Page 1

November 2002

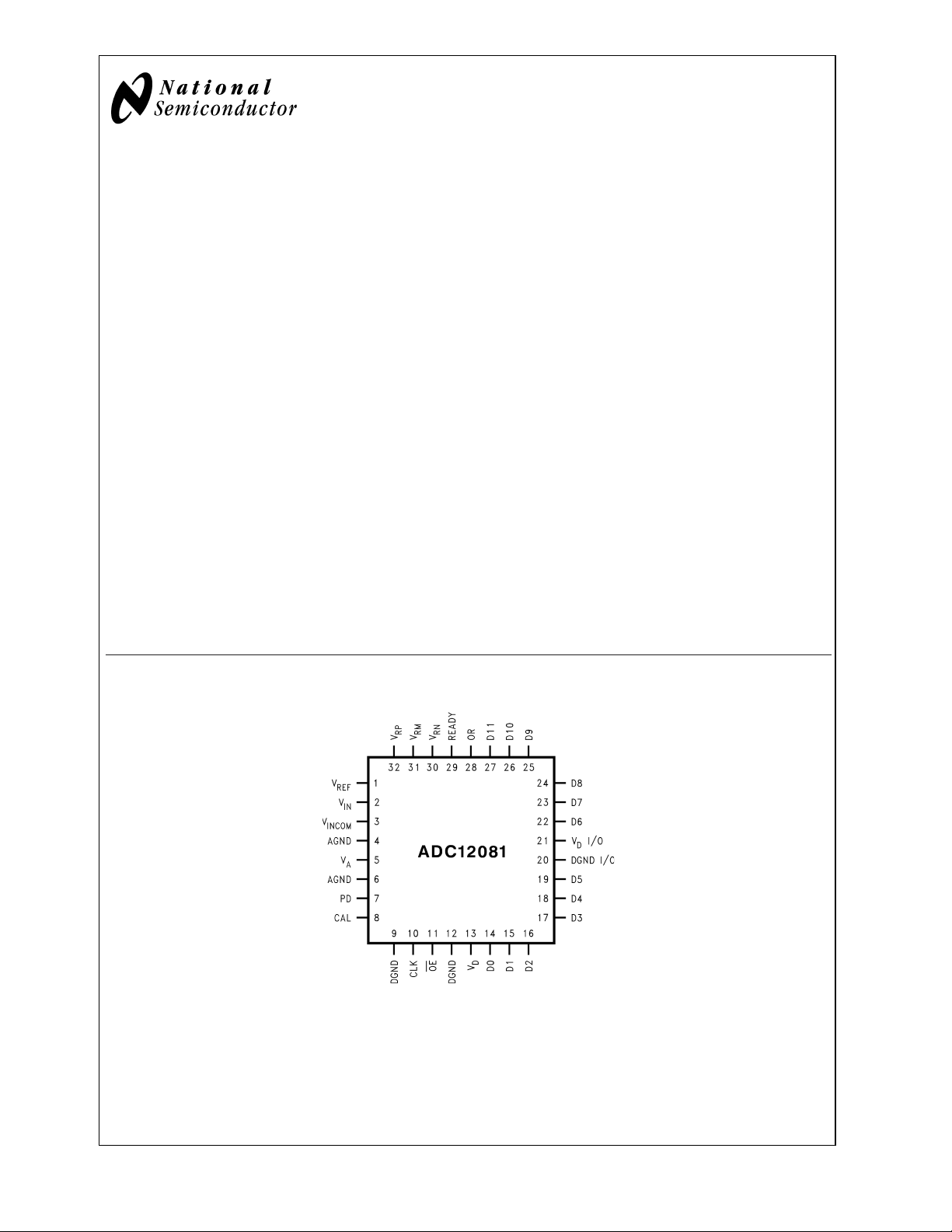

ADC12081

12-Bit, 5 MHz Self-Calibrating, Pipelined A/D Converter

with Internal Sample & Hold

General Description

The ADC12081 is a monolithic CMOS analog-to-digital converter capable of converting analog input signals into 12-bit

digital words at 5 megasamples per second (MSPS). The

ADC12081 utilizes an innovative pipeline architecture to

minimize die size and power consumption. The ADC12081

uses self-calibration and error correction to maintain accuracy and performance over temperature.

The ADC12081 converter operates on a 5V power supply

and can digitize analog input signals in the range of 0 to 2V.

A single convert clock controls the conversion operation. All

digital I/O is TTL compatible.

The ADC12081 is designed to minimize external components necessary for the analog input interface. An internal

sample-and-hold circuit samples the analog input and an

internal amplifier buffers the reference voltage input.

The ADC12081 is available in the 32-lead LQFP package

and is designed to operate over the extended commercial

temperature range of -40˚C to +85˚C.

Features

n Single 5V power supply

n Simple analog input interface

n Internal Sample-and-hold

n Internal Reference buffer amplifier

n Low power consumption

Key Specifications

n Resolution 12 Bits

n Conversion Rate 5 Msps (min)

n DNL

n SNR 68 dB (typ)

n ENOB 10.9 Bits (typ)

n Analog Input Range 2 Vpp (min)

n Supply Voltage +5V

n Power Consumption, 5 MHz 105 mW (typ)

±

0.35 LSB (typ)

Applications

n Image processing front end

n PC-based data acquisition

n Scanners

n Fax machines

n Waveform digitizer

ADC12081 12-Bit, 5 MHz Self-Calibrating, Pipelined A/D Converter with Internal Sample & Hold

±

5%

Connection Diagram

10015001

© 2002 National Semiconductor Corporation DS100150 www.national.com

Page 2

Ordering Information

ADC12081

ADC12081CIVT 32 pin LQFP

ADC12181 EVAL Evaluation Board

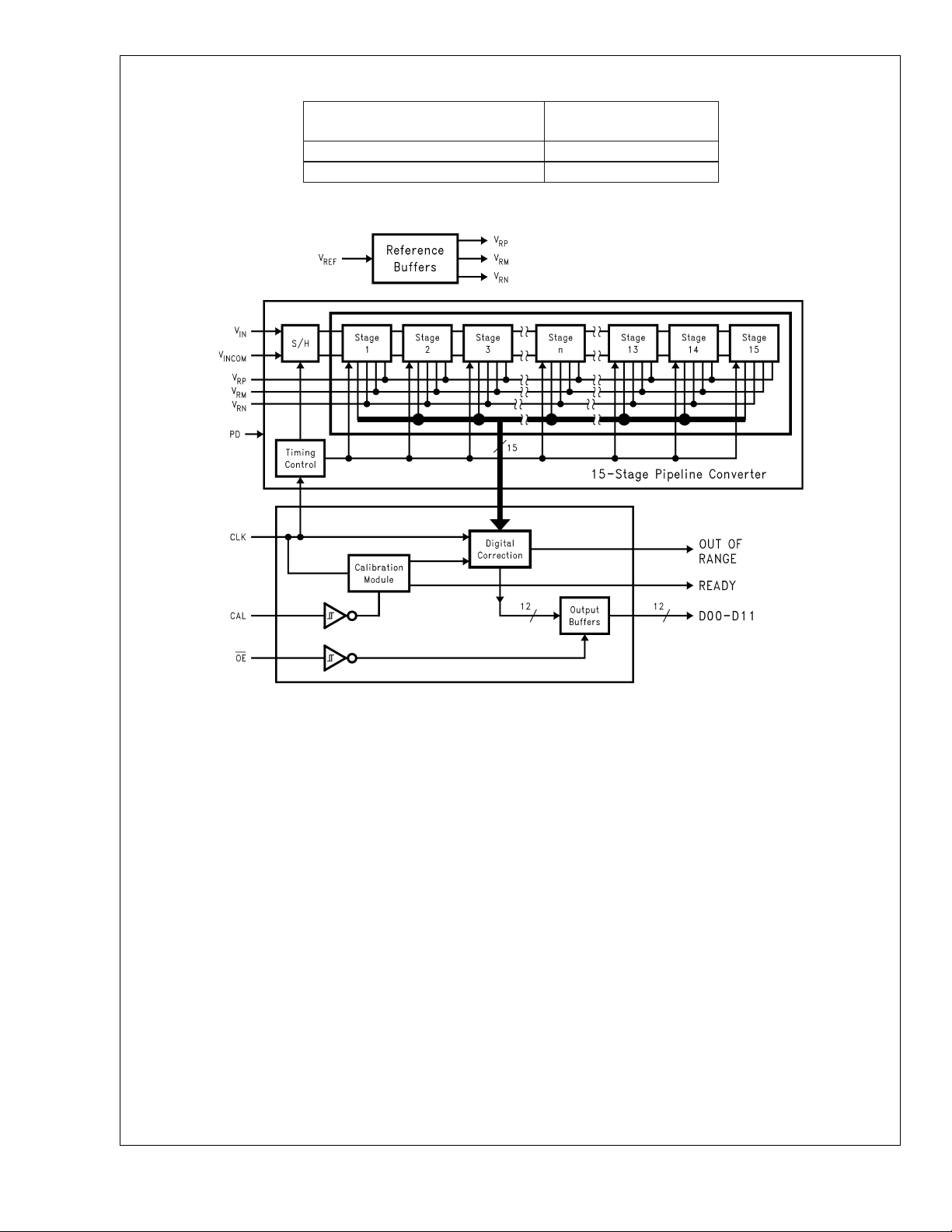

Simplified Block Diagram

Industrial

(−40˚C ≤ TA ≤ +85˚C) Package

10015002

www.national.com 2

Page 3

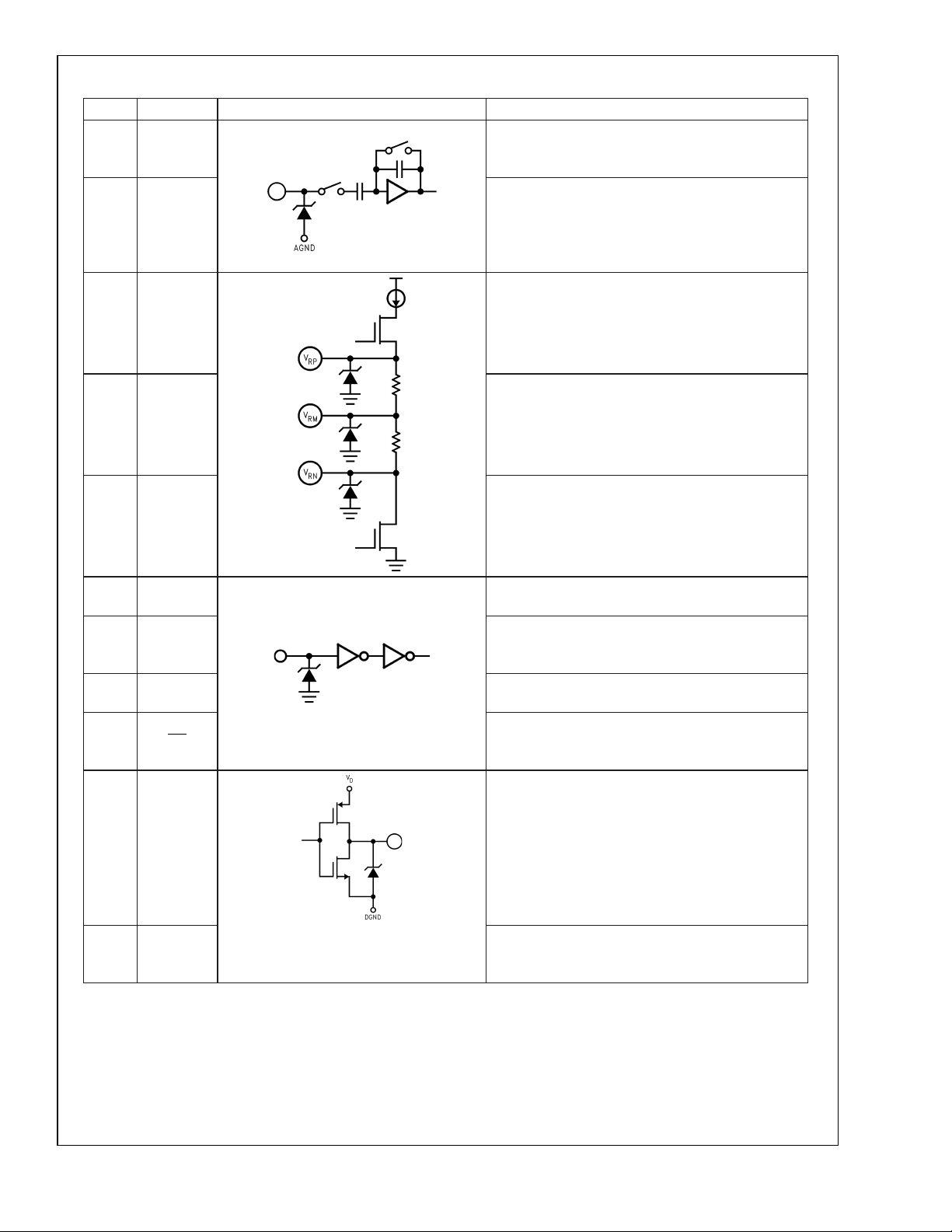

Pin Descriptions and Equivalent Circuits #2

No. Symbol Equivalent Circuit Description

Analog signal input. With a 2.0V reference voltage,

2V

1V

32 V

31 V

IN

REF

RP

RM

input signal voltages in the range of 0 to 2.0 Volts

will be converted. See section 1.2.

Reference voltage input. This pin should be driven

from an accurate, stable reference source in the

range of 1.8 to 2.2V and bypassed to a low-noise

analog ground with a monolithic ceramic capacitor,

nominally 0.01µF. See section 1.1.

Positive reference bypass pin. Bypass with a 0.1µF

capacitor. Do not connect anything else to this pin.

See section 3.1

Reference midpoint bypass pin. Bypass with a 0.1µF

capacitor. Do not connect anything else to this pin.

See section 3.1

ADC12081

30 V

RN

10 CLOCK

8 CAL

7PD

11 OE

28 OR

29 READY

Negative reverence bypass pin. Bypass with a 0.1µF

capacitor. Do not connect anything else to this pin.

See section 3.1

Sample Clock input, TTL compatible. Maximum

amplitude should not exceed 3V.

Calibration request, active High. Calibration cycle

starts when CAL returns to logic low. CAL is ignored

during power-down mode. See section 2.2.

Power-down, active High, ignored during calibration

cycle. See paragraph 2.4

Output enable control, active low. When this pin is

high the data outputs are in Tri-state

(high-impedance) mode.

Over range indicator. This pin is at a logic High for

V

IN

<

0 or for V

>

V

REF

.

IN

Device ready indicator, active High. This pin is at a

logic Low during a calibration cycle and while the

device is in the power down mode.

www.national.com3

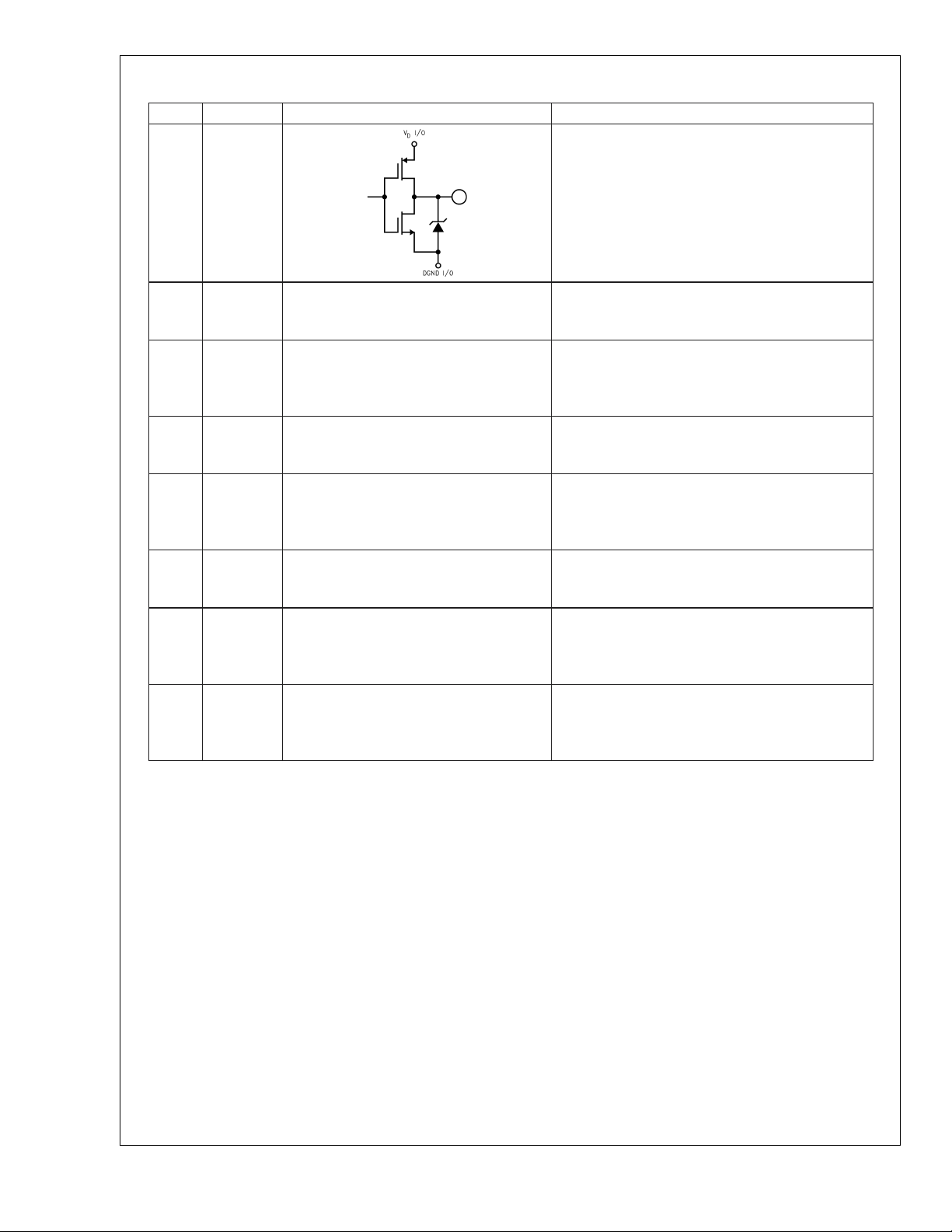

Page 4

Pin Descriptions and Equivalent Circuits #2 (Continued)

ADC12081

No. Symbol Equivalent Circuit Description

14-19,

22-27

3V

5V

4, 6 AGND

13 V

9, 12 DGND

21 V

20 DGND I/O

D0 - D11

IN com

A

D

I/O

D

Digital output word, CMOS compatible. D0 (pin 14) is

LSB, D11 (pin 27) is MSB. Load with no more than

50pF.

Analog input common. Connect to a quiet point in

analog ground near the driving device. See section

1.2.

Positive analog supply pin. Connect to a clean, quiet

voltage source of +5V. V

and VDshould have a

A

common supply and be separately bypassed with a

5µF to 10µF capacitor and a 0.1µF chip capacitor.

The ground return for the analog supply. AGND and

DGND should be connected together close to the

ADC12081 package. See section 5.0.

Positive analog supply pin. Connect to a clean, quiet

voltage source of +5V. V

and VDshould have a

A

common supply and be separately bypassed with a

5µF to 10µF capacitor and a 0.1 µF chip capacitor.

The ground return for the analog supply. AGND and

DGND should be connected together close to the

ADC12081 package. See section 5.0

The digital output driver supply pin. This pin can be

operated from a supply voltage of 3V to 5V, but the

voltage on this pin should never exceed the V

D

supply pin voltage.

The ground return for the output drivers. This pin

should be returned to a point in the digital ground

that is removed from the other ground pins of the

ADC12081.

www.national.com 4

Page 5

ADC12081

Absolute Maximum Ratings (Notes 1,

2)

Storage Temp. −65˚C to +150˚C

Maximum Junction Temp. 150˚C

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage 6.5V

Voltage on Any Output −0.3V to V

Input Current at Any Pin (Note 3)

Package Input Current (Note 3)

+

+0.3V

±

25mA

±

50mA

Package Dissipation See (Note 4)

ESD Susceptibility

Operating Ratings

Operating Temp. Range −40˚C ≤ TA≤ +85˚C

Supply Voltage +4.75V to +5.25V

V

I/O +2.7V to V

D

V

Input 1.8V to 2.2V

REF

CLOCK, CAL, PD, OE −0.05V to V

|AGND −DGND| ≤100mV

+ 0.05V

D

Human Body Model 1500V

Machine Model 150V

Soldering Temp., Infrared, 10

300˚C

sec.(Note 6)

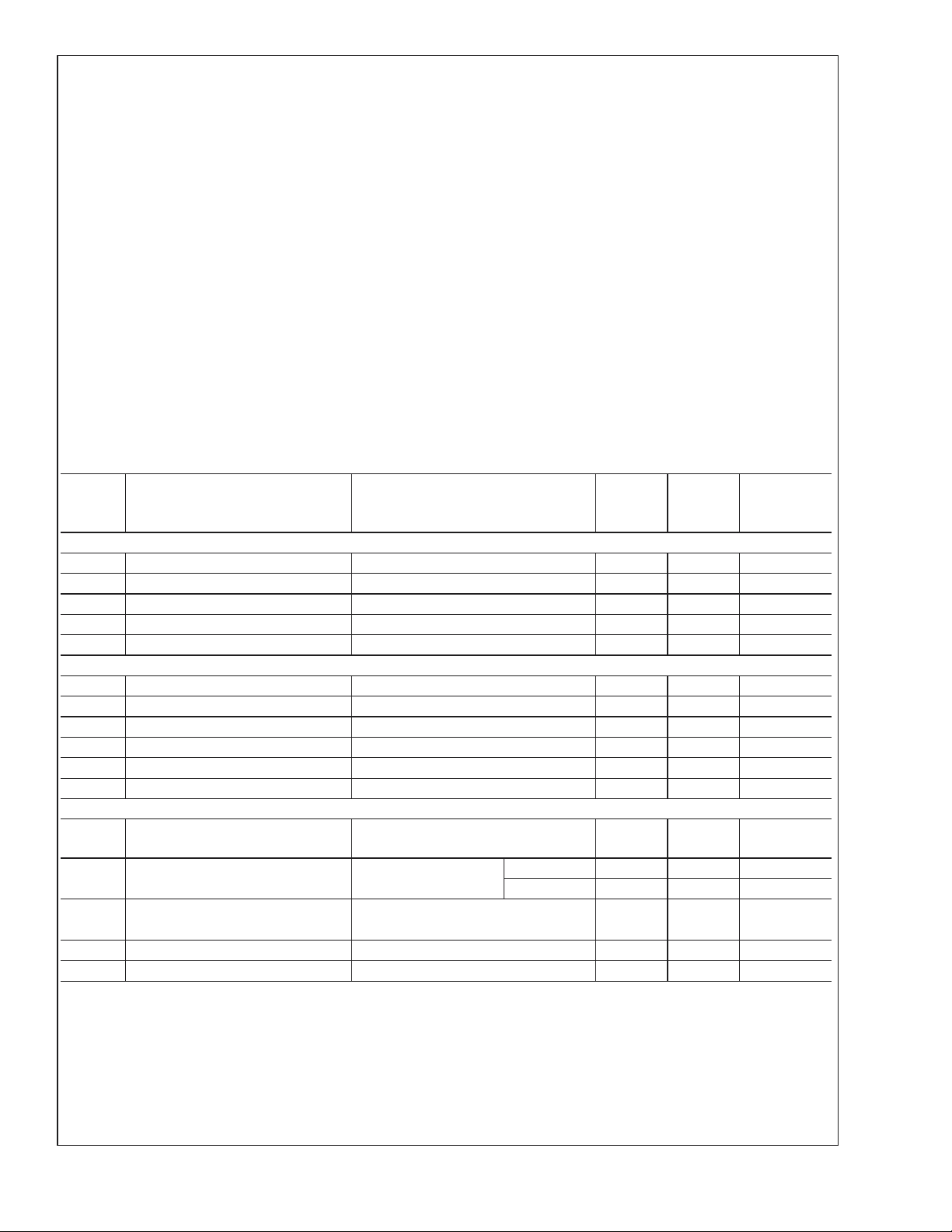

Converter Electrical Characteristics

The following specifications apply for AGND = DGND = DGND I/O = 0V, VA=VD=VDI/O = +5V, PD = +5V, V

= 5MHz, CL= 50 pF/pin. After Auto-Cal at Temperature. Boldface limits apply for TA=TJto T

f

CLK

limits T

= 25˚C (Notes 7, 8) and (Note 9)

A=TJ

Symbol Parameter Conditions

Typical

(Note

10)

MIN

Limits

(Note

to T

11)

Static Converter Characteristics

Resolution with No Missing Codes 12 Bits(min)

INL Integral Non Linearity

DNL Differential Non Linearity

Full-Scale Error

Zero Error

±

±

±

±

0.6

0.35

0.05

0.15

±

1.7 LSB( max)

±

0.75 LSB( max)

±

0.1 %FS(max)

±

0.24 %FS(max)

Dynamic Converter Characteristics

BW Full Power Bandwidth 100 MHz

SNR Signal-to-Noise Ratio f

SINAD Signal-to-Noise & Distortion f

ENOB Effective Number of Bits f

THD Total Hamonic Distortion f

SFDR Spurious Free Dynamic Range f

= 2.5 MHz, VIN= 2.0V

in

= 2.5 MHz, VIN= 2.0V

in

= 2.5 MHz, VIN= 2.0V

in

= 2.5 MHz, VIN= 2.0V

in

= 2.5 MHz, VIN= 2.0V

in

P-P

P-P

P-P

P-P

P-P

68 65 dB

67.6 64.5 dB

10.9 10.4 Bits

79 dB

79 dB

Reference and Analog Input Characteristics

V

IN

C

IN

V

REF

Input Voltage Range V

VINInput Capacitance

= 2.0V

REF

V

= 1.0Vdc +

IN

0.7Vrms

(CLK LOW) 10 pF

(CLK HIGH) 15 pF

Reference Voltage (Note 14) 2.00

0

V

REF

1.8 V(min)

2.2 V(max)

Reference Input Leakage Current 10 µA

Reference Input Resistance 1 MΩ(min)

REF

MAX

= +2.0V,

: all other

Units

(Limits)

V(min)

V(max)

D

www.national.com5

Page 6

DC and Logic Electrical Characteristics

The following specifications apply for AGND = DGND = DGND I/O = 0V, VA=VD=VDI/O = +5V, PD = +5V, V

= 50MHz, CL= 50 pF/pin. After Auto-Cal at Temperature. Boldface limits apply for TA=T

f

CLK

ADC12081

T

= 25˚C (Note 7) (Note 8) and (Note 9)

A=TJ

Symbol Parameter Conditions

CLK, OE Digital Input Characteristics

V

IH

V

IL

I

IH

I

IL

C

IN

Logical "1" Input Voltage V+ = 5.25V 2.0 V(min)

Logical "0" Input Voltage V+ = 4.75V 0.8 V(min)

Logical "1" Input Current VIN= 5.0V 5 µA

Logical "0" Input Current VIN=0V −5 µA

VINInput Capacitance 8 pF

D0 - D11 Digital Output Characteristics

V

OH

V

OL

I

OZ

+I

SC

−I

SC

Logical "1" Output Voltage I

Logical "0" Output Voltage I

TRI-STATE®Output Current V

Output Short Circuit Source

Current

= −1mA 4 V (min)

OUT

= 1.6mA 0.4 V (max)

OUT

=3Vor5V 10 µA

OUT

V

= 0V −10 µA

OUT

VDDO= 3V, V

Output Short Circuit Sink Current VDDO= 3V, V

Power Supply Characteristics

I

A

I

D

Analog Supply Current

Digital Supply Current

Total Power Consumption

PD = VDDO

PD = DGND

PD = VDDO

PD = DGND

PD = VDDO

PD = DGND

= 0V −14

OUT

OUT=VO

MIN

Typical

(Note

10)

16 mA(min)

2.5

20

0.5

1

15

105

to T

Limits

; all other limits

MAX

(Note

11)

4

26

2

2

30

140

REF

mA(max)

mA(max)

mA(max)

mA(max)

mW(max)

mW(max)

= +2.0V,

Units

(Limits)

mA(min)

AC Electrical Characteristics

The following specifications apply for AGND = DGND = DGND I/O = 0V, VA=VD=VDI/O = +5V, PD = +5V, V

= 5 MHz, CL= 50 pF/pin. After Auto-Cal at Temperature. Boldface limits apply for TA=T

f

CLK

=TJ= 25˚C (Note 7) (Note 8) and (Note 10)

Symbol Parameter Conditions

f

CLK

Clock Frequency

Clock Duty Cycle 50 %

t

CONV

t

AD

t

OD

t

DIS

t

EN

t

WCAL

t

RDYC

t

CAL

t

WPD

t

RDYPD

t

PD

Conversion Latency 10.25

Aperture Delay Time 3.5 ns

I/O=3V 44

Data output delay after rising clk

edge

V

D

V

I/O=5V 40

D

Data outputs into Tristate mode 21 nA (max)

Data outputs active after Tristate 21 ns (max)

Calibration request pulse width 3 Tclk(min)

Ready Low after CAL request 3 Tclk

Calibration cycle 4000 Tclk

Power-down pulse width 3 Tclk(min)

Ready Low after PD request 3 Tclk

Power down mode exit cycle 4000 Tclk

Typical

(Note

to T

MIN

MAX

Limits

(Note

10)

11)

0.5 MHz(min)

5 MHz(max)

= +2.0V,

REF

; all other limits T

Units

(Limits)

Clock

Cycles

ns

A

www.national.com 6

Page 7

AC Electrical Characteristics (Continued)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test

conditions.

Note 2: All voltages are measured with respect to GND = AGND = DGND = 0V, unless otherwise specified.

Note 3: When the input voltage at any pin exceeds the power supplies (that is, V

to 25 mA. The 50 mA maximum package input current rating limits the number of pins that can safely exceed the power supplies with an input current of 25 mA to

two.

Note 4: The absolute maximum junction temperatures (T

junction-to-ambient thermal resistance (θ

TQFP, θ

of this device under normal operation will typically be about 125 mW (typical power consumption + 20 mW TTL output loading). The values for maximum power

consumption listed above will be reached only when the ADC12081 is operated in a severe fault condition (e.g. when input or output pins are driven beyond the

power supply voltages, or the power supply polarity is reversed). Obviously, such conditions should always be avoided.

Note 5: Human body model is 100 pF capacitor discharged through a 1.5kΩ resistor. Machine model is 220 pf discharged through ZERO Ohms.

Note 6: See AN450, "Surface Mounting Methods and Their Effect on Product Reliability", or the section entitled "Surface Mount" found in any post 1986 National

Semiconductor Linear Data Book, for other methods of soldering surface mount devices.

Note 7: The inputs are protected as shown below. Input voltage magnitudes up to 5V above V

is limited per Note 3. However, errors in the A/D conversion can occur if the input goes above V

the full-scale input voltage must be ≤4.85V to ensure accurate conversions.

is 74˚C/W, so PDMAX = 1,689 mW at 25˚C and 1,013 mW at the maximum operating ambient temperature of 75˚C. Note that the power consumption

JA

), and the ambient temperature, (TA), and can be calculated using the formula PDMAX=(TJmax - TA)/θJA. In the 32-pin

JA

max) for this device is 150˚C. The maximum allowable power consumption is dictated by TJmax, the

J

<

IN

AGND, or V

>

VA,VDor VDI/O), the current at that pin should be limited

IN

or to 5V below GND will not damage this device, provided current

A

or below GND by more than 100 mV. As an example, if VAis 4.75V,

A

ADC12081

10015008

Note 8: To guarantee accuracy, it is required that |VA-VD| ≤ 100mV and separate bypassed capacitors are used at each power supply pin.

Note 9: With the test condition for V

Note 10: Typical figures are at T

Note 11: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 12: Integral Non Linearity is defined as the deviation of the analog value, expressed in LSBs, from the straight line that passes through positive full-scall and

zero.

Note 13: Timing specifications are tested at the TTL logic levels, V

to 1.4V.

Note 14: Optimum SNR performance will be obtained by keeping the reference input in the 1.8V to 2.2V range. The LM4041CIM3-ADJ (SOT-23 package), the

LM4041CIZ-ADJ (TO-92 package), or the LM4041CIM-ADJ (SOT-8 package) bandgap voltage reference is recommended for this application.

= +2.0V, the 12-bit LSB is 488µV.

REF

= 25˚C, and represent most likely parametric norms.

A=TJ

= 0.4V for a falling edge and VIH= 2.4V for a rising edge. TRI-STATE output voltage is forced

IL

www.national.com7

Page 8

ADC12081

10015009

FIGURE 1. Transfer Characteristic

FIGURE 2. Errors Minimized by the Auto-Cal Cycle

Typical Performance Characteristics

INL vs Temperature DNL vs Temperature

10015011

10015010

10015012

www.national.com 8

Page 9

Typical Performance Characteristics (Continued)

SNR vs Temperature SINAD vs Temperature

10015013 10015014

THD vs Temperature

ADC12081

10015015

www.national.com9

Page 10

Specification Definitions

APERTURE JITTER is the variation in aperture delay from

sample to sample. Aperture jitter shows up as input noise.

ADC12081

APERTURE DELAY See Sampling Delay.

CLOCK DUTY CYCLE is the ratio of the time that the clock

waveform is high to the total time for one clock cycle.

DIFFERENTIAL NON-LINEARITY (DNL) is the measure of

the maximum deviation from the ideal step size of 1 LSB.

EFFECTIVE NUMBER OF BITS (ENOB, or EFFECTIVE

BITS) is another method of specifying Signal-to-Noise and

Distortion Ratio, or SINAD. ENOB is defined as (SINAD -

1.76) / 6.02 and says that the converter is equivalent to a

perfect ADC of this (ENOB) number of bits.

FULL POWER BANDWIDTH is the frequency at which the

reconstructed output fundamental drops 3 dB below its low

frequency value for a full scale input.

FULL SCALE ERROR is the difference between the input

voltage just causing a transition to positive full scale and

-1.5 LSB.

V

REF

INTEGRAL NON-LINEARITY (INL) is a measure of the

deviation of each individual code from a line drawn from

negative full scale (

through positive full scale (1

transition). The deviation of any given code from this straight

line is measured from the center of that code value. The end

point test method is used. INL is commonly measured at

rated clock frequency with a ramp input.

INTERMODULATION DISTORTION (IMD) is the creation of

additional spectral components as a result of two sinusoidal

frequencies being applied to the ADC input at the same time.

It is defined as the ratio of the power in the intermodulation

products to the total power in the original frequencies. IMD is

usually expressed in dB.

1

⁄2LSB below the first code transition)

1

⁄2LSB above the last code

PIPELINE DELAY (LATENCY) is the number of clock cycles

between initiation of conversion and the availability of that

conversion result at the output. New data is available at

every clock cycle, but the data lags the conversion by the

pipeline delay plus the Output Delay.

SAMPLING (APERTURE) DELAY is the time after the edge

of the clock to when the input signal is acquired or held for

conversion.

SIGNAL TO NOISE PLUS DISTORTION (S/(N+D) or SINAD) is the ratio expressed in dB, of the rms value of the

input signal to the rms value of all of the other spectral

components below half the clock frequency, including harmonics but excluding dc.

SIGNAL TO NOISE RATIO (SNR) is the ratio of the rms

value of the input signal to the rms value of the other spectral

components below one-half the sampling frequency, not including harmonics or dc.

SPURIOUS FREE DYNAMIC RANGE (SFDR) is the difference, expressed in dB, between the rms values of the input

signal and the peak spurious signal, where a spurious signal

is any signal present in the output spectrum that is not

present at the input.

TOTAL HARMONIC DISTORTION (THD) is the ratio of the

rms total of the first six harmonic components, to the rms

value of the input signal.

ZERO SCALE OFFSET ERROR is the difference between

the ideal input voltage (

1

⁄2LSB) and the actual input voltage

that just causes a transition from an output code of zero to

an output code of one.

ZERO ERROR see Zero Scale Offset Error.

www.national.com 10

Page 11

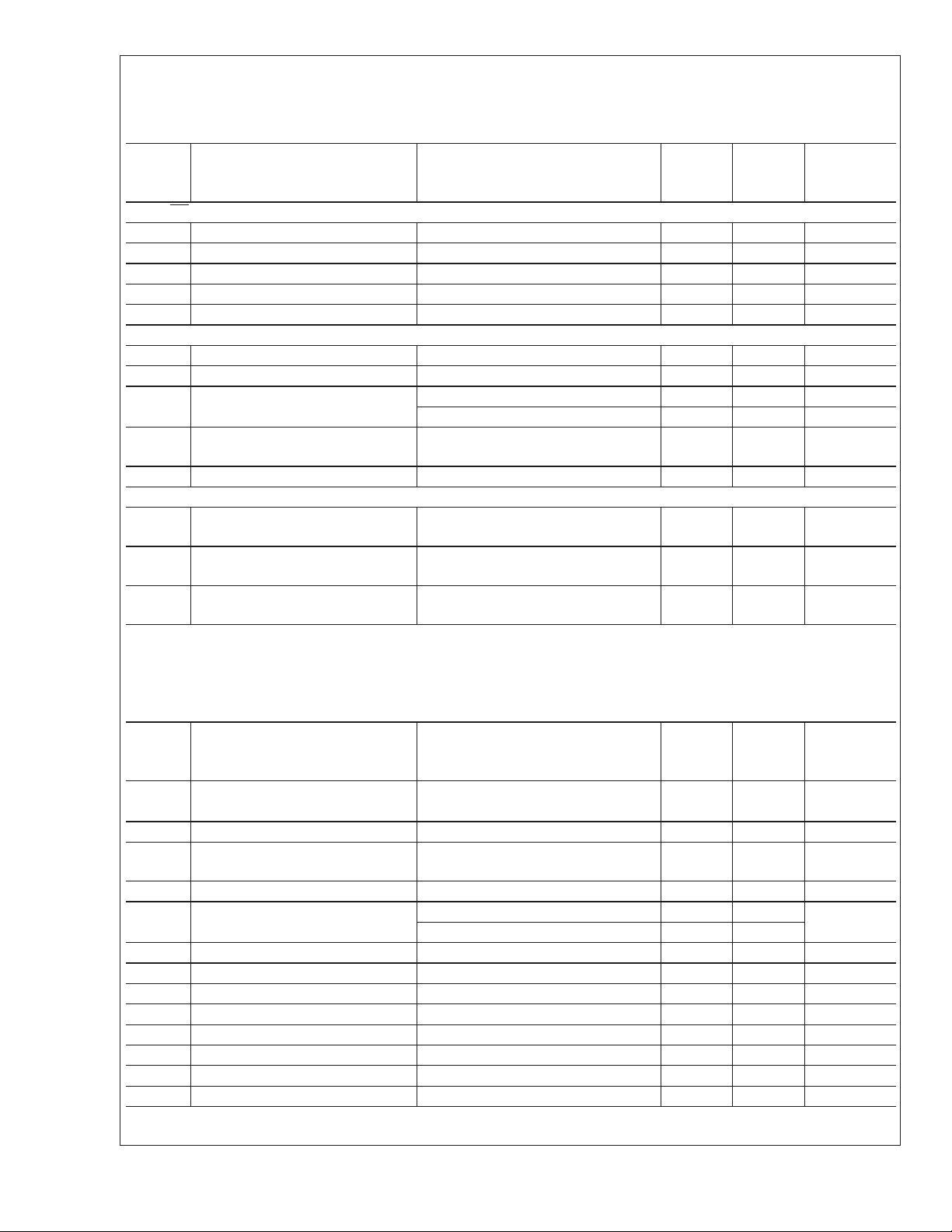

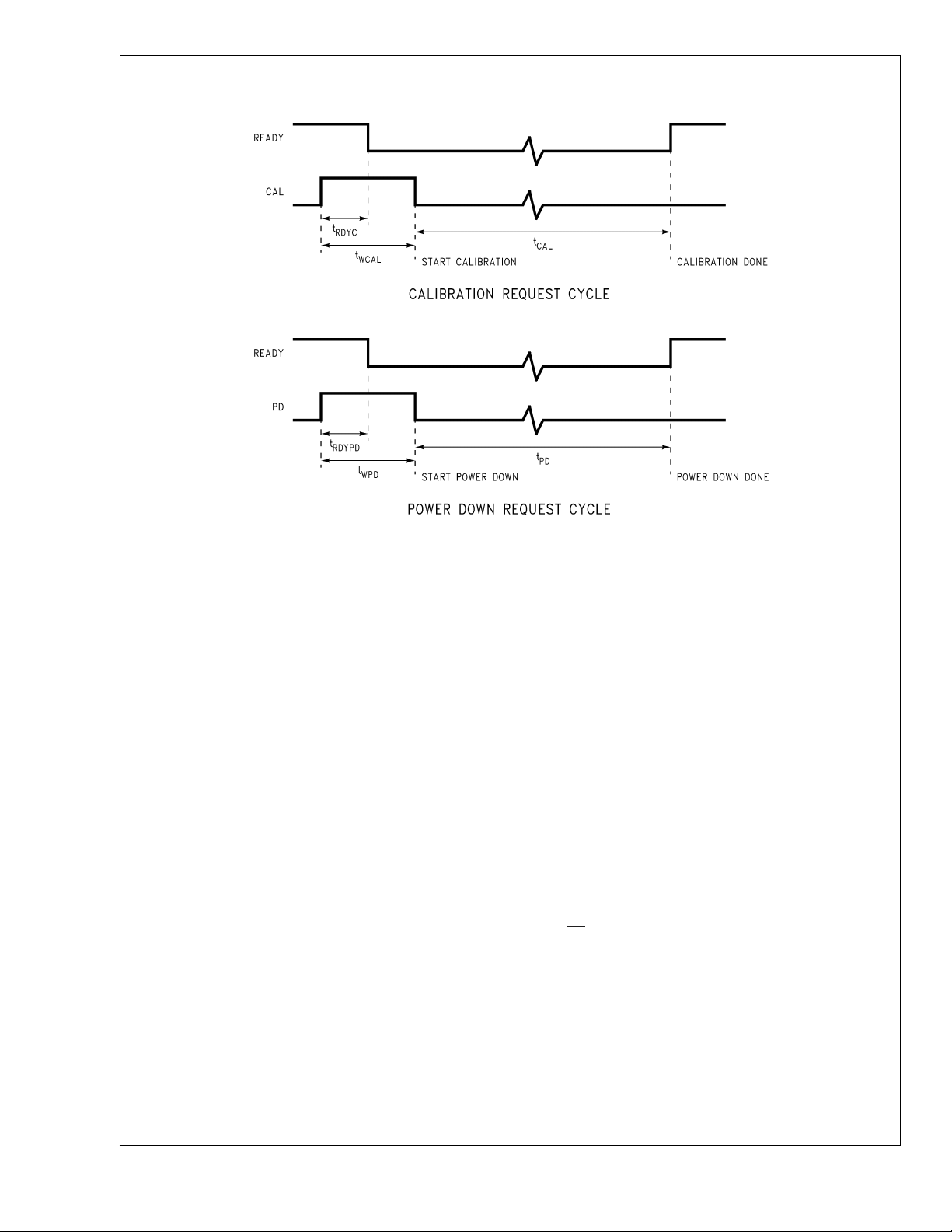

Timing Diagrams

ADC12081

FIGURE 3. Data Output Timing

10015021

www.national.com11

Page 12

Timing Diagrams (Continued)

ADC12081

10015022

FIGURE 4. Reset and Calibration Timing

Functional Description

The ADC12081 is a monolithic CMOS analog-to-digital converter capable of converting analog input signals into 12-bit

digital words at 5 megasamples per second (MSPS). This

device utilizes a proprietary pipeline architecture and algorithm to minimize die size and power consumption. The

ADC12081 uses self-calibration and digital error correction

to maintain accuracy and performance over temperature.

The ADC12081 has an input sample-and-hold amplifier and

internal reference buffer. The analog input and the reference

voltage are converted to differential signals for internal use.

Using differential signals in the analog conversion core reduces crosstalk and noise pickup from the digital section and

power supply.

The pipeline conversion core has 15 sequential signal processing stages. Each stage receives an analog signal from

the previous stage (called “residue” ) and produces a 1-bit

digital output that is sent to the digital correction module. At

each stage the analog signal received from the previous

stage is compared to an internally generated reference level.

It is then amplified by a factor of 2, and, depending on the

output of the comparator, the internal reference signal may

be subtracted from the amplifier output. This produces the

residue that is passed to the next stage.

The calibration module is activated at power-on or by user

request. During calibration the conversion core is put into a

special mode of operation in order to determine inherent

errors in the analog conversion blocks and to determine

correction coefficients for each digital output bit from the

conversion core and stores these coefficients in RAM. The

digital correction module uses the coefficients in RAM to

convert the raw data bits from the conversion core into the

12-bit digital output code.

Applications Information

1.0 ANALOG INPUTS

The ADC12081 has two single-ended analog inputs. V

the reference input and V

is the signal input.

IN

1.1 Reference Input

The V

input must be driven from an accurate, stable

REF

reference voltage source. of 1.8V to 2.2V, and bypassed to a

clean, quiet point in analog ground.

1.2 Analog Signal Input

The V

input must be driven with a low impedance signal

IN

source that does not add any distortion to the input signal.

The ground reference for the V

V

pin must be connected to a clean, quiet point in

INCOM

input is the V

IN

INCOM

analog ground.

2.0 DIGITAL INPUTS

The ADC12081 has four digital inputs. They are CLOCK,

CAL, OE and PD.

2.1 CLOCK

The CLOCK signal drives an internal phase delay loop to

create timing for the ADC. The clock input should be driven

with a stable, low phase jitter TTL level clock signal in the

range of 0.5 to 5 MHz. The trace carrying the clock signal

should be as short as possible. This trace should not cross

any other signal line, analog or digital, not even at 90˚. A 100

Ohm resistor should be placed in series with the CLOCK pin,

as close to the pin as possible.

REF

pin. The

is

www.national.com 12

Page 13

Applications Information (Continued)

2.2 CAL

The level sensitive CAL input must be pulsed high for at least

three clock cycles to begin ADC calibration. For best performance, calibration should be performed about ten seconds

after power up, after resetting the ADC, and after the temperature has changed by more than 50˚C since the last

calibration was performed.

Calibration should be performed at the same clock frequency that the ADC12081 will be used for conversions to

minimize offset errors. Calibration takes 4000 clock cycles.

Irrelevant data may appear during CAL.

2.3 OE Pin

The OE pin is used to control the state of the outputs. When

the OE pin is low, the output buffers go into the active state.

When the OE input is high, the output buffers are in the high

impedance state.

2.4 PD Pin

The PD pin, when high, holds the ADC12081 in a powerdown mode where power consumption is typically less than

15 mW to conserve power when the converter is not being

used. The ADC12081 will begin normal operation within t

after this pin is brought low, provided a valid CLOCK input is

present. The data in the pipeline is corrupted while in the

power down mode. The ADC12081 should be re-calibrated

after a power-down cycle to ensure optimum performance.

3.0 OUTPUTS

The ADC12081 has three analog outputs: reference output

voltages V

RN,VRM

, and VRP. There are 14 digital outputs:

12 Data Output pins, Ready and OR (Out of range).

3.1 Reference Output Voltages

The reference output voltages are made available only for

the purpose of bypassing with capacitors to a clean analog

ground. The recommended bypass capacitors are 0.1µF

ceramic chip capacitors. Do not load these pins.

3.2 Ready Output

The Ready output goes high to indicate that the converter is

ready for operation. This signal will go low when the converter is Calibration or Power Down made.

PD

3.3 OR (Out of Range) Output

The OR output goes high when the analog input is below

GND or above V

is in the valid range of operation (0V ≤ V

. This output is low when the input signal

REF

≤ V

IN

REF

).

3.4 Data Outputs

The Data Outputs are TTL/CMOS compatible. The output

data format is 12 bits straight binary.

Minimizing the digital output currents will help to minimize

noise due to output switching. This can be done by connecting buffers between the ADC outputs and any other circuitry.

Only one buffer input should be connected to each output.

Additionally, inserting series resistors of 47 to 56 Ohms right

at the digital outputs, close to the ADC pins, will isolate the

outputs from other circuitry and limit output currents.

4.0 POWER SUPPLY CONSIDERATIONS

Each power pin should be bypassed with a parallel combination of a 10µF capacitor and a 0.1µF ceramic chip capacitor. The chip capacitors should be within 1/2 centimeter of

the power pins. Leadless chip capacitors are preferred because they provide low lead inductance.

The converter’s digital logic supply (V

) should be well iso-

D

lated from the supply that is used for other digital circuitry on

the board. A common power supply should be used for both

(analog supply) and VD(digital supply), and each of these

V

A

supply pins should be separately bypassed with a 0.1µF

ceramic capacitor and a low ESR 10µF electrolytic capacitor.

A ferrite bead or inductor should be used between V

and V

A

to prevent noise coupling from the digital supply into the

analog circuit.

I/O is the power pin for the output driver. This pin may be

V

D

supplied with a potential between 2.7V and V

. This makes

D

it easy to interface the ADC12081 with 3V or 5V logic families. Powering the V

I/O from 3 Volts will also reduce power

D

consumption and noise generation due to output switching.

DO NOT operate the V

! All power supplies connected to the device should be

V

A

I/O at a voltage higher than VDor

D

applied simultaneously.

As is the case with all high speed converters, the ADC12081

is sensitive to power supply noise. Accordingly, the noise on

the analog supply pin should be minimized, keeping it below

100mV P-P.

ADC12081

D

www.national.com13

Page 14

Applications Information (Continued)

ADC12081

FIGURE 5. Basic Connections Diagram

5.0 LAYOUT AND GROUNDING

Proper grounding and routing of all signals is essential to

ensure accurate conversion. Separate analog and digital

ground planes that are connected beneath the ADC12081

are required to achieve specified performance. The analog

and digital grounds may be in the same layer, but should be

separated from each other and should never overlap each

other. Separation should be at least 1/8 inch, where possible.

The ground return for the output buffer digital supply (DGND

I/O) carries the ground current for the output drivers. This pin

should be connected to the system digital ground. The current on this pin can exhibit high transients that could add

noise to the conversion process. To prevent this from happening, the DGND I/O pin should NOT be connected in close

proximity to any of the ADC12081’s other ground pins. See .

Capacitive coupling between the typically noisy digital

ground plane and the sensitive analog circuitry can lead to

poor performance that may seem impossible to isolate and

remedy. The solution is to keep the analog circuitry separated from the digital circuitry and from the digital ground

plane.

Digital circuits create substantial supply and ground current

transients. The logic noise thus generated could have significant impact upon system noise performance. The best

10015023

logic family to use in systems with A/D converters is one

which employs non-saturating transistor designs, or has low

noise characteristics, such as the 74LS, 74HC(T) and 74

AC(T)Q families. The worst noise generators are logic families that draw the largest supply current transients during

clock or signal edges, like the 74F and the 74AC(T) families.

Since digital switching transients are composed largely of

high frequency components, total ground plane copper

weight will have little effect upon the logic-generated noise.

This is because of the skin effect. Total surface area is more

important than is total ground plane volume.

An effective way to control ground noise is by connecting the

analog and digital ground planes together beneath the ADC

with a copper trace that is very narrow compared with the

rest of the ground plane. This narrowing beneath the converter provides a fairly high impedance to the high frequency

components of the digital switching currents, directing them

away from the analog pins. The relatively lower frequency

analog ground currents do not create a significant voltage

drop across the impedance of this narrow ground connection.

To maximize accuracy in high speed, high resolution systems, avoid crossing analog and digital signal traces. It is

important to keep any clock lines isolated from ALL other

lines. Even the generally accepted 90 degree crossing

www.national.com 14

Page 15

Applications Information (Continued)

should be avoided as even a little coupling can cause problems at high frequencies. This is because other lines can

introduce phase noise (jitter) into the clock line, which can

lead to degradation of SNR.

Best performance at high frequencies and at high resolution

is obtained with a straight signal path. That is, the signal path

through all components should form a straight line wherever

possible.

Be especially careful with the layout of inductors. Mutual

inductance can change the characteristics of the circuit in

ADC12081

which they are used. Inductors should not be placed side by

side, even with just a small part of their bodies beside each

other.

The analog input should be isolated from noisy signal traces

to avoid coupling of spurious signals into the input. Any

external component (e.g., a filter capacitor) connected between the converter’s input and ground should be connected

to a very clean point in the analog ground plane.

FIGURE 6. Layout example

Figure 6 gives an example of a suitable layout. All analog

circuitry (input amplifiers, filters, reference components, etc.)

should be placed on or over the analog ground plane. All

digital circuitry and I/O lines should be placed over the digital

ground plane.

All ground connections should have a low inductance path to

ground.

6.0 LAYOUT AND GROUNDING

The ADC12081 can achieve impressive dynamic performance. To achieve the best dynamic performance with the

ADC12081, the clock source driving the CLK input must be

free of jitter. For best ac performance, isolating the ADC

clock from any digital circuitry should be done with adequate

buffers, as with a clock tree. See Figure 7.

10015024

10015025

FIGURE 7. Isolating the ADC clock from other circuitry

with a clock tree.

It is good practice to keep the ADC clock line as short as

possible and to keep it well away from any other signals.

Other signals can introduce phase noise (jitter) into the clock

signal, which can lead to increased distortion. Even lines

with 90˚ crossings have capacitive coupling, so try to avoid

even these 90˚ crossings of the clock line.

www.national.com15

Page 16

Applications Information (Continued)

7.0 COMMON APPLICATION PITFALLS Driving the inputs (analog or digital) beyond the power

ADC12081

supply rails. For proper operation, all inputs should not go

more than 300mV beyond the supply rails (more than

300mV below the ground pins or 300mV above the supply

pins). Exceeding these limits on even a transient basis may

cause faulty or erratic operation. It is not uncommon for high

speed digital circuits (e.g., 74F and 74AC devices) to exhibit

undershoot that goes more than a volt below ground above

the power supply. A resistor of about 50 to 100Ω in series

with the offending digital input will eliminate the problem.

Care should be taken not to overdrive the inputs of the

ADC12081 with a device that is powered from supplies

outside the range of the ADC12081 supply. Such practice

may lead to conversion inaccuracies and even to device

damage.

Attempting to drive a high capacitance digital data bus.

Capacitive loading on the digital outputs causes instantaneous digital currents to flow from the V

DGND I/O ground plane. These large charging current

spikes can couple into the analog section, degrading dynamic performance. Adequate bypassing and maintaining

I/O supply into the

D

separate analog and digital ground planes will reduce this

problem. The digital data outputs should be buffered (with

74ACQ541, for example). Dynamic performance can also be

improved by adding series resistors at each digital output,

close to the ADC12081, reducing the energy coupled back

into the converter output pins by limiting the output slew rate.

A reasonable value for these resistors is 47Ω.

Using an inadequate amplifier to drive the analog input.

The analog input circuits of the ADC12081 place a switched

capacitor load on the input signal source. Therefore the

amplifier used to drive the ADC12081 must have a low

impedance output and adequate bandwidth to avoid distortion of the input signal.

Operating with the reference pins outside of the specified range. As mentioned in section 1.1, V

the range of 1.8V ≤ V

≤ 2.2V. Operating outside of these

REF

should be in

REF

limits could lead to signal distortion.

Using a clock source with excessive jitter, using excessively long clock signal trace, or having other signals

coupled to the clock signal trace. This will cause the

sampling interval to vary, causing excessive output noise

and a reduction in SNR performance.

www.national.com 16

Page 17

Physical Dimensions inches (millimeters)

unless otherwise noted

ADC12081 12-Bit, 5 MHz Self-Calibrating, Pipelined A/D Converter with Internal Sample & Hold

32-Lead LQFP Package

Ordering Number ADC12081CIVT

NS Package Number VBE32A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...