Page 1

Features

•

Utilizes the ARM7TDMI™ ARM® Thumb® Processor Core

– High-performance 32-bit RISC Architecture

– High-density 16-bit Instruction Set

– Embedded ICE (In-circuit Emulation)

•

128 Kbytes Internal RAM

•

Fully Programmable External Bus Interface (EBI)

– Maximum External Address Space of 64 MB

– Up to Four Chip Selects

– Software Programmable 8-/16-bit External Data Bus

•

16-channel GPS Correlator

– Accuracy: TBD

– Time to First Fix: TBD

•

8-channel Peripheral Data Controller (PDC)

•

8-level Priority, Individually Maskable, Vectored Interrupt Controller

– Three External Interrupts

•

20 Programmable I/O Lines

•

Three USARTs

– Two Dedicated Peripheral Data Controller (PDC) Channels per USART

•

Master/Slave SPI Interface

– Two Dedicated Peripheral Data Controller (PDC) Channels

– 8- to 16-bit Programmable Data Length

– Four External Slave Chip Selects

•

Programmable Watchdog Timer

•

Power Management Controller (PMC)

– CPU and Peripherals Can Be Deactivated Individually

•

Clock Manager (CLM)

– Geared Master Clock to Reduce Power Consumption

– Sleep State with Disabled Master Clock

•

PWM Controller

– Two PWM Signals

•

Real Time Clock (RTC)

– Time in GPS Format and 15-bit Fractional Part of a Second

– Programmable Interrupt

– Timer with a 8-bit Fractional Part of a Second and Parallel Load

•

2.3V to 3.6V or 1.8V Supply Voltage

•

Includes Power Supervisor

•

Battery Backup Memory

•

9 mm × 9 mm 100-pin BGA Package

GPS Baseband

Processor

ATR0620

Summary

Preliminary

Rev. 4574CS–GPS–05/05

Page 2

1. Description

The GPS baseband processor ATR0620 includes a 16-channel GPS correlator and is based on

the ARM7TDMI processor core.

This processor has a high-performance 32-bit RISC architecture with a high-density 16-bit

instruction set and very low power consumption. In addition, a large number of internally banked

registers result in very fast exception handling, making the device ideal for real-time control

applications.

The ATR0620 has a direct connection to off-chip memory, including flash, through the External

Bus Interface (EBI).

The ATR0620 is manufactured using Atmel’s high-density CMOS technology. By combining the

ARM7TDMI microcontroller core with on-chip SRAM, 16-channel GPS correlator and a wide

range of peripheral functions on a monolithic chip, the ATR0620 provides a highly flexible and

cost-effective solution for GPS applications.

2

ATR0620 [Preliminary]

4574CS–GPS–05/05

Page 3

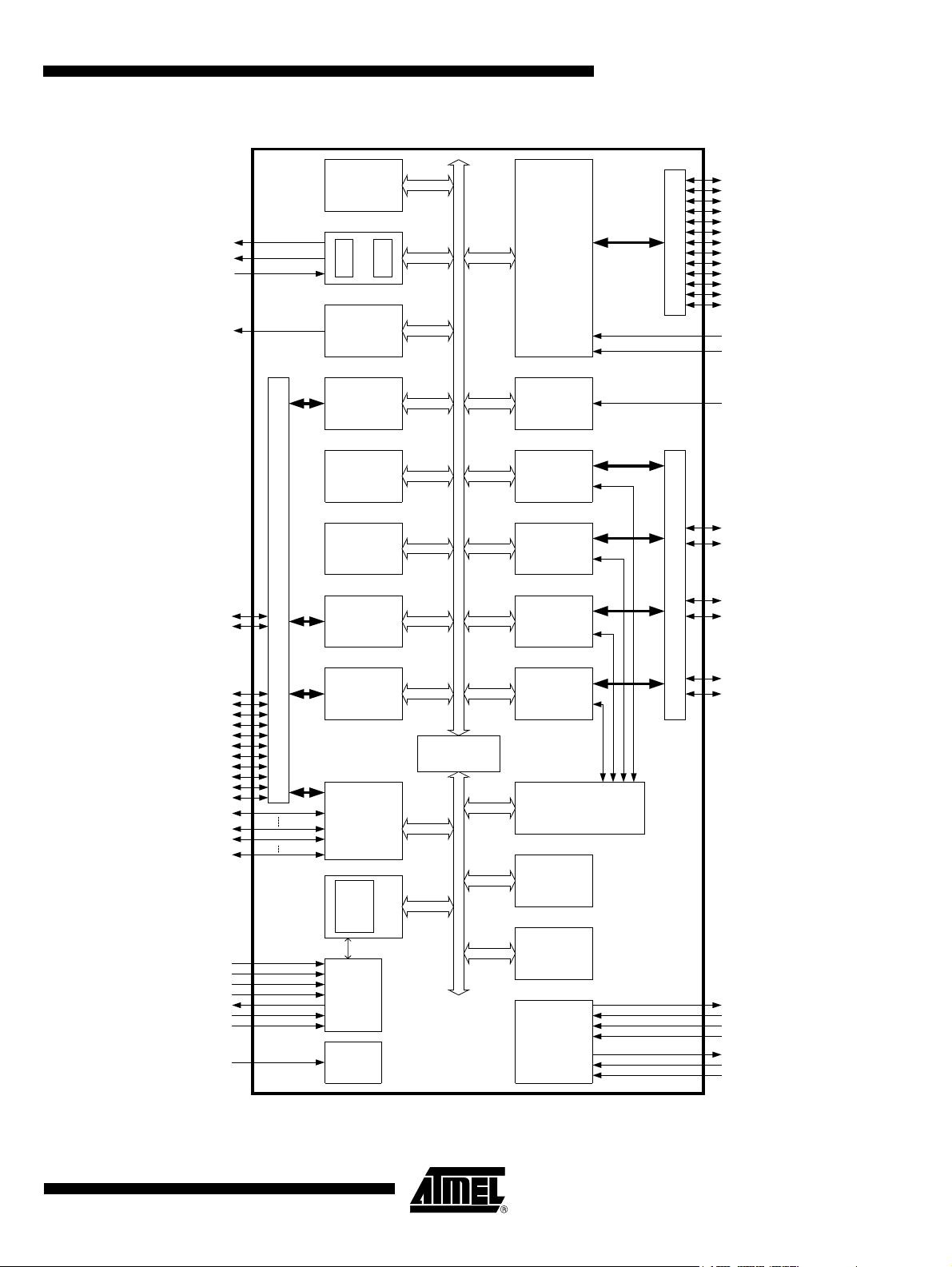

Figure 1-1. Block Diagram

nSHDN

nSLEEP

CLK32768

RF_ON

RTC

Power

ATR0620 [Preliminary]

P29/GPSMODE10

GPS

Accelerator

PIO2

GPS

Correlators

Manage-

ment

SRAM

Controller

P27/GPSMODE7

P26/GPSMODE5

P25/GPSMODE3

P24/GPSMODE2

P23/GPSMODE4

P20/TIMEPULSE

P19/GPSMODE9

P17/GPSMODE1

P14/GPSMODE0

P13/GPSMODE11

P12/GPSMODE8

P1/GPSMODE6

SIGLO

SIGHI

P11/EXTINT2

P9/EXTINT0

P16/NWD_OVF

P30/BOOT_MODE0

P28/EM_A20

P10/EM_A0/NLB

P8/PDSR8

P7/NUB/NWR1

P6/NOE/NRD

P5/NWE/NWR0

P4/nCS0

P3/nCS1

P2/BOOT_MODE1

EM_A19

EM_A1

EM_DA15

EM_DA0

PWM

Generator

Clock

Manager

(CLM)

CLK23

APB

PIO2

Controller

P21/TXD2

P22/RXD2

Special

Function

PIO2

Interrupt

Controller

Advanced

Watchdog

(EBI)

Interface to

Off-Chip Memory

B

RID

E

G

USART0 USART1 USART2 SPI

PDC2

PIO2

P18/TXD1

P31/RXD1

P15/TXD0

P0/RXD0

4574CS–GPS–05/05

DBG_EN

TEST_MODE

nTRST

TDO

TCK

TMS

nRESET

288K

ASB

ROM

ICE

Embedded

ARM7TDMI

128K

SRAM

TDI

JTAG

Con-

Reset

VBAT18_O

VBAT

VBAT18_I

Power

Supply

Manager

troller

LDOBAT_IN

LDO_OUT

LDO_IN

LDO_EN

3

Page 4

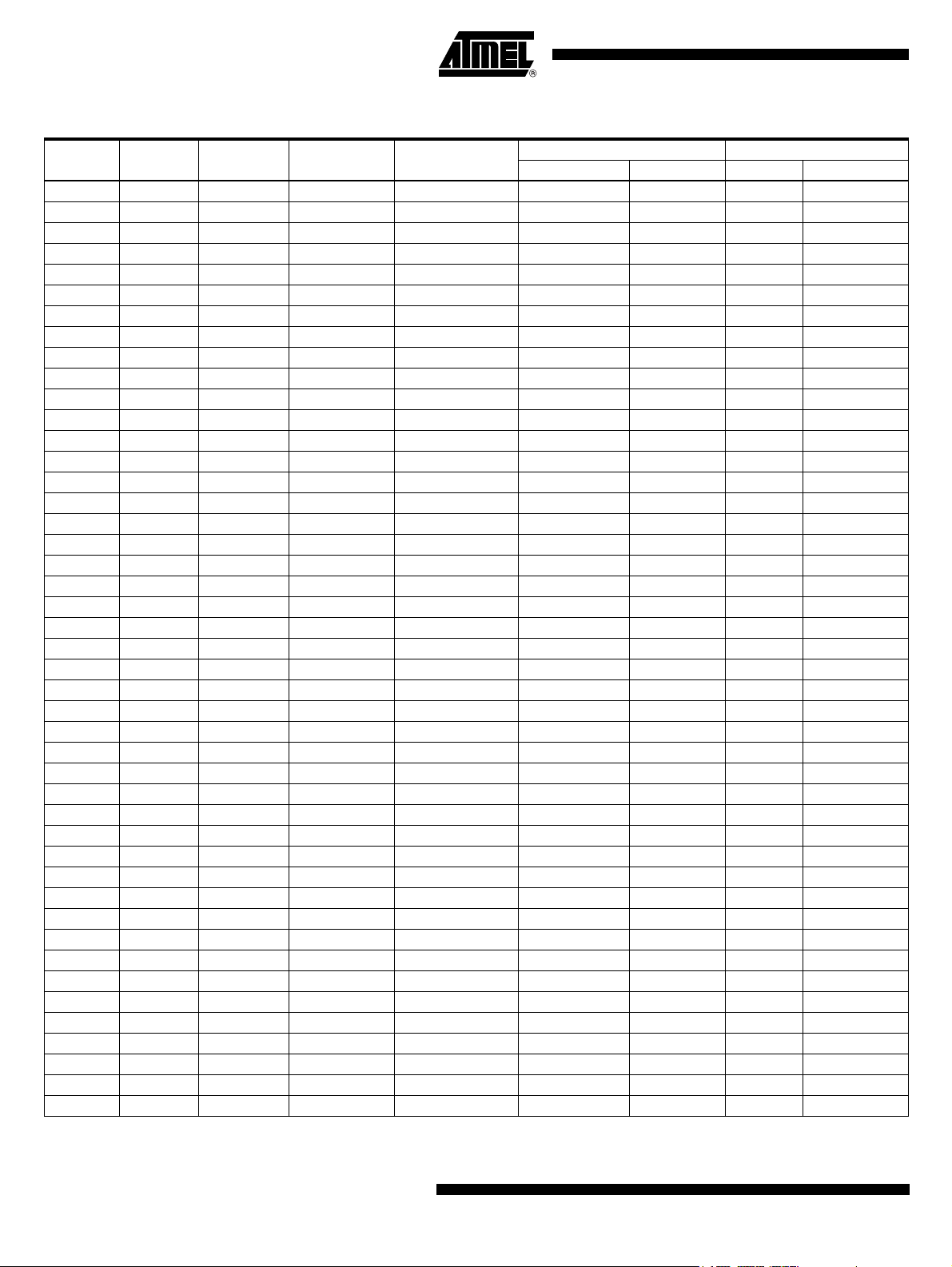

Table 1-1. Pin Configuration

Serial

Number BGA 100 CPGA 144 Pin Name

1 B6 C8 EM_DA0 (1) (1) (1) (1) (1)

2 B10 D13 EM_DA1 (1) (1) (1) (1) (1)

3 C7 B10 EM_DA2 (1) (1) (1) (1) (1)

4 C10 C15 EM_DA3 (1) (1) (1) (1) (1)

5 D10 F13 EM_DA4 (1) (1) (1) (1) (1)

6 E7 E15 EM_DA5 (1) (1) (1) (1) (1)

7 E9 F15 EM_DA6 (1) (1) (1) (1) (1)

8 B7 C9 EM_DA7 (1) (1) (1) (1) (1)

9 B8 B11 EM_DA8 (1) (1) (1) (1) (1)

10 A9 A14 EM_DA9 (1) (1) (1) (1) (1)

11 C8 B12 EM_DA10 (1) (1) (1) (1) (1)

12 B9 B13 EM_DA11 (1) (1) (1) (1) (1)

13 D8 E13 EM_DA12 (1) (1) (1) (1) (1)

14 C9 C14 EM_DA13 (1) (1) (1) (1) (1)

15 D9 D15 EM_DA14 (1) (1) (1) (1) (1)

16 E8 G14 EM_DA15 (1) (1) (1) (1) (1)

17 K5 N9 P15 TXD0 (1) TXD0 (1) MSOUT

18 K9 P14 P0 RXD0 RXD0 (1) (1) (1)

19 J5 Q10 P14 GPSMODE4 SCK0 SCK0 (1) GPS_MON5

20 K4 Q7 P18 TXD1 (1) TXD1 (1) NUB/NWR1

21 H9 N15 P31 RXD1 RXD1 (1) (1) (1)

22 J4 P8 P17 GPSMODE5 SCK1 SCK1 (1) GPS_MON6

23 F9 H14 SIGHI (1) (1) (1) (1) (1)

24 E10 G13 SIGLO (1) (1) (1) (1) (1)

25 J9 N14 XT_IN (1) (1) (1) (1) (1)

26 J10 P15 XT_OUT (1) (1) (1) (1) (1)

27 J6 Q11 nSLEEP (1) (1) (1) (1) (1)

28 G9 J13 CLK23 (1) (1) (1) (1) (1)

29 G5 N8 P30 BOOT_MODE0 (1) NWD_OVF (1) GPS_MON0

30 G4 P7 P2 BOOT_MODE1 (1) 1PPS (1) GPS_MON1

31 J1 P2 TMS (1) (1) (1) (1) (1)

32 J3 P6 TCK (1) (1) (1) (1) (1)

33 J2 P4 TDI (1) (1) (1) (1) (1)

34 K2 Q3 nTRST (1) (1) (1) (1) (1)

35 K3 N6 TDO (1) (1) (1) (1) (1)

36 F4 N1 TEST_MODE (1) (1) (1) (1) (1)

37 H4 N7 DBG_EN (1) (1) (1) (1) (1)

38 K6 N10 RF_ON (1) (1) (1) (1) (1)

39 C4 B3 nRESET (1) (1) (1) (1) (1)

40 G7 L14 nSHDN (1) (1) (1) (1) (1)

41 A6 B8 EM_A1 (1) (1) (1) (1) (1)

42 A5 A6 EM_A2 (1) (1) (1) (1) (1)

43 A4 A5 EM_A3 (1) (1) (1) (1) (1)

44 A2 C3 EM_A4 (1) (1) (1) (1) (1)

45 A3 C5 EM_A5

Firmware

Label

Note: 1. No selection option for PIO.

PIO Bank A PIO Bank B

IOIO

4

ATR0620 [Preliminary]

4574CS–GPS–05/05

Page 5

ATR0620 [Preliminary]

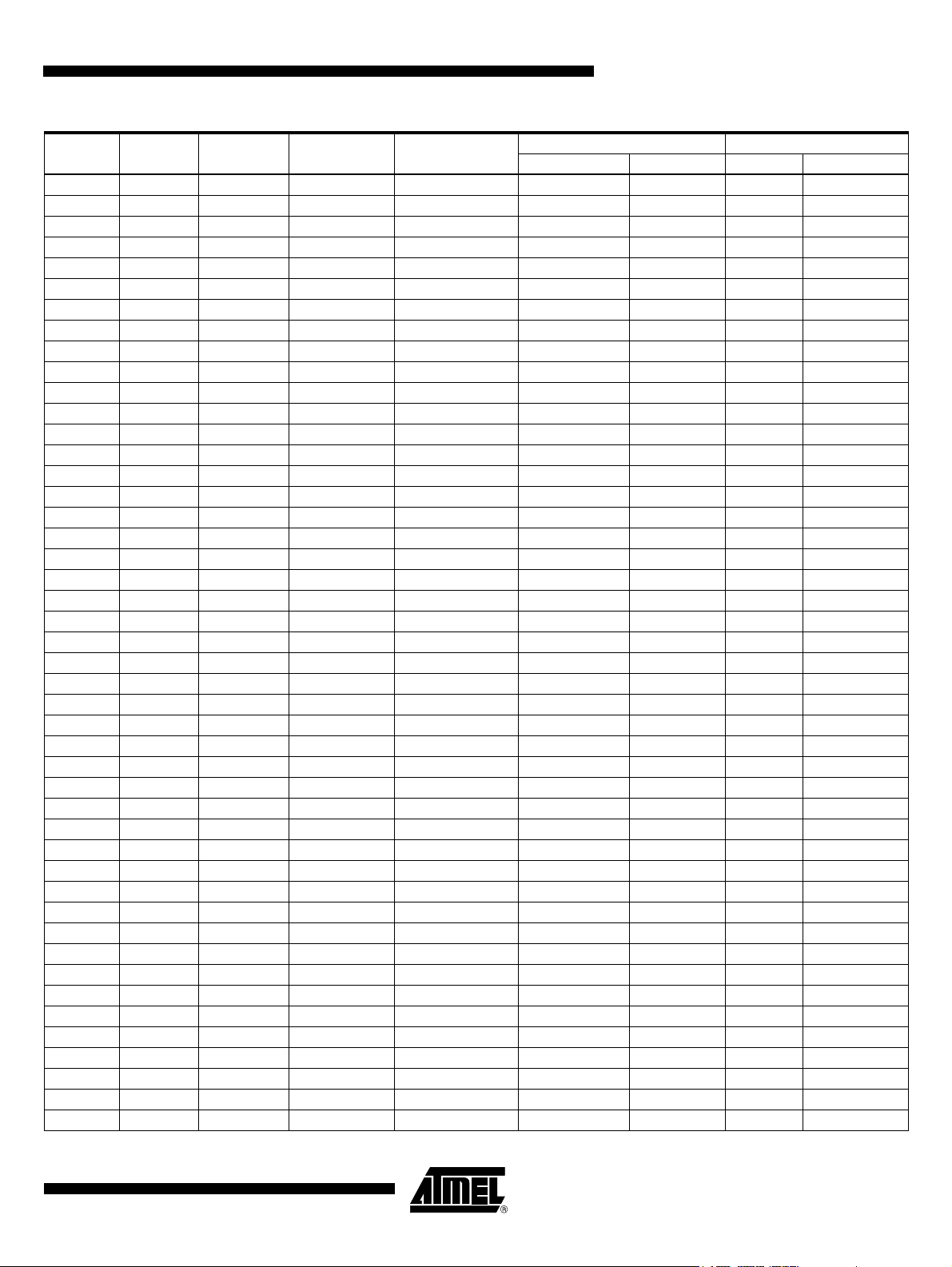

Table 1-1. Pin Configuration (Continued)

Serial

Number BGA 100 CPGA 144 Pin Name

46 B5 B7 EM_A6 (1) (1) (1) (1) (1)

47 B4 A3 EM_A7 (1) (1) (1) (1) (1)

48 B2 B1 EM_A8 (1) (1) (1) (1) (1)

49 D4 F2 EM_A9 (1) (1) (1) (1) (1)

50 C2 F3 EM_A10 (1) (1) (1) (1) (1)

51 D6 A9 EM_A11 (1) (1) (1) (1) (1)

52 D7 C10 EM_A12 (1) (1) (1) (1) (1)

53 C3 C1 EM_A13 (1) (1) (1) (1) (1)

54 C1 E2 EM_A14 (1) (1) (1) (1) (1)

55 D5 A4 EM_A15 (1) (1) (1) (1) (1)

56 C6 C7 EM_A16 (1) (1) (1) (1) (1)

57 F8 H13 EM_A17 (1) (1) (1) (1) (1)

58 B3 C4 EM_A18 (1) (1) (1) (1) (1)

59 C5 C6 EM_A19 (1) (1) (1) (1) (1)

60 E5 Q1 VDD18_R (1) (1) (1) (1) (1)

61 E6 A1 VDD18_B (1) (1) (1) (1) (1)

62 F7 K15 VDD18_L2 (1) (1) (1) (1) (1)

63 F6 A15 VDD18_L1 (1) (1) (1) (1) (1)

64 J7 P13 VBAT (1) (1) (1) (1) (1)

65 A1 D3 GND_R (1) (1) (1) (1) (1)

66 A10 C12 GND_B (1) (1) (1) (1) (1)

67 K1 N4 GND_T (1) (1) (1) (1) (1)

68 F10 J15 GND_L (1) (1) (1) (1) (1)

69 K10 M13 GND_BAT (1) (1) (1) (1) (1)

70 H1 N2 P24 GPSMODE8 MOSI MOSI (1) GPS_MON2

71 D1 G3 P25 GPSMODE9 MISO MISO (1) GPS_MON3

72 H3 P5 P23 GPSMODE7 SCK SCK (1) MCLK_OUT

73 G8 M15 P26 GPSMODE10 NSS NPCS0 (1) GPS_MON4

74 J8 N13 P9 GPSMODE1 EXTINT0 (1) (1) EM_A0/NLB

75 H7 N12 LDO_EN (1) (1) (1) (1) (1)

76 H6 Q13 LDO_OUT (1) (1) (1) (1) (1)

77 H5 P9 P3 (OH) nCS1 (1) nCS1 (1) AGCOUT0

78 A7 B9 P4 (OH) nCS0 (1) nCS0 (1) (1)

79 B1 D2 P5 (OH) NWE/NWR0 (1) NWE/NWR0 (1) (1)

80 A8 A13 P6 (OH) NOE/NRD (1) NOE/NRD (1) (1)

81 K7 P12 LDO_IN (1) (1) (1) (1) (1)

82 D2 G1 P7 (OH) NUB/NWR1 (1) NUB/NWR1 (1) (1)

83 E4 H2 P10 (OH) EM_A0/NLB (1) EM_A0/NLB (1) MCLK_OUT

84 H10 L13 P11 EM_A21 EXTINT2 (1) (1) EM_A21

85 G2 L3 P8 OUT (RFU) (1) AGCOUT0 (1) GPS_MON10

86 E1 H3 P16 NWD_OVF SIGHI2 (1) (1) NWD_OVF

87 F1 J2 P19 GPSMODE6 SIGLO2 (1) (1) EM_A20

88 G3 M3 P1 GPSMODE0 (1) AGCOUT1 (1) GPS_MON7

89 K8 Q14 LDOBAT_IN (1) (1) (1) (1) (1)

90 F2 K3 P21 TXD2 (1) TXD2 (1) EM_A22

91 H8 M14 P22 RXD2 RXD2 (1) (1) EM_A23

Firmware

Label

Note: 1. No selection option for PIO.

PIO Bank A PIO Bank B

IOIO

4574CS–GPS–05/05

5

Page 6

Table 1-1. Pin Configuration (Continued)

Serial

Number BGA 100 CPGA 144 Pin Name

92 H2 N3 P20 1PPS SCK2 SCK2 (1) 1PPS

93 E2 J3 P27 GPSMODE11 (1) NPCS1 (1) GPS_MON11

94 G1 M1 P28 EM_A20 (1) NPCS2 (1) EM_A20

95 E3 K1 P29 GPSMODE12 (1) NPCS3 (1) MSOUT

96 F3 L1 P12 GPSMODE2 (1) nCS2 (1) GPS_MON8

97 G10 K13 P13 GPSMODE3 EXTINT1 nCS3 (1) GPS_MON9

98 G6 N11 VBAT18_O (1) (1) (1) (1) (1)

99 F5 Q15 VBAT18_I (1) (1) (1) (1) (1)

100 D3 G2 TOUT1 (1) APB_SELECT (1) (1) (1)

101 (1) C13 EM_DA16 (1) (1) (1) (1) (1)

102 (1) E3 EM_DA17 (1) (1) (1) (1) (1)

103 (1) D14 EM_DA18 (1) (1) (1) (1) (1)

104 (1) E1 EM_DA19 (1) (1) (1) (1) (1)

105 (1) F14 EM_DA20 (1) (1) (1) (1) (1)

106 (1) H1 EM_DA21 (1) (1) (1) (1) (1)

107 (1) H15 EM_DA22 (1) (1) (1) (1) (1)

108 (1) K2 EM_DA23 (1) (1) (1) (1) (1)

109 (1) J14 EM_DA24 (1) (1) (1) (1) (1)

110 (1) M2 EM_DA25 (1) (1) (1) (1) (1)

111 (1) P1 EM_DA26 (1) (1) (1) (1) (1)

112 (1) Q2 EM_DA27 (1) (1) (1) (1) (1)

113 (1) B2 EM_DA28 (1) (1) (1) (1) (1)

114 (1) A2 EM_DA29 (1) (1) (1) (1) (1)

115 (1) B4 EM_DA30 (1) (1) (1) (1) (1)

116 (1) B5 EM_DA31 (1) (1) (1) (1) (1)

117 (1) Q6 TMON0 (1) (1) (1) (1) (1)

118 (1) Q8 TMON1 (1) (1) (1) (1) (1)

119 (1) Q9 TMON2 (1) (1) (1) (1) (1)

120 (1) P10 TMON3 (1) (1) (1) (1) (1)

121 (1) P11 TMON4 (1) (1) (1) (1) (1)

122 (1) Q12 TMON5 (1) (1) (1) (1) (1)

123 (1) L15 TMON6 (1) (1) (1) (1) (1)

124 (1) L2 TMON7 (1) (1) (1) (1) (1)

125 (1) J1 TMON8 (1) (1) (1) (1) (1)

126 (1) G15 TMON9 (1) (1) (1) (1) (1)

127 (1) F1 TMON10 (1) (1) (1) (1) (1)

128 (1) E14 TMON11 (1) (1) (1) (1) (1)

129 (1) D1 TMON12 (1) (1) (1) (1) (1)

130 (1) B15 TMON13 (1) (1) (1) (1) (1)

131 (1) C2 TMON14 (1) (1) (1) (1) (1)

132 (1) B14 TMON15 (1) (1) (1) (1) (1)

133 (1) C11 TMON16 (1) (1) (1) (1) (1)

134 (1) A12 TMON17 (1) (1) (1) (1) (1)

135 (1) A11 TMON18 (1) (1) (1) (1) (1)

136 (1) A10 TMON19 (1) (1) (1) (1) (1)

137 (1) A8 TMON20 (1) (1) (1) (1) (1)

Firmware

Label

Note: 1. No selection option for PIO.

PIO Bank A PIO Bank B

IOIO

6

ATR0620 [Preliminary]

4574CS–GPS–05/05

Page 7

ATR0620 [Preliminary]

Table 1-1. Pin Configuration (Continued)

Serial

Number BGA 100 CPGA 144 Pin Name

138 (1) A7 TMON21 (1) (1) (1) (1) (1)

139 (1) B6 TMON22 (1) (1) (1) (1) (1)

140 (1) Q5 TMON23 (1) (1) (1) (1) (1)

141 (1) Q4 TMON24 (1) (1) (1) (1) (1)

142 (1) N5 TMON25 (1) (1) (1) (1) (1)

143 (1) P3 TMON26 (1) (1) (1) (1) (1)

144 (1) K14 POR_VEXT (1) (1) (1) (1) (1)

Firmware

Label

Note: 1. No selection option for PIO.

Table 1-2. Pin Description

Module Name

Function

EM_A0 – 23 Address bus Output – All valid after reset

EM_DA0 – 31 Data bus I/O – –

NCS0 – NCS3 Chip select I/O Low –

NWR0 Lower byte 0 write signal I/O Low Used in byte write option

NWR1 Lower byte 0 write signal I/O Low Used in byte write option

NRD Read signal I/O Low Used in byte write option

EBI

NWE Write enable I/O Low Used in byte select option

NOE Output enable I/O Low Used in byte select option

NUB Upper byte select (16-bit SRAM) I/O Low Used in byte select option

NLB Lower byte select (16-bit SRAM) Output Low Used in byte write option

NWAIT Wait signal I/O Low –

BOOT_MODE0 Boot mode input I/O – PIO-controlled after reset, pull up

BOOT_MODE1 Boot mode input I/O – PIO-controlled after reset, pull down

TXD0-2 Transmit data output I/O – PIO-controlled after reset

USART

RXD0-2 Receive data input I/O – PIO-controlled after reset

SCK0-2 External serial clock I/O – PIO-controlled after reset

AIC EXTINT0-2 External interrupt request I/O High/Low PIO-controlled after reset

PWM AGCOUT0-1 Automatic gain control Output – PIO-controlled after reset

PMC RF_ON – – – ATR0600

nSleep Clear sleep output (AF-LDO) Output Low PIO-controlled after reset

RTC

nSHDN Clear sleep output (1.8LDO) I/O Low PIO-controlled after reset

XT_IN Oscillator input Input – OSC

XT_OUT Oscillator output Output – OSC

SCK SPI clock I/O – PIO-controlled after reset

SPI

MOSI Master out slave in I/O – PIO-controlled after reset

MISO Master in slave out I/O – PIO-controlled after reset

NPCS0-3 Slave select I/O Low PIO-controlled after reset

WD NWD_OVF Watchdog timer overflow I/O – PIO-controlled after reset

PIO PDSR0-31 Programmable I/O port I/O – Input after reset

Type Active Level Comment

PIO Bank A PIO Bank B

IOIO

4574CS–GPS–05/05

7

Page 8

Table 1-2. Pin Description (Continued)

Module Name

GPSMODE0-12 GPS mode I/O – PIO-controlled after reset

SIGHI – Input – –

SIGLO – Input – –

GPS

JTAG/

ICE

CLOCK

RESET nReset Reset input Input Low –

POWER

LDOBAT

LDO

TEST

SIGHI2 – Input – –

SIGLO2 – Input – –

1PPS – Output – –

MSOUT – Output – –

GPS_MON0-11 GPS monitor I/O – –

TMS Test mode select Input – Pull down

TDI Test data in Input – Pull down

TDO Test data out Output – –

TCK Test clock Input – Pull down

NTRST Test reset input Input Low Pull down

DBG_EN Debug enable Input – Pull down

CLK23 Clock input Input – Schmitt trigger

MCLK_OUT Master clock output Output – –

VDD18 – Power – –

GND – Power – –

VBAT18_I – IN Power – Backup power In

LDOBAT_IN – Power – –

VBAT – Power – –

VBAT18_O – Out – Backup power out

LDO_IN LDO in Power – –

LDO_OUT LDO out Power – –

LDO_EN LDO enable Input – –

TEST_MODE Test mode select Input – Production test

POR_VEXT Test input Input – For POR18 test

TMON0-26 Test monitor output Output – Debug package

TOUT1/APB_Select Test output Output – –

Function

Type Active Level Comment

8

ATR0620 [Preliminary]

4574CS–GPS–05/05

Page 9

2. Architecture Overview

The ATR0620 architecture consists of two main buses, the Advanced System Bus (ASB) and

the Advanced Peripheral Bus (APB). The ASB is designed for maximum performance. It interfaces the processor with the on-chip 32-bit memories and the external memories and devices by

means of the External Bus Interface (EBI). The APB is designed for accesses to on-chip peripherals and is optimized for low power consumption. The AMBA bridge provides an interface

between the ASB and the APB.

An on-chip Peripheral Data Controller (PDC2) transfers data between the on-chip USARTs/SPI

and the on- and off-chip memories without processor intervention. Most importantly, the PDC2

removes the processor interrupt handling overhead and significantly reduces the number of

clock cycles required for a data transfer. It can transfer up to 64 K continuous bytes without

reprogramming the starting address. As a result, the performance of the microcontroller is

increased and the power consumption reduced.

The ATR0620 peripherals are designed to be easily programmable with a minimum number of

instructions. Each peripheral has a 16-Kbyte address space allocated in the upper 3 M bytes of

the 4-GB address space. Except for the interrupt controller, the peripheral base address is the

lowest address of its memory space. The peripheral register set is composed of control, mode,

data, status and interrupt registers.

To maximize the efficiency of bit manipulation, frequently-written registers are mapped into three

memory locations. The first address is used to set the individual register bits, the second resets

the bits and the third address reads the value stored in the register. A bit can be set or reset by

writing a one to the corresponding position at the appropriate address. Writing a zero has no

effect. Individual bits can thus be modified without having to use costly read-modify-write and

complex bit-manipulation instructions.

ATR0620 [Preliminary]

3. PDC2

All of the external signals of the on-chip peripherals are under the control of the parallel I/O controller. The PIO2 controller can be programmed to insert an input filter on each pin or generate

an interrupt on a signal change. After reset, the user must carefully program the PIO2 controller

in order to define which peripheral signals are connected with off-chip logic.

The ARM7TDMI processor operates in little-endian mode in the ATR0620 GPS baseband. The

processor’s internal architecture and the ARM and Thumb instruction sets are described in the

ARM7TDMI data sheet. The memory map and the on-chip peripherals are described in detail in

the ATR0620 data sheet. The electrical and mechanical characteristics are also documented in

the ATR0620 data sheet.

The ARM standard In-Circuit Emulation (ICE) debug interface is supported via the ICE port of

the ATR0620.

The ATR0620 has an 8-channel PDC2 dedicated to the three on-chip USARTs and to the SPI.

One PDC2 channel is connected to the receiving channel and one to the transmitting channel of

each peripheral.

The user interface of a PDC2 channel is integrated in the memory space of each USART channel and in the memory space of the SPI. It contains a 32-bit address pointer register and a 16-bit

count register. When the programmed data is transferred, an end-of-transfer interrupt is generated by the corresponding peripheral. See the USART section and the SPI section for more

details on PDC2 operation and programming.

4574CS–GPS–05/05

9

Page 10

4. EBI: External Bus Interface

The EBI generates the signals that control the access to the external memory or peripheral

devices. The EBI is fully programmable and can address up to 64 bytes. It has four chip selects

and a 20-bit address bus.

The 16-bit data bus can be configured to interface with 8- or 16-bit external devices. Separate

read and write control signals allow for direct memory and peripheral interfacing. The EBI supports different access protocols, allowing single clock cycle memory accesses.

The main features are:

• External memory mapping

• 4 active low chip select lines

• 8- or 16-bit data bus

• Byte write or byte select lines

• User interface for remap function of boot memory

• Two different read protocols

• Programmable wait state generation

• Programmable data float time

• Programmable write protection for each memory bank

5. AIC: Advanced Interrupt Controller

The ATR0620 has an 8-level priority, individually maskable, vectored interrupt controller. This

feature substantially reduces the software and real time overhead in handling internal and external interrupts.

The interrupt controller is connected to the NFIQ (fast interrupt request) and the NIRQ (standard

interrupt request) inputs of the ARM7TDMI processor. The processor’s NFIQ line can only be

asserted by the external fast interrupt request input: FIQ. The NIRQ line can be asserted by the

interrupts generated by the on-chip peripherals and the external interrupt request lines: IRQ0 to

IRQ3.

An 8-level priority encoder allows the customer to define the priority between the different NIRQ

interrupt sources. Internal sources are programmed to be level sensitive or edge triggered.

External sources can be programmed to be positive or negative edge triggered or high- or lowlevel sensitive.

6. PIO2: Parallel I/O Controller

The ATR0620 features 32 programmable I/O lines. The I/O lines are multiplexed with on-chip

peripheral I/O signals in order to optimize the use of available package pins. The PIO2 controller

provides an internal interrupt signal to the Advanced Interrupt Controller (AIC).

10

ATR0620 [Preliminary]

4574CS–GPS–05/05

Page 11

ATR0620 [Preliminary]

7. USART2: Universal Synchronous/ Asynchronous Receiver/Transmitter

The ATR0620 provides three identical, full-duplex, universal synchronous/asynchronous

receiver/transmitters that interface to the APB and are connected to the peripheral data

controller.

The main features are:

• Programmable baud rate generator

• Parity, framing and overrun error detection

• Line break generation and the detection

• Automatic echo, local loopback and remote loopback channel modes

• Multi-drop mode: address detection and generation

• Interrupt generation

• Two dedicated peripheral data controller channels

• 5-, 6-, 7-, 8-, and 9-bit character length

• Protocol ISO 7816 T = 0 and T = 1

8. SPI: Serial Peripheral Interface

The ATR0620 features an SPI, which provides communication with external devices in master or

slave mode. The SPI has four external chip selects that can be connected to up to 15 devices.

The data length is programmable from 8- to 16-bit. The PDC is used to move data directly

between memory and SPI without CPU intervention for maximum real-time processing

throughput.

9. WD: Watchdog Timer

The ATR0620 features an internal watchdog timer, which can be used to guard against system

lock-up if the software becomes trapped in a deadlock. The watchdog timer can be programmed

to generate an interrupt or an internal reset.

10. PMC: Power Manager Controller

The power management controller allows optimization of power consumption. The PMC

enables/disables the clock inputs to most of the peripherals as well as to the ARM processor.

When the ARM clock is disabled, the current instruction is processed before the clock is

stopped. The clock can be re-enabled by any enabled interrupt or by a hardware reset. When a

peripheral clock is disabled, the clock is immediately stopped. When the clock is re-enabled the

peripheral resumes action where it left off.

Due to the static nature of the design, the contents of the on-chip RAM and registers for which

the clocks are disabled remain unchanged.

11. CLM: Clock Manager

In addition to the Power Management Controller (PMC) the Clock Manager (CLM) is another

possibility to reduce power consumption. The clock manager provides fixed divided clocks for

the USARTs, SPI and watchdog timer and generates the master clock which can be divided.

The master clock is programmable for frequencies between 175 kHz and 23.1 MHz.

4574CS–GPS–05/05

11

Page 12

12. SF: Special Function

The ATR0620 provides registers that implement the following special functions:

• Chip identification

• RESET status

13. PWM

The PWM includes two PWM channels. They can be programmed separately. It is possible to

generate an output voltage range from 0 to (255/256) × VDD18.

14. RTC

The RTC provides the time in GPS format. The structure of the GPS system time: zero point is

midnight Universal Time (UT) 5

and the 15-bit fractional part of a second are counted. Each week has 604800 seconds (GPS

system time does not count leap seconds. Therefore, compared to UT, the GPS time is shifted

some seconds).

Additional the RTC provides a programmable interrupt (maximum period: one week).

15. GPS Correlator

The GPS correlator incorporates 16 GPS channels and provides all the functionality required for

sampling, down-converting and correlating GPS signals.

th/6th

of January 1980. From the zero point weeks, time of week

The GPS correlator processes GPS signal data to acquire the GPS satellite signals using a

model of the satellite codes and multiply/accumulate circuits (correlators) to spread the signal to

a bandwidth low enough to detect it above thermal noise.

16. GPS Accelerator

The ATR0620 features an accelerator which reduces the time to identify the correct GPS signal.

12

ATR0620 [Preliminary]

4574CS–GPS–05/05

Page 13

ATR0620 [Preliminary]

17. Ordering Information

Extended Type Number Package Remarks

ATR0620-100 CTBGA100 9 mm × 9 mm, 0.80 mm pitch

ATR0620-144 CPGA144 Debug package

18. Package Outline CTBGA100

TOP VIEW SIDE VIEW

1.10 ± 0.10

9.00 ± 0.05

9.00 ± 0.05

0.30 ± 0.05

0.40 Dia. TYP

0.60 ± 0.05

0.80 ± 0.050.90 ± 0.05

10

BOTTOM VIEW

A1 BALL PAD CORNER

0.90 ± 0.05

231564897

A

B

C

D

E

F

G

H

J

K

0.80 ± 0.05

4574CS–GPS–05/05

13

Page 14

19. Package CPGA144

TOP VIEW

1.575 ± 0.16

1.575 ± 0.16

BOTTOM VIEW

1.400 ± 0.012

0.100 TYP

SIDE VIEW

0.090 ± 0.009

0.018 ± 0.002

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

123456789101112131415

14

ATR0620 [Preliminary]

4574CS–GPS–05/05

Page 15

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Atmel’s products are not

intended, authorized, or warranted for use as components in applications intended to support or sustain life.

© Atmel Corporation 2005. All rights reserved. Atmel®, logo and combinations thereof, Everywhere You Are® and others, are registered trade-

marks or trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

Printed on recycled paper.

4574CS–GPS–05/05

Loading...

Loading...