Page 1

User Manual

E2R WEIGHING RECORDS Software

Manual number:

ITKU-56-01-01-11-A

MANUFACTURER OF ELECTRONIC

WEIGHING INSTRUMENTS

RADWAG Wagi Elektroniczne, 26–600 Radom 28 Bracka Street - POLAND

Tel. +48 48 38 48 800, tel/fax. +48 48 385 00 10

Sales Department +48 48 366 80 06

www.radwag.com

Page 2

TABLE OF CONTENTS

1. GENERAL INFORMATION..................................................................................4

1.1. Intended use.................................................................................................4

1.2. Database.......................................................................................................5

1.3. System requirements....................................................................................5

1.4. Scales cooperating with the system..............................................................6

2. SOFTWARE INSTRUCTION................................................................................7

2.1. Databases.....................................................................................................7

2.2. Installation of E2R Weighing Records...........................................................7

3. E2R SYNCHRONIZER.......................................................................................10

3.1. RADWAG Synchronizer – Windows Service...............................................11

3.2. Adding new scales to the Synchronizer......................................................13

3.3. Deleting and editing of existing scale..........................................................16

3.4. Global settings and scale settings...............................................................16

4. E2R MANAGER..................................................................................................19

4.1. Setting connection to Radwag Synchronizer...............................................20

4.2. Show / hide the panel of connection with server.........................................21

5. E2R WEIGHING RECORDS ..............................................................................21

5.1. Starting program.........................................................................................21

5.2. Main program window.................................................................................22

5.3. Program settings.........................................................................................23

5.3.1. Database.............................................................................................24

5.3.2. Updating the database........................................................................25

5.3.3. Connection configuration.....................................................................25

5.3.4. Connection checking...........................................................................26

5.3.5. Authorization and groups of users.......................................................26

5.3.6. Service settings ...................................................................................28

5.4. Other settings..............................................................................................29

5.4.1. Changing the active window................................................................29

5.4.2. Language change ...............................................................................29

5.4.3. Program appearance ..........................................................................29

5.4.4. Logging out .........................................................................................30

5.4.5. Closing program..................................................................................30

5.5. Working window of the program..................................................................31

5.5.1. Sorting information..............................................................................31

5.5.2. Additional filtering options ...................................................................31

5.5.3. Filter creator........................................................................................33

2

Page 3

6. DATABASES......................................................................................................37

6.1. Assortment..................................................................................................37

6.1.1. Adding / editing assortments...............................................................38

6.1.2. Deleting product..................................................................................39

6.1.3. Searching and filtering assortments....................................................39

6.1.4. Reports from Products........................................................................40

6.2. Contractors .................................................................................................40

6.2.1. Adding / editing contractors.................................................................41

6.2.2. Deleting contractors............................................................................42

6.2.3. Filtering and searching contractors .....................................................42

6.2.4. Reports from Contractors....................................................................43

6.3. Stocks.........................................................................................................43

6.3.1. Adding / changing stocks ....................................................................44

6.3.2. Deleting a stock...................................................................................44

6.3.3. Filtering and searching stocks.............................................................45

6.4. Packagings .................................................................................................45

6.4.1. Adding / changing packagings ............................................................46

6.5. Operators....................................................................................................47

6.5.1. Adding / changing operators ...............................................................48

6.5.2. Deleting operators...............................................................................49

6.5.3. Filtering and searching operators........................................................49

6.5.4. Reports from operators.......................................................................49

7. MODULE WEIGHING RECORDS – Reports ....................................................49

7.1. The main window in E2R Weighing Records ..............................................49

7.2. Raport for the Materials...............................................................................52

7.3. Report for Operator.....................................................................................52

7.4. Report for Cooperants.................................................................................53

7.5. Report for Batch Number............................................................................54

7.6. Report for the Balance................................................................................55

7.7. Header and Report Title..............................................................................56

7.8. Archive Weighings ......................................................................................57

8. TOOLS...............................................................................................................58

8.1. Scale Restart ..............................................................................................58

3

Page 4

1. GENERAL INFORMATION

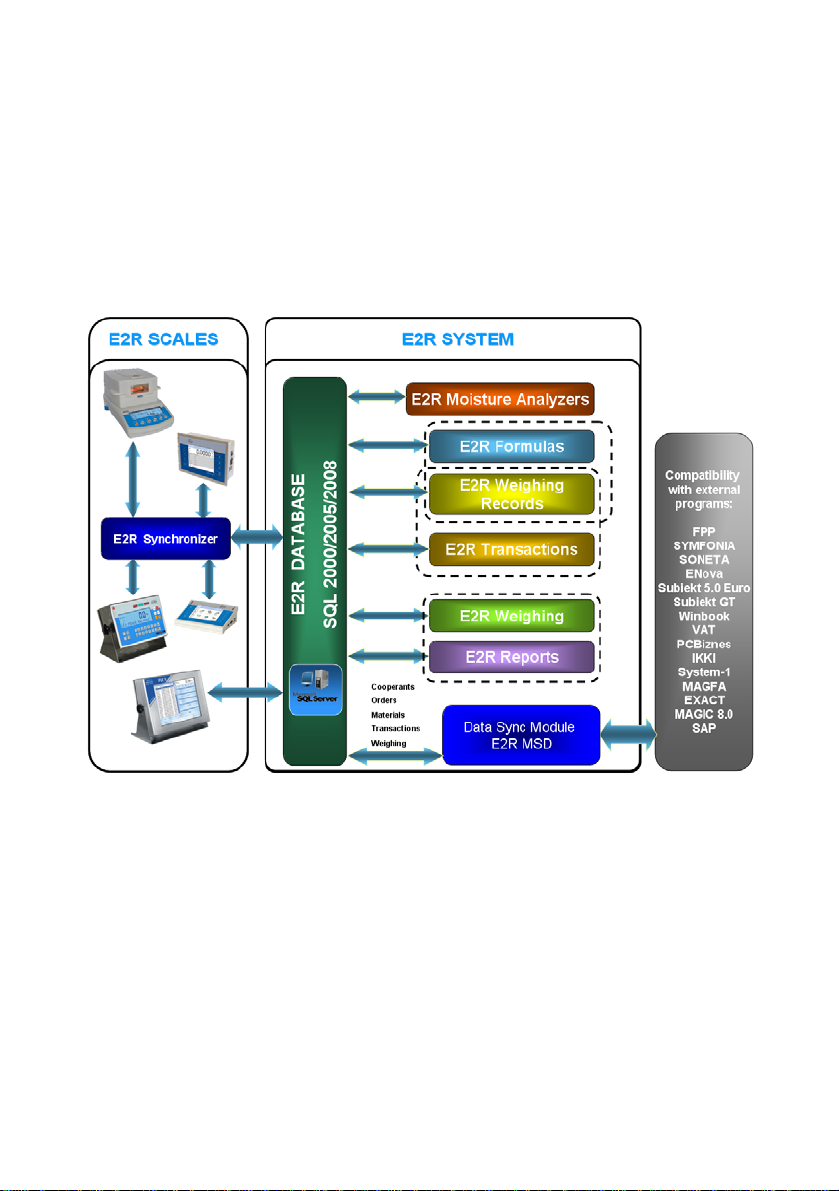

1.1. Intended use E2R System is a modular system for complex management of production

processes that are associated in some points with weighing. Owning to the

modular structure the system is versatile and can be easily tailored to the

profile, characteristics and needs of a firm as well as individual customer

requirements.

E2R SYSTEM

Module E2R Weighing Records is intended to recording weight

measurements performed on RADWAG weighing terminals, which work

connected in the Ethernet network, and saving them in the computer

database.

4

Page 5

The network of scales can be combined with one or more types of scales.

E2R SYSTEM based on Ethernet

The program allows for full supervision and reporting from measurements

collected from scales WPW, TMC, TMX, WLY, WPY.

Notice:

1. Due to continual updates, there is a possibility of minor discrepancies

between the contents of this manual and the program.

2. RADWAG takes no responsibility for the unexpected effects of program

operation, and possible consequences resulting from wrong use of the

program.

1.2. Database

The engine of installed database can be any distribution of MS

SQL Server (MS SQL 2000/2005/2008). Due to the performance,

scalability and reliability of the system it is recommended to use a

commercial platform SQL Server, e.g.: SQL Server 2008.

1.3. System requirements

The minimum requirements for the program:

• Windows 2000/XP/ 2003/Vista/Windows7 operating system,

5

Page 6

• processor 2 GHz or faster,

• minimum 1 GB RAM (recomended 2 GB),

• minimum 5 GB of free space on HD,

• monitor and graphic card allowing for resolution at least 1024x768

pixels,

• DVD drive,

• Default system font size (96 dpi)!

Notice:

1. It is advisable not to install other applications on the computer with E2R

system.

2. If the program is to be installed on a computer that is not delivered,

together with installed software, by RADWAG (customer ownership),

take following steps:

• install SQL server on your computer (if it has not been installed

before),

• connect databases (is SQL server is installed).

3. If the program has been installed on a customer’s computer any

resulting hardware and software problems are of the user (computer

owner) concern.

4. RADWAG takes no responsibility for:

• Any influence of E2R system and/or SQL server on operation of

other programs installed on the same computer,

• Any malfunctions of E2R system and/or SQL server cosed by

operation of other programs installed on the computer (system

overload).

1.4. Scales cooperating with the system

Program E2R Weighing Records, considering the communication

protocol, can cooperate only with scales manufactured by RADWAG.

Following series of scales can cooperate with this program: WPW, TMX,

WLY and WPY.

6

Page 7

Before starting cooperation with the program, each scale requires setting

adequate user parameters for assuring the expected measurement

accuracy and appropriate cooperation with the program. Setting

parameters for each scale is described in user manuals.

2. SOFTWARE INSTRUCTION

2.1. Databases

As a database engine can be used any distribution of MS SQL Server (MS

SQL 2000/2005/2008). The database of E2R System is created during

installation of E2R Weighing Records.

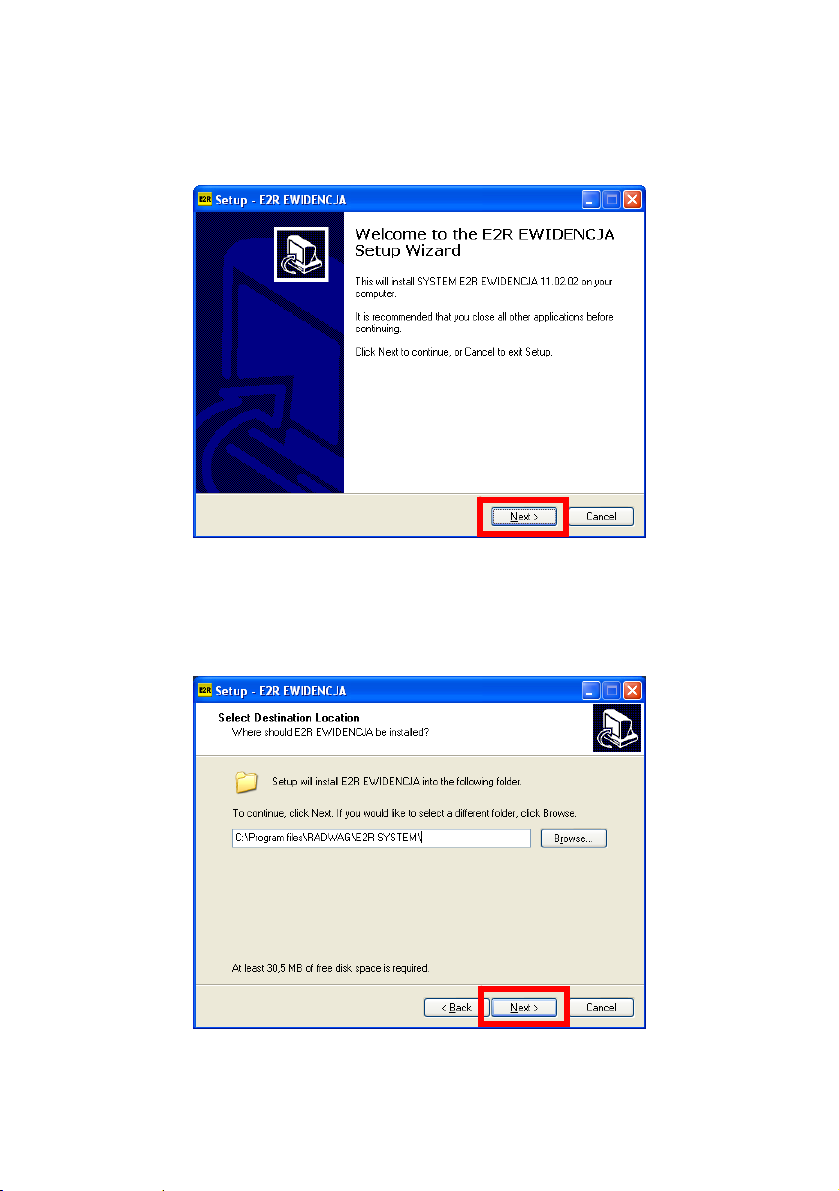

2.2. Installation of E2R Weighing Records This instruction comprises description of version „System E2R Weighing

Records 11.02.02”.

After running the file the following dialogue window appears with the

possibility of choosing the language to be used during the installation:

Choose the language and press „OK”.

7

Page 8

In further steps follow the instructions displayed in subsequent windows.

Welcome window:

In order to continue press „Next”.

Window with installation path:

8

Page 9

Choose a folder for program (it is advisable to keep the default path),then

press „Next”.

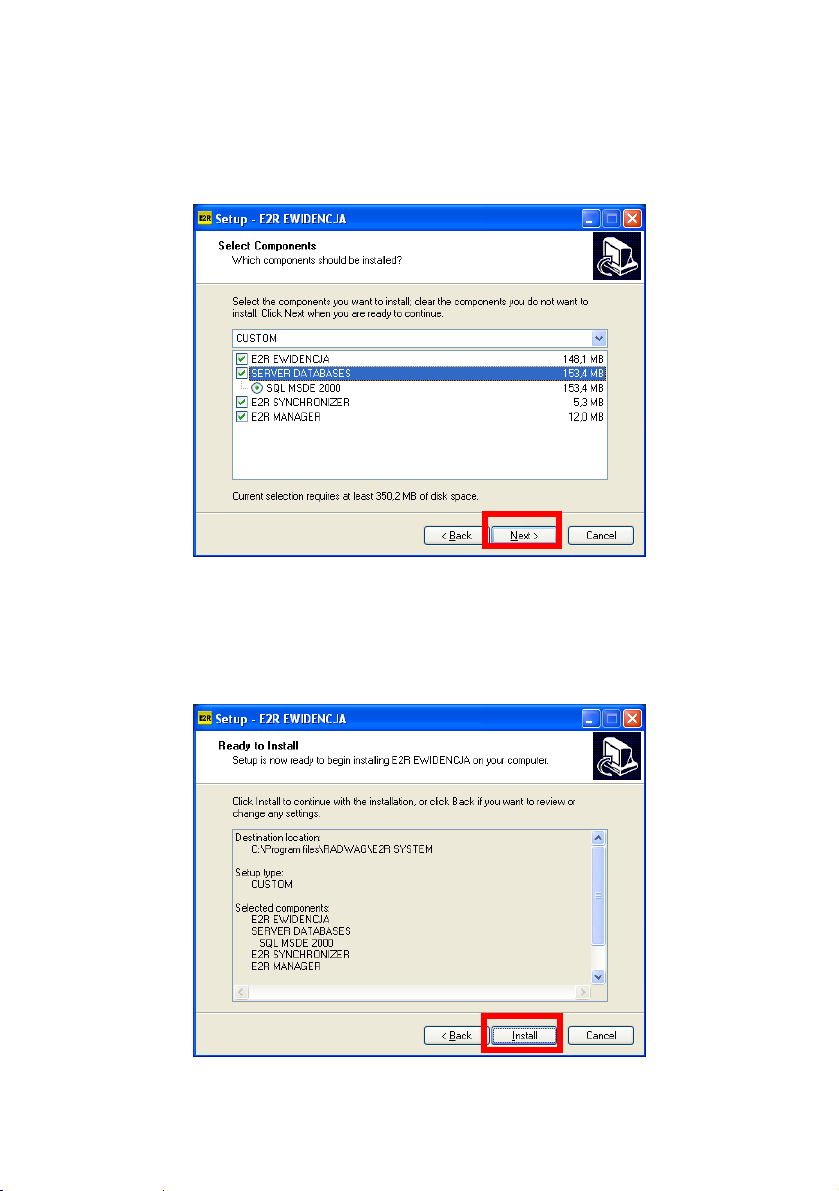

Window for selecting components to be installed:

Choose components you want to install (all elements needed for

appropriate operation are ticked), and then press „Next”.

Ready-to-install window:

9

Page 10

In order to start the installation process press button „Install”.

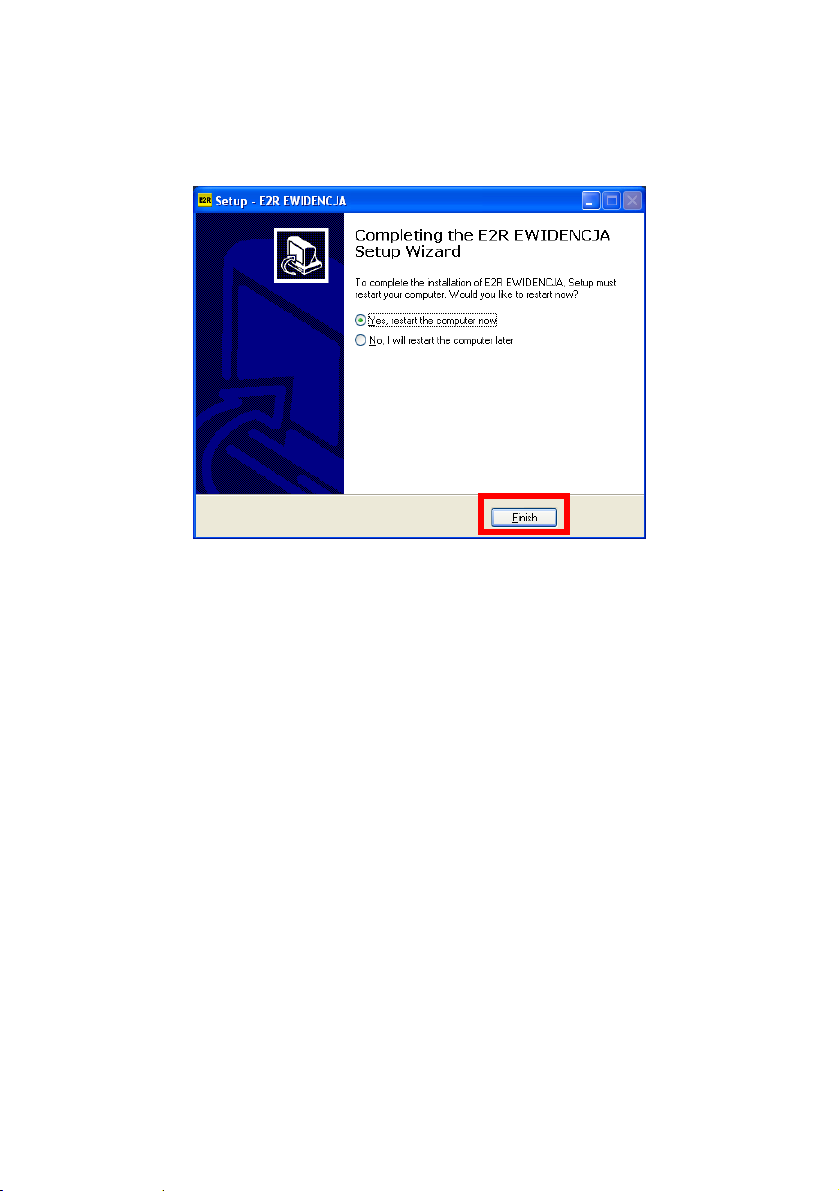

Completing installation window:

After the installation is completed the computer restart is required and the

option is selected by default.

Press button „Finish” in order to complete the installation.

Together with the program are installed: database of E2R System (SQL

base), „E2R Synchronizer” and „E2R Manager”.

3. E2R SYNCHRONIZER

Program E2R Synchronizer is designed for saving registered weighings in

the MS SQL database and monitoring scales based on terminals other

than PUE5 (e.g. PUE C41, PUE 7).

The program operates as a service – if properly configured it does not

require any user intervention. It is run automatically by starting operating

system (no user logging in is required). After establishing connection with

the indicated database collects data with choosen scales.

10

Page 11

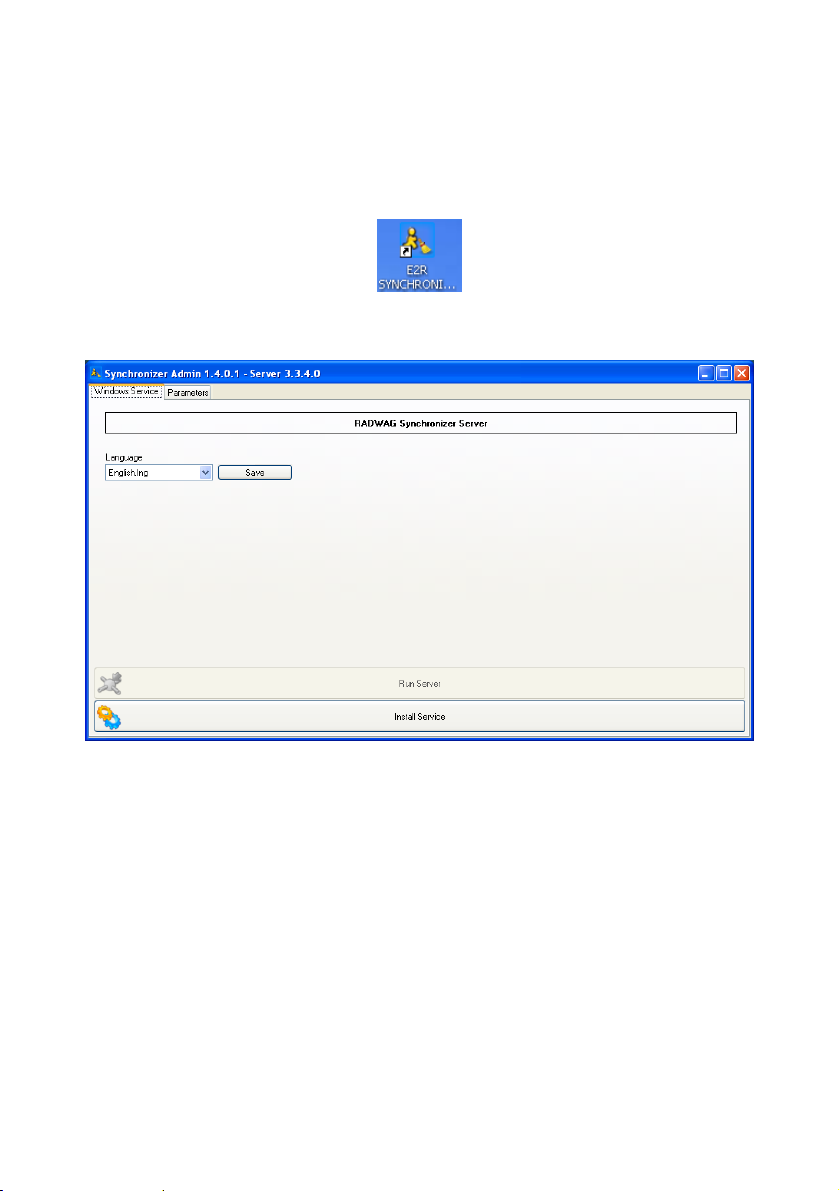

3.1. RADWAG Synchronizer – Windows Service

In the main window of E2R SYNCHRONIZER (SynchAdmin.exe), a button

for changing the language and configuring the Radwag Synchronizer

sercice is accessible.

Main program window:

In the title bar of the window there is information about of programs that are

parts of „RADWAG Synchronizer”.

Description:

Install Service Before running RADWAG Synchronizer the

service needs to be installed in MS Windows

operating system.

Uninstall Service Uninstalling the service RADWAG Synchronizer

from MS Windows

Run Server Running the service server RADWAG

Synchronizer

11

Page 12

Stop Server

Stopping the server responsible for communication

with scales.

Language

Language selection window. Accessible languages

Polish, English, German and Spanish. After the

language change program restart is required.

Save Saving language change. Caution! The language

change will be applied after program restart.

Notice:

In case of any problems with the service it should be stopped and

uninstalled. Meanwhile a test program can be used C:\RADWAG\E2R

SYSTEM\E2R EWIDENCJA\E2R SYNCHRONIZER\SynchServer.exe. It

is also a service. But only one of the programs can opperate.

If the „Windows Firewall” is enabled the program needs to be unlocked

after the first program start.

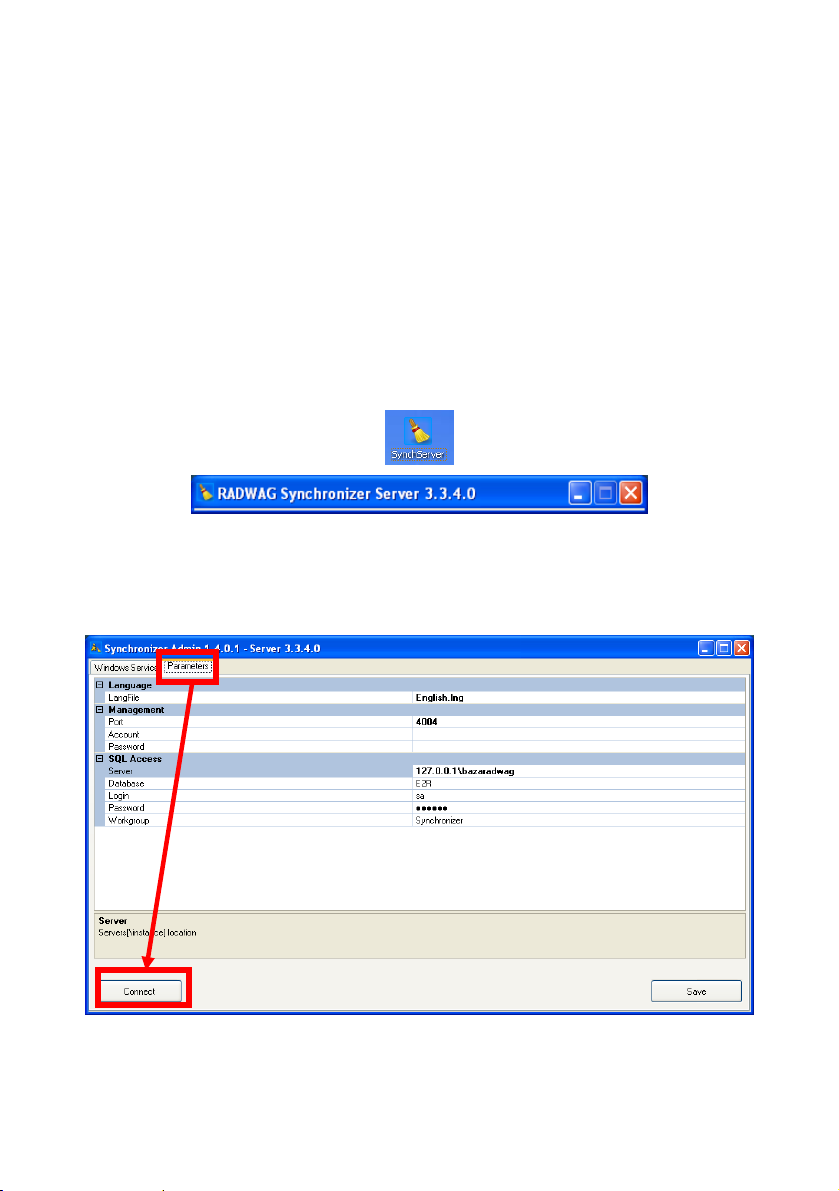

After starting the program go to overlap „Parameters”.

Connect to the database by pressing button „Connect” to configure

scales.

12

Page 13

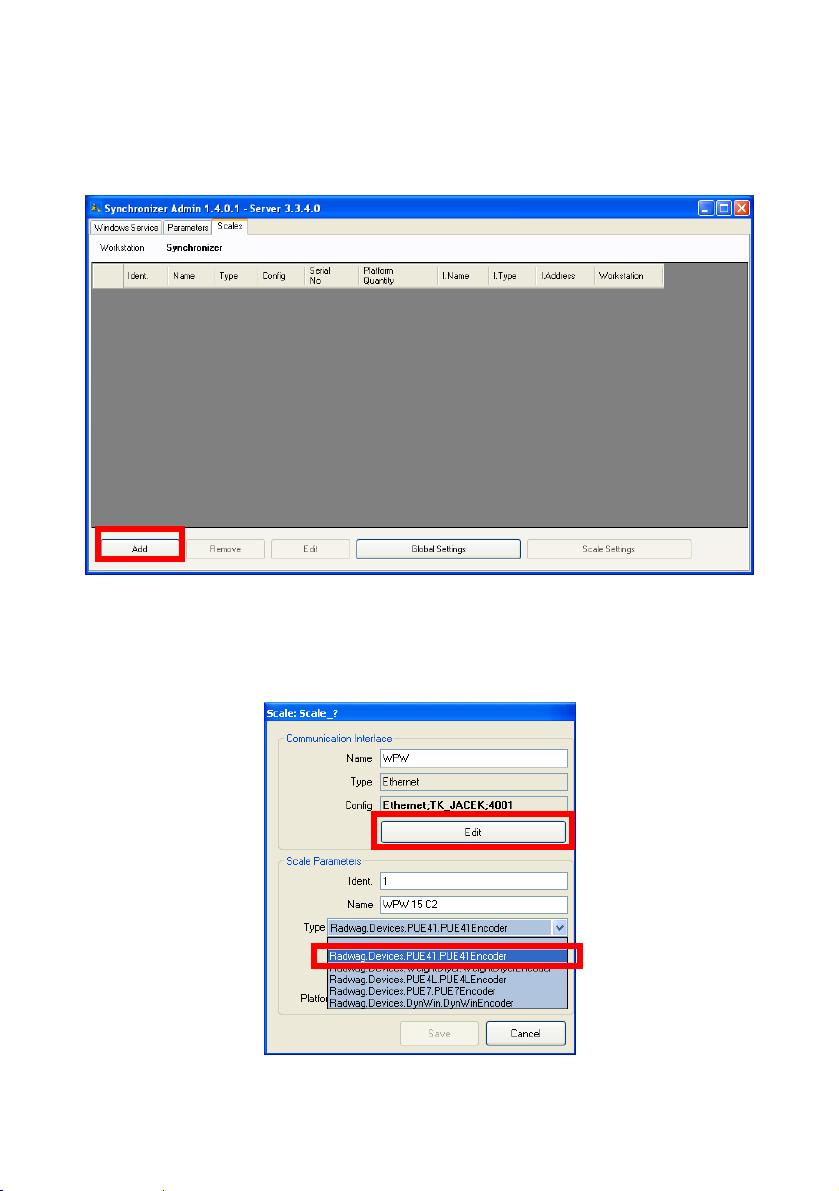

3.2. Adding new scales to the Synchronizer

After connecting to the database adding new scales to the Synchronizer on

overlap „Scales” is possible. Press button „Add” to add a new scale.

Then a scale window appears which needs to be filled in according to the

example below. Adding an new scale is shown on the scale WPW.

Identically can be added other scales that can cooperate with „E2R

System”.

13

Page 14

Scale settings:

Name

Type

Config

Edit

Ident.

Name

Type

Any interface name

Field to display interface type (serial, Ethernet)

Field to display interface configuration

Button for interface edition

Scale identification number (numerical field)

Any scale name

Types of conection with scales:

• Radwag.Devices.PUE41.PUE41Encoder – connection

with indicator PUEC41H

• Radwag.Devices.WeightDryer.WeightDryer

Encoder – connection with moisture analyser MAX

• Radwag.Devices.PUE7.PUE7Encoder – connection with

indicator PUE 7

• Radwag.Devices.PUE4L.PUE4LEncoder – connection

with indicator PUE4L

Serial No.

Adress

Platform

Quantity

Scale serial number

Scale address (set in the scale)

Platform Number

For scales with WPW indicators „Type” choose an appropriate setting:

Radwag.Devices.PUE41.PUE41Encoder.

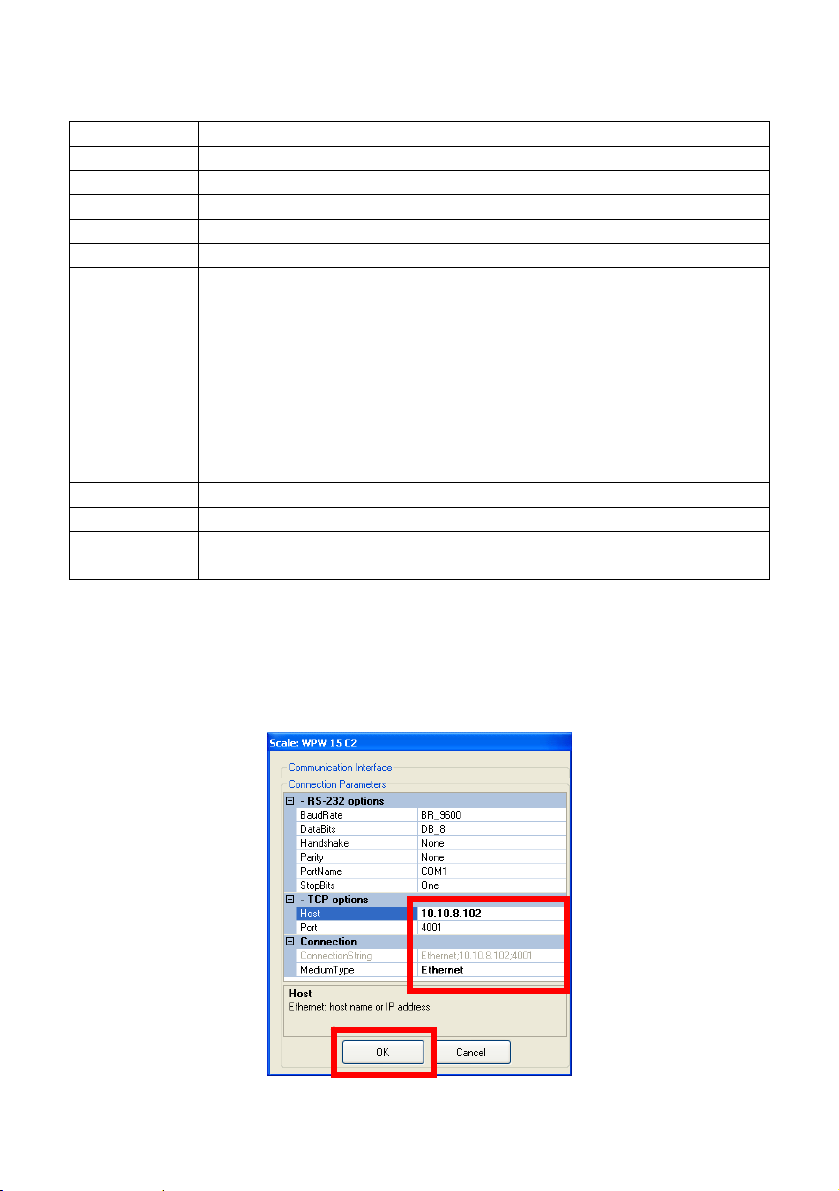

Press button „Edit” to see a window for setting parameters of the

communication interface with the scale.

14

Page 15

Interface settings:

MediumType

Connection type (None – no connection,

Serial – scale connected via RS232,

Ethernet – scale connected via Ethernet)

ConnectionString

String of characters with encoded

configuration parameters

Host

Name or IP of remote host (for Ethernet

connections) – scale IP on which the

Synchronizer server runs.

Port Remote host port (default 4001)

BaudRate

Baud rate of RS232 (default for moisture

analysers 9600 bps, for WPW and PUE7 set

115200 bps)

DataBits Number of data bits (default DB_8)

Handshake

Device presence and transmission

acknowledge (default None)

Parity Parity check (default None)

PortName

StopBits Number of stop bits (default One)

Notice:

Communication port number

All of the above settings need to be compared with settings in scales and

the system settings of the communication port in MS Windows.

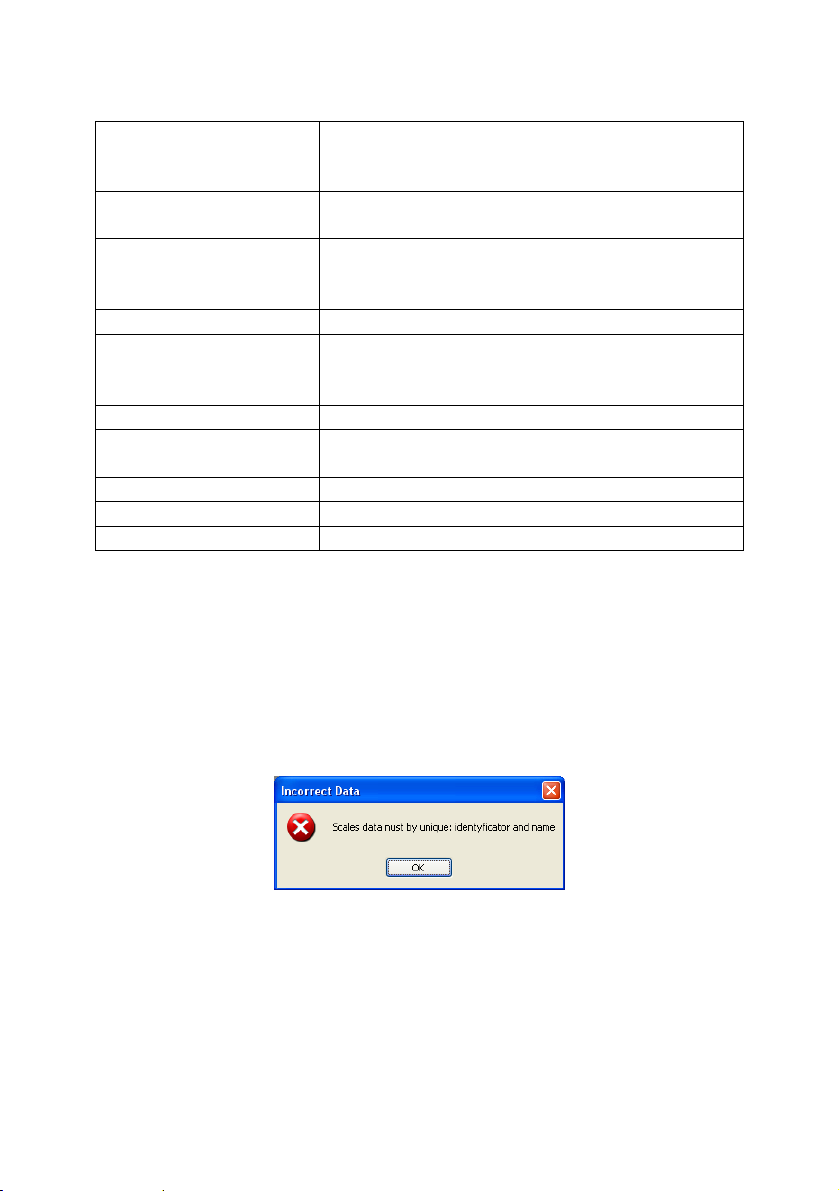

If adding a scale (after pressing „Save” in the window for adding scale)

triggers the message box below it means that the scale identifier already

exists in the database.

Then the Identifier needs to be changed and saved again by pressing

„Save”.

15

Page 16

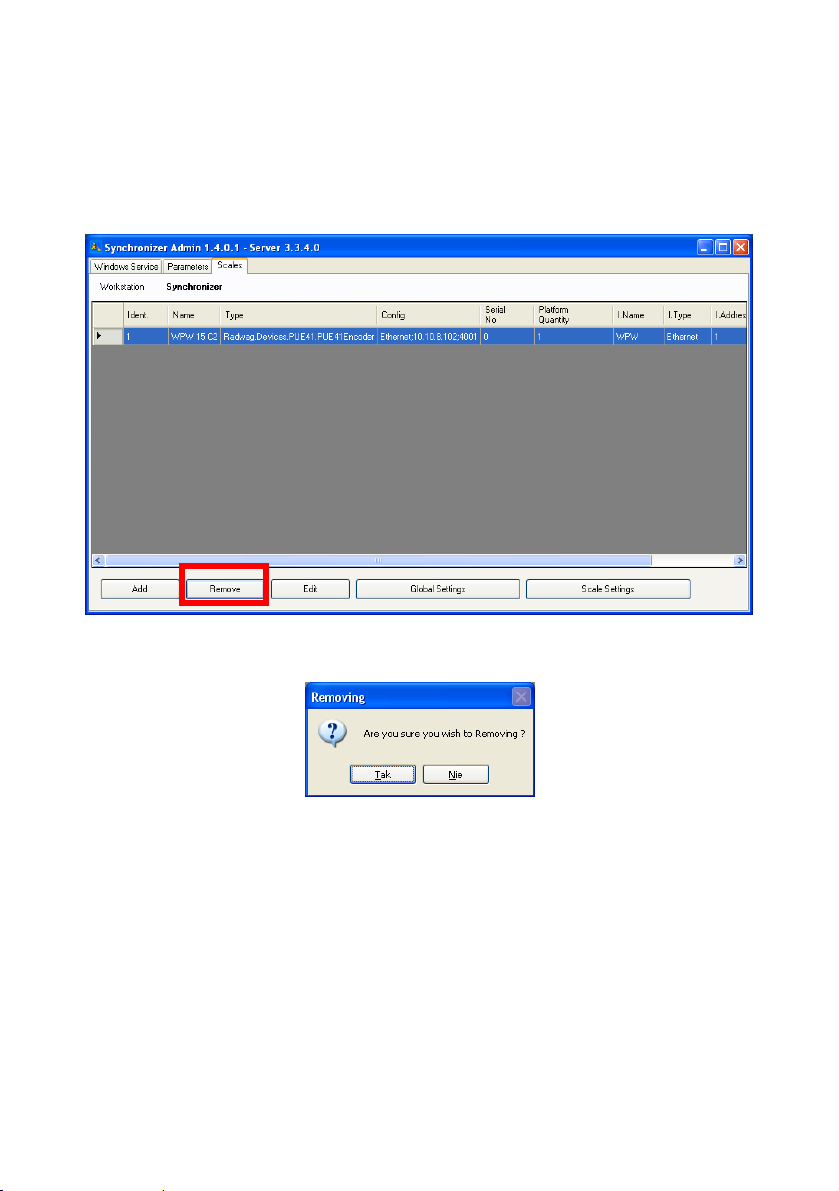

3.3. Deleting and editing of existing scale

If the scale no longer works in the system it can be removed from the

Synchronizer in order to avoid searching for the scale during

synchronisation. Choose the scale to be deleted and press button

„Delete”.

Then the following window appears:

This question appears in order to avoid the risk of accidental removing of a

scale. Press „Yes” if you want to remove the scale from the synchronizer.

Button „Edit” opens the window of the selected scale (the same as for

adding a scale) and allows for making some changed.

3.4. Global settings and scale settings

On overlap „Scales” „Global settings” and „Scale settings” can be

changed.

16

Page 17

NOTICE:

Some parameters are only for service purposes and is described in the

service manual.

Below you can find settings of functions that are crucial for proper

operation of the synchroniser and parameters that extending the

functionality.

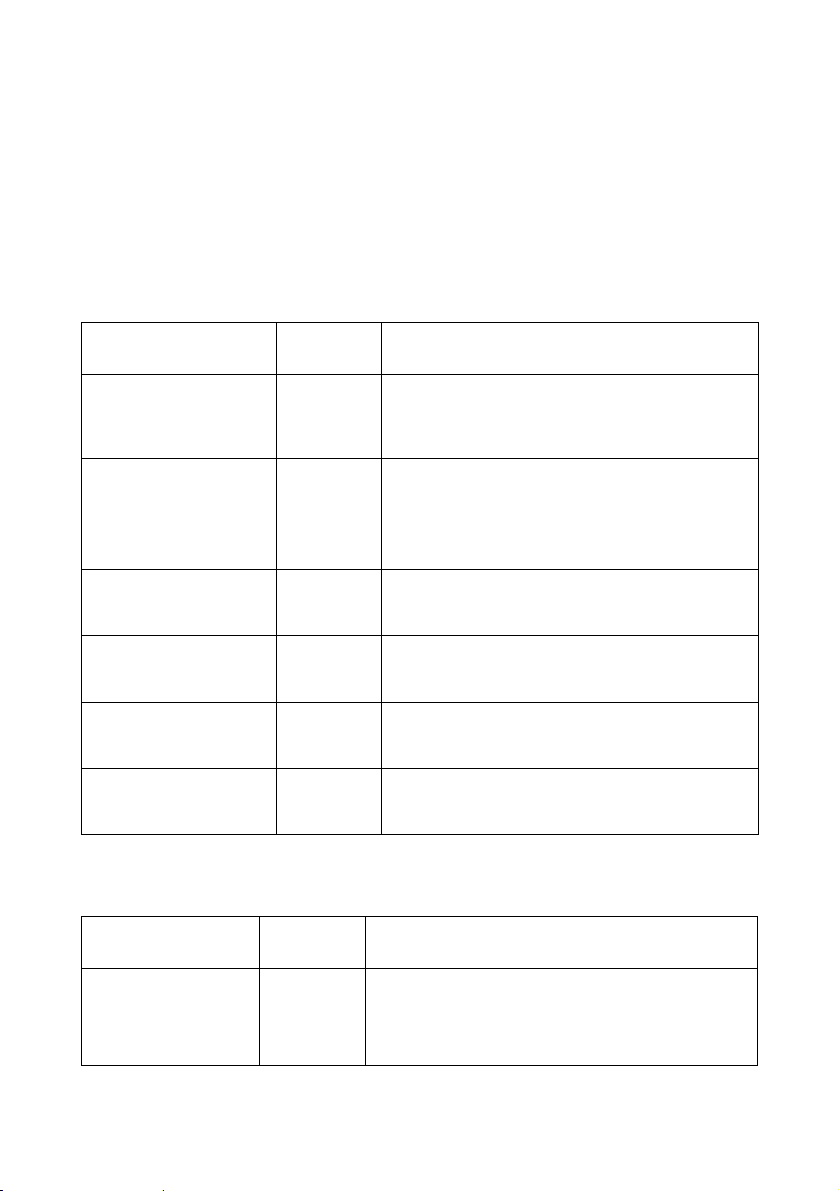

Global settings:

Parameter

pue41Oper_id2kod 0

pue41Towary_id2kod 0

Default

value

Description

Setting to „1” causes sending operators‘ IDs

from the database to scales with indicator

PUE_C41 instead of code (code cannot be

longer than 6 characters)

Setting to „1” causes sending products’ IDs

from the database to scales with indicator

PUE_C41 instead of code (code cannot be

longer than 6 characters); productname=

Code+name and code=id

Synch_Towar

MasaEnabled

Synch_Towar

MinMaxEnabled

Synch_Towar

TaraEnabled

Synch_Towar

UpdateEnabled

0

0

0

0

Setting to „1” causes enabling the update of

mass standards in all scales

Setting parameter to „1” causes enabling the

update of thresholds in all scales

Setting parameter to „1” causes enabling the

update of tare in all scales

Setting parameter to „1” causes enabling

updates from all scales to the database

Scale settings:

Parameter

ew_wazenia 0

Default

value

Description

Weighings from the scale are saved in the

database: 0 - ew1_wazenia (for modules E2R

Weighing Records, E2R Transactions i E2R

Formulas); 1 – ew_wazenia (E2R Weighing)

17

Page 18

Synch_Towar

MasaEnabled

0

Setting parameter to „1” causes enabling the

update of mass standard in the scale

Synch_Towar

MinMaxEnabled

Synch_Towar

TaraEnabled

Synch_Towar

UpdateEnabled

ReconnectTimeout

OnNoRespond

Signalling lamp 0

0

0

0

0

Setting parameter to „1” causes enabling the

update of thresholds in the scale

Setting parameter to „1” causes enabling the

update of tare in the scale

Setting parameter to „1” causes enabling the

update of tare in the scale

A parameter for setting the maximum timeout

in seconds (waiting for a scale reply). After the

time elapses the scale is disconnected and

reconnected to Synchronizer.

Parameter values:

0 – no timeout, 1 to 60 – timeout in seconds.

Setting parameter to „1” sets the

checkweighing mode of a scale based on

indicator PUE4-L

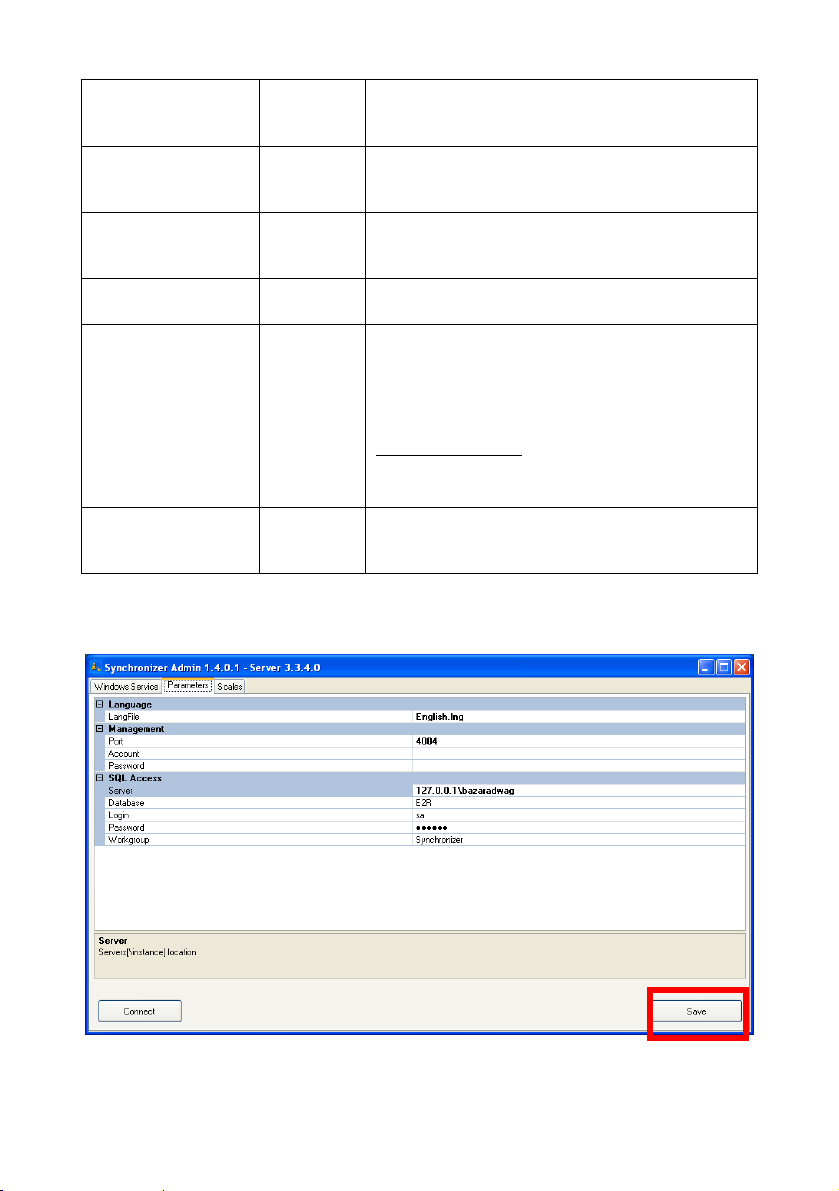

After making changes (adding scales and changing parameters) press

button „Save”.

18

Page 19

After saving go to overlap „Windows Sevice” and check if „RADWAG

Synchronizer Server” operates.

If the server runs you can see a visualization of operating scales connected

to the system using program E2R Manager.

4. E2R MANAGER

Program „E2R Manager” is designed for displaying the state of

communication with scales and current weighings. Additionally, there

are displayed information about: operator, production order, weitghted

product, batch number, contractor, product tare and working mode.

All messages are of informational character which means that it is not

possible to save or print in program „E2R Manager”. These functionalitied

are present in program „E2R WEIGHING RECORDS”.

After installing „E2R WEIGHING RECORDS”, a shortcut to the program

is created on the desktop.

19

Page 20

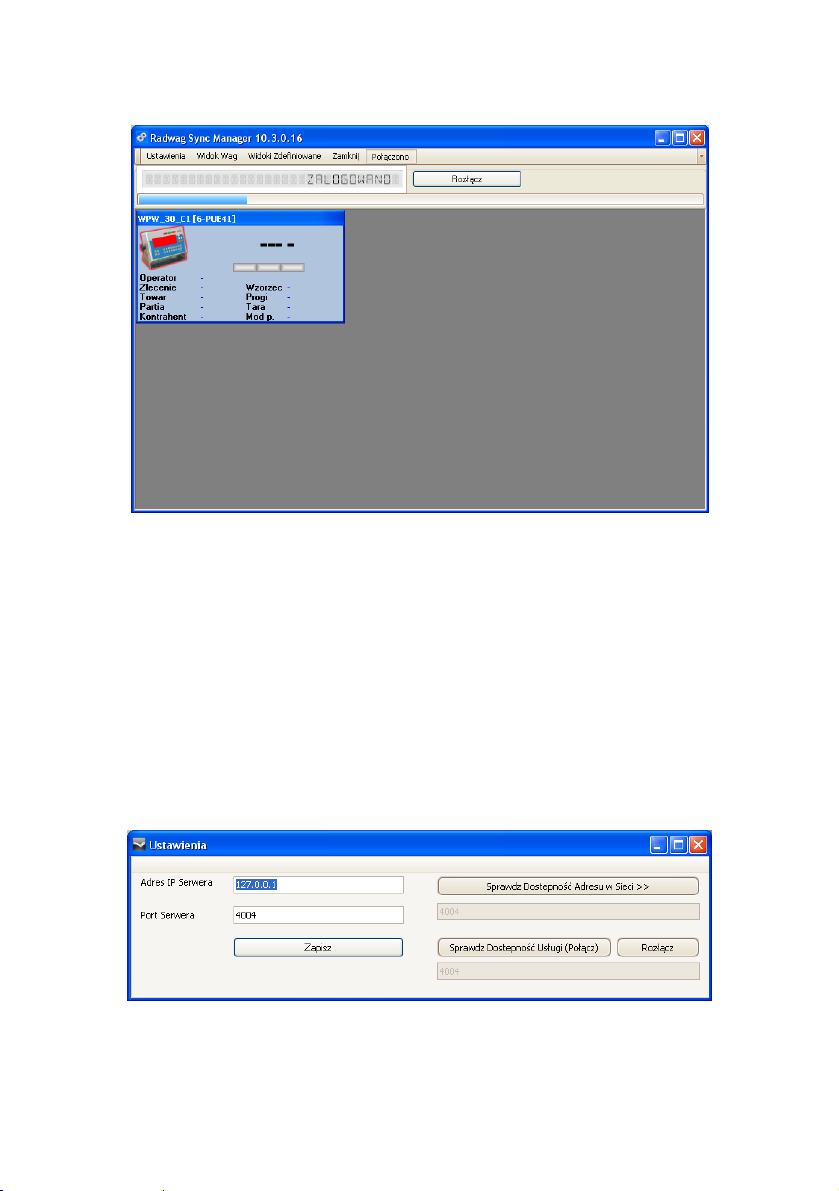

Main window of E2R Manager:

Notice:

In case of lack of communication between „E2R Manager” and service

Radwag Synchronizer or when the service is off no scale window is

displayed.

4.1. Setting connection to Radwag Synchronizer In window „Radwag Synch Manager” set address IP and a

communication port for a computer with running the service of

connecting with scales.

20

Page 21

4.2. Show / hide the panel of connection with server

In the menu Program settings of „E2R Manager” users can access the

panel of connection sith service „Radwag Synchronizer”. If the program

runs and no scale is displayed in the window it means the lack of

connection with the service „Radwag Synchronizer”. In such a case

make sure if the service is running in system MS Windows and press

„Connect” in the connection panel.

Window indicating the lack of connection:

Window indicating the establishment of connection:

5. E2R WEIGHING RECORDS

This manual describes version 10.3.10.0 of „E2R Weighing Records” and

may not include descriptions of functionalities and corrections made in

upper versions.

5.1. Starting program

After the program starts running the logging in procedure is initiated.

Enter Login and Password for an operator.

Press OK to confirm, then the program goes to the main window.

21

Page 22

5.2. Main program window

After an operator has logged in the main window appears:

There are 4 areas in the main window:

• Top Bar – System,

• Side Bar – Work,

• Pasek Dolny – Information,

• Workspace.

In the top bar there are program settings, appearance options (colours), a

LOGOUT and EXIT buttons.

In the side bare, there are modules and operating functions of the program.

22

Page 23

The bottom bar displayes information about the program version and

logged in user their authorization.

In the workspace, there are displayed all windows related to the Side Bar,

holding all data and information.

5.3. Program settings

Press button in the top bar to display settings.

23

Page 24

5.3.1. Database

In order to display database settings, press button in module

<Settings>.

Functions of database settings:

• Update Database,

• Check Connection,

• Configure Connection.

In the top part of the window there is displayed the status of connection

with the database.

In the lower part of the window there are displayed parameters of

connection with the database.

In order to cancel introduced changes press button

.

24

Page 25

5.3.2. Updating the database

After pressing button the database version will be

updated.

Notice:

1. Updating the database overwrites the existing database. For that the

current database needs to be archived before updating;

2. Users can update the current database after consulting with

RADWAG.

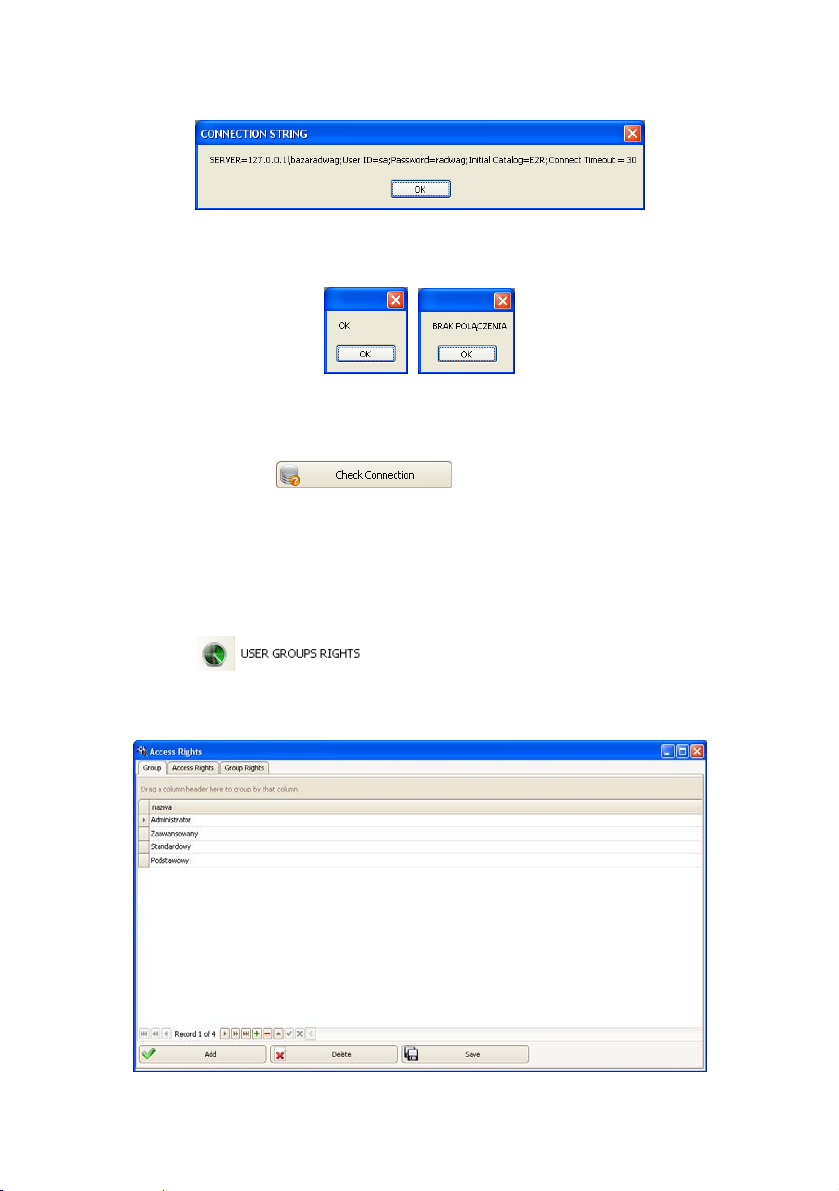

5.3.3. Connection configuration

After pressing button a window with parameters of

connection with the database is displayed.

Fields:

Server

Database

User User name, default sa

Password User password, default radwag

After pressing button <Test connection> the connection of database will

be checked.

IP or server name on which SQL server runs (if the

database has a declared instance, it also needs to be

given). Format: SERVER\INSTANCE

SQL database name

25

Page 26

Then the window with information given earlier is displayed:

After pressing OK in the window above a message box is displayed with

information about the connection status.

5.3.4. Connection checking

After pressing button the connection with the

database is checked.

5.3.5. Authorization and groups of users

In order to enable the access of users and groups to different functionalities

press button

in module <Settings>.

In overlap <Groups> groups of users are defined.

26

Page 27

Buttons’ description:

Add

Delete

Save

Adding the new group of users

Erasing a group of users

Recording changes

In overlap <Access Rights> all codes with names ascribed to them ,which

are used for defining group rights, are accessible.

In overlap <Group Rights> each group of users can have set accessibility

to different program modules.

27

Page 28

After choosing a group from menu <Group> add or take off authorization

according to the predetermined pattern.

5.3.6. Service settings

In order to get access to the service settings press button

in module Settings.

Notice:

All service settings are accessible only for RADWAG authorized services.

28

Page 29

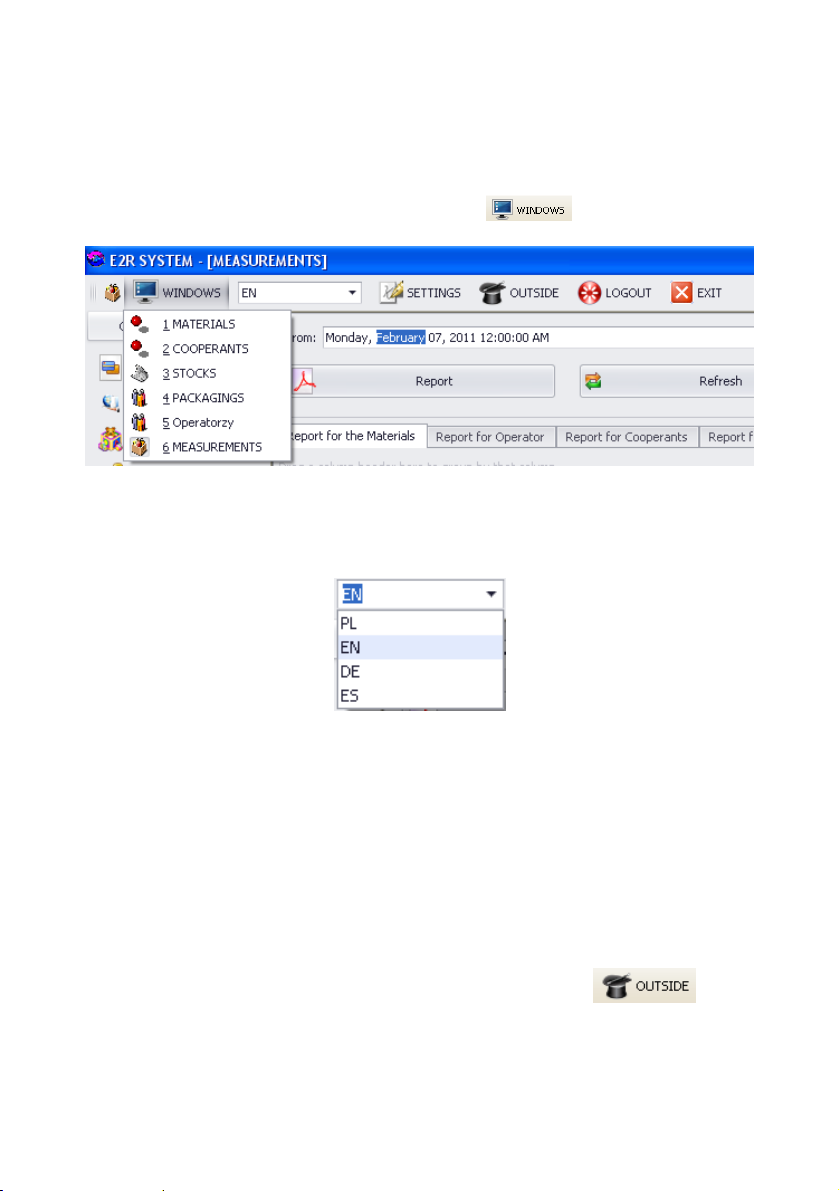

5.4. Other settings

5.4.1. Changing the active window

Only one window is to be displayed after choosing it from the list (setting a

tick next to it) displayed after pressing button

.

5.4.2. Language change

Choose the language from the listbox below.

Fields:

PL

EN

DE

ES

Polish

English

German

Spanish

5.4.3. Program appearance

The program outlook can be changed by pressing button

choosing one item from the list.

and

29

Page 30

Accessible colour schemes:

Caramel

Money Twins

Lilian

The Asphalt World

iMaginary

Black

Blue

Brown

Light-blue

Light-blue

Light-gray

Dark gray

Black

Dark blue

5.4.4. Logging out

After pressing button , the user is logged out.

Then another operator can be logged in by enaring a Login and the

Password. Then press button

to log in.

5.4.5. Closing program

Press button and the program will be closed.

30

Page 31

5.5. Working window of the program

5.5.1. Sorting information

In the working window of all accessible modules all information displayed

can be freely sorted.

In order to group displayed data choose a column header and drag it to the

place indicated in the image below.

The selected header will be displayed as a button with the same caption.

Pressing the button causes sorting the list in an ascending or descending

way.

5.5.2. Additional filtering options

After pressing the right side of a column header additional filtering options

appear to be choosen from the list.

After right-clicking the header a pop-up menu

will be displayed.

31

Page 32

Fields:

Sort Ascending

Sort Descending

Clear Sorting

Group By This Column

Sorting from A to Z

Sorting from Z to A

Disable sorting filter

Group data according the selected

column

Hide Group By Box

Remove This Column

Hides the field of quick grouping

Deletes a selected column from the

window

Column Chooser

Starts columns configurator in the

window

Best Fit

Change the column width to get the best

view

Best Fit (all columns)

Change the width of all columns to get

the best view

Filter Editor…

Advanced filter

In each window, a navigation bar is available in where we can add, edit,

delete and jump between records.

In the upper part of the bar there is a data filter which allows you to

generate five basic statistics for that column. The selection of statistics is

displayed by pressing the right mouse button in the upper part of the

navigation bar.

Basic statistics:

Sum

Min

Max

Count

Average

None

Displays the sum of all values in the column

Displays the minimum value in the column

Displays the maximum value in the column

Displays the number of rows in the column

Displays the average value of the data in the column

Statistics are off

32

Page 33

5.5.3. Filter creator

After choosing button „Filter editor…” you start the window of filter creator

where you can freely filter data from the database.

Using the creator you can set one or many filtering conditions, which allows

for detailes filtering and generating reports from the filtered data.

Filtering criteria:

a) Filtering groups (and, or, not and, not or)

33

Page 34

Definitions:

And

Or

Not And

Not Or

Add Condition

The condition that endorces fulfilment of all

filtering criteria

The condition that endorces fulfilment of any

filtering criterium

The condition that endorces fulfilment of the

opposites to all the set filtering criteria

The condition that endorces fulfilment of any

opposite to set filtering criteria

Allows for adding another condition of filtering

Add Group

Allows for adding another group of filtering

(each group can include many conditions of

filtering)

Clear All

Causes clearing (deleting) of all filtering

conditions

b) Filtering conditions – outlines the data to be filtered and the

methods of filtering:

- choosing a column for filtering

- choosing filtering range and method

34

Page 35

Designations:

Equals

Does not equal

Is greater than

Is greater than or

equal to

Is less than

Is less than or

equal to

Is between

Is not between

Contains

Does not contain

Displaying only records from the selected column

which are ecactly the same as the entered value

Displaying all records from the selected column

which are different from the entered value (opposite

to filter „Equal”)

Displaying only records from the selected column

which values are greaterer than the entered value,

Displaying only records from the selected column

which values are greaterer or equal to the entered

value,

Displaying only records from the selected column

which values are lower than the entered value,

Displaying only records from the selected column

which values are lower or equal to the entered value,

Displaying only records from the selected column

which values are in the range between two given

values

Displaying only records from the selected column

which values are beyond the range between two

given values

Displaying only records from the selected column

which include the given string of characters

Displaying only records from the selected column

which do not include the given string of characters

35

Page 36

Begins with

Displaying only records from the selected column

which start form the given string of characters

Ends with

Displaying only records from the selected column

which end with the given string of characters

Is like

Displaying only records from the selected column

which has the same beginning and end, the filtering

criterion has the following format „begin%end”

Is not like

Displaying only records from the selected column

which has not the given beginning and end, the

filtering criterion has the following format

„begin%end”

Is blank

Displaying only records from the selected column

which are empyt

Is not blank

Displaying only records from the selected column

which are not empyt

Is any of

Displaying only records from the selected column

which are the same as one of the given patterns

Is none of

Displaying only records from the selected column

which are different from all of the given patterns –

opposite to „Is any of” filtering

Here you can specify the exact criterion for filtering the selected column,

e.g.: if you want to get a result concerning product „Apple” choose „Name

- Equals – value: Apple”. If additionally you want to filter add another

criterion by pressing „+” next to the filtering critrion.

After completing the configuration of filters confirm the settings by pressing

button

, which causes the filter to run.

At the same time in the bottom bar the filtering method is displayed.

Pressing button „Edit filter” calls for the filter creator window.

36

Page 37

6. DATABASES

E2R Weighing Records includes following databases:

• Assortment,

• Contractors,

• Stocks,

• Packagings,

• Operators.

All databases are editable also from the software of terminals PUE 5

(Terminal E2R Weighing Records).

6.1. Assortment

On database <Assortment> a list of articles or materials.

In order to start the module choose option Assortment in the back side

window.

Window of assortment:

37

Page 38

6.1.1. Adding / editing assortments

After pressing button

database.

After pressing button an existing assortment can be edited.

a new assortment can be added to the

Window of adding or editing assortments:

Description:

Code

Name

MAX

MIN

Pcs Mass

Unit

Tare

Product code for scales

Product name

The upper threshold of weighing

The lower threshold of weighing

Single piece nominal weight

Weight unit

Tare value (package weight) for producte

with constant tare

EAN 13

EAN 128

Price

VAT [%]

Validity Days

Barcode EAN 13

Barcode EAN 128

Unit price

Value Added Tax

Number of days to the expiery date

38

Page 39

After editing all required data save settings by pressing button <Save> and

then <Close>.

6.1.2. Deleting product

After pressing button the assortment can be deleted from the

database.

Records are protected from accidental erasing and a confirmation is

required for such action.

If the database holds weighings related to the product it cannot be erased,

but is attributed as an archive record.

6.1.3. Searching and filtering assortments

Each product entered to the system can be found by inscribing an

appropriate string of characters in the column.

After typing the characters in the column a list of products with the same

string of characters is displayed.

In order to delete a displaying filter from the window of products press

.

39

Page 40

Notice:

In the working window of <Assortment> displayed information can be

sorted and use additional options of filtering. See details in section 5.5.2

and 5.5.3 of this manual.

6.1.4. Reports from Products

In order to print a report from the list of products press button in

the main window. Then a window called <Preview> with the generated

report appears. Press <Print> in this window to send the report to the

printer.

6.2. Contractors

In the database of <Contractors> the included list of contractors can be

supervised.

To run the module choose Contractors in the side menu.

Window of contractors:

40

Page 41

In this window you can add, erase or modify contractors that are attributed

to products to be weighed.

6.2.1. Adding / editing contractors

After pressing button you can add a new contractor to the

database.

After pressing button

you can edit and change data for a

choosen contractor.

A window for adding or editing contractors:

Fields:

Weighing code

Name

Address

City

Post code

Tax ID

Discount [%]

Label file name

Contractor code for scales

Contractor name

Contractor address

City or town

Post code

Tax Identification Number

Discount in % for the contractor

A label file name in format of *.lb file,

which is situated in the program folder

All changes in the contractor’s data can be recorded by pressing <Save>

and then the window can be closed by pressing <Close>.

41

Page 42

6.2.2. Deleting contractors

After pressing button you can delete the selected contractor f

the database. Records are protected from accidental erasing and a

confirmation is required for such action.

rom

If the database holds weighings that are attributed to the selected

contractor it will not be deleted.

6.2.3. Filtering and searching contractors

Each contractor introduced to the system can be found by inscribing an

appropriate string of characters in the column.

Postcode

After typing the characters in the column a list of contractors with the same

string of characters is displayed.

In order to delete a displaying filter from the window of products press

.

Notice:

In the working window of <Contractors> displayed information can be

sorted and use additional options of filtering. See details in section 5.5.2

and 5.5.3 of this manual.

42

Page 43

6.2.4. Reports from Contractors

In order to print a report from the list of contractors press button in

the main window. Then a window called <Preview> with the generated

report appears. Press <Print> in this window to send the report to the

printer.

6.3. Stocks

In database <Stocks> the included list of different storage areas can be

supervised.

To run the module choose Stocks in the side menu.

Window of stocks:

In this window you can add, erase or modify stocks that have been added

to the database.

43

Page 44

6.3.1. Adding / changing stocks

After pressing button you can add a new stock to the

database.

After pressing button

you can change any data in the selected

stock.

A window for adding or editing a stock:

Fields:

Code

Name

Long name

Data Name

Stock code for a scale

Stock name

Full stock name

Database name to which a stock is attributed

All changes in the stock’s data can be recorded by pressing <Save> and

then the window can be closed by pressing <Close>.

6.3.2. Deleting a stock

After pressing button you can delete the selected stock from the

database. Records are protected from accidental erasing and a

confirmation is required for such action.

44

Page 45

If the database holds weighings that are attributed to the selected stock it

will not be deleted.

6.3.3. Filtering and searching stocks

Each warehouse introduced to the system can be found by inscribing an

appropriate string of characters in the column.

After typing the characters in the column a list of warehouses with the

same string of characters is displayed.

In order to delete a displaying filter from the window of products press

.

Notice:

In the working window of <Stocks> displayed information can be sorted

and use additional options of filtering. See details in section 5.5.2 and 5.5.3

of this manual.

6.4. Packagings

In database Packaging the included list of different storage areas can be

supervised.

To run the module choose <Packagings> in the side menu.

45

Page 46

Window of packagings:

In this window you can add, erase or modify warehouses that have been

added to the database.

6.4.1. Adding / changing packagings

After pressing button you can add a new package to the

database.

After pressing button

you can change any data in the selected

package.

A window for adding or editing a package:

46

Page 47

Fields:

Code

Name

Mass

Barcode

Package code for scales

Package name

Nominal package weight – tare

Package Barcode

All changes in the package’s data can be recorded by pressing <Save>

and then the window can be closed by pressing <Close>.

6.5. Operators

In database <Operators> the included list of different storage areas can be

supervised.

To run the module choose Operators in the side menu.

Window of operators:

In this window you can add, delete or modify operators and attribute them

an authorization level. Operators can be logged in both on

„E2R Weighing Records” and „Terminal E2R Weighing Records”.

47

Page 48

6.5.1. Adding / changing operators

After pressing button you can add a new operator to the

database.

After pressing button

you can change any data in the selected

operator.

A window for adding or editing an operator:

Fields:

Code

Name

Password

Group

Operator code for scales

Operator name

Operator’s password

Ascribing to an authorization level group. There are

four groups with different access levels:

administrator, advanced, standard and basic. The

general settings of accessability of different program

modules within the group can be found in Program

Settings.

Card number

Archive

Work card number

Giving the “archive” attribute to the operator. Notice:

having this attribute set you cannot log in the

operator.

All changes in the operator’s data can be recorded by pressing <Save>

and then the window can be closed by pressing <Close>.

48

Page 49

6.5.2. Deleting operators

After pressing button you can delete the selected operator from

the database. Records are protected from accidental erasing and a

confirmation is required for such action:

6.5.3. Filtering and searching operators

Notice:

In the working window of <Operators> displayed information can be

sorted and use additional options of filtering. See details in section 5.5.2

and 5.5.3 of this manual.

6.5.4. Reports from operators

In order to print a report from the list of operators press button in

the main window. Then a window called <Preview> with the generated

report appears. Press <Print> in this window to send the report to the

printer.

7. MODULE WEIGHING RECORDS – Reports

7.1. The main window in E2R Weighing Records

The main window of Weighing Records is displayed after pressing button

in the side panel.

49

Page 50

It allows to display all weighings collected in the SQL database. Generation

of simple reports from weighings is also possible.

In the main window of Measurements you can freely set columns in any

report using the tool „Choose column”.

50

Page 51

The tool can be started by choosing it from the pop-up menu called by

right-clicking on the bar with column names.

Two additional windows are displayed:

¾ Edit Kolumn Properties

¾ Customization.

Window „Edit Column Properties” allows for modification of appearance

of the selected column as well as window and printing properties.

Window „Customization” allows to add or remove of the selected column

from the view of the selected report. Columns are added or removed by the

„drag and drop” method.

Description:

- enables or disables quick data sorting

- enables or disables of the value filter

in columns

- enables or disables displaying a filter that allows for

generating 5 basic statistics for the column.

51

Page 52

7.2. Raport for the Materials

Overlap „Material Report” allows for sorting weighings according to the

product name. Different sorting criteria can be applied e.g: weighing date,

product name. Grouping sorting conditions depends on the sequence of

adding them. The time interval for the report is set in the upper part of the

window.

After outlining all required conditions of grouping and pressing button

, a report in PDF file will be generated. It can be

saved or printed on a local printer connected to the computer with

application „E2R Weighing Records”.

An example of grouping a report for a product is shown in figure below.

7.3. Report for Operator

Overlap „Report for Operator” allows for sorting weighings according to

the Operator that have performed them. Different criteria can be applied for

sorting data e.g.: date of weighing, operator.

52

Page 53

Grouping sorting conditions depends on the sequence of adding them. The

time interval for the report is set in the upper part of the window.

After outlining all required conditions of grouping and pressing button

, a report in PDF file will be generated. It can be

saved or printed on a local printer connected to the computer with

application „E2R Weighing Records”.

7.4. Report for Cooperants

Overlap „ Report for Cooperants” allows for sorting weighings according to

the contractor for whom/which weighings have beem performed. Different

criteria can be applied for sorting data e.g.: date of weighing, contractor.

53

Page 54

Grouping sorting conditions depends on the sequence of adding them. The

time interval for the report is set in the upper part of the window.

After outlining all required conditions of grouping and pressing button

, a report in PDF file will be generated. It can be

saved or printed on a local printer connected to the computer with

application „E2R Weighing Records”.

7.5. Report for Batch Number

Overlap „Report for batch number” allows for sorting weighings

according to the one batch number they belong to. Different criteria

can be applied for sorting data e.g.: date of weighing, batch number.

54

Page 55

Grouping sorting conditions depends on the sequence of adding them. The

time interval for the report is set in the upper part of the window.

After outlining all required conditions of grouping and pressing button

, a report in PDF file will be generated. It can be

saved or printed on a local printer connected to the computer with

application „E2R Weighing Records”.

7.6. Report for the Balance

Overlap „Report for the Balance” allows for sorting weighings according

to the scale on which they have been performed on. Different criteria can

be applied for sorting data e.g.: date of weighing, scale.

55

Page 56

Grouping sorting conditions depends on the sequence of adding them.

The time interval for the report is set in the upper part of the window.

After outlining all required conditions of grouping and pressing button

, a report in PDF file will be generated. It can

be saved or printed on a local printer connected to the computer with

application „E2R Weighing Records”.

Additionally, in each report window an advanced sorting can be applied

with the use of filter editor (described in details in section 5.5.3 of this

manual).

7.7. Header and Report Title

Overlap „ Header and Report Title” allows for setting any name in the

report header. Such a header can be placed in any of five kinds of reports.

After applying any change in the header the new title will appear in the

choosen kind of report after pressing

.

56

Page 57

7.8. Archive Weighings Overlap „Archive Weighings” allows for archiving selected weigings. Accessible functions:

• Move selected to Archive

• Restore selected from Archive

• Delete selected Archival weighings

Weighings can be archived one by one by highlighting a weighing and

pressing „Move selected to Archive”. It is also possible to archive groups

of weighings. The group can be selected in different ways:

• Using data filtering for choosing weighings that are the subject of our

interest (see sections 5.5.2 and 5.5.3 of this manuals for details),

• Select weighings while keeping a SHIFT key pressed (range) or CTRL

key pressed (choosing separately),

• Selecting all weighings by pressing „Ctrl + A”.

57

Page 58

Restoring the archival weighings is performed similarly using button

„Restore selected from the Archives”.

Deleting weighings is possible ONLY after removing them to the archive.

8. TOOLS

8.1. Scale Restart

Tool

Synchronizer accessible from the PC application. It causes reconnection to

scales based on indicators PUE7 and PUEC41 conncected to the system.

is identical to function „Re-Connect scales” in

58

Page 59

MANUFACTURER

OF ELECTRONIC WEIGHING

INSTRUMENTS

RADWAG WAGI ELEKTRONICZNE

26 – 600 Radom, 28 Bracka Street

POLAND

Tel. +48 48 38 48 800, tel./fax. + 48 48 385 00 10

Sales department + 48 48 366 80 06

www.radwag.com

59

Loading...

Loading...