Radiant R1K 50 Installation, Use And Maintenance Manual

Installation, Use

and Maintenance Manual

for model

R1K 50

Premix condensing system boiler

only heating

0476

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

SUMMARY

SUMMARY

INTRODUCTION 4

1. INSTALLER SECTION 7

1.1. INSTALLATION 8

1.1.1. GENER A L INS TALLATION WARNINGS 8

1.1.2. BOILER LOCATION ENVIRONMENTAL REQUIREMENTS 8

1.1.3. REFERENCE LEGISL ATION 9

1.1.4. BOILER OVERALL DIMENSIONS 10

1.1.5. JIG 10

1.1.6. OVERALL DIMENSIONS OF THE HEATING ONLY MODULE 10

1.1.7. OVERALL DIMENSIONS OF THE MODULE FOR REMOTE BOILER SUPPLY 11

1.1.8. MECHANICAL SYSTEM DIAGRAM 12

1.1.9. SYSTEM ACCES SORIES 14

1.1.10. CIRCULATOR PREVALENCE/FLOW DIAGRAM 16

1.1.11. GENERATOR INSTAL L ATION 17

1.1.12. HYDRAULIC CONNECTION 20

1.1.13. CHARACTERISTICS OF THE WATER OF THE SYSTEM 21

1.1.14. SYSTEM FILLING 23

1.1.15. FILLING THE CONDENSATE COLLECTION SIPHON 24

1.1.16. ANTI-FREEZE PROTECTION 25

1.1.17. GAS CONNECTION 26

1.1.18. ELECTRICA L CONNECTION 26

1.1.19. POWER SUPPLY 27

1.1.20. OPTIONAL ELECTRICAL CONNECTIONS 28

1.1.21. FUME EXHAUST FITTINGS 31

1.1.22. T YPES OF FUME EXHAUST SYSTEMS 32

R1K 50_EN

2. SUPPORT CENTER SECTION 37

2.1. FIRST START-UP 38

2.1.1. PRELIMINARY OPERATIONS FOR FIRST START-UP 38

2.1.2. BOILER COMMISSIONING 39

2.1.3. CO2 VALUE CHECK AND CALIBRATION 40

2.1.3. ACCESSING AND PROGRAMMING THE PARAMETERS 41

2.1.4. DIGITECH CS PARAMETERS TABLE 43

2.1.6. ELECTRIC FAN FREQUENCY/HEAT CAPACITY DIAGRAM 50

2.2. MAINTENANCE 51

2.2.5. GENERAL MAINTENANCE WARNINGS 51

2.2.8. TECHNICAL DATA 52

2.2.9. TECHNICAL ASSEMBLY 54

2

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

SUMMARY

2.2.6. HYDRAULIC BOARD 55

2.2.7. WIRING DIAGRAM 56

2.2.13. ACCESSING THE BOILER 57

2.2.8. ACCESSING THE ELECTRONIC BOARD 58

2.2.16. SYSTEM EMPTYING 59

2.2.9. FAULT SIGNALLING CODES 60

2.2.10. ACTIVE FUNCTIONS SIGNALLING CODES 63

2.2.11. GAS CONVERSION 64

3. USER SECTION 65

3.1. USE 66

3.1.1. GENERAL USE WARNINGS 66

3.1.2. CONTROL PANEL 67

3.1.3. DISPLAY ICONS 68

3.1.4. INFO MENU DISPLAY DATA 69

3.1.5. START-UP 70

3.1.6. OPERATING MODE 70

3.1.7. INFORMATIONAL NOTE ON ANTI-FREEZE FUNCTION 71

3.1.8. FAULT SIGNALLING CODES 72

3.1.9. ACTIVE FUNCTIONS SIGNALLING CODES 74

R1K 50_EN

3

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

INTRODUCTION

1.

INTRODUCTION

WARNING

Before starting any operation it is mandatory to

read this instruction manual, in relation to the

activities to be carried out as described in each

relevant section. Proper operation and optimal

performance of the boiler are ensured by strict

compliance with all the instructions given in this

manual.

The installation, use and maintenance manual is

an integral and essential part of the product and

must be delivered to the user.

MANUAL USERS

The manual users are all those who install, use

and maintain the boiler.

The boiler must be used and accessed only by

qualified operators that fully read and understood

the use and maintenance manual, paying par ticular

attention to the warnings.

READING AND SYMBOLS OF THE MANUAL

To ease the understanding of this manual,

recurrent symbols where used, in particular:

› On the outer margin of the page is placed a

thumb index indicating the type of user to which

the instructions in that section address.

DANGER

It identifies an information related to a

general danger that if not complied with, may cause

serious personal damage or even death.

ATTENTION

It identifies an information that if not

complied with may cause small or medium level

lesions to the person or serious deterioration to the

boiler.

WARNING

It identifies a precaution information that

must be observed in order to avoid damaging the

machine or parts of it.

MANUAL STORAGE

The manual must be carefully stored and replaced

in case of deterioration and/or low legibility.

If you misplace the use and maintenance manual,

you can request it from the Technical Support

Centre giving the serial number and model of the

boiler indicated on the plate placed on the right

side of its casing.

As an alternative, the use and maintenance manual

can be downloaded free from the on-line site www.

radiant.it, accessing the “download” section and

entering the boiler model.

_Prefazione_EN

› The titles are differentiated by thickness and

size in accordance with their hierarchy.

› The images contain important parts described

in the text, marked with numbers or letters.

› (See chap “chapter name”): this entry indicates

another section in the Manual that you should

refer to.

› Device: this term is used referring to the boiler.

4

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

INTRODUCTION

1 .

MANUFACTURER WARRANTY AND

RESPONSIBILITY

The warranty of the Manufacturer is provided only

through its own authorized Technical Support

Centres, listed for each Region and Provence on

the site www.radiant.it, and covers all conformity

defects at the moment of sale.

The technical and functional features of the device

are ensured by its use in compliance:

1. with the use and maintenance instructions

contained in the manuals accompanying the

product, the content of which the customer

certifies that he is aware;

2. with the conditions and purposes to which

assets of the same type are intended.

For more information on the warranty validity,

its duration, the obligations and the exemptions,

please consult the First start-up certificate

attached to this manual.

› Energy labeling Directive 2010/30/CE,

› EU regulation 811/2013,

› EU regulation 813/2013,

› Gas Directive 2016/426/EU,

› Electromagnetic compatibility Directive

2014/30/CE,

› Performance Directive 92/42/CE,

› Low voltage Directive 2014/35/CE.

The materials used such as copper, brass,

stainless steel create a homogeneous, compact

and functional assembly, easy to install and

manage. In its simplicity, the boiler is equipped

with all accessories necessary to render it a

veritable independent heating unit. All boilers

are tested and delivered with a quality certificate

signed by the tester.

_Prefazione_EN

The manufacturer reserves:

› the right to modify the tools and relative

technical documentation without any obligation

to third parties; neither will the company be

held responsible for any inaccuracies in this

handbook deriving from printing or translation

errors;

› the material and intellectual ownership of

this manual and forbids its distribution and

duplication, even partial, without prior written

authorization.

PRODUCT CONFORMITY

RADIANT BRUCIATORI spa declares that its gas

boilers comply with the European Directives and

with the requirements provided in the European

standards below:

› Eco-design Directive 2009/125 CE,

5

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

1. INSTALLER SECTION1. INSTALLER SECTION

The installation operations described in this section should

be performed only by qualified personnel, having the

appropriate technical training in the field for the installation

and maintenance of components of civil and industrial

domestic hot water production and heating plants.

INSTALLER

1.1. INSTALLATION

2. INSTALLATION

1.1.1. GENERAL INSTALL ATION

WARNINGS

ATTENTION

This machine may be used only for the

purpose for which it has been designed: heat water

to a temperature below boiling point at atmospheric

pressure. Any other use is considered wrong and

dangerous. The manufacturer is excluded from

any contractual or out of contract responsibility for

damage caused to people, animals or property due

to errors during installation.

ATTENTION

This boiler should be installed only

by qualified personnel, having the appropriate

technical training in the field for the installation and

maintenance of components of civil and industrial

domestic hot water production and heating plants.

ATTENTION

After having removed the packing, make

sure the equipment is intact. In case of doubt, do not

use the equipment and contact the supplier.

BEFORE INSTALLING THE BOILER, THE

INSTALLER MUST MAKE SURE THAT THE

FOLLOWING CONDITIONS ARE MET:

› The device is connected to a heating plant and a

water supply network appropriate for its power

and performance.

› The location must be properly vented through

an air vent.

› The air vent must be placed at floor level to

prevent it from being obstructed, protected by

a grid that does not hamper the useful section

of passage.

› The device is suitable for use with the type of

gas available by checking the boiler data plate

(placed on the inner side of the front casing.

› Make sure that the tubes and couplings are

perfectly sealed, without any gas leaks.

› Make sure that the grounding system works

properly.

› Make sure that the electrical systems is

suitable for the maximum power absorbed by

the equipment, value indicated on the data plate.

WARNING

Use only original RADIANT optional or kit

accessories (including electrical).

1.1.2. BOILER LOCATION

ENVIRONMENTAL

REQUIREMENTS

The boiler has a thermal power over 35 kW and,

therefore, it must be installed only into a heating

unit.

The device's installation location should be vented

due to the presence of threaded joints on the gas

adduction line. The location should be therefore

provided with vents as to ensure air exchange,

with output grid in the natural accumulation area

of eventual gas losses.

WARNING

DO NOT install the boiler in a technical

compartment near a swimming pool or a laundry, to

avoid that the combustion air is exposed to chlorine,

ammonia or alkaline agents that may worsen the

corrosion phenomenon of the heat exchanger. Failure

to observe this caution will void the warranty of the

heat exchanger.

1 Avvertenze gener ali per l'installazione_Locale c aldaia _cond _ alta potenza_EN

8

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

WARNING

If the temperature in the boiler installation

location goes below -10 centigrades, please fill

the plant with anti-freeze liquid and insert and

electrical resistances kit (see chapter ‘ANTI-FREEZE

PROTECTION’).

WARNING

The manufacturer will not be held

responsible for damages caused by incorrect

installation not in conformity with the over mentioned

instructions and not protected adequately from the

freeze.

1.1.3. REFERENCE LEGISLATION

The installation must be realized according to

the requirements of current legislation and in

compliance with local technical regulations,

according to the indications of the good technique.

2. INSTALLATION

INSTALLER

1 Avvertenze gener ali per l'installazione_Locale c aldaia _cond _ alta potenza_EN

9

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

INSTALLER

3. INSTALLATION

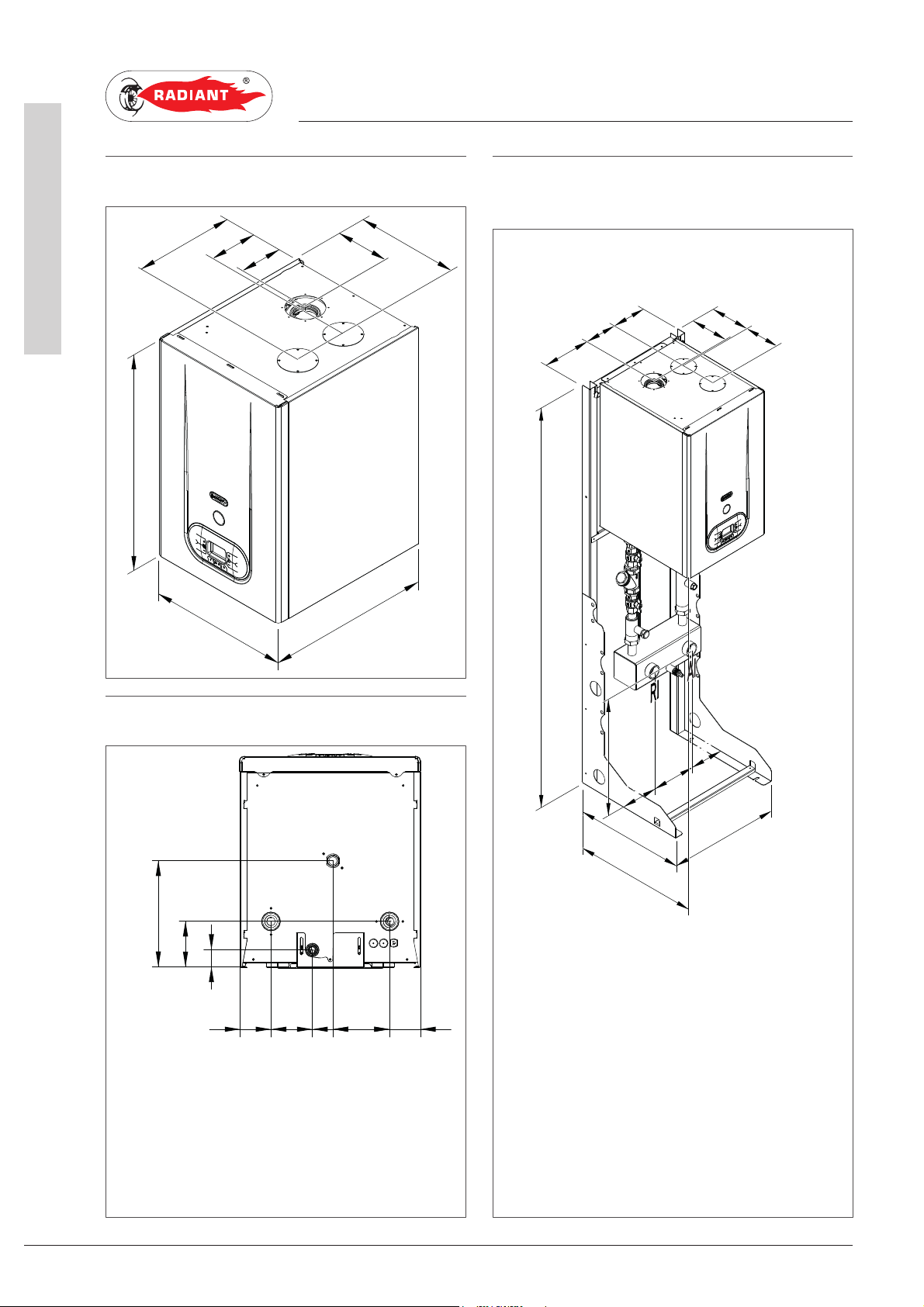

1.1.4. BOILER OVERALL DIMENSIONS

302

157

480

640

306

150

136

410

1.1.6. OVERALL DIMENSIONS OF THE

HEATING ONLY MODULE

160

145

209

1794

178

192

155

1.1.5. JIG

244

R- HEATING RETURN Ø 1” 1/4

G- GAS Ø 3/4

A- HEATING FLOW Ø 1” 1/4

SC- CONDENSATE DRAIN Ø 25 mm

107

42

70 94 47 129 70

RGsc A

157

530

157

157

504

524

524

RI RETURN SYSTEM Ø 1”1/2

AI DELIVERY SYSTEM Ø 1”1/2

157

200

514

1 Dimensioni_R1K 50_no INAIL_EN

10

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

1.1.7. OVERALL DIMENSIONS OF THE

MODULE FOR REMOTE BOILER

SUPPLY

3. INSTALLATION

INSTALLER

209

1794

145

227 99227 99282282

160

178

192

155

1 Dimensioni_R1K 50_no INAIL_EN

157

157

200

157

157

504

524524

RI RETURN SYSTEM Ø 1”1/2

AI DELIVERY SYSTEM Ø 1”1/2

RB HEATING FLOW TO DHW

STORAGE CYLINDER

AB HEATING FLOW TO DHW

STORAGE CYLINDER

514

Ø 1”

Ø 1”

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

11

INSTALLER

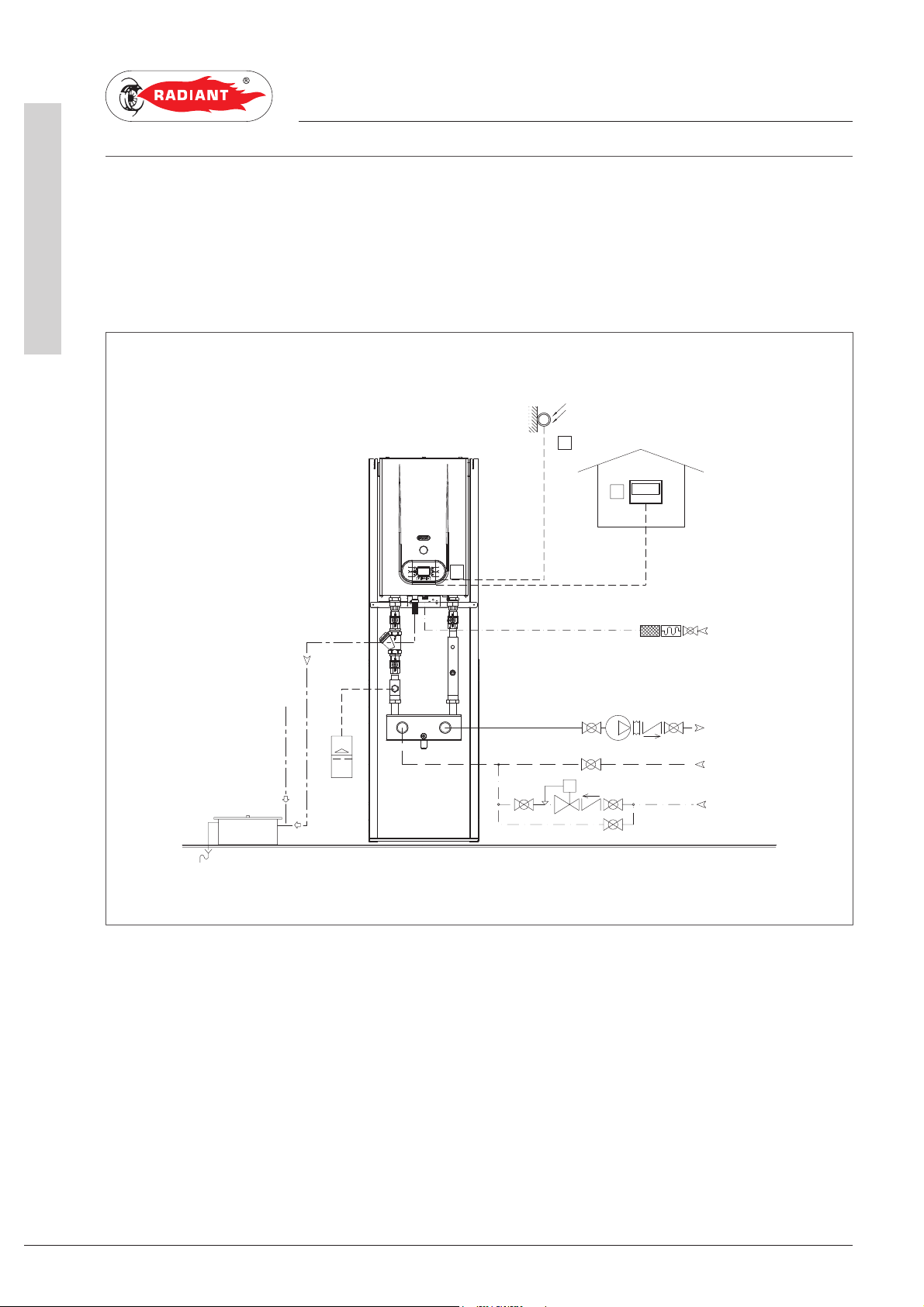

1.1.8. MECHANICAL SYSTEM DIAGRAM

HEATING ONLY INSTALLATION

The boiler can manage a heating system at a fixed point delivery temperature or in climatic compensation

with an external probe, managing the modulation according to the actually requested thermal load.

1. INSTALLATION

1

2

fume exhaust system

3

GAS

DELIVERY

SYSTEM

RETURN

SYSTEM

condensate

LOAD

SYSTEM

1 Schema meccanico impianto_R1K 50_no INAIL _EN

12

DESCRIPTION

1 EXTERNAL PROBE

2 REMOTE OPEN THERM

3CONTROL PANEL

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

1. INSTALL ATION

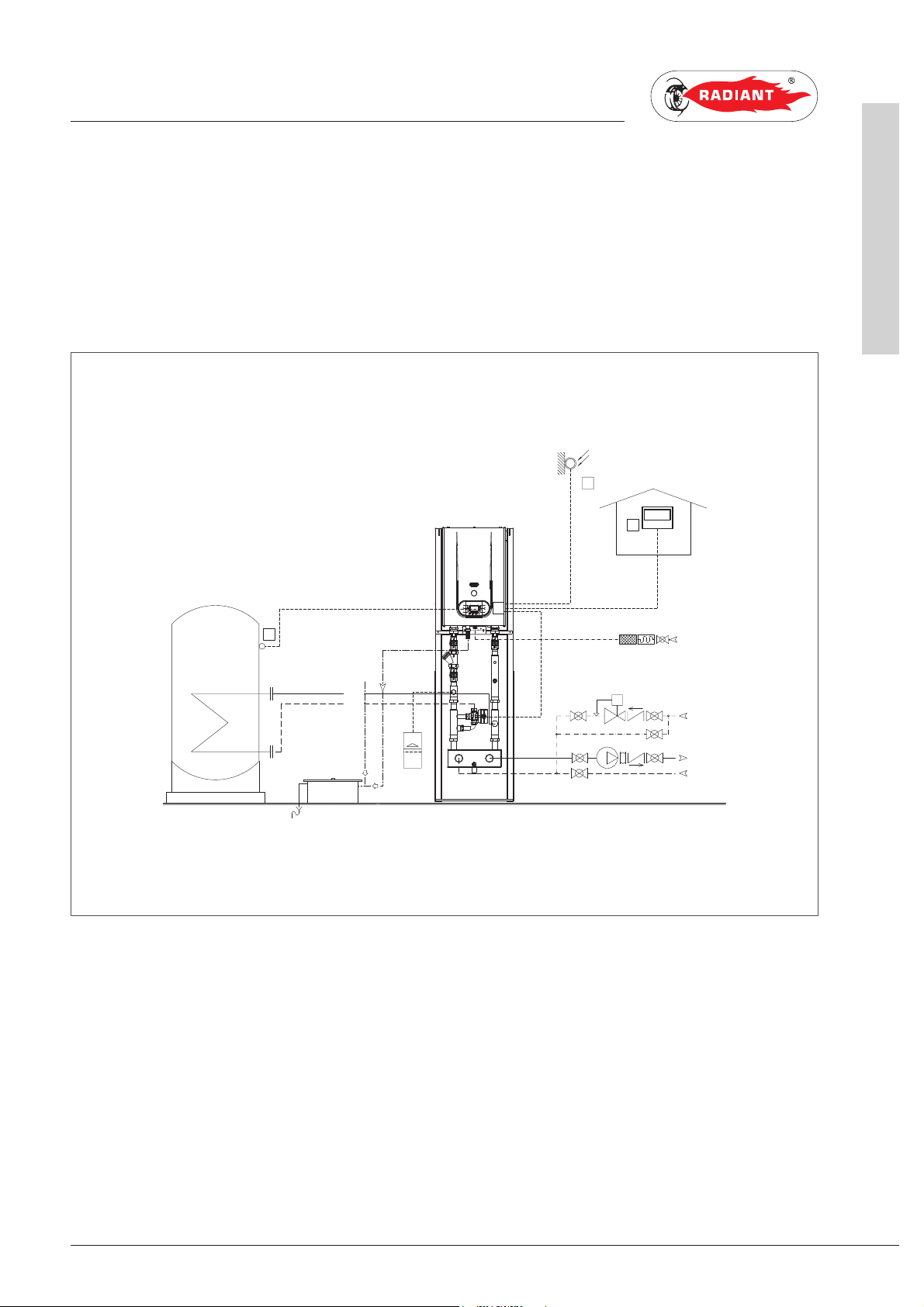

HEATING INSTALLATION + REMOTE BOILER SUPPLY SYSTEM

The boiler can manage a heating system at a fixed point delivery temperature or in climatic compensation

with an external probe, managing the modulation according to the actually requested thermal load.

The boiler probe activates the system in order to pre-heat the boiler, the boiler will be put into domestic

circuit mode and the deviating valve switches to the remote boiler.

1

2

INSTALLER

1 Schema meccanico impianto_R1K 50_no INAIL _EN

4

DESCRIPTION

1 EXTERNAL PROBE

2 REMOTE OPEN THERM

3CONTROL PANEL

4 REMOTE BOILER NTC PROBE

fume exhaust system

condensation

3

GAS

LOAD SYSTEM

DELIVERY SYSTEM

RETURN SYSTEM

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

13

INSTALLER

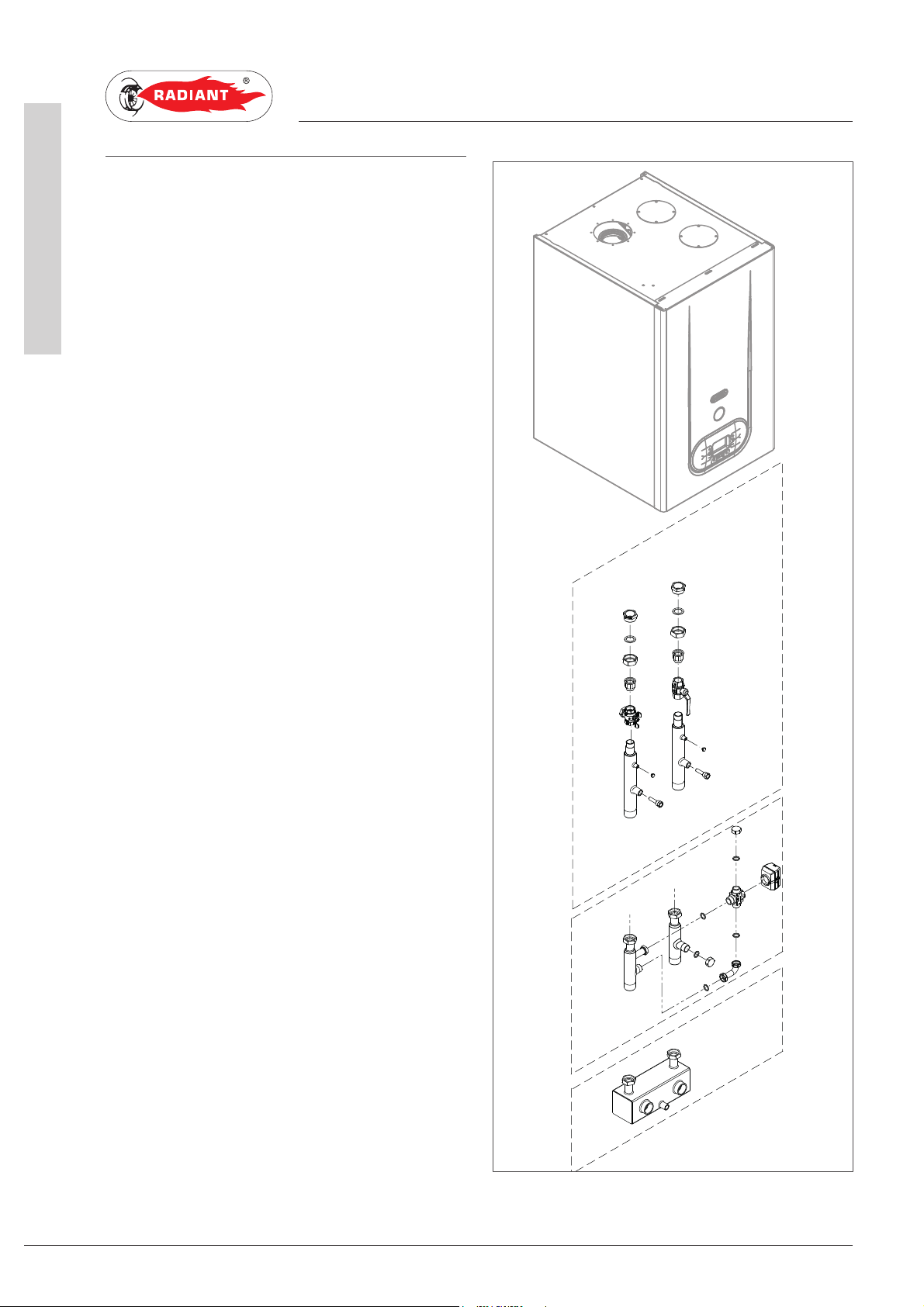

1.1.9. SYSTEM ACCESSORIES

DIVERTER VALVE KIT

The kit allows combining the thermal generator

with a remote boiler for the production of domestic

hot water (cod. 26097LP, fig. 1).

In this configuration, it is possible to manage the

domestic circuit in an independent manner, by

implementing a diverter valve which ensures the

power supply of the serpentine upon the preheating request of the boiler.

The kit is completed with a probe for the external

boiler and with a power supply cable of the diverter

valve which is connected directly to the electronic

board of the generator.

1. INSTALLATION

HYDRAULIC SEPARATOR

In order to always ensure to the heat generator an

operation without problems related to two low heat

capacities (due, for example, to closed radiators or

to impurities of various type), it is strictly necessary

to install a trip unit, as an alternative, a heat

exchanger which separates the hydraulic circuit.

Choosing a separation system in the detriment of

another is exclusively imposed by the type of the

system.

In case of a new system o r in case of replacem ent of

the generator with the possibility to wash the water

pipes, it is recommended to install a hydraulic

separator (code 26205LA, fig. 1).

The hydraulic separator creates an area with

reduced load loss, which allows hydraulically

rendering independent the primary and secondary

circuits connected to it. With the hydraulic separator

you can thus have a production circuit with constant

heat capacity and a distribution circuit with variable

heat capacity, operation conditions typically specific

to modern air-conditioning systems.

1 Accessori impianto_R1K 50_no INAIL_EN

cod. 26097LPcod. 26205LA cod. 65-00440

fig. 1

14

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

Particular attention should be given, during the

design phase, to possible temperature variations

to which the circuits can be subject due to the

generated mixing inside the hydraulic separator.

A secondary circuit with a heat capacity higher

than the circulatory one of the primary circuit

generates, in fact, by means of the hydraulic

separator, a delivery temperature lower than the

one of the primary circuit.

1. INSTALL ATION

INSTALLER

1 Accessori impianto_R1K 50_no INAIL_EN

15

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

INSTALLER

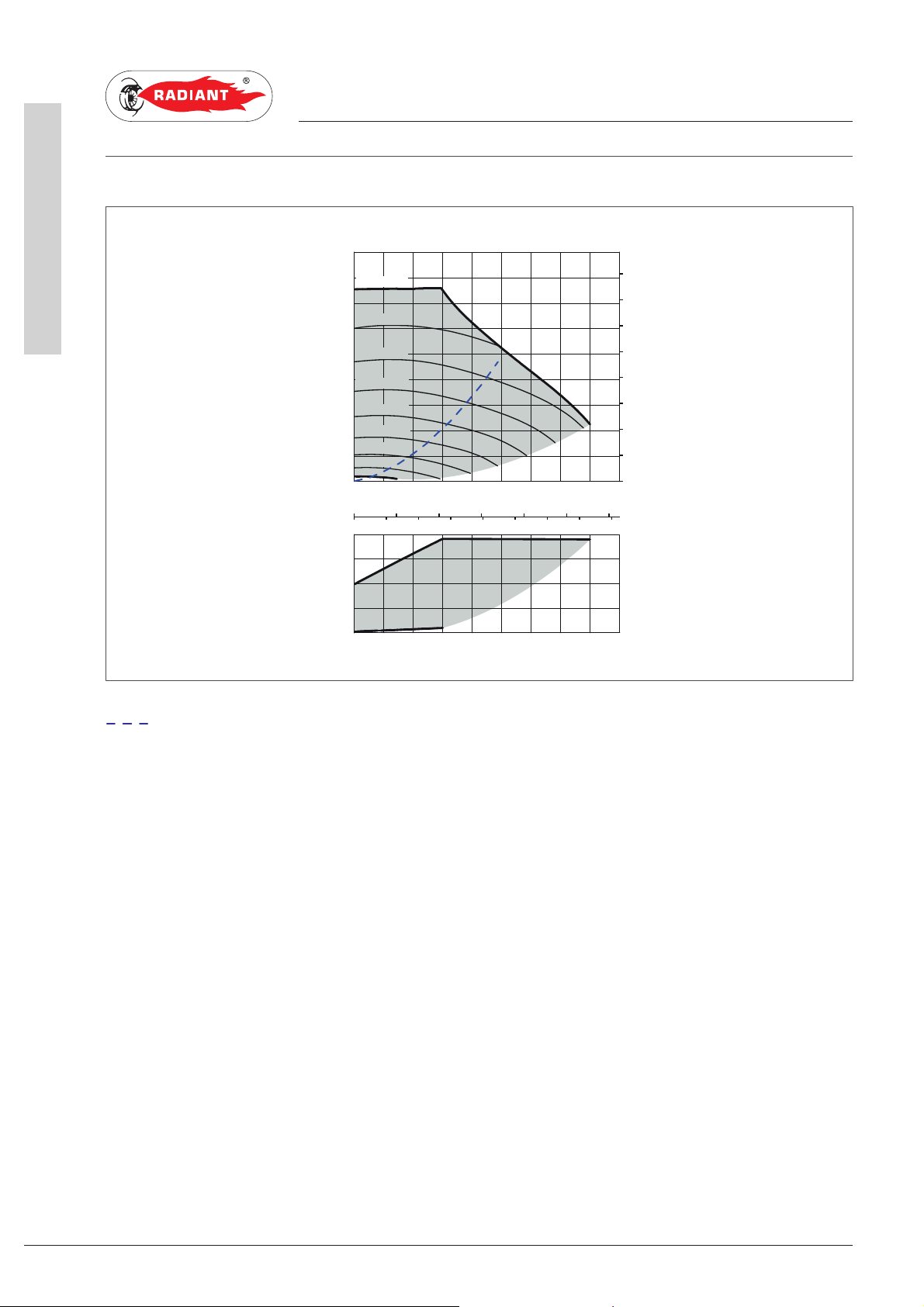

1.1.10. CIRCULATOR PREVALENCE/FLOW DIAGRAM

1. INSTALLATION

Wilo-Yonos PARA RS 15/7.5

H/m

8

PWM1

4770/ 5

7

PWM1

4270/ 15

6

PWM1

5

3780/ 25

4

PWM1

3280/ 35

3

PWM1

2780/ 45

PWM1

2

2280/ 55

PWM1

1780/ 65

1

PWM1

1290/ 75

PWM1

790/ 85

0

PREVALENCE (m)

0 0,5 1,0 1,5 2,0 2,5 3,0 3,5

0 0,2 0,4 0,6 0,8 1,0

20 4 6 8 10 12 14

/W

P

1

60

40

20

0

0 0,5 1,0 1,5 2,0 2,5 3,0 3,5

max.

4,0

4,0

Q/m³/ h

Q/l/s

Q/Igpm

max.

Q/m³/ h

p/kPa

80

70

60

50

40

30

20

10

0

Appliance Loss

FLOW RATE (m3/h)

1 Diagramma portata-prevalenza circol atore _R1K 50_YONOS PARA RS 15-7.5_EN

16

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

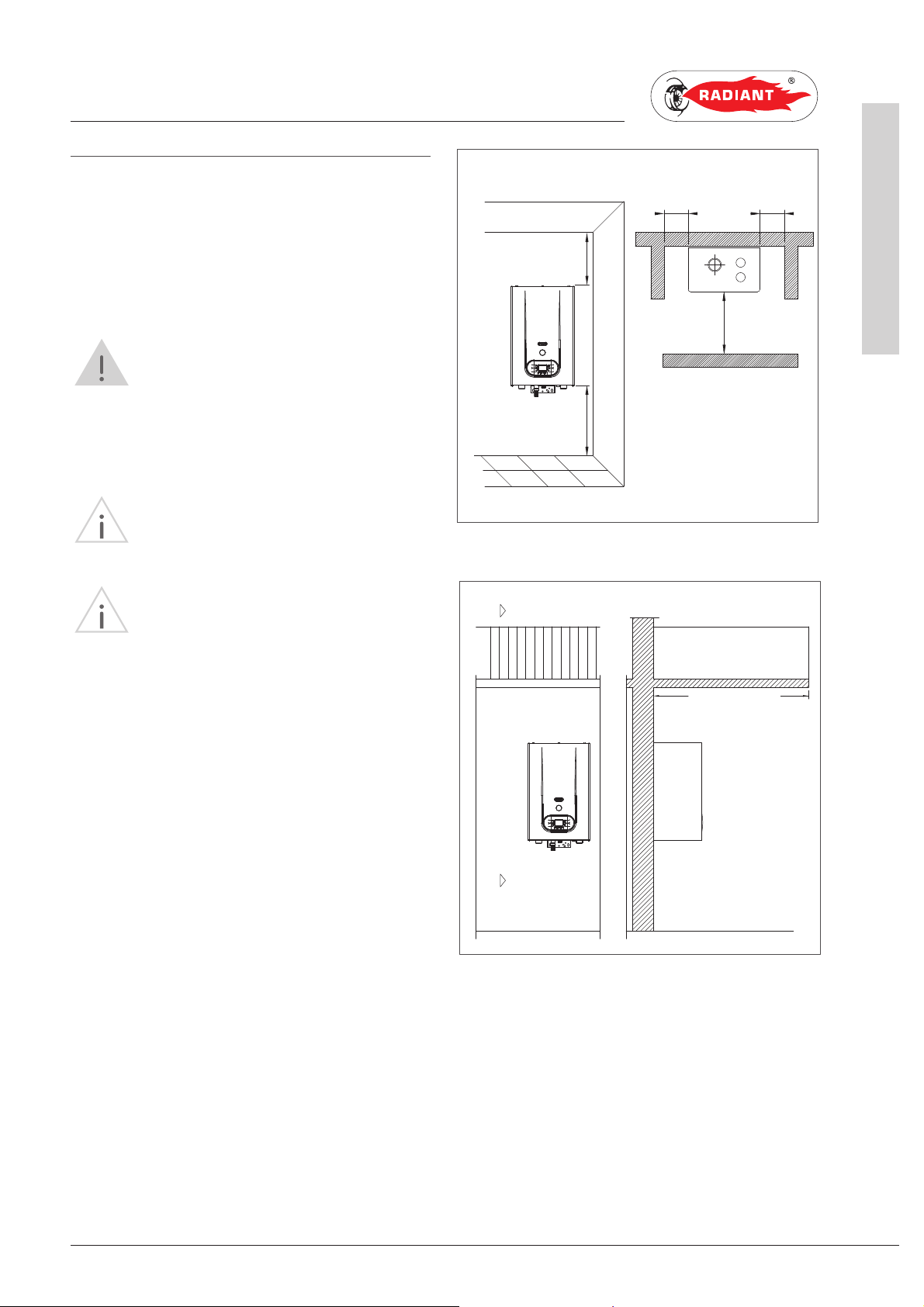

1.1.11. GENERATOR INSTALLATION

MINIMAL TECHNICAL SPACES

1. INSTALL ATION

INSTALLER

X Y

In order to allow the access inside the boiler for

maintenance operations, you have to respect the

minimum technical spaces indicated in figure 1.

WARNING

The incorrect slopes of the device can

cause the incorrect discharge of condensate by

means of the discharge duct with consequent

condensate stagnation inside the condensate

module.

WARNING

The boiler must be installed only on a

vertical solid wall, able to sustain its weight.

WARNING

The boilers have the electrical

protection degree IPX5D. The outdoor installation

in partially protected environments (platform roof,

balcony - see fig. 2) is allowed in compliance with

the related standards. The Company is not held

liable for installations in environments with a

temperature under –10°C or non-compliant with

the above indications.

A

H

B

A

A - 200 mm

B - 300 mm

X - 60 mm

Y - 60 mm

H - 1,000 mm

balcony/ platform roof

1,200 mm minimum

fig.1

A

SECTION A-A

1 Installazione generatore_R1K 50_EN

fig. 2

17

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

INSTALLER

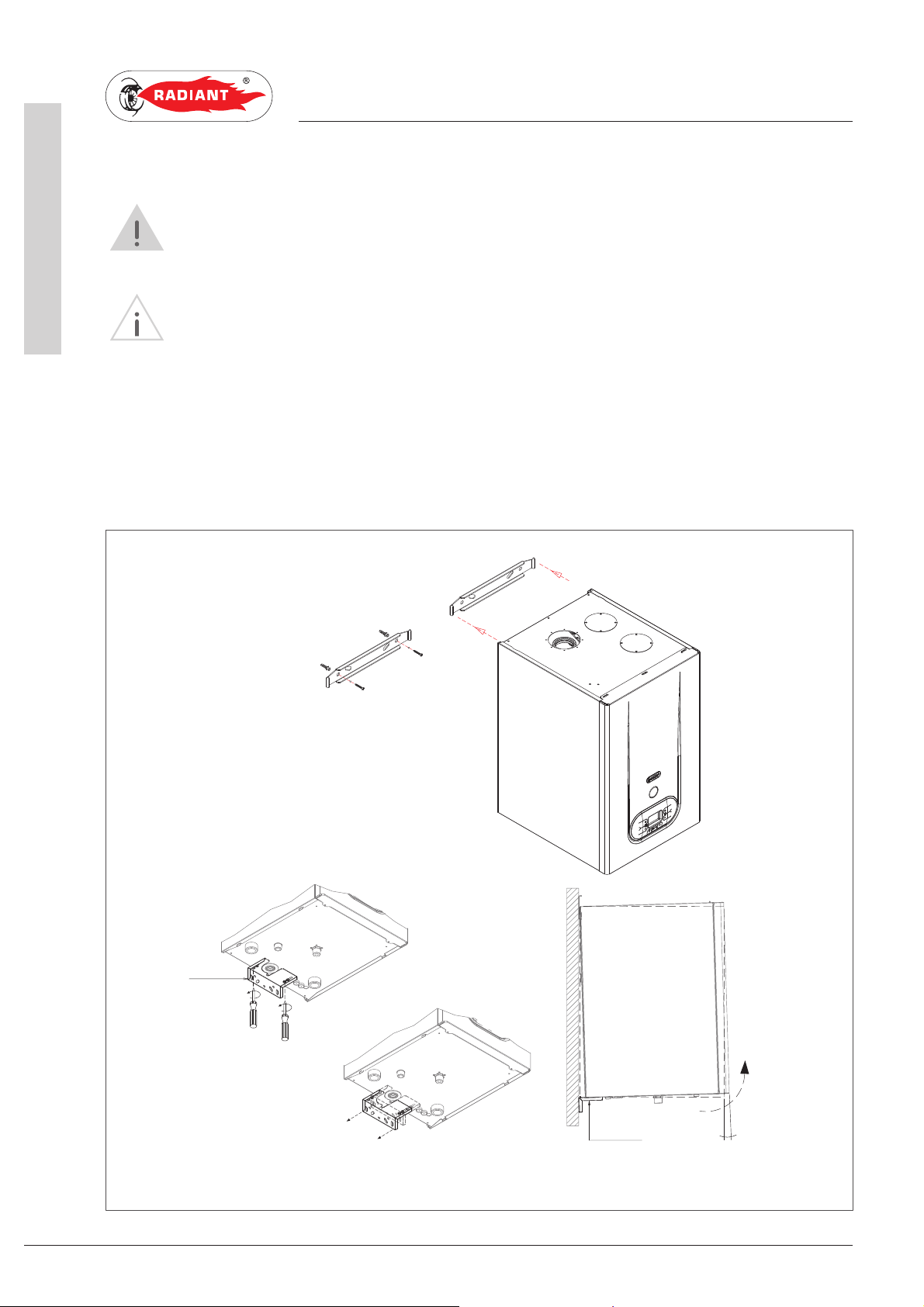

WALL MOUNTING BY MEANS OF FIXING BRACKET

is slightly inclined towards the rear part (1-1.5°) in order to evacuate the condensate.

In order to fix the thermal generator on the wall, proceed as follows:

1. fix on the wall (fig. 1), using the fisher, the upper bracket;

2. hook the eyelets of the boiler into the adequate hooks (fig. 2);

3. unscrew the fixing screws of the lower bracket (fig. 3) ensuring the free sliding of the bracket (fig. 4)

4. adjust the inclination of the boiler (fig. 5) by sliding the lower bracket ensuring an inclination of the

1. INSTALLATION

WARNING

In order to avoid condensate stagnations inside the condensate module, check that the boiler

WARNING

The device must be installed only on a vertical solid wall, able to sustain its weight.

towards the boiler;

boiler, against the vertical, of about 1–1.5°.

LOWER

BRACKET

fig. 3

fig. 2

fig.1

1 Installazione generatore_R1K 50_EN

fig. 5

18

fig. 4

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

LOWER

BRACKET

1-1.5°

1. INSTALL ATION

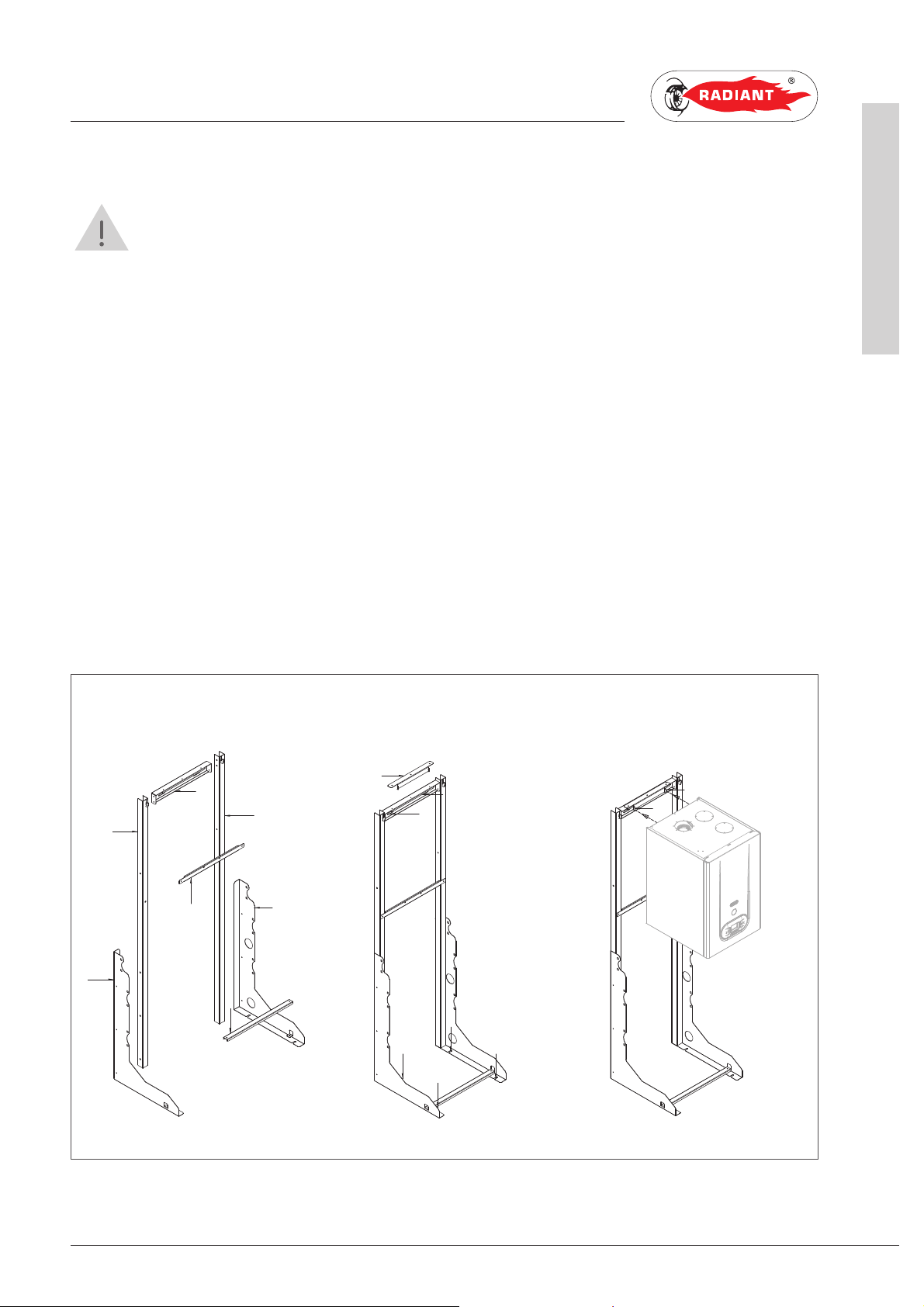

INSTALLATION ON SELF-SUPPORTING FRAME

WARNING

During the installation of the heat generator, pay maximum attention to the installation of the

self-supporting frame. The frame must rest on a perfectly flat surface and, when supported against

the wall, the latter must be perfectly angled. The incorrect slopes of the device can cause the incorrect

discharge of condensate by means of the discharge duct with consequent condensate stagnation inside

the condensate module. The correct installation of the frame allows obtaining, acting on the lower

bracket, a counterslope of the device against the perpendicular.

In order to mount the frame and therefore the generator, proceed as follows:

1. check the angle of the wall with the floor;

2. assemble the side profiles 3 and 4 on the pillars 1 and 2 (fig. 1);

3. assemble the side pillars 1 and 2 on the horizontal crossbeam 5;

4. assemble the central crossbeam 8 and the lower one 7;

5. complete the assembly, position the frame binding it to the wall 9 (if provided) and on the floor 10;

6. mount the upper bracket 6 and hook the eyelets of the boiler into the adequate hooks 11;

7. make sure that the frame is angled, adjust the inclination of the boiler by means of the lower bracket

(see "Wall mounting by means of fixing bracket") ensuring an inclination of the boiler, against the

vertical, of about 1–1.5°;

8. complete the installation by assembling the hydraulic components.

INSTALLER

5

1

2

1 Installazione generatore_R1K 50_EN

8

4

7

3

6

9

9

10

10

10

10

11

11

fig.1

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

19

INSTALLER

1. INSTALLATION

1.1.12. HYDRAULIC CONNECTION

DANGER

Make sure that the tubes of the water and

heating plant are not used as grounding system for

the electrical plant. There are not suitable for such

use.

WARNING

To prevent voiding the warranty and to

ensure the proper operation of the boiler, please

wash the plant (if possible when hot) with suitable

pickling or descaling solutions in order to remove the

impurities coming from tubes and radiators.

WARNING

If the boiler is installed in a hydrostatic

position lower than those of the user devices

(radiators, fan coils, etc.), mount the shut-off valves

on the domestic water heating circuit to ease the

performance of the maintenance operations if it is

necessary only to empty the boiler.

DOMESTIC CIRCUIT

In order to prevent limestone build-up and

damages to the domestic water heat exchanger,

the hardness of the domestic supply water

should not exceed 15 °f. However, please check

the characteristics of the water used and install

suitable treating devices.

The heat exchanger coil cleaning frequency

depends on the hardness of the supply water and on

the presence of solid residues or impurities inside

the water that are often present in case of recently

installed plants. Based on the characteristics of

the infeed water, you should install suitable water

treating devices, for residues presence please

install a line filter.

The pressure of the cold infeed water should be

between 0.5 and 6 bar. In case of greater pressure

values, please install a pressure reducer upstream

from the boiler.

WARNING

When connecting the equipment to

water supply, avoid excessive bending and recovery

operations from any off axis positioning that may

damage the tubes causing leaks, malfunction or

early wear.

WARNING

In order to avoid any vibrations and noises,

do not use tubes with small diameters or elbows with

small radius and significant cut-off of the passage

sections.

WARNING

Connect the boiler safety drains to a

discharge funnel. The manufacturer is not responsible

for any floods due to safety valve opening in case of

plant overpressure.

HEATING CIRCUIT

In order to avoid any scale or deposits on the

primary exchanger, the hardness of the heating

circuit infeed water should not exceed 25 °f.

However, please check the characteristics of the

water used and install suitable treating devices.

This treatment is mandatory if frequent episodes

of return water or partial or total emptying of the

plant occur.

WARNING

In case the boiler is installed as part of

a low temperature circuit, please install a safety

thermostat on the heating flow, which can stop

the boiler activity in case of high heating flow

temperature. The company assumes no liability for

damage caused to persons or for failure to comply

with these instructions.

1 Allacciamento idraulico_combinata_EN

20

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

1. INSTALL ATION

INSTALLER

1.1.13. CHARACTERISTICS OF THE

Water treatment

WATER OF THE SYSTEM

In order to preserve the integrity of the water-

For a correct operation of the system, it is

necessary to make sure that:

1. The system does not present losses or that the

most obvious are at least eliminated;

2. If an automatic filling system is present, a litre

meter must be installed in order to precisely know

the extent of any losses;

3. The filling in of the system and the top ups are

performed with softened water in order to reduce

the total hardness. The water must also be treated

in order to maintain the pH within the provided

threshold so as to avoid corrosion phenomena.

4. Either on new systems or on replacements, the

system must be fitted with efficient systems which

ensure the elimination of the air and impurities:

Y filters, micro impurity separators and micro

bubbles of air separators;

5. Avoid draining the water of the system during the

routine maintenance even if it is about apparently

insignificant quantities: for example, in order to

clean the filters, provide the system with adequate

shut-off valves;

1 Riempimento dell'impianto_MIAH4_R1K 10 0_v.1_ EN

6. Always perform an analysis of the water of

the system before opening the communication

between the new generator and the system, in

order to establish if the parameters present in the

water indicate the need to fully drain the system,

to use the water already present in the system or

to chemically wash the system using utility water

adding a detergent when it is suspected that the

system might be dirty or particularly clogged and

at the next loading with new treated water.

fume exchanger and to guarantee optimal thermal

exchanges, it is necessary that the water of the

primary circuit, circulating inside the exchanger

of the condensate boiler, has the characteristics

defined and constant in time. To obtain this, it

is fundamental to perform a series of system

preparation and maintenance operations such as:

• washing the system;

• check the characteristics of the water of the

system;

The type of treatment to be performed will be

chosen based on the characteristics of the water

to treat, of the type of system and on the requested

purity limits

Oxygen

A certain amount of oxygen always enters the

system, both during the filling phase and during

the use in case of reintegration or presence of

hydraulic components without oxygen barriers.

The reaction between the oxygen and the stainless

steel creates corrosion and forms sludge. While

the water fume exchanger is made of stainless

steel, and therefore it is not subject to corrosion,

the sludge created in the carbon steel system

is deposited in the warm points, including the

exchanger. This has the effect to reduce the heat

capacity and thermally insulate the active parts of

the exchanger, which might cause damages.

The precautions to limit the phenomena are:

- Mechanical systems: a deaerator combined with

a sludge remover, correctly installed, reduce the

quantity of oxygen circulating inside the system.

- Chemical systems: the additives allow the oxygen

to dissolve in water.

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

21

INSTALLER

Hardness

The filling and make-up water hardness brings

a certain amount of limestone into the system.

It attacks the warm parts of the exchanger, thus

creating load losses and thermal insulation losses

on the active parts. This phenomena can cause

damages.

The filling and make-up water of the system, if

it does not fall under the values indicated below,

should be softened. Moreover, additives can be

added in order to maintain the limestone into

the solution. The hardness must be periodically

checked and registered.

1. INSTALLATION

Acidity 7 < pH < 8.5

Conductivity < 400 μs/cm (at 25°C)

Chlorides < 125 mg/l

Iron < 0.5 mg/l

Copper < 0.1 mg/l

If the above indicated limits are exceeded, a water

must be chemically treated.

The type of treatment to be performed will be

chosen based on the characteristics of the water

to treat, of the type of system and on the requested

purity limits.

1 Riempimento dell'impianto_MIAH4_R1K 10 0_v.1_ EN

22

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

1. INSTALL ATION

INSTALLER

1.1.14. SYSTEM FILLING

WARNING

For system filling use only clean tap

water. In order to prevent limestone build-up and

damages to the domestic water heat exchanger,

the hardness of the domestic supply water

should not exceed 15° Fr. However, please check

the characteristics of the water used and install

suitable treating devices.

WARNING

If the system is filled by adding ethylene

glycol-type chemical agents you have to install on

the loading system a hydraulic trip unit in order

to separate the heating circuit from the domestic

circuit.

Before powering up the boiler, fill the system as

follows:

tap until the pressure gauge reaches the

design pressure.

fig. 1

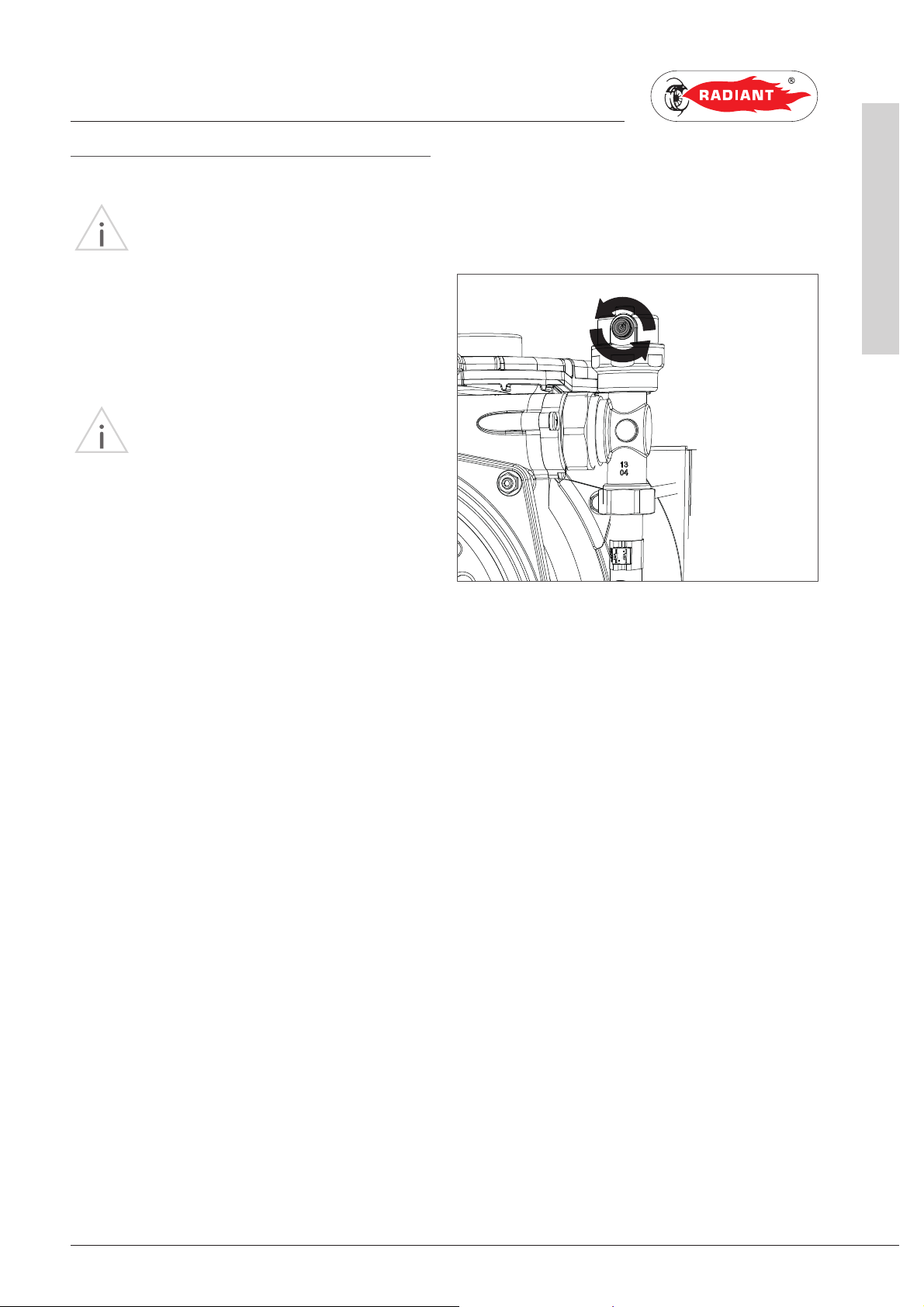

1. slightly loosen the cap of the jolly valve placed

on the top of the condensing block to release

the air form the top of the system (fig.1);

2. check that the jolly valves vent the air present

in the system are not blocked

3. open the general domestic water input tap and

load the system by exhaling all the air;

4. use pressure gauge present in the system to

1 Riempimento dell'impianto_MIAH4_R1K 10 0_v.1_ EN

make sure that the system pressure reaches

the design value;

5. after performing this operation, make sure

that the loading tap is properly closed.

6. Open the air relief valves of the radiators and

check the air removal process. When the

water starts to leak close the radiators air

relief valves.

7. If after performing these operations you

observe a decrease of the water pressure

inside the system, open once again the loading

23

R1K 50 - RAD - ING - Manuale - 1801.1_SK.3

Loading...

Loading...