Page 1

The Intelligent Use of Water™

Page 2

Design, Installation and Maintenance Guide

INDEX | TABLE OF CONTENTS

SECTION 1 INTRODUCTION ...........................................3

About Rain Bird / The Intelligent Use of Water ...............5

Leed Library ................................................6

Benets of Dripline Irrigation ...............................7

SECTION 2 PREPARATION FOR DESIGN ..............................8

XF Series Dripline | Where is it used? ........................9

Preparation for Design .................................... 10

Determine Soil Type ...................................... 11

SECTION 3 DETERMINE DRIPLINE SPECIFICATIONS ................12

SECTION 4 DETERMINE TYPE OF DRIPLINE LAYOUT ...............14

End Feed / Center Feed ................................... 15

Loop / Curved Edge ...................................... 16

Branching Out or Joining Row ............................ 17

Slopes ...................................................18

Determine Lateral Row Spacing ........................... 19

SECTION 5 ZONE WATER CALCULATIONS .......................... 20

Calculating Zone Water Requirements .................... 21

Calculating Application Rates ............................. 22

Calculations for Dripline Irrigation ........................23

Irrigation Formulas ....................................... 24

SECTION 6 DRIPLINE MODELS FOR EVERY APPLICATION .......... 25

XFS-CV Dripline for On/Subsurface Elevated Applications . . . . . . 26

XFS-CV Dripline - Specications ........................... 27

XFCV Dripline for On-Surface Elevated Applications ........... 28

XFCV Dripline - Specications ............................. 29

XFS Dripline for Subsurface Applications ..................... 30

XFS Dripline - Specications .............................. 31

XFD Dripline for On-Surface - Level Grade Applications ........ 32

XFD Dripline - Specications .............................. 33

1/4” Dripline for Potted/Small Bed Applications .............. 34

SECTION 7 SUBSURFACE DESIGN, INSTALLATION & OPERATION . . . . . . 35

Best Subsurface Applications ............................. 36

Adjust for Trees / Curved Edges ........................... 37

Design for Conned Areas ................................ 38

Design for Large Areas .................................... 39

Installation Methods ................................... 40-41

Recommended Practices .................................42

SECTION 8 SPECIFYING PRODUCTS IN THE ZONE .................. 43

QF Dripline Header .................................... 44-46

Control Zone Kits ......................................... 47

Control Zone Kit Selection Chart ........................... 48

Fittings ................................................49-51

Spray-to-Drip Retrot Kits ................................. 52

Air Relief Valve / Stakes / Flush Point ...................... 53

Drip System Operation Indicator .......................... 54

SECTION 9 FAQ’S, GLOSSARY, AND RESOURCES ................... 55

Preventative Maintenance: Flushing / Winterizing .......... 56

Written Specications and CAD Detail Drawings ........... 57

Frequently Asked Questions ............................ 58-59

Glossary ...............................................60-61

Notes .................................................. 62-63

XF Series Dripline

XFS-CV Dripline

17mm XF Insert Fittings

XF Insertion Tool

Subsurface Design, Installation and Operation

Control Zone Kit

2

www.rainbird.com

Page 3

Section 1:

Introduction

SECTION 1: Introduction

This guide covers the basics of design, installation, and maintenance for

Rain Bird’s XF Series Dripline. Included are design steps, technical data,

installation layouts and design details to assist in the design of the more

common dripline applications.

www.rainbird.com

For help selecting the proper XF Series Dripline

products, visit: www.rainbird.com/calculator

Access from your laptop, tablet or smart phone.

For more in-depth resources, visit:

www.rainbird.com/drip

3

Page 4

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

This guide covers the basics of design, installation, and maintenance

for Rain Bird’s XF Series Dripline. Included are design steps, technical

data, installation layouts and design details to assist in the design of

SECTION 1

the more common dripline applications.

A low volume irrigation system typically applies water slowly, at

low pressure, at or near the root zones of plant material. Whether

referred to as Drip, Xerigation®, micro irrigation, or low volume,

these systems feature emission devices that apply water in gallons

per hour (GPH) or liters per hour (L/HR) as opposed to the gallons

per minute (GPM) or liters per minute (L/MIN) of a conventional

overhead spray irrigation system. Low-volume irrigation can greatly

reduce or eliminate water waste while promoting healthier plant

growth because you can:

• Match the amount of water applied to the specic need

of each plant

• More closely match the application rate to the soil’s

inltration rate

Section 1:

Introduction

SECTION 1: INTRODUCTION

• Apply water directly to the root zone, reducing overspray

and evaporation

Low-volume systems also reduce or eliminate runo on walks and

paved areas, and overspray onto windows, fences, pavement and

walls. The Rain Bird Xerigation® line of drip products oer a full

range of water-saving choices for both turf and non-turf landscape

applications, including control zone components, dripline, ttings,

blank tubing, emission devices and tools.

Use of dripline is a preferred method in many low-volume

irrigation applications. Rain Bird’s XF Series Dripline has Rain Bird

designed and manufactured emitters that provide pressure

compensation for precise ow control throughout the zone.

XF Series Dripline is made with advanced polymers that provide

kink-resistance and reduce coil memory for easier installation.

With emitter ow rates of 0.4 GPH, 0.6 GPH, and 0.9 GPH

(1.6 L/HR, 2.3 L/HR, and 3.4 L/HR) and emitter spacing of 12” and

18” (0.30 m and 0.45 m) the XF Series provides a full product line

to meet the needs of any application.

The Rain Bird XF Series of dripline products consists of:

• XFD –for on-surface applications

• XFCV for on-surface, sloped applications

• XFS with Copper Shield™ Technology

– for subsurface applications

• XFS-CV with Heavy Duty Check Valve

– for on-surface, subsurface and sloped applications

For complete performance and technical specications, please see

Rain Bird’s Landscape Irrigation Products Catalog or visit

Rain Bird’s website at www.rainbird.com. The website provides

specications and detail drawings in downloadable les.

4

XFCV for on-surface, sloped applications.

www.rainbird.com

Page 5

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

– HE-VAN Series Nozzles

Section 1:

Introduction

ABOUT RAIN BIRD AND THE INTELLIGENT USE OF WATER

A privately held company founded in 1933, Rain Bird

Corporation is the leading manufacturer and provider of

irrigation products and services. Since its beginnings, Rain

Bird has oered the industry’s broadest range of irrigation

products for farms, golf courses, nurseries, sports arenas,

commercial developments and homes in more than 130

countries around the world. With the broadest product line

in the industry, architects, designers and contractors

recognize Rain Bird as the industry leader in irrigation

solutions.

Rain Bird is committed to The Intelligent Use of Water™.

It is our legacy to design and manufacture only those

products of the highest value, quality, and ecient

application of water. We work for long-term, responsible

partnerships with our customers and our suppliers. This is

who we are, and this is how we wish to be perceived in the

irrigation industry and our communities.

Please visit The Intelligent Use of Water section of our

website to explore additional resources to help you design

the most water-ecient projects.

http://www.rainbird.com/landscape/resources/IUOW.htm

SECTION 1

Water Source

Need

Preserve potable water through alternative

sourcing that taps into underutilized supplies

such as underground well water, grey

water and rain water.

Rain Bird Solution

• Non-potable-water-ready:

– Drip products

– Valves

– Rotors

– Sprays

MAXIMUM

Design & Manage

Need

Receive support from a certied professional trained to

design, install, operate and maintain a water-ecient system.

Rain Bird Solution

Rain Bird’s Contractor Referral Program helps you quickly and

easily nd a qualied irrigation contractor in your area.

WATER

Apply

Need

Distribute water to your landscape

as eciently as possible.

Rain Bird Solution

• Xerigation®/Landscape Drip: Direct-to-plant-root watering devices.

• Water-smart rotor and spray features:

– Pressure Regulating Stem (PRS) technology

– Seal-A-Matic™ (SAM) check valves

• High-eciency Nozzles:

– Rain Curtain™ Nozzles

– U-Series Nozzles

– Matched Precipitation Rate (MPR) Nozzles

– Square Pattern Nozzles (SQ)

– R-VAN Series Nozzles

EFFICIENCY

Schedule

Need

Flexible programming schedules that help you customize

a watering schedule based on the needs of your landscape.

Rain Bird Solution

Our controllers oer:

• Cycle+Soak feature allowing for

the most ecient water delivery

• Easy, push-of-the-button adjustments

for seasonal changes

• Weather-based controllers which

adjust based on hourly weather data

www.rainbird.com

5

Page 6

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 1:

Introduction

LEED LIBRARY

SECTION 1

WHAT IS LEED?

The Leadership in Energy and Environmental Design (LEED) Green Building Rating System™ is a point rating system

devised by the United States Green Building Council (USGBC) to evaluate the environmental performance of a building

over its life cycle and to encourage market transformation towards sustainable design. LEED is the nationally recognized

benchmark for the design, construction, and operation of high performance green buildings. LEED provides building

owners and operators with the tools they need to have an immediate and measurable impact on their buildings’

performance. LEED promotes a whole-building approach to sustainability by recognizing performance in ve key areas

of human and environmental health: sustainable sites, water savings, energy eciency, materials selection, and indoor

environmental quality.

Detailed information on obtaining credits and the project certication process is available from the USGBC on their

website: www.usgbc.org.

DESIGN & TECHNICAL RESOURCES

• WATER EFFICIENCY CREDIT 1.1

• WATER EFFICIENCY LANDSCAPING: Reduce by 50% 2 points

Intent

Limit or eliminate the use of potable water, or other natural surface water resources available on or near the project site,

for landscape irrigation.

Requirements

Reduce potable water consumption for irrigation by 50% from a calculated mid-summer baseline case. Reductions shall

be attributed to any combination of the following items:

• Plant species factor

• Irrigation eciency

• Use of captured rainwater

• Use of recycled wastewater

• Use of water treated and conveyed by a public agency for non-potable uses.

Rain Bird Notes

The designer on the LEED project will need to provide an irrigation plan and legend, as well as calculations, a

description of the baseline, and cut sheets of the irrigation system demonstrating how water consumption is

reduced by 50%.

Learn more at: http://www.rainbird.com/landscape/resources/LEEDlibrary.htm

6

www.rainbird.com

Page 7

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 1:

Introduction

SECTION 1

Dripline irrigation can greatly reduce or eliminate water

waste while promoting healthier plant growth for the

following reasons:

• Match the water application to the specic needs of

each plant

• More precisely match the application rate to the soil’s

inltration rate

• Apply water directly to the root zone to reduce

overspray and evaporation

• A properly designed and installed dripline irrigation

system can be over 90% ecient

There are many advantages of dripline irrigation that can

provide solutions for dicult-to-irrigate landscape areas

including:

• Narrow turf areas

• Curved narrow landscape areas

• Sloped areas

• Subsurface turf irrigation applications

• Parking lot islands

• Steep sloped areas

BENEFITS OF DRIPLINE IRRIGATION

Other benets of on-surface or subsurface Drip Irrigation:

• Eliminate runo on walks and paved areas

• Prevent overspray onto windows, walls and fences

• Increase watering uniformity

• Reduce susceptibility to vandalism

• Promote healthy plant growth

To view all dripline models online, visit:

http://www.rainbird.com/drip

www.rainbird.com

7

Page 8

SECTION 1

SECTION 4

SECTION 7

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 2: PREPARATION FOR DESIGN

SECTION 2

SECTION 2:

Preparation for Design

8

www.rainbird.com

Page 9

SECTION 1

SECTION 4

SECTION 7

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 2:

Preparation for Design

XF SERIES DRIPLINE | WHERE IS IT USED?

SECTION 2

Small Conned Areas

Flower BedsCurved LandscapesTurf Grass (XFS, XFS-CV)

Narrow LandscapesShrub & Ground Cover Beds

Eliminate Overspray on Buildings Sloped Areas

www.rainbird.com

Potted Plants (¼” Dripline

9

Page 10

SECTION 1

SECTION 4

SECTION 7

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 2:

Preparation for Design

PREPERATION FOR DESIGN

Dripline system design follows many of the same rules as spray and rotor design. Similar design factors must be considered, such

as point of connection, static and operating pressures, ow rates, and plant material.

A dripline system when properly designed and installed will deliver full irrigation coverage to the planted area. A dripline system

is normally divided into zones. A typical zone contains a water source, a control zone (valve, lter, and pressure regulator), and the

dripline with connection ttings.

SECTION 2

During the preparation for design you will gather essential information to design the dripline system:

• Obtain or draw a scaled plan of the site to be irrigated

• Identify all of the slopes on the plan

• Determine the types of plants to be irrigated

(groundcover, shrubs, turfgrass, and trees)

• Identify the type of soil (Clay, Loam, Sand)

• Identify the type of water from the water source

(potable, non-potable, well, surface water, etc)

• Identify static and operating pressures, and volume

available from the water source

• Select appropriate system components for installation

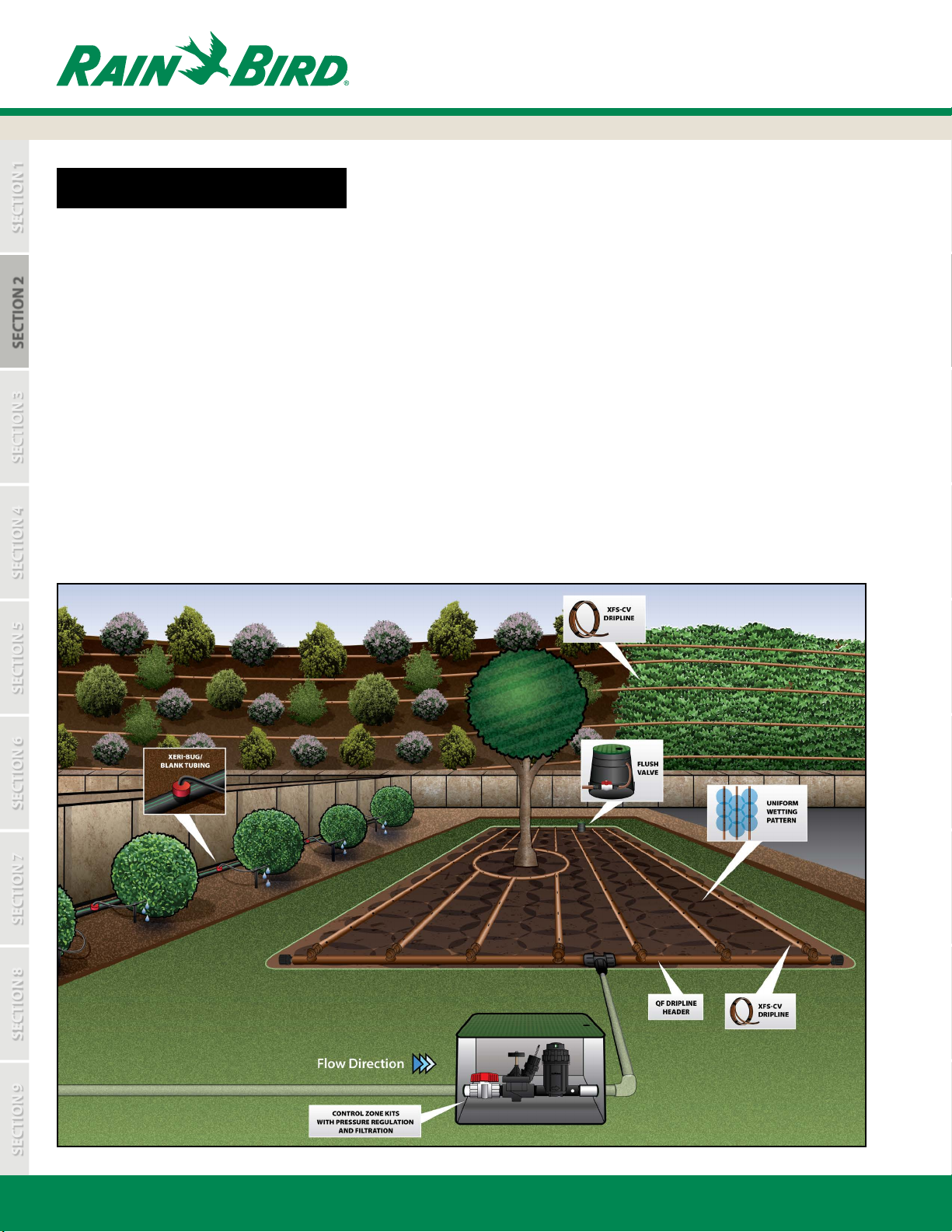

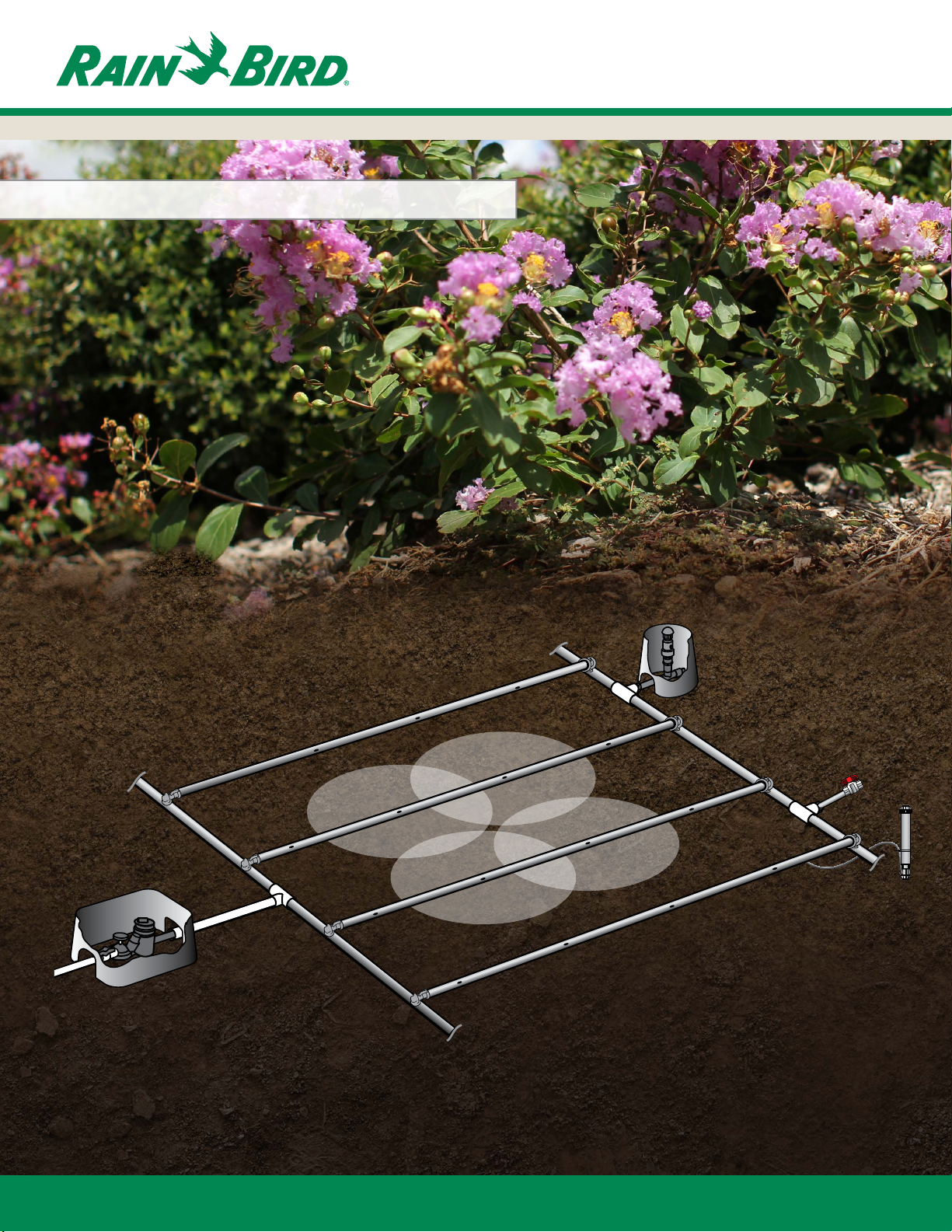

EXAMPLE OF A SUBSURFACE DRIPLINE SYSTEM LAYOUT

10

www.rainbird.com

Page 11

SECTION 1

SECTION 4

SECTION 7

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 2:

Preparation for Design

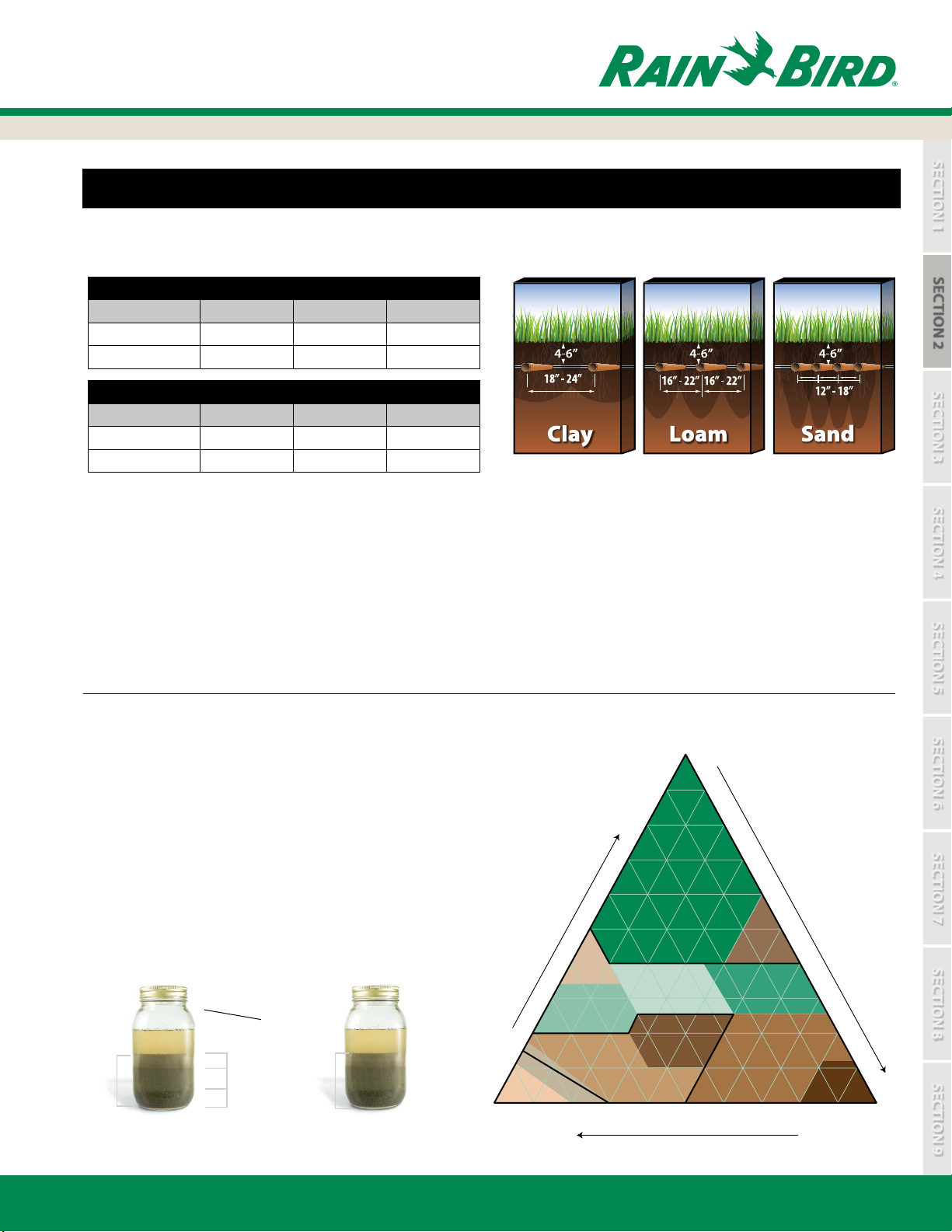

DETERMINE SOIL TYPE | WHAT IS YOUR SOIL TYPE?

OVERALL DESIGN PLAN FOR THE SITE

Soil Inltration Rates (in Inches per Hour)

Percent of Slope

0% - 4% 0.13 - 0.44 0.44 - 0.88 0.88 - 1.25

5% - 8 %

Soil Inltration Rates (in cm per Hour)

Percent of Slope

0% - 4% 0.33 -1.12 1.12 - 2.24 2.24 - 3.18

5% - 8 %

Note: As the slope increases, inltration rates will continue to decrease.

These values are derived from USDA information.

Clay Loam Sand

0.1 - 0.35 0.35 - 0.7 0.7 - 1

Clay Loam Sand

0.25 - 0.89 0.89 - 1.78 1.78 - 2.54

SECTION 2

These illustrations show water movement in a subsurface application.

These guidelines apply to on-surface as well as subsurface installations.

The objective of a well-designed dripline system is to create an even wetting pattern of water in the soil throughout

the planting zone. There are four factors to consider for planting areas to create an even wetting pattern:

• Soil type (Clay, Loam, Sand)

• Emitter ow rate: 0.4 GPH, 0.6 GPH or 0.9 GPH (1.6 L/HR, 2.3 L/HR or 3.4 L/HR)

• Emitter spacing: 12” or 18” (0.30 m or 0.45 m)

• Lateral spacing (distance between the dripline rows)

SOIL TYPE TEST

1. Remove 1 to 2 cups of soil from the zone to be irrigated.

2. Place into a glass jar, like a mason jar.

3. Fill the jar half way with water. Shake and let sit for

2 hours so the particles can settle. The heavier sand particles

will settle to the bottom, then silt, then clay on top.

4. Measure the combined height of all three layers of the soil

then the height of each layer; divide the height of each layer

by the total height to gure out the percentage of each soil in

80 20

70 30

60

the jar.

5. Apply these gures to the “Soil Classication” chart.

In the example, now you know the landscape soil is silt loam.

Measure total height and layer heights

Layer Height

Total Height

= Soil Percentage

Total Height

Clay Height

Silt Height

Sand Height

For Example:

3” Total Height

17% 1/2” Clay

66% 2” Silt

17% 1/2” Sand

20

10

Sand

100 90 80 70 60 50 40 30

rcentage of Clay

Pe

40

30

Sandy Clay

Sandy Loam

Loamy

Sand

50

Sandy

Clay

Loam

100

90 10

Clay

Clay Loam

Loam

Percentage of Sand

40

50

Silty

Clay

Silty Clay

Loam

Silt Loam

Pe

rcentage of Silt

60

70

80

90

Silt

20 10 0

100

www.rainbird.com

11

Page 12

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 6

SECTION 9

SECTION 3: Determine Dripline Specications

SECTION 3

SECTION 3:

Determine Dripline Specications

12

www.rainbird.com

Page 13

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 6

SECTION 9

SECTION 3:

Determine Dripline Specications

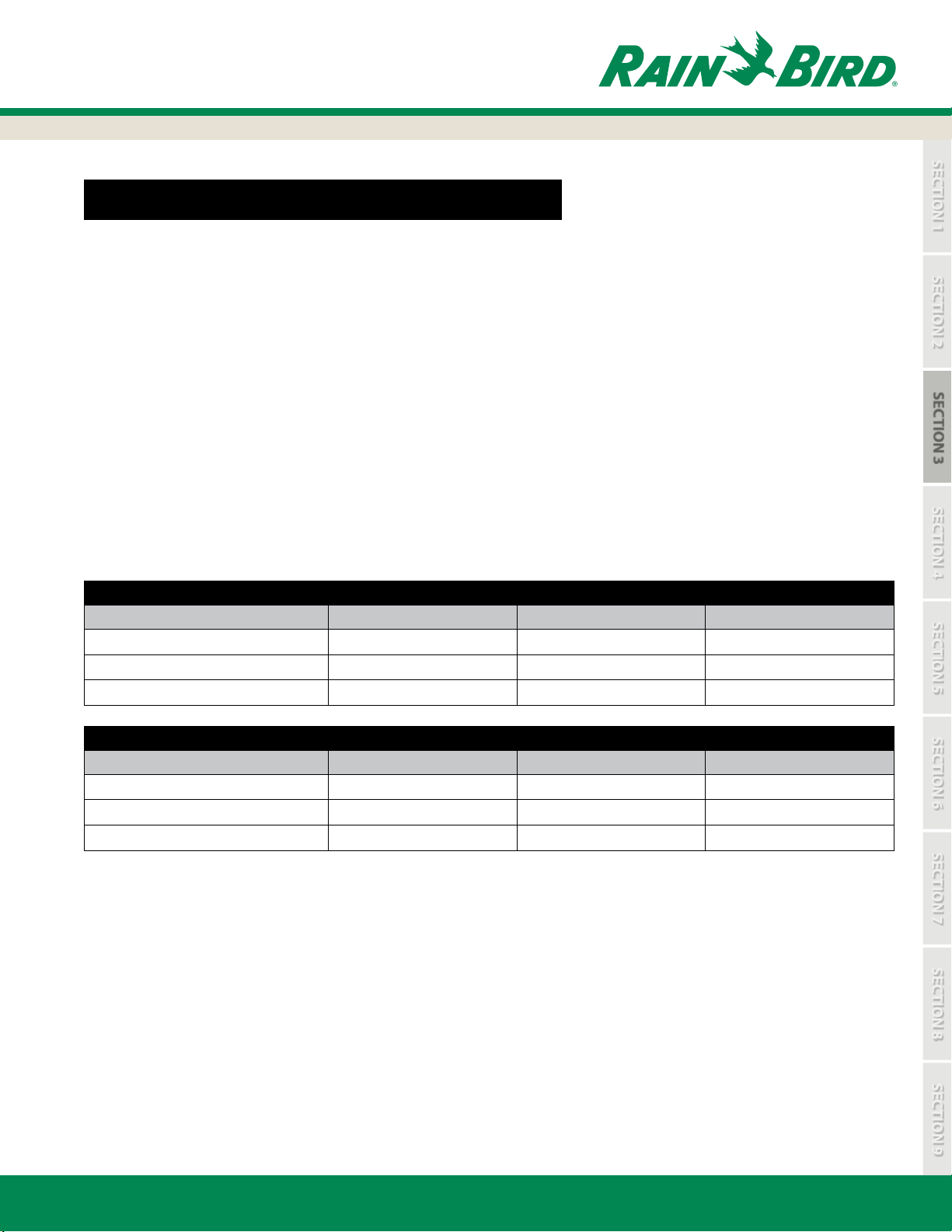

SECTION 3: DETERMINE DRIPLINE SPECIFICATIONS

CHOOSE THE EMITTER FLOW RATE, SPACING BETWEEN EMITTERS, AND

SPACING BETWEEN ROWS

To determine the specication for the emitter ow rate and emitter spacing for the XF Series Dripline, follow the column

under the proper soil type for your application to nd the emitter ow and emitter spacing.

Table 2 gives recommended emitter ow rates and spacing for three basic soil types. If the soil type is not known, or if there is

a good chance that there will be many dierent types of soil at the site, use the shortest distance between emitters and rows

from the table to be sure that the root zone is well irrigated. If there is heavy loam or clay subsoil, these soil types will reduce

the downward ow of water in the soil and allow for wider lateral spacing between rows.

SECTION 3

TABLE 2: XF SERIES DRIPLINE RECOMMENDATION TABLES

XF Series Dripline Recommendations (English)

Soil Type Clay Loam Sand

Emitter Flow Rate (gallons per hour) 0.4 GPH

Emitter Spacing (inches)

Dripline Lateral Spacing (inches)

XF Series Dripline Recommendations (Metric)

Soil Type Clay Loam Sand

Emitter Flow Rate (liters per hour) 1.6 L/HR

Emitter Spacing (meters)

Dripline Lateral Spacing (meters)

Note: These are general guidelines, eld conditions may require modication to emitter ow rate, emitter spacing and lateral spacing. XF Series Dripline is to be installed at a depth of 4”-6”

(10.2-15.24 cm) in subsurface and groundcover applications. Use only XFS or XFS-CV dripline in subsurface applications. XF Series Dripline may also be installed on-surface under mulch in

shrub and groundcover applications.

If you are not quite sure of the soil type, here is a test you can use by squeezing the soil in your hand:

18” 18” 12”

18” - 24” 16 - 22” 12” - 18”

0.45 0.45 0.3

0.45 - 0.61 0.41 - 0.56 0.3 - 0.45

0.6 GPH 0.9 GPH

2.3

L/HR

3.4

L/HR

Clay - When dry it forms hard clumps. When damp it is exible and can be molded into shapes.

Loam - A moderate sand or dirt and very little clay. When dry it breaks easily. When wet it forms a lump.

Sand - Soil particles are loose, sandy grains. When dry it will fall apart when you open your hand. When damp it will form a lump

but it will crumble easily when touched.

www.rainbird.com

13

Page 14

SECTION 1

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 4: Determine Type of Dripline Layout

SECTION 4:

Determine Type of Dripline Layout

SECTION 4

14

www.rainbird.com

Page 15

SECTION 1

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 4:

Determine Type of Dripline Layout

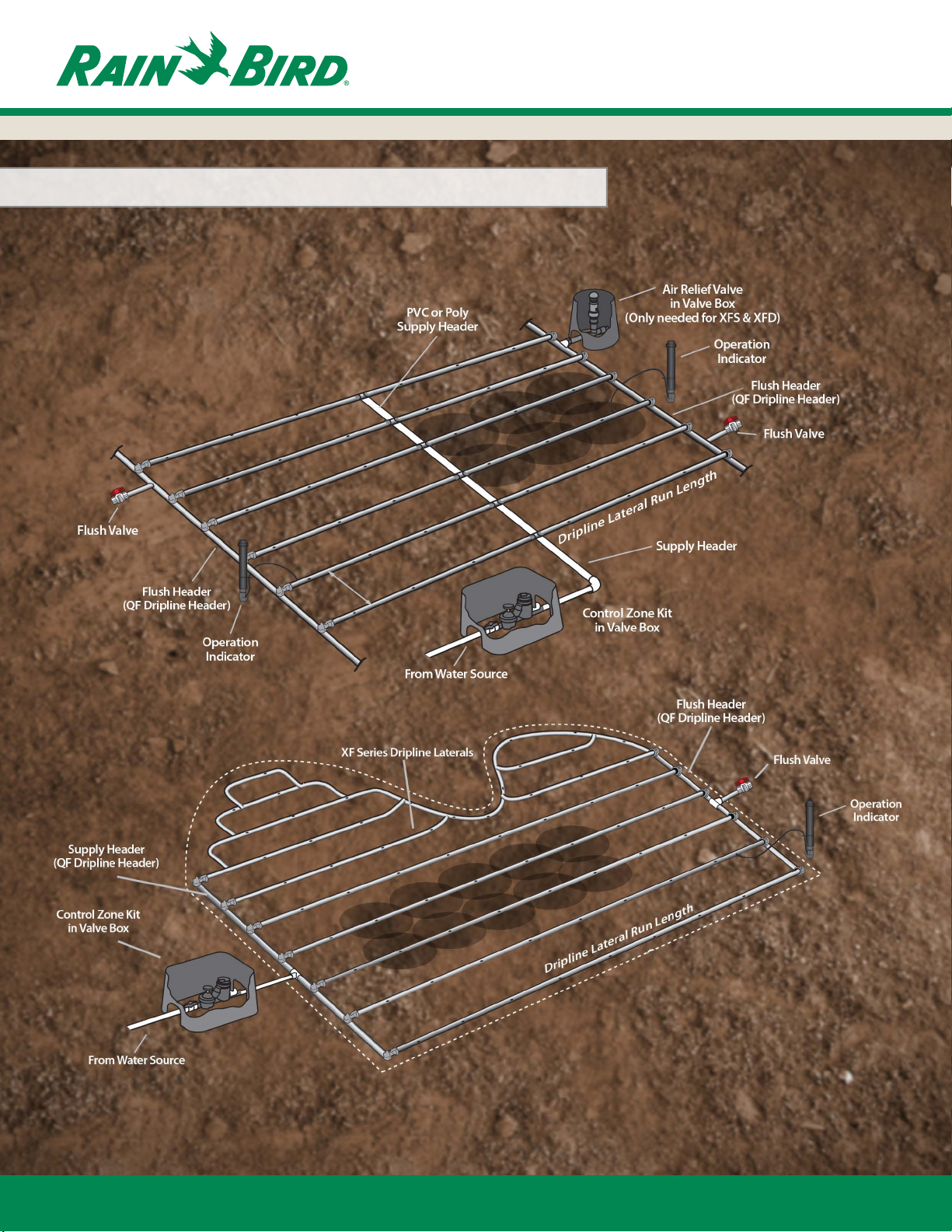

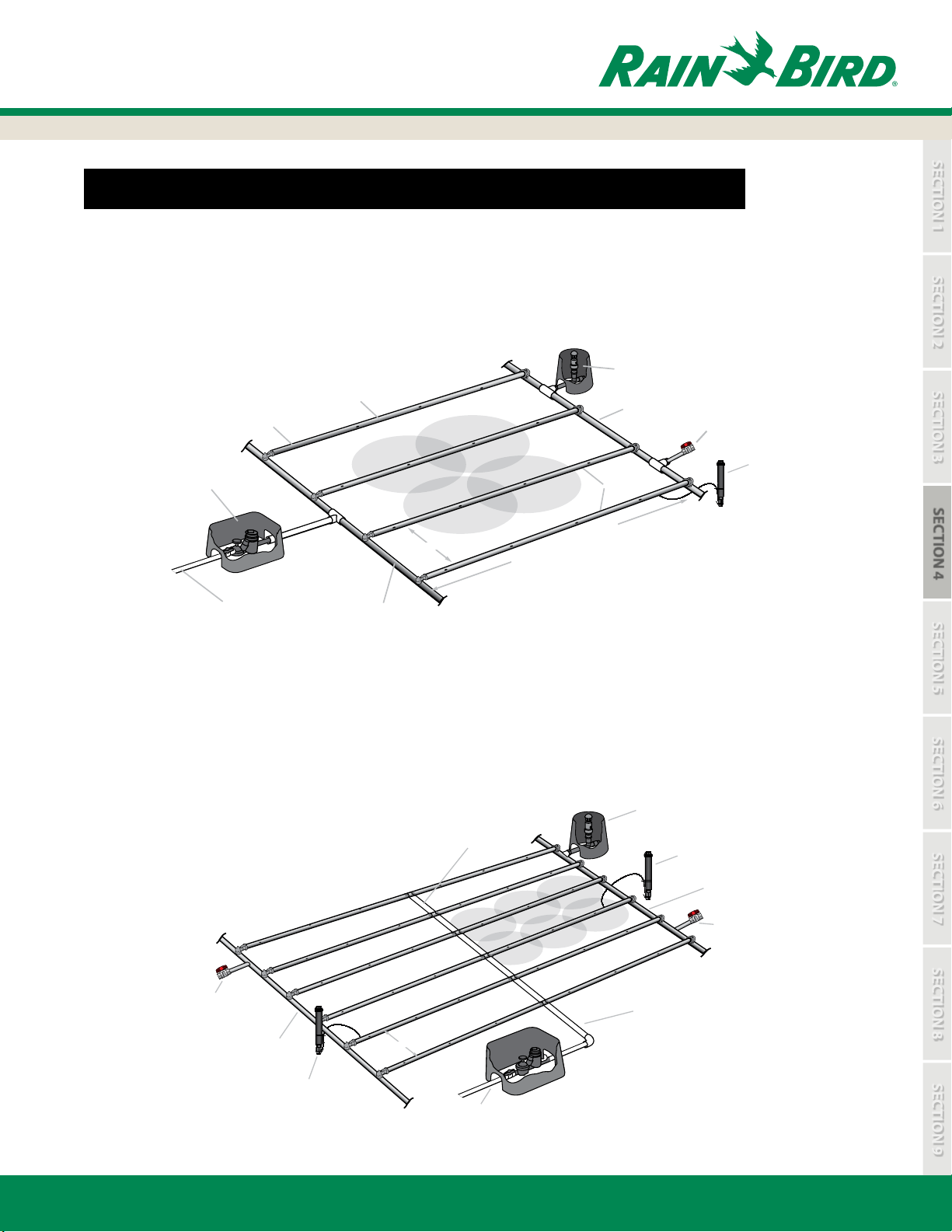

SECTION 4: DETERMINE TYPE OF DRIPLINE LAYOUT | SUBSURFACE

END FEED LAYOUT

This Grid layout is primarily used for dense plantings. The layout uses supply headers and ush headers with rows of dripline

connected at each end. The supply header and ush header form a continuous loop where all rows of dripline are being

supplied from both ends.

Inline Emitters

Control Zone Kit

in Valve Box

XF Series Dripline

Laterals

Wetted Area

Air Relief Valve

in Valve Box

(Only needed

for XFS & XFD)

Flush Header

(QF Dripline Header)

Lateral lines

Flush Valve

Operation

Indicator

SECTION 4

From Water Source

Lateral spacing

QF Dripline Header, PVC

or polyethylene tubing

Dripline Lateral Run Length

CENTER FEED LAYOUT

Where layout exibility exists, it is recommended that Center Feed layouts be used. This allows for the most even ow of

water through the zone. Center Feed layouts also potentially allow you to increase the size of the zone by providing lateral

runs on both sides of the supply header. Center Feed layouts are an excellent option for median strips, road sides, and other

homogenous planting zones.

Air Relief Valve

in Valve Box

(Only needed for XFS & XFD)

Operation

Indicator

Flush Header

(QF Dripline Header)

Flush Valve

Supply Header

Flush Valve

PVC or Poly

Supply Header

Dripline Lateral Run Length

Flush Header

(QF Dripline Header)

Operation

Indicator

www.rainbird.com

Lateral spacing

From Water Source

Control Zone Kit

in Valve Box

15

Page 16

SECTION 1

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 4:

Determine Type of Dripline Layout

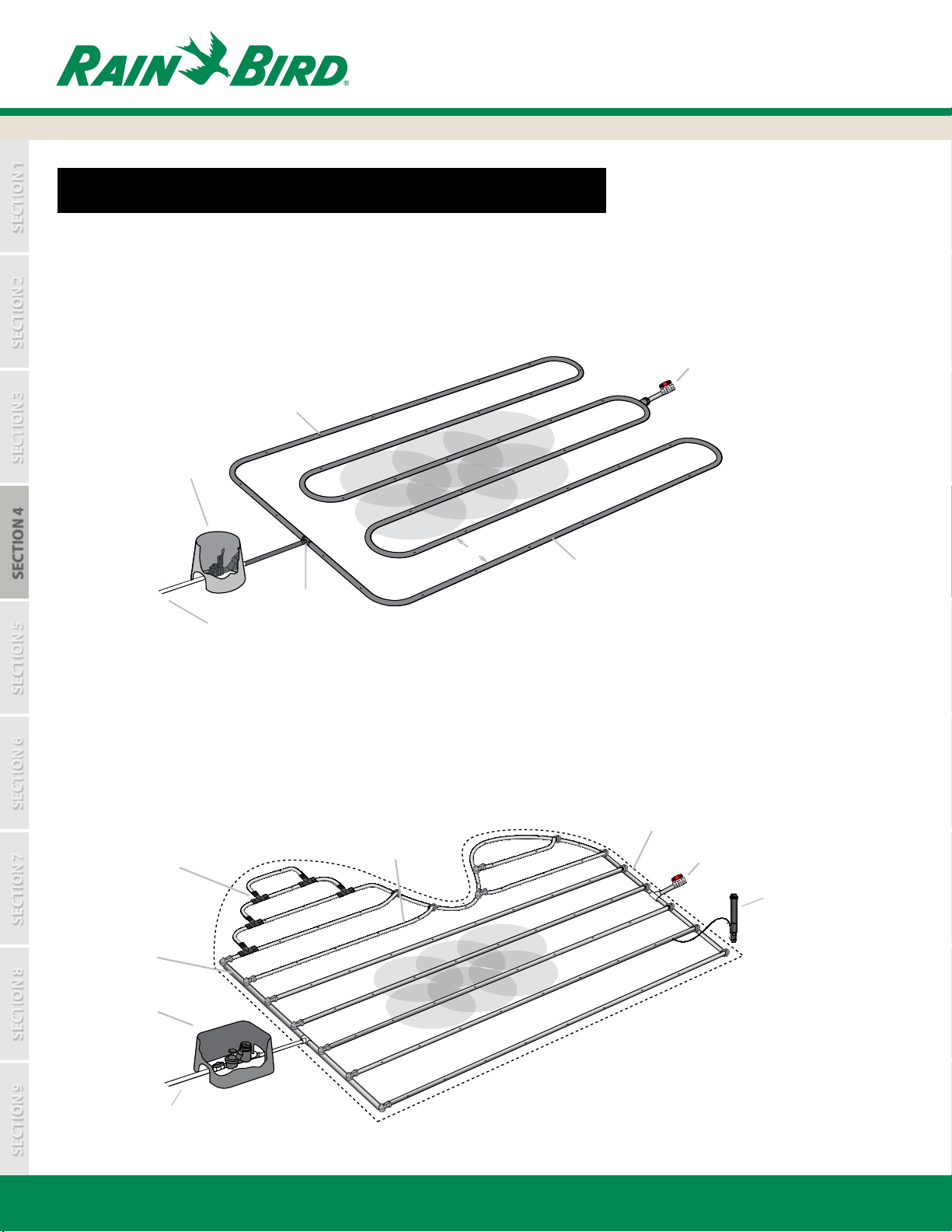

DETERMINE TYPE OF DRIPLINE LAYOUT | ON-SURFACE

QUICK LOOP LAYOUT

The Loop layout is one continuous loop that weaves back and forth throughout the zone in evenly spaced laterals (rows).

Flush Valve

Inline Emitters

Control Zone Kit

in Valve Box

Lateral spacing

SECTION 4

Insert or

Compression

From Water Source

Fitting

Wetted

Area

XF Series Dripline

CURVED EDGE LAYOUT

The Curved Edge layout is primarily used for dense planting areas. The layout uses supply and ush headers with rows of

dripline connected at the end. The supply and ush header form a continuous loop and the dripline can be attached to

the adjacent driplines with “tee” ttings to accommodate curved applications.

Flush Header

(QF Dripline Header)

Insert or

compression tting

XF Series Dripline Laterals

Flush Valve

Operation

Indicator

Supply Header

(QF Dripline Header)

Control Zone Kit

in Valve Box

Dripline Lateral Run Length

PVC or Poly

Supply Header

From Water Source

16

Control Zone

www.rainbird.com

Page 17

SECTION 1

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

T

Check longest lateral

against Table 2 for

maximum lateral

length.

Supply Header

Exhaust Header

SECTION 4:

Determine Type of Dripline Layout

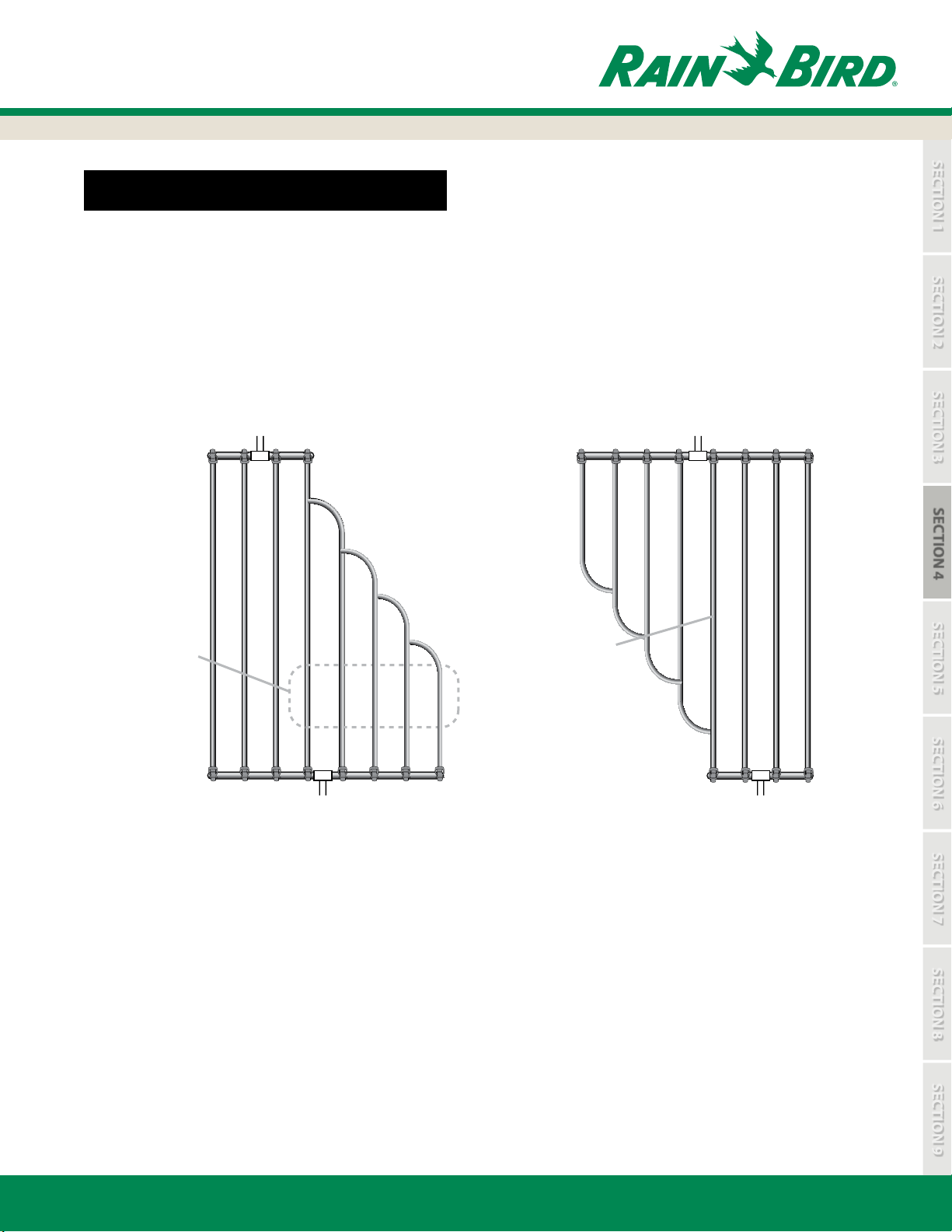

OTHER COMMON GRID LAYOUTS

BRANCHING OUT OR JOINING LAYOUTS

When branching out from a supply header with XF Series dripline, maximum lateral run length should be considered.

Add up all the “branched out” dripline and check it against the maximum lateral run lengths listed in Tables 6, 7, 8, or 9.

This will vary depending on the type of tubing being used.

When joining lateral rows from a supply header, check only the longest lateral against the maximum lateral run length

listed in Tables 6, 7, 8, or 9.

Branching Out

with XF Series

Laterals

otal the combined

length of these XF Series

Dripline laterals and

compare it against the

maximum lateral length

allowed in Table 6.

Supply Header

(QF Dripline Header)

Flush Header

(QF Dripline Header)

Joining Rows

with XF Series

Laterals

Check longest lateral

against Tables 6,7,or 8

for maximum lateral

length.

Supply Header

(QF Dripline Header)

SECTION 4

Flush Header

DESIGN CONSIDERATIONS

• Header should be spaced 2” - 4” (5cm-10.2 cm) from hardscape or other planting areas

• Headers may be QF Header, PVC, blank poly tubing or dripline

• Lateral spacing is a design consideration and can be calculated as shown on page 19 in “How to Calculate

Equal Lateral (Row) Spacing”

• The lateral run length should not exceed the maximum lateral run length shown in Tables 6, 7, 8, or 9

• When using “Center Feed Layout” the run length should be measured from the supply header to the ush

header and should not exceed the maximum run length shown

• When using “Loop Layout”, because water is split into two separate paths that meet in the middle, the total

continuous loop length of dripline should not exceed twice the maximum lateral length

• In subsurface applications an air vacuum relief valve should be installed at the highest point in the system

to avoid back siphoning debris into the emitter

• Flush valves should be installed at the low point in the ush header or at the mid point of the loop layout

www.rainbird.com

17

Page 18

SECTION 1

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

10 FT. SLOPE

ZONE 1

CONTROL ZONE 1

Top of Slope

Toe of Slope

SECTION 4:

Determine Type of Dripline Layout

SLOPES

• The design of the dripline system should account for

slopes on the site since runo may occur at low points

• Slopes less than 3% do not require special design

considerations

• Slopes greater than 3% should increase the dripline

spacing by 25% in the bottom 1/3 of the zone

• Dripline should run perpendiculur (across) the slope when

possible

ELEVATION CHANGES SLOPE LAYOUT

SECTION 4

*Increase the dripline

row spacing by 25%

in the bottom 1/3 of

the zone

SLOPES GREATER THAN 10 FT

USING XFSCV DRIPLINE:

• With steep sloping landscapes

greater than 10 ft., it is recommended

that additional zones are installed to

reduce runo

• The use of XFS-CV can eliminate low

emitter drainage

ZONE 1

ZONE 2

SLOPES UP TO 10 FT. USING XFSCV DRIPLINE:

• With sloping landscapes up to 10 ft. of elevation

change, no seperate zones or check valves are required

Top of Slope

30 FT. SLOPE

CONTROL ZONE 1

CONTROL ZONE 2

CONTROL ZONE 3

ZONE 3

18

Toe of Slope

www.rainbird.com

Page 19

SECTION 1

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 4:

Determine Type of Dripline Layout

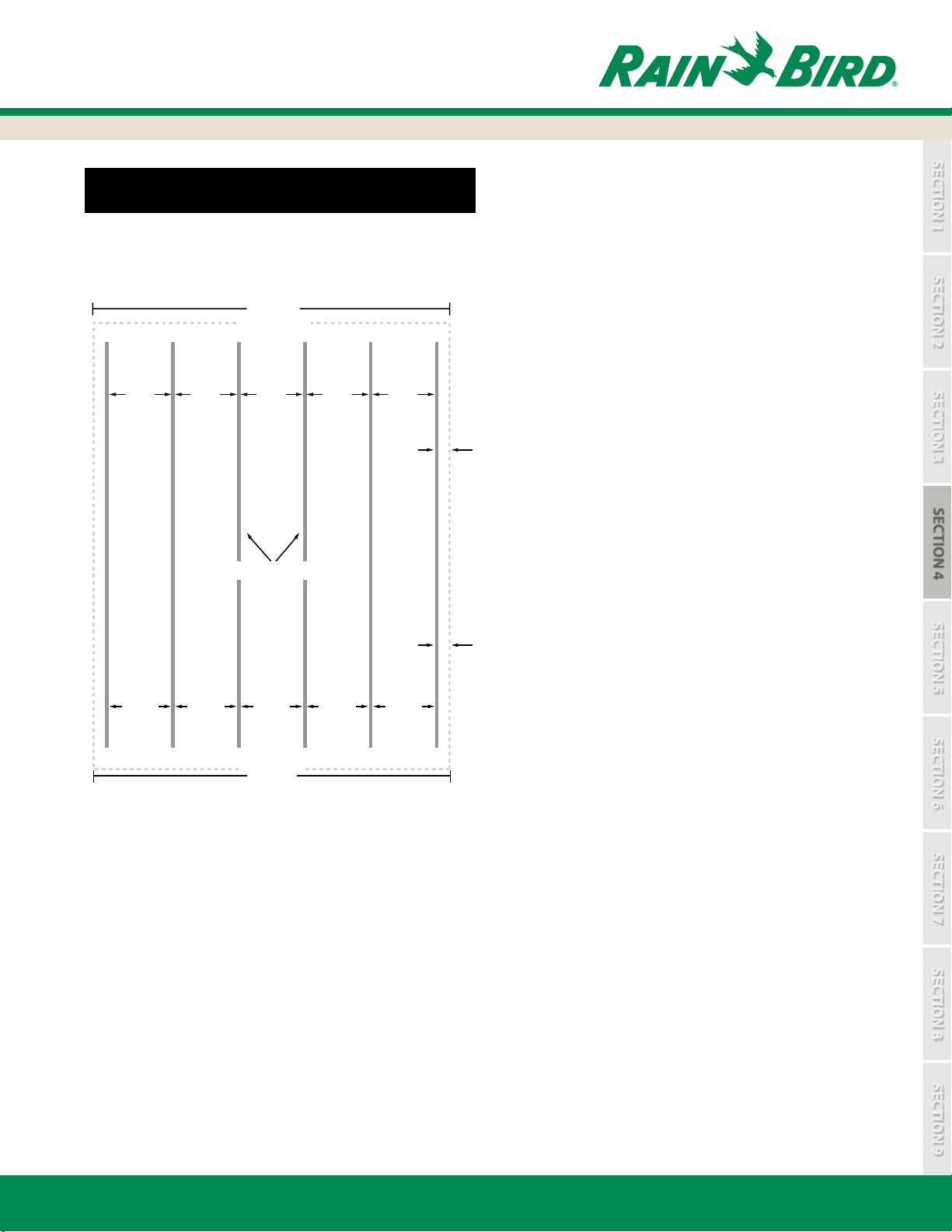

DETERMINE LATERAL ROW SPACING

Application Width

8 feet

(96 inches)

18.4”

45cm

18.4” 18.4” 18.4” 18.4”

XF Series Dripline

45cm

45cm

2.4 m

(243 cm)

45cm

2”–4”

from

hardscape

5 cm–10.2 cm

from

hardscape

45cm

HOW TO CALCULATE EQUAL

LATERAL ROW SPACING WHEN

MAKING CUSTOM PVC HEADERS

Loam soil is assumed for the example below with a

recommended lateral row spacing of 16”-22” as shown in

Table 2 on Page 13. To calculate the specic lateral row

spacing within this range, you need to know the width of the

zone being irrigated and then use the calculation as show in

Example 1.

Example 1: How to Calculate Equal Lateral (Row) Spacing

• Application width = 8’ (2.4 m)

• Convert into inches: 8’ x 12” = 96”

or (Convert into centimeters: 2.43 m x 100 = 243 cm)

• It is recommended to space dripline 2” (5 cm) from

hardscapes and 4” (10.2 cm) from separate planting zones

In this example there are hardscapes on each side of the

planting zone. Remove the hardscape spacing on each

side from the total width:

96” - (2x2”) = 92” (243 cm - (2x5 cm) = 233 cm)

• For loam soil, the range of lateral row spacing is 16”-22”

(40.6 cm - 55.9 cm). Choosing 18”, calculate the number of

spaces between rows: 92” ÷ 18” = 5.1 (233 cm ÷ 0.45 m =

5.1). Round to get whole spaces. Round up if the decimal

is 0.5 or higher, round down if it is less than 0.5. In this case

you should round down to 5 whole spaces between rows.

SECTION 4

• Calculate the equal lateral row spacing: 92” ÷ 5 = 18.4” (233

cm ÷ 5 = 45 cm)

• Calculate the number of dripline rows by adding 1 to the

number of spaces between rows: 5 + 1 = 6 dripline rows

www.rainbird.com

19

Page 20

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 5: Zone Water Calculations

SECTION 5:

Zone Water Calculations

SECTION 5

20

www.rainbird.com

Page 21

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 5:

Zone Water Calculations

TABLE 3: CALCULATING ZONE WATER REQUIREMENTS

XF Series Dripline Flow (per 100 feet)

Emitter Spacing 0.4 GPH Emitter 0.6 GPH Emitter 0.9 GPH Emitter

Inches GPH GPM GPH GPM GPH GPM

12” 42 0.70 61 1.02 92 1.53

18” 28 0.47 41 0.68 61 1.02

Control Zone

in Valve Box

Inline Emitters

XF Series Dripline

Laterals

Wetted Area

Air Relief Valve

in Valve Box

(Only needed

for XFS & XFD)

Flush Header

(QF Dripline)

Flush Valve

XF Series Dripline Flow (per 100 Meters)

Emitter Spacing 1.6 L/HR

Emitter

2.3 L/HR

Emitter

3.4 L/HR

Emitter

Centimeters L/HR L/MIN L/HR L/MIN L/HR L/MIN

From Water Source

PVC, polyethylene

tubing, or QF Dripline

header

Lateral spacing

Dripline Lateral Run Length

30cm 533 8.89 767 12.78 1133 18.89

46cm 348 5.80 500 8.33 739 12.32

Note: This example represents approximately 650’ of dripline.

After the dripline layout design is complete, you will need to identify total zone ow. This is used to help select mainline, supply and

ush headers, and control zone kit (valve, lter, and regulator).

1. Calculating zone water requirements can be done by adding up the total length of dripline in the zone. Convert the total

dripline length to hundreds of feet (meters). 650 feet (198 m) would be 6.5 in hundreds of feet (1.98 m).

2. Multiply total dripline length in hundreds of feet (meters) by the ow per 100 feet (meters) for your specied dripline. This can

be found in Table 3. To read the table, select the emitter ow rate in the row across the top (0.4 GPH (1.6 L/HR), 0.6 GPH (2.3 L/

HR), or 0.9 GPH (3.4 L/HR) and then select the emitter spacing in the left column (12” (0.30 m) or 18” (0.46 m). Follow emitter

ow rate down and emitter spacing across to nd the ow per 100 feet (meters) for the XF Series dripline specied.

3. For example, for a zone that has 650 feet (198 m) of 0.9 GPH (3.4 L/HR) emitters and 18” (0.46 m) emitter spacing, the calculation

would be 6.50 x 1.02 GPM = 6.6 GPM (1.98 m x 12.32 L/MIN = 24.4 L/MIN) for the zone.

4. Supply lines and headers should be sized to provide the ow to the zone without exceeding 5 feet (meters) per second velocity.

This can be done using the zone water requirement and referencing information on the appropriate piping located at

www.rainbird.com/reference or in the back reference section in the Rain Bird catalog.

SECTION 5

TABLE 4: DETERMINE MAXIMUM FLOW PER ZONE

Maximum Flow Per Zone (English)

Sch.

40 PVC

or QF

Header

Size

Max.

Flow*

GPM

psi

Loss**

Poly

Pipe

Header

Size

Max.

Flow*

GPM

psi

Loss**

½” 4.7 GPM 7.7 psi ½” 4.7 GPM 8.8 psi

¾” 8.3 GPM 5.6 psi ¾” 8.3 GPM 6.3 psi

1” 13.5 GPM 4.2 psi 1” 13.5 GPM 4.8 psi

1-¼” 23.1 GPM 3.1 psi 1-¼” 23.1 GPM 3.1 psi

1-½” 33.9 GPM 2.9 psi 1-½” 33.9 GPM 2.9 psi

2” 52.4 GPM 1.9 psi 2” 52.4 GPM 1.9 psi

* Based on maximum velocity of 5’ per second

** Per 100’ of tubing

Sch.

40 PVC

or QF

Header

Size

1.27 cm 17.8 0.53 1.27 cm 17.8 0.61

1.91 cm 31.4 0.39 1.91 cm 31.4 0.43

2.54 cm 51.1 0.29 2.54 cm 51.1 0.33

3.18 cm 87.4 0.21 3.18 cm 87.4 0.22

3.81 cm 128.3 0.20 3.81 cm 128.3 0.20

5.08 cm 198.4 0.13 5.08 cm 198.4 0.13

* Based on maximum velocity of 1.52 m per second

** Per 30.5 meters of tubing

www.rainbird.com

Maximum Flow Per Zone (Metric)

Max.

Flow*

L/MIN

psi

Loss**

Poly

Pipe

Header

Size

Max.

Flow*

L/MIN

psi

Loss**

21

Page 22

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 5:

Zone Water Calculations

CALCULATING APPLICATION RATES

APPLICATION RATE

The application rate is the rate that XF Series Dripline applies water to the soil. This is used to determine run times for the zone

based on the plant watering requirements. Table 5 is provided to make it easy to determine application rates for every model of

XF Series Dripline when using common row spacing (12”-24” / 30cm-61cm). The table is divided into three sections, a 0.4 GPH

(1.6 L/HR) emitter ow section, a 0.6 GPH (2.3 L/HR) emitter ow section and a 0.9 GPH (3.4 L/HR) emitter ow section. Go to the

section for the specied emitter ow rate and nd in the left hand column the specied emitter spacing. Next, nd the lateral row

spacing across the top of the table. Follow the lateral row spacing column down and the emitter spacing row across until the two

meet. This is the application rate in inches per hour (centimeters per hour). For example, a 0.6 GPH (2.3 L/HR) emitter ow rate

with 18” (46 cm) lateral row spacing and 18” (46 cm) emitter spacing has an application rate of 0.43 (1.09 cm/hr) inches per hour.

TABLE 5: APPLICATION RATE

Emitter

Spacing

SECTION 5

Emitter

Spacing

30cm 1.78 1.62 1.48 1.40 1.30 1.24 1.16 1.11 1.05 0.95 0.87

46cm 1.16 1.05 0.97 0.92 0.85 0.81 0.76 0.72 0.68 0.62 0.57

30cm 2.44 2.26 2.11 1.96 1.86 1.73 1.63 1.55 1.47 1.35 1.22

46cm 1.63 1.50 1.40 1.30 1.22 1.14 1.09 1.02 0.99 0.89 0.81

30cm 3.66 3.38 3.15 2.95 2.74 2.59 2.44 2.31 2.21 2.01 1.83

46cm 2.44 2.26 2.11 1.96 1.83 1.73 1.63 1.55 1.47 1.35 1.22

Lateral Row Spacing (in Inches)

12” 13” 14” 15” 16” 17” 18” 19” 20” 22” 24”

0.4 GPH Emitter Flow (Inches per hour)

12” 0.67 0.62 0.58 0.54 0.51 0.48 0.45 0.43 0.40 0.37 0.34

18” 0.45 0.41 0.39 0.36 0.34 0.32 0.30 0.28 0.27 0.25 0.22

0.6 GPH Emitter Flow (Inches per hour)

12” 0.96 0.89 0.83 0.77 0.72 0.68 0.64 0.61 0.58 0.53 0.48

18” 0.64 0.59 0.55 0.51 0.48 0.45 0.43 0.41 0.39 0.35 0.32

0.9 GPH Emitter Flow (Inches per hour)

12” 1.44 1.33 1.24 1.16 1.08 1.02 0.96 0.91 0.87 0.79 0.72

18” 0.96 0.89 0.83 0.77 0.72 0.68 0.64 0.61 0.58 0.53 0.48

Lateral Row Spacing (in Centimeters)

30 33 36 38 41 43 46 48 51 56 61

1.6 LPH Emitter Flow (cm per hour)

2.3 LPH Emitter Flow (cm per hour)

3.4 LPH Emitter Flow (cm per hour)

At this point the emitter ow rate and spacing between emitters and rows has been selected.

Use the tables to determine the overall water application rate for the landscape area.

22

www.rainbird.com

Page 23

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 5:

Zone Water Calculations

CALCULATIONS FOR DRIPLINE IRRIGATION

HOW DO I DETERMINE THE APPLICATION RATE?

_______________________________________________

Lateral Row Spacing in Inches x Emitter Spacing in Inches

Example:

Emitter Flow Rate 0.6 GPH

Emitter Spacing 12 inches

Lateral Row Spacing 18 inches

0.6 x 231.1

_________

12 x 18

Emitter Flow Rate in GPH x 231.1

= 0.64 inches/hour

__________________________________________

Lateral Row Spacing in cm x Emitter Spacing in cm

Example:

Emitter Flow Rate 2.3 L/HR

Emitter Spacing 30 cm

Lateral Row Spacing 41 cm

2.3 x 1,000

_________

30 x 41

Emitter Flow Rate in L/HR x 1000

= 1.86 cm/hr

WHAT IS THE TOTAL FLOW WITHIN THE DRIP ZONE?

Irrigated Area in Sq Ft. x Emitter Flow in GPH x 2.4

_______________________________________________

Lateral Row Spacing in Inches x Emitter Spacing in Inches

Example:

Irrigated Area 2500 Sq Ft

Emitter Flow Rate 0.6 GPH

Emitter Spacing 18 inches

Lateral Row Spacing 18 inches

2500 x 0.6 x 2.4

_____________

18 x 18

= 11.11 GPM

Irrigated Area in Sq Meters x Emitter Flow in L/HR x 166.7

______________________________________________

Lateral Row Spacing in cm x Emitter Spacing in cm

Example:

Irrigated Area 800 Sq Meters

Emitter Flow Rate 3.4 L/HR

Emitter Spacing 46 cm

Lateral Row Spacing 48 cm

800 x 3.41 x 166.7

__________________

46 x 48

METRIC

SECTION 5

= 206 L/MIN

HOW MUCH DRIPLINE DO I NEED BASED ON SIZE OF IRRIGATED AREA?

Area in Sq Ft. x 12

_________________________

Lateral Row Spacing in Inches

Example:

Irrigated Area 2165 Sq Ft

Lateral Row Spacing 18 inches

2165 x 12

________

18

= 1443 feet of dripline needed

Example:

Irrigated Area 425 Sq Meters

Lateral Row Spacing 36 cm

425 x 100

________

36

= 1180 meters of dripline needed

Area in Sq. Meters x 100

__________________________

Lateral Row Spacing in cm

HOW MANY FEET OF DRIPLINE CAN I USE IF I KNOW THE AVAILABLE FLOW

Available Flow

_____________________

Flow per 100 Foot Length

Obtain “Flow per 100 Feet”

Example:

You have 11 GPM available ow

0.6 GPH emitters on 18” spacing - See table 3

11 GPM

________

0.68 GPM

x 100 feet = 1618 maximum feet of dripline

x 100 = Maximum Feet

_________________________

Obtain “Flow per 100 Meters”

Example:

You have 130 L/MIN available ow

2.3 L/HR emitters on 0.46 meter spacing - See table 3

130 L/MIN

________

2.31 L/HR

Available Flow

Flow per 100 Meter Length

x 100 meters = 5628 maximum feet of dripline

x 100 = Maximum Meters

www.rainbird.com

23

Page 24

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 8

SECTION 3

SECTION 6

SECTION 9

Zone Water Calculations

IRRIGATION FORMULAS

PLANT WATER REQUIREMENT FOR A DENSE PLANTING SCHEME

The water requirement for a densely planted hydro-zone is measured in inches per day.

SECTION 5:

Plant Water Requirement = PET x K

Potential Evapotranspiration (PET) - The amount of water that us used by the combination of evaporation from

the soil and transpiration from plants growing in the soil. PET is generally expressed in inches per day.

Kc - Adjustment factor to PET that accounts for the needs of a specic plant in growing conditions. It is also known

as the “crop coecient” or the “plant factor.”

Example: The PET for a day in the summer for Las Vegas is: 0.30” (0.76 cm)

The Kc or “plant factor” for a certain type of plant and it’s surroundings is 0.84 (2.13 cm)

Plant Water Requirement = 0.30” x 0.84 = 0.25”/day (0.76 cm x 2.13 cm = 1.62 cm per day)

SYSTEM RUN TIME

SECTION 5

The formula for system run time for dense plants is based on a measurement of ow in inches per day.

System Run Time = (PWR / Application Rate x Application Eciency) x 60

c

Example: (0.25” / 0.64” x 0.90) x 60 = 26 minutes

(0.63 cm/1.62 x 0.90) x 60 = 26 minutes

Example:

Plant Water Requirement: 0.25”/day (0.63 cm/day)

Application Rate: 0.64” (1.62 cm)

Drip Application Eciency: 90%

System Run Time = (0.25/0.64 x 0.90) x 60 = 26 minutes (0.63 cm/1.62 x 0.90) x 60 = 26 minutes

More detailed information on calculating Plant Water Requirement and System Run Time can be found in the Low-Volume Landscape Irrigation

Design Manual; Chapters 4 & 5. This manual is only available for download on our website:

https://www.rainbird.com/sites/default/les/media/documents/2018-02/LowVolumeGuide.pdf

24

www.rainbird.com

Page 25

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

SECTION 6:

DRIPLINE

PRODUCT

XFSCV

DRIPLINE

XFCV

DRIPLINE

XFS

DRIPLINE

XFD

DRIPLINE

1/4”

DRIPLINE

LANDSCAPE

CHALLENGES

ON-SURFACE AND

SUBSURFACE

Sloped and

Level Grade

ON-SURFACE

Sloped and

Level Grade

SUBSURFACE

Level Grade

ON-SURFACE

Level Grade

Installations

ON-SURFACE

Potted/Small Bed

Installations

SUB SURFACE

APPLICATIONS

X X

SLOPED AREAS

X X

SHRUB & GROUND

COVER BEDS

X X X X X

CONTAINER PLANTS

X X X X X

CURVED LANDSCAPES

X X X X X

NARROW LANDSCAPED

AREAS

X X X X X

MEDIANS OR

PARKING ISLANDS

X X X X

TURF GRASS

X X

DRIPLINE

FEATURES

XFS-CV

DRIPLINE

• Heavy-Duty 4.3 psi

Check Valve provides

10 ft. of holdback

• Copper Shield™

emitter root intrusion

• Longer lateral runs

• Exceptional durability

• Available in purple

and purple stripe for

non-potable water

XFCV

DRIPLINE

• 3.5 psi Check Valve

provides 8 ft. of

holdback

• Longer lateral runs

• Exceptional durability

XFS

DRIPLINE

• Copper Shield™

emitter root intrusion

• Exceptional durability

• Available in purple

and purple stripe for

non-potable water

XFD

DRIPLINE

• Greater exibility

• Longer lateral runs

• Exceptional durability

• Available in purple

and purple stripe for

non-potable water

1/4”

DRIPLINE

• In-line non-pressure

compensated emitters

• Perfect for pots and

small beds

• Easy installation

Dripline Models for Every Application

SECTION 6: Dripline Models for Every Application

SECTION 6

www.rainbird.com

25

25

Page 26

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

On/Sub Surface

Sloped Applications

SECTION 6:

Dripline Models for Every Application

XFS-CV DRIPLINE FOR ON/SUB SURFACE ELEVATED APPLICATIONS

ELEVATED PERFORMANCE

With a patented check valve in every emitter that

holds back 10’ of elevation change, XFS-CV dripline

eliminates low-point drainage and provides uniform

irrigation throughout the zone.

COPPER SHIELD™ TECHNOLOGY

Only XFS-CV dripline

includes a pure

copper chip in every

emitter to protect

against root intrusion.

Others use diluted

copper compounds

encapsulated in

plastic.

LOWPROFILE FLAT EMITTER

10 ft. of Holdback

SECTION 6

GREATER FLEXIBILITY

Rain Bird’s low-prole at

emitter design reduces

in-line pressure loss,

allowing longer

lateral runs, simplifying

design and reducing

installation time.

Rain Bird’s proprietary blend

provides industry-leading

exibility allowing for tighter

turns with fewer elbows for fast

and easy installation.

EASY IDENTIFICATION

All dripline models feature

color coded stripes to easily

identify the ow rate:

Black stripes = 0.9 GPH

Tan stripes = 0.6 GPH

LEED COMPLIANT

Contains at least 20% post consumer recycled

polyethylene which qualies for LEED credit 4.2.

26

www.rainbird.com

Page 27

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

SECTION 6:

Dripline Models for Every Application

XFS-CV DRIPLINE - SPECIFICATIONS

Applications

Rain Bird® XFS-CV dripline features Copper

Shield™ Technology and a heavy-duty 4.3 psi

check valve, making it perfect for subsurface

and on-surface applications with level grades

or slopes. A check valve in every emitter

keeps the dripline charged in elevation

changes up to 10 feet, XFS-CV can be used

where no other dripline will work.

Keeping water in the dripline at all times

helps for better irrigation uniformity

throughout the zone. The check valve also

helps prevent puddling and oversaturated

soil at the low point in the zone.

Features

Industry-Leading Protection

• Rain Bird’s XFS-CV dripline with patented

Copper Shield™ Technology protects the

emitter from root intrusion. Unlike other

manufacturers who use harsh chemicals or

diluted copper compounds encapsulated

in plastic, the Copper Shield™ Technology

from Rain Bird provides root intrusion

protection with a pure copper chip at each

emitter

• Rain Bird’s industry leading 4.3 psi emitter

check valve technology keeps the dripline

charged with water when elevation

changes are up to 10 feet, increasing

uniformity of watering and conserving

water by eliminating the need to recharge

the line at the beginning of each irrigation

cycle

Easy to Use

• Through the use of a proprietary tubing

material, the XFS-CV dripline is the most

exible dripline tubing in the industry,

making it the easiest dripline to design

with and install

• It accepts Rain Bird® XF dripline barbed

insert ttings and other 17 mm barbed

insert ttings

• Rain Bird’s low-prole emitter design

reduces in-line pressure loss, allowing

longer lateral runs, simplifying design and

reducing installation time

• A variety of industry standard emitter

ow rates, emitter spacing and coil lengths

provide design exibility for applications

with or without elevation changes

Reliable

• The pressure-compensating emitter design

provides a consistent ow over the entire

lateral length, ensuring higher uniformity

for increased reliability in the pressure

range of 20 to 60 psi

Durable

• Dual-layered tubing (copper over black)

provides unmatched resistance to

chemicals, algae growth and UV damage

Grit Tolerant

• Rain Bird’s proprietary emitter design resists

clogging by use of an extra wide ow path

combined with a self-ushing action

Made with Recycled Content

• All Rain Bird XF Dripline products qualify for

LEED credit 4.2 because they contain at

least 20% polyethylene post-consumer

recycled material by cost

Operating Range

• Opening Pressure: 14.5 psi (1,0 bar)

• Pressure: 20 to 60 psi (1,38 to 4,14 bar)

• Flow Rates: 0.6 and 0.9 GPH (2,3 and 3,5 L/HR)

TABLE 6: LATERAL RUN LENGTHS

XFS-CV Dripline Maximum Lateral Lengths (Feet)

12” Emitter Spacing 18” Emitter Spacing

psi 0.6 GPH 0.9 GPH 0.6 GPH 0.9 GPH

20 192 136 254 215

30 289 205 402 337

40 350 248 498 416

50 397 281 573 477

60* 436 309 637 529

XFS-CV Dripline Maximum Lateral Lengths (Meters)

30,5 cm Emitter Spacing 45,7 cm Emitter Spacing

Bar 2.3 L/HR 3.4 L/HR 2.3 L/HR 3.4 L/HR

1,38 58,5 41,5 77,4 65,5

2,07 88 62,5 122,5 102,7

2,76 107 75,6 151,8 126,8

3,45 121 85,6 174,7 145,4

4,14* 133 94,2 194,2 161,2

* When using 17mm insert ttings with design pressure over 50 psi (3.5 bar), it is recommended that stainless steel clamps be installed on each tting.

• Filtration Requirement: 120 mesh

• Temperature:

– Water: Up to 100° F (37,8° C)

– Ambient: Up to 125° F (51,7° C)

Specications

• OD: 0.634” (16 mm)

• ID: 0.536” (13.61 mm)

• Thickness: 0.049” (1.25 mm)

• Emitter spacing: 12” & 18” (30,5 & 45,7 cm)

• Coil lengths:

100’, 250’, 500’, and 1000’ (special order)

(30,5, 76,5, 152,4, and 304,9 m)

• Coil color: Copper, Purple and Purple Stripe

1,000’ coils available via special order

Models

• XFSCV0612100

• XFSCV0612250

• XFSCV0612500

• XFSCV0618100

• XFSCV0618250

• XFSCV0618500

• XFSCV0912100

• XFSCV0912250

• XFSCV0912500

• XFSCV0918100

• XFSCV0918250

• XFSCV0918500

• XFSCVP612500

• XFSCVP618500

• XFSCVP912500

• XFSCVP918500

• XFSCVPS612500

• XFSCVPS618500

• XFSCVPS912500

• XFSCVPS918500

SECTION 6

www.rainbird.com

27

Page 28

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

On-Surface

Sloped Applications

SECTION 6:

Dripline Models for Every Application

XFCV DRIPLINE FOR ON-SURFACE ELEVATED APPLICATIONS

Elevated Performance

Keeps dripline charged with water even with elevation changes

to 8 feet. The check valve also helps to prevent over-watering

at the low-point in the zone, avoiding puddling from water

draining from the dripline.

SECTION 6

Conserves Water

Prevents puddling and water loss at the low point in the zone.

LEED Compliant

Contains at least 20% post consumer recycled

polyethylene which qualies for LEED credit 4.2.

8 ft. of Holdback

Low-Prole Flat Emitter

Rain Bird’s low-prole at

emitter design reduces in-line

pressure loss, allowing longer

lateral runs, simplifying design

and reducing installation time.

Greater Flexibility

Rain Bird’s proprietary blend

provides industry-leading

exibility allowing for tighter

turns with fewer elbows for

fast and easy installation.

Easy Identication

All dripline models feature

color coded stripes to easily

identify the ow rate:

Black stripes = 0.9 GPH

Tan stripes = 0.6 GPH

28

www.rainbird.com

Page 29

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

SECTION 6:

Dripline Models for Every Application

XFCV DRIPLINE - SPECIFICATIONS

Applications

Rain Bird® XFCV Dripline with a heavy-duty 3.5

psi check valve for on-surface applications is

a valuable addition to the Rain Bird XF Series

dripline family. Rain Bird’s patent-pending

emitter check valve keeps the dripline charged

in elevation changes to 8 feet.

Keeping water in the dripline at all times

improves irrigation uniformity for plants

throughout the zone. The check valve also

helps to prevent over-watering at the lowpoint in the zone, avoiding puddling from

water draining from the dripline.

Features

Simple

• Rain Bird’s patent-pending 3.5 psi check

valve technology keeps the dripline charged

with water at all times, increasing uniformity

of watering, and conserves water by

eliminating the need to recharge the zone

at the beginning of each watering cycle

• Through the use of a proprietary tubing

material, the XFCV Dripline with

heavy-duty check valve is the most exible

dripline tubing in the industry, making it

the easiest dripline to design with and

install

• It accepts Rain Bird Easy Fit Compression

Fittings, XF Dripline Barbed Insert Fittings

and other 17 mm barbed insert ttings

• Rain Bird’s low-prole emitter design

reduces in-line pressure loss, allowing

longer lateral runs, simplifying design and

reducing installation time

• Variety of emitter ow rates, emitter spacing

and coil lengths provide design exibility for

on-surface areas with or without elevation

changes

Made with Recycled Content

• All Rain Bird XF Dripline (XFD, XFS, XFCV,

and XFS-CV) qualify for LEED credit 4.2

because they contain at least 20% post

consumer recycled polyethylene. These

come in an assortment of coil sizes, ow

rates and emitter spacing

Reliable

• The pressure-compensating emitter design

provides a consistent ow over the entire

lateral length ensuring higher uniformity for

increased reliability in the pressure range of

20 to 60 psi

Durable

• Dual-layered tubing (brown over black)

provides unmatched resistance to

chemicals, algae growth and UV damage

Grit Tolerant

• Rain Bird’s proprietary emitter design resists

clogging by use of an extra wide ow path

combined with a self-ushing action

Specications

• OD: 0.634” (16 mm)

• ID: 0.536” (13.61 mm)

• Thickness: 0.049” (1.25 mm)

• Emitter spacing: 12” & 18” (30,5 & 45,7 cm)

• Coil lengths: 100’, 250, and 500’

(30,5, 76,2, and 152,4 m)

• Coil color: Brown

Models

• XFCV0612100

• XFCV0612250

• XFCV0612500

• XFCV0618100

• XFCV0618250

• XFCV0618500

Operating Range

• Opening Pressure: 14.5 psi (1,0 bar)

• Operating Pressure: 20 to 60 psi

(1,38 to 4,14 bar)

• Flow rates: 0.6 and 0.9 GPH

(2,3 and 3,5 L/HR)

• Temperature:

Water: Up to 100° F (37,8° C)

Ambient: Up to 125° F (51,7° C)

TABLE 7: LATERAL RUN LENGTHS

XFCV Dripline Maximum Lateral Lengths (Feet)

12”

Emitter

Spacing 18”

psi 0.6 GPH 0.9 GPH 0.6 GPH 0.9 GPH

20 192 136 254 215

30 289 205 402 337

40 350 248 498 416

50 397 281 573 477

60* 436 309 637 529

XFCV Dripline Maximum Lateral Lengths (Meters)

30.5 cm

Emitter

Spacing 45.7 cm

Bar 1.6 L/HR 2.3 L/HR 1.6 L/HR 2.3 L/HR

1.4 59 41 77 66

2.1 88 63 123 103

2.8 107 76 152 127

3.5 121 86 175 145

4.1* 133 94 194 161

Emitter

Emitter

Spacing

Spacing

• XFCV0912100

• XFCV0912250

• XFCV0912500

• XFCV0918100

• XFCV0918250

• XFCV0918500

SECTION 6

* When using 17 mm insert

ttings with design pressure

over 50psi, it is recommended

that stainless steel clamps be

installed on each tting.

* When using 17 mm insert

ttings with design pressure

over 3.5 bar, it is recommended

that stainless steel clamps be

installed on each tting.

www.rainbird.com

29

Page 30

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

SECTION 6:

Dripline Models for Every Application

XFS DRIPLINE FOR SUBSURFACE APPLICATIONS

Subsurface

Subsurface Applications

Rain Bird’s XFS Subsurface Dripline with Copper Shield™ Technology is the rst subsurface dripline to eectively protect the

emitter from root intrusion without the use of Triuralin. Copper Shield™ Technology is the environmentally-responsible

alternative to chemical inhibitors.

XFS can be used on turf grass or shrub and groundcover areas. It’s also perfect for small, narrow and tight planting areas, as

well as areas with tight curves or many switchbacks. It accepts Rain Bird Easy Fit Compression Fittings, XF Dripline Barbed

Insert Fittings and other 17 mm barbed insert ttings.

WATER EFFECIENT INNOVATIVE

Expands use of subsurface irrigation which can be

90% ecient, resulting in up to 70% water savings.

Ground-breaking solution to root intrusion with

patent-pending Copper Shield™ Technology.

ENVIRONMENTALLY RESPONSIBLE RELIABLE

Grit tolerant emitter resists clogging by use of an

extra-wide ow path combined with a self-ushing

action.

NEW PRODUCT CONTEST

WINNER

TURF/LANDSCAPE

the “Best New Product” for 2010 by

the Irrigation Association

XFS Subsurface Dripline, winner of

2010

EXHIBITOR

SECTION 6

Environmentally responsible solution to root

intrusion without the use of harsh chemicals.

30

www.rainbird.com

Page 31

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

SECTION 6:

Dripline Models for Every Application

XFS DRIPLINE - SPECIFICATIONS

Applications

Rain Bird® XFS Dripline includes the patentpending Copper Shield™ technology only

available from Rain Bird. The Copper

Shield™ Technology protects the emitter

from root intrusion, creating a longlasting, low maintenance subsurface drip

irrigation system for use under turf grass or

shrub and groundcover areas. XFS Series

Dripline with Copper Shield™ is perfect for

small, narrow and tight planting areas, as

well as areas with tight curves or many

switchbacks.

Features

Simple

• Rain Bird’s patent pending copper colored XFS dripline with Copper Shield™

Technology protects the emitter from root

intrusion with out requiring EPA-approved

handling procedures - unlike some

manufacturers who use harsh chemicals

or treated lters to protect the emitter

from root intrusion

• Through the use of a proprietary tubing

material, the copper-colored XFS Dripline

with Copper Shield™ is the most exible

dripline tubing in the industry making it

the easiest subsurface dripline to design

with and install

• Accepts Rain Bird XF Dripline Insert

Fittings and Easy Fit Compression Fittings

Reliable

• XFS emitters are protected from root

intrusion by Rain Bird’s patent-pending

Copper Shield™ Technology resulting in a

system that does not require maintenance

or replacement of chemicals to prevent

root intrusion

• The pressure-compensating emitter

design provides a consistent ow over

the entire lateral length ensuring higher

uniformity for increased reliability in the

pressure range of 8.5 to 60 psi

Durable

• Dual-layered tubing (copper over

black) provides unmatched resistance to

chemicals, algae growth and UV damage

• Grit Tolerant: Rain Bird’s proprietary

emitter design resists clogging by use of

an extra-wide ow path combined with a

self-ushing action

Operating Range

• Pressure: 8.5 to 60 psi (,58 to 4,14 bar)

• Flow rates: 0.42, 0.6, and 0.9 GPH

(1,6, 2,3, and 3,5 L/HR)

• Temperature:

Water: Up to 100° F (37,8° C)

Ambient: Up to 125° F (51,7° C)

• Required Filtration: 120 Mesh

Specications

• OD: 0.634” (16 mm)

• ID: 0.536” (13.61 mm)

• Thickness: 0.049” (1.25mm)

• Emitter Spacing: 12”, 18”, 24” (30,5, 45,7,

and 61,0 cm)

• Coil lengths: 100’ and 500’ (30,5 and

152,4 m)

• Coil Color: Copper, purple, purple stripe

Models

• XFS-04-12-100

• XFS-04-12-500

• XFS-04-18-100

• XFS-04-18-500

• XFS-06-12-100

• XFS-06-12-500

Non Potable Purple (XFSP)

or Purple Stripe (XFSPS)

• XFSP-04-12-500

• XFSP-04-18-500

• XFSP-06-12-500

• XFSP-06-18-500

• XFSP-09-12-500

• XFSP-09-18-500

All dripline models feature color coded

stripes to easily identify the ow rate:

• XFS-06-18-100

• XFS-06-18-500

• XFS-09-12-100

• XFS-09-12-500

• XFS-09-18-500

• XFSPS-04-12-500

• XFSPS-04-18-500

• XFSPS-06-12-500

• XFSPS-06-18-500

• XFSPS-09-12-500

• XFSPS-09-18-500

Black stripes = 0.9 GPH

Tan stripes = 0.6 GPH

Green stripes = 0.4 GPH

SECTION 6

• Rain Bird’s low-prole emitter design

reduces in-line pressure loss, allowing

longer lateral runs, simplifying design

and reducing installation time

• Variety of emitter ow rates, emitter

spacing and coil lengths provide design

exibility for either subsurface turf grass

or subsurface shrub and groundcover

applications

www.rainbird.com

TABLE 8: LATERAL RUN LENGTHS

XFS Dripline Maximum

Lateral Lengths (Feet)

12” Emitter Spacing 18” Emitter Spacing

0.4

0.5

0.9

0.4

0.5

psi

GPH

GPH

GPH

GPH

15 352 273 155 374 314 250

20 399 318 169 417 353 294

30 447 360 230 481 413 350

40 488 395 235 530 465 402

50 505 417 285 610 528 420

60* 573 460 290 734 596 455

* When using 17 mm insert ttings with design pressure

over 50psi, it is recommended that stainless steel clamps be

installed on each tting.

GPH

0.9

GPH

* When using 17 mm insert ttings with design pressure over 3.5

bar, it is recommended that stainless steel clamps be installed

on each tting.

XFS Dripline Maximum

Lateral Lengths (Meters)

30.5 cm Emitter Spacing 45.7 cm Emitter Spacing

1.6

Bar

L/HR

1.03 107.2 83.2 47.2 114 95.7 76.2

1.38 121.6 96.9 51.5 127.1 107.6 89.6

2.07 136.2 109.7 70.1 146.6 125.9 106.7

2.76 148.7 120.4 77.7 161.5 141.7 122.5

3.45 153.9 127.1 86.9 185.9 160.9 128.0

4.14* 174.6 140.2 88.4 223.7 181.7 138.7

2.3

L/HR

3.4

L/HR

1.6

L/HR

2.3

L/HR

3.4

L/HR

31

Page 32

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

On-Surface

Level-Grade Applications

SECTION 6:

Dripline Models for Every Application

XFD DRIPLINE FOR ON-SURFACE LEVEL-GRADE APPLICATIONS

RAIN BIRD FLAT EMITTER TECHNOLOGY

Superior Design for Superior Reliability

State-of-the-art assembly technology

helps resist bending and collapsing

under extreme eld use

SECTION 6

Chemical-resistant silicone

diaphragm for longer life

Self-ushing emitter design clears grit and

debris to provide a reliable supply of clean

water to plant roots

Larger inlet holes let debris

pass instead of plugging

emitter lter

ADDITIONAL FEATURES

XFD Dripline Coil

32

Reinforcing members make

emitter structurally more

robust

Widest emitter ow channel in the

industry let debris pass instead of

internally plugging emitter

Low-prole design draws cleanest

available water and reduces

friction loss

• Unique, extra-exible tubing material allows for tighter turns with fewer elbows for fast

and easy installation

• Dual-layered tubing (brown over black or purple over black) provides unmatched

resistance to chemicals, UV damage and algae growth

• Low-prole emitter design results in reduced friction loss, allowing longer maximum

lateral runs and more cost-eective system designs

• Continuous ushing action and wide ow path ensure that water will keep owing,

thus minimizing maintenance, and saving you time and money

www.rainbird.com

Page 33

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

SECTION 6:

Dripline Models for Every Application

XFD DRIPLINE - SPECIFICATIONS

Applications

Rain Bird® XFD Dripline is the most

exible, kink-resistant tubing available

in the marketplace today, making

it ideal for irrigating areas where

traditional drip tubing is dicult to

install. XFD Dripline is perfect for small,

narrow and tight planting areas, as

well as areas with tight curves or many

switchbacks. XFD Dripline is simple,

reliable and durable.

Features

Simple

• Unique material oers signicantly

greater exibility and kink-resistance

for fast, easy installation

• Greater exibility assures design

capability for tight curves and spaces

• Rain Bird’s self-dispensing coils make

it easy to use exactly what is needed

while keeping the balance of the coil

ready for the next job

• Accepts Rain Bird XF Dripline Insert

Fittings and Easy Fit Compression

Fittings

• Variety of ow rates, spacings, and coil

lengths provides design exibility for

many non-turfgrass applications

Reliable

• Pressure-compensating emitter

design provides consistent ow over

the entire lateral length, ensuring

higher uniformity for increased

reliability in the pressure range of 8.5

to 60 psi

Durable

• Dual-layered tubing (brown over

black or purple over black) provides

unmatched resistance to chemicals,

algae growth and UV damage

Operating Range

• Pressure: 8.5 to 60 psi (.58 to 4.14 bar)

• Flow rates: 0.6, and 0.9 GPH

(2.3 and 3.41 L/HR)

• Temperature:

Water: Up to 100° F (37.8° C)

Ambient: Up to 125° F (51.7° C)

• Required ltration: 120 mesh

Specications

• OD: 0.634” (16 mm)

• ID: 0.536” (13.61 mm)

• Thickness: 0.049” (1.25 mm)

• Emitter spacing: 12” or 18”

(30.5 or 45.7 cm)

• Coil lengths: 100’, 250’, and 500’

(30.5, 76,5, and 152.4 m)

• Coil color: Brown, purple or purple

stripe

TABLE 9: LATERAL RUN LENGTHS

XFD Dripline Maximum Lateral Lengths (Feet)

12” Emitter Spacing 18” Emitter Spacing

psi 0.6 GPH 0.9 GPH 0.6 GPH 0.9 GPH

15 273 155 314 250

20 318 169 353 294

30 360 230 413 350

40 395 255 465 402

50 417 285 528 420

60* 460 290 596 455

XFD Dripline Maximum Lateral Lengths (Meters)

30.5 cm Emitter Spacing 45.7 cm Emitter Spacing

Bar 2.3 L/HR 3.4 L/HR 2.3 L/HR 3.4 L/HR

1.03 83.2 47.2 95.7 76.2

1.38 96.9 51.5 107.6 89.6

2.07 109.7 70.1 125.9 106.7

2.76 120.4 77.7 141.7 122.5

3.45 127.1 86.9 160.9 128.0

4.14* 140.2 88.4 181.7 138.7

* When using 17mm insert ttings with design pressure over 50 psi (3.5 bar), it is recommended that stainless steel clamps be installed on each tting.

Models

0.6 GPH Emitters

• XFD-06-12-100

• XFD-06-12-250

• XFD-06-12-500

• XFD-06-18-100

• XFD-06-18-250

• XFD-06-18-500

Non Potable Purple (XFSP)

or Purple Stripe (XFSPS)

• XFDP-06-12-500

• XFDP-06-18-500

• XFDP-09-12-500

• XFDP-09-18-500

All dripline models feature color coded

stripes to easily identify the ow rate:

0.9 GPH Emitters

• XFD-09-12-100

• XFD-09-12-250

• XFD-09-12-500

• XFD-09-18-100

• XFD-09-18-250

• XFD-09-18-500

• XFDPS-06-12-500

• XFDPS-06-18-500

• XFDPS-06-12-500

• XFDPS-09-18-500

Black stripes = 0.9 GPH

Tan stripes = 0.6 GPH

SECTION 6

www.rainbird.com

33

Page 34

SECTION 1

SECTION 4

SECTION 7

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 9

¼” LANDSCAPE DRIPLINE FOR POTTED/SMALL BED APPLICATIONS

Rain Bird non-pressure compensating ¼” Dripline is a perfect

choice for small-sized areas such as planter boxes, container

gardens, loops around trees, vegetable gardens and shrubs.

Features

• Simple to use, as the exible tubing makes watering pots and

container gardens easy

• 1/4” tubing size complements the aesthetics of any garden

SECTION 6:

Dripline Models for Every Application

• Emitters are clog-resistant through built-in ltration and two outlet

holes, 180 degrees apart

• Brown “colored” tubing aesthetically matches XFD and XFCV Dripline

• Unobtrusive size and exibility provide a low-prole, aesthetically

pleasing means to irrigate plants

• Works with Rain Bird 1/4” barbed Fittings

• Available with 6” (15.25 cm) or 12” (30.5 cm) spacing, and a coil

length of 100’ (30.5 m) for design exibility

Operating Range

• 10 to 40 psi (0.7 to 2.7 bar)

• Flow rate at 30 psi (2.0 bar): 0.8 GPH (3.0 L/HR)

SECTION 6

• Required ltration: 200 mesh (75 microns)

Specications

• OD: 0.250” (6 mm)

• ID: 0.170” (4 mm)

• Wall thickness: 0.040” (1 mm)

• Emitter spacing: 6’’ or 12” (15.25 and 30.5 cm)

• Coil length: 100’ (30.5 m)

• Coil color: Brown

Models

• LDQ-08-06-100

• LDQ-08-12-100

Flow Characteristics

Model Flow at 30 psi Spacing Coil Length

(GPH) (L/HR) (in.) (cm) (ft.) (m)

LDQ-08-06-100 0.8 3.0 6 15.25 100 30.50

LDQ-08-12-100 0.8 3.0 12 30.5 100 30.5

1

”

/

Landscape Dripline Performance

4

U.S.

1.2

1.0

0.8

0.6

0.4

Flow Rate (GPH)

0.2

0.0

0 10 15 20 25 30 40 50

Pressure (psi)

METRIC

4.0

3.5

3.0

2.5

2.0

1.5

1.0

Flow Rate (l/h)

0.5

0.0

0 0.5 1.0 1.5 2.0 2.5 3.0

Pressure (bar)

TABLE 10: LATERAL RUN LENGTHS

Maximum Length of Run (Feet)

Emitter Maximum Flow per Ft.

Spacing Length of Run @ 15psi

6” 19 feet 1 GPH/ft

12” 33 feet 0.5 GPH/ft

34

www.rainbird.com

Page 35

SECTION 1

SECTION 4

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 7:

Subsurface Design, Installation and Operation

SECTION 7: Subsurface Design, Installation and Operation

SECTION 7

www.rainbird.com

35

35

Page 36

SECTION 1

SECTION 4

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 7:

Subsurface Design, Installation and Operation

BEST SUBSURFACE APPLICATIONS

BENEFITS OF SUBSURFACE

DRIP IRRIGATION

• Curves and edges

• Narrow turf areas

• Large turf areas

• Subsurface shrub and ground cover areas

• Near buildings

• Adjacent to parking lots

• Small, conned areas

• Athletic Fields

• Increased eciency

• Lower water use

• Elimination of overspray

• Resistant to vandalism

• Healthy plant growth

• Increased watering uniformity

• No damage to fences or trees

• Less water run-o into sewers & drains

• Lower maintenance

• Increased time for eld or turf usage

• No wind issues

• Less evaporative loss

AREAS WHERE OVERSPRAY MUST BE AVOIDED

It is a challenge to avoid overspray in narrow turf areas. Examples include

median strips, parking lot islands and turf around parked cars. Also consider

adding adjacent to right-of-ways. Subsurface drip is an excellent option to

avoid overspray in these challenging applications.

Car dealerships or parking lots

SECTION 7

Narrow strips or next to roadways

Adjacent to buildings or hardscapes

36

www.rainbird.com

Page 37

SECTION 1

SECTION 4

SECTION 2

SECTION 5

SECTION 8

SECTION 3

SECTION 6

SECTION 9

SECTION 7:

Subsurface Design, Installation and Operation

ADJUST FOR TREES

Trees. Trees planted in turf areas should be on a separate zone. This is particularly true with subsurface drip because over

time, tree roots could push the buried subsurface drip lines up to the surface. Also, trees are more costly to replace than

grass, so if the zone for the grass area needs to be turned o to reduce water consumption, then a separate zone can still be

operated to maintain tree health.

The best method for establishing, transplanting, and irrigating trees on a separate zone is by using the Rain Bird Root

Watering System. More information can be found at http://www.rainbird.com/rws.

Tree

Zone

The tree is on a separate zone and there is full

separation between the tree and the turf grass.

Recommended

Although the tree and turf grass are on the same

Acceptable

zone, the buried dripline should be placed far

enough away from the trunk so that tree roots do

not push the dripline to the surface.

Not recommended

There is no additional water for the tree.

The dripline is close to the trunk and

the tree roots will probably push the

buried dripline up to the surface.

ADJUST FOR CURVED EDGES

Curved Edges. Rain Bird XFS/XFS-CV Dripline is exible enough to follow

curves that are 3 inch (7.6 cm) in radius and larger. When there are curved

shapes in the landscape, avoid designing dripline rows that follow the

curves. Instead, lay out as many straight lines as possible to simplify

the installation, then ll in missed areas with additional straight lines

Recommended

if possible. When the landscape design layout is nished, make a grid

pattern overlay to scale with the selected emitter and row spacing (for