Radiodetection ND241C Users Manual

DRILLTRACK

USER MANUAL

Revision 1 05.2001

Foreword

It is important that you read this user guide before operating your Radiodetection DrillTrack G2 system.

This manual and all its contents are subject to change. Radiodetection products are under continuous

development and are subject to change. Radiodetection Limited reserves the right to modify the product

without notice. Some product changes may have taken place after this user guide was published.

Contact your local Radiodetection dealer for the latest information on Radiodetection DrillTrack G2.

Copyright © by RADIODETECTION TRENCHLESS PRODUCTS, a division of RADIODETECTION LTD.

All rights reserved.

The DrillTrack G2 system is covered by the following Patents: US 5,917,325; US6,107,801;

GB2,330,204; EP 0,815,472; and other Patents pending

IMPORTANT NOTICE

Radiodetection makes every effort to ensure that all technical information, statements and

recommendations about Radiodetection Trenchless products are based on information believed to be

reliable, but the accuracy or completeness thereof is not guaranteed. In no event shall Radiodetection be

liable for any loss, inconvenience, damage or problems caused through use of the equipment.

Before utilizing the product, the user should determine the suitability of the product for its intended use.

The user assumes all risks and liability whatsoever in connection with such use.

COMPLIANCE STATEMENT

When used in accordance with the user manual, relevant parts of this product comply with ‘The

Radio Equipment and Telecommunications Terminal Equipment Directive’ (1999/5/EC) and/or EMC

Directive (89/336/EEC) for use in a residential, commercial and light industry environment, as

required.

As appropriate, this equipment complies with the following:FCC Part 90

FCC Part 15

EN 300 220-3

EN 300 330

EN 301 489-3

Appropriate radio transmissions from the equipment have been certified by the FCC. The following

FCC IDs apply:

E86DTR100: K68ND2415A; K68ND2415B; K68ND2415C; K68ND2415D

This product must only be used with the antennas supplied with it. This product must not be

connected to the mains supply, either directly or indirectly via an adaptor or battery eliminator. Such

connection, use with other antenna or any changes, or modifications made to this product not

expressly approved by Radiodetection Ltd could void the user's authority to operate the equipment.

I

Note: Appropriate parts of this equipment have been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection in a residential installation. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to correct the interference by one or more of the following measures:

- reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

- Consult the dealer or an experienced radio/TV technician for help.

All DrillTrack G2 units are weatherproof to NEMA 3R and IP54

All DrillTrack G2 units are shock and vibration tested to IEC68

All DrillTrack G2 units are manufactured according to the International Quality Norm ISO 9001

ll

Table of Contents

Foreword I

Warnings and Safety Precautions III

(1) DrillTrack G2 System Overview

Introduction 1-1

Features of DrillTrack G2 Receiver and DataView 1-2

(2) DataSonde

The Radiodetection DataSondes 2-1

Powersave Modes 2-3

Overheat Warning 2-3

DataSonde Magnetic Field 2-4

Dual Frequency DataSonde change method 2-4

(3) DrillTrack G2 Accessories

DrillTrack G2 Tripod 3-1

Calibration Jig 3-1

Hard carry case 3-2

Soft carry bag 3-2

(4) DrillTrack G2 Function keys

Receiver 4-1

DataView 4-2

(5) DrillTrack G2 Operating Instructions

Before starting 5-1

How to setup the DrillTrack G2 Rec e iv er 5-1

Calibration of the DrillTrack G2 Receiver 5-6

Tilt angle compensation 5-7

Borelogger 5-8

Locating 5-9

Steering 5-12

High Temperature Alarm 5-14

(6) DrillTrack G2 DataView

DataView information 6-1

Remote Steering 6-1

(7) Tips and Tricks

Troubleshooting Guide 7-1

Angle conversion table 7-3

Warranty

Registration Card

lII

Warnings and Safety Precautions

It is very important that Directional drilling operators note the operating procedures and safety

precautions before operating the Radiodetection DrillTrack G2 system.

- Priority must be given to local and national safety requirements all times.

All other safety procedures should be followed.

- All underground utilities MUST be located before starting the drilling operation.

Contact your local Radiodetection dealer for pipe and cable locating equipment.

- Serious injury and death can result if underground drilling equipment accidentally

hits an underground utility.

- Operators must wear protective safety clothing such as insulated boots, insulated

gloves, high visibility safety vests, safety glasses and hard hats.

The DrillTrack G2 system is not explosion-proof and is not approved for use in areas

where hazardous gases may be present.

The DrillTrack G2 system should never be used near flammable or explosive substances.

Prior to the start of each drilling, the following actions must be taken:

- An orientation working practice should be selected which is done in the

DrillTrack G2 Receiver Setup Menu.

Confirm that the DrillTrack G2 system is operating properly and check for an

accurate location of the drillhead and accurate depth readings, tilt angle and roll

position with the DataSonde inside the drillhead.

During drilling, the depth readings and locate position will not be accurate unless:

- A consistent orientation working practice will be maintained. (changing from facing

the Drilling machine to working with one’s back to the Drilling machine or visa versa)

could result in both a mis-locate positi on/depth error.

This effect is more likely to happen after approximately 10% Grade (5°) of Tilt angle.

Note, at any time the user may go back into the “Setup Menu” and change the

orientation method. This will not effect the Receiver’s calibration.

- The DrillTrack G2 Receiver has been calibrated correctly.

IV

Warnings and Safety Precautions

Interference can cause inaccuracies in depth readings, loss of tilt angle and/or roll position and

inaccurate location and heading of the rill head.

- Sources of interference could be power lines, cable TV, traffic signal loops, telecom

lines, pipelines, metal structures, invisible dog fences, radio frequencies,

transmission towers and cathodic protection systems.

- Due to the nature of the equipment it may be susceptible to electromagnetic fields

emitted by other apparatus. This may cause incorrect data to be displayed.

Care must be taken when using Lithium batteries to avoid drilling conditions which would result in

the DataSonde exceeding the battery manufacturers recommended maximum operating

temperature. In the event of exceeding this temperature the battery may vent toxic fumes into the

sealed battery compartment and may explode if the temperature rises further.

Ensure that the battery manufacturers specified maximum operating temperature exceeds

100°C.

Follow all safety and handling precautions specified and supplied by the battery manufacturer.

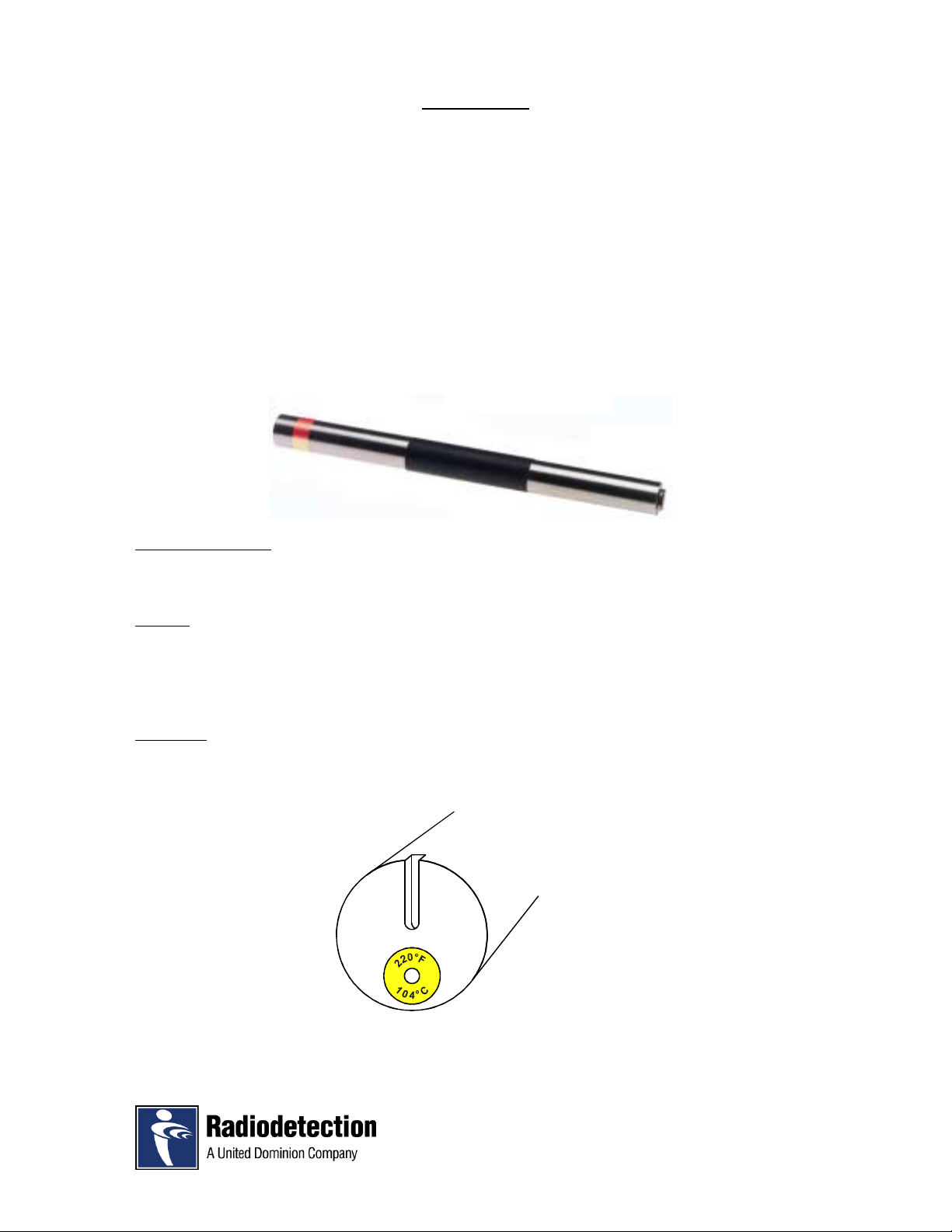

If the warranty temperature indicator of the DataSonde, located next to the slot of the anti-roll pin,

has turned black then the DataSonde temperature has exceeded 104° C. Do not remove the

battery end cap as toxic fumes or harmful chemicals may be released.

Ni-Cad batteries should be disposed of in accordance with your Company’s work practice, and/or

the relevant law or guidelines in your country.

Carefully review this user guide. If you have any questions regarding the operation of the

equipment or if you have difficulty on the job, please contact your local Radiodetection dealer for

help.

V

Dear Customer:

We would like to congratulate you with the purchase of your Radiodetection DrillTrack G2 system, the fastest

and most accurate guiding system in the world for guiding directional drill ing machines.

Please take the time to read this user guide and fill out this page for your own records. When contacting your

Radiodetection dealer, it is important to quote the equipment serial numbers.

Also, please fill out the warranty registration card, that you will find on the last page of this user guide and

send it to your Radiodetection dealer. Registration entitles you to free software updates.

The DrillTrack G2 system comprises:

DrillTrack G2 Receiver Serial Nr. ................................................

DrillTrack G2 DataView Serial Nr. .................................................

Short Range DataSonde (SDS) Serial Nr. .................................................

Serial Nr. .................................................

Medium Range DataSonde (MDS Black) Serial Nr. .................................................

Serial Nr ..................................................

Long Range DataSonde (LDS Red) Serial Nr. ..................................................

Serial Nr. ..................................................

Medium Range Dual Frequency DataSonde (MDF Yellow) Serial Nr. .................................................

Serial Nr. .................................................

Long Range Dual Frequency DataSonde (LDF Purple) Serial Nr. .................................................

Serial Nr. ................................................

G2 Medium Range Dual Frequency DataSonde (G2M Green) Serial Nr. .................................................

Serial Nr. .................................................

G2 Long Range Dual Frequency DataSonde (G2L Orange) Serial Nr. .................................................

Serial Nr. .................................................

Thank you for choosing the Radiodetection DrillTrack G2 system.

Radiodetection Trenchless Products

Vl

DrillTrack G2 System Overview

(

(

(

(

(

(

Introduction.

The Radiodetection DrillTrack G2 system is designed to provide guidance information for horizontal

directional drilling machines.

The DrillTrack G2 System comprises:

- DrillTrack G2 Receiver (1)

- DrillTrack G2 DataView (2)

- DataSondes (3)

- DrillTrack G2 Tripod (4)

- Calibration jig (5)

- Hard Carry Case (6)

- Soft Carry Bag (7)

2)

(1)

5)

4)

3)

7)

6)

1-1

DrillTrack G2 System Overview

Features of DrillTrack G2 Receiver and DataView.

The DrillTrack G2 Receiver has been developed with the needs of the operator as the main priority.

Providing essential information automatically makes the equipment very easy to use and allows the

operator to work with confidence.

Once drilling has started the operation is fully automatic and the large LCD shows the operator

information about the drillhead.

The DrillTrack G2 Receiver LCD provides automatic walkover positioning of the drillhead.

Four arrows automatically direct the operator left/right and forward/backward.

When all four arrows are displayed the depth automatically appears on the screen and can be stored in

the integral Borelog.

The display also provides the operator with a Drill Heading (compass), Tilt angle (Inclination), Roll

Position and in the Manual Mode a Signal Strength reading (if selected in the user Setup).

Feature highlights include:

- Integral Borelogger

- Automatic tracking arrows that indicate Go... Left/Right/Forward/Backward.

- Drill head direction compass indicator.

- Interference rejection technology.

- Filtered rejection of standard line locator frequencies.

- No mis-locates due to ‘ghost signals’.

- No confusion caused by +/- locates.

- Down hole frequency change to overcome localised interference.

- Tilt angle compensated locate position and depth measurements.

- Automatic Depth readout.

- Metric or Imperial readout selection.

- Continuous display of Tilt angle and Roll.

- Tilt angle in % of Grade or degrees.

- Display Backlight.

- Comfortable working height to min im iz e fati gue.

1-2

DrillTrack G2 System Overview

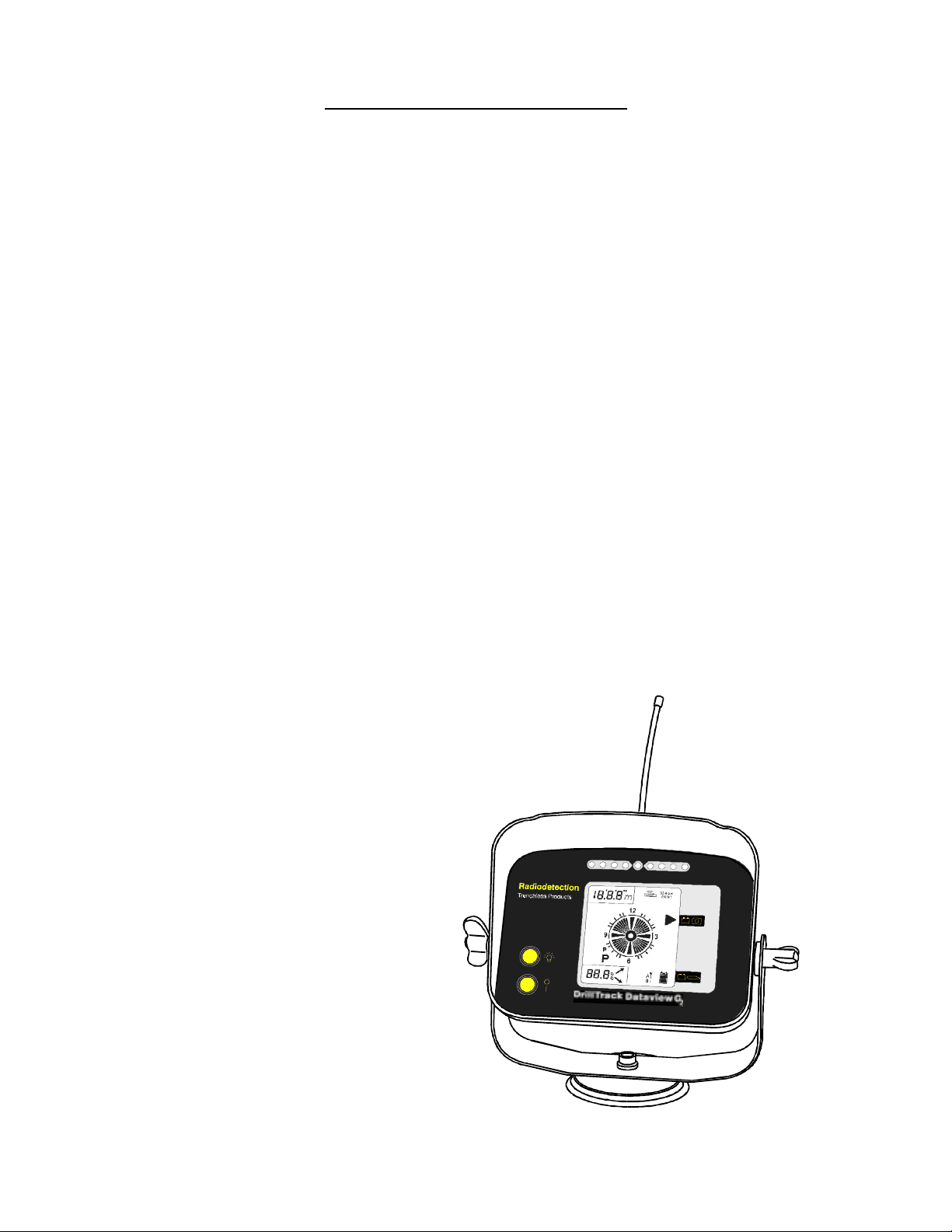

The DrillTrack G2 DataView has been developed with the needs of the Drilling machine operator as the

main priority.

With its magnetic base the portable DrillTrack G2 DataView provides essential information that allows

the Drilling machine operator to work with confidence.

Once drilling has started the operation is fully automatic and the large LCD shows the Drilling machine

operator with all the relevant data transmitted from the DataSonde to the DrillTrack G2 Rec eiver and

which is then relayed to the DrillTrack G2 DataView in real time.

The information includes, Tilt angle (Inclination), Roll (clock), Depth, Remote Left/Right steering and

Alarm Conditions.

Feature highlights include:

- Fully automatic with no operational buttons or controls.

- Depth readout upon request.

- Automatic selection of Metric or Imperial readout.

- Continuous display of Tilt angle and Roll in real time.

- Tilt angle in % of Grade or degrees.

- Continuous display of DataSonde Temperature and DataSonde Battery status.

- Remote Left/Right steering.

- Display Backlight.

2

DataSonde

The Radiodetection DataSondes.

The DataSonde is installed in the drillhead/DataSonde housing.

To ensure optimum DataSonde performance and protection, the DataSonde should be securely fitted in

the drillhead/DataSonde housing. DataSondes may need minor modifications to ensure a secure fit.

O-rings or electrical tape are an acceptable means.

All Radiodetection DataSondes are constructed in three main sections.

Electronics

Antenna

Battery Compartment

Battery compartment

Batteries are inserted in the back end of the DataSonde with the positive end first. Always use ALKALINE

batteries.

Antenna

The antenna is positioned in the middle section of the DataSonde. The slots in the drillhead/DataSonde

housing should be positioned over the antenna section of the DataSonde to allow the electro magnetic

field from the DataSonde to be generated without any restriction.

Wrong positioning or length of the slots will effect the signal range and battery life of the DataSonde.

Electronics

The sensors for measuring the Roll (clock), the Tilt angle (Inclination), the DataSonde Temperature and

the Battery Status are located in the electronics section of the DataSonde.

The slot in the front end of the DataSonde fits the anti-roll pin in the drillhead/DataSonde housing

to stop the DataSonde from rotating inside the drillhead DataSonde housing, when drilling.

2-1

DataSonde

Short Range DataSonde (SDS)

Approximate Signal range 4m (12 ft)

Battery life 10 hrs

Size 25,4 x 203 mm (1 x 8 in)

Medium Range DataSonde (MDS Black)

Approximate Signal range 10m (33 ft)

Battery life 20 hrs

Size 32 x 380 mm (1.3 x 15 in)

Long Range DataSonde (LDS Red)

Approximate Signal range 15m (50 ft)

Battery life 12 hrs

Size 32 x 380 mm (1.3 x 15 in)

Medium Range Dual Frequency DataSonde (MDF Yellow)

Approximate Signal range 10m (33 ft)

Battery life 20 hrs

Size 32 x 380 mm (1.3 x 15 in)

Long Range Dual Frequency DataSonde (LDF Purple )

Approximate Signal range 15m (50 ft)

Battery life 12 hrs

Size 32 x 380 mm (1.3 x 15 in)

G2 Medium Range Dual Frequency DataSonde (G2M Green)

Approximate Signal range 10m (33 ft)

Battery life 20 hrs

Size 32 x 380 mm (1.3 x 15 in)

G2 Long Range Dual Frequency DataSonde (G2LOrange )

Approximate Signal range 15m (50 ft)

Battery life 12 hrs

Size 32 x 380 mm (1.3 x 15 in)

2-2

Loading...

Loading...