Page 1

1X2

Page 2

TABLE OF CONTENTS

2

1. Symbols …..…………………..………………………………………………………………………………………....………….….…..3

2. Important Information……….…………………………………………………………………………………………………..………...4

3. Introduction.....……….……..………………………………………………………………………………………….………..…….…...5

4. How it Works...……….……..……………………………………………………………………………………..…………...…….…….6

4.1 Filtration Phase……………..………………….……………………………………………….………………………..…….6

4.2 Backflushing Phase………………………………………………………………………………………………..…….……7

5. Product Identification……..…..………………………………………….……………………………………………………..…..……..8

5.1 Assembly Part Identification .……………………………………………………………………………………..….……..…8

5.2 Product Labeling.……………………….……………………………………………………………………………………....8

5.3 Filter Part Identification.……………………………………………………………….…….…………………………..……..9

6. Installation Instructions...……...…………………………………………………………………………………………………………10

6.1 Installation Steps…………………………..……………………….…….…………………………………………….……..10

6.2 Adjusting the Height of the Equipment..……………………………….……………………………………….…..…….....10

6.3 Securing the Equipment……….………………………………………………………….………………………...….….…10

6.4 Connection of the main manifolds, inlet, outlet and drainage…...…………………...……………….………….…….....10

7. Control Unit Connection………………………………………………………………………………………………………………….10

8. Operation Instructions………………………………………………………………………………………………………………........10

8.1 Before Starting –Up……………..…………….…………...…………………………………….……………………………10

8.2 Start-Up……………..………………..………….………………….……………………………………….…………………10

9. Maintenance…………………………………………………………………………………………………………………………….…10

9.1 Inspection of the Filters ………….…….……….………...……………………….………………………………..………....15

9.2 Manual Clean of the Discs ……..………….………………..……………………………………..……………………...….15

9.3 Checking o-rings in the Filter Element.. …….…………………………………………..………………………..……...….16

9.4 Checking the Removable Elements of the Filter.……………....…………………………………………………………. 16

9.5 Inspecting the Piston Element …………………..….…………….…………………………………………….….…….….16

9.6 Checking Component s…………………………..……………..…….……………………………………………........…...17

10. Possible Problems and Solutions……………………………………………………………………………………………….……….18

11. Warranty……………………………………………………………………………………………………………………………..…….. 20

Page 3

3

System of symbols used in this manual:

Failure to obey the instructions and warnings

could cause serious injury and an electrical

hazard.

The Warning and Safety Information provided are guidelines only; use all necessary security

and accident prevention methods to guarantee your security.

The improper use of the equipment may cause injury to people, damage to property or the

environment. Improper use or modification of the equipment voids its warranty

3

1. SYMBOLS

Failure to obey the instructions and warnings could

cause injury to people, damage to the equipment or

to the surrounding areas.

Page 4

2. IMPORTANT INFORMATION

4

Rain Bird filtration equipment has been designed to filter water, in accordance with the operating

conditions outlined in this manual and the label on the equipment.

• Rain Bird filtration systems are NOT designed for the filtration of hazardous liquids (such as those

specified in section 2 of article 2 of the Executive Committee 67/548/CEE, 27th June 1967) or liquids

for food use.

• This equipment has been designed and manufactured to satisfy the requirements communicated to

the manufacturer by the customer. Any change in its use could cause damage not covered by the

warranty.

• Save this manual so the user of the equipment can familiarize themselves with it.

• These are general instructions for safe operation of the equipment. These instructions are not a

complete list; the user must adopt as many security measures as necessary to guarantee their

safety.

• Follow the instructions described in this manual.

• Do not open the filter clamp when the equipment is pressurized, it could cause serious injury to

people, the equipment or to the surrounding area.

• Do use adequate personal protective equipment (proper working clothing, safety glasses, steel toed

boots and other elements of personal protection).

• Determine the chemical compatibility between the equipment's materials and the characteristics of

the water to be filtered.

• Before using the equipment, make sure that all the covers are properly closed and the connections

are in good condition.

• Make sure that the equipment is depressurized by reading the gauges (0 PSI) on the filters inlet and

outlet manifold before exposing the interior of the equipment to atmosphere (before opening any

filter, removing any coupling, etc.)

• Do not forget to close the safety lock on the clamp. It will prevent its accidental opening.

• Do not exceed the maximum pressure or operation intervals (pressure, temperature, PH, and flow

rate) indicated in the Technical Data.

• In freeze areas, empty the filtration system to prevent damage.

Page 5

Thank you for selecting a Rain Bird HDF 1X2 Disc filtration system. Please read this manual

carefully as it will help you find answers to most of your questions.

IF YOU HAVE ANY QUESTION OR NEED ADITIONAL INFORMATION; PLEASE CONTACT

US AT (520) 806-5620 or filters@RainBird.com

Rain Bird HDF Disc Filters systems are subject to strict quality control tests and are

manufactured under a production process which complies with the requirements of ISO

9001/2000.

Rain Bird is committed to the environment, and Rain Bird HDF Disc Filters Series 2 filtration

systems are certified under the Environmental Management System of the standard ISO 14001.

This manual includes instructions and warnings for correct installation, operation and

maintenance of the equipment.

5

3. INTRODUCTION

Page 6

6

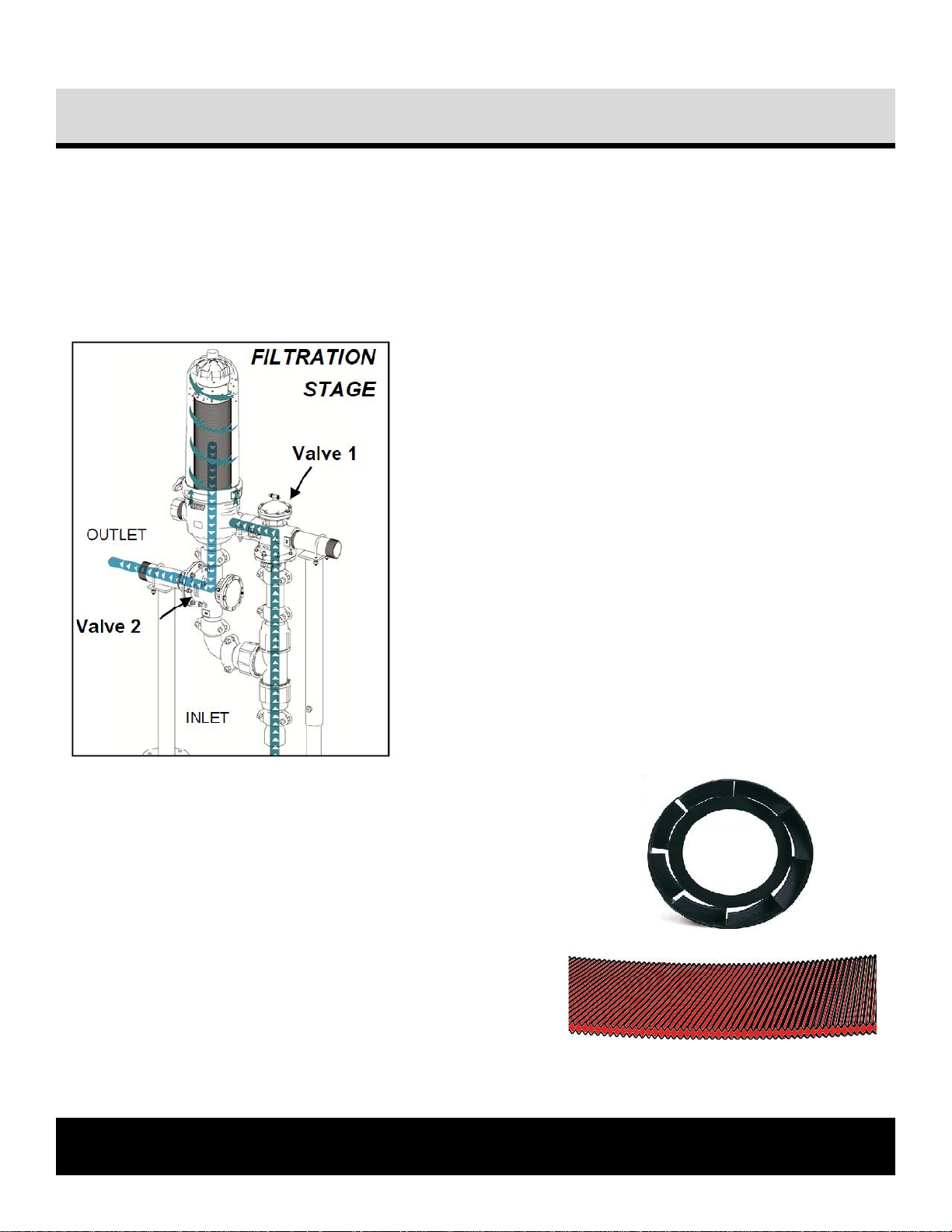

4.1 Filtration Phase

In the filtration phase, water is carried from the inlet

manifold, through the backflushing three-way valve

(valve 1), to the interior of the filter through the inlet.

Once the water enters the filter, the only paths for it to

follow are the channels of the discs. The particles are

trapped by the channels in the discs.

The stack is compressed by the spring action and the

hydraulic power itself.

The filtered water goes through the 2” hydraulic valve

and proceeds through the rest of the installation. The

outlet manifold is responsible for collecting the filtered

water and carrying to the exterior.

Rain Bird HDF 1X2 Disc Filters consists of a filtering element comprised of grooved discs that allows

the retention of particles of a size larger than the required filtration grade. The equipment combines the

advantages of the disc filters with those of the helico-centrifugal effects of the Rain Bird HDF 1X2.

The system carries out two independent phases, one called the FILTRATION PHASE and the other

called the BACKFLUSHING PHASE.

4. HOW IT WORKS

Thanks to the filters helico-centrifugal effect, the number

of backflushings are dramatically reduced, minimizing

water consumption.

This is achieved by the patent-pending design located on

the base of the cartridge.

Page 7

7

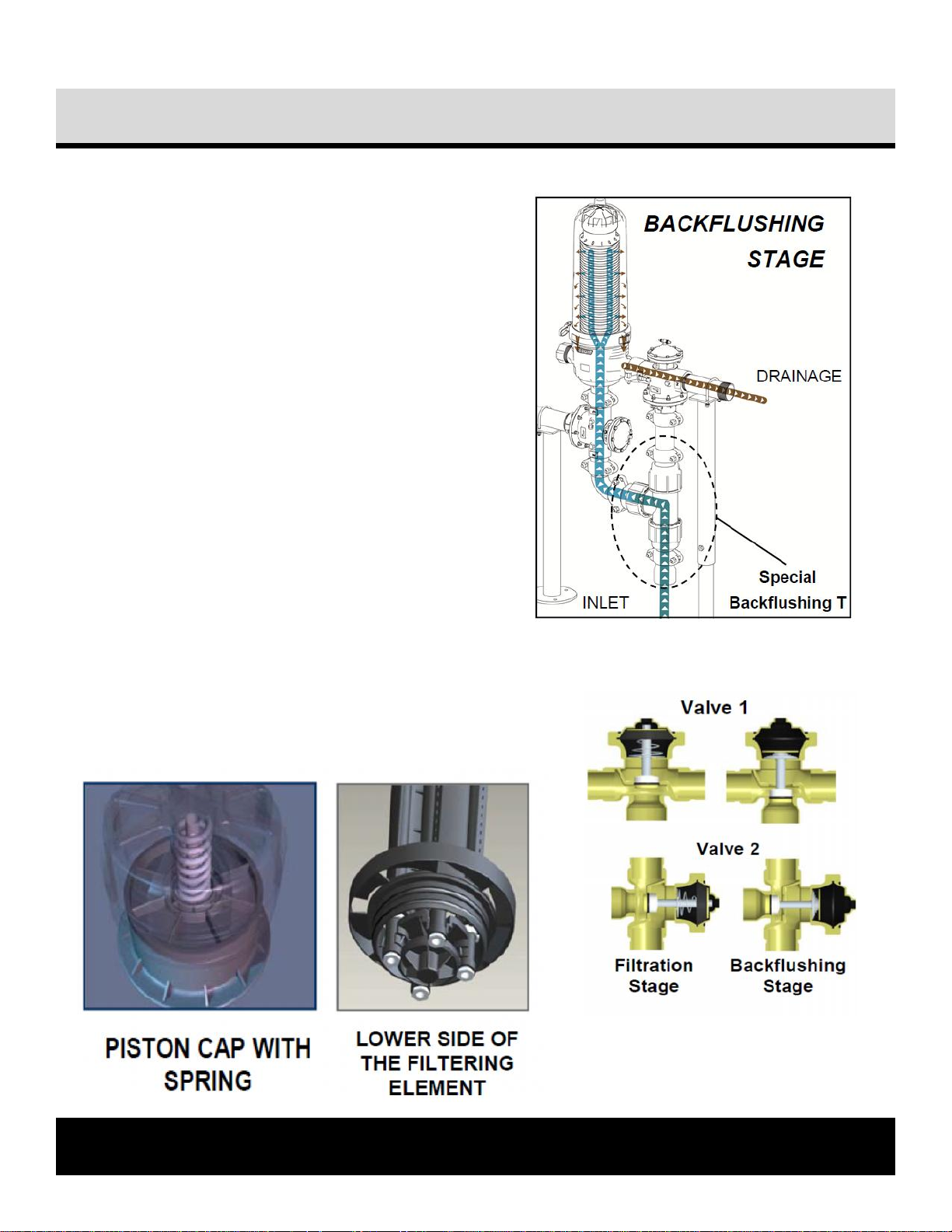

4.2 Backflushing Phase

Through the feeding of the three-ways valves

chamber, the inlet of water to the filter closes,

beginning the inner of the filter with the drainage

manifold, thus starting the backflushing cleaning.

The filtered water given by the Special backflushing T,

is introduced in the filter.

The available hydraulic power is used to overcome the

pressure exerted by the spring on the discs stack,

generating a decompression due to the piston

displacement (raising).

The release of the discs creates rotation due to the

tangential projection of the water coming from the

feeder bars which at the same time are used as a

structural shoulder for the discs stack.

The end of the backflushing coincides with the closure

of the drainage outlet and the opening of the outlet

manifold, allowing water coming from the feeder

manifold to come into the interior of the filter. This

allows the systems to re-establish the filtration phase.

Page 8

8

10

5.2 Product Labeling

The equipment is identified by two labels, one is placed on one of the main

manifolds, the other is placed on the filters.

The modification or elimination of this

label voids any warranty; and impedes

the identification of the Equipment.

Serial number

Max. Pressure

Year of Manufacturing

Manufacturer

Model

Max. Temperature

5.1 Assembly Part Identification

COMPONENTS

Nº DESCRIPTION

1 RAIN BIRD HDF DISC FILTER

2

INLET MANIFOLD – GROOVED

CONNECTION

3

OUTLET MANIFOLD– GROOVED

CONNECTION

4 DRAINAGE MANIFOLD

5 MANIFOLD SUPPORTS

6 3 WAY HYDRAULIC VALVE 2”

7 VICTAULIC COUPLING 2”

8

PRESSURE GAUGE

0 – 10 bar / 145 psi

9 AUXILIARY FILTER ¾” KIT

10 CONTROL UNIT

5. PRODUCT IDENTIFICATION

1

3

2

4

5

8

6

9

7

Page 9

9

1

2

3

4

7

8

9

6

5.3 Filter Part Identification

COMPONENTS

Nº

DESCRIPTION

1

BODY CAP

2

CLAMP

3

BODY

4

MICRON RATING LABEL

5

AUTOMATIC CARTRIDGE

6

SEALING GASKET BODY

5

Nº DESCRIPTION

7 FRAME PISTON

8 DISCS

9

FILTERING

ELEMENT FRAME

14

15

16

13

10

11

12

7

Nº DESCRIPTION

CHECK VALVES

WITH

ACCESORIES

SET OF

PISTON

GASKETS

SPRINGS

MAINTENANCE

KIT

FILTERING

ELEMENT

O-RING

FRAME

FRAME

O-RING

PISTON

GASKET

10 PISTON SPRING 1 1

11

PISTON O-RING

13 x 2

2 2

12 ELASTIC RING 1 1 1

13

PiISTON GASKET

92.6 x 100 x 4

1 1 1 10

14 CHECK VALVE 1 1

15

SPRING CHECK

VALVE

1 1 1

16 O-RINGS FRAME 2 2 10

To request spare parts please indicate the serial number of the assembly

Page 10

Regulation of the supports of the Equipment.

10

6. INSTALLATION INSTRUCTIONS

- Installation should be made by QUALIFIED PERSONNEL.

- The location for the installation of the equipment should be made on solid ground.

- You should take into account the weight of the equipment when you choose to use slings.

- Make sure that the length of the lifting system is correct so that the filtration system is in

a horizontal position when raised.

- Secure the equipment to the lifting system to avoid accidents.

- Follow all operation and safety instructions for transporting equipment .

6.1 Installation Steps

The Rain Bird HDF 1X2 Disc Filtration System equipment is shipped in a box semi-assembled.

Please follow the steps below for a proper installation.

1. Unpack the equipment carefully and check that there no is no evident damage.

2. Confirm that all installation parameters are met in accordance with those of the equipment.

3. You can modify the height of the equipment with the adjustable supports. Once the supports

are in place adjust their height as required. Due to the equipment dimensions, the shoulders

height should be adjusted so that, the upper part of the drainage manifold is placed at a

distance of 33,2" (843 mm) from the ground. The separation between the shoulders should be

560 mm.

4. Screw the stainless steel bushing to the outlets of the three-way hydraulic valves. It is very

important to use sealer in the threads of both bushings.

5. Assemble the equipment, connecting the inlet, outlet and drainage manifolds using their

connections.

6. Install a glycerin pressure gauge 0-145 psi (0-10) bar to measure the pressure coming into the

valve. It is recommended you use liquid sealer or LOCTITE 5331, but not in excess.

7. Place the 2” NPT Cap in the open outlet of the filter base. The cap does not need sealing

because it is provided with an o-ring.

8. Place the cartridge in the filter base. Once this is completed, place the lid on the unit and close

the clamp.

9. Check all connections of the equipment and secure the base to the ground in order to avoid

vibration.

To close the filter check for debris on the 0-ring in the base. Carefully install the lid and close the

filter clamp. To close the clamp, place the bolt in the grooved seat and adjust the lever then

clamp the anti-opening device and thread the saftey screw without forcing it.

Page 11

6.4 Securing the Equipment

Before securing the equipment to the ground, verify that

the equipment is level. Secure the equipment to the

ground using the appropriate type screws or bolts for the

type of ground the equipment will be resting on. The

screws should be placed in the 10 mm diameter

manifold holes.

6.5 Connection of the main manifolds, inlet, outlet and drainage

The main manifolds connections (inlet and outlet manifolds) are grooved. Use the supplied

accessories (as required) to connect the equipment to the rest of the system.

The drainage manifold has a PVC grooved coupling from factory that glues to a 3” PVC pipe.

Connect the inlet, outlet and drainage manifolds with its corresponding connections.

LEVEL AND SECURE TO

THE GROUND TO AVOID

VIBRATION

11

6.3 Adjusting the Height of the Equipment

You can modify the height of the equipment with the adjustable

supports. Prior to doing so it is important to be sure that the

equipment is properly supported by a lifting system. Once this

has been secured, unthread the screws of the supports and

adjust the height with the help of the lifting system.

The equipment must always be horizontal when positioning.

Verify that the equipment is supported by the lifting system before

unthreading the M10 screws of the supports.

33,2" (43 mm)

Page 12

CLOSE

AUTO

OPEN

E1:

ELECTROVALVE

FEEDING

D: DRAINAGE

P2: Low Presure

P1: High Presure

L1

E1

E1

T:

PRESSURE

T: PRESSURE

The microtubes and unions are labelled according to the following nomenclature:

12

7. CONTROL UNIT CONNECTION

* : P1 and P2 are the

pressure in the inlet and

outlet manifold. Their

difference is the head loss

of the Equipment.

Page 13

8.2 Start-Up

Connect the pumping system for the water inlet

Make sure that the Operation Conditions (pressure, temperature, flow rate and pH) are in

accordance with the specifications.

Monitor the equipment head loss.

Follow the instructions of the Equipment's Controller Manual.

13

8. OPERATION INSTRUCTIONS

8.1 Before Starting-Up

•Before operating the equipment, use adequate personal protection (proper clothes, safety

glasses, gloves and other elements of personal protection).

•Make sure that the flow rate, pressure, temperature and PH are permitted by the equipments

specifications (indicated in the equipment technical data) before starting up. Do not operate

outside of the recommended working conditions.

•Equipment Pressure: Make sure that the filter is depressurized before opening it.

•Make sure that all the filters are properly closed to avoid leaks. Do not forget to lock the

safety clip on the clamp. This will prevent accidental opening

•Make sure that the auxiliary filter key is opened before starting-up the equipment

•We recommend the installation of an upstream and downstream valve to isolate the system

during maintenance operations.

1. Place the correct number of discs on each filter.

2. Adjust it until the filter base is straight

3. Install the lid.

4. Close the clamp.

5. Check the adjustment of the cap of each filter.

6. The filter battery is ready to operate.

Page 14

Maintenance of the Equipment. The maintenance intervals depend on the operating conditions,

characteristics of water to be filtered, length of operation, number of backflushings, recuperation of

the differential pressure after the backflushings. Rain Bird recommends maintenance be

performed every three month for components which means the disassembly of the filtering

element. The actual frequency should be determined by the user according to the particular

characteristics of their installation.

• Be sure the equipment is depressurized before exposing the

interior of the equipment to the atmosphere.

• All maintenance should be performed by a qualified professional.

• The maintenance frequency should be determined by the user according to the

particular conditions of their installation.

DAILY ACTION

1. Visual inspection of the

equipment

2. Check for leakage in the

equipment

3. Check the Operation Conditions

(pressure, temperature, flow rate,

PH).

4. Evaluation of the equipment head

loss (P1* - P2*)

PERIODIC ACTION

1. Check the base o-ring

2. Check the filters cleaning state. If they are

very dirty, clean the discs manually.

3. Manually activate a backflush to check

operation of the backflushing phases to

confirm all the stations are operating

correctly.

4. Check gaskets.

5. Check the elements of the piston.

6. Check ¾” intake filter

7. Check ¼” intake filter.

8. Maintenance of grooved couplings.

Below are some general maintenance recommendations:

• Every time you start the equipment perform a visual inspection

• Do not allow particles to dry in the discs. Activate a backflush just before stopping the

equipment, if it will not be used for an extended period of time.

• Watch the equipment head loss as well as its recovery after backflushes.

14

9. MAINTENANCE

Page 15

Discs Removal

9.1 Inspection of the Filters

Clean the discs using clean water. or

an acid solution if you cannot

remove the dirt from the discs. In

which case you should follow the

protection measures according to

the Safety Sheet regarding

the acid to use.

•Do not mix discs from different filters

to avoid changes in the number of

discs per filtering element.

•Placing the filtering element

improperly can cause breakage.

•Check the chemical compatibility

between the lubricant used in the

base of the filtering element and

the materials of the filter.

15

•Pressure Equipment:

•Be sure the filter is depressurized before opening it.

•If necessary, clean only the discs in an acid solution.

•If an acid solution is used to clean the discs, use the

adequate protection (clothes, glasses, gloves, face shield

...) Consult the Safety Sheet of the product used.

•Do not contact any part of the filter with the acid solution

except for the discs

9.2 Manual clean of the Discs

1.Open the clamp and take away the lid

2.Remove the filtering element carefully.

3.Turn the piston until it is released; take away the piston.

4.Take away the discs

5.To assemble the filtering element proceed the other way round.

6. Place all the discs

7.Thread the piston making a soft pressure at the same time it is turned to its adjustment.

8.Lubricate the base o-ring of the filtering element, with neutral petroleum jelly if possible.

9.Place the filtering element pushing carefully downwards

10.Close the filter.

Discs Installation

Page 16

VASELINA

9.3 Checking o-rings in the Filter Element:

1.Thread the piston of the filter element using a light pressure and turn to

adjust.

2.Lubricate the area of the O-rings

3.Inert the filter element pushing carefully in the base of the filter.

4.Replace the lid and close the clamp

92.6x100x4 O-RING

103x4.00 O-RING

Do not force the screws in the

assembly, you can damage

the threads.

Petroleum Jelly

PIECE H

PIECE L

16

9.4 Checking the Removable Elements of the Filter:

1.Unscrew the screws of the filtering element base with a number 17 box wrench. Always begin by

unscrewing two opposite screws. Hold the spring retainer while unscrewing.

2.Remove the spring holder, the spring and the disc cap. Clean carefully with water.

3.Correctly fit all the pieces on the bars.

4.Manually replace the opposite screws, then use the wrench; thread the rest of screws manually

and then use the wrench.

5.Lubricate the base of the filter element O-ring, with a product chemically compatible with the

material of the filter. Insert the filtering element pushing carefully.

9.5 Inspecting the Piston Elements:

1.Remove the elastic ring from the washers with a pair of straight nosed

pliers by inserting the tips in the ring holes and opening. Separate L piece

from H piece.

2.Check the two o-rings housed in the piece L. Also, check the washers and

the spring of piece H.

3.Apply lubricant in the threaded rod of piece H.

4.Install one washer in the spring and the other in the rod of piece H.

5.The two o-rings in the interior housings of the L pieces.

6.Install piece L on the axis of piece H. Fit the elastic ring on the axis of

piece L using the pliers until it seats in the groove of the rod.

Place the piston in the filter element, lubricate the base of

the filter element with a product chemically compatible

with the material of the filter and insert the filter element;

pushing it carefully into the base of the filter.

Page 17

9.6 Checking Components

Be sure that the equipment is depressurized before carrying out

any maintenance operation, in which the interior of the equipment

is exposed to atmosphere.

Applying too much

Sealer or forcing

the threads may

damage them

A. Maintenance of Grooved Couplings

I. Disassemble the grooved coupling with a wrench.

II. Apply grease to the coupling joint.

III. Assemble the coupling.

17

B. Checking the ¼” Intake Filters

I. Disconnect P1 and P2 micro tubes

II. Remove the ¼” intake filters on the inlet and outlet

manifolds with a wrench

III. Clean them

IV. Replace the ¼” filter on the manifolds with a wrench,

applying sealer to the threads

V. Connect the command micro tubes P1 & P2 to the

8 x ⅛” male elbows

P1

P2

Unbolt the upper

coupling and the one

below it (key n. 22)

Disconnect

1º

2º

Clean the

cartridge of the

punched steel

plate

C. Checking the Auxiliary Filter

Page 18

BACKFLUSHES ARE NOT MADE

ANY STATION MAKES

THE BACKFLUSH

ONE OR SOME STATIONS

DO NOT MAKE THE

BACKFLUSH

VERIFY THE MAINS SUPPLY OF THE

CONTROL UNIT AND THE FEEDING

FUSE*

CHECK OUTPUTS

FUSES*

CHECK SOLENOIDS

CHECK HYDRAULIC

VALVES

COMPLETE OR

PARTIAL REDUCTION

OF FEEDING IN THE

COMMAND

VERIFY THAT THE

FEEDING VALVE OF

THE INTAKE FILTER IS

OPENED

CLEAN THE FILTERING

ELEMENT OF THE

AUXILIARY FILTER.

NON-OPERATIVE

CONTROLLER

If the problem persists or you have

any doubt, contact your

distributor.

WATER IN THE DRAINAGE MANIFOLD

CONTROLLER

FILTRATION PROCESS

INSPECT EACH OF THE COMMAND MICROTUBES

WHICH FEED THE HYDRAULIC VALVES CHAMBERS

CHECK THE

CORRESPONDING

HYDRAULIC VALVE

CHECK THE

CORRESPONDING

SOLENOID

CHECK THE CONTROLLER

SITUATION

PRESENCE OF FLUID

THROUGH ANY OF THE

MICROTUBES WHICH

FEED THE VALVES

CHAMBERS

THERE IS NO FLOW OF FLUID

IN THE MICROTUBES WHICH

FEED THE VALVES

CHAMBERS

If the problem persists or you have any doubt, contact your distributor.

Water still remains in the drainage

CONTROLLER IN

BACKFLUSH PROCESS

Wait until backflushing cycle is

finished

18

10. POSSIBLE PROBLEMS AND SOLUTIONS

Page 19

CONTINUOUS OR TOO FREQUENT BACKFLUSHES

PRESSURE BELOW THE MINIMUM

REQUIRED. See section “Technical Data”

from the Filtration Equipment Manual

PRESSURE EQUAL OR ABOVE THE

MINIMUM REQUIRED. See section “Technical Data”

INCORRECT

PROGRAMMING

OF THE

CONTROLLER

ACTIVATE A

BACKFLUSH AND

CHECK THE PRESSURE

IN THE OUTLET

MANIFOLD

TOO SHORT TIME

BETWEEN

BACKFLUSHES. Rise

the value. See section

“Time between

backflushes phases”

from the Control Unit

Manual

INFLUENT

WATER QUALITY

LOWER THAN

THE ESTIMATED

RUNNING FLOW

HIGHRER THAN

DESIGN

TOO SHORT OF

BACKFLUSH

DURATION. Raise the

value. See section

“Backflushing time of

each station” from the.

PROBLEM

WITH THE

DIFFERENTIAL

PRESSURE

GAUGE

CHECK THE

REGULATED

VALUE IN THE

DIFFERENTIAL

PRESSURE

GAUGE. See

section “Differential

Pressure Gauge

Delay” from the

Control Unit Manual

CHECK

CONNECTIONS OF

THE DIFFERENTIAL

PRESSURE GAUGE

If the problem persists or you have any

doubt, contact your distributor.

DOES IT HAVE A

MASTER VALVE?

CHECK THE PUMP

SYSTEM WHEN

BACKFLUSHING

THE MASTER VALVE

DOES NOT WORK

PROPERLY Check the

components of the

sustaining valve

according to section

Maintenance

Instructions from the

Manual and the

regulation of the Relief

Pilot according to

section Operating

Instructions from the

Manual

CHECK THE

INSTALLATION

(POSSIBLE LEAKS)

INAPPROPRIATE

MEASURE OF THE

FEEDING PUMP

INLET FLOW

SUPERIOR TO THE

ONE ESTIMATED IN

DESIGN

YES

NO

YES

NO

19

Page 20

11. WARRANTY

Rain Bird Filtration Products Professional Customer Satisfaction Policy Terms and Conditions

Rain Bird guarantees that its Filtration Products will be free of manufacturer defects for one year from date of authorized start-up but not

beyond sixteen months from date of invoice.

Start-up or service by other than Rain Bird authorized personnel will void these terms and conditions.

Provided that all installation, start-up and operation responsibilities have been properly executed, Rain Bird will replace or repair, at Rain Bird’s

option, any part found to be defective under normal recommended use during this period. Repairs performed and parts used at Rain Bird’s

expense must be authorized by Rain Bird prior to repairs being performed. Upon request, Rain Bird shall provide advice on trouble-shooting a

defect during the effective period of this Customer Satisfaction Policy. However, no service, replacement or repair under this Customer

Satisfaction Policy will be rendered while the customer is in default of any payments due to Rain Bird.

Rain Bird will not accept responsibility for costs associated with the removal, replacement or repair of equipment in difficult-to-access locations.

Difficult-to-access locations include (but are not limited to) locations where any of the following are required:

1) Cranes larger than 15 tons

2) Divers

3) Barges

4) Helicopters

5) Dredging

6) Roof removal or other such construction/reconstruction requirements

7) Any other unusual means or requirements

Such extraordinary cost shall be the responsibility of the customer, regardless of the reason requiring removal of the equipment from service.

The terms and conditions of this Customer Satisfaction Policy do not cover damage, loss or injury caused by or resulting from the following:

1) Misapplication, abuse, or failure to conduct routine maintenance (to include winterization / winter lay-up procedures).

2) Pumping of liquids other than fresh water as defined by the U.S. Environmental Protection Agency, unless the Filtration Products

quoted by Rain Bird specifically lists these other liquids and their concentrations.

3) Use of pesticides (to include insecticides, fungicides and herbicides), free chlorine or other strong biocides.

4) Exposure to electrolysis, erosion or abrasion.

5) Use or presence of destructive gases or chemicals unless these materials and their concentrations are specified in the Rain Bird quotation.

6) Electrical supply voltages above or below those specified for correct Filtration Products operation.

7) Electrical phase loss or reversal.

8) Use of a power source other than that specified in the original quotation.

9) Non-WYE configured power supplies such as open delta, phase converters or other forms of unbalanced three phase power supplies (if

used).

10) Improper electrical grounding or exposure to incoming power lacking circuit breaker or fused protection.

11) Using the control panel as a service disconnect.

12) Lightning, earthquake, flood, windstorm or other Acts of Nature.

13) Failure of Filter packing seal (unless the failure occurs on initial start-up).

14) Any damage or loss to plants, equipment or groundwater or injury to people caused by the failure of or improper use of an injection system

or improper concentration of chemicals or plant nutrients introduced into the Filtration Products by an injection system.

15) Any failure of nutrient or chemical storage or spill containment equipment or facilities associated with the Filtration Products location.

The foregoing terms and conditions constitute Rain Bird’s entire Customer Satisfaction Policy. Rain Bird does not offer any other or additional

warranty, with respect to the pumping system or its components. Rain Bird makes no implied warranty, with respect to fitness for a particular

purpose or merchantability of the pumping system or its components. In the case of any components or injection systems manufactured by

others (as noted on the Filtration Products Quotation), there is no warranty provided by Rain Bird and these items are covered solely by and to

the extent of the warranty, if any, offered by the manufacturer. Rain Bird shall not be liable to the customer or any other person or entity for any

liability, loss or damage caused or alleged to be caused, directly or indirectly, by the Filter system or by any injection system. Rain Bird shall not

be responsible for incidental, consequential, collateral or indirect damages or loss of profit or damages related to the customer’s business

operations, nor for those caused by Acts of Nature. In no case and under no circumstances shall Rain Bird’s liability exceed the Rain Bird

Corporation’s net sale price of the Filter system.

Laws concerning customer warranties and disclaimers vary from state to state, and therefore some of the foregoing limitations may not apply to

you.

20

Page 21

Rain Bird Corporation

Tel. (520) 741-6100

Fax: (520) 741-6191

E-mail: Filters@Rain Bird.com

http:// www.RainBird.com

Request your spares to:

RAIN BIRD DISC FILTER ASSY-DISC Series User’s Manual – 2013/00

21

4.2. Identification of the product.

Loading...

Loading...