Page 1

User manual no.:

LMI-53-05/11/12/A

BALANCES

APP/2C

SERIES

MANUFACTURER

OF ELECTRONIC WEIGHING INSTRUMENTS

RADWAG 26 – 600 Radom, Bracka 28, POLAND

phone +48 48 38 48 800, fax. +48 48 385 00 10

e-mail: export@radwag.com

www.radwag.com

Page 2

- 2 -

NOVEMBER 2012

Page 3

- 3 -

TABLE OF CONTENTS

1. TECHNICAL DATA ............................................................................... 5

2. BASIC INFORMATION ......................................................................... 6

2.1. Intended use ............................................................................................... 6

2.2. Inappropriate use........................................................................................ 6

2.3. Warranty ..................................................................................................... 6

2.4. Monitoring metrological parameters of the instrument ................................ 7

2.5. Data included in this user manual............................................................... 7

2.6. Staff training ............................................................................................... 7

3. TRANSPORT I STORAGE ................................................................... 7

3.1. Delivery check ............................................................................................ 7

3.2. Packaging ................................................................................................... 7

4. UNPACKING, ASSEMBLING AND STARTUP ..................................... 8

4.1. Assembling and place of use ...................................................................... 8

4.2. Unpacking .................................................................................................. 8

4.3. Standard delivery components ................................................................. 10

4.4. Cleaning ................................................................................................... 10

4.5. Plugging to mains ..................................................................................... 10

4.6. Connecting peripheral equipment ............................................................. 11

5. BASIC FUNCTIONS ........................................................................... 11

6. BALANCE KEYBOARD ...................................................................... 13

7. START-UP .......................................................................................... 14

8. USER MENU ....................................................................................... 15

8.1. Moving through user menu ....................................................................... 15

8.2. Return to weighing mode .......................................................................... 18

9. WEIGHING .......................................................................................... 18

9.1. Selection of basic measuring unit ............................................................. 19

9.2. Temporary measuring unit ........................................................................ 21

9.3. Setting accessibility of balance working modes ........................................ 21

9.3.1. Selection of working modes available for a user ............................. 23

9.3.2. Means of selecting one of available working modes ....................... 24

9.4. Dual range balance (APP 6/35/2C) .......................................................... 25

10. BALANCE MAIN PARAMETERS ....................................................... 26

10.1. Setting filtering level ................................................................................. 26

10.2. Value release ........................................................................................... 27

10.3. Autozero function...................................................................................... 28

10.4. Blanking of the last digit on the display ..................................................... 29

10.5. Weighing mode RAPID ............................................................................. 30

11. OTHER PARAMETERS ...................................................................... 31

11.1. Backlight of weighing result (display backlight) ........................................ 31

11.2. Adjusting display brightness ..................................................................... 32

11.3. “Beep” sound – reaction on pressing function key .................................... 33

11.4. Printout of all balance parameters through RS 232 port ........................... 34

12. BALANCE ADJUSTMENT .................................................................. 35

12.1. Internal adjustment ................................................................................... 35

12.2. Menu adjustments settings ....................................................................... 37

12.3. Adjustment test ......................................................................................... 41

Page 4

- 4 -

12.3.1. Balances with internal adjustment system.................................. 41

12.3.2. Balances with external adjustment system ................................. 42

12.4. Manual adjustment ................................................................................... 43

12.4.1. Internal adjustment ..................................................................... 43

12.4.2. External adjustment ................................................................... 44

12.5. Adjustment report printout ........................................................................ 44

13. DETERMINING CONTENT OF A PRINTOUT FOR GLP

PROCEDURE ..................................................................................... 46

14. BALANCE WORKING MODES .......................................................... 49

14.1. Parts counting of the same unit mass ....................................................... 50

14.2. Checkweighing (HiLo) with reference to set standard .............................. 54

14.3. Percent setup with reference mass .......................................................... 57

14.3.1. Reference mass determined by weighing .................................. 57

14.3.2. Reference mass inserted to balance memory by a user ............ 58

14.4. Density determination of solids and liquids ............................................... 60

14.4.1. Density determination of solids .................................................. 61

14.4.2. Density determination of liquids ................................................. 65

14.5. Totalizing .................................................................................................. 69

14.6. Working mode FILL .................................................................................. 72

15. RS 232 FUNCTIONS .......................................................................... 73

15.1. Baud rate .................................................................................................. 73

15.2. Continuous transmission .......................................................................... 74

15.2.1. Continuous transmission in basic measuring unit ...................... 74

15.2.2. Continuous transmission – in current measuring unit ................. 75

15.3. Setting operation mode for RS 232 interface ............................................ 76

15.4. Determination of data type sent through RS 232 output ........................... 77

15.5. Minimal mass required for activation of automatic printout ....................... 78

16. COOPERATION WITH A PRINTER OR A COMPUTER ................... 79

16.1. Cross-section through connecting conductors .......................................... 80

16.2. Printing date with specified date and time ................................................ 81

16.3. Cooperation with statistic printer Kafka SQS ............................................ 81

16.4. Format of data sending ............................................................................. 81

16.4.1. Format of data sent on pressing of PRINT key .......................... 82

16.4.2. Format of data sent as response for commands generated from a

computer .................................................................................... 82

17. UNDER HOOK WEIGHING ................................................................ 83

18. LIST OF COMMANDS COMPUTER – BALANCE ............................. 84

19. ERROR MESSAGES .......................................................................... 85

20. ADDITIONAL EQUIPMENT ................................................................ 86

20.1. Anti-Vibration table ................................................................................... 86

20.2. Additional display...................................................................................... 86

20.3. Computer software ................................................................................... 86

Page 5

- 5 -

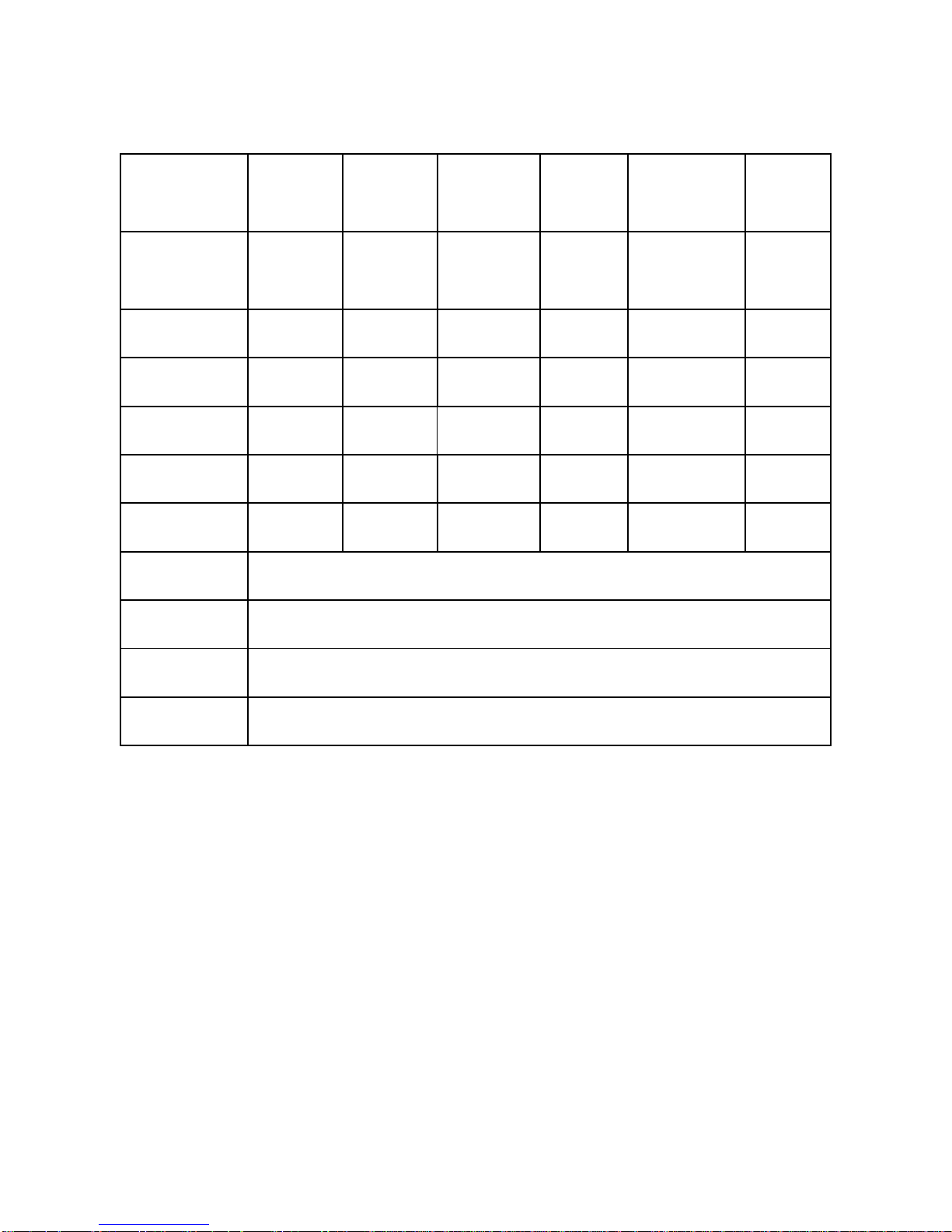

1. TECHNICAL DATA

Balance with

external

adjustment

system

APP

10/2C/1

APP

25/2C/1

APP

30/2C/1

APP

35/2C/1

APP

6/35/2C/1

APP

50/2C/1

Balance with

internal

adjustment

system

APP

10/2C

*

APP

25/2C

*

APP

30/2C

APP

35/2C

APP

6/35/2C

*

-

Max. capacity

10 kg 25 kg 30 kg 35 kg 6/35 kg 50 kg

Tare range

-10 kg -25 kg -30 kg -35 kg -35 kg -50 kg

Linearity

± 0,02 g ± 0,1 g ± 0,3 g ± 0,3 g ± 1/5 g ± 0,5 g

Readability

0,01 g 0,1 g 0,1 g 0,1 g 1/5 g 0,1 g

Repeatability

0,01 g 0,1 g 0,1 g 0,1 g 1/5 g 0,15 g

Working

temperature

+10 °C - +40 °C

Power supply

110 ÷ 230 V AC / 50 ÷ 60 Hz / 13,5 ÷ 16 V DC / 1,6A

Sensitivity drift

2 ppm/°C in temperature +15°C - +35°C

Pan size

347 x 259 mm

*

- verified balance

Page 6

- 6 -

2. BASIC INFORMATION

2.1. Intended use

Precision balance APPC series is designed to determine the weighing value of

loads in laboratory environment. It is intended for application as a nonautomatic weighing instrument only, i.e. the material to be weighed is manually

and carefully placed in the center of the weighing pan. Weighing result should

be read only after stable reading has been obtained – stability pictogram is

visible on balance’s display.

2.2. Inappropriate use

Do not use the balance as a dynamic weighing instrument. Even if small

quantities of weighed material are added or removed from the weighing pan of

the instrument, the reading should be taken only after stabilization of the

measurement result. Do not place any magnetic materials on the weighing pan,

as this can cause damage of the measuring system of the instrument. Be sure

to avoid impact shock and overloading the balance in excess of the prescribed

maximum measuring range (max capacity), minus any possible tare weight that

has been applied. Never use the balance in an environment endangered by an

explosion. This balance has not been adjusted for operation in explosive areas.

There must not be any modification made to the balance.

2.3. Warranty

Warranty is not valid at the following:

• Non-observation of the guidelines of this user manual,

• Use of balance other than specified in this manual,

• Alternation to or opening of the device,

• Mechanical damage and damage caused by media, natural water,

and tear,

• Inappropriate assembling or defects of electric installation,

• Overloading of the measuring instrument.

Page 7

- 7 -

2.4. Monitoring metrological parameters of the instrument

Metrological characteristics of the balance requires periodical inspection

carried out by its operator. Inspection frequency is conditioned by ambient

conditions in which the balance is used, types of performed processes and

accepted quality management system in an organization.

2.5. Data included in this user manual

Please read the user manual carefully before assembling and startup, even if

the user is experienced with this type of weighing instruments.

2.6. Staff training

This balance should only be operated and maintained by personnel who is

trained and experienced in using this type of balances.

3. TRANSPORT I STORAGE

3.1. Delivery check

Please check the packaging immediately upon delivery and the device during

unpacking for any visible signs of external damage.

3.2. Packaging

Please retain all parts of the original packaging should the balance be

transported in the future. Only the original packaging should be used for

dispatching the balance. Before packing, disconnect all attached cables and

remove any loose/movable parts (weighing pan, anti-draft shields, etc.). Please

place balance and its components in their original packaging, and protect them

against damage during transport.

Page 8

- 8 -

4. UNPACKING, ASSEMBLING AND STARTUP

4.1. Assembling and place of use

• Balance should be stored and used in locations free of vibrations and

shakes, free of air movement and dust,

Ambient air temperature should not exceed the range of: +10

o

C ÷ +40oC,

• Ambient relative humidity should not exceed 80%,

• During balance operation, ambient temperature in the weighing room should

not change more than 3°C within one hour,

• The balance should be located on a stable wall console desk or a stable

working table which is not affected by vibrations and distant from heat

sources,

• Take special safety measures when weighing magnetic objects, as part of

the balance is a strong magnet. Should such loads be weighed, use under

hook weighing option, which removes the weighed load from area influenced

by the balance’s magnet. For assembling the hook for under hook weighing

option see the bottom section of balance’s housing,

• In order to avoid influence of static electricity on the measurement process,

ground the balance’s housing. the grounding bolt is located at the back of

balance’s housing.

4.2. Unpacking

Cut protective tape. Carefully remove the balance from its packaging. Remove

any accessories from their packaging needed to correct balance operation.

Page 9

- 9 -

• Remove the weighing pan from balance’s housing and remove the

transport protections, as shown on above figure.

• After unpacking, unscrew bolt (1) locking balance’s adjustment

mechanism.

• Assembly the weighing pan.

• Pay attention to correct positioning of the weighing pan on balance’s

mandrels – the weighing pan must not touch balance’s housing, and it

should rest steadily.

• After removing transport protections, and assembling the weighing pan

connect the terminal to balance’s socket located at the back of the housing

– only non legalization balaces, and next connect needed peripheral

equipment. Only then plug the balance to mains (power socket is located

at the back of balance’s housing).

• Place the balance in its intended place of use.

Page 10

- 10 -

• Level the balance by turning its adjustable feet. Then using a wrench (3)

tighten up the nut (2) on the adjustable foot (1) to balance’s basis until

refusal point.

Setting

Before plugging to mains, level the balance using adjustable

feet. Turn the feet in a way that the air bubble of the level is

located centrally.

• Only then plug the balance to mains (power socket is located at the back

of balance’s housing).

4.3. Standard delivery components

• Balance.

• Weighing pan.

• Power adapter.

• User manual.

4.4. Cleaning

Balance should be cleaned with damp cloth by gentle wiping the smudges of

dirt. In order to clean the weighing pan of the balance, please remove it from

the weighing chamber. Cleaning of the pan when assembled may cause

damage of the measuring system of the balance.

4.5. Plugging to mains

Balance can be plugged to mains only with a power adapter that comes

standard with the balance. Nominal power supply of the power adapter

(specified on the data plate of the power adapter) should be compatible to

the power from mains. Plug the balance to mains – the plugging socket is

located at the back of balance’s housing. Balance display will light and show

name and number of software, after which balance will display 0.00g (in case

of balances with readability 0,01g) or 0.0g (for balances with readability 0,1g). .

If indication is other than zero, press ZERO/TARE key.

Page 11

- 11 -

4.6. Connecting peripheral equipment

The balance must be unplugged from the mains before connecting or

disconnecting any peripheral equipment (printer, PC computer). Use only

peripheral equipment recommended by the manufacturer with your balance.

These have been ideally coordinated to your balance. On connecting a

peripheral device, plug the balance to mains.

5. BASIC FUNCTIONS

• Functions related to measuring unit

- setting default measuring unit <StUn>,

- weighing in grams [g],

- weighing in kilograms [kg],

- weighing in carats [ct],

- weighing in units from beyond SI (available only in non-verified

balances): lb], [oz], [ozt], [dwt], [t], [mom], [gn],

• functions related to working modes

- parts counting <PcS>,

- checkweighing (+/- control) <HiLo>,

- percent setup <PrcA>, <PrcB>,

- density determination of solids <d_Co>,

- density determination of liquid <d_Li>,

- totalizing <Add>,

- FiLL mode <FiLL>

• functions related to setting a balance to ambient and working conditions

at a workstation

- enabling / disabling autozero system <Auto>,

- setting the parameter of measurement result averaging <AuE>,

- measurement result value release <ConF>,

- weighing mode <rAPd>,

- display backlight <bl>,

- display brightness <bLbA>,

- beep signal (balance reaction on pressing a function key) <bEEP>,

• functions related to use of RS 232 interface

- setting baud rate <bAud>,

- Continuous data transmission in basic measuring unit <CntA>,

- Continuous data transmission in current measuring unit <Cntb>,

- Automatic operation mode <rEPL>.

Page 12

- 12 -

Balance APPC series can be used to weigh loads under the weighing platform – i.e.

under hook weighing option. Balance software enables printing a report from

adjustment process containing a set of data on adjustment conditions and criteria

(see GLP procedures).

Page 13

- 13 -

6. BALANCE KEYBOARD

ON/OFF key enables switching on and off balance’s display. If

switched off balance components other than the display are

powered, and balance is in stand-by mode.

F key. Function key, which enables quick entering the settings

of an active working mode.

MODE key for selecting balance’s working mode.

UNITS key, changes measuring units.

PRINT/ENTER key - Sends current display status to a

peripheral device (PRINT) or accepts selected value of a

parameter or function (ENTER).

ESC/ZERO/TARE key – zeroing / tarring of balance’s

indication.

Adjustment – function key of immediate initiating the

adjustment / calibration process.

Function key for entering the main menu of a balance.

Navigating arrows for moving in balance’s menu or changing

parameter value

Page 14

- 14 -

7. START-UP

When plugged to mains, the balance displays name and number of software, and

afterwards proceeds to weighing mode.

Balance temperature stabilization period.

Before start of measuring processes, it is necessary to wait until the balance is

thermally stabilized. It is a period of so called balance self-heating. In case of

balances APP series self-heating period takes approximately 15 minutes. The

specified time interval refers to balances that have been stored in room temperature

before plugging to mains.

For balances that were stored in much lower temperatures before plugging to mains

(e.g. during winter period) thermal stabilization should last approximately 4 hours.

Correct operation of a balance is possible within temperature range specified in the

technical parameters, see point 1. If the balance is placed in area which ambient

temperature is out of temperature range specified in the technical data, then

balance’s display may signal such situation by lighting an appropriate marker (a

black triangle).

In case the balance displays the marker, increase or decrease ambient

temperature, depending on present temperature value. It is recommended that

ambient temperature changes at balance’s place of use are very small (slow).

Page 15

- 15 -

8. USER MENU

Balance menu is divided into 7 basic function groups. Each group has individual

name.

8.1. Moving through user menu

An operator moves through balance menu using keys on overlay’s keyboard:

Setup key. Entering balance’s main menu.

Selecting group of parameters one by one d

ownwards or

changing parameter value by one value downwards.

Selecting group of parameters one by one upwards or changing

parameter value by one value upwards.

Selecting group of parameters for activating. On pressing the

key, the display indicates t

he first parameter in a selected group.

Exit to previous menu level, e.g. to main menu.

Esc/TARE key. Abandon parameter changes.

PRINT/ENTER key. Accept / confirm introduced changes.

Page 16

- 16 -

Name of function groups and their content:

P1 CAL [Adjustment/Calibration]

P1.1 iCAL | [internal adjustment]

P1.2 ECAL | [external adjustment]

P1.3 tCAL | [adjustment triggered by temperature]

P1.4 ACAL | both/nonE/tenno/tinnE [automatic adjustment]

P1.5 CALt | 1 h ÷ 12h [time of automatic adjustment]

P1.6 CALr | YES/no [report from adjustment]

P2 GLP [Good Laboratory Practice]

P2.1 USr | _ [name of user]

P2.2 PrJ | _ [name of project]

P2.3 Ptin | YES/no [printout of measurement time]

P2.4 PdAt | YES/no [printout of measurement date]

P2.5 PUSr | YES/no [printout of user name]

P2.6 PPrJ | YES/no [printout of project name]

P2.7 PId | YES/no [printout of balance’s factory no.]

P2.8 PFr | YES/no [printout of frames]

P3 rEAd [Main user parameters]

P3.1 AuE | Stand/Slouu/FASt [filtering level]

P3.2 ConF | FASt_rEL/Fast/rEL [value release]

P3.3 Auto | On/OFF [autozero]

P3.4 Ldi9 | ALuuAYS/neper/uu_StAb [blanking last digit]

P3.5 rAPd I YES/no [weighing mode RAPID]

P4 Print [Data transmission – RS 232]

P4.1 bAud | 2400/4800/9600/19200 [baud rate]

P4.2 CntA | YES/no [continuous printout in current

measuring unit]

P4.3 Cntb | YES/no [continuous printout in basic measuring

unit]

P4.4 rEPL | YES/no [manual or automatic operation]

P4.5 PStb | YES/no [result printout: stable or unstable]

P4.6 Lo | 000.0000 [minimum mass threshold for automatic

operation]

Page 17

- 17 -

P5 Unit [Measuring units]

P5.1 StUn | g/mg/kg/ct/lb/oz/ozt/dwt/t/mom/G [basic measuring units –

e.g. gram]

P5.2 mg | YES/no [mg - milligram]

P5.3

└

g | YES/no [kg– kilogram]

P5.4 Ct | YES/no [ct – carat]

P5.5 lb | YES/no [lb – pound]

P5.6 oZ | YES/no [oz – ounce]

P5.7 oZt | YES/no [ozt – ounce troy]

P5.8 dwt | YES/no [dwt – pennyweight]

P5.9 t | YES/no [t – tael]

P5.10 nno | YES/no [mom - momme]

P5.11 Gr | YES/no [gr – grain]

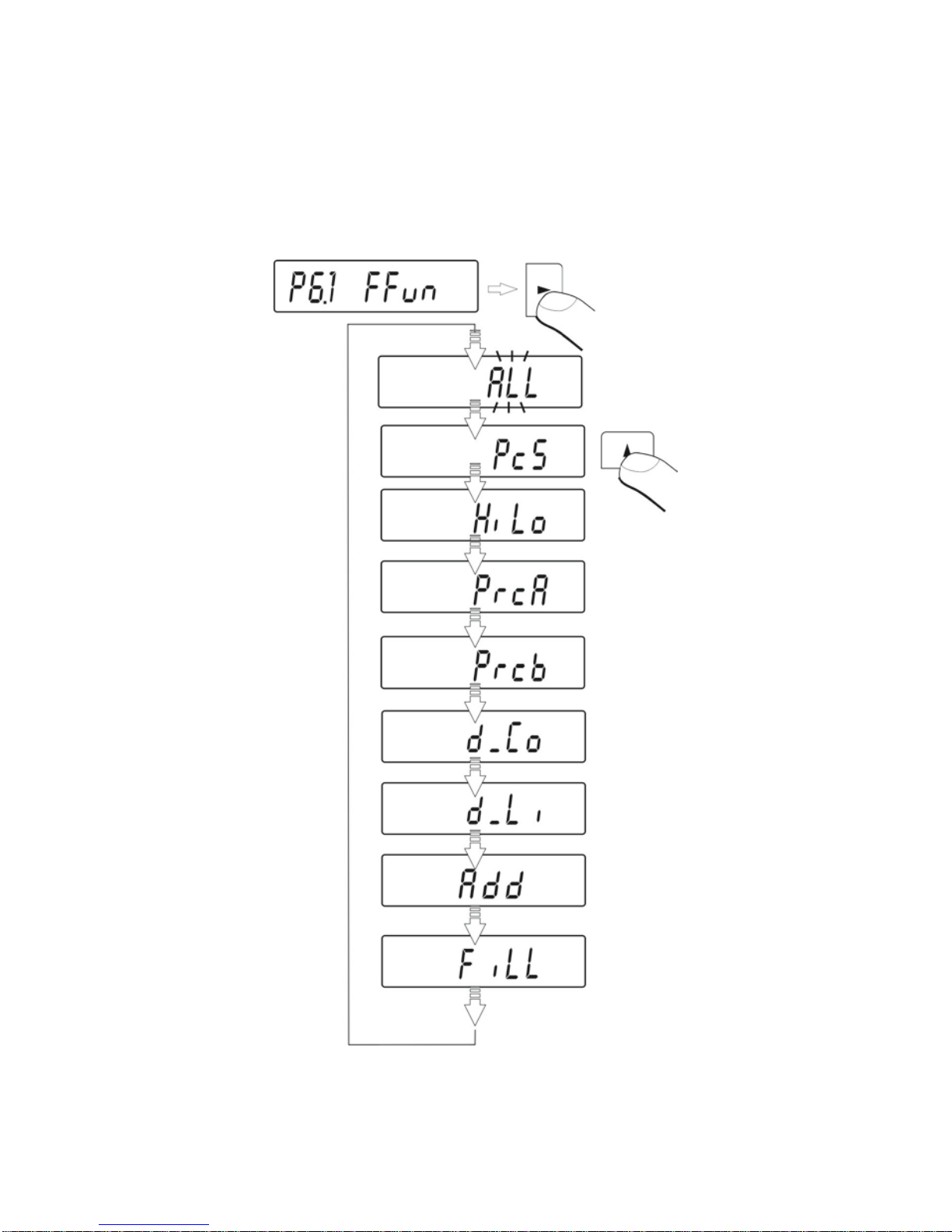

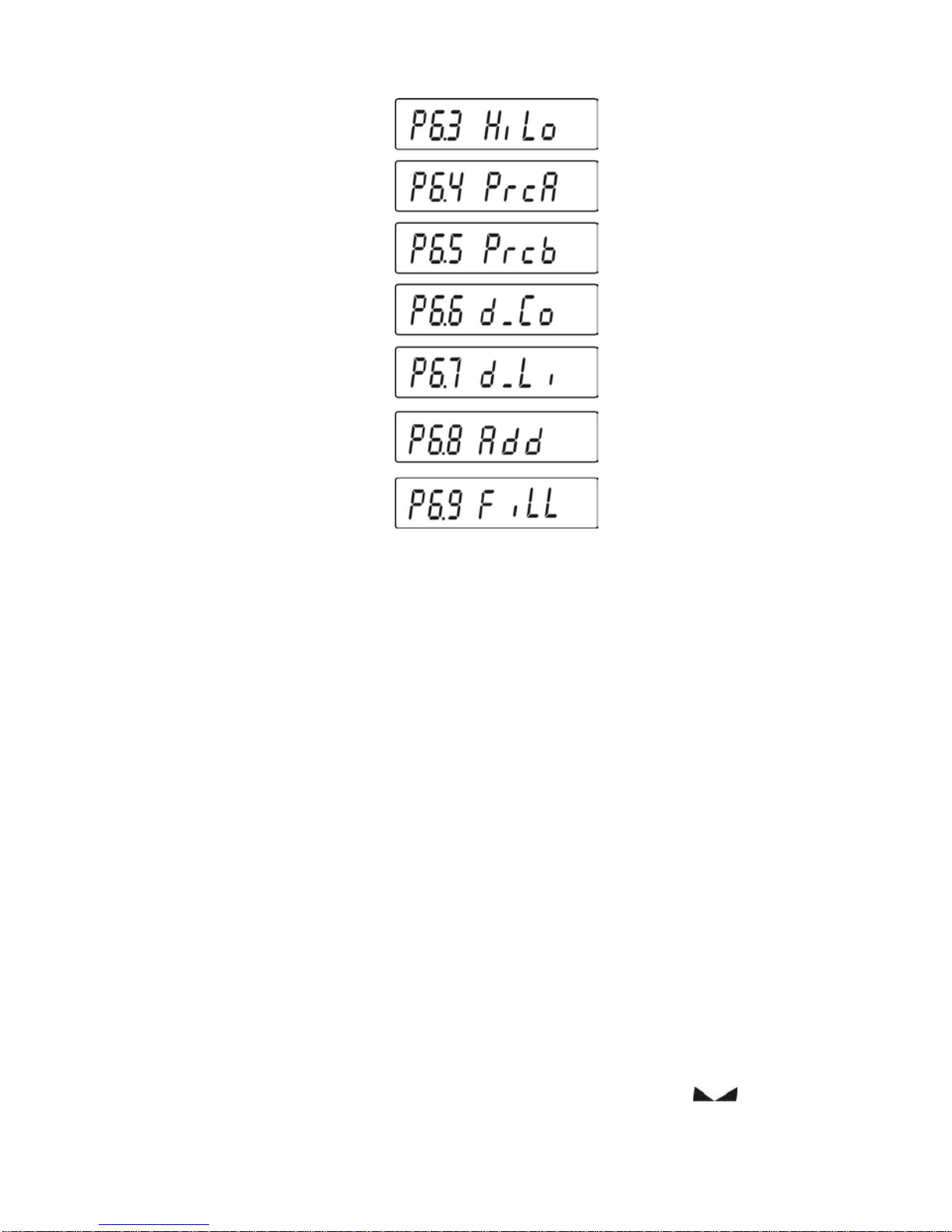

P6 Func [Working modes]

P6.1 FFun | ALL/PcS/HiLo/PrcA/Prcb/d_Co/d_Li/Add/FiLL [working mode

selection]

P6.2 PcS | YES/no [parts counting]

P6.3 HiLo | YES/no [checkweighing]

P6.4 PrcA | YES/no [percent setup with reference to

weighed standard]

P6.5 Prcb | YES/no [percent setup with reference to

declared standard]

P6.6 d_Co | YES/no [density determination of solids]

P6.7 d_Li | YES/no [density determination of liquids]

P6.8 Add I YES/no [totalizing]

P6.9 FiLL I YES/no [working mode FiLL]

P7 othEr [Other functions]

P7.1 bL | On/Aut/OFF [display backlight]

P7.2 bLbA |no/20/30/40/50/60/70/80/90/100 [display brightness]

P7.3 bEEP | On/OFF [beep sound]

P7.4 PrnS | [printout of balance parameters]

Page 18

- 18 -

8.2. Return to weighing mode

CAUTION

Changes introduced in balance memory will be saved on return to

weighing with procedure of saving changes.

Press ESC/TARE key for several times, until the display shows

command SAvE?.

When display indicates the above command for saving changes, press on e

of below options:

PRINT/ENTER – save changes

or ESC/TARE – abandon introduced changes, and leave to

balance menu.

After pressing an appropriate key, balance goes back to weighing

mode.

9. WEIGHING

Before start of weighing process or in case of essential change of ambient

conditions at a workstation (e.g. ambient temperature change at a workstation more

than 3

o

C) the balance requires adjusting. The procedure of balance adjustment is

described further in this user manual.

• Before start of weighing procedure, it is recommended to load the balance’s

weighing pan a few times with mass close to balance max capacity,

• Check if unloaded balance indicates “precise zero” - and whether

measurement is stable -

, if not press ESC/TARE key;

• Press Units key to set a measuring unit:

[g], [kg], [ct], and also if enabled in factory menu [lb], [oz], [ozt], [dwt], [t],

[mom], [gn],

• place weighed object on balance’s weighing pan and read result only on

stabilization of measurement result,

Page 19

- 19 -

• mass indication of a load placed on balance’s weighing pan can be tarred for

multiple times by pressing ESC/TARE key ((pay attention not to exceed

maximal capacity of a balance by applying multiple tare function),

During times between carrying out the following measurement series do not unplug

the balance from mains. It is recommended to switch off balance’s display by

pressing ON/OFF key. On repeated pressing of the ON/OFF key the balance is

ready for operation and carrying out the following measurements.

9.1. Selection of basic measuring unit

Function is used to set the measuring unit which will be displayed on balance

switching on.

In order to set the measuring unit go to submenu P5 Units,

Page 20

- 20 -

press key for a few times. The display indicates available measuring

units in turns

After selecting the basic measuring unit press PRINT key. The balance returns

to displaying parameter name.

Available settings:

• For verified balances, a user can select from the following measuring units:

[g], [kg], [ct]

• For non-verified balances, a user can select from the following measuring

units: [g], [kg], [ct], [lb], [oz], [ozt], [dwt], [t], [mom], [gn].

Page 21

- 21 -

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

CAUTION:

On switching on, the balance will start operating with set basic

measuring unit.

9.2. Temporary measuring unit

Function enables selecting a measuring unit which will be indicated next to

mass readout during weighing process. Set measuring unit will be in use from

the moment of its activation until its change or switching off and on the balance.

Each pressing the Units key, causes change of the measuring unit.

Available settings:

• For verified balances, a user can select from the following measuring units:

[g], [kg], [ct]

• For non-verified balances, a user can select from the following measuring

units: [g], [kg], [ct], [lb], [oz], [ozt], [dwt], [t], [mom], [gn].

9.3. Setting accessibility of balance working modes

This group of parameters enables the user to declare functions (working

modes) which are accessible on pressing of MODE key.

Enter group of parameters P6 Func,

Page 22

- 22 -

Page 23

- 23 -

9.3.1. Selection of working modes available for a user

Function enables selecting (by pressing MODE key) which working modes

are accessible during weighing function – if all – then select (ALL) and if

only one from all available (described below).

After setting the parameter press PRINT key. Balance goes back to

displaying submenu name P6.1 FFun.

Page 24

- 24 -

If a mode other than ALL is selected, procedure of returning to weighing

mode differs from other ones.

If for instance PcS mode is selected, follow procedure in accordance with

point 14.1 point, to return to weighing:

Press Esc/TARE key, balance returns to weighing.

9.3.2. Means of selecting one of available working modes

Balance user can enable or disable modes which are not used in the

weighing process. This provides quicker access to modes used on a

balance.

Page 25

- 25 -

YES - mode enabled; no - mode disabled

On selecting, press PRINT key. The balance returns to displaying

submenu name.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

9.4. Dual range balance (APP 6/35/2C)

Balance APP 6/35/2C series is a dual range weighing instrument. The accuracy of

the I weighing range is d

1

=1g, and of the II weighing range it is d

2

=5g.

Transfer from weighing with the accuracy of the I weighing range to weighing with

the accuracy of the II weighing range takes place automatically on exceeding Max

1

point at 6kg (with no operator activity needed). On switching to weighing with the

accuracy of the II weighing range, the display signals it by indicating II pictogram on

its right side.

From now on the balance weighs mass with the accuracy of the II weighing range.

In order to return to weighing in the accuracy of the I weighing range:

• Take the weighed load off the weighing pan

• As the indication returns to zero and pictograms

→0←

and are lit

press

→

0/T

←

key on balance’s keyboard.

Page 26

- 26 -

The balance returns to weighing with the accuracy of the I weighing range d1=1g

and II weighing range pictogram is blanked.

10. BALANCE MAIN PARAMETERS

It is possible to adjust balance’s operation to ambient conditions at a workstation

(by setting filter range and value release parameters) or user requirements

(autozero settings, last digit visibility). These parameters are set in group P3

rEAd.

10.1. Setting filtering level

- using UNITS key to select desired value of filter settings

StAnd – (normal) – normal operation conditions

Slouu – (slow) – harsh operation conditions - vibrations, etc.

Fast – (fast) – good operation conditions – no vibrations, etc.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

CAUTION:

The higher filtering setting the longer weighing time.

Page 27

- 27 -

10.2. Value release

Due to various ambient conditions at workstations, and in order to set balance

to present conditions, it is necessary to determine the value release parameter

as: FAST_rEL, Fast or rEL. Depending on selected option, weighing time will

be shorter or longer.

Fast_rEL - fast + reliable

Fast - fast

rEL - reliable.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 28

- 28 -

10.3. Autozero function

In order to ensure balance’s precise mass indication, autozero (Auto) software

parameter has been introduced. The application of this function is automatic

control and correction of zero indication. When function is enabled, it

compares balance indications at declared time interval e.g. 1 s, on conditions

that weighing pan is unloaded and display indication is close to zero.

If results vary less than declared AUTOZERO range e.g. one division, balance

will zero automatically, display marker of stable measurement result

and

precise zero marker .

If AUTOZERO function is enabled, then each weighing process starts from

precise zero point. There are, however, some cases when this function can be

a disturbing factor of measuring process; for instance very slow placing of load

on the weighing pan (e.g. load pouring) – in such case system of zero

indication correction can also correct actual indication of loaded mass.

OFF - autozero disabled

On - autozero enabled.

Go back to weighing mode with procedure of saving ch anges

(see point - 8. 2. – return to weighing).

Page 29

- 29 -

10.4. Blanking of the last digit on the display

Function enables blanking of the last displayed digit.

ALuuAYS - always

nEuEr - never

uu_StAb - when measurement result is stabilized.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 30

- 30 -

10.5. Weighing mode RAPID

Weighing mode RAPD is located in menu parameter P3.rEAd and it offers

two options:

RAPID = NO – balance operates with settings as set in menu AUE and

CONF, i.e. standard weighing.

RAPID = YES – (default settings) balance operates with settings specific for

software mode “FILL”, and:

- The value of CONF parameter is automatically set to: Fast+rel,

independently on previous setting of this parameter;

-

The value of AuE parameter is automatically set to: Standard,

independently on previous setting of this parameter;

- The value of Stabilization time parameter is automatically

decreased (factory setting is decreased by 4). Such parameter

setting speeds up the time of stability pictogram

appearance on

the display.

The values of AuE and CONF parameters are editable if mode rAPd is

enabled for setting shorter or longer measurement time.

Mode enabling or disabling

Page 31

- 31 -

11. OTHER PARAMETERS

Balance APPC series features a set of parameters which enable influencing its

functionality. The parameters are contained in group: P7 othEr and they are:

backlight and “beep” signal and printout of all balance parameters through RS 232

port.

In order to edit the above parameters enter menu group P7 Other.

11.1. Backlight of weighing result (display backlight)

OFF – backlight disabled

On – backlight enabled

Aut – backlight disabled automatically if weighing result does not

change within10 seconds.

Go back to weighing mode with procedure of saving changes

Page 32

- 32 -

(see point - 8. 2. – return to weighing).

CAUTION:

Balance software has implemented option of automatic backlight switch

off bl = Aut. In case of this setting, the backlight is switched

automatically off if weighing results does not change within 10 seconds.

Backlight is automatically activated at the moment of weighing result

change on balance display.

11.2. Adjusting display brightness

100 - maximum brightness of display backlight

20 - minimum brightness of display backlight

no - backlight off

Page 33

- 33 -

11.3. “Beep” sound – reaction on pressing function key

OFF - signal of pressing function key disabled

On - signal of pressing function key enabled.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 34

- 34 -

11.4. Printout of all balance parameters through RS 232 port

After pressing F key balance parameters are sent to a peripheral device

connected to balance’s RS 232 port.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 35

- 35 -

12. BALANCE ADJUSTMENT

As the gravitational acceleration force has different value at various latitudes and

altitudes, a balance should be adjusted to present working conditions. This process

should take place at the first installation of the instrument on site and at its every relocation – as in case of ambient temperature changes.

In order to ensure the highest weighing accuracy, it is recommended to periodically

introduce to balance memory a corrective factor of indications in relation to a mass

standard – i.e. balance adjustment.

Adjustment should be carried out:

- Before the beginning of weighing procedure,

- If long breaks between following measuring series occur

- If temperature inside the balance changes more than: 3°C.

Types of adjustment:

- Internal automatic adjustment

* triggered by temperature change

* triggered by elapsing time

- Manual internal adjustment

* initiated from balance’s keyboard

- Adjustment with external weight

* with declared mass which cannot be modified.

CAUTION

In case of verified balances (with internal automatic adjustment system)

only the automatic internal adjustment and manual internal adjustment

system are available for a user.

Remember to carry out adjustment process only when there is no load on

the weighing pan! In case there is load on the weighing pan, the display

will indicate a comm and Er1 Hi. It is comment of unloading the pan.

Adjustment process can be aborted if necessary by pressing Esc/TARE

key.

12.1. Internal adjustment

Adjustment process can be initiated automatically or manually.

Manual means of activating adjustment procedure is realized by pressing CAL

key on balance’s keyboard. System of automatic adjustment will carry out the

process fully automatically inform the operator on successive process stages.

Cycle of automatic adjustment process:

Page 36

- 36 -

- balance software detects necessity of carry out adjustment and signalizes it

by Celsius degree pictogram or by black colour pictogram on balance

display,

- since pictogram occurrence, time interval of 5 minutes is counted within

which weighing procedure can be completed,

- as the 5 minutes time elapses, balance display indicates message CAL_30

and starts counting down from 30..29..28 to 0 (indicated value is the

counter),

- balance user has 30 seconds to make a decision:

in order to start adjustment, do not take any actions,

in order to complete weighing procedure, press ESC/TARE key, If

pressed, balance returns to weighing procedure and displays last

weighing result. In 5 minutes balance will again indicate CAL_30

message

- the adjustment process can be postponed for multiple times, but it needs to

be stressed that long postponing of adjustment may be a reason of bigger

errors of weighing process. The errors are effect of temperature changes

and as a consequence changes of balance sensitivity.

Automatic adjustment process takes place in three different cases:

• adjustment on plugging the balance to mains. After approximately 6

minutes from plugging the balance to mains, it automatically initiates

adjustment process,

• adjustment triggered by temperature changes. Balance APPC series

is equipped with very precise system for monitoring temperature. At

each adjustment process, the temperature is saved in system. The

next adjustment is automatically initiated if temperature changes

more than 3

o

C from last saved temperature.

Page 37

- 37 -

• adjustment triggered by elapsing time. It is possible to declare time

intervals which are a criteria for balance adjustment. Accessible

settings are: adjustment after 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 hours

since last carried out adjustment procedure,

CAUTION

Declaring time interval for balance adjustment is available only in

non-verified balances. In case of verified balances the time interval

between following adjustments is set for 3 hours.

12.2. Menu adjustments settings

P1 CAL

P1.1 iCAL |

P1.2 ECAL |

P1.3 tCAL |

P1.4 ACAL | both

P1.5 CALt | 1 h

P1.6 CALr | YES

• P1.1 iCAL – internal adjustment

Start of internal adjustment process. Adjustment is conducted automatically,

and no operator assistance is required. If weighing pan of the balance is

loaded, balance will display a command to unload the weighing pan. If

weighing pan is loaded with relativaly small mass (up to 4 % of balance max

capacity) than adjustment process will be carried out automatically, but

measuring results may differ by the amount that was present on balance

weighing pan.

or

Page 38

- 38 -

• P1.2 ECAL – External adjustment (with an external weight)

adjustment with external weight, which value is saved in factory menu of

balance, function unavailable in verified balances.

balances with internal adjustment balances with external adjustment

• P1.3 tCAL – Adjustment test

mass comparison of internal adjustment weight with its value saved in

balance memory.

balances with internal adjustment balances with external adjustment

• P1.4 ACAL – Automatic adjustment (balance with internal adjustment

system)

determination of factor, which conditions start of automatic internal adjustment.

Page 39

- 39 -

nonE – none of factors will cause start of adjustment

tEmP – adjust ment triggered by change of temperature

timE – adjustment triggered by time interval set in

both – adjustment triggered by time and temperature.

Page 40

- 40 -

• P1.5 CALt - Time of automatic adjustment (balances with internal

adjustment system)

Determination of time interval, after which automatic adjustment process is

initiated.

• P1.6 CALr – printout of adjustment report

Printout activated on completion of automatic adjustment procedure.

balances with internal adjustment balances with external adjustment

no – report printout disabled

YES – report printout enabled

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 41

- 41 -

12.3. Adjustment test

12.3.1. Balances with internal adjustment system

Adjustment test is a comparison of internal adjustment weight with its value

stored in balance’s memory. This process is automatic and its result is

shown on the display (if a balance is connected to a computer or a printer

through RS 232 socket, data on adjustment test is printout). Press

ESC/TARE key to return to previous display.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 42

- 42 -

12.3.2. Balances with external adjustment system

It is mass comparison of external adjustment weight with its value stored in

balance’s memory during adjustment process. This process is automatic

and its result is shown on the display (if a balance is connected to a

computer or a printer through RS 232 socket, data on adjustment test is

printout). Press ESC/TARE key to return to previous screen.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 43

- 43 -

12.4. Manual adjustment

12.4.1. Internal adjustment

Press Cal key or follow below guidelines

The balance performs internal adjustment automatically. During

adjustment process do not load the weighing pan with any load.

On completion of adjustment process, balance saves its result in memory

and returns to weighing mode.

CAUTION:

- Press ESC/Tare key to abort adjustment process

- If during adjustment process, weighing pan of a balance is

loaded, than balance display will show order informing on

error occurrence. Adjustment process will be stopped. As weighing pan is

unloaded, the adjustment process will continue and complete.

Page 44

- 44 -

12.4.2. External adjustment

External adjustment in balances APPC series should be carried out with an

external mass standard / weight class F

2

Start of external adjustment process,

Balances with internal adjustment balances with external adjustment

Balance will display a command ordering unloading of weighing pan unloAd

(weighing pan should be empty). When weighing pan is unloaded, press

PRINT key. The balance determines mass of empty pan. Place an external

adjustment weight with mass determined on balance’s display and press

PRINT key. On completing adjustment process the balance returns to

submenu.

Go back to weighing mode with procedure of saving ch anges

(see point - 8. 2. – return to weighing).

If a balance is verified, then user does not access to carrying out

external adjustment process.

12.5. Adjustment report printout

On completion of any type of adjustment process, the balance enables

preparing a report from adjustment process. The report can be printed on a

connected printer and sent to a computer and saved in a form of file for

records. Printout process is described in details in point 9.2 of this user manual.

The user can select between two options.

Page 45

- 45 -

no – report is not printed

YES – report is printed

.

Remember, that if the parameter is set for YES, then a report is generated and

sent automatically.

Content of report from adjustment process depends on settings of GLP

parameters. Any option in the GLP submenu which attribute is YES is included

in a report from adjustment process.

P2 GLP – Good Laboratory Practice

P2.1 uSr |

P2.2 PrJ |

P2.3 Ptin | YES

P2.4 PdAt | YES

P2.5 PuSr | YES

P2.6 PPrJ | YES

P2.7 PId | YES

P2.8 PFr | YES

Apart from information set in menu group the report contains:

• Mass of adjustment weight stored in balance’s memory from last

carried out adjustment;

• Mass of adjustment weight determined in current adjustment process;

• Adjustment deviation, i.e. difference between the two mass records.

Page 46

- 46 -

13. DETERMINING CONTENT OF A PRINTOUT FOR GLP PROCEDURE

P2 GLP is group of the parameters which enables declaring variables that are

present on an adjustment printout and printout activated after a measurement.

P2 GLP

P2.1 USr |

P2.2 PrJ |

P2.3 Ptin | YES

P2.4 PdAt | YES

P2.5 PUSr | YES

P2.6 PPrJ | YES

P2.7 PId | YES

P2.8 PFr | YES

• P2.1 USr

The parameter enables determining name of a operator who works with the

balance. User name contains maximally 8 alphanumeric characters. The name

is inserted using navigating arrows (keys) on balance’s keyboard and PRINT

key.

Page 47

- 47 -

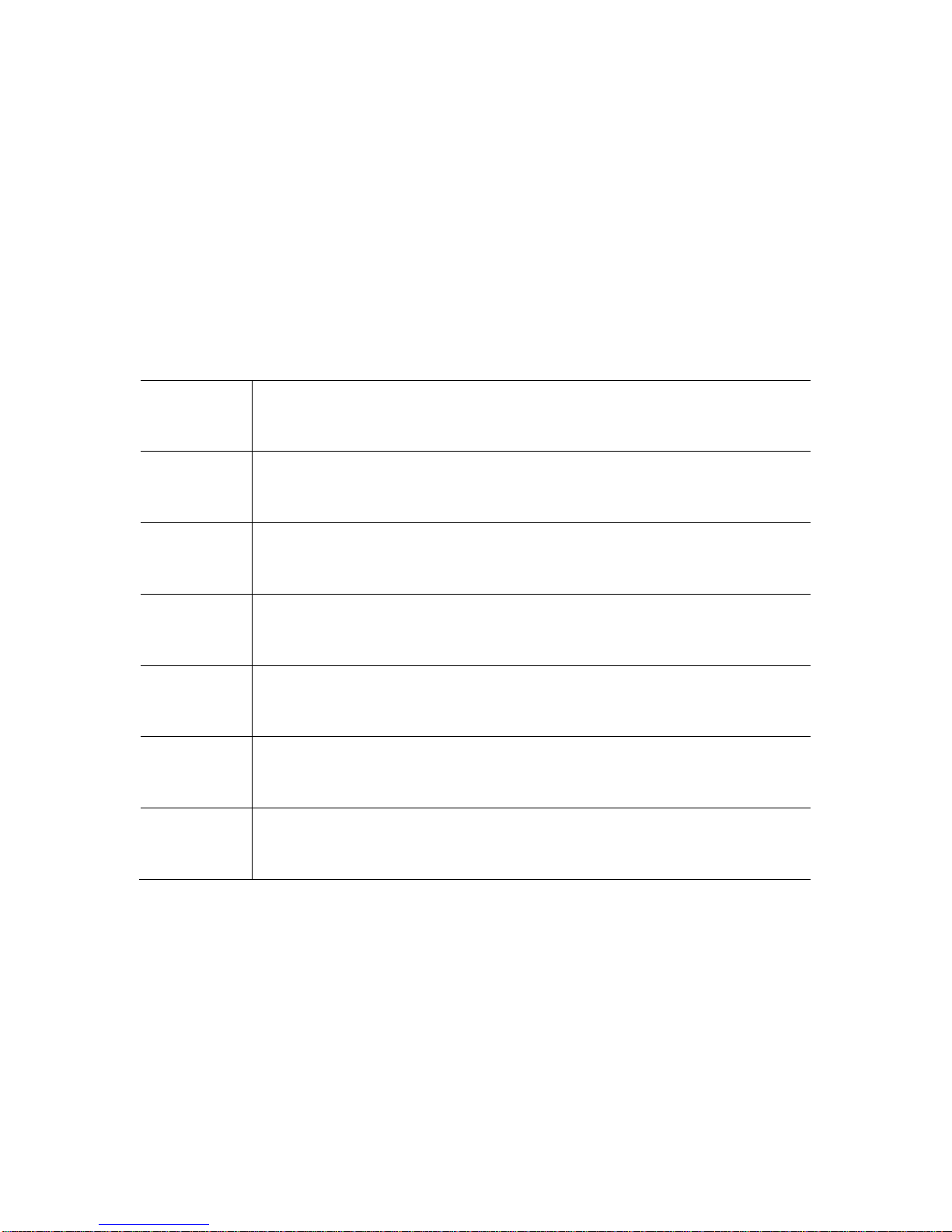

Accessible characters and their equivalents displayed by a balance:

An instance of a user name inserted to a balance using capital letters takes

below form:

OP1_WILK (operator 1 WILK)

An instance of a user name inserted to a balance using small letters takes

below form:

op1_wilk (operator 1 wilk)

• P2.2 PrJ

The parameter enables determining name of a project (e.g. related to a specific

type of weighing process).

An instance of project name inserted to a balance using capital letters takes

below form:

PRRADWAG

Page 48

- 48 -

An instance of project name inserted to a balance using small letters takes

below form:

prradwag

• P2.3 Ptin

Option determining presence of measurement time on a printout (data on

measurement time is acquired from a connected printer).

• P2.4 PdAt

Option determining presence of measurement date on a printout

(measurement date is acquired from a connected printer).

• P2.5 PUSr

Option determining presence of user name on a printout.

• P2.6 PPrJ

Option determining presence of project name on a printout.

• P2.7 PId

Option determining presence of balance factory number on a printout.

• P2.8 PFr

Option enabling printing frames on a printout.

For above parameters please select one of two available settings:

no – variable absent on a printout

YES – variable present on a printout

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 49

- 49 -

14. BALANCE WORKING MODES

- Weighing mode - bASic

- Parts counting - PcS

- Checkweighing - HiLo

- Percent setup with reference mass – PrcA or PrcB

- Density determination of solids - d_Co; Density determination of liquids - d_Li.

- Totalizing – Add

- Working mode - FiLL

Press MODE key,

Page 50

- 50 -

Pressing MODE key causes displaying the first of available modes. Each next

pressing of or key causes displaying name of next available mode.

The way of setting a working mode is described in further section of this manual.

14.1. Parts counting of the same unit mass

Balance in its standard version is equipped with an option for counting parts

and small objects of the same unit mass. Parts counting mode does not

cooperate with other working modes of balance APPC series.

• Enable PcS mode,

• Press key to set sample quantity: 10, 20, 50 or FrEE,

Page 51

- 51 -

• in order to select one of the options, e.g. 20 pcs press ENTER/PRINT

key and as the display indicates value “20” proceed as shown on below

figure,

Page 52

- 52 -

• If option FrEE (sample quantity is declared by a user) is selected, insert

sample quantity used for determining mass of single part,

Press key to select a digit to be altered,

Use key to select digit value,

• Accept inserted value by pressing PRINT key,

• Display indicates a command LoAd – load the weighing pan with as

many details as inserted while determining sample quantity,

• Press PRINT key – balance indicates sample’s quantity (pcs pictogram

is visible on the display),

• add remaining parts, the display indicates their total quantity.

Page 53

- 53 -

Return to weighing

CAUTION:

While determining sample quantity, and before accepting it, it is necessary

to wait until stable measurement pictogram

is displayed. Only if

visible on balance’s display, it is allowed to accept the declared quantity of

parts by pressing PRINT key. Otherwise balance will not accept the

measurement.

Page 54

- 54 -

14.2. Checkweighing (HiLo) with reference to set standard

• Enter the checkweighing mode,

During setting limit values the following relations occur:

Page 55

- 55 -

SET LOW LIMIT (LOW THRESHOLD)

- digit selection; - set digit value; - accept inserted digit value

SET HIGH LIMIT (HIGH THRESHOLD)

- digit selection; - set digit value; - accept inserted digit value

Page 56

- 56 -

CAUTION:

If by mistake the value of low threshold is set higher than high threshold, balance

will indicate error message and return to weighing.

Return to weighing:

Page 57

- 57 -

14.3. Percent setup with reference mass

Balance software enables controlling deviation (in %) of weighed loads with

determined reference mass. Mass of a reference load can be determined by

its weighing (PercA) or entered to balance memory by a user (PercB).

14.3.1. Reference mass determined by weighing

• Enter the PrcA mode:

• on balance weighing pan place a load which mass will be

accepted as the reference,

• press PRINT to accept this working mode,

• after few seconds indication 100,00% will be displayed.

Page 58

- 58 -

From now on the display will not indicate mass of weighed load but

deviation of mass placed on the pan in relation to the reference (in %).

14.3.2. Reference mass inserted to balance memory by a user

• Enter the PrcB mode:

• Display will indicate as above,

• Using function keys:

Select a digit

Select digit value

Page 59

- 59 -

• Determine the value of reference mass, insert it to balance

memory and accept it by pressing PRINT key – display will indicate:

0,00 %

From now on the display will not indicate mass of weighed load but

deviation of mass placed on the pan in relation to the reference (in %).

Return to weighing

Page 60

- 60 -

14.4. Density determination of solids and liquids

The software enables determining density of solids (with determined

dimensions) and liquids.

Before carrying out density determining process, it is necessary to place a

balance on a dedicated rack which provides access to assembling a hook in

the bottom section of the balance (the rack is additional equipment of a

balance, and it is manufactured on individual client’s order). Using the opening

in the bottom of balance’s housing dedicated for under hook weighing

assembly a special weighing pan for density measurement process (the pan for

density determination is additional equipment of a balance, and it is

manufactured on individual client’s order). Assembling procedure is provided in

point 17 of this user manual.

Additionally, use a vessel for water to test density of a solid or liquid.

An example of a density determining kit assembled on a balance APPC series:

1. Rack

2. Vessel with liquid of determined density

3. Weighing pan

4. Tested sample

Caution: the density kit presented above is additional equipment of a balance

APPC series and it is supplied only on client’s individual order).

Page 61

- 61 -

14.4.1. Density determination of solids

Procedure:

• Press Mode key, then use navigating arrows to select submenu F 6 d_Co,

• Select one of the 3 available liquid types H20 (distilled water), C2H5OH

(spirit 100% ± 0.1% in temp. 20

0

C) or Another (other liquid with known

density),

• for H20 and C2H5OH, give liquid temperature value and follow instructions

given on below figure:

• For selected liquid: Another, give liquid’s density and follow the

instructions given on below figure:

Page 62

- 62 -

• After selecting liquid type the balance displays command Load A and zero

indication (if indication on balance’s display is other than zero, press

ESC/ZERO/TARE key),

• Then load the sample on the top weighing pan (as indicated on below

figure), and weigh the sample in the air:

Page 63

- 63 -

• When the balance displays stability marker press Print/Enter key,

• When the balance displays command Load L – load the sample on the

bottom weighing pan of the density kit (in the liquid). After displaying

stability marker press Print/Enter key,

Page 64

- 64 -

• The balance displays density measurement result expressed in [g/cm

3

].

CAUTION:

Pay special attention to presence of air bubbles during measuring process. If

air bubbles are on sample’s surface during measuring process, they may be a

source of unreliable measurements.

To carry out repeated liquid selection, press F key:

To return to weighing mode press Mode key, and then Zero/Tare key:

Page 65

- 65 -

In order to weigh a sample again, press Units key:

14.4.2. Density determination of liquids

Basic element for determining density of liquids is a glass sinker with

precisely determined volume. Before starting liquid density determination,

insert the value of sinker’s volume to balance memory. In order to measure

the density of liquid, first determine mass of the sinker in the air. Then

measure mass of the same sinker in tested liquid.

Procedure

:

•

Press Mode key, then using navigating arrows go to submenu F7 d_Li,

•

Insert sinker’s volume that is specified on its hook,

Page 66

- 66 -

•

After inserting sinker’s volume and storing the data in balance’s memory

(using Print/Enter key), balance’s display indicates a command Load A

and zero (if the indication is other than zero , press ESC/ZERO/TARE

key),

•

Hang the sinker on the density kit and in the air to determine its mass in

the air

,

Page 67

- 67 -

•

When the balance indicates stable measurement pictogram press

Print/Enter key,

•

As the display indicates a command Load L – place the beaker with tested

liquid on the rack’s basis under the balance and hang the sinker on the

hook. The sinker has to be fully immersed in the tested liquid

,

•

Then determine the density measurement result by pressing Print/Enter

key; the balance indicates the density of tested liquid in [g/cm

3

].

CAUTION:

Pay special attention to presence of air bubbles during measuring process.

If air bubbles are on sample’s surface during measuring process, they may

be a source of unreliable measurements.

Page 68

- 68 -

To repeat inserting sinker’s volume procedure press F key:

To return to weighing mode press Mode key, and then Zero/Tare key:

In order to once again weigh the sinker in the air press Units key:

Page 69

- 69 -

14.5. Totalizing

Totalizing mode is basically adding the following components in order to

prepare a mixture. After adding following component of the mixture, the

balance totalizes mass of the mixture and exposes its total mass on the

display. During totalizing process mass of each added component is sent

through RS232 interface to a connected computer of a printer (e.g. Kafka

printer).

CAUTION

Totalizing mode functions only in grams.

Enter the working mode Add (Totalizing):

Black pictograms indicate that the working mode “Totalizing” is enabled.

Page 70

- 70 -

Page 71

- 71 -

Return to weighing mode

Page 72

- 72 -

14.6. Working mode FILL

Working mode FiLL enables two settings:

FiLL = NO – mode disabled, i.e. not available in the working modes.

FiLL = YES – mode enabled, i.e. available in the working modes.

If FiLL is enabled, then the balance operates with settings, that are stored in

balance’s settings as default and ensuring quicker operation. The settings

automatically decrease Autozero range to 1 reading interval. Mode activation

is signaled by a black triangle pictogram visible on display’s right hand side

(and above the measuring unit). Working mode FiLL is set to YES as default,

thus it is accessible in the working modes. The mode can be disabled from

the working modes by setting it to NO. To disable FiLL mode, set availability

of working mode FiLL to NO in balance’s menu.

Enabling FiLL mode in the working modes

The balance operates in accordance with the settings of AUE and CONF

options. The options enable setting shorter or longer measurement time.

Disabling FiLL mode

On disabling FiLL mode, the measurement are carried out in accordance with

user settings.

Page 73

- 73 -

15. RS 232 FUNCTIONS

P4 Print

P4.1 bAud | 4800

P4.2 CntA | YES

P4.3 CntB | YES

P4.4 rEPl | YES

P4.5 PStb | YES

P4.6 Lo | 0.005

P4.1 bAud - baud rate setting (speed of transmission)

P4.2 CntA - continuous data transmission in basic measuring unit

P4.3 CntB - continuous data transmission in current measuring unit

P4.4 rEPl - setting operation mode for RS 232 output (manual / automatic)

P4.5 PStb - stable / unstable measurement for RS 232 transmission

P4.6 Lo - minimal mass required for activation of automatic printout

15.1. Baud rate

Page 74

- 74 -

Select required baud rate value

- 2400 bit/s

- 4800 bit/s

- 9600 bit/s

- 19200 bit/s.

Go back to weighing mode with procedure of saving ch anges

(see point - 8. 2. – return to weighing).

15.2. Continuous transmission

15.2.1. Continuous transmission in basic measuring unit

no – continuous transmission disabled

YES – continuous transmission enabled.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 75

- 75 -

15.2.2. Continuous transmission – in current measuring unit

no – continuous transmission disabled

YES – continuous transmission enabled.

Go back to weighing mode with procedure of saving ch anges

(see point - 8. 2. – return to weighing).

Page 76

- 76 -

15.3. Setting operation mode for RS 232 interface

no - manual operation (enabled on pressing PRINT key)

YES - automatic operation (enabled on stabilization of weighing result).

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Automatic operation takes place according to the following scheme:

press Esc/TARE key to zero the balance (display will indicate

pictograms of stable measurement

and precise zero )

place the load, balance will send first stable measurement through the

RS232 interface

remove the weighed load from the weighing pan,

next measurement can be conducted if a weighing result equals +/- 50

reading units from zero (it is not necessary to reach precise zero to

start another measurement).

Page 77

- 77 -

15.4. Determination of data type sent through RS 232 output

no - sending stable or instantaneous (unstable) measuring result

YES - sending stable weighing result.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 78

- 78 -

15.5. Minimal mass required for activation of automatic

printout

Balance software is equipped with a function for setting automatic operation.

While in automatic operation, data will not be transmitted through RS 232 to a

connected computer or printer until mass reading is above Lo value.

• Press key to select a digit which should be changed;

• Press

key to change value o f selected digit.

Go back to weighing mode with procedure of saving changes

(see point - 8. 2. – return to weighing).

Page 79

- 79 -

16. COOPERATION WITH A PRINTER OR A COMPUTER

CAUTION

A peripheral device that is connected to RS 3232 output of a balance, has

to be powered from the common low voltage power network equipped with

common anti-shock protection in a way to preclude possible occurrence of

different potentials in zero cables of the peripheral device and the balance.

Transmission parameters programmed in a balance:

- Baud rate - 2400 – 19200 bit / s

- Data bits - 8

- Stop bit - 1

- Parity control - none.

The value indicated on balance display can be sent through RS 232 output

to a peripheral device in one of four accessible ways:

• manually – on pressing PRINT key

• automatically – on stabilization of weighing result

• continuously – on activation of a function or sending a

command

• on command sent from a peripheral device (see additional functions).

Value indicated on balance’s display can be sent through RS232 output in

the following form:

• stable – data is sent immediately on stabilization of weighing

result

• unstable – on pressing of PRINT key causes immediate sending

of display status to a peripheral device (on a printout

such status is marked with <?> symbol proceeding the

weighing result).

Page 80

- 80 -

16.1. Cross-section through connecting conductors

BALANCE

COMPUTER

2 (RxD)

3 (TxD)

3 (TxD)

2 (RxD)

4 (DTR)

6 (DSR)

5 (GND)

5 (GND)

6 (DSR)

6 (DTR)

7 (RTS)

8 (CTS)

8 (CTS)

7 (RTS)

Page 81

- 81 -

16.2. Printing date with specified date and time

Every weighing result can be printed with specification of measurement date

and time. The presence of date and time on a printout is conditioned by

connection of printers type Kafka 1/Z or Kafka SQ S to a balance.

When connected, go to balance menu and set parameters from group P2 GLP:

PdAt - YES

Ptin - YES

16.3. Cooperation with statistic printer Kafka SQS

On connecting a statistic printer KAFKA SQ S to a balance, it is possible to

carry out statistics from completed measurements. An instance of a printout

including statistics from series of measurement:

1 9:02:15 + 7.0016 g

2 9:02:39 + 5.0152 g

3 9:02:58 +

12.0171 g

4 9:03:15 + 9.9937 g

5 9:03:34 + 12.0169 g

6 9:03:48 + 22.0111 g

Date 13.09.2001 Time 9:04

n 6 number of samples

sum x 68.0556 g total mass of samples

x

11.34260 g average value

s 5.92328 g standard deviation

srel 52.22 % variance factor

min 5.0152 g min value

max 22.0111 g max value

R 16.9959 g max – min difference

16.4. Format of data sending

Weighing result can be sent to a peripheral device by pressing PRINT key on a

balance keyboard or by setting a control command from computer level.

Page 82

- 82 -

16.4.1. Format of data sent on pressing of PRINT key

Depending on setting of P4.5 PStb parameter only stable measurement or

instantaneous mass indication will be sent.

CAUTION:

For verified balances printout of instantaneous measurement data is

blocked.

Printout format

1 2 3

4 - 12

13

14 - 16

17

18

stability

marker

space

sign

mass

space

unit

CR

LF

stability marker – [space] if stable

- [?] if unstable

- [^] if there is an error of range exceeding on +

- [v] if there is an error of range exceeding on -

sign – [space] for positive values or [-] for negative values

mass – 9 marks alignment to the right

unit – 3 marks alignment to the left

16.4.2. Format of data sent as response for commands generated

from a computer

On receipt of a command, balance responses with:

XX_A CR LF – command understood, in progress

XX_I CR LF – command understood, but currently not available

XX _ ^ CR LF – command understood, but max range is exceeded

XX _ v CR LF – command understood, but min range is exceeded

XX _ E CR LF – error occurred while carrying out the command – time

limit exceeded while waiting for stable measurement result (time

limit is characteristic parameter of balance)

XX – name of command

And followed by:

Page 83

- 83 -

1 – 3

4 5 6 7 8 – 16

17

18 - 20

21

22

command

space

stability

marker

space

sign

mass

space

unit

CR

LF

Command – 1 ÷ 3 characters

stability marker – [space] if stable

– [?] if unstable

– [^] if there is an error of range exceeding on +

– [v] if there is an error of range exceeding on sign – [space] for positive values or [-] for negative values

mass – 9 marks alignment to the right

unit – 3 marks alignment to the left

17. UNDER HOOK WEIGHING

In standard analytical and precision balances loads can be weighed under the

weighing pan. Such means of operation requires placing a balance on a uplifted

position.

For under hook weighing follow below procedure:

• Place a balance on an optional rack enabling assembling a hook under

balance’s mechanism (opening in bottom section of balance’s housing) (the

rack does not come standard with a balance),

• Remove plastic hole plug in basis of a balance,

• There is suspension place for hook visible in the hole – the suspension is

installed permanently to balance mechanism,

• In the opening install a dedicated weighing pan for under hook weighing (the

weighing pan for under hook weighing option does not come standard with a

balance),

• Weigh loads using under hook weighing option,

• On completing under hook weighing process, close the hole in balance basis

with plastic hole plug.

CAUTION:

The suspension for hook must not be turned, twisted or manipulated

in any direction. Such actions may cause damage to balance

mechanism.

Mass of all additional elements of under hook weighing kit, like: the hook,

weighing pan, string, etc. should be zeroed by pressing Esc/TARE key.

Page 84

- 84 -

18. LIST OF COMMANDS COMPUTER – BALANCE

• Function TARE

Command T CR LF (balance tarring)

• Function ZERO

Command Z CR LF (balance zeroing)

• Function IMMEDIATELY SEND WEIGHING RESULT IN BASIC

MEASURING UNIT

Command SI CR LF (immediately send of balance indication)

• Function SEND WEIGHING RESULT IN BASIC MEASURING UNIT

Command S CR LF (send result when stable)

• Function SEND WEIGHING RESULT IN CURRENT MEASURING UNIT

Command SU CR LF (send result with current unit when stable)

• Function IMMEDIATELY SEND WEIGHING RESULT IN CURRENT

MEASURING UNIT

Command SUI CR LF (send result in current unit now – do not wait for stable

reading)

• Function CONTINUOUS TRANSMISSION IN BASIC MEASURING UNIT

Command C1 CR LF (start continuous transmission in basic unit)

• Function END OF CONTINUOUS TRANSMI S S ION IN BASIC

MEASURING UNIT

Command C0 CR LF (finish continuous transmission in basic unit)

• Function CONTINUOUS TRANSMISSION IN CURRENT MEASURING

UNIT

Command CU1 CR LF (start continuous transmission in current unit)

• Function END OF CONTINUOUS TRANSMISSION IN BASIC

MEASURING UNIT

Command U0 CR LF (finish continuous transmission in current unit)

CAUTION

If a non-existing or incorrect command finished with CR LF will be sent

to a balance, it responses with ES CR LF. Space between characters

should be omitted, as they are added only for the purpose of proper

legibility.

Page 85

- 85 -

19. ERROR MESSAGES

Er1 Hi – mass out of range on balance start and adjustment

Er2 nuLL – value from AD converter ≤ 0 (A/D ≤ 0)

Er3 FuL1 – values from A/D converter ≥ maximal converter range (A/D ≥ 0)

Er4 FuL2 – maximal capacity of the balance exceeded (over load)

Er5 rout – mass value out of range (during adjustment, determining reference for

sample quantity and percent setup, etc.),

Er7 tout – timeout error for zeroing and tarring

Er8 outr – enter value (from keyboard level) out of range (setting thresholds / limits

values)

Er9 Lock – function blocked (e.g. by LFT),

Er10 cal – adjustment error (change of mass or incorrect mass of adjustment

weight / mass standard).

Page 86

- 86 -

20. ADDITIONAL EQUIPMENT

20.1. Anti-Vibration table

It is a very stable basis which eliminates all kinds of vibration and

ground shakes. The inner part of the table holds a marble plate,

which is a foundation for balance positioning.

20.2. Additional display

Features: Length of conductor between additional display and

balance – 1,5m, plastic casing, possibility of tilting the

additional display head.

20.3.

Computer software

PW-WIN 2004 – gathering data. Data is gathered in tabular or chart

format. It is possible to calculate statistics from a series of weighing

records.

RAD-KEY 2000 – implements a set of commands for controlling a

balance, e.g. tarring, start of continuous transmission, cyclic

commands set to a balance.

REC-FS 2000 – application for control of formulas. It enables

creation of a formula, declare tolerance limits for each ingredient

and measure mass of each ingredient of a formula.

Number of instruction:

LMI-53-04/11/12/A

Page 87

- 87 -

MANUFACTURER

OF ELECTRONIC WEIGHING INSTRUMENTS

RADWAG WAGI ELEKTRONICZNE

26-600 Radom

28 Bracka

POLAND

phone +48 48 38 48 800

fax. + 48 48 385 00 10

e-mail: export@radwag.com

www.radwag.com

Loading...

Loading...