Radijator EK 06 Smart MONO, EK 12 Smart EU, EK 09 Smart EU, EK 09 Smart MONO EU, EK 16 Smart EU Technical Instructions For Assembly, Operation And Maintenance

...

Živojina Lazića Solunca 6, 36000 Kraljevo, Serbia,

tel: 036/390-140, 390-150, e-mail: radijator@radijator.rs

TECHNICAL INSTRUCTIONS FOR ASSEMBLY,

OPERATION AND MAINTANCE OF ELECTRIC

ENG

BOILER

06-09-12-16-18-21-24-27 kW

EK SMART EU

Table of content

1. Explanation of the symbols and safe work instructions ...................................................................................... 3

1.1 Introduction ................................................................................................................................................... 3

1.2 List of symbols with explanations ................................................................................................................ 3

1.3 General boiler safe work instructions ........................................................................................................... 3

2. Information about the boiler ............................................................................................................................... 5

2.1 Description of the product ............................................................................................................................ 5

2.2 Electro-boiler models .................................................................................................................................... 8

2.3 Declaration of conformity ............................................................................................................................. 8

2.4 Minimum separation distance and flammability of building materials............................................................. 9

2.5 Tools, materials and auxiliary aids ................................................................................................................ 9

2.6 Antifreeze protection .................................................................................................................................... 9

2.7 Waste disposal .............................................................................................................................................. 9

2.8 Scope of delivery .......................................................................................................................................... 9

2.9 Name plate .................................................................................................................................................. 10

2.10 Dimensions and technical data .................................................................................................................. 10

4.1 Caution when assembling the boiler ........................................................................................................... 12

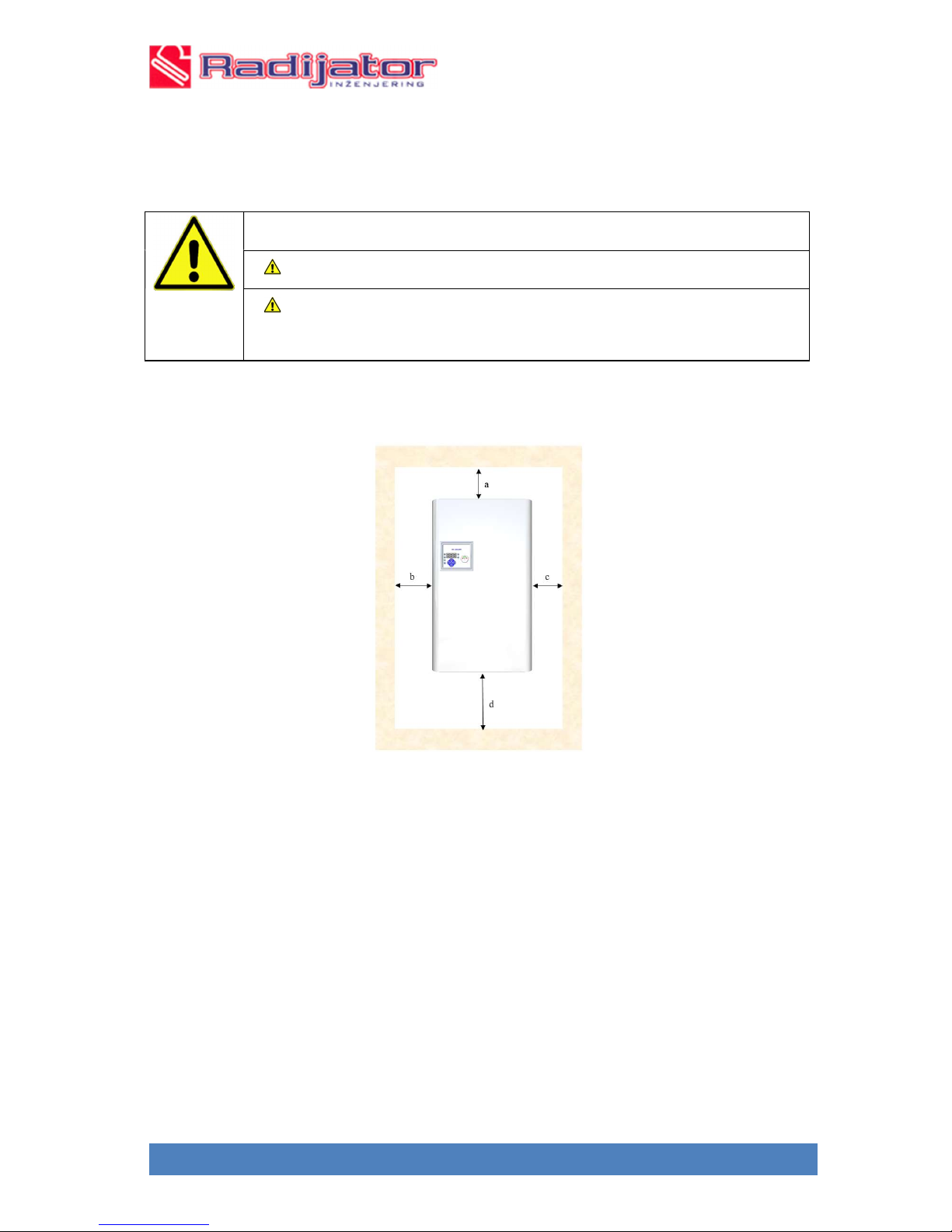

4.2 Clearance around the boiler to floor, wall and ceiling ................................................................................. 13

4.3 Removal of the boiler front casing ............................................................................................................. 13

4.4 Assembly of the boiler ................................................................................................................................. 14

5. Boiler hydraulic scheme ................................................................................................................................... 15

6.1 Position of electrical cable grommets in the boiler ...................................................................................... 18

6.2 Connecting the electric boiler to permanent electrical installation .............................................................. 18

7. Operating the boiler ......................................................................................................................................... 23

7.1 Safety instructions ...................................................................................................................................... 23

7.2 Overview of elements for operating the boiler ........................................................................................... 23

7.3 Alarm .......................................................................................................................................................... 24

7.4 Blockade ..................................................................................................................................................... 24

7.8 Turning the boiler on/off ............................................................................................................................ 25

7.9 Automation deblocade of pump .................................................................................................................. 25

7.9 Communications port.................................................................................................................................. 25

7.11 Master application .................................................................................................................................... 25

7.13 Room thermostat ....................................................................................................................................... 25

8. Hidden menu ................................................................................................................................................ 25

9. Boiler commissioning ...................................................................................................................................... 28

10. Cleaning and maintenance of boiler ............................................................................................................... 28

11. Operating problems and solutions .............................................................................................................. 29

12. Product disposal after use ............................................................................................................................ 29

13. Designing manual .......................................................................................................................................... 30

13.1 Systems to which the boiler may be connected ............................................................................... 30

14. Warranty ......................................................................................................................................................... 31

2

1. Explanation of the symbols and safe work instructions

1.1 Introduction

These technical instructions contain important information about adequate assembly,

commissioning, handling and maintains of the device.

It is intended for authorized installers, authorized service technician’s and end – users of the

electro-boiler.

Please read and retain the instructions for future reference in case of need.

1.2 List of symbols with explanations

Warning symbols

RISK OF ELECTRIC SHOCK

Risk of electric shock symbol is presented by a lightning bolt arrow in a triangle

warning symbol

WARNING

Warning symbol in the text is presented by the warning sign in a triangle

IMPORTANT INFORMATION

Important information for which there is no risk of injury or material damage

SETTINGS

Settings intended for service technicians or experts and end user should not

perform them by themselves.

Key words at the beginning of the safety notice denote the type of hazard and potential

consequences if one does not comply with the measures for preventing hazard.

- NOTE indicates that there might be some material damage.

- CAUTION indicates that there might be minor or moderate bodily injuries.

- WARNING indicates that there might be severe or life-threatening bodily injures.

- DANGER indicates that might be life – threating bodily injuries.

1.3 General boiler safe work instructions

General safety instructions

This device is not intended for use by persons with limited mental or psychophysical

capabilities, as well as by inexperienced persons including children. Children above 8

may handle this device only if an adult is present or if they are instructed for date

handling and are aware of all hazards.

Non-compliance with the safe work instructions may result in severe injuries, death,

material damage, and may jeopardize environment.

Before assembling the boiler professional inspection and control testing of the

electrical installation is required.

All works on the electrical installation should be performed by a competent and

authorized person in accordance with relevant regulations.

Commissioning, maintenance and repair may only be performed by an authorized

service technician.

3

Ensure technical approval of the installation in accordance with the relevant

regulations.

Danger due to compromising one’s own safety in case of need, e.g. in case of fire

Never put yourself in a life-threatening situation. Your safety should always come

first.

Damage due to errors in operating the boiler

Error in operating the device may cause bodily injuries or material damage.

Ensure that only persons who are able to use this boiler adequately have access to it.

Errors in operating the boiler may cause injuries and/or damage to the installations.

Assembly and commissioning of the boiler

Assembly of the boiler should be carried out only by authorized service technician.

The commissioning of the boiler should always be performed only if there is

appropriate pressure in the installation, while the working pressure must be in

accordance with the data of manufacturer. Do not close safety valves in any case, as

the material damage that may be caused by high pressure will thus be avoided.

The boiler should be installed only in a room in which water cannot freeze.

Do not use or store flammable materials (paper, thinner, paint, etc.) near the boiler.

Maintain safe separation distance from the boiler, in accordance with the regulations

in effect.

Life-threatening risk of electric shock

Electrical connection works should be done by authorized service technicians. Please

comply with the connection scheme.

Prior to works on electrical installations disconnect the power supply and ensure that

it may not be accidentally connected again.

The device must not be assembled in damp premises.

Maintained/check-up

We recommend that you sign a contract on inspection/maintenance with an expert

company, so that the inspection and necessary maintenance of the device may be

carried out once a year.

End-user of the boiler is responsible for ensuring that the hearing installation is safe

and environmentally friendly.

Adhere to the safe work instructions in the section

Spree parts

No liability shall be accepted for damage caused by use of spare parts which have not

been delivered by the manufacturer.

Use only original spare parts.

Damage to the system as a result of freezing temperatures

In case of freezing temperatures, protect the heating system from freezing. Heating

water should be drained at the lowest point of the heating system.

Instructions for service technicians

Inform the end-users about the manner of work and the maintenance of the boiler.

Warn the end-users that they must not make any change or repairs on their own.

Ensure that the children do not use this boiler without supervision and not play with it.

4

Hand over boiler technical documentation to the end-user.

Environmental protection/Disposal of waste

Dispose of packaging in an environmentally friendly manner.

Dispose of the boiler in an environmentally friendly manner at the recycling spot.

Cleaning of the boiler

Clean the boiler on the outside with a damp cloth.

2. Information about the boiler

2.1 Description of the product

EK-SMART EU is produced with the following powers:

6kW, 9kW, 12kW, 16kW, 18kW, 21kW, 24kW, 27kW.

Advantages of electric boilers: reliable heating, quiet work, not requiring, a separate room for

installation, small dimensions, low price, high level of operational safety, absence of

chimney, no harmful emissions during operation (environmental protection). Smaller power

boilers of up to 9kW may require Single Phase or Three Phase power supply, while boilers of

greater power exclusively require Three Phase power supply.

In addition to standard elements of an electric boiler, the EK Smart EU electric boiler contains:

expansion vessel, circulation pump, safety valve, filling and drainage tap, automatic air vent,

etc.

The device is equipped with a protective assembly unit which guarantees complete safety.

Heating elements and pump valve are turned on through controller in charge of maximum work

optimisation.

Specially designed logarithm measures the time of work of each heating element and

periodically turns off the heating elements which worked the most and turns on those that

worked the least. In this way, equal exploitation of the heating elements is ensured, which

significantly extends the working life of the product.

Algorithm is designed upon the principle of modulation, so, as the boiler approaches the set

temperature, it reduces its power output and thus achieves maximum comfort with minimum

consumption.

Additional equipment: room thermostat is recommended since they significantly increase the

efficient energy use of the product and retain the same comfort with reduced consumption.

Electric boiler may be used:

1) As a principal source of heating (through radiators: in houses, holiday cottages,

apartments...)

2) As an auxiliary/additional source of heating (systems with a heat pump, solar systems,

pyrolytic boiler...)

3) For heating through heat accumulator (accumulation)

In addition to already mentioned inputs and outputs, EK-Smart EU boiler controller also

contains additional equipment and functions which provide maximum comfort and safety to

the end-user with minimum consumption.

5

Picture 1. Boiler overview: isometric view, front side, left and right side, top side, bottom side

6

Picture

Picture

7 -

Pump

Picture 2. Boiler components

1 - LCD display

2 – Expansion vessel

3 – Automatic air vent

4 – Pressure safety valve

5 – Safety thermostat

6 – Exchanger

3. Connection for hot and cold water

8 - Cold water

9 - Hot water

4. Cross-section of the exchanger

7

2.2 Electro-boiler models

It is important to emphasise that the boilers of 6kW and 9kW are produced in

two versions, with Single Phase and Three Phase connector. The boilers with Single Phase

connectors are EK 06 Smart MONO EU and EK 09 Smart MONO EU, boilers with Three

Phase connectors are EK 06 Smart EU and EK 09 Smart EU. When purchasing the product,

you should emphasise which connector you want. Subsequent “reconnections” are not

approved by the manufacturer.

Electro-boiler models Power

EK 06 Smart EU 6 kW

EK 06 Smart MONO EU 6 kW

EK 09 Smart EU 9 kW

EK 09 Smart MONO EU 9 kW

EK 12 Smart EU

12 kW

EK 16 Smart EU 16 kW

EK 18 Smart EU

EK 21 Smart EU

EK 24 Smart EU

EK 27 Smart EU

Table 1. Electro-boiler models

18 kW

21 kW

24 kW

27 kW

2.3 Declaration of conformity

We declare that these boilers have been examined in accordance with the Directives 2006/95/EC

(Low Voltage Directive - LVD) and 2014/30/EU (Electromagnetic Compatibility Directive EMC).

8

Delivery Item

No of units

Boiler

1

Assembly set

1

Instruction for use

1

Pine wood, larch and spruce wood,

2.4 Minimum separation distance and flammability of building

materials

Minimum separation distance from inflammable materials may differ from country to country.

Please adhere to the regulations on electrical installations and prescribed minimum distances

in your country. The following table shows the classification of flammability of building

materials as per DIN 4102.

Flammability of building materials

A

A1

A2

B Flammable

B1

B2

Non-combustible

Non-combustible

Containing minor

quantities of

flammable additives

(organic ingredients)

Not easily flammable

Flammable

Asbestos, stone, ceramic wall tiles, terracotta,

plaster (without organic additives).

Gypsum-cardboard plates, base felt plates, glass

fibre, plates of AKUMINE, lycopene

RAYOLITE, LIGNOS, VELOX and

HERACLITE

Beech and oak wood, composite wood, felt, plates

of HOBREX, VERSALITE and UMAKART

veneered wood

Easily flammable

B3

Asphalt, cardboard, cellulosic material, tar paper,

particle board, cork, polyurethane, polystyrene,

polyethylene, floor fibres

Table 2. Flammability of building materials per DIN 4102

2.5 Tools, materials and auxiliary aids

For assembly and maintenance of the boiler, standard tools for doing thermo-technical,

plumbing and electrical installations are required.

2.6 Antifreeze protection

If the use of antifreeze additives cannot be avoided, use those additives which are permitted

for heating installations.

2.7 Waste disposal

- Dispose of the packaging in an environmentally friendly manner.

- Dispose of the components which should be replaced in an environmentally friendly

manner.

2.8 Scope of delivery

During delivery of the boiler, adhere to the following:

- Check whether the packaging is undamaged

During delivery.

- Check whether the delivery is complete.

9

2.9 Name plate

Standard plate of the boiler is located on the outside of the boiler and contains the following

technical data: model, voltage, power, serial number, year of production.

2.10 Dimensions and technical data

Picture 5. Dimensions

A=640mm; B=400mm; C=290mm

10

EK 27 Smart

Max

. temperature

of the water

Models

EU

Power

Number of levels of power

Division of levels of power

Mains voltage

Built-in fuse

Min. cross-section of connection

cable

Safety valve

Max. allowable working pressure

Min. allowable working pressure

boiler

Water volume in the boiler lit

Volume of the expansion vessel

Hot water connection

Cold water connection

Boiler dimensions

Handling

kW

Vac

A

mm2

bar

bar

bar

°C

lit

cola

cola

mm

EK 06 Smart MONO EU

EK 06 Smart EU

6 6 9 9 12 16 18 21 24 27

3 3 6 6 6 6 9 9 9 9

3x2 3x2 6x1.5 6x1.5 6x2 6x2.67 9x2 9x2,33 9x2.67 9x3

230 400 230 400 400 400 400 400 400 400

1x32 3x10 1x40 3x16 3x20 3x25 3x32 3x32 3x40 3x40

3x6 5x2.5 3x10 5x2.5 5x4 5x4 5x6 5x6 5x6 5x10

EK 09 Smart MONO EU

EK 09 Smart EU

EK 12 Smart EU

EK 16 Smart EU

EK 18 Smart EU

3

3

0.8

80

11

10

1

1

650x400x290

PCB board

EK 21 Smart EU

Table 3. Technical data

NOTE: Electro-boiler already has built-in fuses, so, when choosing the fuses

outside the electro-boiler, make sure that they are of greater rated current

than those in the electro-boiler. When purchasing the boiler of 6kW or 9kW,

emphasise whether you want a model with Single Phase or Three Phase connection.

EK 24 Smart EU

11

3. Transport of the boiler

NOTE: Transport damages

Pay attention to transport instructions found on the packaging

Use a suitable transport vehicle, e.g. a trolley with a tightening strap.

During the transport, the boiler must be in a lying position.

Avoid blows or collision with various objects.

- Put the packed boiler onto a trolley, if needed tie it with a tightening strap and transport

it to the place where it will be installed.

- Take off the packaging additions.

- Remove the packaging and dispose of it in an environmentally friendly way.

4. Installation of the boiler

CAUNT: Incorrect installation of the boiler may cause injuries or material

damage!

Never install the boiler without the expansion vessel (AG) and safety valve.

Use a suitable transport vehicle, e.g. a trolley with a tightening strap.

NOTE: Material damage may be caused due to freezing!

The boiler should be installed only in a room in which freezing cannot

occur.

4.1 Caution when assembling the boiler

NOTE: Material damage may be caused for failure to adhere to the following

instructions!

Adhere to the instructions for the boiler and all installed components

Prior to installing, pay attention to the following:

- All electrical connections, protection measures and fuses should be connected by a

professional from the authorised service, complying with all the norms and regulations,

as well as local regulations in effect.

- EK Smart boiler has a built-in automatic fuse, the characteristics of which are given in

the Table 3: Technical data.

- Electrical connection must be linked as per the connection schemes.

- After the prescribed installation of the boiler, the ground wire should be connected.

12

- Prior to any works on the heating installations, the power supply should be disconnected.

- Unskilled and unauthorised attempts of connecting under voltage may cause material

damage on the boiler, which may further lead to dangerous electric shocks.

4.2 Clearance around the boiler to floor, wall and ceiling

DANGER: Risk of fire due to flammable materials or liquids!

Do not store flammable materials or liquids in the vicinity of the boiler.

Inform the end-user about the regulations in effect relating to minimum

clearance from easily flammable materials (more information in the

table 2)

- Comply with the regulations on electrical installations and minimum clearance that

are in effect in the relevant country.

- Mount the boiler on the wall in such a way that there remains free space, as shown in

picture 6.

Picture 6. Minimum clearance after the assembly of the boiler

a=60mm; b=c=150mm; d=500mm

13

4.3 Removal of the boiler front casing

Prior to any intervention (removal of the casing), disconnect the boiler

from the installation.

Boiler casing may be removed for easy handling and installation. Boiler removal is

performed in the following way:

1. Unscrew the screws at the left, as shown in the picture.

2. Unscrew the screws at the right, as shown in the picture.

3. Remove the boiler front casing by easily pulling it towards yourself.

Picture 7. Opening of the boiler (removing the boiler front casing)

4.4 Assembly of the boiler

The boiler should be assembled on the wall in a vertical position.

The manufacturer is not responsible for damage caused as a result of

unprofessional assembly.

NOTE: Material damage may be caused by inadequate assembly on the

wall!

This section describes the assembly of the boiler on the wall.

NOTE: The boiler must be assembled vertically on the wall.

Assembly procedure:

1. Mark the position of the hole to be drilled in the wall.

2. Drill holes as per the measures shown in picture 5.

3. Drill holes with adequate drill.

4. Put in the drilled holes the plastic screw anchors, contained in the delivery of

the boiler, or some other screw anchors suitable for non-standard type of wall.

5. Afterwards, put in the screw anchors the screws delivered in the assembly set

(or some other screws). Screws delivered in the assembly set should stick out

from 5 to 10mm.

6. Carefully mount the boiler on the wall.

7. The boiler must be assembled in the vertical position.

Adequate fastener tools should be used.

14

Picture

5. Position of screw anchors for assembly

a=220mm; b=80mm; c=23mm; d=560mm

5. Boiler hydraulic scheme

Heat pipes should be connected in the following manner:

- Connect the cold water connection to the connection 8, picture 3.

- Connect the hot water connection to the connection 9, picture 3.

Filling the boiler with heating water and testing welded joints and tightness:

Testing tightness should be carried out before commissioning the boiler.

DANGER: Injuries and/or material damage may be caused by exceeding pressure

during testing tightness!

High pressure may damage regulation and safety devices, as well as the cylinder

itself.

Fill the boiler up to the pressure that corresponds to the opening pressure of

safety valve.

Comply fully to the pressure of built-in components.

After testing the tightness, open the valves again.

Check whether all pressure regulators and installation safety elements work

properly

15

SRB

DANGER: Health risks due to mixing the drinking water and water from heating

installation!

Comply with the existing regulations and norms related to avoiding mixing

drinking water and water from heating installation.

Comply with the norm EN1717.

DANGER: Risk of fire due to flammable materials or liquids!

Do not store flammable materials or liquids in the vicinity of the boiler.

Inform the end-user about the regulations in effect relating to minimum

clearance from easily flammable materials (more information in the table 2).

NOTE: Damage on installations caused by poor quality of water! Depending on

the water characteristics, there might be damages of corrosion or lime scale on the

heating installations.

Comply with the requests relating to filling water as per VDI2035, i.e. as per

the design documentation and catalogue.

NOTE: Material damage caused by temperature strain. If the boiler is filled in a

warm state, thermal stress may lead to cracks. The boiler will start to leak.

Fill the boiler only in cold state (the temperature of the flow may be

maximum 40°C)

Check the pre-pressure of the expansion vessel.

- Open the filling and drainage tap.

- Slowly fill the boiler.

- At the same time monitor the pressure on the sphygmomanometer. When the working

pressure has been reached, close the filling and drainage tap.

- Purge the boiler through air vent.

- Purge the installation through a valve on the radiator.

- Once the working pressure has been reduced by purging of air, the water in the system

must be refilled.

- Test the tightness in accordance with the regulations in effect.

- Check whether all safety elements work properly.

- If the tightness has been tested and no leakage has been observed, regulate the right

working pressure.

16

SRB

- Take off the hose from the filling and drainage tap.

- Note down the value of the working pressure and water quality in the instruction for

use.

During the first filling or refilling or changing the water

- Comply with the request related to filling water.

Purging and unblocking the heating pump

- Pump installed in this boiler has an automatic manner of purging, therefore,

there is no need to undertake any actions to purge the pump.

When the heating pump is blocked, please do the following:

- If the pump gets blocked after a long period of inactivity, you should unscrew the front

stopper and turn the camshaft using the screwdriver.

- Do this operation carefully to avoid the damage.

Purging the boiler and installation

- Through the screw on the air vent, carefully release the vent and purge the

boiler. This vent is automatic, therefore, if the filling of the installation and

the boiler is carried out properly, additional manual purging will not be

necessary.

- Boiler electrical wiring diagram.

Picture 9. Hydraulic scheme

17

SRB

During connecting the boiler to electrical installation, observe the connection

WARNING

Only qualified person can do the works on electric installations.

Prior to opening the boiler, disconnect the power supply from all poles

and ensure that it is not accidentally connected again.

Comply with the regulations for installation.

IMPORTANT INFORMATIONS

Electric boiler is connected to the permanent electrical installation as per the

connection scheme and with a certain cross-section of voltage cable.

Connection should be made via outer switch for separating poles with

minimum distance between contacts of 3mm.

schemes. Cables must have the prescribed cross-section, and the fuses must

have the prescribed power.

Models EK 06 Smart EU, EK 09 Smart EU, EK 12 Smart EU,

EK 16 Smart EU, EK 18 Smart EU, EK 21 Smart EU, EK 24 Smart EU, EK

27 Smart EU (400V 3N ~).

Modes EK 06 Smart MONO i EK 09 Smart MONO may also be connected

to a Single Phase connection (230V N ~).

6.1 Position of electrical cable grommets in the boiler

This boiler is equipped with two sets of electrical cable grommets. The grommets are

located on the left and right sides.

A set of grommets consists of two rings, with the large ring being intended for voltage

cable and the smaller ring for equipment shown in the hydraulic scheme.

6.2 Connecting the electric boiler to permanent electrical installation

WARNING

The boiler is exclusively connected to permanent electrical installation

- Connection is carried out according to the connection scheme, with a certain crosssection of voltage cable.

- Instead of classic clamp for connecting voltage cable, the boiler contains three-way

automatic switches in which the voltage cable is connected.

according to the existing standards for electrical installations.

Connecting the boiler to permanent electrical installation must be

performed through the device for power supply disconnection from the

network which has a space between contacts of 3mm in all fields that

provide complete disconnection under III category overvoltage

conditions.

18

SRB

- The set of tree-way automatic switches is supplemented by remote voltage relay, this

providing a safety assembly unit which, in addition to short-term over-current

protection, also reacts to thermal overload (a signal from safety thermostat activates

voltage relay) and in the same moment, interrupts the power supply of all three

phases to the boiler.

- In models EK 06 Smart MONO EU and EK 09 Smart MONO EU phase conductor

is connected to single-pole switch (L1).

- In models EK 06-27 Smart EU phase conductors are connected to three-way switch

(L1, L2, and L3).

- Neutral zero conductor is connected to the adequate clamp with the sign N. The

clamp of the zero conductor is blue in colour.

ATTENTION! When connecting phase conductors it is mandatory to

tighten well the screw in automatic switches in order to make as better link

as possible between cable and clamps.

DANGER! If the link between cable and clamp is not tight, there may be

incontrollable heating of the switch and eventually result in breakdown.

NOTE! Remote voltage relay is connected by the manufacturer and

nothing in additionally connected to it.

- When connecting the voltage cable in the boiler, through any of the chosen sets of

grommets, carefully pull the cable to three-way automatic switches, taking care not

to damage sets of cables inside the boiler.

- Additional equipment shown in the hydraulic scheme is connected as per the wishes

of the user.

- After connecting the voltage cable and/or additional equipment, before closing the

boiler, i.e. before the assembly of the front casing, the set of switches and remote

voltage relay should be lifted to ensure power supply in the boiler.

19

SRB

Picture 10. Electrical wiring diagram EK 06 Smart EU

Picture 11. Electrical wiring diagram EK 06 Smart MONO EU

20

SRB

Picture 12. Electrical wiring diagram EK 09 Smart EU, EK 12 Smart EU, EK 15 Smart EU

Picture 13. Electrical wiring diagram EK 09 Smart MONO EU

21

SRB

Q1 Circuit breaker

G1, G2, G3

Relays

20A

X1-1 Terminal Blocks

-

blue

K2 STB thermostat

Picture 14. Electrical wiring diagram EK 18 Smart EU, EK 21 Smart EU, EK 24 Smart EU

LEGEND:

K1 Voltage release H1, H2, H3 Heaters

X1 Terminal Blocks

EK Smart EU

EK 06 Smart EU: H1=3x2kW

X1-2 Terminal Blocks-ground

X1-3 Fuse terminal block 2A

EK 09 Smart EU: H1=H2=3X1,5kW

EK 12 Smart EU: H1=H2=3X2kW

EK 15 Smart EU: H1=H2=3X2,667kW

P1 Pump

P5 Room thermostat connection point

R1 Water temperature sensor KTY 81-210

EK 18 Smart EU: H1=H2=H3=3X2kW

EK 21 Smart EU: H1=H2=H3=3X2.333kW

EK 24 Smart EU: H1=H2=H3=3X2.667kW

EK 27 Smart EU: H1=H2=H3=3X3kW

22

SRB

7. Operating the boiler

7.1 Safety instructions

The user may use and adjust only the functions found in the user menu turn on and turn

off the boiler. All other adjustments should be performed by a professional (authorized

service technician).

Only adults acquainted with the instruction and the manner of work of the boiler may

operate the boiler.

Be careful not to let children without supervision stay in the vicinity of the boiler during

operation.

Do not leave or store flammable materials.

The user must comply with the instruction for use.

Authorized professional who performed the heating installation is obliged to inform the

user about handling, adequate and safe work of the boiler.

7.2 Overview of elements for operating the boiler

1. Position 1 is lighting when pump is active;

2. Position 2 is lighting when room thermostat is active;

3. Position 3 is lighting when system is in heating mode;

4. Position 4 is lighting when system is antfreezing mode;

In the operating mode, under normal conditions, the values of current water temperature in °C

and current boiler power in kW interchange on the display. Depending on which of these

Picture 15. Display look

23

SRB

values is currently on the display, the adequate LED indicator also beams. The temperature

and power interchange approximately every 3 seconds.

7.3 Alarm

Warning bearing the A sign are alarms. Their role is to signalize a potential problem, and that

the parameters are approaching border values for safe work of the system.

A1 – Temperature is too low, that is ≤ 12°C

A2 – Temperature is too high, that is ≥85°C

7.4 Blockade

Warning with the sign E is blockade. Blockade means that one of the vital parameters has

crossed the critical value for safe work of the boiler. Blockade also appears if the controller

detects short circuit/interruption or illogical readout of the temperature. In such a situation, the

controller automatically turns off all relay outputs. Reset of the blockade is performed by

pressing the ON/OFF button. Turn off the controller, remove the cause of the blockade and turn

on the controller again.

E1 –Temperature too low that is ≤ 0°C

E2 –Temperature too high that is ≤ 12°C

E3 – Boiler temperature sensor failure

In case of alarm or blockade, the following is shown on the display:

- For 1.5 seconds, the temperature value is displayed and the temperature indicator beams

- For 2.5 seconds, the error code is displayed and both indicators, for temperature and power

beam

- For 1.5 seconds, the current power value is displayed and the power indicator beams

- For 2.5 seconds, the error code is displayed and both indicators, for temperature and power

beam

In the user menu, it is possible to set the following parameters:

- Temperature (“t” symbol on the display), ranging from 2F28+F29 to 80°C

- Power (“P” symbol on the display), ranging from 1 to the number of heating elements

- Mode (symbol on the display “Fun”, from function) – the value of this parameter set on 1

denotes the heating mode, the value set on 2 denotes antifreeze protection

To set the operating parameters, press the “MODE” key. By pressing multiple times or

holding the “MODE” key, the symbols t, P, FUn will interchange on the display.

By releasing the “MODE” key, the symbols t, P, Fun will interchange on the display.

By releasing the “MODE” key, you will stop at the desired function. Current valid value

recorded for given parameter will soon be shown on the display. By pressing the keys “UP”

(upwards arrow) and “DOWN” (downwards arrow), you may change the value of the

recorded parameter for the chosen function. When you set the desired value of the parameter,

you may leave the menu immediately by pressing OK key or you may change the values of

other parameters. If you do not wish to leave the menu after you have set the value of one

parameter, press MENU key again, the set value of the parameter will be recorded and you

will move to the next parameter from the menu which you may also change and so on.

If you set the value of some parameter and do not press OK, after ten seconds the device will

automatically exit the menu and recorded the set value of the parameter.

Service menu

Press and hold the MENU key, then shortly press the UP key. The sign PAS (from password)

will appear on the display, soon the sign 000 will appear on the display and then the password

should be entered. The password is 64. Electronics does not have the option of changing the

password.

24

SRB

When you enter the password, press OK and the symbols of parameters from the service

menu will appear on the display.

Resetting the boiler

For resetting the boiler, press and hold OK key for a few seconds.

7.8 Turning the boiler on/off

When there is no need for the boiler to work, press ON/OFF button and hold it for at least half

a second. All relay outputs will turn off, as well as the display of the device. When you wish to

turn on the boiler again, press the button again. The device will check the temperature condition

whether it is higher than Tmin, and if it is, the device will start, and if it is not, a message will

appear on the display. Checking whether the T>Tmin when turning on the boiler is not

performed in the antifreeze protection mode.

7.9 Automation deblocade of pump

The pump will run every day at the same time, it will be the time of the day when you switch

boiler off.

If you set the boiler off mode at 6 p.m. the timer will activate the pump every day for 15

minute starting at around 6 p.m.

Important: Do not cut power supply off between heating season.

7.9 Communications port

Communications port RS232 is used for GSM modem or WiFi modem.

7.11 Master application

The input can be used for master applications. If you use this input, you must also set the F25

parameter that determines the behaviour of the boiler.

7.13 Room thermostat

Settings (intended for service technicians):

1. Install the room thermostat at the adequate connection.

2. HIDDEN MENU: Set parameter F04 on 1.

3. Check whether position 2 (symbol ,,t” ) blinking on the main display.

4. When signal from room thermostat is active in the symbol ,,t” (position 2) flash red.

5. When the room thermostat is switched off, pump will be working for three minute more.

8. Hidden menu

Press and hold MENU key, then shortly press the UP key. The sign PAS (from

password) will appear on the display, soon the sign 000 will appear on the display

and then the password should be entered. The password is 64.

25

SRB

Parameters of the hidden menu

Factory

value

Scope of

setting

F01 3/6/9 3/6/9

F02 2,0 1,0-3,0

F04 0 0 or 1

F05 0 0 or 1

F06 45 0 to 99

F07 3 0 to 99

F12 12 0 to 99

Unit DESCRIPTION

-

Number of relay outputs supported by automation

system

kW

Power of one heating element built-in in the boiler

- ROOM THERMOSTAT

0 –room thermostat is installed

1 –room thermostat is not installed

- ANTIFREEZE PROTECTION LIQUID

0 –antifreeze protection liquid is poured in

1 –antifreeze protection liquid is not poured in

°C

°C

Temperature at which the pump turns on

Minimum temperature of water in the boiler at which

the boiler starts up; if the water temperature is lower

than that set by parameter F07, it is impossible to turn

on the boiler.

°C

Minimum value of temperature for alarm

F13 0 0 to 99

F14 85 0 to 99

F15 90 0 to 99

F16 5 0 to 99

F19 3 0 to 6

F27* 15 0-99

F28 0,8 0-99

F29 0,4 0-99

F30 3 1-20

F31 1 0 or 1 -

°C

°C

°C

°C

kW

°C

°C

°C

min

Minimum value of temperature for blockade

Maximum value of temperature for alarm

Maximum value of temperature for blockade

Set temperature of water in boiler for antifreeze

protection mode

Boiler power in the antifreeze protection mode

Difference (hysteresis) boiler and water heater (see

also the parameter F25)

Hysteresis for heating elements**

Hysteresis for heating elements ***

Time of rotation of heating elements

LANGUAGE

1-Serbian language and 0-English language

26

SRB

Hysteresis for heating elements – more about this parameter in the section principle of

operating the electric boiler.

Sz – set boiler power;

Sz-1 – boiler power reduced by one level of power;

Sz-2 – boiler power reduced by two.

Picture 27. Output power of the boiler in the function of temperature and hysteresis

27

SRB

9. Boiler commissioning

NOTE: First commissioning must be carried out by an expert – authorised service technician.

- Before commissioning, check the tightness of the hydraulic network. All the valves in the

network, including thermostat if any, must be in a position (open) which enables smooth water

circulation through the boiler and pipe network. The pressure in the system must be within the

limits prescribed by the Instruction.

- Check whether the device is properly connected to the electrical network. Check whether all

switches on the device and turned off (0), and the regulation thermostat is at the far-left position.

- Turn on the fuses in the distribution cabinet of the house electrical wiring.

- Turn on the automation system of the boiler by pressing ON/OFF button.

- If the room thermostat is connected to the boiler, it should also be turned on.

10. Cleaning and maintenance of boiler

WARNING: Material damage caused by unprofessional maintenance!

Insufficient or unprofessional maintenance of the boiler may result in

damage or destruction of the boiler, as well as in the loss of guarantee.

Ensure regular, comprehensive and professional maintenance of the

heating installation.

Protect electrical components and working units from water damp.

- Use only original spare parts of the manufacturer or those approved by the manufacturer.

For damages resulting from the use of spare parts not delivered by the manufacturer, the

manufacturer does not hold any liability.

Cleaning the boiler

- The boiler should be cleaned on the outside using a wet cloth.

The quantity of newly filled water is reduced in the first days after filling, as a result of

heating. It, thus, creates airbags which obstruct the work of the heating installation.

Testing the working pressure

-Working pressure of the new heating installation should be checked daily at the beginning.

In case of need, fill up the heating installation with water and purge it.

- Later, working pressure should be checked once a month. In case of need, fill up the heating

installation with water and purge it.

- Test the working pressure. If the pressure drops under 1bar, fill up the installation with

water.

- Purge the heating installation.

- Check the working pressure again.

Fill up with water and purge the installation

WARNING: Material damage caused by temperature strain. If the

heating installation is filled in a warm state with cold water, it may result

in cracks.

Heating installation should be filled only in cold state (temperature

of the flow is maximum 40°C).

28

SRB

WARNING: Material damage caused by frequent filling up of water!

Due to frequent filling up of the heating installation with water,

depending on the water characteristics the installation may be

damaged by corrosion or lime scale.

Tightness of the heating installation and functional operation of the

expansion vessel should be tested.

- Connect the hose to the filling and drainage tap.

- Fill the hose with water and set the connection of the hose of the filling and drainage

tap.

- Tighten the hose with a hose clamp and open the filling and drainage tap.

- Slowly fill the heating installation. At the same time, monitor the pressure value on

manometer.

- During the filling, purge the system.

- When the working pressure has been reached, close the filling and drainage tap.

- When the pressure value has been reduced by purging, the water must be filled up.

- Remove the hose from the filling and drainage tap.

11. Operating problems and solutions

1. Boiler is working, but the temperature is unsatisfactory?

- Boiler power is insufficient => Increase the power by selecting another group of heating

elements.

- Selected temperature is insufficient => Increase the temperature on the regulation

thermostat.

- There is excess air in the system => Purge the whole system.

- One of the heating elements is faulty => Call the repair service in order to do the

replacement.

- The boiler does not have all three phases => Call a professional to check.

2. Heating is not functioning and the boiler shows a certain temperature?

- A valve or coil in the system is closed and the flow disabled => Check the valves and open

them if necessary.

- Ball valve on voltage/return line is closed => you must open the valves.

- Pump is not working or is blocked for some reason=> Call a professional for repair.

12. Product disposal after use

Crossed-out “wheelie-bin” symbol on the label of this product means that the product

should not be disposed of with other household waste. In order to prevent potential negative

consequences for the environment and human health, please separate this product from other

waste, so that it could be recycled in a way that is environmentally-friendly.

29

SRB

In accordance with the WEEE Directive 2012/19/EU (Waste Electrical

and Electronic Equipment),Law on Environmental Protection (Official Gazette of the

Republic of Serbia, No.135/2004, 36/2009,36/2009– as amended,72/2009– as

amended,43/2011- decision of the Constitutional Court and 14/2016), Law on Waste

Management (Official Gazette of the Republic of Serbia, No.36/2009,88/2010and14/2016) and

Rulebook on the list of electrical and electronic products, measures restricting or prohibiting

the use of electric and electronic equipment containing hazardous substances, the manner

and procedure for management of waste originating from electrical and electronic products

(Official Gazette of the RS, No. 99/2010).

13. Designing manual

13.1 Systems to which the boiler may be connected

- All the systems for space heating that are designed for temperatures lower than 80°C.

- Closed heating systems.

- Systems in which there is a solid fuel boiler.

ATTENTION! When connecting a boiler to such a system, it is

compulsory to pat attention that both pumps in the system push water in

the same direction in order to prevent collision of flows.

Potential great hydraulic system strains, as well as cracking of some components.

- It may be used as a device for heating sanitary water in the accumulation boiler through the

heat exchanger.

- It may also be used in certain technological processes on condition that there is no need for

water temperature above 60°C.

- It must not be used for direct heating of sanitary water.

30

SRB

14. Warranty

1. Co. “Radiator Engineering” covers different warranty periods for different parts (as

specified further on) only if the following conditions of the warranty are fulfilled:

1.1. The boiler must be connected to the aforementioned hydraulic diagram from the

Technical instructions;

1.2. Wiring connection must be performed in accordance with the Technical Instructions;

1.3. The user must comply with the stated instructions on use and maintenance of the boiler.

2. Warranty statement

We hereby declare:

2.1. That the product has the prescribed and declared quality properties.

2.2. We undertake, at the request of the buyer, if the request for repair is submitted in due

time within the warranty period, to perform, at our expense, all repairs of failures so that the

product works in accordance with the declared properties.

2.3. That the product will work impeccably during the warranty period, if the instructions for

use, operation and assembly are observed.

2.4. That in the warranty period, we will be ready to remove all product failures and keep in

stock all the necessary spare parts.

2.5. The warranty period starts from the DAY OF PURCHASE AND LASTS for 60

MONTHS OR 72 MONTHS FROM THE DATE OF PRODUCTION (the date of production

is on the sticker on the back of the boiler).

2.6. T h e 60 MONTHS WARRANTY IS VALID ONLY IF THE BOILER IS

REGULARLY SERVICED BY THE CENTRAL SERVICE OF CO. “Radiator

Engineering”, within the period specified for the product (in the text below).

2.7. The warranty is valid if the warranty card has been verified by the Seller, if the date of

purchase has been entered and the attached bill presented. IT IS ALSO IMPORTANT TO

HAVE THE ORDER FOR COMMISSIONING (certified by the Authorised Service).

3. Warranty period of 12 months applies to the following parts:

- Heating elements of electro-boiler, under normal conditions of exploitation.

4. Warranty period of 18 months applies to the following parts:

-Automatic switch; name: Acti9iC60

- Voltage relay; name: IMX + off

-Contactors; name: Acti9iCT

5. Warranty period of 24 months applies to the following parts:

-Expansion vessel

-Pump

6. Warranty period does not apply:

6.1. If a regular service is not performed after each heating season;

6.2. For replacement of parts within regular annual maintenance in accordance with the

instructions;

6.3. In case of defects caused by the customer due to improper handling of the product;

6.4. For mechanical defects made during transport and during use (solid objects);

6.5. If the product has been installed improperly, contrary to the applicable regulations in this

area;

31

SRB

6.6. If it has been established that the hydraulic scheme has not been made according to the

recommendations of the company "Radiator Engineering";

6.7. If the customer was using the product over the declared properties and under normal

circumstances.

7. The warranty period shall cease to be valid:

7.1. If it has been established that the failures have been repaired by an unauthorized person

or an unauthorized service.

7.2. If the original parts were not used in the repair;

7.3. W hen the warranty period expires.

8. When reporting failure, it is obligatory to provide the following information:

Name and type of product,

Date of purchase,

Factory number of the boiler,

A brief description of the failure, or shortcomings,

The correct address and contact telephone, email.

9. Regular annual service

Regular service is performed at the end of every heating season in the period from 15th April

to 31st August and is charged according to the set Price list of the company "Radiator

Engineering". The service procedure by technicians who perform regular annual services,

who are authorized by the manufacturer for doing it, include the following operations:

32

Loading...

Loading...