Page 1

WS-PRO Weather Station

INSTALLATION,

MAINTENANCE

AND

TROUBLESHOOTING

MANUAL

November 2004 GT27145D

Page 2

Page 3

WS-PRO Weather Station

Table of Contents

Description Page

1.0 General........1

2.0 Tools & Supplies.......2

Tools Required......2

Supplies Required......2

3.0 Weather Station Site Selection.....3

Temperature/Relative Humidity....4

Solar Radiation......4

Precipitation.......5

Determining True North for Wind Vane Operation. 5

Prompts from Geomag.....7

4.0 Weather Station Concrete Base.....9

Supplied Components .....9

Installer Supplied......9

Tools Required......9

Installation.......9

5.0 External Wiring to Weather Station....12

Wiring Valve Access Box.....12

Weather Station Power Wiring....12

Weather Station Communication Wiring (PRO-SH) . 13

Grounding Communication Cable....13

Weather Station Communication Wiring (PRO-PH) . 15

6.0 Tower Assembly and Installation ....15

Supplied Components .....15

Installation.......15

7.0 ET Instrumentation Enclosure Installation...18

General.......18

Mounting ET Enclosure to the Tower...18

Page i

Page 4

Table of Contents - Cont’d.

Description Page

Installation of Lightning Rod....19

Power Supply Rechargeable Battery....19

AC External Power Wiring.....21

Power Supply Option Solar Panel....22

8.0 Installation of Instrumentation.....24

General.......24

Supplied Components .....24

Installation of Cross-Arm to ET Enclosure...24

Installation of 034A Wind Sensor ....26

Installation of Relative Humidity/Temperature

Sensor and Radiation Shield....28

Installation of Solar Radiation Pyranometer . . 29

Sensor Cable Connections.....30

Configure Sensor Switch Settings ....31

Sensor Verification and Clock Set....31

Short Haul Modem Installation....31

Telephone Modem Installation....33

9.0 Sealing & Desiccating the Enclosure....34

10.0 Installation at Central Computer....35

Supplied Components .....35

Installation.......35

Model PRO-PH ~ Phone Connected....38

Supplied Components ....38

Installation - General.....38

Standard Installation Method . . 38

11.0 Maintenance & Troubleshooting....40

General Maintenance .....40

Instrumentation Maintenance....40

Batteries.......40

Rechargeable Battery.....40

Desiccant.......40

Sensor Maintenance......40

Page ii

Page 5

Table of Contents - Cont’d.

Description Page

1 Week ......40

1 Month......41

6 Months......41

1 Year.......41

2 Years ......41

3 Years ......41

4-5 Years......41

General Maintenance .....41

Sensor Maintenance......42

Rain Gage......42

Calibrating a Rain Bucket...42

Suggestions.....42

Solar Sensor......43

Wind Sensor......43

Relative Humidity Sensor....43

Temperature Sensor.....44

Other Maintenance......44

Seal of ET Enclosure.....44

Battery Check......45

Sensor Testing ......45

Wind Speed Sensor.....46

Wind Direction Sensor....46

Solar Radiation Sensor (Pyranometer) . . 46

Tipping Bucket Rain Gage....46

Temperature/Relative Humidity Sensor . . 47

Troubleshooting......48

Isolating the Problem.... 48

Checking the Weather Station...48

Using the ML 10-KD Keyboard Display . 48

Datalogger Location Table ...49

Troubleshooting Problems....49

No display on the ML 10-KD keyboard . 49

No response using the keyboard and/or

erroneous letters in the display . 50

Page iii

Page 6

Table of Contents - Cont’d.

Description Page

No Response from Datalogger through SC32A

or Modem Peripheral.....50

At the datalogger ...50

At the computer...50

-99999 Displayed in an Input Location . . 51

Unreasonable Results Displayed

in an Input Location.....51

6999 or 99999 Stored in Final Storage . . 51

Using a Laptop Computer....51

Checking the Communications Wire Path...53

Loop Resistance .....53

Ground Resistance.....53

WS-PRO-SH Direct Connect Weather Station . 53

Weather Station will not answer . . 53

Checking the RAD modem...53

Checking the Communication Wire Path . 54

WS-PRO-PH Phone Connect Weather Station . 55

Weather Station will not answer . . 55

Computer Modem & Communication Troubleshooting . 57

Weather Software will not communicate

with the weather station....57

Testing the Short Haul Modem . . 57

Testing the Phone Modem...58

Page iv

Page 7

Appendix

Description Page

Upgrading the Model JR Weather Station

to a Model PRO Weather Station....59

Typical 3-Rod Grounding Grid.....59

Ground Resistance......59

Bentonite Contact......60

Rocky Conditions ......60

Rock Layer.......60

Improving Earth Grounds.....61

MSP-1 Pipe Surge Arrestors.....61

Page v

Page 8

Table of Figures

Figure # Description Page

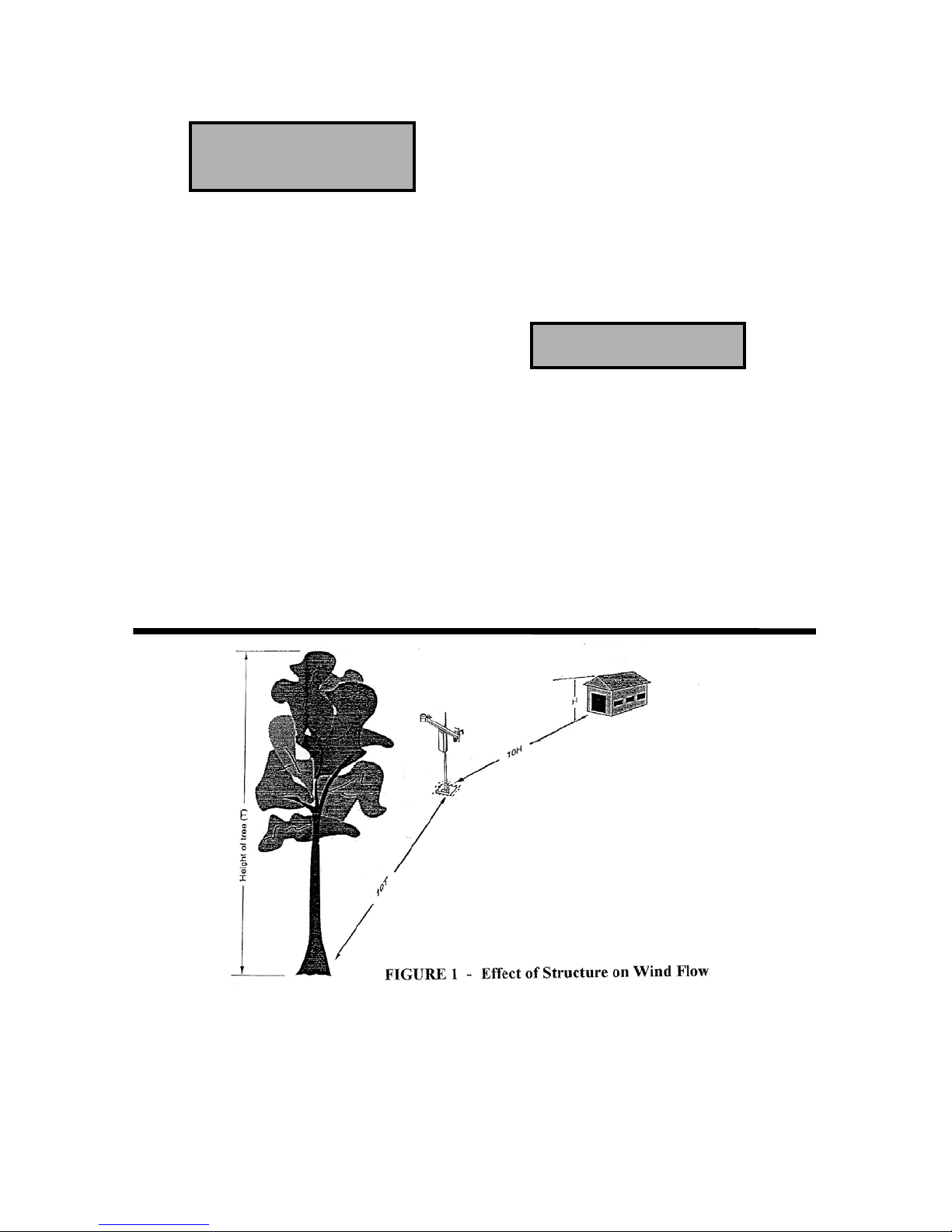

#1 Effect of Structure on Wind Flow...4

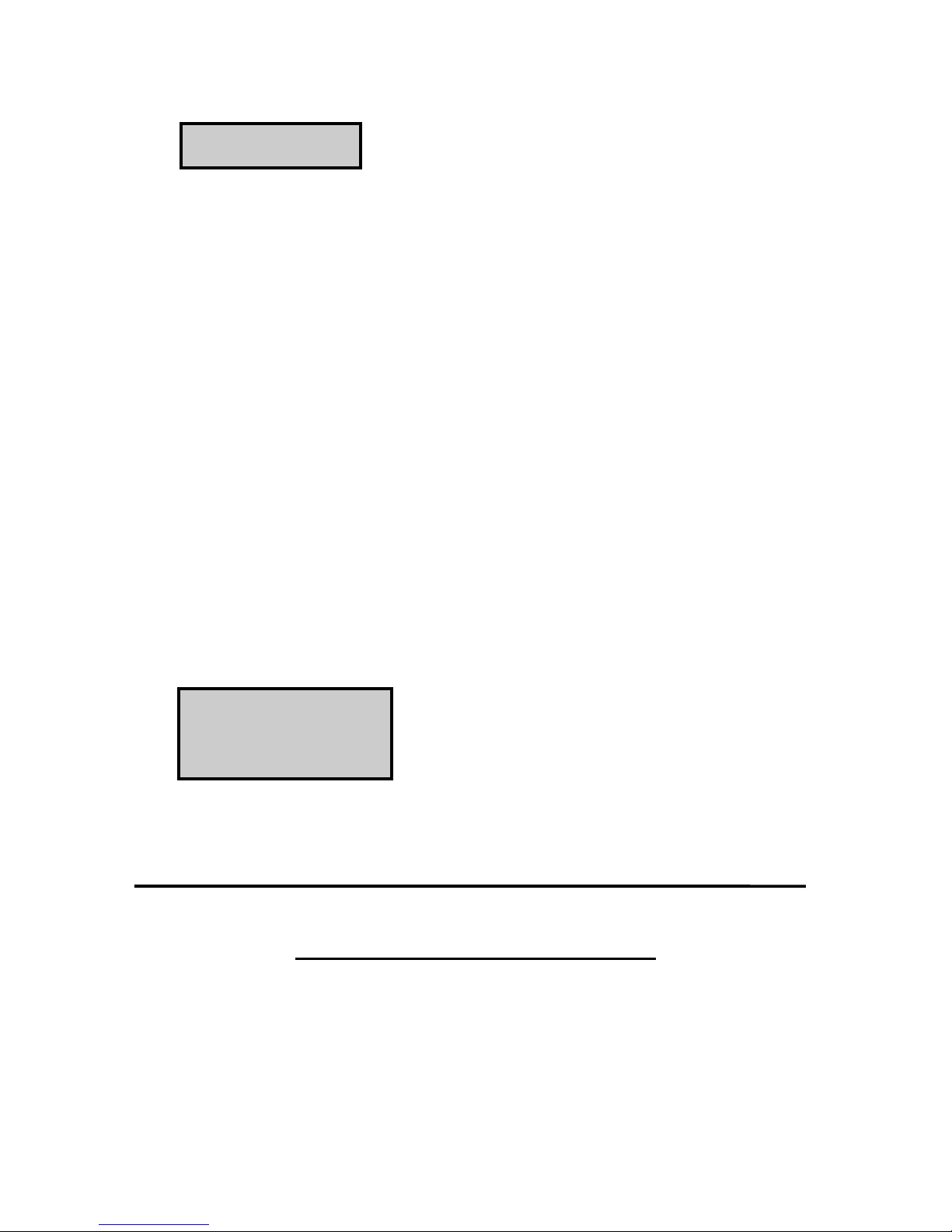

#2 Magnetic Declination for the Contiguous

United States......6

#3 Declination Angles.....8

#4 Concrete Base Detail.....11

#5 Anchor Bolt/Template Detail. . . 11

#6 External Wiring Detail at the PRO-SH Station . 14

#7 External Wiring Detail at the PRO-PH Station . 17

#8 Mounting ET Enclosure on Tower...18

#9 16VAC Connection & Rechargeable

Battery Installation....20

#10 Solar Pane Installation Detail...23

#11 Cross-Arm Mounting Detail....25

#12 Wind Sensor Installation Detail...27

#13 Temperature/RH Sensor Installation Detail. . 28

#14 Solar Radiation Sensor Installation Detail . . 29

#15 Sensor Cable Connections....30

#16 Sensor Switch Settings ....31

#18 Short Haul Modem Installation in ET Enclosure . 32

#19 Telephone Modem Installation in ET Enclosure . 34

Page vi

Page 9

Table of Figures Cont’d.

Figure # Description Page

#20 Desiccant Pack Installation....34

#21 Installation at Central Computer for Direct

Connected Weather Station....37

#22 Installation at Central Computer for

Telephone Connected Weather Station . . 39

#23 Using the ML 10-KD Keyboard Display . . 48

#24 Configuration of Serial Cable...52

#25 Test of Short Haul Modem....54

#26 Test of Communication Wires...55

#28 Typical 3-Rod Grounding Grid Detail . . 62

#29 Testing of Wind Sensor....63

#30 Testing of Solar Radiation Sensor...64

#31 Testing of Rain Gage.....65

#32 Testing of Temperature/RH Sensor...66

#33 Testing of Air Temperature Probe...67

Page vii

Page 10

Page viii

Page 11

WS-PRO Weather Station

1.0 GENERAL:

The Rain Bird “Model PRO” Weather

Station, when used in conjunction with

the Rain Bird MAXI 5, MAXI

“Nimbus” or MAXI “Cirrus” Central

Control system, provides the irrigation

manager with a powerful tool to aid in

the growing of lush, healthy, green

turfgrass, while conserving important

resources, such as water, power, etc.

The MAXI 5, MAXI Nimbus or MAXI

Cirrus software interrogates the Weather

Station to gather information that has

been gathered on a daily basis, on 5

second intervals for short haul modem

only, of the climatic conditions that

affect the irrigation application for the

area.

The MAXI 5, MAXI Nimbus or MAXI

Cirrus software subjects the climatic

information that it gathers to a version of

the modified Penman Equation. The

Penman Equation has been proven

through over 35 years of university

research, to be one of the most reliable

predictors of turfgrass water use

requirements.

The Weather Station monitors the

following climatic conditions:

Rainfall

Wind Speed & Direction

Air Temperature

Relative Humidity

Solar Radiation

The basic PRO Weather Station

configuration includes sensors to

monitor these conditions, a micrologger

to capture this data, a modem to

communicate the information to the

MAXI Central Computer and a power

supply.

The Rain Bird Model “PRO” Weather

Station is available in two (2) basic

configurations;

Model PRO-SH, which is a

direct wire system intended for

use when the weather station is

within 20,000 feet of the MAXI

Central Computer and

communication is via a wire

path, between the weather

station and the computer.

Model PRO-PH, which is a

phone modem system for use

when the weather station is

further than 20,000 feet from the

MAXI Central Computer or

when they cannot be connected

by a communication wire path.

The system communicates

utilizing a standard, dedicated

phone service.

Page 1

Page 12

2.0 TOOLS & SUPPLIES:

(Installer Supplied)

The installer needs access to the following tools and supplies for installation of the

Weather Station.

TOOLS REQ’D.

Shovel

SUPPLIES REQ’D.

Rake

Wire Strippers

Screw driver, regular blade

Flat Metal File

Screw driver, thin regular blade

Wheelbarrow

Screw driver, Phillips head

Hand Saw

Open End Wrench 7/16”

(2) - Open End Wrench 9/16”

Open End Wrench ½”

Open End Wrench 3/8”

Claw Hammer

Magnetic Compass

Tape Measure 12’ - 20’

Matr’l. for Concrete Base Form:

(4) 12” Wood Stakes

(1) 2”x 4”x 10’ piece of wood

(8) 8p double-head nails

(8)16p double-head nails

20 ft. of form wire

½ yard of concrete

6 Ft. Step Ladder

Concrete trowel & edger

Saw Horse

Wire

Fish Tape or small dia. rope

(2) Standard Size (12” x 18”)

Rectangular Valve Boxes

(3) MGP-1 Maxi Grounding Plate

Assembly

(5) MSP-1 Maxi Surge Arrestor (Pipe

Type) (for “PRO-SH” model ONLY).

(6) 5/8” Dia. X 8’-0” copper clad

grounding rods

#10 Gauge or larger bare copper

grounding wire - length as required.

Brass Grounding Clamps - as required

(20) 3-M model DBY or DBR Direct

Burial splice kits or 3-M Scotch-lok

3500 series Connector Packs.

Belden #9883 or PE-39 direct burial,

communication cable - length as

required.

(2) Lengths of type UF power wire

(white and black) - size and length as

required.

(1) 4” x 4” electrical junction box with

cover plus connectors as required for

transformer mounting.

(2) Open Spade, crimp-on type

connectors - for connecting power

wiring to transformer.

3.0

Page 2

Page 13

WEATHER STATION SITE SELECTION:

Site selection for the Weather Station is

one of the most crucial steps in a

successful installation and an efficiently

operating irrigation system. The site

selection will greatly impact the

accuracy of the meteorological data

collected by the station. The site

selection process has many constraints

placed on it, and although the “perfect”

site is often non-existent, the following

generalities should be kept in mind.

In general, the site should be

representative of the general area of

interest and reflect the general

conditions of the project’s turf. The

more “typical” the site, in this regard,

the more useful will be the information

gathered. The site should also be away

from the influence of obstructions such

as buildings, trees, etc.

The weather station should not be

located where sprinkler irrigation water

will strike sensors or instrument

enclosure. The turf around the weather

station needs to be irrigated however - so

it is recommended that half-circle

sprinklers be placed around the base of

the weather station and ”throwing OUT’

away from the weather station. In this

way the turf can be irrigated and at the

same time water can be kept off the

sensors and instrument enclosure of the

weather station.

The sensors of the weather station

should be eight (8) to ten (10) feet above

the turfgrass. Remember that the roof

of a building IS NOT a good site for the

weather station.

The weather station does NOT need to

be “hidden”. The Rain Bird weather

station has been engineered to be

aesthetically pleasing. The urge to

“hide” the station needs to be balanced

with the selection of the most “typical”

turfgrass area. The station should NOT

negatively impact the turfgrass

environment or utility. In fact, many

installations prominently display the

Weather Station to demonstrate their

commitment to water conservation.

If the site may be prone to vandalism,

an open, chain-link, 6 foot high

security fence with a lockable access

gate should be placed around the

weather station. The fence shall be a

minimum of eight (8) feet out from the

weather station on all sides and should

be a type that will not interfere with the

accuracy of the sensors.

In your selection of a site - try to avoid

sites on or near open dirt fields and

asphalt parking areas. These sites are

prone to high invective heats that can

distort the information. Any areas that

are within 90 to 100 feet “up wind” of

the weather station can adversely affect

the weather station reading accuracies.

The requirements of each weather

station sensor must be considered when

selecting the proper location for a

weather station site. In addition to these

generalities, each sensor has its own

specialized constraints. While complete

information is available, upon special

request, for each individual sensor, the

following are the highlights of each.

Page 3

Page 14

(a) TEMPERATURE AND

RELATIVE HUMIDITY:

Sensors should be located over an open

level turf area at least 30 feet in

diameter. The surface should be the

typical turfgrass of the area in interest.

Sensors should be located a distance

away of at least four (4) times the height

of any nearby obstruction and at least 90

feet from large paved areas. Sensors

should be protected from thermal

radiation, and adequately ventilated.

Situations to avoid include:

• large industrial heat sources

• rooftops

• steep slopes

• sheltered hollows

• high vegetation

• shaded areas

• top of a hill

• bottom of a swale

• swamps

• areas where snow drifts occur

• low places holding standing

water

(b) SOLAR RADIATION:

Pyranometers should be located to avoid

shadows on the sensor at any time.

Mounting it on the southern most

portion (northern hemisphere) of the

weather station will minimize the chance

of shading from other weather station

structures. Reflective surfaces and

sources of artificial radiation should be

avoided. The height at which the sensor

is mounted is not critical.

Page 4

Page 15

(c ) PRECIPITATION

A rain gage should be located over level

ground that is covered with short grass

or gravel. In open areas, the distance to

obstructions should be two to four times

the height of the obstruction.

The height of the opening should be as

low as possible, but should be high

enough to avoid splashing from the

ground.

The gage must be mounted above the

average level of snow accumulation in

areas that experience significant

snowfall.

Standard measurement heights:

1.0 meter +/- 1.0 cm (AASC)

30.0 centimeter minimum

(WMO, EPA)

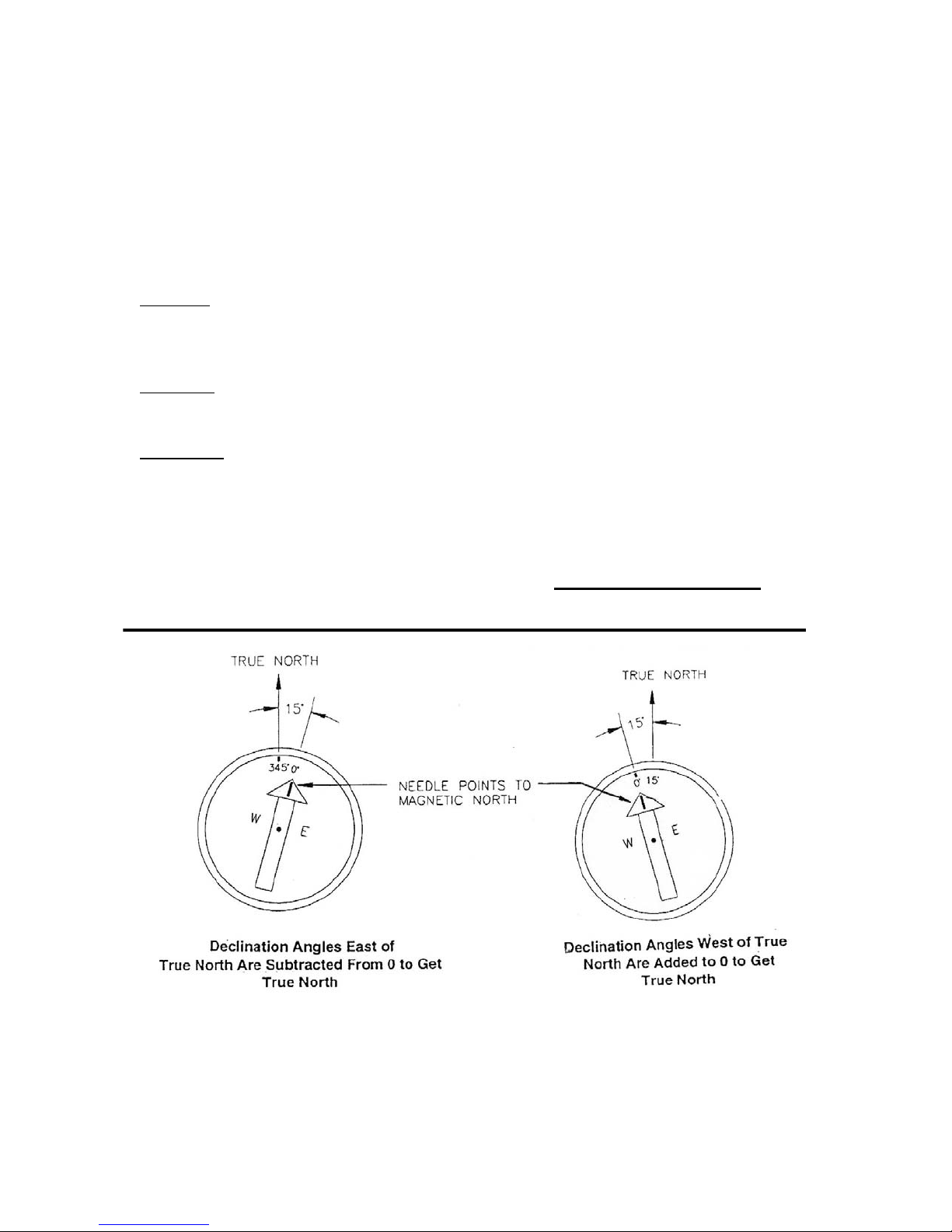

(d) DETERMINING TRUE

NORTH FOR WIND

VANE OREINTATION

Magnetic declination, or other methods

to find True North, should be

determined prior to installing the

weather station. True North is usually

found by reading a magnetic compass

and applying the correction for magnetic

declination. (Other methods employ

observations using the North Star or the

sun, and are discussed in the Quality

Assurance Handbook for Air Pollution

Measurement Systems, Volume IV Meteorological Measurements.) The

magnetic declination is the number of

degrees between True North and

Magnetic North. Magnetic declination

for a specific site can be obtained from a

USFA map, local airport, or through a

computer service offered by the USFS

called GEOMAG (see page 7). A

general map showing magnetic

declination for the contiguous United

States is shown below in FIGURE 2.

Declination angles east of True North

are considered negative and are

subtracted from 0 degrees to get True

North. Declination angles west of True

North are considered positive and are

added to 0 degrees to get True North.

For example, the declination for Logan,

Utah is 16 degrees East. True North is

360 degrees minus 16 degrees, or 344

degrees as read on a compass.

REFER TO NEXT PAGE FOR FIGURE 2

Page 5

Page 16

FIGURE 2 - MAGNETIC DECLINATION FOR THE

CONTIGUOUS UNITED STATE

Page 6

Page 17

PROMPTS FROM GEOMAG

GEOMAG is accessed by phone with a

PC and telephone modem and a

communications program such as Pro

Comm or Windows 95 Hyperterminal.

GEOMAG prompts the caller for site

latitude, longitude and elevation, which

it uses to determine the magnetic

declination and annual change. The

following information, menu and

prompts are from GEOMAG.

Username: QED

[RETURN}

Main Menu:

Type

Q for Quick Epicenter

Determinations (QED)

L for Earthquake Lists (EQLIST)

M for Geomagnetic Field

values (GEOMAG)

X to log out

GEOMAG is a user-friendly program

that provides estimates of the

geomagnetic field elements, including

declination and total field intensity,

based upon Magnetic Models. The

program is accessible by modem or

through the Internet.

Modem Access:

Modem settings: No parity, 8 data bits

and 1 stop bit (i.e., N81).

Telephone numbers:

Phone Number Baud Rates

303-273-8672 2400

303-273-8673 1200

303-273-8678 1200

Upon carrier-signal detection, press

Return once or twice.

ENTER program option: “M”

Would you like information on how to

run GEOMAG (Y/N)? Enter N

OPTIONS:

1 = Field Values (D,I,H,X,Z,F)

2 = Magnetic Pole Positions

3 = Dipole Axis and Magnitude

4 = Magnetic Center [1] : 1

Display values twice [N]: press return

Name of field model [USCON90]:

press return

Date [current date]:

press return

Latitude :42/2 N

Longitude : 111/51/2W

Elevation : 4454 ft

If you are using one of the commercial

numbers, the following prompts will

appear. Type the responses shown

(followed by pressing RETURN):

GLDSV1> c neis

[RETURN]

Page 7

Page 18

Example of report generated by

GEOMAG:

Model: USCON90 Latitude: 42/2 N

Date: 7/27/93 Longitude: 111/51/2W

Elevation: 4454.0 ft

Declination is:

deg min

15 59.6

Annual change:

deg min

0 -6.1

EXITING:

press “Cntrl-Z” to exit GEOMAG

When the main menu reappears either

select another option or Type “X” to log

out.

If you used one of the commercial

numbers, the GLDSV1> prompt will

reappear.

Type “LO” to disconnect.

Use of GEOMAG is free (except for

telephone charges). If possible, please

avoid using GEOMAG between 9 a.m.

and 4 p.m., mountain time, Monday

through Friday.

The declination in the example above is

listed as 15 degrees and 59.6 minutes.

Expressed in degrees, this would be

15.99 degrees. As shown in FIGURE 2,

the declination for Utah is east, so True

North for this site is 360 - 15.99, or 344

degrees. The annual change is -6.1

minutes.

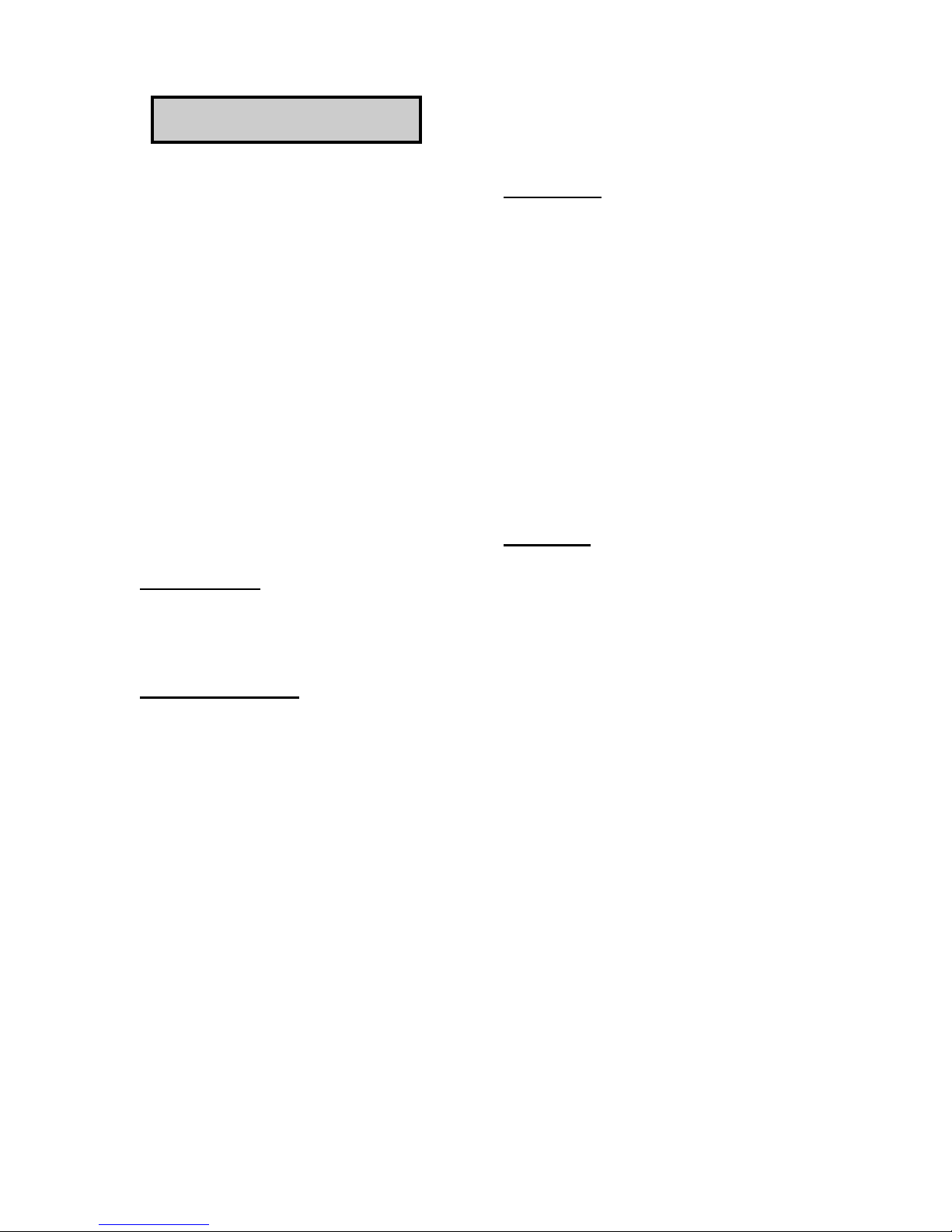

Refer to FIGURE 3 below:

FIGURE 3 - DECLINATION ANGLES

Page 8

Page 19

4.0 WEATHER STATION CONCRETE BASE:

SUPPLIED COMPONENTS

(1) 2” x 4” x 10’-0” piece of

forming lumber

(3) ½” x 12” long “L” Anchor

Bolts

(9) ½” Nuts

(3) Flat Steel Washers

(4) 16p Double Headed nails

10’-0 “ length of form wire

½ yard of concrete

Duct Tape

(1) Stainless Steel Template

(1) 1 ½” Dia. Long Sweep

TOOLS REQUIRED

Elbow

Claw Hammer

INSTALLER SUPPLIED

Hand Saw

Saw Horse

Shovel

Pliers & Wire Cutters

INSTALLATION:

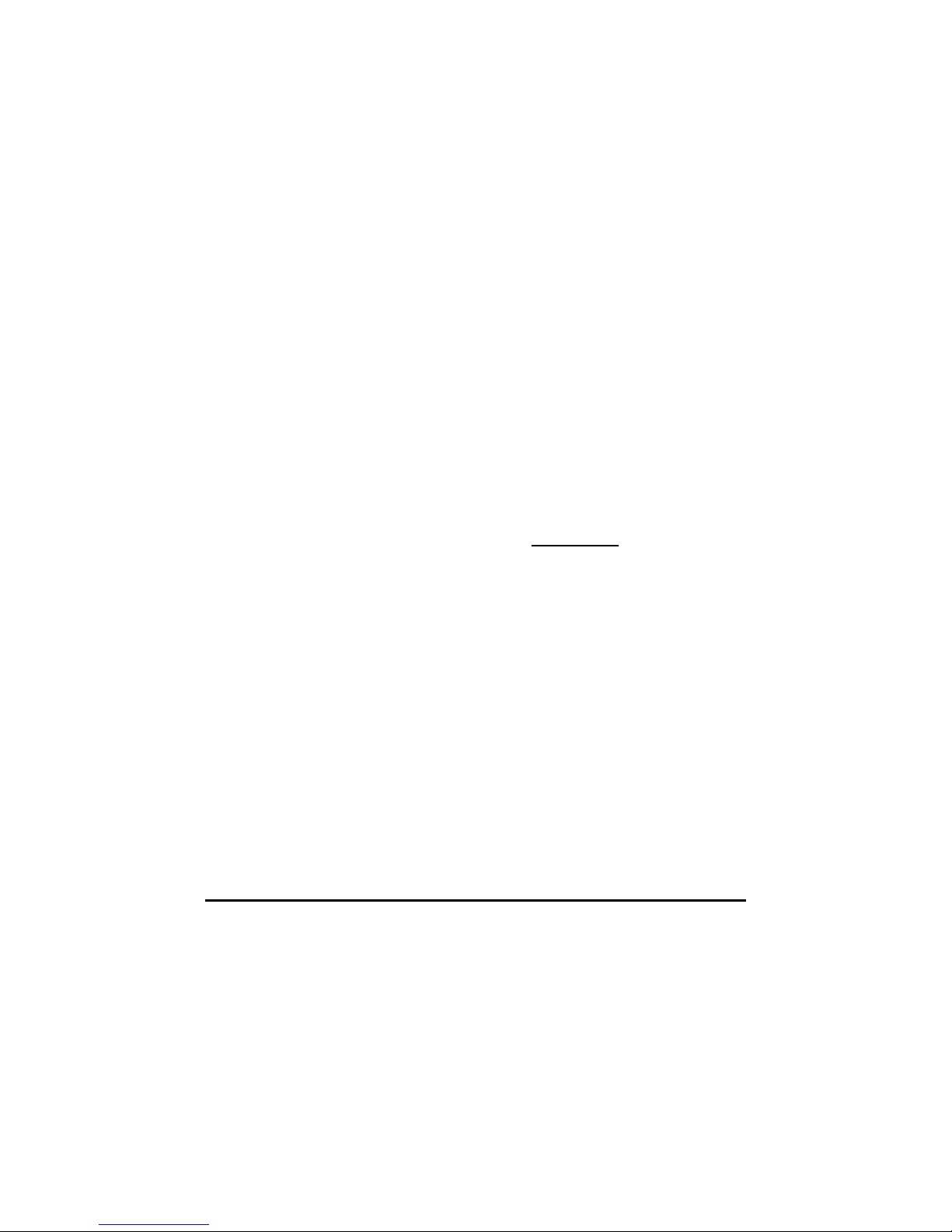

For the following procedures - Refer to FIGURE 4 below.

1.0 The Tower for the “PRO”

4.0 Construct the concrete form

Weather Station - attaches to a user

supplied poured concrete

foundation - constructed as shown

in FIGURE 4 below.

2.0 Dig the required foundation

hole - with a 24” square top

and slanting outward sides, to the

bottom of 32” square. The

“Sloping” sides of the foundation are

very IMPORTANT in providing the

necessary support to the weather

station tower, in preventing it from

5.0 Place a piece of duct tape

“leaning” or falling over, due to

wind load on the station.

3.0 Determine the proper location of the

long sweep elbow and dig a small

cavity to accept the end of the elbow

that will protrude beyond the

concrete base.

with 2” x 4” lumber and 16p

double-headed nails.

Center the form over the dug

hole. Adjacent to the long

legs of the form that extend

beyond the hole, drive four

stakes into the soil. Level

the form. Secure the form

to the stakes with 8p nails making sure that the form

remains “level”.

over one end of the 1 ½”

diameter long sweep elbow.

Insert the elbow into the

hole, with the taped end

into the small cavity that

you have dug on one side of

the hole.

Page 9

Page 20

6.0 Insert the other end of the long

sweep elbow into the center hole in

the stainless steel template. Tape

the end of the elbow with duct tape.

7.0 Take the three ½” x 12” long “L”

anchor bolts and install two (2) hex

huts on to each bolt. Insert one in

each of the holes in the template and

install one of the flat washers and a

nut to secure the anchor bolt to the

template.

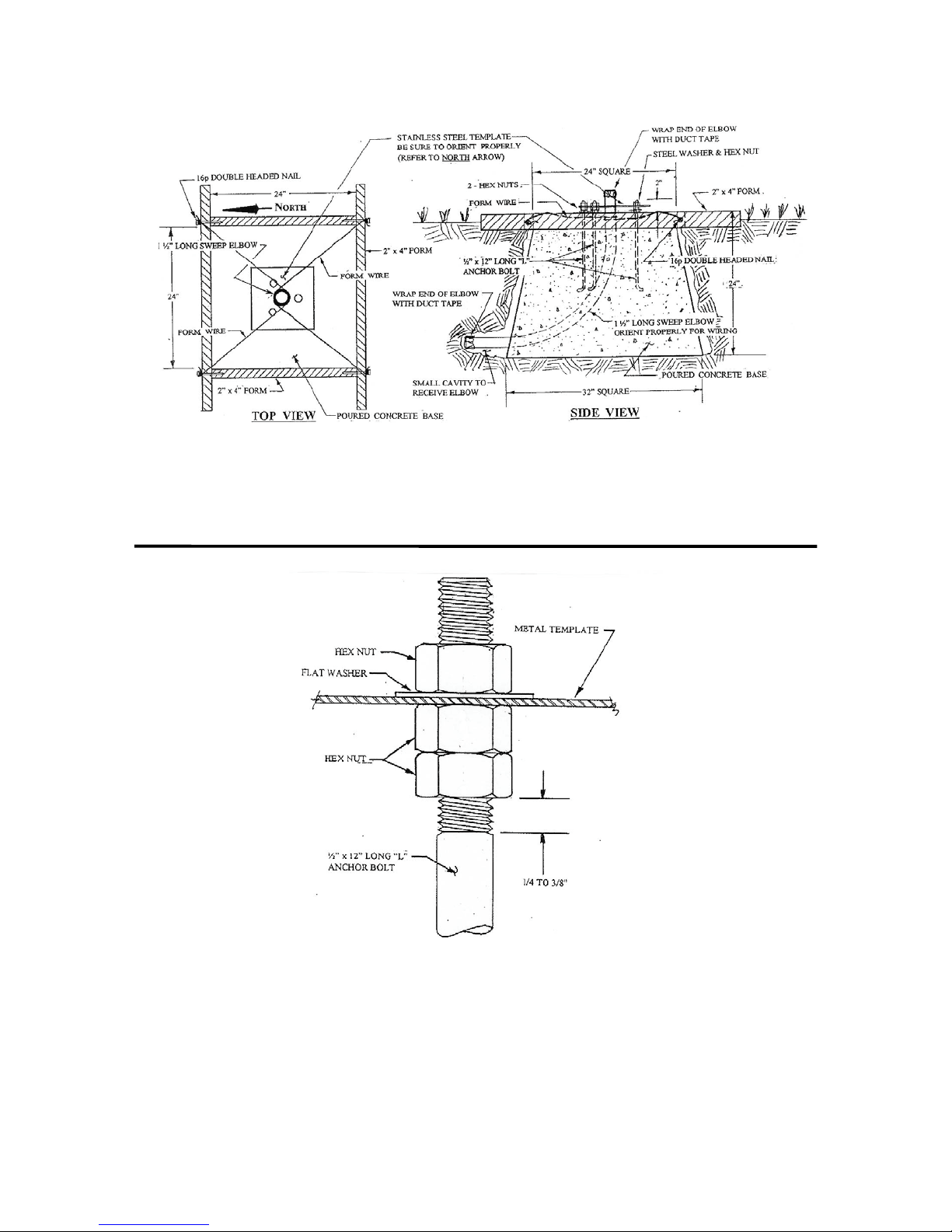

Refer to FIGURE 5.

8.0 Take the form wire and cut it into

two (2) equal lengths. Attach one

end of one of the wires to one of the

16p nails on the form. String the

wire up over the form and to the long

sweep elbow - making a turn around

it. Continue the wire over to the

16p nail at the other corner of the

form (located on the same side of the

form as the other nail) and centering

the template and elbow attach the

wire securely to the nail. Repeat

this same process with the other

piece of form wire - going to the

opposite nails and further securing

the template, elbow and anchor bolts

in the form.

9.0 Steady the template assembly by

putting a 2” spacer between the

template and the top of the form.

Pour the concrete into the hole and

form - it will require approximately

½ yard - screed the concrete level

with the top of the form. Check to

make sure the template is correctly

orientated and centered. The bottom

of the anchor bolt threads should be

about ½” above the top of the

concrete. Check to be sure the

template is “level” in two (2)

dimensions. Use a trowel and edger

to finish the concrete.

BE SURE THAT YOU HAVE THE

TEMPLATE PROPERLY

ORIENTATED IN RESPECT TO

“NORTH”. Refer to FIGURE 4.

The template should have the two (2)

bolt holes, that are parallel with one

side of the template, on the north

side of the base.

10.0 Wait 24 hours before removing the

concrete form. Wait 7 days before

mounting the weather station to the

base.

REFER TO NEXT PAGE FOR FIGURES 4 & 5

Page 10

Page 21

FIGURE 4 - CONCRETE BASE DETAIL

FIGURE 5 - ANCHOR BOLT/TEMPLATE DETAIL

Page 11

Page 22

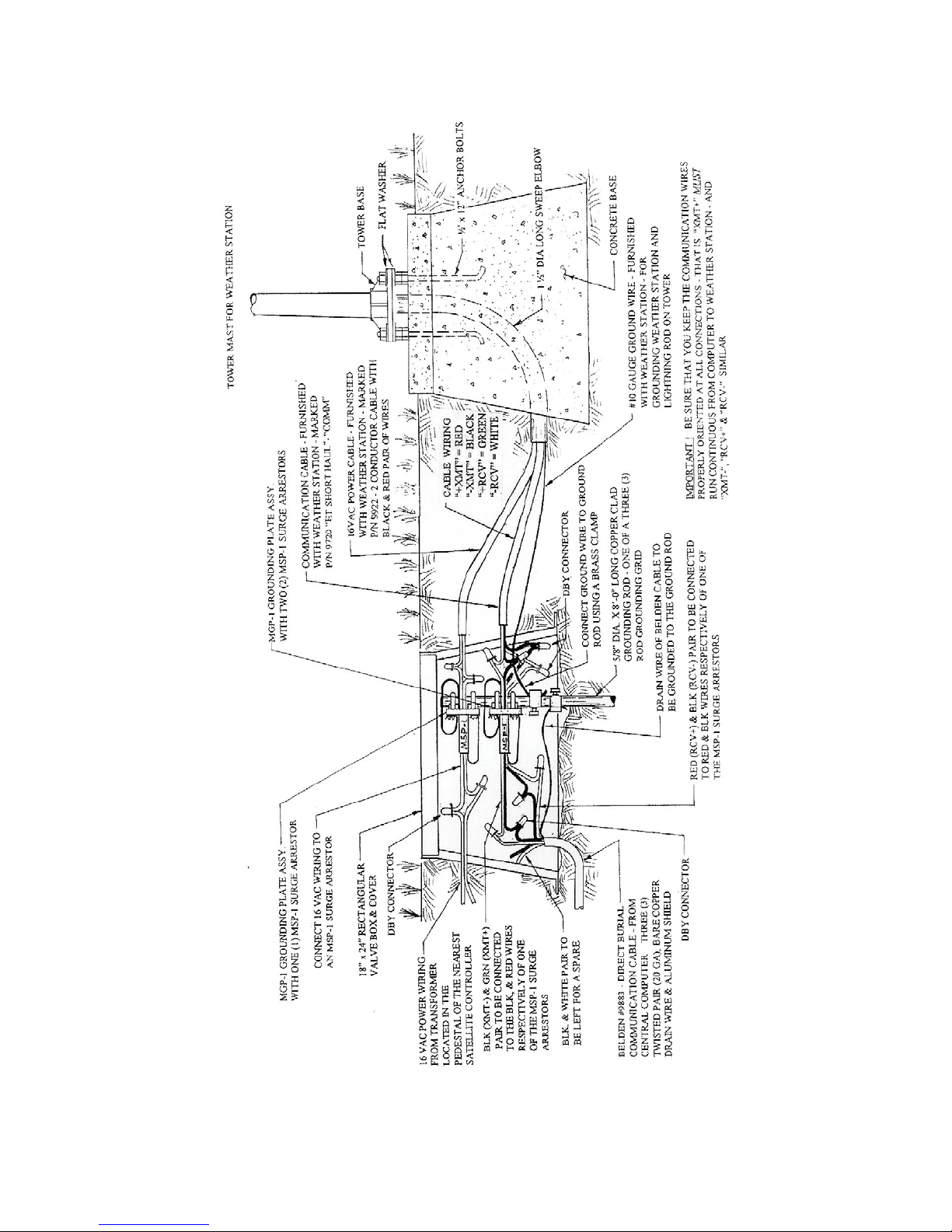

5.0 EXTERNAL WIRING TO WEATHER STATION: ( Refer to FIGS. 6 & 7)

WIRING VALVE ACCESS BOX

At the base of the Weather Station and

as near to the base as feasibly possible,

dig a hole large enough to install a

standard 18” x 24” rectangular valve box

and cover. The valve box shall

accommodate all wiring connections,

one rod of a 3-rod grounding grid,

MGP-1 grounding plate assemblies and

MSP-1 surge arrestors.

WEATHER STATION

POWER WIRING

Furnished as part of the Weather Station

is a 120VAC to 16VAC power

transformer. This transformer can be

located in the pedestal of a field satellite

controller that is in the near proximity of

the weather station or some other

convenient weather proof location.

Install the transformer in a 4”x 4” metal

electrical box with cover. Connect the

120VAC power wires of the transformer

to a source of 120VAC power that is not

easily turned off. To the output of the

transformer, connect a pair of UF wires,

of proper size, using “crimp-on” open

spade connectors.

The power wires shall be direct buried

and run over to the weather station.

Connect the 16VAC power wires to the

“LINE” side of an MSP-1 surge

arrestor, which shall be mounted in an

MGP-1 grounding plate assembly. The

MGP-1

grounding plate assembly shall be

securely mounted on a 5/8” dia. copper

clad, ground rod - one of a 3-rod

grounding grid.

NOTE ! The minimum voltage to

the transformer shall be not less than 112

volts.

Wire sizing shall be in accordance with

the chart given below.

Wire shall be Type “UF” (underground

feeder cable) with PVC insulation. The

16VAC power is used to provide

constant charging of the battery within

the weather station, through the battery

charging circuit.

WIRE SIZING CHART

WIRE SIZE DISTANCE

(feet)*

18 500

16 800

14 1275

12 2000

10 3250

8 5100

* Transformer to Weather Station

The “EQUIPMENT’ side of this MSP-1

surge arrestor shall be connected to

“red” and “black” wires of the 20’power

wire cable, which is furnished as part of

Page 12

Page 23

the weather station, and MARKED

“P/N 9922”. This cable shall be routed

through the 1 ½” dia. long sweep elbow

to the base of the weather station. All

wire connections and splices in the

power wiring shall be made using 3-M

DBY direct burial connectors. DO

NOT apply power to transformer at this

time.

WEATHER STATION

COMMUNICATION WIRING

DIRECT CONNECTED - USING

SHORT HAUL MODEMS:

(MODEL PRO-SH - Only)

cable furnished with the weather station

and marked P/N 9720 “ET SHORT

HAUL” “COMM”.

The RED (+RCV) & BLACK (-RCV)

pair shall be connected to the RED &

BLACK wires respectively, at the

“LINE” end of the other MSP-1 surge

arrestor. The RED (+RCV) and the

BLACK (-RCV) wires from the

“EQUIPMENT” end of this MSP-1

surge arrestor shall be connected to the

RED (+RCV) and the BLACK (-RCV)

wires of the communication cable

furnished with the weather station and

marked P/N 9720 “ET SHORT HAUL”

“COMM”.

Coming from the Central location,

furnish and install a Belden #9883,

Direct Burial Type, communication

cable over to the weather station

location. The Belden cable shall consist

of three (3) twisted pair of wires (20

Gauge), a bare copper drain wire and an

aluminum shield. The three (3) twisted

pair shall be color coded as follows; 1

pair “black” and “white”, 1 pair “black”

and “green” and 1 pair “black” and

“red”.

The BLACK (-XMT) & GREEN

(+XMT) pair shall be connected to the

BLACK & RED wires respectively, at

the “LINE” end of one of the MSP-1

surge arrestors. The BLACK (-XMT)

and the RED (+XMT) wires from the

“EQUIPMENT” end of this MSP-1

surge arrestor shall be connected to the

WHITE (-XMT) and the GREEN

(+XMT) wires of the communication

This communication cable shall be

routed through the 1 ½” diameter long

sweep elbow to the base of the weather

station. All wire connections and

splices in the communication wiring

shall be made using 3-M DBY direct

burial connectors. DO NOT attempt to

use any other type connectors as

communication signal may be impaired

and poor communication resulting.

GROUNDING

COMMUNICATION CABLE

The bare copper drain wire of the Belden

cable shall be grounded to the grounding

rod, using a brass ground wire clamp.

IMPORTANT ! DO NOT ground the

drain wire at the Central end of the cable

- just leave the drain wire un-used.

Page 13

Page 24

FIGURE 6 - EXTERNAL WIRING DETAIL AT THE

PRO - SH WEATHER STATION

Page 14

Page 25

WEATHER STATION

COMMUNICATION WIRING

TELEPHONE CONNECTED - USING

TELEPHONE COMPANY LINES:

(MODEL PRO-PH - Only)

The Telephone Company needs to run a

of the telephone patch cable (P/N 9661).

direct burial telephone cable to the

weather station and terminate it near the

base of the weather station. This needs

to be a modem quality type telephone

line with a separate call number.

Splices shall be made using 3-M DBY

Direct Burial connectors. The splices

for the phone line shall be made in the

valve box, where the power wiring

splices are made and where the MGP-1

The “TIP” line of the telephone cable

shall be connected to the WHITE

(“TIP”) wire of a 20’telephone patch

cable, furnished as part of the weather

grounding plate assembly with an MSP-

1 surge arrestor mounted in it, is

attached to one rod of a 3-rod grounding

grid. Refer to FIGURE 7 below.

station, marked P/N 9661 - 2 conductor

cable with WHITE (“TIP”) and BLACK

(“RING”) pair of wires. The “RING”

line of the telephone cable shall be

connected to the BLACK (“RING”) wire

This telephone patch cable (P/N 9661)

shall be routed through the 1 ½”

diameter long sweep elbow to the base

of the weather station.

6.0 TOWER ASSEMBLY AND INSTALLATION:

INSTALLATION

SUPPLIED COMPONENTS

(1) Upper Tower Section

(Tapered)

(2) Lower Tower Section w/Base

(6) ½” Washers

(1) 12 foot 10 AWG Ground

Cable

(1) Tower Plastic Cap

Take the 12 foot 10 AWG Ground

Cable, furnished as part of the weather

station and cut a 9” piece from on end of

it. (This 9” piece will be used later).

Attach one end of the ground wire to the

ground rod, of the 3-rod grounding grid,

that is located in the valve box using a

brass clamp. Refer to FIGURE 6 or 7.

Feed this ground wire through the 1 ½”

long sweep elbow up to the base of the

weather station.

Page 15

Page 26

Remove the three (3) “top” nuts and flat

washers from the anchor bolts at the

weather station template. Next remove

the metal template - slipping it up over

the cables that are extending from the

1 ½’ long sweep elbow. Be careful

NOT to damage the cables or the

connectors on the cables.

Take the lower section (with the base

attached) of the weather station tower

and feed, from the base end, the power

cable (P/N 9922) up through this section.

Also feed, from the base end, the short

haul communication cable (P/N 9720 for the Model JR-SH weather station) or

the telephone communication patch

cable (P/N 9661 - for the Model JR-PH

weather station, up through this section

of the tower. Finally feed the ground

wire up through the lower section of the

tower.

Lay this Lower Section of the tower, on

the ground, next to the concrete base,

with the cables extending out the top of

the tower section.

Take the Upper Section of the tower (the

tapered section) and position it above the

lower section on the ground. Feed the

cables, coming from the lower section,

up through the upper section of the

tower. Secure the cables at the top of

the upper section with tape, so that they

cannot pull back down into the tower as

you assemble the two tower sections.

Now assemble the upper tower section

to lower tower section, being careful

NOT to damage the cables as you do so.

IMPORTANT ! Be sure that you have

everything in proper order BEFORE

you assemble the two tower sections

together -because once assembled they

cannot be taken apart.

Place one of the flat washers on top of

the two (2) nuts on each of the anchor

bolts. Raise the tower and position the

base on the three (3) anchor bolts that

have been embedded in the poured

concrete base. Be careful NOT to

damage the cables in doing so. Next

install a flat washer and a nut on each of

the bolts and hand tighten the nuts just

enough to hold the tower in position.

Next check the level of the tower by

placing a level on the north and east

sides of the lower tower base. Adjust

the topmost nut of the two (2) lower nuts

(leveling nuts) on each bolt, as

necessary to level the base. When level

is established, lock the leveling nut in

place by tightening the lowest nut

against it. Tighten the three top nuts

with a wrench to secure the tower to the

base. The tower should now be ready

for the final assembly of the Enclosure,

Sensors and Lightning Rod, etc.

REFER TO NEXT PAGE FOR FIGURE 7

Page 16

Page 27

FIGURE 7 - EXTERNAL WIRING DETAIL AT THE

PRO - PH WEATHER STATION

Page 17

Page 28

7.0 INSTRUMENTATION ENCLOSURE INSTALLATION:

GENERAL:

The Model PRO weather station

datalogger, power supply, sensor

connection panel, communications

devices and data retrieval peripherals are

mounted in the ET Enclosure with the

sensors themselves mounted on a crossarm, which mounts to the top of the

Enclosure.

MOUNTING

ET ENCLOSURE TO THE

TOWER

Mount the Enclosure to the top of

the weather station tower, by sliding the

enclosure brackets down the tower,

from the top of the tower.

Position the Enclosure so that the top of

the enclosure is even with the top of the

tower and on the north side of the tower

(for northern hemisphere). Tighten the

bolts, on the clamps, to secure the

enclosure to the tower. DO NOT over-

tighten the bolts since doing so may

damage the tower or the enclosure.

Refer to FIGURE 8 below

FIGURE 8 - MOUNTING ENCLOSURE ON TOWER

Page 18

Page 29

INSTALLATION OF

LIGHTNING ROD

Refer to FIGURE 8 above:

Carefully mount the lightning rod

bracket, furnished with the weather

station, to the top of the weather station

tower. Locate it above the Enclosure

top bracket and near the top of the tower.

Clearance between the clamp and the

Enclosure is minimal. Care should be

taken not to scratch the enclosure or

sensor assembly. Insert the lightning

rod into the bracket, with approximately

½” to 1” of the rod extending below the

bracket, and tighten the set screw to

secure the rod in the bracket.

Take the ground wire, that has been fed

up the weather station tower, strip the

insulation from the end and curl the end

so as to be able to connect the wire

under the head of one of the bolts on the

lightning rod bracket. Be sure that you

wrap this wire completely around the

bolt and that you get a good contact with

the bolt and bracket. Tighten the bolt

securely so that you have a good tight

connection. This connection is

EXTREMELY important to give

maximum protection to the weather

station against damage from lightning

surges. This connection should be

INSPECTED on a regular basis to

assure it remains tight and making good

contact.

Take the 9” piece of ground wire, that

you previously cut off the ground wire,

and strip the insulation from each end of

it. Insert one end of this wire into the

brass grounding lug, located at the top

of the Enclosure on the back panel.

Tighten the set screw to secure the wire

in the clamp. Curl the other end so as to

be able to place it around the other bolt

of the lightning rod bracket. Be sure that

you wrap this wire completely around

the bolt and that you get a good contact

with the bolt and bracket. Tighten the

bolt securely so that you have a good

tight connection. This connection is

EXTREMELY important to give

maximum protection to the weather

station against damage from lightning

surges. This connection should be

INSPECTED on a regular basis to

assure it remains tight and making good

contact.

POWER SUPPLY

RECHARGEABLE BATTERY

The weather station is furnished as

standard with a Sealed Rechargeable

Battery and including the mounting

bracket. This battery is to be installed

on the back panel of the Enclosure.

Refer to FIGURE 9 below.

Page 19

Page 30

FIGURE 9 - 16VAC CONNECTION AND RECHARAGEABLE BATTERY

INSTALLATION

with the screws. Tighten all four screws

Loosen the four (4) screws located on

the back panel of the Enclosure. Slip

the end of the battery bracket, that has

the two (2) keyhole slots in it over the

to properly secure the battery to the back

panel of the ET Enclosure.

upper two (2) screws. Line up the

battery bracket slotted holes, in the

other end of the bracket, with the two

(2) lower screws. Now push “down” on

the battery - seating the bracket in place

Plug the connector on the wire leads of

the battery to the “top” battery

connection - marked “LA” - which is

located on the Enclosure panel

assembly just above the battery location.

Page 20

Page 31

AC EXTERNAL

POWER WIRING

the cap on the Heyco fitting to seal

around the cable. The wires can be

Refer to FIGURE 8 & 9 above:

attached to these connectors by

“depressing” the lever on the connector

for each wire and while doing so, insert

The 16VAC power wiring, that you

have fed up through the weather station

tower, shall be routed down the back

side of the Enclosure and into the

Enclosure through the Heyco fitting,

marked “power”. Unscrew the cap of

the Heyco fitting (on the back side of the

enclosure) and push the plug out of the

fitting. This plug can be discarded as it

will not be used. Feed the power wires

through the Heyco fitting and connect

them to the the connectors of the

the stripped end of the wire. Upon

release of the lever, the wire will be

secured in the connector. CAUTION !

Be careful in depressing the lever so as

not to break the lever. The polarity of

the 16VAC power wiring does not

matter, therefore it makes no difference

which wire goes into which connector.

At this point you can now connect the

power to the transformer or wait until

you have connected the sensors, which

ever you prefer.

Enclosure, marked “CHG”. Tighten

It will be noted that on the panel assembly there are connectors marked “ALK”.

These connectors are NOT to be USED. The use of an Alkaline battery is NOT an

option.

CONTINUE ON THE NEXT PAGE

POWER SUPPLY

Page 21

Page 32

OPTION

SOLAR PANEL

Refer to FIGURE 10 below:

Model Numbers shall be as; PRO-SH-SP

or PRO-PH-SP. (SP designating the

Solar Panel Option).

An option is for use of a Solar Panel, for

the power supply, rather than the

standard 120VAC/16VAC transformer.

Mount the solar panel to the weather

station tower using the mounting

brackets furnished as part of the solar

panel assembly. Mount the solar panel

to the tower so it faces south (northern

hemisphere). Position the solar panel as

high off the ground as practical,

ensuring it cannot interfere with air flow

or sunlight around the sensors.

The solar panel should be oriented to

receive maximum sun light exposure

over the course of the year. It is also

necessary that the solar panel have the

proper “tilt”. Suggested “tilt” angles

(reference to the horizontal plane) are

listed below.

Site Latitude Tilt Angle

0 to 10 degrees 10 degrees

11 to 20 deg. Latitude +5

degrees

21 to 45 deg. Latitude +10

degrees

46 to 65 deg. Latitude +15

degrees

65 deg. 80 degrees

After determining the “tilt” angle,

loosen the two (2) bolts that attach the

solar panel to the mounting bracket.

Adjust the angle of the solar panel, then

tighten the bolts to secure it in the proper

position. Secure the lead wire, coming

from the solar panel, to the Tower mast

using wire ties.

The solar panel cable shall be routed up

and through the Heyco fitting on the

back panel of the Enclosure and marked

“power”. Unscrew the cap of the Heyco

fitting (on the back side of the enclosure)

and push the plug out of the fitting.

This plug can be discarded as it will not

be used. Now feed the solar panel

power cable through the Heyco fitting

and connect it to the connectors of the

Enclosure, marked “CHG”. The wires

can be attached to these connectors by

“depressing” the lever on the connector

for each wire and while doing so, insert

the stripped end of the wire. Upon

release of the lever,, the wire will be

secured in the connector. CAUTION !

Be careful in depressing the lever so as

not to break the lever. The polarity of

the wires does not matter, therefore it

makes no difference which wire goes

into which connector. The solar panel

installation should now be completed.

Page 22

Page 33

FIGURE 10 - SOLAR PANEL INSTALLATION DETAIL

Page 23

Page 34

8.0 INSTALLATION OF INSTRUMENTATION

GENERAL:

The Model PRO weather station comes

with the some of the sensing

instruments, and sensor wiring to

datalogger completely assembled as a

unit on a cross-arm. The Solar

Radiation Pyranometer - along with the

leveling device are mounted on a

bracket, which in turn is mounted on the

cross-arm of the Enclosure. On this

end of the cross-arm the “Tipping Rain

Bucket” is also mounted at the factory.

On the opposite end of the cross-arm is

attached the mounting bracket, which

has been factory installed, for the Wind

speed and Wind direction sensing

instruments. The Temperature and

Relative Humidity sensors are on the

end of their cable and only need

installing into the radiation shield. The

cables for each of these sensors are

mounted in the cross-arm and terminated

at the proper location of each sensor.

The cables only need to be routed and

plugged into the proper connectors on

the back of the back panel of the ET

Enclosure.

SUPPLIED COMPONENTS

(1) Sensor Cross-Arm

(1) Met One 034A Wind Sensor

(1) 034A Mounting Shaft

(1) Radiation Shield

INSTALLATION OF CROSS-ARM

TO ET ENCLOSURE:

Refer to FIGURE 11 below:

Remove the four (4) Phillips head

screws from the bottom center of the

cross-arm. With the Enclosure cover

removed, place the cross-arm on top of

the Enclosure. The cross-arm needs to

be oriented along a due east to due west

axis. If necessary adjust the Enclosure

on the tower to properly orient the cross-

arm. Also be sure that the opening in

the middle and one side of the cross-

arm, where the sensor cables exit, is to

the back of the Enclosure so that the

cables can enter the top of the cover that

fits over the cable connectors on the

back of the Enclosure. Line up the four

threaded holes on the under side of the

cross-arm (where you just removed the

screws) with the four holes in the top of

the Enclosure. Attach the cross-arm to

the Enclosure by inserting the four (4)

screws, from in side the enclosure up

through the top and into the threaded

holes of the cross-arm. Tighten the

screws securely.

REFER TO NEXT PAGE FOR FIGURE 11

Page 24

Page 35

FIGURE 11 - CROSS-ARM MOUNTING

INSTALLATION OF 034A WIND SENSOR:

Page 25

Page 36

Refer to FIGURE 12 below:

With the Sensor Cross-Arm securely

installed to the Enclosure you are ready

to install the 034A Wind Sensor

instrument. The wind vane is oriented

after the datalogger has been

programmed and the location of True

North has been determined. Orientation

is most easily done with two people,

one to aim and adjust the sensor, while

the other observes the wind direction

displayed by CR10KD Keyboard

Display or a laptop PC computer.

Remove the aligning screw from the

base of the 034A wind sensor unit.

Place the 034A wind sensor into the

mounting shaft, that is clamped to the

end of the sensor cross-arm by means of

a U-Bolt clamp.

(The short, black mounting shaft,

included with the 034A wind sensor will

NOT be used).

Secure the 034A wind sensor in the

mounting shaft, by aligning the threaded

hole in the wind sensor with the hole in

the side of the mounting shaft, and reinstalling the aligning screw.

Next loosen the set screw in the top of

the 034A wind sensor (the set screw

opposite the one securing the wind

direction point). Place the end of the

wind vane into the hole. Properly orient

the vane to be in a true vertical position

and secure it by tightening the set screw.

Attach the wind sensor cable connector

to the connector on the 034A wind

sensor.

Without allowing the mounting shaft for

the 034A wind sensor to “slip down” (it

may be a good idea to mark the position

of the U-Bolt on the shaft so that you

can correctly position it should is “slip”)

slightly loosen the nuts of the “U-Bolt”

clamp of the mounting shaft - just

enough so you can rotate the mounting

shaft but not allow the shaft to “slip

down”.

Establish a reference point on the

horizon for True North.

Sighting down the instrument center

line, aim the counter weight at True

North. Display input location #8 for

wind direction, using the *6 Mode of

the datalogger.

REFER TO NEXT PAGE FOR FIGURE 12

While holding the wind vane position,

slowly rotate the sensor base/mounting

shaft until the datalogger indicates 0

degrees. Securely tighten the clamp

nuts.

Page 26

Page 37

FIGURE 12 - WIND SENSOR INSTALLATION DETAIL

HUMIDITY / TEMPERATURE

SENSOR AND RADIATION

SHIELD:

INSTALLATION OF RELATIVE

Refer to FIGURE 13 below:

Page 27

Page 38

On the bottom of the Cross-Arm, on the

end where the wind sensor has been

installed, remove the two screws for the

Relative Humidity/Temperature sensor

Radiation Shield.

Un-tape the RH/Temperature sensor

from the bottom of the Cross-Arm.

Remove the “yellow” protective plastic

cap from the end of the sensor, by

slipping it off the end of the sensor.

This can be discarded as it will not be

used.

Insert the RH/Temperature sensor into

the end of the shaft of the Radiation

Shield. Insert it to a depth where it is

securely seated. Now secure the

Radiation Shield to the bottom of the

sensor Cross-Arm with the two (2)

screws you have previously removed.

FIGURE 13 - TEMPERATURE/RH SENSOR INSTALLATION DETAIL

INSTALLATION OF SOLAR

RADIATION PYRANOMETER:

Refer to FIGURE 14 below:

Page 28

Page 39

The Solar Radiation Pyranometer, (with

the leveling device) is mounted, at the

factory, on a mounting bracket at the

opposite end of the cross-arm near the

Tipping Rain Bucket gage. By using

the three (3) leveling screws - level the

Pyranometer. After leveling - remove

the “RED” protective cap from the

Pyranometer.

FIGURE 14 - SOLAR RADIATION SENSOR INSTALLATION DETAIL

Refer to FIGURES 12 & 15:

SENSOR CABLE CONNECTIONS:

The Sensor Cables exit from the center

back of the Cross-Arm. The cables

need to be routed down the back of the

Page 29

Page 40

Enclosure and plugged into the

connectors on the back panel of the

Enclosure as follows:

Temp/RH #10090 cable - connect

to #1 connector [labeled

“TEMP/RH”]

Solar Radiation #10105 cable -

connect to #3 connector [labeled

“SOLAR RADIATION”]

Rain #10094 cable - connect to #5

connector [labeled “RAIN

(PRECIP)”]

WD/WS (Wind Direction/Wind

Speed) #10408 cable - connect to

#2 connector [labeled “WS/WD”]

Making sure that all cables are properly

enclosed behind the cover - replace the

cable cover. Be sure that you do not

pinch any of the cables between the

cover and the back panel of the

Enclosure.

FIGURE 15 - SENSOR CABLE CONNECTIONS

Page 30

Page 41

CONFIGURE SENSOR SWITCH

SETTINGS:

Refer to FIGURE 16 below:

The Sensor Switches are located on the

ET Enclosure panel just below the

modem and to the right of the the “Heat

Sink” located to the right of the battery

connectors. These switches or pots

need to be set as indicated in FIGURE

16 below.

FIGURE 16 - SENSOR SWITCH SETTINGS

SHORT HAUL MODEM

INSTALLATION

Refer to FIGURE 18 below: (PRO-SH)

The Short Haul Modem, at the weather

station, is normally installed at the

factory in the ET Enclosure. The Short

Haul Modems enable communication

between the datalogger and the central

computer over two (2) twisted pairs of

wires. The maximum distance between

modems is determined by the baud rate

and the wire gauge. At 9600 baud, the

approximate range is 4.0 miles. DCE/

DTE switches on the modems must be

set to DCE.

INSTALLATION:

For installation of the Short Haul RAD

Modem inside the Enclosure, the

following components are provided in

the Short Haul modem kit:

SC932C Interface w/ribbon cable

RAD Modem

RAD/SC932C Mounting Bracket

Velcro Mounting Strap w/Buckle

Mounting Screws

12 inch 4-wire Patch Cable

Partially install three (3) of the furnished

screws in the holes on the left side of the

Enclosure housing for the datalogger.

Hold the Modem mounting bracket in

the position it will be in the Enclosure.

Page 31

Page 42

Thread the Velcro mounting strap

through the two outer slots of the lower

set of slots in the modem mounting

bracket. Thread from the top down on

the far left slot first. The side of the

strap with Velcro should be facing

“down” toward the datalogger housing.

Then carry the strap across the back of

the bracket and thread it to the front of

the bracket through the far right slot of

the lower set of slots.

Slide the bracket flange, with the three

screw slots, under the heads of the three

(3) mounting screws you have partially

installed in the holes on the left side of

the datalogger housing. With the

bracket fully seated tighten the three (3)

screws to secure the mounting bracket to

the datalogger housing.

Connect the SC932C Interface to the

RAD Modem. Position this assembly

on the mounting bracket with the

SC932C Interface pointing “down”.

Strap the SC932C Interface unit securely

to the mounting bracket, using the

Velcro strap.

Connect the SC932C 9-pin port to the

internal Enclosure 9-pin port (located

just below the Phone Modem port) using

the blue ribbon cable provided.

Wire the RAD modem to the Enclosure

with the 12 inch 4-wire patch cord

provided. Black (-XMT) wire to -XMT

connections at the RAD modem and at

the connector on the Enclosure. The

RED (+XMT) wire to the +XMT

connections, the White (-RCV) wire to

the -RCV connections and the Green

(+RCV) wire to the +RCV connections

at the RAD modem and at the terminal

blocks: RED to +RCV, Black to -RCV,

Green to +XMT, White to -XMT.

Page 32

Page 43

FIGURE 18 - SH MODEM INSTALLATION IN ET ENCLOSURE

TELEPHONE MODEM

INSTALLATION

Refer to FIGURE 19 below:

(PRO-PH)

The Telephone Modem, at the weather

station, is normally installed at the

factory in the Enclosure. The

telephone modems enable

communication between the datalogger

and a Hayes compatible modem at the

Page 33

Page 44

central computer over a dedicated

telephone line. Phone line surge

protection is built into the Enclosure.

INSTALLATION

For installation of the phone modem

inside the Enclosure, the following

components are provided in the modem

kit:

COM200 or COM 300 Modem

12 inch RJ-11 Patch Cord

Modem Mounting Bracket

Mounting Screws

12 inch #14 AWG Ground Wire

4 Screws and Nuts

Partially install three (3) of the furnished

screws in the holes on the left side of the

Enclosure housing for the datalogger.

in the bracket over the top two (2)

screws that you have previously installed

in the datalogger housing. Be sure the

open slot in the bracket is in line with

the lower screw. Seat the modem

properly and tighten the screws to secure

the modem to the datalogger. Connect

the 9-pin connector of the Blue Ribbon

Cable to the phone modem 9-pin port.

Connect the other end of the ribbon

cable to the 9-pin port (marked “CS

I/O”) on the Enclosure. Secure it with

the two screws on the connector.

Connect the modem RJ-11 Patch Cord to

the RJ-11 jack on the phone modem

(located to the right of the 9-pin port).

Connect the other end of the RJ-11 Patch

Cord to the RJ-11 jack on the

Enclosure, marked “phone modem”.

Attach the phone modem to the

mounting bracket, using the four screws

and nuts.

Taking the phone modem and bracket

assembly - install the two keyhole slots

REFER TO NEXT PAGE FOR FIGURE 19

Connect one end of the 12 inch #14

AWG ground wire to the terminal,

marked “GND” and located on the right

side of the phone modem. Connect the

other end of this ground wire to the

connector on the Enclosure that is

marked “GND”.

The installation of the phone modem is

now completed.

Page 34

Page 45

FIGURE 19 - TELEPHONE MODEM INSTALLATION IN ET ENCLOSURE

latch for extra security.

9.0 SEALING & DESICCATING

THE ENCLOSURE:

The Enclosure is supplied with a

desiccant pack. The desiccant

maintains a low humidity in the

enclosure to minimize the chance of

condensation on the instrumentation

Desiccant should be changed when the

internal Enclosure humidity sensor

measures 30% or higher. Install the

desiccant as shown in FIGURE 21

below.

Keep unused desiccant tightly sealed

inan airtight container.

Take the desiccant pack out of its sealed

plastic bag. Place it under the dessicant

strap just before leaving the station.

Be sure to close the enclosure hasp

securely. A padlock may be used on the

FIGURE 20 - DESSICANT PACK

INSTALLATION

Page 35

Page 46

10.0 INSTALLATION AT CENTRAL COMPUTER

WHITE (XMT-) wire to the upper right

MODEL PRO - SH ~ Direct

Connected:

connector, connect the RED (RCV+)

wire to the lower right connector and the

BLACK (RCV-) wire to the lower left

Refer to FIGURE 22 below:

connector of the surge arrestor box.

SUPPLIED COMPONENTS

(1) SMR-5A RAD Modem

(1) 5 Foot 4-Wire Patch Cord

(1) 25 Foot #10 AWG Ground

Wire

(1) Surge Protection Box

INSTALLATION

Attach the 5 foot 4-wire patch cord to

the SRM-5A RAD modem unit, which

is furnished as part of the weather

station. Connect the GREEN (XMT+)

wire to the “XMT+” terminal of the

RAD modem. Connect the WHITE

(XMT-) wire to the “XMT-“ terminal,

the RED (RCV+) wire to the “RCV+”

terminal and the BLACK (RCV-) wire to

the “RCV-“ terminal.

Connect the SRM-5A RAD modem

directly to the serial port of the computer

or use a 9-pin to 25-pin adapter if

required.

Mount the Surge Arrestor Box, which is

furnished as part of the weather station,

in a suitable location near the computer

(within less than 5 feet, as the patch

cord is only 5 feet long).

Take the other end of the Patch Cord,

that you have previously connected to

the modem, and connect the GREEN

(XMT+) wire to the upper left connector

in the Surge Arrestor Box. Connect the

Just outside the building of the central

computer location, install an 18” x 24”

rectangular valve box with cover over

one ground rod of a 3-rod grounding

grid. (You may use the 3-rod grounding

grid for the central Interface unit, etc. if

located nearby).

Furnish and install and MGP-1

grounding plate assembly on the ground

rod in the valve box. Furnish and install

in the MGP-1 grounding plate assembly

two (2) MSP-1 Pipe Surge Arrestors.

Be sure to have the end marked

“EQUIP” toward the central equipment

and the “LINE” end toward the weather

station. Ground both ends of each of

the MSP-1 Surge Arrestors to a screw on

the

MGP-1 grounding plate assembly.

Using a piece of Belden #9883 direct

burial cable (of sufficient length to reach

from the Surge Arrestor Box to the

Valve box) take the Green and Black

twisted pair of wires and connect the

GREEN (XMT+) wire to the upper left

terminal in the Surge Arrestor Box.

Connect the BLACK (XMT-) wire to the

upper right terminal in the Surge

Arrestor Box. Take the Red and Black

twisted pair of wires and connect the

RED (RCV+) wire to the lower right

terminal of the Surge Arrestor Box.

Connect the BLACK (RCV-) wire to the

lower left terminal of the Surge Arrestor

Box. Leave the third pair of twisted

wires, consisting of a Black and White

wire disconnected and for a spare pair.

Page 36

Page 47

The copper drain wire shall also be left

disconnected.

Route the Belden cable, out of the

building, under ground and out to the

valve box. Taking the Green and Black

twisted pair of wires, connect the

GREEN (XMT+) wire to the RED wire,

on the end marked “EQUIP”, to one of

the MSP-1 Pipe Surge Arrestor that you

have installed in the MGP-1 Grounding

Plate Assembly. The BLACK (XMT-)

wire shall be connected to the BLACK

wire, on the end marked “EQUIP”, of

this MSP-1 Surge Arrestor.

Next take the Red and Black twisted pair

of wires of the Belden cable and connect

the RED (RCV+) wire to the RED wire,

on the end marked “EQUIP”, of the

second MSP-1 pipe surge arrestor.

Connect the BLACK (RCV-) wire to the

BLACK wire, on the end marked

“EQUIP”, of this second MSP-1 pipe

surge arrestor.

The third twisted pair, consisting of a

Black and White wire pair, shall be left

as a spare and un-connected. The

copper drain wire shall also be left

disconnected.

A Belden #9883 Cable, consisting of

three twisted pair of wires, a copper

drain wire and an aluminum shield with

an outer insulation for direct burial,

shall be run underground form the

central

location valve box out to the weather

station location. At the valve box, at

the central location, take the Green and

Black pair of wires and connect the

GREEN (XMT+) wire to the RED wire,

coming from the end marked “LINE”,

of the first MSP-1 pipe surge arrestor.

Connect the BLACK (XMT-) wire from

this pair, to the BLACK wire, coming

from the end marked “LINE”, of the

first MSP-1 pipe surge arrestor.

Take the Red and Black twisted pair of

wires, of the Belden cable and connect

the RED (RCV+) wire from this pair, to

the RED wire coming from the end

marked “LINE”, of the second MSP-1

pipe surge arrestor. Connect the

BLACK (RCV-) wire from this pair, to

the BLACK wire coming from the end

marked “LINE”, of the second MSP-1

pipe surge arrestor.

The third twisted pair, consisting of a

Black and White wire pair, shall be left

as a spare and un-connected. The

copper drain wire shall also be left

disconnected.

To the center ground terminal in the

Surge Arrestor Box - connect one end of

the #10 gauge bare copper ground wire.

Route this wire out the bottom of the

box, underground out to the valve box

and connect it to the ground rod using a

brass clamp. Keep this ground wire as

short and as straight as possible with NO

sharp bends or “kinks”.

For connections and wiring at the

Weather Station, refer to Section 5.0 of

this manual.

REFER TO NEXT PAGE FOR FIGURE 21

Page 37

Page 48

FIGURE 21 - INSTALLATION AT CENTRAL COMPUTER FOR

DIRECT CONNECTED WEATHER STATION

Page 38

Page 49

MODEL PRO - PH Phone Connected:

Refer to FIGURE 22 below:

SUPPLIED COMPONENTS

(1) Telephone Patch Cable

(2) 25 Foot #10 Gauge Ground Wire

(1) Surge Arrestor Box

INSTALLATION

Furnish and install a Hayes Compatible 9600 baud modem. Using the ribbon

cable that comes with the modem

connect one end to the RS232C cable

connector on the Modem. Connect the

other end of this ribbon cable to the

serial port of the computer. Use a 9-pin

to 25-pin adapter if required.

Plug the “Plug-In” type transformer,

that has been supplied with the modem,

in to an 120 VAC electrical outlet.

Surge protection, for protection against

surges coming in on the telephone lines,

is built into the Weather Station. In

addition the telephone company also

furnishes surge protection on their lines.

Therefore no additional surge protection

is required upon installation of the

Weather Station.

STANDARD INSTALLATION

METHOD

Taking the telephone patch cable,

connect the WHITE (“TIP”) wire, of

this cable, to the “Tip” line of a piece of

underground telephone cable. Connect

the BLACK (“Ring”) wire, of this patch

cable, to the “Ring” line of this piece of

underground telephone cable.

Route this piece of direct burial

telephone cable, out of the building,

under ground and out to the valve box,

located just outside the building. In the

valve box connect the “TIP” wire

(white) to the WHITE “TIP” wire of the

direct burial underground telephone

cable installed by the telephone

company. Connect the “RING” wire

(black) to the BLACK “RING” wire of

the direct burial underground telephone

cable installed by the telephone

company.

REFER TO NEXT PAGE FOR

FIGURE 22

Page 39

Page 50

FIGURE 22 - INSTALLATION AT CENTRAL COMPUTER FOR

TELEPHONE CONNECTED WEATHER STATION

Page 40

Page 51

11.0 MAINTENANCE & TROUBLESHOOTING

GENERAL MAINTENANCE:

Be aware of battery voltage that

Proper maintenance of weather station

components is essential to obtain

accurate data. Equipment must be in

consistently decreases over time, which

indicates a failure in the charging

circuitry.

good operating condition, which

requires a program of regular inspection

DESICCANT:

and maintenance. Routine and simple

maintenance can be accomplished by the

person in charge of the weather station.

More difficult maintenance such as

sensor calibration, sensor performance

testing (i.e., bearing torque), and sensor

Enclosure humidity is monitored in the

Enclosure. Change the desiccant packs

when the enclosure RH exceeds 35%.

The RH chip should be changed every 5

to 8 years.

component replacement, generally

requires a skilled technician, or that the

SENSOR MAINTENANCE:

instrument be sent to Campbell

Scientific for repair or updating.

Contact your local Rain Bird distributor

for instructions.

Sen0sor maintenance should be

performed at regular intervals,

depending on the desired accuracy and

the conditions of use. A suggested

A station log should be maintained for

maintenance schedule is outlined below.

each weather station that includes serial

numbers, dates that the site was visited

1 Week -

and maintenance that was performed.

• Visually inspect the station and all

INSTRUMENTATION

MAINTENANCE:

sensors. Look for any damage and

debris that may disturb sensor

readings.

The instrumentation requires a minimum

of routine maintenance. A few

preventative maintenance steps will

optimize battery life and decrease the

• Check the pyranometer for level and

contamination. Gently clean with a

soft bristle brush, if needed.

chances of datalogger failure.

• Check and Clean the Tipping Bucket

BATTERIES:

Rain Gage, especially the bucket

screen and the small funnel outlet.

RECHARGEABLE

To check accuracy of the rain gage -

Rechargeable power supplies should be

connected to an AC transformer or

unregulated solar panel at all times.

16 ounces of fluid is equal to 1” of

rainfall. Fluid must be poured into

the gage VERY SLOWLY to get an

accurate bucket tipping count.

Page 41

Page 52

1 Month -

• Check the temperature/relative

humidity sensor for contamination.

• An occasional cleaning of the glass

on the solar panel will improve its

efficiency.

6 Months -

• Clean the temperature/relative

humidity sensor.

• Check battery by disconnecting the

AC Power and allow it to stabilize

for at least 2 hours. Then check the

voltage. Reconnect battery to AC

Power.

1 Year -

• Replace the RH chip if necessary.

2 Years -

• Calibrate the Pyranometer (some

suggest yearly).

• Check sensor leads and cables for

cracking, deterioration, proper

routing and strain relief.

• Check the tower for structural

damage, proper alignment and for

level/plumb.

• Replace RH chip in Air Temp/RH

Sensor.

• Calibrate the Tipping Bucket Rain

Gage. To check accuracy of the rain

gage - 16 ounces of fluid is equal

to 1” of rainfall. Fluid must be

poured into the gage VERY

SLOWLY to get an accurate bucket

tipping count.

4 - 5 Years -

• Replace sensor cables as requires.

General Maintenance

Page 42

Page 53

SENSOR MAINTENANCE

RAIN GAUGE

Inspect and clean every two to three

months - removing leaves, debris, etc.

In extreme environmental conditions it

may be necessary to do this on a

MONTHLY basis.

• Check that the tipping mechanism

moves freely and that it registers

0.01 inches per tip.

the large center drain hole. Adjust both

screws the same number of turns or

partial turns. Rotation clockwise

increases the number of tips per 16

ounces of water, counter clockwise

rotation decreases the number of tips per

16 ounces of water. One half turn of

both screws causes a 2% to 3% change.

• Check and Re-Level the Rain Bucket

lid.

Factory Calibration is available through

your Rain Bird Distributor.

• Check and Re-Level the Rain

Bucket, if necessary.

• Calibrate the Rain Gage every 2

years.

Calibrating the Rain Bucket:

• Secure a metal can that will hold at

least one quart of water.

• Punch a VERY SMALL HOLE in

the bottom of the can.

• Place the can in the top of the funnel,

of the Rain Bucket, and pour 16 fluid

ounces (1 pint) of water into the can.

• If it takes LESS than 45 minutes for

this water to run out, the hole in the

can is TOO LARGE.

• One hundred (100) tips plus or

minus three tips should occur and

register from 0.97 inches to 1.03

inches. (0.01 inches per each tip).

Adjusting screws are located on the

bottom of the Rain Bucket, adjacent to

Suggestions:

Devices for dripping water are available

through a chemistry equipment supply

house.

In order to see the 100 tips, configure a

FAKE weather station within the

weather software, to use for this testing.

Drip the water and then do an upload

using the new test configuration to see

the number of tips (0.01 inches = 1 tip).

CAUTION ! Be sure to disable any

Automatic Uploads, since the 100 tips

will contaminate the every day weather

data.

After the calibration is complete, reset

the datalogger by removing the power

and the battery connections in the

Enclosure. Contact Campbell Scientific

for further instructions. You will have

to reset the time of day and year in the

datalogger by up loading one day of data

(#6 from the Weather Main Menu). The

7 days of data that are stored in the

datalogger will be lost when you

disconnect the power, so be sure to have

done an upload before you begin the

calibration process.

Page 43

Page 54

SOLAR SENSOR

• Inspect and clean the Solar Sensor

(Pyranometer) every two (2) to three

(3)months. It is best cleaned with a

blast of clean, dry air or with a soft

bristle, camel hair brush. Be careful

NOT to scratch the surface of the

sensor. DO NOT use Windex,

soap or any other cleaning agent as

it may scratch or more likely leave a

film on the surface, which will

affect its accuracy.

• The bearings can only be replaced by

the factory and therefore need to be

returned to the factory through your

local Rain Bird Distributor.

Checking the bearings of the 034A

Wind Sensor.

• Remove the Wind Sensor from the

Weather Station cross-arm, by

removing the set screw that is

securing the sensor in the mounting

shaft and raising the sensor up and

out of the mounting shaft.

• In EXTREME environmental

conditions it may be necessary to

clean the Solar Radiation Sensor

(Pyranometer) on a monthly basis.

• Be sure the DRAIN hole in the side

of the sensor housing near the top, is

OPEN and free of debris.

• Re-Calibration of the Solar

Radiation Sensor (Pyranometer)

should be done every two (2) years.

Return the sensor, through your Rain

Bird Distributor, for calibration.

WIND SENSOR

• Inspect bearings and operation of the

Wind Sensor (wind speed and wind

direction) on a regular basis, at least

once a year. They should move

freely and react to a wind speed of 2

to 3 mph.

• Hold the Wind Sensor in a horizontal

position (with one of the wind speed

cups “down” toward the ground).

• On one of the cups hang an ordinary

paper clip (0.5 gm weight) on the

outer edge of one of the cups.

• Position this cup in the “up” position

and release. The cup should rotate

downward. Failure to rotate

indicates the bearings need

replacement.

RELATIVE HUMIDITY SENSOR

• The life of the RH chip is dependent

upon air quality in your area. As a

General Rule the RH chip should be

replaced EVERY 2 YEARS, if

necessary.

• In extreme environmental

conditions, the RH chip may need to

be replaced every year.

The bearings have a life expectancy of 3

to 5 years, except in very high wind

areas, where their life may only be 1

year.

• The best time to change the chip is at

the beginning of the most critical

Page 44

Page 55

time for watering (spring and fall in

the desert areas).

• Clean the screen, on the tip of the

RH chip enclosure, every six (6)

months more often, if required. If

the screen gets dirty quickly, this

will reflect how often the chip will

need to be replaced.

The seal on the panel assembly of the

Enclosure forms the seal between the

Enclosure cover and the Enclosure back

panel.

• This seal should be inspected on a

regular basis, looking for cracks,

hardening of the foam rubber and/or

loosening from the back panel

assembly.

TEMPERATURE SENSOR

• Inspect and clean, at least every 2 to

3 months and more often in extreme

environmental conditions.

CAUTION

Be careful of the thermister, as it is

very delicate.

• Carefully clean insects and debris

from the temperature probe.

• The temperature probe can NOT be

calibrated, so if the readings are

poor the complete probe must be

replaced.

• After several years the

temperature/RH sensor may become

corroded and should be replaced.

NOTE ! Water will affect the

temperature readings, so be sure no

direct water is hitting the weather station

from sprinklers in the area.

• Any time the Enclosure is opened,

upon closing it the desiccant pack

should be replaced with a new

desiccant pack.

• At least once a year the desiccant

pack should be replaced with a new

pack.

• The Enclosure internal moisture

should be monitored. The desiccant

pack maintains a low humidity in the

enclosure an minimizes the chance

of condensation on the datalogger

and other electronic components.

• The desiccant pack should be

changed when the internal

Enclosure humidity sensor measures

35% or higher.

• If the moisture level gets too high the

Enclosure should be opened and

dried out. The desiccant pack needs

to be replace with a new pack.

• All parts should be dried with a

clean, dry cloth and components

inspected for corrosion.

SEAL OF ET ENCLOSURE

• When replacing the cover on the