Page 1

WORKHORSE

500 Series Rack & Mixer

True to the Music

™

Order No. R700 0100

USER GUIDE

Radial Engineering Ltd.

1588 Kebet Way, Port Coquitlam BC V3C 5M5

tel: 604-942-1001 • fax: 604-942-1010

www.radialeng.com

email: info@radialeng.com • web: www.radialeng.com

Specifi cations and appearance are subject to change without notice.

Copyright © 2011 Radial Engineering Ltd.

www.radialeng.com

Page 2

THIS PAGE INTENTIONALY LEFT BLANK

Page 3

Radial Workhorse

™

500 Series Rack and Mixer

Congratulations and thank you for purchasing the Radial Workhorse, an innovative eight channel card frame

and mixer designed to take full advantage of 500 series modules. This manual covers installation and operation

of the Workhorse. We recommend that you take a few minutes to read through this manual in order to familiarize

yourself with the many innovative features incorporated into the Workhorse. Inside, you will fi nd important safety

features along with tips on how to get the most out of your 500 modules while using the Radial Workhorse.

To make the manual as easy to understand as possible, we have divided it into several sections. It begins with

on overview, then descriptions of each function, ending with some real world applications. Should you have any

questions, comments or concerns not covered in these pages, we invite you to log onto the Radial web site at

www.radialeng.com and visit the Workhorse FAQ section. This is where we post the latest details and applications. If you do not fi nd what you need, feel free to send us an email at info@radialeng.com and we will do our

best to answer your question as quickly as possible. Get ready to Plug in, Turn on and Tune in your 500 modules

with the Radial Workhorse.

Table of Contents Page

Front Panel Feature Set Overview ...............................................................................1

Rear Panel Feature Set Overview ................................................................................2

Introduction To The Workhorse ....................................................................................3

Feature Set Overview ...................................................................................................4

Power Supply Capacity ................................................................................................7

Installing The Workhorse ..............................................................................................7

Slide-in Card Slot Tray and Removal ...........................................................................8

Workhorse Signal Flow and Levels ..............................................................................8

Using The Workhorse ...................................................................................................9

Workhorse Applications ................................................................................................11

Frequently Asked Questions ........................................................................................14

Specifi cations and Block Diagram ................................................................................15

Connector Pin-out ........................................................................................................16

Card Edge Connector Specifi cations ...........................................................................16

Radial Limited Warranty ................................................................................ Back Cover

IMPORTANT SAFETY & USER NOTICE - FOR PROFESSIONAL USE ONLY

!

The Radial Workhorse is specifi cally designed for use by qualifi ed professional audio engineers. The

open frame design is not intended for use by consumers or those unfamiliar with this format. Even

though the current and voltage levels are relatively low, we recommend that all slots be fi lled with a

module or covers be placed over unfi lled slots. This will help protect you from electrical shock.

The Workhorse™ rack frame and mixer is designed to be used with 500 series or what are commonly

known as Lunchbox™ modules. The Workhorse has been designed following the framework as

outlined by the VPR Alliance as described on the API™ website. Although some manufacturers

build modules that are not VPR compliant, they may in fact work with the Workhorse. Please consult

those specifi c manufacturers for details regarding their compatibility. The Radial Workhorse Open

Source Document outlines the required technical specifi cations for manufacturers that intend to

have their modules used in the Workhorse. Compatibility of any modules other than a module made

by Radial Engineering Ltd. is the sole responsibility of the user. Please read the Limited Radial

Warranty for details. There are no replacement or user serviceable parts inside.

Radial Engineering Ltd.

1588 Kebet Way, Port Coquitlam BC V3C 5M5

tel: 604-942-1001 • fax: 604-942-1010

info@radialeng.com • www.radialeng.com

Specifi cations and appearance are subject to change without notice.

Copyright © 2011 Radial Engineering Ltd.

www.radialeng.com

Page 4

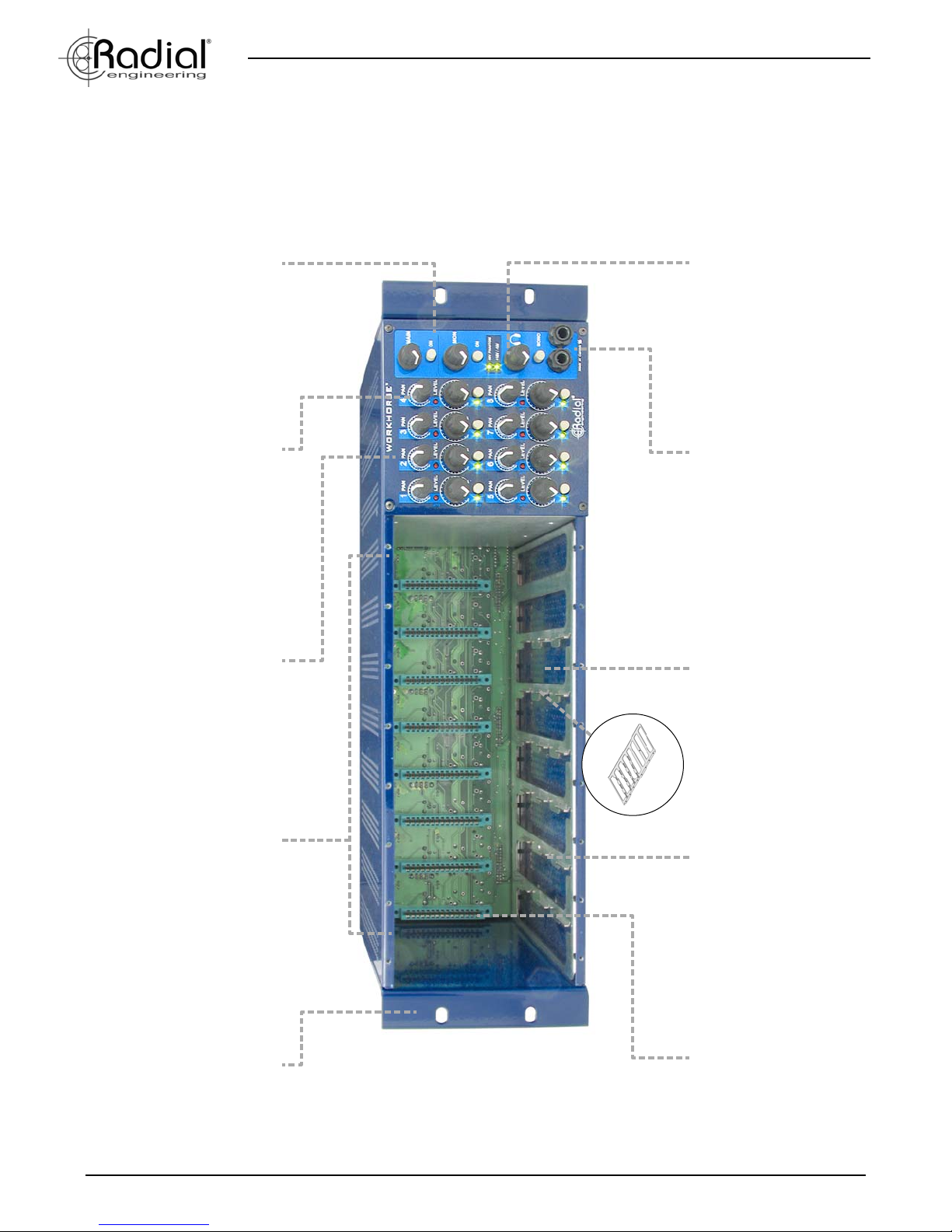

OUTPUT SECTION: Separate

stereo controls for main,

monitors and headphones

make it easy to adjust levels

or mute signals when needed.

True to the Music

LED INDICATORS: Provide

visual power status for the

+/- 16 volt module rails and

48V phantom power.

MIXER CHANNEL INPUTS:

Each Workhorse channel is

equipped with volume control,

left-right pan, LED overload

indicator and channel on-off

for muting.

MIXER SECTION: Ultra quiet

built-in mixer lets you tap

signals from each module and

mix them to the main, monitor

or headphones.

EIGHT CARD SLOTS: Up to

eight 500 series compatible

modules may be loaded into

the Workhorse and connected

via standard card edge

receptacle.

DUAL HEADPHONES: Super

high output dual headphone

amp with level control to

ensure you can mix in any

environment. Mono check

switch.

FITS ALL MODULE SIZES:

Both single and double

wide modules will fi t in the

Workhorse. Removable tray

for non-standard modules.

EASY-GLIDE TRAY: Slide-in

platform for modules makes

connecting to back plane

easy by properly aligning

card edge height.

FRONT PANEL FEATURE SET

1

Radial Engineering Ltd.

STEEL CASE: The

Workhorse chassis is made

from heavy steel to provide

extra shielding against stray

magnetic fi elds and RF.

DEEP CURRENT POOL:

Modules can draw as much

current as they need from a

shared pool. Up to 1200mA

total current is available.

Workhorse User Guide

Page 5

True to the Music

CARD SLOT CONNECTORS:

Follows original XLR I/O

format and adds parallel

1/4” TRS jacks for easy

connectivity to workstations.

OMNIPORT™: 1/4” TRS

connector add functionality

to enhance each module’s

capability as set by the

manufacturer.

BALANCED 25-PIN D-SUBS:

Eight channel D-Subs follow

ProTools standard for easy

connectivity to workstations.

Wired in parallel to XLR inputs

and outputs.

STEREO LINK: Makes it easy

to pair up modules equipped

with a stereo link function in

standard API master slave

confi guration.

FEED FUNCTION: Lets you

connect one module into

the next to set up elaborate

channel strips without having

to hard patch with cables.

MAIN OUTPUTS: Jensen

transformer isolated to

eliminate noise and add

warmth. Equipped with TRS

insert jacks for effects.

SUMMING MIXER: Built-in

eight channel summing mixer

lets you mix ‘outside the box’

in the analogue domain for

added warmth and character.

STUDIO GROUNDING:

External grounding lugs

makes it easy to set up star

grounding schemes for high-

end studio wiring.

EXTERNAL POWER: High

current external switching

supply delivers 1600mA to

the Workhorse plus separate

48V phantom feed for mic

preamps.

REAR PANEL FEATURE SET

Radial Engineering Ltd. Workhorse User Guide

MONITOR OUTPUTS: Used

to send signal to your nearfi eld

monitors with choice of XLR

and 1/4” TRS jacks. Features

independent level control.

EXPANSION BUSS: Expand

the workhorse to 16x2 or

larger by connecting one

Workhorse into another.

Simple 1/4” connections

makes it easy.

2

Page 6

INTRODUCTION

True to the Music

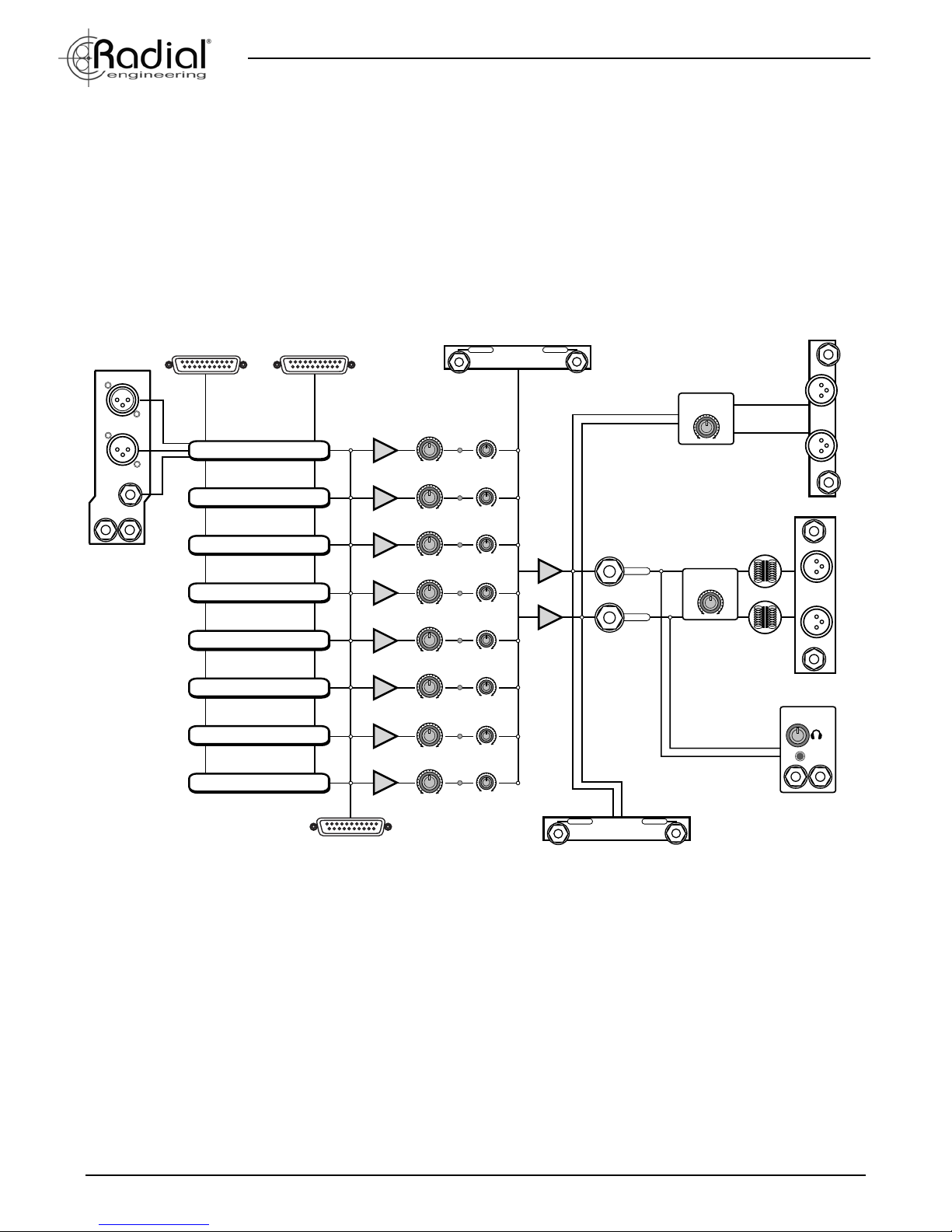

The Workhorse is an eight channel card frame and mixer designed

for 500 series modules. Up to eight modules may be used at any

one time. Once ‘plugged in’, the Workhorse automatically routes

the module’s signal to the XLR, ¼” and D-sub connectors on the

rear panel via a 15-pin card-edge connector and receptacle. Radial

modules and those that have been designed by other manufacturers

OUTPUTS 1~8INPUTS 1~8

INPUT

OUTPUT

OMNIPORT

OUT

-10dB

CARD SLOT 1

CARD SLOT 2

IN

CARD SLOT 3

CARD SLOT 4

CARD SLOT 5

CARD SLOT 6

Mix Buss

Mixer Control Section

LEVEL PAN

LEVEL PAN

LEVEL PAN

LEVEL PAN

LEVEL PAN

LEVEL PAN

to take advantage of the Workhorse’s extra features will enjoy the

added convenience of having the signal sent to the internal mix buss

and the built-in 8x2 stereo summing mixer. For older generation

modules, the individual channel outputs can be routed to the

summing mixer using a D-sub cable affording them much the same

functionality as newer Radial designs.

LEFT IN RIGHT IN

EXPANSION

BUSS

Master Stereo Buss

MONITOR

LEVEL

CLIP

CLIP

CLIP

CLIP

CLIP

CLIP

1/4” TRS - TIP SEND / RING RETURN

INSERT

INSERT

MAIN

LEVEL

JENSEN

TRANSFORMERS

LEFT RIGHT

MON

LEFT RIGHT

OUT

MAIN

OUT

+4dB

+4dB

LEVEL PAN

CARD SLOT 7

LEVEL PAN

CARD SLOT 8

SUMMING MIXER INPUTS

SIGNAL FLOW

The signal fl ow chart above shows the basic signal routing that the

Workhorse provides. Flowing from left to right, the signal comes into

the Workhorse via the rear panel XLR female and ¼” TRS connector.

Once the signal goes into a module, it is then sent back out after it is

processed to the male XLR and ¼” TRS. This of course happens on

all eight channels. Simultaneously, Radial modules send the signal

to the internal mix buss which feeds the mixer.

CLIP

CLIP

LEFT OUT RIGHT OUT

EXPANSION

BUSS

After the signal has been panned left or right, it can go to the

expansion buss if feeding a second Workhorse. It is then fed into the

master output stage where it is once again buffered and sent to the

main, monitors and headphones. Note the main outputs are Jensen

transformer isolated. The next section in this manual discusses

each feature in detail following the signal fl ow.

HEADPHONE

MONO

3

Radial Engineering Ltd.

Workhorse User Guide

Page 7

True to the Music

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

-

+

G

-

+

G

-

+

G

1

234

5

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

FEATURE SET

Card Slot I/O Connections

Each of the Workhorse card slots is equipped with XLR, ¼” TRS and

D-sub inputs and outputs. The input sensitivity will be dependant

on the type of module being used. For instance if you are using a

microphone preamplifi er, the input will of course be suited for a low

level microphone. If you are using a dynamic processor like a limiter

or an EQ, then the input will usually be set to handle a professional

+4dB balanced signal.

CARD SLOT 1CARD SLOT 2

FEED

OFF

LINK

INPUT

INPUT

FEED

OFF

OUTPUT OUTPUT

OFF

OMNIPORT

OMNIPORT

12

INPUT

OUTPUT

Because the Workhorse is equipped with an internal mix buss most

Radial modules are equipped with an internal buffer so that the

output can be sent along the buss to the mixer section. As such,

the XLR male and TRS outputs will usually follow suit with a +4dB

balanced line level signal that is able to feed a professional recording

system or line level mixing console. This may sound a bit complex,

but as we look into applications later in this document, it will become

very clear.

Put simply, the input level is determined by the type of module being

used while the output level will typically be a balanced +4dB line level

signal. If you use ¼” mono cables you will unbalance the signal. This

will reduce the level by about -6dB but everything will still remain

completely functional. Simply adjust the levels to compensate.

Omniport

Omniport™ is a special ¼” TRS jack located on the rear panel that

has been left ‘open’ to allow the module to perform a unique task.

In other words, depending on the type of module, the manufacturer

can assign the Omniport to perform a function that may be most

appropriate. This could be a key input on a gate, a footswitch on a

guitar effect or maybe an instrument input on a mic preamp.

The card-edge pins 7 and 9 (unused in the original spec) have

been assigned to the Omniport™ TRS connector. The application

here is only limited to one’s imagination as to the function that best

relates to a given module. As the Omniport function is determined

by the module, you will need to consult the module manufacturer’s

specifi cation for details on how it was designed to be used.

Radial Omniport Assignment:

Module Omniport function

PowerPre Instrument input

JDV Direct box output (low Z out for live touring)

X-Amp Instrument input

Phazer Balanced direct out (original dry signal out)

JDX Direct box output (low Z out for live touring)

EXTC TRS insert for patch bay

Komit Compressor key input

OUTPUT

INPUT

Feed Switch

As you delve further into the functionality of the 500 series, you will

fi nd that the modular format allows all kinds of connectivity options.

With older 500 series racks, connections between modules were

done using an XLR cable whereby the output from one module

would plug into the input of another. The Workhorse simplifi es

the process by introducing a Feed switch on the rear panel. This

connects the balanced output of one module to the balanced input of

the adjacent module to the immediate right. The Feed switch allows

you to daisy chain a series of adjacent modules making it easy to

create ‘customized’ channel strips whereby a mic preamp could feed

an EQ which in turn could feed a compressor. Changing the order is

simply a matter of relocating the modules or patching using an XLR

cable. The UP position turns the Feed connection on.

FEED FEED INPUT

CARD SLOT 1CARD SLOT 3 CARD SLOT 2

FEED

OFF

LINK

OFF

INPUT

OMNIPORT

OUTPUT

INPUT

FEED

OUTPUT OUTPUT OUTPUT

LINK

OFF

FEED

OFFOFF

INPUT

OMNIPORTOMNIPORT

123

INPUT

OUTPUT

Stereo Link Switch

Every second card slot is equipped with a Link switch. The Link

function allows modules that are ‘stereo ready’ to be linked together.

A typical example would be using two limiters on a stereo track where

you want the dynamics to be the same for both channels. Pin-6 on

the card edge connector is designated for this function and used to

send control voltage from one module to the other. One module will

take on the master role while the second will act as the slave. This is

a ‘standard’ function on all API Lunchbox™ generations.

D-Sub I/O Connectors

To add fl exibility, all eight balanced card-slot input and output

connections are duplicated on two 25-pin D-Subs wired to the

Tascam™/ProTools™ pin-out standard. These parallel connections

are designed to make it easy to integrate the Workhorse with

recording systems that employ this industry standard.

WORKHORSE RACK & MIXER

LEFT

MAIN

OUT

INSERTINSERT

1/4” TRS - TIP SEND / RING RETURN

LEFT RIGHT

MON

OUT

LEFT RIGHT

EXPANSION

OUT

IN

SPLIT VOLTAGE POWER SUPPLY

OUT

BUSS

IN

POWER SUPPLY

COM

+18VDC

+48VDC

COM

+18VDC

CHASSIS CIRCUIT

GROUND

INPUTS

RIGHT

OUTPUT

INPUT

INPUT

FEED

OUTPUT

OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT

LINK

OFF

78

INPUT

INPUT

OUTPUT

SUMMING MIXER INPUTS 1 ~ 8

PROTOOLS INTERFACE

OUTPUT

INPUT

FEED

OFFOFF

INPUT

OUTPUT

Radial Engineering Ltd.

Made in Canada

INPUT

INPUT

FEED

FEED

OFFOFF

LINK

OFF

INPUT

OUTPUT

OUTPUT

DIRECT OUT 1 ~ 8 INPUTS 1 ~ 8

OUTPUT

INPUT

INPUT

INPUT

FEED

LINK

OFF

INPUT

OUTPUT

PIN DIAGRAM - PANEL VIEW

13

+

+

G

G

-

-

-

4

2

-

-

5

3

1

G

G

G

+

+

+

6

INPUT

8

7

OUTPUTS

CARD SLOT 1CARD SLOT 3CARD SLOT 5CARD SLOT 7 CARD SLOT 2CARD SLOT 4CARD SLOT 6CARD SLOT 8

INPUT

INPUT

FEED

FEED

OFF

OFFOFF

LINK

OFF

OMNIPORT

OMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORT

123456

INPUT

INPUT

OUTPUT

OUTPUT

Radial Engineering Ltd. Workhorse User Guide

4

Page 8

True to the Music

-

+

G

The D-sub pin confi guration is printed on the back panel so you can

ensure the cable that is being used is properly wired. The good news

is that today, most music shops carry these types of cables and they

are usually wired correctly.

13

Pin #

1 Channel 8 Hot

2 Channel 8 Ground

3 Channel 7 Cold

4 Channel 6 Hot

5 Channel 6 Ground

6 Channel 5 Cold

7 Channel 4 Hot

8 Channel 4 Ground

9 Channel 3 Cold

10 Channel 2 Hot

11 Channel 2 Grond

12 Channel 1 Cold

13 Not Used

+

G

-

1

G

25

-

2

-

3

G

+

+

+

G

-

4

-

6

-

5

G

+

Pin #

14 Channel 8 Cold

15 Channel 7 Hot

16 Channel 7 Ground

17 Channel 6 Cold

18 Channel 5 Hot

19 Channel 5 Ground

20 Channel 4 Cold

21 Channel 3 Hot

22 Channel 3 Ground

23 Channel 2 Cold

24 Channel 1 Hot

25 Channel 1 Ground

1

+

G

-

8

-

7

G

+

14

Mixer Section

The mixer section in the Workhorse features an eight channel

summing mixer with stereo outputs. It derives its signal via pin11 from the slot card-edge connector or from the D-sub summing

mixer input connector. Each channel features an ON-OFF switch

that enables you to select or mute the signal from the designated

card slot. Individual channel gain controls are used to adjust the mix

level while the pan control lets you position the signal across the

stereo spectrum. To assign a channel to a left or right output, one

simply hard-pans the module using the pan control. A channel-on

LED lets you know when a channel is activated plus an overload

peak indicator lets you monitor signal levels to ensure you are not

overloading the summing mixer’s input.

Mixer Master Section and Outputs

The mixer’s master section features three stereo outputs: main,

monitor and headphones, each with individual level control. The

main stereo output is equipped with TRS insert jacks for connecting

effects or equalizers and Jensen transformers that isolate the

output to reduce the hum and buzz caused by ground loops. This

is particularly useful in live recording environments where control

over the electrical system is often compromised. These also play an

important role by introducing the warm ‘Jensen sound’ at the mixers

main output. Jensen transformers are legendary in their ability to

withstand huge transients without distortion while delivering a

smooth articulated sound.

The monitor output provides a second stereo pair that can be used

in the studio for monitoring, as a direct output for recording or to

feed a PA system in a live environment. Both the main and monitor

outputs are equipped with individual on-off switches and outfi tted

with balanced XLR-male and 1/4” TRS connectors. Although both

the main and monitor outputs are balanced +4dB line level, you can

use an unbalanced ¼” cable if need be. This will of course unbalance

the signal and reduce the output by about -6dB.

Headphone Amplifi er

The Workhorse is equipped with a high-output stereo headphone

amplifi er with two standard ¼” TRS headphone connections. This

enables the engineer to share the mix and discuss the situation with

the producer while both are listening. To use, simply plug in and

adjust the level to suit.

The headphone buss is equipped with a switch that sums the stereo

image to mono. This switch only affects the headphone out and

is intended to provide the engineer with a quick reference to hear

how the mix correlates when sent as a mono broadcast. This handy

feature also helps identify stereo pairs that may be out of phase.

When set to mono, instead of summing together and getting louder,

they will get quieter and sound thin.

PAN

PAN

3

2

LEVEL

CLIP

ON

5

CLIP

LEFT RIGHT

LEFT RIGHT

LEVEL

CLIP

ON

PAN PANPANPAN

6

LEVEL

LEVEL

CLIPON

CLIP

ON

78

CLIPON

1/4” TRS - TIP SEND / RING RETURN

PAN

LEVEL

LEVEL

MAIN

OUT

MON

OUT

PAN

41

LEVEL

LEVEL

CLIP

ON

LEVEL

LEVELONLEVEL

CLIPON

48V PHANTOM

+16V / -16V

Made in Canada

INSERTINSERT

MAIN

ON

MON

ON

MONO

It is important to note that the Workhorse is intended for professional

use in high Sound Pressure Level (SPL) environments and the

headphone amplifi er is capable of producing very high audio volume

levels with most headphones. In fact, the maximum sound level

is much louder than what battery operated portable music players

can produce. Care and attention must be paid to ensure you do

not damage your hearing by setting the signal too loud. Always test

signals at a low volume before increasing the listening level.

!

Headphone Safety Warning

Caution: Very Loud Amplifi er

As with all products capable of producing high Sound Pressure

Levels (SPL) users must be very careful to avoid the hearing

damage that may occur from prolonged exposure. This is

particularly important as it applies to headphones. Prolonged

listening at high SPLs will eventually cause tinnitus and can lead

to partial or complete loss of hearing. Please be aware of the

recommended exposure limits within your legal jurisdiction and

follow them very closely. The user agrees that Radial Engineering

Ltd. remains harmless from any health effects resulting from the

use of this product and the user clearly understands that he or

she is entirely responsible for the safe and proper use of this

product. Please consult the Radial Limited Warranty for further

details.

5

Radial Engineering Ltd.

Workhorse User Guide

Page 9

True to the Music

-

+

G

-

+

G

-

+

G

1

234

5

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

-

+

G

-

+

G

-

+

G

1

234

5

Expansion Buss

The Workhorse stereo expansion buss is designed to allow multiple

Workhorses to be used together to create larger mixing systems. This

also lets you create ‘sub-zones’ and ‘group’ mixes. Standard unbalanced

¼” cables are used to connect between units with choice of input or output

depending on which Workhorse will be set as the ‘master’ and which will be

designated as the ‘slave’. All you do to link one to the other is connect two

cables (left and right). The output from the ‘slave’ will now feed the input on

the ‘master’ essentially combining the two to create a 16x2 mixer.

Workhorse 1

Slave

Workhorse 2

Master

LEFT RIGHT

IN

LEFT RIGHT

IN

OUT

OUT

EXPANSION

BUSS

EXPANSION

BUSS

OUT

IN

OUT

IN

You can take things a step or two further by adding more Workhorses with

the each subsequent unit delivering more and more channels. This could

for instance be used in a live scenario where channels 1~8 from the fi rst

Workhorse are vocals with the output being treated like a sub-group sent

to a wedge monitor system while the full mix from the master (1~16 or

1~24 channels) is sent to the PA and recording system.

D-Sub Summing Mixer Input

One of the cool extras built into the Workhorse is the ability to use it as

a stand-alone eight channel analog summing mixer. This feature also

enables older 500 series modules to be hard wired into the

Workhorse

mix buss. A dedicated unbalanced 25-pin D-Sub input on the rear

panel provides access to the eight mixer inputs and accepts both

+4dB and -10dB line level sources.

For instance, if you prefer the sound of analog summing, and want

to mix eight channels from your ProTools™ rig, you simply connect

the output of your recording interface to the Workhorse summing

mixer D-Sub input and you can now mix using the eight front panel

level and pan controls.

WORKHORSE RACK & MIXER

LEFT

MAIN

OUT

INSERTINSERT

1/4” TRS - TIP SEND / RING RETURN

LEFT RIGHT

MON

OUT

LEFT RIGHT

EXPANSION

OUT

IN

SPLIT VOLTAGE POWER SUPPLY

OUT

BUSS

IN

POWER SUPPLY

COM

+18VDC

+48VDC

COM

+18VDC

CHASSIS CIRCUIT

GROUND

RIGHT

INPUT

INPUT

FEED

OUTPUT

OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT

LINK

OFF

78

INPUT

INPUT

OUTPUT

OUTPUT

SUMMING MIXER INPUTS 1 ~ 8

Radial Engineering Ltd.

INPUT

INPUT

FEED

FEED

OFFOFF

LINK

OFF

INPUT

INPUT

OUTPUT

OUTPUT

Made in Canada

DIRECT OUT 1 ~ 8 INPUTS 1 ~ 8

FEED

OFFOFF

OUTPUT

OUTPUTS

INPUT

INPUT

INPUT

FEED

LINK

OFF

INPUT

OUTPUT

PIN DIAGRAM - PANEL VIEW

13

+

+

G

G

-

-

-

4

2

-

-

3

5

1

G

G

G

+

+

+

6

7

CARD SLOT 1CARD SLOT 3CARD SLOT 5CARD SLOT 7 CARD SLOT 2CARD SLOT 4CARD SLOT 6CARD SLOT 8

INPUT

INPUT

FEED

FEED

OFF

OFFOFF

LINK

OFF

OMNIPORT

OMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORT

123456

INPUT

INPUT

OUTPUT

OUTPUT

8

PROTOOLS INTERFACE

Expansion Buss Expansion Buss

PAN

PAN

PAN

PAN

PAN

PAN

PAN

PAN

PAN

PAN

2341

MAIN

ON

LEVEL

LEVEL

LEVEL

LEVEL

LEVEL

CLIP

CLIP

CLIP

CLIP

MON

ON

ON

ON

ON

ON

48V PHANTOM

PAN PANPANPAN

5

78

6

+16V / -16V

LEVEL

LEVEL

LEVELONLEVEL

LEVEL

LEVEL

CLIP

CLIPON

CLIPON

CLIPON

MONO

Made in Canada

PAN

2341

MAIN

ON

LEVEL

LEVEL

LEVEL

LEVEL

LEVEL

CLIP

CLIP

CLIP

CLIP

MON

ON

ON

ON

ON

ON

48V PHANTOM

PAN PANPANPAN

5

78

6

+16V / -16V

LEVEL

LEVEL

LEVELONLEVEL

LEVEL

LEVEL

CLIP

CLIPON

CLIPON

CLIPON

MONO

Made in Canada

PAN

2341

MAIN

ON

LEVEL

LEVEL

LEVEL

LEVEL

LEVEL

CLIP

CLIP

CLIP

CLIP

MON

ON

ON

ON

ON

ON

48V PHANTOM

PAN PANPANPAN

5

78

6

+16V / -16V

LEVEL

LEVEL

LEVELONLEVEL

LEVEL

LEVEL

CLIP

CLIPON

CLIPON

CLIPON

MONO

Made in Canada

RL RL RL

Slave 1 - Channels 1 - 8 Slave 2 - Channels 1 - 16 Master - Channels 1 - 24

Keep in mind that the Workhorse’s modular fl exibility also enables you to

use the individual XLR or ¼” outputs from each module card slot to feed a

recorder should this be desired. Once you get to know the Workhorse the

creative options are almost endless!

Radial Tech Note: Expansion Buss

The Radial ‘open source’ approach also enables the expansion buss

to be interfaced with other manufacturer’s electronic equipment

that is equipped with similar functionality such as products made

by Rupert Neve Designs™. The expansion buss is essentially the

inverting (virtual earth) input of an op-amp in the mixer section of the

rack with a 4.75K Ohm resistor in series for unity gain connectivity.

This can be used by an external device so long as it can operate

into a 4.75K Ohm load. There is no DC blocking. This means that

if there is any DC on the output of the external device, the clipping

response of this stage will be non-symmetrical and headroom will

be reduced.

Using The Summing Mixer Input To Mix Older Modules

If you have a bunch of older API™ preamps and want to mix their

outputs using the built-in mixer, simply connect the individual

card-slot outputs to the summing mixer input using a D-Sub cable

and you are all set. The modules output signal will appear at the

corresponding mixer channel.

WORKHORSE RACK & MIXER

LEFT

MAIN

OUT

INSERTINSERT

1/4” TRS - TIP SEND / RING RETURN

LEFT RIGHT

MON

OUT

LEFT RIGHT

EXPANSION

OUT

IN

SPLIT VOLTAGE POWER SUPPLY

OUT

BUSS

IN

POWER SUPPLY

COM

+18VDC

+48VDC

COM

+18VDC

CHASSIS CIRCUIT

GROUND

RIGHT

INPUT

INPUT

FEED

OUTPUT

OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT OUTPUT

LINK

OFF

78

INPUT

INPUT

OUTPUT

OUTPUT

SUMMING MIXER INPUTS 1 ~ 8

Radial Engineering Ltd.

INPUT

INPUT

FEED

FEED

OFFOFF

LINK

OFF

INPUT

INPUT

OUTPUT

OUTPUT

Made in Canada

DIRECT OUT 1 ~ 8 INPUTS 1 ~ 8

FEED

OFFOFF

OUTPUT

INPUT

INPUT

INPUT

FEED

LINK

OFF

INPUT

OUTPUT

PIN DIAGRAM - PANEL VIEW

13

+

+

G

G

-

-

-

4

2

-

-

5

3

1

G

G

G

+

+

+

6

7

CARD SLOT 1CARD SLOT 3CARD SLOT 5CARD SLOT 7 CARD SLOT 2CARD SLOT 4CARD SLOT 6CARD SLOT 8

INPUT

INPUT

FEED

FEED

OFF

OFFOFF

LINK

OFF

OMNIPORT

OMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORTOMNIPORT

123456

INPUT

INPUT

OUTPUT

OUTPUT

8

Grounding Posts

The connection between chassis and circuit (analog) ground is made

between the binding posts on the rear panel (factory set). Opening

this connection will separate these grounds in the Workhorse itself

so the only connection point between them is in the power supply.

Further separation is not allowed by electrical safety authorities. It

will only be in rare and unusual circumstances these grounds will

need to be separated.

Tie Bar

Factory Installed

Radial Engineering Ltd. Workhorse User Guide

CHASSIS CIRCUIT

GROUND

6

Page 10

True to the Music

Power Supply and Capacity

The Workhorse employs a universal power supply that will

automatically convert the various voltages used around the world

and regulate them before sending the power to the Workhorse. A

standard male IEC/EIN power input connector makes it easy to

travel as you need only change the cable to suit the local power

connector type.

The Workhorse does not have a power switch. As soon as you

connect the 5-pin XLR from the external supply to the Workhorse

it will be activated. Two front panel LEDs in the master section will

illuminate as soon as power is established. These indicate 48V

Phantom power is available and the +/-16V power supply for the

modules is active.

COM

+48VDC

1

234

+16VDC

5

COM

48V PHANTOM

+16V / -16V

-16VDC

The Workhorse power supply is a 1600 milliamps (mA) external

‘brick’ that provides 48 volts for phantom power and the required +/16 volts to supply each module. Pin-15 on the card-edge connector

provides phantom power. Turning phantom power on or off is module

dependent. So for instance if you plug in a mic preamp, it will normally

be set up to feed the phantom power from the Workhorse supply

to the microphone input thus enabling you to send +48V phantom

power to a condenser microphone or active DI. For modules such

as dynamic processors or EQs that do not use phantom power, the

module simply ignores pin-15 as if it were not there.

Single Slot Modules Double Slot Modules

1 Mic Preamp 80mA 1 Tube Mic Pre 250mA

2 Equalizer 60mA 2

3 Compressor 60mA 3 Tube Limiter 250mA

4 Gate 60mA 4

5 Mic Preamp 80mA 5 Tube Mic Pre 250mA

6 Equalizer 60mA 6

7 Compressor 60mA 7 Tube Limiter 250mA

8 Gate 60mA 8

TOTAL DRAW 520mA TOTAL DRAW 1000mA

Installing The Workhorse

The Workhorse can be either mounted in a standard IEC 19 inch

rack system or placed on the desktop with the user installed rubber

feet that are included in the packaging.

Unlike some 500 series racks that are ‘power limited’, the Workhorse

pools the available current so that the user can confi gure the system

based on his or her requirements. The 1600 milliamps are fi rst

divided whereby 400 milliamps are reserved for the master mix

section. This leaves 1200 milliamps that can be shared among the 8

module slots and supplied via pins 12, 13 and 14.

EXTERNAL POWER SUPPLY

INPUT: 100V - 240V

(50 ~ 60 Hz)

CARD SLOTS: 1200mA

1 2 3 4 5 6 7 8

OUTPUT: +/-16V and

+48V Phantom (1600mA)

COM

+48VDC

PAN

PAN

2341

LEVEL

LEVEL

CLIP

CLIP

CLIP

MIXER:

ON

ON

ON

PAN PANPANPAN

5

78

6

400mA

LEVEL

LEVEL

CLIP

CLIPON

CLIPON

+16VDC

5

1

234

COM

-16VDC

PAN

PAN

MAIN

ON

LEVEL

LEVEL

LEVEL

CLIP

MON

ON

ON

48V PHANTOM

+16V / -16V

LEVEL

LEVELONLEVEL

LEVEL

CLIPON

MONO

Made in Canada

So for instance if you have a couple of power-hungry tube preamps

in slots 1 and 2 that require 250 milliamps of current, you still have

700 milliamps of current left to power the other six slots. Considering

most 500 series modules use between 40 and 80 milliamps of

current, it is unlikely you will ever exceed the Workhorse’s available

power. Note: The original API spec calls for 130mA on each slot.

The Workhorse not only exceeds this (150mA when current draw is

divided equaly between eight card slots) but allows you to distribute

the available power as needed.

The Workhorse is 19” wide, 7” deep and uses three standard vertical

rack spaces or 5.25”. The total rack depth needed for installation is

11” (280mm) to accommodate rear panel cable connectors. It is a

good idea to provide some means of support and strain relief for the

cable bundle connecting to the rear panel.

3RU

11”

Installing Modules In The Workhorse

Modules slide into the Workhorse card slots and make contact with

the card edge connector on the inside rear plane. Once in place,

modules are fastened using two 4/40 thread machine screws.

7

Radial Engineering Ltd.

Workhorse User Guide

Page 11

True to the Music

Slide-In Card Slot Tray

Another innovative feature in the Workhorse is the slide-in tray for

the card slots. The tray is designed to make sliding modules in and

out easier while lessening the frustration of trying to line up the cardedge connectors. The tray is equipped with a series of guide tabs

to help align single and dual width modules. The tray comes factory

installed with slots 1 ~ 4 set up for single wide modules, and then

Signal Flow And Levels

Because the Workhorse is modular, it can accept a multitude of

different devices. This also means that you need to understand the

signal fl ow so that you can be sure what you want to do will work.

In the world of audio there are basically four low level signal groups

to contend with before you get to high power output levels such as

those produced by power amplifi ers to drive loudspeakers.

5/6 and 7/8 set up for double wide modules. The tray can also be

rotated 180º so that the double wide modules can be installed in the

fi rst four slots.

Guide Tabs

Slots 1 Thru 4

1

2

3

4

5

R

O

T

A

T

E

1

8

0

6

7

8

The workhorse is designed to accept modules that adhere to the

4.5” height dimensions outlined by the VPR Alliance. Compliant

modules will easily slide in and out of the Workhorse card slots with

the slide-in tray in place. However there are some modules that

are in violation of the height specifi cation. To accommodate noncompliant modules, the slide-in tray may have to be removed.

+4dB

0dB

NOMINAL

-10dB

-20dB

-50dB

MIC / DI

1

WORKHORSE MIX BUSS

ACOUSTIC

2

1. MIC LEVEL RANGE: Microphones and direct boxes

produce the weakest signals. These typically range from

-60dB to -40dB depending on type. Some such as ribbon

microphones can be as low as -70dB while condenser

mics will generally be at the top end of this range. With a

Workhorse, one would connect a microphone to a preamp

like the PowerPre™. This would elevate the signal to either

-10dB to feed the internal mix buss or produce +4dB at the

XLR direct out.

2. INSTRUMENT LEVEL RANGE: The output levels produced

by instruments can range widely. A single coil electric guitar

can produce as little as -40dB while an electronic keyboard,

MIXER

4

3

sampler or digital piano is capable of producing as much as

-10dB. For low level instruments, 500 series modules like

the JDV™ amplify the signal to -10dB for the internal buss

while also producing +4dB at the XLR output for direct

recording. High output keyboards can also be connected

directly to the Workhorse summing input and mixer as this

is set at -10dB (nominal).

3. UNBALANCED -10dB LINE LEVEL RANGE: Unbalanced

outputs from CD players, keyboards, mixers and home

hi-fi components are usually specifi ed at -10dB and are

often referred to as consumer line level. The internal

Two Phillips screws on the bottom of the Workhorse allow the slide-in

tray to be taken out. To remove, turn the workhorse upside down and

locate the two Phillips head screws on the bottom chassis. Remove

the two screws and lift out the tray. Replacing the two screws back

into the slide-in tray will help keep them handy if the tray is to be

re-installed.

Exchanging Modules

When making any electrical connection, it is always safer to do

so with the power disconnected. The Workhorse power supply is

equipped with internal protective measures intended to provide a

margin of safety should a module exchange be performed in error

with the power on. However, the Workhorse is not designed to allow

repeated insertion and removal of modules while the power supply

is active. Always disconnect the power from the Workhorse before

exchanging modules.

mix buss inside the Workhorse is designed to accept an

unbalanced -10dB signal. (In fact it can handle more.)

Once a microphone signal has been amplifi ed using, for

instance, the Radial PowerPre™, the preamp output will

feed the Workhorse mix buss. And when a +4dB balanced

line level signal is brought into the Workhorse via a device

like the Radial Komit™ compressor-limiter, the Workhorse

will unbalance the signal before it is sent to the internal

buss which in turn will feed the mixer. The D-Sub summing

mixer input is also a -10dB unbalanced input.

4. BALANCED +4dB LINE LEVEL RANGE: Most electronic

devices process unbalanced audio signals. In other words,

after the balanced signal arrives at the input, it is usually

unbalanced inside, processed and then balanced again to

deal with the outside world. This is how most 500 series

modules work and is why the direct output is balanced line

level. After it is unbalanced, the Workhorse internal buss

follows the same architecture whereby the signal is fi rst

mixed, then the Workhorse mixer output steps up the level

SAFETY NOTICE - NO HOT SWAPPING

!

“Hot Swapping”, or exchanging modules while the power is on is not

covered under the Radial Limited Warranty. The user is responsible for

any damage to the Workhorse or module arising out of hot swapping and

the user shall save Radial Engineering Ltd. harmless should any damage

occur. Please consult the Radial Limited Warranty for further details.

and balances the signal to a full +4dB professional balanced

output. Depending on how much signal the mixer gets, this

can increase to as much as +22dB before distortion.

Matching the output level of one device to the input of the next

will help you avoid distortion and maximize signal-to-noise. For

instance, using a +4dB output to drive a -10dB input could overload

the input and cause distortion. Conversely, a -10dB output may not

have enough gain to drive the input of a +4dB device resulting in a

higher noise fl oor.

Radial Engineering Ltd. Workhorse User Guide

8

Page 12

True to the Music

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

With this in mind let’s track the signal fl ow and level as it passes

through the Workhorse. The diagram below shows the signal chain

starting with a microphone.

MIC / DI MIX-BUSS MAIN

PREAMP RECORD

+4dB

-10dB

BUSS

-10dB

BUSS

-50dB

DIRECT OUT

+4dB

The mic is connected to a mic preamp like the PowerPre™ that

boosts the signal from -50dB to line level. The preamp direct output

increases the signal to +4dB so that it can feed a recorder or another

processor such as a compressor or EQ. While this is happening,

Radial modules and others compatible with the Workhorse have a

special buffer to unbalance the signal and drive it on to the internal

-10dB mix buss where it fl ows to one of the mixer channels. The

mixer then amplifi es and balances the signal at the main outputs to

deliver a +4dB (nominal) level.

Because each of the Workhorse module slots is equipped with a

balanced line level input and a balanced line level direct output

(depending on the module), you are free to interconnect modules

or route signals to other devices using standard XLR patch cables.

Once you start working with your Workhorse, you will quickly come

to understand all of the capabilities and how easy it is to use.

USING THE WORKHORSE

Because the Workhorse is a modular device, there are practically no

limits as to what kind of signal chain you can create. For instance

it can be used as an analog effects router for your workstation,

as a customizable channel strip, a multi-channel preamp for live

recording or as part of a play-back and overdub system. The magic

is the simplicity that manages to bring unlimited fl exibility together.

An example here could be connecting two limiters to tame a stereo

drum track during mix down. Take the output from your recording

system; plug it into the Workhorse XLR inputs and then take the

direct output back from the same card slots. Adjust the limiter to suit.

This is the most basic function.

MULTI-TRACK

INPUT

OUTPUT

OUTPUT

INPUT

LIMITERLIMITER

Setting Up A Channel Strip

The next stage is using several modules together to create a channel

strip. For instance, when recording a vocal track, you may want to

run a mic preamp into an EQ to add some presence and then into a

limiter so that the track stays out of the ‘red’.

Using the old API system, you would connect the microphone to the

mic preamp using a standard XLR cable. The mic preamp output

would then connect to the EQ which in turn would connect to the

limiter. The direct XLR output from the limiter would then be sent to

the recording system.

As with all electronic equipment, turn off the power and turn down

levels before making connections. This will avoid the loud on-off

transient that can damage equipment or blow speakers. Plugging

in a module is merely a matter of sliding it into the Workhorse and

carefully aligning the 15-pin card edge connector. Once plugged in,

secure the module in place using the supplied Phillips screws. After

the module is connected, it will automatically route the signal from

the rear panel connectors to and from the module. If you are using

a Radial 500 series module or one that has been designed to take

advantage of the internal mix buss and Omniport features, these too

will automatically be routed.

Old School Lunchbox

The fi rst step in approaching the Workhorse is going back to the

original API lunchbox. This device was basically a steel enclosure

that fed power to a number of modules. Connecting to and from

modules was done using the XLR connector that was associated with

each card slot. The Workhorse retains all of this connectivity while

adding the convenience of 1/4” TRS and 25-in D-sub connectors.

FROM

MODULE TO

NEXT DEVICE

OUTPUT

9

Radial Engineering Ltd.

SOURCE TO

INPUT

FROM

MODULE

PATC H

CABLE

PATC H

CABLE

MIC PREAMPEQUALIZERCOMPRESSOR

The Workhorse simplifi es the process with a FEED function. This

basically replaces inter-module patch cables. Instead of using an

XLR cable, you simply push the FEED switch into the UP position

and it routes the signal to the adjoining module. When engaged, the

FEED function always sends the signal to the next module working

from left to right (front view). Because the FEED function is tied to

the XLR connector, it will work with new Radial modules and older

500 series modules.

FEEDFEED

MIC PREAMPEQUALIZERCOMPRESSOR

Workhorse User Guide

Page 13

True to the Music

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

INPUT

OMNIPORT

FEED

LINK

1

OFF

OFF

CARD SLOT 1

OUTPUT

OUTPUT

INPUT

-

+

G

-

+

G

-

+

G

Now consider another variation that uses both a patch cable and the

FEED function to split the signal and route it to a fourth module. The

image below shows how this is done by connecting a patch from the

fi rst module to the fourth module while the FEED function routes the

signal to the second and third modules. The mic signal has been

split into two signal paths that can be processed seperately.

FEEDFEED

COMPRESSOR

EQUALIZERCOMPRESSOR

MIC PREAMP

Using Modules In Series And Parallel

When you are using Radial modules, the signal will automatically

be sent to the Workhorse’s internal mix buss while still making the

output available at each card slot. The way this works is quite simple;

each module output is sent to the Workhorse mixer where it can be

turned on, panned left or right and be adjusted. This is where things

can really get wild.

Using the same ‘channel strip’ example as above, you can set up a

mic preamp to connect to an EQ which then will feed a compressor.

The signal will not only be available at the direct output of the

compressor module, but each of the module outputs will also be

routed to the individual mixer channels 1~3. This means that you

can turn on or off each module at the mixer and listen to the signal

before it goes into the next module. This lets you optimize the signal

fl ow for distortion and sonic character. You can record the combined

signal via the warm sounding Jensen transformers on the main

outputs, while still capturing the sound of the original unprocessed

signal using the mic preamp’s direct output at the card slot I/O.

Using The Workhorse For Overdubs

Begin by setting up a channel strip using a mic preamp, EQ and

limiter. These are plugged into slots 1, 2 and 3. Set the FEED switch

in the up position on modules 1 and 2 so that the signal is routed

in series. Plug your mic in turn on the phantom power on the mic

preamp if you are using a condenser microphone. Take the XLR

output from card-slot 3 (limiter) and send this to your recorder. Turn

on channel-3 on the Workhorse mixer to monitor the level via the

monitor outputs or headphones.

To overdub, send the stereo playback tracks into the Workhorse

using mixer channels 7 and 8 via the summing input D-Sub. Pan

channel-7 left, and channel-8 right. Adjust the relative signals

between the channel strip on mixer channel-3 and the stereo

program on channels 7 and 8. Hit record!

MIC

MAIN OUT

23

MIC PREAMPEQUALIZERCOMPRESSOR

CLIP

ON

5

CLIP

PAN

LEVEL

PAN PANPANPAN

LEVEL

CLIP

ON

CLIPON

2341

6

PAN

LEVEL

LEVEL

PAN

LEVEL

CLIP

CLIP

ON

ON

78

LEVEL

CLIPON

CLIPON

PAN

LEVEL

LEVEL

LEVEL

LEVELONLEVEL

Made in Canada

SUMMING MIXER INPUT

PLAYBACK

TRACKS 7~8

MULTI-TRACK

MAIN

ON

MON

ON

48V PHANTOM

+16V / -16V

MONO

FEED FEED

DIRECT OUT

RECORD

TRACK 1

Mix Buss

Channel 2

FEED FEED

CLIP

ON

5

CLIP

PAN

LEVEL

PAN PANPANPAN

LEVEL

2341

CLIP

ON

6

CLIPON

PAN

LEVEL

LEVEL

PAN

LEVEL

CLIP

CLIP

ON

ON

78

LEVEL

CLIPON

CLIPON

Mix Buss

Made in Canada

Channel 3

MAIN

ON

MON

ON

48V PHANTOM

+16V / -16V

MONO

PAN

LEVEL

LEVEL

LEVEL

LEVELONLEVEL

MAIN OUT

MULTI-TRACK

Radial Engineering Ltd. Workhorse User Guide

MIC

Mix Buss

Channel 1

23

MIC PREAMPEQUALIZERCOMPRESSOR

DIRECT OUT

10

Page 14

VARIOUS SETUPS USING THE WORKHORSE

The following setups show how the Workhorse can be used

in the studio or in a live recording environment. There are of

course an unlimited number of possibilities… but these will give

you some ideas of how you can use your Workhorse to create

simple recording channels to advanced reamping systems as

you mix and match various 500 series modules.

Standard setup for a vocal track

This setup uses a microphone, EQ and compressor. The

microphone feeds the PowerPre™ mic preamplifi er which

simultaneously sends a dry, unprocessed track to the recording

system. This track is saved in case further reamping will be

required. The PowerPre™ feeds the EQ which in turn, feeds

the Komit™ compressor-limiter where the signal is sent to the

Workhorse’s internal mix buss. The main output is used to record

the track while the monitor out feeds the near-fi eld playback

system.

True to the Music

Eight Channel Live Recording

This example discusses recording a small jazz ensemble using

eight microphones. For this set up, Radial PowerPre™ mic

preamps are used. Each module’s direct output is connected to

an eight channel recording system so that the each instrument

can be recorded individually and properly mixed back in the

studio. The main outputs are used to feed the PA system. As

these are transformer isolated, ground loops will not pose a

problem. The monitor out is connected to a two channel fi eld

recorder. This will enable the engineer to give the band a

reference recording right after the show. Back at the studio, the

recorder output will feed the Workhorse D-Sub summing input

where the mix will be fi nalized.

Stereo Channel Strip

This setup is used to record a solo acoustic instrument such

as an acoustic guitar, viola or piano using two microphones by

creating two high-performance recording channels using the

Workhorse FEED function. Two PowerPre™ mic preamplifi ers

feed equalizer modules like the Radial Q3™ coil EQ. The output

of the equalizers feed the Komit™ compressor-limiters. The

output of the Komit™ compressor-limiters are routed to the

mixer through the Workhorse internal mix buss. The Workhorse

main output sends the mix to the recorder taking advantage of

the added warmth afforded by the Jensen™ transformers. On

‘recording channel #2’ we have added a Radial Phazer™ module

to the setup. This enables us to focus the two microphone

signals by bringing the fundamentals into phase. Phase aligning

the fundamentals creates for greater realism which can produce

astonishingly clear results. We have turned off the output of most

modules going to the mix buss, choosing instead to only capture

the signal at the end of each chain. At any time, you can audition

the signal from any of the modules going into the mixer section

to compare or if you like, mix it in by adjusting the level to suit.

11

Radial Engineering Ltd.

Workhorse User Guide

Page 15

True to the Music

Crazy Sounding Vocal Track

This is an example of how one can create a weird, wonderful,

extreme vocal track by inserting guitar pedals into the mix and

then creating a radical EQ curve using the Phazer™. This is

done ‘live’ by connecting a mic into the PowerPre™ and

feeding the signal using the feed function into the EXTC™

and Phazer™. The effects send from the EXTC is used to feed

various pedals such as a tube distortion for added grit or maybe

a warm sounding analog chorus instead of the usual digital

plug-in. Notice that only the outputs from the PowerPre and the

Phazer feed the Workhorse mix buss. This allows you to mix in

the Phazer’s effect for radical EQ by either phase cancelling or

phase adding certain frequencies.

Reamping Using The Workhorse

The Workhorse is ideally suited for reamping. This is a two-stage

process whereby you start by recording a dry track and then

once recorded, you send the dry track back from the recorder

to the effects and amplifi ers. Reamping allows the engineer to

change tones and position microphones to optimize the sounds

during the recording process.

Part-1 Recording

The guitar is connected to the JDV™ where the signal is split to

feed the guitarist’s amplifi er using the front panel aux out (you

can take this a step further by adding a Radial X-Amp™ module

which would then allow the guitarist to audition two amps at the

same time). While the guitarist is playing, you are also capturing

a clean track directly from the JDV’s balanced XLR output. This

feeds a spare track on your recording system. You could also

put some mics up in front of the amps to capture the guitarist’s

performance. This may be used later to thicken up tracks. Once

the magical performance is recorded, you can send the guitar

player home. You are now set for part-2 and Reamping. You can

monitor the whole process using headphones or by connecting

your monitors to the Workhorse mixer outputs.

Part-2 Reamping

Send the clean recorded track back into the Radial X-Amp™.

The signal will then be converted to high impedance and sent

to two amplifi ers. You can also introduce effects. Both guitar

amplifi er outputs are transformer isolated to eliminate ground

loops. The amps are captured using microphones that connect to

two PowerPre™ mic preamps. The output from each PowerPre

FEEDs the Komit™ compressors limiters to keep the levels

under control. The stereo signal is sent to the Workhorse mix

buss. Best part here is that you can take your time to move the

microphones around the room to fi nd the best tone (alternately,

if you do not want to use a ‘live’ amp, you can send the signal

into the Radial EXTC™ which can feed a bunch of pedals. Then

bring the signal back and process the tone using the Radial JDX

guitar cabinet emulator. This will produce a much more ‘natural’

sounding recording).

Radial Engineering Ltd. Workhorse User Guide

12

Page 16

FREQUENTLY ASKED QUESTIONS

Q: How do I turn the Workhorse phantom power off?

A: There is no reason to turn the phantom power off. Only modules

such as mic preamps will connect to the phantom power supply

on the edge card connector pins. Turning on or off phantom is

usually done on the mic preamp module.

Q: How do I know that there is suffi cient power for all my

modules?

A: Most manufacturers specify the draw required to properly run

their modules. The Workhorse has 1200mA of current available.

Simply add up the draw and make sure you do not exceed

1200mA.

Q: What happens if I exceed 1200mA?

A: Sometimes nothing will happen as most times you will not be

running the modules to their fullest. But when they are run hard,

starving the module will result in distortion and reduced signal

handling.

Q: Can I damage a module due to under-powering?

A: No. It just won’t sound as good.

Q: Why is there no power switch on the Workhorse?

A: Mostly because there is no more space. We recommend that all

studio equipment be routed to a central power strip. These are

usually equipped with an on-off switch that would enable you to

turn on or off all your gear at one time. For safety, always turn

the speakers on after other equipment. This will avoid turn-on

transients from damaging your speakers.

Q: I fi nd that putting in and pulling modules is diffi cult. Is this

normal?

A: Yes. Most modules are designed to fi t snugly. Just patiently

wiggle them in and out. Be careful when putting them in so that

they align properly with the card edge connector. Once you

have done this a few times it will become easier.

Q: I fi nd some non-Radial modules very tight. Is this normal?

A: Unfortunately, due to lack of standards, you may fi nd this to

be the case. You can usually wiggle them in. In some cases,

you will have to remove the bottom tray. This is why we have

created the Workhorse Open Source Document. Hopefully most

manufacturers will adopt this standard as we move forth.

Q: Can I hurt myself by touching the back plane PC board?

A: This is a low power device so getting a shock is unlikely. Due

to legal liability, we cannot recommend the practice. This is why

the Workhorse comes with a protective plastic cover that can be

cut as needed to keep dust and roaming hands out.

True to the Music

Q: The headphone out is very loud. Can this damage some

headphones?

A: Yes. Always set the headphone level down low and increase

until comfortable. The extra loud headphone out is designed

to accommodate all types of headphones and enable the

Workhorse to be used in very loud environments such as in

night clubs. Read the warnings in the manual for safe use.

Q: Do I need to worry about the red and black ground lugs on

the back panel?

A: No. These are coupled together from the factory. These are

only made available for professional studios that have special

grounding requirements.

Q: What is the difference between the XLR and 1/4” TRS

jacks?

A: There is no difference. They are wired in parallel and there for

convenience.

Q: I notice that there are air vents on the top. Will covering

these pose a problem?

A: Air vents are designed to allow modules to cool down. Try to

leave a space above for ventilation. Most modules will not run

so hot as to be a concern. Simply touch the module to see if it

runs hot.

Q: Can I plug a keyboard directly into the Workhorse summing

mixer?

A: Yes. There is plenty of gain in the mixer to handle most buffered

instruments.

Q: Why is the power supply external?

A: The main reason for an external power supply is to free up

space inside the chassis for the Workhorse mixer section.

Additional benefi ts include reduced electromagnetic

interference (EMI) and easy adaptability to international AC

power standards.

Q: Will the FEED function work on old API modules?

A: Yes, the FEED switch connects the card slot’s output jack to the

input of the next card slot.

Q: Can I damage the card edge connector?

A: Although unlikely, you can damage anything if you are not

careful. The Workhorse employs high-quality EDAC connectors

that are designed for many insertions. Just take it easy when

plugging in or out. Always disconnect the power before inserting

or removing modules.

Q: What happens if I use a 1/4” mono connector instead of a

1/4” TRS?

A: You will unbalance the signal and the level will drop by around

6dB. This means it will not be as loud and, if you are running

cables beyond 20 feet, you are more likely to pick up noise.

Otherwise, it should work fi ne.

13

Radial Engineering Ltd.

Workhorse User Guide

Page 17

True to the Music

TROUBLE SHOOTING

1. No Power:

• Check the power 5-pin XLR connection on the rear panel.

• Ensure the power supply is plugged into a working outlet.

2. No sound at individual XLR outputs outputs:

• Check the front panel LED Power indicators and ensure the

Workhorse is powered up.

• Check that all modules are seated properly and secured.

• Check audio cable connecting to and from the Workhorse.

• If you are using the mixer section, ensure the it is setup

correctly and the channel is on. Also check the level and pan

settings.

• Check that the eight FEED switches are set to the proper

setting for your setup.

3. No sound at mixer outputs:

• Ensure the correct mixer channels are active and their LED

indicators are illuminated.

• Check that the level controls are set to a nominal level and the

pan controls are positioned at the center mark.

• Ensure the main and monitor master level controls are set to a

nominal level and that the ‘ON” switch is depressed.

• If you are using the main outputs check the insert jack and any

equipment connected there.

3. A loud humming noise is audible in the system:

• Check the source device for proper connections and settings.

• If the module(s) you are working with allow it you can try lifting

the signal ground.

• Plug all your equipment into the same power source to

minimize ground loops.

• Use the Workhorse Main outputs. These are transformer

isolated to eliminate hum and buzz caused by ground loops.

4. Some modules are louder than others:

• Use the mixer section to amplify a low output module and bring

it up to par with other modules.

5. Sound is distorted when using the Summing Mixer input:

• Although the 25-pin D-Sub input for the summing mixer is

based on the Tascam™ analog audio pin-out it unbalances

the signal by grounding the cold (-) lead. Most devices with

a balanced 25-pin D-Sub output will work fi ne driving the

unbalanced summing mixer input. However, in the remote

chance that the source device creates distortion with this

arrangement you can solve the issue with a custom 25-pin

D-Sub to XLRF cable wherein the XLRs pin-3 (cold) is left

unconnected inside the shell.

6. Sound from one module is appearing on different output:

• Check the FEED switch on the rear panel. It may be mistakenly

engage causing the signal from one module to be routed to the

next.

Radial Engineering Ltd. Workhorse User Guide

14

Page 18

SPECIFICATIONS

True to the Music

Circuit type: Virtual earth mix buss integrated

operational amplifi er - Class AB

Max output level: +22dB (20Hz to 20kHz)

Voltage Gain: Up to +23dB on the main output

Distortion: 0.007% @ 1kHz with 10dB in and 10dB

out

0.05% @ 20Hz with 10dB in and 10dB out

Signal to Noise: -91dB with +20dB output

Card Slot Inputs: 8 x balanced XLR, ¼” TRS, D-SUB

Card Slot Outputs: 8 x balanced XLR, ¼” TRS, D-SUB

Card Slot Impedance: Depends on modules used

Internal Mix Buss: 4.75k Ohms input coupling resister

Summing Mixer Input: DB-25, Unbalanced +4dB/-10dB

with up to +20dB capacity;

input impedance = 4.75K Ohms

WORKHORSE BLOCK DIAGRAM

D-SUB INPUTS D-SUB OUTPUTS SUMMING MIXER INPUTS

OTHER

INPUTS

4K75

INPUT OUTPUT INPUT OUTPUT

4K75

CHANNEL 8

Main Output: +4dB balanced stereo XLR and ¼” TRS

outputs; Jensen™ transformer isolated

Main Inserts: ¼” TRS - tip = send; ring = return

Monitor Output: +4dB balanced stereo XLR and ¼” TRS

outputs; transformerless; +4dB balanced

Headphone Out: ¼” TRS Stereo - 2.8VRMS @ 8 Ohms

(up to 7VRMS depending on headphone

impedance)

Ground: Red: audio, Black: chassis

Power Supply Input: 100V - 240V AC (50~60Hz)

Power Supply Output: 1600mA - External switching type with

5-pin XLR, +/-16 VDC; 48V phantom

Dimensions: 19” wide x 5.25” tall x 7.44” deep

482.6 wide x 134 tall x 189mm deep

Weight: 22lbs / 10kg

INSERT: TIP=SEND / RING=RETURN

MAINS INSERT

MONITOR

ON/OFF

MONITOR

LEVEL

MONITOR OUTPUT

LEFT

PIN 11

MIX BUSS

PIN 9

PIN 7

OMNIPORT

15

Radial Engineering Ltd.

EXPANSION BUSS

FEED SW

CARD SLOT 1

LINK SW

PIN 11

MIX BUSS

PIN 9

PIN 7

CARD SLOT 2

FEED TO

NEXT CHANNEL

MIXER CH. 1

LEVEL

MIXER CH. 2

LEVEL

OVERLOAD

LED

OVERLOAD

LED

STEREO INPUTS

EXPANSION BUSS

MAINS INSERT

PAN

MIXER CH. 1

ON/OFF

PAN

MIXER CH. 2

ON/OFF

MASTER BUSS

STEREO OUTPUTS

MASTER

ON/OFF

MONO / STEREO SW

MASTER

LEVEL

HEADPHONE

LEVEL

MONITOR OUTPUT

TRANSFORMER

ISOLATION

TRANSFORMER

ISOLATION

HEADPHONE

OUTPUT

RIGHT

MAIN OUTPUT

LEFT

MAIN OUTPUT

RIGHT

OMNIPORT

Workhorse User Guide

Page 19

True to the Music

-

+

G

D-SUB CONNECTOR FOR CARD SLOT I/O

13

Pin #

1 Channel 8 Hot

2 Channel 8 Ground

3 Channel 7 Cold

4 Channel 6 Hot

5 Channel 6 Ground

6 Channel 5 Cold

7 Channel 4 Hot

8 Channel 4 Ground

9 Channel 3 Cold

10 Channel 2 Hot

11 Channel 2 Ground

12 Channel 1 Cold

13 Not Used

+

G

-

1

G

25

-

2

-

3

G

+

+

+

G

-

4

-

6

-

5

G

+

Pin #

14 Channel 8 Cold

15 Channel 7 Hot

16 Channel 7 Ground

17 Channel 6 Cold

18 Channel 5 Hot

19 Channel 5 Ground

20 Channel 4 Cold

21 Channel 3 Hot

22 Channel 3 Ground

23 Channel 2 Cold

24 Channel 1 Hot

25 Channel 1 Ground

1

+

G

-

8

-

7

G

+

14

D-SUB CONNECTOR FOR UNBALANCED

SUMMING MIXER INPUT

13

Pin #

1 Channel 8 Hot

2 Channel 8 Ground

3 Channel 7 Ground

4 Channel 6 Hot

5 Channel 6 Ground

6 Channel 5 Ground

7 Channel 4 Hot

8 Channel 4 Ground

9 Channel 3 Ground

10 Channel 2 Hot

11 Channel 2 Ground

12 Channel 1 Ground

13 Not Used

+

G

2

1

GG G G

+

+

G

4

3

G

+

+

GGGG

6

5

G

G

+

Pin #

14 Channel 8 Ground

15 Channel 7 Hot

16 Channel 7 Ground

17 Channel 6 Ground

18 Channel 5 Hot

19 Channel 5 Ground

20 Channel 4 Ground

21 Channel 3 Hot

22 Channel 3 Ground

23 Channel 2 Ground

24 Channel 1 Hot

25 Channel 1 Ground

+

GGG

8

7

+

CONNECTOR WIRING

XLR Connector

GROUND

TRS ¼” Phone Connector

5-Pin XLR Power Connector

COM

+48VDC

GROUND

1

3

COLD (-)

1

234

-16VDC

2

+16VDC

5

COLD (-)

COM

HOT (+)

HOT (+)

CARD-EDGE CONNECTOR SPECIFICATIONS

The following details the pin confi guration as used in the Workhorse. The ‘Old’ refers to the published API/VPR specifi cations. The ‘Current’

refers to the various racks we have investigated on the market. The ‘New’ is the Radial standard as outlined in the Workhorse Open Source

Document.

Pin # Old API Specifi cation Current use in market New Radial Specifi cation

1 Chassis Ground Chassis Ground Chassis Ground

2 Output +4dB Hot Output +4dB Hot Output +4dB + Phase

3 Output -2 Hot - - - - - -

4 Output Cold Output Cold Output +4db - Phase

5 A- Ground A- Ground Analog Ground

6 Stereo link Stereo link Stereo link

7 Input -2 Cold - - - ¼” TRS Omniport - Ring

8 Input +4dB Cold Input +4dB Cold Input +4dB - Phase

9 Input -2 Hot - - - ¼” TRS Omniport - Tip

10 Input +4dB Hot Input +4dB Hot Input +4dB + Phase

11 Gain adjustment - - - Radial Buss feed

12 +16VDC supply +16VDC supply +16VDC supply

13 Power Ground - 0V ref Power Ground - 0V ref Power Ground - 0V ref

14 -16VDC supply -16VDC supply -16VDC supply

15 +48VDC Phantom +48VDC Phantom +48VDC Phantom

Due to the lack of clear standards, we have worked within the

limitations of keeping the old standards while making the Workhorse

as fl exible as possible. For instance Pin-3 has been left open

because sometimes (on some modules) it is paralleled with Pin-2.

This arrangement eliminates problems between other modules. We

also discovered that sometimes Pin-7 and Pin-9 can be paralleled

with Pin-8 and Pin-10, so the Omniport™ jack will not interfere.

The BUSS FEED (Pin-11) is simply whatever signal the designer

will want to send to the buss (main out of module typically) and is

essentially an amplifi er feeding a 4K7 resistor to Pin-11. That is

connected to the inverting (virtual earth) input of an op-amp (in the

mix section of the rack) with a 4K75 feedback resistor. This is called

Radial Engineering Ltd. Workhorse User Guide