Page 1

User manual no.:

IMMU-11-02-03-14-ENG

MOISTURE

ANALYZER

MAX

SERIES

BALANCES AND SCALES

RADW AG 26 – 600 Radom, Bracka 28, POLAND

Phone: +48 (0-48) 38 48 800, fax. +48 (0-48) 385 00 10

export@radwag.com

www.radwag.com

Page 2

- 2 -

MARCH 2014

Page 3

- 3 -

TABLE OF CONTENTS

1. TECHNICAL DATA .............................................................................. 6

2. GENERAL SAFETY INFORMATION ................................................... 7

2.1. Definitions of signals and warning signs .................................. 7

2.1.1 Warning descriptions ......................................................... 7

2.1.2. Warning signs ................................................................... 7

2.2. Safety information .................................................................... 8

2.3. Intended use ........................................................................... 10

2.4. Inappropriate use ................................................................... 11

2.5. Principles of safety use .......................................................... 11

2.6. Warranty ................................................................................. 12

2.7. Monitoring metrological parameters of the instrument ........... 12

2.8. Data included in this user manual .......................................... 12

2.9. Staff competence ................................................................... 12

2.9.1. Protective clothing .................................................................. 13

3. TRANSPORT AND STORAGE .......................................................... 14

3.1. Delivery check ........................................................................ 14

3.2. Packaging ............................................................................... 14

4. UNPACKING, ASSEMBLING AND STARTUP ................................. 14

4.1. Assembling and place of use ................................................. 14

4.2. Unpacking .............................................................................. 15

4.3. Level setting ........................................................................... 16

4.4. Standard delivery components ............................................... 16

4.5. Cleaning ................................................................................. 16

4.6. Plugging to mains ................................................................... 16

4.7. Connecting peripheral equipment .......................................... 17

5. KEYBOARD ........................................................................................ 17

5.1. Moisture analyzer temperature stabilization period ............... 18

6. MOISTURE ANALYZER’S MEN U ..................................................... 18

7. USER MENU OPERATION ................................................................ 19

7.1. Menu operation using moisture analyzer keyboard ............... 20

7.2. Menu operation using external computer keyboard ............... 22

8. USER MENU ....................................................................................... 23

8.1. Moisture analyzer adjustment ................................................ 23

8.1.1. Adjustment ............................................................................. 23

8.1.2. User adjustment ..................................................................... 24

8.1.3. Adjustment test ....................................................................... 25

8.1.4. Temperature adjustment ........................................................ 25

8.1.5. Adjustment report printout ...................................................... 28

8.1.6. Drying test .............................................................................. 29

8.2. Determining content of a printout for GLP procedures .......... 31

Page 4

- 4 -

8.2.1. User ........................................................................................ 31

8.2.2. Project .................................................................................... 32

8.2.3. Parameters determining content of the GLP procedures....... 32

8.3. Date and time settings............................................................ 33

8.3.1. Setting date format ................................................................. 33

8.3.2. Setting time format ................................................................. 34

8.3.3. Setting time ............................................................................ 34

8.3.4. Setting date ............................................................................ 35

8.3.5. Setting displaying criteria for date and time ........................... 35

8.4. Setting moisture analyzer operating parameters ................... 35

8.4.1. Entering menu group P4 Readout .......................................... 35

8.4.2. Filter settings .......................................................................... 36

8.4.3. Autozero function ................................................................... 36

8.4.4. Previewing temperature value inside the drying chamber ..... 36

8.5. RS 232 Functions ................................................................... 37

8.5.1. RS 232 parameter settings .................................................... 37

8.6. Printouts ................................................................................. 38

8.6.1. Standard printout template ..................................................... 38

8.6.2. Non-standard printout templates ............................................ 39

8.6.3. Inserting text into strings ........................................................ 39

8.6.4. Printout selection .................................................................... 42

8.6.5. Enabling non-standard printout templates ............................. 43

8.6.6. Non-standard printout templates in drying mode ................... 43

8.7. Moisture analyzer parameter settings. ................................... 44

8.7.1. Entering menu group P7 Other .............................................. 44

8.7.2. Parameter settings ................................................................. 45

9. DRYING PROCESS WITH USE OF SHORTENED MENU ............... 47

9.1. Enabling shortened menu ...................................................... 47

9.2. Means of setting drying parameters: ...................................... 48

9.3. Means of drying process according to parameters set in the

shortened menu .................................................................................. 53

10. DRYING PROCESS WITH USE OF DRYING PROGRAM LIBRARY

57

10.1. Defining a drying procedure ................................................... 57

10.2. Entering name of a drying program ........................................ 58

10.3. Drying mode selection ............................................................ 59

10.4. Drying temperature setting ..................................................... 60

10.5. Auto switch off settings........................................................... 61

10.6. Setting the type of displayed and printed measurement result

61

10.7. Setting printout interval........................................................... 62

10.8. Setting size of a sample to be tested ..................................... 62

10.9. Setting a corrective coefficient ............................................... 63

Page 5

- 5 -

10.10. Restore default setting ........................................................... 64

°

10.11. Printout of software settings ................................................... 65

10.12. Saving drying mode settings in moisture analyzer’s permanent

memory ............................................................................................... 67

11. TESTING PROCEDURE USING A DRYING PROGRAM FROM THE

LIBRARY OF DRYING PROGRAMS ................................................. 68

12. SAMPLE PREPARATION FOR A DRYING PROCESS .................... 69

12.1. Principles of humidity content determination in a moisture

analyzer ............................................................................................... 69

12.2. Sampling and preparation ...................................................... 70

13. SELECTION OF DRYING PARAMETERS ........................................ 72

13.1. Selecting optimum sample mass ........................................... 72

13.2. Influence of sample mass on measurement result repeatability

72

13.3. Drying temperature ................................................................. 73

13.4. Selecting a drying mode ......................................................... 74

13.5. Selecting drying time .............................................................. 75

13.6. Drying mode analysis ............................................................. 76

14. COOPERATION WITH A PRINTER OR A COMPUTER ................... 77

14.1. Connecting cables .................................................................. 77

15. LIST OF COMMANDS COMPUTER - BALANCE ............................. 78

16. USER GUIDELINES ........................................................................... 80

17. MOISTURE ANALYZER MAINTENANCE ACTIVITIES .................... 81

17.1. Cleaning moisture analyzer components ............................... 81

17.2. Temperature sensor cleaning ................................................ 82

17.3. Replacing the fuses ................................................................ 83

17.4. Troubleshooting ...................................................................... 84

17.5. Error messages ...................................................................... 85

18. MEMORY OF CARRIED OUT MEASUREMENTS ............................ 86

19. MEANS OF USING A MOISTURE ANALYZER FOR DRYING IN

TEMPERATURE OVER 160

C .......................................................... 87

Page 6

- 6 -

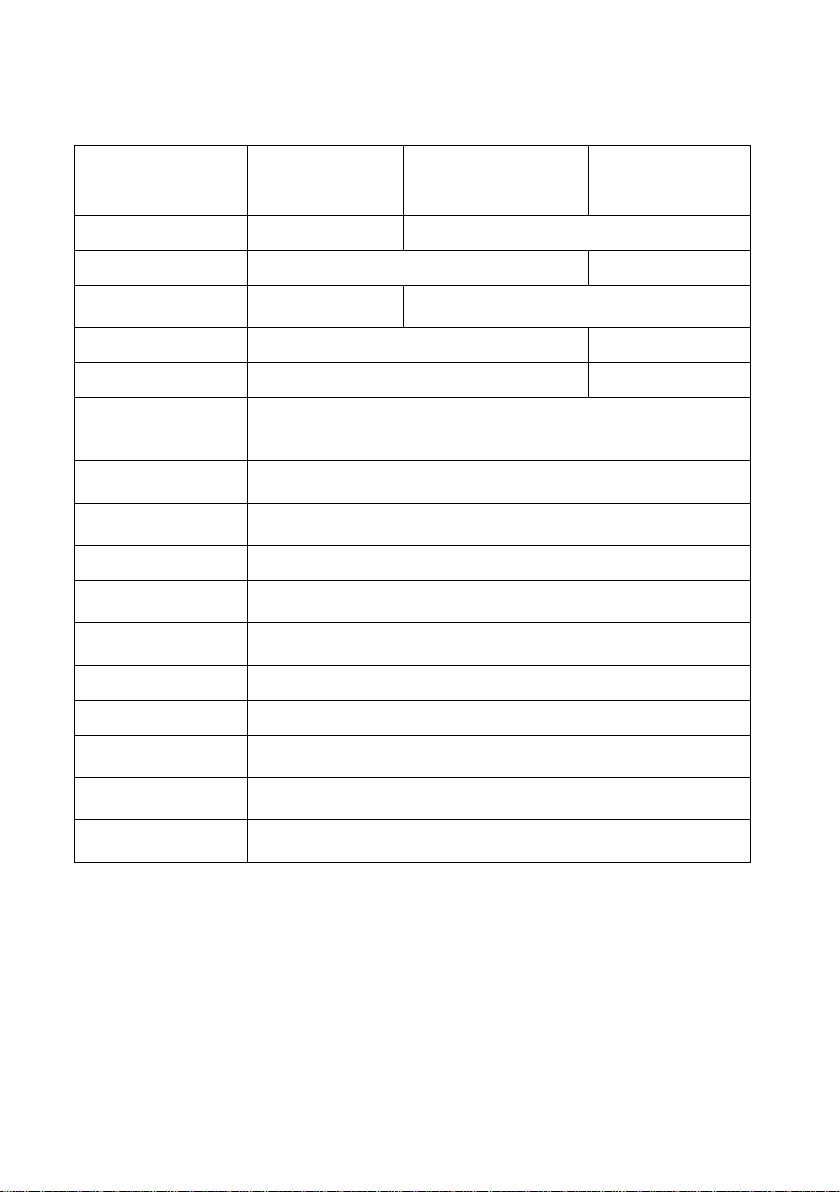

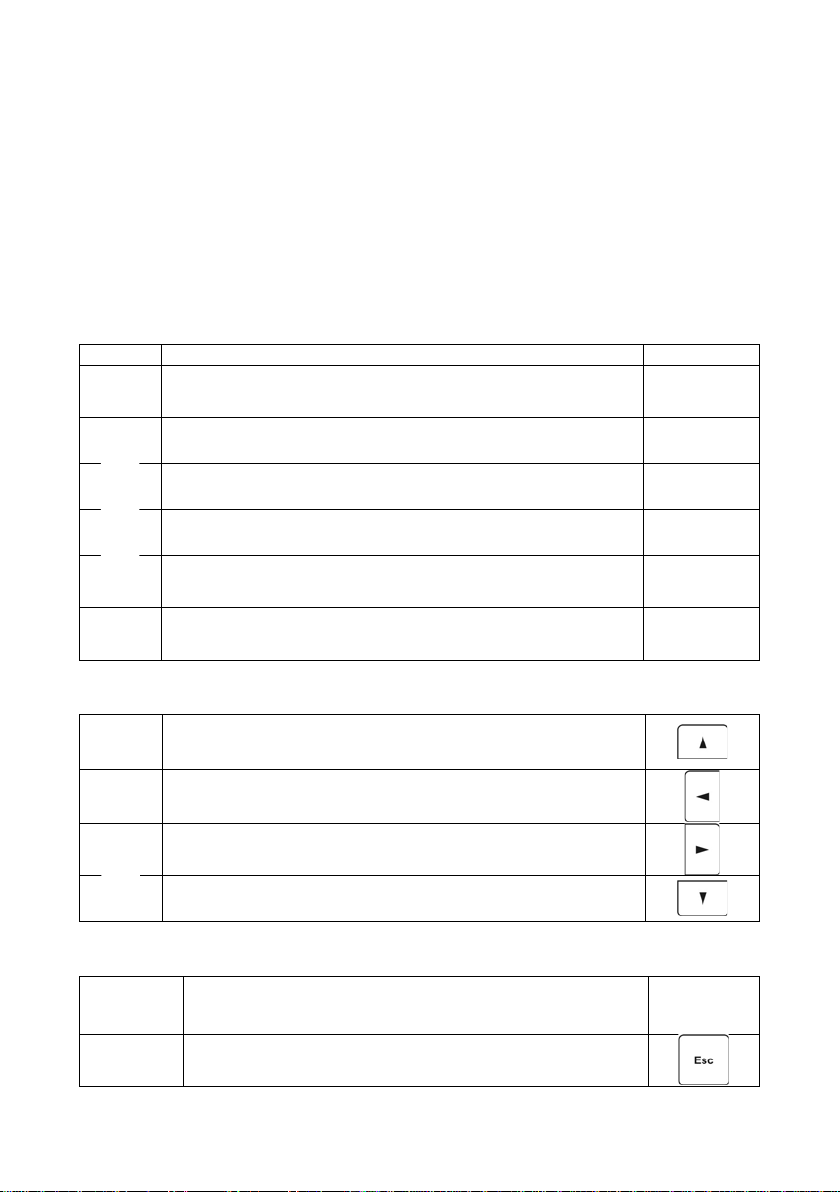

1. TECHNICAL DATA

Reading interval of

moisture content

Repeatability of

reading

Drying

temperature range

max. 160 °C

max. 250 °C (WH)

infrared emitter

halogen (WH)

Auto switch off

options

4 modes: time defined, moisture content stabilization, time

optimized, manual

Working

temperature

Max height of

sample

Net weight /

Gross weight

Packaging

dimensions

Type

MAX 50/1

MAX 50 MAX 60

Reading interval 0,1 mg 1 mg

Max. capacity 50 g 60 g

0,0001% 0,001%

Tare range - 50 g - 60 g

Max. sample mass 50 g 60 g

moisture content

+/-0,05% (sample ~ 2g), +/-0,01% (sample ~10g)

Heating module

Drying modes 4 modes: standard, quick, step, mild

+10 °C ÷ +40 °C

Power supply 230V 50Hz AC / 420W

Display graphic (backlit)

5,1 / 6,6 kg

470 x 380 x 336 mm

20 mm

Page 7

- 7 -

2. GENERAL SAFETY INFORMATION

WARNING

Dangerous situations of high risk. These

CAUTION

Dangerous situations of low risk. These

situations can cause damage of the

instrument or its functions, loss of data as

ATTENTION

Important information related to the moisture

2.1. Definitions of signals and warning signs

Safety precautions are marked with special descriptions and warning signs.

They inform and warn a user of possible dangers. Ignoring the safety warnings

may cause injuries, damage of the moisture analyzer, its inappropriate

operation and errors of measurements.

2.1.1 Warning descriptions

situations can cause serious injuries or death

if the safety precautions are not taken.

well as minor or moderate body injuries.

analyser.

2.1.2. Warning signs

Electric shock ris k

Acid / Corrosion

Danger

Page 8

- 8 -

Flammable or explosive substances

Nominal voltage for a moisture analyzer is 230 VAC. It

means that safety usage precautions for low voltage

core power supply cable with grounding pin comes

If necessary, an extension cord can be used as long as it

the applicable standards and has a protective ground

Drying chamber cannot be opened during operation (drying

process). It is due to the fact that a halogen lamp and its

prevent heat from building up and to keep your analyzer

from

Toxic substances

Hot surfaces

2.2. Safety information CAUTION!

The use of moisture analyzer MA 3Y regardless of both, safety

information and user manual guidelines may cause health damage and

even death

WARNING:

devices must be abide by while operating the device.

Threestandard with a moisture analyzer.

meets

conductor. Intended disconnection of the grounding cable is

forbidden.

CAUTION:

glass shield may reach the temperature of up to 400 C.

When setting up the moisture analyzer leave enough space

to

Page 9

- 9 -

overheating. Leave about 20 cm around the instrument and

about 1 m above.

drying chamber: the sample itself, the drying chamber,

drying chamber), the moisture analyzer must be switched

Wait until all the components have cooled down. Do not

Same types of samples require taking particular safety precautions.

They can pose a danger for people and objects. It is always the user who

is liable for possible damages caused by the use of an inappropriate

sample.

Substances that release aggressive vapours (e.g. acids)

the heating process. In this case, it is recommended to

housing parts and cause corrosion.

solvents or releasing flammable or explosive gases or

mples apply the drying temperatures as

low as possible to prevent flames or explosion. During the

necessary to wear protective glasses and gloves. The

should be relatively small.

Air vents that are located in the housing cannot be covered,

sealed or blocked in any other way.

Do not put any flammable substances on, under or near the

moisture analyzer.

Be particularly careful when removing the sample from the

shields

and the pan can still be extremely hot.

In case of any maintenance work (cleaning the inside of the

off.

perform

any modification to the heating module.

CAUTION:

Corrosion

during

work wi th

small samples. Otherwise, vapours can condense on cold

WARNING:

Fire or explosion

Flammable or explosive substances, substances containing

vapours.

Perform a risk analysis when in doubt relating to the sample

characteristics before carrying out the procedure.

For this type of sa

analysis it is

samples

Page 10

- 10 -

Under no circumstances can the instrument be left

Unsupervised!

irritations (eyes, skin or respiratory system), illnesses or

WARNING:

Substances containing toxic and caustic or corrosive

components

Substances that release toxic gases or vapours can cause

even death. Dry such substances only in fume hood.

Under no circumstances should the instrument be used in an area with

any risk of explosion. The moisture analyzer is not designed to operate in

hazardous areas.

2.3. Intended use

A moisture analyzer MAX series is designed to determine relative moisture

content in small samples of various substances, determine dry mass content in

small samples and determine mass of weighed objects.

MAX series ensures fast and precise determination process of water content in

a tested sample, and application of a graphic display considerably simplifies

functioning, operation and carrying out measurement processes. Moisture

analyzer MAX series can be used to determine humidity content of different

materials.

At the initial stage of measurement, the device precisely determines the mass

of an object placed on instrument’s weighing pan. As mass reading is

stabilized, the sample is quickly heated by halogen lamps or IR emitters,

causing humidity evaporation from the tested sample. While sampling, the

moisture analyzer is continuously checking the decline of mass, and on

calculation, it displays current moisture content in a tested sample.

Compared to conventional methods of humidity content determination of

various substances, application of moisture analyzer MAX series considerably

shortens measurement time and simplifies testing procedure. The moisture

analyzer allows for setting multiple parameters which influence the procedure

of moisture content determination in a sample, such as: temperature, time,

drying modes, etc.

Page 11

- 11 -

2.4. Inappropriate use CAUTION!

Do not open the drying chamber during drying process. Moisture analyzer

features a halogen lamp which is a very powerful heat source. Thus, user

should pay special attention no to touch those elements of a moisture analyzer

that get hot while drying procedure (i.e.: disposable pan, pan handle, and inner

shields of the drying chamber).

Remember that some of tested samples may become dangerous if heated

(appearance of poisoning vapours, danger of ignition or explosion).

A moisture analyzer MAX series is not intended for dynamic weighing. Even if

small amounts of a sample are added to taken off the weighing pan, the mass

readout should be taken only on stabilization of measurement result

(appearance of stability pictogram on the display).

Do not place any magnetic materials on the weighing pan, as this can cause

damage of the measuring system of the instrument. Be sure to avoid impact

shock and overloading the moisture analyzer in excess of the prescribed

maximum measuring range (max capacity), minus any possible tare weight that

has been applied).

Never use the moisture analyzer in an environment endangered by an

explosion!

This moisture analyzer has not been adjusted for operation in explosive areas.

There must not be any modification made to the moisture analyzer.

2.5. Principles of safety use

Moisture analyzer is in accord with all binding safety regulations. Nevertheless

there are exceptional circumstances that may cause danger.

It is forbidden to open an instrument housing. Inside there are no parts that

would require maintenance, repair or replacement carried out by a user. In

case of any problems it is recommended to contact RADWAG service or a

distributor. It must be always remembered to use the device in accordance with

this service manual and especially to follow instructions on installation and

configuration of a new device.

Use of a moisture analyzer MA 3Y series conversely to safety principles and

user manual guidelines may be hazardous to operator’s health and life. It is

obligatory to acknowledge the safety principles listed in the user manual:

- use a moisture analyzer only to determine humidity content in

samples and determine mass of a tested sample. Any other use of

the moisture analyzer may be dangerous both to the device and the

user,

- before commissioning the moisture analyzer, make sure that the

nominal power of the device specified on its data plate, is compatible

with the supply in the mains to which the moisture analyzer will be

plugged in,

- replecemant of halogen lamps can only be carried out by

authorized service,

Page 12

- 12 -

- protect moisture analyzer against contacts with liquids, it might

lead to electrocution, fire, emission of substances containing toxic or

caustic vapour, emission of explosive substances.

2.6. Warranty

Warranty does not cover the following cases:

• Not observing the regulation listed in user manual,

• Using the moisture analyzer conversely to its intended use,

• Any modifications of moisture analyzer or cases when its housing is

opened (damaged protective s tick ers),

• Mechanical defects and defects caused by media, liquids, water and

natural wearing off,

• Improper placing of defects of electrical network / mains,

• Overloading of measuring mechanism of the moisture analyzer.

2.7. Monitoring metrological paramet ers o f the instr um ent

Metrological characteristics of the moisture analyzer requires periodical

inspection carried out by its operator. Inspection frequency is conditioned by

ambient conditions in which the moisture analyzer is used, types of performed

processes and accepted quality manageme nt sy stem in an organizat i on.

2.8. Data included in this user manual

Please read the user manual carefully before instrument’s plugging to mains

and startup, even if the user is experienced with this type of moisture

analyzers.

2.9. Staff competence

Moisture analyzer MA 3Y series should only be operated and maintained by

personnel who is trained and experienced in using this type of instruments.

In order to use the moisture analyzer, first read the user manual. Keep these

instructions for the future reference.

Do not make any structural modifications. Additional equipment, which can be

connected to the moisture analyzer, should be supplied by RADWAG or an

authorized distributor.

Page 13

- 13 -

2.9.1. Protective clothing

The use of protective clothing is highly recommended while working with the

instrument in order to take safety precautions against potential hazards

resulting from tested samples and ingredients.

Use the following while carrying out tests:

• protective apron,

• protective glasses,

• protective gloves (while working with hazardous chemical

substances).

Before the use of the above-mentioned protective clothing, make sure that they

are designed to be used with specific samples and they are not damaged.

Page 14

- 14 -

3. TRANSPORT AND STORAGE

3.1. Delivery check

Please check the packaging immediately upon delivery and the device during

unpacking for any visible signs of external damage.

3.2. Packaging

Please retain all parts of the original packaging should the moisture analyzer

be transported in the future. Only the original packaging should be used for

dispatching the moisture analyzer. Before packing, disconnect all attached

cables and remove any loose/movable parts (weighing pan, shields, inserts).

Place moisture analyzer and its components in their original packaging, and

protect them against damage during transport.

4. UNPACKING, ASSEMBLING AND STARTUP

4.1. Assembling and place of use

* A moisture analyzer should be stored and used in locations free of vibrations

and shakes, free of air movement and dust, located at the max altitude of

2000 above sea level,

* Moisture analyzer’s place of use should ensure good air circulation around

the instrument (approximately 20 cm fee space around the moisture

analyzer and 1 m free space over it),

* Ambient air temperature in the weighing room should not exceed the range

of: +10 °C ÷ +40 °C,

* Ambient relative humidity should not exceed 80% in the temperature up to

31°C, and decrease linearly to 50 % of relative humidity in temperature

40°C,

* A moisture analyzer should be located on a stable wall console desk or a

stable working table which is not affected by vibrations and distant from heat

sources,

* Take special safety measures when weighing magnetic objects, as part of

the moisture analyzer is a strong magnet,

Page 15

- 15 -

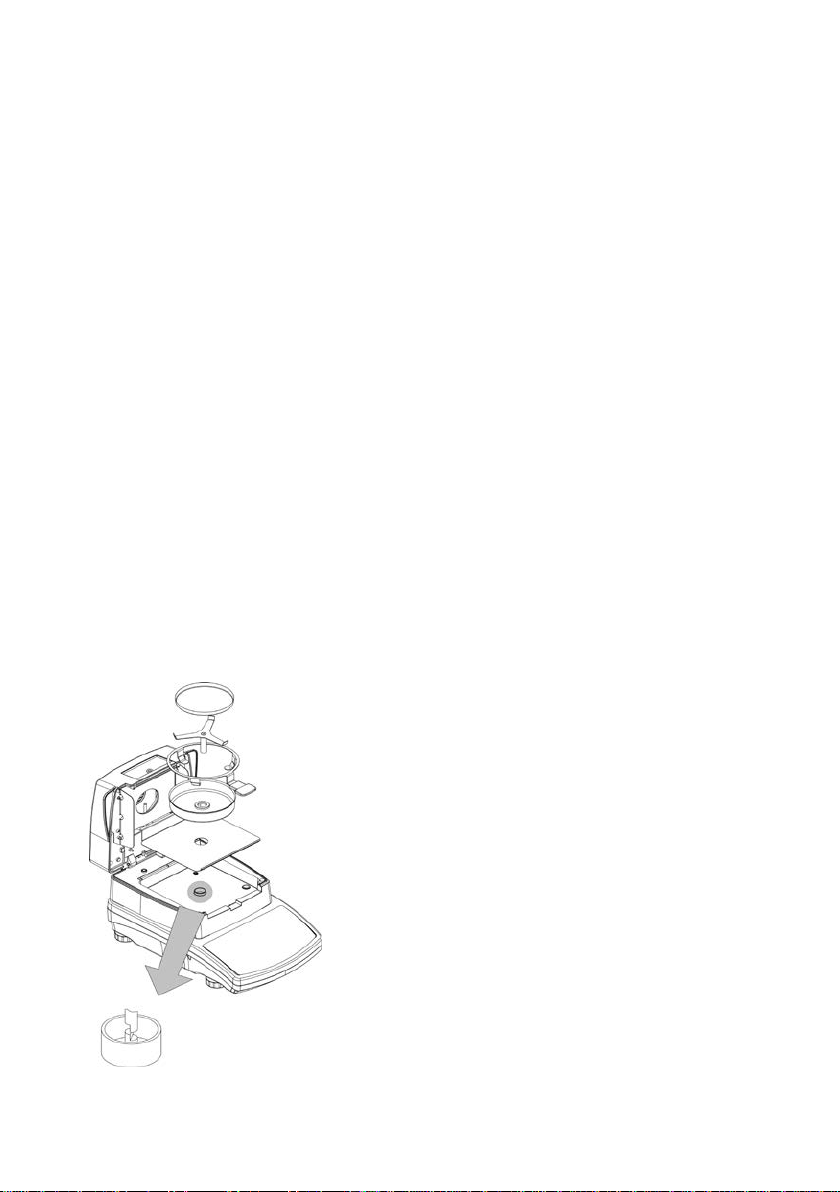

4.2. Unpacking

Carefully remove the moisture analyzer from its packaging, remove the plastic

and foil transport protective elements. Gently place the moisture analyzer in its

intended place of use.

Assembly the components of drying chamber, following guidelines from below

figure:

Assembling moisture analyzer com pone nts :

- Assembly insert of the drying

chamber’s basis

- Assembly drying chamber cover,

- Assembly drying pan handle,

- Assembly drying pan bracket,

- Assembly the disposable drying

pan..

Setting drying pan’s supporter (brac ket) .

When assembling the pan supporter (bracket) pay

special attention to the correct positioning of its

mandrel. The mandrel features a cut for its unique

positioning against the pan handle, thus

preventing their contact and frictio n.

Setting pan’s bracket:

- On assembling the pan bracket onto the

mandrel, turn the bracket slightly, so that the

cut on the mandrels are located in their

unique and correct position,

- When turning the mandrel use most gentle

movements not to damage moisture

analyzer’s measuring system.

Page 16

- 16 -

4.3. Level setting

Before plugging to mains, level the moisture analyzer using

adjustable feet. Turn the feet in a way that the air bubble of the

level is located centrally.

4.4. Standard delivery components

• A moisture analyzer MAX series

• Insert of drying chamber basis.

• Drying chamber shield.

• Drying pan handle.

• Drying pan bracket.

• Disposable pan.

• Power cord.

• User manual.

4.5. Cleaning Remember to unplug the moisture analyzer from mains before any

cleaning activities.

Clean the moisture analyzer using a damp cloth by gentle rubbing

contaminated places.

Remember to remove the drying pan from the drying chamber before its

cleaning. If the drying pan assembly is installed while cleaning it may

damage instrument’s measuring system, thus remove it from the bracket.

4.6. Plugging to mains A moisture analyzer can be plugged to mains only by means of original

power cord, which comes standard with the moisture analyzer. Rated

voltage (specified on device’s data plate) must be compatible with mains

rated voltage.

The power cord can be connected only to socket with ground contact. Plug the

power cord to the moisture analyzer. The moisture analyzer’s power plug is

located at the back of instrument’s housing.

On plugging to mains moisture analyzer’s displays software’s name and

number, after which the indication changes to 0.000 g (in c ase of a moisture

analyzer with measuring accuracy 1 mg) or 0.0000 g (in case of a moisture

analyzer with measuring accuracy 0,1 mg). In mass indication is other than

zero press TARE key located on the overlay.

Page 17

- 17 -

4.7. Connecting peripheral equipment

starting / ending drying process according

key, abandoning introduced changes / exit one level

change of parameters value;

sending display status to peripheral

device (Print) or confirmation of selected value or function

The moisture analyzer must be unplugged from the mains before connecting or

disconnecting any peripheral equipment (printer, PC computer). Use only

peripheral equipment recommended by the manufacturer with your moisture

analyzer. These have been ideally coordinated to your moisture analyzer. On

connecting a peripheral device, plug the moisture analyzer to mains.

5. KEYBOARD

Start/Stop key –

to selected drying mode.

Esc

higher in menu structure.

Group of navigation keys –

moving in moisture analyzer’s menu.

Print/Enter key –

(Enter).

Zero / Tare key – zeroing moisture analyzer’s indication.

Page 18

- 18 -

On/Off key – switch on/off display of moisture analyzer. On

switching off the display of the device, other subassemblies

are continuously supplied, and the moisture analyzer is in

standby mode.

changes type of data displayed during and

Display key –

after drying process.

Setup key – enter to main menu.

Test menu key – function key for selecting drying modes.

5.1. Moisture analyzer temperature stabilization period

Before start of measuring processes, it is necessary to wait until the moisture

analyzer is thermally stabilized. It is a period of so called moisture analyzer’s

self-heating.

For moisture analyzer MAX series which before plugging to mains was stored

in room temperature, self-heating period takes approximately 30 minutes. For

moisture analyzers that were stored in much lower temperatures before

plugging to mains (e.g. during winter period) thermal stabilization should last

approximately 4 hours.

During self-heating period the indications on moisture analyzer’s display may

change. Correct operation of a moisture analyzer is possible within

temperature range specified in the technical parameters, see point 1.

It is recommended that ambient temperature changes at moisture analyzer’s

place of use are very small (slow).

6. MOISTURE ANALYZER’S MENU

User menu of the moisture analyzer MAX series is divided into two sections.

The first one is made available on pressing SETUP key. This menu enables

setting the following parameters: moisture analyzer and temperature sensor

adjustment, setting date and time format, programming printouts and

communication parameters with peripheral equipment, and setting user profile

parameters.

The second menu is accessible on pressing TEST MENU key, and it is

dedicated to setting parameters of basic drying mode, including: drying

temperature, drying mode, time and other parameters. The menu additionally

provides access to the library of drying programs. The library stores up to 99

different drying procedures containing detailed settings on drying modes of

various substances.

Page 19

- 19 -

P1 Adjustment

P7 14 Previous version

P1 01 External adjustment

P1 02 User adjustment

P1 03 Adjustmen t test

P1 04 Temperature adjust.

P1 05 Adjustment report

printout

P1 06 Drying test

P2 GLP

P2 01 User

P2 02 Project

P2 03 Print time

P2 04 Print date

P2 05 Print user name

P2 06 Print project name

P2 07 Print ID

P2 08 Print adjustment data

P3 Date/Time

P3 01 Date format

P3 02 Time format

P3 03 Time

P3 04 Date

P3 05 Display tim e

P3 06 Display date

P4 Readout

P4 01 Filter

P4 02 Autozero

P4 03 Temperature

P4 04 Negative

P5 RS-232

P5 01 Baud rate

P5 02 Parity

P5 03 Data bits

P5 04 Stop bits

P5 05 Handshake

P5 06 Print stable

P5 07 Printout type

P5 08 Paper cut off

P6 Printouts

P6 01 Printout n o.

P6 02 Header no.

P6 03 Line no.

P6 04 Footer no.

P6 05 Printout 1 start

P6 06 Printout 1 stop

P6 13 Text 1

P6 14 Text 2

P7 Other

P7 01 Password

P7 02 Database of drying

programs

P7 03 Beep sound

P7 04 Language

P7 05 Display backlight

P7 06 Display brightness

P7 07 Display contrast

P7 08 Factory no.

P7 09 Software version

P7 10 Parameters printout

P7 11 Upload parameters

P7 12 Set ID

P7 13 ID automatic printout

7. USER MENU OPERATION

User menu may be operated with the use of a moisture analyzer’s keyboard,

external computer keyboard of PS type or by commands sent from a computer to

the moisture analyzer.

Page 20

- 20 -

7.1. Menu operation using moisture analyzer keyboard

Entering option of selecting a

the moisture analyzer.

Entering moisture analyzer’s main

menu and its parameters.

Selecting a desired option in the

against a desired menu option.

ARROW key.

Changing parameter and function settings:

of a parameter or change setting of an active parameter (e.g.

drying mode:

Press Test Menu key to open a list

with drying programs saved in

moisture analyzer’s memory. The

library can contain up to 100 drying

programs. Each of drying programs is

optionally configurable, and available

for multiple times during operation of

Exit menu without saving changes:

Press Esc key.

menu:

Press Setup key to get access to user

Exit menu without saving changes:

Press Esc key twice.

menu:

Press one of navigating arrows to

move the cursor (black triangle) up or

down the menu structure and set it

Entering selected menu option / function:

Set the cursor (black triangle) against a desired function, and press RIGHT

or

Use UP / DOWN navigating arrows to select accessible value

Page 21

- 21 -

or

name) when its value is flashing.

parameter/function.

Use RIGHT / LEFT navigating arrows to select a character

while entering a parameter value (while its flashing).

Accepting changes in function / parameter settings:

Press PRINT/ENTER key to save settings of a modified

Changing displayed data during drying process:

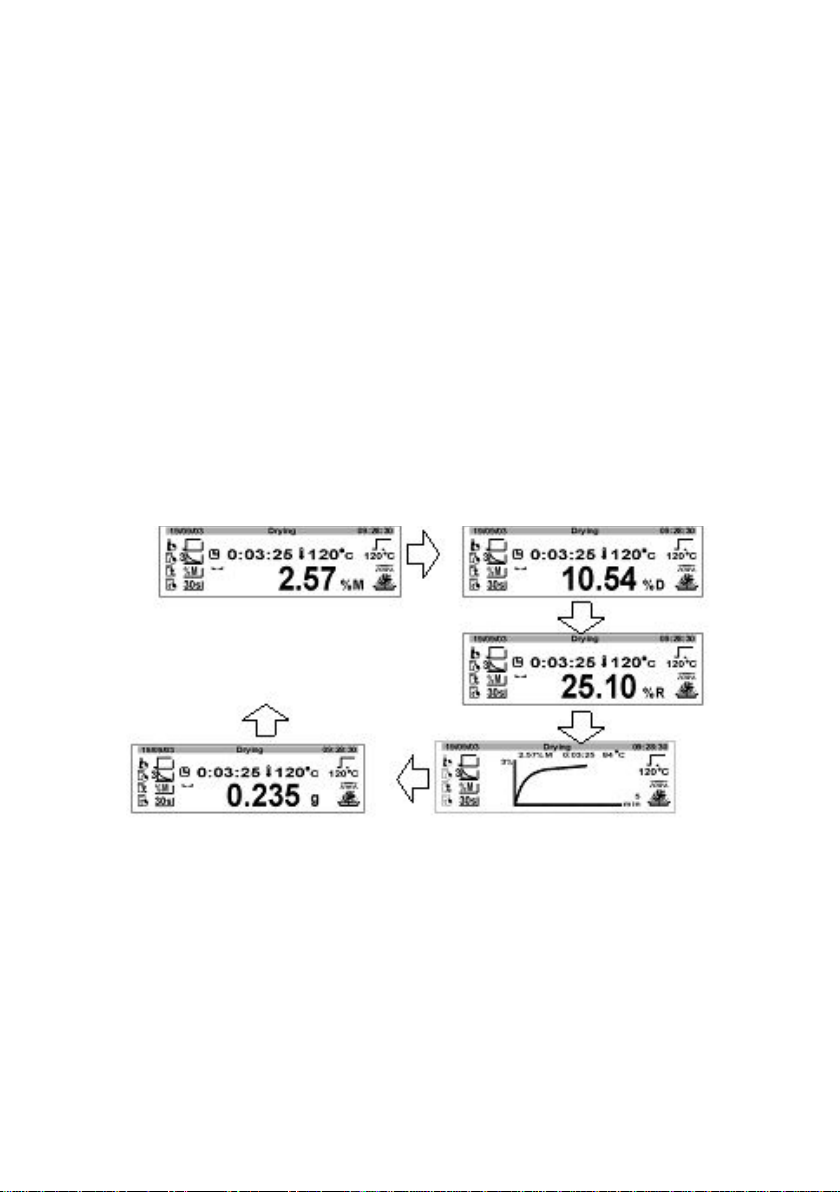

A moisture analyzer MAX series enables previewing five types

of measurement result while the drying process is in progress

or on its completion.

The measuring units are previewed by pressing DISPLAY key.

Each pressing of the key changes the measuring unit and

automatic recalculation of measurement result.

Additionally, the display of MAX series contains the following:

drying time interval, current temperature in drying chamber,

drying mode, target (set) temperature, drying process result in

a form of: %M; %D; %R; chart, mass loss in [g].

Changes made to software settings are effective only on exiting to main

menu with procedure of saving changes.

Page 22

- 22 -

On making all changes in the parameter settings, exit to main menu by

Description

Overlay

pressing the ESC key for a few times, until the software displays a message

box with below two option:

ENTER – save changes and exit

ESC – abandon changes and exit

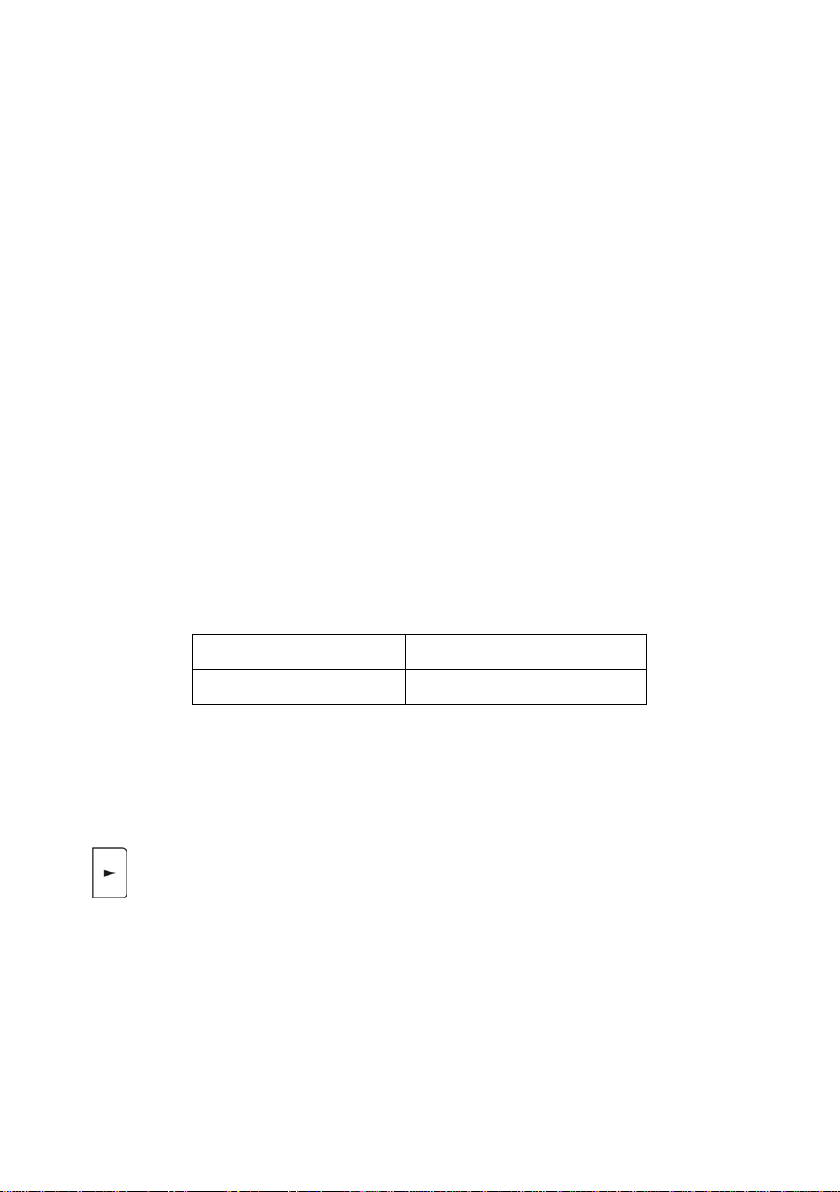

7.2. Menu operation using external computer keyboard

All keys present on moisture analyzer’s overlay have their equivalents on a

computer keyboard PS type, described in below table:

- function keys

Start / End drying process in an active drying mode.

Entering main menu.

Entering selection menu and settings of the drying mode.

Changing the type of displayed data on drying process.

Sending current display status to a connected peripheral

device (PRINT).

Zeroing/Tarring moisture analyzer’s indication.

- navigating arrows

Moving the cursor up

Exiting one level back in menu structure

Entering the settings of a selected parameter

Moving the cursor down

- keys: ENTER / PRINT and ESC

Accepting entered value (of a parameter)

Abandoning and exiting a function / parameter without

changes

Page 23

- 23 -

8. USER MENU

Enter group of parameters P1 Adjustment.

Press RIGHT ARROW KEY, which displays

After emptying the pan press ENTER key.

User menu is accessible on pressing SETUP key on moisture analyzer’s overlay.

The user enables: moisture analyzer adjustment, setting transmission parameters,

setting time and date and their format, and also other user parameters. This section

of the user manual presents software possibilities of the moisture analyzer and

means of changing the parameter settings.

8.1. Moisture analyzer adjustment

8.1.1. Adjustment

Should a moisture analyzer MAX series be used as a laboratory balance, then

before carrying out the measurements it has to be adjus ted sui ng and external

mass standard / weight).

Adjustment is a set of processes determining relation between the value

indicated by a moisture analyzer / balance, and mass of a weighed standard

(adjustment weight). The process enables correcting the indication if

necessary.

Adjustment process on a moisture analyzer MAX series should be carried out

with use of a mass standard / adjustment weight class F

. The weight is an

2

additional equipment of the moisture analyzer.

Moisture analyzer type Adjustment weight mass

MAX 50g

Set the cursor next to a parameter 01

External adjustment.

a command to unload the moisture

analyzer’s pan (the pan has to be empty).

Page 24

- 24 -

The moisture analyzer gives a command on

determining mass of an empty pan, followed

Enter group of parameters P1 Adjustment.

Press RIGHT ARROW KEY. The moisture

flashing, i.e. it can be modified.

weight.

Accept entered mass of the adjustment

by a command to place a 50 g weight

(standard) on the pan.

a) After completing adjustment process the moisture analyzer returns to

submenu P1 - Adjustment

b) Press ESC for a few times until the display indicates below message

c) Depending on needs press ENTER or ESC key.

d) The moisture analyzer returns to the main window (weighing mode).

8.1.2. User adjustment

User adjustment should be carried out with a mass standard (weight) in

accuracy class F

.

2

Set the marker next to a parameter 02 User

adjustment.

analyzer displays a command to enter mass

of an adjustment weight to its memory.

in the displayed mass value the first digit is

Use navigating arrow keys to enter the new mass value of the external adjustment

weight. Then the moisture analyzer

proceeds to the adjustment process and

displays corresponding mesag es on its

display.

Page 25

- 25 -

The moisture analyzer gives a

On placing the weight on the pan

Adjustment.

As specified in the previous point return to the weighing mode.

It is recommended that the mass of an external adjustment weight is

approximately ¾ of the maximum capacity of a balance / moisture

analyzer.

8.1.3. Adjustment test

Adjustment test is a comparison of mass of an adjustment weight value with

the value of current measurement result. The process is aimed at checking the

comparison results, and it does not affect coefficients saved in software

settings. On previewing the test results press ESC key.

Carrying out adjustment test

a) Go to submenu P1 – Adjustment.

b) Set the marker next to the Adjustment test function

c) Press RIGHT ARROW navigating key

d) The moisture analyzer automatically carries out the test process

Factory adjustment – name of last carr ie d out adju stme nt proce ss

Adj (Cal) – value of a load currently placed on moisture analyzer’s

pan

Curr. – mass value of an adjustment weight saved in moisture

analyzer’s memory

Dev. – calculated difference between the above two values

e) Return to the weighing mode =, as specified in point 6 of this user

manual.

command on determining mass of an

empty pan, followed by a command to

place a weight with pre-determined

mass.

accept the process by pressing Enter

key. After completing the user

adjustment process the moisture

analyzer returns to submenu P1 -

8.1.4. Temperature adjustment

Temperature adjustment of the drying chamber is carried out using a dedicated

set available as additional equipment of the moisture analyzer.

Page 26

- 26 -

Step 1.

1. Thermometer

2. Thermometer holder with a shield

Adjustment is a simple process aimed at adjusting the temperature sensor

assembled in moisture analyzer’s drying chamber. Before carrying out the

temperature adjustment process, install the adjustment set inside the drying

chamber following below figures.

Remove from the drying

chamber the following:

• Disposable pan

• Pan holder

• Pan bracket

• Chamber cover

Page 27

- 27 -

Step 2.

Step 3.

Place in the drying chamber the

components of the temperature

adjustment set:

• Drying chamber shield

with assembled control

thermometer

After assembling the adjustment

set close drying chamber’s lid

and start the temperature

adjustment process.

CAUTION: remember to carry out all the processes with great care not to

damage the mass measuring mechanism of a moisture analyzer.

Page 28

- 28 -

Enter menu group P1 Adjustment.

Press RIGHT ARROW navigating key. The

Enter the temperatrure value as indicated on

pressing Print/Enter key.

Set the marker next to a parameter 04

Temperature adjustment.

moisture analyzer previews current

temperature value. After 8 minutes, the

display indicates flashing temperature value.

the external (control) thermometer.

Press Print/Enter key to proceeed to the

following step of drying chamber adjustmen t

process. The moisture analyzer switches on

the halogen heating element and for the

following 8 minutes it heats the drying

chamber, and simultaneously indicates on

its display the curr ent tem perature value.

After the 8 minute time interval the moisture

analyzer’s display indicates the flashing

temperature value. Enter the temperatrure

value as indicated on the external (control)

thermometer.

Press Print/Enter key to proceeed to the

following step of drying chamber adjustment

process. The moisture analyzer continutes

heating the drying chamber for another 8

minutes and simultaneously indicates on its

display the current temperature value. After

the 8 minute time interval the moisture

analyzer’s display indicates the flashing

temperature value. Enter the temperatrure

value as indicated on the external (control)

thermometer. After entering the temperature

value finish the adjustment process by

After completing the process return to the main menu with procedure of saving

changes.

8.1.5. Adjustment report printout

On completing each of adjustment processes the moisture analyzer enables

generating a report from adjustment process. The report can be printed on a

connected printer and sent to a computer and saved in a form of file for future

records.

Page 29

- 29 -

P1 05 Report printout : 1 : YES – report is printed

The printout content depends on

group, a report contains the following data:

mass of an adjustment weight stored in

moisture analyzer memory from last

), mass of an adjustment weight

from adjustment process (described as

), i.e. the difference between the two

mass values.

Enter menu group P1 Adjustment.

P1 05 Report printout: 0 : NO – report is not printed

Remember that on enabling report printout (set to 1), the report is generated

and sent automatically.

An example of a printout of a report from adjustment process:

parameters set in group P2 GLP (see point

8.2 of this user manual). Variables that are

printed have an attribute set to 1: yes.

Apart from the content set in this menu

completed adjustment process (described as

Curr:

determined in current adjustment process

(described as Adj: (or Cal) and a deviation

Dev:

8.1.6. Drying test

Parameter <Drying test> enables monitoring correctness of temperature

indications as recorded by the moisture analyzer’s internal thermometer.

The testing procedure is carried out using a dedicated set (a thermometer with a

holder) that is available as additional equipment of a moisture analyzer MAX

series. (It is the same set that is used for carrying out temperature adjustment

process). Means of assembling the set is descri bed in the ch apter on

temperature adjustment of this user manual.

Enabling the testing procedure requires assembling the control set inside the

moisture analyzer’s drying chamber, and entering a menu group <Adjustment>

in instrument’s parameters. Start the process by following below specified

instructions.

Remember to assembly the control thermometer set before starting the testing

procedure and then close the drying chamber lid.

Set the marker next to a parameter 06

Drying test

Page 30

- 30 -

Press RIGHT ARROW navigating key. The

The moisture analyzer displays another

button to accept.

The moisture analyzer displays another

button to accept.

The temperature is maintained for 8 minutes

press ENTER button to accept it.

Then the display opens a mssage box with

moisture analyzer opens a window for

entering the temperature value for carrying

out the drying test. Use the navigsting keys

to enter the desired temperature value and

press ENTER button to accept.

message for entering the permissibl e

temperature error that is acceptable by an

operator. Use the navigating keys to enter

the desired error size and press ENTER

message for entering the factory number of

the adjustment set used for carrying out the

test. Use the navigating keys to enter the

factory number data and press ENTER

After accepting the factory number of the

adjustment set, the software automati cally

starts heating the drying chamber until

reaching a pre-defined temperature value.

The moisture analyzer’s display indicates

data on tim and temperature of the drying

chamber sensor.

(as in case of temperature adjustment).

After this time interval, a message box is

opened on moisture analyzer’s display for

entering the temperature value as recorded

by the control thermometer set assembled

inside the drying chamber. Use the

navigating keys to enter the temperature

value from the control thermometer and

the temperture error of the drying chamber

as recorded by the control thermometer set.

Page 31

- 31 -

----------------------------------------

Test the drying chamber

----------------------------------------

17/04/2013 15:03:42

Balance Id: 01

Number of calibration kit: 0

Temperature setpoint: 120

The temperature measured: 119

Permissible error: 3

Status: OK

Return to the main menu by

of times.

The final temperature: 120

----------------------------------------

The test result can be printed on

a printer connected to a moisture

analyzer by pressing PRINT

button. An example of a report

from drying chamber test is

presented in the table on the left.

8.2. Determining content of a printout for GLP procedures

This group of parameters enables determining name of a user and project, and

declaring other data to be printed in reports and standard printouts. All data can

be easily inserted using either moisture analyzer’s keyboard or an external

computer keyboard PS/2 type connected to balance’s port.

It is recommended to use an external computer keyboard PS/2 type, as it

is a much faster and easier means of entering text.

8.2.1. User

Enter menu group P2 GLP

Enter user name:

Using moisture analyzer’s keyboard

Press navigating arrow to enter the settings of parameter 01 User, where a

name or a number of a user operating the moisture analyzer is entered. The

name/number can include letters and/or numbers , maximum 8 characters. Use

navigating arrow keys. All letters and numbers are displayed in sequence and

in a closed circuit. Select a neede character. Next move the cursor to the right

pressing Esc button for a number

Page 32

- 32 -

and enter the following character. On entering all of the characters press

ENTER key.

Using external computer keyboard PS/2 type

Press F2 key to enter the main menu, press F3 key or use navigating arrows to

set the marker next to a parameter 01 User and press F2 key to enter

parameter settings (flashing first character of an existing number or flashing

cursor if not number is specified). Use computer keyboard to enter a new User

name and accept it by pressing Enter key. Use Esc and Enter keys to return to

weighing mode.

8.2.2. Project

Name of a project can contain maximum 8 alphanumeric characters. The

project name is set as in the case of user namespecified above (see point 8.2.1

above).

8.2.3. Parameters determining content of the GLP procedures

A standard printout template can comprise the following parameters to be

printed:

P2 03 print time – measurement time or report time acquired from moisture

analy z er’s real time clo ck

P2 04 print date – measurement date or report date acquired from moisture

analy z er’s real time clo ck

P2 05 print user – user name as specif ied in param eter P2 01 User

P2 06 print project – project name as specified in parameter

P2 02 Project

P2 07 print ID – moisture analyzer factory number given by the manufacturer

P2 08 print adjustment – data on last completed adjustment process

including: adjustment date and time, adjustment type and deviation.

Page 33

- 33 -

Data to be printed must have an attribute set to “1 yes”.

P2 03 print time: 1:yes

Date : 16/01/2002

130.0500 g

P2 03 print time: 0:no

P2 08 print adjustment: 0:no

Date : 16/01/2002

EXAMPLES OF PRINTOUTS FOR DIFFERENT GLP SETTINGS:

P2 04 print date: 1: yes

P2 05 print user: 1: yes

P2 06 print project: 1: yes

P2 07 print ID: 1: yes

P2 08 print adjustment: 1: yes

Time : 13:12:30

User : R. Wilk

Project : Check

Balance : 11111111

Last adjustment:

---------------------16/01/2002 13:02

External adjustment

Dev.: 0.0001 g

----------------------

P2 04 print date: 1:yes

P2 05 print user: 1:yes

P2 06 print project 0:no

P2 07 print ID: 1:yes

User : R. Wilk

Balance : 11111111

? 12.0085 g

8.3. Date and time settings

Group of parameters enabling setting date and time of the real time clock in

moisture analyzer memory, and setting their displaying and printing format.

Enter menu group P3 Date/Time

8.3.1. Setting date format

Press navigating arrow key to enter submenu 01 Date format.

Select one of available values:

1. Date format - Month/Day/Year

2. Date format - Day/Month/Year

On selecting the appropriate value accept it by pressing ENTER key.

Page 34

- 34 -

8.3.2. Setting time format

Place the cursor next to

a value to be changed

(i.e. Hour, Minute,

Second) .

Enter the value settings

the first digit starts

flashing)

Use navigating arrow

Select a digit to

Accept set value of time

(the last changed digit

stops flashing)

Press navigating arrow key to enter submenu 02 Time format.

Select one of available values:

1. Time format – 12 hours

2. Time format – 24 hours

On selecting the appropriate value accept it by pressing ENTER key. 12 hour

time format is differentiated by letters PM or AM visible on a printout.

8.3.3. Setting time

Press navigating arrow key to enter

settings of parameter 03 Time

Set current time:

or

or

be changed

or

Select digit value

Repeat the process for the following values (minute, second). On setting the

new values press ENTER key. The moisture analyzer returns to submenu P3

Date/Time. The time value visible in the upper bar of the display is changed.

mode

(

keys to set time

Page 35

- 35 -

After setting the time to a needed value return to the weighing mode following

procedure described in point 7.1 of this user manual.

8.3.4. Setting date

Press navigating arrow key to enter settings of parameter 04 Date

Following procedure described in point 8.3.3 set current date value. After

setting the date return to the weighing mode following procedure specified in

point 7.1 of this user manual.

8.3.5. Setting displaying criteria for date and time

Moisture analyzer MAX series enables declaring whether date and time should

be visible in the upper bar of the display during instrument operation. The

displaying criteria are modifiable by setting an appropriate value of the

parameter.

The value is changed in accordance with specification given in point 7.1 of this

user manual. If the parameter value is set to 1 then date and time re visible in

the upper bargraph of the display.

8.4. Setting moisture analyzer oper ating parameters

Moisture analyzer MAX series enables adjusting its operation to current

ambient conditions (filter) or user needs (display refreshment, autozero, last

digit). The parameters are grouped in menu <P4 Readout>.

8.4.1. Entering menu group P4 Readout

Enter menu group P4 Readout

Page 36

- 36 -

8.4.2. Filter settings

Set the cursot next to a parameter P4 03

Press right arrow navigating key which opens a

indicating temperature inside the drying

Return to the previous window by

pressing Esc key.

Depending on current ambient conditions at a workstation it is necessary to set

filtering value. In case of perfect operating conditions set the filter value to very

fast (set value of parameter 01 Filter to 1). If the conditions are bad (i.e.

vibrations, air movement) it is recommended to set the filter value to slow or

very slow (set value of parameter 01 Filter to 4 or 5). The efficiency of filter

operation differs in relation to the measuring range. The filter operates with

lower accuracy while the mass i ndication is quickly increasing after placing a

load on the pan, Filter accuracy is increased when weighed mass is within

filter’s set operation range (parameter: filter operation range is available only

in balance’s service menu, and it is inaccessible for the user).

8.4.3. Autozero function

In order to ensure moisture analyzers’s precise mass indication, “AUTOZERO”

software parameter has been introduced. The application of this function is

automatic control and correction of zero indication.

The parameters determining the range and time of autozero operation are

set by the manufacturer and they are not accessible for the user.

If AUTOZERO function is enabled, then each weighing process starts from

precise zero point. Disabling AUTOZERO operation may result in result

instability while the pan is not loaded with a mass to be weighed. There are,

however, some cases when this function can be a disturbing factor of

measuring process; for instance very slow placing of a load on the weighing

pan (e.g. load pouring). Enabling and disabling AUTOZERO operation is

carried out in parameter P4 02.

8.4.4. Previewing temperature value inside the drying chamber

Temperature.

window

chamber.

Page 37

- 37 -

8.5. RS 232 Functions

Parameter

name

Parameter value

Parameter

Parameter value

01 Baud rate:

0 : 2400;

3 : 19200

05 Handshake

0 : no;

02 Parity

0 : no;

2 : odd

06 Print stable

0 : no;

03 Data bits

07 Printer type

0 : Standard

4 : PC-RADWAG

04 Stop bits

1 : 1 bit;

2 : 2 bits

08 Paper cut

0 : no

1 : yes

Moisture analyzer MAX series enables determining communication parameters

with a computer or a printer.

Enter menu group P5 RS-232

8.5.1. RS 232 parameter settings

Use function keys to set required parameters values (see point 7 of this user

manual – moving through user menu) which determine correct cooperation

between a moisture analyzer and a computer or a moisture analyzer and a

printer:

number and

1 : 4800;

2 : 9600;

1 : even;

1 : 7 bits;

2 : 8 bits

Caution:

In case of parameter set to P5 07 – 3 : PC – the data sent to a printer is only a

line. The data from the header and the footer is not printed.

For parameter set to P5 07 – 4 : PC-RADWAG – each printout is proceeded by

a special controlling signs, which enable moisture analyzer cooperation with

the computer software E2R MOISTURE ANALYZER.

number and name

1 : RTS/CTS;

2 : XON/XOFF

1 : yes

1 : Kafka

2 : Epson

3 : PC

Page 38

- 38 -

8.6. Printouts

User of a moisture analyzer MAX

series can set up to 5 different

h are sent

peripheral device (a printer or a

Date: 22/10/2001

Date: 22/10/2001

? 62.685 g

62.690 g

8.6.1. Standard printout template

On pressing ENTER / PRINT key the moisture analyzer sends through the RS

232 interface current display status (mass of weighed load) and variables

declared in submenu P2 GLP.

Examples of standard printout templates in weighing mode:

A question mark preceding the mass value means that the mass readout was

unstable at the moment of printout release.

A printout can be divided into three sections:

• Header (containing data on selected drying mode and start mass of a

sample to be dried)

• Line (containing partial drying time and humidity content result)

• Footer (containing end mass, total drying time and final drying result).

Hour: 13.04.23

User: Wilk

Project: XW/456

62.690 g

printout templates whic

from the instrument to a connected

computer) through the RS 232 slot.

- A single STANDARD

printout containing data

enabled in the GLP

procedures

- Four NON-STANDARD

customized printout

templates

Hour: 13.16.49

User: Wilk

Project: XW/456

Balance: 10

Page 39

- 39 -

%%

%K

Type of last completed

adjustment process

%N

Current net mass in basic measuring

unit

%I

Deviation in last completed

adjustment process

%d

Current date

%1

Code 1

%t

Current time

%2

Code 2

%i

Balance factory no.

%3

Code 3

%r

Software no.

%4

Code 4

%P

Project no.

%5

Code 5

%U

User no.

%6

Code 6

%k

Date and time of las t completed

adjustment process

8.6.2. Non-standard printout templates

Principles of creating non-standard printout templates:

1. Moisture analyzer MAX series enables creating up to 4 custom

printout templates;

2. each template must have the string of text start and end specified,

e.g. Printout no. 1 Start – 1 and Printout no. 1 Stop – 40. In this

case the Printout no. 1 contains text strings from 1 to 40.

3. Next insert the texts into the specified text strings, i.e. 1 ÷ 40.

It is recommended to use an external computer keyboard

connected to moisture analyzer’s port. This means of text input is

much simpler and quicker.

4. Non-standard printout templates may overlap each other, i.e.:

Printout 1 Start – 1

Printout 1 Stop – 40

Printout 2 Start – 20

Printout 2 Stop – 40

A non-standard printout can contain:

Variables dependent on user needs (mass, date, project no., temperature

of the drying chamber, etc.)

Texts inserted in moisture analyzer’s user menu

A custom non-standard printout template can contain up to 640 characters

inserted in 80 text strings, 8 character each. (starting with parameter String 1

to String 80). A balance user can create up to 4 non-standard printout

templates.

8.6.3. Inserting text into strings

Variables in printouts

Printout of a single character “%”

Page 40

- 40 -

Variables available in drying mode only

%C

Drying chamber temperature

%c

Drying time

%M

Drying result – humidity content

%S

Start mass of a sample

%D

Drying result – dry mass

%E

End mass of a sample

%R

Drying result – humid/dry ratio

%p

Parameters of an enabled

drying mode

%N

Drying result – current net ma ss in

\\

Single “\” sign

\c

CRLF

\r

CR

\n

LF

\t

Tabulator

\s

Skip to the following text ”string”

\0

End of a printout template

Text string no.

Text

1 2 3 4 5 6 7

8

19 Text 10

M a x i m u m

20 Text 11

m a s s c a

n

21 Text 12

n o t e x c

e

22 Text 13

e d 1 1 . 2

5

23 Text 14

0 g !

basic measuring unit

Special signs for designing a non-standard printout template

Each text string (Text 1 ÷ 89 Text 80) can contain up to 8 characters (letters,

digits, special signs, space). Inputting a sentence comprising multiple words and

signs requires using a set of neighbouring 8-character text strings. A user can add

special signs to include needed variables in a non-standard printout temp late.

Example no 1:

Maximum mass cannot exceed 11.250 g!

Inputting this sentence requires using 36 characters grouped in the neighbouring

text strings. Enter text strings settings and input 8 characters from the above text

into each of the text strings until completing the sentence.

Example no. 2:

“RADWAG” Balances & Scales

Date:

Hour:

Page 41

- 41 -

Load mass

Text string no.

Text

1 2 3 4 5 6 7

8

25 Text 16

“ R A D W A G

“

26 Text 17

B a l a n c

e

27 Text 18

s & S c a

l

28 Text 19

e s \ c D a

t

29 Text 20

e : d \ c H o

U

30 Text 21

r : % t \ r \

n

31 Text 22

L o a d m a

s

32 Text 23

s : % N \ c \

c

33 Text 24

* * * * * S i

g

34 Text 25

n a t u r e :

.

35 Text 26

. . . . . . .

.

36 Text 27

. \ c * * * %

F

37 Text 28

* * *

*****Signature:.........

***<active working mode >***

Enter text strings settings and input 8 characters from the above text into each of

the text strings until completing the printout.

Text string selection

Enter group of parameters P6 Printouts

Place the cursor next to a selected text string (from string 1 to string 80). od tekst 1

do tekst 80). Press navigting arrow key to enter parameter settings (if the selected

field was empty, then the first available space for a character starts flashing. If a text

is inserted to a string, then the first character of a line starts flashing).

Page 42

- 42 -

Principles of inserting texts:

Selecting a character for modification by moving the cursor to the RIGHT

text)

Selecting a character for modification by moving the cursor to the LEFT

the erased one.)

a) Using keys on balance’s overlay

Toggling upwards through all available characters: digits, letters, and

signs by one value.

Toggling downwards through all availab le char act er s: dig its, letters, and

signs by one value.

(the following pressing of the the right arrow key causes activating a

character for modification (char acter is fli ck ering ; if no charac ter is

inserted, then repeated pressing of this key causes adding a space in the

(another pressing of the left arrow key causes a erasing a flickering

character, and causes flieckering of a character located on the left from

Accept an inserted character

b) Using computer keyboard PS/2 type

Press F2 key to enter main menu of a balance. Press F3 or use navigating

arrows to place the cursor next to a group of parameters P6 Printouts and by

pressing F2 key enter the submenu group. Then, using the navigating arrows place

the cursor next to a desired parameter and press F2 key to activate text inserting

procedure. Use keyboard text keys to insert a text into the strings (max 8

characters per one text string) and accept it by pressing Enter key. Repeat the

process for the other text strings.

8.6.4. Printout selection

Enter menu group P6 Printouts. Select one of available values for the parameter

P6 01 Printout no.:

0 : standard

1 : printout 1

2 : printout 2

3 : printout 3

4 : printout 4

On selecting an appropriate value accept it by pressing ENTER key.

Page 43

- 43 -

8.6.5. Enabling non-standard printout templates

Printout 2

Printout 3

Enabling a non standard printout template, e.g. printout n o. 1:

Enter group of parameters P6 Printouts. In a parameter determining printout type

01 Printout no. enter 1: printout 1 and in parameter 02 printout 1 start ent e r t he

text string of printout start. Available values for start of a non-standard printout: from

1 to 80 !

After entering the number of a text string starting a printout, set number of a

text string finishing the non-standard printout template:

Enter parameter settings 03 printout 1 stop and enter the text string of printout

stop (end). Available values for start of a non-standard printout: from 1 to 80!

After accepting the selected parameters and returning to a weighing mode with

procedure of saving changes each pressing of PRINT key causes printing of a

declared non-standard printout template.

8.6.6. Non-standard printout templates in drying mode

The process of designing non-standard printout templates for drying mode is the

same as in case of weighing mode. The only feature of the printout template in

dying mode differentiating it from the printout in weighing mode is the need to

determine thee sections of a printout template (see standard printout in drying

mode): Header, Line and Footer.

An example of determining a printout template for a drying mode:

Header – Printout 2

Line – Printout 3

Footer – Printout 4

Page 44

- 44 -

Printout 4

8.7. Moisture analyzer parameter settings.

Depending on user needs the moisture analyzer enables setting parameters

influencing its operation. These parameters are grouped in menu P7 Other, for

instance: beep sound on pressing a key/button, screen contrast, etc.

8.7.1. Entering menu group P7 Other

Enter submenu group P7 Other.

Page 45

- 45 -

8.7.2. Parameter settings

The parameters are set as specified in case of previous menu groups.

01 Password

The password protects the moisture analyzer against making changes in its

settings

02 Database of drying programs

Enabling / disabling accessibility of the database of drying programs.

03 Beep sound

Determines whether each pressing of a key/button on balance overlay is

confirmed by a beep sound, available settings: YES/NO

04 Language

Selecting language version of software menu, available settings Polish or

English

05 Display backlight

Determines whether the backlight of the balance’s graphic display should be

enabled or disabled (enabling the backlight option improves data visibility on

the display)

06 Screen brightness

Enables changing the brightness of the balance’s graphic display – entering

the function opens a window for setting brightness level using buttons on the

balance’s overlay

07 Screen contrast

Enables changing the contrast of the balance’s graphic display – entering the

function opens a window for setting contrast level using buttons on the

balance’s overlay

Page 46

- 46 -

If accepted, the moisture analyzer starts

232 slot.

08 Balance no.

This function serves for information purpose only, and it enables previewing

factory number of a balance

09 Software no.

Enables previewing number of software revision operating in a balance

10 Parameter printout

Enabling this function causes printing balance parameters set in the user

menu. The user specifies numbers of parameters that should be printed.

After entering the parameter printout

option a window with the following

question is displayed

11 Acquire (upload) parameters

Enabling this function causes uploading all parameters sent via RS 232

interface from a connected computer.

On entering the function the following window is opened:

On completing uploading process the balance informs a user on number of

accepted and changed parameters, and number of incorrectly declared

parameters which are rejected by the balance.

Printing and uploading balance parameters is a very simple and intuitive

means of setting new values of balance parameters. On printing to a file

current parameter values on a connected computer, the user can simply and

quickly change parameter values. After saving made changes, the updated file

is sent from the computer level to balance’s software. On completing of

uploading process and saving changes the balance accepts new parameter

settings. The procedure requires that a user is familiar with balance

parameters and has good knowledge of computers.

12 ID setting

Enables entering codes to moisture analyzer memory

13 Automatic ID Printout

sending current user parameter setting s

to a connected printer/computer via RS

Page 47

- 47 -

Determines whether a code entered to moisture analyzer’s memory should be

automatically sent via RS 232 interface.

14. Previous version

The parameter enables functioning of a moisture analyzer as it would be if

previous software version was running, i.e. after setting the parameter value to

<YES> the moisture analyzer operates the drying process and the drying

temperature range similarly to the one specific for the previous software

version (in comparable temperature conditi ons).

The parameter enables using the drying process settings specific for the

previous version of this type of moisture analyzers if such are in use of an

organization. The parameter of a new moisture analyzer allows an operator to

use already determined and verified drying procedures for materials to be

tested, as implemented in older devices of the same type.

9. DRYING PROCESS WITH USE OF SHORTENED MENU

This section of the user manual presents the means of carrying a moisture content

determining process using the shortened procedures.

Menu of drying mode enables setting the following parameters:

- Drying mode with its profile (temperature, time)

- Means of drying process finish mode

- Type of displayed measurement result

- Frequency of printing data from a drying process

9.1. Enabling shortened menu

In order to start drying process with use of shortened menu, disable access to

libraries of drying programs – go to menu group P7 Other, parameter P7 02

Database of drying programs and set it to “0” - disabled).

Database of drying programs disabling procedure:

or

Press Setup key which opens a

window with groups of parameters.

Page 48

- 48 -

Press navigating arrow keys to set the

Press Test Menu key which opens a

parameters of the shortened menu.

cursor next to a menu group P7 Other.

On returning to the main window (with procedure of saving changes) the use

can carry out a drying process after setting the basic parameters for drying a

sample to be tested. There is no need to select a specific drying program from the

database. W hen setting the parameter Database of drying programs to value 0 –

disabled. The user does not have access to the database records saved in the

moisture analyzer memory.

Press key. The software automatically goes to setting the basic drying

parameters.

9.2. Means of setting drying parameters:

window with the first step of the drying

Page 49

- 49 -

Press right arrow navigating key to

left corner of the display)

Press UP or DOWN navigating arrow

modes: Standard, Quick, Mild or Step.

If selected drying mode is QUICK, then

to the following step of drying mode

enable selection of a drying profile (name

of a drying mode is previewed abov e the

mode’s graphic presentation. T he

pictogram denoting drying mode

selection menu is flashing in the upper

keys to select one of available drying

set the drying temperature and heating

time in temperature exceeded by 30 %

than the actual drying temperature. The

heating time is calculated from the

moment of reaching the set temperature

by the moisture analyzer.

If selected drying mode is STEP, then set

the drying temperatures for thresholds 1

and 2 and the drying temperature and

their corresponding time intervals for

each of the thresholds. The heating time

in each of the thresholds is calculated

from the moment of reaching a set

temperature in each of the steps.

On selecting appropriate drying mode

press the right arrow navigating key to go

Page 50

- 50 -

parameters. Pressing the arrow key

causes appearing of a cursor (black

presentation).

Press UP or DOWN navigating arrow

keys to select needed parameter value.

If a Mild or Step drying mode is selected

the following criteria of a drying process.

In order to set other parameters of the

window.

Press DOWN navigating arrow key to

Mode.

triangle) next to the first parameter of

selected drying mode (visible on the right

hand side of the drying mode graphic

Press right arrow navigating key to

change parameter value (the displayed

value starts flashing)

After setting the parameter value accept

it by pressing ENTER key (the value

stops flashing).

then go to other mode settings. If

selected mode is Standard or Quick set

drying process press ENTER key. The

software returns to displaying the initial

go to the following step of drying

process determination, i.e. Finish

Use navigating arrow keys (procedure

as in case of drying mode selection) to

set one of available finish modes and

determine its parameters.

Page 51

- 51 -

After setting the Finish mode criteria go

drying process.

In order to set other parameters of the

window.

Press DOWN navigating arrow key to go

determination, i.e. Result.

Use navigating arrow keys (procedure as

- 52 -

to setting the following parameters of a

drying process press ENTER key. The

software returns to displaying the initial

to the following step of drying process

in case of drying mode selection) to set

the type of displayed measurement

result.

Page 52

After setting the Result criterion go to

drying process.

In order to set other parameters of the

window.

Press DOWN navigating arrow key to

Interval.

The printout interval is a period of time

After setting the printout interval

ready to start drying process of a

setting the following parameters of a

drying process press ENTER key. The

software returns to displaying the initial

go to the following step of drying

process determination, i.e. Printout

measured in seconds in which a

moisture analyzers sends current

measurement result to a connected

peripheral device.

criterion the moisture analyzer is

Page 53

- 53 -

sample to be tested.

In order to finish setting the drying

window.

Once more press ENTER key. The