Page 1

User Manual

Scales of WPY/KB series

Manual number:

ITKU-47-12-05-12-A

Mass Comparator

MANUFACTURER OF ELECTRONIC

WEIGHING INSTRUMENTS

RADWAG Wagi Elektroniczne, 26–600 Radom Bracka 28 Street - POLAND

Phone +48 48 38 48 800, phone/fax. +48 48 385 00 10

Selling department +48 48 366 80 06

www.radwag.com

Page 2

MAY 2012

2

Page 3

Table OF CONTENTS

USE ..........................................................................................................................7 INTENDED

1.

2.

PRECAUTIONARY MEASURES ................................................................................................7

3. WARRANTY CONDITIONS ........................................................................................................7

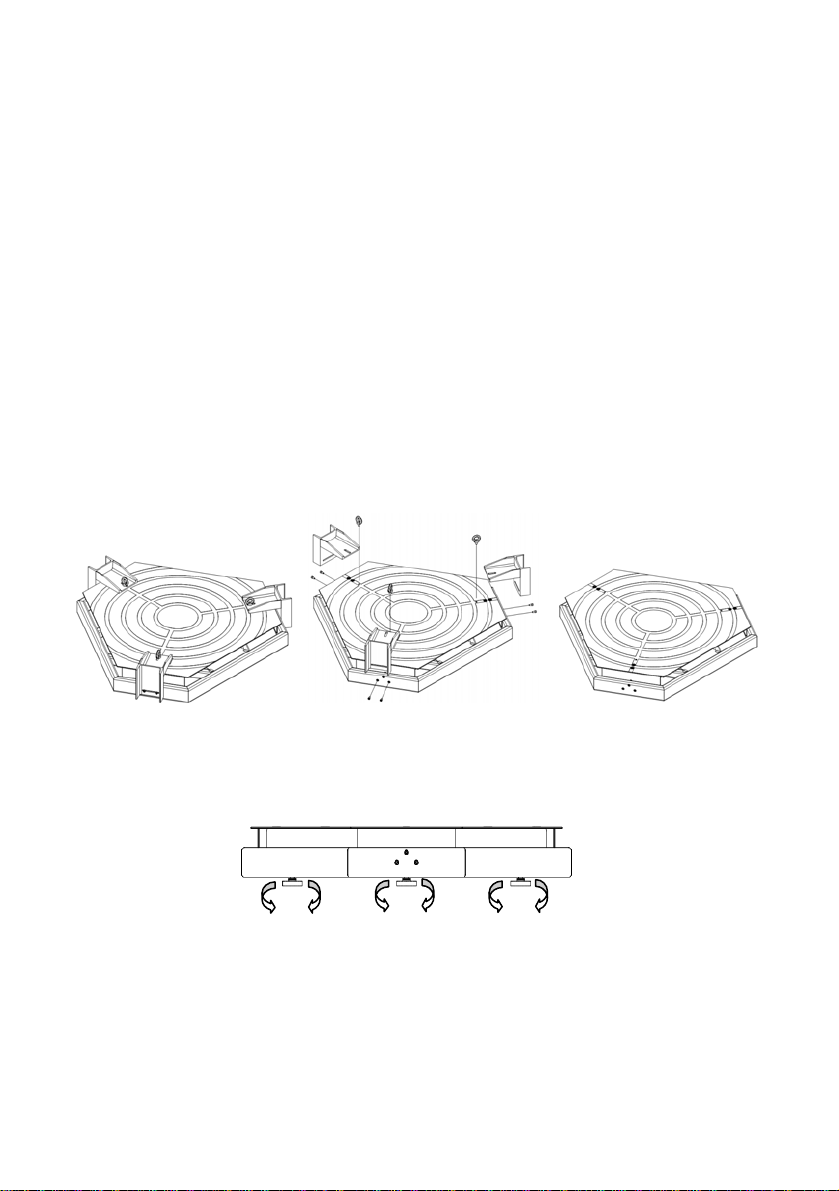

4. UNPACKING AND MOUNTING..................................................................................................8

4.1. Comparator WPY/KB – preparation for work .......................................................................9

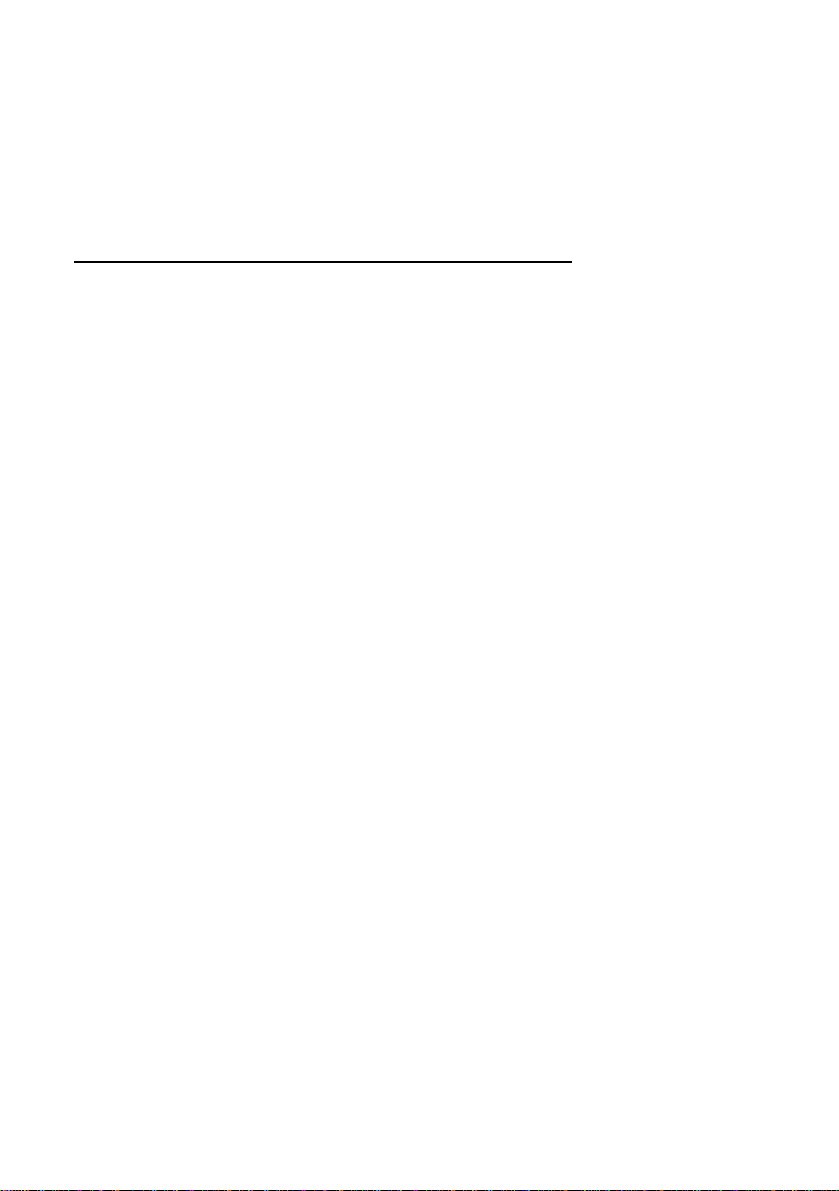

5. CONSTRUCTION......................................................................................................................10

5.1. Main dimensions ................................................................................................................10

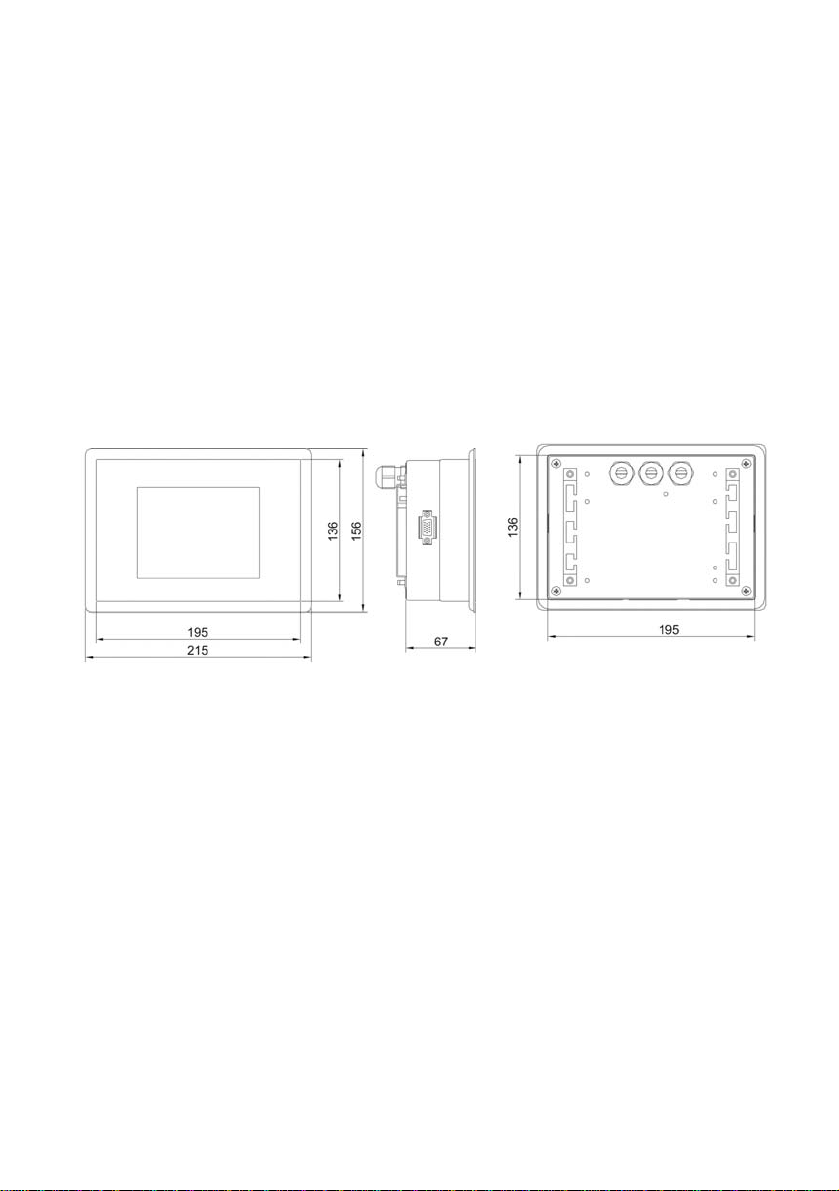

5.2. Description of connectors...................................................................................................11

5.2.1. .............................................................................11 Connectors’ description in PUE 7

5.2.2.

...........................................................................11 Connectors’ description in PUE 7P

5.2.3.

..................................................................................11 Description of glands PUE 7P

Connector with RS232 and I/O.................................................................................12

5.2.4.

6. GETTING STARTED.................................................................................................................12

7. KEYPAD OVERLAY..................................................................................................................13

8. TIONS OF KEYS .............................................................................................................13 FUNC

9.

PROGRAM STRUCTURE.........................................................................................................14

9.1. Main menu items ................................................................................................................14

9.1.1. ...............................................................................................................14 Parameters

9.1.2.

.................................................................................................................15 Databases

Scale Info..................................................................................................................15 9.1.3.

9.2.

Inventory of parameters .....................................................................................................16

9.2.1. ....................................................................................16 Scale parameters - weighing

.........................................................................................................16 Working modes

9.2.2.

9.2.3.

.........................................................................................................19 Communication

9.2.4.

.....................................................................................................................19 Devices

9.2.5.

......................................................................................................................21 Display

uts ........................................................................................................22 Inputs / Outp

9.2.6.

9.2.7.

...........................................................................................................23 Authorizations

9.2.8.

.........................................................................................................................23 Other

User Calibration........................................................................................................24

9.2.9.

10. ATING WINDOW ...........................................................................................................24 INDIC

11.

LOGGING ON..........................................................................................................................26

11.1. dure ........................................................................................................26 Logging in proce

11.2.

rocedure......................................................................................................26 Logging out p

11.3.

Authorization access levels...............................................................................................27

12. NAVIGATING WITHIN THE MENU.........................................................................................28

12.1. ..............................................................................................................................28 Buttons

Return to weighing............................................................................................................29

12.2.

13. WEIGHING...............................................................................................................................30

13.1. erational use ...........................................................................................30 Conditions of op

13.2.

..............................................................................................................................31 Zeroing

13.3.

...............................................................................................................................31 Tarring

....32 Inscribing tare................................................................................................................

13.4.

13.5.

l range scales.........................................................................................32 Weighing for dua

13.6.

Toggling between weight units..........................................................................................32

14. SCALE PARAMETERS...........................................................................................................33

14.1. .....34 Median filter..................................................................................................................

..................................................................................................................................34 Filter

14.2.

14.3.

............................................................................................................................34 Autozero

14.4.

Minimum weight for different functions (LO) .....................................................................35

3

Page 4

15. COMMUNICATION..................................................................................................................35

15.1. .................................................................................................................36 RS 232 settings

15.2.

T setting...........................................................................................................36 ETHERNE

TCP protocol setting .........................................................................................................37 5

1 .3.

DEVICES .................................................................................................................................37

16.

16.1. Computer ..........................................................................................................................37

16.1.1. .........................................................................................................37 Computer port

16.1.2.

ss ..................................................................................................38 Computer addre

mission ........................................................................................38 Continuous trans

16.1.3.

16.1.4.

t pattern........................................................................................39 Weighing printou

16.1.5.

16.2. Printer................................................................................................................................40

16.3. Barcode scanner...............................................................................................................43

16.4. Transponder card reader ..................................................................................................44

16.5. Additional display..............................................................................................................45

17. DISPLAY..................................................................................................................................47

17.1. Text strings........................................................................................................................47

17.2. ys....................................................................................................................50 Function ke

17.3.

17.4.

18. INPUTS / OUTPUTS................................................................................................................53

18.1. nputs......................................................................................................53 Configuration of i

18.2.

19. AUTHORIZATION ...................................................................................................................55

19.1. ymous Operator........................................................................................................55 Anon

19.2.

19.3.

19.4.

19.5.

20. OTHER PARAMETERS ..........................................................................................................57

20.1. ........................................................................................................................58 Languages

20.2.

20.3.

20.4.

21. CUSTOMER CALIBRATION...................................................................................................59

21.1. dure........................................................................................................60 Calibration proce

21.2.

Cooperation with „E2R System” .............................................................................39

16.2.1. ..............................................................................................................40 Printer port

16.2.2.

e ...................................................................................................41 Printer code pag

Patterns for printouts..............................................................................................41

16.2.3.

16.3.1. arcode scanner ........................................................................................43 Port for b

......................................................................................................................43 Offset

16.3.2.

16.3.3.

Code length............................................................................................................44

16.4.1. or transponder card readers ..................................................................44 Com port f

16.4.2.

Procedure of attributing the card number to an operator........................................45

16.5.1. y port.............................................................................................45 Additional displa

16.5.2.

Communication protocol frame...............................................................................46

17.1.1. patterns......................................................................................................48 Display

17.1.2.

.............................................................................................................49 Screen font

.................................................................................................................49 Font size

17.1.3.

17.1.4.

Bold fonts................................................................................................................49

ing platforms..........................................................................................................50 Display

Bargraph type ...................................................................................................................51

17.4.1. weighing”........................................................................................52 Bargraf “Quick

Bargraph “Signalling checkweighing ranges”.........................................................52

17.4.2.

Configuration of outputs....................................................................................................54

....................................................................................................................55 Date and time

............................................................................................................................56 Printouts

.........................................................................................................................56 Databases

Delete older data...............................................................................................................57

time........................................................................................................58 Setting date and

.....................................................................................................................59 Sound signal

Touch panel calibration.....................................................................................................59

Start mass adjustment ......................................................................................................62

4

Page 5

22. SPECIAL FUNCTIONS OF WORKING MODES.....................................................................63

22.1. ................................................................................................................64 Recording mode

22.2.

wn-weighing .................................................................................................................64 Do

eighing..................................................................................................................65 Checkw

22.3.

22.4.

de.........................................................................................................................65 Tare mo

22.5.

Labelling mode..................................................................................................................66

22.5.1. mber of labels to print...................................................................66 Setting of the nu

22.5.2.

mber of cumulative labels to print.................................................67 Setting of the nu

22.5.3.

mber of CC labels to print.............................................................67 Setting of the nu

cumulative labels...............................................................68 Automatic triggering of

22.5.4.

22.5.5.

22.6. ............................................................................................................................71 Statistics

22.7.

22.8.

22.9.

22.10. Declaration of the number of measurement series.........................................................73

23. WORK MODE - WEIGHING....................................................................................................74

23.1. Starting the working mode ................................................................................................74

24. WORKING MODES – COUNTING PIECES............................................................................74

24.1. working mode................................................................................................74 Starting the

24.2.

24.3.

24.4.

2 .5.

WORKING MODES – DEVIATIONS.......................................................................................77

25.

25.1. rating mode..............................................................................................77 Starting the ope

25.2.

25.3.

26. WORKING MODES – COMPARATOR...................................................................................78

26.1. working mode................................................................................................80 Starting the

26.2.

26.3.

27. DATABASES...........................................................................................................................85

27.1. Searching databases ........................................................................................................85

27.2. w items in databases........................................................................................87 Adding ne

27.3.

27.4.

27.5.

27.6.

27.7.

Automatic triggering cumulative labels of cumulative labels...................................69

mass ...........................................................................71 Automatic correction of reference

ce mass..................................................................................................72 Minimum referen

Selecting the series type................................................................................................... 73

ce unit by entering known piece mass ...................................................75 Setting a referen

ce unit by weighing a sample.................................................................75 Setting a referen

rence mass by entering single piece mass directly to the database ........76 Setting the refe

Inscribing the unit mass to the database ..........................................................................76 4

ass estimated by weighing ....................................................................78 Reference unit m

Rederence unit mass inscribing into the memory.............................................................78

eight mass ......................................................................................................80 Selecting w

The process of large weights comparison ........................................................................80

27.1.1. .................................................................................................86 Quick name search

..................................................................................................86 Quick code search

27.1.2.

27.1.3.

Weighing date search.............................................................................................86

..............................................................................................87 Deleting items in databases

ta............................................................................................................87 Deleting older da

..........................................................................................88 Printing items from databases

a database to a file................................................................................................88 Export

Database edition...............................................................................................................90

27.7.1. ase...............................................................................................90 Operators’ datab

roducts..............................................................................................90 Database of p

27.7.2.

27.7.3.

ghings / Alibi.................................................................................91 Database of Wei

27.7.4.

ractors..........................................................................................92 Database of cont

kages............................................................................................93 Database of pac

27.7.5.

27.7.6.

warehouses ........................................................................................94 Database of

27.7.7.

ls..................................................................................................94 Database of labe

Database of universal variables..............................................................................95

27.7.8.

5

Page 6

28. COMMUNICATION PROTOCOL ............................................................................................95

28.1. ral information ..........................................................................................................95 Gene

28.2.

of RS commands...............................................................................................96 Inventory

.................................................................................................97 Respond message format

28.3.

28.4.

Command’s description ....................................................................................................97

28.4.1. ....................................................................................................................97 Zeroing

.....................................................................................................................97 Tarring

28.4.2.

28.4.3.

re value .........................................................................................................98 Get ta

28.4.4.

..........................................................................................................98 Set tare value

in basic unit.........................................................................99 Send the stable result

28.4.5.

28.4.6.

mmediately in basic unit ...............................................................99 Send the result i

28.4.7.

......................................100 Send immediate results from all platforms in basic units

nit....................................................................100 Send the stable result in current u

28.4.8.

28.4.9.

Send the result immediately in current unit...........................................................101

28.4.10. Switch on continuous transmission in basic unit.................................................102

28.4.11. Switch off continuous transmission in basic unit.................................................102

28.4.12. Switch on continuous transmission in current unit..............................................102

28.4.13. Switch off continuous transmission in current unit..............................................103

28.4.14. Set lower threshold .............................................................................................103

28.4.15. Set upper threshold.............................................................................................103

28.4.16. Read lower threshold..........................................................................................103

28.4.17. Read upper threshold.........................................................................................104

28.4.18. Send all implemented commands.......................................................................104

28.5. Manual printouts / automatic printouts............................................................................104

29. NECTING EXTERNAL DEVICES..................................................................................105 CON

DIAGRAMS OF CONNECTION CABLES.............................................................................105

30.

31. TECHNICAL PARAMETERS................................................................................................107

32. ERROR MESSAGES.............................................................................................................109

33. DDITIONAL EQUIPMENT...................................................................................................109 A

34.

APPENDIX A – Variables for printouts...............................................................................110

34.1. of variables......................................................................................................110 Inventory

34.2.

Formatting variables .......................................................................................................114

35. APPENDIX B – Functions of programmable buttons .......................................................116

36. APPENDIX C – Label pattern...............................................................................................120

36.1. rminal level........................................................................120 Designing a label from the te

....................................................................................121 Designing a label on a computer

36.2.

36.3.

s in the scale ...................................................................................124 Saving label pattern

36.4.

l to a product........................................................................................125 Attributing a labe

l to a contractor....................................................................................125 Attributing a labe

36.5.

3 .6.

Printing labels..................................................................................................................125 6

APPENDIX D - CITIZEN printer setting...............................................................................126

37.

38. APPENDIX E - ZEBRA printer setting ................................................................................126

39. APPENDIX F - Communication with barcode scanners ...................................................127

6

Page 7

1. INTENDED USE

Mass comparators are devices designed for determining the differences

between masses of calibration weight (B) and reference weight (A).

Comparators are most often used in measuring laboratories for calibration

of weights and masses. Radwag offers comparators designed for calibration

of weights and masses class M1 according to OIML R111.

2. PRECAUTIONA RY ME ASUR ES

A. Please, read carefully this user manual before and use the device

according to its intended use;

B. Weighed loads should be placed in possibly central pa rt of scale pan;

C. Do not clean the device with agents causing corrosion;

D. Weighing pan should be loaded with goods having gross mass lower

than maximal capacity of the scale;

E. Do not leave loads on the pan for longer period of time ;

F. In case of failure, immediately disconnect scale power supply;

G. Devices that are to be withdrawn from usage should be utilized

according to the law.

3. WARRANTY CONDITIONS

A. RADWAG is obliged to repair or change those elements that appears

to be faulty because of production and construction reason,

B. Defining defects of unclear origin and outlining methods of elimination

can be settled only in participation of a user and the manufacturer

representatives,

C. RADWAG does not take any responsibility connected with destructions

or losses derives from non-authorized or inappropriate (not adequate

to manuals) production or service procedures,

D. Warranty does not cover:

• Mechanical failures caused by inappropriate maintenance of

the device or failures of thermal or chemical origin or caused

by atmospheric discharge, overvoltage in mains or other

random event,

7

Page 8

• Inappropriate cleaning.

E. Forfeiture of warranty appears after:

• Access by an unauthorized service,

• Intrusion into mechanical or electronic construction

of unauthorized people,

• Installing another operating system,

• Removing or destroying protection stickers.

F. The detailed warranty conditions one can find in warranty certificate.

G. Contact with the central authorized service:

+48 48 384 88 00 ext. 106 or 107.

4. UNPACKING AND MOUNTING

Before using the scale remove the transport protections (if installed):

Place the scale on the spot of use on the flat, stable ground far away from

sources of heat. The platform should be levelled out by putting pads under

feet and the use of an external level device.

Every foot can be screwed in or out. This way only a smal range of level

regulation is achievable. Basic levelling should be performed by putting

steel pads under legs and observing the level on external level device.

8

Page 9

4.1. Comparator WPY/KB – preparation for work

Comparators of WPY/KB series, because of its construction (sensitive strain

gauges), require appropriate conditions to work properly, including stable

temperature. Temperature drifts in rooms with comparators should not

exceed 1°C per hour.

Proceeding in case of preparing the comparator to work:

1. After unpacking and taking off transport protections put the scale

in the destination place and level the komparator platform.

2. The room temperature must be stable – maximum allowable

temperature change is 1°C / h – and protected from accidental draughts

air flows e.g. from air conditioning directed on the comparator pan.

3. Then switch on the device and leave unloaded and on for 4 hours. This

is warming time during which electronical and mechanical parts reach

stable temperature conditions.

4. After 4 hours in stable ambient conditions the comparator can be

prepared for adjustment.

5. First load the comparator pan to the maximum capacity 1000kg and

keep this state at least 2.5 minuty (150 seconds).

6. Secondly unload the pan and wait at least 2 minuts (120 seconds),

to allow the scale to return to the minimum stable value close to „zero”.

7. The operation of initial loading should be repeated 5 times, every time

in reference to time intervals given above.

8. After the 5-time initial loading the comparator can undergo the

adjustement procedure: 2 minutes after unloading the pan and start

the adjustment procedure from factory menu – first start mass is

determined then load the calibration weight following hints that appear

on the display. Confirm the stable result after 2 minutes. This way the

adjustement procedure will be completed.

9. The comparator is ready for work.

Notice:

If working conditions are changed (temperature change greater than 1°C,

humidity change, sudden long lasting air flow causing a change of ambient

conditions) the adjucement procedure described above needs to be repeated.

9

Page 10

5. CONSTRUCTION

5.1. Main dimensions

Dimensions of PUE 7 in plastic casing

Dimensions of PUE 7P with stainless housing

Dimensions of platform

10

Page 11

5.2. Description of connectors

5.2.1. Connectors’ description in PUE 7

1 – Ethernet RJ45

2 – RS232 (COM1)

1 – power supply socket

2 – I/O, RS232 (COM2)

3 – USB

5.2.2. Connectors’ description in PUE 7P

1 – Ethernet RJ45

2 – RS232 (COM1)

3 – USB

1 – I/O, RS232 (COM2)

5.2.3. Description of glands PUE 7P

1 – Supply cord gland

2 – Gland for platforms 1, 2

3 – Gland for platforms 3, 4

11

Page 12

5.2.4. Connector with RS232 and I/O

RS232 - DB9/M (male),

top view:

Pin2 - RxD

Pin3 - TxD

Pin5 - GND

I/O, RS232 DSUB15/F (female),

top view:

Pin1 - GNDWE

Pin2 - OUT1

Pin3 - OUT2

Pin4 - COMM

Pin5 - 6÷9VDC

Pin6 - IN4

Pin7 - IN3

Pin8 - TxD2

Pin9 - 5VDC

Pin10 - GNDRS

Pin11 - IN2

Pin12 - IN1

Pin13 - RxD2

Pin14 - OUT4

Pin15 - OUT3

6. GETTING STARTED

• After the terminal is connected to power the ON/LOAD

diode starts to light.

• Press

Windows CE together with RADWAG software loading is signalled

by blinking the red diode ON/LOAD.

• When the loading procedure is completed the main software

window appears.

to start the operating system loading procedure.

12

Page 13

7. KEYPAD OVERLAY

8. FUNCTIONS OF KEYS

Key Description

Turning on/off the scale

Zeroing

Tarring

Printing out the result or confirming some entered data

Function key (entering the menu)

Selecting products

Selecting contractors

Inscribing a tare value

13

Page 14

9. PROGRAM STRUCTUR E

The main menu has been divided into three functional groups.

In every group there are parameters of similar use.

9.1. Main menu items

The main menu comprises three functional groups:

Parameters

Databases

Info

9.1.1. Parameters

Icon Description

Scale

Working Modes

Communication

Devices

Display

Inputs / Outputs

Authorization

Other

User Calibration

14

Page 15

9.1.2. Databases

Icon Description

9.1.3. Scale Info

Products

Operators

Weighings / Alibi

Contractors

Recipes

Recipes reports

Comparisons

Packages

Warehouses

Labels

Universal variables

Delete older data

Export database weighings to a file

Submenu < Info> is for viewing information:

• Scale factory number,

• Program version,

• Scale program version.

15

Page 16

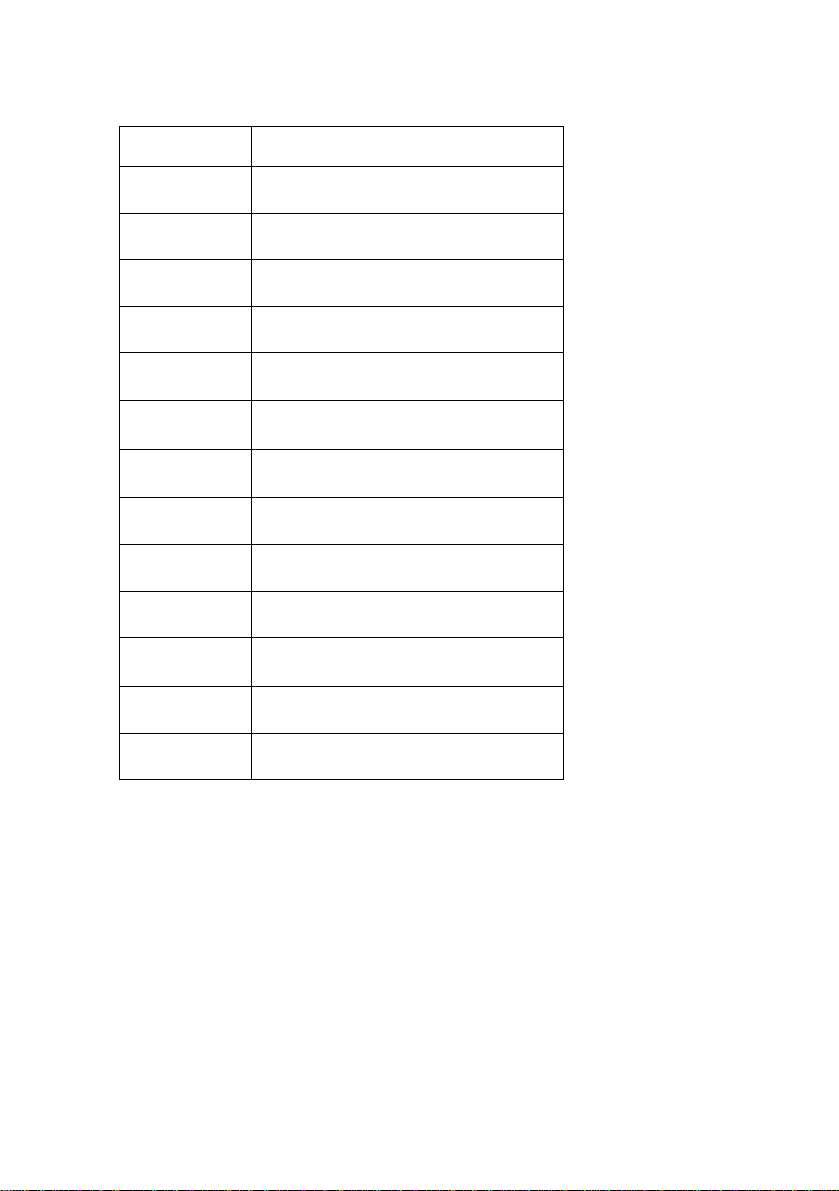

9.2. Inventory of parameters

9.2.1. Scale parameters - weighing

Icon Description Value

Platform 1 -

Median Filter None

Filter Slow

Autozero No

LO threshold 0.1

9.2.2. Working modes

Icon Description Value

Weighing -

Save Mode

Down-weighing No

Checkweighing No

Tare mode No

Labelling mode -

Number of labels 1

No. of cumulative labels 1

No. of CC labels 1

C label automatic triggering -

Mode None

Manual, each

stable

16

Page 17

Threshold 100

CC label automatic triggering Mode None

Threshold 100

Statistics Global

Counting pieces -

Save Mode

Down-weighing No

Checkweighing No

Tare mode No

Labelling mode -

Number of labels 1

No. of cumulative labels 1

No. of CC labels 1

C label automatic triggering -

Manual, each

stable

Mode None

Threshold 100

CC label automatic triggering Mode None

Threshold 100

Statistics Global

Automatic correction of reference mass No

Deviations -

17

Page 18

Save Mode

Down-weighing No

Checkweighing No

Tare mode No

Labelling mode -

Number of labels 1

No. of cumulative labels 1

No. of CC labels 1

C label automatic triggering -

Manual, each

stable

Mode None

Threshold 100

CC label automatic triggering Mode None

Threshold 100

Statistics Global

Comparator -

Save Mode

Checkweighing No

Tare mode No

Statistics Global

Method ABBA

Number of measurements 6

Ask for numbers of standards No

Automatic

first stable

18

Page 19

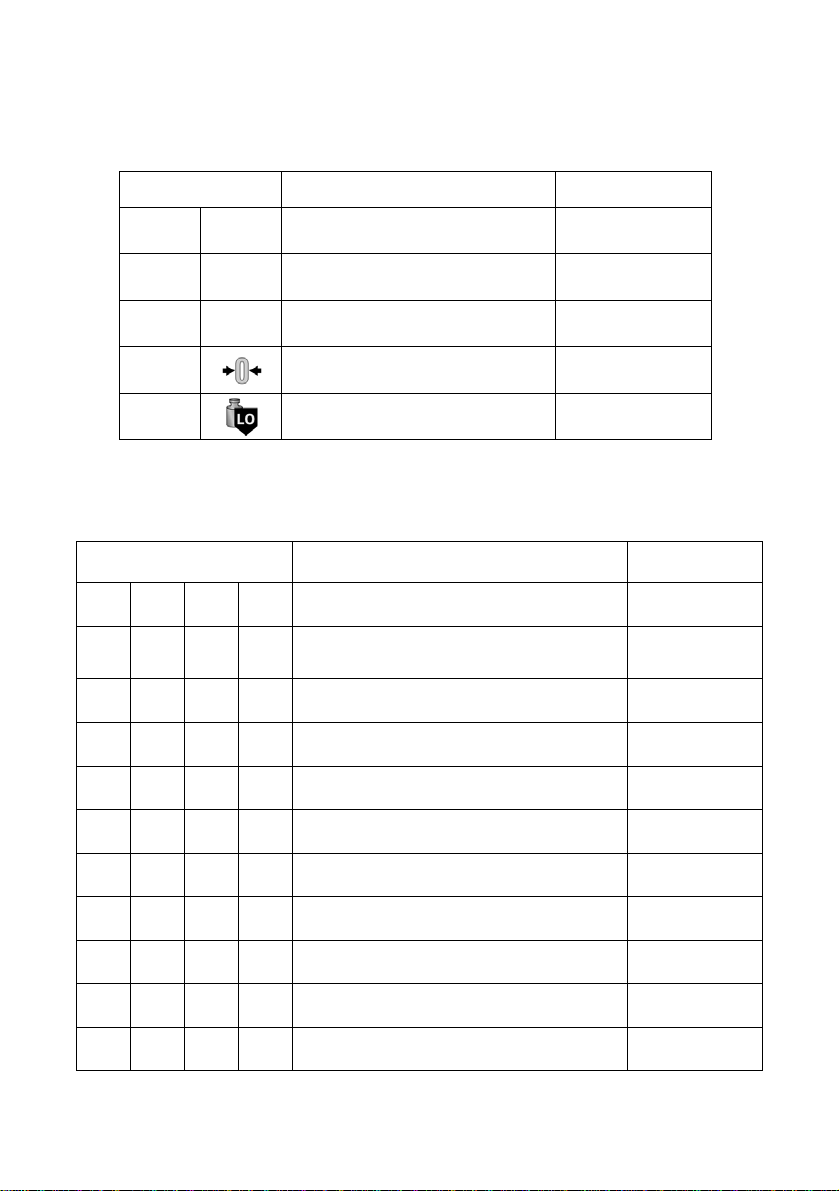

9.2.3. Communication

Icon Description Value

COM1 Baud Rate 9600

Data bits 8

Stop bits 1

Parity None

COM2 Baud Rate 9600

Data bits 8

Stop bits 1

Parity None

Ethernet DHCP No

IP Address 192.168.0.2

Subnet mask 255.255.255.0

Gateway 192.168.0.1

Tcp Port 4001

9.2.4. Devices

Icon Description Value

Computer

19

Page 20

Port None

Address 1

Continuous transmission No

Weighing Printout Pattern E2R System System is active No

Lock selecting products No

Printer Port COM1

Code page 1250

Printouts Weighing printout pattern See ch. 16.2.3

Product printout pattern See ch. 16.2.3

Cumulative printout pattern See ch. 16.2.3

Cumulative printout pattern

for cumulative data

Operator printout pattern See ch. 16.2.3

Contractor printout pattern See ch. 16.2.3

Warehouse printout pattern See ch. 16.2.3

Package printout pattern See ch. 16.2.3

CPG report printout pattern

(Control of Packaed Goods)

Average tare report printout pattern

(Control of Packaed Goods)

Barcode reader Port None

See ch. 16.2.3

*

*

20

Page 21

Offset 0

Code length 0

Transponder card reader Port None

Additional display Port None

Pattern See ch. 16.2.3

*) Not related to „Comparator”.

9.2.5. Display

Icon Description Value

Text information Displaying pattern See ch. 17.1.1

Font Arial

Font size Small

Bold No

Actions

F1 Button Choose product

F2 Button Choose contractor

F3 Button Set tare

Screen button 1 Local parameters

Screen button 2 Set MIN and MAX

21

Page 22

Screen button 3 Statistics C: Print

Screen button 4 CCStatistics : Print

Screen button 5 C Statistics : Zero

Screen button 6 Choose package

Screen button 7 Edit batch number

Screen button 8 None

Screen button 9 None

Left proximity sensor None

Right proximity sensor None

Set Default Show all platforms No

Bargraph type*

*) Not related to „Comparator”.

9.2.6. Inputs / Outputs

Icon Description Value

None

Inputs Input 1 None

Input 2 None

Input 3 None

Input 4 None

Outputs Output 1 None

22

Page 23

9.2.7. Authorizations

Icon Description Value

9.2.8. Other

Icon Description Value

Output 2 None

Output 3 None

Output 4 None

Anonymous operator Operator

Date & Time Administrator

Printouts Administrator

Databases

Products Administrator

Contractors Administrator

Packages Administrator

Warehouses Administrator

Labels Administrator

Delete older data Advanced Oper ator

Language Polish

Date & Time -

23

Page 24

Beep Buttons

Touch screen calibration -

9.2.9. User Calibration

Icon Description Value

Platform 1 -

Setting of start mass -

Calibration -

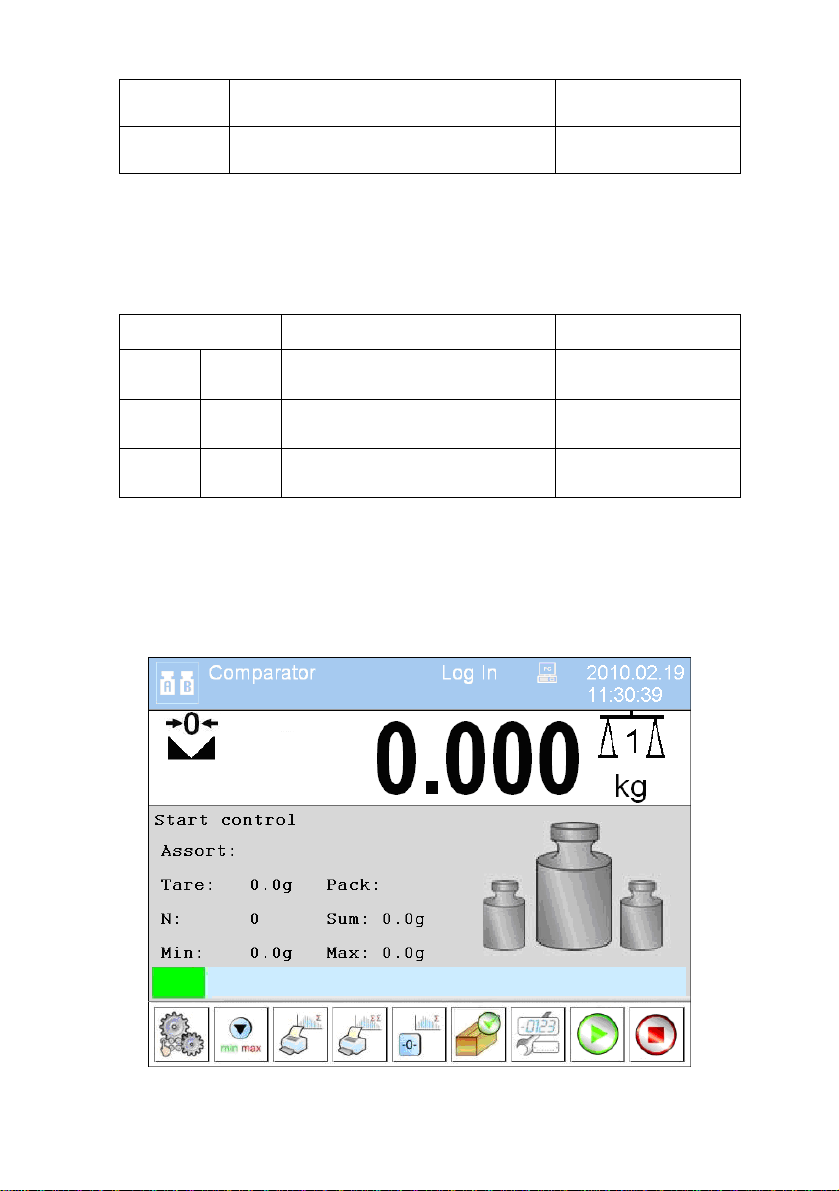

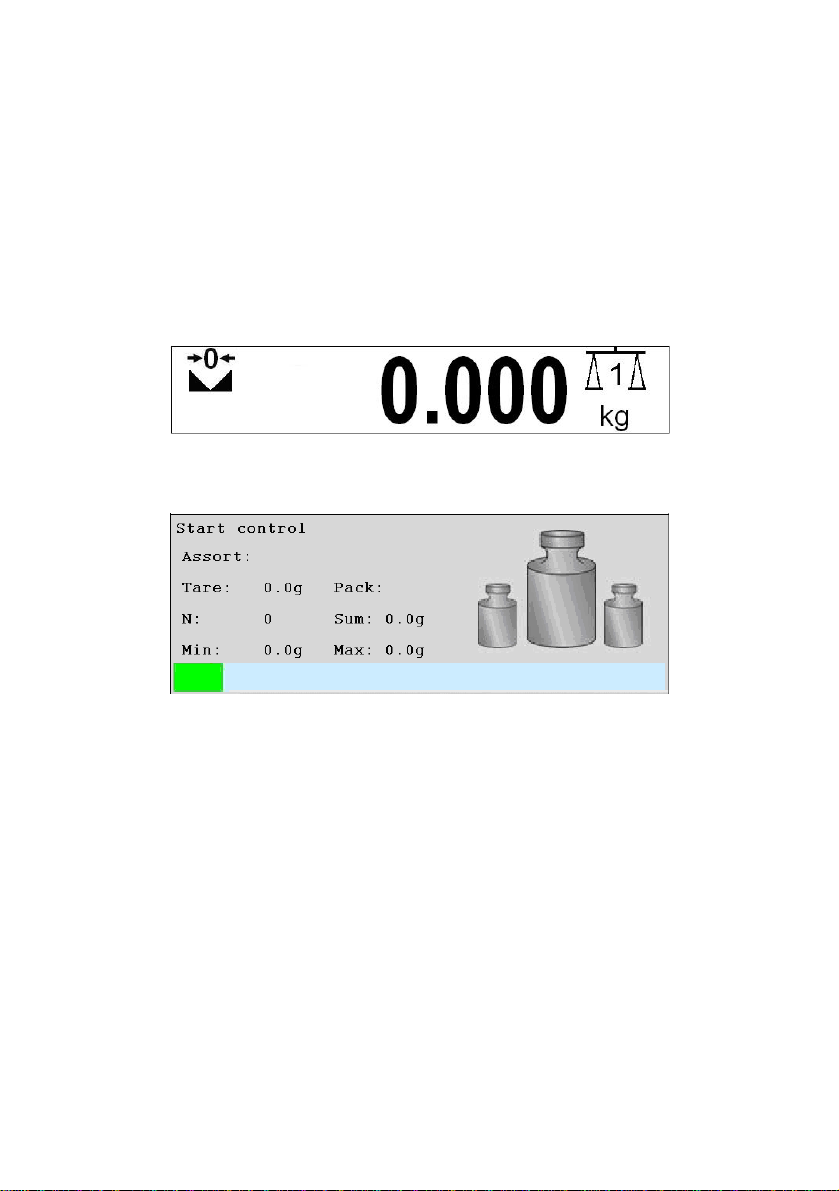

10. INDICATING WINDOW

Main view:

An option only for non-verified scale

24

Page 25

In the main application window one can see four separate parts:

• In the top part of the window there is a status bar where a work mode,

logged-in user and time&date are displayed and active connection with

a computer are displayed.

• Below the status bar you can see weighing window(s).:

• There is a workspace below this window:

Notice:

The workspace is freely programmable. The default pattern is

described in ch. 17.1.1 of this manual.

• There are screen buttons below the workspace:

Notice:

1. Users can define screen function buttons. See the procedure

in ch. 17.2 of this manual;

2. The number of buttons to be defined depends on the selected

operating mode i.e.:

25

Page 26

• In operating mode <Weighing> 9buttons are at ones disposal

displayed subsequently from 1 to 9 starting from the left side,

• In operating modes: <Counting pieces> or <Deviations> one

can define up to 7 screen buttons displayed subsequently from

1 to 7 starting from the left side. Two buttons on the right side

are attributed permanently to the modes mentioned above

because of the functions that are ascribed to them.

11. LOGGING ON

In order to have full access to user parameters and databases the user

should log on as an <Administrator>.

11.1. Logging in procedure

• While in the main window press <log in> on the top of the screen

and the window with operators attributed to <

• After entering <

Admin> a screen keyboard runs with editing

Admin> will appear,

window for inscribing a password,

• Type password „1111” and confirm by pressing

,

• The program returns to the main window and in the title bar you will

see <Admin> instead of <log in>.

11.2. Logging out procedure

• While in the main applilcation window press the name of a logged in

operator in the top bar on the screen to open the database of operators,

• Press logging out button situated in the top bar of the operators’

database window:

• The program returns to the main window and in the top bar the

operators name is substituted by <Log in>.

26

Page 27

11.3. Authorization access levels

Weighing software uses four access levels: administrator, advanced

operator, operator, none. Every user with any attributed access level

can perform weighings and select data from in databases to be used

during weighing.

Access to user parameters, databases and working modes depending

on the authorization access level attributed:

Operator type Access level description

None

No access to user parameters. No weighing can be confirmed.

Cannot start procedure „Comparison”. Cannot enter the reference

mass unit and estimate the reference mase unit by weiging in

„Counting Pieces” and „Deviations”. No access to <Export the

weighing database to a file> in menu <Databases>

Operator

Access to parameters in submenu: <Weighing>, <Display>

(excluding the group <Actions>), <Others>

1)

. Can start and

perform all weighing procedures. Access to <Export the

weighing database to a file> in menu <Databases>

Advanced

Operator

Administrator

Access to parameters in submenus: <Weighing>, <Working

modes>, <Communication>, <Devices>

<Others>

Access to <Export the weighing database to a file> in menu

<Databases>

1)

. Can start and perform all weighing procedures.

2)

.

1)

, <Display>1),

Access to all user parameters, functions and databases

Can start and perform all weighing procedures.

1. Authorization level for editing functions:

• < Printouts> in submenu „ Devices / Printer”,

• <

Sample> in submenu „ Devices /

Additional display”,

2)

.

1)

2)

.

2)

.

• <

• <

Displaying pattern> in submenu „ Display /

Text information”,

Date and Time> in submenu < Others>,

27

Page 28

It can be declared in submenu < Authorizations>, which is

accessable only for users with the <Administrator> authorization

level (see ch. 19 of this manual).

2. A user logged in as <Administrator> in submenu

<

Authorizations> (see ch. 19 of this manual) can change

authorization levels for accessing different databases and functions

Delete older data>. The exception are database

<

<

Weighings / Alibi>, that have the status „Read only”.

12. NAVIGATING WITHIN THE MENU

Owing to the colour display with the touch panel navigating within the menu

is simple and intuitive.

12.1. Buttons

Entering the main menu

Menu list „up”

Menu list „down”,

Scrolling „up-down”

Enter (OK)

Abort

Add a new item in a database

Disabeling the formerly selected record e.g. logging out the operator

Searching a database according to a date

28

Page 29

Searching a database according to a name

Searching a database according to a code

Printing on item from a database

Clearing an editing field

Screen keyboard on / off

Reading a printout pattern from a *.lb file

(active after connecting a pendrive)

Variables for a printout pattern

One level up

12.2. Return to weighing

The changes introduced are saved for good after they are

confirmed. Press

several times until the following

message box appears:

Press:

– to confirm changes or – to abort

changes. The program returns to weighing.

29

Page 30

13. WEIGHING

Put a load on the weight pan. When pictogram

indication is ready to read.

Notice:

A weighing can be saved after stabilising a measurement over zero

(pictogram

).

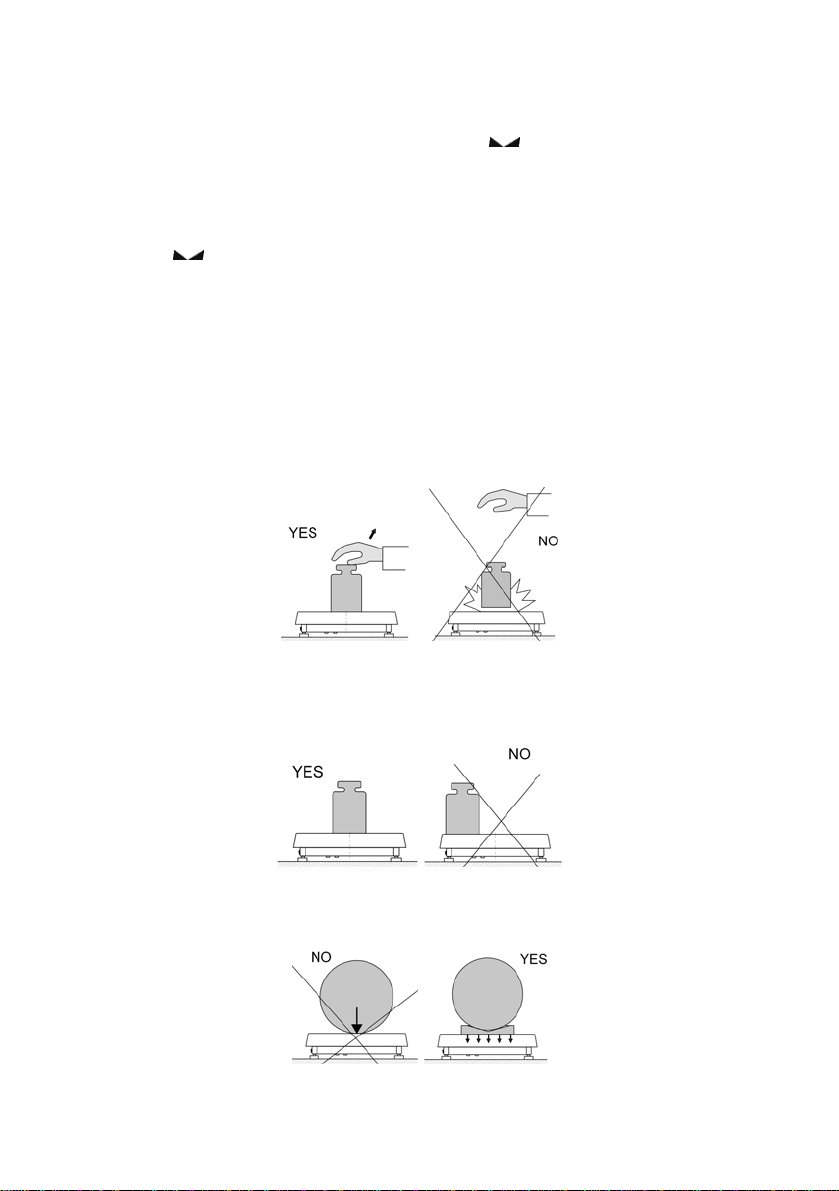

13.1. Conditions of operational use

In order to assure a long term operating period with appropriate

measurements following principles should be adhered to:

• Avoid applying mechanical shocks to the weight pan:

is displayed the

• Loads should be placed in the centre of the pan (eccentric errors

are outlined in PN-EN 45501 chapter 3.5 and 3.6.2):

• Do not apply concentrated forces (all load in one point):

30

Page 31

• Avoid side loads, particularly side strokes:

13.2. Zeroing

In order to zero the indication choose a platform on the touch panel and

press

following symbols usually appear:

Zeroing is possible only when the indication is stable.

Notice:

Zeroing is possible only within ±2% of full range around zero. If the

zeroed value is beyond the interval of ±2%, Err2 is displayed.

13.3. Tarring

In order to tare the scale choose a platform on the touch panel if necessary,

put a package on the pan and press

equal zero and following symbols usually appear:: Net and

After placing a load on the weight pan net mass will be shown. Tarring is

possible within the whole range of the scale. After unloading the pan the

display shows the tarred value with minus sign.

You can also inscribe tare values to the assortment database. Every product

has a field “Tare”. In that case tare is automatically set to this value after

selecting the product.

Notice:

Tarring cannot be performer when a negative or zero value is being

displayed. In such case Err3 appears on the display.

. After zeroing is performed the indication is equal zero and

and .

. You will see the indication

.

31

Page 32

13.4. Inscribing tare

It is possible to inscribe a tare value.

Procedure:

• While in any work mode press

,

then the screen keyboard is displayed,

• Inscribe tare and press

,

• The program returns to weighing and the and the display shows

the entered value with the „–” sign provided there was zero before

on the display.

13.5. Weighing for dual range scales

Switching between the I range and the II range happens automatically

(exceeding Max of the I range).

Weighings in the second range is signalled by a pictogram in the top left

corner of the display

of the II range to the moment of returning to zero (autozero range

. Then weighings is done with the accuracy

)

where the scale switches back to the I range.

Switching between the II range and I range is automatic both in the

switching point the autozero zone. While in AUTOZERO

– pictogram

appears. Then pictogram is off and a scale returns to

weighing in the I range.

13.6. Toggling between weight units

Operators can change the weight unit in two ways:

• Pressing the unit symbol on the screen,

• Pressing formerly defined button or proimity sensor < Change unit>.

32

Page 33

Notice:

The procedure of attributing functions to buttons and proximity sensors

is described in ch. 17.2 of this manual.

Possible selection:

• gram [g]

• kilogram [kg]

• carat [ct]

• pound [lb]

• ounce [oz]

• Newton [N]

14. SCALE PARAMETERS

Users can set the scale according to the ambient conditions (filtering level)

or own needs (autozero) and set the LO threshold for minimum load that

enables operation of some functions. This parameters are placed in

Weighing>.

<

In order to enter submenu < Weighing>, press

and then

: „ Parameters / Weighing / Platform 1”.

Notice:

Weighing parameters are directly related to a specific weighing platform,

so at the beginning the weighing platform should be selected for which

we want to set parameters.

Inventory of scale parameters:

Median Filter

Filter

Autozero

LO Threshold

33

Page 34

14.1. Median filter

The median filter is intended for eliminating short-lasting mechanical shocks.

Procedure:

• Enter <

<

Accessible settings:

Weighing> according to ch. 14 of the manual, select

Median Filter> and then set an appropriate value.

None - median filter is off

0.5, 1, 1.5, 2, 2.5 - filtering level to choose

14.2. Filter

This filter is intended to suppress continuous mechanical vibrations at the

cost of stabilization time.

Procedure:

• Enter <

<

Accessible settings:

Weighing> according to ch. 14 of the manual, select

Filter> and then set an appropriate value.

None, V.Fast, Fast, Average, Slow.

Notice:

The higher filtering level the longer stabilization time.

14.3. Autozero

The autozero function has been implemented in order to assure precise

indications. This function controls and corrects „0” indication.

While the function is active it compares the results continuously with

constant frequency. If two sequentional results differ less than the declared

value of autozero range, so the scale will be automatically zeroed and the

pictograms

and will be displayed.

34

Page 35

If AUTOZERO is disabled zero is not corrected automatically. However,

in particular cases, this function can disrupt the measurement process e.g.

slow pouring of liquid or powder on the weighing pan. In this case, it is

advisable to disable the autozero function.

Procedure:

• Enter < Weighing> according to ch. 14 of the manual, select

Autozero> and then set an appropriate value.

<

Accessible settings:

NO

YES

- Autozero off

- Autozero on

14.4. Minimum weight for different functions (LO)

Parameter <LO THRESHOLD> is associated with automatic weighing.

Next weighing will not be saved until the indication goes under the

THRESHOLD LO (net).

Procedure:

• After entering <

Threshold Lo> according to ch. 14 of this manual

a keyboard is displayed,

• Inscribe LO and confirm by pressing

.

15. COMMUNICATION

The scale can communicate with external devices via different ports:

• COM 1 (RS232),

•

•

•

The communication can be configured in parameters’ group

Communication>.

<

COM 2 (RS232),

Ethernet,

Tcp.

35

Page 36

In order to enter < Communication>, press and then:

„ Parameters / Communication”.

15.1. RS 232 settings Procedure:

• Enter < Communication> according to ch.15 of the manual, select

<

COM1> or < COM2>, and then set an appropriate value.

For RS 232 following parameters are accessible:

• Baud Rate - 4800, 9600, 19200, 38400, 57600, 115200 bit/s

• Data bits - 5, 6, 7, 8

• Stop Bit - No, 1, 1.5, 2

• Parity - No – Odd – Even – Mark – Space

15.2. ETHERNET setting Procedure:

• Enter < Communication> according to ch.15 of the manual,

select <

Ethernet> and then set an appropriate value.

Following settings are accessible for Ethernet:

• DHCP - Yes – No

• IP Address - 192.168.0.2

• Subnet Mask - 255.255.255.0

• Default gateway - 192.168.0.1

Notice:

The settings above are only for information purposes. Transmission

parameters should be matched to the local client network.

• After making changes press , then a new message is displayed:

<Restart to apply the changes>,

36

Page 37

• Go back to weighing saving parameters and restart the device.

15.3. TCP protocol setting

TCP (Transmission Control Protocol) is a protocol for communication

between two computers. It operates in mode client-server. Server awaits

on connection iniciation on a specified port while client initiates connection

to the server. Scale software allows setting the port for the „Tcp” protocol.

Procedure:

• Enter < Communication> parameter group as described

in chapter 16 of the manual,

• Select: „

with the screen keyboard,

• Enter the required number and press

16. DEVICES

16.1. Computer The scale can cooperate with a computer. Active connection scale-computer

Tcp / Port” then you will see window <Port>

.

is signalled by icon

Computer> some settings needs to be configured for cooperation

<

in the top bar of the main window. In submenu

with computers.

Enter submenu < Computer>, press and then:

„ Devices / Computer”.

16.1.1. Computer port Procedure:

• Enter parameters’ group < Devices> according to ch.

16 of this manual, select „

Computer / Port” and then

set the appropriate option.

37

Page 38

The scale can communicate with a computer via following ports:

• RS 232 (COM1),

• RS 232 (COM2),

• Tcp.

16.1.2. Computer address Procedure:

• Enter < Devices> parameter group as described in chapter

16 of the manual,

• Choose „

Computer / Address” then the window <Address>

with the screen keyboard appears,

• Enter the required address and confirm it by pressing

.

16.1.3. Continuous transmission

Users can enable continuous transmission from the scale to a computer.

Setting parameter <

sending data from <

„Setup /

Devices / Computer / Weighing Printout Pattern”.

Continuous transmission> starts subsequent

Weighing Printout Pattern> set in submenu:

Procedure:

• Enter parameters’ group < Devices> according to ch. 16 of this

manual,

• Choose „

Computer / Continuous transmission” and then

set an appropriate value.

Accessible settings:

No

Yes

- Continuous transmission off

- Continuous transmission on

38

Page 39

16.1.4. Weighing printout pattern

Users in parameter < Weighing Printout Pattern> can define variables

included in the printout from the scale to a computer.

Procedure:

• Enter < Devices> parameter group as described in chapter

16 of the manual,

• Choose „

Computer / Weighing Printout Pattern” then

the editing field <Weighing Printout Pattern> with the screen

keyboard appears,

• Modify the pattern if necessary and confirm the changes by pressing

.

Notice:

There are additional buttons in the bottom line of the screen keyboard.

They can be used while modifying a printout pattern.:

Screen keyboard on/off

Reading a printout pattern from a *.lb file (button active while

connecting a USB pendrive)

List of variables for printout patterns (see the list in APPENDIX A

of this manual)

Clear the editing field

16.1.5. Cooperation with „E2R System”

Scales can cooperate with computer software „E2R System” that is

a modular system for complex production supervising by monitoring

of weighings processes. In order to allow the cooperation with

„E2R System” enable parameter <

Notice:

The parameter <

E2R System> can be activated by an authorized

service or the manufacturer.

E2R System>.

39

Page 40

Procedure:

• Enter <

Devices> parameter group as described in chapter

16 of the manual,

• Choose „

Computer / E2R System / System is active”

and then set an appropriate value.

Accessible settings:

No

Yes

- System is not active

- System is active

• If during cooperation with < E2R System> product selection lock

is required for operators, go to parameter <

Lock selecting

products> and set its value to <Yes>.

16.2. Printer

In < Printer> submenu users can:

• Setting communication with a printer,

• Setting code page of a printer,

• Setting patterns of printouts.

To enter <

Printer>, press and then: „ Parameters /

Devices / Printer”

16.2.1. Printer port Procedure:

• Enter < Devices> parameter group as described in chapter 16

of the manual, choose „

Printer / Port” and then select an

appropriate option.

40

Page 41

Printers can be attached to:

• RS 232 (COM1),

• RS 232 (COM2),

• USB,

• Tcp.

16.2.2. Printer code page Procedure:

• Enter parameters < Devices> as described in chapter 16

of the manual,

• Choose „

Printer / Code Page” then the scre en keyboard

will be displayed,

• Write the required code page and confirm by pressing

.

Notice:

The default value is 1250 – code page for Middle-East Europe.

16.2.3. Patterns for printouts

Enter < Printouts> to define printout patterns.

Procedure:

• Enter parameter group < Devices> as described in chapter

16 of the manual, then choose „

Printer / Printouts”,

• After editing a pattern a memo box with the default content and the

screen keyboard,

• Modify the pattern according to your requirements and confirm it by

pressing

Notice:

.

There are additional buttons in the bottom line of the screen keyboard.

They can be used while modifying a printout pattern.:

41

Page 42

Screen keyboard on/off

Reading a printout pattern from a *.lb file (button active while

connecting a USB pendrive)

List of variables for printout patterns (see the list in APPENDIX A

of this manual)

Clear the editing field

Default printouts’ settings:

Weighing Printout Pattern {0}

Product Printout Pattern {50}

Cumulative Printout Pattern N={15} SUM={16}

Cumulative of Cumulative Printout Pattern N2={20} SUM2={21}

Operator Printout Pattern {75}

{51}

{76}

Contractor Printout Pattern {85}

Warehouse Printout Pattern {130}

Package Printout Pattern {80}

CPG report printout pattern

(Control of Packaed Goods)

Average tare report printout pattern

(Control of Packaed Goods)

*) Not related to „Comparator software”.

42

{86}

{131}

{81}

{82}

*

*

Page 43

16.3. Barcode scanner

Cooperating with a barcode scanner allows immediate finding of the product

in the assortment database the wanted product immediately. Configuration

of communication can be configured in <

Barcode reader>. Users can

set the following things:

• Communication port for a barcode scanner,

• Offset setting (a number of characters that are omitted while reading),

• Code length (number of characters that are analysed counting from

the offset).

Notice:

In submenu <

Communication> set the baud rate (default 9600b/sec).

The detailed description of cooperation scale – barcode scanner can be

found in APPENDIX F in this manual.

16.3.1. Port for barcode scanner Procedure:

• Enter < Devices> according to ch.16 of the manual, choose

„

Barcode reader / Port” and then set the appropriate value.

Barcode scanners can be connected to:

• RS 232 (COM1),

• RS 232 (COM2),

16.3.2. Offset

It outlines the first character that is significant for searching the assortment

database. All preceding characters are skipped.

Procedure:

• Enter < Devices> according to ch.16 of the manual,

• Choose „

Barcode reader / Offset” , then the screen

keyboard is displayed,

43

Page 44

• Write a new offset and confirm it by pressing .

16.3.3. Code length

Number of characters that is considered while searching the assortment

database.

Procedure:

• Enter < Devices> according to ch.16 of the manual,

• Choose „

Barcode Scanner / Code Length” then the screen

keyboard is displayed,

• Write a new length and confirm it by pressing

.

16.4. Transponder card reader

Selecting operator (logging in) can be done in two ways:

• Typing a password on a keyboard,

• Approaching a transponder card to the reader.

The card needs to be registerd first.

Notice:

In case of problems with reading transponder cards check the submenu

Communication> and set appropriate baud rate (default 9600b/s).

<

16.4.1. Com port for transponder card readers Procedure:

• Enter group of parameters < Devices> according to ch. 16

of this manula, select „

Transponder cards reader / Port”

and set appropriate option.

44

Page 45

The scale can communicate with the reader via following ports:

• RS 232 (COM1),

• RS 232 (COM2).

16.4.2. Procedure of attributing the card number to an operator

To use a transponder card to log on an operator the card needs to be

ascribed to the operator in the database of operators.

Procedure:

• Connect the transponder card reader to the required communication

port (RS 232 COM1 or RS 232 COM2),

• Choose a communication port for the reader (see ch. 16.4.1 in this

manual),

• In submenu <

as in the reader (default 9600b/s),

Communication> set the baud rate to the same

• Enter the database of operators and edit the selected operator going

to the field <

• After entering the field <

field <Card Number> with the screen keyboard,

Card Number>,

Card Number> you will see the editing

• Having approached the card to the reader the program automatically

displays in editing field <Card Number> the number of read card,

• Confirm the number by pressing

and return to weighing.

16.5. Additional display

16.5.1. Additional display port Procedure:

• Enter parameters group < Devices> according to ch. 16

of this manual, select „

Additional display / Port”

and then choose an appropriate option from the list.

45

Page 46

Communication with additional displays can be performed via following

ports:

• RS 232 (COM1),

• RS 232 (COM2),

• Tcp.

16.5.2. Communication protocol frame

PUE 7 weighing indicator with following displays:

• WD display,

• WWG display.

To start cooperation of PUE 7 with displays go to parameter <

Sample>

and define an appropriate communication protocol.

Procedure:

• Enter parameters’ group < Devices> according to ch. 16 of this

manual,

• Choose „

<Sample> with the screen keyboard appears,

Additional display / Sample” then the editing field

• Inscribe the required frame pattern using the screen keyboard or

choose the it from the list after pressing

.

Specified patterns for displays:

{141}

{142}

- Protocol pattern for WD displays

- Protocol pattern for WWG display

• Confirm the changes by pressing .

Notice:

In default settings parameter <

Sample> has ascribed {141}

(WD display).

46

Page 47

17. DISPLAY

Users can adapt the main display and visible information to their needs.

All parameters of the display can be found in the parameters’ group

Display>.

<

Entering <

• Direct pressing in the work area of the main display,

Display> can be made in two ways:

• Pressing and then: „ Parameters / Display”.

Inventory of parameters of the main display:

Text information

Buton functions

Show all platforms

Bargraph Type

17.1. Text strings

In < Text information> users can set:

Display pattern

Screen font

Font size

Bold font

47

Page 48

17.1.1. Display patterns

The main application window comprises a work area inclu ding information

that can be freely configured by a user.

Procedure:

• Enter < Display> according to ch. 17 of this manual,

• Choose: „

Text information / Displaying pattern”, then an

editing field with prompted value is displayed together with the screen

keyboard,

• Modify the pattern if necessary and confirm the changes by pressing

.

Notice:

There are additional buttons in the bottom line of the screen keyboard.

They can be used while modifying a display pattern. :

Screen keyboard on/off

Reading a display pattern from a *.lb file (button active while

connecting a USB pendrive). *.lb files with the default patterns

of display in every language version are accessible on the CD

attached to the device

List of variables for display patterns (see the list in APPENDIX A

of this manual)

Clear the editing field

Default display pattern:

Assort: {50}

Tare: {9}{11} Pack: {80}

N: {15} Sum: {16}{10}

Min: {12}{10} Max: {13}{10}

Series: {14}

48

Page 49

17.1.2. Screen font

The font type can be changed in the display workspace.

Procedure:

• Enter < Display> according to ch. 17 of this manual,

• Choose: „

Text information / Font” and set the required font

type.

Accessible fonts:

• Arial,

• Courier.

17.1.3. Font size

Setting the font size for the workspace in the display.

Procedure:

• Enter < Display> according to ch. 17 of this manual,

• Choose: „

Text information / Font size and set the required

font size.

Accessible sizes:

• small,

• Average,

• Large.

17.1.4. Bold fonts

Setting bold fonts in an area of the workspace of the display.

Procedure:

• Enter < Display> according to ch. 17 of this manual,

49

Page 50

• Choose: „ Text information / Bold” and choose a setting.

Accessible settings:

NO

YES

- Bold is off

- Bold is on

17.2. Function keys

In submenu < Actions> users can set actions following keys:

function keys,

screen keys,

proximity sensors.

If a button has been attributed a function it has been activated at the same

time. If a button or sensor has no ascribed a function in stays inactive.

Procedure:

• Enter < Display> according to ch. 17 of this manual,

• Choose <

Buton functions> and choose a required setting for

a choosen button: F1, F2, F3, 9 screen buttons or proximity sensors.

Notice:

The list of functions that can be attributed to keys or buttons is listed

in APPENDIX B of this manual.

17.3. Displaying platforms

If a terminal is equipped with two platforms users can switch between

platforms in three ways:

• By pressing the platform number on the scale screen,

50

Page 51

• By pressing a formerly defined button or proximity sensor

<

Change platform>.

• By activating in parameters all platforms that will be separately

placed in the main window of the program. In that case platforms

can be activated by pressing the area of this platform.

Notice:

The procedure of attributing functions to buttons and proximity sensors

is described in ch. 17.2 of this manual;

To activate all platforms press , choose:

„ Parameters / Display / Show all platforms”, and set

appropriately.

- Displaying all platforms disabled

NO

YES

- Displaying all platforms enabled

17.4. Bargraph type

A bargraph is a typical visualisation procedure. It helps in quick weighing.

It requires less concentration to read if a weighing is between minimum

and maximum thresholds.

To see the bargraph on the screen enable it in parameters.

Procedure:

• Enter < Display> according to ch. 17 of this manual,

• Choose <

Bargraph type> and set the required bargraph type.

Accessible bargraphs:

• Quick weighing,

• None (Bargraph is not displayed),

• Signalling checkweighing ranges.

51

Page 52

17.4.1. Bargraf “Quick weighing”

• The bargraph consists of 8 red fields and three green fields.

• The green fields signal weighings between MIN and MAX

threshold, where:

MIN = the minimum threshold of acceptable weighing - LO

MAX = the maximum threshold of acceptable weighing - HI

• If a measurement is over the MIN (to the value of 1/3 of MIN-MAX) the

green field with a triangle on the left is visible. If the measurement is

between 1/3 and 2/3 of MIN-MAX the rectangular green field is visible.

If the measurement is between 2/3 of MIN-MAX and MAX a green field

with a triangle on the right is visible.

• If the mass value is below the MIN threshold red fields with red arrows

on the left are visible. The lower mass value the more red arrows are

visible.

• If the mass value is over the MAX threshold red fields with red arrows

on the right are visible. The higher mass value the more red arrows

are visible.

Thresholds MIN and MAX are on the borders between red and green fields.

17.4.2. Bargraph “Signalling checkweighing ranges”

• This type of bargraph comprises one green and 2 red fields.

• The left red field – signals that the load on the pan is lower than

the minimum weighing threshold (Min threshold);

52

Page 53

• The central green field – signals that the load on the pan is within the

set required interval for the weighed product (OK value between Min

and Max thresholds);

• The right red field – signals that the load on the pan is greater than

the maximum weighing threshold (Max threshold).

18. INPUTS / OUTPUTS

WPY/KB scales are equipped with 4 inputs / 4 outputs. To adjust software

to the users needs configure inputs outputs in the submenu

Inputs / Outputs>:

<

• indicator inputs,

•

In order to enter submenu < Inputs / Outputs>, press

indicator outputs.

and then

: „ Parameters / Inputs / Outputs”.

18.1. Configuration of inputs Procedure:

• Enter < Inputs / Outputs> according to ch. 18 of this manual,

• Choose < Inputs> and enter the selected input you will see

a list of functions to ascribe,

• Choose the required function from the list and return to weighing

saving the changes according to ch. 12.2 of this manual.

Notice:

The list of functions to ascribe to inputs are described in APPENDIX B

of this manual. By default inputs have no ascribed functions <None>.

53

Page 54

18.2. Configuration of outputs

Ascribing a function to the output enables the output at the same time.

If an output has no ascribed function it is disabled.

Procedure:

• Enter < Inputs / Outputs> according to ch. 18 of this manual,

• Choose < Outputs> and enter the required output, then you

will see the list of functions:

None

Output disabled

Stabile

MIN stable

MIN non-stable

OK stable

OK non-stable

MAX stable

MAX non-stable

Confirmation of

cycle completion *

Stable weighing result over LO threshold value

Stable weighing result below the MIN threshold

Non-stable weighing result below the MIN threshold

Stable weighing result between MIN and MAX

thresholds

Non-stable weighing result between MIN and MAX

thresholds

Stable weighing result over the MAX threshold

Non-stable weighing result over the MAX threshold

Signal that confirms that a cycle of dosing has been

completed (the defined amount)

*) Not applicable to „Comparator” software.

• Choose the required function from the list and return to weighing saving

the changes according to ch. 12.2 of this manual.

Notice:

By default all outputs have no function attributed – setting <None>.

54

Page 55

19. AUTHORIZATION

The submenu < Authorization> is accessible only while being logged

in as the Administrator. In this group of parameters access levels can be

outlined.

To enter submenu < Authorization>, press and then:

„ Parameters / Authorization”.

19.1. Anonymous Operator

The program allows to attribute the authorization access level to an operator

who does not perform the log-in procedure (anonymous operator).

Procedure:

• Enter < Authorization> according to ch. 19 of this manual,

choose <

Anonymous Operator>, and then set the

authorization access level.

Accessible authorization levels:

None, Operator, Advanced Operator, Administrator.

19.2. Date and time

Default settings allow a logged-in Administrator to change settings of date

and time. Software however allows to change the access level to this option:

Date and time>.

<

Procedure:

• Enter parameters’ group < Authorization> according to ch.

19 of the manual, choose <

Date and time>, and then set

the parameter.

55

Page 56

Accessible authorization levels:

None, Operator, Advanced Operator, Administrator.

Notice:

Setting <None> allows free access to settings of date and time

(without the need of logging in).

19.3. Printouts

Default settings of the scale allows a logged on Administrator to edit

printout patterns. Software allows to change the access level to option

Printouts>.

<

Procedure:

• Enter parameter group < Authorization> according to ch. 19

of this manual, choose <

Printouts>, and set appropreately.

Access levels to printouts that can be set:

None, Operator, Advances Operator, Administrator.

Notice:

When you choose setting <None> printout patterns can be changed

even without logging on.

19.4. Databases

It is possible to set the access levels to the following databases:

• Database of Products,

• Database of Contractors,

• Database of Packages,

• Database of Warehouses,

• Database of Labels.

56

Page 57

Procedure:

• Enter parameters’ group < Authorization> according to ch. 19

of the manual, choose <

Databases>, and then set the parameter.

Accessible authorization levels:

None, Operator, Advanced Operator, Administrator.

Notice:

Setting <None> allows free access to settings of date and time

(without the need of logging in).

19.5. Delete older data

Default settings allow a logged-in Advanced Operator delete older data

from the <

to change the access level to this option: <

Weighings / Alibi> database. Software however allows

Delete older data>.

Procedure:

• Enter parameters’ group < Authorization> according to ch. 19

of the manual, choose: „

Databases / Delete older data”,

and then set the parameter.

Accessible authorization levels:

None, Operator, Advanced Operator, Administrator.

20. OTHER PARAMETERS

There is a group of parameters different from others which influence the

operation of the scale. They are gathered in group <

language, beep etc. To enter <

„

Parameters / Others”.

Others>, press and then:

57

Others> e.g.

Page 58

20.1. Languages Procedure:

• Enter submenu < Others> according to ch. 20 of this manual,

choose <

Language> and set the parameter.

Accessible languages:

• Polish,

• English,

• German,

• French,

• Russian,

• Spanish,

• Czech,

• Hungarian.

20.2. Setting date and time

Users can set date and time that are visible in the main window of the