

10101-11111

100

11

The MCU Control Register contains control bits for general MCU functions.

Bit 76543210

$35 ($55) – PUD SE SM1 SM0 – ISC01 ISC00 MCUCR

Read/Write R R/W R/W R/W R/W R R/W R/W

Initial Value 0 0 0 0 0 0 0 0

• Bits 7 – Res: Reserved Bit

This bit is a reserved bit in the ATtiny26/L and always reads as zero.

• Bit 6 – PUD: Pull-up Disable

(2)

When this bit is set (one), the pull-ups in the I/O ports are disabled even if the DDxn and

PORTxn Registers are configured to enable the pull-ups ({DDxn, PORTxn} = 0b01). See

“Configuring the Pin” on page 91 for more details about this feature.

• Bit 5 – SE: Sleep Enable

The SE bit must be set (one) to make the MCU enter the Sleep mode when the SLEEP

instruction is executed. To avoid the MCU entering the Sleep mode unless it is the programmers purpose, it is recommended to set the Sleep Enable SE bit just before the

execution of the SLEEP instruction.

• Bits 4,3 – SM1/SM0: Sleep Mode Select Bits 1 and 0

These bits select between the four available Sleep modes, as shown in the following

table.

Table 18. Sleep Modes

SM1 SM0 Sleep Mode

0 0 Idle mode

0 1 ADC Noise Reduction mode

1 0 Power-down mode

1 1 Standby mode

For details, refer to the paragraph “Sleep Modes” below.

1477B–AVR–04/02

• Bit 2 – Res: Reserved Bit

This bit is a reserved bit in the ATtiny26/L and always reads as zero.

39

Page 40

• Bits 1, 0 – ISC01, ISC00: Interrupt Sense Control 0 Bit 1 and Bit 0

The External Interrupt 0 is activated by the external pin INT0 if the SREG I-flag and the

corresponding interrupt mask is set (one). The activity on the external INT0 pin that activates the interrupt is defined in the following table.

Table 19. Interrupt 0 Sense Control

ISC01 ISC00 Description

0 0 The low level of INT0 generates an interrupt request.