Page 1

Troubleshooting

Decoders

Rain Bird® Decoders

Decoders are a cost-effective alternative to traditional in-field controllers.

Installed underground and featuring simple, low-cost wiring, decoders are

an aesthetically pleasing and economical option for reliable, in-field control.

Installation requires up to 80 percent less wire than conventional controller

systems. Electronic components are completely encapsulated to protect

against the elements. And system expansion is easy: simply splice into the

communication line to add additional decoders.

Learn more about this simple, reliable technology and how to service it in

the following topics:

• General Information

• No Control Over Field Decoders

• Shorted Wire Path

• Suspected Broken Wire Path

• Suspected Ground Fault

1

Page 2

Troubleshooting

Decoders

General Information

Calculate expected “At Rest” current

draw on each wire path and each

LDI or SDI interface.

• FD-101 = 0.5 mA

• FD-102 = 0.5 mA

• FD-202 = 1.0 mA

• FD-401 = 1.0 mA

• FD-601 = 1.0 mA

Prior to troubleshooting when using

a clamp meter, make sure you know

the static current draw of the wire

path or sections of wire path you will

be troubleshooting. (1) To calculate

the static current draw at an individual

wire path section, add the number of

decoders that are downstream from the

test point, and multiply it by the current

draw of each decoder to determine

the total calculated current draw of

the wire section after the test point. (2)

To calculate the static current draw of

an entire wire path, add the number

of decoders on the entire wire path,

and multiply it by the current draw of

each decoder to determine the total

calculated current draw of the wire path.

(3) To calculate the static current draw of

an entire interface, add up all calculated

wire path current draws that are

connected to the interface.

Example:

BLUE WIRE

• 100 FD-101 x 0.5 mA = 50 mA

• 25 FD-202 x 1.0 mA = 25 mA

• 10 FD-401 and FD-601 = 10 mA

• Total Blue Wire current = 85 mA

RED WIRE

• 80 FD-102 x 0.5 mA = 40 mA

• 20 FD-202 x 1.0 mA = 20 mA

• 15 FD-401 and FD-601 = 15 mA

• Total Red Wire current = 75 mA

• Total Current for LDI or SDI = 85 +

75 = 160 mA

Tool List

• Spare Decoders

• Clamp Meter (current specifications are

available by calling 1-866-GSP-XPRT)

• Digital Multi-Meter

• Direct Bury Wire Splice Kits

• Maxi Wire Strippers

• Wire Strippers

• Linesman Pliers

• Extra Maxi Wire

• Updated “As-Built” drawing (“As Built”

should show wire path colors, decoder locations,

expected current draw per wire path and expected

current draw per LDI/SDI.)

NOTE: If the wire path has been looped,

you must break the loop in order to

properly troubleshoot current draw

using a clampmeter.

(see Locating A Bad Decoder on page 4).

2

Page 3

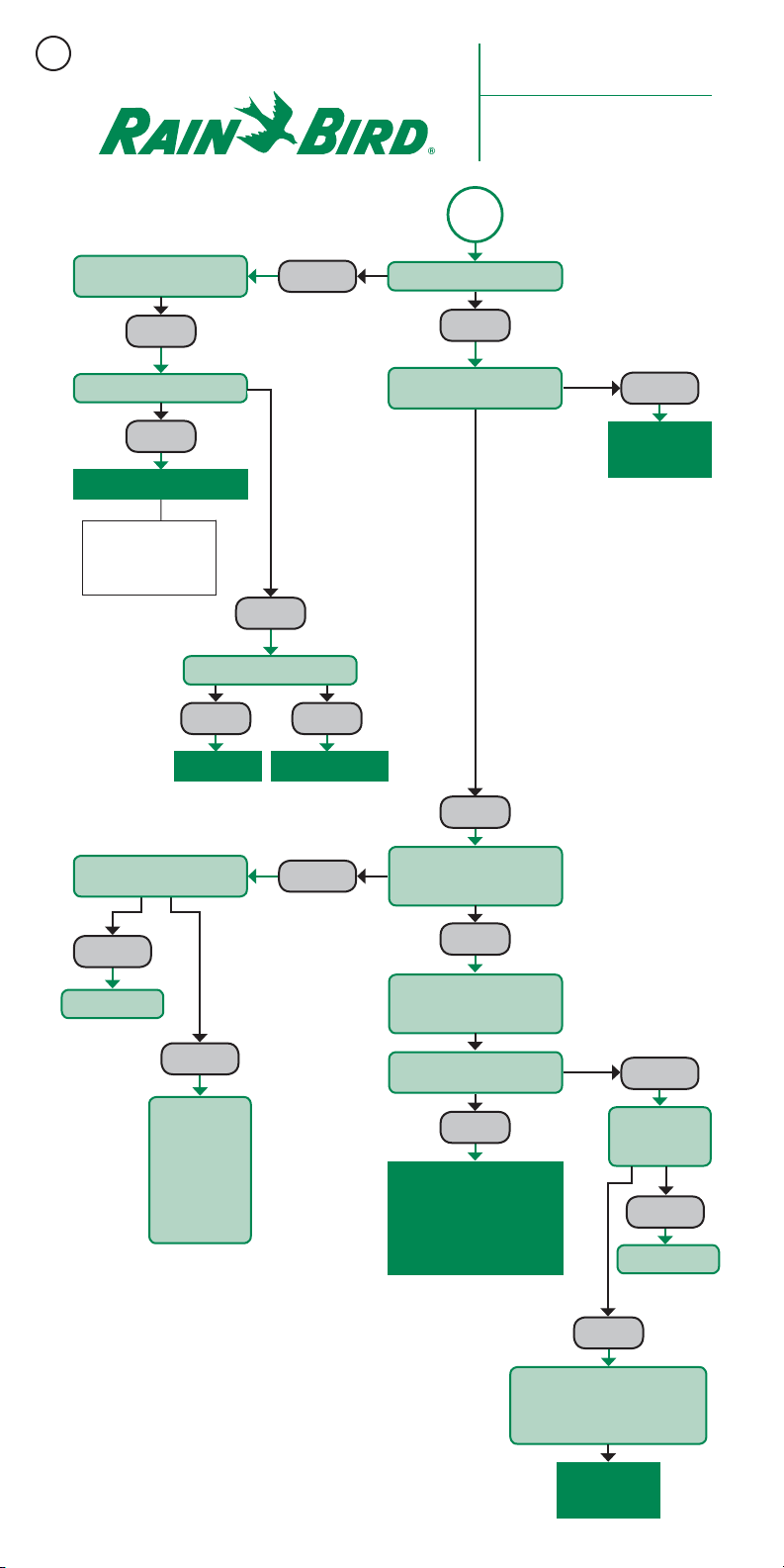

STAR T

Recommended Rain Bird®

Troubleshooting Procedure for

“No Control Over

Field Decoders”

Symptoms: No control over field

decoders and zeros in course log.

Check switch and incoming

power at 120VAC.

OKAY

Check incoming 24VAC.

OKAY

Replace LDI/SDI

If replacing transformer,

connec t 24VAC wires to

termin al screws be fore

plugging transformer in.

Replace Fu se Replace Transformer

OFF

BAD

Check Transformer Fuse

BLOWN GOOD

Verif y Power LED is on

OKAY

Confirm Sy stem Status is O K

in centr al control so ftware.

OKAY

BAD

Troublesh oot as

Necessary

Turn off wire p ath

slide sw itch and cyc le power.

SOLID LED

Replace L DI or SDI

Turn on one fie ld

wire pat h at a

time to fin d wire

path wit h short

condition. LED

will be so lid when

short ed wire path

OKAY

is activated.

SOLID LED

Check fie ld LED for

alternating GREEN/RED colors

every 0.5 seconds.

OKAY

Start 50/6 0Hz test in Dec oder

Diagnostic section of central

control software.

Verif y output volt age on each

wire pat h is 33± VAC.

OKAY

Run ON/OFF Test in D ecoder

Diagnostic Section of

Central Co ntrol Soft ware

and Proce ed to Field

Troubleshooting

expec ted and act ual “at rest ” current

draw in De coder Diagn ostic sec tion of

LOW

Disconnect

field wires and

recheck voltage.

LOW

Replace LDI/SDI

OKAY

Reconn ect field wir e. Compare

central control software.

Procee d to Field

Troubleshooting

3

Page 4

Troubleshooting

VOLT METER

Decoders

INSTALLATION DETAILS LARGE AND SMALL DECODER INTERFACE

Use one or t wo screws at t he top and one at t he

bottom, depending on support.

CAU TION

Mains- and s ystem-groun d are

not internally connected and must

be separa ted to provide the be st

protection against surges.

On when po wer is on. LED is co ntrolled by

proces sor. Will not tu rn on if no firmw are is

downlo aded. Blink s when there i s an error

condition (see below).

ON OFF

24V-AC MAINS

@2A GND

SENS-1

SENS-2

EARTH

POWER/ERROR

PC -> DATA

DATA->PC

LINE

1A-1B 2A-2B 3A-3B4A-4B

OFF

ON

PC-COM

Normal ly off. Blinks wh en data is received from PC.

Normal ly off. Blinks wh en data is sent to PC.

Line ind icator, toggl es betwee n red and green w ith

line volt age polari ty.

Switche s for discon nection o f line with pro blem.

Field wi res. Up to four t wo-wire p aths may be

connected.

Serial c able, 9 PIN-9 PI N for PC commun ication.

Connec t to 24 VAC

transformer

To System Gro und

SENSOR 1 (e.g. R ain Sensor)

SENSOR 2 (No t Shown) (e.g. Alarm S ensor)

During p ower up, the LED ’s will blink in se quence endi ng with POWER L ED on for 5 secon ds.

If the POWE R LED blinks, i t means that an err or is d etected b y the unit. The r eason for th e error is ind icated by the o ther LED’s:

• If D ATA-> PC is ON = line volt age has been s witched off b ecause con nection t o the PC is lost .

• If LINE is ON = lin e voltage is be low 25 V (shor t).

LOCATING A BAD DECODER USING A CLAMP METER

• In the D ecoder Dia gnostic s screen sel ect 60Hz te st mode to all ow the clamp me ter to measure c urrent. Wh en done with

troubl eshootin g remember to c ancel the 60 Hz test mode to r esume irr igation.

CAM

HIGHER THAN

CALCULATED

VALUE

33v±

CLAMP METER

0.5±

HIGHER THAN

0.5±

1.0±

CALCULATED VALUE

HIGHER THAN

CALCULATED VALUE

BAD

DECODER

HIGHER THAN

CALCULATED VALUE

LESS THAN CALCULATED VALUE

HIGHER THAN

CALCULATED VALUE

LESS THAN

33 VOLTS ± WHEN IN 60Hz TEST MODE

CALCULATED VALUE

4

Page 5

STAR T

Recommended Rain Bird®

Troubleshooting Procedure for

“Shorted Wire Path”

Symptoms: No Decoder

Operation on Wire Path or LDI.

Field LED may be solid or faint.

Go To Troubleshooting Card:

“No Contro l Over

Field Decoders”

Replace MSP-1

DOWNS TREAM

LESS THAN

UPSTREAM

Use clam pmeter to che ck RED

and BLACK w ires on upst ream

or “EQUIP ” end of MSP-1.

UPSTREAM

EQUAL TO

DOWNSTREAM

Break c ritical pat h wire loop

(if present). Choose point

half way out on wire p ath.

Using cl amp meter, chec k RED

and BLACK wires individually.

Compar e each value to

expected current draw.

HIGH

Choose point halfway

between measurement point

and end of w ire path.

NOT NORMAL

HIGH “AT REST ”

CURRE NT DRAW

MEASURED

LOW/ZERO

Turn off all LDI fi eld wire pat h

slide sw itches and co nfirm

normal LDI operation.

OKAY

Open Decoder Diagnostics

window i n central

control software.

Turn on wir e path slide sw itches

one at a tim e. Monitor cur rent to

verif y it reaches e xpected

“at rest ” draw for wir e path.

Choose point halfway back

to centr al control an d

measure current draw.

Repeat to n arrow down

locati on of wire pat h short.

SHORT

FOUND

Confirm b y using

clampm eter on singl e BLUE

communication wire.

CONFIRMED

OKAY

Turn Off Field W ire Path

Slide Switch — Repeat

for Each Additional

Wire Path

Short c ould be caus ed

by conta ct betwee n

RED and BL ACK

conductors or internal

to a decod er or LSP-1.

Single Address

Decoder = 0.5mA

Multi-Address

Decode r = 1.0 mA

LSP-1 = 0.0 mA

Run ON/OFF Test in D ecoder

Diagno stics to Validate

System Operation

NOT EQUAL

Repair or replace components

as necessary.

COMPLETE

Compar e “at rest” cu rrent to

expected “at rest” current.

EQUAL

No Further Action

5

Page 6

STAR T

Recommended Rain Bird®

Troubleshooting Procedure for

“Suspected Broken

Wire Path”

Symptoms: Zeros in course log.

No response on parts of wire path

or partial connection (Bad Splice).

Compar e stations a nd areas that

pass wit h stations a nd areas that

do not pas s ON/OFF test.

LOW

Good “As Buil t”

Open Decoder Diagnostics

in centr al control so ftware.

Compar e actual “at re st” curr ent

draw to ex pected cu rrent draw.

LOW

No “As Built ”

Turn off all LDI fi eld output w ire

path slide switches.

Turn on firs t wire path. Co mpare

expec ted actua l “at rest” cu rrent

draw to ex pected cu rrent draw

in Decoder Diagnostic window in

central control software.

LOW

Run ON/OFF t est in Decode r

Diagnostic window of central

contro l softwa re to locate

last passing decoder and first

failing decoder.

GO TO FIEL D

Activate 50/60Hz mode.

Use clam pmeter to find

broken wire.

NORMAL

Problem Unlikely a

Broken Wi re Path

NORMAL

Repeat for each

wire path

NORMAL

Problem Unlikely a

Broken Wi re Path

CURRENT = 0

Break is b etween

centra l control and

measurement point.

Break c ritical pat h wire loop (if

present). Choose point halfway out

on wire p ath. Using cla mpmeter,

check RE D and BLACK wire s

individually. Compare each value

to expe cted curr ent draw.

Repeat to determine exact

locati on of broken w ire or parti al

connection (Bad Splice).

LOW

Break is b etween

measurement point

and end of w ire path.

6

Page 7

Severity of Ground Fault

can var y based on so il

moisture content.

“Suspected Ground Fault”

STAR T

Visual ly check Fiel d LED on

LDI/SDI fo r clean alter ation

from RED t o GREEN at

0.5 second intervals.

NOT CLEAN

Recommended Rain Bird®

Troubleshooting Procedure for

(Leakage to Ground)

Symptoms: Lower run times or zeros

in the course log. Fluctuating current

reported in Decoder Diagnostics. No

clean alternating color in

Field LED on LDI/SDI.

Replace LDI

NOT CLEAN

Turn off LDI wi re path slide

switch es. Cycle LDI Power Sw itch

from OFF t o ON.

CLEAN

Turn on each w ire path one at a

time. Af ter 10 seconds, v erify no

“Flicke r” on Field LED.

FLICKER

If visib le on Field LED, ope n

Decoder Diagnostics window in

central control software.

Verif y “at rest” cu rrent draw.

HIGH

Activate 50/60Hz mode test.

Using a cl ampmeter, at the

downstream (field) side of the

MSP-1, compare the m A draw

of RED and BL ACK wires.

If Wire Path i s

Activated, Consider

Possibility of Ground

Fault on Path

Normal s ystems sho uld

expec t “at rest” c urrent

draw to fluc tuate

betwe en 2 mA – 5 mA.

Choose point halfway

between measurement point

and central control. Retest.

Repeat t his method to n arrow

down loc ation of dama ged

insula tion and leak age to

ground. Repair as necessary.

When rep airs are com plete,

verif y “at rest” cu rrent draw

matches expected current draw.

Run ON/OFF t est to validat e

system operation.

DRAW CL OSE

TO ZERO

VALIDATED

The wire w ith the highe r

draw will have leakage.

At LDI, disc onnect wi re with lower

draw and c hoose point h alfway

to end of wi re path. Meas ure

draw in co nnected (ac tive) wire.

Disconnect any critical path loops

before testing.

DRAW GREATER

THAN ZERO

Choose point halfway

between measurement point

and end of w ire path. Rete st.

No Further Action.

7

Page 8

The Intelligent Use of Water.

Leadership • education • partnerships • produc ts

™

At Rain Bird, we believe it is our

responsibility to develop products and

technologies that use water efficiently.

Our commitment also extends to

education, training and services for our

industry and our communities.

The need to conserve water has never

been greater. We want to do even

more, and with your help, we can. Visit

www.rainbird.com for more information

about The Intelligent Use of Water.

™

Rain Bird Corporation

6991 East Southpoint Road

Tucson, AZ 85756, U.S.A.

Phone: (800) 984-2255; (520) 741-6100

Fax: (520) 741-6522

Email: rbgolf@rainbird.com

Technical Service and Support

(800) RAINBIRD (U.S. and Canada only)

The Intel ligent Use of Water™ — Vis it www.rainbi rd.com to learn abo ut our efforts .

Registered trademark of Rain Bird Corporation

®

© 2012 Rain Bird Corpo ration 2/12

Rain Bird International, Inc.

1000 West Sierra Madre Ave

Azusa, CA 91702 U.S.A.

Phone: (626) 963-9311

Fax: (626) 852-7343

www.rainbird.com

8

D3745 6

Loading...

Loading...