Page 1

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

Installation, Use

and Maintenance Manual for

model

WARNING

If the information in these instructions is not followed exactly, a fire or explosion may result,

causing property damage, personal injury or loss of life.

-Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

-WHAT TO DO IF YOU SMELL GAS

>Do not try to light any appliance.

>Do not touch any electrical switch; do not use any phone in your building.

>Immediately call your gas suppl ier fr om an out side phone. F ollow the ga s supplier ’s instructio ns.

>If you cannot reach your gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer, service agency or the gas supplier.

R1K 34 /B

Page 2

2

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

SUMMARY

SUMMARY

INTRODUCTION 4

1. INSTALLER SECTION 7

1.1. INSTALL ATION 8

1.1.1. GENERAL INSTALLATION WARNINGS 8

1.1.2. BOILER LOCATION ENVIRONMENTAL REQUIREMENTS 8

1.1.3. REFERENCE LEGISLATION 9

1.1.4. UNPACKING 10

1.1.5. OVERALL DIMENSIONS (inch) 11

1.1.6. PIPING LAYOUT/IDENTIFICATION 11

1.1.7. HYDRAULIC CONNECTION KIT 11

1.1.8. POSITIONING AND CLEARANCES TO COMBUSTIBLE MATERIAL AND SERVICE CLEARANCES 12

1.1.9. CIRCULATOR PERFORMANCE CURVES 13

1.1.10. WAT ER CONNECT ION S 14

1.1.11. PRESSURE RELIEF VALVE KIT 15

1.1.12. SYSTEM FILLING 16

1.1.13. FILLING THE CONDENSATE COLLECTION SIPHON 17

1.1.14. ANTI-FREEZE PROTECTION 19

1.1.15. GA S CONNEC TION 20

1.1.16. ELECTRICAL CONNECTION 20

1.1.17. POW ER SUP PLY 21

1.1.18. OPTIONAL ELECTRICAL CONNECTIONS 22

1.1.19. DHW SENSOR INSTALL ATION 24

1.1.20. VENTING 25

1.1.21. TYPES OF EXHAUST SYSTEMS 27

1.1.22. TABLE 1: ALLOWABLE VENT LENGTHS 32

2. SEZIONE CENTRO ASSISTENZA 33

2.1. FIRST START-UP 34

2.1.1. PRELIMINARY OPERATIONS FOR FIRST START-UP 34

2.1.2. BOILER COMMISSIONING 35

2.1.3. CO2 VALUE CHECK AND CALIBRATION 36

2.1.4. ACCESSING AND PROGRAMMING THE PARAMETERS 37

2.1.5. DIGITECH CS (MIAH402) PARAMETERS TABLE 39

2.1.6. COMBUSTION BLOWER FREQUENCY/HEAT CAPACITY DIAGRAM 45

2.2. MAINTENANCE 46

2.2.7. GENERAL MAINTENANCE WARNINGS 46

2.2.8. TECHNICAL DATA 47

2.2.9. TECHNICAL ASSEMBLYTECHNICAL ASSEMBLY 49

Page 3

3

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

SUMMARY

2.2.10. INTERNAL PIPING SCHEMATIC 50

2.2.11. 3-WAY VALVE OPERATION 51

2.2.12. WIRING DIAGRAM 52

2.2.13. ACCESSING THE BOILER 53

2.2.14. ACCESSING THE ELECTRONIC BOARD 54

2.2.15. SYSTEM EMPTYING 55

2.2.16. FAULT SIGNALLING CODES 56

2.2.17. ACTIVE FUNCTIONS SIGNALLING CODES 59

2.2.18. CONVERSION TO A DIFFERENT GAS TYPE 60

2.2.19. POSITIONS OF THE ELECTRODES 61

3. USER SECTION 63

3.1. USE 64

3.1.1. GENERAL USE WARNINGS 64

3.1.2. CONTROL PANEL 69

3.1.3. DISPLAY ICONS 70

3.1.4. INFO MENU DISPLAY DATA 71

3.1.5. START-UP 72

3.1.6. OPERATING MODE 72

3.1.7. INFORMATIONAL NOTE ON ANTI-FREEZE FUNCTION 73

3.1.8. SYSTEM FILLING 74

3.1.9. FAULT SIGNALLING CODES 75

3.1.10. ACTIVE FUNCTIONS SIGNALLING CODES 77

3.1.11. MAINTENANCE 78

3.1.12. COV ER CLE ANING 78

3.1.13. DISPOS AL 78

Page 4

4

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2.

INTRODUCTION

WARNING

Before star ting any operation it is mandator y to read

this instruction manual, in relation to the activities

performed as described in each relevant section.

Proper operation and optimal performance of the

boiler are ensured by strict compliance with all the

instructions given in this manual.

The installation, use and maintenance manual is

an integral and essential part of the product and

must be delivered to the user.

MANUAL USERS

The manual users are all those who install, use

and maintain the boiler.

The boiler must be used and accessed only by

qualified operators that fully read and understood

the use and maintenance manual, paying particular

attention to the warnings.

READING AND SYMBOLS OF THE MANUAL

To ease the understanding of this manual,

recurrent symbols where used, in particular:

› On the outer margin of the page is placed a

thumb index indicating the type of user to which

the instructions in that section address.

› The titles are differentiated by thickness and

size in accordance with their hierarchy.

› The images contain important parts described

in the text, marked with numbers or letters.

› (See chap “chapter# name”): this entry indicates

another section in the Manual that you should

refer to.

› Device: this term is used referring to the boiler.

DANGER

It identifies information related to a

general danger that if not complied with, may cause

serious personal damage or even death.

ATTENTION

It identifies information that if not complied

with may cause small or medium level burns to the

person or serious damage to the boiler.

WARNING

It identifies a precaution information that

must be observed in order to avoid damaging the

machine or various parts.

MANUAL STORAGE

The manual must be stored carefully and replaced

in case of deterioration and/or low legibility.

If you misplace the use and maintenance manual,

you can request a copy from the Technical Support

Center. It is important to provide the model number

and serial number of the unit which is found on the

inside surface of the right panel.

INTRODUCTION

Page 5

5

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2.

MANUFACTURER WARRANTY AND

RESPONSIBILIT Y

The Manufacturer’s warranty is provided only

through its own authorized Technical Support

Centers, listed for each Region on the site

www.radianthydronics.com, and covers all

manufacturing defects at the time of sale.

The technical and functional features of the unit are

ensured when proper installation and miantenance

is carried out. Conditions of Manufacturer’s

warranty includes the following:

1. The customer is aware of and follows

instructions contained in the manuals that

accompany the product.

2. Annual service check up is required to keep

warranty valid.

3. The unit is installed and operated in the

conditions in which it is designed to.

For more information on the warranty validity,

its duration, the obligations and the exemptions,

please consult the First start-up certificate

attached to this manual.

The manufacturer reserves:

› the right to modify the tools and relative

technical documentation without any obligation

to third parties;

› the material and intellectual ownership of

this manual and forbids its distribution and

duplication, even partial, without prior written

authorization.

PRODUCT CONFORMITY

RADIANT BRUCIATORI spa with reference to

ANSI Z21.13-2014 • CSA 4.9-2014 GAS FIRED LOW

PRESSURE STEAM AND HOT WATER BOILERS,

declares that its gas boilers are professionally

manufactured.

The materials used such as copper, brass,

stainless steel create a homogeneous, compact

and functional assembly, easy to install and

maintain. The boiler is equipped with all

accessories necessary to provide a dependable

independent heating unit. All boilers are tested

and delivered with a quality certificate signed by

the testing department.

INTRODUCTION

Page 6

Page 7

The installation operations described in this section should

be performed only by qualified personnel, having the

appropriate technical training in the field for the installation

and maintenance of components of civil and industrial

domestic hot water production and heating plants.

1. INSTALLER SECTION

1. INSTALLER SECTION

Page 8

8

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

1.1. INSTALLATION

1.1.1. GENERAL INSTALLATION

WARNINGS

This boiler must be installed in accordance with

local codes, if any; if not, follow the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or the Natural

Gas and Propane Installation Code, CAN/CSA

B149.1, as applicable.

WARNING

This unit may be used only for the

purpose for which it has been designed: heat water

to a temperature below boiling point at atmospheric

pressure. Any other use is considered wrong and

dangerous. The manufacturer is excluded from

any contractual or out of contract responsibility for

damage caused to people, animals or property due

to errors during installation.

WARNING

This boiler should be installed only by

qualified service technician, having the appropriate

technical training in the field for the installation and

maintenance of components of civil and industrial

domestic hot water production and heating plants.

WARNING

After having removed the packing, make

sure the equipment is intact. In case of doubt, do not

use the equipment and contact the supplier.

BEFORE INSTALLING THE BOILER, THE

INSTALLER MUST MAKE SURE THAT THE

FOLLOWING CONDITIONS ARE PRESENT:

› The unit is connected to a heating plant and a

water supply network appropriate for its power

and performance.

› The location must be properly vented through

an air vent.

The air vent must be placed at floor level to prevent

it from being obstructed, protected by a grid that

does not hamper air flow.

› The unit is suitable for use with the type of

gas available by checking the boiler data plate

placed on the inner side of the front casing.

› Make sure that the gas lines are properly sealed

without any gas leaks.

› Make sure that the grounding system works

properly.

› Make sure that the electrical system is suitable

for the maximum power required by the

equipment, value indicated on the data plate.

WARNING

Use only original RADIANT optional or kit

accessories (including electrical).

1.1.2. BOILER LOCATION

ENVIRONMENTAL

REQUIREMENTS

The boiler shall be installed so the gas ignition

system components are protected from water

(dripping, spraying, rain, etc.) during appliance

operation and service (circulator replacement,

condensate trap, control replacement, etc.).

The boiler installed using inside air supply must

provide provisions for Combustion Air and

Ventilation Air in accordance with section 5.3, Air

for Combustion and Ventilation, of the National

Fuel Gas Code, ANSI Z 223,1/NFPA 54, or section

7,2, 7.3, or 7.4, of CAN/CSA B 149, Installation

Codes, or local codes having jurisdiction.

Where an exhaust fan or any other air consumption

appliance is installed in the same space as the

Page 9

9

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

boiler, sufficient air openings must be available to

provide fresh air when all appliances are operating

simultaneously. It is essential that in rooms

where the boiler is installed to provide as much

air as required by normal combustion of the gas

consumed by the varius appliances. Consequently,

it maybe necessary to make openings in the walls

to provide air inlet into the rooms.

Application where air from the structure is used

to supply combustion air for the unit, the following

openings are required:

1. Have a total free section of a least 25 mm2 every

kW (1 in2 for every 1000 Btu/hr) of heat input, with

a minimum of 100 cm2 (15.5 in2);

2. Where required by code or when required for

additional opening must be provided at the highest

practical elevation.

With a hermetically sealed combustion chamber

and air supply circuit from outdoors, the boiler may

be installed in any room in the home. Keep boiler

area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

WARNING

If the temperature in the boiler installation

location goes below 14°F centigrades, please fill

the system with anti-freeze liquid and insert and

electrical resistances kit (see 1.1.14 ‘ANTI-FREEZE

PROTECTION’).

1.1.3. REFERENCE LEGISLATION

This boiler must be installed in accordance with

local codes, if any; if not, follow the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or the Natural

Gas and Propane Installation Code, CAN/CSA

B149.1, as applicable.

Page 10

10

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

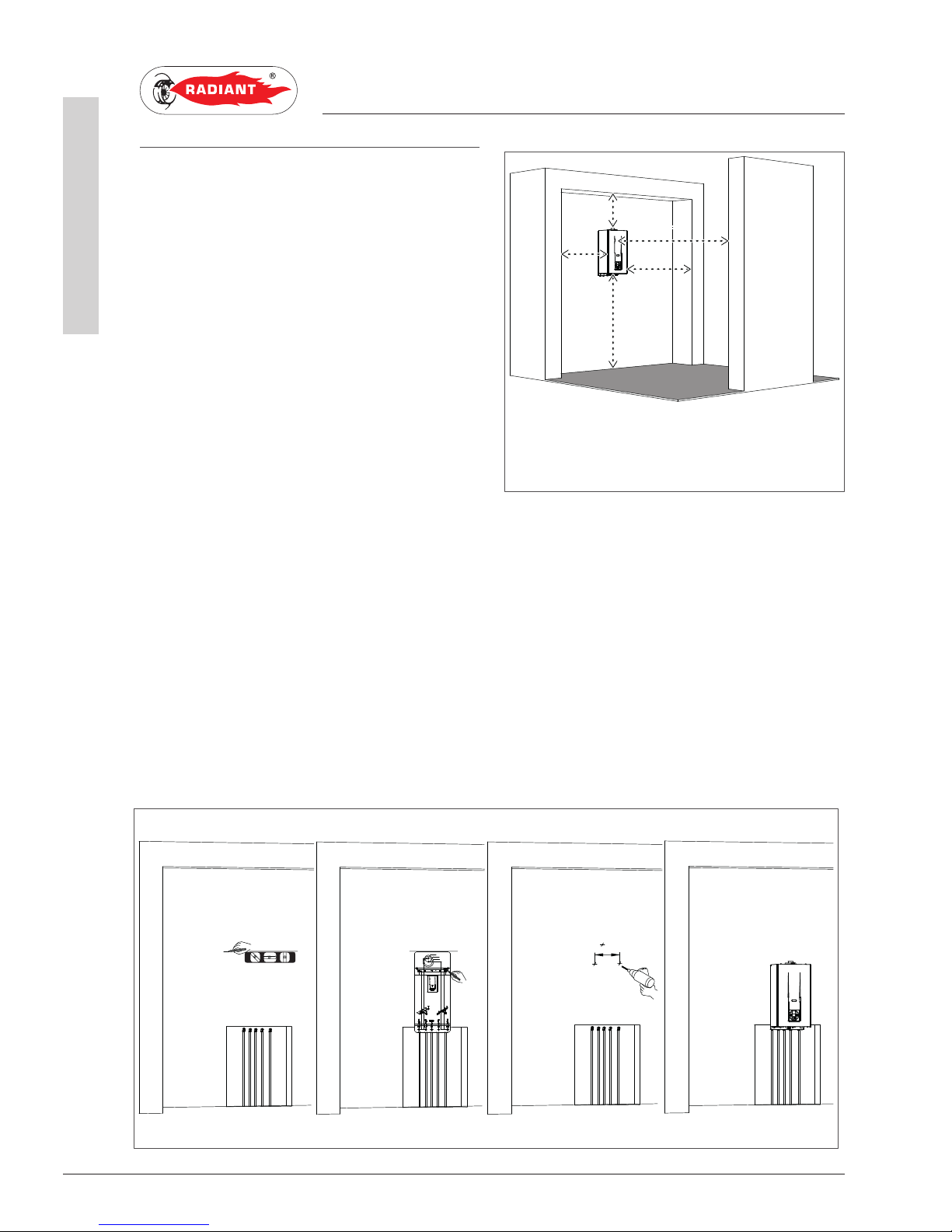

1.1.4. UNPACKING

WARNING

Please unpack the boiler just before

installing it. The Company is not responsible for

the damages caused to the device due to incorrect

storage.

WARNING

The packing elements (cardboard

box, wooden crate, nails, fasteners, plastic bags,

expanded polystyrene, etc.) are dangerous and must

be kept out of the reach of children, they should be

biscarded properly.

To unpack the boiler, proceed as follows:

› Place the packed boiler on the floor (fig. 1-A)

and remove the fasteners opening the four flaps

of the box outwards.

› Turn the boiler at 90° holding it with your hand

(fig. 1-B).

› Lift the box (fig. 1-C) and remove the guards (fig.

1-D).

C

B

D

A

fig. 1

Page 11

11

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

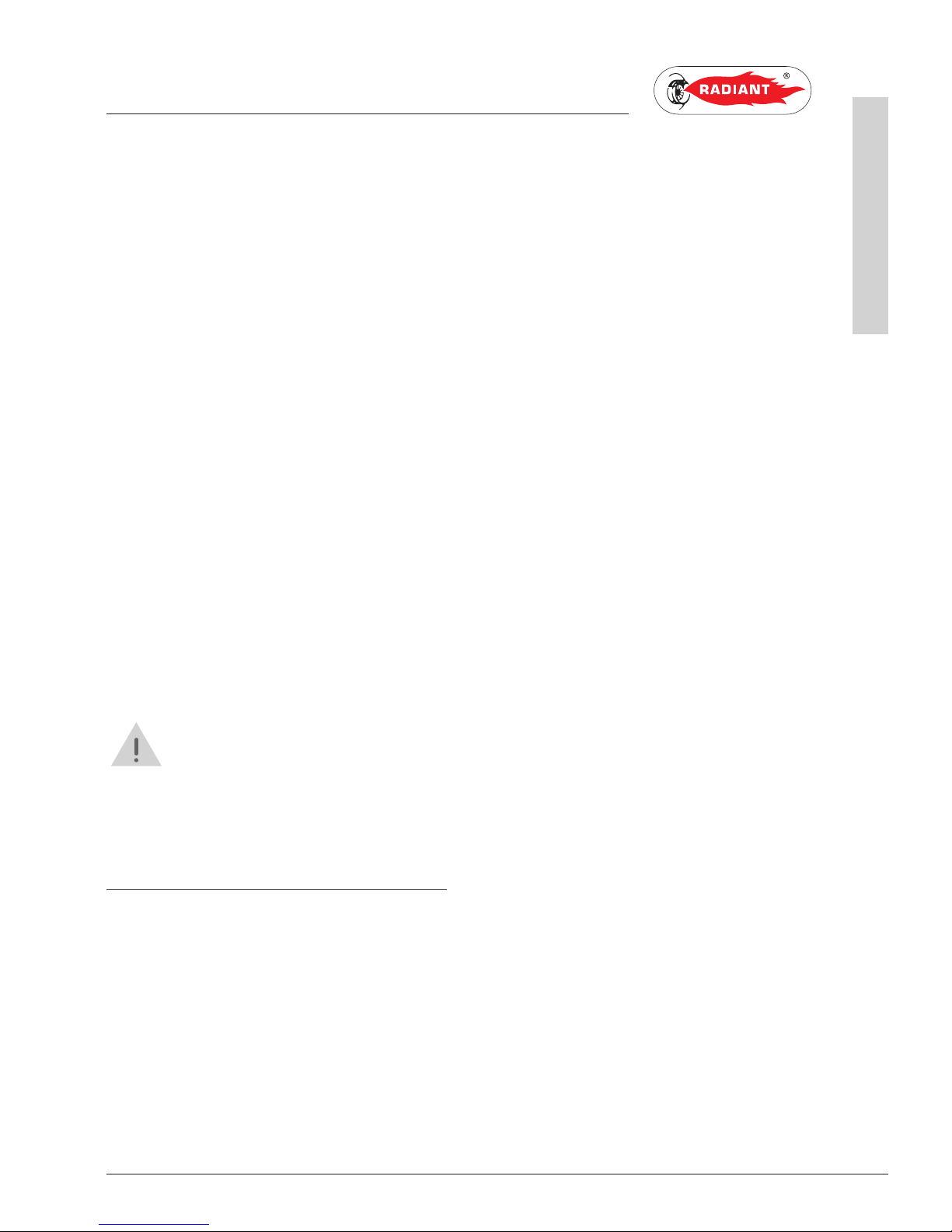

1.1.5. OVERALL DIMENSIONS (inch)

1.1.6. PIPING LAYOUT/IDENTIFICATION 1.1.7. HYDRAULIC CONNECTION KIT

An hydraulic kit equipped is available and supplied

by RADIANT upon demand.

11.8

6.1

5.3

5.9

12.9

16

25.2

1.9 5.8 3.1 4 1.2

5.7 6.9

1.6

4.2

R

RB

G F A

AB

3.4

VS

R F

A

fig. 2

fig. 3

fig. 4

R- RETURN Ø 3/4

G- GAS Ø 3/4 NPT

F- COLD Ø 1/2

A- INFEED Ø 3/4

RB- REMOT E D.H.W. CYLINDER RETURN Ø 3/4 NPT

AB- REMOTE D.H.W. CYLINDER FLOW Ø 3/4 NPT

R - CENTRAL HEATING RETURN Ø 3/4 NPT

F - COLD WATER INLET Ø 1/2 SWEAT

A - CENTRAL HEATING SUPPLY Ø 3/4 NPT

Page 12

12

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

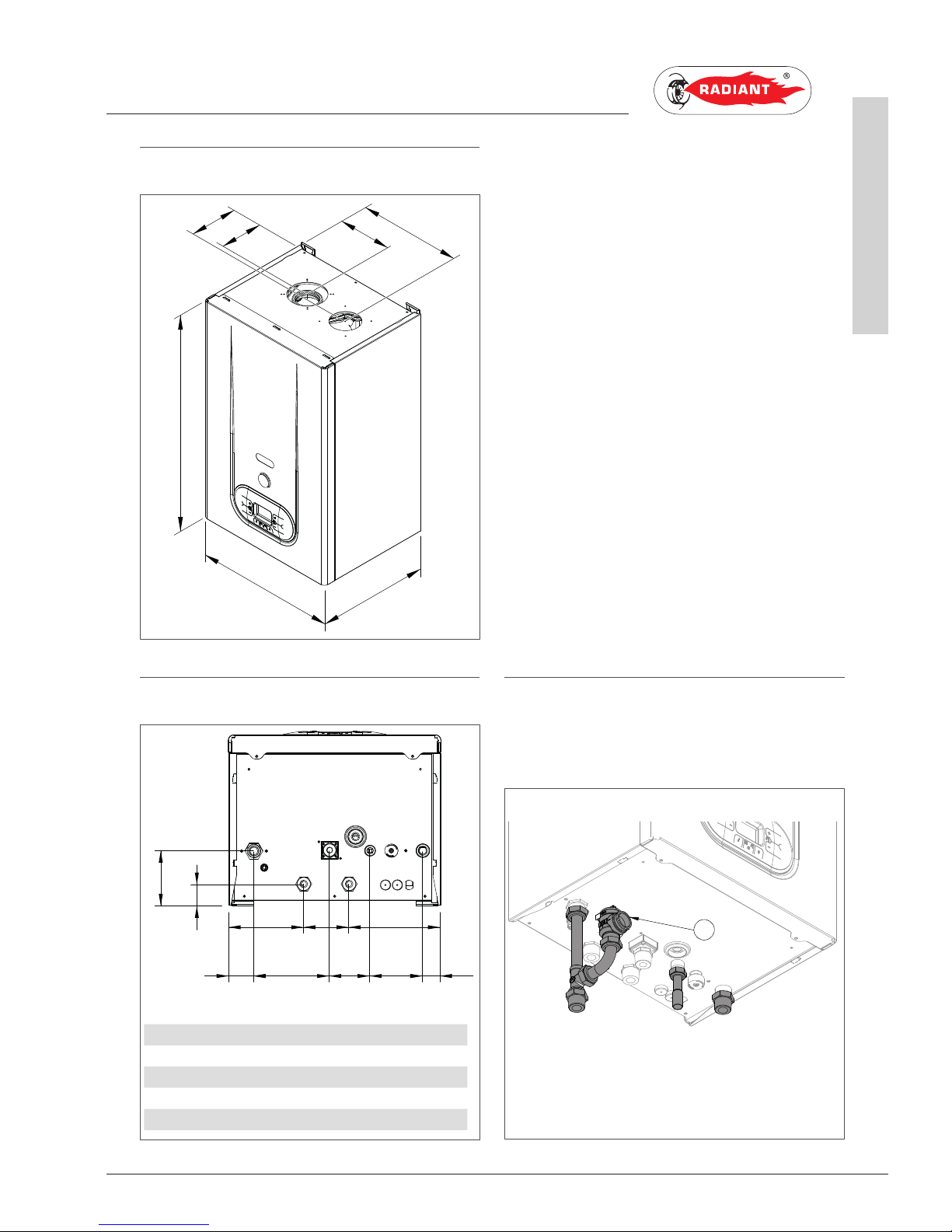

1.1.8. POSITIONING AND

CLEARANCES TO

COMBUSTIBLE MATERIAL AND

SERVICE CLEARANCES

The boiler must be installed only on a vertical solid

wall, able to sustain its weight.

This boiler has been certified to be installed with

“0” clearances to combustible material.

In order to allow the access inside the boiler for

maintenance operations, follow the minimum

service clearances indicated in figure 5.

To facilitate the installation, the boiler is provided

with a jig that allows setting in advance the

connections to the tubes providing the ablility

of connecting the boiler to completed masonry

structure.

To position the unit, proceed as follows (see fig. 6):

1. Trace a line using a spirit level (min. length 9.8 inch) on the installation wall.

2. Place the top of the jig along the traced line respecting the distances of the water connections; then

mark the two points to insert the fasteners, then trace the points for the exhaust vent;

3. Remove the jig and drill the wall;

4. Fix the wall bracket using the screws provided. Hang the unit on the bracket.

3

1

42

70 80 10249 3178

Ø80

Ø125

Ø100

35826 26

54 54

821

681

699

302

785

H

B

A

Y

X

A - 7.8 inch

B - 11.8 inch

X - 2.3 inch

Y - 2.3 inch

H - 36 inch

fig. 5

fig. 6

Page 13

13

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

WARNING

Using a level, make sure the boiler is

properly level (see fig. 6) to allow the condensate to

drain.

1.1.9. CIRCULATOR PERFORMANCE CURVES

fig. 7

UPSO 15-58 AOKR

III

II

I

H (ft)

Q (US gpm)

0 2 4 6 8 10

22

20

18

16

14

12

10

8

6

4

2

0

PRE VALENCE (m)

FLOW RATE US gpm

III

Circulator priority maximum speed

- - - - Appliance Loss fig. 8

Page 14

14

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

1.1.10. WATER CONNECTIONS

DANGER

Make sure that the tubes of the water and

heating unit are not used as grounding system for the

electrical unit. There are not suitable for such use.

WARNING

To prevent voiding the warranty and to

ensure the proper operation of the boiler, wash the unit

(if possible when hot) with suitable descaling solution to

remove the impurities coming from tubes and radiators.

WARNING

If the boiler is installed in a hydrostatic

position lower than those of the user devices (radiators,

fan coils, etc.), mount the shut-off valves on the domestic

water heating circuit to ease the performance of the

maintenance operations if necessary to only empty the

boi ler.

WARNING

When connecting the equipment to water

supply, avoid excessive bending and recovery operations

from improper positioning that may damage the tubes

causing leaks, malfunction or premature wear.

WARNING

In order to avoid any vibrations and noises, do

not use tubes with small diameters or elbows with small

radius and significant cut-off of the passage sections.

DOMESTIC CIRCUIT

In order to prevent limestone build-up and damages

to the domestic water heat exchanger, the hardness

of the domestic supply water should not exceed 8.4°

dh (degrees hardness). However, please check the

characteristics of the water used and install suitable

treating devices.

The heat exchanger coil cleaning frequency depends

on the hardness of the supply water and on the

presence of solid residues or impurities inside

the water that are often present in case of recently

installed plants. Based on the characteristics of

the inlet water, you should install suitable water

treatment devices, for residues presence. Please

install an inline filter.

The pressure of the cold inlet water should be

between 7.2 psi (0.5 bar) and 150 psi (10.34 bar). In

case of greater pressure values, please install a

pressure reducer upstream from the boiler.Please

refer to local jurisdictions on the requirements for

cold inlet water pressure.

HEATING CIRCUIT

In order to avoid any scale or deposits on the primary

exchanger, the hardness of the heating circuit inlet

water should not exceed 14° dh (degrees hardness).

However, please check the characteristics of the

water used and install suitable treatment devices.

To protect the central heating system from damaging

corrosion, flakes or deposits it is important to clean

the hydronic system using cleaners such as Fernox F3

Cleaner. For long term protection against corrosion

and deposits, the use of inibitor (such as Fernox F1

inhibitor) is required after cleaning and flushing of

the hydronic system. It is important to monitor the

concentration of the inibitor during commisioning and

during servicing of unit.

WARNING

Failure to clean the central heating system

or add adequate inibitor invalidates the compliance

warranty.

Connect the boiler safety drains (heating circuit safety

valve) to a discharge funnel. The manufacturer is not

responsible for any floods due to safety valve opening

in case of unit excessive presure build up.

WARNING

In case the boiler is installed as part of a low

temperature circuit, please install a safety thermostat

on the heating flow, which can stop the boiler activity

in case of high heating flow temperature. The company

assumes no liability for damage caused to persons or for

failure to comply with these instructions.

Page 15

15

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

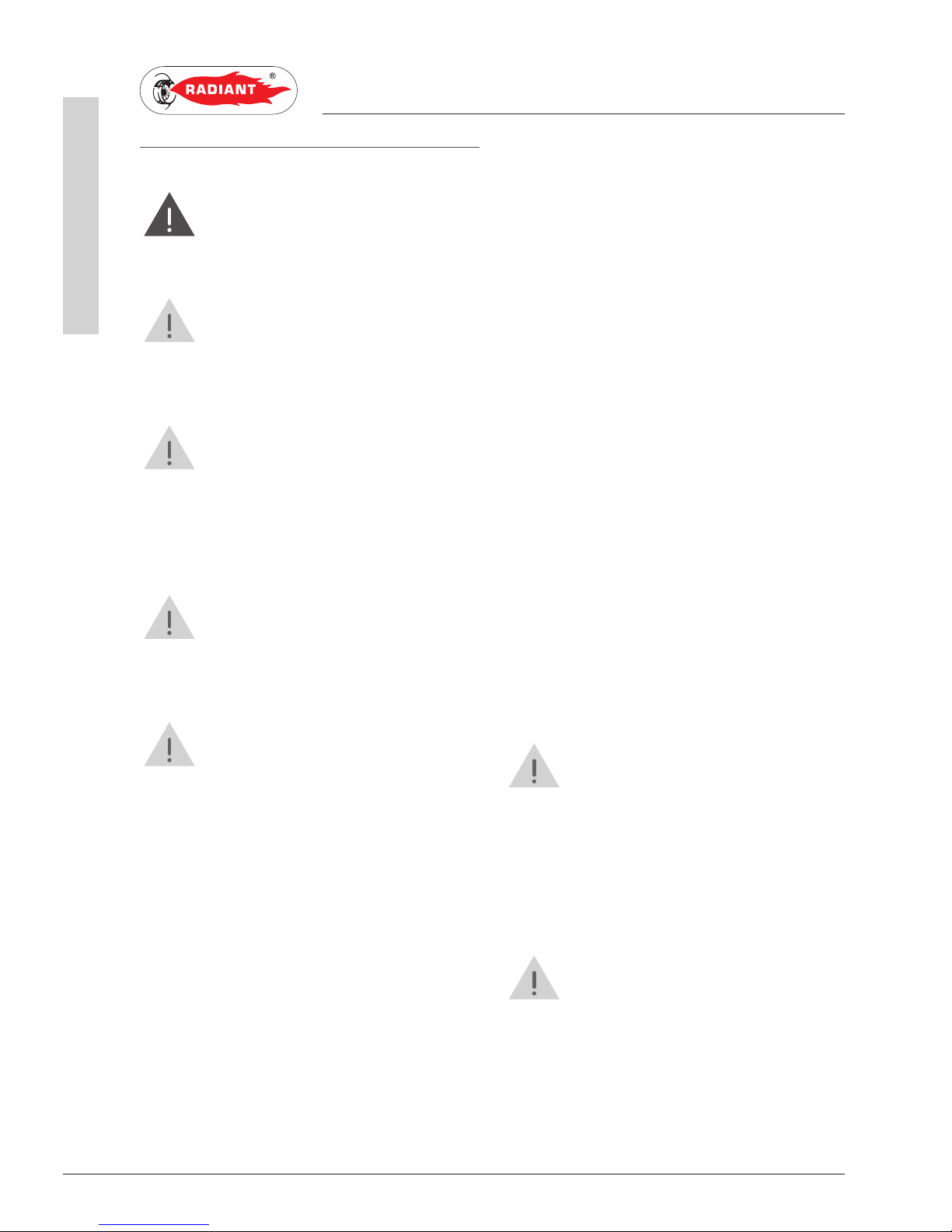

1.1.11. PRESSURE RELIEF VALVE KIT

To complete the installation of the boiler, you must

install an approved 3/4”, maximum 30 PSI (2 bar)

pressure relief valve on the heating return.

A hydronic kit equipped with hydronic connections

and safety valve (see ‘VS’ fig. 9) is available and

supplied by RADIANT.

ATTENTION

The pressure relief valve MUST TO BE

INSTALLED in any case.

ATTENTION

The pressure relief valve should be placed

as close to the boiler as possible. No other valve

should be placed between the pressure relief valve

and the boiler.

DANGER

Improper installation of the pressure

relief valve may result in property damage, personal

injury, or death. Follow all instructions and guidelines

when installing the pressure relief valve. The valve

should be installed only by a licensed professional.

When installing the valve, follow these guidelines:

› Direct the discharge piping of the pressure relief

valve so that hot water will not splash on anyone

or any nearby equipment.

› Attach the discharge line to the pressure relief

valve and run the end of the line to within 6-12”

(150-300mm) of the floor.

› Ensure that the discharge line will allow free and

complete drainage without restriction. Do not

install a reducing coupling or other restriction

on the discharge line.

VS

R F

A

fig. 9

Page 16

16

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

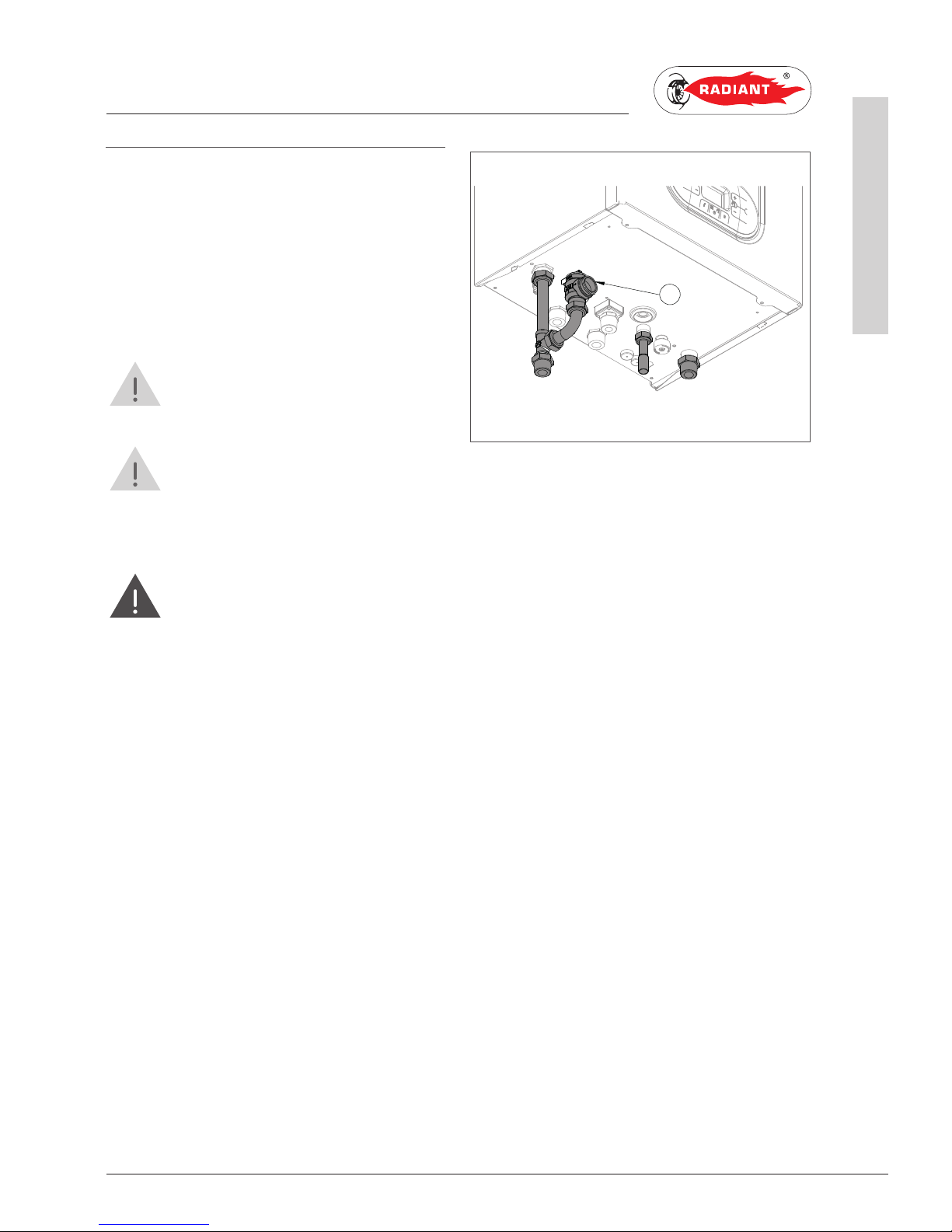

1.1.12. SYSTEM FILLING

WARNING

For system filling use only clean tap water.

WARNING

If the system is filled by adding ethylene

glycol-type chemical agents it is suggested to install

a system fender on the hydronic system in order to

separate the heating circuit from the domestic circuit.

Before powering up the boiler, fill the system as

follows:

1. Make sure the circulator is not blocked;

2. Slightly loosen the cap of the circulator air

eliminator (1-fig. 10) to release the air from

the system;

3. Slightly loosen the cap of the air eliminator

placed on the top of the condensing block

(fig. 12) to release the air form the top of the

system;

4. Open the feeding tap “R” (fig. 11);

5. Release all the air;

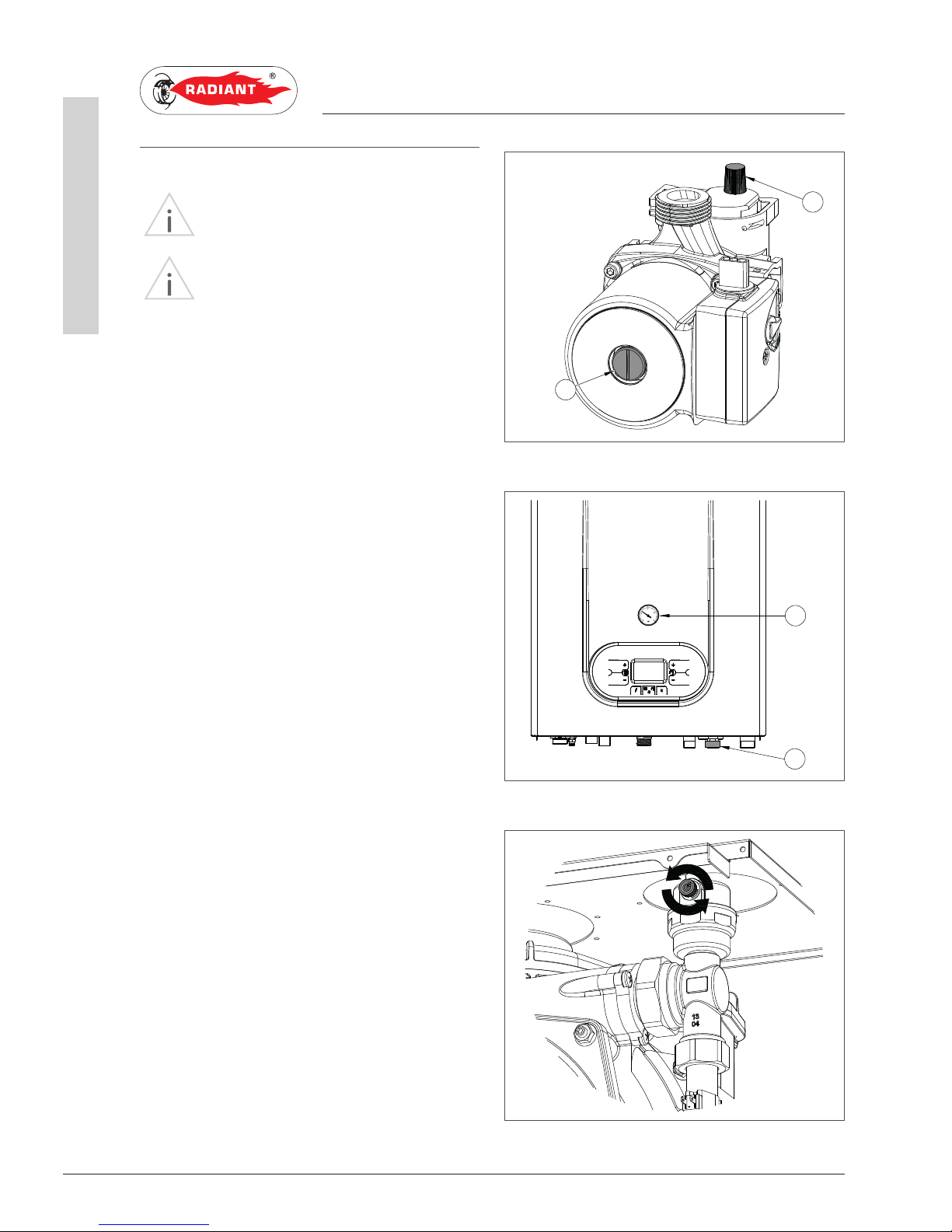

6. Use pressure gauge “M” (fig. 11) to make sure

that the system pressure reaches 1.2 bar (fig.

13);

7. After performing this operation, make sure

that the loading tap “R” (fig. 12) is properly

closed.

1

2

M

R

fig. 10

fig . 11

fig. 12

Page 17

17

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

8. Unscrew the circulator cap (2-fig.10) to release

any air bubbles and close it to prevent water

leakage;

9. Open the air relief valves of the radiators and

check the air removal process. When the

water starts to leak close the radiators air

relief valves.

10. If after performing these operations you

observe a decrease of the water pressure

inside the system, open once again the loading

tap “R” until the pressure gauge indicates the

value of 1.2 bar (fig. 13)

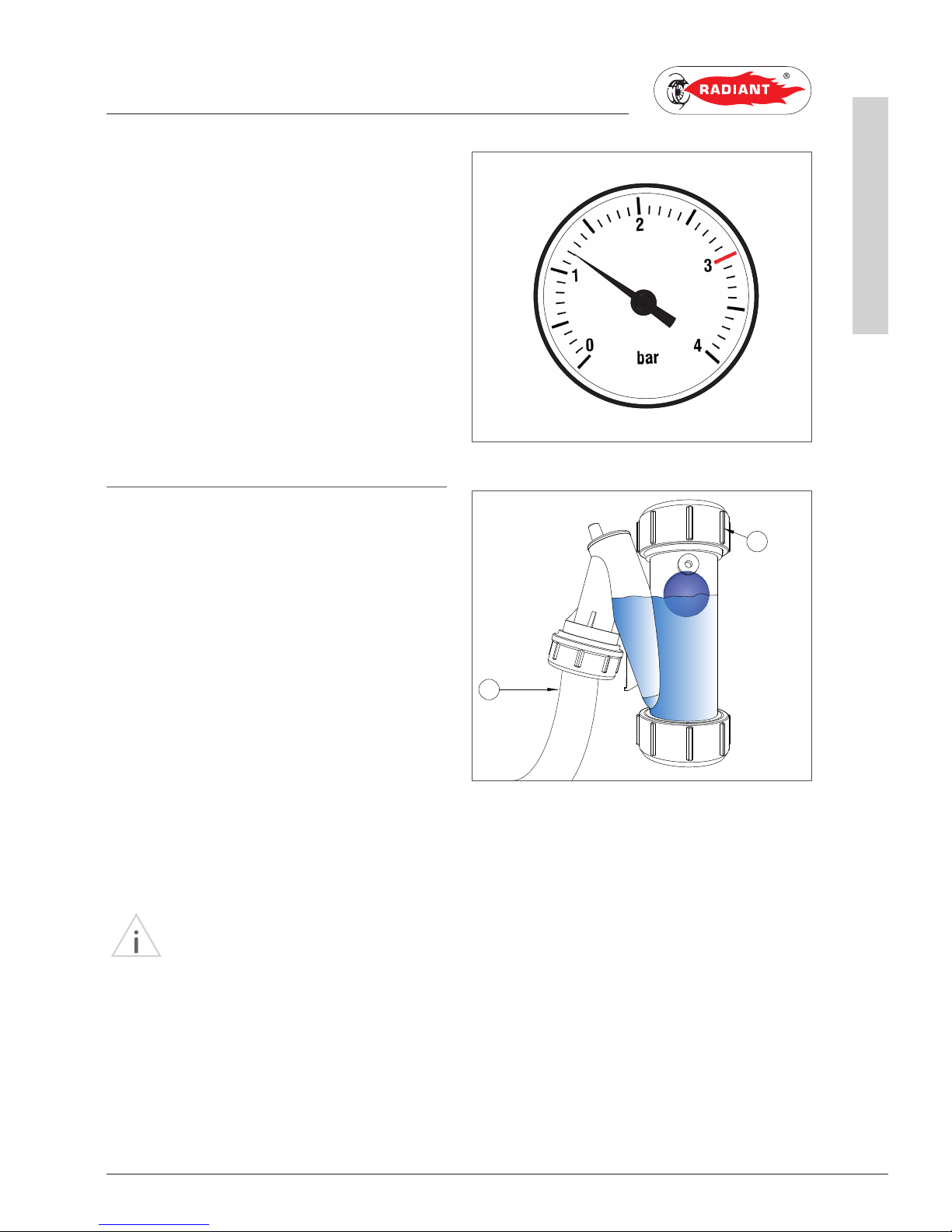

1.1.13. FILLING THE CONDENSATE

COLLECTION SIPHON

Before starting the boiler you have to fill the

condensate collection siphon in order to avoid fuel

back up through the siphon.

Fill the condensate collection siphon as follows

(see fig. 14):

› Unscrew the “T” cap from the siphon, fill three

quarters of the the siphon with water and screw

the “T” cap back in;

› Connect the dedicated flexible condensate

draining tube “P” to a waste disposal system.

The condensate can be drained directly in the

sewer system by inserting an easily serviceable

siphon.

WARNING

After the fir st months of boiler operation,

it is recommended to clean the condensate trap, to

eliminate possible deposits coming from the first

flow of the condensate inside the boiler technical

components. These deposits could cause a

malfunctioning of the trap.

P

T

fig. 13

fig. 14

Page 18

18

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

CONDENSATE DRAIN

The boiler produces a significant amount of

condensate during operation. This condensation

has an acidic pH of 3-5. Follow all local codes and

regulations when disposing of condensate from

the boiler.

The project engineer should consider the

possibility of installing systems to eliminate the

acidic condensation, according to system power

and buildings’ use.

The system should be designed to avoid

the condensate freezing. Before the boiler

commissioning, check the correct condensate

flow.

WARNING

Check before connecting the condensate

trap to the drain pipe, for the proper

gradient of boiler as described in paragraph “1.1.8

POSITIONING AND MINIMAL TECHNICAL SPACES”.

WARNING

Properly connect the siphon condensate

from the boiler to a drain system having adequate

slope. Where possible, you should make this

connection using transparent tubing to check for

proper condensate drainage and avoid stagnation that

could cause hazardous backflow of the condensate

into the boiler.

To connect the condensate drain use only

corrosion-resistant material for the drain line.

CONDENSATE NEUTRALIZER KIT

The condensate neutralization system neutralizes

the condensate created by the products of

combustion.

Acid condensate, introduced into the neutralization

box, follows a two-step set course. First phase:

nitrates and sulphates filtration through active

carbons contained in the first part of the carbon

site pipe. In the second phase the pH rises.

The acidity of the condensate can be controlled

through the use of appropriate tools for the

determination of Ph, such as the litmus paper.

Neutralized condensate can then be routed to the

drainage system.

MAINTENANCE

The pH value of the condensate after the neutralizer

must be in between <5,5 – 9,5>.

Every six months, you need to determine the pH of

the condensate treated in the neutralizer. Litmus

paper or a digital instrument can be used to

measure the pH level.

Neutral point is on the 6,8-7 value; in case of lower

value the condensate is acid, in case of a higher

value it is basic.

If necesssary, replace the active carbon and the

reagent granulate.

Page 19

19

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

1.1.14. ANTI-FREEZE PROTECTION

The boiler is protected against freezing using the

electronic board design with a function that start

the burner and heat the water in the boiler when

their water temperature goes below the minimum

pre-set values, protecting the boiler up to an

external temperature of 14 °F (-10 °C).

The device starts when the hot water temperature

goes below 41 °F (5 °C), automatically starting the

burner until the water reaches the temperature of

86 °F (30 °C).

The system starts even if display appears “OFF”,

as long as the boiler is connected to the power (120

V) and gas supply.

For long periods of standby, please empty the

boiler and the plant.

If the temperature goes below 14 °F (-10 °C)

centigrades, please fill the plant with anti-freeze

liquid (CLEANPASS FLUIDO AG cod. 98716LA)

and insert and electrical resistances kit (cod. 65-

00200).

DILUTION PERCENTAGE OF CLEANPASS

FLUIDO AG

ANTIFREEZE ETHYLENE GLYCOL

TEMPERATURE

FREEZING POINT

(%) VOLUME °F (°C)

20 18 (-7.5 )

30 8.6 (-13)

35 -0. 4 (-18)

40 -8.5 (- 22.5)

45 -18 (-28)

50 -28 (-33.5)

55 -44 (-42)

60 -58 (-50)

RECOMMENDED MINIMUM PERCENTAGE OF

GLYCOL : 20 %

Page 20

20

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

1.1.15. GAS CONNECTION

WARNING

The gas piping must be installed according

to all local and state codes, or in absence of local and

state codes, with the latest “Natural gas and propane

installation code”, CAN/CSA-B 149.1 or “National

Fuel Gas Code”, ANSI Z223.1 (NFPA 54). Consult

the “Natural gas and propane installation code” or

“National Fuel Gas Code” for the recommended gas

pipe size of other materials.

BEFORE PERFORMING THE GAS CONNECTION,

MAKE SURE THAT:

› The gas line size and length meets requested;

› The gas line is equipped with all safety and

control devices required by the standards in

force;

› The internal and external seals of the gas inlet

lines of the plant are checked;

› The device is suitable for use with the type of

gas available by checking the boiler data plate

(located on the inner side of the front casing. If

they do not match you must take the necessary

measures to adapt the boiler to another type of

gas (see 2.2.18 CONVERSION TO A DIFFERENT

GAS TYPE);

› The gas supply pressure falls within the values

indicated on the data plate.

1.1.16. ELECTRICAL CONNECTION

DANGER

The equipment is electrically safe only

if it is properly connected to an efficient grounding

system, performed in compliance with the safety

standards in force (National Electrical Code, ANSI/

NFPA 70 and or the Canadian Electrical Code Part

I, CSA C22.1, Electrical Code). You should check this

essential safety requirement. If in doubt, request an

accurate check of the electrical system performed by

qualified staff, as the manufacturer is not responsible

for any damages caused by lack of grounding system.

› Make sure that the electrical systems is

suitable for the maximum power consumed by

the equipment, value indicated on the data plate.

› Make sure that the cables section is appropriate

for the maximum power consumed by the

equipment.

› The equipment works with alternating current

of 120 V and 60 Hz. The electrical connection

must be installed using an all-pole switch with

an opening of at least 0.12 in (3 mm) between

contacts placed upstream from the device.

WARNING

Make sure that the phase and neutral

cables connection is installed in compliance with the

wiring diagram (see 1.1.17 POWER SUPPLY).

WARNING

It is strictly forbidden to use adaptors,

multiple plugs and/or extensions for the general

power supply of the equipment from the electrical

supply.

Page 21

21

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

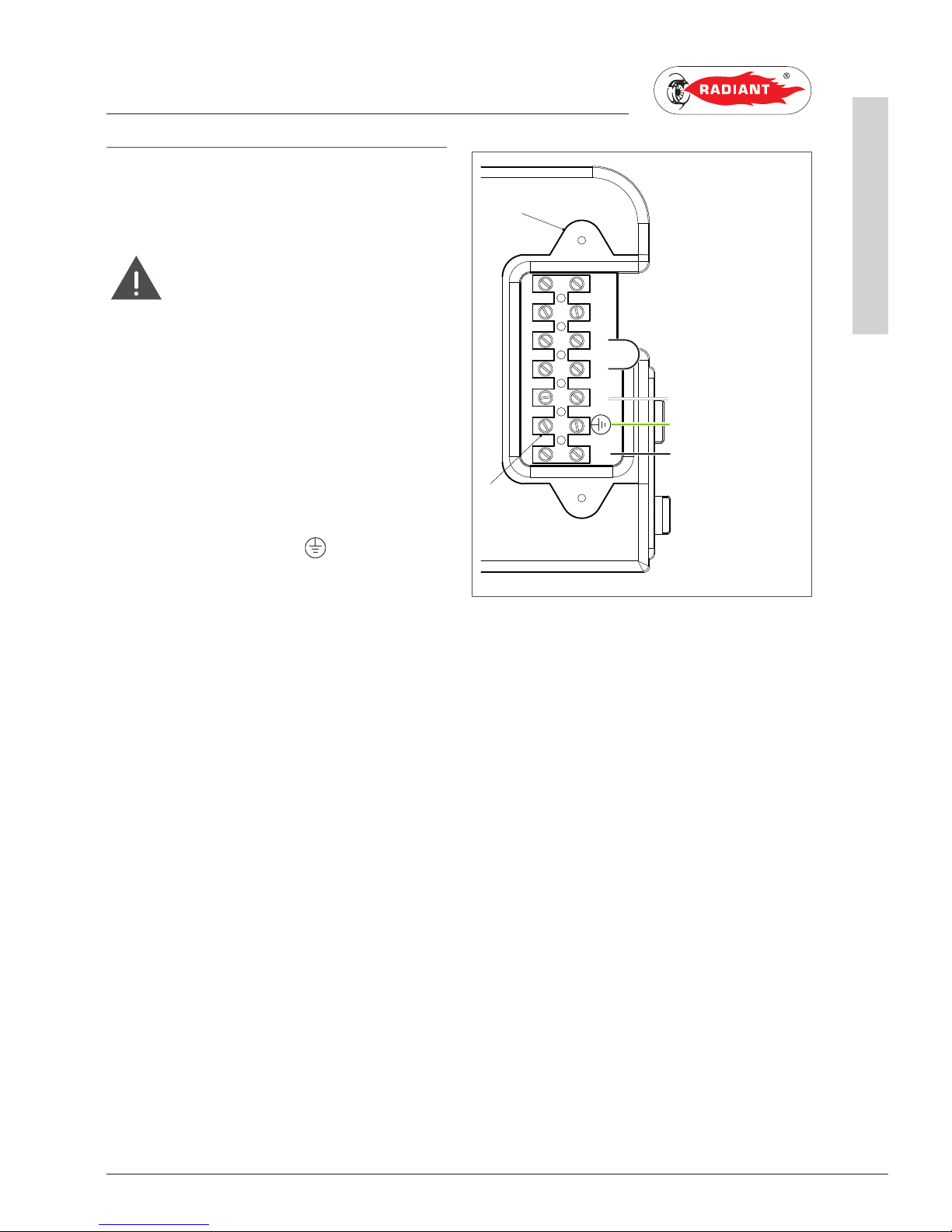

1.1.17. POWER SUPPLY

To power the boiler connect the electrical cables

to the terminal inside the control panel as follows:

DANGER

Cut off the voltage from the main switch.

› remove the boiler's front casing (refer to 2.2.13

ACCESSING THE BOILER).

› loosen the two screws and remove the plate “A”

(see fig. 15).

› after removing the plate, connect the electrical

cables to terminal “B” (see fig. 15):

· the yellow/green cable to the terminal marked

with grounding symbol “ ”.

· the blue cable to the terminal marked with

“N”.

· the brown cable to the terminal marked with

“ L”.

After performing these operations, remount plate

“A” and the front casing.

Note: A 3-prong plug is provide with every unit and

the above wiring has been performed.

L

N

SeSe

A

TaTa

B

fig. 15

WHITE

YELLOW/GREEN

BLACK

Page 22

22

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

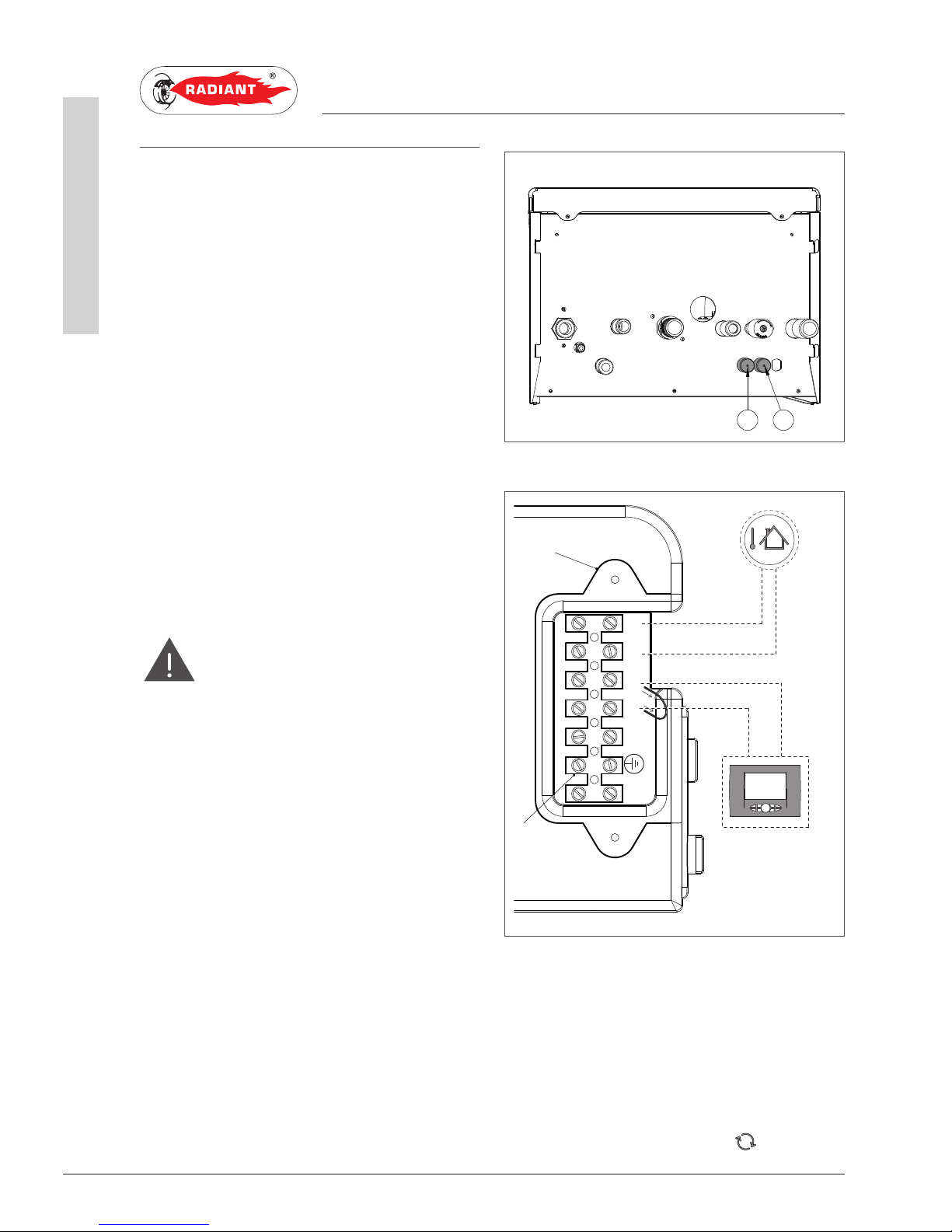

1.1.18. OPTIONAL ELECTRICAL

CONNECTIONS

The cables should be inserted inside the boiler

using the cable glands ‘P1’ and ‘P2’ placed under

the board (see fig. 16). Make a hole on the cable

gland, smaller than the cable diameter, to make

sure that the air cannot pass through.

To wire the options below:

• (SE) EXTERNAL TEMPERATURE PROBE COD.

73518L A

• (TA) ENVIRONMENT THERMOSTAT

• (CR) REMOTE CONTROL OPEN THERM COD. 4000017

use the terminal placed inside the control panel

as follows:

DANGER

Shutoff the voltage from the main switch.

› Remove the front casing of the boiler (see 2.2.13

ACCESSING THE BOILER); unscrew the screws

and remove plate “A” (see fig. 16-B).

› After removing the plate, connect the electrical

cables to terminal “B” (see fig. 16-B):

· For the external temperature Probe connect

the two non-polarized conductors to the SeSe contacts.

· For the environment Thermostat or Remote

control, first remove the bridge on the TaTa contacts and then connect the two nonpolarized conductors to the Ta-Ta contacts.

After performing these operations, remount plate

“A” and the front casing.

NB: In case of simultaneous presence of external probe and

remote control, the modulation board only sends the external

temperature value to the remote device without using it for

modulation.

The communication between board and remote control takes

place independently from the boiler’s operating mode and after

establishing the connection, the used interface on the board is

disabled and the display shows the symbol ‘ ’.

P1 P2

L

N

SeSe

A

TaTa

B

SE

TA

CR

fig. 16-B

fig. 16

Page 23

23

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

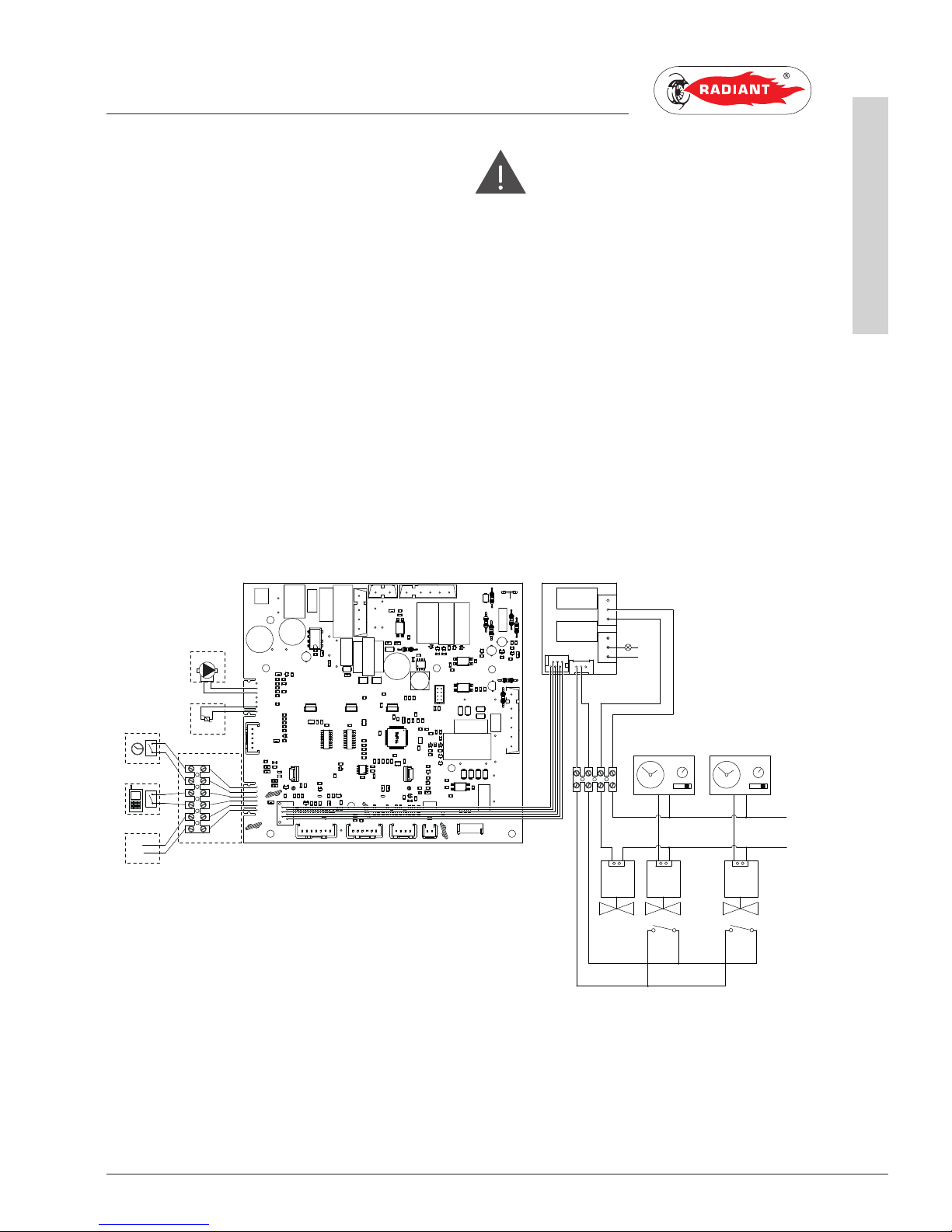

To wire the options below:

• (PM) MODULATING PUMP

• (TP) DOMESTIC HOT WATER PRE-HEATING

DEACTIVATION TIMER

• (CT) TELEPHONE DIALER

• BUS 0-10V

• (SVZ) CONTROL BOARD FOR AREA VALVES

CONNECTED TO A REMOTE CONTROL COD. 6500030

Use the electronic board placed inside the control

panel as follows:

DANGER

Shutoff the voltage from the main switch.

› Remove the boiler's front casing (refer to 2.2.13

ACCESSING THE BOILER).

› Remove the crankcase of the control panel (see

2.2.14 ACCESSING THE ELECTRONIC BOARD).

› After removing the crankcase, connect the

items below to the electronic board (see fig. 17):

After performing these operations, remount the

crankcase and the front casing.

TP

CT

BUS 0-10V

GND

BUS+

11

10

98

7

12

13

14

15

16

17

M12

M9

M7

M5

M2

M4

M8

M10

M15

M16

1

2

3

4

57

61

60

59

58

4443424140

39

38

3736353433

32

31

30

29

28

27

26

MIAH4

bl

br

PM

SR

62

63

64

65

66

67

68

51

52

53

54

55

56

5

6

M13

M14

o

o

bk

bk

bl

br

120 V - 60 Hz

L

N

VZR

VZ2 VZ1

FC FC

TAZ 2

TAZ 1

SRB

N

1

2

3

4

5

6

9 8

7

M1

M4

M2

M3

SVZ

L

gy

o

r

bk

COD.40-00133

fig. 17

SR: RETURN PROBE FC: AREA VALVES LIMIT SWITCH

SRB: REMOTE LED FOR SIGNALLING BOILER LOCKOUT GY: G RE Y

TAZ1: ENVIRONMENT THERMOSTAT AREA 1 O: ORANGE

TAZ 2: ENVIRONMENT THERMOSTAT ARE A 2 BK: BLACK

VZ1: AREA 1 VALVE BR: BROWN

VZ2: ARE A 2 VALVE BL: LIGHT BLUE

VZR: REMOTE CONTROLLED AREA VALVE R: RED

Page 24

24

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

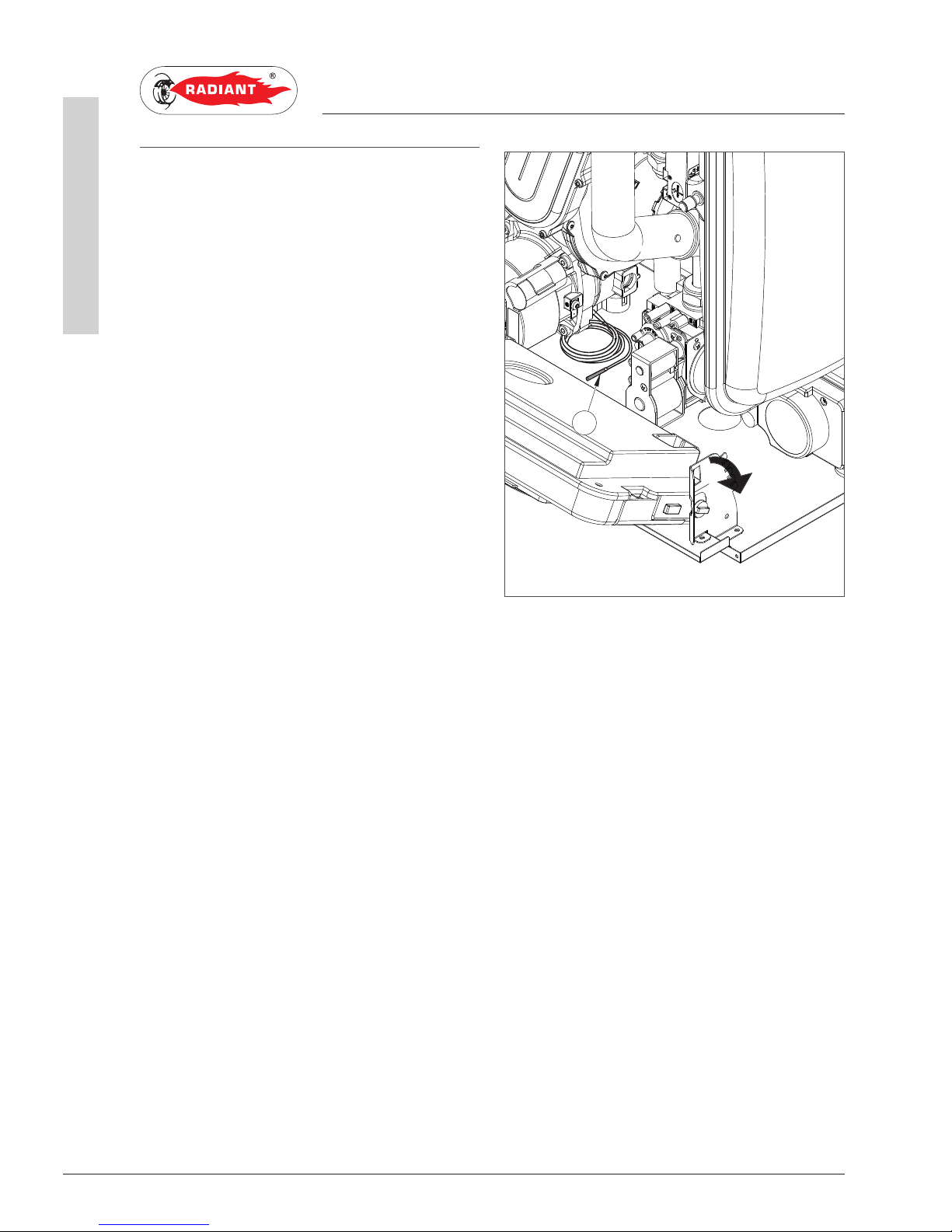

1.1.19. DHW SENSOR INSTALLATION

To install the DHW sensor inside the remote water

tank, please proceed as follows:

Remove the boiler front case panel (see Paragraph

ACCESSING THE BOILER);

Grasp the left and right control panel support

brackets and pull them outwards, at the same

time rotating the panel downwards;

Take the 8 m. length DHW sensor cable (see

C-figure), located onto the boiler bottom plate,

and insert the sensor inside the water tank sensor

holder.

Once this operation has been completed, rotate

the control panel upwards and install the front

case panel back to its original position.

C

Page 25

25

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

1.1.20. VENTING

WARNING

In order to ensure proper operation and

efficiency of the device you have to connect the

boiler fume exhaust fitting to the exhaust and fresh

air adapters (loosely supplied in water heaters). It is

recommended to install discharge systems approved

by Radiant.

WARNING

All termination kits must be located and

installed in accordance with local building code and

CSA B149.1 Natural Gas and Propane Installation

Code.

WARNING

For condensate collection please follow

the local codes.

› All exhaust runs shall be sloped such that any

condensate would move towards the combustion

chamber so that it can be collected and drained

via the internal condensate trap of the appliance

(Refer to section 1.1.20).

› All combustion air intake runs where possible

should be sloped in a manner to avoid rain

water, dust or foreign objects from entering the

appliance (Refer to section 1.1.20).

› In case of horizontal polypropylene co-axial

system installation, properly orientate the

horizontal co-axial terminal in relation to the

slopes inside the exhaust pipe and to protect

the combustion air pipe from adverse weather

conditions (Refer to section 1.1.20, sub-section

III (a) and figure 20).

This appliance is certified to be installed using

polypropylene, PVC and CPVC. For Canada use

System 636 polypropylene, PVC and CPVC Type

BH Gas Venting Systems certified to ULC S636.

Types of venting configurations for this appliance

are, co-axial vent (pipe with in a pipe), co-linear

vent (separate pipes for exhaust and combustion

air), and single exhaust vent (uses room air for

combustion).

Page 26

26

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

TABLE MINIMUM DISTANCE feet mm

A- below openable window or

door

3* 900*

B- below ventilation opening

(non mechanical)

3* 900*

C- below soffits 1 300

D- below balcony 1 300

E- from adjacent window or

door

3* 900*

F- from adjacent ventilation

opening (non mechanical)

3* 900*

G- from horizontal or vertical

soil or drain pipes

1 300

H- from corner of building 1 300

I - from recess in building 1 300

L - above a paved sidwalk or a

paved driveway that is located

on public property

7 2100

M- between two terminals set

vertically

2 600

N- between two terminals set

horizontally

2 600

(*)- FOR APPLIANCE WITH INPUTS UP TO

AND INCLUDING 100,000 Btu/h (29.3 kW) THIS

DISTANCE REDUCES TO 1 ft (300 mm).

1. The vent shall not terminate:

a) where it may cause hazardons frost or ice

accumulations on adjacent property surfaces;

b) less that 7 ft (2.1 m) above a paved sidewalk or a

paved driveway that is located on public property;

c) within 6 ft (1.8 m) of a mechanical air-supply

inlet to any building;

d) above a regulator wi thin 3 ft (900 mm) horizontally

of the vertical centerline of the regulator vent outlet

to a maximum vertical distance of 15 ft (4.5 m);

e) within 3 ft (900 mm) of any gas service regulator

vent outlet;

f) less than 1 ft (300 mm) above grade level plus

expected snow level;

g) within the following distances of a window or

door that can be opened in any building, of any

non-mechanical air supply inlet to any building, or

of any combustion air inlet of any other appliance;

· i) 12 in (300 mm) for inputs up to and including

100,000Btu/h.

· ii) 3 ft (900 mm) for inputs exceeding 100,000

Btu/h.

h) Underneath a veranda, porch, or deck unless;

· i) the veranda, porch, or deck is fully open

on a minimum of two sides beneath the floor;

and

· ii) the distance between the top of the vent

termination and the underside of the veranda,

porch, or deck is greater than 1 ft (300 mm);

2. Building material within 5 ft (1,5m) of a vent

terminal will be subjec ted to products of combustion

and therefore may be subject to discoloration or

deterioration, of building materials.

fig. 18

Page 27

27

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

1.1.21. TYPES OF EXHAUST SYSTEMS

GENERAL INTRODUCTION

The venting installation must conform to the

requirements of the authority having jurisdiction or,

in the absence of such requirements, to the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, and/or Natural

Gas and Propane Installation Code, CAN/CSA B149.1.

Horizontal exhaust runs shall slope upwards not less

than 1/4 in/ft [21 mm/m] from the boiler to the vent

terminal. Venting shall be installed so as to prevent

the accumulation of condensate throughout the vent

run. Provide means for drainage of condensate on all

vertical exhaust runs and where necessary.

Horizontal combustion air intake runs should slope

downwards not less than 1/4 in/ft [21 mm/m] from

the boiler to the air intake terminal where possible.

For installations in which the combustion air run

cannot slope to the outdoors, it is recommended that

a trap be installed closed to the appliance (see figure

‘H’).

Where not possible a water trap shall be installed so

as to collect moisture or water from entering into the

air box of the boiler. Provide means for drainage of

moisture and water on all vertical air intake runs and

where necessary.

Traps, if used, should have pipe slopes not less

than 1/4 in/ft [21 mm/m] downwards to the trap.

I - CO-LINEAR VENT (FRESH AIR AND EXHAUST)

The Gas-Fired wall mounted hot boilers can be

installed with two separate pipes. The two separate

pipes consists of one for the exhaust an the other for

combustion air intake.

Please refer to Table 1: Allowable vent lengths for

maximum vent and combustion air intake runs.

Co-linear vent installations can be either be installed

through the wall or through the roof.

I (a) - THROUGH THE WALL LNSTALLATION:

Through the wall installations can terminate with two

separate pipes or with a concentric terminal.

Please refer to figure ‘A’ for installations using

terminations using co-linear vent.

Refer to figure ‘B’ for installations using co-linear

vent with co-axial terminal.

INSULATED

EXHAUST

12” minimum12” minimum

TRAP

6”minimum

Exhaust

Air Intake

12” minimum

12” minimum

above average

snow fall

Air Intake

Distance above avg.

snow fall or grade

Ref: CSA B149.1

Exterior wall

1” Min

2” Max

(From wall

or Face Plate)

Clamp or Strap

(Field Supplied)

Exhaust

Air Intake

Exhaust

fig. A

fig. B

fig. H

Page 28

28

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

I (b) - THROUGH THE ROOF LNSTALL ATION:

Through the roof installations can terminate with

two separate pipes or with a co-axial terminal.

Please refer to figure ‘C’ for installations using colinear vent with vertical termination.

Refer to figure ‘D’ for installations using a colinear vent with vertical co-axial terminal.

II - SINGLE VENT

This gas-fired wall mounted hot boilers can be

installed with one single vent pipe for exhaust.

Please refer to Table 1: Allowable vent lenghts for

maximum vent run.

Single vent installations can be either be installed

through the wall or through the roof.

II (a) - THROUGH THE WALL INSTALLATION:

Please refer to figure ‘E’ for through the wall single

vent installations.

II (b) - THROUGH THE ROOF INSTALLATION:

Please refer to figure ‘F’ for through the roof single

vent installations.

12” minimum

12” minimum

Roof

Exhaust

12” minimum

above average

snow fall

Air

Intake

Air Intake

Distance above avg.

snow fall or grade

Ref: CSA B149.1

Flashing

(Field Supplied)

Roof

Clamp or Strap

(Field Supplied)

Exhaust

Air Intake

Exhaust

12” minimum

above average

snow fall

Roof

Exhaust

12” minimum

above average

snow fall

fig. C

fig. D

fig. E

fig. F

Page 29

29

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

AIR INTAKE / FLUE EXHAUST Ø 3” (80 MM)

ADAPTORS WITH PP TEST POINT (COD.: 65-

00433)

These adapters are to be installed on co-linear vent

(two separate pipes for exhaust and combustion

air), and single exhaust vent (using room air for

combustion). Additional bushings or couplings are

required to transition from 3” schedule 40 pipe

to 2” or 4” schedule 40 pipe only for installations

using 2” or 4” schedule 40 pipe. Additional

transition adapters are not needed for installations

using only 60 mm or 80 mm polypropylene, or 3”

schedule 40 PVC or CPVC pipe.

Ensure that the adapters are installed correctly

into the correct locations as per the attached

figure 19.

Installation instructions:

· Remove the air intake cover plate.

· Clean the inspection collar surface and the

area of the air intake hole.

· Stick the appropriate neoprene gaskets onto

the underside of the mounting flange of the

adapters. Pay attention to aligning the four

mounting through holes.

· Mount the intake/flue exhaust adaptors with

self tapping screws provided with the flue kit.

· Install the first piece of 60 mm or 80 mm

polypropylene or 3” schedule 40 PVC or CPVC

pipe until it bottoms out.

· Finally use the gear clamp to tighten the first

piece of pipe to the adaptor.

cod.: 65-00433

FLUE EXHAUST

COMBUSTION AIR INTAKE

fig. 19

Page 30

30

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

III (a) - KIT M&G HORIZONTAL CO-AXIAL

SYSTEM Ø3.1/4.9 in (Ø80/125 mm) INTERNAL

POLYPROPYLENE DUCT ADJUSTABLE AT 360°.

It allows exhaust and air intake from external wall.

Suitable only for condensing unit.

It allows exhaust and air intake for combustion

through co-axial ducts, the external one for air

intake, the plastic internal one for exhaust.

PLEASE SEE THE MAXIMUM EXHAUST LENGTH

IN THE TABLE IN 1.1.21 “ALLOWABLE VENT

LENGTHS”.

The maximum exhaust length (or linear reference

length) can be calculated by summing the length

of the linear tube.

When terminating horizontally, install an elbow at

the end of the terminal. For area where snow is

a concern it is recommended to point the elbow

downwards.

90°

L= 3.9 in(100 mm)

Ø4.9 in (Ø125 mm)

Ø3.1 in (Ø80 mm)

fig. 20

fig. 21

Page 31

31

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

III (b) - KIT M&G VERTICAL CO-AXIAL

SYSTEM Ø3.1/4.9 in (Ø80/125 mm) INTERNAL

POLYPROPYLENE DUCT.

It allows exhaust and air intake directly from roof.

Suitable only for condensing boilers.

It allows exhaust and air intake for combustion

through co-axial ducts, the external one for air

intake, the plastic internal one for exhaust.

PLEASE SEE THE MAXIMUM EXHAUST LENGTH

IN THE TABLE IN 1.1.21 “ALLOWABLE VENT

LENGTHS”.

The maximum exhaust length (or linear reference

length) can be calculated by summing the length

of the linear tube.

Ø4.9 in (Ø125 mm)

Ø3.1 in (Ø80 mm)

fig. 22

fig. 23

Page 32

32

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

1. INSTALLATION

INSTALLER

1.1.22. TABLE 1: ALLOWABLE VENT LENGTHS

Vent

Configuration Pipe Size

Minimum

Length

Vertical and

Horizontal

for Vent Run

Max

Equivalent

length Vertical

and Horizontal

for vent run Gas Type Exhaust Vent Intake Vent

Co-axial vent Ø2.3/3.9”

(Ø60/100

mm)

1 ft (0.3 m) +

elbow

19 ft (6 m) +

elbow*

Natural or

Propane

Polypropylene Polypropylene

Co-linear vent

(2 Separate

pipes)****

2” (60 mm) 3.3 ft (1 m) 65 ft (20 m)** Natural or

Propane

PVC, CPVC,

Polypropylene

PVC, CPVC,

Polypropylene, ABS

Co-linear vent

(2 Separate

pipes)****

3” (80 mm) 3.3 ft (1 m) 150 ft (46 m) Natural or

Propane

PVC, CPVC,

Polypropylene

PVC, CPVC,

Polypropylene, ABS

Single vent 2” (60 mm) 1.6 ft (0.5 m) 36 ft (11 m)*** Natural or

Propane

PVC, CPVC,

Polypropylene

PVC, CPVC,

Polypropylene, ABS

Single vent 3” (80 mm) 1.6 ft (0.5 m) 100 ft (30 m) Natural or

Propane

PVC, CPVC,

Polypropylene

PVC, CPVC,

Polypropylene, ABS

* The domestic fan maximum speed adjustment (P11) must be changed to a value of 198 Hz and the heating fan

maximum speed adjustment (P13) must be changed to a value of 183 Hz with a total vent run of above 10 ft (3 m).

** The domestic fan maximum speed adjustment (P11) must be changed to a value of 198 Hz and the heating fan

maximum speed adjustment (P13) must be changed to a value of 183 Hz with a total vent run of above 22 ft (7 m).

*** The domestic fan maximum speed adjustment (P11) must be changed to a value of 198 Hz and the heating fan

maximum speed adjustment (P13) must be changed to a value of 183 Hz with a total vent run of above 19 ft (6 m).

**** Vent run consists of allowable vent length for exhaust pipe and an additional allowable vent length for combustible

ai r.

NOTE: In Canada, exhaust vent must be approved to ULC S636 standard.

EQUIVALENT LENGTHS

Each 2”/ 3” (60 mm / 80 mm) 45° elbow equates to 2.5 linear feet to vent pipe.

Each 2”/ 3” (60 mm / 80 mm) 90° short radius elbow equates to 7.5 linear feet to vent pipe.

Each 2”/ 3” (60 mm / 80 mm) 90° long radius elbow equates to 5 linear feet to vent pipe.

Each Ø2.3/3.9” (Ø60/100 mm) co-axial 90° short radius elbow equates to 5 linear feet to vent pipe.

The total maximum equivalent vent pipe distance cannot exceed the maximum length listed for horizontal

and vertical venting distance. The maximum lengths are not including elbows unless otherwise stated.

Exceeding the maximum venting distances will cause the appliance to malfunction or cause an unsafe

condition.

Page 33

All operations described below relative to first start-up,

maintenance and replacement and should be performed

only by qualified service technician.

1. SUPPORT CENTER SECTION

2. SEZIONE CENTRO ASSISTENZA

Page 34

34

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

2.1. FIRST START-UP

2.1.1. PRELIMINARY OPERATIONS

FOR FIRST START-UP

The first start-up operations consist of checking

the correct installation, adjustment and operation

of the device. Proceed as follows:

› Check the inner components and ensure

that they are sealed in accordance with the

specifications provided and by standard and

regulations.

› Check if the gas used is suitable for the boiler;

› Check if the gas capacity and relative pressures

comply with those on the rating plate;

› Check the operation of the safety device in case

of lack of gas;

› Make sure that the device supply voltage

corresponds with that on the plate (120 V – 60

Hz) and that the wiring is correct;

› Make sure that the grounding system works

properly;

› Make sure that the combustion air circulation,

exhaust and condensate discharge take place

properly in compliance with the Local and

National Laws and Standards in force;

› Make sure that the venting and their connections

and comply with the requirements of the Local

and National Laws and Standards;

› Make sure that the heating system valves are

open;

› Make sure that there is no intake of gaseous

products within the system;

› Make sure that there are no flammable liquids

or materials near the device;

› Open the boiler gas valve and make sure that

there are no gas leaks upstream from the device

(the burner gas connection must be checked

while the unit is running);

› In case of new installation of the gas supply

network, the air inside the gas line may lockout

the device at first start-up. Repeat the start-up

procedure to purge all the air inside the gas line.

Page 35

35

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

2.1.2. BOILER COMMISSIONING

WARNING

Make sure that the system is correctly

filled.

Proceed with boiler commissioning as follows:

› Power the boiler.

THE START-UP SYSTEM WILL AUTOMATICALLY

ACTIVATE THE SYSTEM AIR RELIEF CYCLE

FUNCTION DISPLAYED ON SCREEN WITH CODE

“F33” (ONLY AT FIRST START-UP WILL LAST FOR

5 MINUTES). When function “F33” is active, the

pump is enabled and the burner start-up request

is disabled. The boiler can work normally only

after completing the operation.

NOTE: Only at the first start-up the system relief

cycle performed by the boiler lasts 5 minutes.

After each water pressure reset the boiler will

automatically perform a reduced system relief

cycle, of 2 minutes. Throughout this function the

display will show the code “F33”. The boiler can

work normally only after completing the operation.

› Open the gas valve.

› Use the button ‘ ’ to select the desired

operation mode. If the symbol is displayed fixed,

it means that the function was activated.

› The burner will start as soon as the thermostat

contact is closed;

› If the flame is not sensed, the board will repeat

the start-up operations after post-ventilation

(20 seconds).

› You might have to repeat the start-up operation

several times to release all air inside the gas

lines. Before repeating the operation, wait at

least 5 seconds from the last start-up attempt

and unlock the boiler from “E01” error code by

pressing the Reset ‘ ’ key.

Page 36

36

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

2.1.3. CO2 VALUE CHECK AND

CALIBRATION

WARNING

The CO2 value should be measured with

the casing assembled, while the gas valve could only

be adjusted with the casing open.

To check and calibrate the CO2 value to minimum

and maximum heating power proceed as follows:

FOR MINIMUM HEATING POWER

› Enable chimney-sweep function holding the key

‘ ’ for 7 seconds (maximum operating time is

15 minutes), then press key ‘ ’ of the heating

circuit to set minimum power for heating

function, the display will show ‘Lo’.

› Insert the combustion analyser probe in the

provided exhaust tap ‘PF’ (fig. 24), then make

sure that the CO2 value complies with the

requirements indicated in 2.2.8 “Technical data”,

otherwise adjust using screw ‘A’ (fig. 25) and

adjust using a 4 Allen wrench the screw ‘2’ (fig.

25) of the Off-Set adjuster. To increase the CO

2

value, turn the screw clockwise and counterclockwise if you want to decrease it.

› Once completed the adjustment, tighten the

protection screw ‘A’ (fig. 25) on the Off-Set

adjuster.

FOR MAXIMUM HEATING POWER

› Press key ‘ ’ of the heating circuit to

set maximum power for heating function, the

display will show ‘HI’.

› Make sure that the CO2 value complies with the

indications in 2.2.8 “Technical data”, otherwise

adjust using screw ‘1’ (fig. 25) of the gas flow

adjuster. To increase the CO2 value, turn the

screw counter-clockwise and clockwise if you

want to decrease it.

› After each adjustment variation on screw ‘1’

(fig. 25) of the gas flow adjuster you have to wait

for the boiler to stabilize itself to the set value

(about 30 seconds).

› Then press key ‘ ’ of the heating circuit

to set minimum power for heating function and

check that CO2 value hasn’t changed, in case

it has changed, please repeat the setting as

described previously.

› Press the button ‘ ’ to deactivate the

chimney sweep function.

PF

1

2

A

fig. 24

fig. 25

Page 37

37

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

2.1.4 . ACCESSING AND PROGRAMMING THE PARAMETERS

To access the parameters menu and adjust their values, follow the procedure below:

1. Press the button ‘ ’ to select the OFF

mode displayed using the symbol ‘ ’.

2. Hold at the same time the keys ‘ ’ and ‘

’ until on the display appears the symbol ‘

’with the message ‘P00’, and release the keys

‘ ’ and ‘ ’.

3. Use the keys ‘ ’ and ‘ ’ of the heating

circuit to select the parameter to be edited.

fig. 26

fig. 27

fig. 28

Page 38

38

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

4. Use the keys ‘ ’ and ‘ ’ of the domestic

circuit to change the value of the parameter.

5. Press the key ‘ ’ to confirm the action and

wait for the display to stop blinking, indicating

the adjustment was implemented.

6. To exit the parameters menu, hold at the same

time the keys ‘ ’ and ‘ ’ and wait for the

symbol ‘ ’ to appear on the display.

fig. 29

fig. 30

fig. 31

Page 39

39

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

2.1.5. DIGITECH CS (MIAH402) PARAMETERS TABLE

PARAMETER DESCRIPTION RANGE FUNCTION

P00 BOILER MODEL SELECTION 0 - 10 0 - 7 = N.A.

8 = R2K 24 - R2KA 24/8

9 = R2K 34 - R2KA 34/2 0 - R1K 34/B

10 = R1K 55-R2K 55

P01 BOILER TYPE SELECTION 0 - 5 0 = INSTANTANEOUS > R2K

1 = N.A.

2 = ACCUMULATION (STORAGE)>

R1K /B - R2K A

3 = ACCUMULATION (STORAGE)

COMFORT > R1K /B - R2K A

4 = INSTANTANEOUS COMFORT -

FAST H2O> R2K

5 = HEATING ONLY> R1K 55

P02 GAS TYPE SELECTION

ATTENTION:

REA D THE INST RUCTION IN 2 .2.19 ‘CONVER SION TO A DIFF ERENT

GAS T YPE’ BEFOR E CHANGING THIS PAR AMETER.

0 - 1 0 = NATUR AL GAS (AND SE TS FAN

SPEED SETTING AT PARAMETERS

P10 - P11 - P12 - P13)

1 = PROPANE (AND SETS FAN

SPEED SETTING AT PARAMETERS

P10 - P11 - P12 - P13)

P03 SETTING THE HEATING TEMPERATURE

IN CASE THE BOILER IS INSTALLED AS PART OF A LOW

TEMPERATURE CIRCUIT, PLE ASE INSTALL A SAFET Y

THERMOSTAT ON THE HE ATING FLOW, WHICH CAN STOP

THE BOILER ACTI VIT Y IN CASE OF HIGH HEATING FLOW

TEMPERATURE. THE COMPANY ASSUMES NO LIABILITY FOR

DAMAGE CAUSED TO PERSONS OR FOR FAILURE TO COMPLY

WITH THESE INSTRUCTIONS.

0 - 1 0 = STANDARD 86-176 °F (30-80 °C)

(SET BY DEFAULT)

1 = REDUCED 77-113 °F (25-45 °C)

FOR FLOOR SYSTEMS

Page 40

40

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

PARAMETER DESCRIPTION RANGE FUNCTION

P04 HEATING RUN-UP

THROUGH THIS PARAMETER YOU CAN SET THE TIME, DURING

START-UP PHASE, NECESS ARY FOR THE BOILER TO REACH THE

MA XIMUM SE T POWER (ON THE HEATING SIDE).

0 - 4 0 = (DISA BLED)

1 = 50 SECONDS

(SET BY DEFAULT)

2 = 100 SECONDS

3 = 200 SECONDS

4 = 400 SECONDS

P05 ANTI-WATER HAMMER SELECTION

ONCE THIS FUNCTION IS ENABLED, THE DHW CONTACT WILL BE

DELAYED FOR A TIME EQUAL TO THE SET VALUE.

0 - 20 0 = DISA BLED

1 - 20 = THE VALUE IS EXPRESSED

IN SECONDS

P06 DOMESTIC CIRCUIT PRESERVATION FUNCTION

(ONLY FOR INSTANTANEOUS BOILER)

THROUGH THIS PARAMETER YOU CAN PRESERVE THE

CIRCUL ATOR THE DIVERTER VALVE IN DOMESTIC POSITION

FOR A PERIOD OF TIME EQUAL TO THE POST-CIRCULATION

(SEE PARAMETER P09), SO AS TO M AINTAIN THE SECONDARY

EXCHANGER HOT.

0 - 1 0 = DISA BLED

(SET BY DEFAULT)

1 = ENABLED

P07 HEATING TIMING

THROUGH THIS PARAMETER YOU CAN SET THE MINIMUM

TIME FOR WHICH THE BURNER WILL BE TURNED OFF ONCE

THE HE ATING TEMPERATURE REACHED THE USER SET

TEMPERATURE.

0 - 90 VALUE EXPRESSED IN MULTIPLES

OF 5 SECONDS

(PRE-SE T AT 36 X 5 = 180 SECONDS)

P08 POST-CIRCULATION HEATING TIMING

THROUGH THIS PARAME TER YOU CAN SET THE PUMP DURATION

OF OPER ATION DURING HEATING CYCLE, A FTER THE MAIN

BURNER T URNS OFF DUE TO THE ENVIRONMENT THERMOSTAT.

0 - 90 VALUE EXPRESSED IN MULTIPLES

OF 5 SECONDS

(PRE-SE T AT 36 X 5 = 180 SECONDS)

P09 POST-CIRCULATION DOMESTIC / BOILER TIMING

THROUGH THIS PARAMETER YOU CAN SET THE PUMP

OPER ATION DUR ATION ON THE DOMESTIC CIRCUIT, AFTER THE

TAP IS CLOSED.

0 - 90 VALUE EXPRESSED IN MULTIPLES

OF 5 SECONDS

(PRE-SE T AT 18 X 5 = 90 SECONDS)

Page 41

41

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

PARAMETER DESCRIPTION RANGE FUNCTION

P10 DOMESTIC FAN MINIMUM SPEED ADJUSTMENT

THROUGH THIS PARAMETER YOU CAN SET THE FAN MINIMUM

SPEED IN DOMESTIC PHASE, THAT CORRESPONDS TO THE

MINIMUM BURNER POW ER DURING A REQUEST TO OPERATE

IN DOMESTIC MODE. [SEE 2.1.6 ‘COMBUSTION BLOWER

FREQUENCY/HEAT CAPACITY DIAGRAM’].

THE VALUE IS PRE-SE T BASED ON THE SET POWER (SEE

PARAMETER P00) A ND ON THE GAS T YPE (SEE PARAMETER P 02).

45 - VALUE

SET FOR

PARAMETER

P11

THE VALUE IS EXPRESSED IN

HERTZ

(1HZ = 30 RPM)

P11 DOMESTIC FAN MAXIMUM SPEED ADJUSTMENT

THROUGH THIS PARAMETER YOU CAN SET THE FAN MA XIMUM

SPEED IN DOMESTIC PHASE, THAT CORRESPONDS TO THE

MA XIMUM BURNER POWER DURING A REQUEST TO OPERATE IN

DOME STIC MODE [S EE 2.1.6 ‘C OMBUSTI ON BLOWER F REQUENCY/

HEAT CA PACIT Y DIAGR AM’].

THE VALUE IS PRE-SE T BASED ON THE SET POWER (SEE

PARAMETER P00) A ND ON THE GAS T YPE (SEE PARAMETER P 02).

VALUE

SET FOR

PARAMETER

P10 - 203

THE VALUE IS EXPRESSED IN

HERTZ

(1HZ = 30 RPM)

P12 HEATING FAN MINIMUM SPEED ADJUSTMENT

THROUGH THIS PARAMETER YOU CAN SET THE FAN MINIMUM

SPEED IN HEATING PHASE, THAT CORRESPONDS TO THE

MINIMUM BURNER POW ER DURING A REQUEST TO OPERATE IN

HEATING MODE. [SEE 2.1.6 ‘COMBUSTION BLOWER FREQUENCY/

HEAT CA PACIT Y DIAGR AM’].

THE VALUE IS PRE-SE T BASED ON THE SET POWER (SEE

PARAMETER P00) A ND ON THE GAS T YPE (SEE PARAMETER P 02).

45 - VALUE

SET FOR

PARAMETER

P13

THE VALUE IS EXPRESSED IN

HERTZ

(1HZ = 30 RPM)

P13 HEATING FAN MAXIMUM SPEED ADJUSTMENT

THROUGH THIS PARAMETER YOU CAN SET THE FAN MA XIMUM

SPEED IN HEATING PHASE, THAT CORRESPONDS TO THE

MA XIMUM BURNER POWER DURING A REQUEST TO OPERATE IN

HEATING MODE [SEE 2.1.6 ‘COMBUSTION BLOWER FREQUENCY/

HEAT CA PACIT Y DIAGR AM’].

THE VALUE IS PRE-SE T BASED ON THE SET POWER (SEE

PARAMETER P00) A ND ON THE GAS T YPE (SEE PARAMETER P 02).

VALUE

SET FOR

PARAMETER

P12 - 203

THE VALUE IS EXPRESSED IN

HERTZ

(1HZ = 30 RPM)

P14 STARTING STEP ADJUSTMENT

THROUGH THIS PARAMETER YOU CAN SET THE FAN SPEED

DURING START-UP.

THE VALUE IS PRE-SE T BASED ON THE SET POWER (SEE

PARAMETER P00) A ND ON THE GAS T YPE (SEE PARAMETER P 02).

VALUE

SET FOR

PARAMETER

P10 - 203

THE VALUE IS EXPRESSED IN

HERTZ (1HZ = 30 RPM) - (PRE-SET

AT 120 HZ)

Page 42

42

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

PARAMETER DESCRIPTION RANGE FUNCTION

P15 ANTI-LEGIONELLA FUNCTION

(ONLY FOR ACCUMULATION BOILER)

THROUGH THIS PARAMETER YOU CAN ACTIVATE/DEACTIVATE

“ANTI LEGIONELL A” HEAT TRE ATMENT OF THE ACCUMULATION

BOILER. EVERY 7 DAYS THE WATER TEMPERATURE INSIDE THE

ACCUMULATION BOILER IS HEATED BE YOND 140 °F (60 °C) THUS

GENER ATING A BURNING HAZ ARD. KEEP UNDER CONTROL

SUCH DOMESTIC HOT WATER TRE ATMENT ( AND INFORM THE

USERS) TO AVOID UNFORESEEABLE DA MAGES TO PERSONS,

ANIMALS, PROPERT Y. A THERMOSTATIC VALVE SHOULD BE

INSTALLED AT THE DOMESTIC HOT WATER OUTLET TO AVOID

ANY BURNS.

0 - 1 0 = DISA BLED

1 = ENABLED (PRE-SET BY

DEFAULT ON ACCUMULATION

BOILERS)

Page 43

43

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

PARAMETER DESCRIPTION RANGE FUNCTION

P16 CLIMATE COMPENSATION CURVE

(ONLY WITH EXTERNAL PROBE CONNECTED)

YOU CAN CONNECT AN EXTERNAL TEMPER ATURE PROBE (SEE

1.1.16 ‘ELECTRICAL CONNECTIONS’) THAT AUTOMATICALLY

CHANGES THE DELIVERY TEMPERATURE BASED ON THE

EX TERNAL MEA SURED TEMPERATURE. THE NATURE OF THE

CORRECTION DEPENDS ON THE THERMO-A DJUSTMENT VALUE

KD SET (SEE CHA RT).

THE SELECTION OF THE CURVE IS DETERMINED BY THE

MA XIMUM DELIVERY TEMPERATURE TM AND THE MINIMUM

EX TERNAL TEMPERATURE TE TAKING INTO ACCOUNT THE

HOUSE INSULATION DEGREE.

THE VALUES OF THE DELIVERY TEMPERATURES TM, REFER TO

STANDARD SYSTEMS 86-176 °F (30-80 °C) OR FLOOR SYSTEMS

77-113 °F (25-45 °C). THE SYSTEM TYPE CAN BE SET FROM

PARAMETER P03.

0 - 30 (SET BY DEFAULT AT 15) THE

NUMBERING OF THE VALUE

CORRESPONDS TO ‘KD’ CURVES

ON THE CHART (SEE CHART

BELOW).

P17 SETS THE TEMPERATURE MEASUREMENT UNIT

THROUGH THIS PARAMETER YOU CAN SET THE TEMPER ATURE

MEA SUREMENT UNIT DISPLAYED: CELSIUS (°C) OR FAHRENHEIT

(°F) DEGREES.

0 - 1 0 = °C

1 = °F

P18 ENABLING BUS INDUSTRIAL PILOTING 0 -10V

THROUGH THIS PARAMETER YOU CAN ENABLE OR DISABLE THE

BUS INDUSTRIA L INPUT 0-10 V TO SET THROUGH E XTERN AL BUS

THE BURNER POWER OR THE DELIVERY TEMPER ATURE.

0 - 2 0 = DISA BLED

(SET BY DEFAULT)

1 = TEMPERATURE CONTROL MODE

2 = POWER CONTROL MODE

Te (°F)

958677685950

167

176

113 MAX

Tm (°F)

41

32

23

14

149

131

140

122

104

113

95

86

86

5-4

77

MIN

95

158

Kd = 0

Kd = 5

Kd = 10

Kd = 15

Kd = 20

Kd = 25

Kd = 30

fig. 32

Page 44

44

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

PARAMETER DESCRIPTION RANGE FUNCTION

P19 MINIMUM HEATING SETPOINT

THROUGH THIS PARAMETER YOU CAN SET THE USER-

ADJUSTABLE MINIMUM HEATING TEMPER ATURE.

20 - 40 THE VALUE IS EXPRESSED IN °C

P20 MAXIMUM HEATING SETPOINT

THROUGH THIS PARAMETER YOU CAN SET THE USER-

ADJUSTABLE MAXIMUM HEATING TEMPER ATURE.

40 - 90 THE VALUE IS EXPRESSED IN °C

P21 MAXIMUM DOMESTIC SETPOINT

THROUGH THIS PARAMETER YOU CAN SET THE USER-

ADJUSTABLE MAXIMUM DOMESTIC TEMPERATURE.

45 - 75 THE VALUE IS EXPRESSED IN °C

P22 SET POINT ∆T DELIVERY-RETURN

(ONLY WITH MODULATING PUMP AND RETURN PROBE CONNECTED)

THROUGH THIS PARAMETER YOU CAN SET THE TEMPER ATURE

DIFFERENCE BETWEEN DELIVERY AND RETURN.

0 0 = DISA BLED

10 - 40 THE VALUE IS EXPRESSED IN °C

P23 MODUL ATING PUMP MINIMUM SPEED

(ONLY WITH MODULATING PUMP AND RETURN PROBE CONNECTED)

THROUGH THIS PARAMETER YOU CAN SET THE MINIMUM SPEED

VALUE OF THE MODULATING PUMP DURING A REQUEST TO

OPER ATE IN HEATING MODE.

50 - 70 THE VALUE IS EXPRESSED IN

PERCENTAGE

P24 MODUL ATING PUMP MAXIMUM SPEED

(ONLY WITH MODULATING PUMP AND RETURN PROBE CONNECTED)

THROUGH THIS PARAMETER YOU CAN SET THE MAX IMUM

SPEED VALUE OF THE MODULATING PUMP DURING A REQUEST

TO OPER ATE IN HEATING MODE.

70 - 100 THE VALUE IS EXPRES SED IN

PERCENTAGE

P25 CONTROL PERIOD ∆T DELIVERY-RETURN

(ONLY WITH MODULATING PUMP AND RETURN PROBE CONNECTED)

THROUGH THIS PARAMETER YOU CAN SET THE RESPONSE TIME

TO THE PUMP MODULATION.

20 - 100 THE VALUE IS EXPRES SED IN

SECONDS

P26 OUTDOOR RESET FUNCTION 0 - 1 0 = 86-176 °F (30-80 °C)

1 = STANDARD RESE T FUNCTION

77-140 °F (25-60 °C) WITHOUT

OUTDOOR TEMPERATURE SENSOR

OR 86-176 °F (30-80 °C) WITH

OUTDOOR TEMPERATURE SENSOR

(SET BY DEFAULT).

Page 45

45

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. FIRST START-UP

SUPPORT CENTER

2.1.6. COMBUSTION BLOWER FREQUENCY/HEAT CAPACITY DIAGRAM

GAS TYPE

MINIMUM

HEATING

FREQUENCY

MAXIMUM

HEATING

FREQUENCY

MINIMUM

FREQUENCY IN

DOMESTIC HOT

WATER LINE

MAXIMUM

FREQUENCY IN

DOMESTIC HOT

WATER LINE

N a t u r a l

Gas

Hz 43 182 43 182

Propane Hz 43 174 43 174

(btu/h)

Natural Gas

Propane

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

35 50 65 80 95 110 125 140 155 170 185

(kW)

13648

20472

27297

34121

40945

47769

54594

61418

68242

75067

81891

88715

95539

10236

10918

11601

(Hz)

fig. 33

Page 46

46

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. MAINTENANCE

SUPPORT CENTER

2.2. MAINTENANCE

2.2.7. GENERAL MAINTENANCE

WARNINGS

ATTENTION

All maintenance operations must be

performed by qualified staff and authorized by

RADIANT BRUCIATORI spa.

WARNING

The maintenance operations must be

performed once every twelve months starting from

the boiler installation date.

WARNING

To ensure longer life span and proper

operation of the device, during the maintenance

operations use only original spare parts.

DANGER

Before each components cleaning or

replacement operation, ALWAYS cut off the POWER,

WATER and GAS supply of the boiler.

Please perform the following operations once a year:

› check the sealing of the gas components, and

replace the gaskets if necessary;

› check the sealing of the water components, and

replace the gaskets if necessary;

› visually check the flame and the condition of the

combustion chamber;

› if necessary make sure that the combustion is

adjusted correctly and if required proceed as

indicated in section 2.1.3 “CO2 VALUE CHECK AND

CALIBRATION”;

› remove and clean the burner from oxidation;

› check the integrity and the position of the sealed

chamber sealing gasket;

› check the primary exchanger, if necessary, clean

it;

› check the operation of the gas burner start up

and safety systems. If necessary, remove and

clean the flame detection and start up electrodes

from incrustations paying attention to respect the

distances with respect to the burner;

› check the heating circuit safety systems: limit

temperature safety thermostat; limit pressure

safety;

› check the pre-load pressure of the expansion tank;

› make sure that the permanent ventilation outlets

are present, correctly sized and functioning, based

on the installed devices. Follow the requirements

provided by Local and National legislation;

› periodically check the integrity of the venting

system for safety and proper operation;

› check that the wiring is installed in compliance with

the requirements in the boiler instruction manual;

› check the wiring inside the control panel;

› check the flow and temperature of domestic hot

water;

› check the proper operation of the condensate

draining system, including the devices outside

the boiler such as condensate collection

devices installed along the path of the venting or

neutralization devices for acid condensate.

› check that the liquid flow is not obstructed and

that there is on combustion gas build up inside the

internal system.

Page 47

47

R1K 34 /B - RAD - ING - Manuale - 1512.2_CSA_TTS

2. MAINTENANCE

SUPPORT CENTER

2.2.8. TECHNICAL DATA

Model R1K 34 /B

Maximum nominal heat capacity in heating circuit btu/h - (kW) 116013 - (34)

Maximum nominal heat capacity in domestic circuit btu/h - (kW) 116013 - (34)

Minimum nominal heat capacity in heating circuit btu/h - (kW) 15013 - (4.4)

Minimum nominal heat capacity in domestic circuit btu/h - (kW) 15013 - (4.4)

Useful thermal power - 140/176°F (60/80°C) btu/h - (kW) 113215 - (33.18)

Minimum useful thermal power - 140/176°F (60/80°C) btu/h - (kW) 14706 - (4.31)

Performance at 100% Pn - 140/176°F (60/80°C) % 9 7.6

Fumes temperature at nominal heat capacity °F - (°C) 161.96 (72.2)

Fumes temperature at minimum heat capacity °F - (°C) 144.68 (62.6)

CO2 at nominal heat capacity - Natural Gas min-max % 9.2 - 9.5

CO2 at minimum heat capacity - Natural Gas min-max % 8.9 - 9.2

CO2 at nominal heat capacity - Propane min-max % 10.3 - 10.6

CO2 at minimum heat capacity - Propane min-max % 10 - 10.3

CO at nominal heat capacity ppm 78

CO at minimum heat capacity ppm 1

Heating circuit

Adjustable heating temperature °F - (°C) 86-176 / 77-113

(30-80 / 25-45)

Maximum operating temperature for heating circuit °F - (°C) 203 - (95)

Maximum operating pressure for heating circuit psi - (bar) 60 - (4.1)