Page 1

Main Features

• High Sensitivity and High SNR Performance 1/2" CMOS Sensor

• Total Resolution of 1.3M (with 5 µm Square Pixels)

• High Data Rate: 75 Mpixels/s Provides 60 Frame/s at 1M Resolution (for 1M60)

• CameraLink

• Flexible and Easy to Operate via Serial Communication Control

– Gain: 0 dB to 18 dB in 3 dB Steps

– Dynamic Range: 8, 10 or 12-bit Data

– Contrast Expansion

– Shutter Time Pogrammable

– Subsampling: 1/4 and 1/16 Resolution

– Trigger Mode: Free-run or External Trigger Mode

– Programmable ROI

– Test Pattern

• Column FPN Correction

• Programmable Look-up Table

• Single Power Supply: DC 12 V to 24 V Provided on Hirose-6 Connector

• Input TTL Trigger Signal and Output TTL Shutter Signal on Hirose-5 Connector

• Compact Design: 44 × 44 × 45 mm (w, h, l)

• C-mount Adapter

• High Reliability - CE and FCC Compliant

®

Data Format (Base Configuration - 1 Channel)

CameraLink®

Areascan

Cameras

™

ATMOS

ATMOS

1M60

™

1M30

Product Description

This camera features an outstanding sensitivity and SNR, even at maximal speeds.

The ROI allows to increase the frame rate (for instance, 175 fps in VGA format 1M60).

ATMOS™ cameras are based on a rolling shutter CMOS sensor.

The configuration interface provides access to advanced functions (contrast expansion, image calibration, LUT). The versatile and compact mechanical housing enables

you to implement various configurations.

These features combined with a compelling price, make ATMOS

tive for users of megapixel cameras.

an attractive alterna-

Applications

High-speed, SNR performance and reliability of this camera make it suitable for

machine vision, especially:

Material Inspection (e.g. glass, IC, PCB)

•

• Robot Guidance

• Metrology

and various applications like:

•

Microscopy

• Surveillance Demanding Tasks

Preliminary

5429B–IMAGE–04/05

Page 2

1. Typical Performances

Table 1-1. Camera Typical Performances

Sensor Characteristics at Maximum Pixel Rate

1M60 1M30 Unit

Resolution H × V 1312 × 1024 1312 × 1024 Pixels

Pixel size (square) 5 × 5 5 × 5 µm

Maximum frame rate 48 24 Hz

Pixel rate 75 37.5 MHz

Camera Performances

Bit depth 8, 10 or 12 Bits

Spectral range 350–1000 nm

Linearity ±2% in 5% and 95% of FSR

PRNU 1.5% rms

FPN 0.1% rms

Responsivity 10000

(1)

LSB/(Lux.s)

Output RMS Noise

Dynamic range

Conversion factor 10 e-/ LSB

Dark Current 1500 e-/s

Over Illumination Behavior 75 Esat

Mechanical and Electrical Interface

Size (w × h × l) 44 × 44 × 45 mm

Weight 115 g

Lens Mount C-mount

Sensor Alignment

Power supply single 12 to 24 VDC

Power consumption < 2 W

Operating temperature 0 to 55 (non-condensing) °C

Storage temperature -40 to 70 (non-condensing) °C

< 2.7 LSB rms

> 63

(2)

∆x, y = ± 250

∆z = ±150

= ± 0.7

∆0

xy

= 0-200

∆tilt

z

dB

µm

µm

degree

µm

Measured with light source 3200°K and IR filter

Warning:

1. When exposed to such illumination level the sensor might lock-up and should be reset

2

See Register Software Reset @ 206H, Internal Register Mapping on page 17

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 3

[Preliminary] ATMOS -1M60/1M30

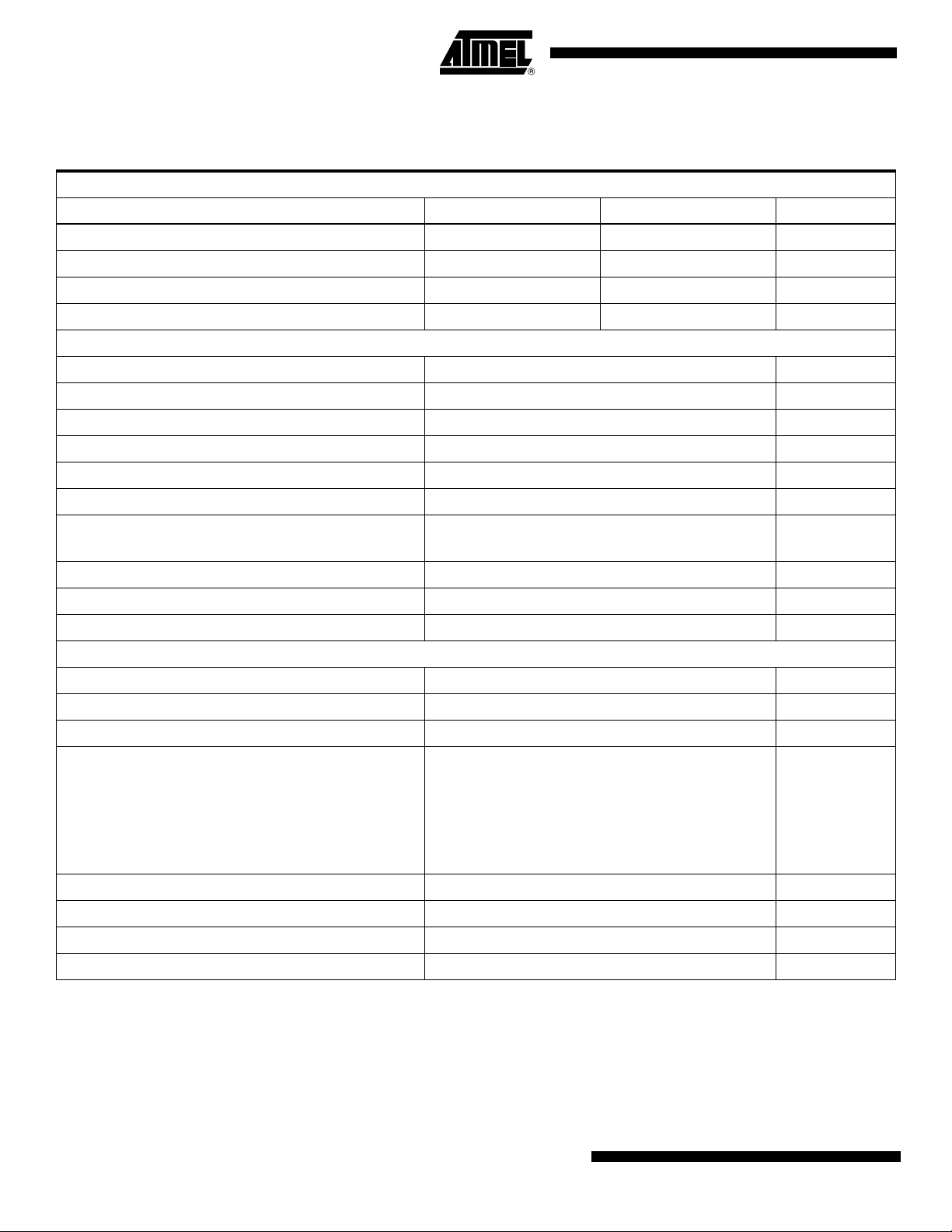

Figure 1-1. Responsivity Diagram

50

45

40

35

)

2

30

25

20

LSB/( nJ/cm

15

10

5

0

300 400 500 600 700 800 900 1000 1100

Figure 1-2. Quantum Efficiency

Responsivity at 0 dB Gain

nm

Quantum Efficiency

0,8

0,7

0,6

0,5

0,4

QE (%)

0,3

0,2

0,1

0

400 500 600 700 800 900 1000

Wavelength (nm)

5429B–IMAGE–04/05

3

Page 4

2. Standard Conformity

The cameras have been tested in the following conditions:

• Camera with complete Atmel housing

• Shielded power supply cable

• CameraLink data transfer cable ref. 14B26-SZLB-500-OLC (3M™)

• Linear AC-DC power supply

Atmel recommends using the same configuration to ensure compliance with the following

standards.

2.1 CE Conformity

The ATMOS cameras comply with the European directive 89/336/CEE (EN55022 A/CISPR22 A,

EN55024, EN61000-6-2).

2.2 FCC conformity

ATMOS Cameras comply with Part 15 of FCC rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may

cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own

expense.

Warning: Changes or modifications to this unit not expressly approved by the party responsible

for compliance could void the user's authority to operate this equipment.

4

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 5

3. Camera Description

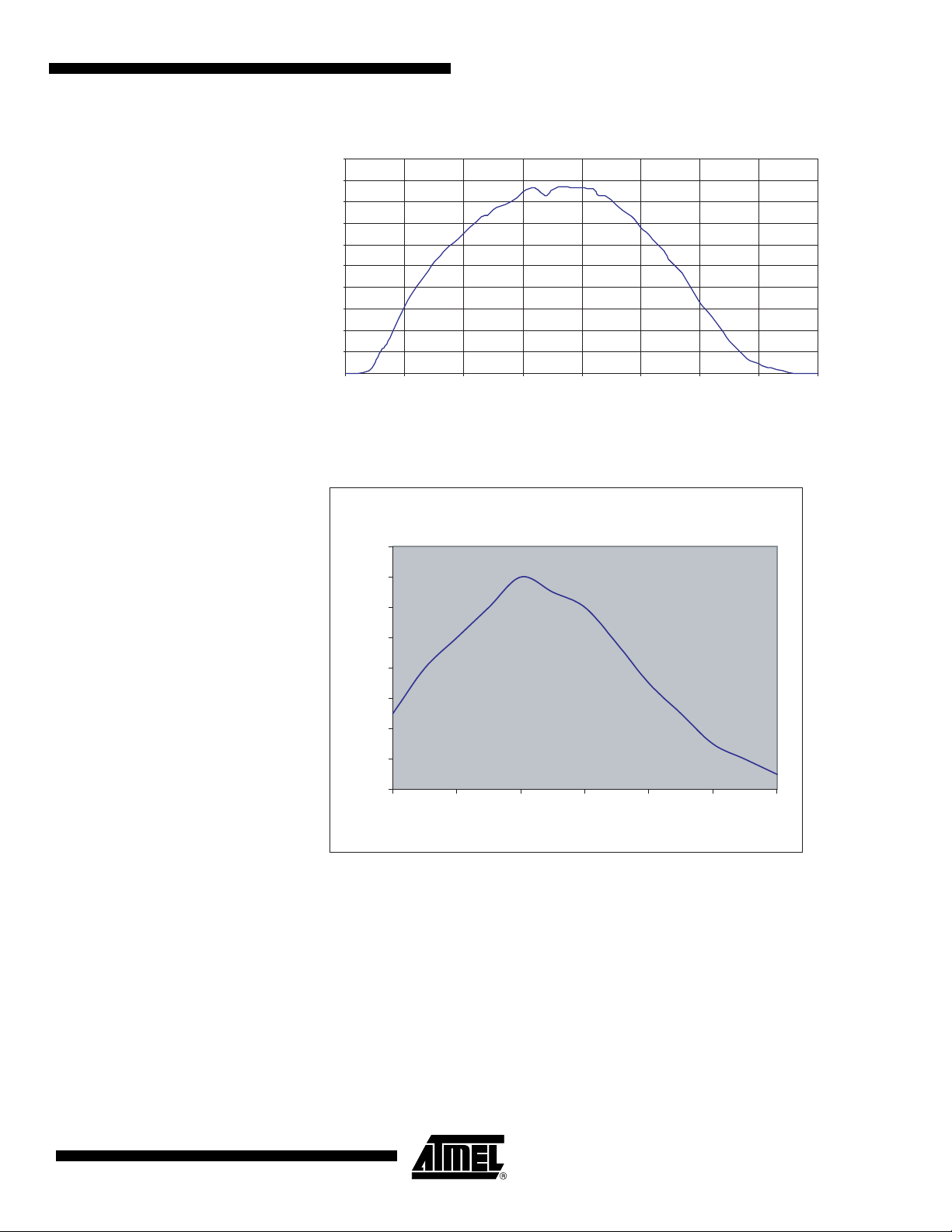

Figure 3-1. Camera Synoptic

[Preliminary] ATMOS -1M60/1M30

DC power

Camera Link

I/F

CameraLink

Transceiver

TX

RX

Power Supplies

Data

Strobe, LVAL

FVAL

Trigger

Shutter

Serial Line

Sequencer

Controller

Microcontroller

CMOS

SENSOR

The camera is based on a single tap CMOS sensor which delivers a 12-bit digital video signal at

its output. An FPGA has been implemented for image processing (FPN column correction, conversion LUT, contrast expansion). The camera is powered by a single DC power supply from

12V to 24V. The functional interface (data and control) is provided with the CameraLink interface. The camera uses the base configuration of the CameraLink standard.

Note: DVAL permanently tied to 1 (high) level.

Data can be delivered on a single channel or two de-multiplexed channels. The data format configuration might be in 12-bit, 10-bit, or 8-bit. It is possible to use external triggers with the camera

(CC1 signal or TTL_IO trigger input) in different trigger modes see ”Synchronization Modes” on

page 6 The camera configuration and settings are done via the CameraLink serial communica-

tion. This interface is used for:

5429B–IMAGE–04/05

• Gain and offset setting

• Data output format

• Synchronization modes: free-run or external trigger modes

• Shutter time

• Test pattern generation

• Upload and download of correction data (FPN column correction, LUT)

5

Page 6

4. Timing

4.1 Synchronization Modes

The camera operates in rolling shutter mode.

4.1.1 Optimal Use of the Rolling Shutter

As shown in the following timing diagrams, Figure 4-1, exposure does not happen at the same

time for all lines, which can lead to image distortion when capturing fast moving objects. The

way to bypass this, is to use the camera with a strobe light or a shutter element so that all the

lines are exposed during the same time and no image distortion is visible when capturing fast

moving objects.

The integration time for each line is: readout (+ programmable shutter time, when used). A shutter signal is provided to strobe a light source or to drive a shutter element. You can set the

camera to operate in one of the following synchronization modes: periodic, triggered, triggered

without full reset and ITC. See register Mode Control @ 204H, Internal Register Mapping on

page 17.

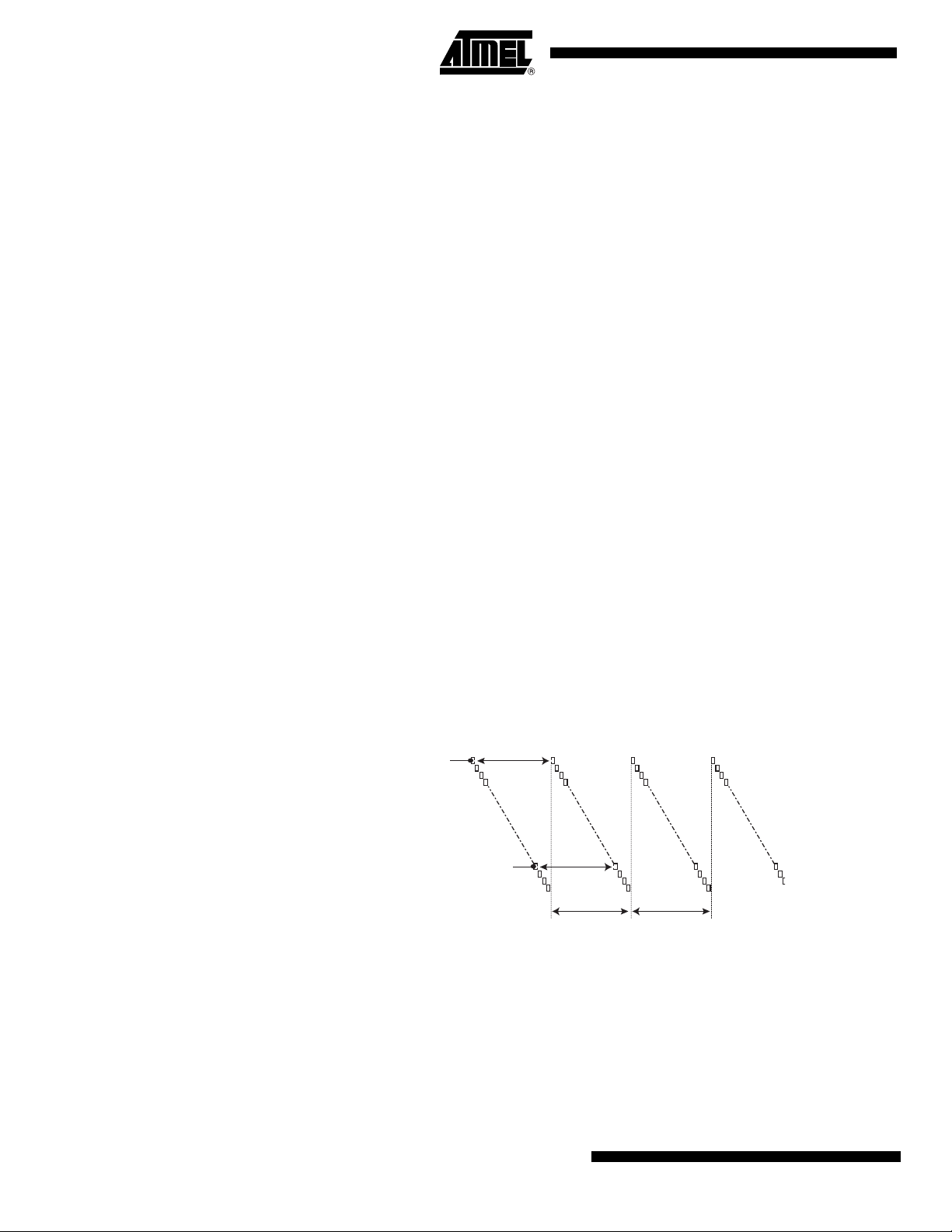

4.1.2 Free-run Mode (or Periodic Mode) Principle: The camera operates in periodic mode.

The period is defined by readout time (+ programmable shutter time, when used). Valid data is

forwarded to the CameraLink interface during the next frame readout starting with the first line.

If shutter time is set to 0:

The frame N is readout while the first line integrates for frame N+1. As soon as the frame N

readout has ended starts the readout of frame N +1.

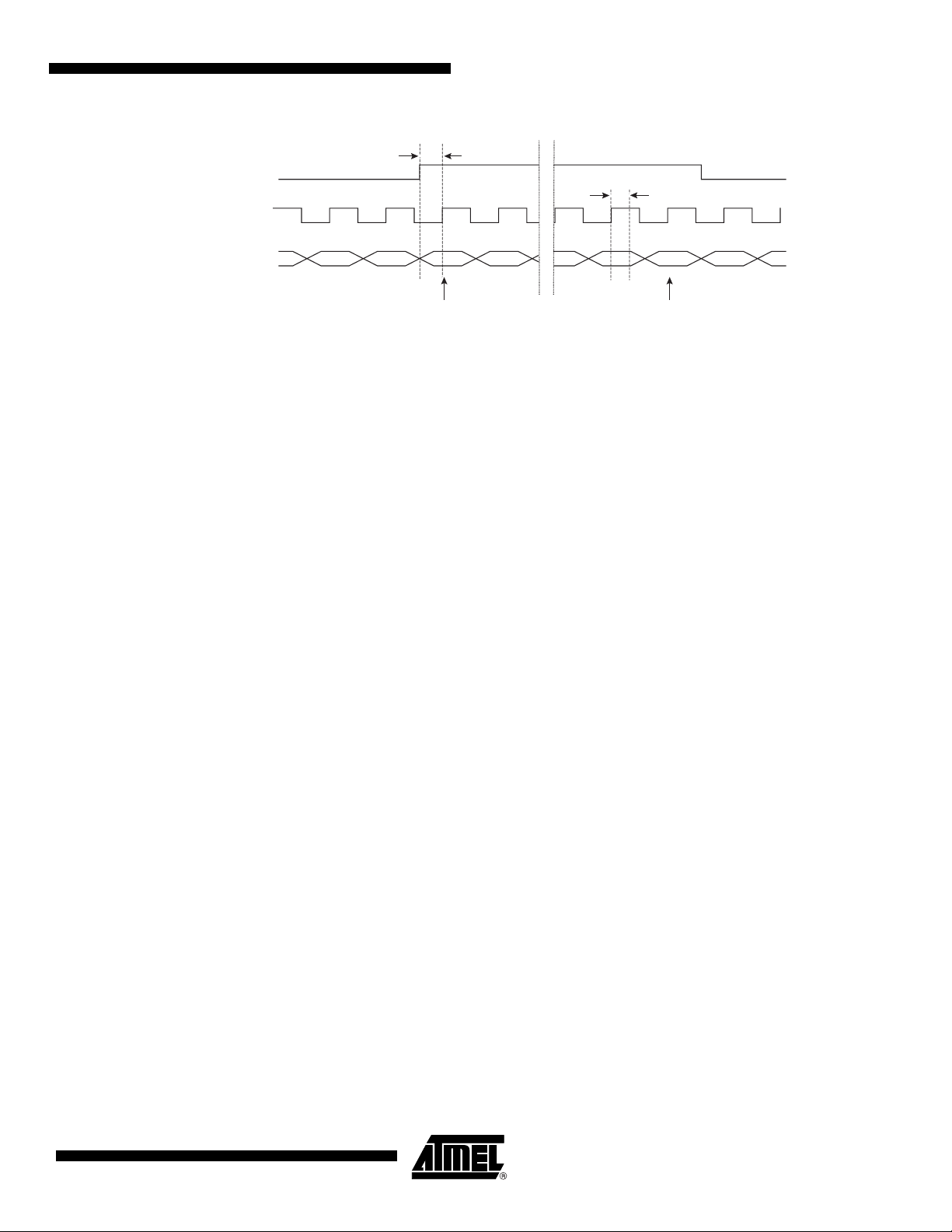

Figure 4-1. Free-run Mode Chronogram

Line 1

Integration

Line 1 Readout

and Reset

Line n Readout

and Reset

(frame N)

Line n

Integration

(Frame N)

Frame N

Readout

Frame N+1

Readout

6

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 7

[Preliminary] ATMOS -1M60/1M30

)

t

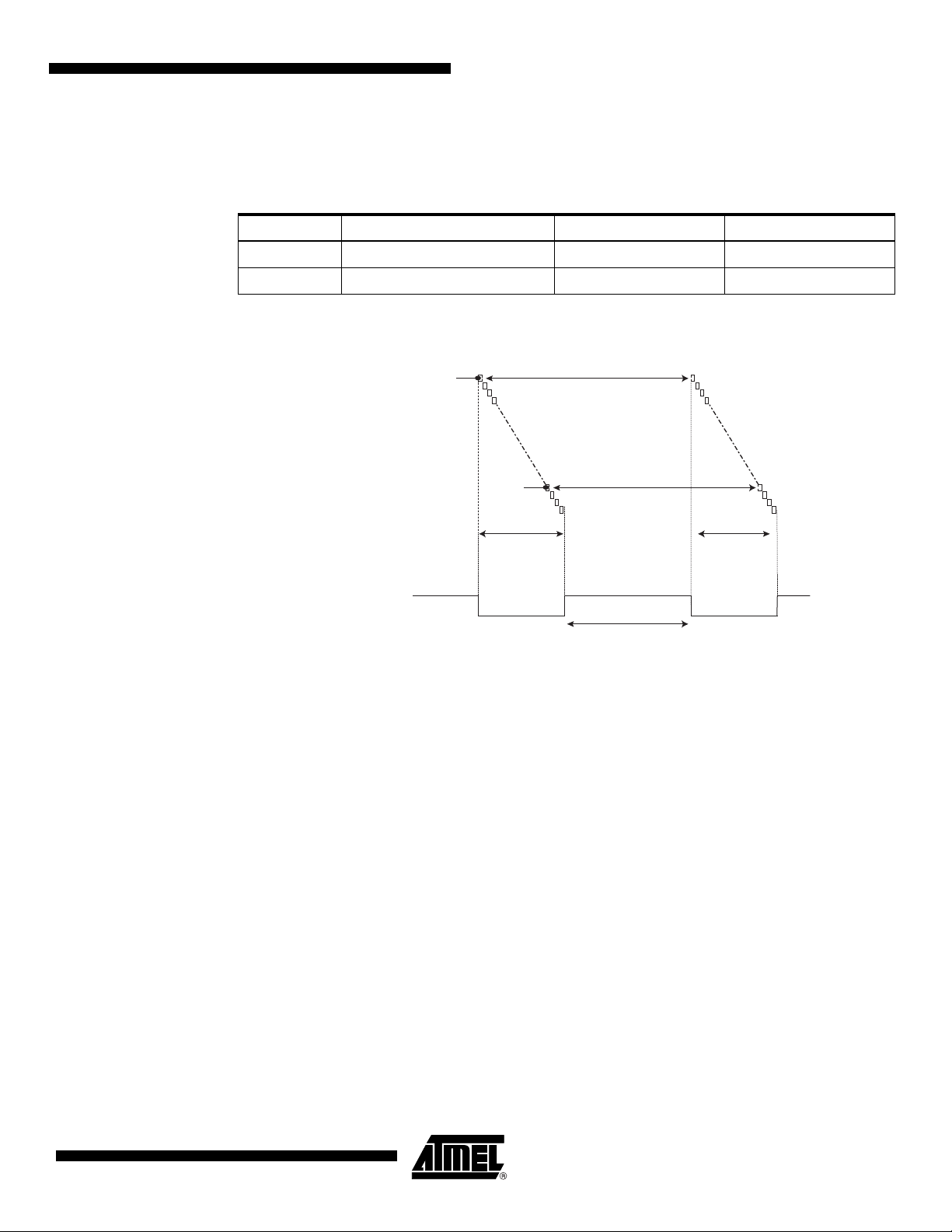

If shutter time is set to > 0:

Readout is suspended between two consecutive frame readout and shutter output signal is activated (programmable polarity) for a time configurable within 0 to Tsh range by step of T1.

Table 4-1. Shutter Time Values at Free-run Mode

Label Description 1M60 1M30

Tsh Maximum shutter time (ms) 655 1310

T1 Step duration (µs) 10 20

Figure 4-2. Free-run Mode and Shutter Chronogram

Line 1

Integration

Line 1

Line n Readout

and Reset

Readout

and Rese

(Frame N

Line n

Integration

(Frame N)

4.1.3 Triggered Mode

Shutter

Frame N - 1

Readout

out

Time

Programmable

Shutter Time

Frame N

Readout Time

The maximum frame rate of 48 frame/s for the 1M60 camera (or 24 frame/s for the 1M30 camera) is given in this mode with a shutter time set to 0.

See register Aperture Shutter Time @ 246H, Internal Register Mapping on page 17.

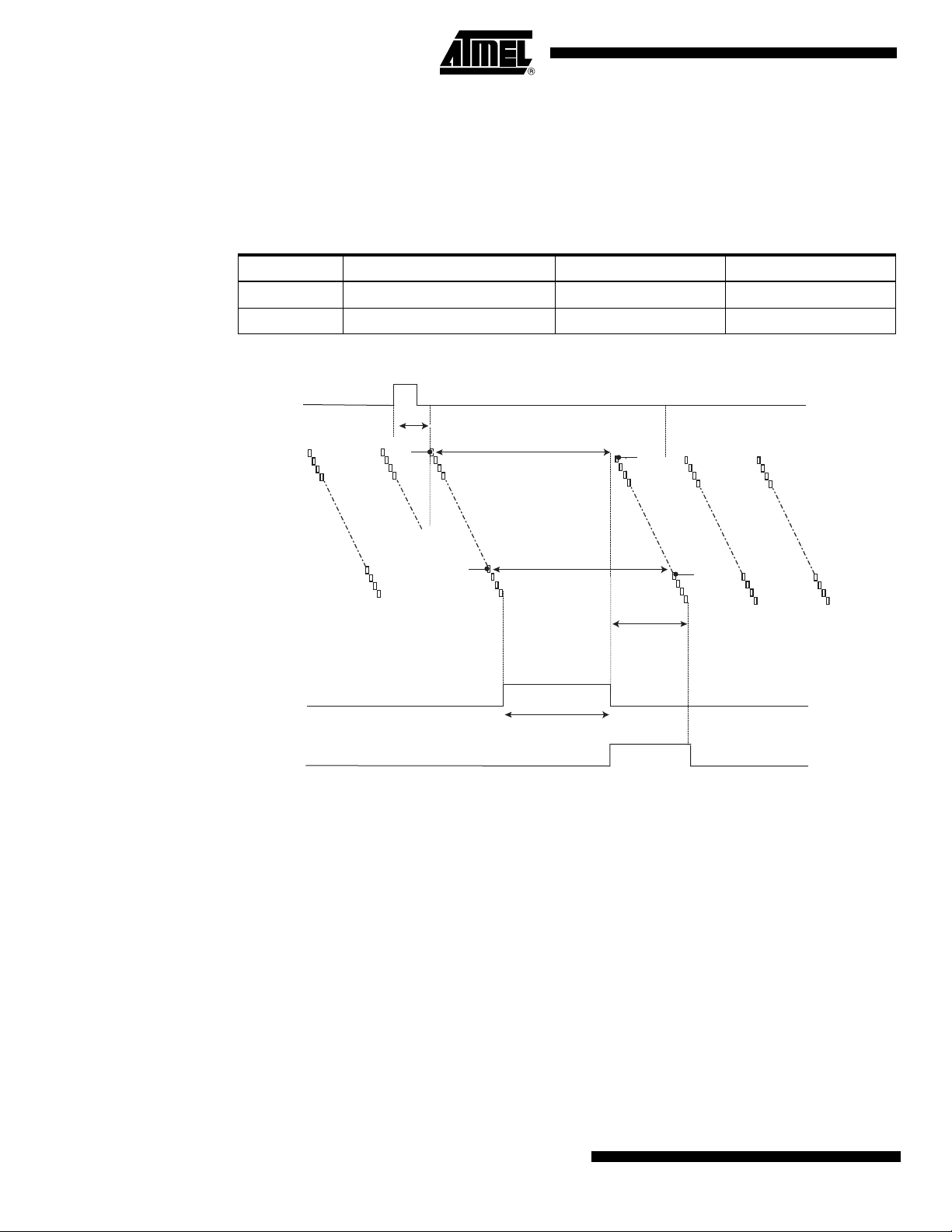

Principle: An external trigger starts the reset of the sensor, then snap and readout of a frame,

the integration time is defined by readout time (+ programmable shutter time, when used).

The trigger event initiates the following sequence:

• Stop of readout frame in progress and reset of readout pointer to line 1

• Readout of previous dummy frame and integration start of the frame N. The readout data of

previous frame is not forwarded on CameraLink interface (FVAL inactive)

• Shutter output signal is activated during a time programmable within 0 to Tsh range by step

of T1

• Readout of frame N. The readout data is forwarded to the CameraLink interface (FVAL

active) starting with the first line

• Readout of dummy frames (to prevent against large dark current integration) while the

camera waits for the next trigger event

5429B–IMAGE–04/05

7

Page 8

The trigger delay is a few µs. The minimum pulse duration is 1µs. The edge of trigger is programmable. The source of trigger is selectable between CameraLink CC1 signal and TTL/IO

trigger input. The period is defined by readout time + programmable shutter time + readout time

+ wait. Therefore the minimum period is 2

× readout time.

See register Aperture Shutter Time @ 246H, Internal Register Mapping on page 17.

Table 4-2. Shutter Time Values at Triggered Mode

Label Description 1M60 1M30

Tsh Maximum shutter time (ms) 655 1310

T1 Step duration (µs) 10 20

Figure 4-3. Triggered Mode Chronogram

Trigger N EventTrigger In

Trigger Delay

Line 1 reset

Line n Reset

Line 1

Integration

(Frame N)

Line n

Integration

(Frame N)

Line 1 Readout

and Reset

Line n Readout

and Reset

Shutter out

FVAL

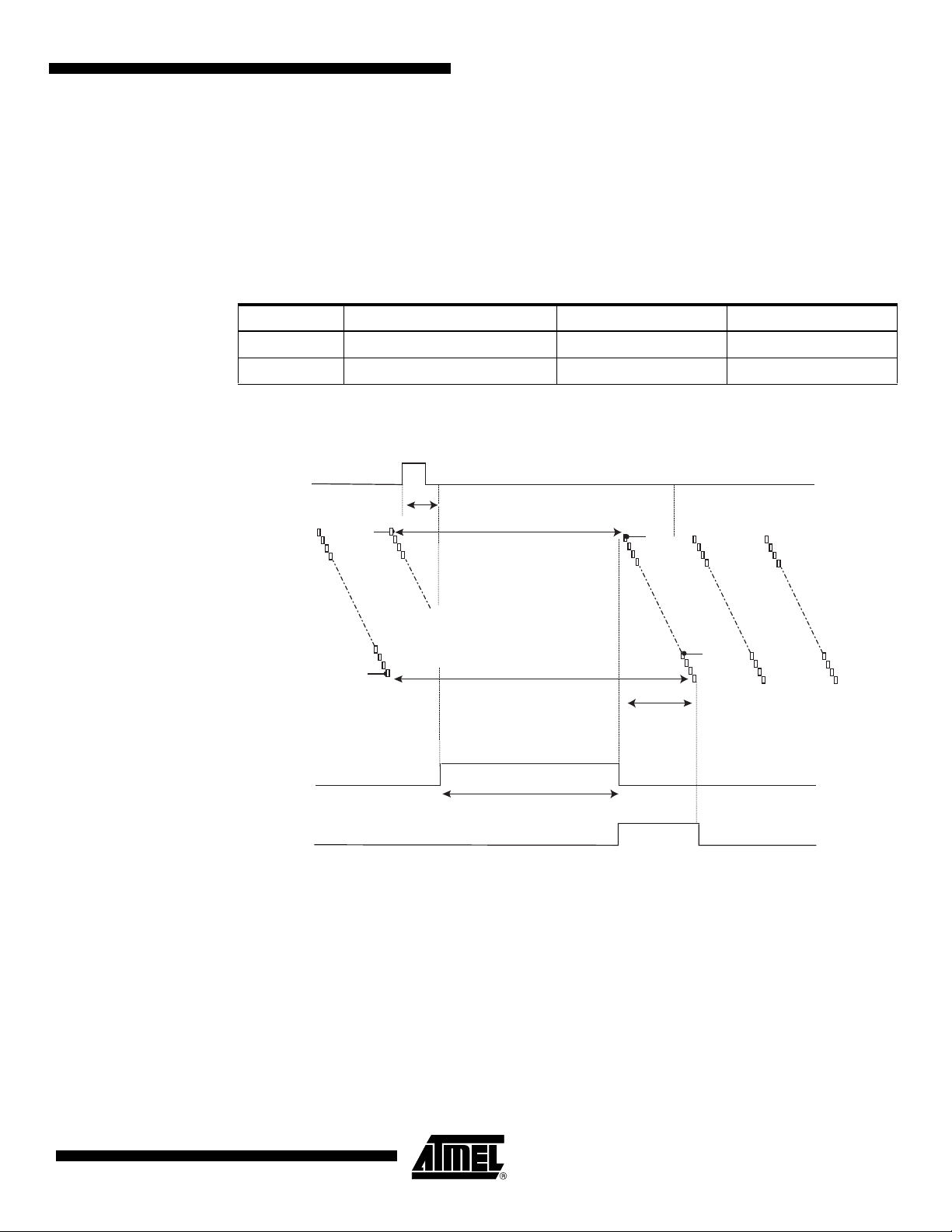

4.1.4 Triggered Mode without Full Reset Principle: An external trigger starts the snap and readout of a frame, without resetting the sen-

sor. The integration time is defined by readout time (+ programmable shutter time, when used).

The trigger event initiates the following sequence:

• Stop of readout frame in progress and reset of readout pointer to line 1

• Shutter output signal is activated during a time programmable within 0 to Tsh range by step

of T1

• Readout of frame N. The readout data is forwarded to the CameraLink interface (FVAL

active) starting with the first line

• Readout of dummy frames (to prevent against large dark current integration) while the

camera waits for the next trigger event

The trigger delay is a few µ s. The minimum pulse duration is 1µs. The edge of trigger is programmable. The source of trigger is selectable between CameraLink CC1 signal and TTL_IO

trigger input. The period is defined by the programmable shutter time + readout time + wait.

Frame N

Readout

Programmable

Shutter Time

8

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 9

[Preliminary] ATMOS -1M60/1M30

Therefore the minimum period is reduced to 1 × readout time. As the integration time is not the

same for all lines (in the following timing diagram line n integration time is greater than line 1

integration time) this mode must be used with a pulsed light source or a shutter element. Moreover any residual light when shutter output signal is inhibited must be avoided. The exposure

time is defined by the shutter time and all the lines are exposed during the same time.

See register Aperture Shutter Time @ 246H Internal Register Mapping on page 15

Table 4-3. Shutter Time Values at Triggered Mode without Full Reset

Label Description 1M60 1M30

Tsh Maximum shutter time (ms) 655 1310

T1 Step duration (µs) 10 20

Figure 4-4. Triggered Mode Without Full Reset Chronogram

Trigger N EventTrigger In

Trigger Delay

Line1 Reset

Line 1

Integration

(Frame N)

Line 1 Readout

and Reset

4.1.5 ITC Mode

Line n

Line n Reset

Shutter out

FVA

Integration

(Frame N)

Frame N

Readout

Programmable

L

Shutter Time

Line n Readout

and Reset

Principle: An external sync controls both the integration time and the frame rate.

The trigger event initiates the following sequence:

• Stop of readout frame in progress and reset of readout pointer to line 1

• Shutter output signal is activated during a time defined by the high state of the ITC signal

• Readout of frame N. The readout data is forwarded to the CameraLink interface (FVAL

active) starting with the first line

5429B–IMAGE–04/05

9

Page 10

• Readout of dummy frames (to prevent against large dark current integration) while the

camera waits for the next trigger event

The integration delay is a few µs. The minimum pulse duration is 1µs. The source of ITC signal

is selectable between CameraLink CC1 signal and TTL_IO trigger input. See Register Mode

Control @ 204H Internal Register Mappingon on page 17

The period is defined by the ITC signal period.

As the integration time is not the same for all lines (in the following timing diagram line n integration time is greater than line 1 integration time) this mode must be used with a pulsed light

source or a shutter element. Moreover any residual light when shutter output signal is inhibited

must be avoided. The exposure time is defined by the ITC signal high state time and all the lines

are exposed during the same time

Figure 4-5. ITC Mode Chronogram

Trigger N Event

ITC in

Trigger Delay

Line 1 Reset

Line 1

Integration

(Frame N)

Line 1 Readout

and Reset

4.2 Ouput Data Timing

Table 4-4. Timing Values

Label Description Min Typ Max

Line n

Integration

Line n Reset

Shutter out

FVAL

Ts Input setup to clock delay 1ns

Th Output hold from clock delay 1ns

(Frame N)

Shutter Time

Line n Readout

and Reset

Frame N

Readout

10

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 11

Figure 4-6. Output Data Chronogram

[Preliminary] ATMOS -1M60/1M30

LVAL

STROBE

DATA

ts

th

First Valid Pixel Last Valid Pixel

5429B–IMAGE–04/05

11

Page 12

5. Camera Features

5.1 Region of Interest

The full resolution of the camera is 1312 pixels by 1024 lines.You might program a smaller resolution in order to reduce the readout time. You must be careful that depending on the

sequencing mode, the exposure time can be reduced too.The authorized values for horizontal

size are 32 to 1312 pixels. This value is rounded to the

rized values for vertical size are 32 to 1024 lines. This value is rounded to the lower multiple of 8

lines. See registers ROI area @ 280H, 282H, 284H and 286H Internal Register Mapping on

page 17.

Examples of frame rate versus resolution:

Table 5-1. R.O.I Performance

5.2 Analog Gain

The analog gain can be adjusted by setting the gain register via the serial communication.

lower multiple of 16 pixels. The autho-

ROI Size Frame Rate 1M60 (fps) Frame Rate 1M30 (fps)

1312 × 1024 48 24

1024 × 1024 60 30

640 × 480 175 85

5.3 Subsampling

• Gain adjusted from 0 dB to 18 dB: code 0 to 6

• Step 3 dB

• Nominal gain (factory configuration): 0 dB

See register Sensor Analog Gain @ 240H, Internal Register Mapping on page 17.

– Subsampling 1: All pixels are readout (1312 × 1024)

– Subsampling 2: Two times lower resolution in both axes (656 × 512)

– Subsampling 4: Four times lower resolution in both axes (328 × 256)

See register Subsampling @ 288H, Internal Register Mapping on page 17.

Subsampling parameters might be combined with the ROI. The minimal window size resulting

from these combinations must be at least 32 × 32 pixels. This leads to the following table of minimal ROI size versus Subsampling:

Table 5-2. Subsampling Minimum Size

Subsampling Minimum ROI Size

1 32 × 32

2 64 × 64

4 128 × 128

5.4 Output Format

12

ATMOS -1M60/1M30 [Preliminary]

The data format available on the CameraLink output interface is programmable via the serial

interface.

5429B–IMAGE–04/05

Page 13

5.5 Test Pattern

[Preliminary] ATMOS -1M60/1M30

1. The pixel depth is set by default at 12-bit, it can be set to 10 or 8-bit. The assignment for

each configuration comply with the specifications of the CameraLink interface standard.

See register Mode Control bits [3:2] @ 204H, Internal Register Mapping page 17 .

2. In standard mode the camera provides output data on a single channel of the CameraLink output interface. You might program the camera in two outputs mode, only with

the 1M60. Pixel data is de-multiplexed (odd and even pixels) on ports A, B and C of the

CameraLink interface and STROBE signal is divided by 2 (37.5 MHz).

See register mode control bit [4] @ 204H,Internal Register Mapping page 17 .

In normal mode, the digital video signal from the sensor is available on the CameraLink output

interface. For test purposes a digital pattern is generated and is available instead of the video

signal in the CameraLink output interface. The pattern can be fixed or sliding. The fixed digital

pattern is ramp-up from 960 LSB code to 2271 LSB code (line width). The same pattern is

shown for each line:

Figure 5-1. Test Pattern View

The sliding pattern starts with the fixed pattern, the first code of each line is then incremented by

two on each frame. It is useful to validate the connection to the acquisition system before the

adjustment settings of the image capture. The Subsampling parameter does not affect the

pattern.

See register Mode Control bits [1:0] @ 204H, Internal Register Mapping on page 17.

5.6 Contrast Expansion

The digital gain and offset can be adjusted via the serial communication in order to focus on a

particular part of the dynamic range.

• Gain adjusted from x1 to x32.875: code 0 to 255

• Step 0.125

• Nominal gain (factory configuration):

See register Digital Gain @ 242H, Internal Register Mapping on page 17.

• Offset adjusted from -4096 to +4095: code 0 to 8191 in 2's complement

• Step 1

• Nominal offset (factory configuration): 0

See register Digital Offset @ 244H, Internal Register Mapping on page 17.

See register Processing Control bits [1:0] @ 202H, Internal Register Mapping on page 17.

× 1

5429B–IMAGE–04/05

13

Page 14

5.7 Look- up Table (LUT)

The look-up Table is a conversion table which applies to the sensor data. At each input pixel

value corresponds a single output value. This allows you to apply a correction table like a

gamma correction for example.

The Look-up Table might be generated by the camera by programming the gamma setting:

• Gamma 0.125 to 7.875: code 1 to 63 (0 not admitted)

You might also write your own correction table via the serial communication channel. Four banks

are available to store four distinct correction tables.

See register LUT Coefficient Save in Dataflash @ 10DH, Internal Register Mapping on page 17.

See register LUT Coefficient Restore in Dataflash @ 10EH, Internal Register Mapping on page

17.

See register Processing Control bit 2 @ 202H, Internal register mapping on page 17

5.8 Fixed Pattern Noise (FPN) Correction

The fixed pattern noise (FPN) is a spatial fluctuation of the sensor data particularly between successive columns. The purpose is to calculate an offset for each column of the frame in the

darkness. The table of column offsets is stored in the internal memory. If the FPN correction is

then enabled the offset values are subtracted to the value of the input pixel. Two methods are

available to realize this processing: the off-line calibration and the online correction.

5.9 Off-line Calibration

A calibration step is required while the camera is in darkness condition. Offset coefficients for

each column are calculated on an average value measured on all 1024 lines. Offset coefficients

are 8-bit data. Therefore to be efficient the pixel value should be always within the values 1LSB

to 255 LSB. If not, the overflow / underflow flags are set in the status register. The calibration

step must be done in full resolution and subsampling 1. Calibration data can be saved in nonvolatile memory and four distinct banks are reserved for this use. You might access to these banks

in read or write mode.

See register Processing Control bits [4:3] @ 202H, Internal register mapping on page 17.

See register Calibration Control @ 200H, Internal register mapping on page 17.

See register FPN Coefficient Save in Dataflash @ 10BH, Internal register mapping on page 17.

See register FPN Coefficient Restore in Dataflash @ 10CH, Internal Register Mapping on page

17.

5.10 Online Correction

No calibration step is required. When online correction is enabled the camera calculates the offset coefficients for each column on masked lines and then processes the input sensor data.

These coefficients are updated at each frame. The online correction applies only in subsampling

1. The calculated values are less accurate with these methods but unlike the off-line calibration

do not depend on the settings like the analog gain.

14

See register Processing Control bits [4:3] @ 202H, Internal Register Mapping on page 17.

See register FPN Coefficient Save in Dataflash @ 10BH,Internal Register Mapping on page 17.

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 15

See register FPN Coefficient Restore in Dataflash @ 10CH, Internal Register Mapping on page

t

17.

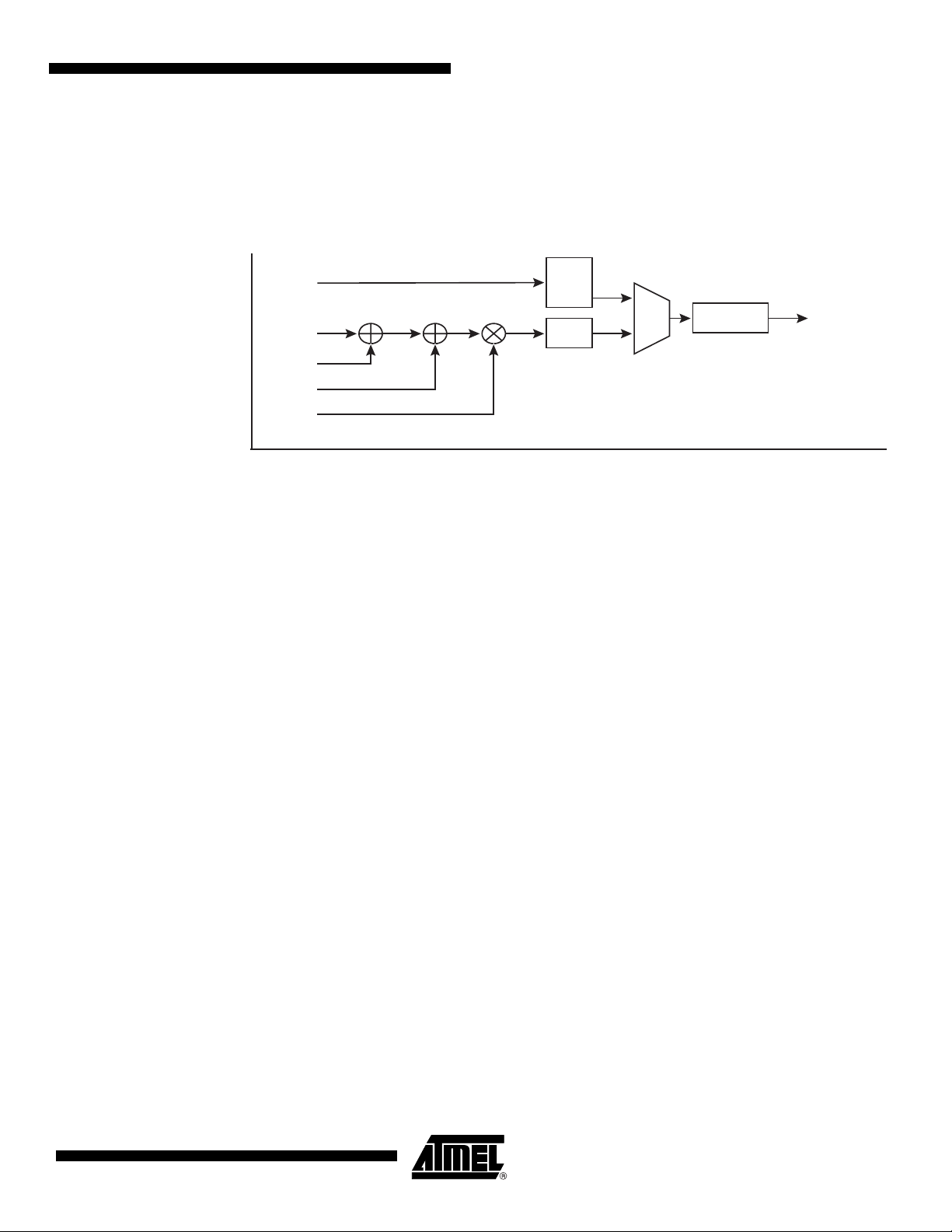

5.11 Processing Synoptic

Figure 5-2. Synoptic

Pattern

Pixel_In

Coef_FPN

Offset

Gain

[Preliminary] ATMOS -1M60/1M30

C

P

T

Pixel_Ou

LUT

MUX

FORMAT

5.12 LED Indicator

The green LED on the rear panel gives information on the internal state of the camera. On

power up, after internal configuration, the LED flashes on and has the following behavior

(decreasing priority order):

• Internal hardware error or configuration error: fast blinking

• Waiting for external trigger (triggered and ITC modes): slow blinking

• All other situation: continuous

5429B–IMAGE–04/05

15

Page 16

6. Electrical Interface

6.1 Power Supply

It is recommended to insert a 1A fuse between the power supply and the camera. The voltage

ripple of the power supply shall be below ±50 mVp-p at BW = 50 MHz to have full camera

performanceI

Table 6-1. Power Supply Description

Signal Name I/O Type Description

PWR P - DC power input: +12 V to + 24 V

GND P - Electrical and mechanical ground

Note: I = input, O = output, I/O = bi-directional signal, P = power/ground, NC = not connected

6.2 Command and Control

The CameraLink interface provides four LVDS signals dedicated to camera control (CC1 to

CC4). On the ATMOS, one of them is used to synchronize the camera on external events.

Table 6-2. CameraLink Input Description

Signal Name I/O Type Description

TRIG1 I RS644 CC1 - Synchronization input

Note: I = input, O = output, I/O = bi-directional signal, P = power/ground, NC = not connected

The TTL/I/O interface provides two TTL signals dedicated to camera control.

Table 6-3. TTL/IO Description

Signal Name I/O Type Description

TRIGGER I 5 V-TTL External trigger input

SHUTTER O 3 V-TTL

Note: I = input, O = output, I/O = bi-directional signal, P = power/ground, NC = not connected

Shutter output, maximum output current

1.6 mA

See register Mode Control @ 204H, Internal Register Mapping on page 17.Video Data.

Data and enable signals are provided on the CameraLink interface.

Table 6-4. Camera Link Output Description

Signal Name I/O Type Description

ODD-D[11-0] O RS644 Odd pixel data, ODD-00 = LSB, ODD-11 = MSB

EVEN-D[11-0] O RS644 Even pixel data, EVEN-00 = LSB, EVEN-11 = MSB

STROBE O RS644 Output data clock, data valid on the rising edge

LVAL O RS644 Line valid or line enable, active high signal

FVAL O RS644 Frame valid or frame enable, active high signal

16

Note: 1. I = input, O = output, I/O = bi-directional signal, P = power/ground, NC = not connected

2. Note: DVAL, as defined in the CameraLink standard, is not used. DVAL is permanently tied to

1 (high) level.

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 17

6.3 Serial Communication

The CameraLink interface provides two LVDS signal pairs for the communication between the

camera and the frame grabber. This is an asynchronous serial communication based on RS-232

protocol.

The configuration of the serial line is:

• Full duplex/without handshaking

• 8-bit data, no parity bit, 1 stop bit

• 9600 bauds at power up, then programmable up to 115200 bauds

Table 6-5. CameraLink Serial Communication Description

Signal Name I/O Type Description

[Preliminary] ATMOS -1M60/1M30

SerTFG O RS644

SerTC I RS644

Differential pair for serial communication

to the frame grabber

Differential pair for serial communication

from the frame grabber

6.3.1 Internal Register

Table 6-6. Internal Register Mapping

Access Type

Start Addr

(Hex)

000 1 RO RO

001 1 RW - 1

040 51 RO - Hardware identifier

080 8 RO - Firmware identifier

0C0 51 RW - User identifier

100 4 RW RW Status (ref. Camera Status Management)

104 4 WO -

108 1 RO -

Size

Dec)

End

Addr (Hex)

Processing Internal Task

Factory

Settings Description

Synchronization register for serial

communication (value 00)

Communication speed multiplier (9600 115,2K): volatile register 1, 2, 3, 4, 6, 8, 12

Lock/Unlock mode: advanced user/user

1: Lock advanced user mode

(into user mode)

Unlock key value: unlock user

Privilege level

1: Advanced user mode

2: User mode

109 1 WO -

10A 1 RW - 0

5429B–IMAGE–04/05

Current configuration save in Eeprom

1: User settings (allowed only for advanced

user mode)

2 to 4: User settings

Current configuration restore from Eeprom

1 to 4: User settings

17

Page 18

Table 6-6. Internal Register Mapping (Continued)

Access Type

Start Addr

(Hex)

10B 1 WO -

10C 1 RW - 1

10D 1 WO -

10E 1 RW - 1

200 2 RW RW 0

202 2 RW - 0

Size

Dec)

End

Addr (Hex)

Processing Internal Task

Factory

Settings Description

FPN coefficient save in dataflash

1 to 4 (1 allowed only for advanced user

mode)

FPN coefficient restore in dataflash

1 to 4

LUT coefficient save in dataflash

1 to 4 (1 allowed only for advanced user

mode)

LUT coefficient restore in dataflash

1 to 4

Calibration control

[0] = off-line calibration enabled

(0: disabled; 1: enabled)

Processing control:

[0] = offset correction enable (0: disabled;

1: enabled)

[1] = gain correction enable (0: disabled; 1:

enabled)

[2] = look-up table correction enable (0:

disabled; 1: enabled)[

[4:3] = fpn correction mode (00: disabled;

01: off-line fpn correction enabled; 11: online fpn correction enabled)

204 2 RW - 0

206 1 WO

Mode control:

[1:0] = test pattern (00: disabled; 01: fixed

test pattern; 10: dynamic test pattern)

[3:2] = output format (00:12-bit; 01:10-bit;

10:8-bit)

[4] = demux mode (for 1M60 then 0:

disabled; 1: enabled) (for 1M30 then 0:

disabled)

[7:5] = synchronization mode (000: Freerun; 001: External triggered; 010: external

triggered without full reset; 011: integration

time controlled); others reserved

[8] = trigger source (0: CameraLink; 1:

external)

[9] = trigger polarity (0:positive edge; 1:

negative edge)

[10] = shutter polarity output (0: positive

edge; 1: negative edge)

Software reset:

1 = camera reset

18

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 19

[Preliminary] ATMOS -1M60/1M30

Table 6-6. Internal Register Mapping (Continued)

Access Type

Start Addr

(Hex)

240 2 RW - 0

242 2 RW - 0

244 2 RW - 0

246 2 RW - 1

248 2 RW - 1600

280 8 287 RW ROI area:

Size

Dec)

End

Addr (Hex)

Processing Internal Task

Factory

Settings Description

Sensor analog gain:

[3:0] = analog gain; value from 0 dB (= 0) to

18 dB (= 6) by step of 3 dB

Digital gain (extended dynamic range):

[7:0] = gain; value from 1.000 (= 0) to

32.875 (= 255) in Q 9.3 representation

Digital offset (extended dynamic range):

[12:0] = offset; value from -4096 to

+ 4095 in 2's complement

Aperture shutter time:

[15:0] = shutter time; value from 0 to 65535

(for 1M60: 0 to 655 ms by step of 10µs)

(for 1M30: 0 to 1310 ms by step of 20µs)

ERS:

[10:0] value from 0% (= 0,Dark) to 100%

(= 1600, clear) in Q11.4 representation

288 1 RW - 1

2C0 2 RW 50

2C2 2 RW 50

2C4 1 RW - 0

Addr 280, size 2, default 0:

ROI horizontal start value (0 to 1311)

Addr 282, size 2, default 0

ROI vertical start value (0 to 1023)

Addr 284, size 2, default 1312

ROI vertical size value from 32 to 1312

Addr 286, size 2, default 1024

ROI vertical size value from 32 to 1024

Subsampling:

[2:0] = Subsampling (001: 1/1; 010: 1/4;

100: 1/16)

Hot pixel detection threshold:

[10:0] = hot pixel threshold

Dead pixel detection threshold:

[10:0] = dead pixel threshold

Defective pixels control:

[0] = hot pixel detection (0: disabled; 1:

enabled

[1] = dead pixel detection (0: disabled; 1:

enabled)

5429B–IMAGE–04/05

19

Page 20

Table 6-6. Internal Register Mapping (Continued)

Access Type

Start Addr

(Hex)

300 1 WO -

1000 1312 151F RW - 0

2000 8192 3FFF RW - linear

Note: RO: Read Only register, WO: Write Only register, RW: Read & Write register

Size

Dec)

End

Addr (Hex)

Processing Internal Task

Factory

Settings Description

6.3.2 Camera Settings Memory

ATMOS cameras have 5 banks to save settings:

• Bank 0 contains the factory settings. This bank cannot be modified by the user

• Bank 1 to 4 are used to store 4 different settings

• Bank 1 might be protected by an advanced user (see Register @ 104H). Contact Atmel for

details

Gamma correction:

[5:0] = gamma settings; value from 0.125

(= 1) to 7.875 (= 63) in Q6.3 representation

FPN coefficients (8-bit):

Format: Fpn [0]; Fpn[1]; Fpn [2];…

Look-up table (4096 × 16-bit):

Format: Lut [0]; Lut [1]; … ; Lut [4095]

value: 0 to 4095

20

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 21

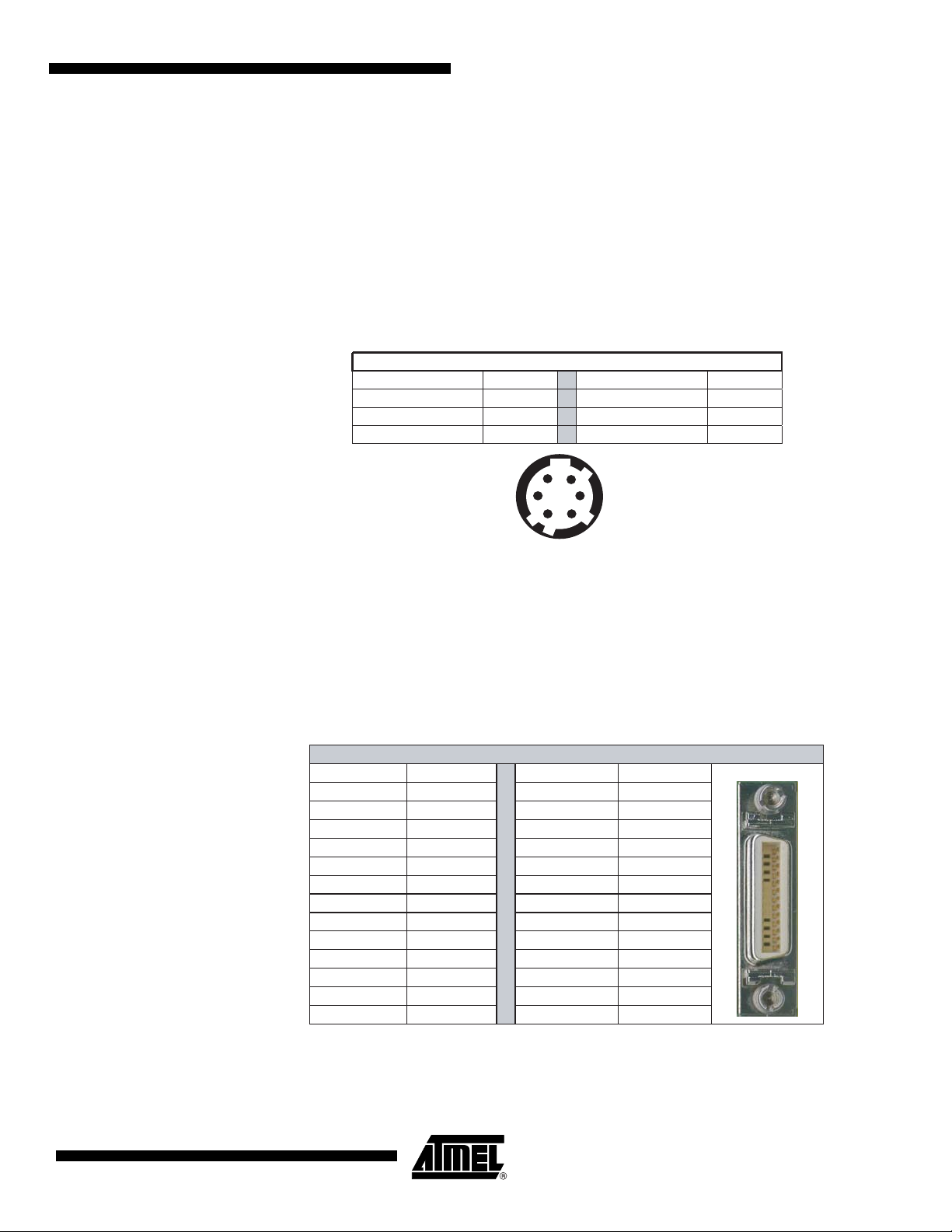

7. Connector Description

All connectors are on the rear panel. Better results are obtained by using shielded cables (foil

and braid shielded).

Note: cables for digital signals shall be twisted pairs.

7.1 Power Supply

Camera connector type: Hirose HR10A-7R-6PB (male)

Cable connector type: Hirose HR10A-7P-6S (female)

Figure 7-1. Power Supply Pinout

[Preliminary] ATMOS -1M60/1M30

Power Connector : J01

Signal Pin Signal Pin

PWR 1 GND 4

NC 2 NC 5

PWR 3 GND 6

7.2 CameraLink Connector

Standard CameraLink cable shall be used to ensure the full electrical compatibility.

• Camera connector type: MDR-26 (female) ref. 3M 10226-2210VE

• We recommend to use a CameraLink standard shielded cable as 3M 14X26-SZLB-XXX-0LC

Figure 7-2. CameraLink Pinout

1

2

3

Receptacle Viewed from Camera Back

Command and Control Connector : J02

Signal Pin Signal Pin

GND 1 GND 14

X0- 2 X0+ 15

X1- 3 X1+ 16

X2- 4 X2+ 17

Xclk- 5 Xclk+ 18

X3- 6 X3+ 19

SerTC+ 7 SerTC- 20

SerTFG- 8 SerTFG+ 21

CC1- 9 CC1+ 22

CC2+ 10 CC2- 23

CC3- 11 CC3+ 24

CC4+ 12 CC4- 25

GND 13 GND 26

6

5

4

5429B–IMAGE–04/05

21

Page 22

7.3 TTL I/O

Camera connector type: Hirose HR10A-7R-5SB (female)

Cable connector type: Hirose HR10A-7P-5P (male)

Figure 7-3. TTL/IO Pinout

TTL IO Connector : J03

Signal Pin Signal Pin

TRIGGER 1 GND 4

GND 2 NC 5

SHUTTER 3

1

4

Receptacle Viewed from Camera Back

2

5

3

22

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 23

8. Mechanical Drawing

Note: (All dimensions are in mm)

Figure 8-1. Front Panel View

[Preliminary] ATMOS -1M60/1M30

Figure 8-2. Front Panel Mechanical Drawing

44

φ35

sensor

38.5

Note: 1. A and B are mechanical reference plans

2. Sensor alignment ∆x, y refers to the optical axis

3. Sensor alignment ∆0

4 x (M3 x

A

8)

B

First Pixel

of Line 1

1 - 32 UN -

(C mount)

xy

2A

refers to the reference plans

Camera

Link

Power

Supply

2 x (M4 x

(on the 4 sides)

44.75

3.75

12

22

8)

5429B–IMAGE–04/05

23

Page 24

Figure 8-3. Rear Panel

Figure 8-4. Rear Panel Mechanical Drawing

44

12-24V

23

CameraLink

31.30

9.90

TTL IO

22.80

®

24

ATMOS -1M60/1M30 [Preliminary]

5429B–IMAGE–04/05

Page 25

[Preliminary] ATMOS -1M60/1M30

9. Ordering Code

Table 9-1. Ordering Code

Part Number Description

AT71-ATM1M60M-B0

AT71-ATM1M30M-B0

ATMOS 1M60 with housing + power supply connector + TTL I/O

Connector + CD-Rom

ATMOS 1M30 with housing + power supply connector + TTL I/O

Connector + CD-Rom

Delivery:

ATMOS areascan cameras are delivered with:

• Power supply connector HR10A-7P-6S

• TTL I/O connector HR10A-7P-5P

• CD-rom with:

– Friendly software CommCam

– Documentation

5429B–IMAGE–04/05

25

Page 26

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Atmel’s products are not

intended, authorized, or warranted for use as components in applications intended to support or sustain life.

© Atmel Corporation 2005. All rights reserved. Atmel®, logo and combinations thereof, and Dataflash® are registered trademarks, and Every-

where You Are

Imaging Association. Other terms and product names may be trademarks of others.

SM

, ATMOS™and others are trademarks of Atmel Corporation or its subsidiaries. CameraLink® is the trademark of Automated

Printed on recycled paper.

5429B–IMAGE–04/05

xM

Loading...

Loading...