Page 1

Number of instruction:

LMI-26-02/06/08/ENG

Precision balances

APP/C series

MANUFACTURER

OF ELECTRONIC WEIGHING INSTRUMENTS

RADWAG 26 – 600 Radom, Bracka 28 Street, POLAND

phone +48 48 38 48 800, phone/fax. +48 48 385 0 0 10

Sales Department +48 48 366 80 06

www.radwag.com

Page 2

- 2 -

JUNE 2008

Page 3

- 3 -

Contents

1. TECHNICAL DATA .................................................................................. 6

2. BASIC INFORMATION ............................................................................ 7

2.1. Intended use ............................................................................................... 7

2.2. Inappropriate use ........................................................................................ 7

2.3. Warranty ..................................................................................................... 7

2.4. Monitoring the metrological parameters of the instrument .......................... 8

2.5. Data included in this user manual ............................................................... 8

2.6. Staff training................................................................................................ 8

3. TRANSPORT AND STORAGE ............................................................... 8

3.1. Acceptance check ....................................................................................... 8

3.2. Packaging ................................................................................................... 8

4. UNPACKING, INSTALLATION AND COMMISSONING ......................... 8

4.1. Installation and operation place .................................................................. 8

4.2. Unpacking ................................................................................................... 9

4.3. Positioning .................................................................................................. 9

4.4. Standard accessories ............................................................................... 10

4.5. Cleaning ................................................................................................... 10

4.6. Connection to mains ................................................................................. 10

4.7. Connection of additional equipment .......................................................... 10

5. BASIC FUNCTIONS OF THE INSTRUMENT ....................................... 11

6. KEYBOARD ........................................................................................... 12

7. USER MENU ......................................................................................... 13

7.1. Moving in user menu ................................................................................ 15

7.1.1. Return to weighing function .............................................................. 15

8. WEIGHING ............................................................................................ 15

8.1. Choice of basic weighing unit ................................................................... 16

8.2. Choice of weighing unit (temporary) ......................................................... 17

8.3. Setting accessibility of balance operating modes ..................................... 18

8.3.1. Choice of modes quantity accessible for user .................................. 18

8.3.2. Setting contents of P6.1 FFun – ALL parameters ............................ 20

9. MAIN SETTING PARAMETERS ........................................................... 21

9.1. Setting level of filtering .............................................................................. 22

9.2. Result confirmation ................................................................................... 23

9.3. Autozero function ...................................................................................... 24

9.4. Light off the last display digit ..................................................................... 25

10.ANOTHER PARAMETERS ................................................................... 26

10.1. Backlight of weighing result ...................................................................... 26

10.2. “Beep” signal – reaction on pressing key .................................................. 27

Page 4

- 4 -

10.3. Printout of all balance parameters through RS 232 port ........................... 27

11.BALANCE CALIBRATION ..................................................................... 28

11.1. Balance with internal calibration ............................................................... 28

11.2. Entering calibration menu ......................................................................... 30

11.3. Calibration test .......................................................................................... 33

11.3.1. Balances with internal calibration ..................................................... 33

11.3.2. Balances with external calibration .................................................... 34

11.4. Manual calibration ..................................................................................... 35

11.4.1. Internal calibration ............................................................................ 35

11.4.2. External calibration ........................................................................... 36

11.5. Calibration report printout ......................................................................... 36

12.SETTING PRINTOUTS FOR GLP PROCEDURES .............................. 37

12.1. Setting the contents of printouts for GLP procedures ............................... 38

13.BALANCE OPERATING MODES ......................................................... 42

13.1. Counting details of the same mass ........................................................... 43

13.2. +/- control referring mass of set standard ................................................. 47

13.3. Control of % deviation referring mass of standard .................................... 49

13.3.1. Mass of standard determined by its weighing .................................. 50

13.3.2. Mass of standard entered to balance memory by user ..................... 51

13.4. Defining thickness of solids and liquids .................................................... 52

13.4.1. Testing thickness solids ................................................................... 52

13.4.2. Testing thickness of liquid ................................................................ 53

13.5. Summing function ..................................................................................... 53

14.FUNCTIONS FOR USING RS 232 ........................................................ 55

14.1. Speed of transmission .............................................................................. 56

14.2. Continuous transmission .......................................................................... 57

14.2.1. Continuous transmission off in actual interval .................................. 57

14.2.2. Continuous transmission of in basic units ........................................ 58

14.3. Setting type of operating for RS 232 joint ................................................. 59

14.4. Designation of data type sent through RS 232 joint .................................. 60

14.5. Designation of minimum mass for operating of some functions ................ 61

15.COOPERATION WITH PRINTER OR COMPUTER ............................. 62

15.1. Schedules of connecting conductors ........................................................ 63

15.2. Printing data with date and time ................................................................ 64

15.3. Cooperation with statistic printout Kafka SQS .......................................... 64

15.4. Format of sending data ............................................................................. 64

15.4.1. Format of sent data after pressing the PRINT button ....................... 65

15.4.2. Format of sent data for orders generated from the computer ........... 65

16.WEIGHING LOADS UNDER BALANCE ............................................... 66

17.LIST OF ORDERS IN RADWAG BALANCES ...................................... 67

18.ERROR MESSAGES ............................................................................. 68

Page 5

- 5 -

19.ADDITIONAL EQUIPMENT ................................................................... 68

19.1. Vibration damping table ............................................................................ 68

19.2. Additional display ...................................................................................... 68

19.3. Computer software ................................................................................... 68

Page 6

- 6 -

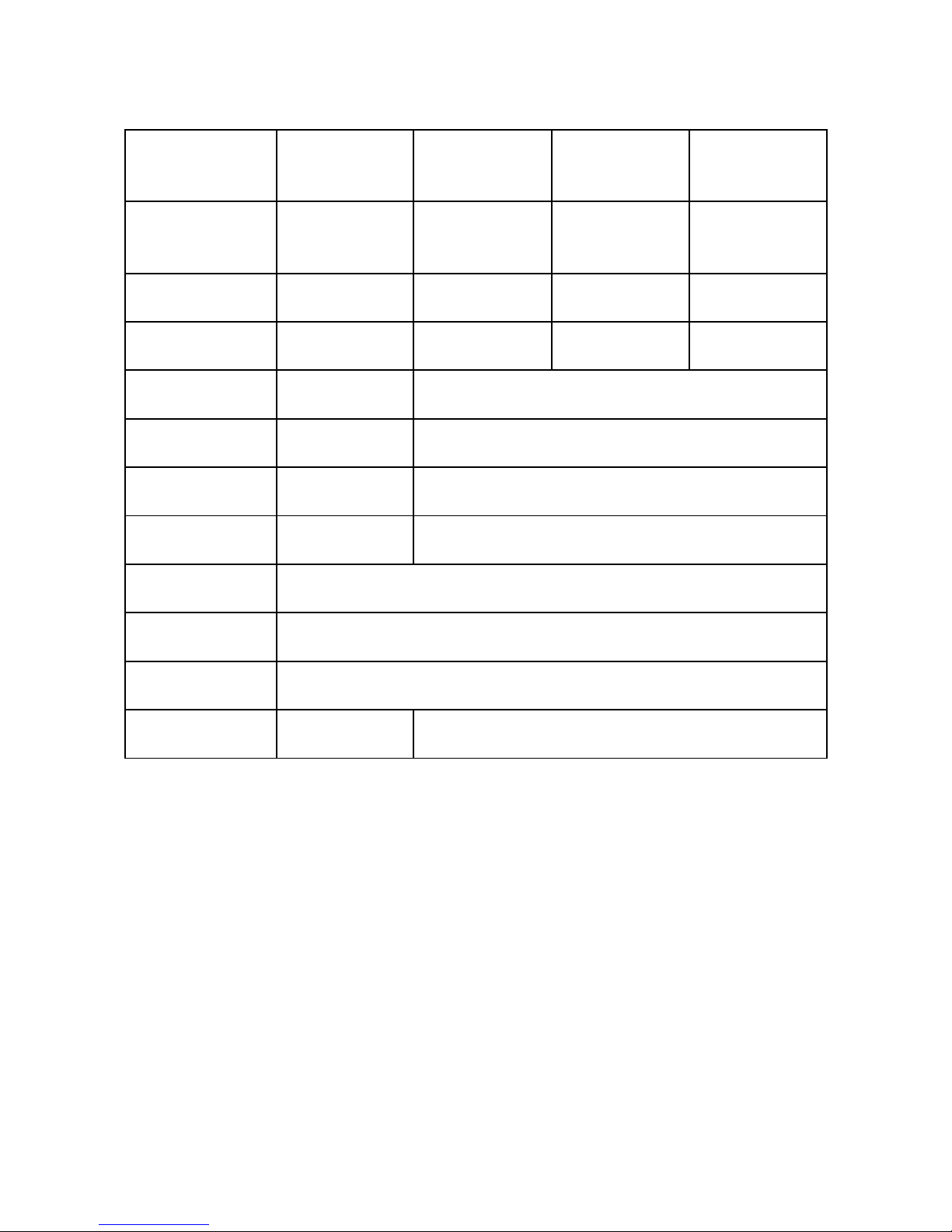

1. TECHNICAL DATA

External

calibration

APP

8/C

APP

10/C

APP

25/C

APP

30/C

Internal calibration

APP

8/C/2

APP

10/C/2

APP

25/C/2

APP

30/C/2

Max capacity

8 kg 10 kg 25 kg 30 kg

Tare range

-8 kg -10 kg -25 kg -30 kg

Min capacity

0,2 g 2 g

Readability

0,01 g 0,1 g

Repeatability

0,01 g 0,1 g

Linearity ±0,02 g

± 0,2 g

Working

temperature

+15 °C - +30 °C

Power

Zasilacz 230V 50Hz AC /11 V AC

Drift sensitivity

2 ppm/°C w temp. +18°C - +30°C

Pan size 300 x 250 mm

365 x 285 mm

Page 7

- 7 -

2. BASIC INFORMATION

2.1. Intended use

Balance you have acquired serves to determine the weighing value of a load in

laboratory environment. It is intended for applic ation as a non-automatic weighing

instrument only, i.e. the material to be weighed is man ually and carefully placed in

the center of the weighing pan. Weighing result should be read only after stable

reading has been obtained.

2.2. Inappropriate use

Do not use the balance as a dynamic weighing instrument. Even if small quantities

of weighed material are added or removed from the weighin g pan of the instrument,

the reading should be taken onl y after stabilization of the result. Do not place any

magnetic materials on the weighing pan, as this can cause damage of the

measuring system of the instrument. Be sure to avoid impact shock a nd overloading

the balance in excess of the prescribed maximum lo ad rating, minus any possible

tare weight that has been applied. Never use the balance in an environment

endangered by an explosion. This balanc e has not been adjusted for operation in

explosive areas. There must not be any modification made to the balance .

2.3. Warranty

Warranty is not valid at the following:

• Non-observation of the guidelines in the user manua l,

• Use of balance other than specified in this manual,

• Alternation to or opening of the device,

• Mechanical damage and damage caused by media, natural water,

and tear,

• Inappropriate erection or electric installation,

• Overloading of the measuring instrument.

Page 8

- 8 -

2.4. Monitoring the metrological parameters of the instrument

Metrological features of the balance should be tested by the user within regular

intervals of time, within scope of quality assurance.

2.5. Data included in this user manual

Please read the user manual carefully before erectin g and commissioning, even if

the user has is experienced with this kind of weighing instruments.

2.6. Staff training

This balance may only be operated and looked after by trained member of staff.

3. TRANSPORT AND STORAGE

3.1. Acceptance check

Please check the packaging immediately upon delivery and the device during

unpacking for any visible signs of external damage.

3.2. Packaging

Please retain all parts of the original packaging in case it should be necessar y to

transport or return items at any time. Only the original packaging should b e used for

return consignments. Before dispatch, disconnect all attached cables and

loose/movable parts (weighing pan, etc). Ple ase place any elements of the b alance

in its original packing. Please protect the balance and its parts against any damage

while in transport.

4. UNPACKING, INSTALLATION AND COMMISSONING

4.1. Installation and operation place

* Balance should be stored and used in locations free of vibrations and

shakes, free of wind and dust.

* Air temperature shou ld not exceed range between:

+15oC ÷ +30oC

* Humidity of air should not exceed 80% (not condensing).

* When operating the balance, room temperature should not change more

than 0,5°C within one hour,

* The balance should be placed on a stabl e surface not affected by vibrations

and distant from heat sources.

Page 9

- 9 -

* Please take special safety measures when weighing magnet ic loads, as part

of this balance is a strong magnet. If there is a necessity to perform

measurement of such load, please use option of under hook weighing, which

removes the load from area influenced by the magnet. For install ation place

of under hook device, please look at the bottom casing of the balance,.

* Avoid static charging of items to be weighed, or weighing container. In case

of static discharges may occur, please ground the device. Grounding bolt is

placed at the back side of the balance’s casing.

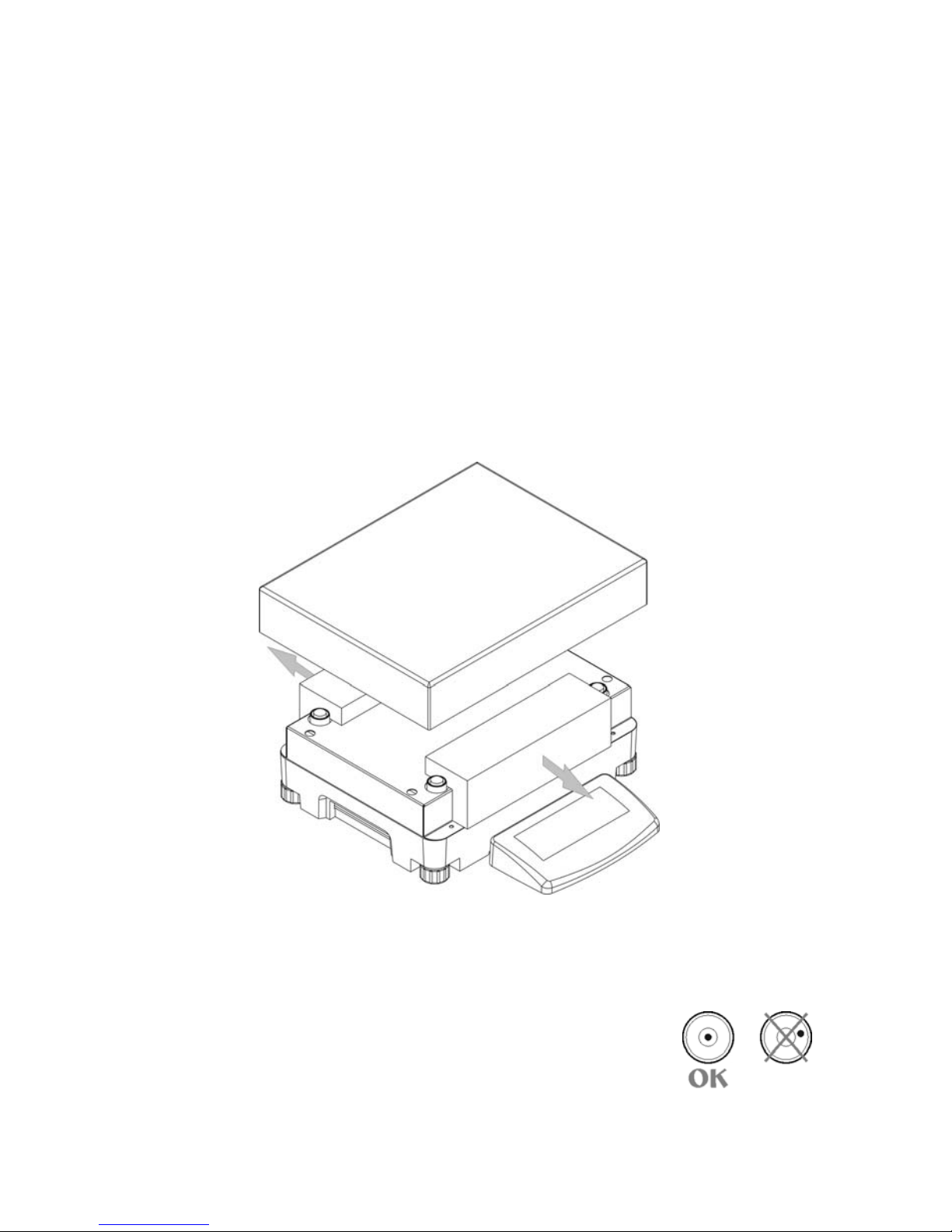

4.2. Unpacking

Cut safety tape off. Take balance off the box. Take out balance from

package. Take all necessary to correct performance of balance elements

off the box.

Take off the pan and remove carrying protection, look at drawing below.

Placing balance in place of using.

4.3. Positioning

Before switching on the balance, please level the device with

two adjusting feet situated at the back of the casing. Please

level the balance so that the air bubble of the level is placed

centrally.

Page 10

- 10 -

4.4. Standard accessories

• Balance.

• Weighing pan.

• Power adapter.

• User manual.

4.5. Cleaning

Balance should be cleaned with damp cloth. In order to clean the weighing pan of

the balance, please remove it from the weighing chamber. Cleaning of the pan

when installed may cause damage of the measuring system of the balan c e.

4.6. Connection to mains

Balance can be connected to mains onl y with a power adapter offered as standard

accessory to the balance. Nominal power supply of the power adapter (sp ecified on

the data plate of the power adapter) should be com patible to the po wer from mains.

Please plug the adapter the socket at the back of the ba lance, the display with light

on and show sequence of digits – display test), after which balance will display

0.00g. if indication is different from zero, please press ESC/TARA button.

4.7. Connection of additional equipment

The balance must be disconnected from the mains before connecting or

disconnecting additional equipment (printer, PC) to or from the data interface. Use

only accessories and peripheral e quipment recommended by the manufacturer with

your balance. These have been ideally coordinated to your balance.

Page 11

- 11 -

5. BASIC FUNCTIONS OF THE INSTRUMENT

Electronic balance is appropriate for precise measurements mass in laboratory

conditions with possibility of setting to zero in all measure range. Balance

calibration is done by CAL on balance keyboard.

9 Functions for weighing units (press Units key)

- select default units of weighing <StUn>,

- Weighing in grams,

- Weighing in [kg],

- Weighing in [ct],

- Weighing in units from beyond SI (only: [oz], [ozt], [dwt], [t], [mom], [gn],

Access to these units is blocked from factory menu level,

9 Functions for calibration and weighing modes

- Counting pieces < PIECES>,

- Control +/- <HiLo>,

- Control of deviations % according to standard mass <Perc A>,

<Perc B>,

- Thickness of liquids <d_Li> or solids <d_Co>,

- Summing <Add>

9 Choice of criteria of stable result depending on usage conditions

- Turn off/on system of autozero <AUTO>,

- Average result of weighing <AvE>,

- Back light function<bl>,

- Beep signal <bEEP>,

9 Function for using RS 232

- Choose speed of transmission,

- Define sent data as: stable / not stable,

- Continuous work,

- automatic work for RS 232.

Moreover balance can be used to weigh hang loads, print report of calibration,

check deviation of calibration and print reports of testing thickness of liquids and

solids.

Page 12

- 12 -

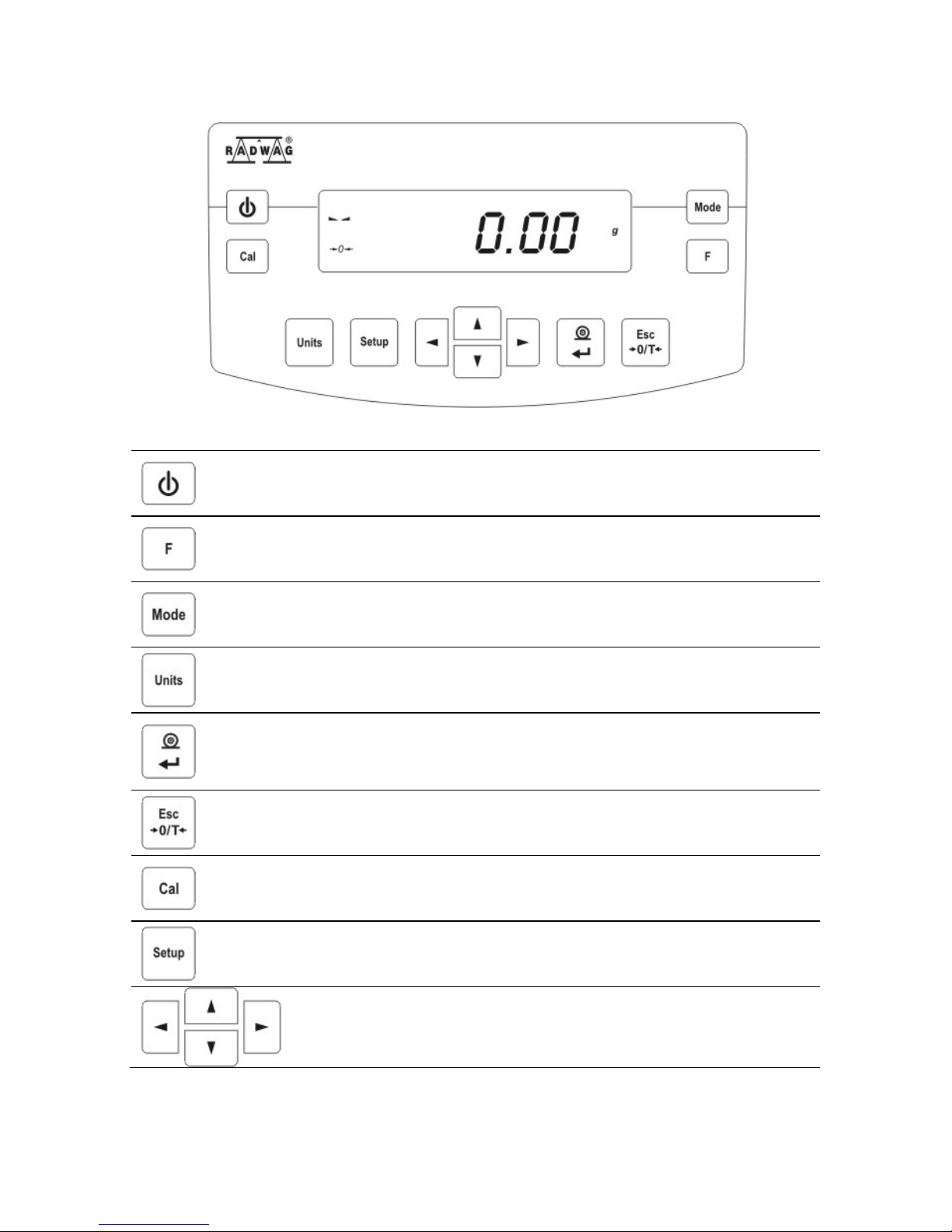

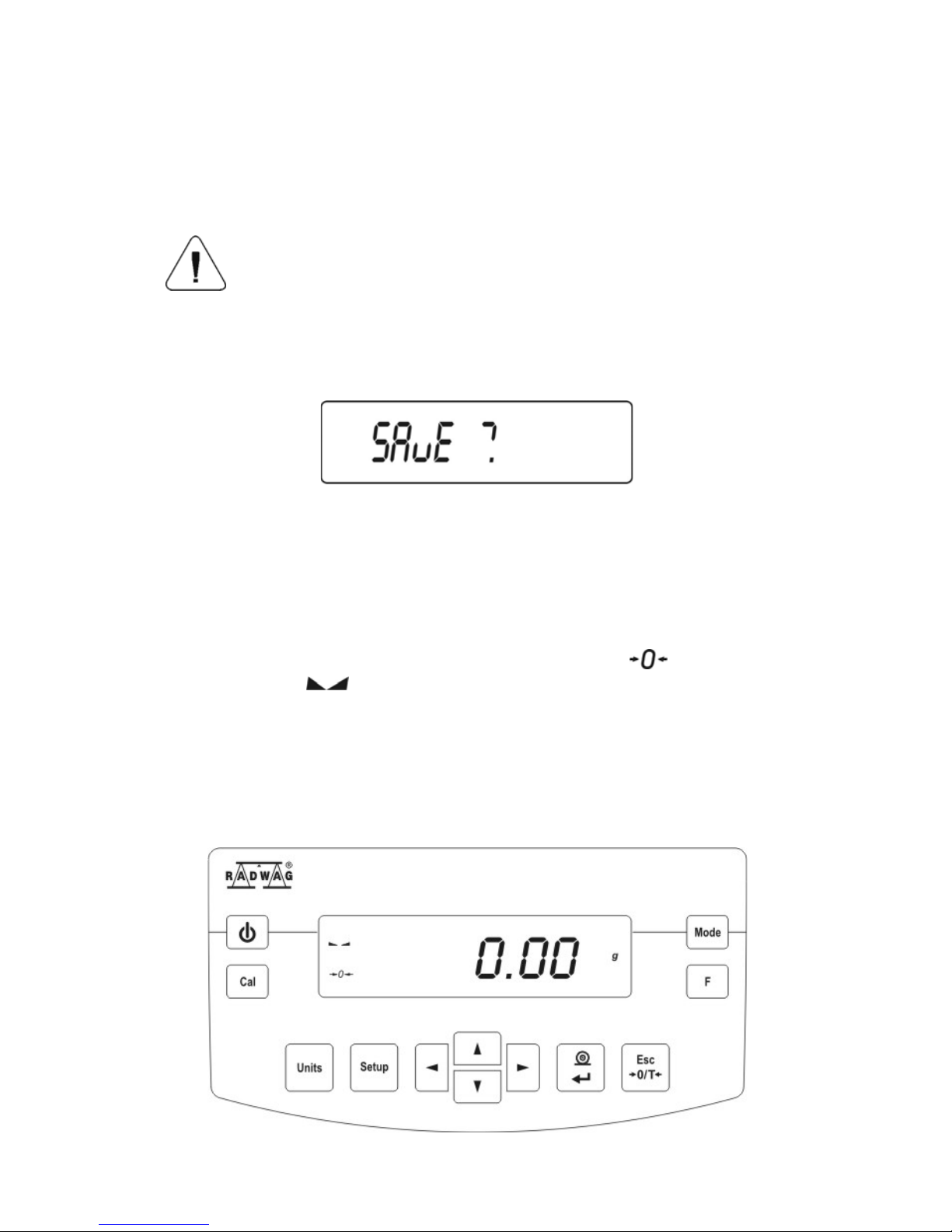

6. KEYBOARD

Switches the display off. ON/OFF key.

Function key. F key.

Selects the work mode. MODE key.

Changes measure units. UNITS key.

Sends information to external instrument (PRINT) or confirms

parameter value or function (ENTER). PRINT/ENTER Key.

Sets indication to zero. Esc/TARA Key.

Calibration (internal or external)

Menu of balances

Navigation bar

Page 13

- 13 -

7. USER MENU

Menu is divided into 7 basic groups. Each group has individual name starting with

capital letter P. Names of groups and their contents is shown below.

P1 CAL [Calibration]

P1.1 iCAL | [internal calibration]

P1.2 ECAL | [external calibration]

P1.3 tCAL | [temperature calibration]

P1.4 ACAL | both/nonE/tenno/tinnE [automatic calibration]

P1.5 CALt | 1 h ÷ 12h [time of automatic calibration]

P1.6 CALr | YES/no [report from calibration]

P2 GLP [Good Laboratory Practice ]

P2.1 USr | _ [name of user]

P2.2 PrJ | _ [name of project]

P2.3 Ptin | YES/no [printout of measurement time]

P2.4 PdAt | YES/no [printout of measurement date]

P2.5 PUSr | YES/no [printout of user name]

P2.6 PPrJ | YES/no [printout of project name]

P2.7 PId | YES/no [printout of factory number of balance]

P2.8 PFr | YES/no [printout of frames]

P3 rEAd [Main user parameters]

P3.1 AuE | Stand/Slouu/FASt [filtering level]

P3.2 ConF | FASt_rEL/Fast/rEL [confirmation of result]

P3.3 Auto | On/OFF [autozero]

P3.4 Ldi 9 | ALuuAYS/never/uu_StAb [light off the last digit]

P4 Print [Data transmission – RS 232]

P4.1 bAud | 2400/4800/9600/19200 [speed of transmission]

P4.2 CntA | YES/no [continuous printout in currently

used unit]

P4.3 Cntb | YES/no [continuous pr intout in basic unit]

P4.4 rEPL | YES/no [manual or automatic operating]

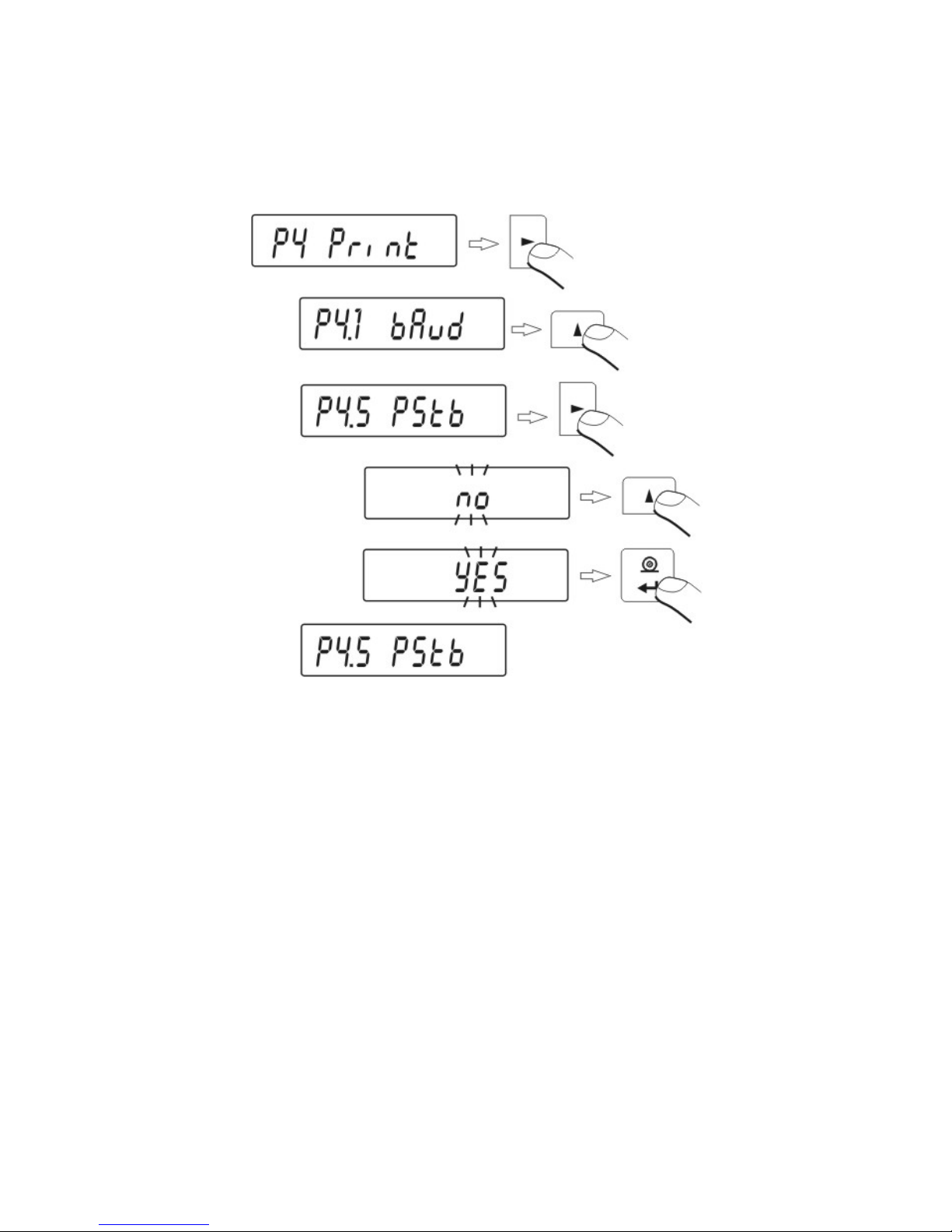

P4.5 PStb | YES/no [result printout: stable or unstable]

P4.6 Lo | 00000.00 [min mass for automatic operating]

Page 14

- 14 -

P5 Unit [Mass units]

P5.1 StUn | g/kg/ct/oz/ozt/dwt/t/mom/G [basic mass unit – e.g. gram]

P5.2 mg | YES/no [kg - milligram]

P5.3 Ct | YES/no [ct – carat]

P5.4 oZ | YES/no [oz – ounce]

P5.5 oZt | YES/no [ozt – troy ounce]

P5.6 dwt | YES/no [dwt – pennyweight]

P5.7 t | YES/no [t – tael]

P5.8 nno | YES/no [mom - momme]

P5.9 Gr | YES/no [gr – grain]

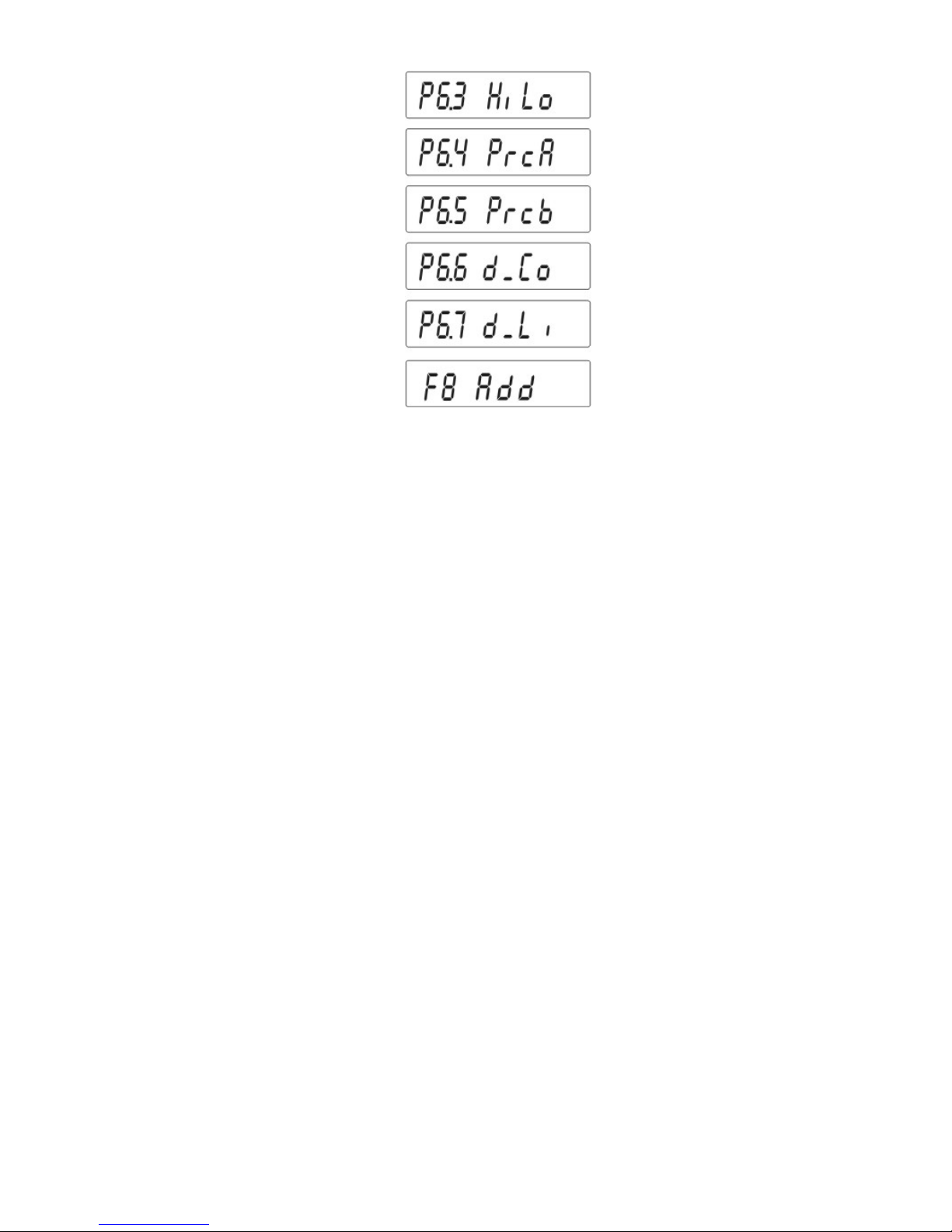

P6 Func [Functions]

P6.1 F F un | [choice of balance function]

P6.2 PcS | YES/no [counting pieces]

P6.3 HiLo | YES/no [check weighing]

P6.4 PrcA | YES/no [% deviation with reference to

weighed standard mass]

P6.5 Prcb | YES/no [% deviation with reference to declared

standard mass]

P6.6 d_Co | YES/no [densit y determination of solids]

P6.7 d_Li | YES/no [density determination of liquids]

P6.8 Add | YES/no [summing]

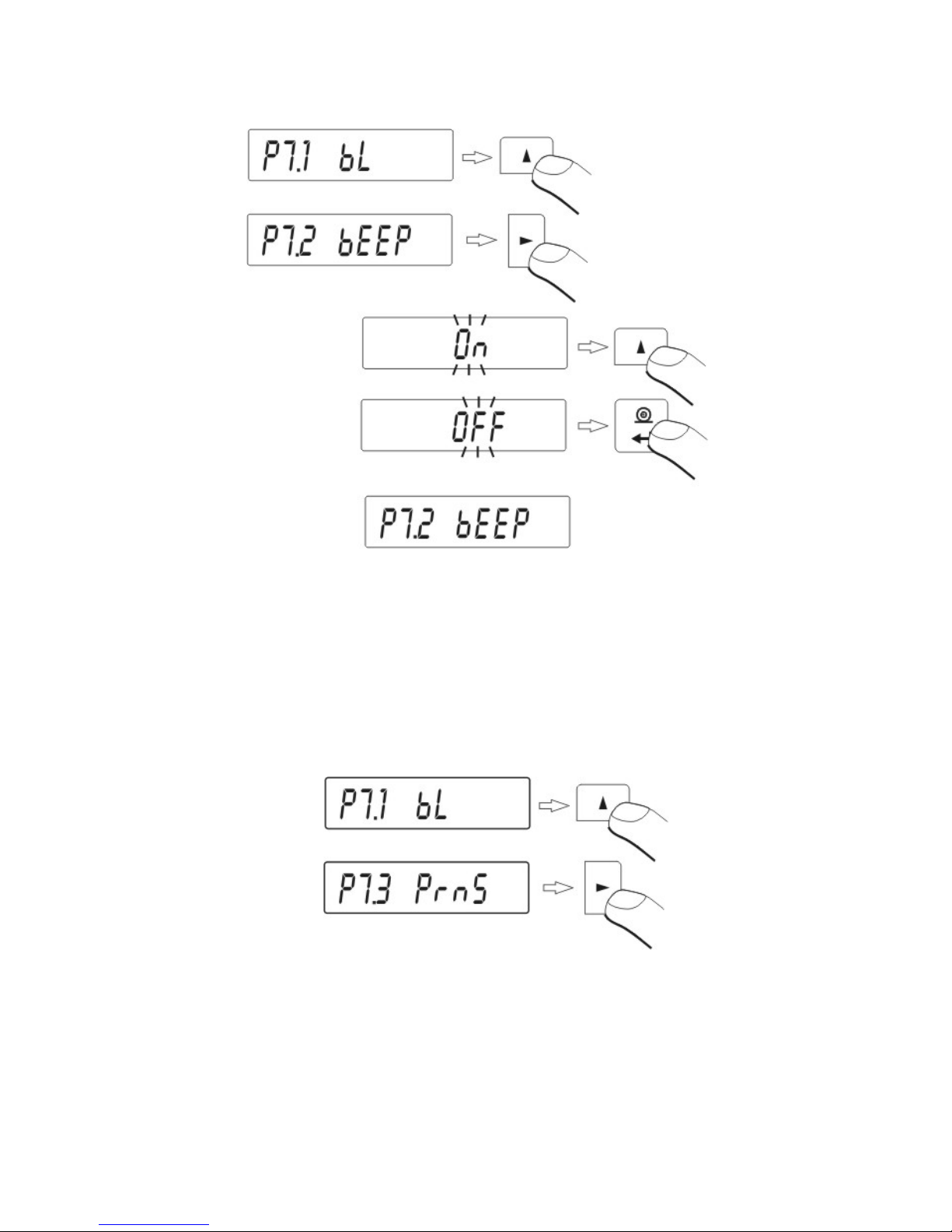

P7 othEr [Other functions]

P7.1 bL | On/Aut/OFF [display backlight]

P7.2 bEEP | On/OFF [keys sound]

P7.3 PrnS | [printout of balance parameters]

Page 15

- 15 -

7.1. Moving in user menu

User moves in menu using balance keyboard (see point no 6)

7.1.1. Return to weighing function

Introduced changes in balance memory will be saved for g ood after

return to weighing with procedure of saving chan ges. Press several

times Esc key until display indicates message SAvE?.

When display indicates question press if necessary: PRINT/ENTER – c onfirmation

of changes or ESC – resignation from introduced changes. After pressing

appropriate key, balance will go back to weighing.

8. WEIGHING

Before weighing or if the conditions of work changes (e.g. if temperature of

surrounding is higher then 3oC) balance should be calibrated.

• Balance should be loaded few times by mass close to max capacity b efore

taking measurements,

• Check if not load balance shows „precise zero” - if measurement is

stable - order , if not press key →0/T←,

• by means of Units key set measure unit : [g], [kg], [ct], and if they are

accessible in factory menu [oz], [ozt], [dwt], [t], [mom], [gn],

• put load on balance and read result on display ,

• indication can be setting to zero many times by pressing key Esc/TARE

(summary of mass loads record to balance memory cannot be bigger then its

max capacity).

Page 16

- 16 -

Don’t unplug the balance from power supply between following measurements.

Switch the balance off by pressing ON/OFF key. If user presses key ON/OFF once

again balance is ready to following measurements

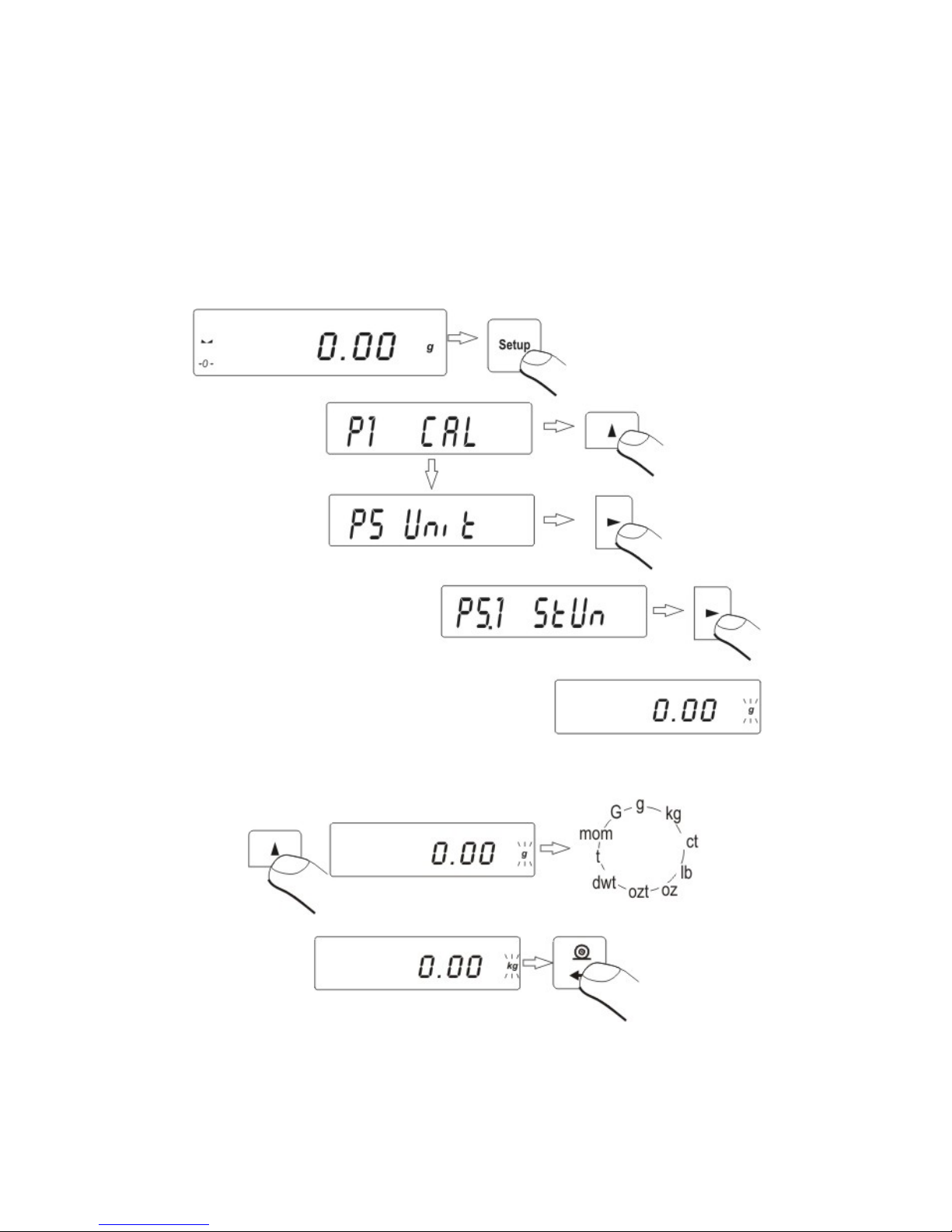

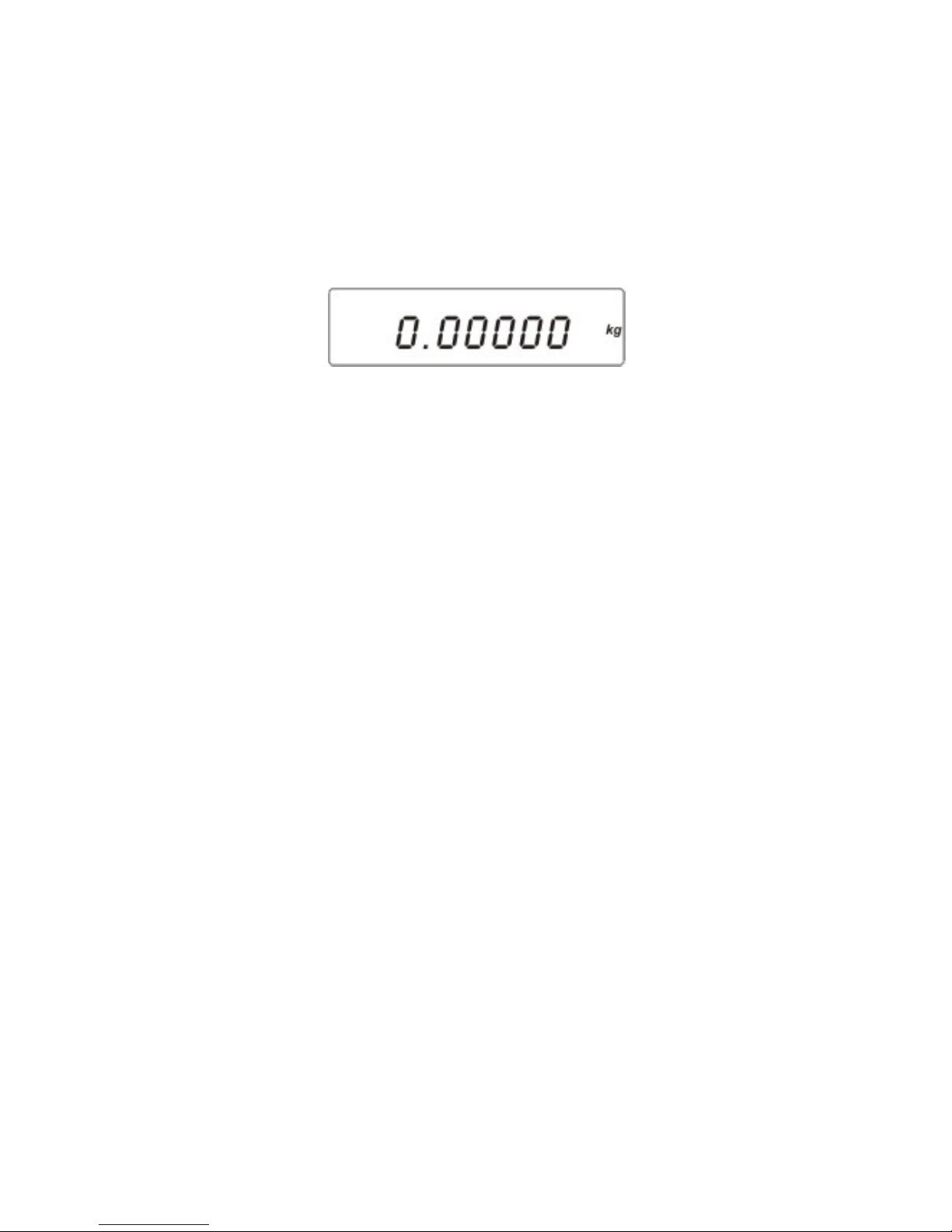

8.1. Choice of basic weighing unit

Function is used to setting the initial unit with which the balance will start after

switching on. Enter to submenu P5 Unit,

press several times UNITS key. Display will indicate by turns available units.

Page 17

- 17 -

After choosing basic unit press ENTER/PRINT key. Chosen unit will stop pulsing.

Possibilities of choice:

• For EC verified balances, user can choose following units: [g], [kg], [ct]

• For non-verified balances, user can choose following units: [g], [ct], [kg],

[oz], [ozt], [dwt], [t], [mom], [gn].

Go back to weighing mode with procedure of saving changes

(see point - 7.1.2. – return to weighing).

ATTENTION:

Balance after switching on will start with set basic unit.

8.2. Choice of weighing unit (temporary)

Function enables choice of unit with which mass on the p an will be indicated. Unit

will be valid until change of unit or s witching on and off the balance. Each pressi ng

the Units key, causes change of measuring unit.

Possibilities of choice:

• For EC verified balances, user can choose following units: [g], [kg], [ct]

• For non-verified balances, user can choose following units: [g], [ct], [kg],

[oz], [ozt], [dwt], [t], [mom], [gn].

Page 18

- 18 -

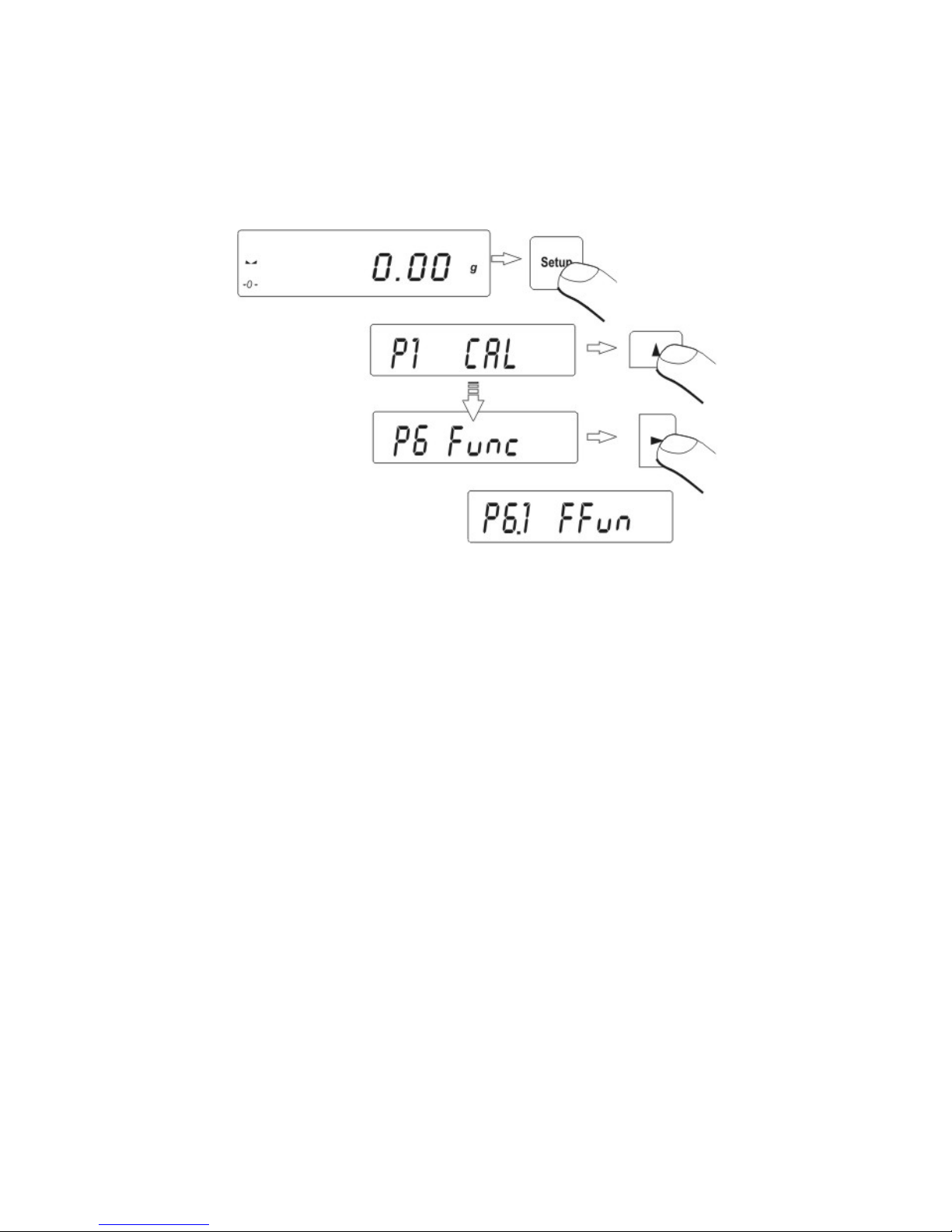

8.3. Setting accessibility of balance operating modes

In this group of parameters user declares functions which are to be accessible for

user after pressing SETUP key.

Enter group P6 Func.

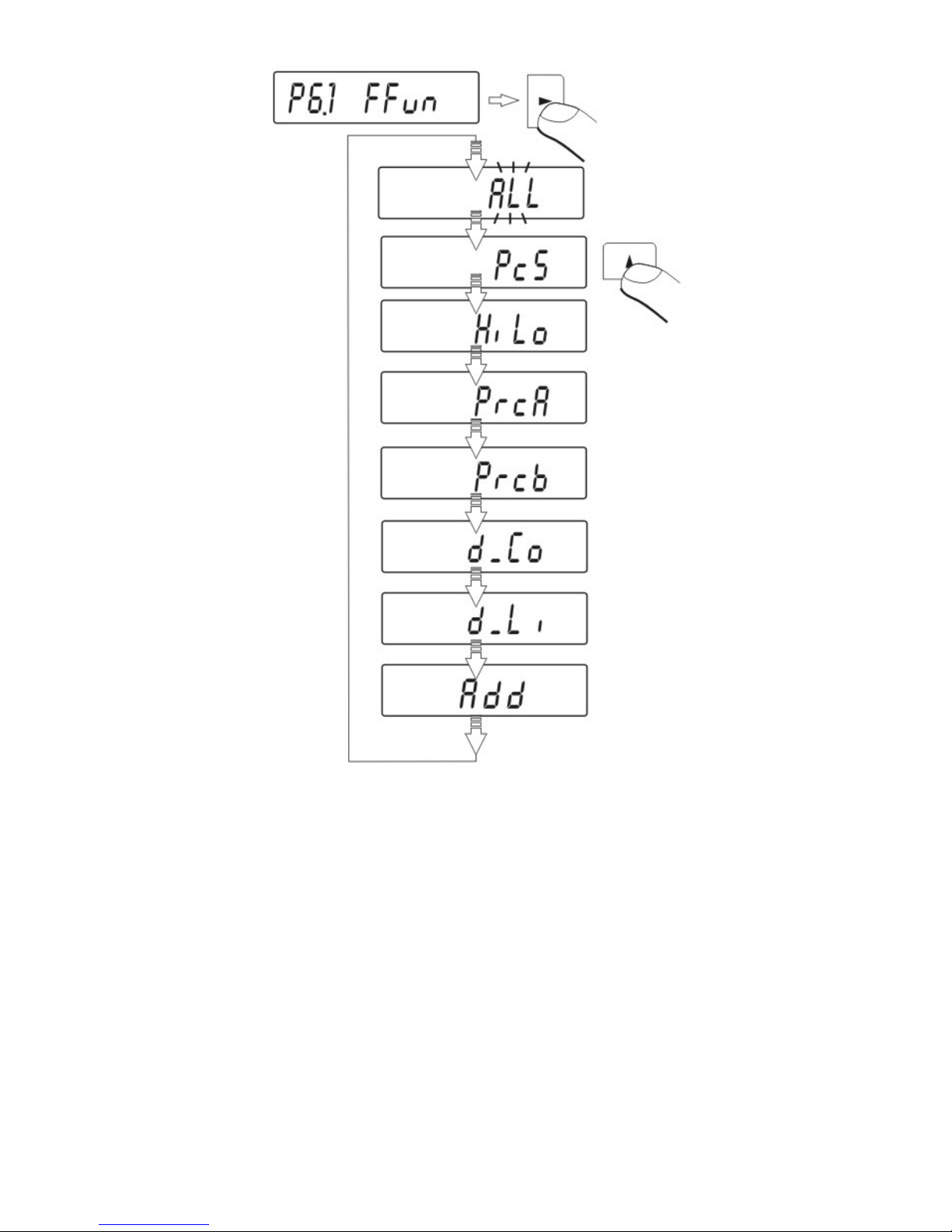

8.3.1. Choice of modes quantity accessible for user

Function enables user to set if after pressing RIGHT ARROW key all operating

modes will be accessible (ALL) or only one from the list chosen and used by

operator, or all functions unavailable (OFF).

Page 19

- 19 -

After choosing setting press ENTER/PRINT key. Balance will go back to displ aying

name ofsubmenu.P6.1 FFun. If function other than ALL is chosen, procedure of

returning to weighing differs from remaining ones. If e.g. function PcS is chosen

(procedure according to 13.1 point), to return to weighing:

Page 20

- 20 -

Press key Esc/TARA, balance will return to weighing.

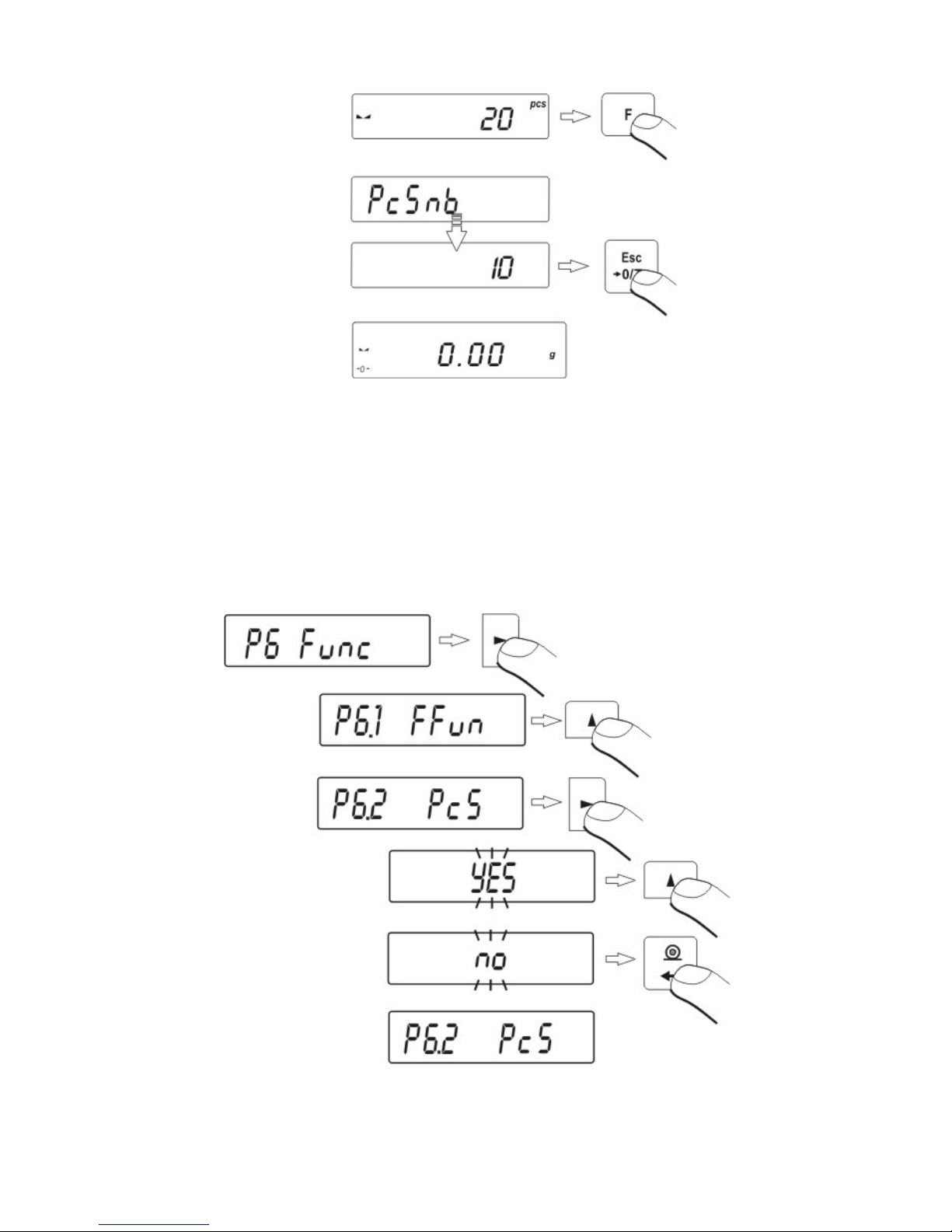

8.3.2. Setting contents of P6.1 FFun – ALL parameters

Function enables switching off modes not used by operator. This causes faster

access to used modes.

Page 21

- 21 -

OFF – inaccessible mode

On – accessible mode.

Return to weighing

(see - 7.1.2. – return to weighing).

9. MAIN SETTING PARAMETERS

User can adjust balance to external condition s (filter range) or o wn needs (autozer o

working, memory of tare value). These parameters are in group <P3 rEAd>.

These functions will help user to adjust balance to external conditions in which

balance operates.

Page 22

- 22 -

9.1. Setting level of filtering

Procedure:

- using NAVIGATION BAR choose value of filter which is needed

1 - filtr FASt – (fast)

2 - filtr StAnd – (standard)

3 - filtr Slouu – (slow).

Return to weighing

(see - 7.1.2. – return to weighing).

ATTENTION:

The higher filtering level the longer time of weighing.

Page 23

- 23 -

9.2. Result confirmation

Because of various environmental co nditions it is a dvisable to ad just the ba lance by

selecting method of result confirmation as: FAST_rEL, Fast or rEL. Depending on

selected option, time of weighing will be shorter or longer.

Fast_rEL - fast + release

Fast - fast

rEL - release.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 24

- 24 -

9.3. Autozero function

In order to ensure precise indication of balance, „AUTOZERO” function was

introduced. The application of this function is automatic control and correction of

zero indication of balance.

When function is active comparison of result s takes place at decl ared time intervals

e.g. every 1 s, only when the pan is unloaded and results are close to zer o.

If results vary by value smaller than declared AUTOZ ERO range e.g. one division,

balance will zero automatically and stable r esult marker– and zero indication

– will be displayed.

When AUTOZERO function is on each result starts from precise zero. However

there are some cases where this function can be disturbance at measurements.

Such instance is very slow placing of load on the pan (e.g. load pouring) in such

case correction system of zero indication can also correct indication of real mass of

load.

Procedure:

AUTOZERO OFF – autozero off

AUTOZERO On - autozero on.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 25

- 25 -

9.4. Light off the last display digit

Function enables light off the last digit on the display.

ALuuAYS - always

nEuEr - never

uu_StAb - when is stable.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 26

- 26 -

10. ANOTHER PARAMETERS

User can set parameters which have influence on work with balance. These

parameters are contained in P5 othEr e.g. backlight and „beep” signal.

Enter to P5 Others group of submenu according to point 6.1.

10.1. Backlight of weighing result

bl OFF – backlight off

bl On – backlight on

bl Aut – If result of weighing doesn’t change for 10 seconds,

backlight will turn off automatically.

Return to weighing

(see - 7.1.2. – return to weighing).

ATTENTION:

If result of weighing doesn’t change for 10 seconds, backlight will turn off

automatically. Backlight is turned on when indication on display changes.

Page 27

- 27 -

10.2. “Beep” signal – reaction on pressing key

bEEP OFF – signal of pressing key off

bEEP On - signal of pressing key on.

Return to weighing

(see - 7.1.2. – return to weighing).

10.3. Printout of all balance parameters through RS 232 port

After pressing F key, balance parameters will be send through RS 23 2 port.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 28

- 28 -

11. BALANCE CALIBRATION

As the acceleration value due to gravit y is not the same at every locatio n on earth,

each balance must be coordinated – in compliance with the underlying physical

weighing principle – to the existing acceleration due to gravit y at its place of locatio n

(only if the balance has not already been adjusted to the location in the factory).

This adjustment process must be carried out for the location in the factory). This

adjustment process must be carried out for the commissioning, after each change

of location as well as in case of fluctuating environment temperature. It is also

recommend to adjust the balance periodically durin g weighing operation in order to

obtain exact measured values.

To ensure high precision of weighing corrective factor in relation to standard mass

must be noted in the balance memory periodically – it is the balance c alibration.

Calibration should be performed:

- Before the weighing,

- When long breaks are between following measure series

- When temperature inside the balance changes more than: 3° C.

Kind of calibration:

- Internal automatic calibration

* started if temperature changes

* started if the time changes

- Manual internal calibration

* initiated from the balance keyboard

- Calibration made with external weight

* with declared mass which cannot be modified.

In verified balances only automatic internal calibration and manual internal

calibration is accessible.

Perform the calibration when there is no load on the pan!

In case when there is load on the pan, display will indicate unload. It is

comment of unloading the pan. Calibration process can be stopped if it’s

necessary. Press then Esc/TARA key.

11.1. Balance with internal calibration

Process of calibration can be started automatically or manually.

Manual way of operation is to press CAL key. System of automatic calibration will

automatically perform calibration informing user about successive stages.

Page 29

- 29 -

Cycle of automatic calibration proceeds as follows:

- balance software detects necessity of calibration and sign alizes it by marker of

Celsius degree or by black marker

- from this moment time of 5 minutes is counted in which weighings can be

performed

- when this time elapses display indicates CAL_30 message and starts count

down 30..29..28 do 0 (indicated value is the counter)

- user has 30 seconds to make a decision:

if calibration is to be performed, does not take any actions

if one wants to finish measurements presses ESC/TARE key, after its

pressing balance returns to weighing showing previous result of weighing

(possibility of finishing series of measurements) in 5 minutes balance will

indicate CAL_30 message again

- process of calibration can be postponed frequentl y, but fact that long postponing

of calibration can be cause of bigger error during weighing should be noticed.

These errors are effect of changes of temperatures and as consequence

changes of balance sensitivity.

Automatic system includes 3 possibilities:

- calibration with regard to changes of temperature

balance is provided with precise system of controlling temperature

changes, temperature of calibration is registered ever y time, next is started

if temperature of surrounding changes 3oC

- calibration with regard to passage of time

user can declare 4 spaces of time that makes criterion for calibration,

following option are accessible: calibration ever y 1 - 12 hou rs.

Page 30

- 30 -

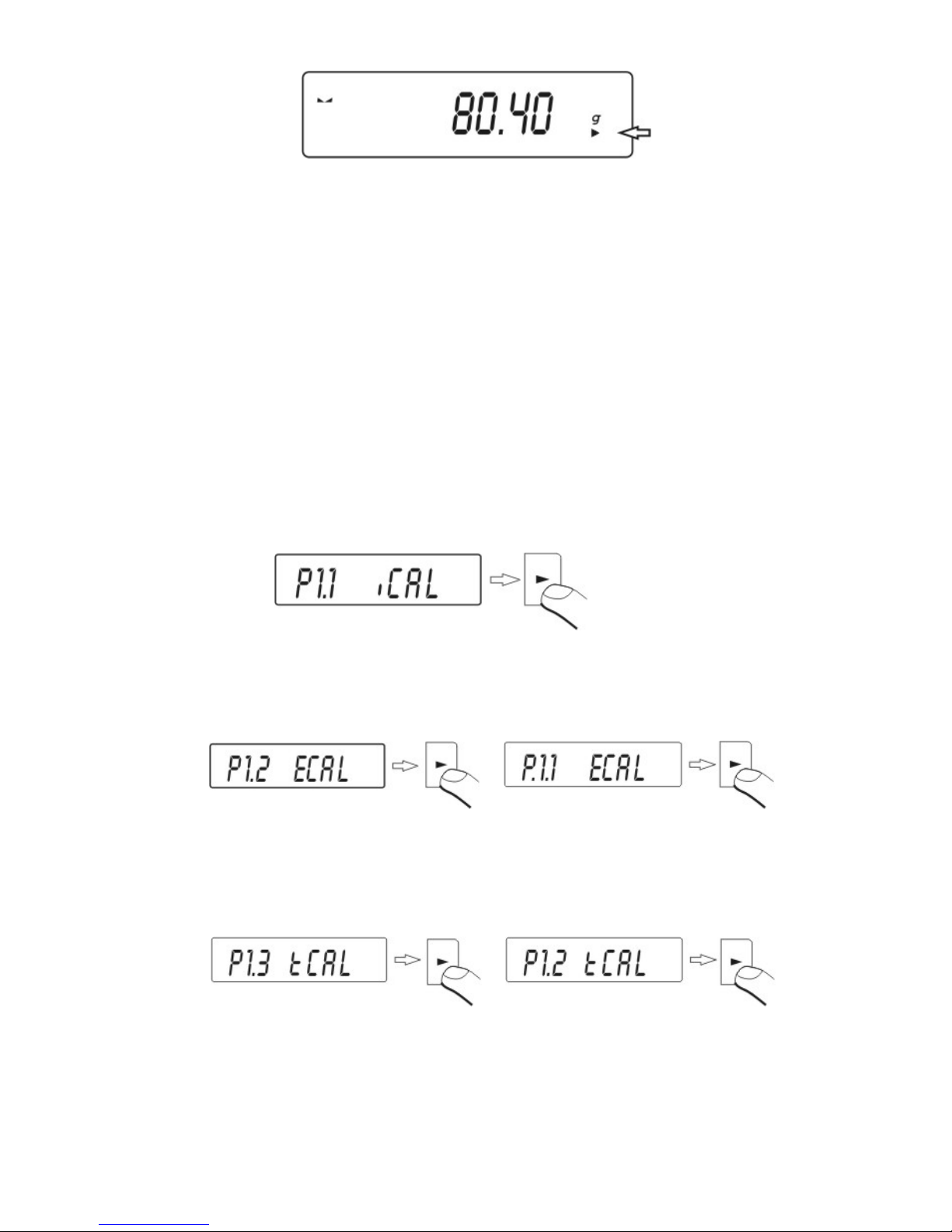

11.2. Entering calibration menu

P1 CAL

P1.1 iCAL |

P1.2 uCAL |

P1.3 tCAL |

P1.4 ACAL | both

P1.5 CALt | 1 h

P1.6 CALr | YES

P1.1 iCAL – Internal calibration

start of internal calibration process, process is completely automatic without

interference of balance operator, if pan is loaded display will indicate message

about necessity of removing the load.

or CAL button

P1.2 ECAL – External calibration

calibration with external weight, which value is saved in factory menu of

balance, function unavailable in verified balances.

balances with internal calibration balances with external calibration

P1.3 tCAL - Test of calibration

comparison of internal calibration mass with its value save d in balanc e memor y.

balances with internal calibration balances with external calibration

Page 31

- 31 -

P1.4 ACAL – Automatic calibration (balances with internal calibration)

determination of factor, which should decide about starting the automatic internal

calibration

nonE – none of factors will cause start of calibration

tEmP – calibration with regard to change of temperature

timE – calibratio n with regard to time set in P1.5 CALt

both – calibration with regard to time and temperature.

Page 32

- 32 -

P1.5 CALt – Time of automatic calibration (balances with internal calibration)

determining the time, after which automatic calibration will start.

P1.6 CALr – printout from calibration report

Setting printout of report after finished calibration

no – printout of report off

YES – printout of report on.

balances with internal calibration balances with external calibration

Page 33

- 33 -

11.3. Calibration test

11.3.1. Balances with internal calibration

Internal calibration mass is compared to its value in the balance memory. This

process is automatic. Its result is shown on the display. Process proceeds

automatically and display indicates its result (if balance is connected to computer or

to printer through RS 232 joint, printout of calibration test will take place). Press

ESC/TARA key to return to previous screen.

Procedure:

Return to weighing

The changes are recorded when the balance returns to weighing

mode with the recording the changes. Press the ESC many times.

Following question appears on the display.

Select one of the options : ENTER – record / ESC – cancel

(Return to weighing 7.1.2. Return to weighing).

Page 34

- 34 -

11.3.2. Balances with external calibration

It consists in comparison of mass of standard with mass previously saved in

balance memory during the calibration. Proc ess proceeds automatically and d isplay

indicates its result (if balance is connected to computer or to printer through RS 232

joint, printout of calibration test will take place). Press ESC/TARA key to return to

previous screen.

Procedure:

Return to weighing

(see - 7.1.2. – return to weighing).

Page 35

- 35 -

11.4. Manual calibration

11.4.1. Internal calibration

1. Press Cal key or

2. The balanc e performs the calibration automatically. During this calibration

do not load the pan.

3. After this process the balance records results of the calibration in the

memory and returns to weighing mode.

ATTENTION:

- Pressing the ESC key stops the calibration process

- If during the calibration load is on the pan display show order about error.

The calibration process is stopped. After take load off the calibration

process is finished.

Page 36

- 36 -

11.4.2. External calibration

The external calibration should be performed with external mass class F

2

1. Start external calibration process

balances witj internal calibration balances with external calibration

2. Order to load off the pan appears on the displa y (no load on the pan). After

yesing load off the pan press the ENTER key.

3. The balance determines mass of empty pan

4. Put load and press the ENTER

5. After the calibration the balance returns to submenu P1.2 u CAL

6. Return to weighing – as in the point 5.1.2.

If balance is verified user does not have the possibil ity to perform external

calibration process.

11.5. Calibration report printout

After calibration user can receive the calibration re port. The report can be printed on

connected printer and sent to computer or recorded in file.

P1.6 CALr: no – report is not printed

P1.6 CALr: YES – report is printed

If the parameter has the value YES, the report is generated and sent automatically.

A content of report depends on setting in submenu GLP. All options with YES

attribute are printed.

Page 37

- 37 -

P2 GLP

P2.1 uSr |

P2.2 PrJ |

P2.3 Ptin | YES

P2.4 PdAt | YES

P2.5 PuS | YES

P2.6 PPrJ | YES

P2.7 PId | YES

P2.8 PFrn | YES

Apart from information settled in menu group the report contains: difference

between calibration mass remembered by balance after last calibration and

calibration mass determined during actual calibration and other information.

12. SETTING PRINTOUTS FOR GLP PROCEDURES

P2 GLP is group of the parameters which declares factors on the calibration

printout.

P2 GLP

P2.1 uSr |

P2.2 PrJ |

P2.3 Ptin | YES

P2.4 PdAt | YES

P2.5 PuS | YES

P2.6 PPrJ | YES

P2.7 PId | YES

P2.8 PFrn | YES

Page 38

- 38 -

For fields:

- user (max 8 alphanumerical signs)

- design (max 8 alphanumerical signs)

introduce names by the balance keyboard.

For the rest select:

- no (do not print during report)

- yes (print during report)

12.1. Setting the contents of printouts for GLP procedures

P2 GLP group of parameters enabling to declare variables, which will appear on

calibration printout and printout from measurement.

P2 GLP

P2.1 USr |

P2.2 PrJ |

P2.3 Ptin | YES

P2.4 PdAt | YES

P2.5 PUSr | YES

P2.6 PPrJ | YES

P2.7 PId | YES

P2.8 PFr | YES

Page 39

- 39 -

• P2.1 USr

Option enabling to introduce name of user who operates the scale. User has

possibility to introduce the name consisting of max 8 alpha numeric characters.

Introduction the name is possible by the means of scale keyboard with

NAVIGATION BAR and ENTER key.

Page 40

- 40 -

Available characters and their equivalents displayed by scale are sh own on the

drawing below:

Exemplary user name introduced to scale with capital letters:

OP1_WILK (operator 1 WILK)

Exemplary user name introduced to scale with small letters:

op1_wilk (operator 1 wilk)

Page 41

- 41 -

• P2.2 PrJ

Option enabling to introduce the Project name (e.g. associated with specific

weighing type).

Exemplary project name introduced to scale with capital letters:

PRRADWAG

Exemplary project name introduced to scale with small letters:

prradwag

• P2.3 Ptin

Option enabling to print time of performed measurement.

• P2.4 PdAt

Option enabling to print data of performed measurement.

• P2.5 PUSr

Option enabling to print user name.

• P2.6 PPrJ

Option enabling to print project name.

• P2.7 PId

Option enabling to print factory number of scale.

• P2.8 PFr

Option enabling to print frames on printout.

Parameters described above, choose the values:

no - not to print during report

YES - to print during report.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 42

- 42 -

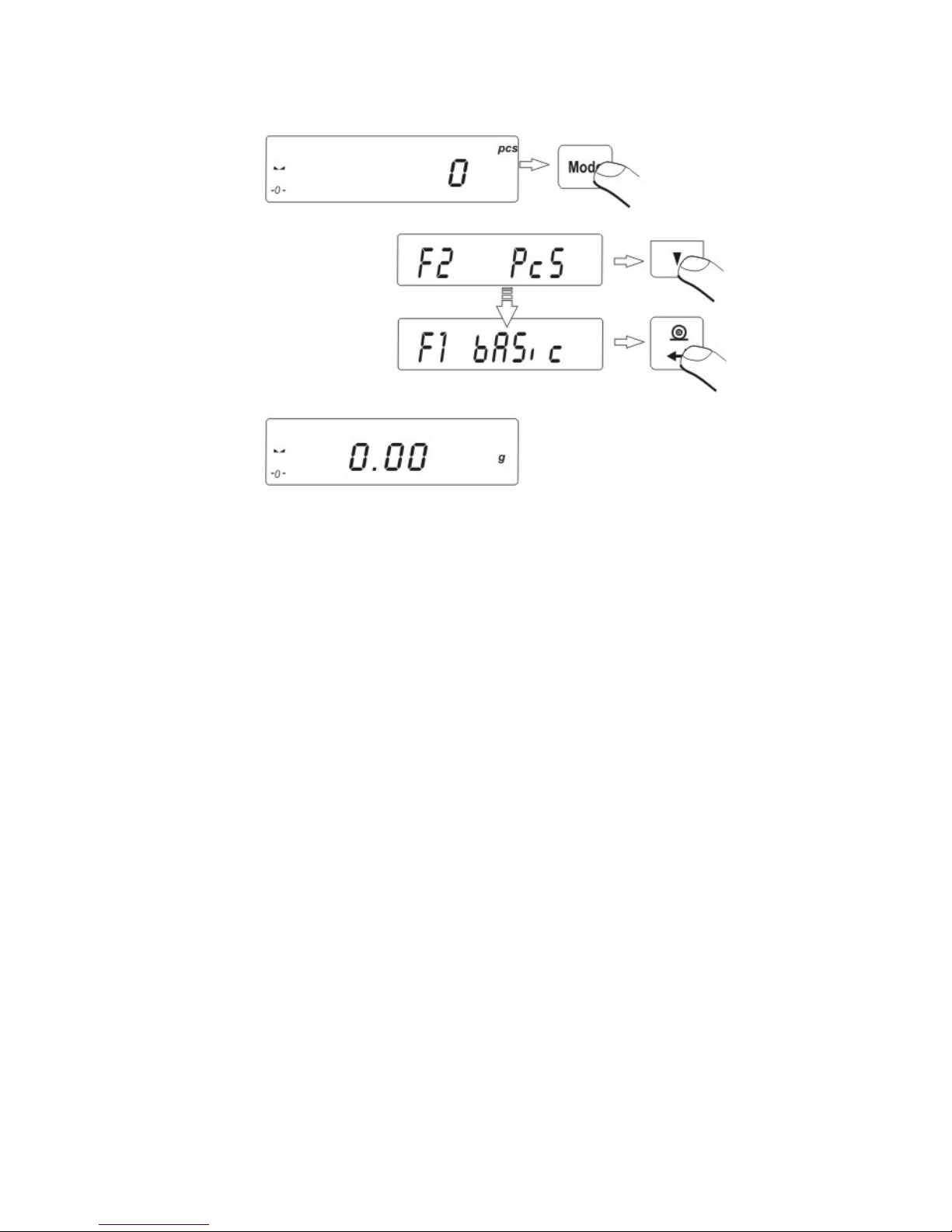

13. BALANCE OPERATING MODES

- Weighing mode (basic)

- Counting pieces

- +/- control referring mass of set standard

- Control of % deviation referring mass of standard

- Definition thickness of solids and liquids.

- Summing

Press MODE key:

Page 43

- 43 -

After pressing MODE key, name of first available function will be indicated. Each

next pressing DOWN or TOP ARROW key causes displaying name of next

available functions, way of setting the functi ons is described in further part of this

manual.

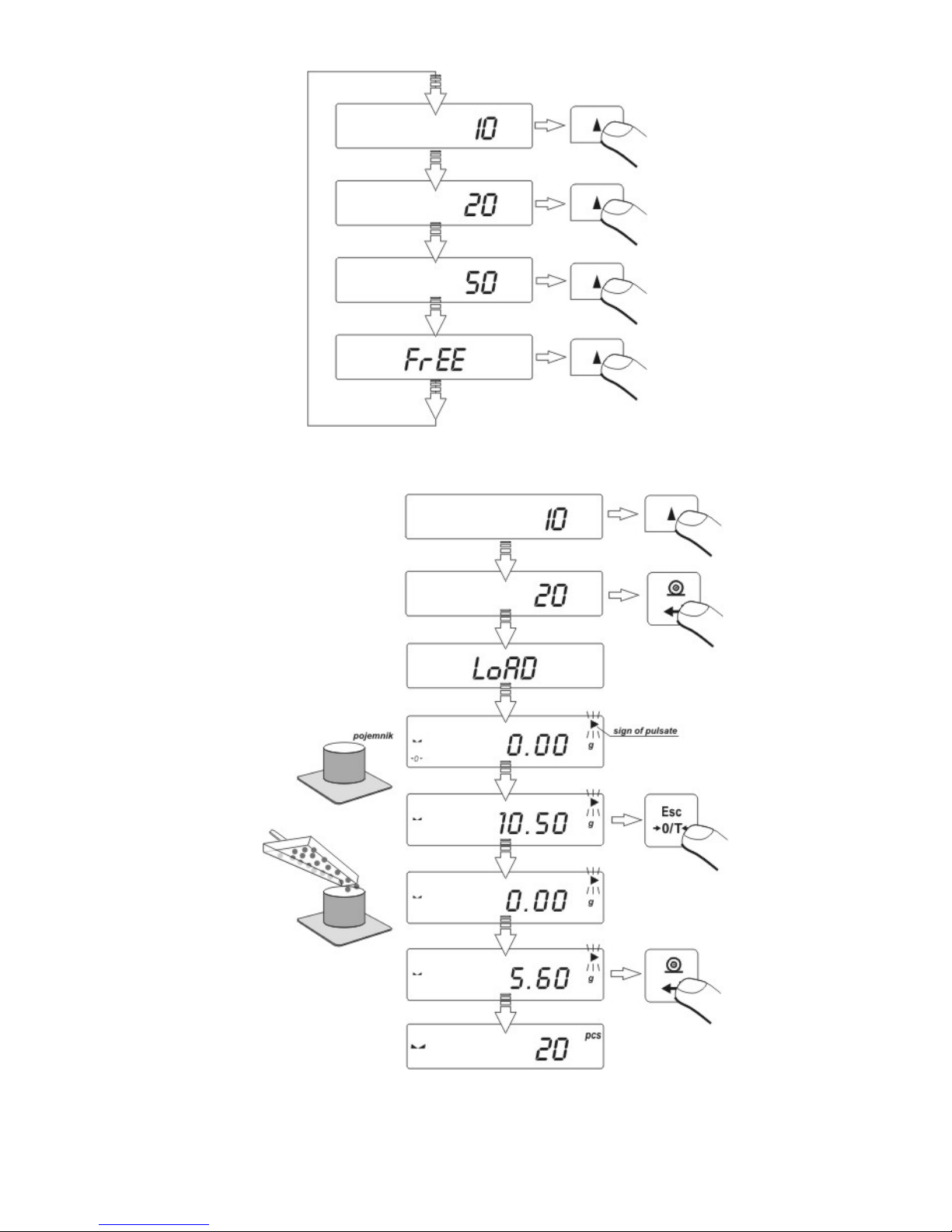

13.1. Counting details of the same mass

Balance in standard execution is equipped with option of counting small pieces of

the same mass. Counting pieces doesn’t operate with other balance fu nctions.

To use this option:

• enter to PIECE function.

• press TOP or DOWN ARROW key to start setting quantity of sample, you

have at choice few options

Page 44

- 44 -

• if you want to choose one them e.g. 20pcs press ENTER/PRINT and

proceed as shown on picture

− If option FrEE was chosen, you must enter quantity of sample, which will

serve to determine mass of single detail

Page 45

- 45 -

− Pressing RIGHT ARROW key chooses digit which will be changed

− Pressing TOP ARROW changes value of digit

• Confirm entered value by pressing ENTER/PRINT key

• Display will indicate LoAd message – place on the pan as many details as

entered during option

• Press ENTER/PRINT key – balance will indicate quantity of sample (PCS

symbol is active)

• add remaining details, display will indicate their quantity.

Page 46

- 46 -

Return to weighing

(see - 7.1.2. – return to weighing).

ATTENTION:

If user presses ENTER key when details are not placed on the pa n, message Er8

outr will be indicated for few second and balance will automatically return to

weighing.

Page 47

- 47 -

13.2. +/- control referring mass of set standard

Procedure of operating:

Enter to function

During setting threshold values following dependences take place:

Page 48

- 48 -

SET LOWER THRESHOLD

RIGHT ARROW – choice of set digit; TOP/DOWN ARROW - choice of value of

digit; ENTER/PRINT – confirmation of entered values

SET UPPER THRESHOLD

RIGHT ARROW – choice of set digit; TOP/DOWN ARROW - choice of value of

digit; ENTER/PRINT – confirmation of entered values

Page 49

- 49 -

ATTENTION:

If user by mistake enters value of lower threshold higher than upper, balance will

indicate error message and will return to weighing.

Return to weighing

(see - 7.1.2. – return to weighing).

13.3. Control of % deviation referring mass of standard

Balance software enables control of deviation (in %) of weighed loads mass

referring mass of standard. Mass of standard can be determined by its

weighing (PERC A function) or entered to balance memory by user ( PERC B

function).

Page 50

- 50 -

13.3.1. Mass of standard determined by its weighing

Procedure:

• Enter to function

• place on the pan load which mass will be accepted as standard

• press ENTER/PRINT to confirm this operating mode

• after few seconds indication 100,00% will be displayed.

From this moment display will not indicate mass of weighed load but deviation of

load mass placed on the pan referring mass of standard (in %).

Page 51

- 51 -

13.3.2. Mass of standard entered to balance memory by user

Procedure:

• Enter to function.

• Display will show indication as above

• Using keys choice of set digit and choice of digit value

set value of mass of standard, enter it to balance memory using PRINT

key – display will indicate: 0,00%

Page 52

- 52 -

From this moment display will not indicate mass of weighed load but deviation of

load mass placed on the pan referring mass of standard (in %).

Return to weighing

(see - 7.1.2. – return to weighing).

13.4. Defining thickness of solids and liquids

There is equipment to defining thickness of solids and liquids in additional

equipment. For user request RADWAG service can render special software to

determine thickness by balance accessible.

13.4.1. Testing thickness solids

Thickness of solids can be tested in one of 3 liquids:

• H2O (distilled water),

• C2H5OH (spirit 100% +/- 0.1% in temp. 200C),

• AnotHEr (a nother liquid with known thickness)

Give temperature of liquid for distilled water and spirit. For liquid with known

thickness value is written on keyboard.

To test thickness weigh sample on pan and weigh th e sam e sample in liq uid. R esult

is represented on display automaticall y after replacing sample in liquid.

Page 53

- 53 -

13.4.2. Testing thickness of liquid

Basic element for measuring thickness of liquid is plunger. It has precise capacity.

Before final measurements this value sho uld be introduced to balance memor y. To

test thickness of liquid weigh plunger on pan and in tested liquid. Result of testing is

shown on display automatically after introducing mass of plunger.

13.5. Summing function

In sum procedure following components are added in order to make mixture. After

adding following component composition of the mixture is presented on the display.

During sum procedure masses of the components are sent to joint RS 232 (printout

on the printer or sending to computer application).

Procedure:

• Enter to function.

Page 54

- 54 -

Page 55

- 55 -

Return to weighing

(see - 7.1.2. – return to weighing).

14. FUNCTIONS FOR USING RS 232

- Choose speed of transmission

- Define sent data as: stable / not stable

- Continuous work

- Setting data as additional element of parameter in printout s

- Turn on/off sign of last digit in printout

- automatic operating for RS 232.

Page 56

- 56 -

14.1. Speed of transmission

Method of setting speed of transmission:

− choose required speed of transmission

- 2400 bit/s

- 4800 bit/s

- 9600 bit/s

- 19200 bit/s.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 57

- 57 -

14.2. Continuous transmission

14.2.1. Continuous transmission off in actual interval

Procedure:

CntA no – continuous transmission off

CntA YES - continuous transmission on.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 58

- 58 -

14.2.2. Continuous transmission of in basic units

Procedure:

Cntb no – continuous transmission off

Cntb YES - continuous transmission on.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 59

- 59 -

14.3. Setting type of operating for RS 232 joint

Procedure:

rEPL no – manual operating / after pressing PRINT key

rEPL YES - automatic operating / after stabilization of weighing

result.

Return to weighing

(see - 7.1.2. – return to weighing).

Automatic operating takes place according to following scheme:

press TARE key to zero the balance (display will indicate marker of

stable measurement and marker of zero)

place the load, balance will send through the RS232 first stable

measurement

remove load from the pan,

next measurement will be possible when weighing result +/- 50

reading units referring to zero (by next measurement zero stat is not

required).

Page 60

- 60 -

14.4. Designation of data type sent through RS 232 joint

(only for non-verified balances)

Procedure:

PStb no – sending stable or temporary result of weighing

PStb YES – sending stable result of weighing.

Return to weighing

(see - 7.1.2. – return to weighing).

Page 61

- 61 -

14.5. Designation of minimum mass for operating of some

functions

Software enables setting operating of function automatic operating.

- for automatic operating result will not be sent to computer or printer until

indication of mass goes below set Lo net value

Procedure:

Return to weighing

(see - 7.1.2. – return to weighing).

Page 62

- 62 -

15. COOPERATION WITH PRINTER OR COMPUTER

Every pressing of key < PRINT > sends signal of current display state with

measuring units to computer or printer. Balance has factory setting speed of

transmission 4800 bit/s. If external mechanism (printer, computer) require different

setting of speed of transmission, change factory setting on speed in menu

(parameter bod)

Transmission parameters programmed in balance:

- Speed of transmission - 2400 – 19200 bit / s

- Data bits - 8

- Stop bit - 1

- Parity control - none.

Sending weighing results to computer can take place:

- manually - after pressing PRINT key

- continuously – after function activating or sending steering commend

- automatically – when result is stable (if REPL YES and before

placing weighed load balance indicated value below set Lo value)

- on demand computer – see List of messages

Value indicated by display can be sent through connection i n series as:

- stable – start of sending the information will take place when weighing

result is stable

- unstable – state of display is sent to external device when pressing

PRINT key, and on printout such state is marked with <?> before

weighing result.

Page 63

- 63 -

15.1. Schedules of connecting conductors

WEIGHT COMPUTER

2 (RxD) 3 (TxD)

3 (TxD) 2 (RxD)

4 (DTR) 6 (DSR)

5 (GND) 5 (GND)

6 (DSR) 6 (DTR)

7 (RTS) 8 (CTS)

8 (CTS) 7 (RTS)

Page 64

- 64 -

15.2. Printing data with date and time

Every printout of weighing can be printed with date and time of measurement.

It’s possible if balance is connected to printer Kafka 1/Z or Kafka SQ S.

After connecting balance and printer set in balance menu parameters of P2 GLP

group:

PdAt on value YES

Ptin on value YES

15.3. Cooperation with statistic printout Kafka SQS

After connecting balance to printer KAFKA SQ S statistic of measurement

is possible to do. Example of printout with statistics from series of measurement:

1 9:02:15 + 7.0016 g

2 9:02:39 + 5.0152 g

3 9:02:58 +

12.0171 g

4 9:03:15 + 9.9937 g

5 9:03:34 + 12.0169 g

6 9:03:48 + 22.0111 g

Data 13.09.2001 Godz. 9:04

n 6 batch quantity

sum x 68.0556 g summary of mass of samples

x 11.34260 g average value

s 5.92328 g standar d deviation

srel 52.22 % factor of variancy

min 5.0152 g min value

max 22.01 11 g max value

R 16.99 59 g difference max – min

15.4. Format of sending data

Result of weighing can be sent from bal ance to external device after pressing the

PRINT button on the balance or after sending order from the computer.

Page 65

- 65 -

15.4.1. Format of sent data after pressing the PRINT button

Depending on setting of P4.5 PStb parameter only stable measur ement or mass of

instantaneous mass will be sent.

For verified balance printout of temporary measurements will be blocked

for instantaneous measurements.

Format of printout

1 2 3 4 - 12 13 14 - 16 17 18

stability

marker

space

mark

mass

space

unit

CR

LF

stability marker – [space] if stable

[?] if unstable

[^] if there is an error of exceeding the range on +

[v] if there is an error of exceeding the range on Mark – [space] for positive values or [-] for negative values

mass – 9 marks alignment to the right

units – 3 marks alignment to the left

15.4.2. Format of sent data for orders generated from the

computer

Balance after receiving the command answers first:

XX_A CR LF – commend understood, realization started

XX_I CR LF – commend understood, but unavailable at the moment

XX _ ^ CR LF – commend un derstood, but max range is exceeded

XX _ v CR LF – commend understood, but min range is exceeded

XX _ E CR LF – error occurred while command realization – e xceeded time limit

while waiting for stable result (time limit is characteristic

parameter of balance)

XX – name of command

Page 66

- 66 -

And afterwards

1 - 3 4 5 6 7 8 - 16 17 18 - 20 21 22

Command

space

stability

marker

space

mark

mass

space

unit

CR

LF

Command – 1 ÷ 3 marks

stability marker – [space] if stable

[?] if unstable

[^] if there is an error of exceeding the range on +

[v] if there is an error of exceeding the range on mark – [space] for positive values or [-] for negative values

mass – 9 marks alignment to the right

unit – 3 marks alignment to the left

16. WEIGHING LOADS UNDER BALANCE

In standard analytical and precision balances can weigh load on suspension.

To use this function:

• Remove plastic plug in basic of balance

• There is suspension in the basic of balance. It’s installed for good.

• Install ho ok to hang load (hook isn’t stan dard equipment for bal ance), weigh

load on hook.

Attention:

• Suspension cannot be turned aroun d, move or manipulate. Mechanism of

balance can be damaged this way.

• Mass all additional elements as balance, string should be settled to zero

by pressing key Esc/TARE.

Page 67

- 67 -

17. LIST OF ORDERS IN RADWAG BALANCES

Function TARA

Format T CR LF (setting to tare)

Function ZERO

Format Z CR LF (setting to zero)

Function PRINT

Format SI CR LF (sending results when stab)

Function PRINT

Format S CR LF (sending results now)

Function CONSTANCE WORK - equivalent for key conA on

Format C 1 CR LF (start continuous transmission off in basic interval)

Function MANUAL WORK - equival ent for order conA OFF

Format C 0 CR LF (To change work mode on manual printout)

Function CONSTANCE WORK - equivalent for key conb on

Format CU 1 CR LF (start continuous transmission off in actual interval)

Function MANUAL WORK - equivalent for order conb OFF

Format CU 0 CR LF (To change work mode on manual printout)

Function SEND THE RESULT IN ACTUAL INTERVAL

Command SU CR LF (result in actual unit is sent from the balance after

stability)

Function SEND RESULT IN ACTUAL INTERVAL IMMEDIATELY (result in

actual unit sending results now)

Command SUI CR LF

If command which is not included in the reg ister or is an er ror and ends with CR LF

is sent to the balance the balance returns command E S CR LF.

Page 68

- 68 -

18. ERROR MESSAGES

Er1 Hi - wrong initial mass or calibration

Er2 nuLL - values from A.D converter out of the normal range - under range

Er3 FuL1 - values from A.D converter out of the normal range - over range

Er4 FuL2 - over range

Er5 rout - value out of range for performed function e.g value > +/- 2% from initial

mass for zeroing, e.g. value <= 0 for tarring

Er7 tout - timeout error for zeroing and tarring

Er8 outr - enter value out of range

Er9 Lock - function locked e.g. to protect function if LFt (legal for trade) is on,

Er10 cal - calibration error (change of mass or incorrect mass of standard mass).

19. ADDITIONAL EQUIPMENT

19.1. Vibration damping table

Thanks to this stable base all vibrations are eliminated.Inside of

table marble plate is installed which makes foundation for bala nce.

19.2. Additional display

Characteristics: Length of conductor between additional dis play

and balance – 1,5m, plastic casing, possibility of bending the

display.

19.3. Computer software

PW-WIN 2004 – gathering data from any balance made by

RADWAG.

RAD-KEY 2000 – enables to introduce result of weighing to Exel.

REC-FS 2000 – making mixtures. It has its own programmed

contents base according to recipes are made.

Number of instruction:

LMI-26-02/06/08/ENG

Page 69

- 69 -

MANUFACTURER

OF ELECTRONIC WEIGHING INSTRUMENTS

RADWAG 26-600 Radom

Bracka 28 Street

POLAND

Central phone +48 48 38 48 800

phone/fax. + 48 48 385 00 10

Sales Department + 48 48 366 80 06

www.radwag.com

Loading...

Loading...