Page 1

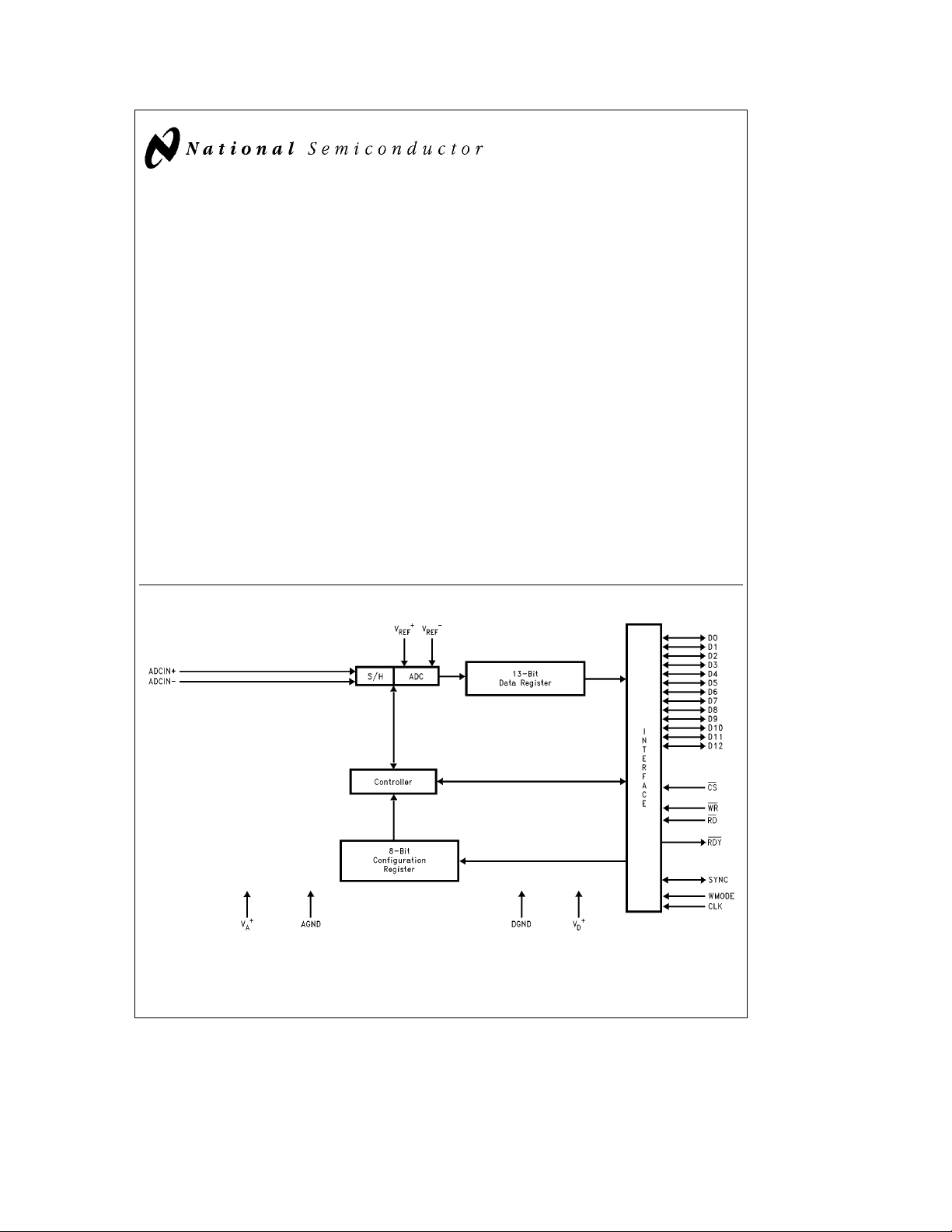

ADC12041

12-Bit Plus Sign 216 kHz Sampling

Analog-to-Digital Converter

ADC12041 12-Bit Plus Sign 216 kHz Sampling Analog-to-Digital Converter

December 1995

General Description

Operating from a single 5V power supply the ADC12041 is a

a

12 bit

sign, parallel I/O, self-calibrating, sampling analogto-digital converter (ADC). The maximum sampling rate is

216 kHz. On request, the ADC goes through a self-calibration process that adjusts linearity, zero and full-scale errors.

The ADC12041 can be configured to work with many popular microprocessors/microcontrollers including National’s

HPC family, Intel386 and 8051, TMS320C25, Motorola

MC68HC11/16, Hitachi 64180 and Analog Devices

ADSP21xx.

For complementary voltage references see the LM4040,

LM4041 or LM9140.

Key Specifications (f

Y

Resolution 12-bitsasign

Y

13-bit conversion time 3.6 ms, max

Y

13-bit throughput rate 216 ksamples/s, min

Y

Integral Linearity Error (ILE)

Y

Single supply

CLK

e

12 MHz)

g

1 LSB, max

a

5Vg10%

Block Diagram

Y

VINrange GND to V

Y

Power consumption:

Normal operation 33 mW, max

Stand-by mode 75 mw, max

Features

Y

Fully differential analog input

Y

Programmable acquisition times and user-controllable

throughput rates

Y

Programmable data bus width (8/13 bits)

Y

Built-in Sample-and-Hold

Y

Programmable auto-calibration and auto-zero cycles

Y

Low power standby mode

Y

No missing codes

Applications

Y

Medical instrumentation

Y

Process control systems

Y

Test equipment

Y

Data logging

Y

Inertial guidance

a

A

TL/H/12441– 1

TRI-STATEÉis a registered trademark of National Semiconductor Corporations.

C

1996 National Semiconductor Corporation RRD-B30M26/Printed in U. S. A.

TL/H/12441

Page 2

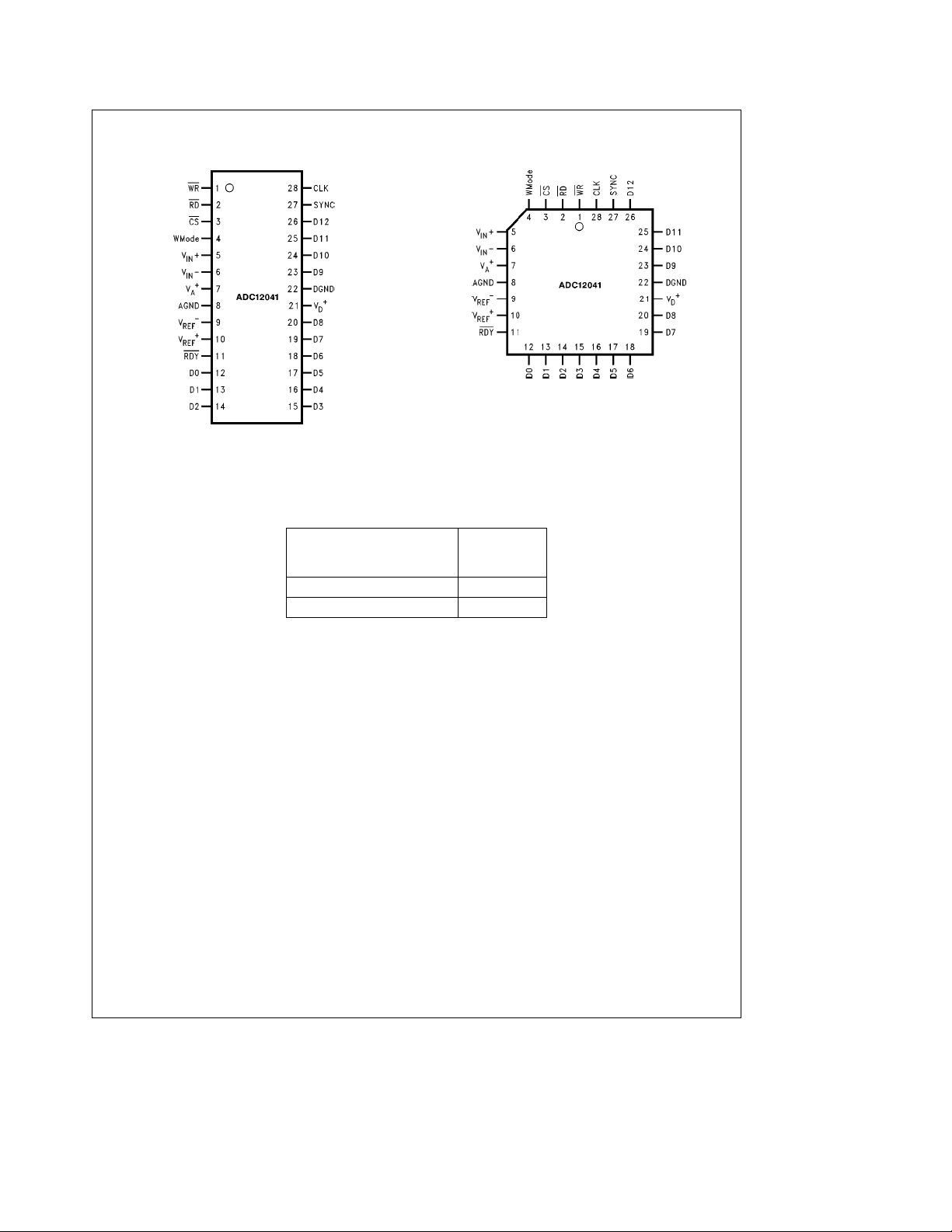

Connection Diagrams

28-Pin SSOP

28-Pin PLCC

Order Number ADC12041CIMSA

See NS Package Number MSA28

Ordering Information

Order Number ADC12041CIV

See NS Package Number V28A

TL/H/12441– 2

Industrial Temperature Range

b

40§CsT

ADC12041CIV V28A

ADC12041CIMSA MSA28, SSOP

s

a

85§C

A

NS

Package

Number

TL/H/12441– 3

2

Page 3

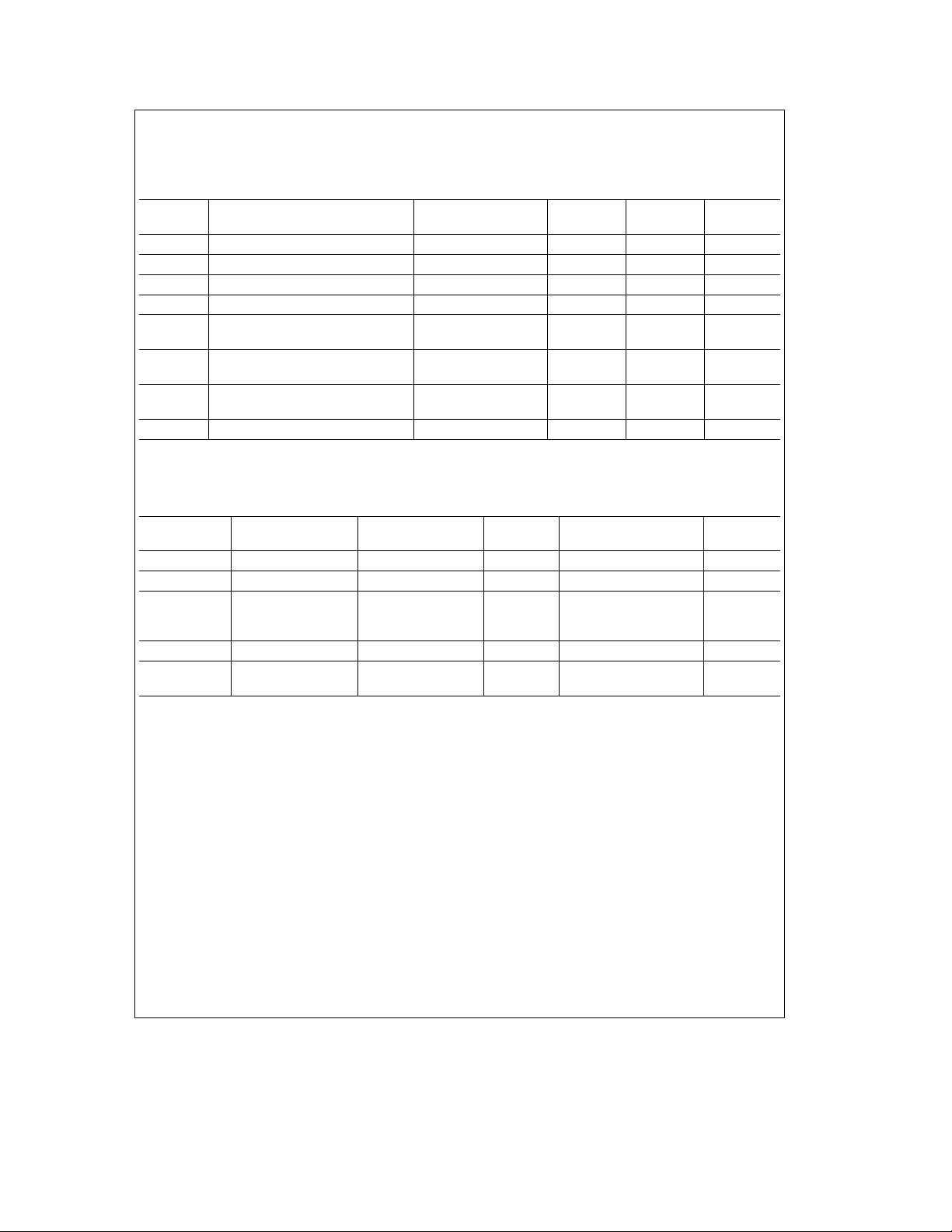

Absolute Maximum Ratings

(Notes 1 and 2)

Supply Voltage (V

Voltage at all Inputs

ab

V

l

A

AGNDbDGND

l

Input Current at Any Pin (Note 3)

Package Input Current (Note 3)

Power Dissipation (Note 4)

e

at T

A

Storage Temperature

Lead Temperature

SSOP Package

Vapor Phase (60 sec.) 210

Infared (15 sec.) 220

V Package, Infared (15 sec.) 300

a

A

a

V

l

D

a

and V

) 6.0V

D

b

0.3V to V

a

l

g

25§C 500 mW

b

65§Ctoa150§C

a

0.3V

300 mV

300 mV

g

30 mA

120 mA

§

§

§

Operating Ratings (Notes 1 and 2)

Temperature Range

s

(T

Supply Voltage

V

A

a

V

l

A

AGNDbDGND

l

VINVoltage Range at all Inputs GNDsV

V

REF

V

REF

V

REF

V

REF

C

C

C

s

T

T

min

a

a

,V

D

a

b

V

D

)

A

max

l

l

a

Input Voltage 1VsV

b

Input Voltage 0sV

a

Common Mode 0.1 V

b

b

V

REF

a

A

ESD Susceptibility (Note 5) 3.0 kV

Converter DC Characteristics The following specifications apply to the ADC12041 for V

a

e

V

and V

otherwise specified. Boldface limits apply for T

REF

4.096V, V

b

s

1X, fully differential input with fixed 2.048V common-mode voltage (V

REF

Symbol Parameter Conditions

b

e

0.0V, 12-bitasign conversion mode, f

REF

e

12.0 MHz, R

CLK

e

e

T

T

A

J

MIN

to T

MAX

e

25X, source impedance for V

S

), and minimum acquisition time, unless

INCM

; all other limits T

e

T

A

Typical Limits Units

(Note 10) (Note 11) (Limit)

Resolution with No Missing Codes After Auto-Cal 13 Bits (max)

ILE Positive and Negative Integral After Auto-Cal

Linearity Error (Notes 12 and 17)

g

0.6

DNL Differential Non-Linearity After Auto-Cal

Zero Error After Auto-Cal (Notes 13 and 17)

e

V

V

V

Positive Full-Scale Error After Auto-Cal (Notes 12 and 17)

Negative Full-Scale Error After Auto-Cal (Notes 12 and 17)

DC Common Mode Error After Auto-Cal (Note 14)

TUE Total Unadjusted Error After Auto-Cal (Note 18)

INCM

INCM

INCM

e

e

5.0V

2.048V

0V

g

1.0

g

1.0

g

2

g

1 LSB

b

40§CsT

s

A

4.5V to 5.5V

s

100 mV

s

100 mV

a

s

IN

a

s

REF

b

REF

1VsV

s

V

REFCM

A

e

25§C

J

g

1 LSB (max)

g

1 LSB (max)

g

5.5

g

2.0

g

5.5

g

2.5 LSB (max)

g

2.5 LSB (max)

g

5.5 LSB (max)

a

s

V

REF

s

REF

s

0.6 V

a

a

e

V

D

LSB (max)

b

e

REF

85§C

V

A

V

A

1V

V

A

A

5V,

a

a

a

a

a

3

Page 4

Power Supply Characteristics The following specifications apply to the ADC12041 for V

a

e

V

and V

specified. Boldface limits apply for T

REF

4.096V, V

b

1X, fully differential input with fixed 2.048V common-mode voltage, and minimum acquisition time, unless otherwise

REF

Symbol Parameter Conditions

PSS Power Supply Sensitivity V

Zero Error V

Full-Scale Error V

Linearity Error

a

I

D

a

V

Digital Supply Current Start Command (Performing a conversion) with SYNC

D

b

e

0.0V, 12-bitasign conversion mode, f

REF

e

T

A

a

e

V

D

a

e

REF

b

e

REF

configured as an input and driven with a 214 kHz

e

J

a

A

4.096V

0V

T

to T

MIN

e

5.0Vg10%

CLK

; all other limits T

MAX

e

12.0 MHz, R

e

25X, source impedance for V

S

e

e

T

A

25§C

J

Typical Limits Unit

(Note 10) (Note 11) (Limit)

g

0.1 LSB

g

0.5 LSB

g

0.1 LSB

signal. Bus width set to 13.

e

f

12.0 MHz, Reset Mode 850 mA

CLK

e

f

12.0 MHz, Conversion 2.45 2.6 mA (max)

a

I

A

a

V

Analog Supply Current Start Command (Performing a conversion) with SYNC

A

CLK

configured as an input and driven with a 214 kHz

signal. Bus width set to 13.

e

f

12.0 MHz, Reset Mode 2.3 mA

CLK

e

f

12.0 MHz, Conversion 2.3 4.0 mA (max)

CLK

I

ST

Symbol Parameter Conditions

I

IN

R

CV

Standby Supply Current Standby Mode

a

a

a

(I

I

D

Analog Input Characteristics The following specifications apply to the ADC12041 for V

a

e

V

REF

a

V

and V

REF

otherwise specified. Boldface limits apply for T

)f

A

b

4.096V, V

a

REF

e

REF

s

0.0V, 12-Bitasign conversion mode, f

1X, fully differential input with fixed 2.048V common-mode voltage, and minimum acquisition time, unless

e

Stopped 5 15 mA (max)

CLK

e

f

12.0 MHz 100 120 mA (max)

CLK

e

12.0 MHz, R

CLK

e

e

T

T

to T

A

J

MIN

; all other limits T

MAX

e

25X, source impedance for

S

Typical Limits Unit

(Note 10) (Note 11) (Limit)

a

V

IN

ADC Input On Resistance V

ON

ADC Input Capacitance 10 pF

IN

and V

b

Input Leakage Current V

IN

a

e

5V 0.05

IN

b

e

V

0V

IN

e

2.5V

IN

Refer to section titled INPUT CURRENT.

b

0.05

1000 X

a

A

a

A

e

T

A

J

2.0 mA (max)

e

e

e

V

D

V

D

25§C

a

e

5V,

a

REF

a

e

5V,

a

a

e

Reference Inputs The following specifications apply to the ADC12041 for V

b

e

V

1X, fully differential input with fixed 2.048V common-mode voltage, and minimum acquisition time, unless otherwise specified.

Boldface limits apply for T

0.0V, 12-bitasign conversion mode, f

REF

e

e

T

A

T

J

MIN

CLK

to T

e

MAX

12.0 MHz, R

S

; all other limits T

e

25X, source impedance for V

e

T

A

Symbol Parameter Conditions

I

REF

Reference Input Current V

a

4.096V, V

REF

Analog Input Signal: 1 kHz 145 mA

REF

b

e

0V

e

V

A

e

25§C

J

5V, V

D

Typical Limits Unit

(Note 10) (Note 11) (Limit)

REF

REF

a

a

and V

e

4.096V,

b

REF

(Note 20) 80 kHz 136 mA

C

REF

Reference Input Capacitance 85 pF

4

s

Page 5

Digital Logic Input/Output Characteristics The following specifications apply to the ADC12041 for

a

a

e

V

A

impedance for V

tion time, unless otherwise specified. Boldface limits apply for T

e

V

D

REF

25§C

Symbol Parameter Conditions

V

IH

V

IL

I

IH

I

IL

V

OH

V

OL

I

OFF

C

IN

Converter AC Characteristics The following specifications apply to the ADC12041 for V

V

REF

and V

otherwise specified. Boldface limits apply for T

Logic High Input Voltage V

Logic Low Input Voltage V

Logic High Input Current V

Logic Low Input Current V

Logic High Output Voltage V

Logic Low Output Voltage V

TRI-STATE Output Leakage Current V

D12–D0 Input Capacitance 10 pF

a

e

4.096V, V

b

s

REF

1X, fully differential input with fixed 2.048V common-mode voltage, and minimum acquisition time, unless

Symbol Parameter Conditions

t

Z

t

CAL

5V, V

a

REF

and V

a

e

4.096V, V

b

REF

s

b

1X, fully differential input with fixed 2.048V common-mode voltage, and minimum acquisi-

e

e

T

A

T

J

MIN

e

0.0V, 12-bitasign conversion mode, f

REF

CLK

to T

e

12.0 MHz, R

; all other limits T

MAX

e

S

25X, source

e

A

Typical Limits Unit

(Note 10) (Note 11) (Limit)

a

a

e

e

V

5.5V 2.2 V (min)

D

a

e

V

4.5V 0.8 V (max)

D

a

V

D

1.6 mA

V

D

1.6 mA

0V

5V

CLK

T

MIN

e

a

e

to T

4.5V

4.5V

e

12.0 MHz, R

MAX

b

0.035

2.4 2.4 V (min)

0.4 0.4 V (max)

e

25X, source impedance for V

S

; all other limits T

b

g

e

T

A

J

2.0 mA (max)

2.0 mA (max)

a

a

e

V

S

D

e

25§C

b

e

0.0V, 12-bitasign conversion mode, f

REF

A

a

e

A

e

5V 0.035 2.0 mA (max)

IN

e

0V

IN

ae

A

eb

I

OUT

a

e

A

e

I

OUT

e

OUT

e

V

OUT

e

e

T

A

J

Typical Limits Unit

(Note 10) (Note 11) (Limit)

Auto Zero Time 78 78 clksa120 ns clks (max)

Full Calibration Time 4946 4946 clksa120 ns clks (max)

e

REF

T

J

5V,

CLK Duty Cycle 50 %

40 % (min)

60 % (max)

t

CONV

t

AcqSYNCOUT

Conversion Time Sync-Out Mode 44 44 clks (max)

Acquisition Time Minimum for 13 Bits 9 9 clksa120 ns clks (max)

(Programmable) Maximum for 13 Bits 79 79 clks

a

120 ns clks (max)

e

a

5

Page 6

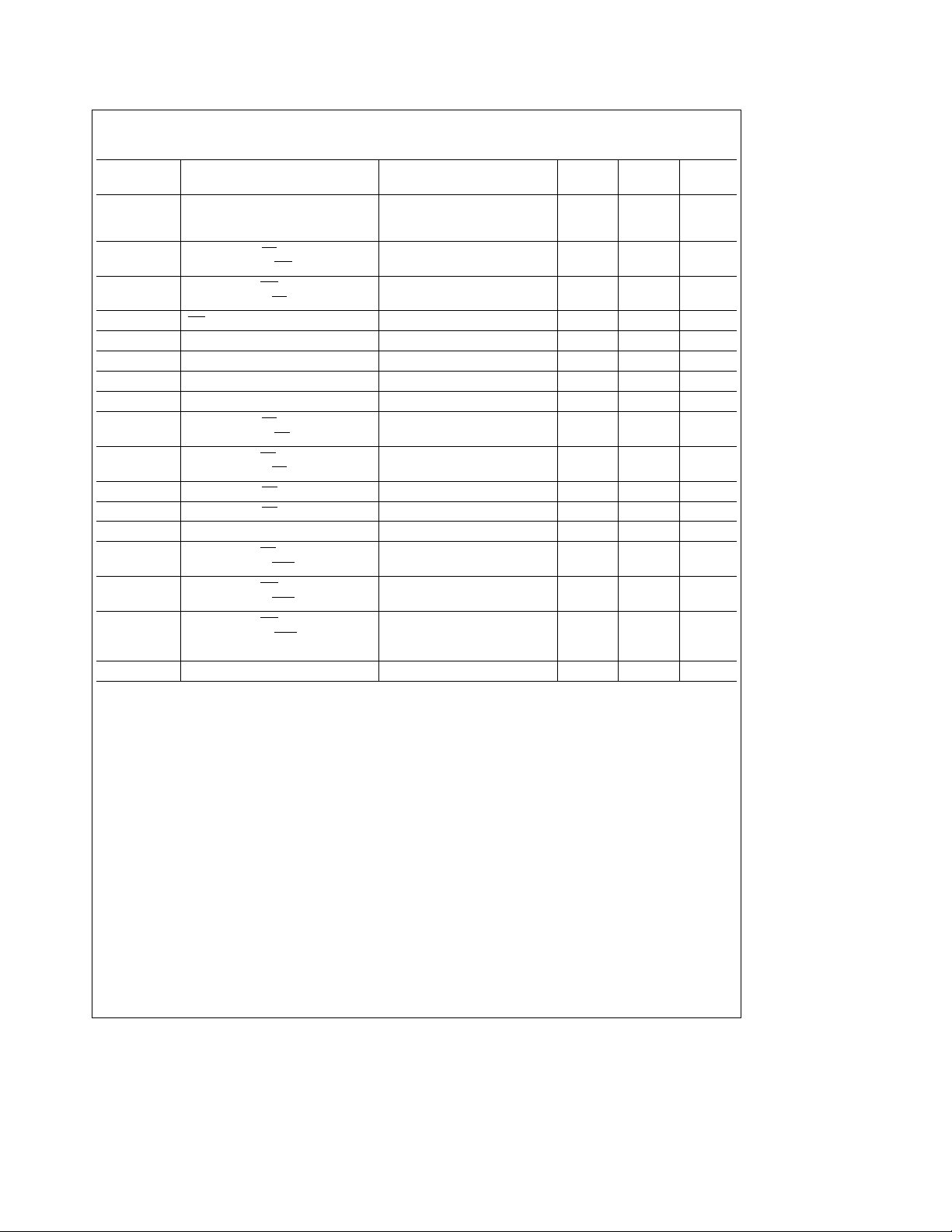

Digital Timing Characteristics The following specifications apply to the ADC12041, 13-bit data bus width,

a

a

e

V

A

Symbol

(Figure 7)

t

TPR

e

V

D

Throughput Rate Sync-Out Mode (SYNC Bite‘‘0’’) 222 kHz

5V, f

CLK

e

12 MHz, t

e

f

3 ns and C

e

50 pF on data I/O lines

L

Parameter Conditions

9 Clock Cycles of Acquisition

Typical Limits Unit

(Note 10) (Note 11) (Limit)

Time

t

CSWR

t

WRCS

t

WR

t

WRSETFalling

t

WRHOLDFalling

t

WRSETRising

t

WRHOLDRising

t

CSRD

t

RDCS

t

RDDATA

t

RDDATA

t

RDHOLD

t

RDRDY

t

WRRDY

t

STDRDY

Falling Edge of CS

to Falling Edge of WR

Active Edge of WR

to Rising Edge of CS

0ns

0ns

WR Pulse Width 20 30 ns (min)

Write Setup Time WMODEe‘‘1’’ 20 ns (min)

Write Hold Time WMODEe‘‘1’’ 5 ns (min)

Write Setup Time WMODEe‘‘0’’ 20 ns (min)

Write Hold Time WMODEe‘‘0’’ 5 ns (min)

Falling Edge of CS

to Falling Edge of RD

Rising Edge of RD

to Rising Edge of CS

0ns

0ns

Falling Edge of RD to Valid Data 8-Bit Mode (BW Bite‘‘0’’) 40 58 ns (max)

Falling Edge of RD to Valid Data 13-Bit Mode (BW Bite‘‘1’’) 26 44 ns (max)

Read Hold Time 23 32 ns (max)

Rising Edge of RD

to Rising Edge of RDY

Active Edge of WR WMODEe‘‘1’’

to Rising Edge of RDY

24 38 ns (max)

37 60 ns (max)

Active Edge of WR WMODEe‘‘0’’. Writing the

to Falling Edge of RDY

RESET Command into the

1.4 2.5 ms (max)

Configuration Register

t

SYNC

Minimum SYNC Pulse Width 5 10 ns (min)

Notes on Specifications

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test

conditions.

Note 2: All voltages are measured with respect to GND, unless otherwise specified.

Note 3: When the input voltage (V

mA. The 120 mA maximum package input current limits the number of pins that can safely exceed the power supplies with an input current of 30 mA to four.

Note 4: The maximum power dissipation must he derated at elevated temperatures and is dictated by T

junction to ambient thermal resistance), and T

or the number given in the Absolute Maximum Ratings, whichever is lower. For this device, T

i

JA

ADC12041 in the V package, when board mounted, is 55

Note 5: Human body model, 100 pF discharged through 1.5 Xk resistor.

) at any pin exceeds the power supply rails (V

IN

(ambient temperature). The maximum allowable power dissipation at any temperature is P

A

C/W, and in the SSOP package, when board mounted, is 130§C/W.

§

IN

k

GND or V

6

a

l

IN

Jmax

a

(V

or V

)), the current at that pin should be limited to 30

A

D

, (maximum junction temperature), iJA(package

Jmax

e

150§C, and the typical thermal resistance (iJA)ofthe

Dmax

e

b

(T

TA)/

Jmax

Page 7

Notes on Specifications (Continued)

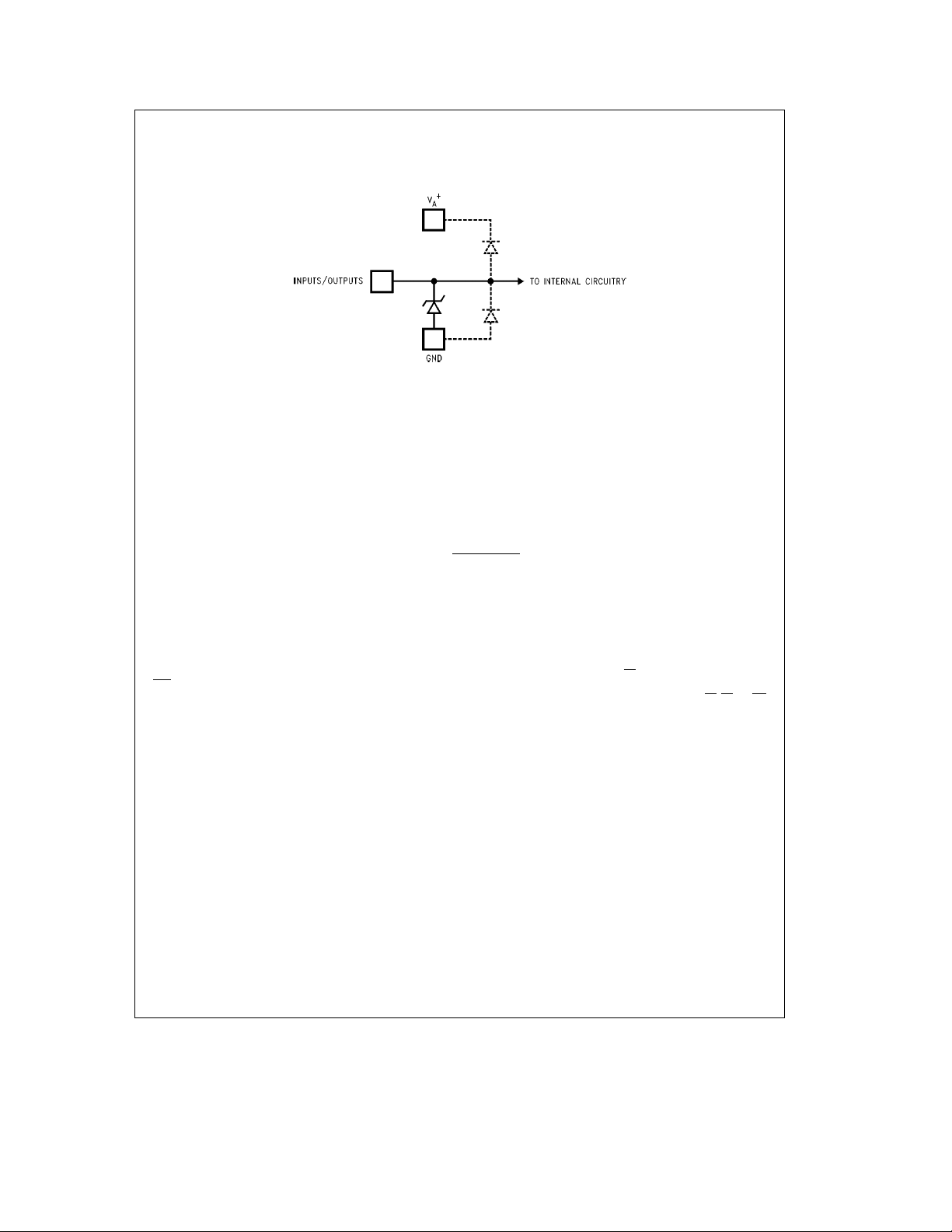

Note 6: Each input is protected by a nominal 6.5V breakdown voltage zener diode to GND, as shown below, input voltage magnitude up to 5V above V

below GND will not damage the ADC12041. There are parasitic diodes that exist between the inputs and the power supply rails and errors in the A/D conversion

can occur if these diodes are forward biased by more than 50 mV. As an example, if V

conversions.

a

is 4.50 VDC, full-scale input voltage must be 4.55 VDCto ensure accurate

A

a

or 5V

A

a

A

TL/H/12441– 4

a

and V

at the specified extremes.

D

a

Note 7: V

conversion/comparison accuracy. Refer to the Power Supply Considerations section for a detailed discussion.

Note 8: Accuracy is guaranteed when operating at f

Note 9: With the test condition for V

Note 10: Typicals are at T

Note 11: Limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 12: Positive integral linearity error is defined as the deviation of the analog value, expressed in LSBs, from the straight line that passes through positive full-

scale and zero. For negative integral linearity error, the straight line passes through negative full-scale and zero.

Note 13: Zero error is a measure of the deviation from the mid-scale voltage (a code of zero), expressed in LSB. It is the average value of the code transitions

b

between

Note 14: The DC common-mode error is measured with both inputs shorted together and driven from 0V to 5V. The measured value is referred to the resulting

output value when the inputs are driven with a 2.5V input.

Note 15: Power Supply Sensitivity is measured after an Auto-Zero and Auto Calibration cycle has been completed with V

Note 16: V

Note 17: The ADC12041’s self-calibration technique ensures linearity and offset errors as specified, but noise inherent in the self-calibration process will result in a

repeatability uncertainty of

a

and V

A

1to0and0toa1 (see

REFCM

must be connected together to the same power supply voltage and bypassed with separate capacitors at each Vapin to assure

D

CLK

a

b

REF(VREF

e

25§C and represent most likely parametric norm.

A

Figure 6

V

REF

).

(Reference Voltage Common Mode Range) is defined as

g

0.20 LSB.

e

12 MHz.

b

) given asa4.096V, the 12-bit LSB is 1.000 mV.

a

b

a

V

V

REF

REF

2

#

J

Note 18: Total Unadjusted Error (TUE) includes offset, full scale linearity and MUX errors.

Note 19: The ADC12041 parts used to gather the information for these curves were auto-calibrated prior to taking the measurements at each test condition. The

auto-calibration cycle cancels any first order drifts due to test conditions. However, each measurement has a repeatability uncertainty error of 0.2 LSB. See Note

17.

Note 20: This is a DC average current drawn by the reference input with a full-scale sinewave input. The ADC12041 is continuously converting with a throughput

rate of 206 kHz.

Note 21: These typical curves were measured during continuous conversions with a positive half-scale DC input. A 240 ns RD

signal went low. The data bus lines were loaded with 2 HC family CMOS inputs (C

RDY

Note 22: Any other values placed in the command field are meaningless. However, if a code of 101 or 110 is placed in the command field and the CS

go low at the same time, the ADC12041 will enter a test mode. These test modes are only to be used by the manufacturer of this device. A hardware power-off and

power-on reset must be done to get out of these test modes.

E

20 pF).

L

pulse was applied 25 ns after the

,RDand WR

7

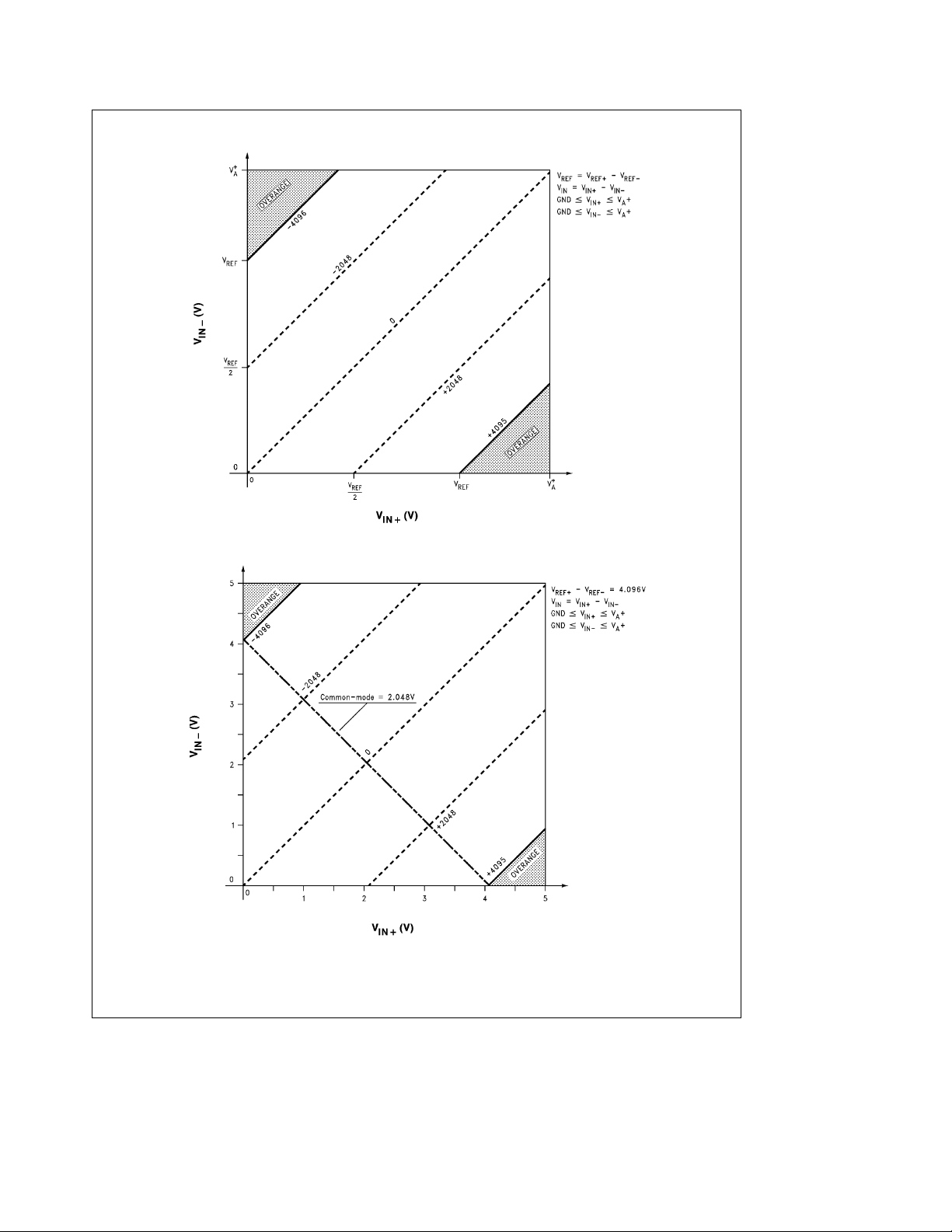

Page 8

Electrical Characteristics

FIGURE 1. Output Digital Code vs the Operating Input Voltage Range (General Case)

FIGURE 2. Output Digital Code vs the Operating Input Voltage Range for V

REF

e

TL/H/12441– 5

TL/H/12441– 6

4.096V

8

Page 9

Electrical Characteristics (Continued)

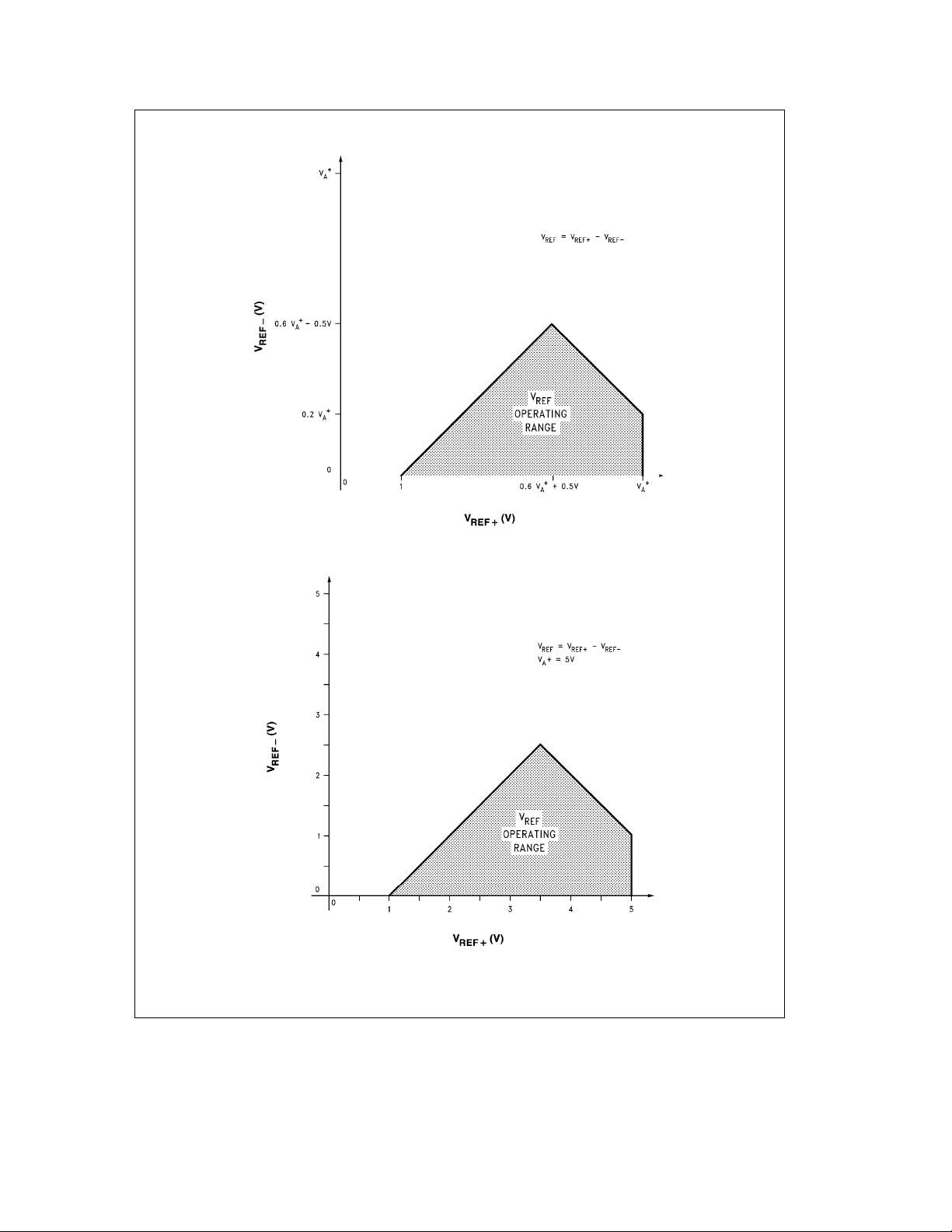

FIGURE 3. V

FIGURE 4. V

Operating Range (General Case)

REF

Operating Range for V

REF

TL/H/12441– 7

e

5V

A

TL/H/12441– 8

9

Page 10

Electrical Characteristics (Continued)

FIGURE 5a. Transfer Characteristic

FIGURE 5b. Simplified Error vs Output Code without Auto-Calibration or Auto-Zero Cycles

TL/H/12441– 9

TL/H/12441– 10

10

Page 11

Electrical Characteristics (Continued)

FIGURE 5c. Simplified Error vs Output Code after Auto-Calibration Cycle

TL/H/12441– 12

FIGURE 6. Offset or Zero Error Voltage (Note 13)

TL/H/12441– 11

11

Page 12

Timing Diagrams

FIGURE 7a. Sync-Out Write (WMODEe1, BWe1), Read and Convert Cycles

FIGURE 7b. Sync-In Write (WMODEe1, BWe1), Read and Convert Cycles

TL/H/12441– 13

TL/H/12441– 14

12

Page 13

Timing Diagrams (Continued)

FIGURE 7c. Sync-Out Write (WMODEe0, BWe1), Read and Convert Cycles

FIGURE 7d. Sync-In Write (WMODEe0, BWe1), Read and Convert Cycles

TL/H/12441– 46

TL/H/12441– 47

13

Page 14

Timing Diagrams (Continued)

FIGURE 7e. Sync-Out Read and Convert Cycles

FIGURE 7f. Sync-In Read and Convert Cycles

TL/H/12441– 48

TL/H/12441– 49

14

Page 15

Timing Diagrams (Continued)

FIGURE 7g. 8-bit Bus Read Cycle (Sync-Out)

FIGURE 7h. 8-bit Bus Read Cycle (Sync-In)

15

TL/H/12441– 50

TL/H/12441– 51

Page 16

Timing Diagrams (Continued)

FIGURE 7i. Write Signal Negates RDY (Writing the Standby, Auto-Cal or Auto-Zero Command)

FIGURE 7j. Standby and Reset Timing (13-Bit Data Bus Width)

TL/H/12441– 15

TL/H/12441– 16

16

Page 17

Typical Performance Characteristics (See Note 19, Electrical Characteristic Section)

Integral Linearity Error (INL)

Change vs Clock Frequency

TL/H/12441– 17

Integral Linearity Error (INL)

Change vs Temperature

TL/H/12441– 20

Integral Linearity Error (INL)

Change vs Reference Voltage

Full-Scale Error Change vs

Clock Frequency

TL/H/12441– 18

Full-Scale Error Change vs

Temperature

TL/H/12441– 21

Full-Scale Error Change vs

Reference Voltage

Zero Error Change vs

Clock Frequency

TL/H/12441– 19

Zero Error Change vs

Temperature

TL/H/12441– 22

Zero Error Change vs

Reference Voltage

TL/H/12441– 23

Integral Linearity Error (INL)

Change vs Supply Voltage

TL/H/12441– 26

TL/H/12441– 24

Full-Scale Error Change

vs Supply Voltage

TL/H/12441– 27

17

TL/H/12441– 25

Zero Error Change

vs Supply Voltage

TL/H/12441– 28

Page 18

Typical Performance Characteristics (See Note 21, Electrical Characteristic Section) (Continued)

Supply Current vs

Clock Frequency

Analog Supply Current

vs Temperature

TL/H/12441– 29

TL/H/12441– 31

Reference Current vs

Clock Frequency

TL/H/12441– 30

Digital Supply Current vs

Temperature

TL/H/12441– 32

18

Page 19

Typical Performance Characteristics (Continued) The curves were obtained under the following condi-

e

tions. R

S

otherwise stated.

50X,T

e

A

25§C, V

a

a

e

e

V

A

5V, V

D

REF

e

4.096V, f

e

12 MHz, and the sampling rate f

CLK

e

215 kHz unless

S

Full Scale Differential 1,099 Hz

Sine Wave Input

Full Scale Differential 38,452 Hz

Sine Wave Input

Half Scale Differential 1 kHz

Sine Wave Input, f

e

S

153.6 kHz

TL/H/12441– 33

TL/H/12441– 35

Full Scale Differential 18,677 Hz

Sine Wave Input

Full Scale Differential 79,468 Hz

Sine Wave Input

Half Scale Differential 20 kHz

Sine Wave Input, f

e

S

153.6 kHz

TL/H/12441– 34

TL/H/12441– 36

Half Scale Differential 40 kHz

Sine Wave Input, f

e

S

153.6 kHz

TL/H/12441– 37

TL/H/12441– 39

TL/H/12441– 38

Half Scale Differential 75 kHz

Sine Wave Input, f

e

S

153.6 kHz

TL/H/12441– 40

19

Page 20

Pin Description

PLCC and

SSOP Pkg.

Pin Number

5V

6V

10 V

9V

4 WMODE The logic state of this pin at power-up determines which edge of the write signal (WR) will latch in data

27 SYNC The SYNC pin can be programmed as an input or an output. The Configuration register’s bit b4 controls

12–20 D0 –D8 13-bit Data bus of the ADC12041. D12 is the most significant bit and D0 is the least significant. The

23–26 D9 –D12 BW(bus width) bit of the Configuration register (b3) selects between an 8-bit or 13-bit data bus width.

28 CLK The clock input pin used to drive the ADC12041. The operating range is 0.05 MHz to 12 MHz.

1WRWR is the active low WRITE control input pin. A logic low on this pin and the CS will enable the input

2RDRD is the active low read control input pin. A logic low on this pin and CS will enable the active output

3CSCS is the active low Chip Select input pin. Used in conjunction with the WR and RD signals to control the

11 RDY RDY is an active low output pin. The signal at this pin indicates when a requested function has begun or

7V

8 AGND Analog ground pin. This is the device’s analog supply ground connection. It should be connected

21 V

22 DGND Digital ground pin. This is the device’s digital supply ground connection. It should be connected through

Pin

Name

a

IN

IN

REF

The analog ADC inputs. V

b

input into the ADC.

a

Positive reference input. The operating voltage range for this input is 1VsV

3

0.1 mF (ceramic) capacitor. The capacitors should be placed as close to the part as possible.

b

REF

Negative reference input. The operating voltage range for this input is 0VsV

Figures 3

and a 0.1 mF (ceramic) capacitor. The capacitors should be placed as close to the part as possible.

from the data bus. If tied low, the ADC12041 will latch in data on the rising edge of the WR

to a logic high, data will be latched in on the falling edge of the WR

not be changed after power-up.

the function of this pin. When programmed as an input pin (b4

ADC’s sample-and-hold to hold the analog input signal and begin conversion. When programmed as an

output pin (b4

completed.

When the BW bit is cleared (BWe0), D7–D0 are active and D12 –D8 are always in TRI-STATEÉ.

When the BW bit is set (BW

buffers of the data pins D12–D0. The signal at this pin is used by the ADC12041 to latch in data on

D12–D0. The sense of the WMODE pin at power-up will determine which edge of the WR

ADC12041 will latch in data. See WMODE pin description.

buffers to drive the data bus.

active data bus input/output buffers of the data bus.

ended. Refer to section Functional Description and the digital timing diagrams for more detail.

a

A

Analog supply input pin. The device operating supply voltage range isa5Vg10%. Accuracy is

guaranteed only if the V

to AGND with a parallel combination of a 10 mF and a 0.1 mF (ceramic) capacitor. The capacitors should

be placed as close to the supply pins of the part as possible.

through a low resistance and low inductance ground return to the system power supply.

a

D

Digital supply input pins. The device operating supply voltage range isa5Vg10%. Accuracy is

guaranteed only if the V

to DGND with a parallel combination of a 10 mF and a 0.1 mF (ceramic) capacitor. The capacitors should

be placed as close to the supply pins of the part as possible.

a low resistance and low inductance ground return to the system power supply.

Description

a

is the non-inverting (positive) input and V

IN

and4). This pin should be bypassed to AGND at least with a parallel combination of a 10 mF and a

and4). This pin should be bypassed to AGND at least with a parallel combination of a 10 mF

b

is the inverting (negative)

IN

a

a

s

V

REF

REF

A

b

s

V

REF

(see

a

Figures

b

1 (see

signal. If tied

signal. The state of this pin should

e

1), a rising edge on this pin causes the

e

0), the SYNC pin goes high when a conversion begins and returns low when

e

1), D12–D0 are active.

signal the

a

a

and V

A

a

and V

A

are connected to the same potential. This pin should be bypassed

D

a

are connected to the same potential. This pin should be bypassed

D

28-Pin SSOP

TL/H/12441– 2

28-Pin PLCC

TL/H/12441– 3

20

Page 21

Register Bit Description

CONFIGURATION REGISTER (Write Only)

This is an 8-bit write-only register that is used to program the functionality of the ADC12041. All data written to the ADC12041

will always go to this register only. The contents of this register cannot be read.

MSB LSB

b

b6b

7

COMMAND

FIELD

Power on State: 10 Hex

b1–b0: The ACQ TIME bits select one of four possible acquistion times in the SYNC-OUT mode (b

Acquisition Time section, page 22).

b

b

5

4

b

3

2b1

SYNC BW SE ACQ TIME

b

0

e

0). (Refer to Selectable

4

b

1

b

0

Clocks

00 9

01 15

10 47

11 79

b

:When the Single-Ended bit (SE bit) is set, conversion results will be limited to positive values only and any negative

2

conversion results will appear as a code of zero in the Data register. The SE bit is cleared at power-up.

b

: This is the Bus Width (BW) bit. When this bit is cleared the ADC12041 is configured to interface with an 8-bit data bus; data

3

pins D

a 16-bit data bus and data pins D

are active and pins D12–D9are in TRI-STATE. When the BW bit is set, the ADC12041 is configured to interface with

7–D0

are all active. The BW bit is cleared at power-up.

12–D0

b4: The SYNC bit. When the SYNC bit is set, the SYNC pin is programmed as an input and the converter is in synchronous

mode. In this mode a rising edge on the SYNC pin causes the ADC to hold the input signal and begin a conversion. When b

cleared, the SYNC pin is programmed as an output and the converter is in an asynchronous mode. In this mode the signal at the

SYNC pin indicates the status of the converter. The SYNC pin is high when a conversion is taking place. The SYNC bit is set at

power-up.

b

: The command field. These bits select the mode of operation of the ADC12041. Power-up value is 000. (See Note 22)

7–b5

b7b6b

5

Command

0 0 0 Standby command. This puts the ADC in a low power consumption mode.

0 0 1 Ful-Cal command. This will cause the ADC to perform a self-calibrating cycle that will correct linearity and zero

errors.

0 1 0 Auto-zero command. This will cause the ADC to perform an auto-zero cycle that corrects offset errors.

0 1 1 Reset command. This puts the ADC in an idle mode.

1 0 0 Start command. This will put the converter in a start mode, preparing it to perform a conversion. If in asynchronous

mode (b

synchronous mode (b

e

‘‘0’’), conversions will immediately begin after the programmed acquisition time has ended. In

4

e

‘‘1’’), conversions will begin after a rising edge appears on the SYNC pin.

4

DATA REGISTER (Read Only)

This is a 13-bit read only register that holds the 12-bitasign conversion result in two’s complement form. All reads performed

from the ADC12041 will place the contents of this register on the data bus. When reading the data register in 8-bit mode, the

sign bit is extended.

MSB LSB

b

b

b

b

b

b

12

11

10

9

8

b

7

6b5

b

b3b

4

b

2

b

1

0

sign Conversion Data

Power on State: 0000Hex

b11–b0: b11is the most significant bit and b0is the least significant bit of the conversion result.

b12: This bit contains the sign of the conversion result. 0 for positive results and 1 for negative.

is

8

21

Page 22

Functional Description

The ADC12041 is programmed through a digital interface

that supports an 8-bit or 16-bit data bus. The digital interface consists of a 13-bit data input/output bus (D

digital control signals and two internal registers: a write only

12–D0

8-bit Configuration register and a read only 13-bit Data register.

The Configuration register programs the functionality of the

ADC12041. The 8 bits of the Configuration register are divided into 5 fields. Each field controls a specific function of

the ADC12041: the acquisition time, synchronous or asynchronous conversions, mode of operation and the data bus

size.

Features and Operating Modes

SELECTABLE BUS WIDTH

The ADC12041 can be programmed to interface with an

8-bit or 16-bit data bus. The BW bit (b

register controls the bus size. The bus width is set to 8 bits

(D

are active and D12–D8are in TRI-STATE) if the BW

7–D0

bit is cleared or 13 bits (D

set. At power-up the default bus width is 8 bits (BW

12–D0

In 8-bit mode the Configuration register is accessed with a

single write. When reading the ADC in 8-bit mode, the first

read cycle places the lower byte of the Data register on the

data bus followed by the upper byte during the next read

cycle.

In 13-bit mode all bits of the Data register and Configuration

register are accessible with a single read or write cycle.

Since the bus width of the ADC12041 defaults to 8 bits after

power-up, the first action when 13-bit mode is desired must

be to set the bus width to 13 bits.

WMODE

The WMODE pin is used to determine the active edge of the

write pulse. The state of this pin determines which edge of

the WR

signal will cause the ADC to latch in data. This is

processor dependent. If the processor has valid data on the

bus during the falling edge of the WR

pin must be tied to V

the data on the falling edge of the WR

a

. This will cause the ADC to latch

D

on the rising edge of the WR

be tied to DGND causing the ADC to latch in the data on the

rising edge of the WR

signal.

ANALOG INPUTS

The ADCIN

a

and ADCINbare the fully differential noninverting (positive) and inverting (negative) inputs into the

analog-to-digital converter (ADC) of the ADC12041.

STANDBY MODE

The ADC12041 has a low power consumption mode (75 mW

@

5V). This mode is entered when a Standby command is

written in the command field of the Configuration register.

The RDY

ouput pin is high when the ADC12041 is in the

Standby mode. Any command other than the Standby command written to the Configuration register will get the

ADC12041 out of the Standby mode. The RDY

mediately switch to a logic ‘‘0’’ when the ADC12041 is out

of the standby mode. The ADC12041 defaults to the Standby mode following a hardware power-up.

) in the Configuration

3

are active) if the BW bit is

e

0).

signal, the WMODE

signal. If data is valid

signal, the WMODE pin must

pin will im-

SYNC/ASYNC MODE

The ADC12041 may be programmed to operate in synchronous (SYNC-IN) or asynchronous (SYNC-OUT) mode. To

enter synchronous mode, the SYNC bit in the Configuration

),

register must be set. The ADC12041 is in synchronous

mode after a hardware power-up. In this mode, the SYNC

pin is programmed as an input and conversions are synchronized to the rising edges of the signal applied at the

SYNC pin. Acquisition time can also be controlled by the

SYNC signal when in synchronous mode. Refer to the syncin timing diagrams. When the SYNC bit is cleared, the ADC

is in asynchronous mode and the SYNC pin is programmed

as an output. In asynchronous mode, the signal at the

SYNC pin indicates the status of the converter. This pin is

high when the converter is performing a conversion. Refer

to the sync-out timing diagrams.

SELECTABLE ACQUISITION TIME

The ADC12041’s internal sample/hold circuitry samples an

input voltage by connecting the input to an internal sampling

capacitor (approximately 70 pF) through an effective resistance equal to the ‘‘On’’ resistance of the analog switch at

the input to the sample/hold circuit (2500X typical) and the

effective output resistance of the source. For conversion

results to be accurate, the period during which the sampling

capacitor is connected to the source (the ‘‘acquisition time’’)

must be long enough to charge the capacitor to within a

small fraction of an LSB of the input voltage. An acquisition

time of 750 ns is sufficient when the external source resistance is less than 1 kX and any active or reactive source

circuitry settles to 12 bits in less than 500 ns. When source

resistance or source settling time increase beyond these

limits, the acquisition time must also be increased to preserve precision.

In asynchronous (SYNC-OUT) mode, the acquisition time is

controlled by an internal counter. The minimum acquisition

period is 9 clock cycles, which corresponds to the nominal

value of 750 ns when the clock frequency is 12 MHz. Bits b

and b1of the Configuration Register are used to select the

acquisition time from among four possible values (9, 15, 47,

or 79 clock cycles). Since acquisition time in the asynchronous mode is based on counting clock cycles, it is also inversely proportional to clock frequency:

ACQ

(ms)

e

f

(MHz)

CLK

T

number of clock cycles

Note that the actual acquisition time will be longer than

T

because acquisition begins either when the multiplex-

ACQ

er channel is changed or when RDY

goes low, if the multiplexer channel is not changed. After a read is performed,

RDY

goes high, which starts the T

Figure 7

).

In synchronous (SYNC-IN) mode, bits b0and b1are ignored, and the acquisition time depends on the sync signal

applied to the SYNC pin. The acquisition period begins on

the falling edge of RDY

, which occurs at the end of the

previous conversion (or at the end of an autozero or autocalibration procedure. The acquisition period ends when

SYNC goes high.

To estimate the acquisition time necessary for accurate

conversions when the source resistance is greater than

1kX, use the following expression:

T

ACQMIN

(ms)

e

0.75 (R

1kXaR

R

)

S/H

S/H

e

0.75 (R

S

a

where RSis the source resistance, and R

hold ‘‘On’’ resistance.

counter (see

ACQ

S

3500

is the sample/

S/H

a

0

2500)

22

Page 23

Features and Operating Modes (Continued)

If the settling time of the source is greater than 500 ns, the

acquisition time should be about 300 ns longer than the

settling time for a ‘‘well-behaved’’, smooth settling characteristic.

FULL CALIBRATION CYCLE

A full calibration cycle compensates for the ADC’s linearity

and offset errors. The converter’s DC specifications are

guaranteed only after a full calibration has been performed.

A full calibration cycle is initated by writing a Ful-Cal command to the ADC12041. During a full calibration, the offset

error is measured eight times, averaged and a correction

coefficient is created. The offset correction coefficient is

stored in an internal offset correction register.

The overall linearity correction is achieved by correcting the

internal DAC’s capacitor mismatches. Each capacitor is

compared eight times against all remaining smaller value

capacitors. The errors are averaged out and correction coefficients are created.

Once the converter has been calibrated, an arithmetic logic

unit (ALU) uses the offset and linearity correction coefficients to reduce the conversion offset and linearity errors to

within guaranteed limits.

AUTO-ZERO CYCLE

During an auto-zero cycle, the offset is measured only once

and a correction coefficient is created and stored in an internal offset register. An auto-zero cycle is initiated by writing

an Auto-Zero command to the ADC12041.

DIGITAL INTERFACE

The digital control signals are CS

ic timing relationships are associated with the interaction of

these signals. Refer to the Digital Timing Diagrams section

for detailed timing specifications. The active low RDY

indicates when a certain event begins and ends. It is recommended that the ADC12041 should only be accessed when

the RDY

signal is low. It is in this state that the ADC12041 is

ready to accept a new command. This will minimize the effect of noise generated by a switching data bus on the ADC.

The only exception to this is when the ADC12041 is in the

standby mode at which time the RDY

ADC12041 is in the standby mode at power up or when a

STANDBY command is issued. A Ful-Cal, Auto-Zero, Reset

or Start command will get the ADC12041 out of the standby

mode. This may be observed by monitoring the status of the

RDY

signal. The RDY signal will go low when the

ADC12041 leaves the standby mode.

The following describes the state of the digital control signals for each programmed event in both 8-bit and 13-bit

mode. RDY

except for the case when the device is in standby mode.

FUL-CAL OR AUTO-ZERO COMMAND

8-bit mode:

sued and the BW bit (b

write pulse on the WR

this time the converter begins executing a full calibration or

auto-zero cycle. The RDY

when the full calibration or auto-zero cycle is done.

should be low before each command is issued

A Ful-Cal or Auto-Zero command must be is-

,RD,WRand RDY. Specif-

signal

is high. The

) cleared. The active edge of the

3

pin will force the RDY signal high. At

signal will automatically go low

13-bit mode:

sued and the BW bit (b

pulse on the WR

time the converter begins executing a full calibration or

auto-zero cycle. The RDY

when the full calibration or auto-zero cycle is done.

STARTING A CONVERSION: START COMMAND

In order to completely describe the events associated with

the Start command, both the SYNC-OUT and SYNC-IN

modes must be considered.

A Ful-Cal or Auto-Zero command must be is-

) set. The active edge of the write

3

pin will force the RDY signal high. At this

signal will automatically go low

SYNC-OUT/Asynchronous

8-bit mode:

tion time, clear the BW and SYNC bit and select the START

command in the Configuration register. In order to initiate a

conversion, two reads must be performed from the

ADC12041. The rising edge of the second read pulse will

force the RDY

tion time selected by bits b

register. The SYNC pin will go high indicating that a conversion sequence has begun following the end of the acquisition period. The RDY

conversion is done. At this time new information, such as a

new acquisition time and operational command can be written into the Configuration register or it can remain unchanged. Assuming that the START command is in the

Configuration register, the previous conversion can be read.

The first read places the lower byte of the conversion result

contained in the Data register on the data bus. The second

read will place the upper byte of the conversion result

stored in the Data register on the data bus. The rising edge

on the second read pulse will begin another conversion sequence and raise the RDY

13-bit mode:

set, the SYNC bit cleared and the START command issued

with a write to the ADC12041. In order to initiate a conversion, a single read must be performed from the ADC12041.

The rising edge of the read signal will force the RDY signal

high and begin the programmed acquisition time selected by

bits b

will go high indicating that a conversion sequence has begun following the end of the acquisition period. The RDY

and SYNC signal will fall low when the conversion is done.

At this time new information, such as a new acquisition time

and operational command can be written into the Configuration register or it can remain unchanged. With the START

command in the Configuration register, a read from the

ADC12041 will place the entire 13-bit conversion result

stored in the data register on the data bus. The rising edge

of the read pulse will immediately force the RDY

and begin the programmed acquisition time selected by bits

b

1

go high at the end of the programmed acquisition time.

A write to the ADC12041 should set the acquisi-

pin high and begin the programmed acquisi-

The acquisition time should be set, the BW bit

and b0of the configuration register. The SYNC pin

1

and b0of the configuration register. The SYNC will then

and b0of the Configuration

1

and SYNC signal will fall low when the

and SYNC signals appropriately.

output high

23

Page 24

Features and Operating Modes (Continued)

SYNC-IN/Synchronous

For the SYNC-IN case, it is assumed that a series of SYNC

pulses at the desired sampling rate are applied at the SYNC

pin of the ADC12041.

8-bit mode: A write to the ADC12041 should set the SYNC

bit, write the START command and clear the BW bit. The

programmed acquisition time in bits b

care condition in the SYNC-IN mode.

A rising edge on the SYNC pin or the second rising edge of

two consecutive reads from the ADC12041 will force the

RDY

signal high. It is recommended that the action of reading from the ADC12041 (not the rising edge of the SYNC

signal) be used to raise the RDY

the conversion result is read during the acquisition period of

the next conversion cycle, eliminating a read from the

ADC12041 while it is performing a conversion. Noise generated by accessing the ADC12041 while it is converting may

degrade the conversion result. In the SYNC-IN mode, only

the rising edge of the SYNC signal will begin a conversion

cycle. The rising edge of the SYNC also ends the acquisition period. The acquisition period begins after the falling

edge of the RDY signal. The input is sampled until the rising

edge of the SYNC pulse, at which time the signal will be

held and conversion begins. The RDY

when the conversion is done and a new operational command may be written into the Configuration register at this

time, if needed. Two consecutive read cycles are required to

retrieve the entire 13-bit conversion result from the

ADC12041’s Data register. The first read will place the lower byte of the conversion result contained in the Data register on the data bus. The second read will place the upper

byte of the conversion result stored in the Data register on

the data bus. With the START command in the configuration

register, the rising edge of the second read pulse will raise

the RDY

signal high and begin a conversion cycle following

a rising edge on the SYNC pin.

and b0is a don’t

1

signal. This will ensure that

signal will go low

13-bit mode:

and the START command issued with a write to the

ADC12041. A rising edge on the SYNC pin or on the RD pin

will force the RDY

action of reading from the ADC12041 (not the rising edge of

the SYNC signal) be used to raise the RDY

ensure that the conversion result is read during the acquisition period of the next conversion cycle, eliminating a read

from the ADC12041 while it is performing a conversion.

Noise generated by accessing the ADC12041 while it is

converting may degrade the conversion result. In the SYNCIN mode, only the rising edge of the SYNC signal will begin

a conversion cycle. The RDY

conversion cycle is done. The acquisition time is controlled

by the SYNC signal. The acquisition period begins after the

falling edge of the RDY

rising edge of the SYNC pulse, at which time the signal will

be held and conversion begins. The RDY

when the conversion is done and a new operational command may be written into the Configuration register at this

time, if needed. With the START command in the Configuration register, a read from the ADC12041 will place the entire

conversion result stored in the Data register on the data bus

and the rising edge of the read pulse will force the RDY

signal high.

STANDBY COMMAND

8-bit mode:

bit and issue the Standby command.

13-bit mode:

and issue the Standby command.

RESET

The RESET command places the ADC12041 into a ready

state and forces the RDY

can be used to interrupt the ADC12041 while it is performing

a conversion, full-calibration or auto-zero cycle. It can also

be used to get the ADC12041 out of the standby mode.

The SYNC bit and the BW bit should be set

signal high. It is recommended that the

signal. This will

signal will go low when the

signal. The input is sampled until the

signal will go low

A write to the ADC12041 should clear the BW

A write to the ADC12041 should set the BW bit

signal low. The RESET command

24

Page 25

Analog Application Information

REFERENCE VOLTAGE

The ADC12041 has two reference inputs, V

b

V

. They define the zero to full-scale range of the ana-

REF

log input signals over which 4095 positive and 4096 negative codes exist. The reference inputs can be connected to

span the entire supply voltage range (V

a

a

e

V

ages when other input spans are required. The reference

REF

V

) or they can be connected to different volt-

A

REF

inputs of the ADC12041 have transient capacitive switching

currents. The voltage sources driving V

must have very low output impedence and noise and must

be adequately bypassed. The circuit in

REF

Figure 8

ple of a very stable reference source.

The ADC12041 can be used in either ratiometric or absolute

reference applications. In ratiometric systems, the analog

input voltage is proportional to the voltage used for the

ADC’s reference voltage. This technique relaxes the system

reference requirements because the analog input voltage

moves with the ADC’s reference. The system power supply

can be used as the reference voltage by connecting the

a

V

REF

lute accuracy, where the analog input voltage varies be-

pin to V

a

A

and the V

b

pin to AGND. For abso-

REF

tween very specific voltage limits, a time and temperature

stable voltage source can be connected to the reference

inputs. Typically, the reference voltage’s magnitude will require an initial adjustment to null reference voltage induced

full-scale errors.

The reference voltage inputs are not fully differential. The

ADC12041 will not generate correct conversions if V

b

V

is below 1V.

REF

ship between V

REF

Figure 9

a

and V

shows the allowable relation-

b

.

REF

REF

b

e

a

and V

is an exam-

a

and

AGND,

REF

a

REF

b

FIGURE 9. V

Operating Range

REF

TL/H/12441– 43

OUTPUT DIGITAL CODE VERSUS ANALOG INPUT

VOLTAGE

The ADC12041’s fully differential 12-bit

a

sign ADC generates a two’s complement output that is found by using the

equation shown below:

a

b

b

(V

V

Output code

IN

e

(V

REF

) (4096)

IN

a

b

b

V

)

REF

Round off the result to the nearest integer value between -

–

*Tantalum

**Ceramic

FIGURE 8. Low Drift Extremely Stable Reference Circuit

Part Number

LM4041CI-Adj

LM4040AI-4.1

LM9140BYZ-4.1

LM368Y-5.0

Circuit of

Figure 8

Output Voltage Temperature

Tolerance Coefficient

g

0.5%

g

0.1%

g

0.5%

g

0.1%

Adjustable

g

100ppm/§C

g

100ppm/§C

g

25ppm/§C

g

20ppm/§C

g

2ppm/§C

25

TL/H/12441– 44

Page 26

Analog Application Information (Continued)

INPUT CURRENT

At the start of the acquisition window (t

ing current (due to capacitive switching) flows through the

analog input pins (ADCIN

a

and ADCINb). The peak value

AcqSYNOUT

of this input current will depend on the amplitude and frequency of the input voltage applied, the source impedance

and the ADCIN

a

and ADCINbinput switch ON resistance

of 2500X.

For low impedance voltage sources (1000

operation), the input charging current will decay to a value

that will not introduce any conversion errors before the end

of the default sample-and-hold (S/H) acquisition time

(9 clock cycles). For higher source impedances (1000

for 12 MHz operation), the S/H acquisition time should be

increased to allow the charging current to settle within specified limits. In asynchronous mode, the acquisition time may

be increased to 15, 47 or 79 clock cycles. If different acquisition times are needed, the synchronous mode can be

used to fully control the acquisition time.

INPUT BYPASS CAPACITANCE

External capacitors (0.01 mF – 0.1 mF) can be connected between the ADCIN

a

and ADCINbanalog input pins and the

analog ground to filter any noise caused by inductive pickup

associated with long leads.

POWER SUPPLY CONSIDERATIONS

Decoupling and bypassing the power supply on a high resolution ADC is an important design task. Noise spikes on the

a

V

(analog supply) or V

A

version errors. The analog comparator used in the ADC will

a

(digital supply) can cause con-

D

respond to power supply noise and will make erroneous

conversion decisions. The ADC is especially sensitive to

power supply spikes that occur during the auto-zero or linearity calibration cycles.

The ADC12041 is designed to operate from a single

power supply. The separate supply and ground pins for the

analog and digital portions of the circuit allow separate external bypassing. To minimize power supply noise and ripple, adequate bypass capacitors should be placed directly

between power supply pins and their associated grounds.

Both supply pins should be connected to the same supply

source. In systems with separate analog and digital supplies, the ADC should be powered from the analog supply.

At least a 10 mF tantalum electrolytic capacitor in parallel

with a 0.1 mF monolithic ceramic capacitor is recommended

for bypassing each power supply. The key consideration for

these capacitors is to have low series resistance and inductance. The capacitors should be placed as close as physically possible to the supply and ground pins with the smaller

capacitor closer to the device. The capacitors also should

have the shortest possible leads in order to minimize series

lead inductance. Surface mount chip capacitors are optimal

in this respect and should be used when possible.

When the power supply regulator is not local on the board,

adequate bypassing (a high value electrolytic capacitor)

should be placed at the power entry point. The value of the

capacitor depends on the total supply current of the circuits

) a charg-

k

X for 12 MHz

l

X

a

5V

on the PC board. All supply currents should be supplied by

the capacitor instead of being drawn from the external supply lines, while the external supply charges the capacitor at

a steady rate.

The ADC has two V

to use a 0.1 mFplusa10mF capacitor between pin

a

21(V

) and 22 (DGND) the SSOP and PLCC package.

D

The layout diagram in

a

and DGND pins. It is recommended

D

Figure 10

shows the recommended

placement for the supply bypass capacitors.

PC BOARD LAYOUT AND GROUNDING

CONSIDERATlONS

To get the best possible performance from the ADC12041,

the printed circuit boards should have separate analog and

digital ground planes. The reason for using two ground

planes is to prevent digital and analog ground currents from

sharing the same path until they reach a very low impedance power supply point. This will prevent noisy digital

switching currents from being injected into the analog

ground.

Figure 10

illustrates a favorable layout for ground planes,

power supply and reference input bypass capacitors. It

shows a layout using a 28-pin PLCC socket and throughhole assembly. A similar approach should be used for the

SSOP package.

The analog ground plane should encompass the area under

the analog pins and any other analog components such as

the reference circuit, input amplifiers, signal conditioning circuits, and analog signal traces.

The digital ground plane should encompass the area under

the digital circuits and the digital input/output pins of the

ADC12041. Having a continuous digital ground plane under

the data and clock traces is very important. This reduces

the overshoot/undershoot and high frequency ringing on

these lines that can be capacitively coupled to analog circuitry sections through stray capacitances.

The AGND and DGND in the ADC12041 are not internally

connected together. They should be connected together on

the PC board right at the chip. This will provide the shortest

return path for the signals being exchanged between the

internal analog and digital sections of the ADC.

It is also a good design practice to have power plane layers

in the PC board. This will improve the supply bypassing (an

effective distributed capacitance between power and

ground plane layers) and voltage drops on the supply lines.

However, power planes are not as essential as ground

planes are for satisfactory performance. If power planes are

used, they should be separated into two planes and the

area and connections should follow the same guidelines as

mentioned for the ground planes. Each power plane should

be laid out over its associated ground planes, avoiding any

overlap between power and ground planes of different

types. When the power planes are not used, it is recommended to use separate supply traces for the V

a

V

pins from a low impedance supply point (the regulator

D

output or the power entry point to the PC board). This will

a

and

A

help ensure that the noisy digital supply does not corrupt

the analog supply.

26

Page 27

Analog Application Information (Continued)

FIGURE 10. Top View of Printed Circuit Board for a 28-Pin PLCC ADC12041

When measuring AC input signals, any crosstalk between

analog input lines and the reference lines (ADCIN

g

V

) should be minimized. Crosstalk is minimized by re-

REF

ducing any stray capacitance between the lines. This can be

done by increasing the clearance between traces, keeping

the traces as short as possible, shielding traces from each

other by placing them on different sides of the AGND plane,

or running AGND traces between them.

Figure 10

also shows the reference input bypass capacitors.

Here the reference inputs are considered to be differential.

The performance improves by having a 0.1 mF capacitor

TL/H/12441– 45

g

manner similar to that described for the supply pins. When a

,

between the V

REF

a

and V

single ended reference is used, V

AGND and only two capacitors are used between V

b

and V

connect the AGND side of these capacitors to the V

(0.1 mFa10 mF). It is recommended to directly

REF

instead of connecting V

capacitors separately to the ground planes. This provides a

b

, and by bypassing in a

REF

b

is connected to

REF

b

and the ground sides of the

REF

REF

REF

a

b

significantly lower-impedance connection when using surface mount technology.

27

Page 28

28

Page 29

Physical Dimensions inches (millimeters)

28-Lead Molded Plastic Leaded Chip Carrier

Order Number ADC12041CIV

NS Package Number V28A

29

Page 30

Physical Dimensions inches (millimeters) (Continued)

28-Lead SSOP

Order Number ADC12041CIMSA

NS Package Number MSA28

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

ADC12041 12-Bit Plus Sign 216 kHz Sampling Analog-to-Digital Converter

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax:

Arlington, TX 76017 Email: europe.support@nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel:

Fax: 1(800) 737-7018 English Tel:

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Fran3ais Tel:

Italiano Tel:

a

49 (0) 180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2308

a

49 (0) 180-530 85 85 Tsimshatsui, Kowloon

a

49 (0) 180-532 78 32 Hong Kong

a

49 (0) 180-532 93 58 Tel: (852) 2737-1600

a

49 (0) 180-534 16 80 Fax: (852) 2736-9960

Loading...

Loading...