Page 1

R1K 18 - RAD - ING - Manuale - 1706.1_V3

Installation, Use

and Maintenance Manual

for model

0476

R1K 18

Premix condensing system boiler

only heating

Page 2

44

R1K 18 - RAD - ING - Manuale - 1706.1_V3

2 Dati tecnici_R1K 18_ErP_EN15502_EN

2. MAINTENANCE

SUPPORT CENTRE

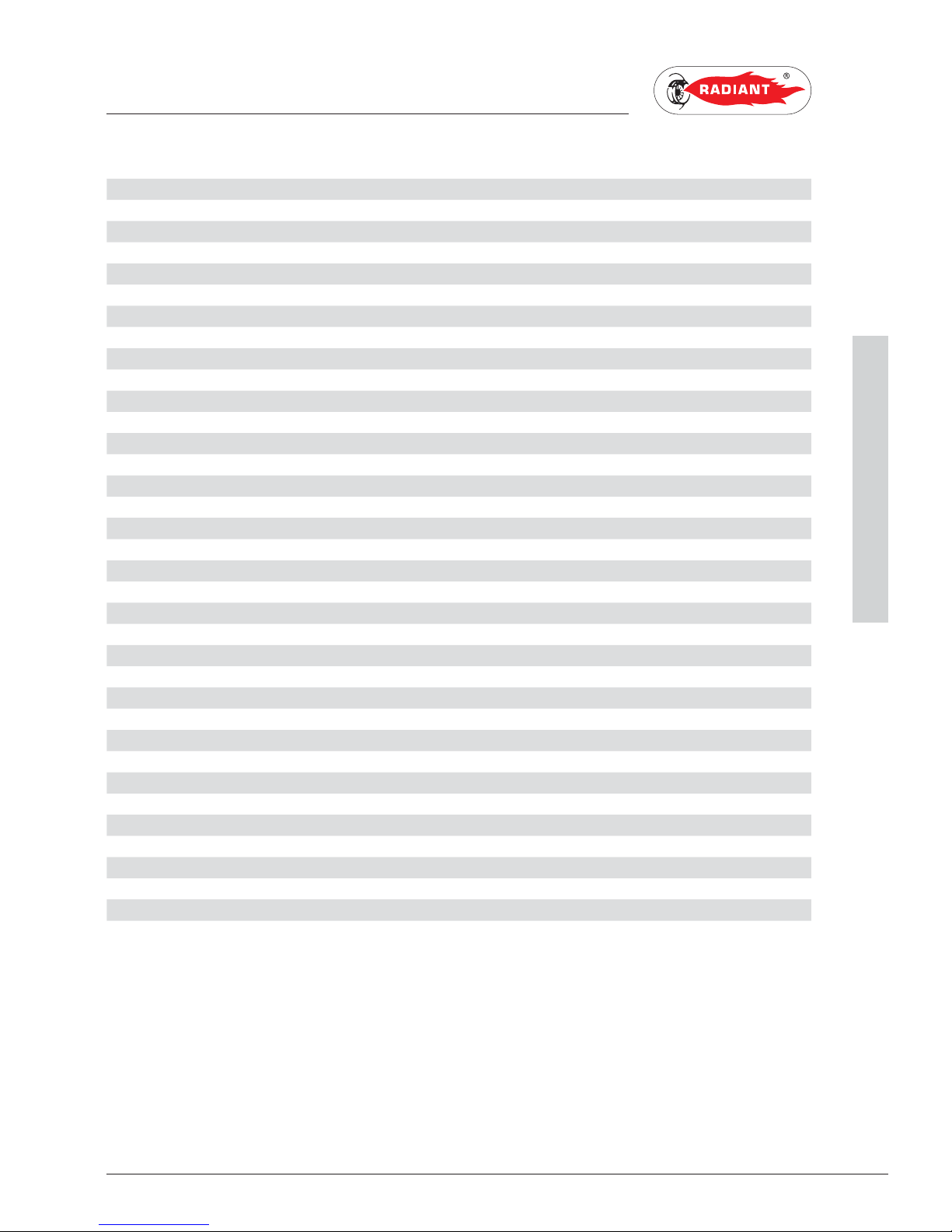

2.2.8. TECHNICAL DATA

Model R1K 18

CE certification no. 0476CQ0134

Gas category 0 II2H3B/P

Discharge type type B23p-B 33 - C13 - C 3 3- C 4 3-

C53-C63-C83-C93

Energy efficiency 92/42 CEE no. stars 4

Energy efficiency EN13203-1 no. stars 3

Maximum nominal heat capacity in heating circuit kW 18

Minimum nominal heat capacity in heating circuit kW 2.9

Useful thermal power - 60/80°C kW 17.4

Minimum useful thermal power - 60/80°C kW Useful thermal power - 30/50°C kW 18.99

Performance at 100% Pn - 60/80°C % 96.4

Performance at 30% Pn - return 47°C % Performance at 30% Pn - return 30°C % 107.5

Performance at 100% Pn - 30/50°C % 105.5

Maximum combustion Performance % 97.4

Fumes temperature at nominal heat capacity °C 73.65

Fumes temperature at minimum heat capacity °C 65.7

CO2 at nominal heat capacity - G20 % 9,3 - 9,1

CO2 at minimum heat capacity - G20 % 9 - 8,8

CO2 at nominal heat capacity - G30 % 11,4 - 11,2

CO2 at minimum heat capacity - G30 % 10,9 - 10,7

CO2 at nominal heat capacity - G31 % 10,5 - 10,3

CO2 at minimum heat capacity - G31 % 10,2 - 10

CO at nominal heat capacity ppm 67

Fumes mass at nominal heat capacity g/s 7.44

Fumes mass at minimum heat capacity g/s 1.26

NOx class class 6

Weighted Nox (0% O2) mg/kWh mg/kWh 35

Heating circuit

Adjustable heating temperature °C 30-80 / 25-45

Maximum operating temperature for heating circuit °C 80

Maximum operating pressure for heating circuit bar 3

Minimum operating pressure for heating circuit bar 0.3

Capacity of the system expansion vessel litres 8

Dimensional characteristics

Width mm 410

Depth mm 307

Height mm 642

Gross weight Kg 35

Water connections

Flow Ø 3/4”

Cold water Ø 1/2”

Gas Ø 3/4”

Page 3

45

R1K 18 - RAD - ING - Manuale - 1706.1_V3

2 Dati tecnici_R1K 18_ErP_EN15502_EN

2. MAINTENANCE

SUPPORT CENTRE

Return Ø 3/4”

Fume exhaust fittings

Maximum electric fan pressure available Pa 100

Minimum electric fan pressure available Pa 21

Max discharge length Ø60/100 - Hor Co-ax m 10

Max discharge length Ø80/125 - Hor Co-ax m 12

Max discharge length Ø50/50 - Hor Split m 10

Max discharge length Ø60/60 - Hor Split m 32

Max discharge length Ø80/80 - Hor Split m 60

Max discharge length Ø50 - Hor duct m 8

Max discharge length Ø60 - Hor duct m 30

Max discharge length Ø80 - Hor duct m 35

Max discharge length Ø60/100 - Vert Co-ax m 10

Max discharge length Ø80/125 - Vert Co-ax m 12

Max discharge length Ø50/50 - Vert Split m 10

Max discharge length Ø60/60 - Vert Split m 32

Max discharge length Ø80/80 - Vert Split m 60

Max discharge length Ø50 - Vert duct m 8

Max discharge length Ø60 - Vert duct m 30

Max discharge length Ø80 - Vert duct m 35

Electrical specifications

Voltage-frequency V/Hz 230/50

Max Absorbed Power W 78

Insulation rate IP X5D

Gas supply

Nominal supply pressure - G20 mbar 20

Heating Max. fan speed - G20 Hz 156

Heating Min. fan speed - G20 Hz 45

Fuel consumption - G20 m

3

/h 1.90

Nominal Supply pressure - G30 mbar 30

Heating Max. fan speed - G30 Hz 141

Heating Min. fan speed - G30 Hz 45

Fuel consumption - G30 kg/h 1.42

Nominal Supply pressure - G31 mbar 37

Heating Max. fan speed - G31 Hz 150

Heating Min. fan speed - G31 Hz 45

Fuel consumption - G31 kg/h 1.40

Page 4

46

R1K 18 - RAD - ING - Manuale - 1706.1_V3

2 Dati tecnici_R1K 18_ErP_EN15502_EN

2. MAINTENANCE

SUPPORT CENTRE

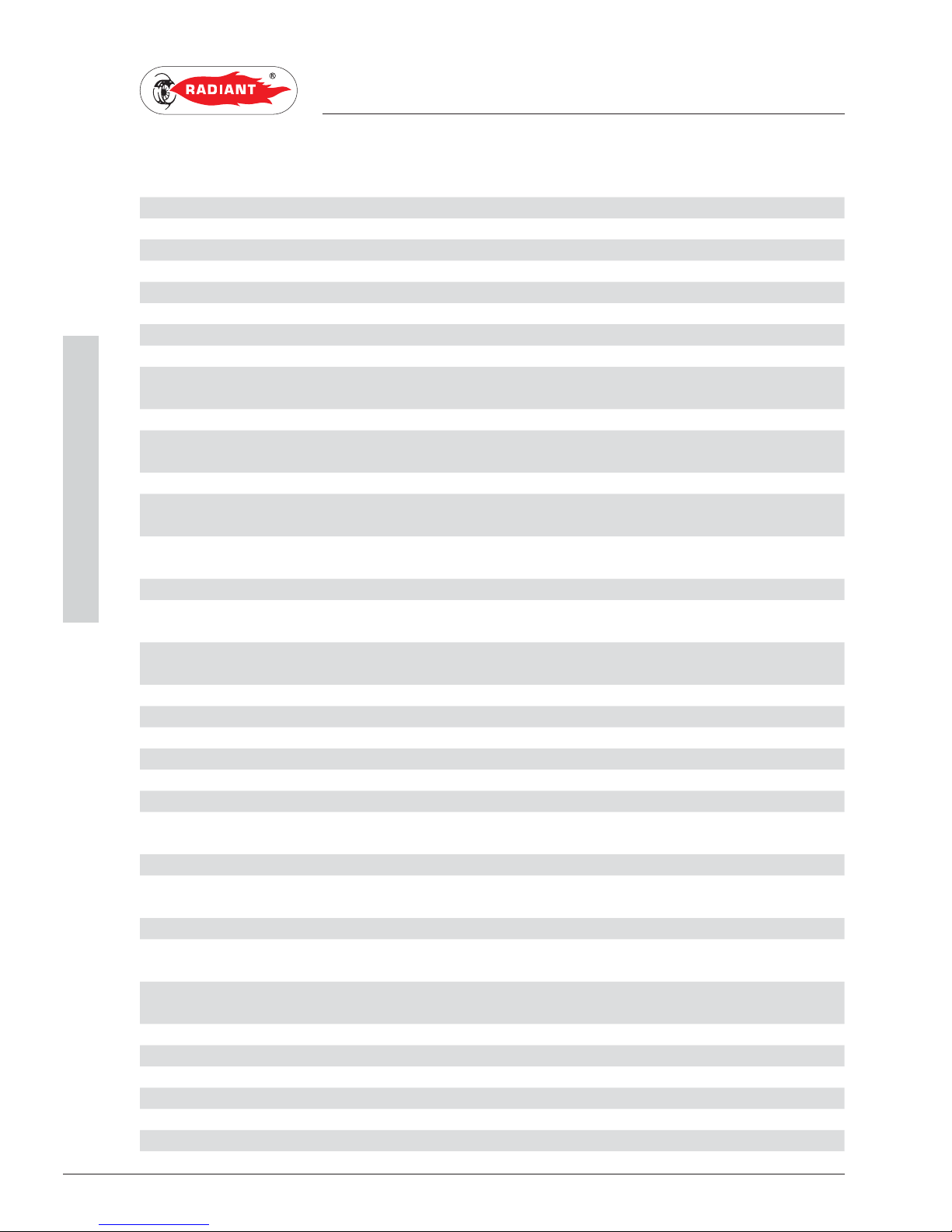

Technical parameters for boiler space heaters, boiler combination heaters and cogeneration

space heaters

Model R1K 18

Condensing boiler

Low-temperature (**) boiler:

B11 boiler

Cogeneration space heater

If yes, equipped with a supplementary heater

Combination heater

Rated heat output Prated

[yes/no] yes

[yes/no] no

[yes/no] no

[yes/no] no

[yes/no] no

[yes/no] no

kW

17.40

For boiler space heaters and boiler combination

heaters: Useful heat output

At rated heat output and high-temperature regime (*) P

4

kW 17.40

At 30 % of ra ted he at ou tp ut an d l ow- te mpe ra tur e r egi me (* *)

P

1

kW 5.40

For cogeneration space heaters: Useful heat output

At rated heat output of cogeneration space heater with

supplementary heater disabled P

CHP100+Sup0

kW -

At rated heat output of cogeneration space heater with

supplementary heater enabled P

CHP100+Sup100

kW -

)RUFRJHQHUDWLRQVSDFHKHDWHUV(OHFWULFDOHI¿FLHQF\

At rated heat output of cogeneration space heater with

VXSSOHPHQWDU\KHDWHUGLVDEOHGȘ

el,CHP100+Sup0

%-

At rated heat output of cogeneration space heater with

VXSSOHPHQWDU\KHDWHUHQDEOHGȘ

el,CHP100+Sup100

%-

$X[LOLDU\HOHFWULFLW\FRQVXPSWLRQ

At full load elmax kW 0.04

At part load elmin kW 0.02

In standby mode PSB kW 0.004

6HDVRQDOVSDFHKHDWLQJHQHUJ\HI¿FLHQF\Ș

s

%91

6HDVRQDOVSDFHKHDWLQJHQHUJ\HI¿FLHQF\FODVV A

For boiler space heaters and boiler combination heaters:

8VHIXOHI¿FLHQF\

$WUDWHGKHDWRXWSXWDQGKLJKWHPSHUDWXUHUHJLPHȘ

4

%86.9

At 30 % of rated heat output and low-temperature regime

Ș

1

%96.8

)RUFRJHQHUDWLRQVSDFHKHDWHUV8VHIXOHI¿FLHQF\

At rated heat output of cogeneration space heater with

VXSSOHPHQWDU\KHDWHUGLVDEOHGȘ

CHP100+Sup0

%-

At rated heat output of cogeneration space heater with

VXSSOHPHQWDU\KHDWHUHQDEOHGȘ

CHP100+Sup100

%-

6XSSOHPHQWDU\KHDWHU

Rated heat output Psup kW Type of energy input -

Other items

Standby heat loss P

stby

kW 0.1

Ignition burner power consumption P

ign

kW 0.0

Page 5

47

R1K 18 - RAD - ING - Manuale - 1706.1_V3

2 Dati tecnici_R1K 18_ErP_EN15502_EN

2. MAINTENANCE

SUPPORT CENTRE

Annual energy consumption Q

HE

kWh / GJ 15833 / 57

Sound power level, indoors L

WA

dB 52

For combination heaters:

'+:HQHUJ\HI¿FLHQF\FODVV -

'HFODUHGORDGSUR¿OH Daily electricity consumption Q

elec

kWh -

Annual electricity consumption AEC kWh -

:DWHUKHDWLQJHQHUJ\HI¿FLHQF\Ș

wh

%-

Daily fuel consumption Q

fuel

kWh Annual fuel consumption AFC GJ Contact details Tel. +39 0721 9079.1 - fax. +39 0721

9079299 - e-mail: info@radiant.it - http://

www.radiant.it

Name and address of the supplier RADIANT BRUCIATORI S.p.A.

Via Pantanelli, 164/166 - 61025 -

Montelabbate (PU)

(*) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature

at heater outlet.

(**) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for

other heaters 50 °C return temperature (at heater inlet).

Page 6

48

R1K 18 - RAD - ING - Manuale - 1706.1_V3

2 Complessivo tecnico_R1K 18_V3_EN

2. MAINTENANCE

SUPPORT CENTRE

2.2.9. TECHNICAL ASSEMBLY

KEY

1. FUMES SAFETY THERMOFUSE

2. HEAT EXCHANGER

3. BURNER UNIT

4. DETECTION ELECTRODE

5. ELECTRIC FAN

6. AIR RELIEF VALVE

7. SAFETY VALVE 3 bar

8. MODULATING PUMP

9. GAS VALVE

10. SYSTEM DRAINING TAP

11. SA F ET Y THERMOSTAT

12. HEATING PROBE

13. LIGHT UP ELECTRODE

14. EXPANSION TANK

15. START-UP TRANSFORMER

16. AIR SUCTION TUBE

17. PROPORTIONAL VENTURI

18. WATER PRESSURE SWITCH

19. CONDENSATE COLLECTION SIPHON

20. SYSTEM FILLING TAP

1

2

3

4

5

6

7

8

9

10

6

11

12

13

14

16

15

17

19

18

20

Page 7

49

R1K 18 - RAD - ING - Manuale - 1706.1_V3

2 Schema idraulico_R1K_EN

2. MAINTENANCE

SUPPORT CENTRE

2.2.10. HYDRAULIC BOARD

KEY

R. HEATING RETURN

G. GAS INLET

SC. CONDENSATE DRAIN

F. COLD WATER INLET

A. HEATING FORWARD

1. FUMES SAFETY THERMOFUSE

2. HEAT EXCHANGER

3. BURNER UNIT

4. ELECTRIC FAN

5. GAS VALVE

6. AIR RELIEF VALVE

7. CIR C U L ATOR

8. SAFETY VALVE 3 bar

9. SYSTEM DRAINING TAP

10. HEATING PROBE

11. SA F ET Y THERMOSTAT

12. EXPANSION TANK

13. AIR SUCTION TUBE

14. PROPORTIONAL VENTURI

15. WATER PRESSURE SWITCH

16. CONDENSATE COLLECTION SIPHON

17. BY-PASS

18. SYSTEM FILLING TAP

R

F

A

G

1

2

3

4

6

7

8

9

6

10

11

12

13

14

15

17

18

sc

5

16

Page 8

61

R1K 18 - RAD - ING - Manuale - 1706.1_V3

3 Pannello comandi_solo risc_MIAH4_R2_G_EN

3. USE

USER

3.1.2. CONTROL PANEL

KEY

1. HEATING TEMPERATURE ADJUSTMENT

KEYS.

2. INFO KEY: PRESS ONCE TO VIEW THE

TEMPERATURES AND OTHER INFORMATION

(see chapter ‘INFO MENU DISPLAY) - HOLD

FOR 5 SECONDS, IN OFF OPERATING MODE,

TO VIEW THE LAST 5 FAULTS.

3. OPERATING MODE SELECTION KEY: ONLY

HEATING / OFF.

4. RESET KEY: FAULTS RESET - CHIMNEY

SWEEP FUNCTION ACTIVATION (HOLD FOR 7

SECONDS).

5. VALUE OF THE PARAMETERS ADJUSTMENT

KEY / HOLD THE KEYS AT THE SAME TIME

FOR 5 SECONDS TO ACTIVATE DISPLAY BACK

LIGHT FOR 10 MINUTES.

6. DISPLAY

5

1

6

2 3 4

Page 9

62

R1K 18 - RAD - ING - Manuale - 1706.1_V3

3 Icone del display_solo risc_MIAH4_EN

3. USE

USER

3.1.3. DISPLAY ICONS

KEY

1. INDICATION OF PARAMETER NUMBER OR

DISPLAYED INFO CODE

2. PARAMETERS PROGRAMMING FUNCTION

ACTIVE

3. SIGNALLING CONNECTED SOLAR BOARD /

SOLAR COLLECTOR TEMPERATURE DISPLAY

(d5)

4. SOLAR PUMP ACTIVE

5. BOILER LOWER TEMPERATURE DISPLAY (d6)

/ BOILER UPPER TEMPERATURE DISPLAY

(d7)

6. EXTERNAL PROBE INSTALLED / EXTERNAL

PROBE TEMPERATURE (d1)

7. TEMPERATURE DISPLAY / SET POINT /

PARAMETER VALUE

8. OPEN THERM COMMUNICATION PRESENT

(REMOTE CONTROL / AREA CONTROL UNIT)

9. INSUFFICIENT SYSTEM WATER PRESSURE

SIGNALLING

10. FLAME PRESENT SIGNALLING / IT ALSO

INDICATES, ON 3 PERCENTAGE LEVELS, THE

MODULATING POWER LEVEL OF THE BOILER

(fig.2)

11. ERROR DISPLAY THAT CAN BE RESET

12. OFF OPERATING MODE

13. ERROR DISPLAY THAT CAN NOT BE RESET

14. OPERATION IN HEATING MODE ENABLED

456 7

9

10

111213

14

1

2

3

8

≤ 33% >33%<66% >66%<100%

fig. 1

fig. 2

Page 10

63

R1K 18 - RAD - ING - Manuale - 1706.1_V3

3 Visualizzazioni del menù Info_MIAH4_EN

3. USE

USER

3.1.4. INFO MENU DISPLAY DATA

To view the boiler data from info menu you just have to press the INFO ‘ ’ key. The info code will be

displayed on the left side of the screen and its relative value will be displayed on the centre of the screen.

Use keys ‘

’ and ‘ ’ of the heating circuit to scroll through the list of displayed data. To exit display

mode press the INFO ‘

’ key.

LIST OF DISPLAYED DATA

INFO CODE ICON DESCRIPTION

d0 DOMESTIC CIRCUIT PROBE TEMPERATURE

d1 E XTERNA L PROBE TEMPERATURE

d2 FAN SPEED

d3 BOTTOM AREA PROBE TEMPERATURE [IF AREA BOARD INSTALLED]

d4 RETURN PROBE TEMPERATURE

d5 SOL AR COLLECTOR TEMPERATURE [IF SOLAR BOARD INSTALLED] (SCS)

d6 SOL AR BOILER TEMPER ATURE (BOTTOM) [IF SOL AR BOARD INS TALLED] (SBSI)

d7 SOL AR BOILER TEMPER ATURE (TOP) [IF SOLAR BOARD INSTALLED] (SBSS)

d8 SOL AR COLLECTOR PROBE TEMPERATURE 2 [IF SOL AR BOARD INSTALLED] (SCS2)

d9 EX TR A SOL AR BOILER TEMPER ATURE [IF SOLAR BOARD INSTALLED] (SBS3)

Page 11

66

R1K 18 - RAD - ING - Manuale - 1706.1_V3

3 Riempimento dell'impianto_MIAH4_R2K_EN

3. USE

USER

3.1.8. SYSTEM FILLING

To restore the water pressure inside the system

open the loading tap “R” (fig. 1) and make sure

using pressure gauge “M” (fig. 1), that the system

pressure reaches 1.2 bar (see fig. 2).

After performing this operation, make sure that

the loading tap “R” (fig. 1) is properly closed.

After the water pressure reset the boiler will

automatically perform a 2 minutes system relief

cycle. Throughout this function the display will

show the code “F33”. The boiler can work normally

only after completing the operation.

M

R

fig. 1

fig. 2

Page 12

67

R1K 18 - RAD - ING - Manuale - 1706.1_V3

3 Codici di segnalazione anomalie_solo risc_MIAH4_EN

3. USE

USER

3.1.9. FAULT SIGNALLING CODES

The boiler might signal some faults by displaying a code. Below you have a list of the codes and of the

operations to be performed in order to unlock the boiler.

CODE ICON FAULT INTERVENTION

E01 FLAME BLOCK MAKE SURE THAT THE BOILER AND CONTACTOR GAS VALVES

ARE OPEN.

PRES S THE RESET ‘ ’ BUT TON ON THE CONTROL PANEL TO

RESE T THE FAULT, AS SOON A S THE ERROR CODE DISAPPE ARS

FROM THE DISPLAY, THE BOILER WILL START AUTOMATICALLY.

IF THE BLOCK PERSISTS CONTACT THE TECHNICAL SUPPORT

CENTRE.

E02

SAFETY THERMOSTAT (95 °C) PRES S THE RESET ‘ ’ BUT TON ON THE CONTROL PANEL TO

RESE T THE FAULT, AS SOON A S THE ERROR CODE DISAPPE ARS

FROM THE DISPLAY, THE BOILER WILL START AUTOMATICALLY.

IF THE BLOCK PERSISTS CONTACT THE TECHNICAL SUPPORT

CENTRE.

E03

FUMES SAFET Y THERMOFUSE (102 °C) CONTACT THE TECHNICAL SUPPORT CENTRE.

E04

WATER MISSING IN THE SYSTEM IF THE SYSTEM PRES SURE IS BELOW 1.2 BAR, F ILL THE SYS TEM

AS DESCRIBED IN CHAPTER “SYSTEM FILLING”.

IF THE BLOCK PERSISTS CONTACT THE TECHNICAL SUPPORT

CENTRE.

E05 HEATING PROBE CONTACT THE TECHNICAL SUPP ORT CENTRE.

E15

RETURN PROBE CONTACT THE TECHNICAL SUPPORT CENTRE.

E16

ELECTRIC FAN CONTACT THE TECHNICAL SUPPORT CENTRE.

E18

INSUFFICIENT CIRCULATION CONTACT THE TECHNICAL SUPPORT CENTRE.

E21

GENERAL INTERNAL BOARD ERROR CUT OFF THE POWER SUPPLY FROM THE MA IN SWITCH AND

THEN RE STORE IT, AS S OON AS THE ERROR COD E DISAPPEAR S,

THE BOILER WILL RESTART AUTOMATICALLY.

IF THE BLOCK PERSISTS CONTACT THE TECHNICAL SUPPORT

CENTRE.

Page 13

68

R1K 18 - RAD - ING - Manuale - 1706.1_V3

3 Codici di segnalazione anomalie_solo risc_MIAH4_EN

3. USE

USER

CODE ICON FAULT INTERVENTION

E22 PARAMETERS PROGRAMMING

REQUEST

CUT OFF THE POWER SUPPLY FROM THE MA IN SWITCH AND

THEN RE STORE IT, AS S OON AS THE ERROR COD E DISAPPEAR S,

THE BOILER WILL RESTART AUTOMATICALLY.

IF THE BLOCK PERSISTS CONTACT THE TECHNICAL SUPPORT

CENTRE.

E35

RESIDUAL FLAME PRESS THE RESET ‘ ’ BUTTON ON THE CONTROL PANEL TO

RESE T THE FAULT, AS SOON A S THE ERROR CODE DISAPPE ARS

FROM THE DISPLAY, THE BOILER WILL START AUTOMATICALLY.

E40

SUPPLY VOLTAGE CONTACT THE TECHNICAL SUPPORT CENTRE.

Loading...

Loading...