Radiant RSF 20 E, RSF 30 E, RSF 24 E Installation And Maintenance Manual

CE

0694 TA05A27.A0504

Technical Specification RADIANT BRUCIATORI S.p.A. Montelabbate (PU) ITALY ENGLISH

INSTALLATION,

AND MAINTENANCE MANUAL

FOR GAS FIRED, WALL-HUNG BOILERS

models RSF 20 E • RSF 24 E • RSF 30 E

TYPE C ROOM SEALED

SEDBUK BAND D

INDEX

PRODUCT CONFORMITY page 1

INSTALLATION INSTRUCTIONS AND WARNINGS page 2

TECHNICAL DATA page 4

OVERALL DIMENSIONS - EXHAUST FLUE SYSTEM page 5

GENERAL INSTALLATION REQUIREMENTS page 8

BOILER INSTALLATION page 10

ELECTRICAL CONNECTIONS page 12

BOILER CONTROL PANEL page 13

STARTING UP THE BOILER FOR THE FIRST TIME page 13

MULTIGAS OPERATION page 15

GAS TABLE - REGULATING THE GAS PRESSURE page 16

GAS PRESSURE DIAGRAMS page 17

MAIN COMPONENTS page 18

WIRING DIAGRAMS page 19

MAINTENANCE page 21

UNPACKING page 21

FAULT FINDING CHART page 22

SHORT LIST OF COMPONENTS page 23

Installation Manual

HEAT TECNOLOGY SINCE 1959

Thank you for choosing RADIANT

Declaration for purposes of Art. 7 of Law 46 of 5 April 1990.

RADIANT BRUCIATORI S.p.A. hereby declares that all of its products are constructed to industry standards as required by the Article in

question and by Article 5 of the law in effect (D.P.R. no. 447/97).

All RADIANT boilers are constructed according to:

• UNI-CIG 7271 (april 1988)

• UNI-CIG 9893 (december 1991 )

• EUROPEAN STANDARD UNI EN 297 Gas-fired central heating boilers - Type B

11

e B

11BS

boilers fitted atmospheric burners of nominal

heat input not exceeding 70 kW;

• EN 483 Gas-fired central heating boilers – Type C boilers of nominal heat input non exceeding 70 kW;

• EUROPEAN STANDARD UNI EN 677 Gas-fired central heating boilers – Specific requirements for condensino boilers with a nominal

heat input not exceeding 70 kW;

• GAS DIRECTIVE 90/396 EEC for CE marking - Appliances burning gaseous fuels

• GAS DIRECTIVE 73/23/EEC - Low voltage

• GAS DIRECTIVE 89/336/EEC - Electromagnetic compatibility

• GAS DIRECTIVE 92/42/ECC requirements for new hot-water boilers fired with liquid or gaseous fuels

All RADIANT boilers are constructed according to UNI - CIG (EC) norms. The materials used, such as copper, brass, and stainless steel

form a compact, homogeneous, highly functional unit that is easy to install and simple to operate. The wall-mounted boiler is equipped with

all of the approved accessories required to make it a true, independent heating plant for home heating and for the production of hot water for

domestic needs. All boilers are fully inspected, and come with a certificate of quality signed by the inspector and with a warranty certificate.

This booklet must be read carefully and stored in a safe place, accompanying the boiler at all times.

RADIANT BRUCIATORI S.p.A. declines any and all responsibility for misinterpretations of this booklet deriving from any

translations of same.

RADIANT BRUCIATORI S.p.A. will not be responsible for non-observance of the instructions contained in this booklet or for the

consequences of any action not specifically described herein.

DOMESTIC HOT WATER WITH STORAGE CYLINDER – TA05A027.A0504

1

Installation Manual

INSTALLATION INSTRUCTIONS - WARNINGS

THIS INSTALLATION, USE, AND MAINTENANCE MANUAL IS AN ESSENTIAL AND INTEGRAL PART OF THE PRODUCT, AND MUST

ALWAYS BE KEPT NEAR THE DEVICE.

THE WARNINGS CONTAINED IN THIS SECTION ARE ADDRESSED BOTH TO THE USER AND TO INSTALLATION AND

MAINTENANCE PERSONNEL.

THE USER WILL FIND INFORMATION ON OPERATION AND LIMITS OF USE IN THE ACCOMPANYING MANUAL, WHICH SHOULD BE

READ VERY CAREFULLY.

STORE THE MANUAL CAREFULLY FOR FUTURE REFERENCE.

1) GENERAL WARNINGS

INSTALLATION MUST BE PERFORMED IN OBSERVANCE OF CURRENT NORMS, ACCORDING TO THE CONSTRUCTOR’S

INSTRUCTIONS, AND BY PROFESSIONALLY QUALIFIED PERSONNEL.

THE INSTALLATION INSTRUCTIONS MANUAL MUST BE ALWAYS ACCOMPANY THE BOILER.

PROFESSIONALLY QUALIFIED PERSONNEL ARE THOSE HAVING TECHNICAL COMPETENCE IN THE SECTOR OF APPLICATION

OF THE DEVICE (CIVIL OR INDUSTRIAL), AND, IN PARTICULAR, THE CONSTRUCTOR’S AUTHORISED SERVICE CENTRES.

INCORRECT INSTALLATION MAY CAUSE DAMAGE TO PERSONS, ANIMALS, OR PROPERTY, FOR WHICH THE CONSTRUCTOR

ASSUMES NO LIABILITY.

• After completely removing the packing, make sure that the contents are in perfect condition.

• In case of doubt, do not use the equipment. Consult the supplier.

• Packing materials (cardboard carton, wooden crate, nails, clips, plastic bags, polystyrene, etc.) are potentially dangerous and must be

kept away from children.

• Before performing any cleaning or maintenance operation, turn off the unit by means of the mains switch and/or by means of the

appropriate cut-off devices.

• Do not block the air intake or heat dissipation grates.

• In the event of breakdown and/or poor functioning of the device, turn it off and do not attempt to repair it or take any direct action. Refer

to professionally qualified personnel only.

• Any repairs must be performed exclusively by a service centre authorised by the constructor, and with original spare parts only.

• Non-observance of the above instruction may compromise the safety of the device. To guarantee efficient and correct operation, the

device should undergo period maintenance by professionally qualified personnel according to the constructor’s instructions.

• Whenever the device is to be put out of service, secure all potentially hazardous parts to prevent accidents or damage.

• If the device is sold or transferred to another owner, or if you move and leave the boiler, make sure that this booklet stays with the boiler

so that it may be consulted by the new owner and/or by the installer.

• Use only original spare parts for all devices with optionals or kits (including electrical ones).

WARNING: this device must be used for its intended purpose, i.e., heating and production of domestic hot water. Any other use is improper

and therefore dangerous. The constructor will have no contractual or extracontractual liability for damage caused by incorrect installation

and/or use or by non-observance of instructions supplied by the constructor.

This device must be used exclusively with a sealed central heating system equipped with an expansion vessel.

2) WARNINGS REGARDING INSTALLATION

Warranty expires 12 months from date of installation and in all cases no later than 18 months from date of construction. First start-up

must be performed by authorised personnel only. For any operation on the hydraulic, gas, or electrical circuit regarding the heating unit,

refer to authorised technicians only and use original spare parts only. Wall-mounted boilers are not to be installed in damp rooms, and

must be protected against sprays or jets of water or other liquids to prevent malfunctions of the electrical and heating devices. They must not

be exposed to direct steam from cookers, and nothing must be placed on top of them. This heating unit has been constructed to heat the

home and to produce hot water. The constructor declines all responsibility for incorrect installation and/or use of the device. Do not

leave the device on when it is not being used: close the gas cock and turn off the mains switch. If you smell gas in the room in which the

device is installed, do not operate any electrical switches, telephones, or any other device that might cause a spark. Immediately open doors

and windows to create an air current to clear the room. Close the main gas cock (at the meter) or the cylinder cock, and request immediate

technical service.

Do not tamper with the device.

DOMESTIC HOT WATER WITH STORAGE CYLINDER – TA05A027.A0504

2

Installation Manual

SYSTEMS WITH THERMOSTATS

A by-pass must be installed in heating systems with radiators thermostats.

As required by current norms, these devices must be installed by qualified personnel only, who must respect norms UNI-CIG 7129 and

7131 and revisions, fire department regulations, and requirements of the local gas company. Before installing the boiler, make sure that the

water and heating systems are compatible with its output. The room must be properly ventilated by means of an air intake (see UNI 7129/92

and UNI 7129/95 FA).

The air intake must be at floor level open flue only, at a point where it cannot be obstructed, and protected by a grate that does not reduce

the useful section of flow.

The use of air flows from adjacent rooms is permitted as long as such rooms are in depression with respect to the outside and as long as

there are no wood-burning fireplaces or fans installed there. If the boiler is to be installed externally (for example, on balconies or

terraces), make sure that it is protected against atmospheric agents to prevent damage to components and voiding of the warranty. In such

cases we recommend building a heat compartment to protect the boiler against inclement weather.

Check the technical data on the packing and on the plate located inside the front casing. Check that the burner is suitable for use with

the type of gas available.

Make sure that all pipes and connections are perfectly sealed and that there are no gas leaks.

All pipework should be chemically flushed to remove any residues that might negative effect the operation of the boiler.

3) GENERAL WARNINGS BASED ON TYPE OF POWER SUPPLY

POWER SUPPLY

Electrical safety is achieved only when the device is correctly and efficiently earthed as per current safety norms (IEC 64-8 Electrical Part).

• This fundamental safety requirement must be checked. In case of doubt, request a check of the electrical system by professionally

qualified personnel. The constructor will not be liable for any damage caused by lack of or improper earthing of the system.

• Have professionally qualified personnel check that the electrical system is adequate for the maximum absorbed power of the device

(indicated on the plate). In particular, make sure that the section of the system wires is suitable for the maximum absorbed power of the

device.

• Do not use adapters, multiple sockets, and/or extension cords to power the device from the electrical mains.

• Provide a unipolar switch as required by current safety regulations to connect the device to the mains.

• The use of any electrical device requires the observance of some fundamental rules, such as:

• do not touch the device with wet or damp parts of the body and/or with bare feet

• do not pull on electrical cables

• do not expose the device to atmospheric agents (rain, sun, etc.) unless specifically provided for

• do not allow the device to be used by children or anyone unfamiliar with its operation

• The power cable must not be replaced by the user.

• If the cable becomes damaged, turn off the device and have the cable replaced by professionally qualified personnel only.

• If you decide not to use the device for an extended length of time, turn off the mains switch that feeds all components of the

system using electrical energy (pumps, burner, etc.).

DOMESTIC HOT WATER WITH STORAGE CYLINDER – TA05A027.A0504

3

Installation Manual

TECHNICAL DATA

Type C unit

Type C devices are devices in which the combustion circuit (air intake,

combustion chamber, exchanger, combustion exhaust) is sealed off

from the place where they are installed.

Coaxial vertical

Coaxial horizontal

C32

C12

C52 Double

MODELS RSF 20 E RSF 24 E RSF 30 E

Maximum rated input kcal/h 22016 25628 29670

kW 25.60 29.80 34.50

Btu/hr 87398 101737 117783

Minimum rated input kcal/h 10320 15050 16340

kW 12 17.5 19

Btu/hr 40968 59745 64866

Maximum rated output kcal/h 20387 23475 27445

kW 23.71 27.30 31.91

Btu/hr 80931 93191 108949

Minimum rated output kcal/h 9030 13191 14559

kW 10.50 15.34 16.93

Btu/hr 35847 52366 57796

Heating temperature adjustment °C 30-80 30-80 30-80

Max. working pressure (heating) bar 3 3 3

Min. working pressure (heating) bar 0.3 0.3 0.3

Expansion vessel capacity (initial pressure 1 bar) litres 10 10 10

Continuous hot water drawing with Dt 30° litres/min 11.33 13.04 15.25

Max. working pressure (water) bar 6 6 6

Min. working pressure (water) bar 0.3 0.3 0.3

Width mm. 410 450 450

Height mm. 800 800 800

Depth mm. 270 320 320

Weight kg. 42 47 50

Coaxial exhaust flue diameter kit A (max. flue lenght) Ø (m) 100/60 (3) 100/60 (3) Coaxial exhaust flue diameter kit G (max. flue lenght) Ø (m) - - 125/80 (3)

Double exhaust flue diameter kit B (max. flue lenght) Ø (m) 80/80 (30) 80/80 (30) 80/80 (30)

Double exhaust flue diameter kit C (max. flue lenght) Ø (m) 118/80 (3) 118/80 (3) 118/80 (3)

Flow/return connections Ø 3/4” - 3/4” 3/4” - 3/4” 3/4” - 3/4”

Cold water connections Ø 1/2” 1/2” 1/2”

Hot water connections Ø 1/2” 1/2” 1/2”

Gas connections Ø 1/2” 1/2” 1/2”

Electrical connection 50 Hz V 230 230 230

Power supply W 170 170 170

Electrical protection IP X4D X4D X4D

Nox class II I II

Burner jets NP 11 G20 Ø 1.30 - Burner jets NP 11 G30/31 Ø 0.78 - Burner jets NP 13 G20 Ø - 1.25 Burner jets NP 13 G30/31 Ø - 0.77 Burner jets NP 17 G20 Ø - - 1.20

Burner jets NP 17 G30/31 Ø - - 0.75

DOMESTIC HOT WATER WITH STORAGE CYLINDER – TA05A027.A0504

4

Installation Manual

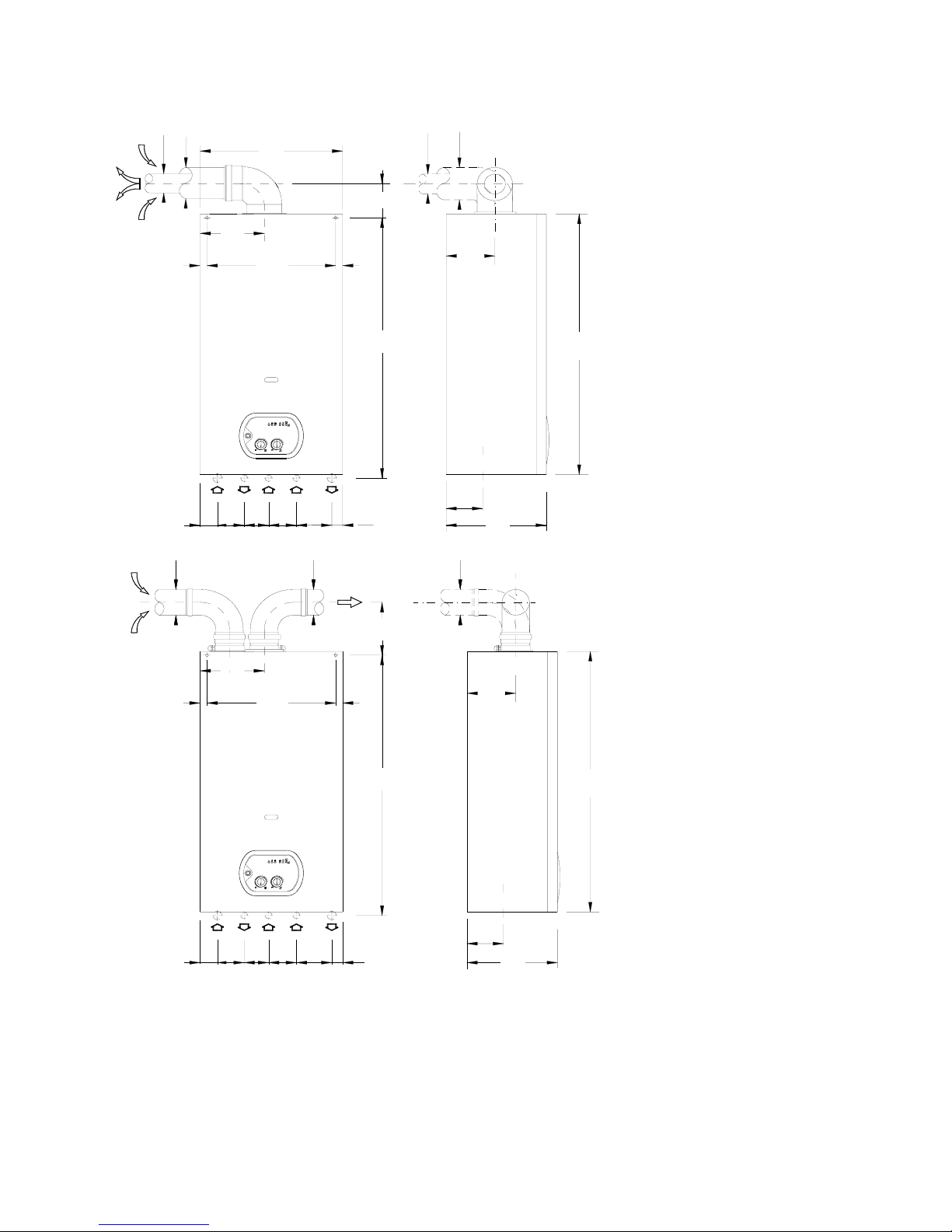

OVERALL DIMENSIONS - EXHAUST FLUE SYSTEM – mod. RSF 20 E

TYPE C WALL-MOUNTED BOILERS

31102807750 70

AF

G

R

C

95770166

ON 40

0.5

706050 80

807060

0.5

50ON 40

800

60

100

140

410

185

20

370

20

60

100

270

800

270

105

80

80

20

370

20

185

80

770

31102807750 70

CRGFA

140

105

SEALED COMBUSTION CIRCUIT:

Kit A

Horizontal coaxial exhaust flue

system with 360° rotation.

It allows the flue exhaust and the

air intake directly to an external

wall.

To insert a bend, reduce total flue

length by 0.8 m.

KEY

R RETURN ¾”

G GAS ½”

C HOT WATER ½”

F COLD WATER ½”

A HEATING FLOW ¾”

Kit B

Double exhaust/emission twin

flue system with 360° rotation.

It allows the flue exhaust into a flue

duct and the air intake directly from

an external wall.

To insert a bend, reduce total flue

length by 1.5 m.

NOTE: USE ORIGINAL RADIANT APPROVED FLUE KIT SYSTEMS, FLUE ACCESSORIES AND FLUE DIAPHRAGMS ONLY.

APPROVED RADIANT FLUE DIAPHRAGMS AND ADJUSTMENT TABLES ARE SUPPLIED WITH RADIANT ORIGINAL FLUE.

DOMESTIC HOT WATER WITH STORAGE CYLINDER – TA05A027.A0504

5

Installation Manual

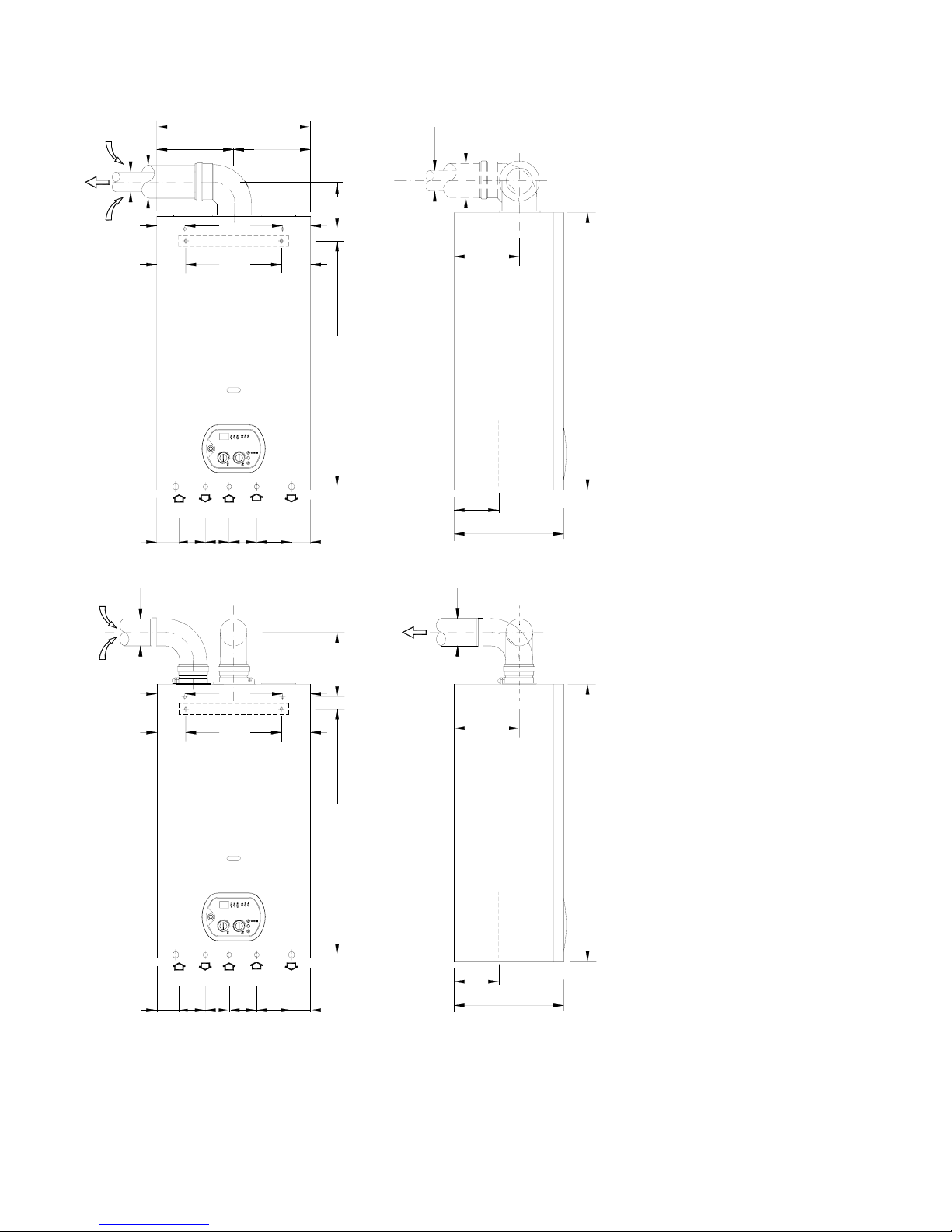

OVERALL DIMENSIONS - EXHAUST FLUE SYSTEM – mod. RSF 24 E

TYPE C WALL-MOUNTED BOILERS

SEALED COMBUSTION CIRCUIT:

kit A

Horizontal coaxial exhaust flue

system with 360° rotation.

It allows the flue exhaust and the air

intake directly to an external wall.

To insert a bend, reduce total flue

EY

URN ¾”

ER ½”

”

t B

e exhaust/emission twin

e

reduce total flue

OTE: USE ORIGINAL RADIANT APPROVED FLUE KIT SYSTEMS, FLUE ACCESSORIES AND FLUE DIAPHRAGMS ONLY.

FLUE KIT

100

60

AFGCR

55.5

65.5 7078 80 102

720

80

85 280 85

82 286 82

19035

55.5

G

65.5R78 70C80F102

A

80

130

320

800

198

320

130

720

85

82

280 85

286 82

= =

450

35 137

800

198

60

100

S

S

length by 0.8 m.

K

R RET

G GAS ½”

C HOT WAT

F COLD WATER ½”

A HEATING FLOW ¾

ki

Doubl

flue system with 360° rotation.

It allows the flue exhaust into a flu

duct and the air intake directly from

an external wall.

To insert a bend,

length by 1.5 m.

N

APPROVED RADIANT FLUE DIAPHRAGMS AND ADJUSTMENT TABLES ARE SUPPLIED WITH RADIANT ORIGINAL

SYSTEMS.

DOMESTIC HOT WATER WITH STORAGE CYLINDER – TA05A027.A0504

6

Loading...

Loading...