RADWAG WLX series, WTX series User Manual

Manual number:

LTI-01-08/03/08/A

Precision balances:

• WLX series

• WTX series

MANUFACTURER OF ELECTRONIC

WEIGHING EQUIPMENT

RADWAG, 26 – 600 Radom, Bracka 28 Street - POLAND

phone +48 48 38 48 800, phone/fax. +48 48 385 0 0 10

Sales Department +48 48 366 80 06

www.radwag.pl

MARCH 2008

- 2 -

Table of contents

1. INTENDED USE....................................................................................................................5

2. PRECAUTIONARY MEASURES..........................................................................................5

3. WARRANTY CONDITIONS..................................................................................................6

4. UN ACKING OF THE BALANCE ........................................................................................6 P

4.1.

WTX series.....................................................................................................................6

4.2. WLX series .....................................................................................................................7

5. GETTING STARTED.............................................................................................................7

5.1. Conditions of appropriate use.........................................................................................7

5.2. Time of warming up........................................................................................................8

5.3. Balance levelling.............................................................................................................8

6. BALANCE DESCRIPTION....................................................................................................8

6.1. Graphic display...............................................................................................................8

6.2. Keyboard ........................................................................................................................9

6.3.

7.

USER MENU .......................................................................................................................10

Connecting sockets ........................................................................................................9

7.1. Overview of parameters................................................................................................10

7.2. Menu - graphic version.................................................................................................12

7.3. Navigating within the menu...........................................................................................13

7.3.1. By means of balance keyboard ...........................................................................13

7.3.2. By means of PC keyboard...................................................................................14

7.4. Return to weighing........................................................................................................15

8. WEIGHING ..........................................................................................................................15

8.1. Tarring ..........................................................................................................................16

8.2. Manual inscribing of tare value.....................................................................................16

8.3. Automatic tare...............................................................................................................17

8.4. Zeroing..........................................................................................................................18

8.5. Functions of keys..........................................................................................................18

9. BALANCE CALIBRATION .................................................................................................18

10. SETTING OF PRINTOUTS CONTENTS FOR GLP PROCEDURES...............................19

11. TIME AND DATE SETTING..............................................................................................20

12. SETTING THE PARAMETERS.........................................................................................23

12.1. ilter.............................................................................................................................23 F

12.2.

.................................................................................................................23 Median filter

12.3.

ro operating ......................................................................................23 Setting of autoze

12.4.

......................................................................................................................24 Autozero

12.5.

......................................................................................................................24 Last digit

12.6.

......................................................................................................................24 Negative

12.7.

Automatic tare.............................................................................................................24

13. FUNCTIONS CONNECTED WITH RS 232 USE ..............................................................25

14. PRINTOUTS......................................................................................................................26

15. SETTING ACCESSIBILITY OF WEIGHT UNITS..............................................................26

16. SETTING ACCESSIBILITY OF WORK MODES ..............................................................27

17. OTHER PARAMETERS ....................................................................................................27

18. USING WORK MODES.....................................................................................................29

18.1. Counting pieces of the same mass.............................................................................29

18.1.1. Counting pieces after writing piece mass..........................................................30

18.1.2. Counting through determine singular element mass from the standard batch..31

18.1.3. Select an item from the database......................................................................33

- 3 -

18.2. eighing............................................................................................................33 Checkw

18.3.

illing...........................................................................................................................35 F

18.4.

......................................................................................................................36 Percents

18.5.

........................................................................................................38 Weighing animals

18.6.

Density of solids and liquids........................................................................................39

18.6.1. Density of liquids................................................................................................40

18.6.2. Density of solids.................................................................................................40

18.7. ..................................................................................................................40 Formulation

1 .8.

Statistics......................................................................................................................45 8

19.

TYPES OF PRINTOUTS ...................................................................................................47

19.1. rintout.........................................................................................................47 Standard p

19.2.

Non-standard printout..................................................................................................48

19.2.1. Inscribing texts...................................................................................................50

19.2.2. Select non-standard printouts............................................................................53

20. ADDITIONAL ID’S.............................................................................................................54

21. COOPERATION WITH PRINTER OR COMPUTER.........................................................55

21.1. Connections.................................................................................................................55

22. TRANSMISSION POTOCOL.............................................................................................56

22.1. mation...............................................................................................56 Some basic infor

22.2.

............................................................................................56 Transmission parameters

22.3.

ypes of transmission..................................................................................................57 T

22.4.

Transmission characteristics.......................................................................................57

22.4.1. Types of printouts ..............................................................................................57

22.4.2. Continuous transmission....................................................................................57

22.4.3. Continuous transmission „with pauses”.............................................................58

22.4.4. Stable result transmission..................................................................................58

22.4.5. Survey of automatic printouts ............................................................................59

22.5. Command and response syntax..................................................................................60

22.5.1. Command syntax...............................................................................................60

22.5.2. Response syntax...............................................................................................60

22.6. List of commands computer - balance ........................................................................61

23. UNDER-FLOOR WEIGHING.............................................................................................64

24. TECHNICAL PARAMETERS............................................................................................65

24.1. ies..................................................................................................................65 WLX ser

24.2.

WTX series ..................................................................................................................65

25. ERROR MESSAGES ........................................................................................................66

- 4 -

1. INTENDED USE

The balances are used to do precise measurements in laboratories.

It is possible to do the zero function in all measure range.

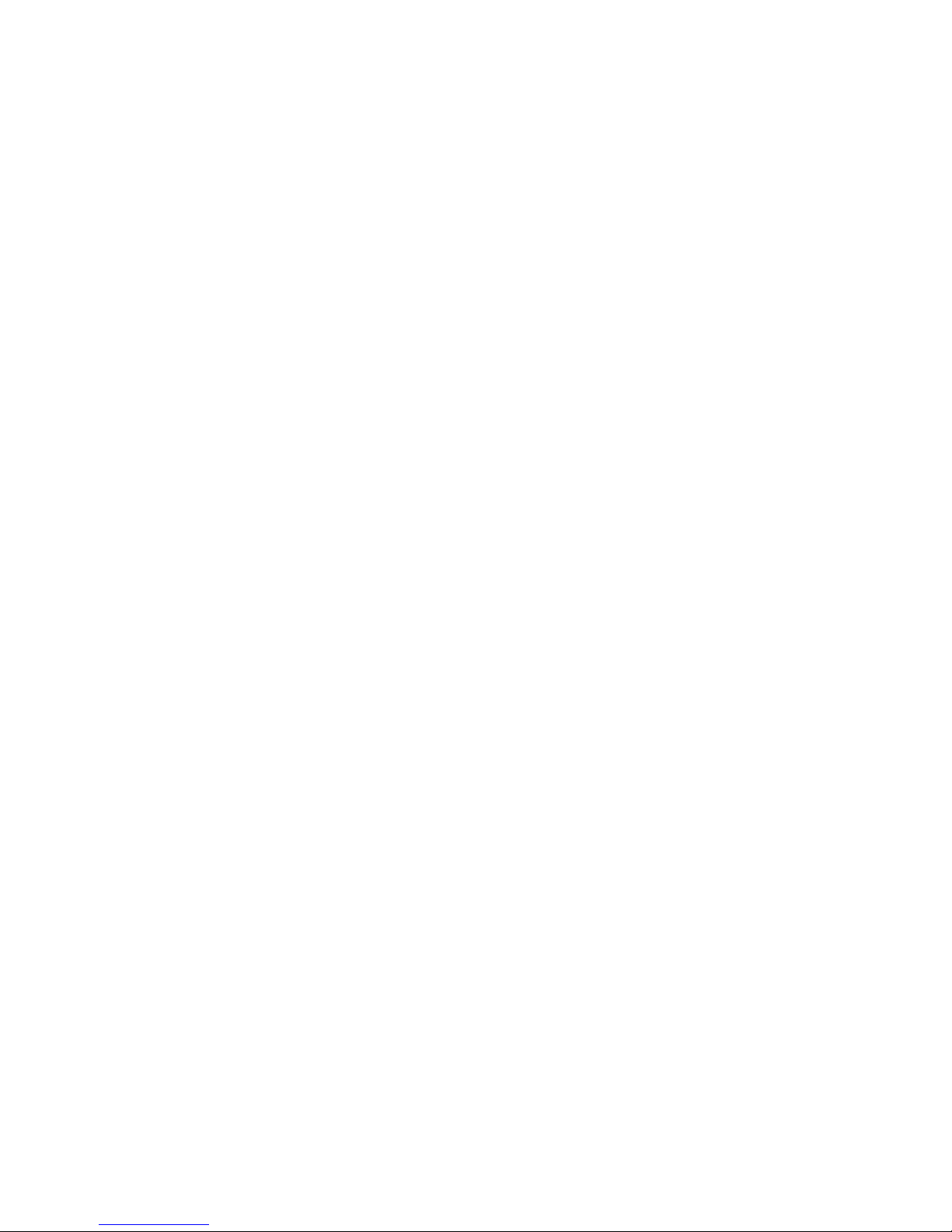

The balance weights in following units:

Measure units

Apart from weighing in various measure units the balance also:

• counts pieces

• weights

• filling

• percent

• weights animals

• determines liquids and solids density

• formulation

• creates statistics

Measure units and particular functions can be inaccessible for u ser.

It is possible to adapt the balance to individual needs and access

functions and units which are necessary at this moment.

It is possible to define accessible or no-accessible in user menu

and it is described in further part of the manual.

2. PRECAUTIONARY MEASURES

A. Please, read carefully this user manual before and use the device

according to its intended use.

B. If the device is about to operate in a strong electrostatic field

(e.g. printing houses etc.) it should be connected to the earthing.

Connect it to the clamp terminal signed

.

- 5 -

3. WARRANTY CONDITIONS

A. RADWAG is obliged to repair or change those elements that appears

to be faulty because of production and construction reason,

B. Defining defects of unclear origin and outlining methods of

elimination can be settled only in participation of a user and the

manufacturer representatives,

C. RADWAG does not take any responsibility connected with

destructions or losses derives from non-authorized or inappropriate

(not adequate to manuals) production or service procedures,

D. Warranty does not cover:

• Mechanical failures caused by inappropriate maintenance of the

device or failures of thermal or chemical origin or caused by

atmospheric discharge, overvoltage in mains or other random

event,

• Inappropriate cleaning.

E. Loss of warranty appears after:

• Access by an unauthorized service,

• Intrusion into mechanical or electronic construction of

unauthorized people,

• Removing or destroying protection stickers.

F. The detailed warranty conditions one can find in warranty certificate.

G. Contact with the central authorized service:+48 48 384 88 00 ext.

106 or 107.

4. UNPACKING OF THE BALANCE

4.1. WTX series

Cut open tape protecting the box. Take out the balance of factory package

and place it on a stable base. Take out all

components and assemble them

according to below drawings:

- 6 -

4.2. WLX series

Unpack and put the scale on a flat even stable surface far away from

sources of heat and then:

• Remove transport protections

• Install the weighing pan according to the drawing below:

5. GETTING STARTED

5.1. Conditions of appropriate use

• Place balance on a stable and flat table or free from vibrations

• Bbalance should not be exposed to draughts and sudden air

movements

• Balance should be placed in room of stable temperature and humidity

• Balance should be placed far from heat sources

• If static electricity influence balances, indications, its base should be

earthed. Earthing clamp is in the back part of balance base

• Balances should be levelled according to a level condition indicator

to guarantee the appropriate weighing accuracy.

- 7 -

5.2. Time of warming up

To do the measurements correctly level the scale. Take the pan off

carefully (without rapid pulls and hits) and turn the legs in order to level

the balance, air bubble should be place in the centre of level condition

indicator.

1 - correct levelling

2 - incorrect levelling

5.3. Balance levelling

Before performing measurements wait until balance reaches temp erature

stabilization. It is so-called warm-up time. It takes about 15 minutes.

For weighing instruments that have been stored in low tempe ratures

(e.g. during winter) the warm-up time is about 2 hours.

6. BALANCE DESCRIPTION

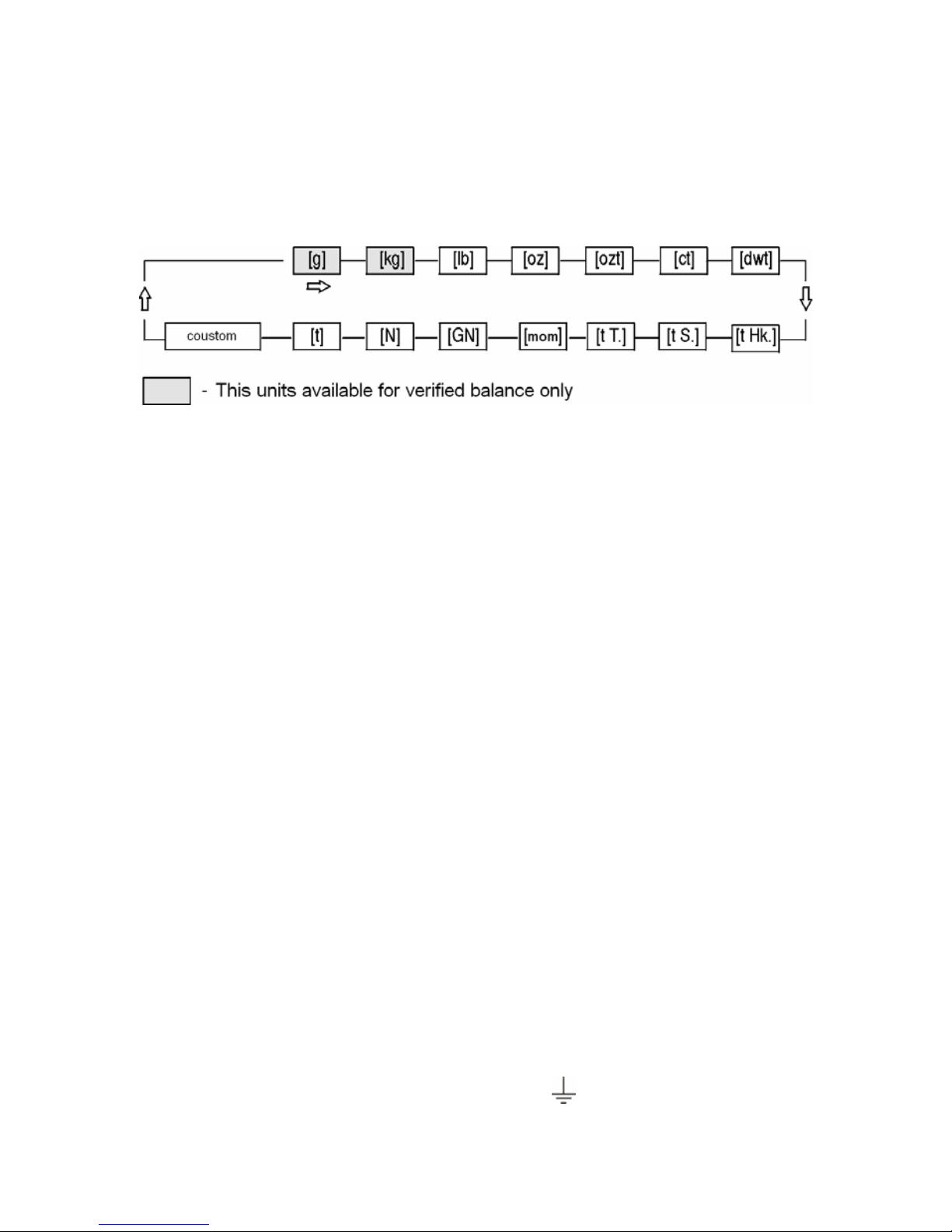

6.1. Graphic display

Graphic display

1 Load mass

2 Measure unit

3 The result is stable

4 Line of max range of the balance

5 Work mode

6 Date

7 Time

8 ZERO indication

- 8 -

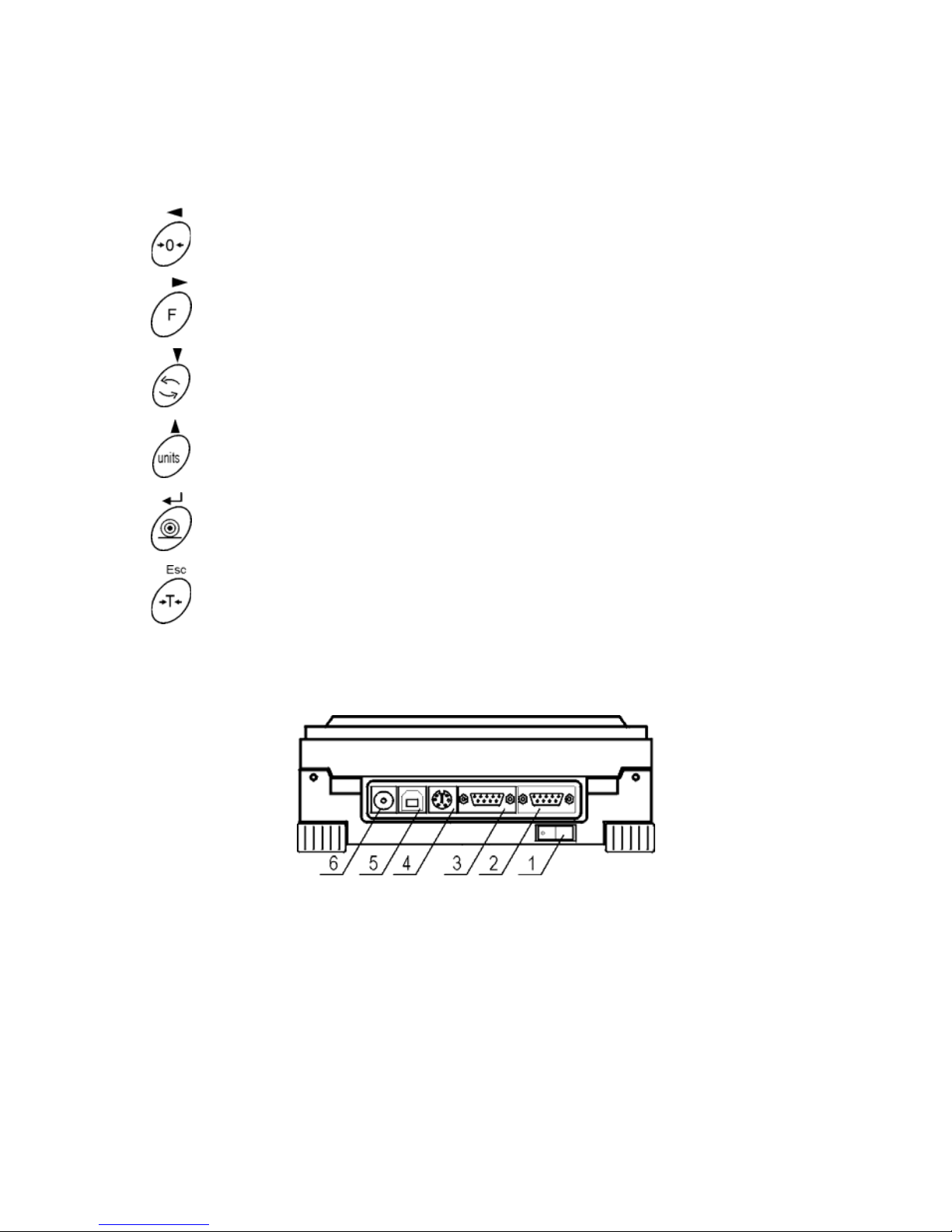

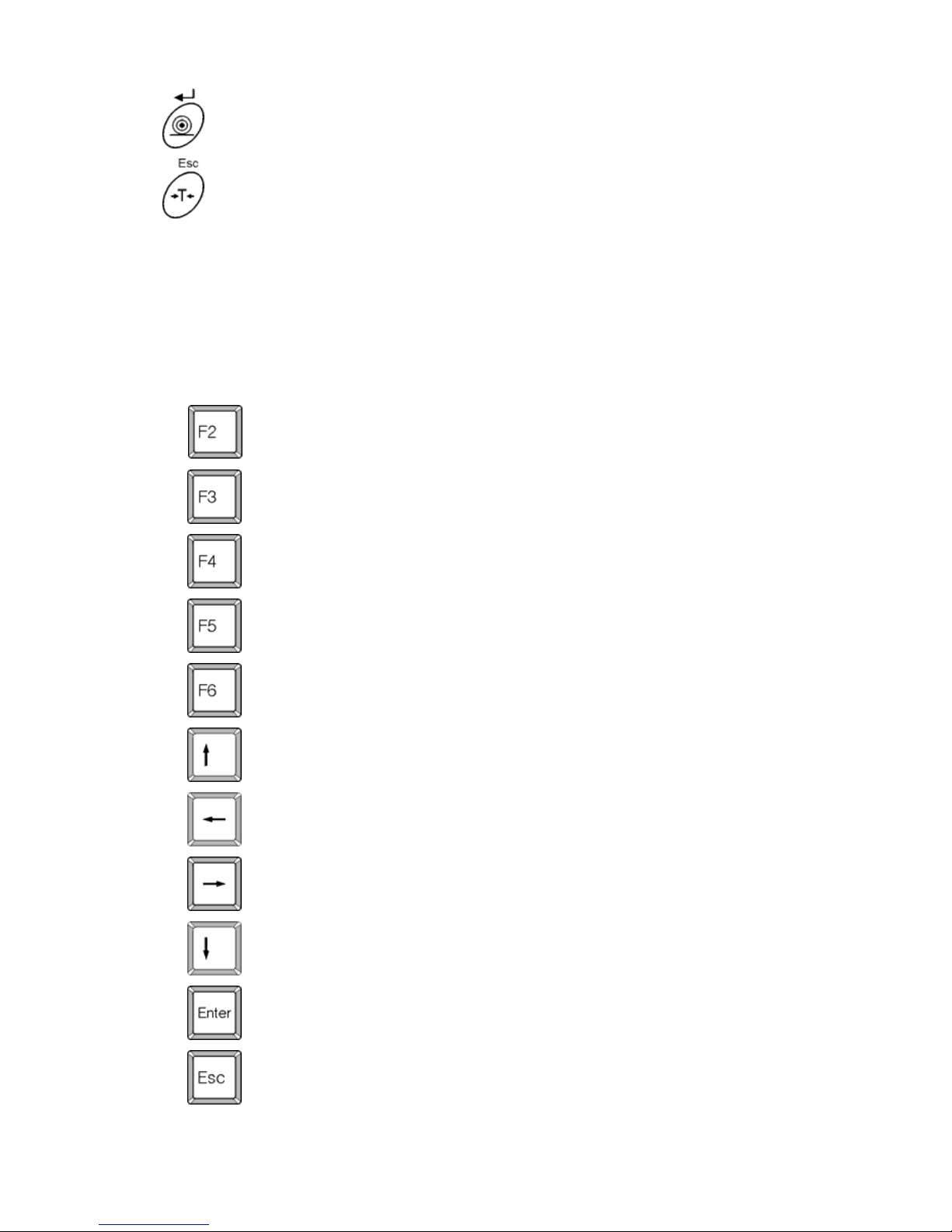

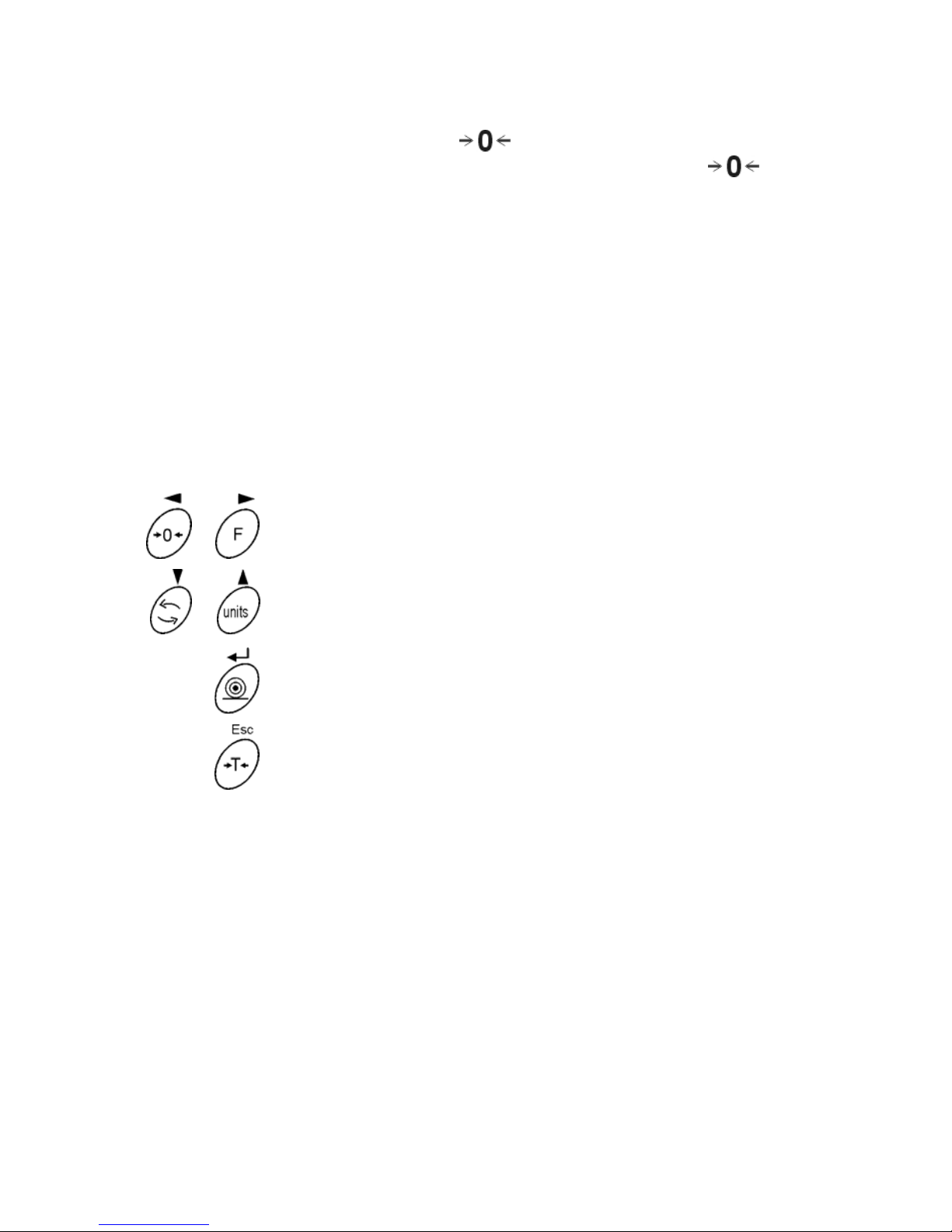

6.2. Keyboard

Each key is dual-function key. Particular function can be done through.

User also can move in the balance menu.

Zeroing

Function key

Selects the work mode

Changes measure units

Sends information to external instrument (PRINT)

or confirms parameter value or function (ENTER).

Tarring

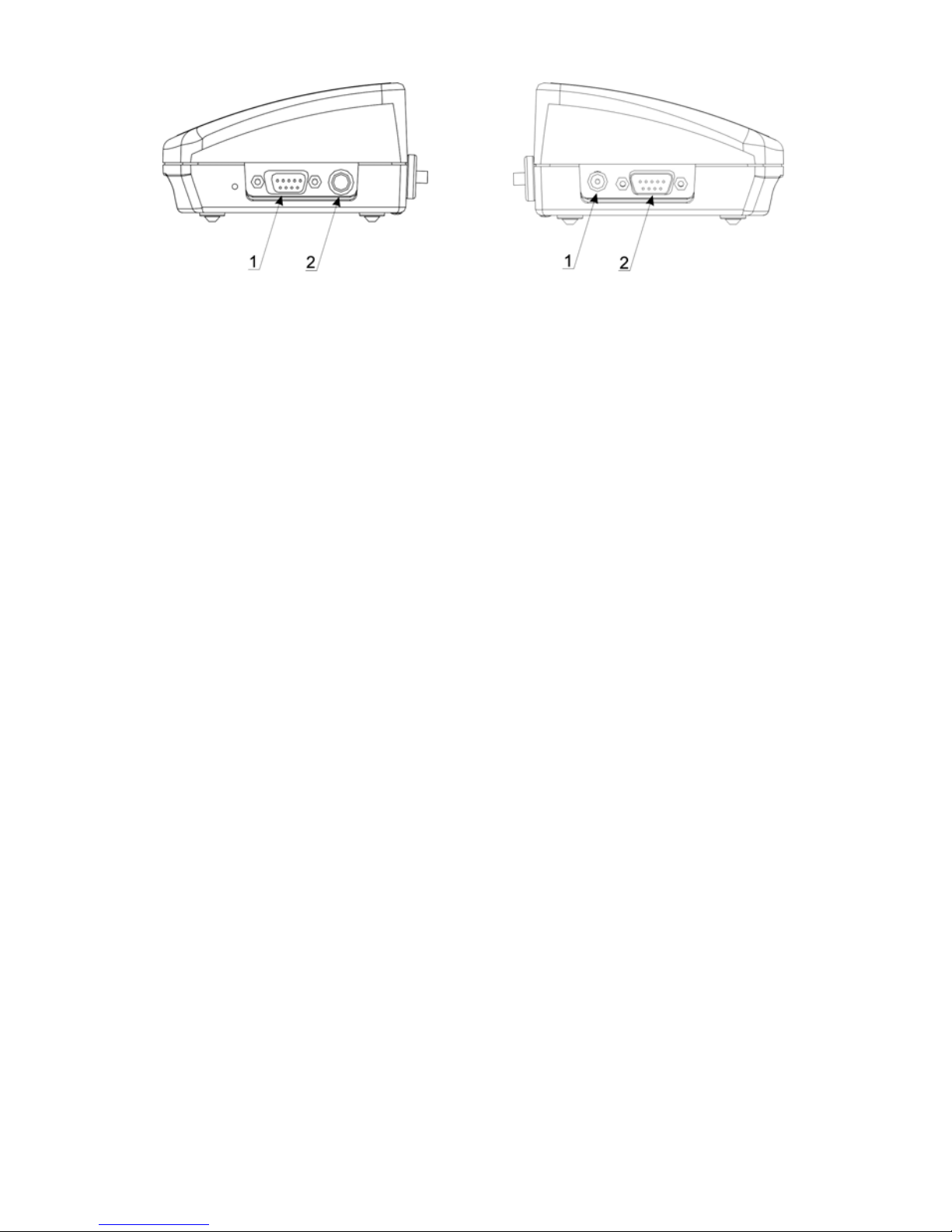

6.3. Connecting sockets

Sockets of the WTX

1 Power adapter socket

2 Add display connector

3 RS 232 port

4 PS keyboard connector

5 RS 485 port

6 Power supply

- 9 -

Sockets of the WLX

1 – Add display connector

2 – PS/2 port

Sockets of the WLX

1 – Power supply

2 – RS 232 port

7. USER MENU

7.1. Overview of parameters

User’s menu comprises 9 groups of parameters signed by P.

Below you can see listed groups and parameters.

P1 Calibration

01 Ext. calibr.

|

********

|

function

02 User calibr.

|

********

|

function

03 Print report

|

1

|

on

P2 GLP

01 User

|

Nowak Jan

|

02 Project

|

AR - 65 / 04

|

03 Time print

|

0

|off

04 Date print

|

0

|off

05 User print

|

0

|off

06 Project print

|

0

|off

07 Id print

|

0

|off

08 Last cal print

|

0

|off

P3 Date/ Time

01 Date format | 0 | DA/MO/YR

02 Time format | 0 | 24 hours

03 Time |

********

| function

04 Date |

********

| function

05 Disp. Time | 1 |

on

06 Disp. Date | 1 |

on

P4 Readout

01 Filter | 3 | normal

02 Median filter | 3 | normal

03 Disp. refresh | 1 | 0.1s

04 Autozero | 1 | on

05 Last digit | 1 |

always

06 Negative

|

0

|

no

- 10 -

07 Aut. tare

|

0

|

no

P5 RS - 232

01 Baud rate

|

1

|

9600

02 Parity

|

0

|

none

03 Data bits

|

2

| 8 bit

s

1 bit

04 Stop bits

|

1

|

05 Handshake

|

0

| none

06 Auto print

|

0

| none

07 Interval

|

1

| * 0.1 s

08 Min. mass

|

4

| 10 d

09 Print on stab

|

1

| enabled

10 Pause

|

0

| * 0.1 s

P6 Printout

01 Printout mem

|

0

|

function

02 Printout dest.

|

0

|

RS

03 Printout No.

|

0

|

Standard

04 Pr. mem. No.

|

0

|

Standard

05 Pr. 1 start

|

1

|

06 Pr. 1 stop

|

1

|

07 Pr. 2 start

|

1

|

08 Pr. 2 stop

|

1

|

.... ……........

|

|

13 String 1

|

|

14 String 2

|

|

.... ……........

|

|

92 String 80

|

|

P7 Units

01 Grams

|

1

|

enabled

02 Kilograms

|

0

| disabled

03 Pounds

|

0

| disabled

04 Ounces

|

0

|

disabled

05 Ounces troy

|

0

| disabled

06 Carats

|

0

| disabled

07 Dwt

|

0

| disabled

08 Taele Hk.

|

0

| disabled

09 Taele S.

|

0

| disabled

10 Taele T.

|

0

| disabled

11 Momms

|

0

| disabled

12 Grains

|

0

| disabled

13 Newtons

|

0

| disabled

14 Tical’ e

|

0

| disabled

15 Custom

|

0

| disabled

16 Custom factor

|

1

|

P8 Work modes

01 Parts Counts

|

1

|

enabled

02 Checkweighing

|

1

|

enabled

03 Filling

|

1

|

enabled

04 Percent

|

1

|

enabled

05 Animal

|

1

|

enabled

06 Density

|

1

|

enabled

07 Formulation

|

1

|

enabled

- 11 -

08 SQC

|

1

|

enabled

09 Statistics

|

1

|

enabled

P9 Globals

01 ID setting

|

********

|

function

02 ID autoprint

|

0

|

off

03 Beep

|

1

|

enabled

04 Language

|

********

|

function

05 Backlight

|

1

|

on

06 Contrast

|

********

|

function

07 Screenserver

|

0

|

enabled

08 Balance ID

|

214493

|

09 Software rev.

|

MBT e31

|

10 Par. Printout

|

********

|

function

11 Par .receive

|

********

|

function

12 Factory deff.

|

********

|

function

13 Password

|

0

|

Parameters in user’s menu are:

• functional – for particular activity e.g. the balance calibration

• selectable – selects one of few values from the balance memory

• noted – changes sets in the balance memory e.g. Date, time, user

number, texts

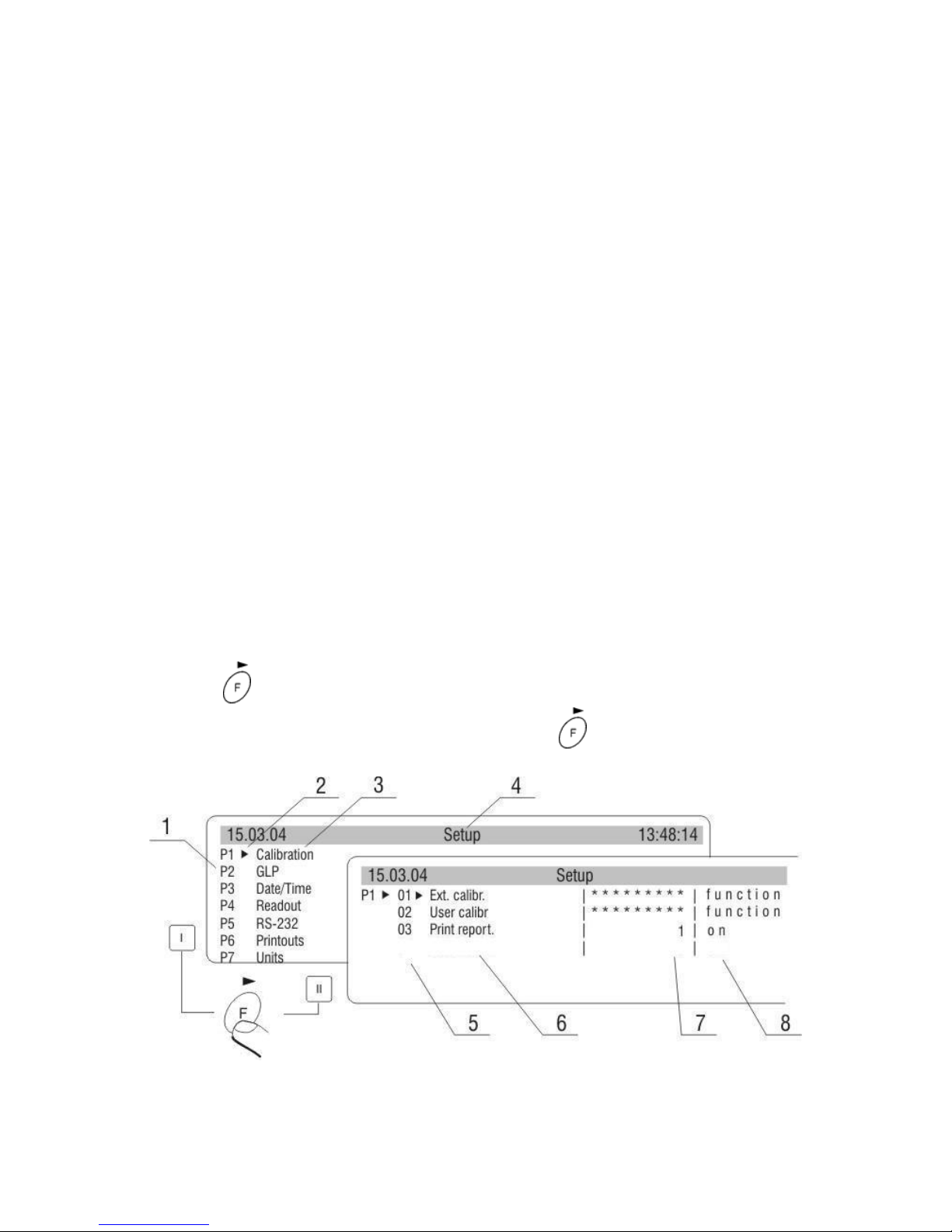

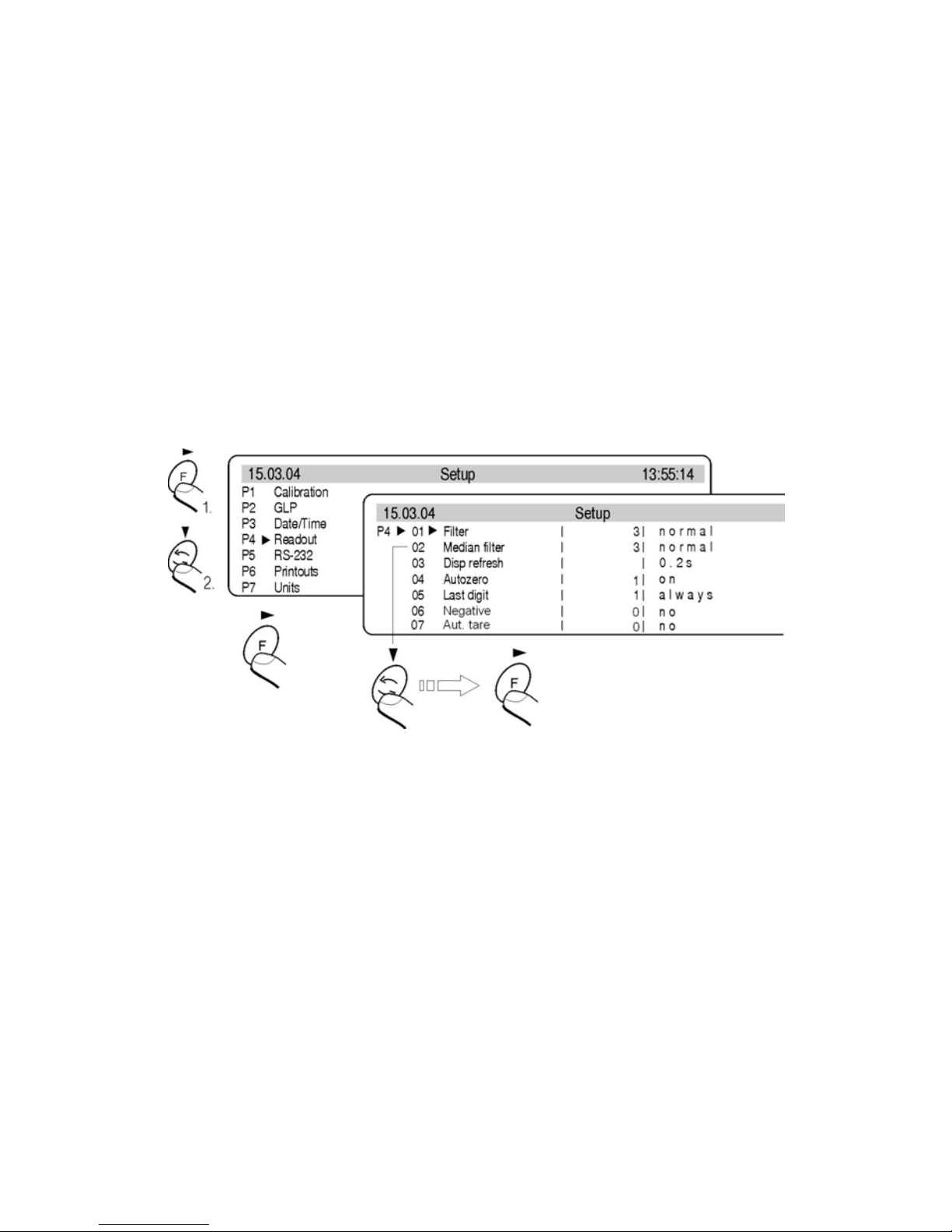

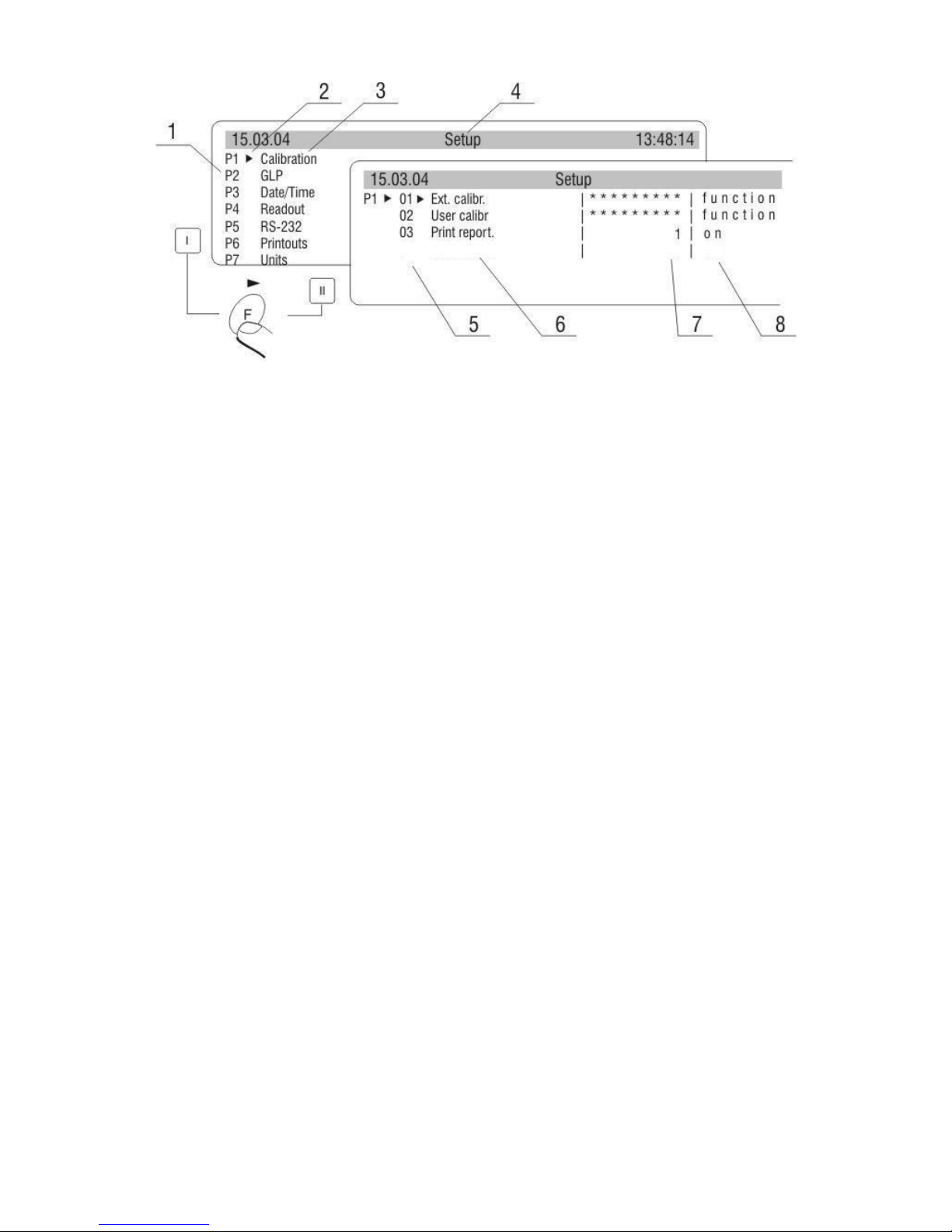

7.2. Menu - graphic version

Press the key to display main menu of the balance. Select the submenu

whose contents is displayed after pressing the

key.

View of balance menu

- 12 -

1 Number of main menu

2 Choice of function marker

3 Name of function

4 Name of currently performed activity

5 Number of submenu

6 Name of submenu

7 Attribute of submenu

8 Value referring to attribute

Press the key. Selected menu appears on the display. Select what will

be changed in this submenu (activate). Select through keys presented on

the drawing above. Press the

key. Reaction of the balance:

• Activity of the balance (e.g. the balance calibration) is done from

submenu described as Function,

• Attribute activation for submenu which is indicated (digit flashing

means the value can be changed and some characters can be

written).

7.3. Navigating within the menu

User moves in the menu by:

• the balance keyboard,

• PS keyboard.

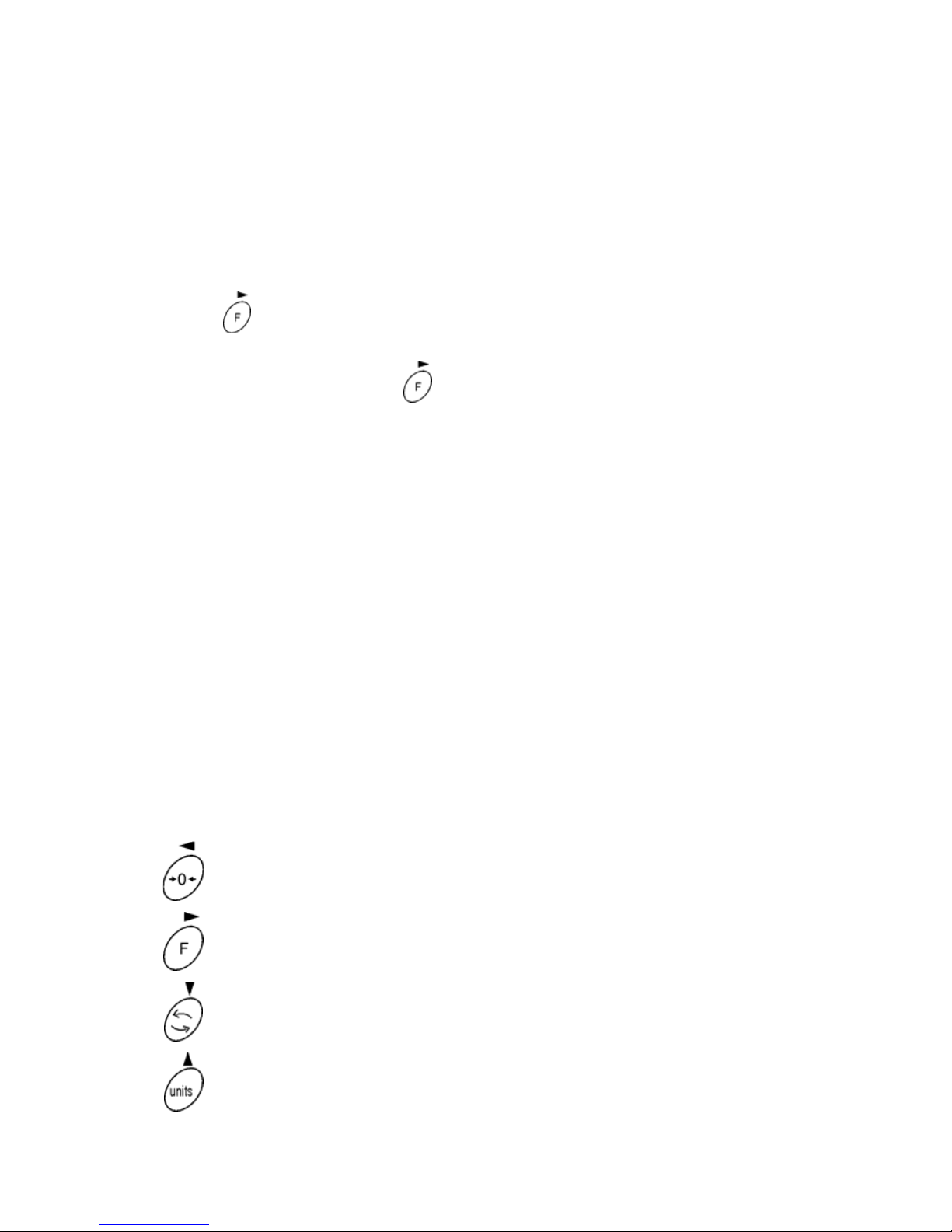

7.3.1. By means of balance keyboard

Exit to one step higher level to menu

Entering parameter edition

Moving cursor downwards

Moving cursor upwards

- 13 -

Confirmation of introduced values

Cancellation of changes, menu exit

7.3.2. By means of PC keyboard

Every operation that can be made from the level of the balance keyboard

Has its equivalent on the PC keyboard level:

Move to the balance menu

Selects work mode

Selects measure unit

PRINT

TARE

Move up

Move to level up

Sets selected parameter

Move down

Confirm changes

Cancel and leave function without changes

- 14 -

7.4. Return to weighing

Introduced changes in settings will be saved after return to

weighing mode with procedure of saving changes. After

introducing all changes in parameters settings press several

times ESC key. When display indicates message, choose

one of two options:

ENTER – save changes

ESC – without saving

8. WEIGHING

Following conditions must be fulfilled to get reliable results:

• Stable temperature

• Stable ground

• Proper parameters for external conditions

Before measurements load the pan and check if the balance show

„precise zero” – displayed

in down left corner of the display

(only if the parameter <P4 06 Autozero> has the value 1: yes) and

check if the measurement is stable –

is displayed in right up

corner of the display. If the balance does not show zero press

the key

If the conditions are unfavourable (no stable result) lines appear on

the display. After settled time the balance returns to weighing mode

without set up to zero. In this case wait until the conditions stabilize

and press Esc again.

By the Units key select measure unit. Put the load on the pan and

after stabilization read out the result. If measure unit user wants to

use is not displayed during pressing the Units key check if it has

access attribute.

The indication can be set to zero many times. Sum of loads noted

in the balance memory cannot be higher than max capacity.

Between following measurements do not unplugged the balance.

The balance should be switched off by the ON/OFF key. After

pressing the key again the balance is ready to work without warm

stabilization.

- 15 -

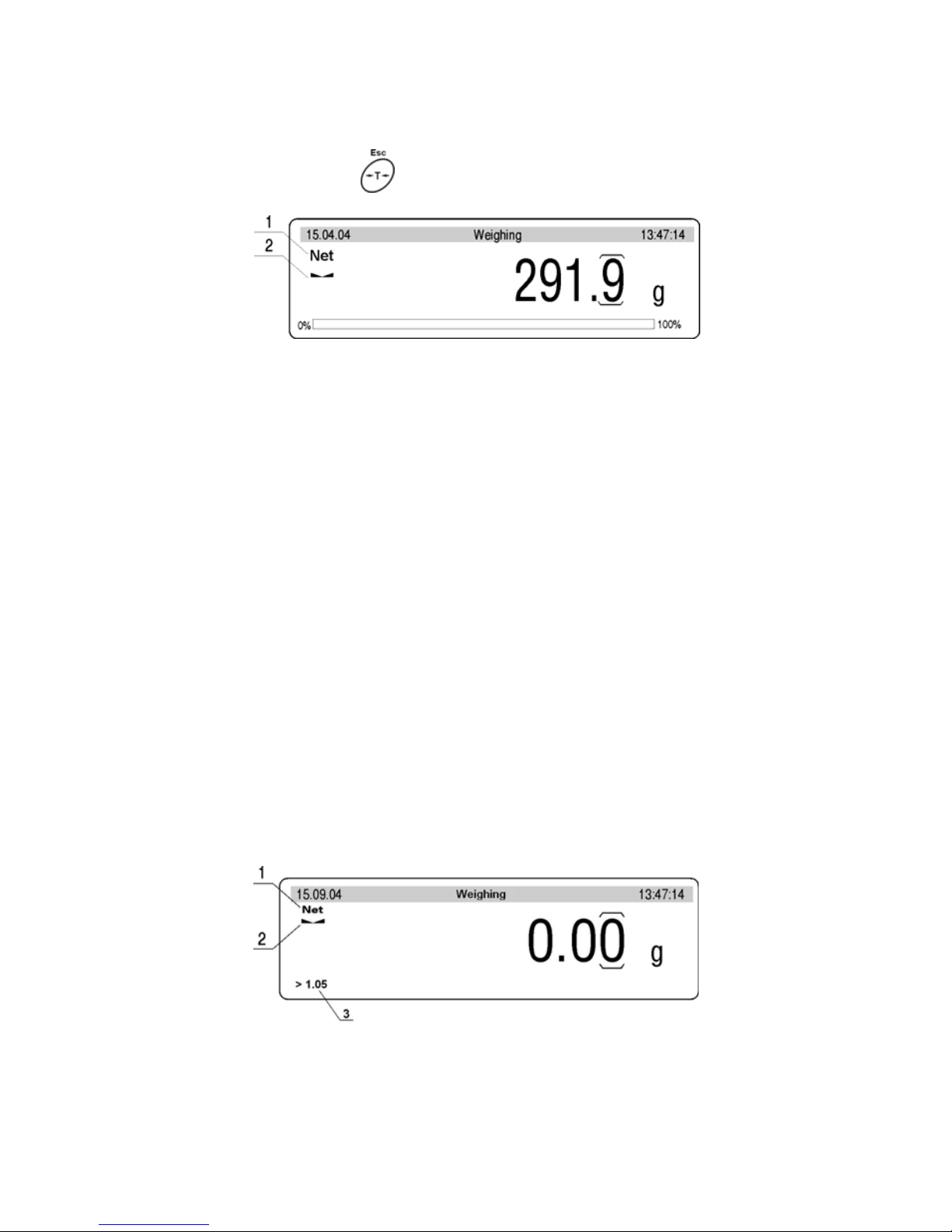

8.1. Tarring

For determining net mass place on the pan package of load and when

indication is stable press

key.

Tarring – display view

1 TARE signature (NET is being displayed)

2 stable result signature

Tarring can be performed repeatedly in the whole balance weighing range.

Using tare function pay attention not to exceed the maximum weighing

range. After removing the load and package display will indicate mass

equal to mass of tare with minus sign.

Notice:

Tare value is not stored in balance memory and is deleted after

disconnecting from mains

8.2. Manual inscribing of tare value

Inscribing the tare value in weighing mode:

• Inscribe a tare value in a display format e.g. if a basic unit is „kg”

with a division 0,005kg and you want to enter 1.05kg as a tare value,

inscribe it as: 1.050,

• After pressing the first digit you can see an editing field in the last line.

Inscribing tare value – display view

1 TARE value entered

2 stable measurement pictogram

3 inscribed tare value

- 16 -

• Press T key

• You will see the tare value with “– “ sign on the display

• Tare value can be inscribed any time during weighing

Notice

Use “point” for decimal fractions.

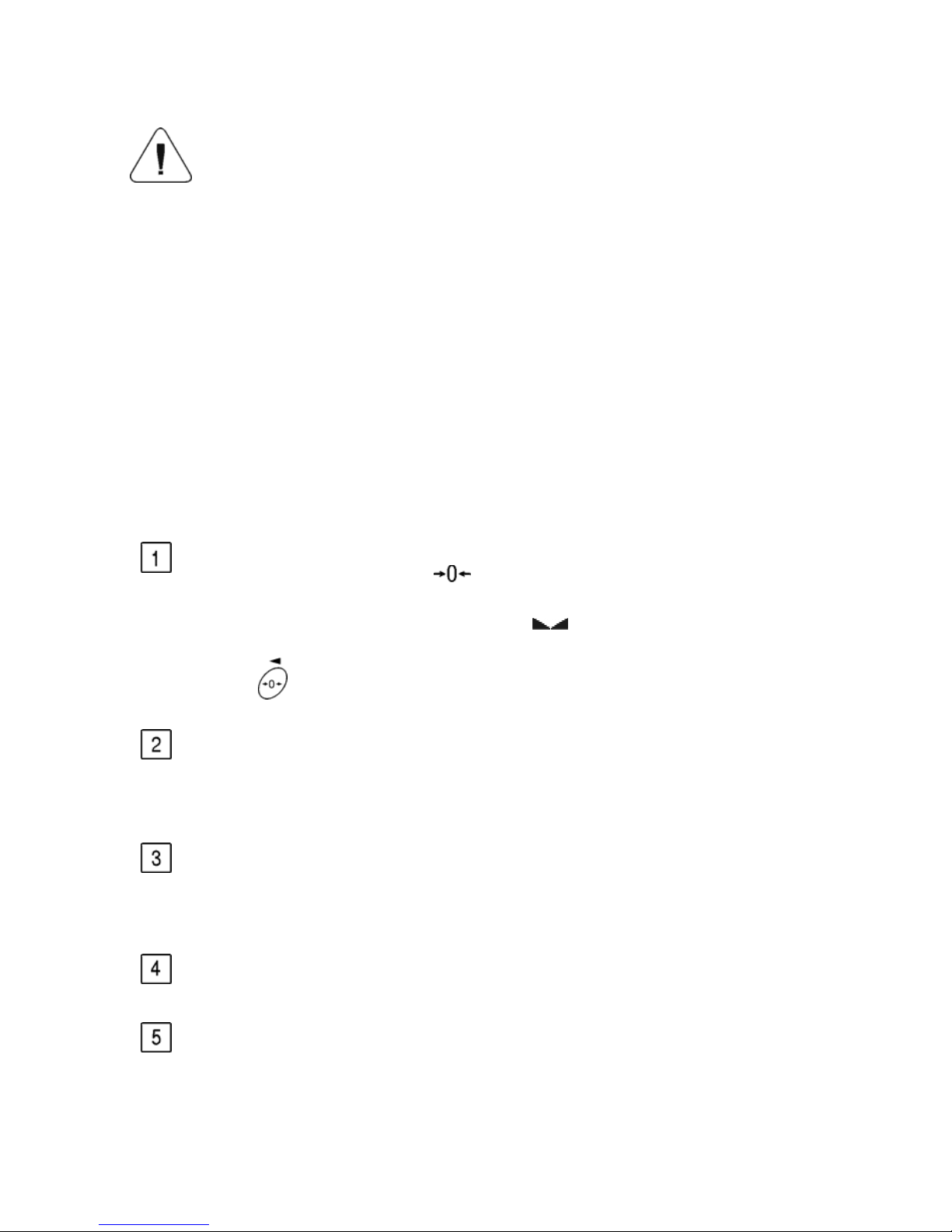

8.3. Automatic tare

This function is useful for quick determining net mass of weighed goods

when tare values are different for each weighings. It is accessible in

<P4 Readout> parameters group.

Enabling function:

Automatic tare – enabling

After setting an appropriate value of the parameter return to weighing

7.4. of this manual.

The way of operation:

• Press ZERO button when the pan is empty,

• Put a package on the pan,

• After stabilizing tarring is performed (Net designator is displayed

in the top left corner of the display),

• Put an article on the pan,

• The display shows the net mass of the article,

• Unload the pan,

• Indication returns to zero,

• Put the next package … and the cycle repeats.

- 17 -

8.4. Zeroing

For zeroing display indication press

key. Indication will return to zero

and display will indicate a graphic signature in left lower corner

.

Zeroing of indication is possible only in range of 2% of maximum capacity

currently displayed balance/platform. If zeroed value is bigger than 2% of

maximum capacity display will indicate error message and return to

displaying previous value – for main balance or displayed mass will

not change.

Notice:

Balance zeroing determines a new zero point treated by balance as precise

zero. Zeroing is possible only in stable states of the indication.

8.5. Functions of keys

+

Select field (digit) to change

+

Change value of selected field

Confirm value

Canceling

9. BALANCE CALIBRATION

To ensure very high accuracy of weighing, periodical entering to memory

correction factor of balance indication referring to standard mass is

required; it is so called balance calibration. The procedure of calibration

can be performed only by authorized services of the manufacturer.

- 18 -

Internal setting of calibration

1 Main menu number

2 Cursor

3 Group of parameters

4 Status bar

5 Parameter number

6 Parameter name

7 Parameter value

8 Parameter description

Notice:

In verified scales calibration can be accessed from the user’s menu.

Calibration should be performed with no load on the pan.

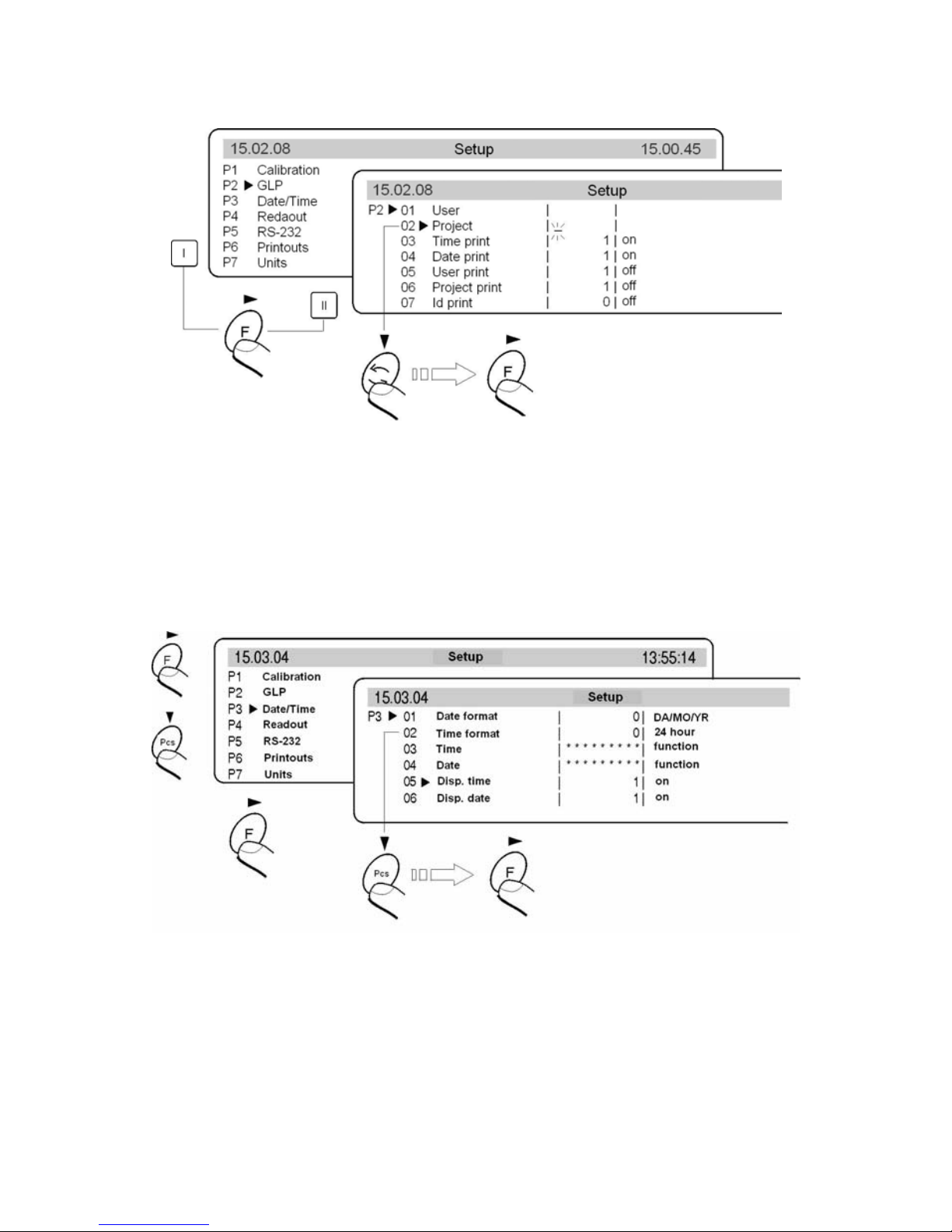

10. SETTING OF PRINTOUTS CONTENTS FOR GLP PROCEDURES

P2 GLP his group of parameters allows to enable/disable printing some

variables on the standard printout and calibration report.

For variables:

User and project name (max 8 alphanumerical characters) enter na mes

with balance keyboard or with PS/2 keyboard.

For remaining fields, select digits:

• 0 no (do not print during report)

• 1 yes (p rint during report)

- 19 -

Main view of GLP parameters:

GLP submenu

11. TIME AND DATE SETTING

Balances have a real time clock, which can be modified. Enter menu

group <P3 Date/Time> according to the below scheme:

Date/Time submenu

01 Date format

Has doublestate choice according to below dependance:

1 date format Month/Day/Year

0 date format Day/Month/Year

After choice of appropriate value confirm with ENTER key.

- 20 -

02 Time format

Has doublestate choice according to below dependance:

1 time format 12 hours

0 time format 24 hours

After choice of appropriate value confirm with ENTER key. Format 12

hours is diffrentiated by placing letters PM or AM on printouts.

03 Time

With F key enter parameter <03 Time> setting according to below scheme.

Submenu Date / Time – time setting

Set cursor next to value which os to be changed (Hour, Minute, Second).

Confirm choice pressing F key. Using keys Pcs and n change values.

Submenu Date/Time – time setting – steering keys

- 21 -

Loading...

Loading...