rada Sense Shower T3 DMV Product Manual

1

IMPORTANT

Installer: This Manual is the property of the customer

and must be retained with the product for

maintenance and operational purposes.

PRODUCT MANUAL

Rada Sense Shower T3 DMV

2

CONTENTS

DESCRIPTION .......................................................................................... 3

SAFETY : WARNINGS .............................................................................3

PACK CONTENTS ....................................................................................5

SPECIFICATION ....................................................................................... 6

Standards and Approvals .....................................................................6

INSTALLATION .........................................................................................7

General .................................................................................................7

Power Supply Unit (PSU) .................................................................... 9

Rada Sense Control Panel ................................................................10

Rada Sense (DMV) ............................................................................ 11

OPERATION ...........................................................................................12

Duty Flush ..........................................................................................12

Disinfection ......................................................................................... 12

COMMISSIONING ..................................................................................13

Maximum Temperature Setting .......................................................... 14

MAINTENANCE ...................................................................................... 15

Planned Maintenance.........................................................................15

Cleaning ............................................................................................16

Checkvalves and Filters .....................................................................17

FAULT DIAGNOSIS ................................................................................ 18

Self-Diagnostic Errors ........................................................................20

SPARE PARTS .......................................................................................21

ACCESSORIES ......................................................................................23

CUSTOMER SERVICE ...........................................................................24

3

A range of concealed 1/2” Digital Mixing Valves (DMV) with wall mounted no-touch

control panel for ow and temperature control. Functions include timed ow control,

duty ush and thermal disinfection.

The sufx ‘3’indicates that this Digital Mixing Valve has been certied for use in UK

Healthcare premises as a Type 3 valve under the BuildCert TMV3 scheme. For

Healthcare installation refer to the TMV3 Requirements Manual.

The approved designations for Type 3 Valves are as follows:

Model Designations

Rada Sense Shower T3 HP - S LP - S

DESCRIPTION

SAFETY : WARNINGS

The function of this DMV is to deliver water consistently at a desired temperature.

This requires that:

1. It is installed, commissioned, operated and maintained in accordance with the

recommendations given in this manual.

2. Periodic attention is given, as necessary, to maintain the product in good

functional order. Recommended guidelines are given in ‘MAINTENANCE’.

3. For Type 3 installations, valves are only to be used for applications covered by

their approved designations. Refer to the TMV3 Requirements Manual.

4. Using this product outside the specication limits given in this manual can

present potential risk to users.

5. The electrical installation must comply with BS 7671 (commonly referred to

as the IEE Wiring Regulations), all relevant national building regulations and

any particular regulations and practices specied by the local electricity supply

company.

6. DO NOT t any form of outlet ow control i.e. trigger handset. Use only

recommended ttings.

The use of the word ‘failsafe’ to describe the function of any mixing valve is both

incorrect and misleading. This electronic valve incorporates additional shut-off

devices to improve the level of safety however, in keeping with every other mechanism

it cannot be considered as being functionally infallible.

4

Where chlorine disinfection is practised, DO NOT exceed a chlorine concentration of

50 mg/l (ppm) in water, per one hour dwell time. Such procedures must be conducted

strictly in accordance with the information supplied with the disinfectant and with all

relevant Guidelines/Approved Codes of Practice.

5

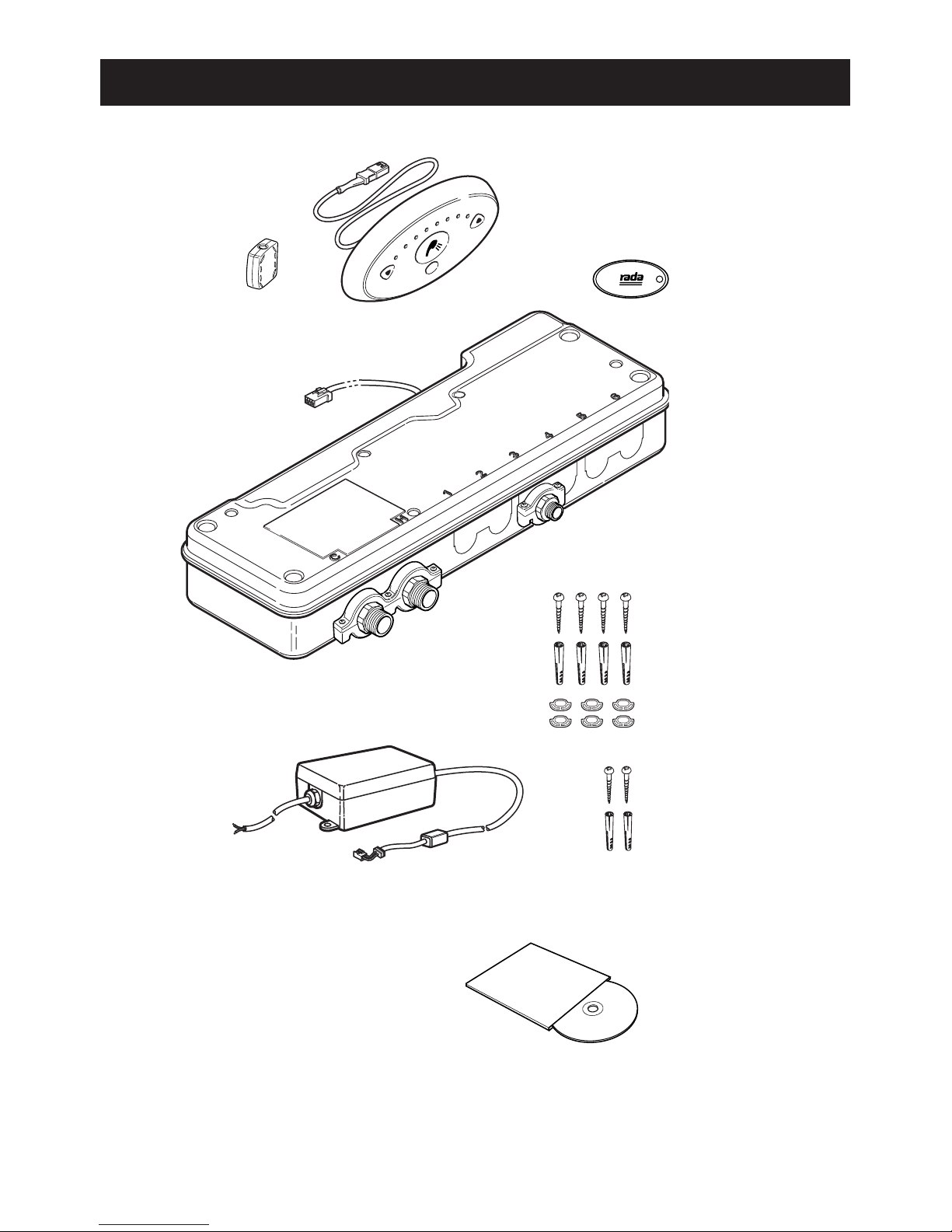

PACK CONTENTS

1 x Shower Control Panel

1 x Magnetic Key

1 x Digital Mixing Valve (DMV)

4 x Fixing Screws

4 x Wall Plugs

1 x Power Supply Unit (PSU)

2 x Fixing Screws

2 x Wall Plugs

2 x Installation Templates

(DMV Installation Template, on the Packaging)

6 x Rubber Feet

1 x UK Rada Sense T3 Programmer CD

1 x Suppression Ferrite

1 x TMV3 Requirements Manual

6

Standards and Approvals

This Rada Sense Digital Mixing Valve (DMV) complies with all relevant directives

for CE marking.

The Rada Sense DMV is a type 1 electronic, independently mounted control for

surface mounting.

For Type 3 valves, the water supply conditions are specified in the TMV3

Requirements Manual.

General

Pollution Degree 3

Rated Impulse Voltage Mains Supply - 2.5 kV

12 V DC supply to valve - 500 V

Suitability for Drinking Not suitable

Connections Flat face union connections

Pressures

Maximum Static Pressure 1000 kPa (10 bar)

Minimum Pressure Loss 20 kPa (0.2 bar)

Supply Pressure Differential Max. 3:1 (Equal pressure recommended)

Minimum Flow Rate 4 L/min (<500 kPa maintained pressure)

6 L/min (>500 kPa maintained pressure)

Temperatures

Factory Pre-set (Blend) Washbasin Max. 41 °C, Min. 30 °C, Default at start-up 38 °C

Factory Pre-set (Blend) Bidet Max. 38 °C, Min. 30 °C, Default at start-up 36 °C

Factory Pre-set Duty Flush 41 °C (Default DISABLED - use Programmer Software to ENABLE)

Programmable Range Max. 33 - 50 °C

Min. 30 - 47 °C (full cold can also be selected)

Default at start-up 30 - 50 °C

Minimum Blend Temperature

Differential from Hot Supply

2 °C

Optimum Thermostatic

Control Range

30 - 50 °C

Cold Water Range 1 - 20 °C

Hot Water Range 50 - 65 °C (85 °C for disinfection)

Temperature Stability ± 1 °C at recommended supply conditions

Ambient Temperature Greater than 1 °C, max. 40 °C

Maximum Relative Humidity 95% non-condensing

Electrical

Supply Voltage 100 - 240 V RMS 50 - 60 Hz

Maximum Load 20 W at 12 V DC

Control Panel Cable Length 3 m supplied (6 m max.)

Times Factory Settings Programmable Range

Flow Time to Auto Shut-off 15 seconds 5 seconds to 60 minutes

Duty Flush Cycle 3 minutes 1 - 59 minutes

Duty Flush Waiting Time 12 hours 1 - 983 hours

Disinfection

Minimum Temperature 60 °C 60 - 85 °C

Minimum Time 5 minutes 0 - 50 minutes

Reduced Flow rate No Yes or No

The pressure loss of a system (valve and outlet tting) is the average of the two inlet pressures minus the back

pressure, where the back pressure is determined by the ow resistance of any outlet tting.

SPECIFICATION

*

*

7

General

Installation must be carried out in accordance with these instructions, be

conducted by designated, qualied and competent personnel.

The installation must comply with the “Water Supply (Water Fittings)

Regulations or Scottish Byelaws”, all relevant national building regulations

and any particular regulations and practices specied by the local water

supply company.

Before commencing, make sure that the installation conditions comply with the

information given in ‘SPECIFICATION’. For Type 3 valves, the water supply

conditions must comply with the information given in the TMV3 Requirements

Manual.

Installation Schematic

Note! The Data Cable must be placed through the Suppression Ferrite and then

looped around the cover. The Suppression Ferrite must be tted as close to the

Control Panel as possible.

INSTALLATION

Metal pipework

must be

earth bonded

3 amp switched

fused spur box

Control panel

PSU

DMV

Showerhead

Outlet

Hot

inlet

Cold

inlet

To mains power supply

Suppression Ferrite,

refer to Note.

8

Outlet

Hot inlet

Cold inlet

Outlet

Hot inlet

Cold inlet

Outlet

Hot inlet

Cold inlet

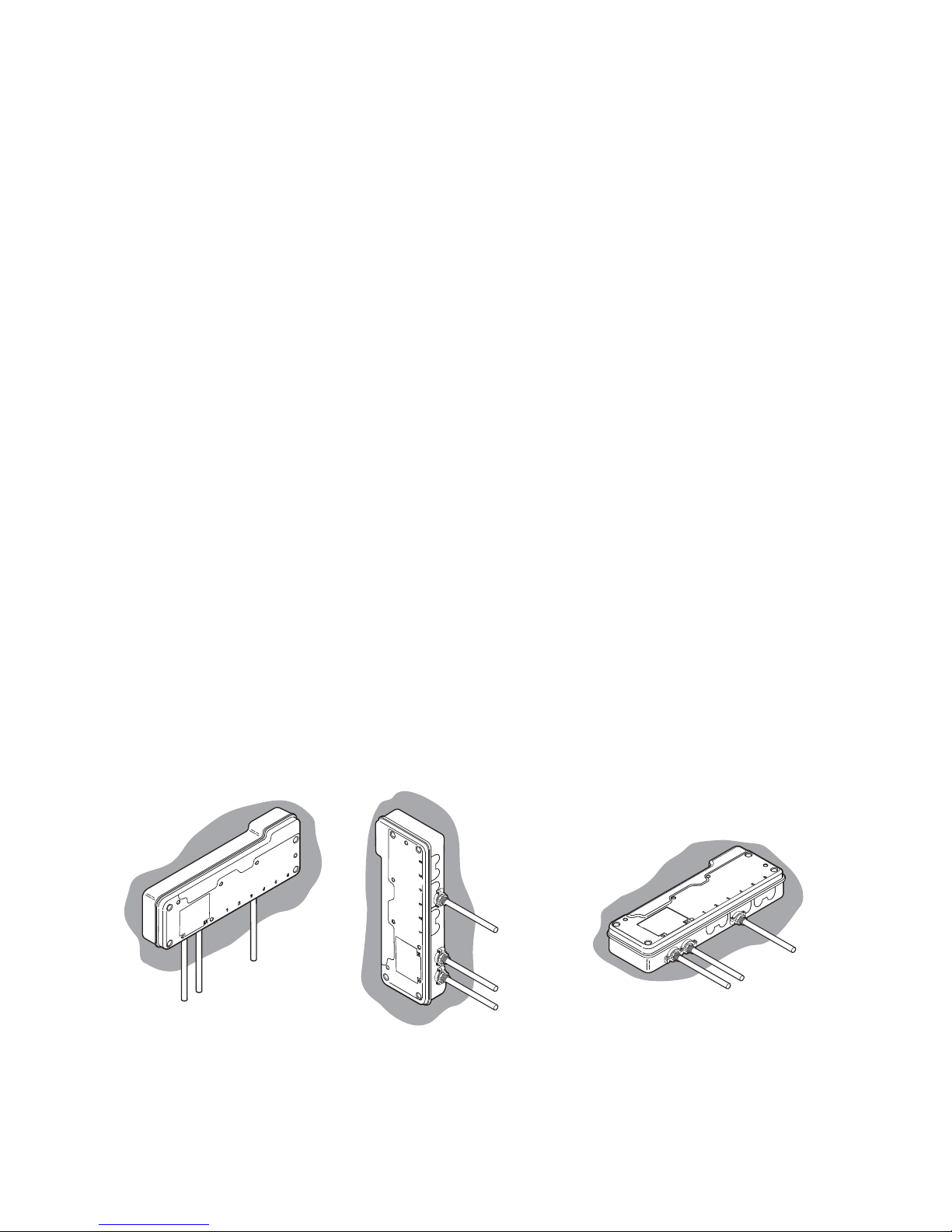

Mounting on a

Vertical Surface

Mounting on a

Horizontal Surface

1. The DMV and PSU must be installed in a dry area and where it will not freeze.

2. The DMV must be installed in an area where it is accessible to do any

maintenance tasks e.g. removal of the cover, cleaning the strainers, etc.

3. Inlet and outlet isolating valves must be installed close to the DMV for ease of

maintenance.

4. Flat face union connections must be used on the inlet and outlet connections

of the DMV for ease of maintenance.

5. The use of supply-line or zone strainers will reduce the need to remove debris at

each mixing valve point. The recommended maximum mesh aperture dimension

for such strainers is 0.5 mm.

6. Inlet pressure tappings which allow measurement of the inlet pressures to

the mixing valve under operating conditions are particularly recommended for

healthcare applications.

7. Pipework must be rigidly supported and avoid any strain on the connections.

8. Pipework dead-legs should be kept to a minimum.

9. Supply pipework layout should be arranged to minimise the effect of other outlet

usage upon the dynamic pressures at the mixing valve inlets.

10. Inlet and outlet threaded joint connections should be made with PTFE tape or

liquid sealant. Do not use oil-based, non-setting joint compounds.

11. To eliminate pipe debris it is essential that supply pipes are thoroughly ushed

through before connection to the spout and to the Rada Sense DMV.

12. The DMV MUST be installed in the orientations shown and mounted on a rigid

vertical surface or on top of a rigid horizontal surface.

Note! If the DMV is installed in a different orientation to those shown above, it may

cause the DMV to malfunction e.g. cause airlocks, water ingress and could effect

the thermal performance of the DMV.

Loading...

Loading...