Page 1

Features

• Serial Peripheral Interface (SPI) Compatible

• Supports SPI Modes 0 (0,0) and 3 (1,1)

– Datasheet describes Mode 0 Operation

• 20 MHz Clock Rate

• Byte Mode and 256-byte Page Mode for Program Operations

• Sector Architecture:

– Eight Sectors with 64K Bytes Each (4M)

– 256 Pages per Sector

• Product Identification Mode

• Low-voltage Operation

– 2.7 (VCC = 2.7V to 3.6V)

• Sector Write Protection

– Protect 1/8, 1/4, 1/2 or Entire Array

• Write Protect (WP) Pin and Write Disable Instructions for

both Hardware and Software Data Protection

• Self-timed Program Cycle (30 µs/Byte Typical)

• Self-timed Sector Erase Cycle (1 second/Sector Typical)

• Single Cycle Reprogramming (Erase and Program) for Status Register

• High Reliability

– Endurance: 10,000 Write Cycles Typical

• 8-lead EIAJ SOIC

SPI Serial

Memory

4M (524,288 x 8)

AT25F4096

Description

The AT25F4096 provides 4,194,304 bits of serial reprogrammable Flash memory

organized as 524,288 words of 8 bits each. The device is optimized for use in many

industrial and commercial applications where low-power and low-voltage operation

are essential. The AT25F4096 is available in a space-saving 8-lead EIAJ SOIC

package.

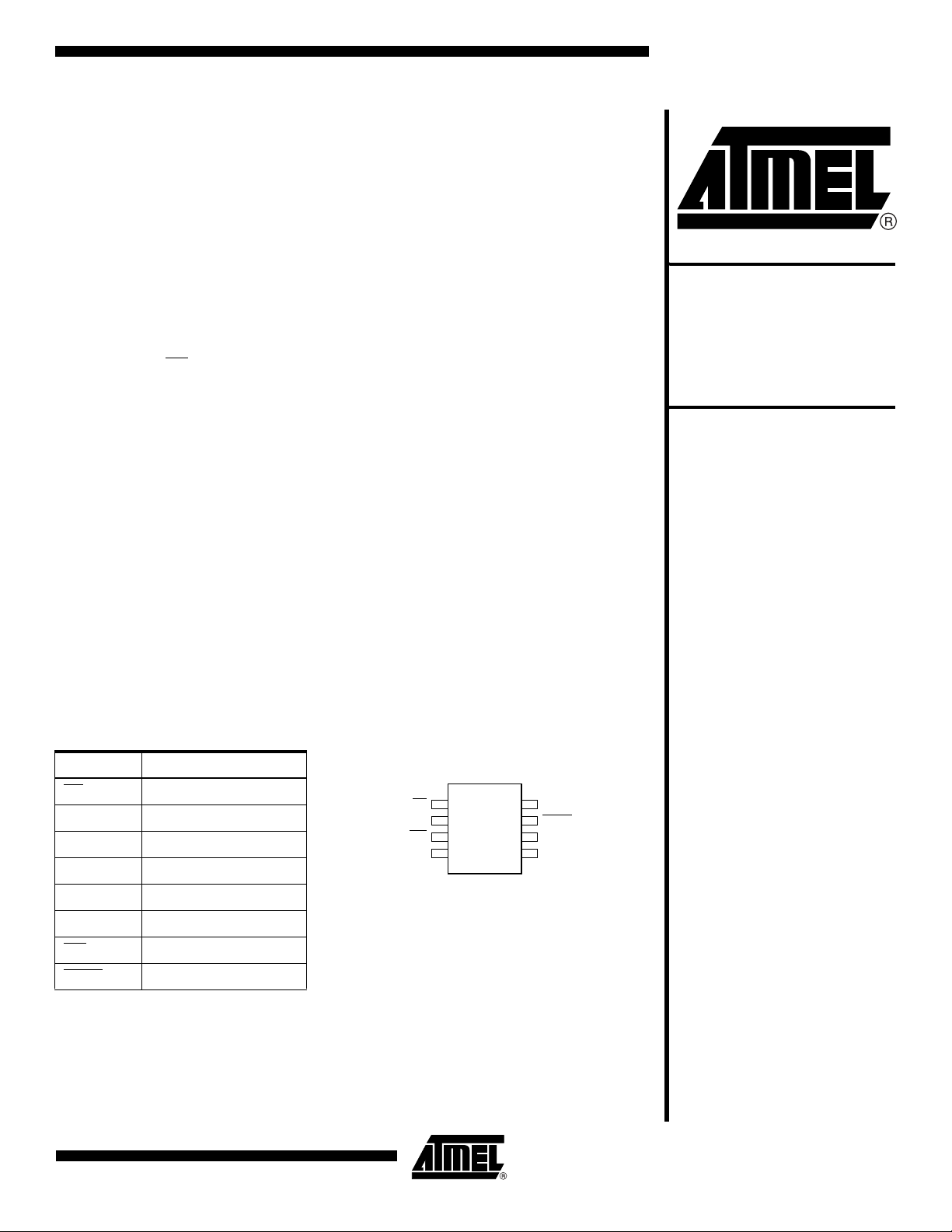

Pin Configurations

Pin Name Function

CS

SCK Serial Data Clock

SI Serial Data Input

SO Serial Data Output

GND Ground

VCC Power Supply

WP

HOLD

Chip Select

Write Protect

Suspends Serial Input

8-lead EIAJ SOIC

1

CS

2

SO

3

WP

GND

4

VCC

8

HOLD

7

SCK

6

SI

5

Advance

Information

2454C–SEEPR–8/04

Page 2

The AT25F4096 is enabled through the Chip Select pin (CS) and accessed via a 3-wire

interface consisting of Serial Data Input (SI), Serial Data Output (SO), and Serial Clock

(SCK). All write cycles are completely self-timed.

BLOCK WRITE protection for top 1/8, top 1/4, top 1/2 or the entire memory array is

enabled by programming the status register. Separate write enable and write disable

instructions are provided for additional data protection. Hardware data protection is provided via the WP

The HOLD

pin to protect against inadvertent write attempts to the status register.

pin may be used to suspend any serial communication without resetting the

serial sequence.

Absolute Maximum Ratings*

Operating Temperature.................................... -40°C to +85°C

Storage Temperature ..................................... -65°C to +150°C

Voltage on Any Pin

with Respect to Ground .....................................-1.0V to +3.6V

Maximum Operating Voltage ............................................ 3.6V

DC Output Current........................................................ 5.0 mA

Block Diagram

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

functional operation of the device at these or any

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect

device reliability.

524,288 x 8

2

AT25F4096 [Advance Information]

2454C–SEEPR–8/04

Page 3

AT25F4096 [Advance Information]

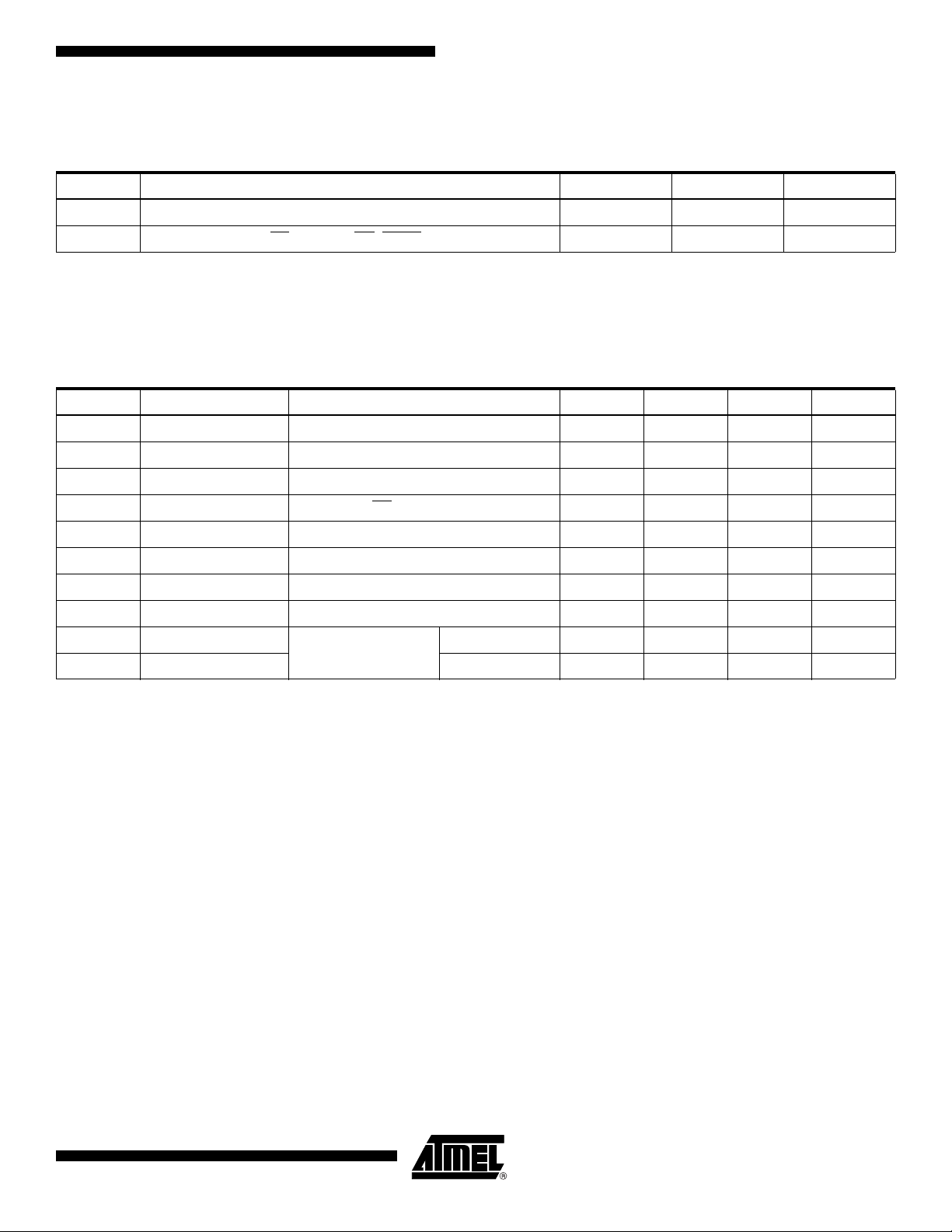

Pin Capacitance

(1)

Applicable over recommended operating range from TA = 25°C, f = 1.0 MHz, VCC = +3.6V (unless otherwise noted).

Symbol Test Conditions Max Units Conditions

C

OUT

C

IN

Output Capacitance (SO) 8 pF V

OUT

= 0V

Input Capacitance (CS, SCK, SI, WP, HOLD) 6 pF VIN = 0V

Note: 1. This parameter is characterized and is not 100% tested.

DC Characteristics (Preliminary – Subject to Change)

Applicable over recommended operating range from: TAI = -40°C to +85°C, VCC = +2.7V to +3.6V,

T

= 0°C to +70°C, VCC = +2.7V to +3.6V (unless otherwise noted).

AC

Symbol Parameter Test Condition Min Typ Max Units

V

CC

I

CC1

I

CC2

I

SB

I

IL

I

OL

(1)

V

IL

(1)

V

IH

V

OL

V

OH

Note: 1. VIL and VIH max are reference only and are not tested.

Supply Voltage 2.7 3.6 V

Supply Current VCC = 3.6V at 20 MHz, SO = Open Read 10.0 15.0 mA

Supply Current VCC = 3.6V at 20 MHz, SO = Open Write 15.0 30.0 mA

Standby Current VCC = 2.7V, CS = V

Input Leakage VIN = 0V to V

CC

CC

-3.0 3.0 µA

2.0 10.0 µA

Output Leakage VIN = 0V to VCC, TAC = 0°C to 70°C -3.0 3.0 µA

Input Low Voltage -0.6 V

x 0.3 V

CC

Input High Voltage VCC x 0.7 VCC + 0.5 V

Output Low Voltage 2.7V ≤ VCC ≤ 3.6V IOL = 0.15 mA 0.2 V

Output High Voltage IOH = -100 µA VCC - 0.2 V

2454C–SEEPR–8/04

3

Page 4

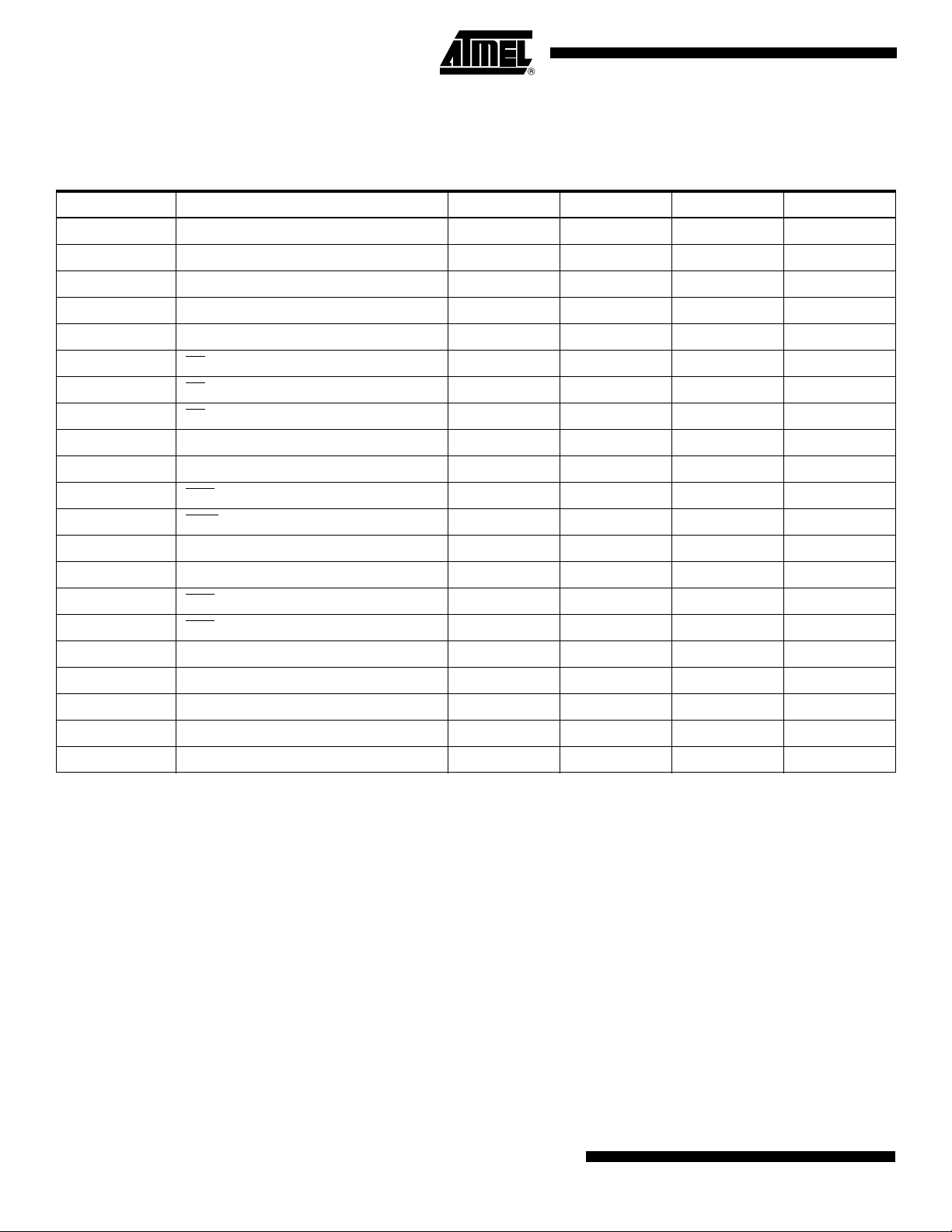

AC Characteristics (Preliminary – Subject to Change)

Applicable over recommended operating range from TA = -40°C to +85°C, VCC = +2.7V to +3.6V

C

= 1 TTL Gate and 30 pF (unless otherwise noted).

L

Symbol Parameter Min Typ Max Units

f

SCK

t

RI

t

FI

t

WH

t

WL

t

CS

t

CSS

t

CSH

t

SU

t

H

t

HD

t

CD

t

V

t

HO

t

LZ

t

HZ

t

DIS

t

EC

t

SR

t

BPC

Endurance

(2)

Notes: 1. The programming time for n bytes will be equal to n x t

2. This parameter is characterized at 3.0V, 25°C and is not 100% tested.

3. One write cycle consists of erasing a sector, followed by programming the same sector.

SCK Clock Frequency 0 20 MHz

Input Rise Time 20 ns

Input Fall Time 20 ns

SCK High Time 20 ns

SCK Low Time 20 ns

CS High Time 25 ns

CS Setup Time 25 ns

CS Hold Time 25 ns

Data In Setup Time 5 ns

Data In Hold Time 5 ns

Hold Setup Time 15 ns

Hold Hold Time 15 ns

Output Valid 20 ns

Output Hold Time 0 ns

Hold to Output Low Z 200 ns

Hold to Output High Z 200 ns

Output Disable Time 100 ns

Erase Cycle Time per Sector 1.0 s

Status Register Write Cycle Time 60 ms

Byte Program Cycle Time

(1)

30 50 µs

10K Write Cycles

.

BPC

(3)

4

AT25F4096 [Advance Information]

2454C–SEEPR–8/04

Page 5

AT25F4096 [Advance Information]

Serial Interface Description

MASTER: The device that generates the serial clock.

SLAVE: Because the Serial Clock pin (SCK) is always an input, the AT25F4096 always

operates as a slave.

TRANSMITTER/RECEIVER: The AT25F4096 has separate pins designated for data

transmission (SO) and reception (SI).

MSB: The Most Significant Bit (MSB) is the first bit transmitted and received.

SERIAL OP-CODE: After the device is selected with CS

received. This byte contains the op-code that defines the operations to be performed.

INVALID OP-CODE: If an invalid op-code is received, no data will be shifted into the

AT25F4096, and the serial output pin (SO) will remain in a high impedance state until

the falling edge of CS

CHIP SELECT: The AT25F4096 is selected when the CS

not selected, data will not be accepted via the SI pin, and the serial output pin (SO) will

remain in a high impedance state.

HOLD: The HOLD

When the device is selected and a serial sequence is underway, HOLD

pause the serial communication with the master device without resetting the serial

sequence. To pause, the HOLD

resume serial communication, the HOLD

(SCK may still toggle during HOLD

is in the high impedance state.

is detected again. This will reinitialize the serial communication.

pin is used in conjunction with the CS pin to select the AT25F4096.

pin must be brought low while the SCK pin is low. To

pin is brought high while the SCK pin is low

). Inputs to the SI pin will be ignored while the SO pin

going low, the first byte will be

pin is low. When the device is

can be used to

WRITE PROTECT: The 25F4096 has a write lockout feature that can be activated by

asserting the write protect pin (WP

sectors will be READ only. The write protect pin will allow normal read/write operations

when held high. When the WP

the status register are inhibited. WP

the status register. If the internal status register write cycle has already been initiated,

WP

going low will have no effect on any write operation to the status register. The WP

pin function is blocked when the WPEN bit in the status register is “0”. This will allow the

user to install the AT25F4096 in a system with the WP

able to write to the status register. All WP

is set to “1”.

). When the lockout feature is activated, locked-out

is brought low and WPEN bit is “1”, all write operations to

going low while CS is still low will interrupt a write to

pin tied to ground and still be

pin functions are enabled when the WPEN bit

2454C–SEEPR–8/04

5

Page 6

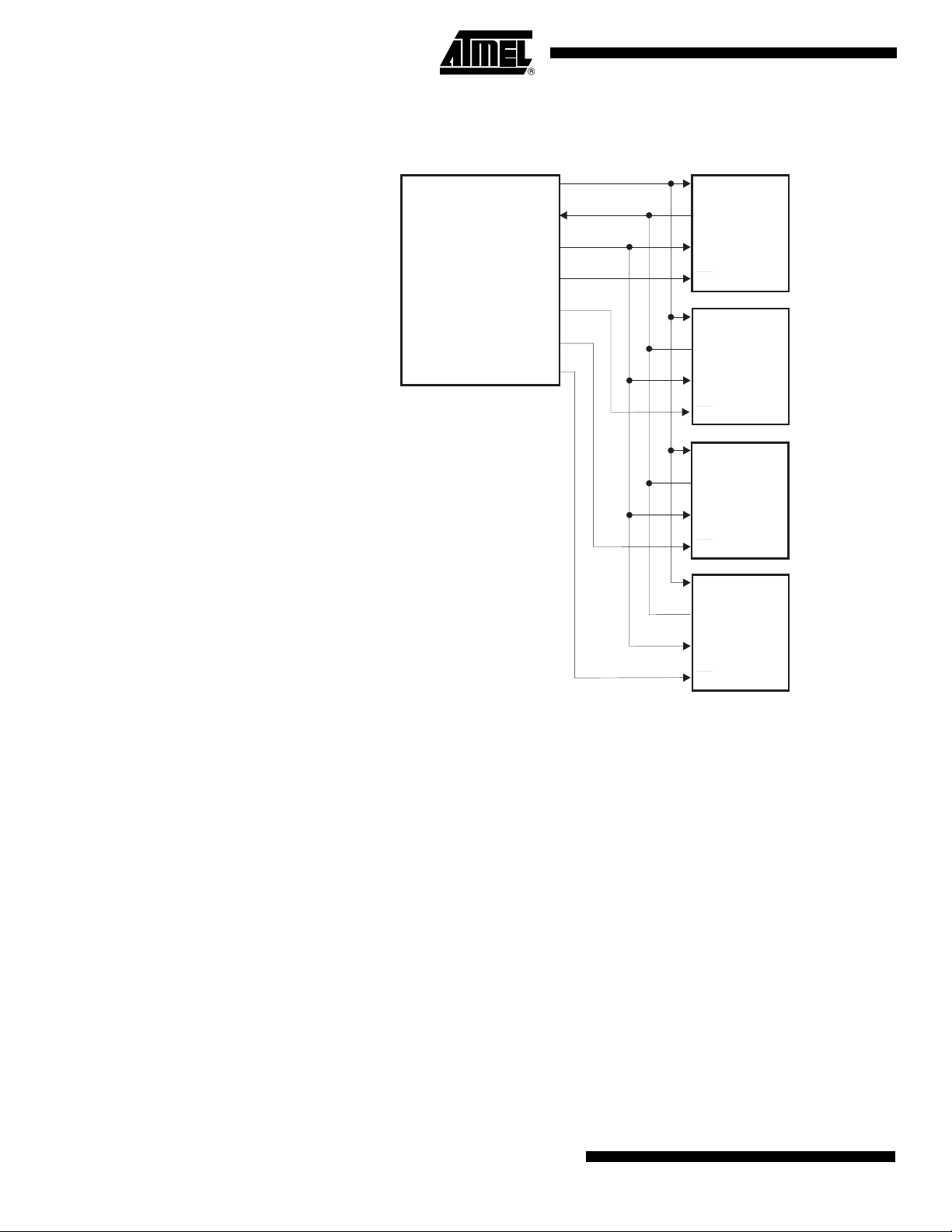

SPI Serial Interface

MASTER:

MICROCONTROLLER

DATA OUT (MOSI)

DATA IN (MISO)

SERIAL CLOCK (SPI CK)

SS0

SS1

SS2

SS3

SLAVE:

AT25F4096

SI

SO

SCK

CS

SI

SO

SCK

CS

SI

SO

SCK

CS

SI

SO

SCK

CS

6

AT25F4096 [Advance Information]

2454C–SEEPR–8/04

Page 7

AT25F4096 [Advance Information]

Functional Description

The AT25F4096 is designed to interface directly with the synchronous serial peripheral

interface (SPI) of the 6800 type series of microcontrollers.

The AT25F4096 utilizes an 8-bit instruction register. The list of instructions and their

operation codes are contained in Table 1. All instructions, addresses, and data are

transferred with the MSB first and start with a high-to-low transition.

Write is defined as program and/or erase in this specification. The following commands,

PROGRAM, SECTOR ERASE, CHIP ERASE, and WRSR are write instructions for

AT25F4096.

Table 1. Instruction Set for the AT25F4096

Instruction

Instruction Name

WREN 0000 X110 Set Write Enable Latch

WRDI 0000 X100 Reset Write Enable Latch

RDSR 0000 X101 Read Status Register

WRSR 0000 X001 Write Status Register

READ 0000 X011 Read Data from Memory Array

PROGRAM 0000 X010 Program Data Into Memory Array

SECTOR ERASE 0101 X010 Erase One Sector in Memory Array

CHIP ERASE 0110 X010 Erase All Sectors in Memory Array

RDID 0001 X101 Read Manufacturer and Product ID

Format Operation

WRITE ENABLE (WREN): The device will power up in the write disable state when V

CC

is applied. All write instructions must therefore be preceded by the WREN instruction.

WRITE DISABLE (WRDI): To protect the device against inadvertent writes, the WRDI

instruction disables all write commands. The WRDI instruction is independent of the status of the WP

pin.

READ STATUS REGISTER (RDSR): The RDSR instruction provides access to the status register. The READY/BUSY and write enable status of the device can be determined

by the RDSR instruction. Similarly, the Block Write Protection bits indicate the extent of

protection employed. These bits are set by using the WRSR instruction. During internal

write cycles, all other commands will be ignored except the RDSR instruction.

Table 2. Status Register Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

WPEN X X BP2 BP1 BP0 WEN RDY

2454C–SEEPR–8/04

7

Page 8

Table 3. Read Status Register Bit Definition

Bit Definition

Bit 0 (RDY)

Bit 1 (WEN)

Bit 2 (BP0) See Table 4.

Bit 3 (BP1) See Table 4.

Bit 4 (BP2) See Table 4.

Bits 5-6 are 0s when device is not in an internal write cycle.

Bit 7 (WPEN) See Table 5.

Bits 0-7 are 1s during an internal write cycle.

Bit 0 = 0 (RDY) indicates the device is READY. Bit 0 = 1 indicates the

write cycle is in progress.

Bit 1 = 0 indicates the device is not WRITE ENABLED. Bit 1 = 1 indicates

the device is WRITE ENABLED.

READ PRODUCT ID (RDID): The RDID instruction allows the user to read the manufacturer and product ID of the device. The first byte after the instruction will be the

manufacturer code (1FH = ATMEL), followed by the device code 64H.

WRITE STATUS REGISTER (WRSR): The WRSR instruction allows the user to select

one of five levels of protection for the AT25F4096. The AT25F4096 is divided into eight

sectors where the top 1/8, top quarter (1/4), top half (1/2), or all of the memory sectors

can be protected (locked out) from write. Any of the locked-out sectors will therefore be

READ only. The locked-out sector and the corresponding status register control bits are

shown in Table 4.

The four bits, BP0, BP1, BP2 and WPEN, are nonvolatile cells that have the same properties and functions as the regular memory cells (e.g., WREN, t

, RDSR).

WC

Table 4. Block Write Protect Bits

Status Register Bits AT25F4096

Array Addresses

Level

0(none) 0 0 0 None None

1(1/8) 0 0 1 070000 - 07FFFF Sector 8

2(1/4) 0 1 0 060000 - 07FFFF Sector 7, 8

3(1/2) 0 1 1 040000 - 07FFFF Sector 5, 6, 7, 8

4(all) 1 x x 000000 - 07FFFF

Note: 1. x = don’t care

BP2 BP1 BP0

Locked Out Locked-out Sector(s)

All sectors

(1 - 8)

The WRSR instruction also allows the user to enable or disable the Write Protect (WP)

pin through the use of the Write Protect Enable (WPEN) bit. Hardware write protection is

enabled when the WP

disabled when either the WP

pin is low and the WPEN bit is “1”. Hardware write protection is

pin is high or the WPEN bit is “0.” When the device is hardware write protected, writes to the Status Register, including the Block Protect bits and

the WPEN bit, and the locked-out sectors in the memory array are disabled. Write is

only allowed to sectors of the memory which are not locked out. The WRSR instruction

is self-timed to automatically erase and program BP0, BP1, BP2 and WPEN bits. In

8

AT25F4096 [Advance Information]

2454C–SEEPR–8/04

Page 9

AT25F4096 [Advance Information]

order to write the status register, the device must first be write enabled via the WREN

instruction. Then, the instruction and data for the four bits are entered. During the internal write cycle, all instructions will be ignored except RDSR instructions. The

AT25F4096 will automatically return to write disable state at the completion of the

WRSR cycle.

Note: When the WPEN bit is hardware write protected, it cannot be changed back to “0”, as

long as the WP

Table 5. WPEN Operation

WPEN WP WEN ProtectedBlocks UnprotectedBlocks Status Register

0 X 0 Protected Protected Protected

0 X 1 Protected Writable Writable

1 Low 0 Protected Protected Protected

1 Low 1 Protected Writable Protected

X High 0 Protected Protected Protected

X High 1 Protected Writable Writable

READ (READ): Reading the AT25F4096 via the SO (Serial Output) pin requires the following sequence. After the CS

is transmitted via the SI line followed by the byte address to be read (Refer to Table 6).

Upon completion, any data on the SI line will be ignored. The data (D7-D0) at the specified address is then shifted out onto the SO line. If only one byte is to be read, the CS

line should be driven high after the data comes out. The READ instruction can be continued since the byte address is automatically incremented and data will continue to be

shifted out of the AT25F4096 until the highest address is reached, the address counter

will roll over to the lowest address allowing the entire memory to be read in one continuous READ instruction.

pin is held low.

line is pulled low to select a device, the READ instruction

PROGRAM (PROGRAM): In order to program the AT25F4096, two separate instructions must be executed. First, the device must be write enabled via the WREN

instruction. Then the PROGRAM instruction can be executed. Also, the address of the

memory location(s) to be programmed must be outside the protected address field location selected by the Block Write Protection Level. During an internal self-timed

programming cycle, all commands will be ignored except the RDSR instruction.

The PROGRAM instruction requires the following sequence. After the CS

line is pulled

low to select the device, the PROGRAM instruction is transmitted via the SI line followed

by the byte address and the data (D7-D0) to be programmed (Refer to Table 6). Programming will start after the CS

pin is brought high. The low-to-high transition of the CS

pin must occur during the SCK low time immediately after clocking in the D0 (LSB) data

bit.

The READY/BUSY status of the device can be determined by initiating a RDSR instruction. If Bit 0 = 1, the program cycle is still in progress. If Bit 0 = 0, the program cycle has

ended. Only the RDSR instruction is enabled during the program cycle.

A single PROGRAM instruction programs 1 to 256 consecutive bytes within a page if it

is not write protected. The starting byte could be anywhere within the page. When the

end of the page is reached, the address will wrap around to the beginning of the same

page. If the data to be programmed are less than a full page, the data of all other bytes

on the same page will remain unchanged. If more than 256 bytes of data are provided,

the address counter will roll over on the same page and the previous data provided will

be replaced. The same byte cannot be reprogrammed without erasing the whole sector

2454C–SEEPR–8/04

9

Page 10

first. The AT25F4096 will automatically return to the write disable state at the completion

of the PROGRAM cycle.

Note: If the device is not write enabled (WREN), the device will ignore the Write instruction and

will return to the standby state, when CS is brought high. A new CS falling edge is

required to re-initiate the serial communication.

Table 6. Address Key

Address AT25F4096

A

N

Dont’ Care Bits A

A18 - A

- A

23

0

19

SECTOR ERASE (SECTOR ERASE): Before a byte can be reprogrammed, the sector

which contains the byte must be erased. In order to erase the AT25F4096, two separate

instructions must be executed. First, the device must be write enabled via the WREN

instruction. Then the SECTOR ERASE instruction can be executed.

Table 7. Sector Addresses

Sector Address AT25F4096 Sector

000000 to 00FFFF Sector 1

010000 to 01FFFF Sector 2

020000 to 02FFFF Sector 3

030000 to 03FFFF Sector 4

040000 to 04FFFF Sector 5

050000 to 05FFFF Sector 6

060000 to 06FFFF Sector 7

070000 to 07FFFF Sector 8

The SECTOR ERASE instruction erases every byte in the selected sector if the sector is

not locked out. Sector address is automatically determined if any address within the sector is selected. The SECTOR ERASE instruction is internally controlled; it will

automatically be timed to completion. During this time, all commands will be

ignored, except RDSR instruction. The AT25F4096 will automatically return to the write

disable state at the completion of the SECTOR ERASE cycle.

CHIP ERASE (CHIP ERASE): As an alternative to the SECTOR ERASE, the CHIP

ERASE instruction will erase every byte in all sectors that are not locked out. First, the

device must be write enabled via the WREN instruction. Then the CHIP ERASE instruction can be executed. The CHIP ERASE instruction is internally controlled; it will

automatically be timed to completion. The CHIP ERASE cycle time typically is 8 seconds. During the internal erase cycle, all instructions will be ignored except RDSR. The

AT25F4096 will automatically return to the write disable state at the completion of the

CHIP ERASE cycle.

10

AT25F4096 [Advance Information]

2454C–SEEPR–8/04

Page 11

AT25F4096 [Advance Information]

Timing Diagrams (for SPI Mode 0 (0, 0))

Synchronous Data Timing

V

IH

CS

V

IL

t

CSS

V

SCK

SO

IH

V

IL

t

SU

V

IH

SI

V

IL

V

OH

HI-Z

V

OL

VAL ID IN

t

WH

t

H

t

CS

t

CSH

t

WL

t

V

t

HO

t

DIS

HI-Z

WREN Timing

WRDI Timing

2454C–SEEPR–8/04

11

Page 12

RDSR Timing

CS

0123456789101112131415

SCK

WRSR Timing

SI

SO

INSTRUCTION

HIGH IMPEDANCE

DATA OUT

76543210

MSB

READ Timing

CS

SCK

SI

SO

12

AT25F4096 [Advance Information]

0123445566778 9 10 11 28

3-BYTE ADDRESS

INSTRUCTION

HIGH IMPEDANCE

23 22 21 3

29 30 31 32 33 34 35 36 37 38 39

...

21

32100

2454C–SEEPR–8/04

Page 13

PROGRAM Timing

CS

AT25F4096 [Advance Information]

SCK

SI

SO

HOLD Timing

HOLD

0123456789101128

3-BYTE ADDRESS

INSTRUCTION

23 22 21 3 1 0 6 5 4 3 2 1 072

HIGH IMPEDANCE

CS

t

CD

SCK

t

HD

t

SO

29 30 31 32 33 34

1st BYTE DATA-IN

t

HD

HZ

2075

2076

t

CD

t

LZ

2077

2078

2079

256th BYTE DATA-IN

SECTOR ERASE Timing

2454C–SEEPR–8/04

X

X = Don’t Care bit

13

Page 14

CHIP ERASE Timing

19

RDID Timing

CS

X

X = Don’t Care bit

SCK

SI

SO

3

1

2

0

0

00 01

HIGH IMPEDANCE

4

5

1

X

8

6

910

7

1

11

12 13 14 15 16 17 18 19

MANUFACTURER

CODE (ATMEL)

7

20

DATA OUT

6543

DEVICE CODE

21 22

21

23

0

14

AT25F4096 [Advance Information]

2454C–SEEPR–8/04

Page 15

AT25F4096 [Advance Information]

Ordering Information

Ordering Code Package Operation Range

AT25F4096W-10SU-2.7 8S2 Lead-Free/Halogen-Free/

Industrial Temperature

(-40°C to 85°C)

Package Type

8S2 8-lead, 0.200" Wide, Plastic Gull Wing Small Outline Package (EIAJ SOIC)

Options

-2.7 Low Voltage (2.7V to 3.6V)

2454C–SEEPR–8/04

15

Page 16

Package Information

8S2 – EIAJ SOIC

C

1

Top View

E

N

∅

E1

L

End View

e

D

Side View

b

A

SYMBOL

A1

A 1.70 2.16

A1 0.05 0.25

b 0.35 0.48 5

C 0.15 0.35 5

D 5.13 5.35

E1 5.18 5.40 2, 3

E 7.70 8.26

L 0.51 0.85

∅

e 1.27 BSC 4

COMMON DIMENSIONS

(Unit of Measure = mm)

MIN

0˚ 8˚

NOM

MAX

NOTE

Notes: 1. This drawing is for general information only; refer to EIAJ Drawing EDR-7320 for additional information.

2. Mismatch of the upper and lower dies and resin burrs are not included.

3. It is recommended that upper and lower cavities be equal. If they are different, the larger dimension shall be regarded.

4. Determines the true geometric position.

5. Values b and C apply to pb/Sn solder plated terminal. The standard thickness of the solder layer shall be 0.010 +0.010/−0.005 mm.

TITLE

8S2, 8-lead, 0.209" Body, Plastic Small

Outline Package (EIAJ)

16

2325 Orchard Parkway

R

San Jose, CA 95131

AT25F4096 [Advance Information]

DRAWING NO.

8S2

2454C–SEEPR–8/04

10/7/03

REV.

C

Page 17

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the Company’s standard

warranty which is detailed in Atmel’s Terms and Conditions located on the Company’s web site. The Company assumes no responsibility for any

errors which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without notice, and

does not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are

granted by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are not authorized for use

as critical components in life support devices or systems.

© Atmel Corporation 2004. All rights reserved. Atmel® and combinations thereof, are the registered trademarks of Atmel Corporation or its

subsidiaries. Other terms and product names may be the trademarks of others.

Printed on recycled paper.

2454C–SEEPR–8/04

Loading...

Loading...