The Accu-Series -

Accu-Pro™

Accu-Dose

Accu-kV

®

Radiation Measurement

Systems

User Guide

Radcal Corporation

426 West Duarte Road

Monrovia, CA 91016-4591 USA

USA (626) 357-7921

Fax USA (626) 357-8863

email Service@radcal.com

www.radcal.com

Radcal Part # MCD/9096

4091099 Rev:K4

Firmware V6.08 (Accu-Pro)

Firmware V7.03/V7.23 (Accu-Dose)

Firmware V5.22 (Accu-kV)

Printed: Feb 2013

INTRODUCTION ................................................................. 4

GETTING STARTED ............................................................. 6

MAKING ION CHAMBER MEASUREMENTS ..................................... 11

REFERENCE .................................................................... 12

Display ................................................................... 12

Sounds ................................................................... 13

Sensors .................................................................. 14

Main–Menu Functions .................................................... 17

Setup–Menu Functions ................................................... 19

Batteries ................................................................. 21

PERFORMANCE ................................................................ 23

Environmental conditions ................................................ 23

kV Sensors ............................................................... 23

Diode Sensors ........................................................... 25

Ion chambers ............................................................ 25

Ion Chamber Dose Timing Specifications ................................. 25

Waveform Output ........................................................ 36

Part numbers ............................................................ 36

OPERATOR MESSAGES ........................................................ 37

Self-test .................................................................. 37

Accu-kV .................................................................. 37

Ion chambers and dose diodes ........................................... 38

ACCESSORIES ................................................................. 41

XLPRO Excel add-in ...................................................... 41

90M9 mAs Sensor ........................................................ 42

90M10 mAs Sensor ....................................................... 43

10A96 Ion chamber Adapter .............................................. 44

Chamber Positioner ...................................................... 45

Accu-Pro™ System Carrying Cases ...................................... 46

APPENDIX - Mammography kVp measurements on Hologic Selenia ..................... 47

3

INTRODUCTION

The Accu-series instruments include the Accu-Pro™ for Dose and kV, the Accu-Dose for Dose only and

Accu-kV for kV only measurements. This manual is applicable to all instruments in the Accu-series.

The Accu-Pro™ system measures the characteristics of a diagnostic x-ray machine. Measurements are

processed and displayed by a microprocessor-based control unit. Sensors connect to the control unit via

a 4m cable that carries only digital signals and operating voltages to eliminate cable noise. Dose is

measured with ion chambers or solid-state detectors. Radcal Accu-kV sensors determine kV, filtration

and half-value measurements (diagnostic sensor) using differential absorption and an array of solid state

detectors. The mammographic (22-40kV) sensor Mo/Mo outputs can be corrected to W/Rh and W/Ag

anode-filter combinations (Hologic Selenia x-ray machine only).

A 13 kHz sample rate for kV measurements is used with FFT-based ripple measurements for accurate

kVp measurements on high-frequency generators.

Automatic compensation of kV measurements for filtration is available for diagnostic x-ray

measurements. This also provides estimates for filtration and half-value layer.

Stand-alone exposure measurements can be made using the Ion chamber digitizer and an ion chamber

or the dose diode digitizer and the DDX6-W or DDX6-M sensors. Using these sensors in conjunction with

the kV sensors provides dose and dose rate measurements synchronized to an x-ray pulse.

Using 40X11-W and DDX10-W or 40X10-M and DDX10-M sensors allows simultaneous dose and kV

waveform measurements

mA, mAs and mA waveform may be measured in conjunction with kV measurements using invasive or

non-invasive mA sensors.

The Accu-Pro™ operates from rechargeable NiMH or alkaline C cells.

The figure on page 46 shows the Accu-Pro™ system in its carry case.

A USB interface allows a PC to control and process measurements performed by the Accu-Pro™ system

. XLPRO, an Excel add-in, uses this capability to produce reports, graphs and to automate

measurements.

The figure on page 40 shows the pushbutton controls and the 2-line display. The connectors for the mA

sensor, USB and waveform are also visible. The battery charger interface is at the rear of the control unit.

The in-beam sensor connector is on the opposite side.

The controls include UP-arrow, DN-arrow and select pushbuttons that are used to navigate the menu

and to activate measurements. A test pushbutton provides a simulated x-ray signal so you can observe

how the measurements work. The power pushbutton provides for orderly shutdown and startup.

Measurement results are presented on the display and are available in digital form on using the USB

connection. The BNC provides calibrated real-time kV, dose or mA waveforms.

4

Accu-Pro™ Diagnostic Ion Chamber and kV Sensor Components

A. Accu-Pro™ (9096) Control Unit

B. 40x12-W Diagnostic Range kV Sensor

C. 10X6-6 Ion Chamber Sensor

D. Positioner

E. 9660 Ion Chamber Digitizer

F. 90C6-4 Sensor Cable

5

GETTING STARTED

This describes initial assembly and operation of an Accu-Pro™ system comprising a control unit, sensor

cable, diagnostic kV sensor and a 6cc ion chamber with an ion-chamber digitizer.

IMPORTANT: Stabilization is required before making any ion chamber measurements.

Stabilization is best done by putting the unit in Dose Rate mode/High Sensitivity and waiting for 3

minutes. See page 11 for details.

Connect the sensor cable to the control unit

:

Insert the rectangular connector on the sensor cable into

the socket on the right side of the instrument with the

Radcal logo facing you. It will click into place. To remove

it, pinch the levers on the side of the connector and pull

back.

Connect the kV sensor to the sensor cable

:

Hold the round connector by the rubber strain relief

and engage the kV sensor by rotating the connector

until it aligns with the mating socket on the sensor and

they move to engage, then press the connector. It

should click into place. To disconnect, pull straight

back on the ring, not on the strain relief, and the

connector will unlatch. Never attempt to unscrew the

connector.

Sensor cable connection

Connect the Ion chamber

Connect the ion chamber to the larger

circular connector on the Ion chamber

digitizer. Align the red dots and push the

connector until the mating surfaces

contact one another. Connect the sensor

cable to the smaller connector in the same

fashion.

kV sensor connection

Ion chamber connection

6

Connect the battery charger:

Connect the charger to the control unit

and plug it into an ac outlet. The charge

indicator should turn on orange indicating

the battery is being charged. The

instrument can operate while the battery

is being charged.

7

Turn on the Accu-Pro™:

Press the green power button. A set of vertical rectangles marches across the display to assure it is

operating, the calibration date is displayed, and self-test is performed. During self-test the control unit

reads the type and calibration factors of each sensor, measures the ion chamber temperature and the

ambient pressure. When self-test completes, the display will show the chamber information:

6cc Corr 1.03

HV Stabilize 13s

while the ion chamber and bias supply stabilizes. When the stabilization times out, pressure and

temperature display:

Press 99.2 kPa

Temp 20.1 deg C

The Corr value shown is the temperature and pressure correction that will be applied to the ion chamber

readings.

The top line of the display will then show:

Change or SELECT

and the second line will show setup or whatever measurement mode was active the last time power off

occurred.

If self-test is unsuccessful, a failure message is displayed. Pressing UP or DN allows operation to

proceed, however you must resolve the problem before accurate measurements can be performed. See

the discussion of error messages on page 37

Setup Defaults

The Accu-Pro™ has a number of options that are controlled from the Setup menu. The following

procedure resets the setup functions to factory defaults. Use UP to get

Change or SELECT

Setup

and press select to enter Setup . Press DN twice. The display should show:

SELECT restores

setup defaults

Then press select:

Accept changes ?

> OK

appears. Use DN until:

Press SELECT to

exit Setup:

appears. Press select.

Accept changes?

> OK

appears again. Press select to return to the main menu with all settings at factory defaults.

8

Functional test

Now that the Accu-Pro™ is operating, you can use the test button to become familiar with the operation

of the unit. The UP and DN arrows move through the main menu. The top line of the display continues to

show

Change or SELECT

while the second line shows the function to be performed.

Dose Rate test

Use UP or DN to reach the Dose Rate function, and press select.

The display will briefly show

6cc Corr 1.02

measuring zero

after which it will become

[ Dose Rate

0.0 mR/min

The up arrow indicates low-sensitivity mode.

Press and hold test

The display becomes:

[ Dose Rate

999.5 mR/min

The dose rate value depends on the ion-chamber calibration factor. It lies between 940 and 1060

mR/min.

KV Pulse test

- Diagnostic sensor 40-160kV

Press UP or DN until the display shows:

Change or SELECT

kV Pulse

Press select.

After a few seconds, the display changes to:

kV Pulse

W

while the kV sensor zero is being determined. After another few seconds, the annunciator beeps, the W

disappears and the system is ready to perform a measurement:

kV Pulse

A

The A indicates automatic filtration correction is active.

Press test. The kV sensor responds as if it had been exposed to a 100kV, 100 ms x-ray signal. When the

kV sensor detects a signal, the display becomes:

kV Pulse

The arrow indicates a signal is being measured. The arrow is replaced by a W when the pulse ends and

kV calculations are being performed. Finally, a beep sounds, the W disappears and the measurement

results are displayed:

The kVp reading results from the filtration correction for 10mm Al.

98.4 kVp

A1.99mR l 100ms

9

Pressing select displays filtration:

0.300 mm Cu HVL

A10.0mm AL 7.12

Pressing select again displays dose measurements:

1.993mR/pls

A1.196R/min C

The C indicates the radiation measurement comes from the dose sensor.

KV Pulse test

- Mammographic sensor 22-40 kV

The factory default setting is for a Mo/Mo track filter combination. To change to another combination see

MODE SELECT in Setup (page 19). See Appendix (page 47) for calibration example.

Attach the mammography kV sensor to the control unit.

Use UP DN to come to

Change or SELECT

kV Pulse

Press SELECT and have the display show

kV pulse

Press test. The kV sensor responds as if it had been exposed to a 30kV, 100 ms x-ray signal. The

display shows for a Mo-Mo setting

30.0kVp

Dx.xxmR 100ms

The D stands for default filtration - 30μm Molybdenum for the Mammography sensor

For a Tungsten/Rhodium setting, you will see a T in the lower left of the display after you select kV pulse.

On pressing the test button, you then have the display show

31.6kVp

Txx.xxmR 100ms

A Tungsten/Silver setting is different from the Tungsten/Rhodium setting. There is a range of calculated

kVp's (25-33kV) that exceed a set error band and the instrument will show an error message as a result.

The test button shows what this looks like. You will get two successive screens. The first reads

Exposure error

Bad W/Ag kV

The next screen reads

The S stands for silver

Once the measurement has been completed, the display retains the values. A subsequent exposure does

not replace them until the measurement is complete The > and W appear to the left of the exposure value

to indicate signal–present and kV– calculation respectively. When the W disappears, a beep sounds and

the new reading is displayed. An exposure made when either > nor W are displayed will not be correctly

analyzed.

kV-try again

SError cleared

10

MAKING ION CHAMBER MEASUREMENTS

1. Allow the system to reach equilibrium by selecting dose rate mode and waiting at least three

minutes. Do not touch digitizer. One does not need to shut the system off when replacing

chambers, however, do not disconnect the chamber when actual measurements are being made.

Each time a new chamber is used, the system must re-stabilized

.

Note: For changing environments, allow 10 minutes per 10 C for the sensor/electronics to

equilibrate.

2. Ensure that the system is set to high sensitivity on

(Setup->Mode SELECT->High sensitivity->On). This ensures that the system performs a fine

zero (as opposed to a coarse zero) prior to every measurement.

3. Do not move or touch the digitizer or the ion chamber during the zero measurement interval. If

low-level measurements are being made and there is a significant delay between measurements

(> 2-3 minutes) it is prudent to force a full re-zero by exiting the mode and re-entering.

11

REFERENCE

Display

The 2-line 16-character LCD displays menu selections and measurement results.

Characters positioned at the left side of the display have special meaning:

> in Setup indicates a parameter choice. Press select to chose the item.

For dose measurements:

? indicates dose-sensor signal was outside calibrated range .

> indicates high-sensitivity mode measurement.

[ indicates low -sensitivity mode measurement.

] indicates cumulative (zero-corrected) dose is negative.

For kV measurements:

W means Wait. The kV system is unable to process another exposure while W is displayed.

A indicates automatic filtration compensation is enabled.

D indicates default filtration will be used: 2.5 mm Aluminum for the diagnostic sensor.

30μm Molybdenum for the Mammography sensor

M indicates a user-selected filter (other than 2.5 mm Al).

T indicates a Tungsten/Rhodium anode/filter

S indicates a Tungsten/Silver anode/filter

In the lower right corner of the display:

C indicates a dose sensor (ion chamber or diode)

K indicates dose from the Accu-kV diode

The kV display may be configured in Setup. The following table shows the selections for each of the four

locations on the display. Default

values are underlined.

Location Measurement

Upper Left kVp

kV practical kV

kV avg

reduced

Upper

Right

Lower

Left

Lower*

Right

mAs

conv dose

width ms

width

pulses

width

pulses

kV diode

dose rate

width

ms

width

ms

rel

dose rate

mA

mA

pulses

* Readout not present if Lower Left is Conv Dose in kV

12

Fluoro Display Scrolling:

The kV displays provide filtration information by scrolling the display using select. A second press of

select in kV Pulse and Dental modes provides exposure information if a dose sensor or Accu-kV diode is

connected and displayed.

Sounds

A brief(5ms) 4 kHz tone is produced whenever a key-press is recognized. A longer (100 ms) tone occurs

when the kV measurement computation finished and a new reading is displayed. The longer sound also

occurs when an error occurs.

13

Sensors

The Accu-Pro™ control unit can connect to various sensors to provide dose and x-ray beam information.

The three main classes of sensors are the Accu-kV sensors that determine x-ray beam characteristics,

the ion chambers that measure radiation dose and the diode-based radiation sensors. Also available are

mA sensors used to determine x-ray anode current.

KV sensors

The Accu-kV sensors use differential absorbers and photodiodes to determine kV. You can select the

filtration to be used for kV calculations in Setup. Automatic filtration correction is available for the

diagnostic sensors. Both mammographic and diagnostic sensors are available that can accept a dose

diode input for observing radiation waveforms and to provide dose measurements synchronized to with

the kV pulse.

Diagnostic sensors are black; mammographic ones are purple.

40X9-M - Basic mammographic Accu-kV sensor.

40X10-M - Same as 40X9-M with provision for DDX-10M diode sensor to observe radiation

waveform using oscilloscope or XLPRO. (Discontinued - see below)

40X9-W - Basic diagnostic Accu-kV sensor. (Discontinued - see below)

40X10-W - Same as 40X9-W with provision for DDX-10W diode sensor to observe radiation

waveform using an oscilloscope or XLPRO (Discontinued - see below)

40X11-W - Same as 40X9-W with provision for DDX-10W and automatic filtration compensation.

(Discontinued - see below)

40X12-W - Same as 40X9-W with automatic filtration compensation.

FFT kV SENSORS with FLASH HVL (diagnostic range)

The D iagn ostic range sens or accu racy is ± 1 kV o r ± 1 % wh ichever is largest. The m amm o sen sor has a n M o -Mo

accuracy of ± 0.5 kV and < ± 1 kV for other track-filters.

40X12-W Accu-kV

The sensor f or Diagnostic range (40 kV to 160 kV) measu rements

Besides kVp , also measures, displays, and compensates for beam hardness (add ± 1 % when

on). Inherently correctly reads AMX4+ and AMX 700 portables. Flash H VL: ± 0.3 mm Al and ±

10 % of reading, 1-23 mm total equivalent thickness Al, 40-160 kVp.

40X9-Mo Accu- kV

The senso r for Mammographic range measurement s

This versatile sensor is designed for 0.5 kV accuracy for Mo-Mo mammographic beams. It may

also be used at < ± 1 kV accuracy for Tungsten-Silver / Rhodium tubes on Hologic Selenia

mammography machines.

Recommended for starter kit configuration.

14

Ion Chambers

Radcal ion chambers are recognized for reliable measurements They exhibit excellent energy response.

Their omnidirectional response makes them suitable for leakage and scatter measurements as well an

CT measurements. They are available in specialized configurations for particular systems. Ion chambers

require care in handling, require a bias voltage which must stabilize after bias is applied, and are much

larger than diode sensors.

ION CHAMBER DOSE SENSORS

The Ion Chamber Dose Sensors feature:

Calibration Accuracy ± 4%, Energy Dependence ± 5%. Plug-and-play.

10X6-6

The General Purpose, in Beam Chamber

A well documented wide dynamic range chamber with many dose

and rate applications.

10X6-6M

The Dedicated Mammography Chamber

A world standard for mammography.

10X6-60

The 'Service' Chamber

This thin profile makes it ideal for low input dose at an image

receptor and many other uses.

10X6-3CT

The Chamber for Computed Tomography Dose Index (CTDI)

Another industry standard.

10X6-180

The Leakage and Low Level Measurements Chamber

For leakage measurements. Cross-section of 100cm

low dose to image receptor.

10X6-1800

The Radiation Protection Chamber

For very low-level radiation measurements such as sheilding,

leakage, and environmental. Superior to typical survey meters for

accuracy.

2

. Also for very

Recommended for starter kit configuration.

15

Diode dose sensors

Diode sensors are compact, rugged, insensitive to handling, “instant-on” and do not require temperature

and pressure correction’ They are somewhat directional which reduces the effect of scatter. Their

energy response is not as uniform as the 10X6 ion chambers. Their directional response makes them

unsuitable for CT, scatter and leakage measurements. Temperature-dependent leakage current makes

them unsuitable for long-term dose measurements.

Accu-kV diode sensors (DDX10) are available that work in conjunction with an Accu-kV sensor. They

allow viewing radiation waveforms captured simultaneously with kV waveforms. They cannot make standalone radiation measurements. (Discontinued

DDX6 diode sensors connect to the DD60 diode digitizer. They are standalone dose sensors providing a

full set of radiation measurements.

DIODE DOSE SENSORS

The Diode Dose Sensors feature:

Calibration Accuracy ± 4%, Energy Dependence and Filtration dependence: see below.

DDX6-W

The Diode Dose Sensor for Diagnostic range measurements

Energy dependence ± 5 %, 40-150 kV at 2.5 mm Al. Filtration

dependence + 5 % to -10 % for 2.5 to 23 mm Al.

DDX6-M

The Diode Dose Sensor for Mammographic range measurements

Energy dependence ± 5 %, 20-40 kV, 25-35 µm Mo. ± 5 % 25-35 kV 30

µm Mo + 2 mm Al. ± 10% 22-40 kV, 30 µm Mo + 2 mm AL.

Recommended for starter kit configuration.

Relative dose:

The relative dose rate output is based on a single channel from the kV sensor. It is uncalibrated and

uncompensated, however it can serve as a measure of relative output for consistency tests and the

analog or USB waveform can assist in troubleshooting.

16

Main–Menu Functions

Italics indicate default functions. Using Setup you can add or remove functions to customize the main

menu. A flow chart representation of the main menu is shown on the enclosed diagram.

Setup

Provides access to configuration settings. See Setup–Menu Functions on page 19.

Dose Rate

Measures and displays dose rate. Performs an auto-zero and measures environmental conditions when

the mode is first selected. Applies that value to each reading. Measurement interval depends on dose

rate and varies between 0.3 and 5 seconds. An arrow in the upper left corner is on when a measurement

is in process. It points upward when low sensitivity mode is selected, and to the right the for high

sensitivity.

Max Dose Rate

Measures Dose rate. Displays the result only if the measured rate is greater than that displayed. select

resets the stored value.

Dose Accum/Hold

Measures total dose. Performs an auto-zero and measures environmental conditions when mode is first

selected and applies those values to the measurements. A down-pointing arrow in the upper left of the

display appears when accumulated zero-corrected dose is negative; up- and right-pointing arrows

indicate measurements in normal and high-sensitivity modes respectively. Updates the display once per

second.

Pressing select resets the accumulation but not the zero.

Auto Dose

Automatically measures the dose and duration of a single exposure. Displays the result until another

exposure occurs. Starts when the dose rate exceeds 0.01% FS; stops accumulating dose 200 ms after

the rate falls below 0.006% FS. Duration is measured between the trigger point and 50% of the peak rate.

The ending delay allows collection of all the charge in the exposure.

Last Dose

Like Dose Accum/Hold except select doesn’t reset the dose accumulator. The accumulator is updated

every 500 ms.

Pulsed Cine

Accumulates dose and displays it in units of dose per pulse or dose rate. Use Setup to define 6

measurement conditions, each of which specifies pulse rate (pulses/s), delay(pulses) , acquisition(pulses)

and threshold(varies with chamber). Available pulse rates include automatic (indicated as 0 pulses /s)

that works up to approximately 16 pulses/s and selected values between 0.25 and 90 pulses/s. The x-ray

machine must be operating during the entire time of the measurement.

kV Pulse

Measures and displays kVp and duration. If a dose sensor is connected measures and displays pulse

dose and dose rate. If the mA sensor is connected integrates mA to obtain mAs. Displays mA or mAs.

kVp measurements are calculated using a 100ms interval near the end of the pulse. Analyzes kV

waveforms up to 5 sec. Use select to access filtration and additional dose measurements. See page 12

for a description of the display options. See Display discussion on page 12 for the meaning of special

characters A, D and M (in filtration) and C and K (in dose).

17

kV Dental

Operates like kV Pulse. Disregards low-intensity preheat pulses if this feature is enabled in Setup.

Duration can display in pulses for 50- and 60-Hz half-wave machines.

kV Fluoro

Operates like kV Pulse. Measures kV for 1 second, computes and displays the result and then repeats.

Displayed values change slightly to adapt to a continuous waveform. Width measurements are omitted;

dose and mAs become dose rate and average mA respectively.

Power off

Turns the unit off. Saves the operating mode and displays

Power off

for several seconds and then removes power.

Occurs automatically after 30 minutes of inactivity or when power is pressed during operation.

18

Setup–Menu Functions

Pressing select at the main menu display

Change or SELECT

setup

enters Setup. The following information and options are provided in this mode::

! Serial No. and firmware Version

This manual applies to version 6.

! Pressure and temperature

Values used for ion-chamber compensation. Prefixed with Std if measured not selected.

! SELECT restores setup defaults.

Restores all items in Setup to default values. Default values are shown as Default

descriptions.

See detailed instructions on page 8

! Mode SELECT

Parameter Choices Accu-Pro Accu-Dose Accu-kV

in the following

Pressure Measured

Temperature Measured

Len/area suffix On(*cm or *cm2)/Off

High sensitivity

1

On/Off XX

Radiation units Roentgens

Auto shutdown On

(30 min)/Off X X X

Time units Seconds/Minutes

Mammo anode/filter Mo/Mo,

DAC output kV

1

The Accu-Pro measures the background zero when you select a dose mode. If high sensitivity is set to

/mA/Rel. intensity/dose rate X X

/Std 101.3 kPa X X

/Std 22 deg C X X

XX

/Grays/Coulombs X X

/Hours X X X

W/Ag, W/Rh X X

off, the system will make a quick coarse zero measurement. Some fluctuations will be observed in dose

rate mode and dose accumulate may exhibit drifting. If high sensitivity is set to on, the system will make

a fine zero measurement which takes 3 to 5 seconds. The dose rate will fluctuate much less and the

dose accumulate drift will be greatly reduced. It is recommended that high sensitivity mode is enabled for

most dose measurements.

! Function SELECT

Add/Remove functions from the main menu. See Page 17 for a list of functions

! kV disp(lay) SELECT

See table on page 12

! Intrinsic filt(ration) SELECT

Selects the filtration used to compute kV in the diagnostic range. Auto enables automatic calculation

based on beam hardness.

Auto

, Cu (32 steps from 0 to 0.695 mm), Al (32 steps from 0 to 23 mm).

19

! Dent(al) thr(eshold) SELECT

Raised threshold for kV-Dental. Values are multipliers of the kV pulse threshold. 1, 10, 25, 50,

100, 250

, 600, and 1500.

! Pulsed Rad Mod Index no. SELECT

Set up presets 0 thru 5 for Pulsed/Cine mode. For each, select four parameters:

Pulse Frequency

00.25.512345

66.2577.5891012.5

15 25 30 40 50 60 75 90

Trig threshold.

Number is relative dose rate. () is dose rate in nR/sec for 10X6-6

3 (55) 5(92) 10 (184) 18 (330) 30 (550)

55 (1000) 100 (1840) 182 (3300) 300 (5500) 500 (9200)

Acquire Delay

Number of frames: 1 - 256

converted to time based on selected pulse frequency

Acquire Interval

Number of frames: 1 - 256

converted to time based on selected pulse frequency

! Press SELECT to exit Setup

If any changes have been made, you then will see

Accept Changes?

> OK

select accepts the changes and returns to main menu.

UP or DN changes OK to Cancel and then select returns to the main menu discarding the changes.

20

Batteries

The Accu-Pro™ is powered by 2 C cells located behind a removable cover at the lower rear of the control

unit. Rechargeable nickel-metal-hydride (NimH) C-cells (Energizer NH35-2500) batteries are supplied

from the factory. Alkaline batteries (IEC LR14) may also be used. Operating time depends on the

measurement mode and battery but is usually in excess of 8 hours. Effective operating time is extended

by a timer that turns off the instrument after 30 minutes of inactivity.

“Battery LOW” appears when the battery voltage falls to where recharging or replacement will soon be

needed. When the battery voltage is too low for proper measurement, "Battery LOW" appears and the

system will not respond to select.. The instrument turns off when the batteries are depleted.

1000 to 6000 mAh NiMH cells are recommended. It takes approximately 3.5 hours to recharge fullydepleted 2500 m Ah cells. The system can operate while the battery is charging or with the charger

connected and no cells installed.

The charge indicator is orange while charging, green when the battery is charged, and red if a fault

occurs. Disconnect the charger power supply to clear the fault indication. The most common fault is

attempting to charge an alkaline battery.

The charger power supply plugs into the rear of the control unit as shown. Refer to the charger label for

input power requirements.

The figure on page 7 shows the charger connector and the charge indicator.

21

USB Interface

The Accu-Pro™ includes a USB interface for communication with a PC. USB driver software required to

implement this communication is automatically installed with XLPRO 4. A virtual serial-port driver is

available; contact Radcal for details

Connect a USB cable from the PC to the Accu-Pro™. If the driver is installed the green LED adjacent to

the USB connector will illuminate.

22

PERFORMANCE

Environmental conditions

Operating temperature:

15EC to 35EC

(30EC for 40X9,10-M sensors)

Pressure

60 to105 kPa

Humidity:

Up to 80% RH or 20 g/m

3

Storage Temperature:

-20EC to +50EC

kV Sensors

40X W Sensors:

Potential 40 kV - 160 kV

Accuracy 1 kV or 1% of value

Repeatability (COV of 10 150 ms exposures)

0.2kV

Long-term drift: 1 kV for 1 yr

Rotation (normal to source-detector line)

about sensor long axis: 1 kV for 6 º

about sensor short axis: 1 kV for 5 º

Alignment (tube anode-cathode vs sensor long axis)

1 kV for 10º

Width accuracy (2 ms - 5 sec): 0.1% of value + 0.2 ms

Ripple Error (Displayed kVp): 0.8 kV for 10%, 0-to-peak, ripple < 4 kHz

Filtration

kV, uncorrected 0.7kV/mm

kV, manual entry 1 kV

kV, automatic 1 kV 1 to 23 mm Al, 0.030 - 0.695 mm Cu

HVL (mm Al) 10% of value + 0.3 mm

Reference conditions:

21 - 23 C

Varian A192M tube (W-Re Anode)

HVL at 70 kV 2.9 mm Al

Anode current: 50 mA, < 1% ripple

Focus - Sensor distance 50 cm

Sensor long axis perpendicular to anode-cathode axis

Sensor plane normal to focus-sensor line

Width measured at 75% of kV waveform

For combined thicknesses, the Al equivalent thickness is 33 times the Cu

value.

23

40X M Sensors:

Potential 22 kV - 40 kV

Accuracy 0.5 kV for Mo/Mo

±1 kV for Hologic Selenia x-ray machines with W anode and Rh filter

Repeatability (COV of 10 150 ms exposures)

0.2kV for Mo/Mo

0.1kV for Hologic Selenia x-ray machines with W anode and Rh filter

Rotation (normal to source-detector line)

about sensor long axis: 0.5 kV for 6º

about sensor short axis: 0.5 kV for 5º

Alignment (tube anode-cathode vs sensor long axis)

0.5 kV for 10º

Long-term drift: 0.5 kV for 1 yr

Width accuracy (2 ms - 5 sec): 0.1% of value + 0.2 ms

Ripple Error (Displayed kVp): 0.5 kV for 10%, 0-to-peak, ripple < 4 kHz

Filtration

25 - 35 μm Mo 0.1kV/μm Mo

28 - 40 kV 0.8 kV/mm Al

Reference conditions:

Temperature 21 - 23 C

Mo Anode, 30 μm Mo total filtration

Anode current 50 mA, <1% ripple

Focus - sensor distance 30 cm

Sensor long axis perpendicular to anode-cathode axis

Sensor plane normal to focus-sensor line

Width measured at 75% of kV waveform

24

Diode Sensors

DDX10 W, DDX6-W diode sensors:

Energy dependence of sensitivity: +5% to -5% from 40 kVp to 120 kVp at 2.5 mm Al

Filtration dependence of sensitivity: +5% to -10% from 2.5 mm Al to 23 mm Al

Typical zero-level dose fluctuations: 1.5 μR, rms, for a 1-s pulse; 0.5 μR, rms, for a 0.1-s pulse

DDX10 M, DDX6-M diode sensors:

These sensors are calibrated for Mo/Mo. No corrections are applied for other anode/filter combinations.

Energy dependence of sensitivity: ± 5% from 25 kVp to 30 kVp at 30 μm Mo

Energy dependence of sensitivity: ± 5% from 25 kVp to 35 kVp at 30 μm Mo + 2 mm Al

Typical zero-level dose fluctuations: 1.8 μR, rms, for a 1-s pulse; 0.8 μR, rms, for a 0.1-s pulse

Ion chambers

Radcal ion chambers are unsealed. The control unit provides automatic correction for temperature,

pressure and chamber calibration using a memory chip and temperature sensor located in the chamber

stem and pressure measured at the control unit.

Overall ion chamber accuracy is ± 5% at reference conditions.

Ion Chamber Dose Timing Specifications

Measuring time (pulse width)

The Auto-Dose mode provides a pulse width (time) measurement capability when you use either ion

chambers or dose diodes.

For ion chambers, the 10X6-6 and 10X6-6M are recommended. The range of pulse width extends from

10 ms to 9999s. The uncertainty is 4 ms (or 50 ms for the 10X6-1800 only) plus 0.1% of width.

The minimum dose rate for the 6cc Chamber is 650 mR/min or 95 μGy/s.

Minimum total dose for the 6cc Chamber is 0.54 mR or 4.7 μGy.

For other 10X6-series chambers, these minimums are inversely proportional to chamber volume.

When using adapters for 10X5 or 10X9 chambers, time measurements are valid for the -6 and -6M

chambers only.

For time less than 10ms, the dose diode or kV sensors are recommended.

For the DDX6 diodes in Auto Dose the width uncertainty is 1.2 ms plus 0.1% of width over a range from 5

ms to 9999 s. Minimum dose rate is 102 μGy/s or 700 mR/min.

The kV Pulse mode provides pulse width measurement starting even lower at 2 ms and going up to

5.03 s when you use the 40X12-W and 40X9-M sensors. Over this range the uncertainty is 0.2 ms plus

0.1% of the width.

25

10X6-0.18

Exposure Rate 50 μR/s - 180

R/s

500 nGy/s - 1.58

Gy/s

Dose 200 μR - 2.0MR2 μGy - 17 kGy

Auto Dose

72 mR/s 631 μGy/s

Threshold

60

Calibration 4% @

Rate

2%, 3 mR/s - 180 R/s

Co

Dependence

Energy

5%, 45 keV - 1.33 Mev

Dependence

Construction C552 air-equivalent walls &

electrode, 0.18 cm

3

active volume.

3 m cable

Application High-intensity gamma radiation in-

beam measurements. Irradiators.

Center of

Sensitive

Volume

9

3Ø

12Ø

Dimensions in millimeters

14Ø

19

45

26

10X6-0.6

Exposure Rate 20 μR/s - 133

R/s

200 nGy/s - 1.17

Gy/s

Dose 100 μR - 589kR1 μGy - 5 kGy

Auto Dose

22 mR/s 189 μGy/s

Threshold

60

Calibration 4% @

Rate

2%, 10 mR/s - 100 R/s

Co

Dependence

Energy

Dependence

Construction C552 air-equivalent walls &

5%, 40 keV - 1.33 Mev

(with buildup cap)

3

electrode, 0.6 cm

active volume.

12 m cable

Application High-intensity gamma radiation in-

beam measurements. Irradiators.

Center of

Sensitive

Volume

3Ø

12

12Ø

2 MeV

Build-up

Cap

Dimensions in millimeters

9Ø

21

54

15Ø

16

38

27

10X6-0.6CT

Exposure Rate 20 μR/s - 133 R/s 200 nGy/s - 1.17 Gy/s

Dose 100 μR - 589 kR 1 μGy - 5 kGy

Auto Dose

22 mR/s 189 μGy/s

Threshold

Calibration 4% @ 150 kV,10.2 mm Al HVL

Rate

2%, 10 mR/s - 100 R/s

Dependence

Energy

5%, 3 - 20 mm Al HVL

Dependence

Construction C552 air-equivalent walls & electrode, 0.6 cm

active volume. 3 m cable

Application CT measurements.

3

28

10X6-6

Exposure Rate 2 μR/s - 17

R/s

20 nGy/s - 149

mGy/s

Dose 10 μR - 59 kR 100 nGy - 516 Gy

Cine (per frame) 0.1 μR - 1 R 1 nGy - 10 mGy

Auto Dose

2 mR/s 19 μGy/s

Threshold

Calibration 4% @ 60 kV, 2.8 mm Al HVL

Rate

Dependence

Energy

Dependence

Construction Coaxial cylinder, 25mm dia X

5%, 0.4 mR/s - 80 R/s

Pulse: 500R/s, 50μs

5%, 30 keV - 1.33 Mev

(with buildup material)

27mm active area. 6cm

3

.

Application General purpose in-beam

measurement

Compatible with CDRH geometry.

29

10X6-6M

Exposure Rate 2 μR/s - 10 R/s 20 nGy/s - 88

mGy/s

Dose 10 μR - 59 kR 100 nGy - 516 Gy

Auto Dose

2 mR/s 19 μGy/s

Threshold

Calibration 4% @ 20 kV,0.26 mm Al HVL

Rate

5%, 20 mR/min - 600 R/min

Dependence

Energy

5%, 10 keV - 40 keV

Dependence

Construction Parallel plate with 0.7 mg/cm

metallized polyester entrance

window. 44 mm dia 26 mm thick.

3

6cm

.

Application Mammographic x-ray

measurements

2

30

10X6-60

Exposure Rate 200 nR/s - 2

R/s

2 nGy/s - 19

mGy/s

Dose 1 μR - 5.9 kR 10 nGy - 52 Gy

Cine (per frame) 0.01 μR - 100mR0.1 nGy - 1.0

mGy

Auto Dose

216 μR/s 2 μGy/s

Threshold

Calibration 4% @ 150 kV,10.2 mm Al HVL

Rate

5%, 2 mR/min - 199 R/min

Dependence

Energy

Dependence

5%, 20 keV - 1.33 MeV

(with buildup material)

Construction Parallel plate. 13 mm thick x 92

mm dia

3

60 cm

, 0.5 m cable

Application General purpose for x-ray service

Use 8231 holder

31

10X6-60E

Exposure Rate 200 nR/s - 2

R/s

2 pGy/s - 19

mGy/s

Dose 1 μR - 5.9 kR 10 nGy - 52 Gy

Cine (per frame) 0.01 μR - 100mR0.1 nGy - 1.0

mGy

Auto Dose

216 μR/s 2 μGy/s

Threshold

Calibration 4% @ 50 kV, 0.88 mm Al HVL

Rate

5%, 2 mR/min - 199 R/min

Dependence

Energy

Dependence

5%, 0.2 mm Al HVL - 1.33 MeV

(with buildup material)

Construction Parallel plate. 13 mm thick x 92

mm dia

3

60 cm

, 0.5 m cable

Application Extended range. General purpose

for x-ray service

Use 8231 holder

1.10

1.05

1.00

0.95

Correction Factor

0.90

10 20 50 100 200 500 1000

Chamber Energy Dependence

Specification Limits

(with build-up)

Tube Voltage (kV)

32

10X6-3CT

Exposure Rate 2 μR/s - 40

R/s

20 nGy/s - 350

mGy/s

Dose 20 μR - 118kR200 nGy - 1.0 k Gy

Auto Dose

4 mR/s 38 μGy/s

Threshold

Calibration 4% @ 150 kV,10.2 mm Al HVL

Rate

2%, 2 mR/s - 40 R/s

Dependence

Energy

5%, 3 - 20 mm Al HVL

Dependence

Construction Concentric cylinder. 9 mm dia x

142 mm. 10 cm active length. 5%

uniformity of response over central

95mm of active length for a

constant volume slice. 3 cm

3

C552 air-equivalent walls and

electrode. 1.5 m cable.

Application CT measurements.

33

10X6-180

Exposure Rate 100 nR/s - 600

mR/s

1 nGy/s - 4.9

mGy/s

Dose 200 nR - 2 kR 2 nGy - 17 Gy

Auto Dose

72 μR/s 1 μGy/s

Threshold

Calibration 4% @ 150 kV,10.2 mm Al HVL

Rate

5%, 20 mR/hr - 2 kR/hr

Dependence

Energy

Dependence

5%, 30 keV - 1.33 MeV

(with buildup material)

Construction Parallel plates. 118 mm dia x 22

mm

180 cm

3

Application Leakage measurements. 100 cm

effective area.

2

34

10X6-1800

Exposure Rate 5 nR/s - 18

mR/s

50 pGy/s -200

μGy/s

Dose 20 nR - 196kR200 pGy -1.7 Gy

Auto Dose

7 μR/s 63 pGy/s

Threshold

Calibration 4% @ 150 kV,10.2 mm Al HVL

Rate

Dependence

Energy

Dependence

Construction Concentric cylinder. 138 mm dia x

+0, -5% 0.1 mR/hr - 20R/hr

-10 % @ 65 R/hr

5%, 30 keV - 1.33 MeV

(with buildup material)

171 mm. 1800 cm

3

Application Shield leakage, low-level

irradiators, environmental

measurements.

35

Waveform Output

Sensitivity 20mV/kV

1

200mV/R/s

0.5mV/mA

2

3

Full scale 4V

Output impedance 100 Ω

Sample Rate 77 μs

0.5 db frequency 1.0 kHz

3 db frequency 2.3 kHz

1

Waveform only available in kV modes

2

Requires 40X11-W and DDX10 -W or 40X10-M and DDX10-M

3

Requires mA sensor 90M9 or 90M10

Part number reference

Part numbers

Description Part Number

Control Unit 9096

Sensor Cable (4m) 90C6-4

Diagnostic Accu-kV sensor (with auto compensation) 40X12-W

Mammographic Accu-kV sensor 40X9-Mo

Dose diode digitizer DD60

Diagnostic Dose diode sensor DDX6-W

Mammographic Dose diode sensor DDX6-M

Description Part Number

Ion Chamber digitizer 9660

6cc Ion Cham ber 10x6-6

Mammographic Ion Chamber 10x6-6M

60cc Ion chamber 10x6-60

CTDI Ion chamber 10x6-3CT

180 cc Ion chamber 10X6-180

1800 cc Ion Chamber 10X6-1800

Extension cable (2m) 90E6-2

Invasive mA Sensor 90M9

Noninvasive mA sensor 90M10

36

OPERATOR MESSAGES

Messages are displayed and a beep sounds when the Accu-Pro™ is unable to perform a measurement.

Pressing SELECT generally proceeds. Pressing UP or DN exits to the main menu.

Self-test

“Battery LOW” Replace or recharge battery

“Analog volt fail” Precision voltages are out of tolerance. Measurement accuracy is questionable.

“Logic volt fail” Logic supply voltage is out of tolerance.

May shutdown or operate erratically.

“No converter” No dose converter connected.

Proceeds after 3 seconds.

“No dose sensor” Press SELECT to proceed.

“EPROM error” Press SELECT to proceed.

“Temp Error 1,2” Unable to read temperature sensor.

Temp Error 3 Temperature out of range.

“No kV sensor” Proceeds after 3 s or SELECT.

“Std 22 deg C” Standard temperature was selected.

“Std 101.3 kPa” Standard pressure was selected.

“Bias failed” Bias voltage is out of tolerance. Measurements may be in error.

Accu-kV

These messages result from operations involving the Accu-kV sensor. They are displayed for at least two

seconds. The underlined header in the following is the first line of the message.

“Exposure Error”

These errors arise from problems with the x-ray signal.

After two seconds, the messages become “kV - try again” and “Error cleared”, and a new measurement

can be performed.

"Too narrow 1,2,3" Waveform was too narrow.

"Too weak 1,2" Intensity was too low.

"Too strong" High intensity caused saturation.

"kV too small" Measured kV was too small.

0.00 kV Measured kV too large. Allows dose outputs.

“KV - wait”

These arise form problems that often clear themselves. If the error condition clears, the messages

become “kV - try again” and “Error cleared”, and a new measurement can be performed.

W Accu-kV zero level is unstable.

"Bad kV zero" Zero level too small.

"Measure abort” Processing was interrupted.

"Bad W/Ag kV" Measured kV is in bad-accuracy range for W/Ag correction.

“kV failure”

These arise from a faulty or missing Accu-kV sensor

If connecting a working Accu-kV sensor clears the error condition, the messages become “kV - try again”

and “Error cleared”, and a new measurement can be performed.

"ADC error" Analog-to-digital converter problem. May be an Accu-Pro™ fault.

"EPROM error" The sensor EPROM did not respond properly.

"No sensor" EPROM not found or zero level too large.

"Zero failed" Zero didn’t stabilize within 2 minutes.

Unstable zero values cause “W” to appear in the lower-left corner of the display.

37

“Dose diode fail”

These errors arise from problems with the DDX10 kV dose diode. If connecting a working diode clears

the error condition, the messages become “kV - try again” and “Error cleared”, and a new measurement

can be performed.

"No kV diode" The diode was not connected to the Accu-KV sensor and a dose-related

measurement is specified.

“Wrong kV diode” The wrong diode is connected to the Accu-kV sensor.

"EPROM error" The diode EPROM did not respond properly.

“System error”

The top line of the display shows “System error”, with the bottom line showing one of several messages.

Exits to the main menu after displaying the message for two seconds. Contact Radcal if it persists.

Ion chambers and dose diodes

These messages arise when measuring dose and dose rate using ion chambers or the DDX6 dose

diodes.

Starting a measurement:

“Dose sync fail” Press SELECT to retry.

While measuring zero:

“Zero too small” Press SELECT to continue. Measurements near minimum dose rate for the

“Zero too small”

selected sensor may be inaccurate.

“Zero unstable”

While measuring dose or dose rate:

“?” In the upper left corner. Indicates the sensor is operating above its specified

maximum rate.

While measuring dose-rate

Automatic retry after 3 s.

“Input negative” The converter output reached zero.

“Conv overload” The input current overloaded the converter.

While measuring dose

Displayed until user presses SELECT, then function exits.

“Input negative” The sensor signal was negative..

“Conv overload” The sensor signal exceeded full-scale.

“Dose overflow” The total dose was too large.

“Time overflow” The dose-accumulation time was too large.

38

Figure 24 - Control Unit Configuration

39

Figure 25 - Connector Locations

40

ACCESSORIES

XLPRO Excel add-in

XLPRO is a Microsoft Excel add-in that provides control and communication within Excel via the USB

connection. It uses the computational and display capabilities of Excel to record, analyze and display

Accu-Pro™ measurement results on a PC. XLPRO can control the Accu-Pro™ system as well, so test

protocols can be automated to provide consistent results and guided operation.

Using XLPRO

! Connect a USB cable between the PC and the Accu-Pro™ control unit. If the green

LED illuminates (it is not very bright) the Radcal USB software is installed on the

PC; otherwise you need to install XLPRO version 4 or later.

! Turn on the Accu-Pro™, wait for self-test to completed, and then start XLPRO.

! XLPRO is now in control of the Accu-Pro™. select, UP and DN are disabled. The

display reads:

Control locked

by PC over USB

While XLPRO is making measurements the display will show measurement results in default units: R,

/min, fixed Temperature and Pressure . Unit conversion and environmental correction is handled within

XLPRO. The user selections are restored when the USB is disconnected or when XLPRO ends.

While the USB is active, the power-off timer is disabled.

Figure 26 - XLPRO sample

41

90M9 mAs Sensor

Battery-powered, isolated, Invasive mA sensor

Synchronized to Accu-kV measurement

Real-time waveform.

Automatic zero and no range switching.

2000 mA or 9999 mAs full-scale

Measures absolute value of mA.

0.2% mA accuracy

5 μAs or 0.2% mAs accuracy (1-s pulse)

Input impedance: Fixed, resistive, 1 ohm plus fuse and wiring.

Withstands1500 vac between input leads and control unit.

77 μs sample rate

-2.6% at 720Hz, -3 dB at 2.33 kHz.

Digital waveform sent over the USB port to XLPRO

Automatic turn-on only when kV function is active

Battery lifetime: Approximately 30 operating hours.

42

90M10 mAs Sensor

Battery-powered, isolated, clamp-on non, invasive mA sensor

Aperature 23mm.

Synchronized to Accu-kV measurement

Real-time waveform.

Automatic zero and no range switching.

2000 mA or 9999 mAs full-scale

Measures absolute value of mA.

Resolution greater of 3-4 digits or .015mA

mA accuracy:

±4% of reading (Limited by 0.6mA RMS noise below 15mA).

mAs accuracy (1-s pulse):

±4% of reading (Limited by 0.6mAs RMS noise below 15ma).

77 μs sample rate.

-2.6% at 720Hz, -3 dB at 2.33 kHz.

Digital waveform sent over the USB port to XLPRO

Automatic turn-on only when kV function is active

Battery lifetime: Approximately 35 operating hours.

Caution: In the presence of strong electromagnetic fields, performance may degrade up to 1 Amp.

43

10A96 Ion chamber Adapter

This adapter adapts the 10X5 ion chambers to

the 9660 ion chamber digitizer. It contains a

microprocessor that translates between the

jumpers, resistors and potentiometer located

within the probe stem of 10X5-series ion

chambers into signals that mimic the EAROM

that holds calibration and chamber-type

information the Accu-Pro™ requires. A

temperature sensor is included to provide that

information also. Its diameter is slightly larger

than that of the chamber stem, with a hardmounted microdot connector on one end and a

9096-style connector on the opposite end. It

draws power from the 9660 Ion Chamber

digitizer.

90E6-2 - Extension cable

The extension cable allows one to place the ion chamber up 2 meters away from the digitizer. (Other

lengths available)

44

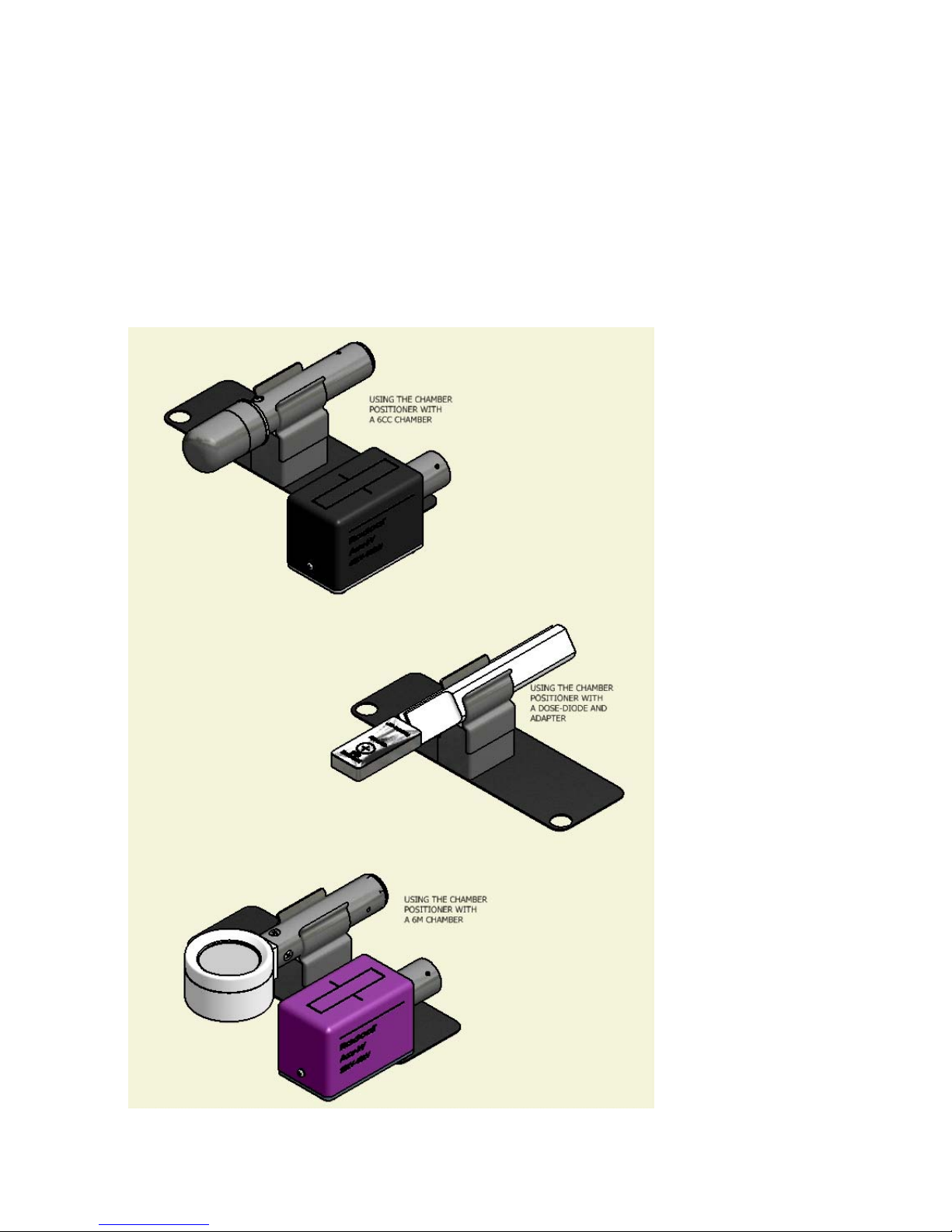

Chamber Positioner

The chamber positioner locates an ion chamber at a fixed height from the x-ray table. Holes in the base

of the chamber positioner locate the kV sensor relative to the ion chamber to control the effect of

backscatter from the kV sensor on exposure measurements. Because mammography measurements

using th 6M chamber are less affected by backscatter, the mammography kV sensor may be positioned

closer to the chamber. The Figure 29 shows suggested arrangements.

Figure 29 - Positioner/Chamber relationship

45

Accu-Pro™ System Carrying Cases

46

APPENDIX - Mammography kVp measurements on Hologic Selenia

Using a Radcal kVp Meter to Measure kVp's on Hologic Selenia Mammographic X-ray

Machine Equipped with a Tungsten-Rhodium, Silver Tube Option

A Radcal kV meter with a 40X series Mo sensor may be used with a look-up correction algorithm to

obtain Selenia W-Rh, Ag kVp's with an accuracy of +/- one kVp. Radcal recommends the Selenia

Tungsten-Ag/Rh tube be calibrated as follows.

After going into manual mode on the Hologic machine and selecting large focal spot,100mAs, place the

Radcal 40X9-Mo kV sensor on top of the Bucky table. The small compression paddle may be left

in-beam. Align the Radcal kV sensor so that its long axis is 90 degrees to the tube anode -cathode axis

so as to eliminate heel effect. Move the sensor about one inch in from the table edge. Center the sensor

right to left. Do not to forget to protect the imaging plate by placing and then smoothing out a lead apron

over it.

Use the Rhodium track to calibrate the 22 to 39 kV Selenia range and the Silver track to refine the 22 to

24 kV range to obtain a few more tenths accuracy if required from 22 to 24 kV. An example Selenia

calibration is shown below.

A Tungsten/Silver setting is different from the Tungsten/Rhodium setting. There is a range of calculated

kVp's (25-33 kV) that exceed a set error band and the instrument will show an error message as a result.

The data used to construct the correction algorithm were recorded by comparing a kVp's obtained with

Radcal Dynalyzer High Voltage Divider (True kVp) and the kVp's displayed on Radcal kVp meters during

Selenia exposures with the small compression paddle in-beam. These data were obtained from five

Selenia machines during Acceptance testing in manual mode.

Example of a Selenia calibration

Dynalyzer Ag Rh Ag Rh

Set kVp True kVp 9096 kVp 9096 kVp Radcal-True Radcal-True

22 22.0 22.5 22.5 0.5 0.5

23 23.0 23.0 23.5 0.0 0.5

24 24.0 24.2 25.0 0.2 1.0

25 25.0 25.6 0.6

26 26.0 26.1 0.1

27 27.0 27.3 0.3

28 28.0 28.1 0.1

29 29.0 29.3 0.3

30 30.0 30.1 0.1

31 31.0 30.9 -0.1

32 32.0 32.1 0.1

33 33.0 33.2 0.2

34 34.0 34.4 34.2 0.4 0.2

35 35.0 35.4 35.1 0.4 0.1

36 36.0 36.3 36.1 0.3 0.1

37 37.0 37.3 37.1 0.3 0.1

38 38.0 38.4 38.1 0.4 0.1

39 39.0 39.4 0.4

47

Warranty for the Accu-Pro™ Measurement System

Radcal Corporation warrants that, in the event that any defects in material or workmanship should

develop within one year of the date of shipment, the company assumes full responsibility for servicing

equipment of its manufacture without charge upon return of the equipment to Radcal, with shipping costs

prepaid by the customer. Costs to return-ship to customer by ground transportation will be paid by Radcal

if the repairs are warranty-applicable. This warranty excludes batteries.

Radcal shall not be held liable for damages or delays caused by defects beyond making repairs or

furnishing replacement parts, nor shall Radcal be liable for any defective material replaced without

Radcal’s consent during the period of this warranty. Radcal reserves the right to perform warranty

services at its own factory.

Non-Warranty Repairs

The calibration of this instrument was correct within specified limits when the instrument left our factory.

Radcal cannot be responsible for injury or damage resulting from improper use or calibration errors which

develop subsequent to our shipment of the instrument.

If Radcal determines that a fault has been caused by misuse, abnormal operating conditions, or repairs

by unauthorized personnel during the warranty period, repairs and shipping costs will be billed at normal

rates.

If the equipment is found to be in proper working condition, Radcal will return-ship the equipment at

customer expense.

48

Declaration of Conformity

According to ISO/IEC 17050 and EN 45014

The Radcal Corporation declares, under our sole responsibility, that the Accu-Pro™ Measurement

System conforms to the following product specifications.

EMC: EN 50081-2 / EN 555011 Class A

EN 50082-1 / IEC801-2, 4 kVcd, 8 kVAD

EN 50082-1 / IEC801-3, 3V/m

Note: The Analog Output is intended for use by trained users. Observe proper ESD precautions when

using this connection.

QA Manager

Date: 2007 September 27

Radcal Corporation

426 West Duarte Road

Monrovia, CA 91016-4591 USA

49

Loading...

Loading...