Page 1

ESP-SMT Smart Modular Control System

Installation & Operation Guide

Page 2

Safety Information

WARNING:

A CIRCUIT BREAKER OR CUTOFF SWITCH IS TO BE PROVIDED IN THE FIXED WIRING TO ISOLATE THE

CONTROLLER. THE CURRENT DATE AND TIME ON THE CONTROLLER IS RETAINED BY A LONG-LIFE LITHIUM

BATTERY, WHICH MUST BE DISPOSED OF IN ACCORDANCE WITH LOCAL REGULATIONS.

LIGHTNING FLASH SYMBOL is intended to

alert the user to the presence of un-insulated

F

“dangerous voltage” within the product’s

enclosure that may be of sucient magnitude to

constitute a risk of electronic shock to persons.

For technical assistance contact Rain Bird at 1-800-247-3782

IMPORTANT

This Installation and Operation Guide supports ESP-SMT control

panels with a date code later than March 31, 2011.

EXCLAMATION POINT SYMBOL is intended

to alert the user to important operating or

!

maintenance (servicing) instructions in the

literature accompanying the product.

Page 3

Contents

Introduction ..........................................................1

Welcome to Rain Bird ....................................................1

The Intelligent Use of Water .................................................1

ESP-SMT Smart Modular Control System ..................1

Features and Benefits ............................................................ 2

Controls, Switches and Indicators .........................5

Controller Panel Features .............................................5

Weather Sensor Features .............................................6

Set Current Date & Time ........................................7

Set Month ................................................................................. 7

Set Day of Month .................................................................... 7

Set Year ...................................................................................... 7

Set Hour ....................................................................................7

Set Minutes .............................................................................. 8

Review Current Date & Time ................................................ 8

Configure Controller .............................................9

Method 1: Select Location by Zip Code .....................9

Method 2: Enter Custom Data for Location ........... 11

Enter Allowed Water Days ......................................... 13

No Restrictions ......................................................................13

By Days of the Week .............................................................13

By Even Days of the Month ................................................14

By Odd Days of the Month .................................................14

Cyclical .....................................................................................15

Block One Day A Week .........................................................15

Set Allowed Watering Windows ............................... 16

Input Zone Information

Method 1: Zone Setup Wizard .................................. 19

Select Specific Zone Number .............................................19

Turn Zone to ENABLE status ...............................................19

Enter Soil Type .......................................................................20

Select Sprinkler Type Method ............................................21

Select Time-Based Method ................................................24

Cycle/Soak ..............................................................................25

Select Plant Type Method - Grass Lawns ........................26

Select Plant Type Method - Non-Grass Lawns ............... 27

Select Plant Water Needs - (Non-Grass Plant Types) .... 27

Custom Plant Factor Method ............................................. 28

Enter Plant Density ...............................................................28

Enter Shade Factor ...............................................................29

Enter Plant Maturity - (Established Method) .................29

Enter Plant Maturity - (Newly Planted Method) ............29

Review Zone Information .................................................. 30

Method 2: Copy Zone to Zone(s) .............................32

Special Features ..................................................34

Event Days Off .......................................................................34

Short Circuit Test ...................................................................35

Advanced Controller Setup ................................................36

Advanced Zone Setup .........................................................37

Save Settings to “Contractor Default” Program ............. 38

Set Units .................................................................................. 39

Fine Tune Watering By Zone ................................40

.......................................19

ESP-SMT Smart Modular Control System

-III-

Page 4

System Review.....................................................42

Controller Settings Review

Zone Settings Review ..........................................................43

Next Irrigation Estimate Review .......................................43

Weather Data Review ..........................................................44

Weather Log Review ............................................................45

Event Log Review..................................................................45

Restore Settings ..................................................48

Restore “Contractor Default” Program Settings ...........48

Restore “Factory Default” Program Settings ..................49

Manual Watering .................................................50

Manually Water Selected Zones ........................................50

Manually Water All Active Zones (Test Program) ..........52

Off Position or Adjust Display

Contrast Function ................................................53

Auto Position or Suspend Watering Function .....54

Installation ..........................................................56

Installing The Controller ............................................ 56

Select Location ...................................................................... 56

Installation Tools Required .................................................57

Mounting the Controller ...........................................58

Connect Field Wiring .................................................. 60

Station Valve Wiring .............................................................60

Master Valve / Pump Start Relay .......................................60

Jumper Setting for Unused Stations ................................61

Connect Sensor Communication Wire To

Controller Panel.....................................................................61

.................................................42

Connect Transformer ................................................. 62

Remote Panel Programming .................................... 65

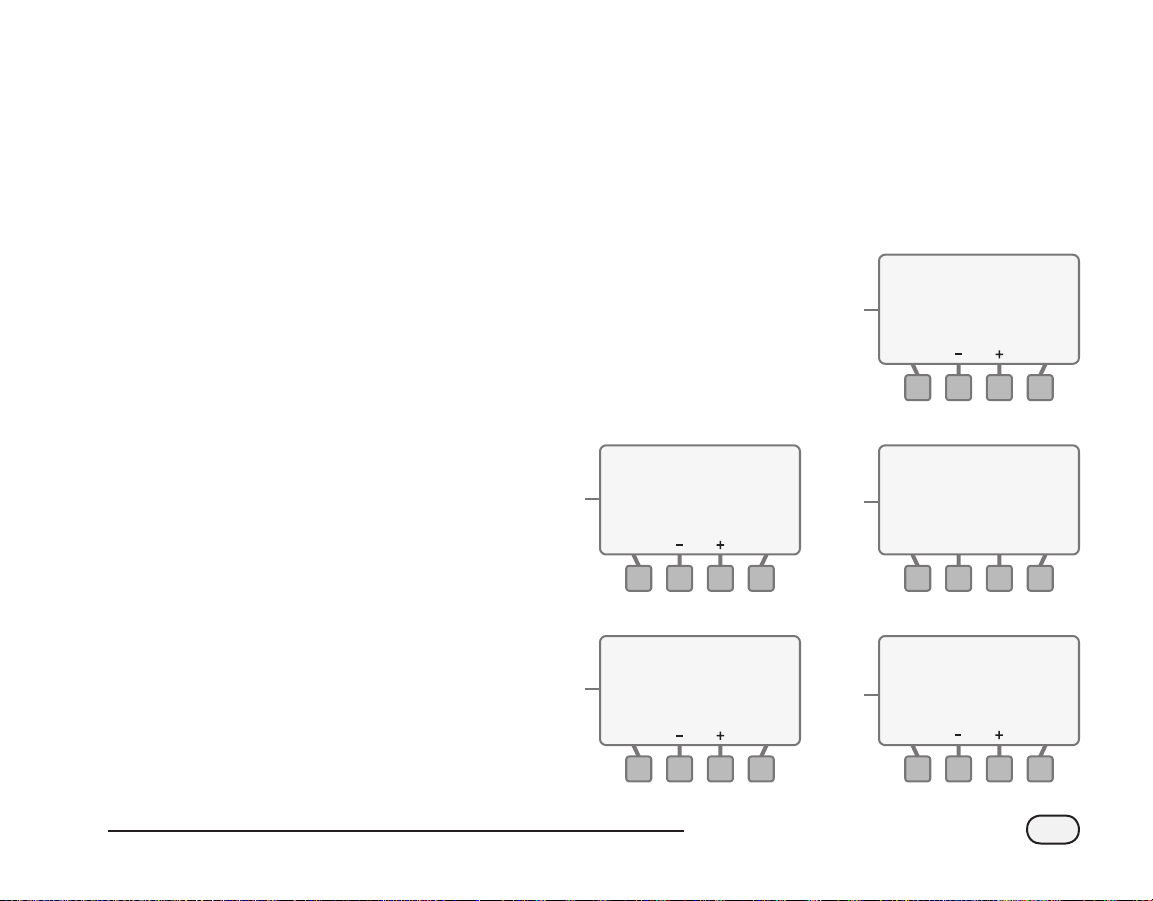

Installing Station Expansion Modules .................... 66

Installing ESP-SMT Upgrade Panel .......................... 67

Installing The Weather Sensor .................................. 68

Locating the SMT Weather Sensor ...................................68

Sensor Installation Procedure ...........................................68

Trouble-shooting ................................................70

Appendix .............................................................73

Irrigation System Overview ...................................... 73

Basic Valve (Zone) Operation .............................................73

Description Of Each Soil Type................................... 74

Simple Test To Determine The Soil Type ..........................75

Soil Classification Triangle ..................................................76

How the ESP-SMT Smart Control System Works ... 77

Evapotranspiration ...............................................................77

Effective Rainfall....................................................................78

Plant Available Water ........................................................... 78

Management Allowed Depletion (MAD) .......................79

“Checkbook” Method of Irrigation ...................................79

Replenish Accumulated Water Requirement (AWR) ....79

Applying the “Cycle and Soak” Principle .........................80

Determine Zone Application Rate ........................... 81

Sprinkler Type Default Method (least accurate) ............ 81

Total Area Covered Method to Determine Precipitation

Rate and Efficiency (moderate accuracy) .......................82

Zone System Audit Method (most accurate) ................83

ESP-SMT Smart Modular Control System

-IV-

Page 5

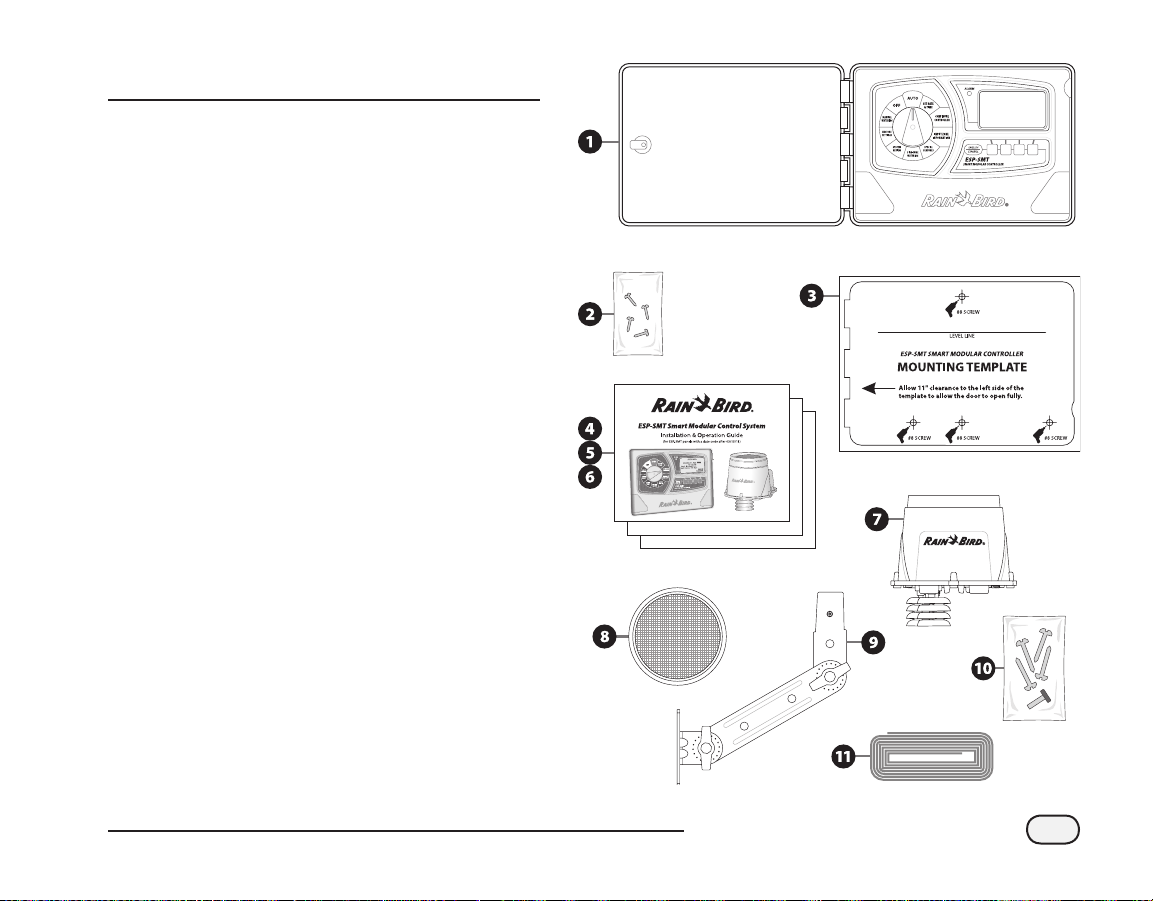

Check Box Contents

ESP-SMT System

It is recommended that you familiarize yourself with

the various items below, prior to beginning the

installation process.

Box Contents

ESP-SMT Modular Controller (1 of 3 models below)

A

a. ESP-SMT4 (outdoor controller with key-lock)

b. ESP-SMT4i (indoor controller)

c. ESP-SMT-UPG (upgrade panel for previously installed

ESP-M controller)

Controller Mounting Hardware (Four #8 screws)

B

Other hardware may be required depending on the

mounting surface and materials)

Mounting Template (controller models only)

C

ESP-SMT Installation & Operation Guide

D

ESP-SMT Site Prole Chart

E

ESP-SMT Installation & Quick Setup Poster

F

SMT Weather Sensor

G

Weather Sensor Debris Screen

H

Weather Sensor Mounting Bracket

I

Mounting Bracket Hardware (Four Phillips head screws +

J

nger screw for mounting sensor to mounting bracket)

Sensor Wire - 25 feet of 20-2 UV rated wire (not

K

rated for direct burial)

ESP-SMT Smart Modular Control System

P/N:637654-01

-V-

Page 6

Introduction

Welcome to Rain Bird

The Intelligent Use of Water

At Rain Bird, we believe it is our responsibility to develop

products and technologies that use water eciently. Our

commitment also extends to education, training and

services for our industry and our communities.

The need to conserve water has never been greater. We want

to do even more and with your help we can.

Visit www.rainbird.com for more information about The

Intelligent Use of Water.

ESP-SMT Smart Modular Control System

Thank you for selecting the new state-of–the-art Rain

Bird ESP-SMT “Smart” Modular Control System. For more

than seven decades, Rain Bird has led the irrigation

industry in meeting professional water management

needs by providing the highest quality water ecient

products and services available. The new Rain Bird smart

control system is designed to keep your landscape

healthy and vibrant by providing you unparalleled

automatic on-site

The Rain Bird ESP-SMT “Smart” Modular Control System

can operate up to 13 dierent zones. The system

consists of a controller and an on-site weather sensor

that communicates weather data on a regular basis back

to the controller. As weather conditions change, the

watering control.

AUTO

OFF

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL

irrigation schedule adjusts accordingly. Studies have

indicated that most traditional “time-based” controllers

are only adjusted on average 2 to 3 times per year. The

lack of appropriate irrigation schedule adjustments

generally result in signicant over-watering.

The Rain Bird ESP-SMT controller automatically adjusts

each zone’s irrigation schedule on a daily basis based on

the actual site weather conditions. When the ESP-SMT

is programmed properly, you will maintain a vibrant,

healthy landscape while consuming 30% to 50% less

water than a traditional time-based control system.

Once the site and zone parameters are set-up in the

controller, the optimal irrigation schedule is developed

automatically for your convenience.

ESP-SMT Smart Modular Control System

1

Page 7

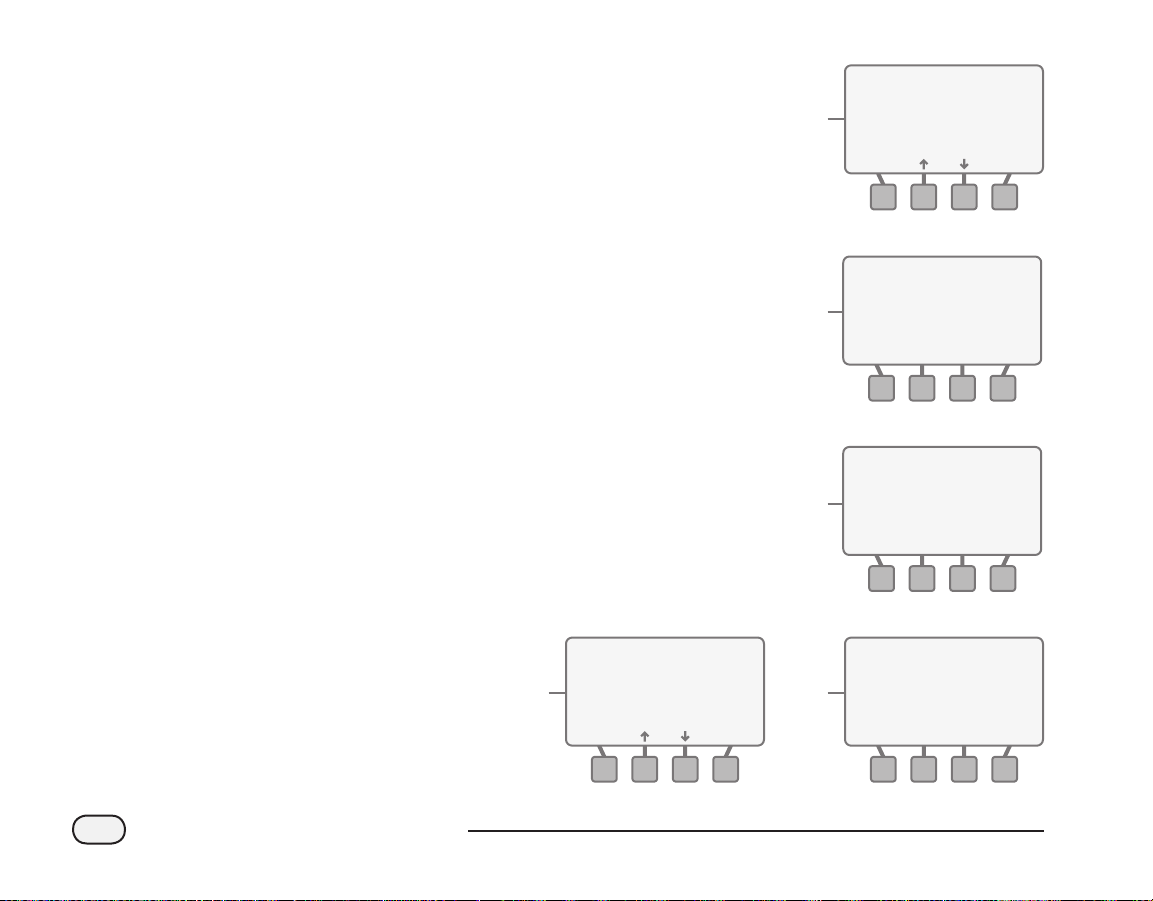

There are three ESP-SMT models:

• 4 Station Indoor Controller (ESP-SMT4i)

• 4 Station Outdoor Controller (ESP-SMT4)

• Upgrade Kit for ESP-Modular (ESP-SMT-UPG)

Each control system can be expanded to operate up to 13

zones by using 3 zone expansion modules (ESPSM3).

Features and Benefits

The ESP-SMT Controller automatically optimizes the daily

irrigation schedule based on weather data collected by

the on-site weather sensor. In addition to this time and

water saving feature, the control system has other unique

features that provide easy installation, set-up, operation

and exibility to customize the unit to your particular site

conditions.

Large Backlit Dot Matrix Display

Up to 8 lines of text are displayed at once with menu

options to help prompt you in making your selections.

The adjustable backlit display dramatically improves the

readability of the display in dimly lit areas.

Programmable with 9 Volt Battery

The backlit display will illuminate under battery power

allowing for remote programming. All pre-programmed

information is saved in non-volatile memory for retrieval

at a future date.

English/Spanish Button

A simple push of the language button will toggle the

display text to read in either English or Spanish.

Color Coded Dial Positions

Ten color coded dial positions enable the user to easily

perform the initial controller set-up and subsequent

operation of the control system.

Alarm Light

Red LED on the front panel illuminates to warn you of

any issues that require immediate attention.

Meet Water Restrictions

Set user-dened watering days and watering times to

meet local water restrictions.

Block Day a Week

Permanently blocks a specic day of the week

independent of the assigned days to irrigate. This is

especially useful if you want to prevent irrigation on a

specic day.

Zone Set-Up Wizard

An automatic data entry system walks the user through

the process of entering all of the required zone set-up

information for each zone.

Grow-In Period

The controller allows the user to set a “grow-in” irrigation

schedule per zone with a user set time period before the

controller automatically converts the irrigation schedule

to the weather based method.

Default Values

Each selection has a common industry standard default

value assigned to assist novice users in setting up the

controller.

ESP-SMT Smart Modular Control System

2

Page 8

Custom Values

For more advanced users, the controller will allow the

user to overwrite the default values with a user selected

value further optimizing the irrigation schedule to

match specic site conditions.

Event Days Off

Allows you to select up to four specic dates in which

you want to block irrigation from occurring. This can be

useful if you have planned an event that will take place

in the yard on specic dates.

Short Circuit Test

Enable you to perform a electronic diagnostic test to

determine on a zone by zone basis if there is a “Short”

circuit or if the circuit is “Good”.

Cold Weather Shutdown

All irrigation will be suspended to prevent potential

freeze damage to the irrigation components if the

measured temperature is below a user set level.

Rainfall Shutdown

Irrigation will be suspended if the measured rainfall

exceeds a user set threshold.

Individual Zone Shutdown

Each individual zone can be either set in an “active” or

“inactive” mode. This is ideal if repairs are necessary on

a zone and you want to continue irrigating the other

zones on the system.

System Review

Allows the user to look at a log of irrigation and alarm

events by date or by zone. Additionally, the user can

view the next estimated scheduled irrigation cycle by

zone and review the current and past weather data.

Suspend Irrigation

Allows the user to suspend irrigation for a period of

time (1 minute to 14 days), at which time the system will

return to the AUTO mode.

Save & Restore Settings

Save your current program in memory, so that if the

program gets changed inadvertently, you can easily

retrieve the previously saved program.

Manually Water Combination of Zones

User can set a zone or any combination of zones to run

manually, each with it’s own run time prior to returning

to the AUTO mode.

Manually Water all Zones (TEST)

All zones that are present in the available modules can

be set to run for the same period of time sequentially.

This is a time-saver in performing a system walkthrough

and/or when winterizing a system.

Fine Tune by Zone

Each zone’s calculated run-time can easily be adjusted

from an increase of up to 30% to a decrease of 30%

without changing any of the other pre-set programming

information that was entered in the initial controller and

zone set-up.

ESP-SMT Smart Modular Control System

3

Page 9

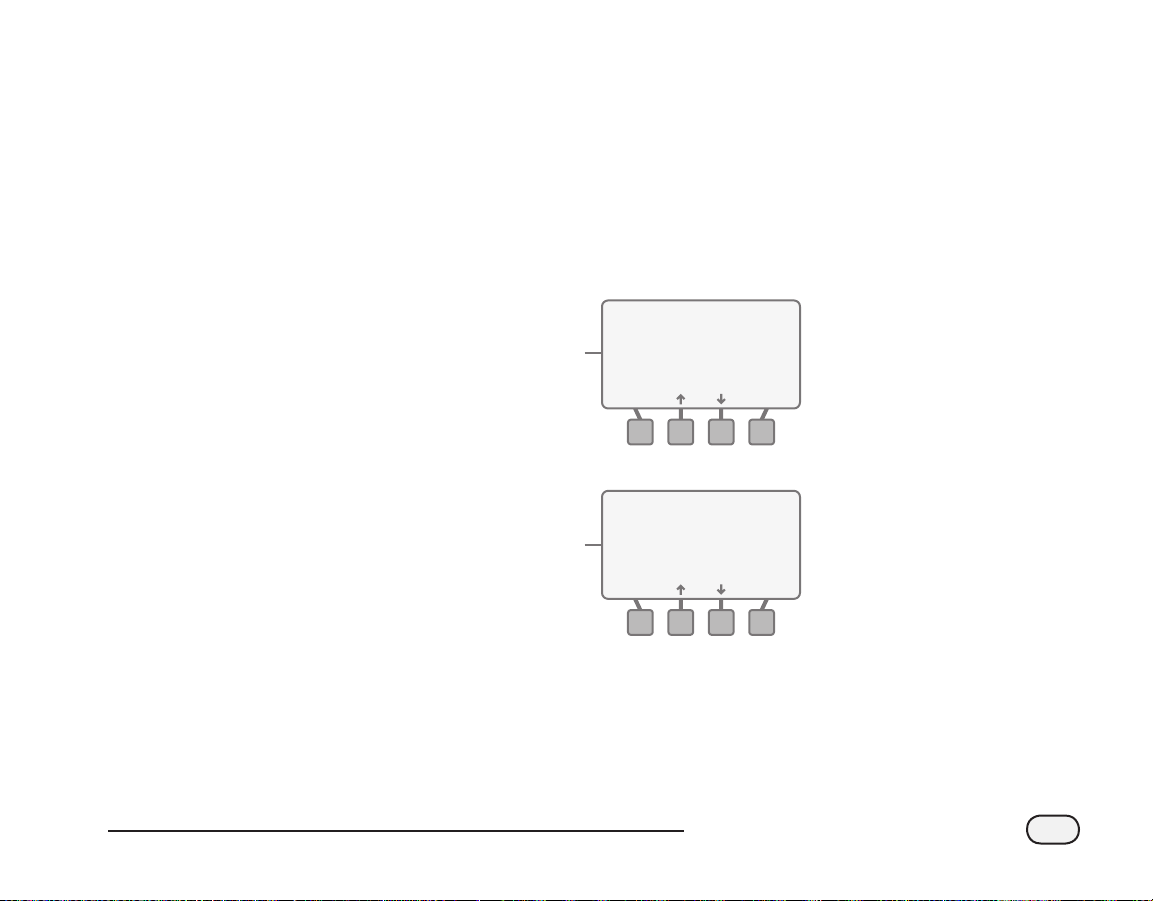

Hot Swap-able Station Expansion Modules

Easily expand the zone capability by inserting up to

three, 3 station expansion modules for a maximum of 13

stations. This can be done while the unit is connected

to AC power.

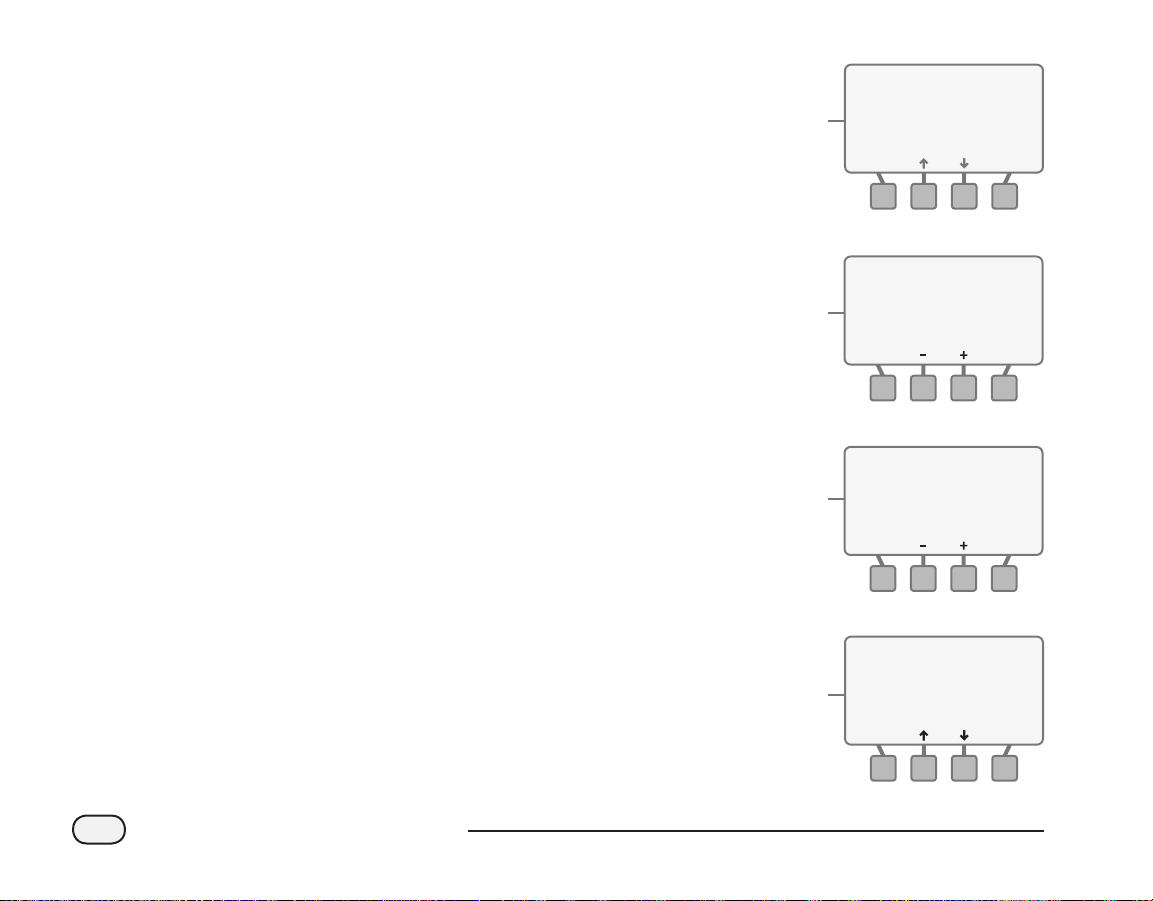

Tool-less Communication Wire Terminal

No tools are required to connect the pair of

communication wires to the controller or the sensor.

There is no polarity required on either the controller or

the sensor connection to provide communication.

LED Light to Validate Sensor Communication

A green LED located in the Sensor communication wire

compartment will blink when power is applied and

continuously illuminate when there is communication

between the controller and the sensor. This prevents

the need of going back to the controller to verify

communication during installation.

Adjustable Sensor Mounting Bracket

Mounting Bracket Arms can be adjusted in ne

increments to assist that the sensor pod is mounted

level in virtually any installation scenario. The arms have

a wire routing mechanism that provides a “strain relief”.

Rain Gauge

The rain gauge not only acts as a rain shut-o device,

it also provides rainfall intensity and accumulation

information to the controller in order to prevent overirrigation by accounting for “eective” rainfall.

Removable Debris Screen

Prevents leaves and other large debris from getting into

the tipping bucket mechanism and preventing accurate

rainfall measurement. It can be easily removed to clean

debris o the screen surface.

Removable “Tipping” Rain Bucket”

The Tipping Rain Bucket can be easily removed from the

sensor housing to clean out debris that may have made

it past the debris screen into the mechanism.

ESP-SMT Smart Modular Control System

4

Page 10

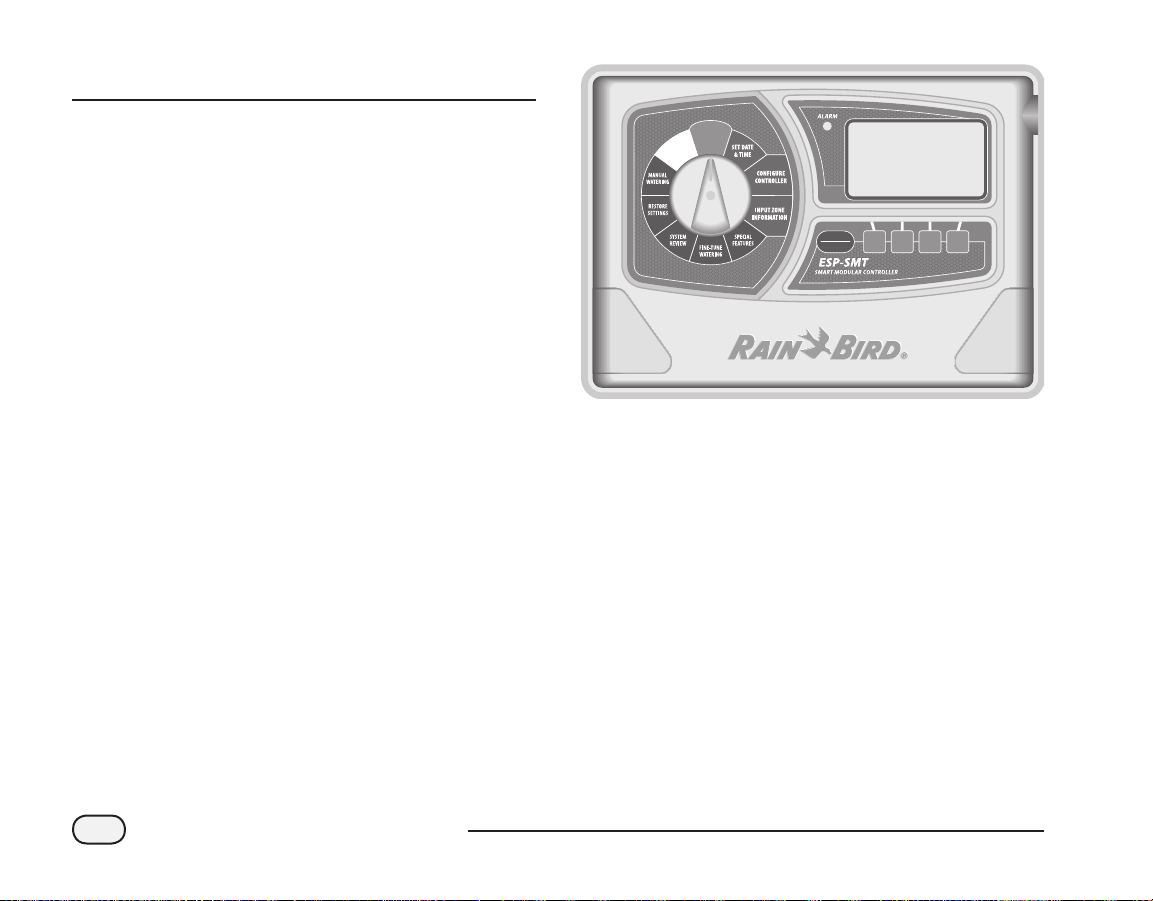

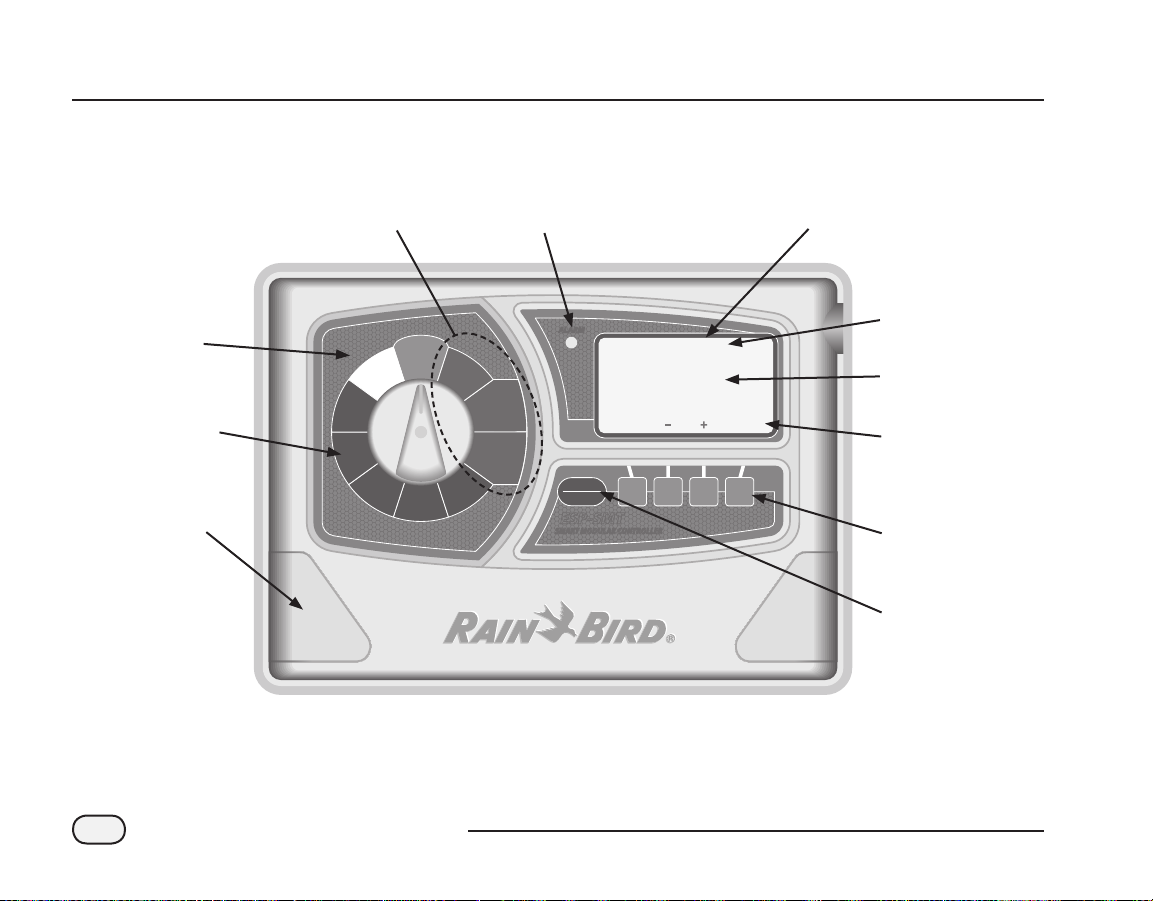

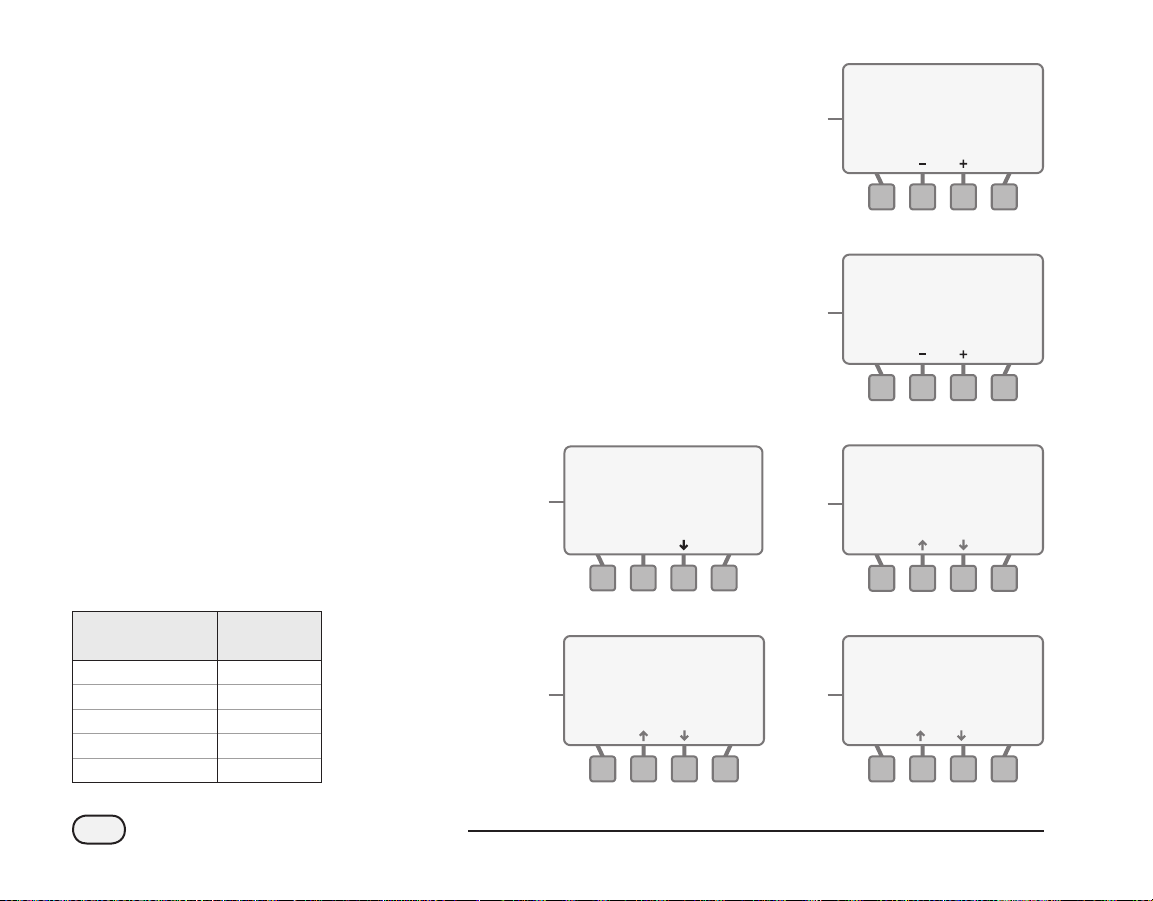

Controls, Switches and Indicators

Controller Panel Features

COLOR-CODED DIAL

POSITIONS FOR

“EASE OF USE”

“CONTRACTOR DEFAULT”

PROGRAM RESTORE

(2) GRIP AREAS

TO ASSIST

INITIAL CONTROLLER

& ZONE SET-UP DIAL

POSITIONS (LIGHT BLUE)

AUTO

OFF

MANUAL

WATERING

RESTORE

SETTINGS

SYSTEM

REVIEW

FINE-TUNE

WATERING

ALARM LIGHT ILLUMINATES

WHEN CONDITIONS PREVENT

IRRIGATION

ALARM

SET DATE

& TIME

CONFIGURE

SPECIAL

FEATURES

CONTROLLER

INPUT ZONE

INFORMATION

BACK NEXT

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL

ESP-SMT

SMART MODULAR CONTROLLER

SET CURRENT

DATE AND TIME

24 M ar 2009

10:16 AM

LARGE BACK-LIT

DOT-MATRIX

DISPLAY

DURING REMOTE

PROGRAMMING

REMOTELY

PROGRAMMABLE

USING 9V BATTERY

The ESP-SMT Smart Modular controller panel is designed to upgrade previously installed ESP-Modular controllers (ESP-SMT-UPG Kit).

SCREEN TITLE

SCREEN TEXT

FUNCTION LABELS

FOR SET-UP &

NAVIGATION

NAVIGATION

BUTTONS WITH

ACCELERATOR

ENGLISH/SPANISH

BUTTON FOR

EASY SWITCHING

OF DISPLAY

LANGUAGE

ESP-SMT Smart Modular Control System

5

Page 11

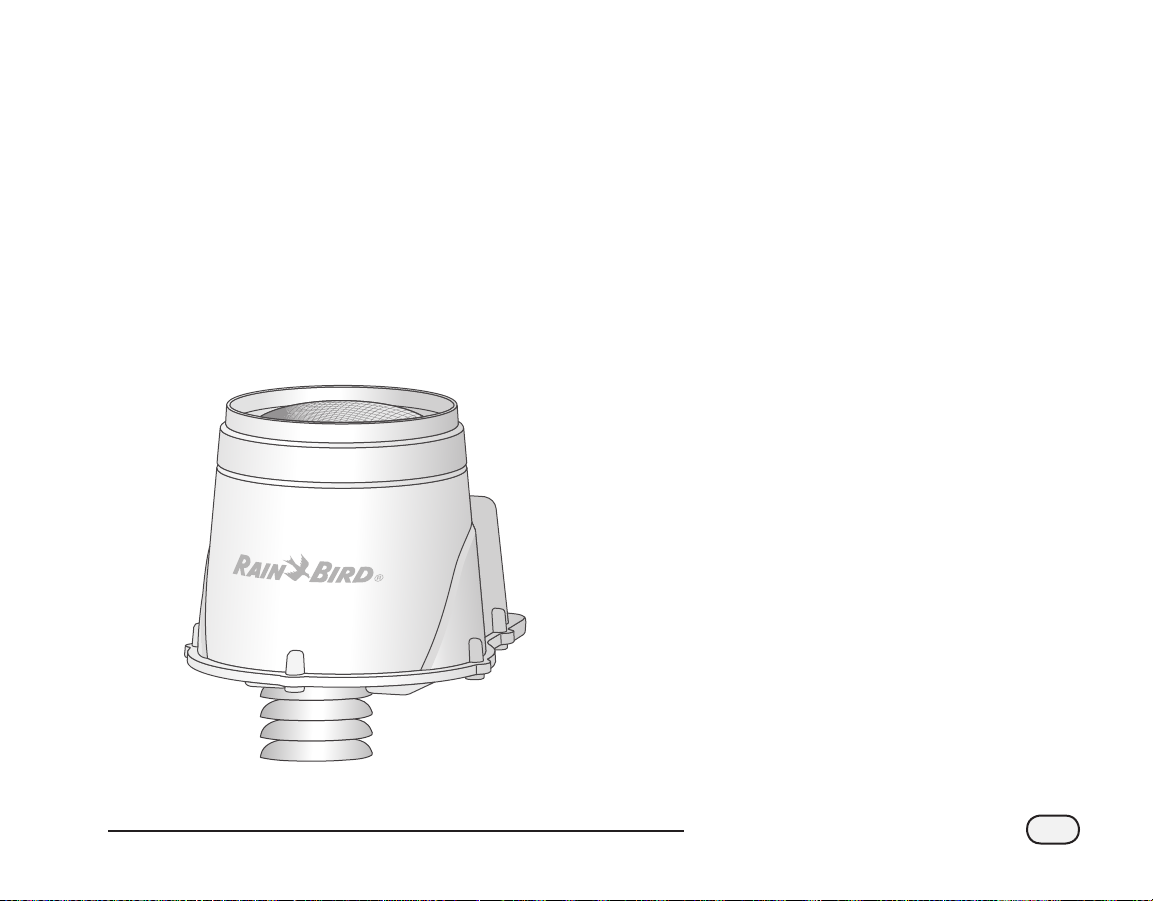

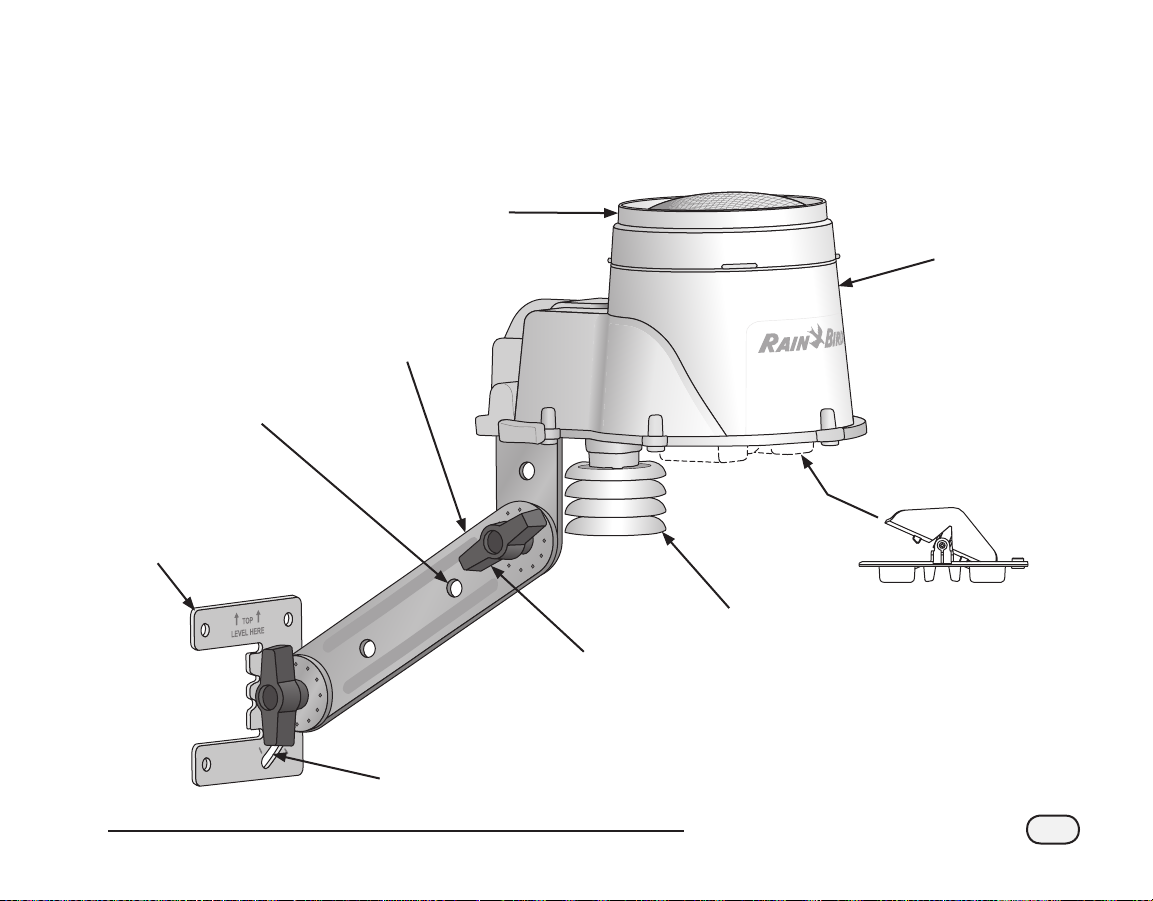

Weather Sensor Features

The durable Weather Sensor provides high and low temperature and rainfall data to the ESP-SMT Controller for daily

irrigation schedule adjustments.

REMOVABLE

DEBRIS SCREEN

SENSOR

HOUSING

ADJUSTABLE

MOUNTING

BRACKET

HOLES IN BRACKET

ARMS (3) TO

ROUTE WIRING

AND PROVIDE

“STRAIN RELIEF”

MOUNTING

BASE

SLOT FOR EASY

LEVELING OF

UNIT

WING NUTS (2)

FOR SENSOR

POSITIONING

ADJUSTMENTS

SOLAR

SHIELD WITH

TEMPERATURE

SENSOR

ESP-SMT Smart Modular Control System

REMOVABLE

TIPPING

RAIN BUCKET

6

Page 12

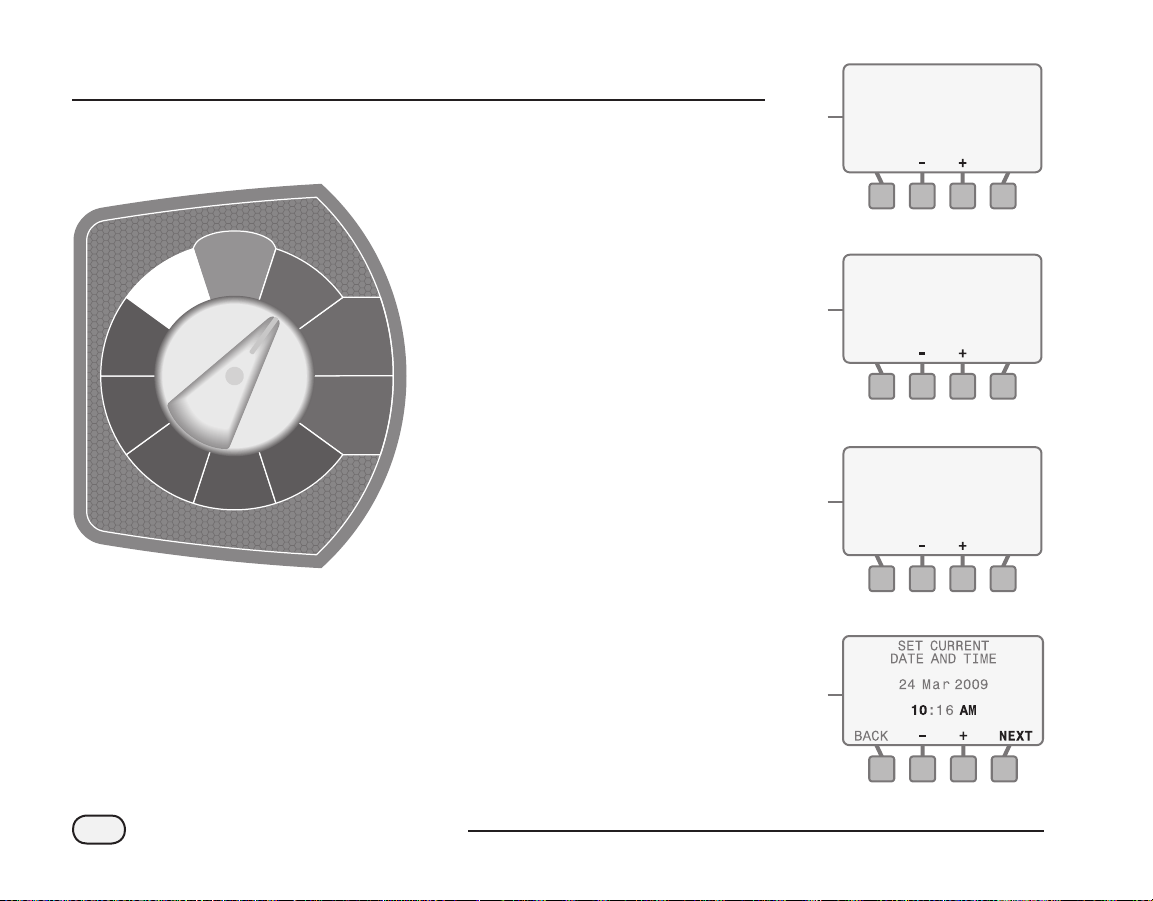

Set Current Date & Time

This section shows you how to set the current date & time on the ESP-SMT Controller.

Rotate the dial to the SET DATE & TIME position...

The SET CURRENT DATE & TIME

A

screen will appear and the three

letter month designation will be

MANUAL

WATERING

RESTORE

SETTINGS

OFF

SYSTEM

REVIEW

AUTO

FINE-TUNE

WATERING

SET DATE

& TIME

SPECIAL

FEATURES

CONFIGURE

CONTROLLER

INPUT ZONE

INFORMATION

blinking on the display.

Set Month

a. Press the - or + button(s) until the

current month is shown; then press

the NEXT button.

Set Day of Month

b. The day of the month will begin to

blink. Press the - or + button(s) until

the current day is shown; then press

the NEXT button.

Set Year

c. The year will begin to blink. Press

the - or + button(s) until the current

year is displayed; then press the

NEXT button.

SET CURRENT

DATE AND TIME

A

a.

A

b.

A

c.

01 Jan 2007

10:16 AM

BACK NEXT

SET CURRENT

DATE AND TIME

01

10:16 AM

BACK NEXT

SET CURRENT

DATE AND TIME

24 Ma r 2007

10:16 AM

BACK NEXT

Ma r 2007

NOTE: Make sure the hour is set

correctly to either AM or PM.

!

ESP-SMT Smart Modular Control System

7

Set Hour

d. The hour will begin to blink. Press

the - or + button(s) until the current

hour appears on the display; then

press the NEXT button.

A

d.

Page 13

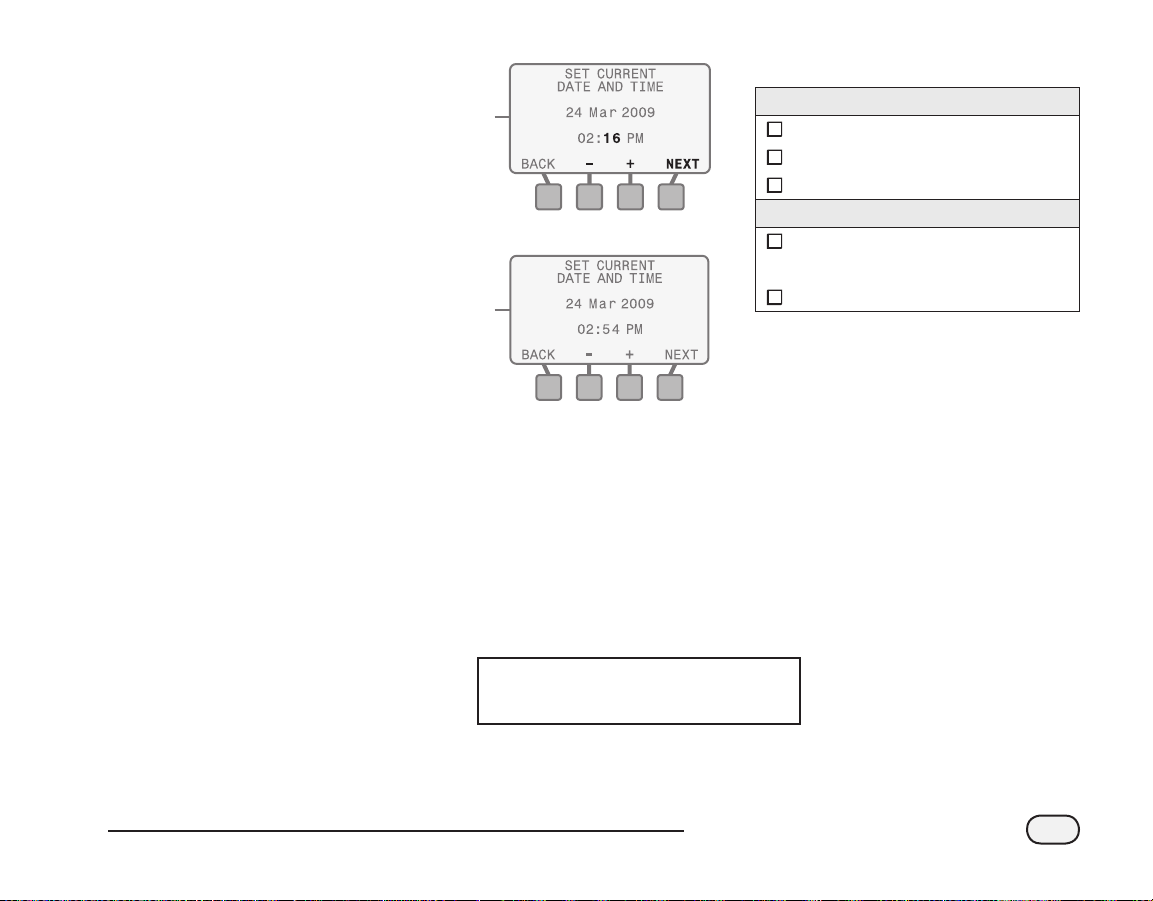

Set Minutes

e. The minutes will begin to blink.

Press the - or + button(s) until the

current minutes are shown; then

press the NEXT button to review

the current Date & Time settings.

Review Current Date & Time

Review the information on the

B

screen to conrm that all settings

are correct:

• If the information is not

correct:

Press either the BACK button

or the NEXT button to navigate

backward or forward to the

section that requires a change;

then follow the instructions

above to make a modication to

that section.

• If the information is correct:

Rotate the dial into any other

position and the entered

information in the SET DATE &

TIME dial position will be saved

in the controller memory. The

internal lithium battery will save

the current date and time during

power outages.

e.

B

NOTE: To rapid advance through

the values shown on various

!

screens, depress and hold the

corresponding navigation button

to activate the “Accelerator”

feature.

You have now completed all of the required

steps to set the current date and time on the

controller.

Review Checklist

Set Current Date

Set Current Month

Set Current Day of Month

Set Current Year

Set Current Time

Set Current Hour

( confirm or is correct)NOTE: AM PM

Set Current Minute

ESP-SMT Smart Modular Control System

8

Page 14

Configure Controller

This section shows you how to configure the ESP-SMT controller for your site

conditions using one of the following Two methods:

1) Select Location by Zip Code; 2) Enter Custom Site Data relative to site location

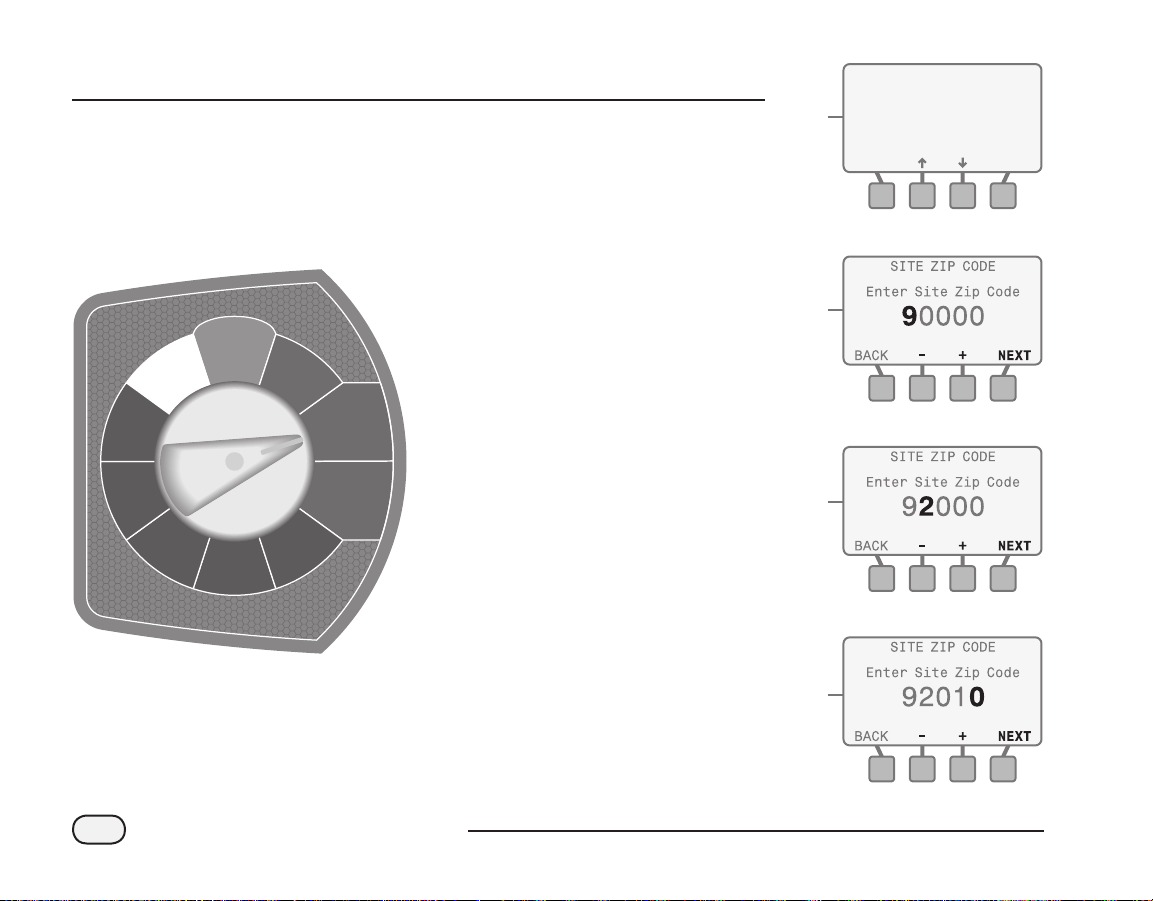

Method 1: Select Location by Zip Code

Rotate the dial to the CONFIGURE CONTROLLER position...

The CONFIGURE CONTROLLER

A

screen will appear and Enter Site

Zip Code will be blinking; press the

MANUAL

WATERING

RESTORE

SETTINGS

OFF

SYSTEM

REVIEW

AUTO

FINE-TUNE

WATERING

SET DATE

& TIME

SPECIAL

FEATURES

CONFIGURE

CONTROLLER

INPUT ZONE

INFORMATION

SELECT button.

The SITE ZIP CODE screen will

B

appear and the 1st digit of the zip

code will be blinking.

a. Press the - or + button(s) to set the

number from 0 to 9 to match the 1st

digit of the site zip code; then press

the NEXT button.

b. The 2nd digit of the zip code will

begin to blink. Press the - or +

button(s) to set the number from 0

to 9 to match the 2nd digit of the

site zip code; then press the NEXT

button.

c. Perform this function until all 5 digits

of the site zip code are entered; then

press the NEXT button.

CONFIGURE CONTROLLER

Enter Site Zip Code

A

Enter Custom Data for

Location

B

a.

B

b.

B

c.

- OR -

SELECT

ESP-SMT Smart Modular Control System

9

Page 15

NOTE: If the zip code you entered

is not found in the controller

!

database, the closest zip code

available will be substituted and

you will be asked “Is this Correct?”

The zip code you entered will be

C

displayed and you will be asked:

Is This Correct?

• If you press the NO button:

The screen will revert back to

allow you to modify the previously

entered zip code values (steps 2

and 3)

• If you press the YES button:

The ALLOWED WATER DAYS screen

D

will appear.

Use the UP or DOWN arrow

button(s) to navigate to enter the

desired Allowed Water Days and

Time (see page 13 for details).

SITE ZIP CODE

C

D

92010

Is This Correct?

NO YES

ALLOWED WATER DAYS

No Restrictions

By Days of the Week

Even Days: 2,4,6,… 30

Odd Days: 1,3,5,…no31

Cyclical:Every _ Days

BACK

SELECT

ESP-SMT Smart Modular Control System

10

Page 16

Configure Controller

Method 2: Enter Custom Data for Location

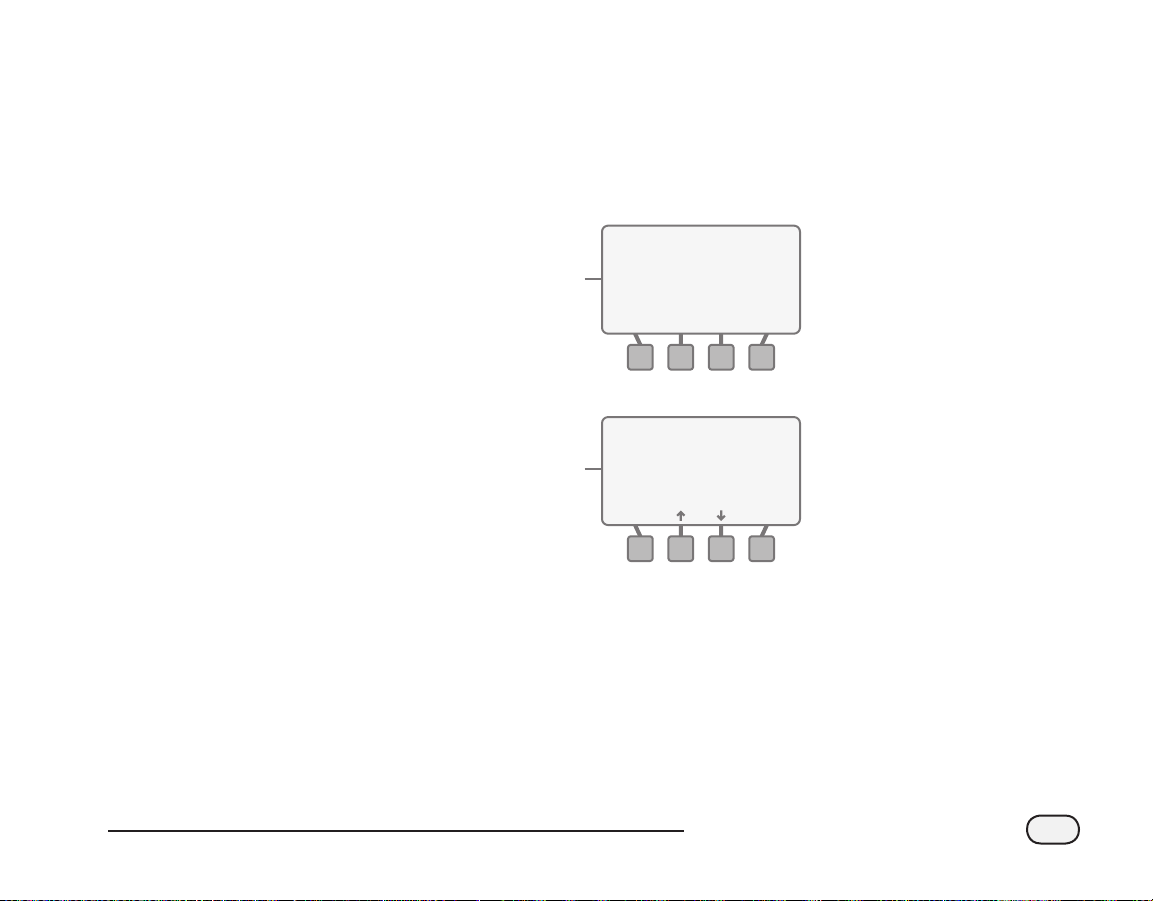

Rotate the dial to the CONFIGURE CONTROLLER position...

The CONFIGURE CONTROLLER

A

screen will appear. Press the UP or

DOWN arrow button(s) until Enter

MANUAL

WATERING

RESTORE

SETTINGS

OFF

SYSTEM

REVIEW

AUTO

FINE-TUNE

WATERING

SET DATE

& TIME

SPECIAL

FEATURES

CONFIGURE

CONTROLLER

INPUT ZONE

INFORMATION

Custom Data for Location begins

to blink; then press the SELECT

button.

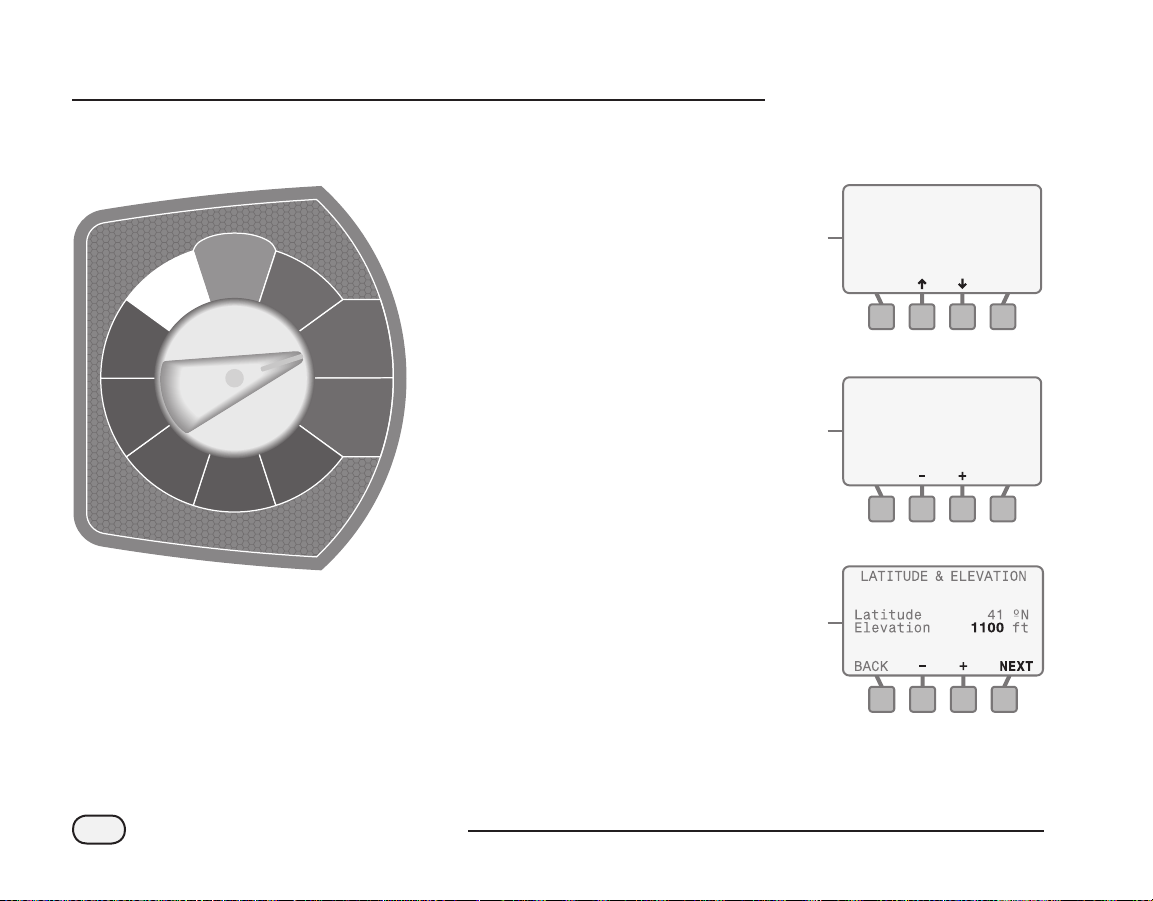

The LATITUDE & ELEVATION

B

screen will appear and the value

corresponding to Latitude will be

blinking.

a. Press the - or + button(s) until the

correct value is entered; then press

the NEXT button.

b. The value for Elevation will begin

to blink. Press the - or + button(s)

until the correct value (100 foot

increments) is entered; then press

the NEXT button.

CONFIGURE CONTROLLER

Enter Site Zip Code

A

Enter Custom Data for

Location

LATITUDE & ELEVATION

Latitude 35 °N

B

Elevation 0 ft

a.

B

b.

- OR -

SELECT

NEXTBACK

ESP-SMT Smart Modular Control System

11

Page 17

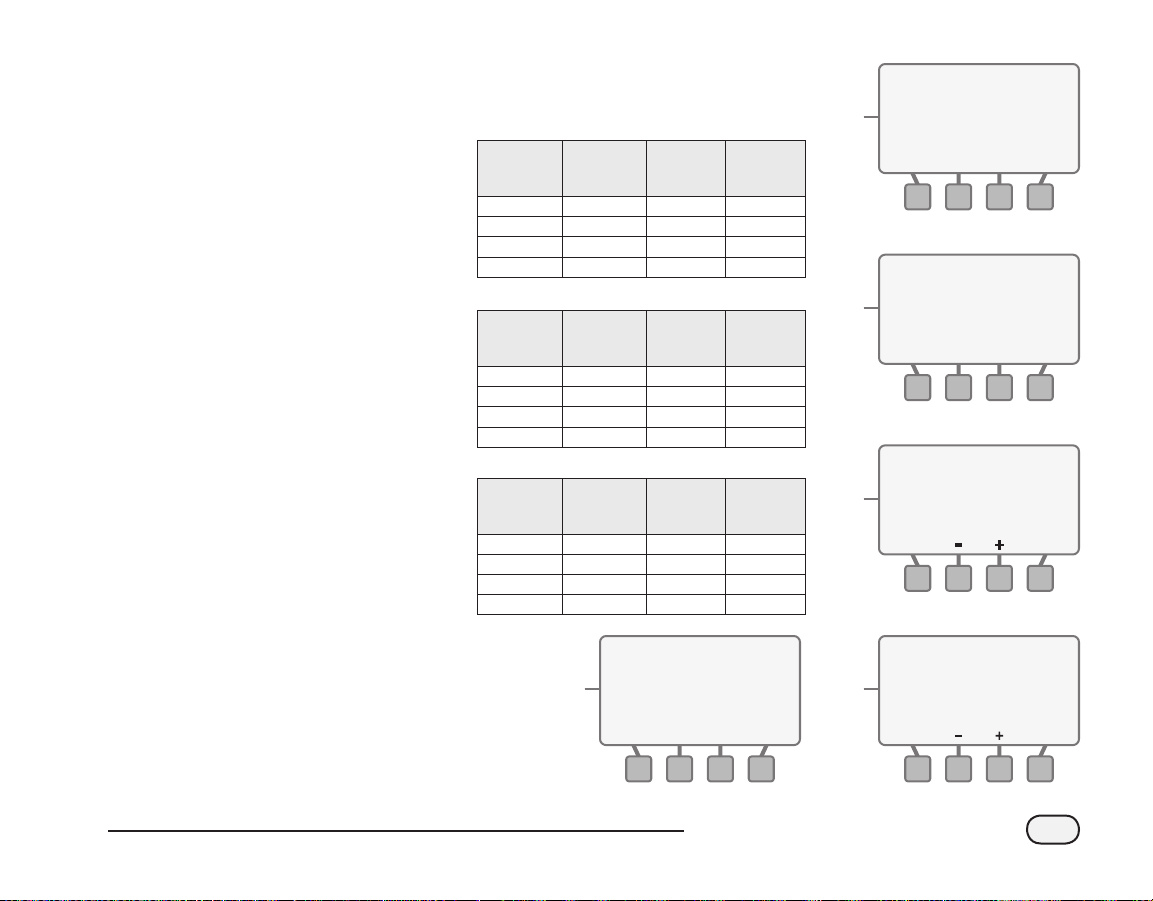

The AVG WIND SPEED screen will

C

appear and the value for January

will be blinking.

a. Press the - or + button(s) until the

correct value is entered and then

press the NEXT button.

b. The value for February will begin to

blink. Press the - or + button(s) until

the correct value is entered; then

press the NEXT button.

c. Perform this function until you have

entered the value for December;

then press the ACCEPT button.

NOTE: Historical weather

information can usually be

!

found at the local airport or local

university web site.

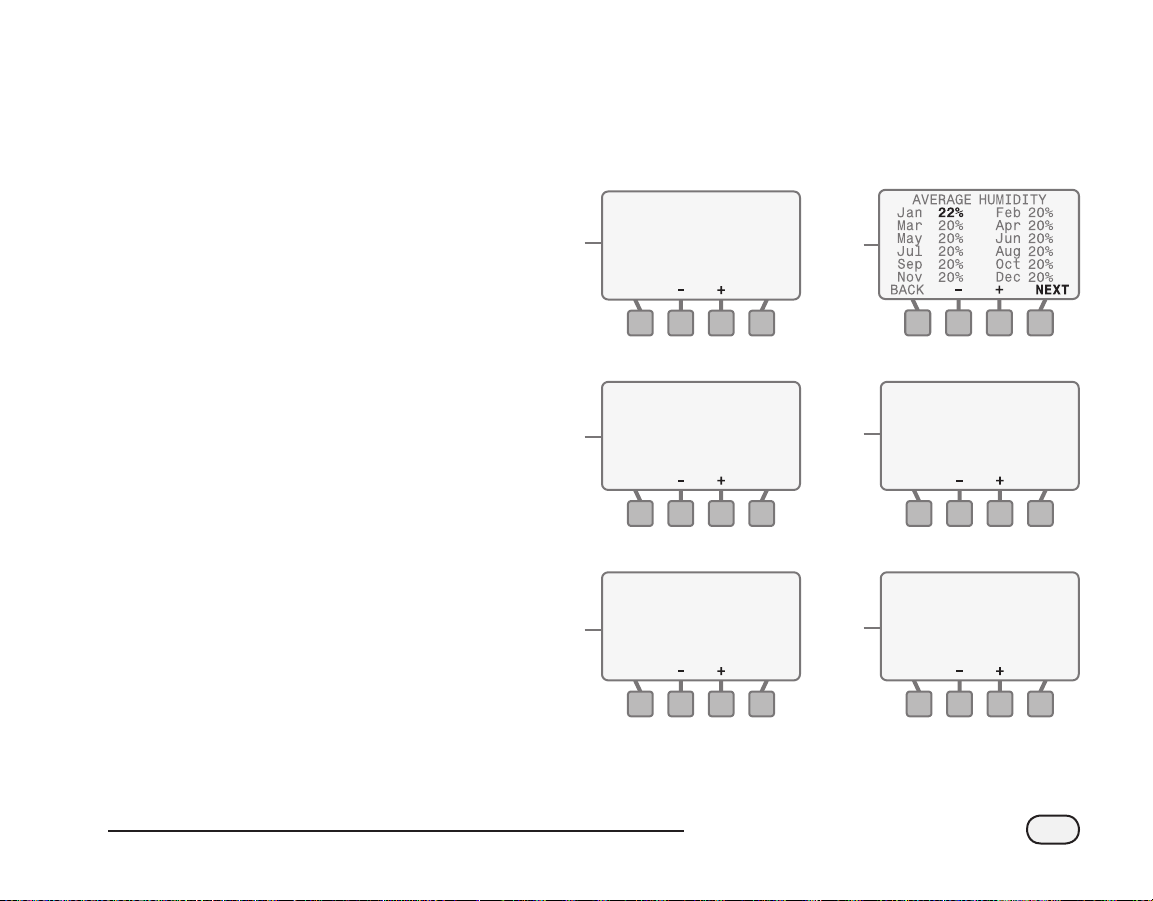

The AVERAGE HUMIDITY screen will

D

appear and the value for January

will be blinking.

a. Press the - or + button(s) until the

correct value is entered; then press

the NEXT button.

b. The value for February will begin to

blink. Press the - or + button(s) until

the correct value is entered; then

press the NEXT button.

c. Perform this function until you have

entered the value for December;

then press the ACCEPT button.

AVG WIND SPEED MPH

Jan 7.5 Feb

Mar 3.0 3.0

May Jun

C

a.

C

b.

C

c.

3.0 3.0

Jul Aug

3.0 3.0

Sep Oct

3.0 3.0

Nov Dec

3.0 3.0

AVG WIND SPEED MPH

Jan Feb

7.5

Mar Apr

3.0

May Jun

3.0 3.0

Jul Aug

3.0 3.0

Sep Oct

3.0 3.0

Nov Dec

3.0 3.0

AVG WIND SPEED MPH AVERAGE HUMIDITY

Jan Feb

7.5

Mar Apr

4.8 4.3

May Jun

3.7 5.1

Jul Aug

4.4 2.3

Sep Oct

6.1 1.8

Nov Dec

2.5 1.2

Apr

3.0

NEXTBACK

5.2

3.0

NEXTBACK

5.2

ACCEPTBACK

D

a.

AVERAGE HUMIDITY

Jan 22% Feb 27%

Mar 20%

May Jun

D

Jul Aug

Sep Oct

b.

Nov Dec

Jan Feb

Mar Apr

May Jun

Jul Aug

D

Sep Oct

c.

Nov Dec

Apr

20%

20%

20%

20%

22% 27%

21% 31%

38% 45%

52% 46%

39% 32%

28% 23%

20%

20%

20%

20%

20%

NEXTBACK

ACCEPTBACK

ESP-SMT Smart Modular Control System

12

Page 18

Enter Allowed Water Days

NOTE: Check with your local

water authorities to see if there

!

are any current water restrictions

in effect that would dictate what

days and/or time of day that you

are permitted to irrigate your

site.

The ALLOWED WATER DAYS screen will

appear with the following options to

chose from:

No Restrictions

Can irrigate on any day(s)

If there are no restrictions on

A

what days you can irrigate, press

the SELECT button when No

Restrictions is blinking on the

display; the BLOCK ON SPECIFIC

DAY OF WEEK screen will appear

(see step 8 on page 15 for details).

By Days of the Week

Set custom 7 day schedule

Press the UP and DOWN arrow

B

button(s) until By Days of the

Week is blinking; then press the

SELECT button.

The rst day of the week, Mo

C

(Monday) will be blinking in the

Allow Watering display.

a. You can either allow watering

to occur or block watering from

occurring on that day by pressing

either the BLOCK or ALLOW

button(s). After the Block or Allow

selection is made, press the NEXT

button.

b. The next day of the week, TU

(Tuesday) will begin to blink. Press

either the BLOCK or ALLOW

button(s) to block or allow watering

to occur for that day as well.

c. Select Block or Allow for each

day of the week and continue the

process until the information is

entered for each day.

ALLOWED WATER DAYS

No Restrictions

By Days of the Week

Even Days: 2,4,6,… 30

A C

Odd Days: 1,3,5,…no31

Cyclical:Every _ Days

BACK

SELECT

ALLOWED WATER DAYS

No Restrictions

By Days of the Week

B

Even Days: 2,4,6,… 30

Odd Days: 1,3,5,…no31

Cyclical:Every _ Days

BACK

WATER BY DAY OF WEEK

Allow Watering:

Tu Th Sa

Mo We Fr Su

Block Watering:

C

a.

C

b.

c.

BLOCK ALLOW NEXTBACK

WATER BY DAY OF WEEK

Allow Watering:

Mo We Fr Su

Block Watering:

Tu

BLOCK ALLOW NEXTBACK

WATER BY DAY OF WEEK

Allow Watering:

Mo We Fr

Block Watering:

Tu Th Sa

BLOCK ALLOW NEXTBACK

SELECT

Th Sa

Su

ESP-SMT Smart Modular Control System

13

Page 19

Once you’ve entered the Block or

Allow information for each day of

the week, press the NEXT button

and the SET ALLOWED WATERING

TIME screen will appear (see page

16 for details).

By Even Days of the Month

Water on all even days of each month

(2nd, 4th… 28th, 30th)

Press the UP and DOWN arrow

D

button(s) until Even Days: 2, 4,

6, ...30 is blinking; then press the

SELECT button; the BLOCK ON

SPECIFIC DAY OF WEEK screen will

appear (see step 8 on page 15 for

details).

NOTE: Some water restrictions

will allow irrigation on all odd days

!

with the exception of the 31st

day of any month. The Odd Days

selection will not allow irrigation

on the 31st of any month or on

Feb. 29th in leap years.

ALLOWED WATER DAYS

No Restrictions

By Days of the Week

D

Even Days: 2,4,6,… 30

Odd Days: 1,3,5,…no31

Cyclical:Every _ Days

BACK

SELECT

By Odd Days of the Month

Water on all odd days of each month (1st,

3rd... 29th, not on 31st)

Press the UP and DOWN arrow

E

button(s) until Odd Days: 1,3,5,

…no31 is blinking; then press the

SELECT button; the BLOCK ON

SPECIFIC DAY OF WEEK screen will

appear (see step 8 on page 15 for

details).

ALLOWED WATER DAYS

No Restrictions

By Days of the Week

E

Even Days: 2,4,6,… 30

Odd Days: 1,3,5,…no31

Cyclical:Every _ Days

BACK

SELECT

ESP-SMT Smart Modular Control System

14

Page 20

Cyclical

Water every 2 to 14 days

Press the UP and DOWN arrow

F

button(s) until Cyclical: Every

_ Day is blinking; then press the

SELECT button.

The CYCLICAL WATERING screen

G

will appear and the value for Water

Every X Days will be blinking.

a. Press the - or + button(s) to enter

a value of between 2 and 14 days

between irrigation cycles; then

press the NEXT button.

b. The date to Begin Watering dd

mmm will begin to blink. Press the

- or + button(s) to set the date in

which you want the rst irrigation

cycle to begin; then press the NEXT

button; the BLOCK ON SPECIFIC DAY

OF WEEK screen will appear.

NOTE: You can delay the actual

start date up to the number of

!

days you set between irrigation

cycles.

Block One Day A Week

Allows a specific day of the week to be

blocked on a regular basis.

The BLOCK WATERING ON SPECIFIC

H

DAY OF WEEK screen will appear.

Press the UP and Down arrow

button(s) until the desired selection

is blinking; then press the SELECT

button and the SET ALLOWED

WATERING TIME SCREEN will appear

(see next page for details).

NOTE: An ideal application of this

feature is to block irrigation on the

!

day the gardener normally comes.

The ESP-SMT controller will always

block irrigation on the specific day

of the week selected independent

of the Allowed Watering Day’s

selection that was entered in

the Configure Controller Section

during step 3 on page 13.

ALLOWED WATER DAYS

No Restrictions

By Days of the Week

Even Days: 2,4,6,… 30

F

Odd Days: 1,3,5,…no31

Cyclical:Every _ Days

BACK

CYCLICAL WATERING

Water Every 3 Days

G

Begin Watering 01 Jan

a.

CYCLICAL WATERING

Water Every 5 Days

G

Begin Watering 04 Jan

b.

BLOCK WATERING ON

SPECIFIC DAY OF WEEK

None Monday

Tuesday Wednesday

Thursday Friday

H

Saturday Sunday

Sat & Sun

BACK

SELECT

NEXTBACK

NEXTBACK

SELECT

ESP-SMT Smart Modular Control System

15

Page 21

Set Allowed Watering Windows

You must set specic time periods

in which irrigation can occur on the

previously set Allowed Watering Days.

When the SET ALLOWED WATER

A

TIME (screen is displayed the

a.

06:00AM is blinking under the

1st Watering Window text that is

displayed on the screen

b. Press the - or + button(s) to set

the time in which the irrigation

schedule will begin if irrigation is

needed on that particular Allowed

Watering Day. Once the desired

time is reached, press the NEXT

button.

c. The text under the 1st Watering

Window representing an ending

time of 6:00PM will begin to blink.

Press the - or + button(s) to set the

time in which the irrigation schedule

must end. Once the desired end

time is reached, press the NEXT

button.

d. If a 2nd Watering Window is desired,

Press the ON button and a second

watering time will be displayed.

Press the NEXT button and the start

time of the 2nd watering window

will begin to blink.

e. Press the - or + button(s) to set the

2nd Watering Window in which

the irrigation schedule will begin

if irrigation is needed on that

particular Allowed Watering Day.

Once the desired time is reached,

press the NEXT button.

SET ALLOWED WATER TIME

1st Watering Window

AM To 06:0006:00 PM

A

A

2nd Watering Window

a.

SET ALLOWED WATER TIME

1st Watering Window

2nd Watering Window

b.

OFF

AM To 06:0005:00 PM

OFF

NEXTBACK

NEXTBACK

SET ALLOWED WATER TIME

1st Watering Window

AM To 09:0005:00 AM

A

2nd Watering Window

c.

SET ALLOWED WATER TIME

1st Watering Window

AM To 09:0005:00 AM

A

A

2nd Watering Window

d.

e.

AM To 11:4506:15 PM

SET ALLOWED WATER TIME

1st Watering Window

AM To 09:0005:00 AM

2nd Watering Window

PM To 11:4506:00 PM

OFF

NEXTBACK

ON

NEXTONOFFBACK

ON

NEXTBACK

ESP-SMT Smart Modular Control System

16

Page 22

NOTE: You must have at least a

15 minute time frame between

!

the end of a water window and

the beginning of another water

window.

f. The text under the 2nd Watering

Time representing the ending

time will begin to blink. Press the

- or + button(s) to set the time in

which the 2nd Watering Time must

end. Once the desired end time is

reached, press the NEXT button.

The Grow-In Water Window screen

B

will appear and the text under the

Grow-In Watering Time representing

the start time will begin to blink.

a. Press the - or + button(s) to set the

time in which the irrigation schedule

will begin every calendar day. Once

the desired time is reached, press

the NEXT button.

b. The text under the Grow-In Watering

Time representing the ending time

will begin to blink. Press the - or +

button(s) to set the time in which

the Grow-In Watering Time must

end. Once the desired end time is

reached, press the NEXT button.

The ALLOWED WATERING review

C

screen will appear. This screen

displays the Allowed Irrigation Days

and the Allowed Watering Times

that you set previously and asks you

to either ACCEPT or to CHANGE

the information.

If you press the CHANGE button,

D

the screen will revert back to

ALLOWED WATERING DAYS. Modify

the information by following the

previous steps in the Set Watering

Days and Set Watering Times

section of this user manual.

If you press ACCEPT then the

CONFIGURE CONTROLLER screen

will appear.

You have now completed all of the required

steps to configure the controller.

SET ALLOWED WATER TIME

1st Watering Window

AM To 09:0005:00 AM

A

2nd Watering Window

f.

ON

PM To 11:4508:00 PM

NEXTBACK

GROW-IN WATER WINDOW

Water every day

between

a.

b.

AM To 05:0009:00 PM

GROW-IN WATER WINDOW

Water every day

between

AM To 04:0009:00 PM

ALLOWED WATERING

By Days of the Week

Mo We Fr

05:00 AM To

08:00

PMAMTo

Grow-in: Daily

09:00

CHANGE ACCEPT

ALLOWED WATER DAYS

No Restrictions

By Days of the Week

Even Days: 2,4,6,… 30

Odd Days: 1,3,5,…no31

Cyclical:Every _ Days

BACK

To

NEXTBACK

NEXTBACK

09:00 AM

11:45

04:00PMPM

SELECT

ESP-SMT Smart Modular Control System

17

Page 23

EXAMPLE:

Watering Restrictions are imposed;

You can only irrigate on even days of the

month from 10:00 PM until 6:00AM; lawn

maintenance occurs every Wednesday.

Lawns on Zones 1 & Zone 2 are newly

seeded and require a grow-in watering

period of 14 days at 3 minutes per cycle

for 8 cycles per calendar day to keep the

seed moist during the warmest part of

the day.

To meet site conditions, CONFIGURE

CONTROLLER as follows:

• Set Allowed Watering Days to Even Days

Of The Month

• Set Block Irrigation on Wednesdays

• Set 1st Watering Window from 10:00 PM

to 11:45PM

• Set 2nd Watering Window from

12:00AM (midnight) to 06:00AM

• Set Grow-In Watering Time from 9:00AM

until 5:00PM – Zone 1 &2 watering will

occur for the next 14 calendar days

for 3 minutes per cycle 8 times evenly

divided by the Grow-In Watering Time

(In this example 8 cycles in 8 hours = 1

cycle every hour)

Review Checklist

Enter Site Data

Location by Zip Code

5 Digit Site Zip Code (OR)

Site Custom Data

Site Latitude

Site Elevation

Monthly Avg. Wind Speed

Monthly Avg. Humidity

Set Allowed Watering Days (select one)

No Restrictions (OR)

Custom Day(s) of the week (OR)

Even Days of the Month (OR)

Odd Days of the Month- not 31st (OR)

Cyclical

Days between Cycle

Beginning Date

Block Day Of Week

Set Allowed Watering Times

Set 1st Watering Window

Set 2nd Watering Window

Set Grow-in Watering Window

ESP-SMT Smart Modular Control System

18

Page 24

Input Zone Information

This section shows you how to input information that is specic to each zone you plan

to irrigate. There are three methods to accomplish this task:

1) Zone Setup Wizard; 2) Advanced User Entry; 3) Copy Zone to Zone(s)

Method 1: Zone Setup Wizard

This method is recommended for new users of the ESP-SMT Controller.

Rotate the dial to INPUT ZONE INFORMATION position...

INPUT ZONE INFORMATION

Zone Setup Wizard

A

Copy Zone to Zone

SELECT ZONE

SELECT

AUTO

OFF

MANUAL

WATERING

RESTORE

SETTINGS

SYSTEM

REVIEW

FINE-TUNE

WATERING

ESP-SMT Smart Modular Control System

19

SET DATE

& TIME

SPECIAL

FEATURES

CONFIGURE

CONTROLLER

INPUT ZONE

INFORMATION

The INPUT ZONE INFORMATION

A

screen will appear with the Zone

Setup Wizard blinking; press the

SELECT button.

Select Specific Zone Number

The SELECT ZONE screen will appear.

B

Press the - or + button(s) until the

desired Zone Number is displayed;

then press the NEXT button.

Turn Zone to ENABLE status

Zone OFF is displayed. Press the

C

ENABLE button to change zone

status.

Zone XX ENABLED is displayed;

D

press the NEXT button.

NOTE: You can still input zone

information with the zone in the

!

OFF mode. This may be beneficial

B

C

D

Zone 3

OFF

SELECT ZONE

Zone 3

OFF

SELECT ZONE

Zone 3

ENABLED

NEXTBACK

NEXTBACK OFF ENABLE

NEXTBACK OFF ENABLE

Page 25

to pre-program all zones of the

controller using a 9V battery prior to

AC power being applied.

Enter Soil Type

The SOIL TYPE screen will appear.

E

Press the DOWN arrow button until

the desired Soil Type begins to blink;

then press the SELECT button.

If you would like a description of the

F

soil type that is blinking, press the

Help button.

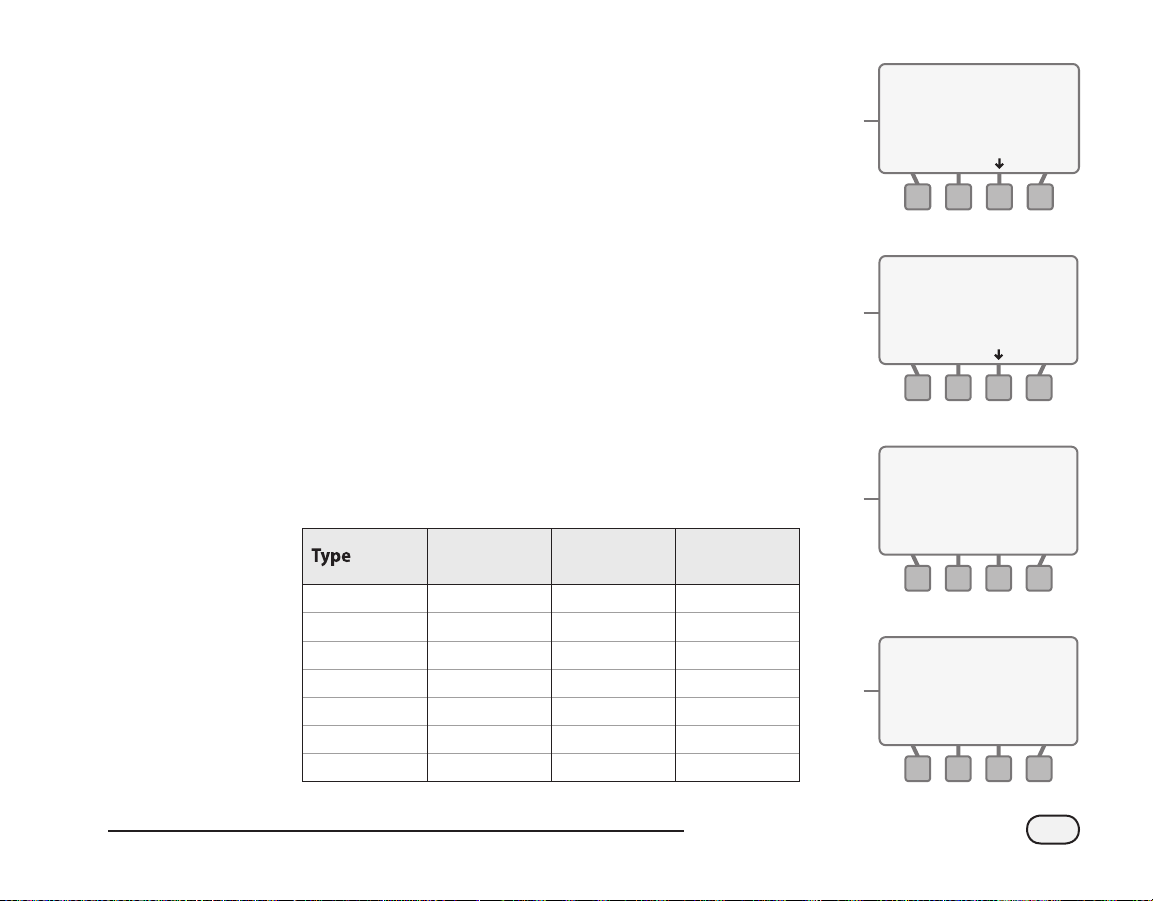

Soil Types

The adjacent table lists

the Soil Type default

values that are used to

determine the irrigation

schedule.

To help you determine

the specific type of soil to

select, see page 73 of the

user manual.

Sand

Loamy Sand

Sandy Loam

Loam

Clay Loam

Silty Clay

Clay

A description screen will appear for

G

the soil type that was blinking when

the Help button was depressed.

a. To view the next page of the soil

description; press the MORE

button.

b. The second Soil Description screen

will appear; After reviewing the

information; press the NEXT button

and the SOIL TYPE screen will

appear. You can then select that soil

type or continue the Help process

to identify the description that best

matches the sites soil type.

Available Water Basic Intake Rate

inch water /inch of soil inchesper hour

0.06”

0.08”

0.12”

0.17”

0.18”

0.17”

0.17”

0.60”

0.50”

0.40”

0.35”

0.20”

0.15”

0.30”

Management

Allowable

Depletion (MAD)

50%

50%

55%

50%

50%

40%

3

5%

SOIL TYPE

Sand Loamy Sand

Sandy Loam Loam

Clay Loam Silty Clay

5

Clay

BACK

Help

SOIL TYPE

Sand Loamy Sand

Sandy Loam Loam

Clay Loam Silty Clay

6

Clay

Help

SANDY LOAM SOIL 1 of 2

Some individual sand

grains can be seen &

felt. Enough silt

7

and/or clay soil

particles to provide

a.

soil cohesion.

SANDY LOAM SOIL 2 of 2

When dry, casts can

be formed that will

not break with

7

careful handling.

b.

See Manual For Details

Zone 2

SELECT

Zone 2

SELECTBACK

MOREBACK

NEXTBACK

ESP-SMT Smart Modular Control System

20

Page 26

Once you’ve identied the correct

H

soil type for the site; press the down

arrow button until the desired soil

type is blinking; press the SELECT

button.

Select Sprinkler Type Method

The SPRINKLER TYPE screen will

I

appear;

Press the up or down arrow button(s)

to navigate to the dominant sprinkler

type for that zone; then press the

SELECT button.

NOTE: It is recommended that

the Default Net Application rate be

!

adjusted to match the actual zone

conditions. See pages 81-83 for

different methods to determine

the correct value.

Sprinkler Type - Default Net

Application Rates

The screen will display the default

J

Net Application Rate for the

sprinkler type selected.

If you need to change this value to

K

better match the actual application

rate, press the - or + button(s) until

the desired value is shown.

If choosing Drip as the sprinkler

L

type, you will be given two types of

drip to select from.

a. When Drip is blinking on the display,

press the SELECT button.

b. Select Point Source or Inline Grid.

SOIL TYPE

Sand Loamy Sand

Sandy Loam Loam

Clay Loam Silty Clay

8

Clay

Help

Zone 2

SELECTBACK

ROTOR Zone 2

Net Application Rate:

J

0.45 in/hr

ROTOR Zone 2

Net Application Rate:

K

0.25 in/hr

SPRINKLER TYPE Zone 2

Sprays Rotors

Bubblers

Rotary Nozzle

L

a.

BACK

Time-Based

Drip

- OR -

NEXTBACK

NEXTBACK

SELECT

Sprinkler Type

Sprays

Rotors

Rotary Nozzle

Bubblers

Point Source Drip

ESP-SMT Smart Modular Control System

21

Net Application

Rate (in/hr)

1.60

0.45

0.50

2.50

0.80

SPRINKLER TYPE Zone 2

Sprays Rotors

Bubblers

9

Rotary Nozzle

Time-Based

BACK

- OR -

Drip

SELECT

DRIP Zone 2

Point Source

L

Inline Grid

b.

SELECTBACK

Page 27

If Point Source Drip is selected, a

M

series of notes will be displayed to

describe how to determine the net

application rate for point source

emitters.

a. Continue to press NEXT to advance

to the next screen.

b. Press the NEXT button.

c. Press the NEXT button.

d. Similar to other sprinkler types, the

default net application rate for point

source drip will appear.

e. Use the - or + button(s) to change

the value until it matches the

conditions of the zone. Press the

NEXT button and the CYCLE/SOAK

screen will appear.

Drip Irrigation Emitter

Application Rates

Clay Soil

Flow in

Gallons per

hour

0.5 2.0’ 3.14 0.26”

Loam Soil

Flow in

Gallons per

hour

0.5 1.5’ 1.77 0.45”

Sandy Soil

Flow in

Gallons per

hour

0.5 1.0’ 0.79 1.02”

Wetted Area

(Dia. Ft.)

1 2.5’ 4.91 0.33”

2 3.0’ 7.07 0.45”

5 3.0’ 7.07 1.13”

Wetted Area

(Dia. Ft.)

1 2.0’ 3.14 0.51”

2 2.5’ 4.91 0.65”

5 2.5’ 4.91 1.63”

Wetted Area

(Dia. Ft.)

1 1.0’ 0.79 2.03”

2 1.25’ 1.23 2.61”

5 1.25’ 1.23 6.52”

Wetted Area

(Sq. Ft.)

Wetted Area

(Sq. Ft.)

Wetted Area

(Sq. Ft.)

Application

Rate (inches

per hour)

Application

Rate (inches

per hour)

Application

Rate (inches

per hour)

POINT SOURCE EMITTERS

Zone GPM is (# of

Emitters * Flow Rate

of Emitters in GPH)

M

and dividing by 60

b.

POINT SOURCE EMITTERS

Net Application Rate

is calculated as

(96.25 * Zone GPM) +

M

Estimated Soil Wetted

Area of all point

c.

source emitters.

DRIP Zone 10

Net Application Rate:

M

0.80 in/hr

d.

NEXTBACK 1 of 3

NEXTBACK 1 of 3

NEXTBACK

POINT SOURCE EMITTERS

Application Rate is

calculated by first

calcuting the Total

M

Zone GPM and

Estimated Wetted Area

a.

in Sq Ft.

DRIP Zone 10

Net Application Rate:

M

0.60 in/hr

e.

NEXTBACK 1 of 3

ESP-SMT Smart Modular Control System

NEXTBACK

22

Page 28

If Inline Grid is selected:

N

a. The Flow Rate value will blink. Use

the - or + button(s) to change the

Flow Rate to the desired value. Press

the NEXT button.

b. The Emitter Spacing value will blink.

Use the - or + button(s) to change

the value as desired. Press the NEXT

button.

c. The Row Spacing value will blink.

Use the - or + button(s) to change

to the desired value. Press the NEXT

button.

d. The Estimated Application Rate

screen will appear with the Adjust

Factor blinking. Use the - or +

button(s) to change to the desired

Adjust Factor value. Press the NEXT

button.

e. The CYCLE/SOAK screen will

appear.

Flow Rate GPH0.90

Emitter Spacing in12

N

a.

Row Spacing in12

Flow Rate GPH0.90

Emitter Spacing in12

N

Row Spacing in12

Flow Rate GPH0.90

Emitter Spacing in18

N

Row Spacing in12

c.

Zone 11INLINE GRID

NEXTBACK

Zone 11INLINE GRID

NEXTBACK

Zone 11INLINE GRID

NEXTBACK

INLINE GRID Zone 11

Est.Application

0.64 in/hr

N

N

Adjust Factor 100%

Net Application Rate:

d.

0.64 in/hr

INLINE GRID Zone 11

Est.Application

0.64 in/hr

Adjust Factor 95%

Net Application Rate:

e.b.

0.61 in/hr

Rate:

NEXTBACK

Rate:

NEXTBACK

ESP-SMT Smart Modular Control System

23

Page 29

Select Time-Based Method

Press the up or down arrow

O

button(s) to navigate to the TimeBased text and press the SELECT

button.

The TIME–BASED screen for the

P

selected zone will appear and the

Every XX Days value will be blinking.

Press the - or + button(s) to set the

desired number of calendar days

between irrigation schedules. Press

the NEXT button.

The Water XXX Minutes value

Q

will begin to blink. Press the - or +

button(s) to set the minutes for each

irrigation cycle. Press the NEXT

button.

The For X Times Per Day value will

R

begin to blink. Press the - or +

button(s) to set the desired number

of irrigation cycles per day. Press the

NEXT button.

NOTE: A typical application for

using the time-based method is

!

for 1) zones that irrigate potted

plants and 2) a zone that may be

used to fill a pool.

SPRINKLER TYPE Zone 1

Sprays Rotors

Bubblers

O

P

Rotary Nozzle

- OR -

Time-Based

BACK

TIME-BASED

Odd Days:1,3,5,...no 31

Except Wednesday

Desired Every

Water For xx Minutes

xx Times Per Day

Drip

SELECT

Zone 12

2 Days

NEXTBACK

TIME-BASED

Odd Days:1,3,5,...no 31

Except Wednesday

Desired Every

Q

R

Water For 8 Minutes

xx Times Per Day

TIME-BASED

Odd Days:1,3,5,...no 31

Except Wednesday

Desired Every

Water For 8 Minutes

3 Times Per Day

Zone 12

2 Days

NEXTBACK

Zone 12

2 Days

NEXTBACK

ESP-SMT Smart Modular Control System

24

Page 30

The CYCLE/SOAK screen will appear

S

with 0° - 2° blinking.

a. Use the up or down arrow

button(s) to select the slope degree

category representative of the

zone topography. Press the NEXT

button.

b. The Automatic Cycle and Soak

Mode will blink. If you agree with the

automatically calculated maximum

cycle value and the minimum soak

value, press the NEXT button.

c. If you want to change the

automatically calculated cycle and

soak values, press either the - or +

button(s) and Custom will blink.

Press the NEXT button.

d. The Maximum Cycle value will blink.

Use - or + button(s) the to increase

or decrease the maximum cycle

time. Press the NEXT button.

e. The Minimum Soak value will blink.

Use the - or + button(s) to change

to the desired minimum soak time

value.

f. Press the NEXT button. The Plant

Type screen will appear.

CYCLE/SOAK

Select Slope in Deg.

0-2° 3-4°

5-7° 8°-up

Cycle/Soak Automatic

S

Max Cycle Min

a.

Min Soak

BACK

Zone xx

(6)

(40) Min

NEXT

CYCLE/SOAK

Slope in deg.

Cycle/Soak Mode

Automatic Custom

S

Max Cycle Min

c.

Min Soak

BACK

CYCLE/SOAK

Slope in Deg.

Cycle/Soak Mode

S

Max Cycle Min

Min Soak

d.

BACK

CYCLE/SOAK

Slope in deg.

Cycle/Soak Mode

Automatic Custom

S

Max Cycle Min

e.

Min Soak

BACK

(4)

(32)

(4)

(32)

(4)

(32)

Zone xx

8°-up

(4)

(32) Min

NEXT

Zone xx

8°-up

Custom

(4)

(32) Min

NEXT

Zone xx

8°-up

(8)

(32) Min

NEXT

ESP-SMT Smart Modular Control System

25

CYCLE/SOAK

Select Slope in Deg.

0-2° 3-4°

5-7° 8°-up

Cycle/Soak Automatic

S

Max Cycle Min

b.

Min Soak

BACK

Zone xx

(6)

(40) Min

NEXT

CYCLE/SOAK

Slope in Deg.

Cycle/Soak Mode

S

Max Cycle Min

Min Soak

f.

BACK

(4)

(32)

Zone xx

8°-up

Custom

(8)

(50) Min

NEXT

Page 31

Select Plant Type Method -

Grass Lawns

While the PLANT TYPE screen is

T

displayed, Grass Lawn will be

blinking; press the SELECT button.

The GRASS VARIETY screen will

U

appear. Press the UP and Down

arrow button(s) until the desired

variety (Cool Season or Warm

Season) is blinking; then press the

SELECT button and the SHADE

FACTOR screen will appear (see

page 29 for details).

PLANT TYPE

Grass Lawn Annuals

Ground Cover Shrubs

Desert Plants Trees

Mixed Planting

T

Custom Plant Factors

BACK

PLANT TYPE

Grass Lawn Annuals

Ground Cover Shrubs

Desert Plants Trees

Mixed Planting

U

Custom Plant Factors

BACK

Zone 1

- OR -

SELECT

Zone 1

- OR -

SELECT

Most “Cool Season” grasses do not spread

through runners, but rather from actual seed

that germinates. Cool Season varieties usually

have individual blades that grow in a vertical

orientation.

Cool Season Variety

Most “Warm Season” grass varieties grow

(spread) through runners that branch out

horizontally from the established lawn or

from planted stolons. In general, Warm Season

grasses go dormant in the winter.

Warm Season Variety

ESP-SMT Smart Modular Control System

26

Page 32

Select Plant Type Method -

Non-Grass Lawns

While the PLANT TYPE screen is

V

displayed, press the UP and DOWN

arrow button(s) until the desired

plant type (non-grass) is blinking;

then press the NEXT button and

the PLANT WATER NEEDS screen will

appear (see next page for details).

Plant Factor & Root Depth by Plant Type - Default Values

The adjacent table lists the

default species factor (Ks)

and root depth values used

to calculate the irrigation

schedule. If you do not want

to use the default values then

use the Custom Plant Factor

method.

The plant choices and their

respective Ks values listed in

the table are representative

of different plant varieties

that fall into these broad

categories.

Plant Type

Grass – Cool Season

Grass – Warm Season

Annual Color

Ground Cover

Shrubs

Desert Plants (Natives)

Trees

Mixed Planting

Select Plant Water Needs -

(Non-Grass Plant Types)

The PLANT WATER NEED screen will

W

appear with the plant type selected

and Average selection blinking.

Use the UP and DOWN arrow

X

button(s) to navigate to the desired

plant water need for that specic

zone. Press the SELECT button and

the PLANT DENSITY screen will

appear.

High

Average

Need

ESP-SMT uses monthly Kc values,

published in the Irrigation Assoc.

SWAT Testing Protocol - 8th Draft.

150%

90%

70%

50%

90%

90%

Need

120%

50%

50%

30%

50%

50%

Low

Need

100%

20%

20%

15%

20%

20%

Root

Depth

3”

3”

2”

6”

8”

12”

12”

6”

PLANT TYPE

Grass Lawn Annuals

Ground Cover Shrubs

Desert Plants Trees

V

Mixed Planting

Custom Plant Factors

BACK

PLANT WATER

NEEDS

Mixed Plants

W

X

Average

BACK

PLANT WATER

NEEDS

Mixed Plants

Average

BACK

- OR -

High

Low

High

Low

Zone 1

SELECT

Zone 1

SELECT

Zone 1

SELECT

For example: a low water need shrub would use 20% of ETo and have

a default root depth of 8 inches.

ESP-SMT Smart Modular Control System

27

Page 33

Custom Plant Factor Method

While the PLANT TYPE screen is

Y

displayed, press the UP and DOWN

arrow button(s) until Custom Plant

Factors is blinking; then press the

SELECT button.

The CUSTOM PLANT FACTORS

Z

screen will appear with the Species

Factor value blinking.

a. Press the - or + button(s) to adjust

Species Factor (Ks) to the desired

value; then press the NEXT

button.

b. The Root Depth value will begin

to blink. Press the - or + button(s)

to adjust Root Depth to the desired

value; then press the NEXT button

and the PLANT DENSITY screen will

appear.

For more plant variety specific information,

it is recommended that you access Water Use

Classifications of Landscape Species (WUCOLS) Guide developed by the University of

California. This guide is available through the

California Department of Water Resources at:

http://ucce.ucdavis.edu/files/

filelibrary/1726/15359.pdf

Enter Plant Density

While the PLANT DENSITY screen is

27

displayed, press the UP and DOWN

arrow button(s) until the desired

plant density description starts to

blink, press the SELECT button

and the SHADE FACTOR screen will

appear.

The following table lists the Density Factor

default values that are applied to the Species

Factor (Ks) above to determine the irrigation

schedule.

Density Factor by Plant Type

Plant Type Dense Medium Sparse

Cool Turf

Warm Turf

Annual Color 1.0 1.0 0.8

Ground Cover 1.1 1.0 0.5

Shrubs 1.1 1.0 0.6

Desert/Native 1.3 1.0 0.6

Trees 1.3 1.0 0.6

Mixed Planting 1.2 1.0 0.6

Custom Plant Factor 1.2 1.0 0.6

Density is not a factor for

Cool Turf or Warm Turf

PLANT TYPE

Grass Lawn Annuals

Ground Cover Shrubs

Desert Plants Trees

Y

Mixed Planting

Custom Plant Factors

BACK

CUSTOM PLANT Zone 2

FACTORS

Species Factor(Ks)1.0

Z

Root Depth 6 in

a.

CUSTOM PLANT Zone 2

FACTORS

Species Factor(Ks)0.8

Z

Root Depth 12 in

b.

PLANT DENSITY

Mixed Plants

BACK

Dense

Medium

Sparse

27

Zone 1

- OR -

SELECT

NEXTBACK

NEXTBACK

Zone 1

SELECT

ESP-SMT Smart Modular Control System

28

Page 34

Enter Shade Factor

The SHADE FACTOR screen will

28

appear. Press the UP and DOWN

arrow button(s) until the desired

Shade Factor description starts to

blink; then press the SELECT button

and the PLANT MATURITY screen

appears.

The following table lists the Sun / Shade

Factor default values that are applied to the

Species Factor (Ks) to determine the irrigation

schedule.

Exposur Non-Turf Turfe

Full Sun

25% Shade

50% Shade

75% Shade

Full Shade

1.30

1.15

1.00

0.75

0.50

1.00

0.89

0.77

0.67

0.56

Enter Plant Maturity -

(Established Method)

While the PLANT MATURITY screen

29

is displayed;

Press the UP and DOWN arrow

button(s) until Established is

blinking on the display; then press

the SELECT button and the ZONE

REVIEW screen will appear.

Enter Plant Maturity -

(Newly Planted Method)

While the PLANT MATURITY screen

30

is displayed:

a. Press the UP and DOWN arrow

button(s) until Newly Planted,

Grow-in Period is blinking on the

display; then press the SELECT

button.

b. The NEWLY PLANTED screen will

appear and the value For the Next

XX Days will be blinking. Press the

- or + button(s) to adjust to the

desired number of days (this value

can be from 0 to 99 days); then press

the NEXT button.

c. The value for Cycles Per Day

will begin to blink. Press the - or +

button(s) to adjust to the desired

Cycles Per Day (this value can be

from 1 to 8 cycles per day); then

press the NEXT button.

SHADE FACTOR

Full Sun

BACK

25% Shade

50% Shade

75% Shade

Full Shade

28 30

Zone 1

SELECT

PLANT MATURITY

Established

29

BACK

PLANT MATURITY

30

a.

BACK

NEWLY PLANTED

Water Every Calendar

Day For Next 14 Days

30

Cycles Per Day 2

Minutes Per Cycle

b.

09:00 AM to 04:00 PM

NEWLY PLANTED

Water Every Calendar

Day For Next 14 Days

Cycles Per Day 6

Minutes Per Cycle 5

c.

09:00 AM to 04:00 PM

- OR -

Newly Planted

Grow-in Period

Established

- OR -

Newly Planted

Grow-in Period

Zone 2

SELECT

Zone 2

SELECT

Zone 2

5

NEXTBACK

Zone 2

NEXTBACK

ESP-SMT Smart Modular Control System

29

Page 35

d. The value for the Minutes Per

Cycle will begin to blink. Press the

- or + button(s) to adjust to the

desired Minutes Per Cycle (this value

can be from 1 to 30 minutes per

cycle); then press the NEXT button

and the ZONE REVIEW screen will

appear.

Review Zone Information

The REVIEW screen displays the

previously entered information for the

specic zone that you entered in the

previous steps following the Zone Input

Wizard

If you want to change any of the

31

information on the REVIEW screen,

press the CHANGE button and the

SOIL TYPE screen will appear. Go

to step 5 on page 20 to change the

information as required.

If you accept all of the information

32

in the REVIEW screen then press the

ACCEPT button.

The SELECT ZONE screen will

33

appear. Select the next zone and

repeat steps starting on page 19 for

all zones that will be enabled either

now or in the future.

As you enter information for each

active zone, it will be saved for recall

in the event of a power outage.

You have now completed all of the required

steps for the INPUT ZONE INFORMATION

dial position (see page 31 for Review

Checklist).

Zone 2

75% Shade

Zone 2

NEXTBACK

8° - up

Average

ACCEPT

NEWLY PLANTED

Water Every Calendar

Day For Next 14 Days

Cycles Per Day 6

Minutes Per Cycle

d.

09:00 AM to 04:00 PM

REVIEW ON

Rotor 0.4 in/hr

Sandy Loam

Slope

31

Shrubs

Sparse

Plants Established

CHANGE

REVIEW ON

Rotor 0.4 in/hr

Sandy Loam

Slope

3230

Shrubs

8

Sparse

Plants Established

CHANGE

33

Zone 2

8° - up

Average

75% Shade

ACCEPT

SELECT ZONE

Zone 3

OFF

NEXTBACK

ESP-SMT Smart Modular Control System

30

Page 36

Review Checklist Zone Method #1 - Zone Setup Wizard

Select Specic Zone Number1

2

Turn Zone to ENABLED or OFF

3 Enter Soil Type

Sand

Sandy Loam

Clay Loam

Loamy Sand

Loam

Silty Clay

Clay

or

Select Time -based Mode

Every XX Days

Water XXX Minutes

For X Times Per Day

4

Select Sprinkler Type

Sprays

Rotary Noz

Rotors

Bubblers

Drip

5 Enter Slope in XX Degrees

0-2°

5-7°

3-4°

8° - up

6

Select Plant Type

Grass Lawn

Cool Season Variety

Warm Season Variety

Annuals

Ground Cover

Shrubs

Desert Plants (Natives)

Trees

Mixed Planting

or

Custom Plant Factors

Species Factor (Ks)

Root Depth

7

Plant Water Needs By Zone

High

Medium

Low

8 Enter Plant Densit y

Dense

Medium

Sparse

9

Enter Shade Factor

Full Sun

25% Shade

50% Shade

75% Shade

Full Shade

10

or

Established

Newly Planted

Water Next XX Days

XX Cycles per Day

XX Minutes per Cycle

11 Review Screen

Accept Data - Select

the next zone and

repeat steps starting

on page 19

Change Data - Go to

step 5 on page 20 to

change the information

as required

ESP-SMT Smart Modular Control System

31

Page 37

Input Zone Information

Method 2: Copy Zone to Zone(s)

This method is useful if the conditions for one zone match other zones.

Rotate the dial to INPUT ZONE INFORMATION position...

The INPUT ZONE INFORMATION

A

screen will appear. Press the UP and

DOWN arrow button(s) until Copy

Zone to Zone is blinking; then

press the SELECT button.

The Copy From Zone value will

B

begin to blink;

a. Press the - or + button(s) until the

source Zone number is displayed;

then press the NEXT button.

b. The To Zone value will blink.

Press the - or + button(s) until

the destination Zone number is

displayed; then press the NEXT

button.

c. The next destination zone will begin

to blink. Press the - or + button(s)

until the destination Zone number

is displayed; then press the NEXT

button. Repeat this process to add a

third destination zone if needed.

MANUAL

WATERING

RESTORE

SETTINGS

OFF

SYSTEM

REVIEW

AUTO

FINE-TUNE

WATERING

SET DATE

& TIME

SPECIAL

FEATURES

CONFIGURE

CONTROLLER

INPUT ZONE

INFORMATION

INPUT ZONE INFORMATION

Zone Setup Wizard

A

Copy Zone to Zone

COPY ZONE DATA

Copy From Zone 1

To Zone

And To Zone

a.

B

b.

B

c.

And To Zone

COPY ZONE DATA

Copy From Zone 2

To Zone

And To Zone

And To Zone

COPY ZONE DATA

Copy From Zone 2

To Zone

And To Zone

And To Zone

SELECT

2

--

--

NEXTBACK

3

--

--

NEXTBACK

3

6

8

NEXTBACK

ESP-SMT Smart Modular Control System

32

Page 38

The COPY ZONE DATA screen will

C

display the information you just

entered.

a. If the information is incorrect then

press the QUIT button.

b. Zone Data NOT copied screen will

appear.

If the information is correct then

D

a.

press the COPY button.

b. A conrmation screen will appear.

Press the NEXT button.

The original INPUT ZONE

E

INFORMATION screen will appear.

COPY ZONE DATA

Copy From Zone 2

C

a.

C

b.

To Zone

And To Zone

And To Zone

Start Copy or Quit

COPY ZONE DATA

Zone Data

NOT Copied

Press NEXT To Continue

COPY ZONE DATA

Copy From Zone 2

3

6

8

COPYQUIT

D

a.

D

NEXT

b.

INPUT ZONE INFORMATION

E

To Zone

And To Zone

And To Zone

Start Copy or Quit

COPY ZONE DATA

And To Zone

And To Zone

Zone Setup Wizard

Copy Zone to Zone

COPYQUIT

Copy Complete

From Zone 2

To Zone

NEXT

SELECT

3

6

8

3

6

8

ESP-SMT Smart Modular Control System

33

Page 39

Special Features

This section shows you how to customize the irrigation schedule for your site to

meet your specific needs by utilizing the ESP-SMT controller’s Special Features.

Rotate the dial to SPECIAL FEATURES position...

The SPECIAL FEATURES screen will

A

appear allowing you to utilize any

combination of the following ve

MANUAL

WATERING

RESTORE

SETTINGS

OFF

SYSTEM

REVIEW

AUTO

FINE-TUNE

WATERING

SET DATE

& TIME

SPECIAL

FEATURES

CONFIGURE

CONTROLLER

INPUT ZONE

INFORMATION

Special Features:

Event Days Off

Allows you to block irrigation on up to 4

specific dates up to 365 days in advance.

If you’d like to block irrigation from

B

occurring on a specic date(s):

when Event Days Off is blinking

on the display press the SELECT

button;

The EVENT DAYS OFF screen will

C

appear;

a. Press the + button and the current

date will appear in the rst available

line of dashes.

b. Press either - or + button(s) to

change to the date that you

would like to block irrigation from

occurring; then press the NEXT

button.

SPECIAL FEATURES

Event Days Off

Short Circuit Test

Adv. Controller Setup

A

Advanced Zone Setup

Save Contractor Dflts

Set Units

C

a.

b.

SELECT

ESP-SMT Smart Modular Control System

34

Page 40

c. The second entry line will begin to

blink. Press the + button and the

current date appears and begins

to blink. Press either - or + button(s)

to change to the date that you

would like to prevent irrigation from

occurring; then press the NEXT

button.

d. Continue this process until all

desired Event Days O are displayed

(maximum of 4 dates). In the screen

example, irrigation will be blocked

from occurring on July 3rd & 4th, as

well as Dec 24th and 25th as there

are parties planned in the yard on

those specic dates.

NOTE: Event Day Off dates can

be entered in any order. The ESP-

!