Page 1

Features

•

Single 2.7V - 3.6V Supply

•

RapidS™ Serial Interface: 66 MHz Maximum Clock Frequency

– SPI Compatible Modes 0 and 3

•

User Configurable Page Size

– 512 Bytes per Page

– 528 Bytes per Page

– Page Size Can Be Factory Pre-configured for 512 Bytes

•

Page Program Operation

– Intelligent Programming Operation

– 8,192 Pages (512/528 Bytes/Page) Main Memory

•

Flexible Erase Options

– Page Erase (512 Bytes)

– Block Erase (4 Kbytes)

– Sector Erase (64 Kbytes)

– Chip Erase (32 Mbits)

•

Two SRAM Data Buffers (512/528 Bytes)

– Allows Receiving of Data while Reprogramming the Flash Array

•

Continuous Read Capability through Entire Array

– Ideal for Code Shadowing Applications

•

Low-power Dissipation

– 7 mA Active Read Current Typical

– 25 µA Standby Current Typical

– 5 µA Deep Power Down Typical

•

Hardware and Software Data Protection Features

– Individual Sector

•

Sector Lockdown for Secure Code and Data Storage

– Individual Sector

•

Security: 128-byte Security Register

– 64-byte User Programmable Space

– Unique 64-byte Device Identifier

•

JEDEC Standard Manufacturer and Device ID Read

•

100,000 Program/Erase Cycles Per Page Minimum

•

Data Retention – 20 Years

•

Industrial Temperature Range

•

Green (Pb/Halide-free/RoHS Compliant) Packaging Options

32-megabit

2.7-volt

DataFlash

®

AT45DB321D

1. Description

The AT45DB321D is a 2.7-volt, serial-interface sequential access Flash memory

ideally suited for a wide variety of digital voice-, image-, program code- and data-storage applications. The AT45DB321D supports RapidS serial interface for applications

requiring very high speed operations. RapidS serial interface is SPI compatible for

frequencies up to 66 MHz. Its 34,603,008 bits of memory are organized as 8,192

pages of 512 bytes or 528 bytes each. In addition to the main memory, the

AT45DB321D also contains two SRAM buffers of 512/528 bytes each. The buffers

allow the receiving of data while a page in the main Memory is being reprogrammed,

as well as writing a continuous data stream. EEPROM emulation (bit or byte alterability) is easily handled with a self-contained three step read-modify-write operation.

Unlike conventional Flash memories that are accessed randomly with multiple

address lines and a parallel interface, the DataFlash uses a RapidS serial interface to

3597J–DFLASH–4/08

Page 2

sequentially access its data. The simple sequential access dramatically reduces active pin

count, facilitates hardware layout, increases system reliability, minimizes switching noise, and

reduces package size. The device is optimized for use in many commercial and industrial applications where high-density, low-pin count, low-voltage and low-power are essential.

To allow for simple in-system reprogrammability, the AT45DB321D does not require high input

voltages for programming. The device operates from a single power supply, 2.7V to 3.6V, for

both the program and read operations. The AT45DB321D is enabled through the chip select pin

(CS

) and accessed via a three-wire interface consisting of the Serial Input (SI), Serial Output

(SO), and the Serial Clock (SCK).

All programming and erase cycles are self-timed.

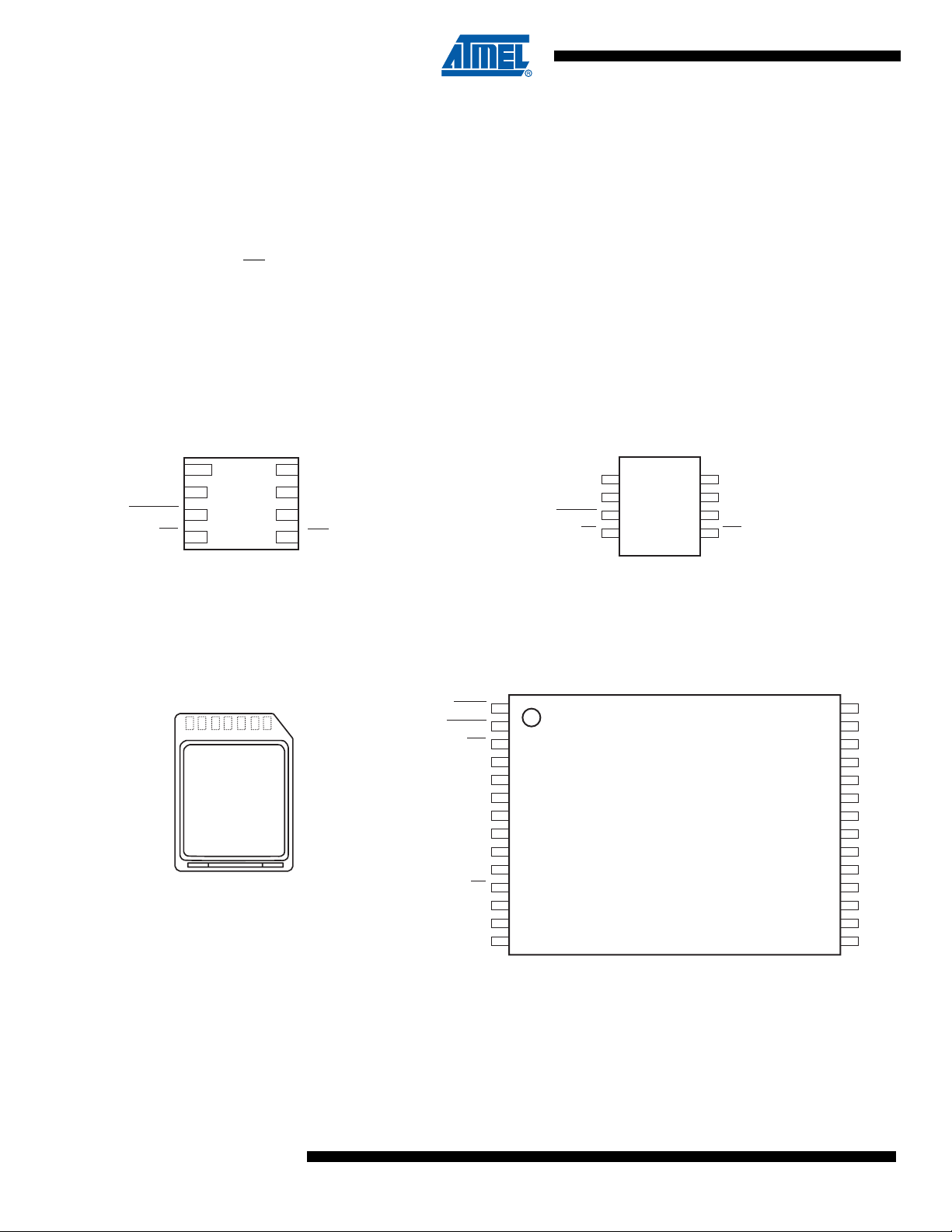

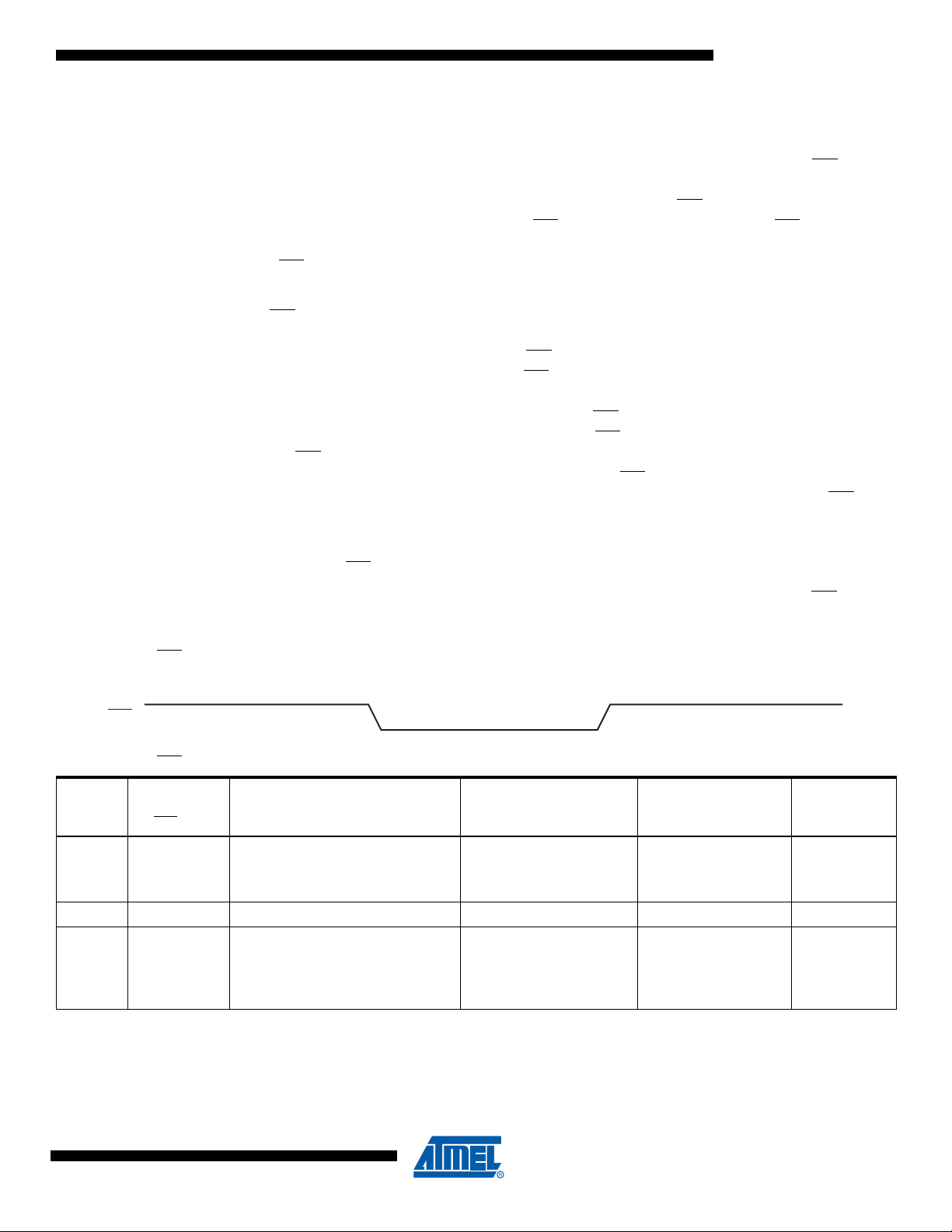

2. Pin Configurations and Pinouts

SI

CS

(1)

(VDFN) Top View

1

2

3

4

8

7

6

5

SO

GND

VCC

WP

Figure 2-1. MLF

SCK

RESET

Note: 1. The metal pad on the bottom of the MLF

package is floating. This pad can be a “No

Connect” or connected to GND.

Figure 2-3. DataFlash Card

(1)

Top View through Package

7654321

Note: 1. See AT45DCB004D Datasheet.

Figure 2-2. SOIC Top View

1

SI

CS

2

3

4

SCK

RESET

Figure 2-4. TSOP Top View: Type 1

NC

NC

NC

NC

NC

CS

SO

1

2

3

4

5

6

7

8

9

10

11

12

13

SI

14

RDY/BUSY

RESET

WP

VCC

GND

SCK

SO

8

GND

7

VCC

6

WP

5

NC

28

NC

27

NC

26

NC

25

NC

24

NC

23

NC

22

NC

21

NC

20

NC

19

NC

18

NC

17

NC

16

NC

15

Note: TSOP package is not recommended for new designs. Future die

shrinks will support 8-pin packages only.

2

AT45DB321D

3597J–DFLASH–4/08

Page 3

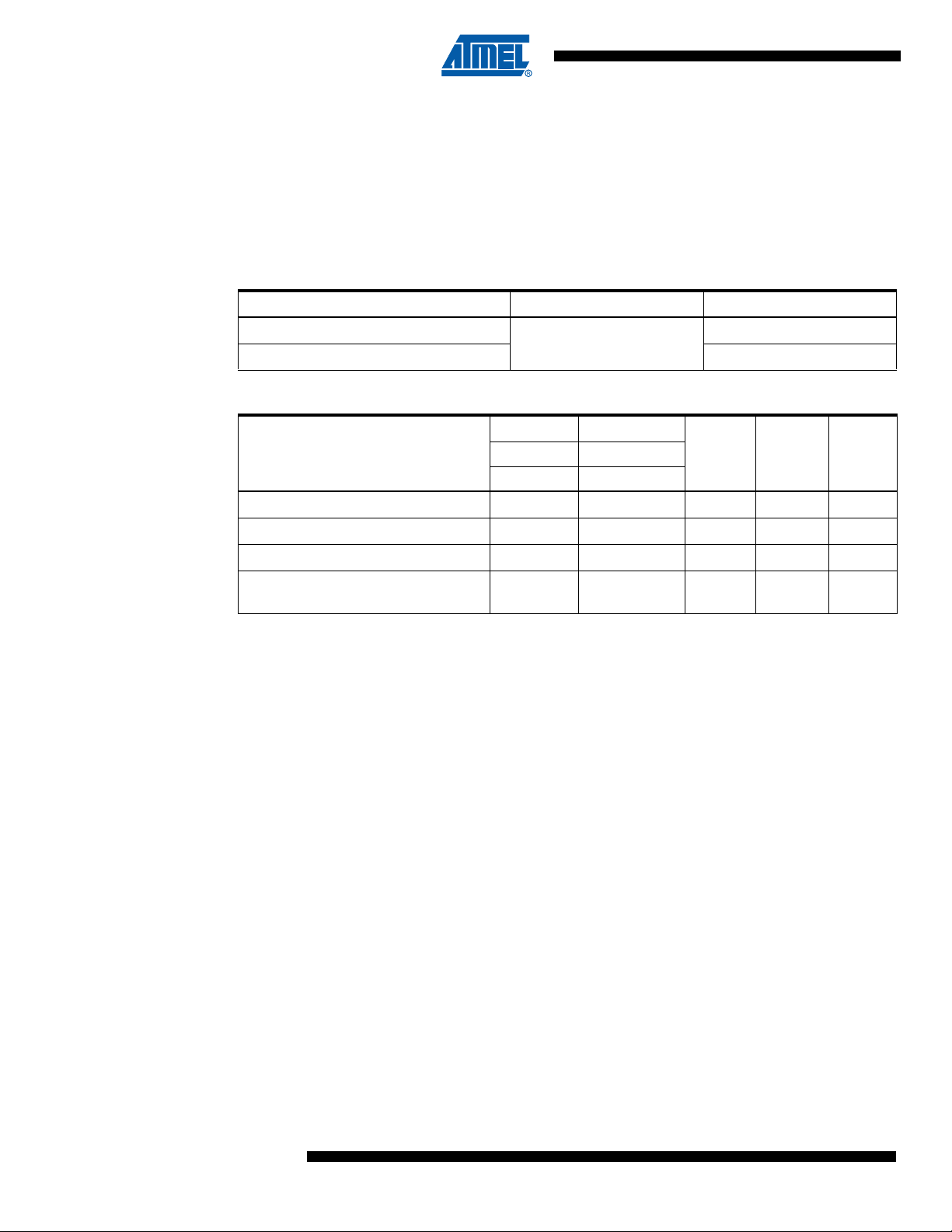

Table 2-1. Pin Configurations

Symbol Name and Function

Chip Select: Asserting the CS pin selects the device. When the CS pin is deasserted, the device

will be deselected and normally be placed in the standby mode (not Deep Power-Down mode),

and the output pin (SO) will be in a high-impedance state. When the device is deselected, data

CS

SCK

SI

SO

WP

RESET

RDY/BUSY

V

CC

GND

will not be accepted on the input pin (SI).

A high-to-low transition on the CS

transition is required to end an operation. When ending an internally self-timed operation such as

a program or erase cycle, the device will not enter the standby mode until the completion of the

operation.

Serial Clock: This pin is used to provide a clock to the device and is used to control the flow of

data to and from the device. Command, address, and input data present on the SI pin is always

latched on the rising edge of SCK, while output data on the SO pin is always clocked out on the

falling edge of SCK.

Serial Input: The SI pin is used to shift data into the device. The SI pin is used for all data input

including command and address sequences. Data on the SI pin is always latched on the rising

edge of SCK.

Serial Output: The SO pin is used to shift data out from the device. Data on the SO pin is always

clocked out on the falling edge of SCK.

Write Protect: When the WP pin is asserted, all sectors specified for protection by the Sector

Protection Register will be protected against program and erase operations regardless of whether

the Enable Sector Protection command has been issued or not. The WP

independently of the software controlled protection method. After the WP pin goes low, the

content of the Sector Protection Register cannot be modified.

If a program or erase command is issued to the device while the WP

will simply ignore the command and perform no operation. The device will return to the idle state

once the CS

Lockdown command, however, will be recognized by the device when the WP pin is asserted.

The WP

not be used. However, it is recommended that the WP pin also be externally connected to VCC

whenever possible.

Reset: A low state on the reset pin (RESET) will terminate the operation in progress and reset

the internal state machine to an idle state. The device will remain in the reset condition as long as

a low level is present on the RESET

brought back to a high level.

The device incorporates an internal power-on reset circuit, so there are no restrictions on the

RESET

that the RESET pin be driven high externally.

Ready/Busy: This open drain output pin will be driven low when the device is busy in an

internally self-timed operation. This pin, which is normally in a high state (through an external

pull-up resistor), will be pulled low during programming/erase operations, compare operations,

and page-to-buffer transfers.

The busy status indicates that the Flash memory array and one of the buffers cannot be

accessed; read and write operations to the other buffer can still be performed.

Device Power Supply: The VCC pin is used to supply the source voltage to the device.

Operations at invalid VCC voltages may produce spurious results and should not be attempted.

Ground: The ground reference for the power supply. GND should be connected to the system

ground.

pin has been deasserted. The Enable Sector Protection command and Sector

pin is internally pulled-high and may be left floating if hardware controlled protection will

pin during power-on sequences. If this pin and feature are not utilized it is recommended

pin is required to start an operation, and a low-to-high

pin functions

pin is asserted, the device

pin. Normal operation can resume once the RESET pin is

AT45DB321D

Asserted

State Type

Low Input

– Input

– Input

– Output

Low Input

Low Input

– Output

–Power

– Ground

3597J–DFLASH–4/08

3

Page 4

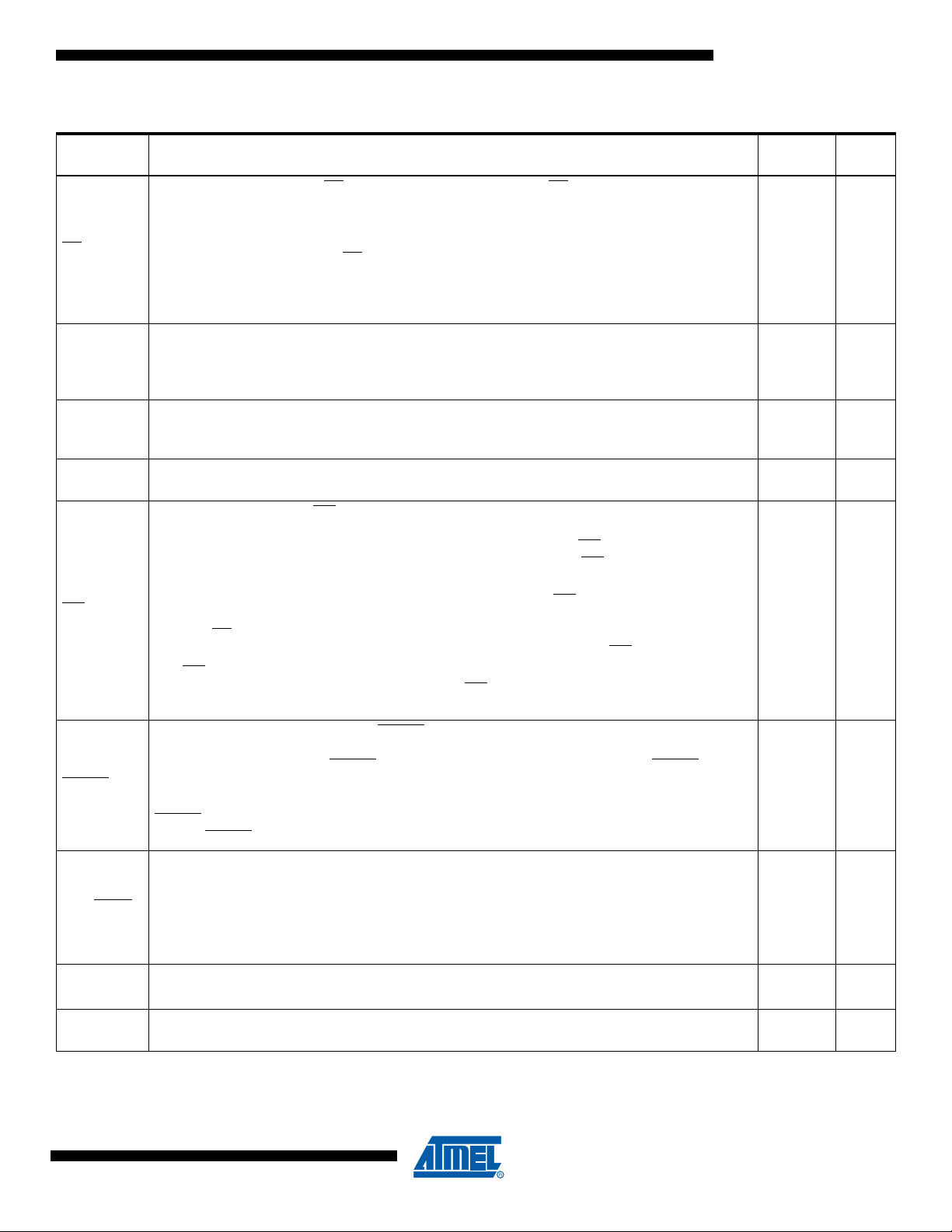

3. Block Diagram

WP

FLASH MEMORY ARRAY

PAGE (512/528 BYTES)

BUFFER 2 (512/528 BYTES)BUFFER 1 (512/528 BYTES)

SCK

CS

I/O INTERFACE

RESET

VCC

GND

RDY/BUSY

SOSI

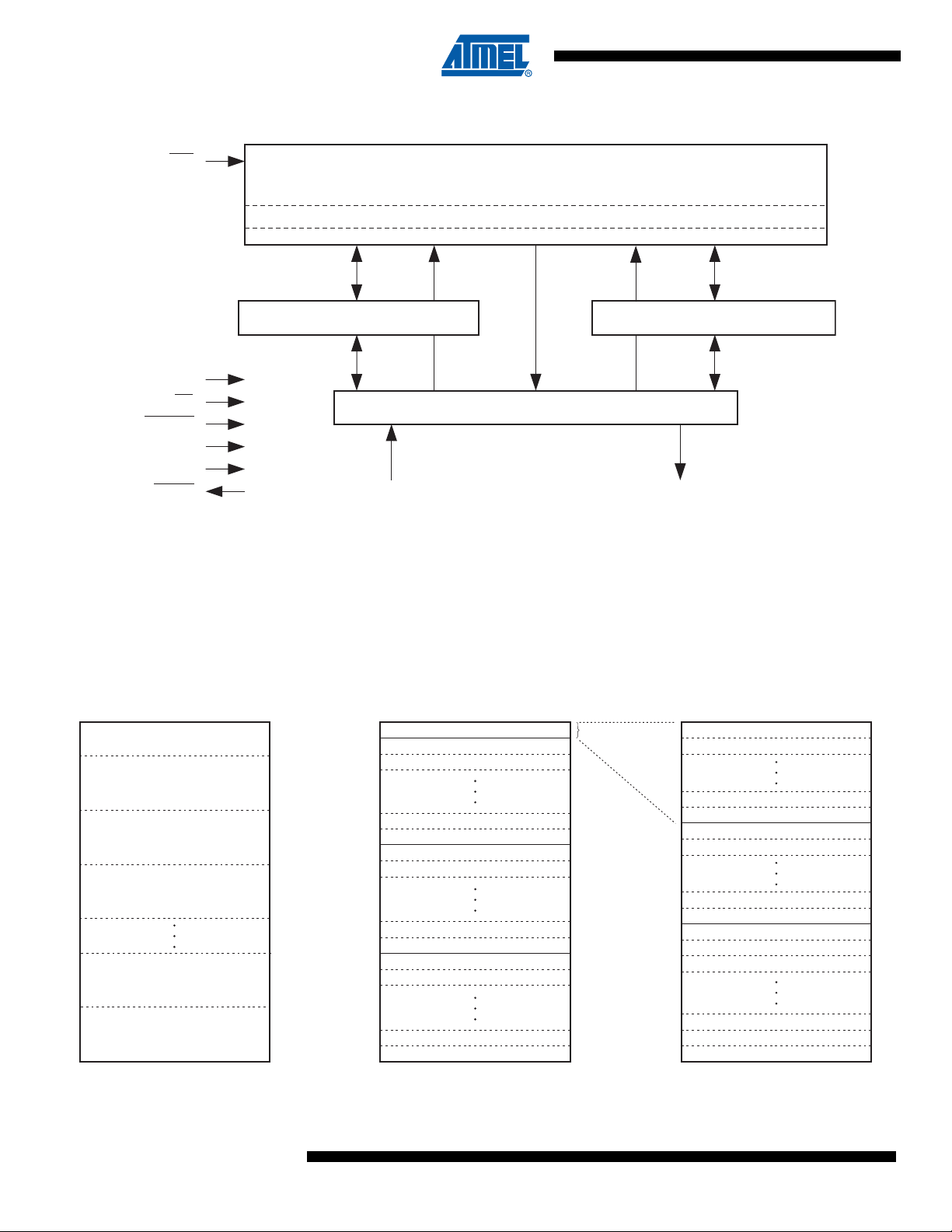

4. Memory Array

To provide optimal flexibility, the memory array of the AT45DB321D is divided into three levels of granularity comprising of

sectors, blocks, and pages. The “Memory Architecture Diagram” illustrates the breakdown of each level and details the

number of pages per sector and block. All program operations to the DataFlash occur on a page by page basis. The erase

operations can be performed at the chip, sector, block or page level.

Figure 4-1. Memory Architecture Diagram

SECTOR ARCHITECTURE BLOCK ARCHITECTURE PAGE ARCHITECTURE

SECTOR 0a = 8 Pages

4,096/4,224 bytes

SECTOR 0b = 120 Pages

61,440/63,360 bytes

SECTOR 1 = 128 Pages

65,536/67,584 bytes

SECTOR 2 = 128 Pages

65,536/67,584 bytes

SECTOR 62 = 128 Pages

65,536/67,584 bytes

SECTOR 63 = 128 Pages

65,536/67,586 bytes

SECTOR 0a

SECTOR 0b

SECTOR 1

BLOCK 126

BLOCK 127

BLOCK 128

BLOCK 129

BLOCK 1,022

BLOCK 1,023

Block = 4,096/4,224 bytes

BLOCK 0

BLOCK 1

BLOCK 2

BLOCK 62

BLOCK 63

BLOCK 64

BLOCK 65

8 Pages

BLOCK 0

BLOCK 1

PAG E 0

PAG E 1

PAG E 6

PAG E 7

PAG E 8

PAG E 9

PAGE 14

PAGE 15

PAGE 16

PAGE 17

PAG E 1 8

PAGE 8,190

PAGE 8,191

Page = 512/528 bytes

4

AT45DB321D

3597J–DFLASH–4/08

Page 5

5. Device Operation

The device operation is controlled by instructions from the host processor. The list of instructions

and their associated opcodes are contained in Table 15-1 on page 28 through Table 15-7 on

page 31. A valid instruction starts with the falling edge of CS

opcode and the desired buffer or main memory address location. While the CS

gling the SCK pin controls the loading of the opcode and the desired buffer or main memory

address location through the SI (serial input) pin. All instructions, addresses, and data are transferred with the most significant bit (MSB) first.

Buffer addressing for the DataFlash standard page size (528 bytes) is referenced in the

datasheet using the terminology BFA9 - BFA0 to denote the 10 address bits required to designate a byte address within a buffer. Main memory addressing is referenced using the

terminology PA12 - PA0 and BA9 - BA0, where PA12 - PA0 denotes the 13 address bits

required to designate a page address and BA9 - BA0 denotes the 10 address bits required to

designate a byte address within the page.

For “Power of 2” binary page size (512 bytes) the Buffer addressing is referenced in the

datasheet using the conventional terminology BFA8 - BFA0 to denote the 9 address bits

required to designate a byte address within a buffer. Main memory addressing is referenced

using the terminology A21 - A0, where A21 - A9 denotes the 13 address bits required to designate a page address and A8 - A0 denotes the 9 address bits required to designate a byte

address within a page.

AT45DB321D

followed by the appropriate 8-bit

pin is low, tog-

6. Read Commands

By specifying the appropriate opcode, data can be read from the main memory or from either

one of the two SRAM data buffers. The DataFlash supports RapidS protocols for Mode 0 and

Mode 3. Please refer to the “Detailed Bit-level Read Timing” diagrams in this datasheet for

details on the clock cycle sequences for each mode.

6.1 Continuous Array Read (Legacy Command: E8H): Up to 66 MHz

By supplying an initial starting address for the main memory array, the Continuous Array Read

command can be utilized to sequentially read a continuous stream of data from the device by

simply providing a clock signal; no additional addressing information or control signals need to

be provided. The DataFlash incorporates an internal address counter that will automatically

increment on every clock cycle, allowing one continuous read operation without the need of

additional address sequences. To perform a continuous read from the DataFlash standard page

size (528 bytes), an opcode of E8H must be clocked into the device followed by three address

bytes (which comprise the 24-bit page and byte address sequence) and 4 don’t care bytes. The

first 13 bits (PA12 - PA0) of the 23-bit address sequence specify which page of the main memory array to read, and the last 10 bits (BA9 - BA0) of the 23-bit address sequence specify the

starting byte address within the page. To perform a continuous read from the binary page size

(512 bytes), the opcode (E8H) must be clocked into the device followed by three address bytes

and 4 don’t care bytes. The first 13 bits (A21 - A9) of the 22-bits sequence specify which page of

the main memory array to read, and the last 9 bits (A8 - A0) of the 22-bits address sequence

specify the starting byte address within the page. The don’t care bytes that follow the address

bytes are needed to initialize the read operation. Following the don’t care bytes, additional clock

pulses on the SCK pin will result in data being output on the SO (serial output) pin.

3597J–DFLASH–4/08

The CS

bytes, and the reading of data. When the end of a page in main memory is reached during a

pin must remain low during the loading of the opcode, the address bytes, the don’t care

5

Page 6

Continuous Array Read, the device will continue reading at the beginning of the next page with

no delays incurred during the page boundary crossover (the crossover from the end of one page

to the beginning of the next page). When the last bit in the main memory array has been read,

the device will continue reading back at the beginning of the first page of memory. As with crossing over page boundaries, no delays will be incurred when wrapping around from the end of the

array to the beginning of the array.

A low-to-high transition on the CS

pin will terminate the read operation and tri-state the output

pin (SO). The maximum SCK frequency allowable for the Continuous Array Read is defined by

the f

specification. The Continuous Array Read bypasses both data buffers and leaves the

CAR1

contents of the buffers unchanged.

6.2 Continuous Array Read (High Frequency Mode: 0BH): Up to 66 MHz

This command can be used with the serial interface to read the main memory array sequentially

in high speed mode for any clock frequency up to the maximum specified by f

continuous read array with the page size set to 528 bytes, the CS

opcode 0BH must be clocked into the device followed by three address bytes and a dummy

byte. The first 13 bits (PA12 - PA0) of the 23-bit address sequence specify which page of the

main memory array to read, and the last 10 bits (BA9 - BA0) of the 23-bit address sequence

specify the starting byte address within the page. To perform a continuous read with the page

size set to 512 bytes, the opcode, 0BH, must be clocked into the device followed by three

address bytes (A21 - A0) and a dummy byte. Following the dummy byte, additional clock pulses

on the SCK pin will result in data being output on the SO (serial output) pin.

The CS pin must remain low during the loading of the opcode, the address bytes, and the reading of data. When the end of a page in the main memory is reached during a Continuous Array

Read, the device will continue reading at the beginning of the next page with no delays incurred

during the page boundary crossover (the crossover from the end of one page to the beginning of

the next page). When the last bit in the main memory array has been read, the device will continue reading back at the beginning of the first page of memory. As with crossing over page

boundaries, no delays will be incurred when wrapping around from the end of the array to the

beginning of the array. A low-to-high transition on the CS pin will terminate the read operation

and tri-state the output pin (SO). The maximum SCK frequency allowable for the Continuous

Array Read is defined by the f

specification. The Continuous Array Read bypasses both

CAR1

data buffers and leaves the contents of the buffers unchanged.

must first be asserted then an

. To perform a

CAR1

6.3 Continuous Array Read (Low Frequency Mode: 03H): Up to 33 MHz

This command can be used with the serial interface to read the main memory array sequentially

without a dummy byte up to maximum frequencies specified by f

read array with the page size set to 528 bytes, the CS

must first be asserted then an opcode,

03H, must be clocked into the device followed by three address bytes (which comprise the 24-bit

page and byte address sequence). The first 13 bits (PA12 - PA0) of the 23-bit address sequence

specify which page of the main memory array to read, and the last 10 bits (BA9 - BA0) of the

23-bit address sequence specify the starting byte address within the page. To perform a continuous read with the page size set to 512 bytes, the opcode, 03H, must be clocked into the device

followed by three address bytes (A21 - A0). Following the address bytes, additional clock pulses

on the SCK pin will result in data being output on the SO (serial output) pin.

The CS pin must remain low during the loading of the opcode, the address bytes, and the reading of data. When the end of a page in the main memory is reached during a Continuous Array

Read, the device will continue reading at the beginning of the next page with no delays incurred

6

AT45DB321D

CAR2

. To perform a continuous

3597J–DFLASH–4/08

Page 7

during the page boundary crossover (the crossover from the end of one page to the beginning of

the next page). When the last bit in the main memory array has been read, the device will continue reading back at the beginning of the first page of memory. As with crossing over page

boundaries, no delays will be incurred when wrapping around from the end of the array to the

beginning of the array. A low-to-high transition on the CS pin will terminate the read operation

and tri-state the output pin (SO). The Continuous Array Read bypasses both data buffers and

leaves the contents of the buffers unchanged.

6.4 Main Memory Page Read

A main memory page read allows the user to read data directly from any one of the 8,192 pages

in the main memory, bypassing both of the data buffers and leaving the contents of the buffers

unchanged. To start a page read from the DataFlash standard page size (528 bytes), an opcode

of D2H must be clocked into the device followed by three address bytes (which comprise the

24-bit page and byte address sequence) and 4 don’t care bytes. The first 13 bits (PA12 - PA0) of

the 23-bit address sequence specify the page in main memory to be read, and the last 10 bits

(BA9 - BA0) of the 23-bit address sequence specify the starting byte address within that page.

To start a page read from the binary page size (512 bytes), the opcode D2H must be

clocked into the device followed by three address bytes and 4 don’t care bytes. The first 13 bits

(A21 - A9) of the 22-bits sequence specify which page of the main memory array to read, and

the last 9 bits (A8 - A0) of the 22-bits address sequence specify the starting byte address within

the page. The don’t care bytes that follow the address bytes are sent to initialize the read operation. Following the don’t care bytes, additional pulses on SCK result in data being output on the

SO (serial output) pin. The CS

address bytes, the don’t care bytes, and the reading of data. When the end of a page in

main memory is reached, the device will continue reading back at the beginning of the same

page. A low-to-high transition on the CS

output pin (SO). The maximum SCK frequency allowable for the Main Memory Page Read is

defined by the f

leaves the contents of the buffers unchanged.

AT45DB321D

pin must remain low during the loading of the opcode, the

pin will terminate the read operation and tri-state the

specification. The Main Memory Page Read bypasses both data buffers and

SCK

6.5 Buffer Read

3597J–DFLASH–4/08

The SRAM data buffers can be accessed independently from the main memory array, and utilizing the Buffer Read Command allows data to be sequentially read directly from the buffers. Four

opcodes, D4H or D1H for buffer 1 and D6H or D3H for buffer 2 can be used for the Buffer Read

Command. The use of each opcode depends on the maximum SCK frequency that will be used

to read data from the buffer. The D4H and D6H opcode can be used at any SCK frequency up to

the maximum specified by f

read operations up to the maximum specified by f

To perform a buffer read from the DataFlash standard buffer (528 bytes), the opcode must be

clocked into the device followed by three address bytes comprised of 14 don’t care bits and

10 buffer address bits (BFA9 - BFA0). To perform a buffer read from the binary buffer

(512 bytes), the opcode must be clocked into the device followed by three address bytes comprised of 15 don’t care bits and 9 buffer address bits (BFA8 - BFA0). Following the address

bytes, one don’t care byte must be clocked in to initialize the read operation. The CS

remain low during the loading of the opcode, the address bytes, the don’t care byte, and the

reading of data. When the end of a buffer is reached, the device will continue reading back at the

beginning of the buffer. A low-to-high transition on the CS

and tri-state the output pin (SO).

. The D1H and D3H opcode can be used for lower frequency

CAR1

.

CAR2

pin will terminate the read operation

pin must

7

Page 8

7. Program and Erase Commands

7.1 Buffer Write

Data can be clocked in from the input pin (SI) into either buffer 1 or buffer 2. To load data into the

DataFlash standard buffer (528 bytes), a 1-byte opcode, 84H for buffer 1 or 87H for buffer 2,

must be clocked into the device, followed by three address bytes comprised of 14 don’t care bits

and 10 buffer address bits (BFA9 - BFA0). The 10 buffer address bits specify the first byte in the

buffer to be written. To load data into the binary buffers (512 bytes each), a 1-byte opcode 84H

for buffer 1 or 87H for buffer 2, must be clocked into the device, followed by three address bytes

comprised of 15 don’t care bits and 9 buffer address bits (BFA8 - BFA0). The 9 buffer address

bits specify the first byte in the buffer to be written. After the last address byte has been clocked

into the device, data can then be clocked in on subsequent clock cycles. If the end of the data

buffer is reached, the device will wrap around back to the beginning of the buffer. Data will continue to be loaded into the buffer until a low-to-high transition is detected on the CS

7.2 Buffer to Main Memory Page Program with Built-in Erase

Data written into either buffer 1 or buffer 2 can be programmed into the main memory. A 1-byte

opcode, 83H for buffer 1 or 86H for buffer 2, must be clocked into the device. For the DataFlash

standard page size (528 bytes), the opcode must be followed by three address bytes consist of

1 don’t care bit, 13 page address bits (PA12 - PA0) that specify the page in the main memory to

be written and 10 don’t care bits. To perform a buffer to main memory page program with built-in

erase for the binary page size (512 bytes), the opcode 83H for buffer 1 or 86H for buffer 2, must

be clocked into the device followed by three address bytes consisting of 2 don’t care bits

13-page address bits (A21 - A9) that specify the page in the main memory to be written and

9 don’t care bits. When a low-to-high transition occurs on the CS

selected page in main memory (the erased state is a logic 1) and then program the data stored

in the buffer into the specified page in main memory. Both the erase and the programming of the

page are internally self-timed and should take place in a maximum time of t

the status register and the RDY/BUSY

pin will indicate that the part is busy.

pin.

pin, the part will first erase the

. During this time,

EP

7.3 Buffer to Main Memory Page Program without Built-in Erase

A previously-erased page within main memory can be programmed with the contents of either

buffer 1 or buffer 2. A 1-byte opcode, 88H for buffer 1 or 89H for buffer 2, must be clocked into

the device. For the DataFlash standard page size (528 bytes), the opcode must be followed by

three address bytes consist of 1 don’t care bit, 13 page address bits (PA12 - PA0) that specify

the page in the main memory to be written and 10 don’t care bits. To perform a buffer to main

memory page program without built-in erase for the binary page size (512 bytes), the opcode

88H for buffer 1 or 89H for buffer 2, must be clocked into the device followed by three address

bytes consisting of 2 don’t care bits, 13 page address bits (A21 - A9) that specify the page in the

main memory to be written and 9 don’t care bits. When a low-to-high transition occurs on the CS

pin, the part will program the data stored in the buffer into the specified page in the main memory. It is necessary that the page in main memory that is being programmed has been previously

erased using one of the erase commands (Page Erase or Block Erase). The programming of the

page is internally self-timed and should take place in a maximum time of t

status register and the RDY/BUSY

8

AT45DB321D

pin will indicate that the part is busy.

. During this time, the

P

3597J–DFLASH–4/08

Page 9

7.4 Page Erase

7.5 Block Erase

AT45DB321D

The Page Erase command can be used to individually erase any page in the main memory array

allowing the Buffer to Main Memory Page Program to be utilized at a later time. To perform a

page erase in the DataFlash standard page size (528 bytes), an opcode of 81H must be loaded

into the device, followed by three address bytes comprised of 1 don’t care bit, 13 page address

bits (PA12 - PA0) that specify the page in the main memory to be erased and 10 don’t care bits.

To perform a page erase in the binary page size (512 bytes), the opcode 81H must be loaded

into the device, followed by three address bytes consist of 2 don’t care bits, 13 page address bits

(A21 - A9) that specify the page in the main memory to be erased and 9 don’t care bits. When a

low-to-high transition occurs on the CS

state is a logical 1). The erase operation is internally self-timed and should take place in a maximum time of t

. During this time, the status register and the RDY/BUSY pin will indicate that the

PE

part is busy.

A block of eight pages can be erased at one time. This command is useful when large amounts

of data has to be written into the device. This will avoid using multiple Page Erase Commands.

To perform a block erase for the DataFlash standard page size (528 bytes), an opcode of 50H

must be loaded into the device, followed by three address bytes comprised of 1 don’t care bit,

10 page address bits (PA12 -PA3) and 13 don’t care bits. The 10 page address bits are used to

specify which block of eight pages is to be erased. To perform a block erase for the binary page

size (512 bytes), the opcode 50H must be loaded into the device, followed by three address

bytes consisting of 2 don’t care bits, 10 page address bits (A21 - A12) and 12 don’t care bits.

The 10 page address bits are used to specify which block of eight pages is to be erased. When

a low-to-high transition occurs on the CS

pages. The erase operation is internally self-timed and should take place in a maximum time of

t

. During this time, the status register and the RDY/BUSY pin will indicate that the part is busy.

BE

pin, the part will erase the selected page (the erased

pin, the part will erase the selected block of eight

Table 7-1. Block Erase Addressing

PA1 2/

A21

3597J–DFLASH–4/08

PA1 1/

A20

0000000000XXX 0

0000000001XXX 1

0000000010XXX 2

0000000011XXX 3

•

•

•

1111111100XXX1020

1111111101XXX1021

1111111110XXX1022

1111111111XXX1023

PA10/

A19

•

•

•

•

•

•

PA9 /

A18

•

•

•

PA8 /

A17

•

•

•

PA 7/

A16

•

•

•

PA6 /

A15

•

•

•

PA5 /

A14

•

•

•

PA4 /

A13

•

•

•

PA3 /

A12

•

•

•

PA2 /

A11

•

•

•

PA1 /

A10

•

•

•

PA0 /

A9 Block

•

•

•

•

•

•

9

Page 10

7.6 Sector Erase

The Sector Erase command can be used to individually erase any sector in the main memory.

There are 64 sectors and only one sector can be erased at one time. To perform sector 0a or

sector 0b erase for the DataFlash standard page size (528 bytes), an opcode of 7CH must be

loaded into the device, followed by three address bytes comprised of 1 don’t care bit, 10 page

address bits (PA12 - PA3) and 13 don’t care bits. To perform a sector 1-63 erase, the opcode

7CH must be loaded into the device, followed by three address bytes comprised of 1 don’t

care bit, 4 page address bits (PA12 - PA9) and 19 don’t care bits. To perform sector 0a or sector

0b erase for the binary page size (512 bytes), an opcode of 7CH must be loaded into the

device, followed by three address bytes comprised of 2 don’t care bit and 10 page address bits

(A21 - A12) and 12 don’t care bits. To perform a sector 1-63 erase, the opcode 7CH must be

loaded into the device, followed by three address bytes comprised of 2 don’t care bits and

4 page address bits (A21 - A18) and 18 don’t care bits. The page address bits are used to specify any valid address location within the sector which is to be erased. When a low-to-high

transition occurs on the CS

internally self-timed and should take place in a maximum time of t

register and the RDY/BUSY

Table 7-2. Sector Erase Addressing

pin, the part will erase the selected sector. The erase operation is

. During this time, the status

SE

pin will indicate that the part is busy.

PA12/

A21

7.7 Chip Erase

PA11/

A20

0000000000XXX 0a

0000000001XXX 0b

000001XXXXXXX 1

000010XXXXXXX 2

•

•

•

111100XXXXXXX 60

111101XXXXXXX 61

111110XXXXXXX 62

111111XXXXXXX 63

PA1 0/

A19

•

•

•

PA9 /

A18

•

•

•

(1)

PA 8/

A17

•

•

•

PA7 /

A16

•

•

•

PA6 /

A15

•

•

•

PA5 /

A14

•

•

•

PA4 /

A13

•

•

•

PA 3/

A12

•

•

•

PA2 /

A11

•

•

•

PA1 /

A10

•

•

•

PA0 /

A9 Sector

•

•

•

•

•

•

The entire main memory can be erased at one time by using the Chip Erase command.

To execute the Chip Erase command, a 4-byte command sequence C7H, 94H, 80H and 9AH

must be clocked into the device. Since the entire memory array is to be erased, no address

bytes need to be clocked into the device, and any data clocked in after the opcode will be

ignored. After the last bit of the opcode sequence has been clocked in, the CS

pin can be deasserted to start the erase process. The erase operation is internally self-timed and should take

place in a time of t

. During this time, the Status Register will indicate that the device is busy.

CE

The Chip Erase command will not affect sectors that are protected or locked down; the contents

of those sectors will remain unchanged. Only those sectors that are not protected or locked

down will be erased.

•

•

•

10

Note: 1. Refer to the errata regarding Chip Erase on page 53.

AT45DB321D

3597J–DFLASH–4/08

Page 11

AT45DB321D

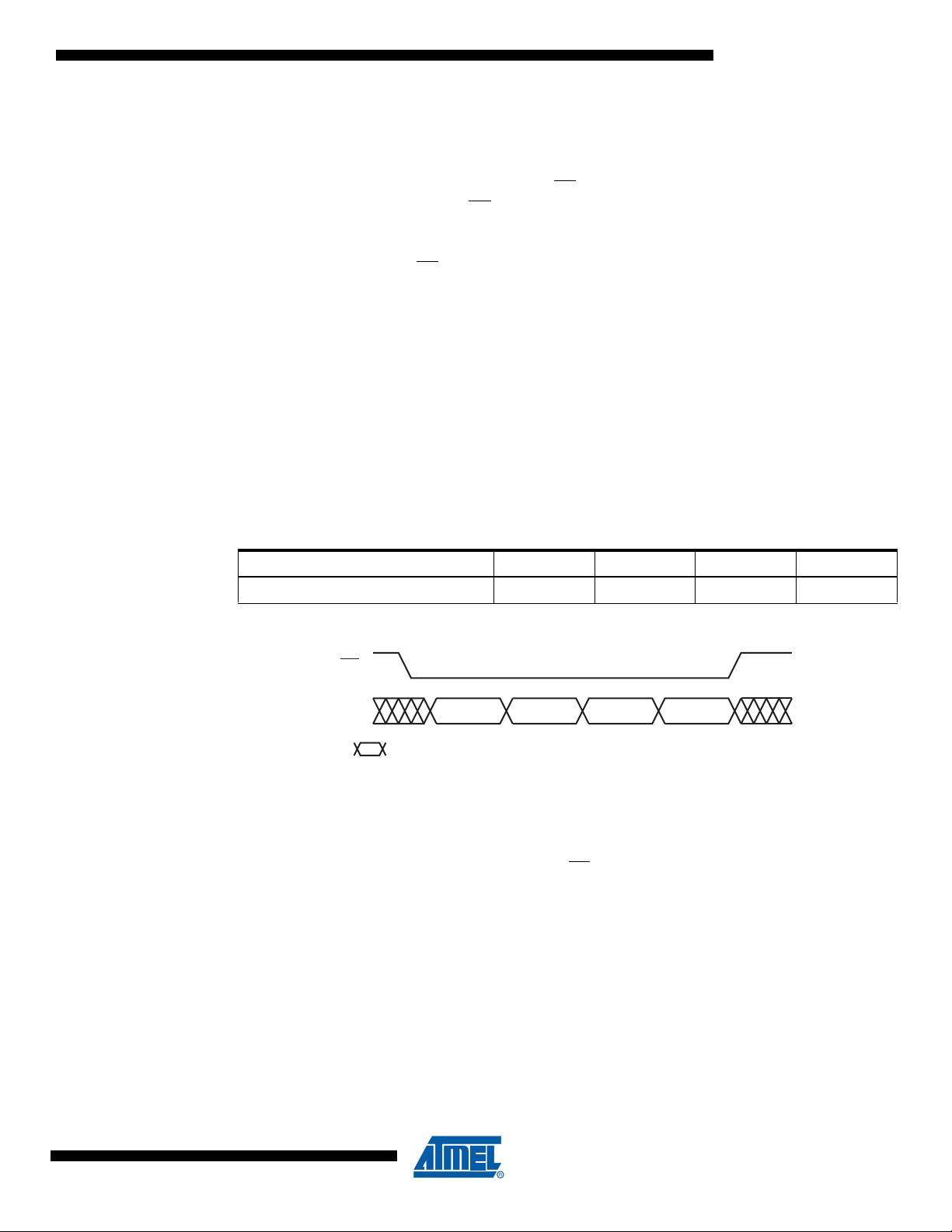

The WP pin can be asserted while the device is erasing, but protection will not be activated until

the internal erase cycle completes.

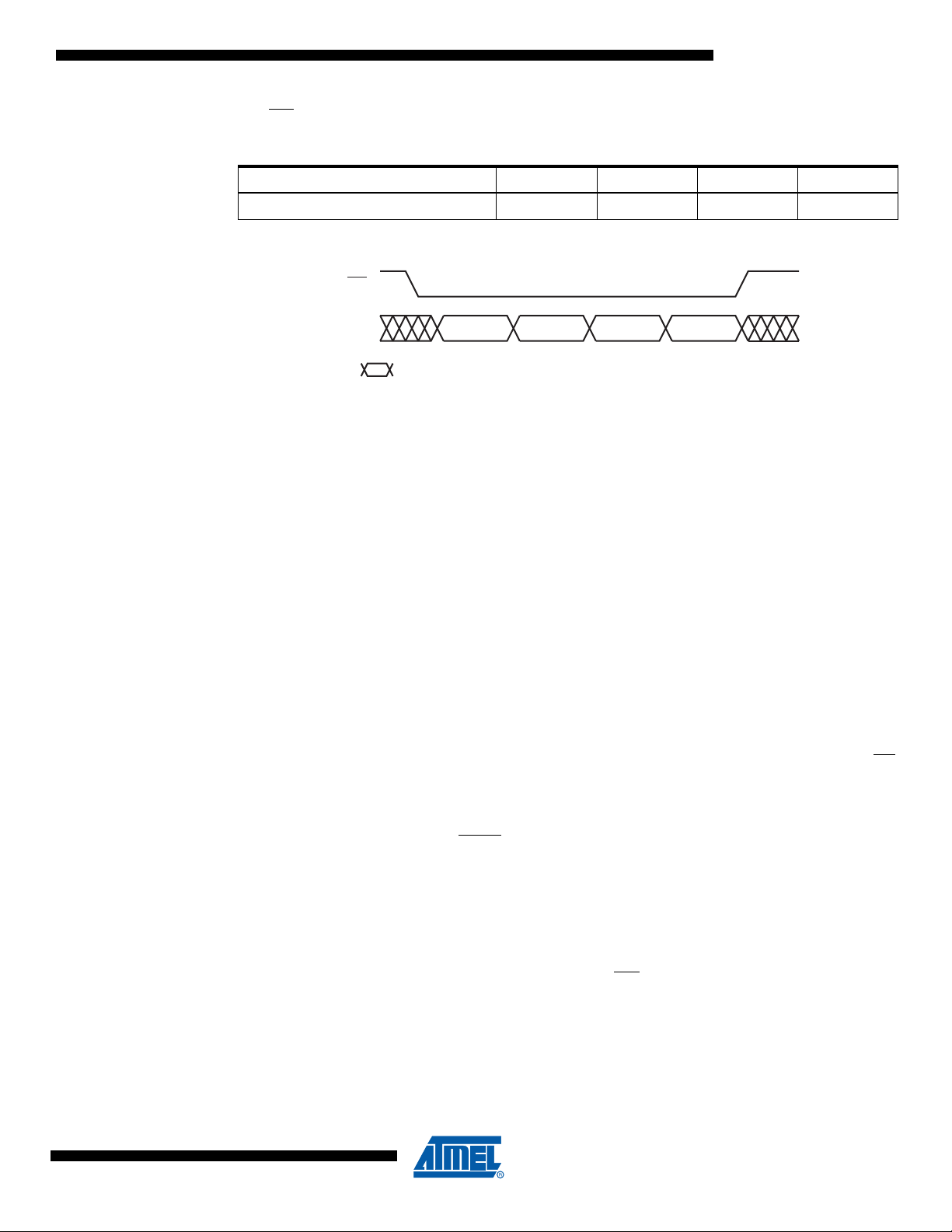

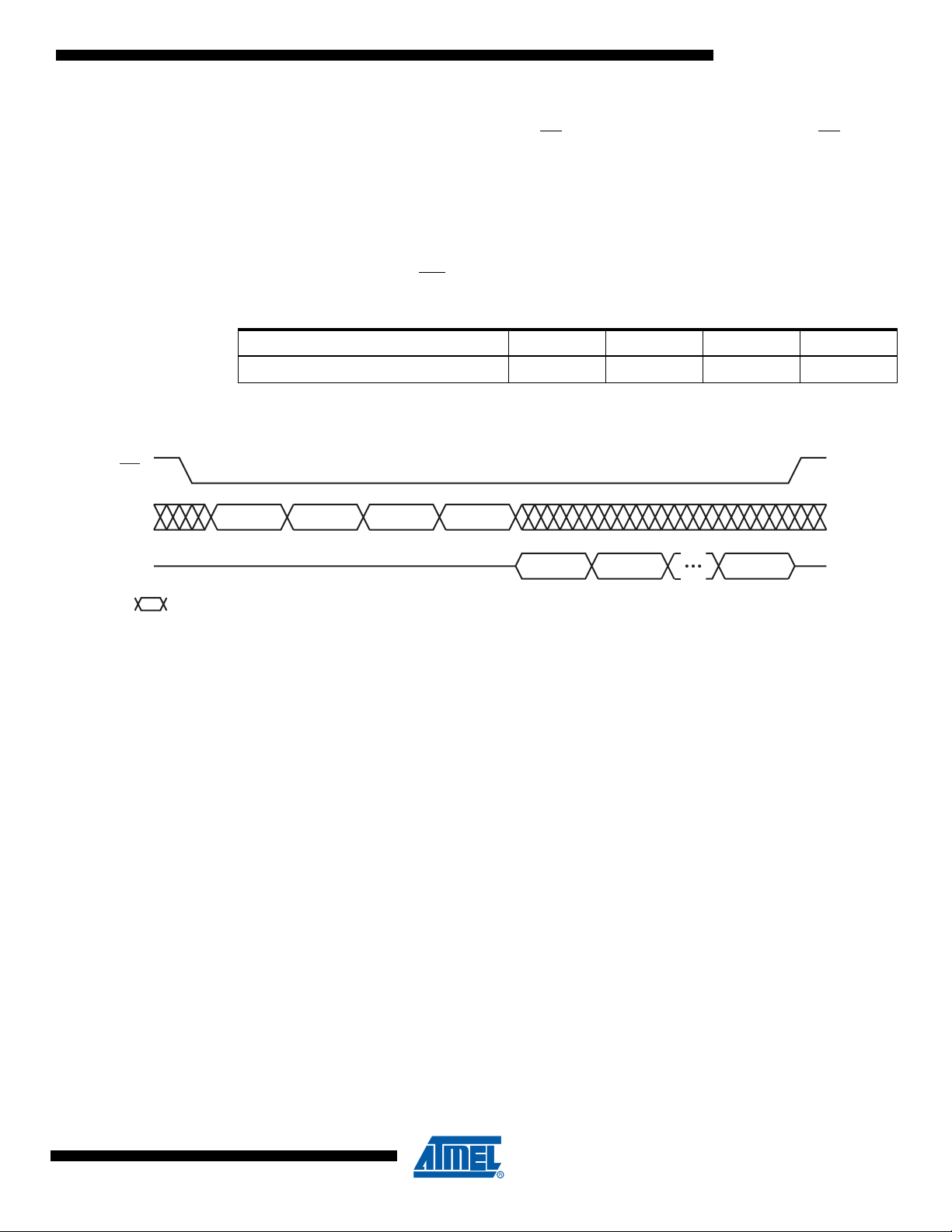

Command Byte 1 Byte 2 Byte 3 Byte 4

Chip Erase C7H 94H 80H 9AH

Figure 7-1. Chip Erase

CS

SI

Each transition

represents 8 bits

Note: 1. Refer to the errata regarding Chip Erase on page 53.

Opcode

Byte 1

7.8 Main Memory Page Program Through Buffer

This operation is a combination of the Buffer Write and Buffer to Main Memory Page Program

with Built-in Erase operations. Data is first clocked into buffer 1 or buffer 2 from the input pin (SI)

and then programmed into a specified page in the main memory. To perform a main memory

page program through buffer for the DataFlash standard page size (528 bytes), a 1-byte opcode,

82H for buffer 1 or 85H for buffer 2, must first be clocked into the device, followed by three

address bytes. The address bytes are comprised of 1 don’t care bit, 13 page address bits,

(PA12 - PA0) that select the page in the main memory where data is to be written, and 10 buffer

address bits (BFA9 - BFA0) that select the first byte in the buffer to be written. To perform a

main memory page program through buffer for the binary page size (512 bytes), the opcode 82H

for buffer 1 or 85H for buffer 2, must be clocked into the device followed by three address bytes

consisting of 2 don’t care bits, 13 page address bits (A21 - A9) that specify the page in the main

memory to be written, and 9 buffer address bits (BFA8 - BFA0) that selects the first byte in the

buffer to be written. After all address bytes are clocked in, the part will take data from the input

pins and store it in the specified data buffer. If the end of the buffer is reached, the device will

wrap around back to the beginning of the buffer. When there is a low-to-high transition on the CS

pin, the part will first erase the selected page in main memory to all 1s and then program the

data stored in the buffer into that memory page. Both the erase and the programming of the

page are internally self-timed and should take place in a maximum time of t

the status register and the RDY/BUSY

Opcode

Byte 2

Opcode

Byte 3

Opcode

Byte 4

pin will indicate that the part is busy.

. During this time,

EP

8. Sector Protection

Two protection methods, hardware and software controlled, are provided for protection against

inadvertent or erroneous program and erase cycles. The software controlled method relies on

the use of software commands to enable and disable sector protection while the hardware controlled method employs the use of the Write Protect (WP

that are to be protected or unprotected against program and erase operations is specified in the

nonvolatile Sector Protection Register. The status of whether or not sector protection has been

enabled or disabled by either the software or the hardware controlled methods can be determined by checking the Status Register.

3597J–DFLASH–4/08

) pin. The selection of which sectors

11

Page 12

8.1 Software Sector Protection

8.1.1 Enable Sector Protection Command

Sectors specified for protection in the Sector Protection Register can be protected from program

and erase operations by issuing the Enable Sector Protection command. To enable the sector

protection using the software controlled method, the CS

with any other command. Once the CS

sequence must be clocked in via the input pin (SI). After the last bit of the command sequence

has been clocked in, the CS

enabled.

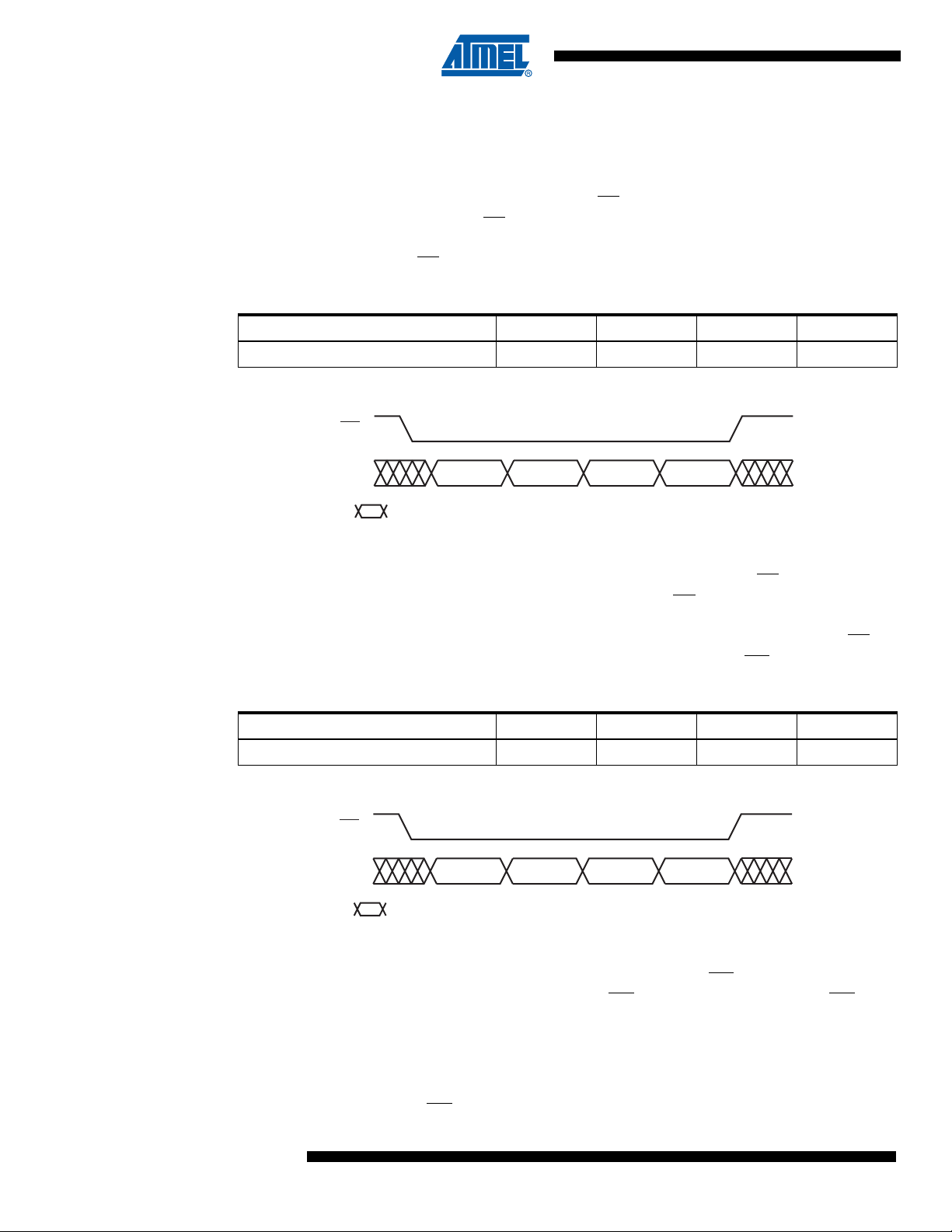

Command Byte 1 Byte 2 Byte 3 Byte 4

Enable Sector Protection 3DH 2AH 7FH A9H

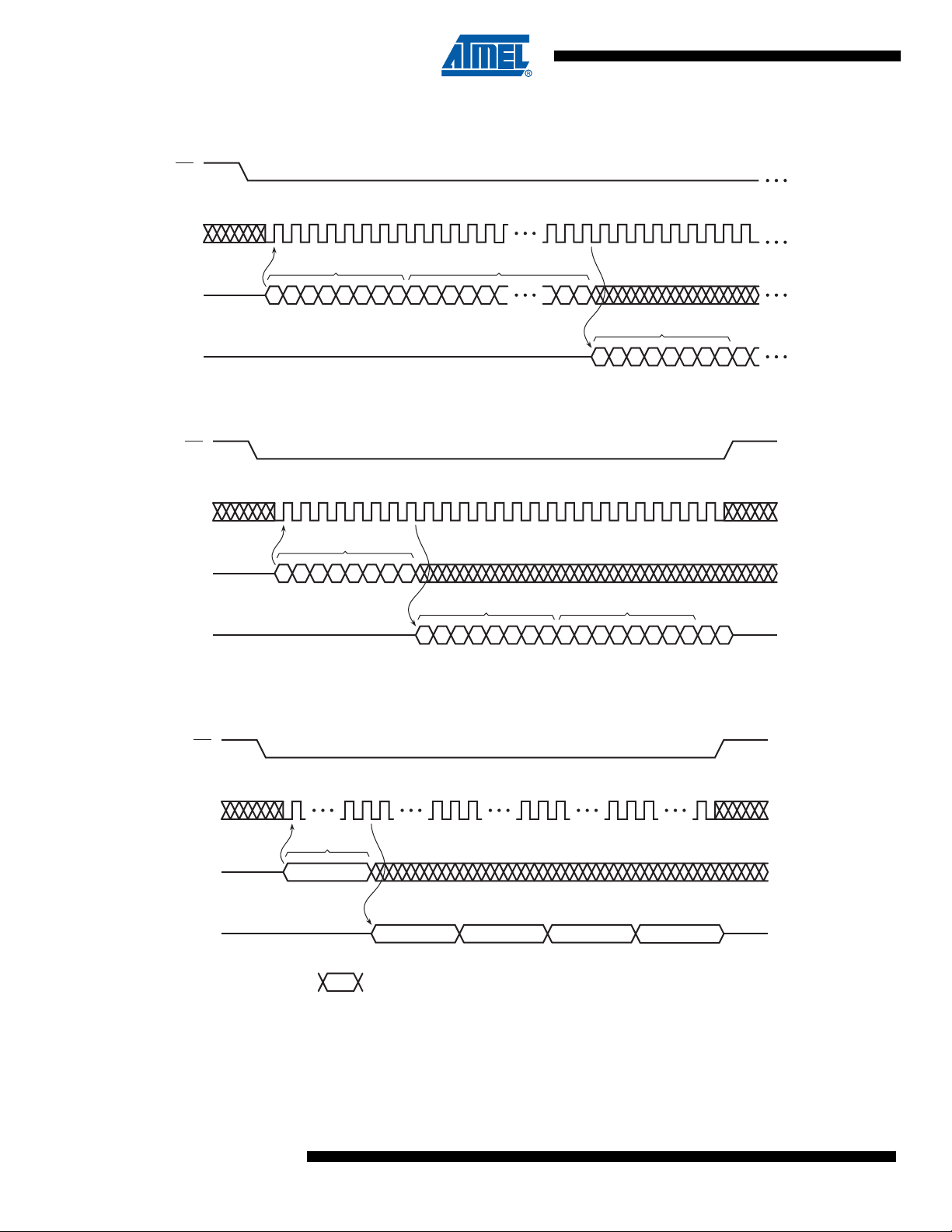

Figure 8-1. Enable Sector Protection

CS

pin must first be asserted as it would be

pin has been asserted, the appropriate 4-byte command

pin must be deasserted after which the sector protection will be

SI

8.1.2 Disable Sector Protection Command

To disable the sector protection using the software controlled method, the CS

asserted as it would be with any other command. Once the CS

appropriate 4-byte sequence for the Disable Sector Protection command must be clocked in via

the input pin (SI). After the last bit of the command sequence has been clocked in, the CS

must be deasserted after which the sector protection will be disabled. The WP

deasserted state; otherwise, the Disable Sector Protection command will be ignored.

Command Byte 1 Byte 2 Byte 3 Byte 4

Disable Sector Protection 3DH 2AH 7FH 9AH

Figure 8-2. Disable Sector Protection

CS

SI

Opcode

Byte 1

Each transition

represents 8 bits

Opcode

Byte 1

Each transition

represents 8 bits

Opcode

Byte 2

Opcode

Byte 2

Opcode

Byte 3

Opcode

Byte 3

Opcode

Byte 4

pin must first be

pin has been asserted, the

pin must be in the

Opcode

Byte 4

pin

8.1.3 Various Aspects About Software Controlled Protection

Software controlled protection is useful in applications in which the WP

controlled by a host processor. In such instances, the WP

internally pulled high) and sector protection can be controlled using the Enable Sector Protection

and Disable Sector Protection commands.

If the device is power cycled, then the software controlled protection will be disabled. Once the

device is powered up, the Enable Sector Protection command should be reissued if sector pro-

12

tection is desired and if the WP

AT45DB321D

pin is not used.

pin is not or cannot be

pin may be left floating (the WP pin is

3597J–DFLASH–4/08

Page 13

9. Hardware Controlled Protection

Sectors specified for protection in the Sector Protection Register and the Sector Protection Register itself can be protected from program and erase operations by asserting the WP

keeping the pin in its asserted state. The Sector Protection Register and any sector specified for

protection cannot be erased or reprogrammed as long as the WP

modify the Sector Protection Register, the WP

nently connected to GND, then the content of the Sector Protection Register cannot be changed.

If the WP

Protection Register can be modified.

pin is deasserted, or permanently connected to VCC, then the content of the Sector

AT45DB321D

pin and

pin is asserted. In order to

pin must be deasserted. If the WP pin is perma-

The WP

pin will override the software controlled protection method but only for protecting the

sectors. For example, if the sectors were not previously protected by the Enable Sector Protection command, then simply asserting the WP

maximum specified t

time. When the WP pin is deasserted; however, the sector protection

WPE

would no longer be enabled (after the maximum specified t

tor Protection command was not issued while the WP

Protection command was issued before or while the WP

ing the WP

pin would not disable the sector protection. In this case, the Disable Sector

Protection command would need to be issued while the WP

pin would enable the sector protection within the

time) as long as the Enable Sec-

WPD

pin was asserted. If the Enable Sector

pin was asserted, then simply deassert-

pin is deasserted to disable the sector protection. The Disable Sector Protection command is also ignored whenever the WP

asserted.

A noise filter is incorporated to help protect against spurious noise that may inadvertently assert

or deassert the WP

pin.

The table below details the sector protection status for various scenarios of the WP

Enable Sector Protection command, and the Disable Sector Protection command.

Figure 9-1. WP

Pin and Protection Status

12

3

WP

Table 9-1. WP Pin and Protection Status

Time

Period WP Pin

1High

2 Low X X Enabled Read Only

3High

Enable Sector Protection

Command

Command Not Issued Previously

–

Issue Command

Command Issued During Period 1

or 2

–

Issue Command

Disable Sector

Protection Command

X

Issue Command

–

Not Issued Yet

Issue Command

–

Sector Protection

Status

Disabled

Disabled

Enabled

Enabled

Disabled

Enabled

pin is

pin, the

Sector

Protection

Register

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

3597J–DFLASH–4/08

13

Page 14

9.1 Sector Protection Register

The nonvolatile Sector Protection Register specifies which sectors are to be protected or unprotected with either the software or hardware controlled protection methods. The Sector Protection

Register contains 64 bytes of data, of which byte locations 0 through 63 contain values that

specify whether sectors 0 through 63 will be protected or unprotected. The Sector Protection

Register is user modifiable and must first be erased before it can be reprogrammed. Table 9-3

illustrates the format of the Sector Protection Register.:

Table 9-2. Sector Protection Register

Sector Number 0 (0a, 0b) 1 to 63

Protected

Unprotected 00H

Table 9-3. Sector 0 (0a, 0b)

Sectors 0a, 0b Unprotected 00 00 xx xx 0xH

Protect Sector 0a (Pages 0-7) 11 00 xx xx CxH

Protect Sector 0b (Pages 8-127) 00 11 xx xx 3xH

See Table 9-3

0a 0b

(Pages 0-7) (Pages 8-127)

Bit 7, 6 Bit 5, 4 Bit 1, 0

Bit 3, 2

FFH

Data

Val ue

Protect Sectors 0a (Pages 0-7), 0b

(Pages 8-127)

Note: 1. The default value for bytes 0 through 63 when shipped from Atmel is 00H.

(1)

x = don’t care.

11 11 xx xx FxH

14

AT45DB321D

3597J–DFLASH–4/08

Page 15

9.1.1 Erase Sector Protection Register Command

In order to modify and change the values of the Sector Protection Register, it must first be

erased using the Erase Sector Protection Register command.

AT45DB321D

To erase the Sector Protection Register, the CS

any other command. Once the CS

pin has been asserted, the appropriate 4-byte opcode

pin must first be asserted as it would be with

sequence must be clocked into the device via the SI pin. The 4-byte opcode sequence must

start with 3DH and be followed by 2AH, 7FH, and CFH. After the last bit of the opcode sequence

has been clocked in, the CS

cycle. The erasing of the Sector Protection Register should take place in a time of t

pin must be deasserted to initiate the internally self-timed erase

, during

PE

which time the Status Register will indicate that the device is busy. If the device is powereddown before the completion of the erase cycle, then the contents of the Sector Protection Register cannot be guaranteed.

The Sector Protection Register can be erased with the sector protection enabled or disabled.

Since the erased state (FFH) of each byte in the Sector Protection Register is used to indicate

that a sector is specified for protection, leaving the sector protection enabled during the erasing

of the register allows the protection scheme to be more effective in the prevention of accidental

programming or erasing of the device. If for some reason an erroneous program or erase command is sent to the device immediately after erasing the Sector Protection Register and before

the register can be reprogrammed, then the erroneous program or erase command will not be

processed because all sectors would be protected.

Command Byte 1 Byte 2 Byte 3 Byte 4

Erase Sector Protection Register 3DH 2AH 7FH CFH

Figure 9-2. Erase Sector Protection Register

CS

SI

Each transition

represents 8 bits

Opcode

Byte 1

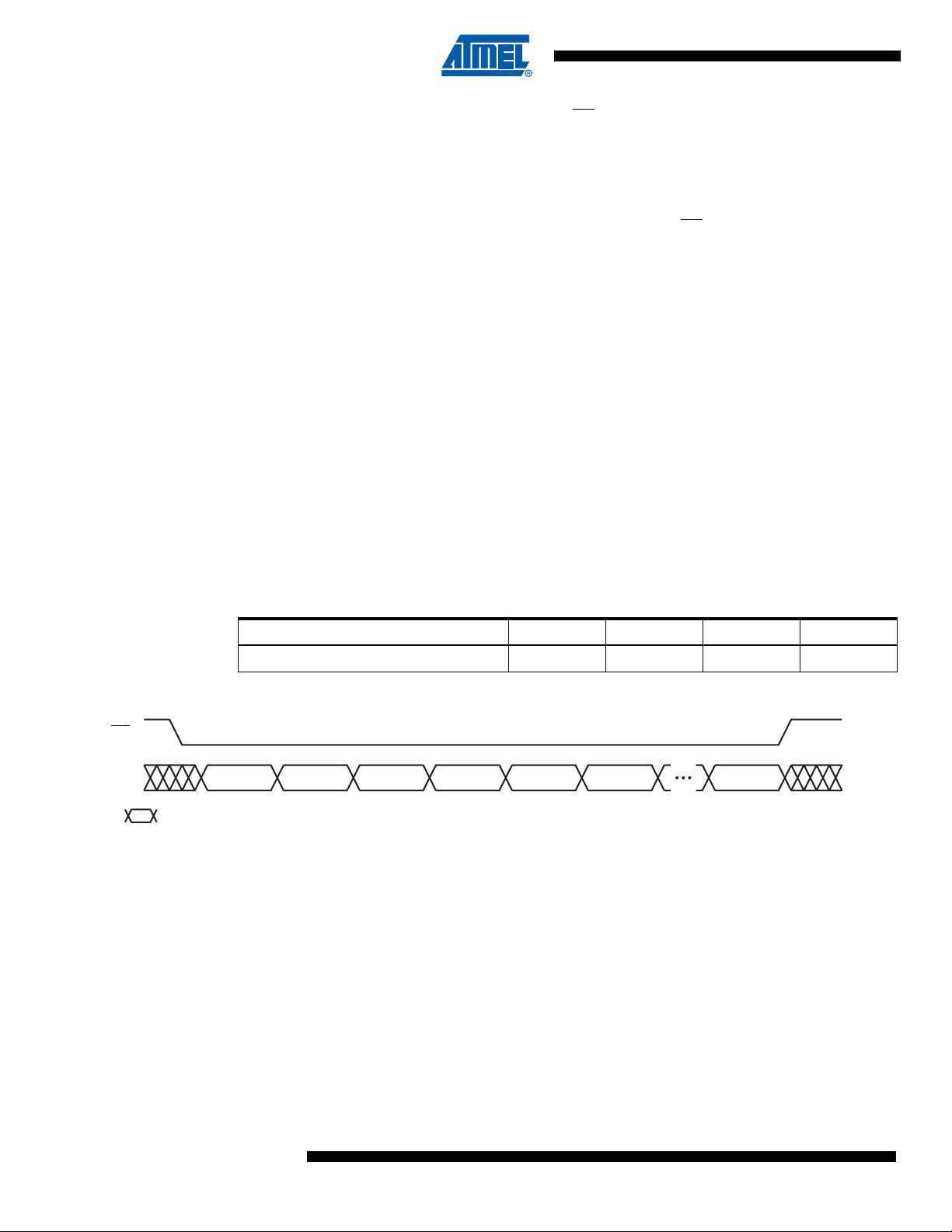

9.1.2 Program Sector Protection Register Command

Once the Sector Protection Register has been erased, it can be reprogrammed using the Program Sector Protection Register command.

To program the Sector Protection Register, the CS

ate 4-byte opcode sequence must be clocked into the device via the SI pin. The 4-byte opcode

sequence must start with 3DH and be followed by 2AH, 7FH, and FCH. After the last bit of the

opcode sequence has been clocked into the device, the data for the contents of the Sector Protection Register must be clocked in. As described in Section 9.1, the Sector Protection Register

contains 64 bytes of data, so 64 bytes must be clocked into the device. The first byte of data corresponds to sector 0, the second byte corresponds to sector 1, and so on with the last byte of

data corresponding to sector 63.

Opcode

Byte 2

Opcode

Byte 3

Opcode

Byte 4

pin must first be asserted and the appropri-

3597J–DFLASH–4/08

15

Page 16

After the last data byte has been clocked in, the CS pin must be deasserted to initiate the internally self-timed program cycle. The programming of the Sector Protection Register should take

place in a time of t

, during which time the Status Register will indicate that the device is busy. If

P

the device is powered-down during the program cycle, then the contents of the Sector Protection

Register cannot be guaranteed.

If the proper number of data bytes is not clocked in before the CS

pin is deasserted, then the

protection status of the sectors corresponding to the bytes not clocked in can not be guaranteed.

For example, if only the first two bytes are clocked in instead of the complete 62 bytes, then the

protection status of the last 62 sectors cannot be guaranteed. Furthermore, if more than

64 bytes of data is clocked into the device, then the data will wrap back around to the beginning

of the register. For instance, if 65 bytes of data are clocked in, then the 65th byte will be stored at

byte location 0 of the Sector Protection Register.

If a value other than 00H or FFH is clocked into a byte location of the Sector Protection Register,

then the protection status of the sector corresponding to that byte location cannot be guaranteed. For example, if a value of 17H is clocked into byte location 2 of the Sector Protection

Register, then the protection status of sector 2 cannot be guaranteed.

The Sector Protection Register can be reprogrammed while the sector protection enabled or disabled. Being able to reprogram the Sector Protection Register with the sector protection enabled

allows the user to temporarily disable the sector protection to an individual sector rather than disabling sector protection completely.

The Program Sector Protection Register command utilizes the internal SRAM buffer 1 for processing. Therefore, the contents of the buffer 1 will be altered from its previous state when this

command is issued.

Command Byte 1 Byte 2 Byte 3 Byte 4

Program Sector Protection Register 3DH 2AH 7FH FCH

Figure 9-3. Program Sector Protection Register

CS

SI

Opcode

Byte 1

Each transition

represents 8 bits

Opcode

Byte 2

Opcode

Byte 3

Opcode

Byte 4

Data Byte

n

Data Byte

n + 1

Data Byte

n + 63

16

AT45DB321D

3597J–DFLASH–4/08

Page 17

9.1.3 Read Sector Protection Register Command

To read the Sector Protection Register, the CS

been asserted, an opcode of 32H and 3 dummy bytes must be clocked in via the SI pin. After the

last bit of the opcode and dummy bytes have been clocked in, any additional clock pulses on the

SCK pins will result in data for the content of the Sector Protection Register being output on the

SO pin. The first byte corresponds to sector 0 (0a, 0b), the second byte corresponds to sector 1

and the last byte (byte 64) corresponds to sector 63. Once the last byte of the Sector Protection

Register has been clocked out, any additional clock pulses will result in undefined data being

output on the SO pin. The CS

ister operation and put the output into a high-impedance state.

Command Byte 1 Byte 2 Byte 3 Byte 4

Read Sector Protection Register 32H xxH xxH xxH

Note: xx = Dummy Byte

Figure 9-4. Read Sector Protection Register

CS

AT45DB321D

pin must first be asserted. Once the CS pin has

must be deasserted to terminate the Read Sector Protection Reg-

SI

Opcode X X X

SO

Each transition

represents 8 bits

9.1.4 Various Aspects About the Sector Protection Register

The Sector Protection Register is subject to a limit of 10,000 erase/program cycles. Users are

encouraged to carefully evaluate the number of times the Sector Protection Register will be

modified during the course of the applications’ life cycle. If the application requires that the Sector Protection Register be modified more than the specified limit of 10,000 cycles because the

application needs to temporarily unprotect individual sectors (sector protection remains enabled

while the Sector Protection Register is reprogrammed), then the application will need to limit this

practice. Instead, a combination of temporarily unprotecting individual sectors along with disabling sector protection completely will need to be implemented by the application to ensure that

the limit of 10,000 cycles is not exceeded.

Data BytenData Byte

n + 1

Data Byte

n + 63

3597J–DFLASH–4/08

17

Page 18

10. Security Features

10.1 Sector Lockdown

The device incorporates a Sector Lockdown mechanism that allows each individual sector to be

permanently locked so that it becomes read only. This is useful for applications that require the

ability to permanently protect a number of sectors against malicious attempts at altering program

code or security information. Once a sector is locked down, it can never be erased or pro-

grammed, and it can never be unlocked.

To issue the Sector Lockdown command, the CS

any other command. Once the CS

sequence must be clocked into the device in the correct order. The 4-byte opcode sequence

must start with 3DH and be followed by 2AH, 7FH, and 30H. After the last byte of the command

sequence has been clocked in, then three address bytes specifying any address within the sector to be locked down must be clocked into the device. After the last address bit has been

clocked in, the CS

sequence.

The lockdown sequence should take place in a maximum time of t

Register will indicate that the device is busy. If the device is powered-down before the completion of the lockdown sequence, then the lockdown status of the sector cannot be guaranteed. In

this case, it is recommended that the user read the Sector Lockdown Register to determine the

status of the appropriate sector lockdown bits or bytes and reissue the Sector Lockdown command if necessary.

Command Byte 1 Byte 2 Byte 3 Byte 4

Sector Lockdown 3DH 2AH 7FH 30H

Figure 10-1. Sector Lockdown

CS

SI

Opcode

Byte 1

Opcode

Byte 2

pin must first be asserted as it would be for

pin has been asserted, the appropriate 4-byte opcode

pin must then be deasserted to initiate the internally self-timed lockdown

, during which time the Status

P

Opcode

Byte 3

Opcode

Byte 4

Address

Bytes

Address

Bytes

Address

Bytes

18

Each transition

represents 8 bits

AT45DB321D

3597J–DFLASH–4/08

Page 19

10.1.1 Sector Lockdown Register

Sector Lockdown Register is a nonvolatile register that contains 64 bytes of data, as shown

below:

Sector Number 0 (0a, 0b) 1 to 63

AT45DB321D

Locked

Unlocked 00H

Table 10-1. Sector 0 (0a, 0b)

Sectors 0a, 0b Unlocked 00 00 00 00 00H

Sector 0a Locked (Pages 0-7) 11 00 00 00 C0H

Sector 0b Locked (Pages 8-127) 00 11 00 00 30H

Sectors 0a, 0b Locked (Pages 0-127) 11 11 00 00 F0H

10.1.2 Reading the Sector Lockdown Register

The Sector Lockdown Register can be read to determine which sectors in the memory array are

permanently locked down. To read the Sector Lockdown Register, the CS

asserted. Once the CS

pin has been asserted, an opcode of 35H and 3 dummy bytes must be

clocked into the device via the SI pin. After the last bit of the opcode and dummy bytes have

been clocked in, the data for the contents of the Sector Lockdown Register will be clocked out

on the SO pin. The first byte corresponds to sector 0 (0a, 0b) the second byte corresponds to

sector 1 and the last byte (byte 16) corresponds to sector 15. After the last byte of the Sector

Lockdown Register has been read, additional pulses on the SCK pin will simply result in undefined data being output on the SO pin.

See Below

0a 0b

(Pages 0-7) (Pages 8-127)

Bit 7, 6 Bit 5, 4 Bit 1, 0

Bit 3, 2

pin must first be

FFH

Data

Val ue

Deasserting the CS

SO pin into a high-impedance state.

Table 10-2 details the values read from the Sector Lockdown Register.

Table 10-2. Sector Lockdown Register

Command Byte 1 Byte 2 Byte 3 Byte 4

Read Sector Lockdown Register 35H xxH xxH xxH

Note: xx = Dummy Byte

Figure 10-2. Read Sector Lockdown Register

CS

SI

Opcode X X X

SO

Each transition

represents 8 bits

3597J–DFLASH–4/08

pin will terminate the Read Sector Lockdown Register operation and put the

Data BytenData Byte

n + 1

Data Byte

n + 63

19

Page 20

10.2 Security Register

The device contains a specialized Security Register that can be used for purposes such

as unique device serialization or locked key storage. The register is comprised of a total of

128 bytes that is divided into two portions. The first 64 bytes (byte locations 0 through 63) of the

Security Register are allocated as a one-time user programmable space. Once these 64 bytes

have been programmed, they cannot be reprogrammed. The remaining 64 bytes of the register

(byte locations 64 through 127) are factory programmed by Atmel and will contain a unique

value for each device. The factory programmed data is fixed and cannot be changed.

Table 10-3. Security Register

Data Type One-time User Programmable Factory Programmed By Atmel

10.2.1 Programming the Security Register

The user programmable portion of the Security Register does not need to be erased before it is

programmed.

Security Register Byte Number

01• • • 62 63 64 65 • • • 126 127

To program the Security Register, the CS

pin must first be asserted and the appropriate 4-byte

opcode sequence must be clocked into the device in the correct order. The 4-byte opcode

sequence must start with 9BH and be followed by 00H, 00H, and 00H. After the last bit of the

opcode sequence has been clocked into the device, the data for the contents of the 64-byte user

programmable portion of the Security Register must be clocked in.

After the last data byte has been clocked in, the CS

pin must be deasserted to initiate the internally self-timed program cycle. The programming of the Security Register should take place in a

time of t

, during which time the Status Register will indicate that the device is busy. If the device

P

is powered-down during the program cycle, then the contents of the 64-byte user programmable

portion of the Security Register cannot be guaranteed.

If the full 64 bytes of data is not clocked in before the CS

pin is deasserted, then the values of

the byte locations not clocked in cannot be guaranteed. For example, if only the first two bytes

are clocked in instead of the complete 64 bytes, then the remaining 62 bytes of the user programmable portion of the Security Register cannot be guaranteed. Furthermore, if more than

64 bytes of data is clocked into the device, then the data will wrap back around to the beginning

of the register. For instance, if 65 bytes of data are clocked in, then the 65th byte will be stored at

byte location 0 of the Security Register.

The user programmable portion of the Security Register can only be programmed one

time. Therefore, it is not possible to only program the first two bytes of the register and then pro-

gram the remaining 62 bytes at a later time.

The Program Security Register command utilizes the internal SRAM buffer 1 for processing.

Therefore, the contents of the buffer 1 will be altered from its previous state when this command

is issued.

Figure 10-3. Program Security Register

CS

20

SI

Each transition

represents 8 bits

Opcode

Byte 1

AT45DB321D

Opcode

Byte 2

Opcode

Byte 3

Opcode

Byte 4

Data Byte

n

Data Byte

n + 1

Data Byte

n + x

3597J–DFLASH–4/08

Page 21

10.2.2 Reading the Security Register

The Security Register can be read by first asserting the CS

of 77H followed by three dummy bytes. After the last don't care bit has been clocked in, the content of the Security Register can be clocked out on the SO pins. After the last byte of the

Security Register has been read, additional pulses on the SCK pin will simply result in undefined

data being output on the SO pins.

AT45DB321D

pin and then clocking in an opcode

Deasserting the CS

pin will terminate the Read Security Register operation and put the SO pins

into a high-impedance state.

Figure 10-4. Read Security Register

CS

SI

Opcode X X X

SO

Each transition

represents 8 bits

11. Additional Commands

11.1 Main Memory Page to Buffer Transfer

A page of data can be transferred from the main memory to either buffer 1 or buffer 2. To start

the operation for the DataFlash standard page size (528 bytes), a 1-byte opcode, 53H for buffer

1 and 55H for buffer 2, must be clocked into the device, followed by three address bytes comprised of 1 don’t care bit, 13-page address bit (PA12 - PA0), which specify the page in main

memory that is to be transferred, and 10 don’t care bits. To perform a main memory page to

buffer transfer for the binary page size (512 bytes), the opcode 53H for buffer 1 or 55H for buffer

2, must be clocked into the device followed by three address bytes consisting of 2 don’t care

bits, 13-page address bits (A21 - A9) which specify the page in the main memory that is to be

transferred, and 9 don’t care bits. The CS

opcode and the address bytes from the input pin (SI). The transfer of the page of data from the

main memory to the buffer will begin when the CS

ing the transfer of a page of data (t

monitored to determine whether the transfer has been completed.

Data BytenData Byte

n + 1

Data Byte

n + x

pin must be low while toggling the SCK pin to load the

pin transitions from a low to a high state. Dur-

), the status register can be read or the RDY/BUSY can be

XFR

3597J–DFLASH–4/08

21

Page 22

11.2 Main Memory Page to Buffer Compare

A page of data in the main memory can be compared to the data in buffer 1 or buffer 2. To initiate the operation for DataFlash standard page size, a 1-byte opcode, 60H for buffer 1 and 61H

for buffer 2, must be clocked into the device, followed by three address bytes consisting of

1 don’t care bit, 13-page address bits (PA12 - PA0) that specify the page in the main memory

that is to be compared to the buffer, and 10 don’t care bits. To start a main memory page to

buffer compare for a binary page size, the opcode 60H for buffer 1 or 61H for buffer 2, must be

clocked into the device followed by three address bytes consisting of 2 don’t care bits, 13 page

address bits (A21 - A9) that specify the page in the main memory that is to be compared to the

buffer, and 9 don’t care bits. The CS

opcode and the address bytes from the input pin (SI). On the low-to-high transition of the CS

the data bytes in the selected main memory page will be compared with the data bytes in buffer

1 or buffer 2. During this time (t

the part is busy. On completion of the compare operation, bit 6 of the status register is updated

with the result of the compare.

11.3 Auto Page Rewrite

This mode is only needed if multiple bytes within a page or multiple pages of data are modified in

a random fashion within a sector. This mode is a combination of two operations: Main Memory

Page to Buffer Transfer and Buffer to Main Memory Page Program with Built-in Erase. A page of

data is first transferred from the main memory to buffer 1 or buffer 2, and then the same data

(from buffer 1 or buffer 2) is programmed back into its original page of main memory. To start the

rewrite operation for the DataFlash standard page size (528 bytes), a 1-byte opcode, 58H for

buffer 1 or 59H for buffer 2, must be clocked into the device, followed by three address bytes

comprised of 1 don’t care bit, 13-page address bits (PA12-PA0) that specify the page in main

memory to be rewritten and 10 don’t care bits. To initiate an auto page rewrite for a binary page

size (512 bytes), the opcode 58H for buffer 1 or 59H for buffer 2, must be clocked into the device

followed by three address bytes consisting of 2 don’t care bits, 13 page address bits (A21 - A9)

that specify the page in the main memory that is to be written and 9 don’t care bits. When a lowto-high transition occurs on the CS

memory to a buffer and then program the data from the buffer back into same page of main

memory. The operation is internally self-timed and should take place in a maximum time of t

During this time, the status register and the RDY/BUSY

pin must be low while toggling the SCK pin to load the

), the status register and the RDY/BUSY pin will indicate that

COMP

pin, the part will first transfer data from the page in main

pin will indicate that the part is busy.

pin,

EP

.

22

If a sector is programmed or reprogrammed sequentially page by page, then the programming

algorithm shown in Figure 25-1 (page 45) is recommended. Otherwise, if multiple bytes in a

page or several pages are programmed randomly in a sector, then the programming algorithm

shown in Figure 25-2 (page 46) is recommended. Each page within a sector must be

updated/rewritten at least once within every 10,000 cumulative page erase/program operations

in that sector.

AT45DB321D

3597J–DFLASH–4/08

Page 23

11.4 Status Register Read

The status register can be used to determine the device’s ready/busy status, page size, a Main

Memory Page to Buffer Compare operation result, the Sector Protection status or the device

density. The Status Register can be read at any time, including during an internally self-timed

program or erase operation. To read the status register, the CS

opcode of D7H must be loaded into the device. After the opcode is clocked in, the 1-byte status

register will be clocked out on the output pin (SO), starting with the next clock cycle. The data in

the status register, starting with the MSB (bit 7), will be clocked out on the SO pin during the next

eight clock cycles. After the one byte of the status register has been clocked out, the sequence

will repeat itself (as long as CS

register is constantly updated, so each repeating sequence will output new data.

Ready/busy status is indicated using bit 7 of the status register. If bit 7 is a 1, then the device is

not busy and is ready to accept the next command. If bit 7 is a 0, then the device is in a busy

state. Since the data in the status register is constantly updated, the user must toggle SCK pin to

check the ready/busy status. There are several operations that can cause the device to be in a

busy state: Main Memory Page to Buffer Transfer, Main Memory Page to Buffer Compare,

Buffer to Main Memory Page Program, Main Memory Page Program through Buffer, Page

Erase, Block Erase, Sector Erase, Chip Erase and Auto Page Rewrite.

The result of the most recent Main Memory Page to Buffer Compare operation is indicated using

bit 6 of the status register. If bit 6 is a 0, then the data in the main memory page matches the

data in the buffer. If bit 6 is a 1, then at least one bit of the data in the main memory page does

not match the data in the buffer.

AT45DB321D

pin must be asserted and the

remains low and SCK is being toggled). The data in the status

Bit 1 in the Status Register is used to provide information to the user whether or not the sector

protection has been enabled or disabled, either by software-controlled method or hardware-controlled method. A logic 1 indicates that sector protection has been enabled and logic 0 indicates

that sector protection has been disabled.

Bit 0 in the Status Register indicates whether the page size of the main memory array is configured for “power of 2” binary page size (512 bytes) or DataFlash standard page size (528 bytes).

If bit 0 is a 1, then the page size is set to 512 bytes. If bit 0 is a 0, then the page size is set to

528 bytes.

The device density is indicated using bits 5, 4, 3, and 2 of the status register. For the

AT45DB321D, the four bits are 1101 The decimal value of these four binary bits does not equate

to the device density; the four bits represent a combinational code relating to differing densities

of DataFlash devices. The device density is not the same as the density code indicated in the

JEDEC device ID information. The device density is provided only for backward compatibility.

Table 11-1. Status Register Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

RDY/BUSY

COMP 1 1 0 1 PROTECT PAGE SIZE

3597J–DFLASH–4/08

23

Page 24

12. Deep Power-down

After initial power-up, the device will default in standby mode. The Deep Power-down command

allows the device to enter into the lowest power consumption mode. To enter the Deep Powerdown mode, the CS

of B9H command must be clocked in via input pin (SI). After the last bit of the command has

been clocked in, the CS

After the CS

maximum t

are ignored except for the Resume from Deep Power-down command.

Command Opcode

Deep Power-down B9H

Figure 12-1. Deep Power-down

pin must first be asserted. Once the CS pin has been asserted, an opcode

pin must be de-asserted to initiate the Deep Power-down operation.

pin is de-asserted, the will device enter the Deep Power-down mode within the

time. Once the device has entered the Deep Power-down mode, all instructions

EDPD

CS

12.1 Resume from Deep Power-down

The Resume from Deep Power-down command takes the device out of the Deep Power-down

mode and returns it to the normal standby mode. To Resume from Deep Power-down mode, the

CS

pin must first be asserted and an opcode of ABH command must be clocked in via input pin

(SI). After the last bit of the command has been clocked in, the CS

terminate the Deep Power-down mode. After the CS

the normal standby mode within the maximum t

the t

down, the device will return to the normal standby mode.

Command Opcode

Resume from Deep Power-down ABH

Figure 12-2. Resume from Deep Power-Down

time before the device can receive any commands. After resuming form Deep Power-

RDPD

SI

CS

SI

Opcode

Each transition

represents 8 bits

RDPD

Opcode

pin must be de-asserted to

pin is de-asserted, the device will return to

time. The CS pin must remain high during

24

AT45DB321D

Each transition

represents 8 bits

3597J–DFLASH–4/08

Page 25

13. “Power of 2” Binary Page Size Option

“Power of 2” binary page size Configuration Register is a user-programmable nonvolatile register that allows the page size of the main memory to be configured for binary page size

(512 bytes) or DataFlash standard page size (528 bytes). The “power of 2” page size is a one-

time programmable configuration register and once the device is configured for “power

of 2” page size, it cannot be reconfigured again. The devices are initially shipped with the

page size set to 528 bytes. The user has the option of ordering binary page size (512

bytes) devices from the factory. For details, please refer to Section 26. ”Ordering Information” on

page 47.

For the binary “power of 2” page size to become effective, the following steps must be followed:

1. Program the one-time programmable configuration resister using opcode sequence

3DH, 2AH, 80H and A6H (please see Section 13.1).

2. Power cycle the device (i.e. power down and power up again).

3. The page for the binary page size can now be programmed.

If the above steps are not followed to set the page size prior to page programming, incorrect

data during a read operation may be encountered.

13.1 Programming the Configuration Register

To program the Configuration Register for “power of 2” binary page size, the CS pin must first be

asserted as it would be with any other command. Once the CS

appropriate 4-byte opcode sequence must be clocked into the device in the correct order. The

4-byte opcode sequence must start with 3DH and be followed by 2AH, 80H, and A6H. After the

last bit of the opcode sequence has been clocked in, the CS

the internally self-timed program cycle. The programming of the Configuration Register should

take place in a time of t

busy. The device must be power cycled after the completion of the program cycle to set the

“power of 2” page size. If the device is powered-down before the completion of the program

cycle, then setting the Configuration Register cannot be guaranteed. However, the user should

check bit 0 of the status register to see whether the page size was configured for binary page

size. If not, the command can be re-issued again.

, during which time the Status Register will indicate that the device is

P

AT45DB321D

pin has been asserted, the

pin must be deasserted to initiate

3597J–DFLASH–4/08

Command Byte 1 Byte 2 Byte 3 Byte 4

Power of Two Page Size 3DH 2AH 80H A6H

Figure 13-1. Erase Sector Protection Register

CS

SI

Opcode

Byte 1

Each transition

represents 8 bits

Opcode

Byte 2

Opcode

Byte 3

Opcode

Byte 4

25

Page 26

14. Manufacturer and Device ID Read

Identification information can be read from the device to enable systems to electronically query

and identify the device while it is in system. The identification method and the command opcode

comply with the JEDEC standard for “Manufacturer and Device ID Read Methodology for SPI

Compatible Serial Interface Memory Devices”. The type of information that can be read from the

device includes the JEDEC defined Manufacturer ID, the vendor specific Device ID, and the vendor specific Extended Device Information.

To read the identification information, the CS

pin must first be asserted and the opcode of 9FH

must be clocked into the device. After the opcode has been clocked in, the device will begin outputting the identification data on the SO pin during the subsequent clock cycles. The first byte

that will be output will be the Manufacturer ID followed by two bytes of Device ID information.

The fourth byte output will be the Extended Device Information String Length, which will be 00H

indicating that no Extended Device Information follows. As indicated in the JEDEC standard,

reading the Extended Device Information String Length and any subsequent data is optional.

Deasserting the CS

the SO pin into a high-impedance state. The CS

pin will terminate the Manufacturer and Device ID Read operation and put

pin can be deasserted at any time and does not

require that a full byte of data be read.

14.1 Manufacturer and Device ID Information

14.1.1 Byte 1 – Manufacturer ID

Hex

Val ue

1FH 0 0 0 1 1 1 1 1 Manufacturer ID 1FH = Atmel

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

14.1.2 Byte 2 – Device ID (Part 1)

Hex

Val ue

27H 0 0 1 0 0 1 1 1 Density Code 00111 = 32-Mbit

Family Code Density Code

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

JEDEC Assigned Code

Family Code 001 = DataFlash

14.1.3 Byte 3 – Device ID (Part 2)

Hex

Val ue

00H 0 0 0 0 0 0 0 1 Product Version 00001 = Second Version

MLC Code Product Version Code

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

MLC Code 000 = 1-bit/Cell Technology

14.1.4 Byte 4 – Extended Device Information String Length

Hex

Val ue

00H 0 0 0 0 0 0 0 0 Byte Count 00H = 0 Bytes of Information

26

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

AT45DB321D

Byte Count

3597J–DFLASH–4/08

Page 27

CS

AT45DB321D

SI

SO

Each transition

represents 8 bits

Note: Based on JEDEC publication 106 (JEP106), Manufacturer ID data can be comprised of any number of bytes. Some manufacturers may have

Manufacturer ID codes that are two, three or even four bytes long with the first byte(s) in the sequence being 7FH. A system should detect code

7FH as a “Continuation Code” and continue to read Manufacturer ID bytes. The first non-7FH byte would signify the last byte of Manufacturer ID

data. For Atmel (and some other manufacturers), the Manufacturer ID data is comprised of only one byte.

9FH

Opcode

1FH

Manufacturer ID

Byte 1

27H 00H

Device ID

Byte 2

Device ID

Byte 3

01H Data Data

Extended

Device

Information

String Length

Extended

Device

Information

Byte x

This information would only be output

if the Extended Device Information String Length

value was something other than 00H.

Extended

Device

Information

Byte x + 1

14.2 Operation Mode Summary

The commands described previously can be grouped into four different categories to better

describe which commands can be executed at what times.

Group A commands consist of:

1. Main Memory Page Read

2. Continuous Array Read