Page 1

User manual

Medical scales

User manual no.:

ITKU-16-08-10-13-EN

Personal scales

Bed scales

Chair scales

Baby scales

BALANCES AND SCALES

RADWAG 26 – 600 Radom, Bracka 28, POLAND

Phone: +48 (0-48) 38 48 800, fax. +48 (0-48) 385 00 10

export@radwag.com

www.radwag.com

Page 2

- 2 -

27 August 2012

Page 3

- 3 -

Table of contents

1. INTENDED USE ................................................................................................................ 5

2. PRECAUTIONATY MEASURES ....................................................................................... 5

2.1. Maintenance .............................................................................................................. 5

2.2. Battery pack ............................................................................................................... 5

2.2.1. Power supply of scales featuring an indicator in plastic housing ......................... 6

2.2.2. Replacement of used batteries ........................................................................... 7

3. WARRANTY CONDITIONS ............................................................................................... 8

4. MAIN D IMENSIONS .......................................................................................................... 9

5. UNPACKING AND ASSEMBLY ...................................................................................... 12

5.1. Personal scale ......................................................................................................... 12

5.2. Bed scale WPT/4B series ......................................................................................... 13

6. CLEANING ...................................................................................................................... 15

7. START UP ....................................................................................................................... 16

8. KEYBOARD .................................................................................................................... 16

9. KEYS AND FUNCTIONS ................................................................................................. 17

10. DI SPLAY INDICATIONS ................................................................................................ 17

11. USER MENU .................................................................................................................. 18

11.1. Sc al e’s paramet er groups....................................................................................... 18

11.2. Moving through user m enu ..................................................................................... 18

11.2.1. Keyboard ........................................................................................................ 18

11.2.2. Return to weighing mode ................................................................................ 19

12. WEIGHING..................................................................................................................... 19

12.1. Tarring f unct i on ...................................................................................................... 19

12.2. Manual tare insertion .............................................................................................. 20

12.3. Zeroing f unct i on ..................................................................................................... 21

12.4. Weighing on dual range scales............................................................................... 21

12.5. Selection of basic measuring unit ........................................................................... 22

12.6. Select i ng an instant aneous m easuring unit ............................................................ 23

13. MAIN SCALE PARAMETERS ....................................................................................... 24

13.1. Setting filtering level ............................................................................................... 24

13.2. Median fil ter ........................................................................................................... 25

13.3. Aut ozero f unct i on ................................................................................................... 26

14. RS 232 PARAMETERS ................................................................................................. 27

14.1. Determining minimum mass for function operation ................................................. 27

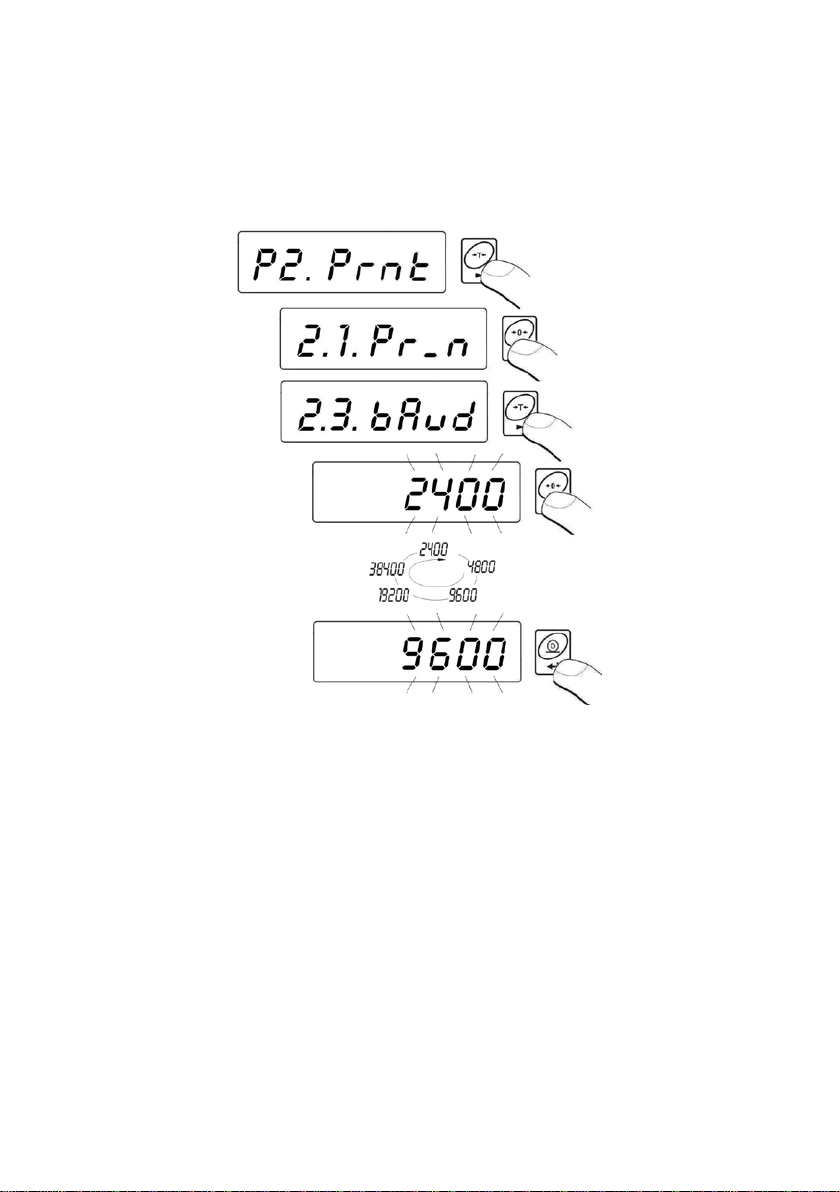

14.2. Baud rat e ............................................................................................................... 28

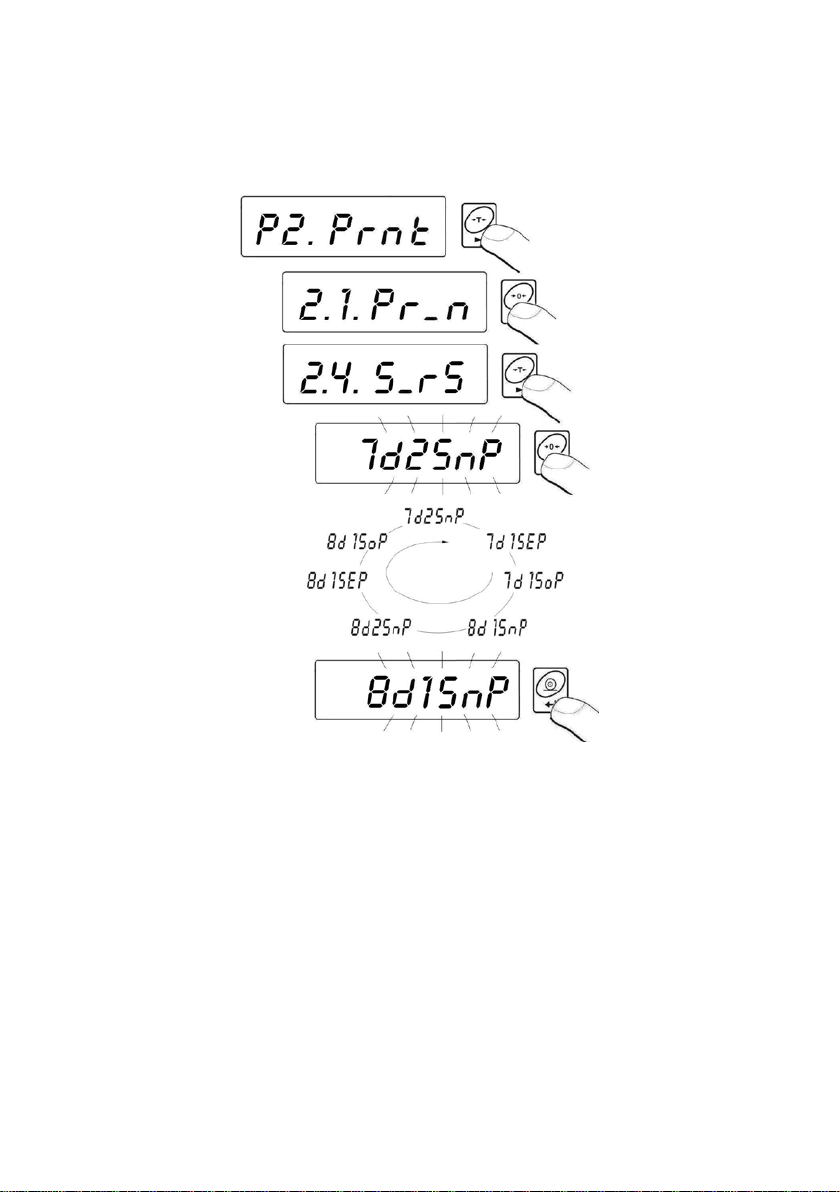

14.3. Serial transmission parameters .............................................................................. 29

15. OTHER PARAMETRS ................................................................................................... 30

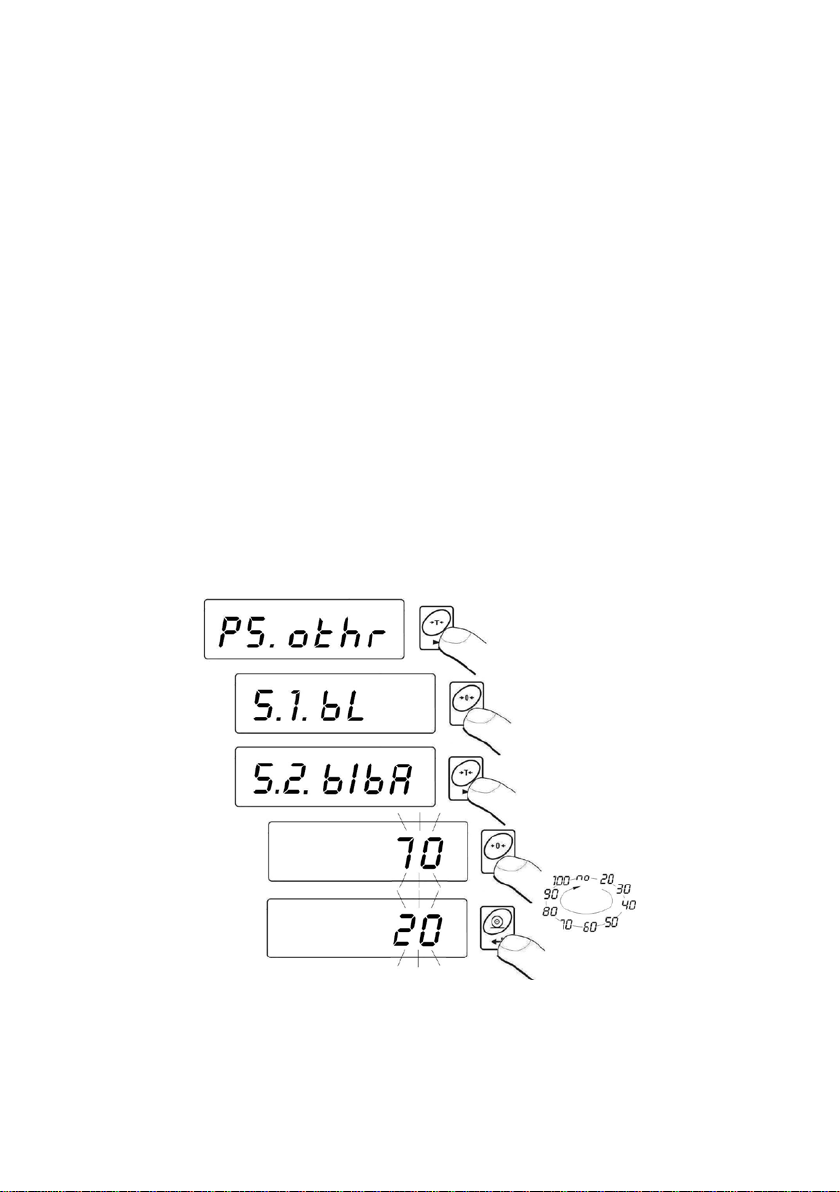

15.1. Displ ay back l i ght .................................................................................................... 30

15.1.1. Display backlight for supply from mains .......................................................... 30

15.1.2. Display backlight for supply from batteries or accumulators ............................ 31

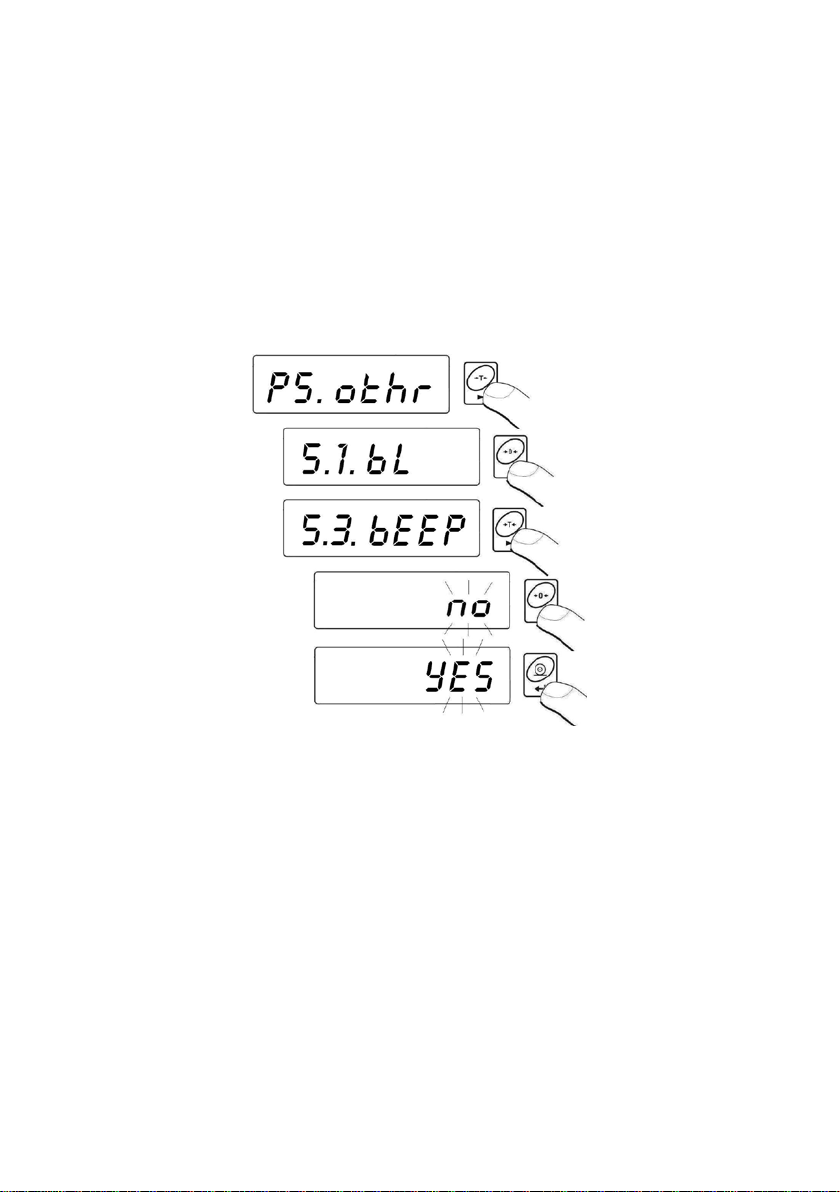

15.2. “beep” sound – sc al e reaction to pressi ng a key ..................................................... 32

15.3. Scale automatic switch off ...................................................................................... 32

15.4. Charging and disc hargi ng bat teries / accumulators ................................................ 34

15.4.1. Battery / accumulator voltage level check ....................................................... 34

15.4.2. Operation of battery / accumulator charge / discharge indication .................... 34

15.4.3. Accumulator charging options ......................................................................... 35

15.4.4. Accumulator charging process ........................................................................ 36

16. WORKING MODES ....................................................................................................... 37

Page 4

- 4 -

16.1. Means of select i ng a working mode........................................................................ 37

16.2. Weighing with lock of measurement result on the display - hoLd ............................ 37

16.3. Determining BMI factor ........................................................................................... 39

17. SCALE ADJUSTMENT .................................................................................................. 41

17.1. Adjustment ............................................................................................................. 41

17.2. Start mass adjustment ............................................................................................ 43

18. COOPERATION WITH A PRINTER ............................................................................... 44

19. COOP ER ATION WITH A COMPUTER .......................................................................... 45

20. COM M UNICATION PROTOCOL ................................................................................... 46

20.1. General information ................................................................................................ 46

20.2. A set of commands recognized by the indic at or ...................................................... 47

20.3. Responses format for commands sent from computer level ................................... 47

20.4. Command’ s descri ption .......................................................................................... 48

20.4.1. Zero scale ....................................................................................................... 48

20.4.2. Tare scale ....................................................................................................... 48

20.4.3. Give tare value................................................................................................ 48

20.4.4. Send stable measurement result in basic measuring unit ................................ 49

20.4.5. Immediately send measurement result in basic measuring unit ....................... 49

20.4.6. Send stable measurement result in current weighing unit................................ 50

20.4.7. Immediately send measurement result in current measuring unit .................... 51

20.4.8. Switch on continuous transmission in basic measuring unit ............................ 51

20.4.9. Switch off continuous transmission in basic measuring unit ............................ 52

20.4.10. Switch on continuous transmission in current measuring unit ........................ 52

20.4.11. Switch off continuous transmission in current measuring unit ........................ 52

20.4.12. Send all implemented commands ................................................................. 52

20.5. Manual printout ...................................................................................................... 53

20.6. Continuous transmission ........................................................................................ 54

20.7. Printout configuration ............................................................................................. 54

21. ERROR MESSAGES ..................................................................................................... 54

22. SCALE TECHNICAL PARAMETERS ............................................................................ 55

22.1. Chair scale ............................................................................................................. 55

22.2. Personal scales ...................................................................................................... 55

22.3. Bed scales ............................................................................................................. 56

22.4. Baby scal es ............................................................................................................ 56

23. TROUBLE SHOOTING .................................................................................................. 57

24. ADDI TIO NAL EQUIPMENT ........................................................................................... 57

25. EMC INFORMATION ..................................................................................................... 58

26. APPENDIX A ................................................................................................................. 62

26.1. Pict ograms on the data plat e .................................................................................. 62

26.2. CE marking ............................................................................................................ 62

Page 5

- 5 -

1. INTENDED USE

RADWAG medical scales are designed to measuring mass of weighed

patients.

In case of personal scales, the mass determining process is carried out

when a patient stands on the scale’s weighing platform, on chair scales –

when a patient is sitting, and on bed scales a patient is weighed while lying

on a bed. Baby scales enable determining body mass of a baby who is

lying on scale’s platform. Each of medical scales enables tarring in the

whole measuring range.

Functions:

• Display backlight,

• Digital filters (adjusting scale’s operation to ambient and operating

conditions of the place of use),

• Median filter,

• Autozero function,

• Manual setting of tare value,

• Baud rate settings,

• Determining minimum mass for operating of automatic functions,

• Automatic scale’s switch off,

• User adjustment (available in non-verified scales),

• Peak hold – weighing wit h locking the measurement result on the

display - HOLD,

• Determining BMI factor.

2. PRECAUTIONATY MEASURES

2.1. Maintenance

A. Read the user manual carefully before commissioning and using the

scale according to its intended use;

B. Instruments to be decommissioned should be decommissioned in

accordance with valid legal regulat ions.

2.2. Battery pack

Medical scales featuring an indicator PUE C/31 series (plastic housing) are

designed for buffer powering by NiMH batteries / accumulators) with rated

voltage 1,2V, size R6 (AA) and capacity from 1800 to 2800mAh.

Page 6

- 6 -

Indicators plugged to mains automatically monitor and maintain batteries /

accumulators charging status.

In case of scale’s / indicator’s elongated storage in low

temperatures, it is not allowed to fully discharge the

accompanied batteries.

The equipment including accumulators does not belong

to your regular household waste. The Europe an legislation

requires that electric and electronic equipment be collected

and disposed separately from other communal waste with

the aim of being recycled.

Hint:

Some symbols on accumulators / batteries identify harmful compounds:

Pb = lead,

Cd = cadmium,

Hg = mercury.

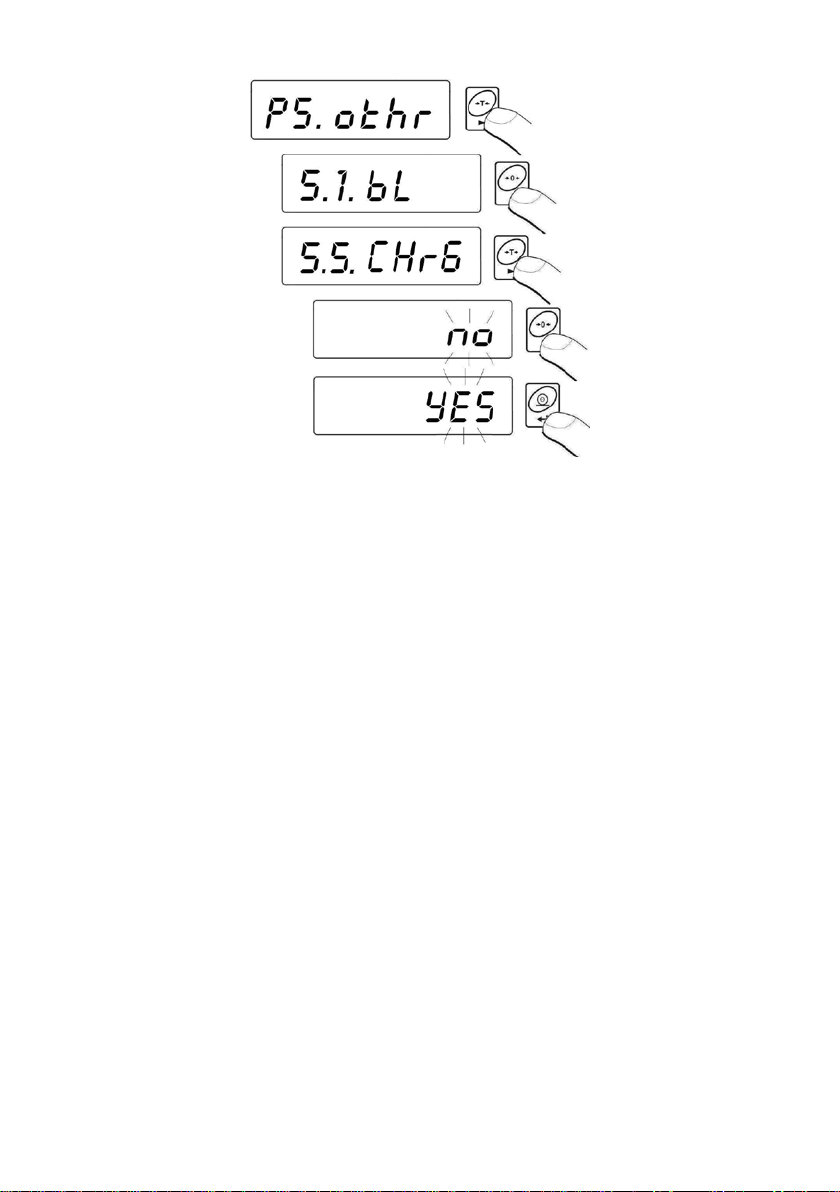

2.2.1. Power supply of scales featuring an in d icator in plastic housing

New NiMH accumulators, which come standard with the indicator PUE

C/31 series in plastic housing require forming in accordance with the

procedure contained in point 15.4.4 of this user manual.

Alternatively, the indicator can be powered by standard R6 / AA batteries.

Should an indicator be powered from standard batteries, not the NiMH

accumulators, then:

• Before installing the batteries inside the indicator’s housing, power the

indicator from mains only, and go to menu parameter <5.5.CHr6> and

change its value to <no>,

• On completing the above step it is possible to assemble standard

batteries to indicator’s batteries compartment.

Page 7

- 7 -

Installing standard batteries without setting the parameter

<5.5.CHr6> to value <no> may, on powering the indicator

from mains, damage the batteries and the indicator.

Powering the scale from mains is permissible using only the

power adapter that comes standard with the scale.

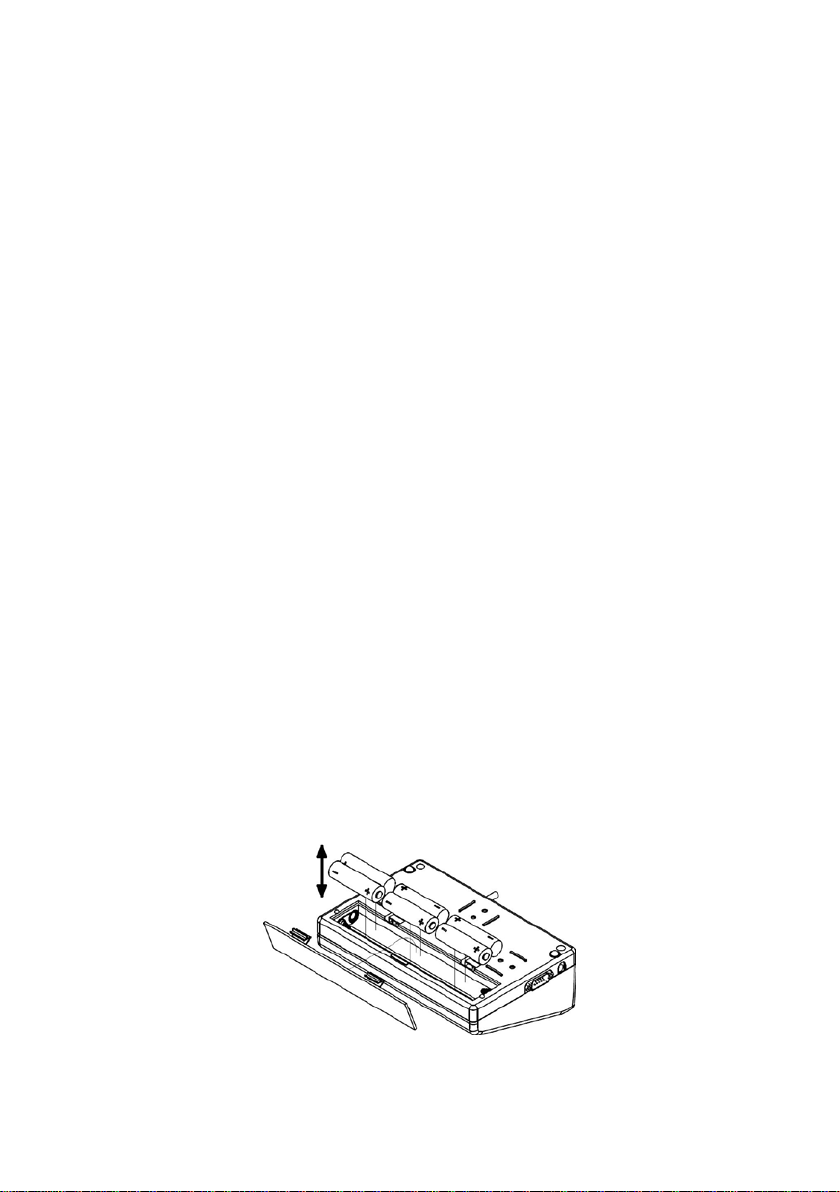

2.2.2. Replacement of used batteries

Scales featuring indicator PUE C/31 series (plastic housing) enable

replacing used batteries with new ones .

Procedure:

• Open the lid of the battery compartment located in the bottom section

of indicator’s housing:

• Remove used (discharged) accumulators / batteries and replace them

with new ones, pay attention to correct polarity (+/-)marked in the

battery compartment:

Page 8

- 8 -

• Close the battery compartment’s lid:

3. WARRANTY CONDITIONS

A. RADWAG feels obliged to repair or exchange all elements that

appear to be faulty by production or their construction,

B. Defining defects of unclear origin and means of their elimination can

only be realized with assistance of manufacturer and user

representatives,

C. RADWAG does not bear any responsibility for defects, losses or

accidents resulting from unauthorized or inadequate performing

of production or service processes,

D. Warranty does not cover:

• Mechanical defects caused by product exploitation other than

intended, defects of thermal and chemical origin, defects caused

by lightning, overvoltage in the power network or other random

event,

• Maintenance activities (cleaning).

E. Loss of warranty takes place if:

• A repair is carried out outside RADWAG sales office or authorized

service point,

• Service claims intrusion into mechanical or electronic construction

by unauthorized people,

• The scale does not bear company’s protective stickers.

F. Accumulators are covered by 6 months warranty period.

G. Detailed warranty conditions are listed on a service card.

Page 9

- 9 -

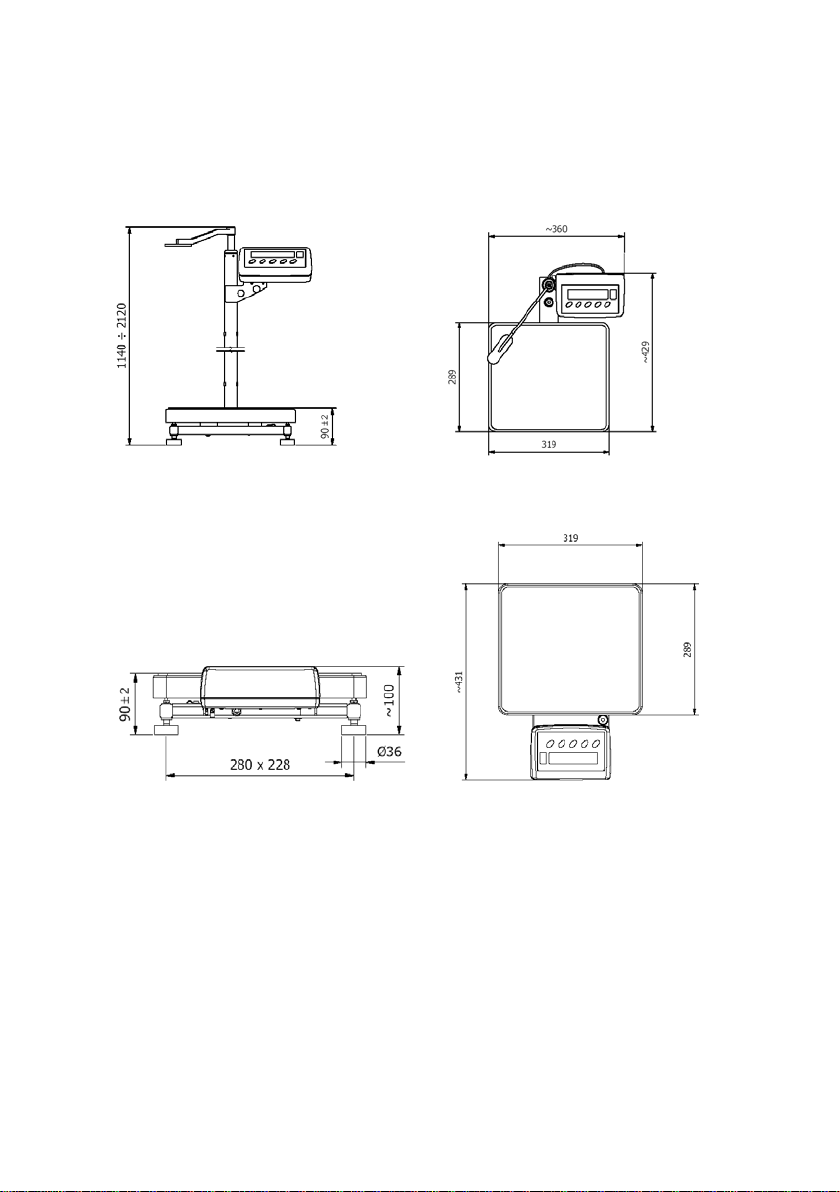

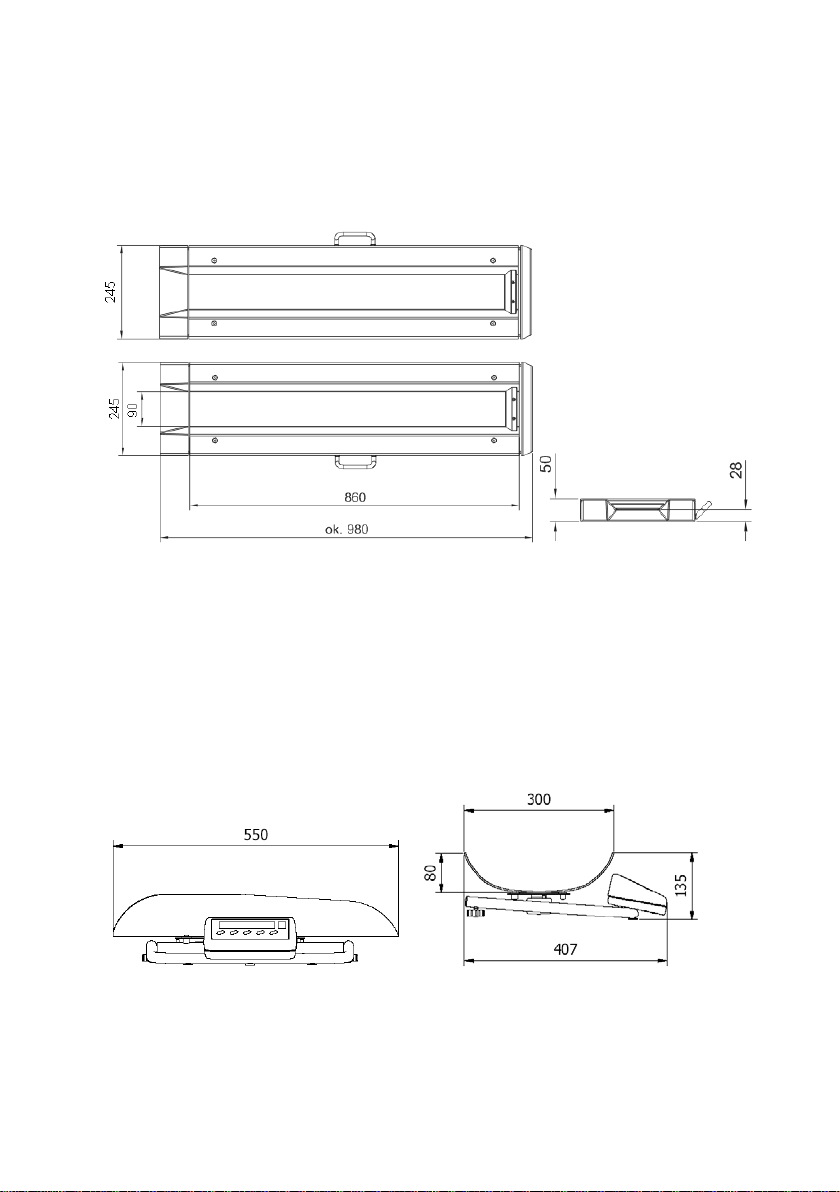

4. MAIN DIMENSIONS

Personal scale WPT xx OW series

Personal scale WPT xx O series

A. Personal scales are available in two versions

– with a height meter (indicator is attached to the height meter);

– without a height meter (indicator is attached to the scale’s weighing

platform).

Page 10

- 10 -

B. Chair scale features a moveable handle and wheels aiding scale’s

transport to intended place of use.

Chair scale – dimensions

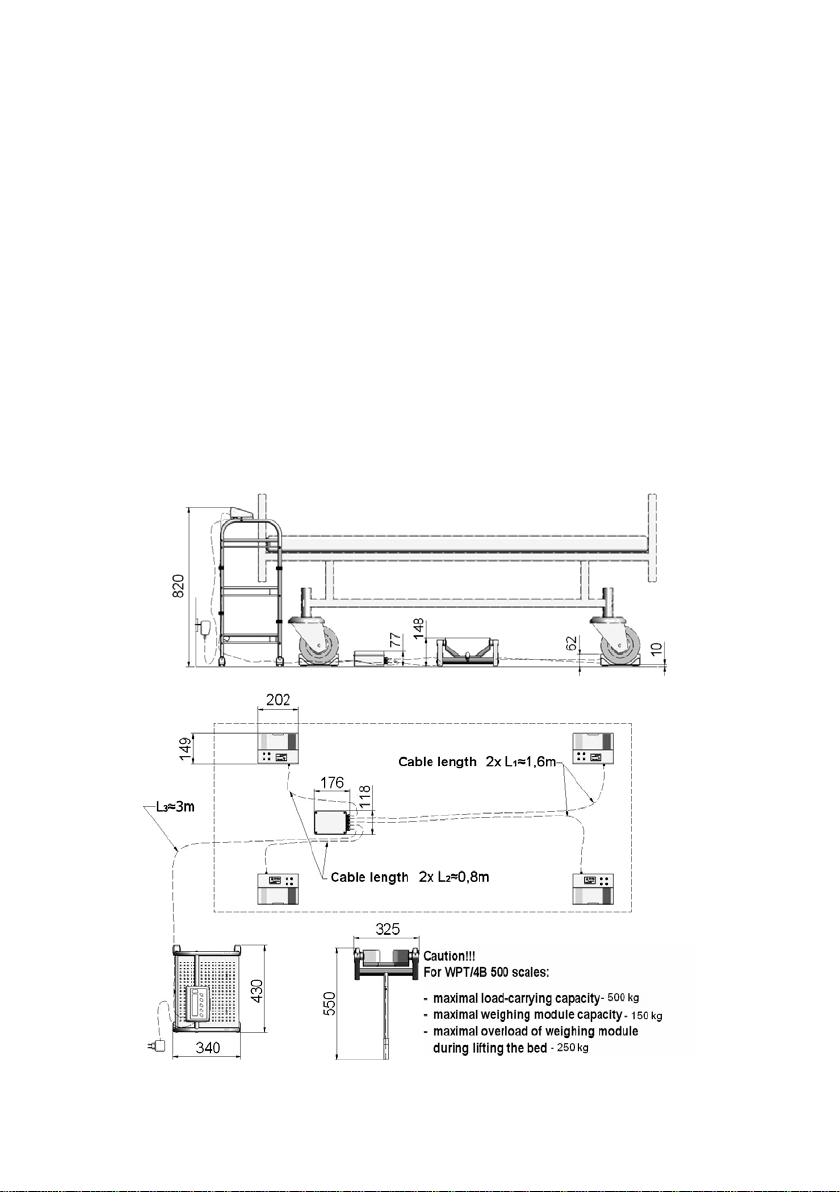

C. Bed scale WPT/4B series features four measuring blocks, which are

placed under the wheels of a bed using a dedicated hoist. The design

of the WPT/4B series enables its using independently on bed type

(beds with wheel diameter from φ100 to φ200) and applied brake

system.

Bed scale WPT/4B series – dimensions

Page 11

- 11 -

D. Bed scale WPT/8B series comprises two weighing beams, which are

unfolded maximall y to 2,5 m eters . A gentle entrance onto the beam

enables easy locating the bed onto the scale’s beams. On positioning

onto the beams, the bed is weighed. The design of bed scale

WPT/8B series enables its using independently on bed type and

applied brake system.

Bed scale WPT/8B series – dimensions

E. Baby scales WPT 6/15D and WPT 10/20D are precise m eas uring

instruments designed in the accuracy class III, and dedicated to

weighing infants. Weighing process can be carried out with indication

lock on stabilization of measurement result, i.e. peak hold function. In

such case, infant’s mass can be precisely read independently on

baby’s movement on scale’s weighing platform.

Baby scale – dimensions

Page 12

- 12 -

5. UNPACKING AND ASSEMBLY

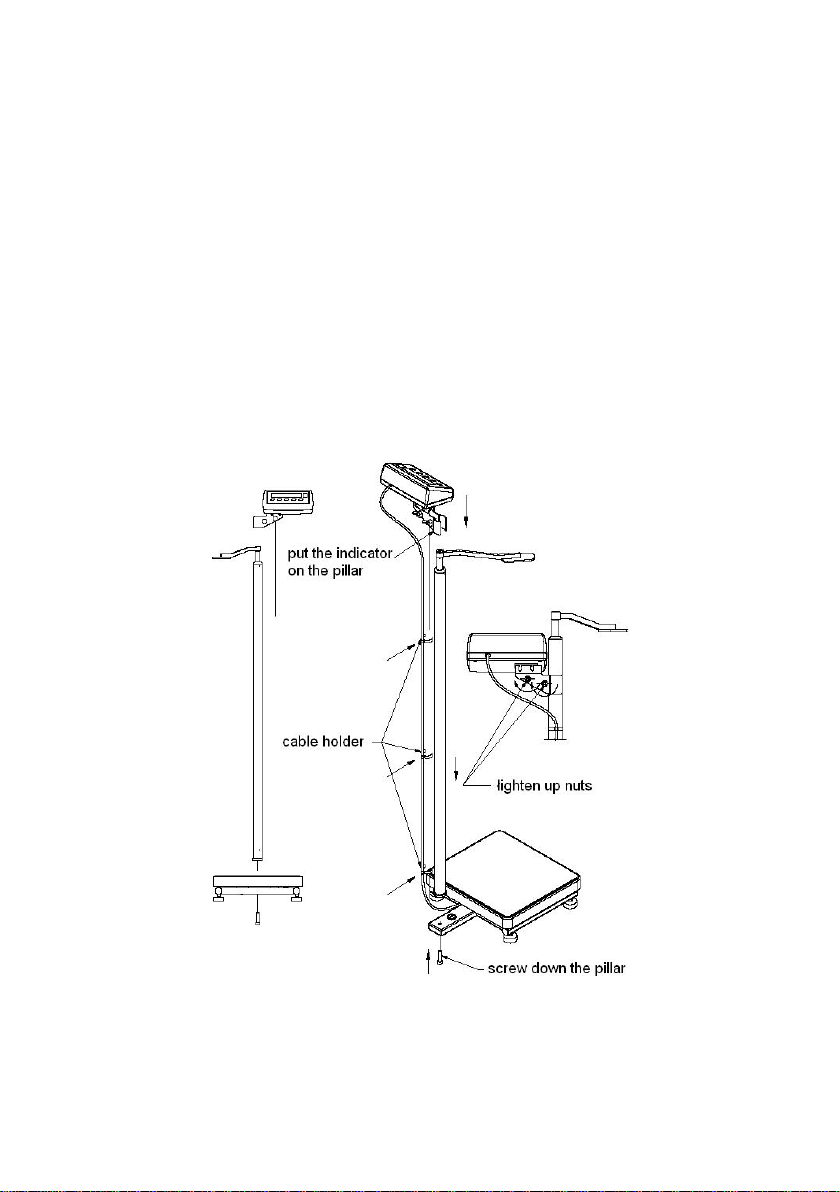

5.1. Personal scale

A. Carefully remove the personal scale from its packaging,

B. In order to ensure precise indications, place the scale on a firm

foundation, distant from heat and cold sources,

• In case of bed scales, place the beams on a firm, stable and

even foundation, and unfold the beams to adjust them to a

type of bed that is weighed,

• In case of personal scales with a height meter, assembly the

height meter to scale’s base using an allen key that comes

standard with the scale,

Assembly of persona l sca le WP T xx OW series

Page 13

- 13 -

5.2. Bed scale WPT/4B series

A. Carefully remove the bed scale from its packaging

General view

B. Assembly the scale’s components:

• Screw down the indicator,

• Push in the castors,

C. Move the assembly to its operation place and place it next to a bed to

be weighed,

D. Lock the castors’ brakes to set the trolley in a determined position,

E. Lock the castors of the bed,

F. Move one of the measuring blocks of the WPT/4B scale to one of the

bed’s wheels,

G. Assemble the hoist:

Page 14

- 14 -

Step 1

Step 2

Step 3

Step 4

H. Use the hoist to place bed’s wheel in the scale’s measuring block.

See below figures:

I. Apply the same procedure to the following bed’s wheels until all of the

bed’s wheels are located on the measuring blocks, as shown below:

Page 15

- 15 -

Caution:

The foundation under the measuri ng block s should b e even and

leveled. Additionally, make sure, that the connecting cable is not

clenched under the measuring block, as it may be source of incorrect

measurements.

6. CLEANING

Scales intended for weighing infants

The scale requires periodical cleaning of the weighing platform. Clean the

weighing platform using disinfectants and cleaning agents dedicated for

medical equipment. While cleaning avoid pressing hard the weighing

platform as it may damage the scale’s measuring system.

Chair scales

The scale requires periodical cleaning of the seat and the arms. Clean the

scale parts using disinfectants and cleaning agents dedicated for medical

equipment. While cleaning avoid turning over the scale or carrying out

other activities which may result in damaging the scale .

Bed scales

Clean the measuring blocks and measuring beams (depending on scale

type) using disinfectants and cleaning agents dedicated for medical

equipment.

Personal scales

Clean the weighing platform and scale’s body using disinfectants and

cleaning agents dedicated for medical equipment.

Caution:

Do not drench the indicator of medical scales in any way (use dry cloth or

alternatively a damp cloth to clean the indicator).

Page 16

- 16 -

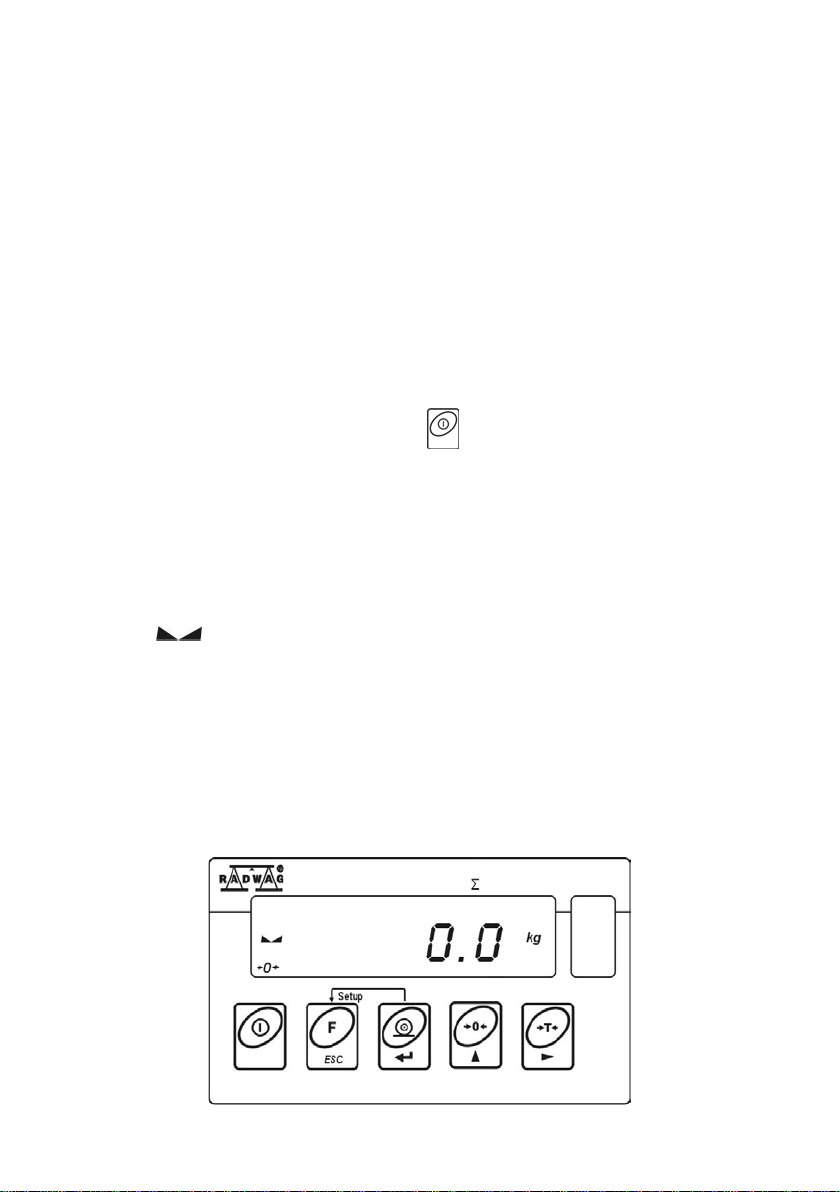

7. START UP

First unpack and assemble the scale (see point 5 of this user manual).

Then:

• Level the scale using its adjustable feet located in the bottom base of

the medical scale. Monitor the level status on the level located in the

base of the medical scale. Leveling is correct if the air bubble

of the level indicator is located in the central location:

• Switch on the scale by pressing

0,5 second,

• On turning on wait until the scale completes the auto test procedure,

key – press and hold the key for

• Then the zero mass indication appears on the display, with the

following pictogram s:

- precise zero indication

- stable measurement result

kg - measuring unit

• If measurement result is other than zero, press zeroin g ke y on

indicator’s overlay.

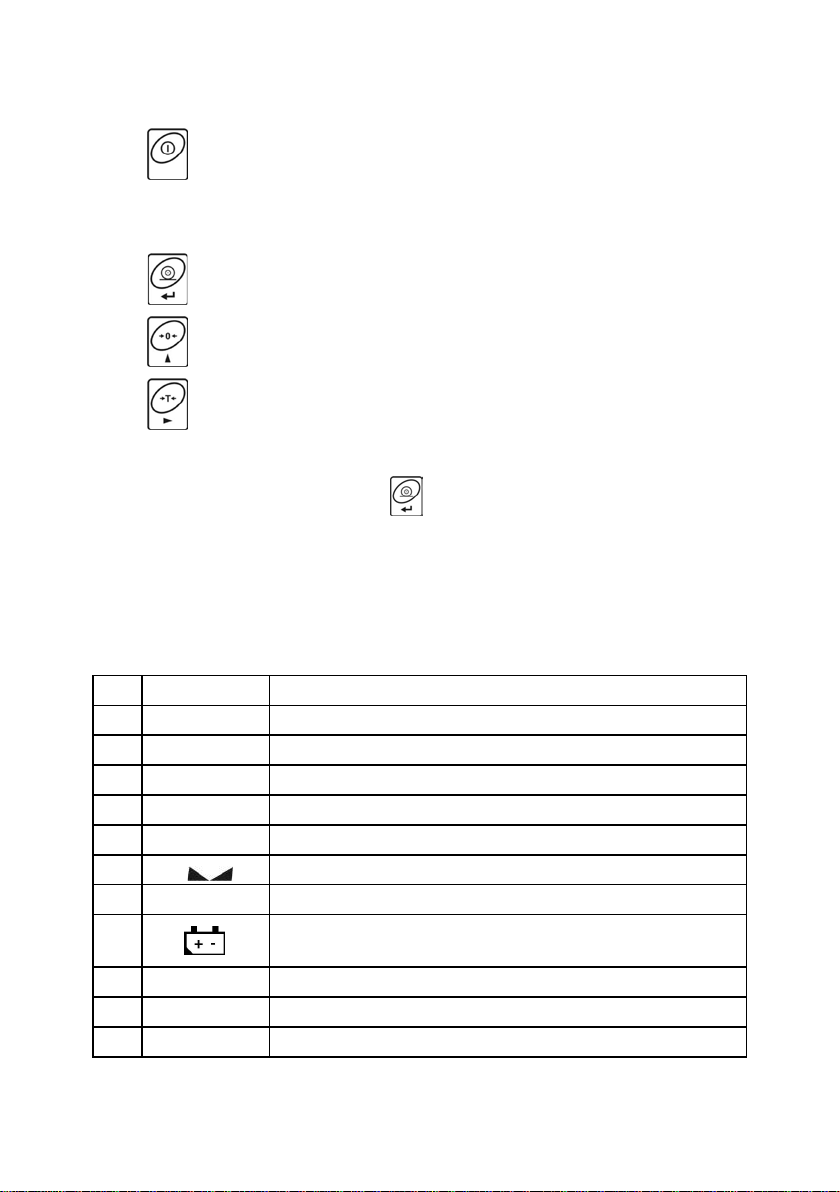

8. KEYBOARD

Page 17

- 17 -

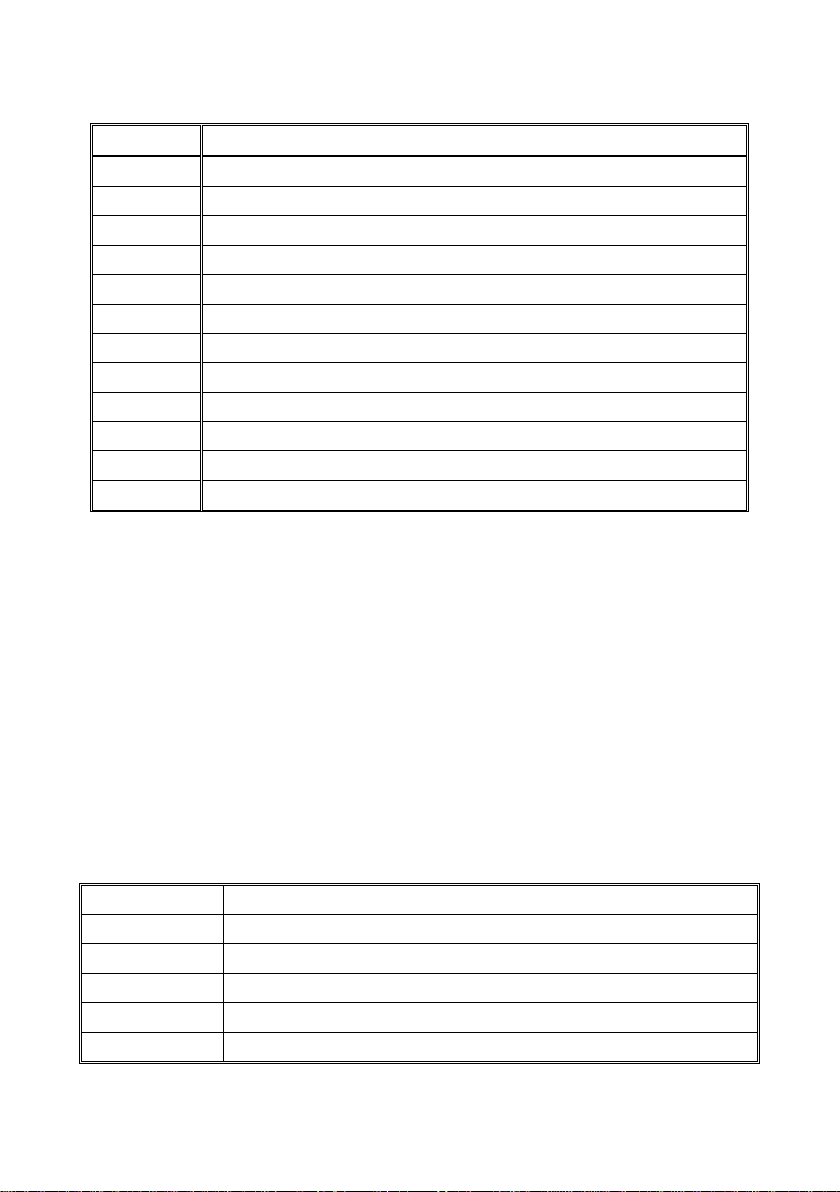

No.

Indication

Description

1.

Fil

2.

bAud

3.

Auto

4.

t1

9.

Net

10.

hold

9. KEYS AND FUNCTIONS

Switching on/off scale’s display – press and hold the

key for about 1 second

Function key (working mode selection)

Sending measurement result to a connected printer or

computer

Zeroing

Tarring

Caution:

Simultaneous pressing of

and keys changes functionality of the

keys for the time of function programming. Means of their use is described

further in this user manual.

10. DISPLAY INDICATIONS

Filtering level of weighing result

Baud rate

Control and correcting scale’s zero indicat ion

Power save mode – time defined scale’s switch off

5.

6.

7. kg (g) Scale in working mode weighing

8.

11. bmi

Indication in autozero mode (indication = zero)

Stable measurement result (ready to read)

Discharged batteries / accumulators / defected

accumulator or defected power adapter

Tare function applied

Weighing with peak hold function applied

Determining BMI factor

Page 18

- 18 -

P1 rEAd

P 1.1 Fil

|

4

P 1.2 Auto

|

YES

P 1.4 Fnnd

|

no

P2 Prnt

P2.2 S_Lo

|

P2.3 bAud

|

9600

P2.4 S_rS

|

8d1SnP

P3 Unit

P3.1 StUn

|

kg

P5 othr

P5.1 bL

|

Auto

P5.2 bLbt

|

70

P5.3 bEEP

|

YES

P5.4 t1

|

Auto

P5.5 CHr6

|

YES

P6 CAL

P6.1 St_u

|

* FUNCTION *

P6.2 uCAL

|

* FUNCTION *

+

Entering main menu

Manual tare inserting in working m ode: weigh in g

+

Check battery / accumulator status

+

Toggling between gross / net values

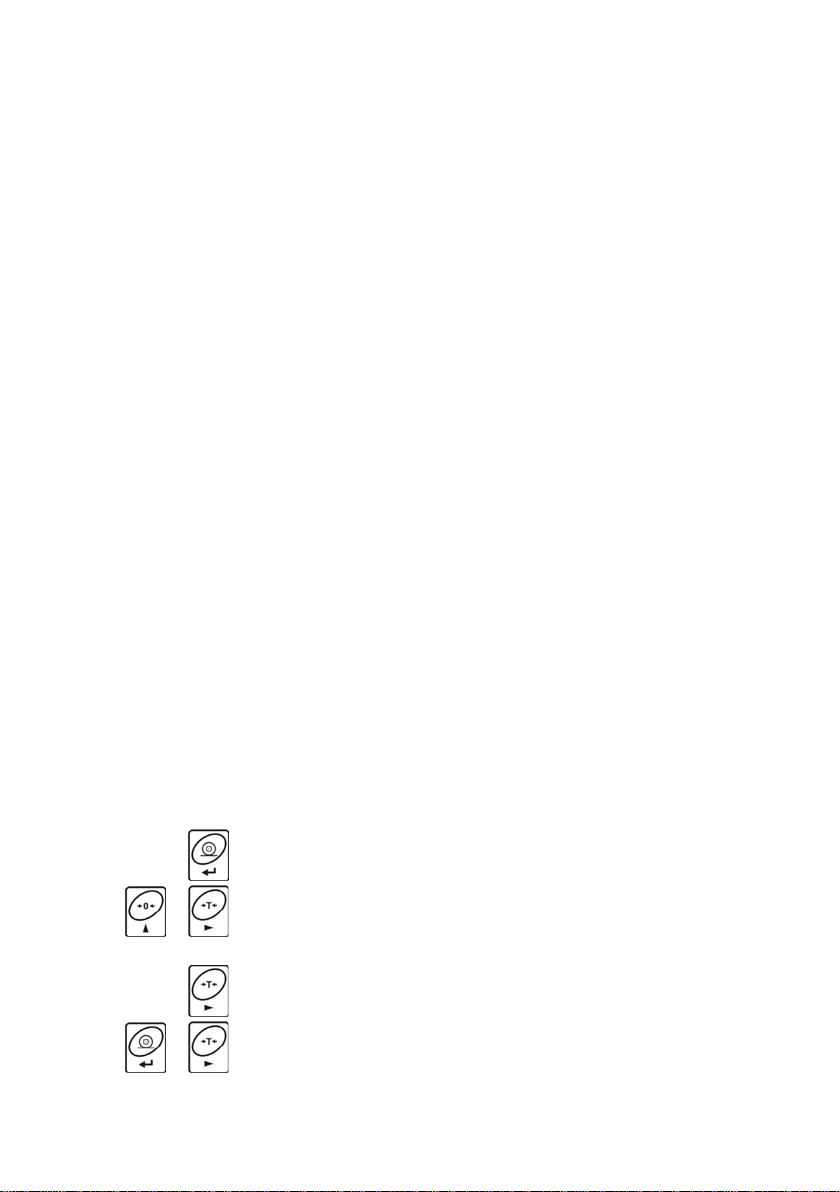

11. USER MENU

11.1. Scale’s parameter groups

Scale menu is divided into 5 basic submenus. Each group has its own

name preceded by a capital letter P:

11.2. Moving through user menu

The user moves in the menu by pressing keys on indicator’s overlay.

11.2.1. Keyboard

+

Change of digit value by “1” up

Scrolling the menu upwards

Page 19

- 19 -

Selecting a parameter on one menu level

Entering a selected submenu

Accepting carried out changes

Leaving a function without saving changes

Changing the value of an active parameter

Activating a parameter for modification

Moving one level “up” in menu structure

11.2.2. Return to weighing mode

The changes made in scale’s memory are permanently saved

on returning to weighing mode with procedure of saving

carried out changes.

Press

key for a few times until the display indicates

message <SAuE?>. Then press :

– to save changes or

– to abandon changes.

On pressing one of the above keys, the scale automatically

returns to weighing mode.

12. WEIGHING

For patients moving on the weighing platform it is recommended to set

higher filtering level (see point 13.1 of this user manual). In such case the

weighing time is longer, but the obtained measurement result is reliable.

12.1. Tarring function

Place a nappy or a blanket on the scale’s weighing platform.

• After indication stabilizing, signaled by accompanying pictograms

press

key (mass indication returns to zero, and Net pictogram is

lit up in the upper left corner of the display).

Page 20

- 20 -

• Place a weighed baby / infant on scale’s weighing platform (baby

scale)

• Stand on scale’s weighing platform (personal scale)

• Sit on the chair (of a chair scale)

• Lie on the bed (bed scale)

After a few seconds, after measurement stabilization, it is possible to read

the result.

Caution:

A. Baby scale is designed to weighing infants in lying position. If it is

used to weight infants / babies in sitting position, pay special

attention to place the infant / baby in the center of weighing platform.

In other case, the weighing platform may rest on the protective

bumpers, thus causing incorrect and unreliable measurement

results.

B. While weighing babies in sitting position pay special attention that

the baby does not loose balance and falls off the weighing platform.

C. Tarring is impossible if the display indicates negative or zero mass

value. In such case the scale signals an error message Err3 and

emits a short beep sound.

12.2. Manual tare insertion

The sale enables manual determining of tare value.

While in weighing mode:

• Simultaneously press

and keys

• The display indicates the following:

Page 21

- 21 -

• Use and keys to set tare value,

• Press key,

• The scale returns to weighing mode and the display indicates value

of inserted tare with ”–” sign

• Tare value can be inserted in the optional moment of weighing

process.

12.3. Zeroing function

Zeroing the indication is carried out by pressing key, which is followed

by zero mass indication and appearing pictograms:

and .

Zeroing is equal to determining new zero point, which is recognized by the

scale as a precise zero. Zeroing option is available only with stable

measurement status.

Caution:

Zeroing of display indication is possible only within the ±2% range from

scale’s maximal capacity. If zeroed value is more than the ±2% of scale’s

maximal capacity the display indicates <Err2> message and short beep

sound is emitted.

12.4. Weighing on dual range scales Transition from weighing in the I weighing range to weighing in the II

weighing range takes place automatically without operator’s interference

(i.e. on exceeding the Max of the I weighing range).

Weighing in the II weighing range is signaled by displaying a

corresponding pictogram in the upper left corner of the display.

On unloading, the scale’s indication returns to zero. Weighing is carried out

with the accuracy of II weighing range until the indication returns to zero.

Return from weighing in the II weighing range to weighing in the I weighing

range takes place automatically on unloading the weighing platform and

Page 22

- 22 -

indication returning to AUTOZERO zone – signaled by pictogram on

the display.

As the indication returns to zero, the pictogram of the II weighing range is

switched off, and the scale measures mass with the accuracy of the I

weighing range.

12.5. Selection of basic measuring unit

The scale enables setting a measuring unit which is activated on scale’s

switch on.

Procedure:

• Enter submenu <P3.Unit> in accordance with point 11.2 of this user

manual, and:

• Press

key for a few times, and the display indicates available

measuring units in sequence:

Available settings:

A. If the main measuring unit is [kg], the user can select between the

following unit s : [kg, lb, N] in case of verified scales [lb] unit is

disabled,

B. If the main measuring unit is [g], the user can select between the

following unit s : [g, ct, lb] in case of verified scales [lb] unit is

disabled.

Page 23

- 23 -

• On selecting a measuring unit press key,

the scale returns to displaying a window:

Return to weighing with procedure o f saving changes:

See point - 11.2.2. – return to weighing.

Caution:

On setting a new basic measuring unit the scale will switch on with the new

measuring unit set as default one.

12.6. Selecting an instantaneous measuring unit

The function enables setting an instantaneous measuring unit used for

indicating mass.

The measuring is active from the moment of its selection until it is changed

or the scale is switched off and on.

Procedure:

• Press

key, and:

Page 24

- 24 -

• On accepting a selected measuring unit, go back to weighing mode

with new measuring unit.

Available settings:

A. If the main measuring unit is [kg], the user can select between the

following units: [kg, lb – not available in verified scales, N],

B. If the main measuring unit is [g], the user can select between the

following units: [g, ct, lb – not available in verified scales

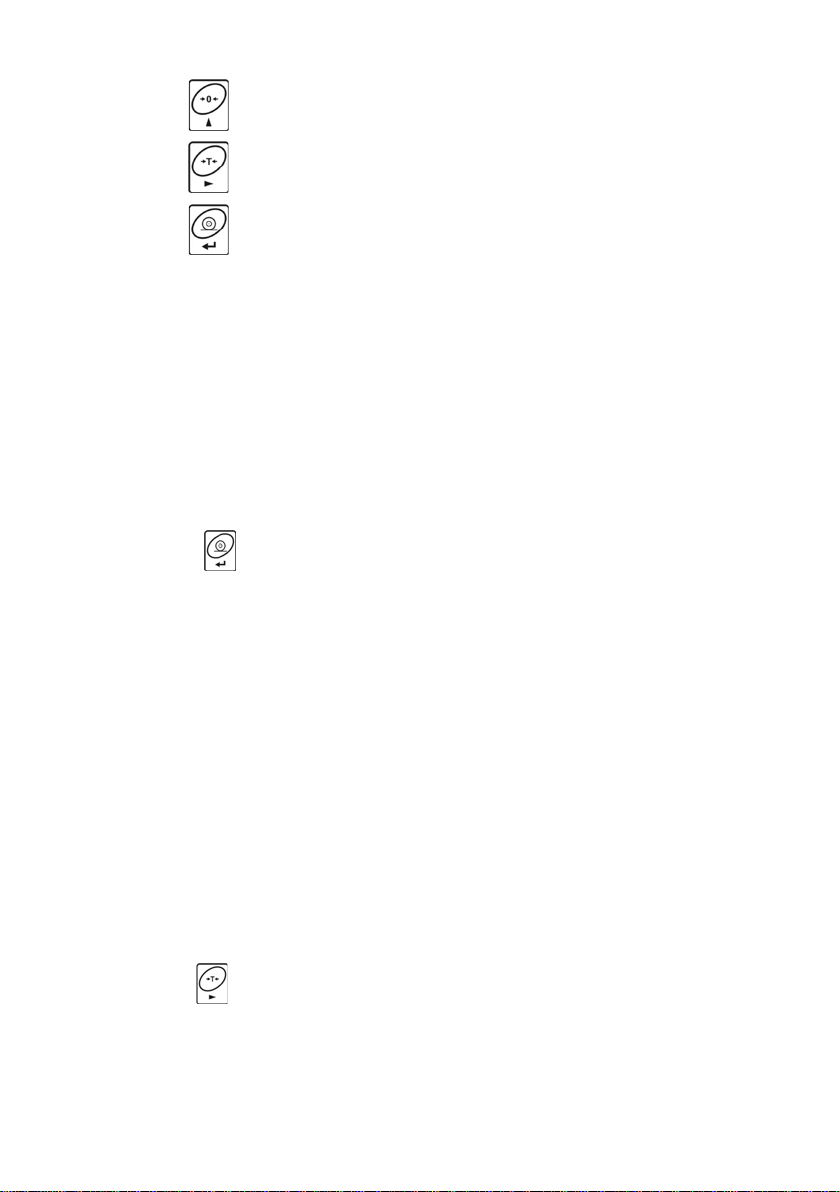

13. MAIN SCALE PARAMETERS

The scale enables adjusting its operation to external and ambient

conditions (filtering level) or user needs (autozero operation, tare value

memory). These parameters are grouped in menu <P1.rEAd>.

13.1. Setting filtering level Procedure:

• Enter submenu <P1.rEAd> in accordance w ith point 11.2 of this user

manual, and:

Page 25

- 25 -

1 - 4 - filtering level set in relation to current ambient and operating

conditions

Return to weighing:

See point - 11.2.2. – return to weighing.

Caution:

The higher filtering level, the longer stabilization time of measurement

result.

13.2. Median filter

The median filter is to eliminate short impulse disturbances (like

mechanical shocks).

Procedure:

• Enter submenu <P1.rEAd> in accordance with point 11.2 of this user

manual, and:

Fnnd no - median filter operation disabled

Fnnd YES - median filter operation enabled

Return to weighing:

See point - 11.2.2. – return to weighing.

Page 26

- 26 -

13.3. Autozero function

The AUTOZERO function is implemented to assure precise scale’s

indications. The function automatically controls and corrects scale’s zero

indication.

When the function is enabled, the following measurement results are

compared in constant time intervals. If the following values differ less than

declared AUTOZERO range, e.g. 1 division, then the scale automatically

zeroes its indication and displays pictograms of stable measurement result

and precise zero – .

–

When the AUTOZERO function is enabled, each measurement result starts

from precise zero point. There are, however, cases when autozero function

may disturb weighing process, like while very slow loading / pouring

weighed object on scale’s weighing platform. In such case, the zero

correcting system can also correct the actual mass indication of weighed

object.

Procedure:

• Enter submenu <P1.rEAd> in accordance with point 11.2 of this user

manual, and:

AUTO no - autozero disabled

AUTO YES - autozero enabled

Return to weighing:

See point - 11.2.2. – return to weighing.

Page 27

- 27 -

14. RS 232 PARAMETERS

14.1. Determining minimum mass for function operation

Scale software enables weighing with peak hold function (HOLD) and

determining BMI* (Body Mass Index) factor of weighed patients. The

functions are enabled if the measurement result is above a value of

minimum mass declared for function operation S_Lo. If the measurement

result is below the declared minimum mass value, then:

• The display shows a message -Lo- (in BMI function).

• The measurement result is not locked (peak hold (HOLD) option

disabled)

* BMI mode is not available in baby scales.

Procedure:

• Enter submenu <P2.Prnt> in accordance with point 11.2 of this user

manual, and:

Return to weighing:

See point - 11.2.2. – return to weighing.

Page 28

- 28 -

14.2. Baud rate Procedure:

• Enter submenu <P2.Prnt> in accordance with point 11.2 of this user

manual, and:

Return to weighing:

See point - 11.2.2. – return to weighing.

Page 29

- 29 -

14.3. Serial transmission parameters

• Enter submenu <P2.Prnt> in accordance with point 11.2 of this user

manual, and:

7d2SnP - 7 data bits; 2 stop bits, no parity control

7d1SEP - 7 data bits; 1 stop bit, EVEN parity control

7d1SoP - 7 data bits; 1 stop bit, ODD parity control

8d1SnP - 8 data bits; 1 stop bit, no parity control

8d2SnP - 8 data bits; 2 stop bits, no parity control

8d1SEP - 8 data bits; 1 stop bit, EVEN parity control

8d1SoP - 8 data bits; 1 stop bit, ODD parity control

Return to weighing:

See point - 11.2.2. – return to weighing.

Page 30

- 30 -

bL

no

-

Backlight disabled

bL

YES

-

Backlight enabled

bL

Auto

-

Backlight in automatic mode, i.e. switched off if

seconds

15. OTHER PARAMETRS

The scale enables setting parameters influencing its operation, like display

backlight, “beep” sound, automatic switch off mode. These parameters are

grouped in menu <P5.othr>,

15.1. Display backlight

The scale software automatically recognizes power supply mode (mains,

accumulators) and adjusts display backlight mode:

• bL – for power supply from mains

• blbA – for power supply from batteries or accumulators

15.1.1. Display backlight for supply from mains Procedure:

• Enter submenu <P5. othr> in accordance with po int 11.2 of the user

manual, and:

display indication does not change for 10

Page 31

- 31 -

Return to weighing:

See point - 11.2.2. – return to weighing.

Caution:

When bL=Auto, and the mass indication does not change for

approximately 10 seconds, then the display backlight is automatically

switched off. The backlight is automatically activated on mass indication

change.

15.1.2. Display backlight for supply from batteries or accumulators

Depending on user needs (and visibility (operation of light) in the scale’s

place of use) the user can adjust brightness of display backlight between 0

% and 100 %. In lower display brightness levels the operation time on

batteries / accumulators in longer. For setting display brightness level,

operation of display backlight is always set to Auto.

Procedure:

• Enter submenu <P5. othr> in accordanc e with po int 11 .2 of the user

manual, and:

Return to weighing:

See point - 11.2.2. – return to weighing.

Page 32

- 32 -

Caution:

Enabled display backlight shortens scale’s operation time on batteries /

accumulators.

15.2. “beep” sound – scale reaction to pressing a key Procedure:

• Enter submenu <P5. othr> in accordanc e with po int 11 .2 of the user

manual, and:

bEEP no - beep sound on pressing a key disabled

bEEP YES - beep sound on pressing a key enabled

Return to weighing:

See point - 11.2.2. – return to weighing.

15.3. Scale automatic switch off

This function is essential to save energy while powering the scale from

batteries / accumulators. If the t1 function is enabled, the scale switches off

within 5 minutes, on condition there is no activity carried out on the scale

(i.e. mass indication on the display does not change).

Page 33

- 33 -

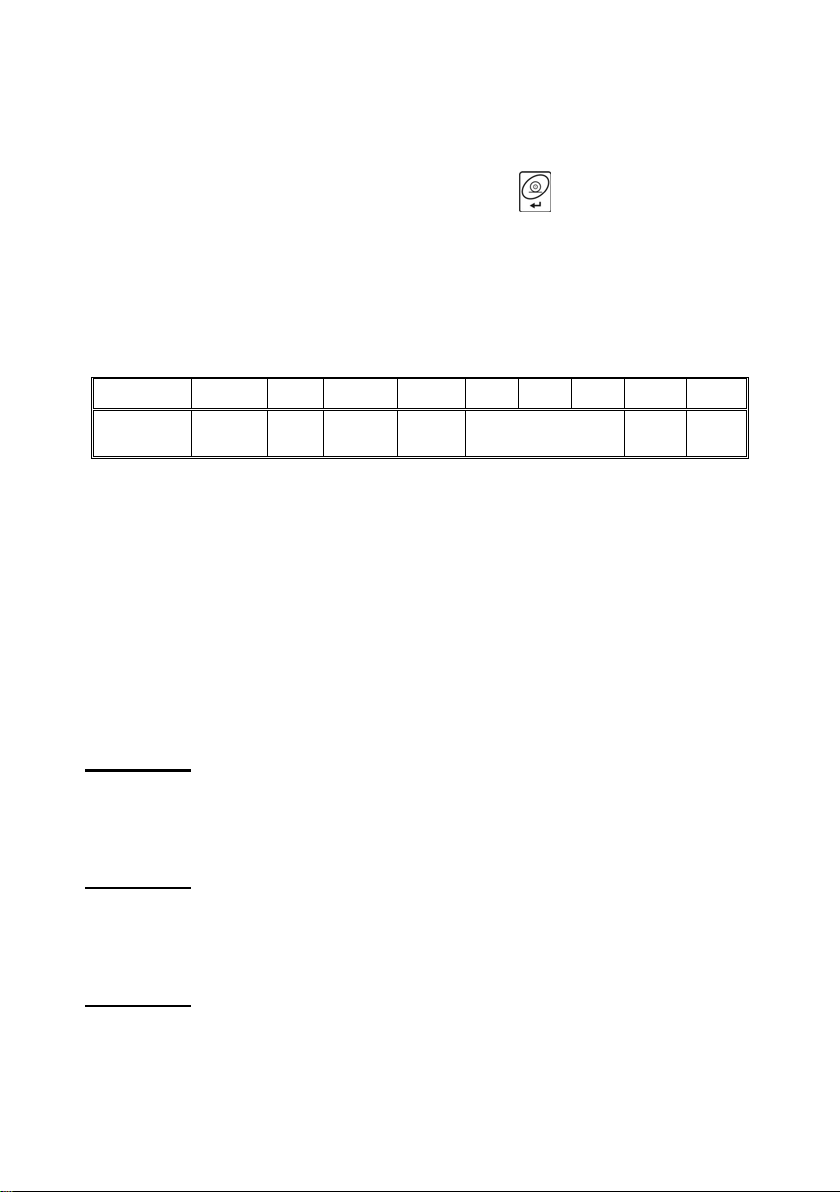

Function operation according to means of power supply:

Function operation

Function settings

t1 = 0 Disabled Disabled

t1 = YES Enabled Enabled

t1 = Auto * Disabled Enabled

Power supply

from mains

Power supply by

batteries/accumulators

* function disabled / enabled automatically according to means of scale’s power

supply.

Procedure:

• Enter submenu <P5. othr> in accordance with po int 11 .2 of the user

manual, and:

Return to weighing:

See point - 11.2.2. – return to weighing.

Page 34

- 34 -

15.4. Charging and discharging batteries / accumulators

If during scale supplying from batteries / accumulators the software detects

too low voltage value, then it is signaled by displaying

pictogram. It is a

message ordering the user to immediately replace the batteries with new

ones or charge the accumulators. Blinking

pictogram denotes

accumulators’ charging process.

15.4.1. Battery / accumulator voltage level check

This function is used to checking the level of voltage in batteries /

accumulators.

The function operates only if:

• The scale is in weighing mode,

• The scale is supplied from batteries / accumulators.

Procedure:

• While in weighing mode simultaneously press

and keys. The

display shows message bAtt for approximately 1 second, which is

followed by information on batteries / accumulators charging status in

% visible for approximately 2 seconds.

• On displaying battery / accumulator status, the scale automatically

returns to weighing mode.

15.4.2. Operation of battery / accumulator charge / discharge indication

In case the scale is supplied by batteries / accumulators, and the software

detects too low voltage level (voltage rate fall below 18 % of permissible

value), the display shows a pictogram

(bat low) which recommends

Page 35

- 35 -

immediate replacing used batteries with new ones or charging the

accumulators.

Low voltage signaling:

•

pictogram appears on the display,

• If a scale operates with low battery pictogram visible on the display,

after some time the software automatically switches off the scale to

protect the accumulators from excessive discharge,

• Accumulator charging process is signaled by blinking pictogram

(blinking interval: 2s) on the display.

15.4.3. Accumulator charging options

The function provides enabling or disabling charging option of NiMH

accumulators.

a) Parameter <5.5.CHr6> is set to <no>:

• Pictogram

is not displayed, charging option is disabled.

• On scale start, the display shows message <bAtt>.

b) Parameter <5.5.CHr6> is set to <YES>:

• Pictogram

is blinking while accumulators charging process

(blinking interval 2s), charging option is enabled.

• On scale start the display shows message <nImh>,

• In case the accumulators are defected or missing, the pictogram

is blinking quickly (with very short intervals ~ 0,5s).

Caution:

The indicator of a medical scale comes standard with a set of new NiMH

accumulators, size AA (R6), and a power adapter.

Procedure:

• Enter submenu <P5. othr> in accordance with point 11.2 of the user

manual, and:

Page 36

- 36 -

CHr6 YES - function enabled (pictogram appears on the

display)

CHr6 no - function disabled (pictogram does not appear on

the display)

Return to weighing:

See point - 11.2.2. – return to weighing.

15.4.4. Accumulator charging process The indicator of a medical scale comes standard with a set of new NiMH

accumulators, size AA (R6), and a power adapter. On scale’s

commissioning it is obligatory to form the accumulators, which extends their

life-span. The process requires full charging and complete discharging the

accumulators. New accumulators have the optimum capacity after

completing three charging / discharging cycles.

Forming process:

1. Plug the power adapter to scale’s indicator.

2. Charge the accumulators for approximately 12 hours – charging time

specified for accumulators with capacity 2200mAh.

3. After 12 hours unplug the power adapter from the indicator.

4. Operate the scale with supply from accumulators until its automatic

switches off.

Page 37

- 37 -

5. After scale’s automatic switch off repeat the forming process twice by

acting as specified in points 1 to 4 above.

The forming process enables obtaining optimum capacity of the

accumulators.

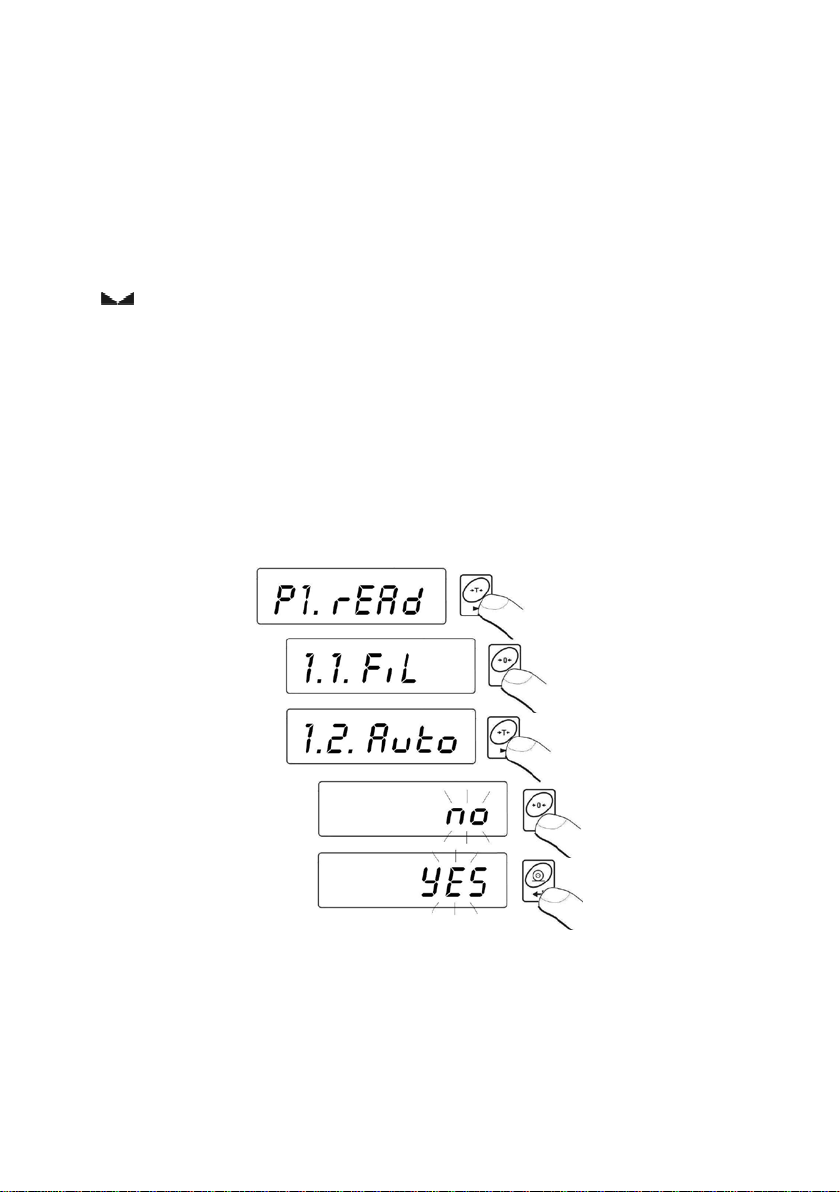

16. WORKING MODES

Medical scales, while in weighing mode have two working modes, which

are enabled on pressing of

key:

• Weighing with peak hold (lock of measurement result on the display

(hoLd)

• Determining BMI factor.

16.1. Means of selecting a working mode

On changing – selecting a working mode, the scale displays name of the

working mode for approximately 1 second. The software stores data on

recently used working mode, and it is displayed as the first one on next

pressing of

key.

Procedure:

16.2. Weighing with lock of measurement resul t o n th e display - hoLd

While in weighing mode press key and select working mode hoLd.

On enabling the mode, the user should set its operation parameters. The

display automatically previews the first of available options.

Page 38

- 38 -

hoLd

Print

-

Scale operation with peak hold of measurement result

key;

hoLd

StAb

-

Scale operation with automatic locking of

key;

hoLd

OFF

-

Exit to weighing mode on pressing key.

enabled on pressing key, the lock is cancelled on

taking the load off the weighing platform and pressing

measurement result, the lock is cancelled on taking

the load off the weighing platform and pressing

• On accepting selecting working mode by pressing

software automatically moves to displaying mass indication window:

Software confirmation for enabling HoLd mode, is appearance of -OKmarker in the top section of the display.

key, the

Page 39

- 39 -

Caution:

In case the mass indication is below set value of S_Lo parameter, then the

measurement result will not be locked (HoLd function will not be activated).

Mode operation:

• Load scale’s weighing platform. On stabilization of measurement result

the display locks mass indication, as required by enabled HoLd mode.

• Take the weighed load off scale’s weighing platf orm,

• Before carrying out the following measurement press

key.

16.3. Determining BMI factor

The mode of determining body mass index BMI is dedicated for adults over

18 years old, therefore the software comprises the following limitations:

• The mode is not available in baby scales (models WPT 6/15D and

WPT 10/20D).

• Body mass limitation for mode activation - min 10kg,

• Height limitation for mode activation - from 1m to 2,5m.

Mode operation:

• Load scale’s weighing platform,

• Press function key

to select working mode bnni,

• If measurement result is stable, the display indicates (for

approximately 2 seconds) the mass value of weighed patient followed

by blinking value of height expressed in m eter s ,

• If measurement result is unstable, the display indicates dashes

< - - - - - - - - - - > until stable measurement result is obtained. Then

the display indicates (for approximately 2 seconds) the mass value of

weighed patient followed by blinking value of height expressed in

meters.

Page 40

- 40 -

H

1.85 m

W

75,82 kg

BMI

22,2

2

H

W

BMI =

where:

W

-

body mass in [kg]

H -

height in [m]

BMI

-

factor’s value rounded to first decimal

place.

• Use indicator’s keyboard to type in the height of weighed patient,

where:

- selects a digit, - selects digit value,

• On typing in the height data, accept it by pressing key, and the

display indicates the value of BMI factor:

• The following pressing of

key causes printing the following data on

a connected printer:

• Take of the load of the scale’s weighing platform,

• Return to weighing mode by pressing

The BMI factor is determined using the following relation:

key.

,

Caution:

In case the mass indication while entering bnni mode is below set value of

S_Lo parameter, then the displays shows a message < -Lo- > and the

scale returns to weighing mode.

Page 41

- 41 -

17. SC ALE ADJUST M ENT

Available in non-verified scales only

Ensuring high weighing accuracy requires periodical controlling scale’s

indications and correcting the adjustment factor stored in scale’s memory –

the process is known as scale adjustment.

Adjustment should be carried out on scale start of operation or if dynamic

change of temperature occurs. Before carrying out adjustment procedure

remove load from the weighing platform.

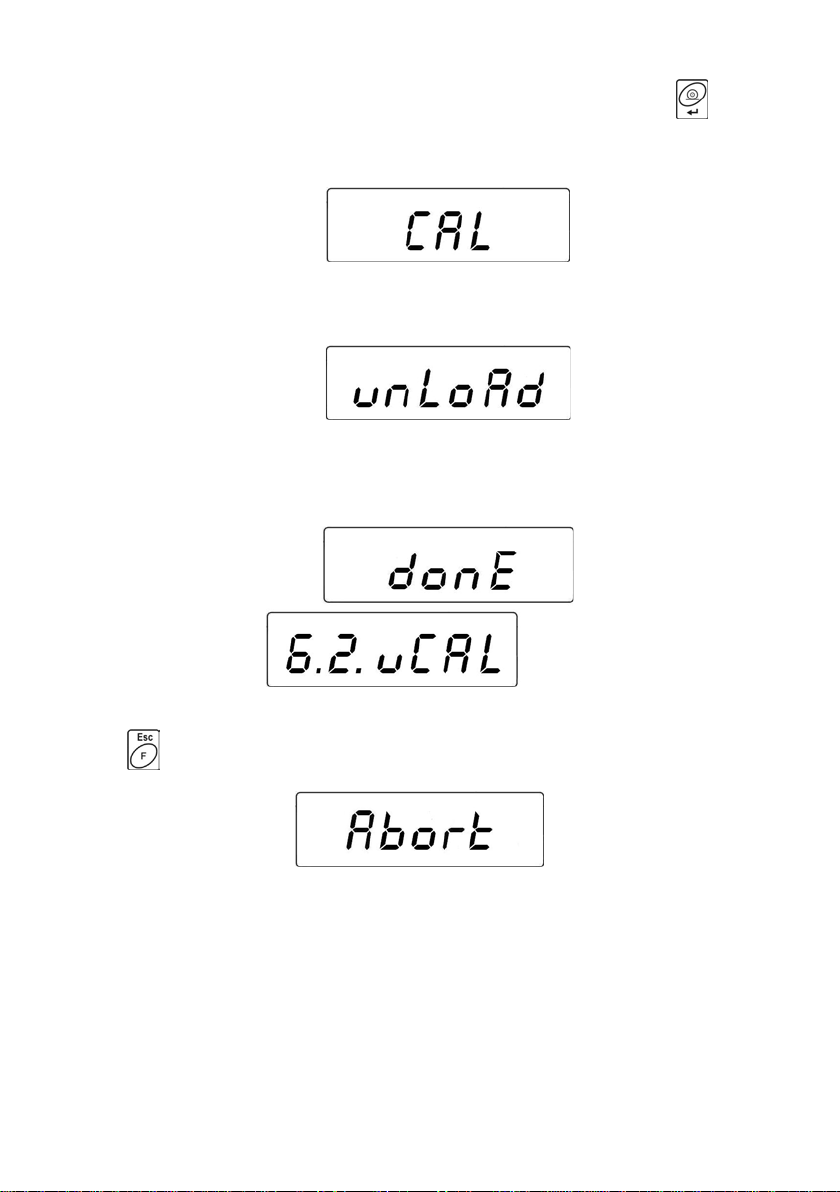

17.1. Adjustment Procedure:

• Enter submenu <P6.CAL> in accordance with po int 11 .2 of the user

manual, and:

• The software displays the following messages / commands:

• During this time the scale adjusts its start mass, and after completing

the procedure, the mass of adjustment weight is

displayed (e.g. 3.000kg).

Page 42

- 42 -

• Place the required weight on the weighing platform and press key.

The adjustment process starts automatically, which is signaled by the

displaying the following message:

• The completion of the adjustment procedure is signaled by the

following message:

• Take off the adjustment weight from the weighing platform, after which

message <donE> is displayed for approximately 1s and the scale

returns to displaying name of submenu: adjustment:

• Adjustment process can be aborted at optional moment by pressing

key, which is signaled by displaying the following message:

Caution:

1. Remember to carry out scale’s adjustment process when there is no

load on the scale’s weighing platform!

2. If the adjustment process (span adjustment) lasts longer than 15

seconds, error message <Err8> is displayed and short beep sound is

emitted. Press

key and repeat adjustment procedure under more

stable ambient conditions!

Page 43

- 43 -

Return to weighing with procedure o f saving changes:

See point - 11.2.2. – return to weighing.

17.2. Start mass adjustment

If the scale does not require the full adjusting process, or the user does not

have sufficient number of adjustment weights, it is possible

to adjust the start mass only.

Procedure:

• Enter submenu <P6.CAL> in accordance with po int 11 .2 of the user

manual, and:

• The software displays the following messages / commands:

• After completing start mass adjustment process, the scale returns to

displaying parameter’s name:

• Start mass adjustment process can be aborted at optional moment by

pressing

key, which is signaled by displaying the following

message:

Page 44

- 44 -

Caution:

If the start mass adjustment lasts longer than 15 seconds, error message

<Err8> is displayed and short beep sound is emitted. Press

key and

repeat adjustment procedure under more stable ambient conditions!

Return to weighing with procedure o f saving changes:

See point - 11.2.2. – return to weighing.

18. COOPER ATION WITH A PRINTER

Each time the

key is pressed causes sending a signal containing

current mass value and a measuring unit.

Depending on setting of STAB parameter, the printout is released with

stable or unstable (instantaneous) value. Depending on setting of REPL

parameter, printout is automatic or manual.

Medical scales enable cooperating with one of the following printers

KAFKA series:

a) KAFKA

Printout of weighing result and measuring unit only

b) KAF KA 1/Z

This printer features an internal real time clock. Both date and time

are printed on plugging the printer to mains and connecting it to the

scale.

c) KAFKA SQ S

This printer features an internal real time clock and possibility of

running statistics from measurements. Statistic contents: quantity of

samples, total mass of weighed samples, average value, standard

deviation, variation factor, min value, max value, difference max –

min.

Page 45

- 45 -

- manually

-

After pressing key,

- continuously

-

After sending a controlling command,

- on a request from the

computer

-

After sending a controlling command

Cable diagram:

Cable: scale – KAFKA printer

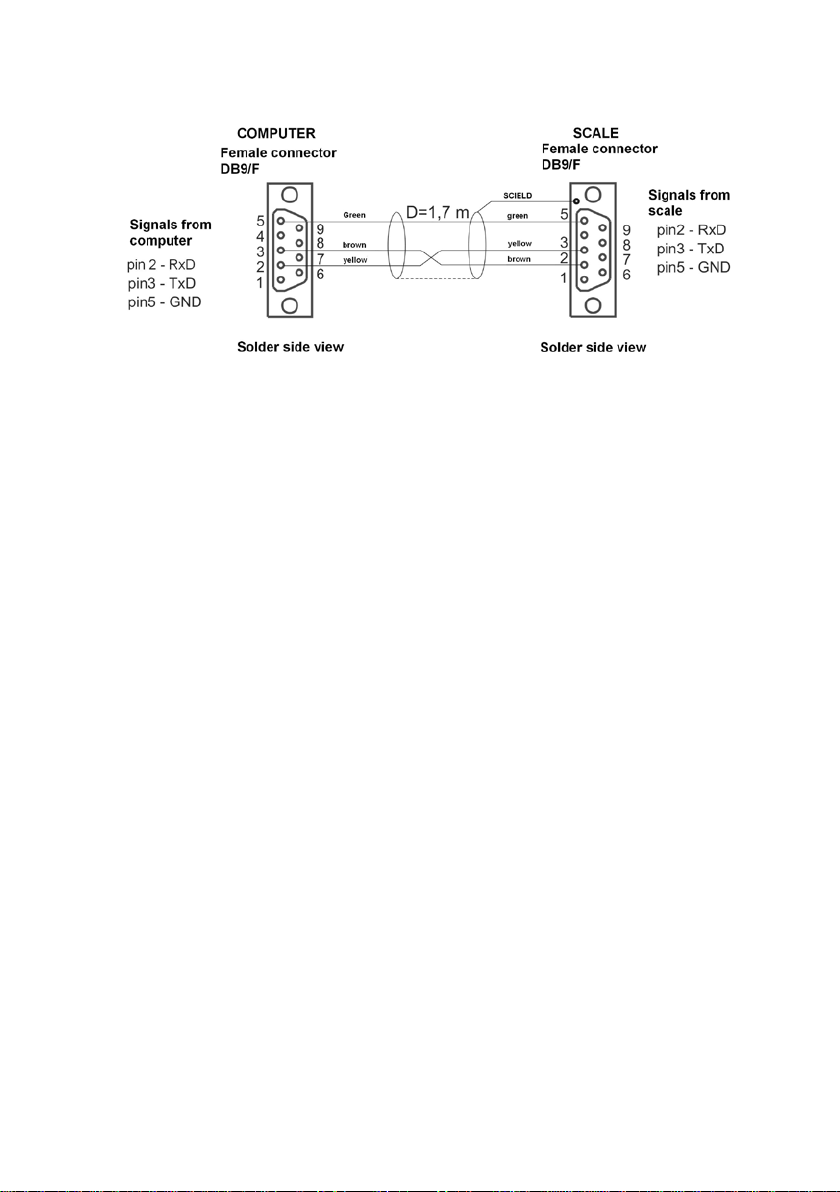

19. COOPERATION WITH A COMPUTER

Medical scales enable communicating with a PC computer featuring an RS

232 interface.

Sending weighing results to a computer can be carried out:

Caution:

In medical scales enabling continuous transmission and automatic printout

by setting an appropriate parameters is not available for a user.

Page 46

- 46 -

Cable diagram:

Cable: scale - computer

Medical scales enable cooperating with a computer software “SCALE

EDITOR”. The software option of displaying indicator’s main weighing

window features the most important data on weighing process previewed

on scale’s display. The software enables simple scale configuration,

including designing printouts according to user needs, editing main

software settings, editing RS 232 parameters, etc. Detailed description of

software cooperation with a scale is provided in the software’s tab “Help...”.

20. COMM UNIC ATION PROTOCOL

20.1. General information

A. A character based communication protocol scale-terminal is

designed for establishing communication between a RADWAG scale

and a peripheral devices via RS 232C interface.

B. It consists of commands sent from a peripheral device to the scale

and responses from the scale.

C. Responses are sent from the scale on each receipt of a command as

a reaction for a specific command.

D. Commands forming the communication protocol enable obtaining

data on scale’s status and influencing its operation, e.g.: request

measurement results from the scale, zero indication, etc.

Page 47

- 47 -

Command

Command description

S

SUI

CU1

Switch on continuous transmission in current measuring unit

XX_A CR LF

XX_D CR LF

XX_I CR LF

XX _ ^ CR LF

XX _ v CR LF

ES_CR LF

20.2. A set of commands recognized by the indicator

Z

T

TO

Zero scale

Tare scale

Give tare value

Send stable measurement result in basic measuring unit

SI

SU

Immediately send measurement result in basic measuring unit

Send stable measurement result in current measuring unit

Immediately send measurement result in current measuring unit

C1

C0

CU0

PC

Switch on continuous transmission in basic measur ing unit

Switch off continuous transmission in basic measur ing unit

Switch off continuous transmission in current mea suring unit

Send all implemented commands

Caution:

1. Each command must end with CR LF characters;

2. Sending a following command without waiting for a response for an

already sent command may result in scale’s loosing (skipping) some

of sent commands. The best policy for communication is not sending

another command until a response for a former command has been

received.

20.3. Responses format for commands sent from computer level

On receipt of a command the indicator sends a response in one of the

following formats:

command understood and in progress

command carried out (appears only after the command XX_A)

command understood but not accessible at this moment

command understood but max range is exceeded

command understood but min range is exceeded

Command carried out (completed)

Page 48

- 48 -

XX _ E CR LF

an error occurred on command carrying out (time limit exceeded

balance’s characteristic param et er)

Z_A CR LF

- command understood and in progress

-

Z_A CR LF

- command understood and in progress

-

Z_A CR LF

Z_E CR LF

- command understood and in progress

-

Z_I CR LF

- command understood but not accessible at this moment

T_A CR LF

- command understood and in progress

-

T_A CR LF

- command understood and in progress

-

T_A CR LF

T_E CR LF

- command understood and in progress

-

T_I CR LF

- command understood but not accessible at this moment

while waiting for stable measurement result (time limit is

XX - stands for a name of sent command

_ - substitutes spaces

20.4. Command’s description

20.4.1. Zero scale

Format Z CR LF

Accessible responses:

Z_D CR LF

Z_^ CR LF

command carried out

command understood but zeroing range exceeded

time limit exceeded while waiting for stable measurement result

20.4.2. Tare scale

Format: T CR LF

Accessible responses:

T_D CR LF

T_v CR LF

command carried out

command understood but tarring range exceeded

time limit exceeded while waiting for stable measurement result

20.4.3. Give tare value

Format: TO CR LF

Response: TO_TARA CR LF - command carried out

Page 49

- 49 -

stability

marker

S_A CR LF

- command understood and in progress

S_I CR LF

- command understood but not accessible at this moment

S_A CR LF

MASS FRAME

- command understood and in progress

- response is mass value in basic measuring unit

stability

marker

SI_I CR LF

- command understood but not accessible at this moment

MASS FRAME

- response is immediate with mass value in basic weighing unit

Frame format:

1 2 3 4 5-6 7-15 16 17 18 19 20 21

T O space

Tare - 9 characters with right justification

Unit - 3 characters with left justification

20.4.4. Send stable measurement result in basic measuring unit

Format: S CR LF

Accessible responses:

space tare space unit CR LF

S_E CR LF

- time limit exceeded while waiting for stable measurement result

Frame format:

1 2-3 4 5 6 7-15 16 17 18 19 20 21

S space

Example:

S CR LF – command sent from a computer

S _ A CR LF - command understood and in progress

S _ _ _ _ - _ _ _ _ _ _ 8 . 5 _ g _ _ CR LF - command carried out, response

is mass value in basic measuring unit.

20.4.5. Immediately send measurement result in basic measuring unit

Format: SI CR LF

Accessible responses:

space sign mass space unit CR LF

Page 50

- 50 -

stability

marker

SU_A CR LF

- command understood and in progress

SU_I CR LF

- command understood but not accessible at this moment

SU_A CR LF

MASS FRAME

- command understood and in progress

- response is mass value in current measuring unit

marker

Frame format:

1 2 3 4 5 6 7-15 16 17 18 19 20 21

S I space

space sign mass space unit CR LF

Example:

S I CR LF – command sent from a computer

S I _ ? _ _ _ _ _ _ _ 1 8 . 5 _ k g _ CR LF - command carried out,

immediate response of mass value in basic weighing unit

20.4.6. Send stable measurement result in current weighing unit

Format: SU CR LF

Accessible responses:

SU_E CR LF

- time limit exceeded while waiting for stable measurement result

Frame format:

1 2 3 4 5 6 7-15 16 17 18 19 20 21

S U space

Example:

S U CR LF – command from a computer

S U _ A CR LF – command understood and in progress

S U _ _ _ - _ _ 1 7 2 . 1 3 5 _ N _ _ CR LF - command carried out,

response is mass value in current measuring unit.

stability

space sign mass space unit CR LF

Page 51

- 51 -

20.4.7. Immediately send measurement result in current measuring

SUI_I CR LF

- command understood but not accessible at this moment

MASS FRAME

- mass value in current measuring unit is returned immediately

stability

marker

C1_I CR LF

- command understood but not accessible at this moment

C1_A CR LF

MASS FRAME

- command understood and in progress

- response is mass value in basic measuring unit

stability

marker

unit

Format: SUI CR LF

Accessible responses:

Frame format:

1 2 3 4 5 6 7-15 16 17 18 19 20 21

S U I

space sign mass space unit CR LF

Example:

S U I CR LF – command from a computer

S U I ? _ - _ _ _ 5 8 . 2 3 7 _ k g _ CR LF - command carried out,

immediate response of mass value in current measuring unit

20.4.8. Switch on continuous transmission in basic measuring unit

Format: C1 CR LF

Accessible responses:

Frame format:

1 2 3 4 5 6 7-15 16 17 18 19 20 21

S I space

space sign mass space unit CR LF

Page 52

- 52 -

20.4.9. Switch off continuous transmission in basic measuring unit

C0_I CR LF

- command understood but not accessible at this moment

C0_A CR LF

- command understood and in progress

CU1_I CR LF

- command understood but not accessible at this moment

CU1_A CR LF

MASS FRAME

- command understood and in progress

- response is mass value in current measuring unit

marker

CU0_I CR LF

- command understood but not accessible at this moment

CU0_A CR LF

- command understood and in progress

Format: C0 CR LF

Accessible responses:

20.4.10. Switch on continuous transmission in current measuring unit

Format: CU1 CR LF

Accessible responses:

Frame format:

1 2 3 4 5 6 7-15 16 17 18 19 20 21

S U I

stability

space sign mass space unit CR LF

20.4.11. Switch off continuous transmission in current measuring unit

Format: CU0 CR LF

Accessible responses:

20.4.12. Send all implemented commands Format: PC CR LF

Accessible responses:

PC_- >_Z,T, TO,S,SI,SU,SUI,C1,C0,CU1,CU0,PC – command carried

out, terminal has sent all implemented commands.

Page 53

- 53 -

Stability marker

[space] if stable

[v] if error of exceeding range to “-“ occurs

sign

[space] for positive values or

[-] for negative values

mass

9 characters with decimal point and right

justification

unit

3 characters with left justification

command

3 characters with left justification

20.5. Manual printout

Medical scale enables generating manual printouts. The manual printout is

generated after placing a weighed load on scale’s weighing platform,

stabilization of measurement result and pressing

key.

Caution:

If the scale is a verified one, then printout of unstable / instantaneous data

in disabled.

Format of mass printout:

1 2 3 4 -12 13 14 15 16 17 18

stability

marker

space sign mass space unit CR LF

[?] if unstable

[^] if error of exceeding range to “+” occurs

Example 1:

_ _ _ _ _ _ 1 8 3 2 . 0 _ g _ _ CR LF - a printout generated from a scale on

pressing ENTER/PRINT key.

Example 2:

? _ - _ _ _ _ 2 . 2 3 7 _ l b _ CR LF - a printout generated from a scale on

pressing ENTER/PRINT key.

Example 3:

^ _ _ _ _ _ _ 0 . 0 0 0 _ k g _ CR LF - a printout generated from a scale on

pressing ENTER/PRINT key.

Page 54

- 54 -

Err2

-

Value beyond the zero range

Err3

-

Value beyond the tare range

Err4

-

Adjustment mass or start mass beyond the

acceptable range (±1% for weight, ±10 for start mass)

Err5

-

Mass of single part (piece) below scale’s reading unit.

Err7

-

Too short scale’s switch off time (recommended time

more than 3 sec.)

Err8

-

Tarring / Zeroing operation time exceeded

null

-

Zero value from the AD converter

FULL2

-

Measurement range (Max. capacity) exceeded

LH

-

Start mass error, indication beyond acceptable range

(from -5% to +15% of start mass)

20.6. Continuous transmission

Scale indicator enables printing mass value in continuous transmission in

basic and in current measuring unit. Continuous transmission mode in

medical scales can be enabled by sending a command via RS 232C

interface (see point 20.4 of this user manual).

20.7. Printout configuration General information

If data contained on a standard printout is excessive or insufficient, and

there is a need to modify it according to user needs, please use SCALE

EDITOR computer software. The freeware is available for downloading

from RADWAG website: http://www.radwag.com

21. ERROR MESSAGES

Caution:

1. Errors: Err2, Err3, Err4, Err8, null, LH, that appear on the display are

also accompanied by a short beep sound (about 1 sec.).

2. Error FULL2 that appears on the display is also accompanied by

a continuous sound until the cause of error (excessive load on the

weighing platform) disappears.

Page 55

- 55 -

22. SCALE TECHNICAL PARAMETERS

22.1. Chair scale

Technical data: WPT/K 250C

Max capacity 250kg

Min load 2kg

Readability [d] 100g

Verification interval [e] 100g

Tare range -250kg

Power supply

Working temperature

Average operation time on accumulators 35 hours

Interface RS 232

100-240VAC/12VDC

and 6xAA (NiMH)

from 0°C to +40°C

22.2. Personal scales

Technical data:

Max capacity 60/150kg 100/200kg

Min load 0,4/1kg 1/2kg

Readability [d] 20/50g 50/100g

Verification interval [e] 20/50g 50/100g

Tare range -150kg -200kg

Height meter max range - 2m - 2m

Power supply

Working temperature

Average operation time on

accumulators

Interface RS 232

WPT

60/150 O

WPT

60/150 OW

230 V 50 Hz/11V AC, I

and 6xAA (NiMH)

from 0°C to +40°C

100/200 O

35 hours

WPT

= 600mA

max

100/200 OW

WPT

Page 56

- 56 -

Average operation time on

accumulators

22.3. Bed scales

Technical data: WPT/4B 500C WPT/8B 300C

Max capacity 500kg 300kg

Min load 4kg 2kg

Readability [d] 200g 100g

Verification interval [e] 200g 100g

Tare range -500kg -300kg

Power supply

Working temperature

Interface RS 232

230 V 50 Hz/11V AC, I

and 6xAA (NiMH)

from 0°C to +40°C

35 hours

= 600mA

max

22.4. Baby scales

Technical data: WPT 6/15D WPT 10/20D

Max capacity 6/15kg 10/20kg

Min load 40/100g 100/200g

Readability [d] 2/5g 5/10g

Verification interval [e] 2/5g 5/10g

Tare range -15kg -20kg

Power supply

Working temperature

Average operation time on accumulators 35 hours

Interface RS 232

230 V 50 Hz/11V AC, I

and 6xAA (NiMH)

from 0°C to +40°C

= 600mA

max

Page 57

- 57 -

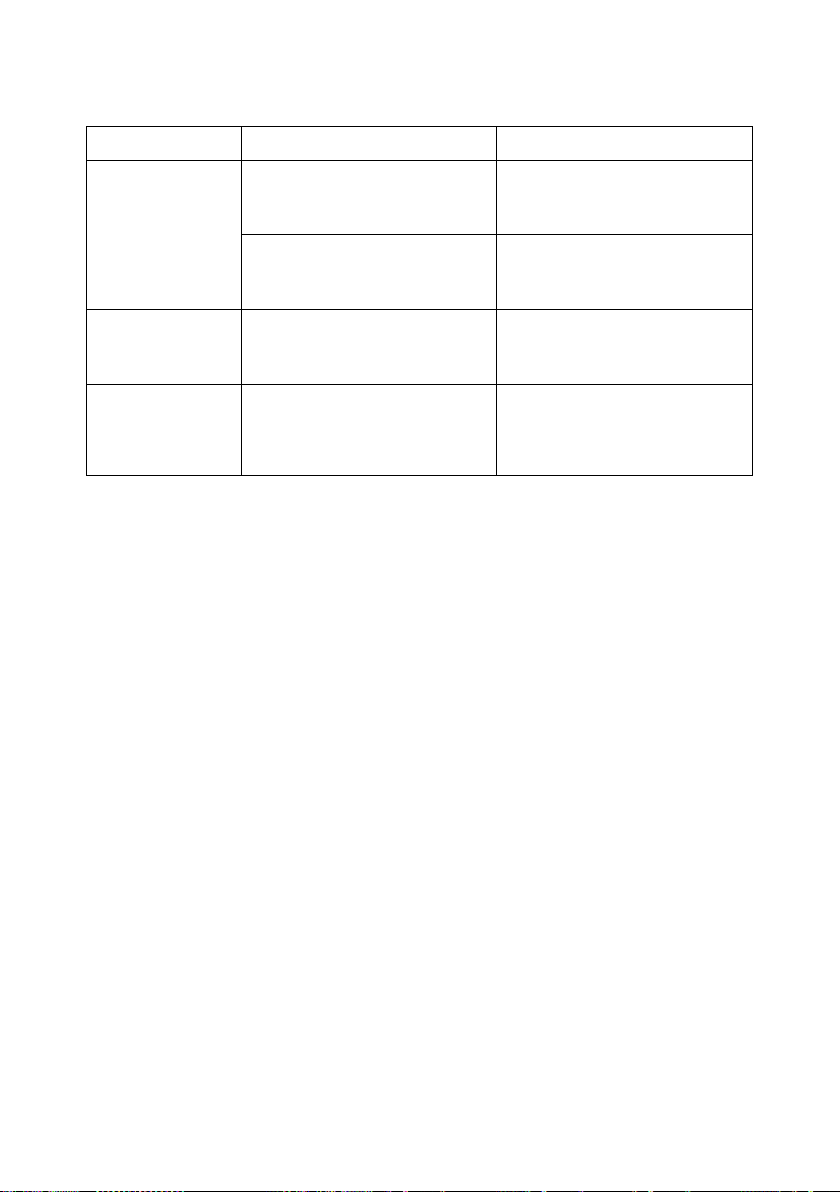

23. TROUBLE SHOOTING

Problem Cause Solution

Connect power adapter to

charge the accumulator /

accumulators.

Check the correctness of

accumulator(s) installation

(polarization).

Go to submenu “othr” and

change parameter

“5.4 t1” to “no”.

Unload the weighing platform.

In short period of time the

scale should indicate zero.

Scale does not

turn on

Scale turns off

automatically

After turning on

message “LH” is

displayed

Discharged accumulator /

accumulators,

No accumulators (not

installed or improperly

installed)

Parameter “t1” set to “YES”

(power saving mode)

Load on scale’s weighing

platform during powering up.

24. ADDITIONAL EQUIPMENT

Accessories:

• KAFKA printer cable - P0136,

• Computer cable - P0108,

• EPSON printer cable - P0151,

• Power cord for car lighter 12V DC - K0047,

• Thermal printer - KAFKA,

• Dot matrix printer - EPSON,

• Additional display in plastic housing - WD- 4/1

(available only as the factory installed option with a new scale),

• RS232 / RS485 converter for PUE C/31 – KR-01,

• RS232 / Ethernet converter for PUE C/31 - KR-04.

Computer software:

• „Scale Editor” computer software,

• "RAD-KEY" computer software,

• "PW-WIN" computer software.

Page 58

- 58 -

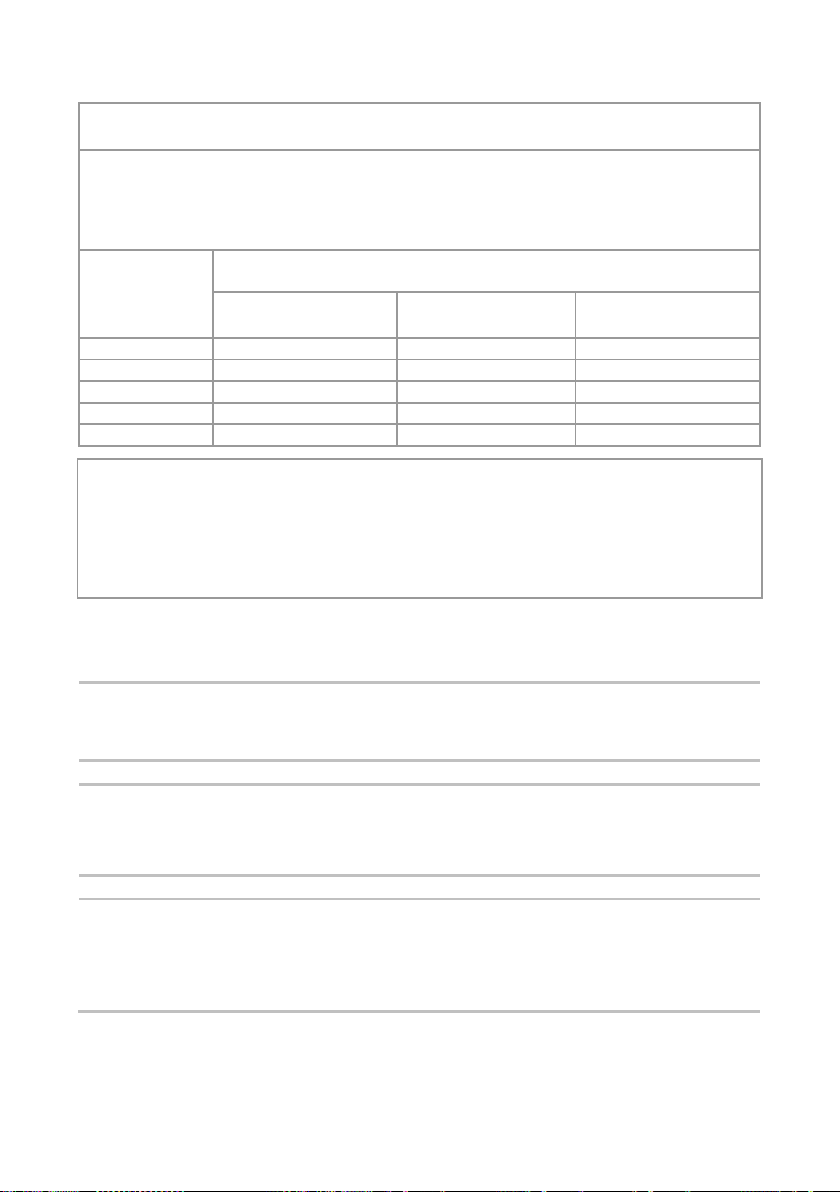

Table 201

Manufacturer declaration and information – electromagnetic emission

The DEVICE is intended to operate in the electromagnetic environment described below.

Recipient or user of the DEVICE should make sure that it operates in such an environment.

Emissivity tests

Compliance

Electromagnetic environ m e nt – information

Emission of RF

Group 1

The DEVICE produces energy in the range of RF only

proximity.

Emission in the range

Class B

The DEVICE is relevant to operate in all premises,

supplies dwelling houses.

RF – frequency from the interval o electromagnetic spectrum which is between the lower

transmission. Limit frequencies are 9 kHz and 3 000 GHz

Table 202

Manufacturer declaration and information - electromagnetic immunity

The DEVICE is intended to operate in the electromagnetic environment described below.

Recipient or user of the DEVICE should make sure that it operates in such an environment.

Immunity tests

Electromagnetic

Electrostatic

+/- 6kV contact

air

+/- 6kV contact

The floor should be wooden,

concrete or made of ceramic

at least 30%.

Transient states

+/- 2 kV

for I/O lines

+/- 2 kV

for I/O lines

The quality of mains should

Surge

+/- 1 kV

associative mode

+/- 1 kV

associative mode

The quality of mains should

25. EMC INFORMATION

according to CISPR 11

as a subsequence of internal functionality. Owing to

that the emission in the range of RF is minimal and it

is unlikely for it to interfere with anything in the near

of RF according to

CISPR 11

including living surface and premises directly

connected to the low-tension system (mains) that

range of radio frequencies of long waves and the infrared range; frequencies useful for radio

Testing level IEC

discharge (ESD)

according to IEC

61000-4-2

and impulses

according to IEC

61000-4-5

60601

discharge

+/- 8kV throughdischarge

for supply lines

+/- 1 kV

Met requirements

discharge

+/- 8kV through-air

discharge

for supply lines

+/- 1 kV

environment – information

plates. If floors are covered

with a synthetic material

relative humidity should be

be on the on the office- or

hospital-level environment.

disturbances

according to IEC

61000-4-5

differential mode

+/- 2 kV

differential mode

+/- 2 kV

be on the on the office- or

hospital-level environment.

Page 59

- 59 -

Short supply

voltage drops and

< 5% UT

through 5 seconds

< 5% UT

through 5 seconds

The quality of mains should

continuous supply during the

Magnetic field with

61000-4-8

3A/m

Magnetic field with frequency

Caution UT is an alternative current (AC) of mains before implementing the test level.

RF – frequency from the interval o electromagnetic spectrum which is between the lower

transmission. The limit frequencies are 9 kHz and 3 000 GHz

Table 204

Manufacturer declaration and information - electromagnetic immunity

The DEVICE is intended to operate in the electromagnetic environment described below.

Recipient or user of the DEVICE should make sure that it operates in such an environment.

Testing

60601

Portable devices for wireless

Advisable minimal distance

changes of supply

voltage in supply

lines according to

IEC 61000-4-11

frequency the

same as the

supply voltage

according to IEC

range of radio frequencies of long waves and the infrared range; frequencies useful for radio

(> 95% voltage

drop UT)

through 0.5 period

40% UT

(60% voltage drop

UT)

through 5 periods

70% UT

(30% voltage drop

UT)

through 25 periods

< 5% UT

(> 95% voltage

drop UT)

(> 95% voltage

drop UT)

through 0.5 period

40% UT

(60% voltage drop

UT)

through 5 periods

70% UT

(30% voltage drop

UT)

through 25 periods

< 5% UT

(> 95% voltage

drop UT)

be on the on the office- or

hospital-level environment.

If a DEVICE user requires

breaks in the mains it is

advisable that the DEVICE is

supplied from UPS or

batteries.

the same as the supply

voltage should be on the

level typical for office or

hospital environment

Immunity tests

level IEC

Met

requirements

Electromagnetic environment –

information

communication and cellular

telephones should not be used within

the distance from the DEVICE lower

than the minimal recommended and

that includes cables/harness. This

distance can be calculated using the

equations applicable for frequencies

of transmitter operation.

Page 60

- 60 -

Electromagnetic

IEC 61000-4-6

3 Vrms

3 Vrms

d=1,2√P

Electromagnetic

3 V/m

3 V/m

d=1,2√P 80 MHz to 800 MHz

Where P is a maximal transmitter output power

Caution 1: For 80 MHz and 800 MHz higher frequency range is taken.

persons.

(a) Powers sourcing from fields of specific transmitters such as base stations in cellular

greater than 3 V/m.

RF – frequency from the interval o electromagnetic spectrum which is between the lower range

transmission. Limit frequencies are 9 kHz and 3 000 GHz

CAUTION! Portable devices for RFI communication can

disturbances within

the RF range

26 kHz to 80

MHz

according to

disturbances within

the RF range

80 MHz to 1

GHz

d=2,3√P 800 MHz to 2,5 GHz

according to

IEC 61000-4-3

value in watts (W) according to information

from a manufacturer.

d is a recommended, minimal distance in

meters (m).

The power of electromagnetic disturbances

from stationary transmitters of RF, settled in

conditions on the spot (a), should be lower

than the level of compliance for every

frequency range (b).

Interference can appear in the proximity of

devices marked with the following sign:

Caution 2: Given information are not applicable in every situation. Propagation of

electromagnetic waves is influenced by absorption and reflection from surfaces, objects and

telephony, radio transmitters, amateur radios, AM and FM radio transmission and TV

transmission cannot be theoretically estimated. To estimate an electromagnetic environment

testing local conditions needs to be considered. If the measured field power on the spot of

DEVICE operation overpasses an acceptable level of compliance, there should be tested if the

DEVICE operates properly. If an inappropriate operation appears it may be necessary make

some preventions such as displacement of the DEVICE.

(b) For frequencies outside the range 150 kHz to 80 MHz, the field power should not be

of radio frequencies of long waves and the infrared range; frequencies useful for radio

influence ELECTRICAL MEDICAL DEVICES

Page 61

- 61 -

Table 206

Recommended minimal distance between portable devices for RFI

communication and the DEVICE

The DEVICE intended to operate in the electromagnetic environment, where electromagnetic

maximal output power of communication devices.

Given maximal

Minimal distance adequate for the transmitter frequencies

[m]

150 kHz to 80 MHz

d

= 1,2√P

80 MHz to 800 MHz

d

= 1,2√P

800 MHz to 2,5 GHz

d

= 2,3√P

0,01

0,12

0,12

0,23

0,1

0,38

0,38

0,73 1 1,2

1,2

2,3

10

3,8

3,8

7,3

100

12

12

23

For transmitters with the maximal output power not mentioned above, the advisable minimal

persons..

RF – frequency from the interval o electromagnetic spectrum which is between the lower

transmission. Limit frequencies are 9 kHz and 3 000 GHz

CAUTION! Operating cellular telephones (in the proximity

CAUTION! Operation in the proximity of (e.g. 1 m) devices

unstable operation of the DEVICE.

CAUTION! Using accessories and cables other than

resistance of the DEVICE.

disturbances of RF are under control. Recipient or user of the DEVICE can prevent

electromagnetic interference by keeping minimal distances between portable devices for

wireless communication (transmitters) and the DEVICE prompted below, according to

transmitter’s

power

[W]

distance d in meters can be estimated by equation adequate to the frequency of the

transmitter, where

CAUTION 1: If f= 80MHz and f=800MHz higher frequency range is taken.

CAUTION 2: Given information are not applicable in every situation. Propagation of

electromagnetic waves is influenced by absorption and reflection from surfaces, objects and

range of radio frequencies of long waves and the infrared range; frequencies useful for radio

P

is a rated maximal power in watts (W).

of 2.8 m) can cause unstable operation of the DEVICE.

for microwave therapy or shortwave therapy can cause

described in present manual may result in increased

emission of electrom ag netic waves and decreased wear

Page 62

- 62 -

CAUTION! The DEVICE should not be used in the proximity

ack of disturbance/influence

intended to be used.

- symbol „product number”

- symbol „temperature limitations” (+ temperatures)

- symbol „ please see the user manual”

of other electric medical equipment and put one over

another. If such situation appears the DEVICE operation

should be observed to see the l

on the operation of the DEVICE in the configuration it is

26. APPENDIX A

26.1. Pictograms on the data plate

- symbol „manufacturer” (+ name & address)

- symbol „production date” (+ production year)

- symbol „serial number”

- symbol „B type application part”

Example:

- WPT 60/150 OW personal scale

26.2. CE marking

Page 63

- 63 -

MANUFACTURER

OF ELECTRONIC WEIGHING INSTRUMENTS