RADWAG WPY/KB series, WPY series, KO series, KB series User Manual

User Manual

Scales of WPY/KB series

Manual number:

ITKU-47-12-05-12-A

Mass Comparator

MANUFACTURER OF ELECTRONIC

WEIGHING INSTRUMENTS

RADWAG Wagi Elektroniczne, 26–600 Radom Bracka 28 Street - POLAND

Phone +48 48 38 48 800, phone/fax. +48 48 385 00 10

Selling department +48 48 366 80 06

www.radwag.com

MAY 2012

2

Table OF CONTENTS

USE ..........................................................................................................................7 INTENDED

1.

2.

PRECAUTIONARY MEASURES ................................................................................................7

3. WARRANTY CONDITIONS ........................................................................................................7

4. UNPACKING AND MOUNTING..................................................................................................8

4.1. Comparator WPY/KB – preparation for work .......................................................................9

5. CONSTRUCTION......................................................................................................................10

5.1. Main dimensions ................................................................................................................10

5.2. Description of connectors...................................................................................................11

5.2.1. .............................................................................11 Connectors’ description in PUE 7

5.2.2.

...........................................................................11 Connectors’ description in PUE 7P

5.2.3.

..................................................................................11 Description of glands PUE 7P

Connector with RS232 and I/O.................................................................................12

5.2.4.

6. GETTING STARTED.................................................................................................................12

7. KEYPAD OVERLAY..................................................................................................................13

8. TIONS OF KEYS .............................................................................................................13 FUNC

9.

PROGRAM STRUCTURE.........................................................................................................14

9.1. Main menu items ................................................................................................................14

9.1.1. ...............................................................................................................14 Parameters

9.1.2.

.................................................................................................................15 Databases

Scale Info..................................................................................................................15 9.1.3.

9.2.

Inventory of parameters .....................................................................................................16

9.2.1. ....................................................................................16 Scale parameters - weighing

.........................................................................................................16 Working modes

9.2.2.

9.2.3.

.........................................................................................................19 Communication

9.2.4.

.....................................................................................................................19 Devices

9.2.5.

......................................................................................................................21 Display

uts ........................................................................................................22 Inputs / Outp

9.2.6.

9.2.7.

...........................................................................................................23 Authorizations

9.2.8.

.........................................................................................................................23 Other

User Calibration........................................................................................................24

9.2.9.

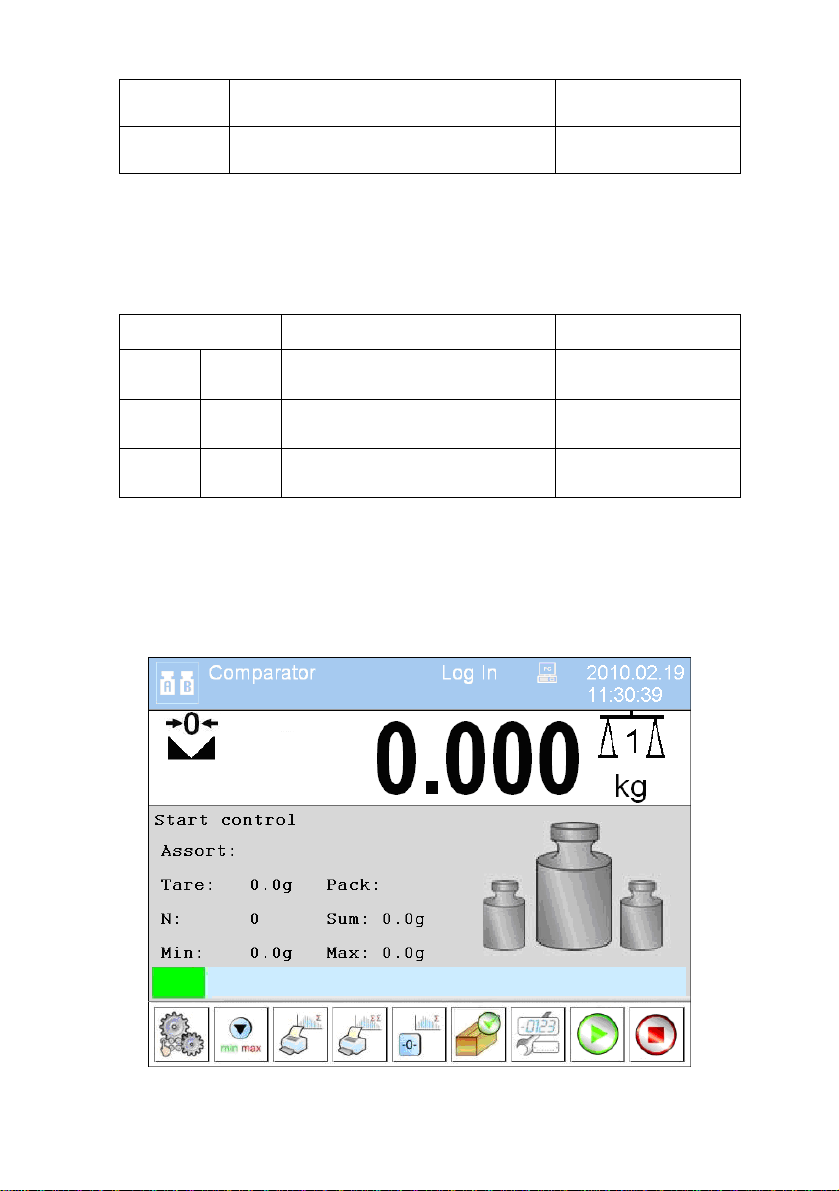

10. ATING WINDOW ...........................................................................................................24 INDIC

11.

LOGGING ON..........................................................................................................................26

11.1. dure ........................................................................................................26 Logging in proce

11.2.

rocedure......................................................................................................26 Logging out p

11.3.

Authorization access levels...............................................................................................27

12. NAVIGATING WITHIN THE MENU.........................................................................................28

12.1. ..............................................................................................................................28 Buttons

Return to weighing............................................................................................................29

12.2.

13. WEIGHING...............................................................................................................................30

13.1. erational use ...........................................................................................30 Conditions of op

13.2.

..............................................................................................................................31 Zeroing

13.3.

...............................................................................................................................31 Tarring

....32 Inscribing tare................................................................................................................

13.4.

13.5.

l range scales.........................................................................................32 Weighing for dua

13.6.

Toggling between weight units..........................................................................................32

14. SCALE PARAMETERS...........................................................................................................33

14.1. .....34 Median filter..................................................................................................................

..................................................................................................................................34 Filter

14.2.

14.3.

............................................................................................................................34 Autozero

14.4.

Minimum weight for different functions (LO) .....................................................................35

3

15. COMMUNICATION..................................................................................................................35

15.1. .................................................................................................................36 RS 232 settings

15.2.

T setting...........................................................................................................36 ETHERNE

TCP protocol setting .........................................................................................................37 5

1 .3.

DEVICES .................................................................................................................................37

16.

16.1. Computer ..........................................................................................................................37

16.1.1. .........................................................................................................37 Computer port

16.1.2.

ss ..................................................................................................38 Computer addre

mission ........................................................................................38 Continuous trans

16.1.3.

16.1.4.

t pattern........................................................................................39 Weighing printou

16.1.5.

16.2. Printer................................................................................................................................40

16.3. Barcode scanner...............................................................................................................43

16.4. Transponder card reader ..................................................................................................44

16.5. Additional display..............................................................................................................45

17. DISPLAY..................................................................................................................................47

17.1. Text strings........................................................................................................................47

17.2. ys....................................................................................................................50 Function ke

17.3.

17.4.

18. INPUTS / OUTPUTS................................................................................................................53

18.1. nputs......................................................................................................53 Configuration of i

18.2.

19. AUTHORIZATION ...................................................................................................................55

19.1. ymous Operator........................................................................................................55 Anon

19.2.

19.3.

19.4.

19.5.

20. OTHER PARAMETERS ..........................................................................................................57

20.1. ........................................................................................................................58 Languages

20.2.

20.3.

20.4.

21. CUSTOMER CALIBRATION...................................................................................................59

21.1. dure........................................................................................................60 Calibration proce

21.2.

Cooperation with „E2R System” .............................................................................39

16.2.1. ..............................................................................................................40 Printer port

16.2.2.

e ...................................................................................................41 Printer code pag

Patterns for printouts..............................................................................................41

16.2.3.

16.3.1. arcode scanner ........................................................................................43 Port for b

......................................................................................................................43 Offset

16.3.2.

16.3.3.

Code length............................................................................................................44

16.4.1. or transponder card readers ..................................................................44 Com port f

16.4.2.

Procedure of attributing the card number to an operator........................................45

16.5.1. y port.............................................................................................45 Additional displa

16.5.2.

Communication protocol frame...............................................................................46

17.1.1. patterns......................................................................................................48 Display

17.1.2.

.............................................................................................................49 Screen font

.................................................................................................................49 Font size

17.1.3.

17.1.4.

Bold fonts................................................................................................................49

ing platforms..........................................................................................................50 Display

Bargraph type ...................................................................................................................51

17.4.1. weighing”........................................................................................52 Bargraf “Quick

Bargraph “Signalling checkweighing ranges”.........................................................52

17.4.2.

Configuration of outputs....................................................................................................54

....................................................................................................................55 Date and time

............................................................................................................................56 Printouts

.........................................................................................................................56 Databases

Delete older data...............................................................................................................57

time........................................................................................................58 Setting date and

.....................................................................................................................59 Sound signal

Touch panel calibration.....................................................................................................59

Start mass adjustment ......................................................................................................62

4

22. SPECIAL FUNCTIONS OF WORKING MODES.....................................................................63

22.1. ................................................................................................................64 Recording mode

22.2.

wn-weighing .................................................................................................................64 Do

eighing..................................................................................................................65 Checkw

22.3.

22.4.

de.........................................................................................................................65 Tare mo

22.5.

Labelling mode..................................................................................................................66

22.5.1. mber of labels to print...................................................................66 Setting of the nu

22.5.2.

mber of cumulative labels to print.................................................67 Setting of the nu

22.5.3.

mber of CC labels to print.............................................................67 Setting of the nu

cumulative labels...............................................................68 Automatic triggering of

22.5.4.

22.5.5.

22.6. ............................................................................................................................71 Statistics

22.7.

22.8.

22.9.

22.10. Declaration of the number of measurement series.........................................................73

23. WORK MODE - WEIGHING....................................................................................................74

23.1. Starting the working mode ................................................................................................74

24. WORKING MODES – COUNTING PIECES............................................................................74

24.1. working mode................................................................................................74 Starting the

24.2.

24.3.

24.4.

2 .5.

WORKING MODES – DEVIATIONS.......................................................................................77

25.

25.1. rating mode..............................................................................................77 Starting the ope

25.2.

25.3.

26. WORKING MODES – COMPARATOR...................................................................................78

26.1. working mode................................................................................................80 Starting the

26.2.

26.3.

27. DATABASES...........................................................................................................................85

27.1. Searching databases ........................................................................................................85

27.2. w items in databases........................................................................................87 Adding ne

27.3.

27.4.

27.5.

27.6.

27.7.

Automatic triggering cumulative labels of cumulative labels...................................69

mass ...........................................................................71 Automatic correction of reference

ce mass..................................................................................................72 Minimum referen

Selecting the series type................................................................................................... 73

ce unit by entering known piece mass ...................................................75 Setting a referen

ce unit by weighing a sample.................................................................75 Setting a referen

rence mass by entering single piece mass directly to the database ........76 Setting the refe

Inscribing the unit mass to the database ..........................................................................76 4

ass estimated by weighing ....................................................................78 Reference unit m

Rederence unit mass inscribing into the memory.............................................................78

eight mass ......................................................................................................80 Selecting w

The process of large weights comparison ........................................................................80

27.1.1. .................................................................................................86 Quick name search

..................................................................................................86 Quick code search

27.1.2.

27.1.3.

Weighing date search.............................................................................................86

..............................................................................................87 Deleting items in databases

ta............................................................................................................87 Deleting older da

..........................................................................................88 Printing items from databases

a database to a file................................................................................................88 Export

Database edition...............................................................................................................90

27.7.1. ase...............................................................................................90 Operators’ datab

roducts..............................................................................................90 Database of p

27.7.2.

27.7.3.

ghings / Alibi.................................................................................91 Database of Wei

27.7.4.

ractors..........................................................................................92 Database of cont

kages............................................................................................93 Database of pac

27.7.5.

27.7.6.

warehouses ........................................................................................94 Database of

27.7.7.

ls..................................................................................................94 Database of labe

Database of universal variables..............................................................................95

27.7.8.

5

28. COMMUNICATION PROTOCOL ............................................................................................95

28.1. ral information ..........................................................................................................95 Gene

28.2.

of RS commands...............................................................................................96 Inventory

.................................................................................................97 Respond message format

28.3.

28.4.

Command’s description ....................................................................................................97

28.4.1. ....................................................................................................................97 Zeroing

.....................................................................................................................97 Tarring

28.4.2.

28.4.3.

re value .........................................................................................................98 Get ta

28.4.4.

..........................................................................................................98 Set tare value

in basic unit.........................................................................99 Send the stable result

28.4.5.

28.4.6.

mmediately in basic unit ...............................................................99 Send the result i

28.4.7.

......................................100 Send immediate results from all platforms in basic units

nit....................................................................100 Send the stable result in current u

28.4.8.

28.4.9.

Send the result immediately in current unit...........................................................101

28.4.10. Switch on continuous transmission in basic unit.................................................102

28.4.11. Switch off continuous transmission in basic unit.................................................102

28.4.12. Switch on continuous transmission in current unit..............................................102

28.4.13. Switch off continuous transmission in current unit..............................................103

28.4.14. Set lower threshold .............................................................................................103

28.4.15. Set upper threshold.............................................................................................103

28.4.16. Read lower threshold..........................................................................................103

28.4.17. Read upper threshold.........................................................................................104

28.4.18. Send all implemented commands.......................................................................104

28.5. Manual printouts / automatic printouts............................................................................104

29. NECTING EXTERNAL DEVICES..................................................................................105 CON

DIAGRAMS OF CONNECTION CABLES.............................................................................105

30.

31. TECHNICAL PARAMETERS................................................................................................107

32. ERROR MESSAGES.............................................................................................................109

33. DDITIONAL EQUIPMENT...................................................................................................109 A

34.

APPENDIX A – Variables for printouts...............................................................................110

34.1. of variables......................................................................................................110 Inventory

34.2.

Formatting variables .......................................................................................................114

35. APPENDIX B – Functions of programmable buttons .......................................................116

36. APPENDIX C – Label pattern...............................................................................................120

36.1. rminal level........................................................................120 Designing a label from the te

....................................................................................121 Designing a label on a computer

36.2.

36.3.

s in the scale ...................................................................................124 Saving label pattern

36.4.

l to a product........................................................................................125 Attributing a labe

l to a contractor....................................................................................125 Attributing a labe

36.5.

3 .6.

Printing labels..................................................................................................................125 6

APPENDIX D - CITIZEN printer setting...............................................................................126

37.

38. APPENDIX E - ZEBRA printer setting ................................................................................126

39. APPENDIX F - Communication with barcode scanners ...................................................127

6

1. INTENDED USE

Mass comparators are devices designed for determining the differences

between masses of calibration weight (B) and reference weight (A).

Comparators are most often used in measuring laboratories for calibration

of weights and masses. Radwag offers comparators designed for calibration

of weights and masses class M1 according to OIML R111.

2. PRECAUTIONA RY ME ASUR ES

A. Please, read carefully this user manual before and use the device

according to its intended use;

B. Weighed loads should be placed in possibly central pa rt of scale pan;

C. Do not clean the device with agents causing corrosion;

D. Weighing pan should be loaded with goods having gross mass lower

than maximal capacity of the scale;

E. Do not leave loads on the pan for longer period of time ;

F. In case of failure, immediately disconnect scale power supply;

G. Devices that are to be withdrawn from usage should be utilized

according to the law.

3. WARRANTY CONDITIONS

A. RADWAG is obliged to repair or change those elements that appears

to be faulty because of production and construction reason,

B. Defining defects of unclear origin and outlining methods of elimination

can be settled only in participation of a user and the manufacturer

representatives,

C. RADWAG does not take any responsibility connected with destructions

or losses derives from non-authorized or inappropriate (not adequate

to manuals) production or service procedures,

D. Warranty does not cover:

• Mechanical failures caused by inappropriate maintenance of

the device or failures of thermal or chemical origin or caused

by atmospheric discharge, overvoltage in mains or other

random event,

7

• Inappropriate cleaning.

E. Forfeiture of warranty appears after:

• Access by an unauthorized service,

• Intrusion into mechanical or electronic construction

of unauthorized people,

• Installing another operating system,

• Removing or destroying protection stickers.

F. The detailed warranty conditions one can find in warranty certificate.

G. Contact with the central authorized service:

+48 48 384 88 00 ext. 106 or 107.

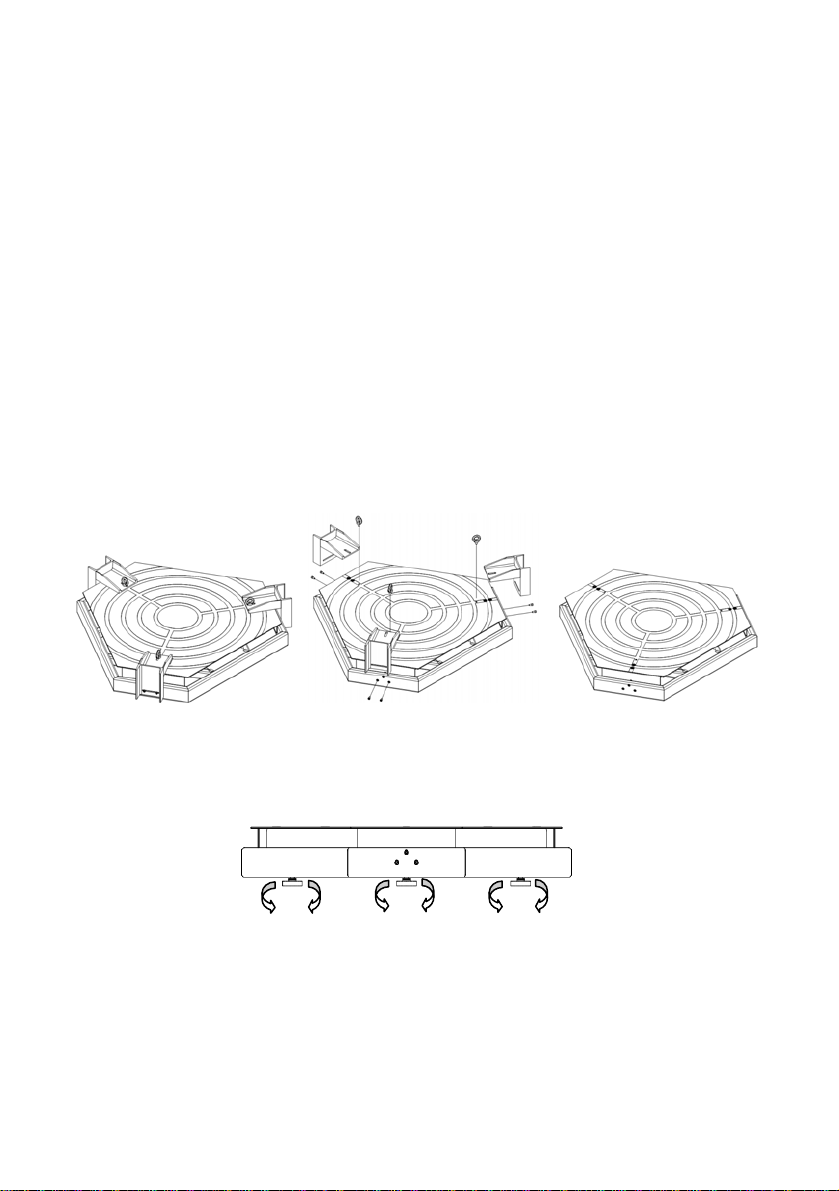

4. UNPACKING AND MOUNTING

Before using the scale remove the transport protections (if installed):

Place the scale on the spot of use on the flat, stable ground far away from

sources of heat. The platform should be levelled out by putting pads under

feet and the use of an external level device.

Every foot can be screwed in or out. This way only a smal range of level

regulation is achievable. Basic levelling should be performed by putting

steel pads under legs and observing the level on external level device.

8

4.1. Comparator WPY/KB – preparation for work

Comparators of WPY/KB series, because of its construction (sensitive strain

gauges), require appropriate conditions to work properly, including stable

temperature. Temperature drifts in rooms with comparators should not

exceed 1°C per hour.

Proceeding in case of preparing the comparator to work:

1. After unpacking and taking off transport protections put the scale

in the destination place and level the komparator platform.

2. The room temperature must be stable – maximum allowable

temperature change is 1°C / h – and protected from accidental draughts

air flows e.g. from air conditioning directed on the comparator pan.

3. Then switch on the device and leave unloaded and on for 4 hours. This

is warming time during which electronical and mechanical parts reach

stable temperature conditions.

4. After 4 hours in stable ambient conditions the comparator can be

prepared for adjustment.

5. First load the comparator pan to the maximum capacity 1000kg and

keep this state at least 2.5 minuty (150 seconds).

6. Secondly unload the pan and wait at least 2 minuts (120 seconds),

to allow the scale to return to the minimum stable value close to „zero”.

7. The operation of initial loading should be repeated 5 times, every time

in reference to time intervals given above.

8. After the 5-time initial loading the comparator can undergo the

adjustement procedure: 2 minutes after unloading the pan and start

the adjustment procedure from factory menu – first start mass is

determined then load the calibration weight following hints that appear

on the display. Confirm the stable result after 2 minutes. This way the

adjustement procedure will be completed.

9. The comparator is ready for work.

Notice:

If working conditions are changed (temperature change greater than 1°C,

humidity change, sudden long lasting air flow causing a change of ambient

conditions) the adjucement procedure described above needs to be repeated.

9

5. CONSTRUCTION

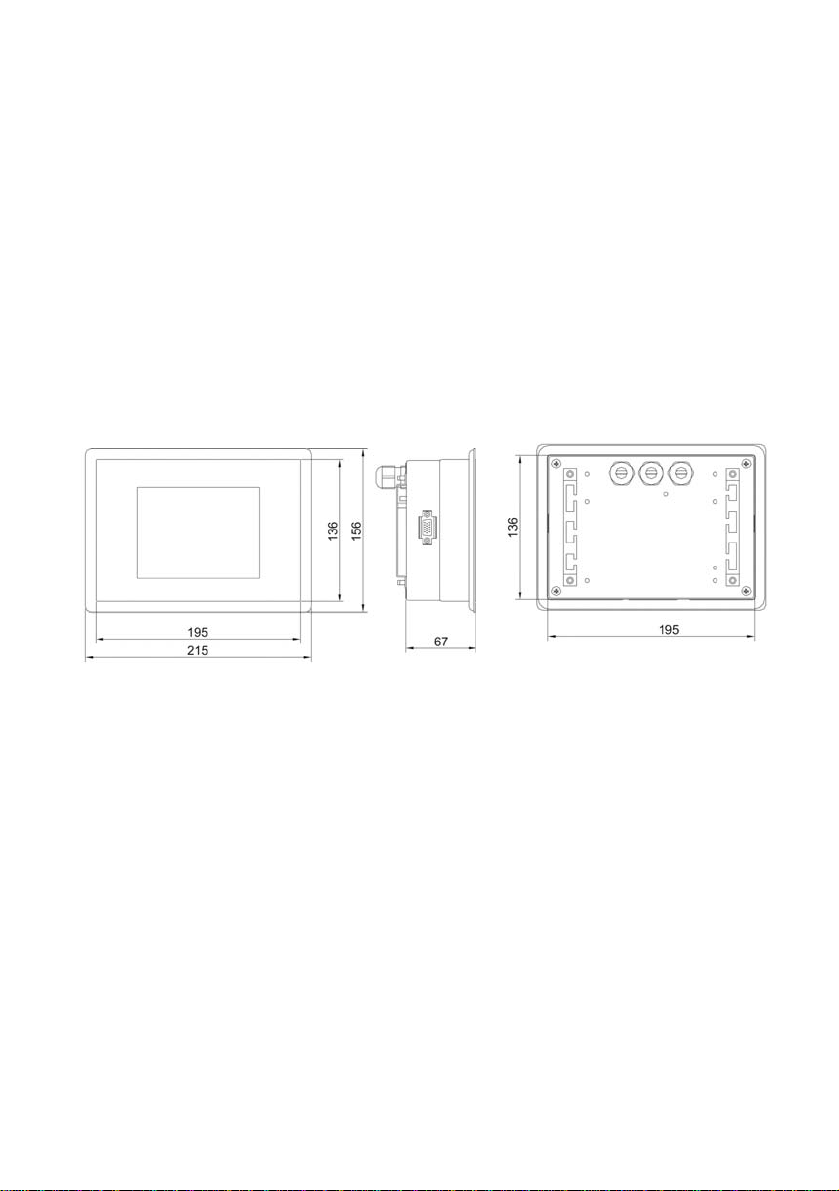

5.1. Main dimensions

Dimensions of PUE 7 in plastic casing

Dimensions of PUE 7P with stainless housing

Dimensions of platform

10

5.2. Description of connectors

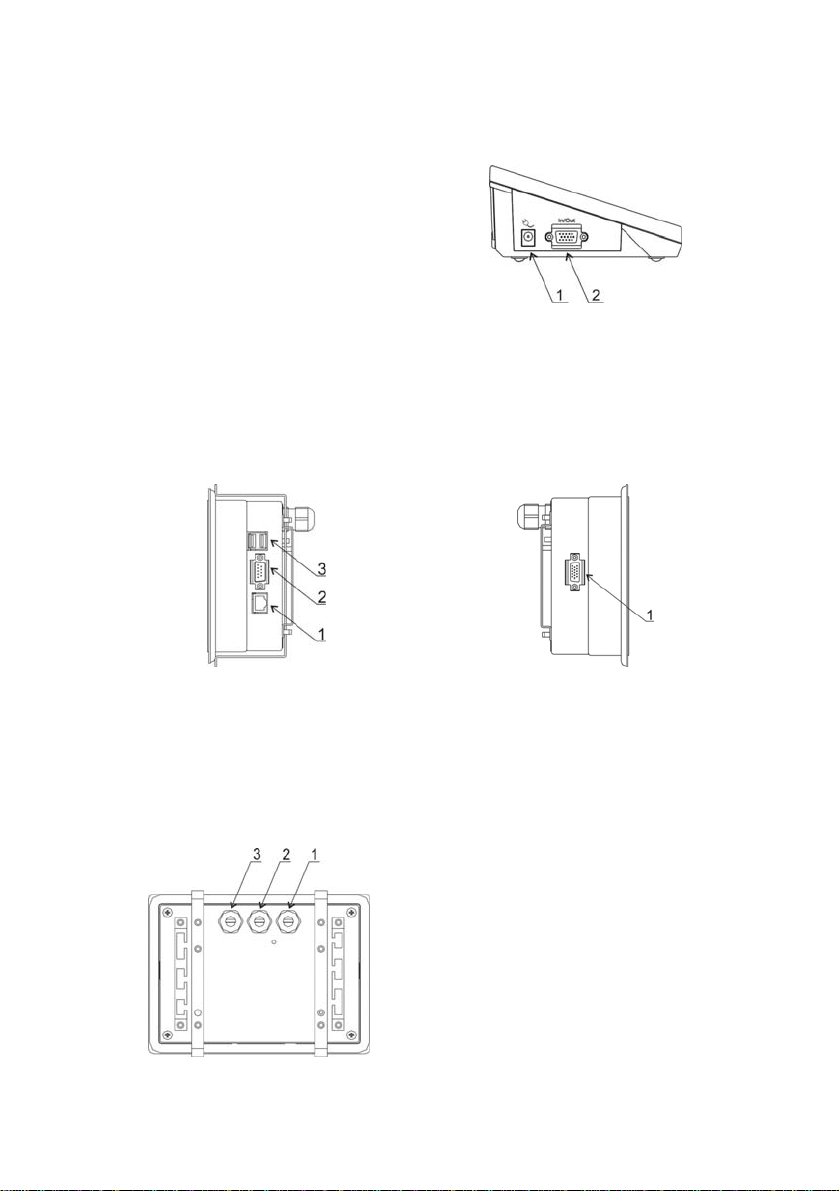

5.2.1. Connectors’ description in PUE 7

1 – Ethernet RJ45

2 – RS232 (COM1)

1 – power supply socket

2 – I/O, RS232 (COM2)

3 – USB

5.2.2. Connectors’ description in PUE 7P

1 – Ethernet RJ45

2 – RS232 (COM1)

3 – USB

1 – I/O, RS232 (COM2)

5.2.3. Description of glands PUE 7P

1 – Supply cord gland

2 – Gland for platforms 1, 2

3 – Gland for platforms 3, 4

11

5.2.4. Connector with RS232 and I/O

RS232 - DB9/M (male),

top view:

Pin2 - RxD

Pin3 - TxD

Pin5 - GND

I/O, RS232 DSUB15/F (female),

top view:

Pin1 - GNDWE

Pin2 - OUT1

Pin3 - OUT2

Pin4 - COMM

Pin5 - 6÷9VDC

Pin6 - IN4

Pin7 - IN3

Pin8 - TxD2

Pin9 - 5VDC

Pin10 - GNDRS

Pin11 - IN2

Pin12 - IN1

Pin13 - RxD2

Pin14 - OUT4

Pin15 - OUT3

6. GETTING STARTED

• After the terminal is connected to power the ON/LOAD

diode starts to light.

• Press

Windows CE together with RADWAG software loading is signalled

by blinking the red diode ON/LOAD.

• When the loading procedure is completed the main software

window appears.

to start the operating system loading procedure.

12

7. KEYPAD OVERLAY

8. FUNCTIONS OF KEYS

Key Description

Turning on/off the scale

Zeroing

Tarring

Printing out the result or confirming some entered data

Function key (entering the menu)

Selecting products

Selecting contractors

Inscribing a tare value

13

9. PROGRAM STRUCTUR E

The main menu has been divided into three functional groups.

In every group there are parameters of similar use.

9.1. Main menu items

The main menu comprises three functional groups:

Parameters

Databases

Info

9.1.1. Parameters

Icon Description

Scale

Working Modes

Communication

Devices

Display

Inputs / Outputs

Authorization

Other

User Calibration

14

9.1.2. Databases

Icon Description

9.1.3. Scale Info

Products

Operators

Weighings / Alibi

Contractors

Recipes

Recipes reports

Comparisons

Packages

Warehouses

Labels

Universal variables

Delete older data

Export database weighings to a file

Submenu < Info> is for viewing information:

• Scale factory number,

• Program version,

• Scale program version.

15

9.2. Inventory of parameters

9.2.1. Scale parameters - weighing

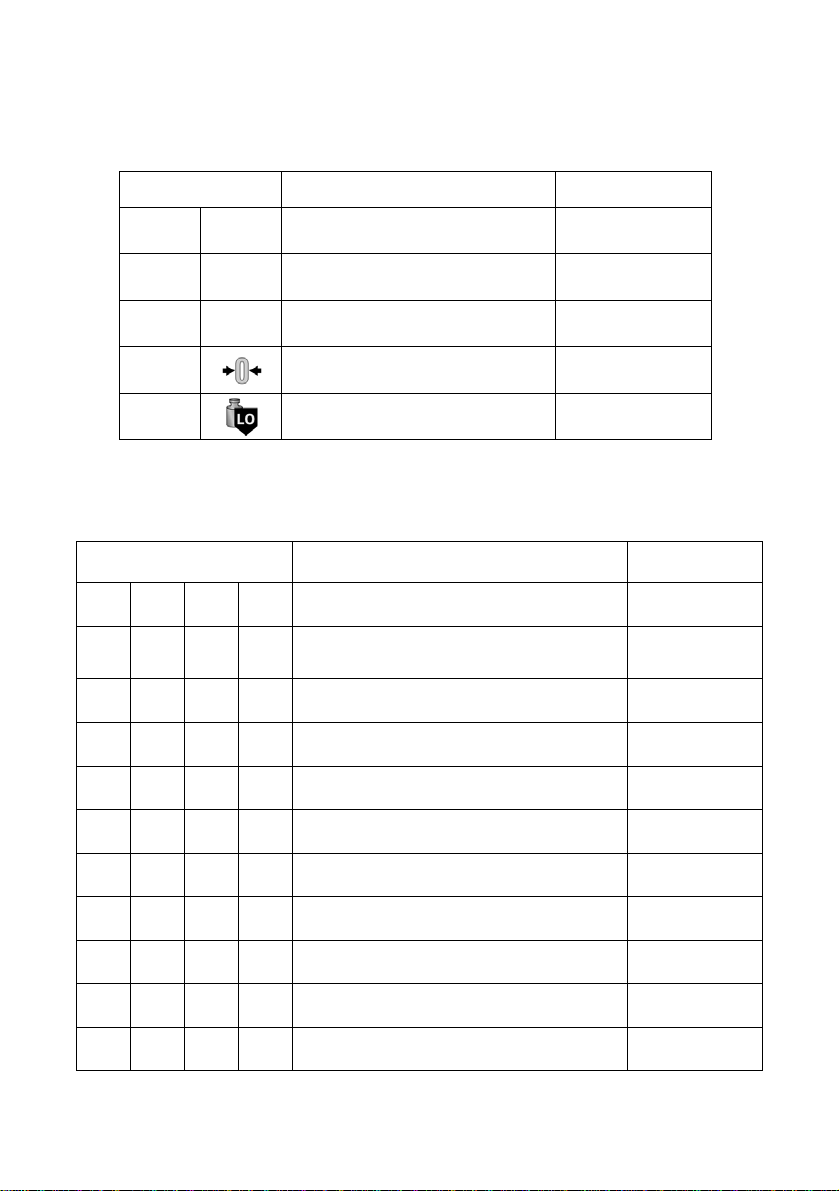

Icon Description Value

Platform 1 -

Median Filter None

Filter Slow

Autozero No

LO threshold 0.1

9.2.2. Working modes

Icon Description Value

Weighing -

Save Mode

Down-weighing No

Checkweighing No

Tare mode No

Labelling mode -

Number of labels 1

No. of cumulative labels 1

No. of CC labels 1

C label automatic triggering -

Mode None

Manual, each

stable

16

Threshold 100

CC label automatic triggering Mode None

Threshold 100

Statistics Global

Counting pieces -

Save Mode

Down-weighing No

Checkweighing No

Tare mode No

Labelling mode -

Number of labels 1

No. of cumulative labels 1

No. of CC labels 1

C label automatic triggering -

Manual, each

stable

Mode None

Threshold 100

CC label automatic triggering Mode None

Threshold 100

Statistics Global

Automatic correction of reference mass No

Deviations -

17

Save Mode

Down-weighing No

Checkweighing No

Tare mode No

Labelling mode -

Number of labels 1

No. of cumulative labels 1

No. of CC labels 1

C label automatic triggering -

Manual, each

stable

Mode None

Threshold 100

CC label automatic triggering Mode None

Threshold 100

Statistics Global

Comparator -

Save Mode

Checkweighing No

Tare mode No

Statistics Global

Method ABBA

Number of measurements 6

Ask for numbers of standards No

Automatic

first stable

18

9.2.3. Communication

Icon Description Value

COM1 Baud Rate 9600

Data bits 8

Stop bits 1

Parity None

COM2 Baud Rate 9600

Data bits 8

Stop bits 1

Parity None

Ethernet DHCP No

IP Address 192.168.0.2

Subnet mask 255.255.255.0

Gateway 192.168.0.1

Tcp Port 4001

9.2.4. Devices

Icon Description Value

Computer

19

Port None

Address 1

Continuous transmission No

Weighing Printout Pattern E2R System System is active No

Lock selecting products No

Printer Port COM1

Code page 1250

Printouts Weighing printout pattern See ch. 16.2.3

Product printout pattern See ch. 16.2.3

Cumulative printout pattern See ch. 16.2.3

Cumulative printout pattern

for cumulative data

Operator printout pattern See ch. 16.2.3

Contractor printout pattern See ch. 16.2.3

Warehouse printout pattern See ch. 16.2.3

Package printout pattern See ch. 16.2.3

CPG report printout pattern

(Control of Packaed Goods)

Average tare report printout pattern

(Control of Packaed Goods)

Barcode reader Port None

See ch. 16.2.3

*

*

20

Offset 0

Code length 0

Transponder card reader Port None

Additional display Port None

Pattern See ch. 16.2.3

*) Not related to „Comparator”.

9.2.5. Display

Icon Description Value

Text information Displaying pattern See ch. 17.1.1

Font Arial

Font size Small

Bold No

Actions

F1 Button Choose product

F2 Button Choose contractor

F3 Button Set tare

Screen button 1 Local parameters

Screen button 2 Set MIN and MAX

21

Screen button 3 Statistics C: Print

Screen button 4 CCStatistics : Print

Screen button 5 C Statistics : Zero

Screen button 6 Choose package

Screen button 7 Edit batch number

Screen button 8 None

Screen button 9 None

Left proximity sensor None

Right proximity sensor None

Set Default Show all platforms No

Bargraph type*

*) Not related to „Comparator”.

9.2.6. Inputs / Outputs

Icon Description Value

None

Inputs Input 1 None

Input 2 None

Input 3 None

Input 4 None

Outputs Output 1 None

22

9.2.7. Authorizations

Icon Description Value

9.2.8. Other

Icon Description Value

Output 2 None

Output 3 None

Output 4 None

Anonymous operator Operator

Date & Time Administrator

Printouts Administrator

Databases

Products Administrator

Contractors Administrator

Packages Administrator

Warehouses Administrator

Labels Administrator

Delete older data Advanced Oper ator

Language Polish

Date & Time -

23

Beep Buttons

Touch screen calibration -

9.2.9. User Calibration

Icon Description Value

Platform 1 -

Setting of start mass -

Calibration -

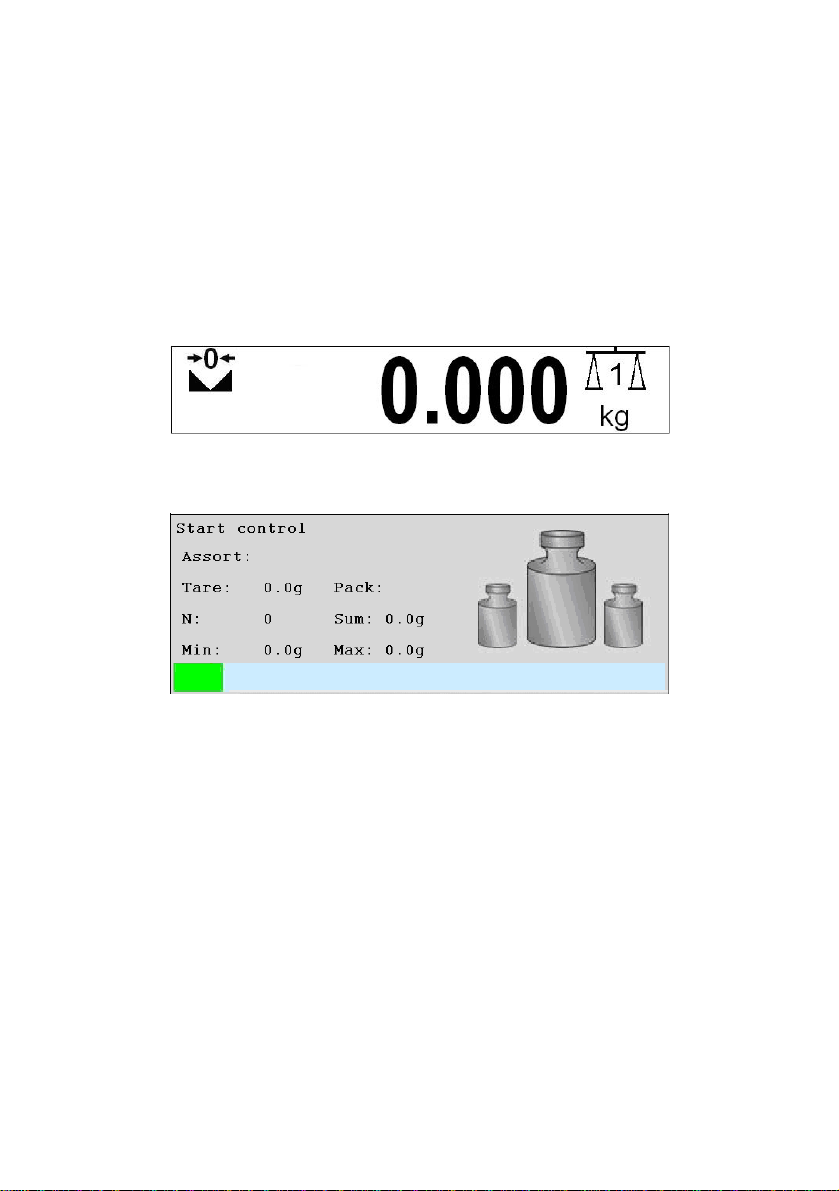

10. INDICATING WINDOW

Main view:

An option only for non-verified scale

24

In the main application window one can see four separate parts:

• In the top part of the window there is a status bar where a work mode,

logged-in user and time&date are displayed and active connection with

a computer are displayed.

• Below the status bar you can see weighing window(s).:

• There is a workspace below this window:

Notice:

The workspace is freely programmable. The default pattern is

described in ch. 17.1.1 of this manual.

• There are screen buttons below the workspace:

Notice:

1. Users can define screen function buttons. See the procedure

in ch. 17.2 of this manual;

2. The number of buttons to be defined depends on the selected

operating mode i.e.:

25

• In operating mode <Weighing> 9buttons are at ones disposal

displayed subsequently from 1 to 9 starting from the left side,

• In operating modes: <Counting pieces> or <Deviations> one

can define up to 7 screen buttons displayed subsequently from

1 to 7 starting from the left side. Two buttons on the right side

are attributed permanently to the modes mentioned above

because of the functions that are ascribed to them.

11. LOGGING ON

In order to have full access to user parameters and databases the user

should log on as an <Administrator>.

11.1. Logging in procedure

• While in the main window press <log in> on the top of the screen

and the window with operators attributed to <

• After entering <

Admin> a screen keyboard runs with editing

Admin> will appear,

window for inscribing a password,

• Type password „1111” and confirm by pressing

,

• The program returns to the main window and in the title bar you will

see <Admin> instead of <log in>.

11.2. Logging out procedure

• While in the main applilcation window press the name of a logged in

operator in the top bar on the screen to open the database of operators,

• Press logging out button situated in the top bar of the operators’

database window:

• The program returns to the main window and in the top bar the

operators name is substituted by <Log in>.

26

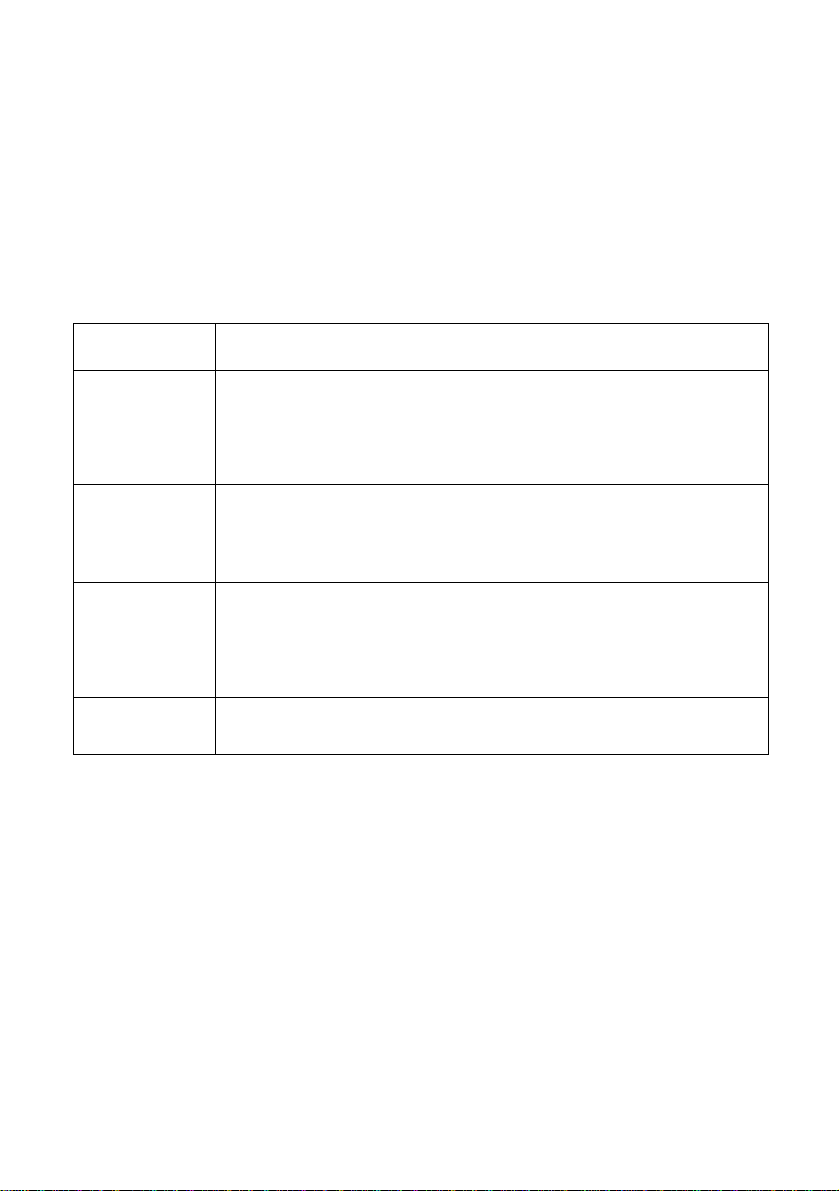

11.3. Authorization access levels

Weighing software uses four access levels: administrator, advanced

operator, operator, none. Every user with any attributed access level

can perform weighings and select data from in databases to be used

during weighing.

Access to user parameters, databases and working modes depending

on the authorization access level attributed:

Operator type Access level description

None

No access to user parameters. No weighing can be confirmed.

Cannot start procedure „Comparison”. Cannot enter the reference

mass unit and estimate the reference mase unit by weiging in

„Counting Pieces” and „Deviations”. No access to <Export the

weighing database to a file> in menu <Databases>

Operator

Access to parameters in submenu: <Weighing>, <Display>

(excluding the group <Actions>), <Others>

1)

. Can start and

perform all weighing procedures. Access to <Export the

weighing database to a file> in menu <Databases>

Advanced

Operator

Administrator

Access to parameters in submenus: <Weighing>, <Working

modes>, <Communication>, <Devices>

<Others>

Access to <Export the weighing database to a file> in menu

<Databases>

1)

. Can start and perform all weighing procedures.

2)

.

1)

, <Display>1),

Access to all user parameters, functions and databases

Can start and perform all weighing procedures.

1. Authorization level for editing functions:

• < Printouts> in submenu „ Devices / Printer”,

• <

Sample> in submenu „ Devices /

Additional display”,

2)

.

1)

2)

.

2)

.

• <

• <

Displaying pattern> in submenu „ Display /

Text information”,

Date and Time> in submenu < Others>,

27

It can be declared in submenu < Authorizations>, which is

accessable only for users with the <Administrator> authorization

level (see ch. 19 of this manual).

2. A user logged in as <Administrator> in submenu

<

Authorizations> (see ch. 19 of this manual) can change

authorization levels for accessing different databases and functions

Delete older data>. The exception are database

<

<

Weighings / Alibi>, that have the status „Read only”.

12. NAVIGATING WITHIN THE MENU

Owing to the colour display with the touch panel navigating within the menu

is simple and intuitive.

12.1. Buttons

Entering the main menu

Menu list „up”

Menu list „down”,

Scrolling „up-down”

Enter (OK)

Abort

Add a new item in a database

Disabeling the formerly selected record e.g. logging out the operator

Searching a database according to a date

28

Searching a database according to a name

Searching a database according to a code

Printing on item from a database

Clearing an editing field

Screen keyboard on / off

Reading a printout pattern from a *.lb file

(active after connecting a pendrive)

Variables for a printout pattern

One level up

12.2. Return to weighing

The changes introduced are saved for good after they are

confirmed. Press

several times until the following

message box appears:

Press:

– to confirm changes or – to abort

changes. The program returns to weighing.

29

13. WEIGHING

Put a load on the weight pan. When pictogram

indication is ready to read.

Notice:

A weighing can be saved after stabilising a measurement over zero

(pictogram

).

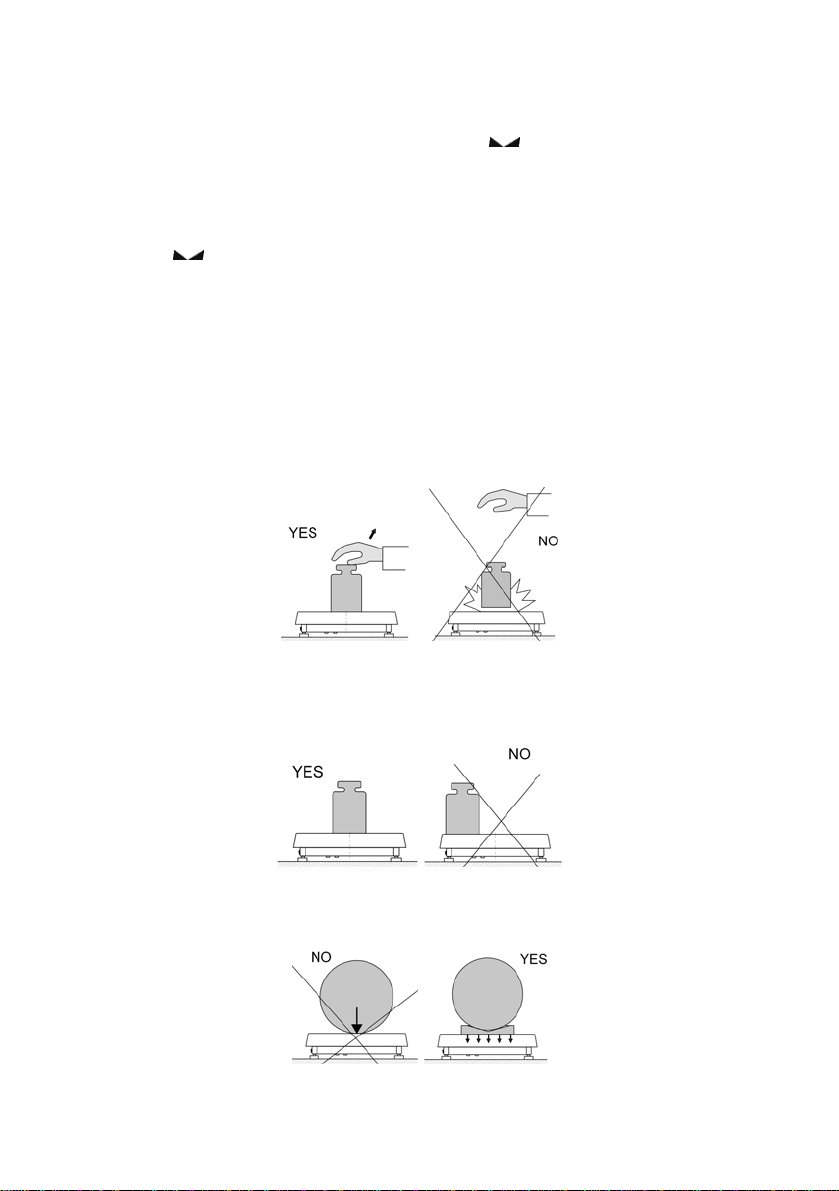

13.1. Conditions of operational use

In order to assure a long term operating period with appropriate

measurements following principles should be adhered to:

• Avoid applying mechanical shocks to the weight pan:

is displayed the

• Loads should be placed in the centre of the pan (eccentric errors

are outlined in PN-EN 45501 chapter 3.5 and 3.6.2):

• Do not apply concentrated forces (all load in one point):

30

Loading...

Loading...