rada Safetherm Product Manual

1

IMPORTANT

Installer: This manual is the property of the customer

and must be retained with the product for maintenance

and operational purposes.

PRODUCT MANUAL

Safetherm

rada

2

CONTENTS

Introduction .............................................................................................3

Safety : Warnings ....................................................................................3

Pack Contents Checklist ........................................................................5

Specications .......................................................................................... 7

Pressures .............................................................................................7

Temperatures ....................................................................................... 7

Thermostatic Shut-down ......................................................................8

Connections .........................................................................................8

Important Points ...................................................................................8

Dimensions .........................................................................................10

Installation ............................................................................................. 11

Panel Mounting ..................................................................................12

Basin Mounting ...................................................................................14

Operation ...............................................................................................16

Commissioning .....................................................................................17

Maximum Temperature Setting ..........................................................17

Fault Diagnosis ......................................................................................19

Maintenance ...........................................................................................21

Planned Maintenance.........................................................................21

Thermostatic Cartridge Renewal ........................................................22

Filter Renewal ....................................................................................23

Checkvalve Cartridge Renewal .......................................................... 24

Spare Parts ............................................................................................25

Notes ......................................................................................................27

Customer Care .......................................................................................28

3

Warning!

Products manufactured by us are safe provided they are installed, used and maintained

in good working order in accordance with our instructions and recommendations.

Caution!

1. Read all of these instructions.

2. Retain this guide for later use.

For Type 3 installations, valves are only to be used for applications covered by

their approved designations, refer to the TMV3 Requirements Manual.

3. Pass on this guide in the event of change of ownership of the installation

site.

4. Follow all warnings, cautions and instructions contained in this guide.

5. The plumbing installation must comply with the requirements of UK Water

Regulations/Bye-laws (Scotland), Building Regulations or any particular

regulations and practices, specied by the local water supplier. The installation

should be carried out by a plumber or contractor who is registered or is

a member of an association such as:

i) Institute of Plumbing (IOP), throughout the UK.

Congratulations on purchasing a quality Rada product. To enjoy the full potential of

your new product, please take time to read this guide thoroughly; having done so,

keep it handy for future reference.

The Rada Safetherm is an exposed thermostatic control for connection to entry

pipework from various directions. The thermostatic control incorporates a wax capsule

temperature sensing unit. This provides an almost immediate response to changes

in pressures or temperature of the incoming water supplies to maintain the selected

temperature. An adjustable maximum temperature stop is provided which limits the

temperature to the desired level. The Safetherm also includes checkvalves, lters

and inlet ow regulators limiting the outlet ow to 8 L/Min.

The Rada Safetherm has been certied for use in UK Healthcare premises as a

Type 3 valve under the BUILDCERT TMV3 scheme. For Healthcare* installations

refer to the TMV3 Requirements Manual. This product also complies with the Water

Supply (water ttings) Regulations 1999.

*Healthcare applications are hospitals, aged person facilities, residential care homes,

etc. and any other application where the user is similarly at risk.

The approved designations for Type 3 Valves are as follows:

Model Designation Code

Rada Safetherm HP-WE, LP-WE

INTRODUCTION

SAFETY : WARNINGS

4

ii) National Association of Plumbing, Heating and Mechanical Services

Contractors (NAPH & MSC), England and Wales.

iii) Scottish and Northern Ireland Plumbing Employers’ Federation (SNIPEF),

Scotland and Northern Ireland.

6. Anyone who may have difculty understanding or operating the controls of any

appliance should be attended whilst operating. Particular consideration should

be given to the young, the elderly, the inrm, or anyone inexperienced in the

correct operation of the controls.

The use of the word “failsafe” to describe the function of a thermostatic mixing valve

is both incorrect and misleading. In keeping with every other mechanism it cannot

be considered as being functionally infallible.

Provided that the thermostatic mixing valve is installed, commissioned, operated

within the specication limits and maintained according to this Manual, the risk of

malfunction, if not eliminated, is considerably reduced.

Malfunction of thermostatic mixing valves is almost always progressive in nature

and will be detected by the use of proper temperature checking and maintenance

routines.

Certain types of system can result in the thermostatic mixing valve having excessive

‘dead-legs’ of pipework. Others allow an auxiliary cold water supply to be added

to the mixed water from the mixing valve. Such systems can disguise the onset of

thermostatic mixing valve malfunction.

Ultimately, the user or attendant must exercise due diligence to make sure that the

delivery of warm water is at a stable, safe temperature. This is particularly important

in such healthcare procedures as supervised bathing of patients unable to respond

immediately to unsafe temperatures.

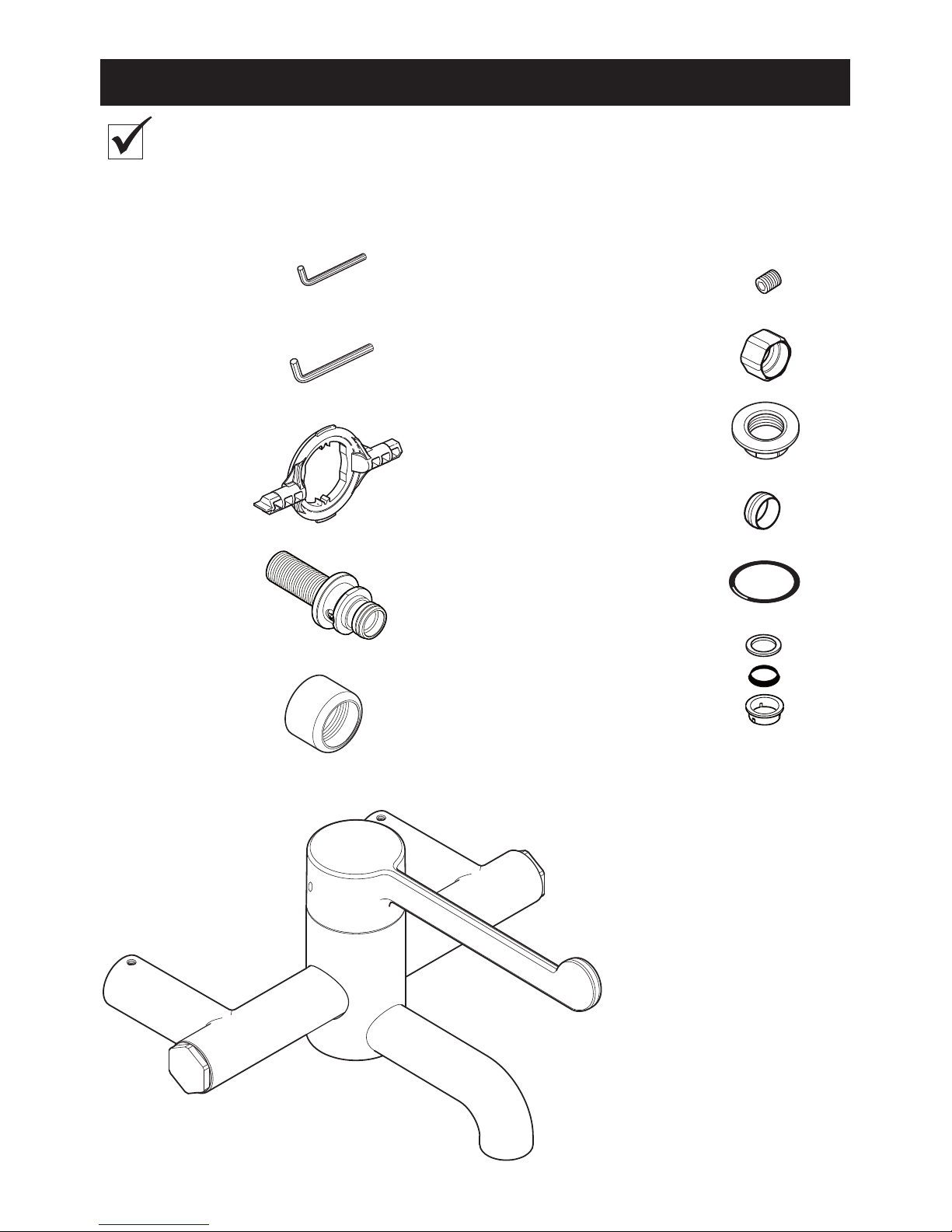

Safetherm Options

The following table indicates temperature control options available for the

Safetherm.

Installation Temperature Adjustment Description

Panel Adjustable Temperature Control

Safetherm

Basin Adjustable Temperature Control

5

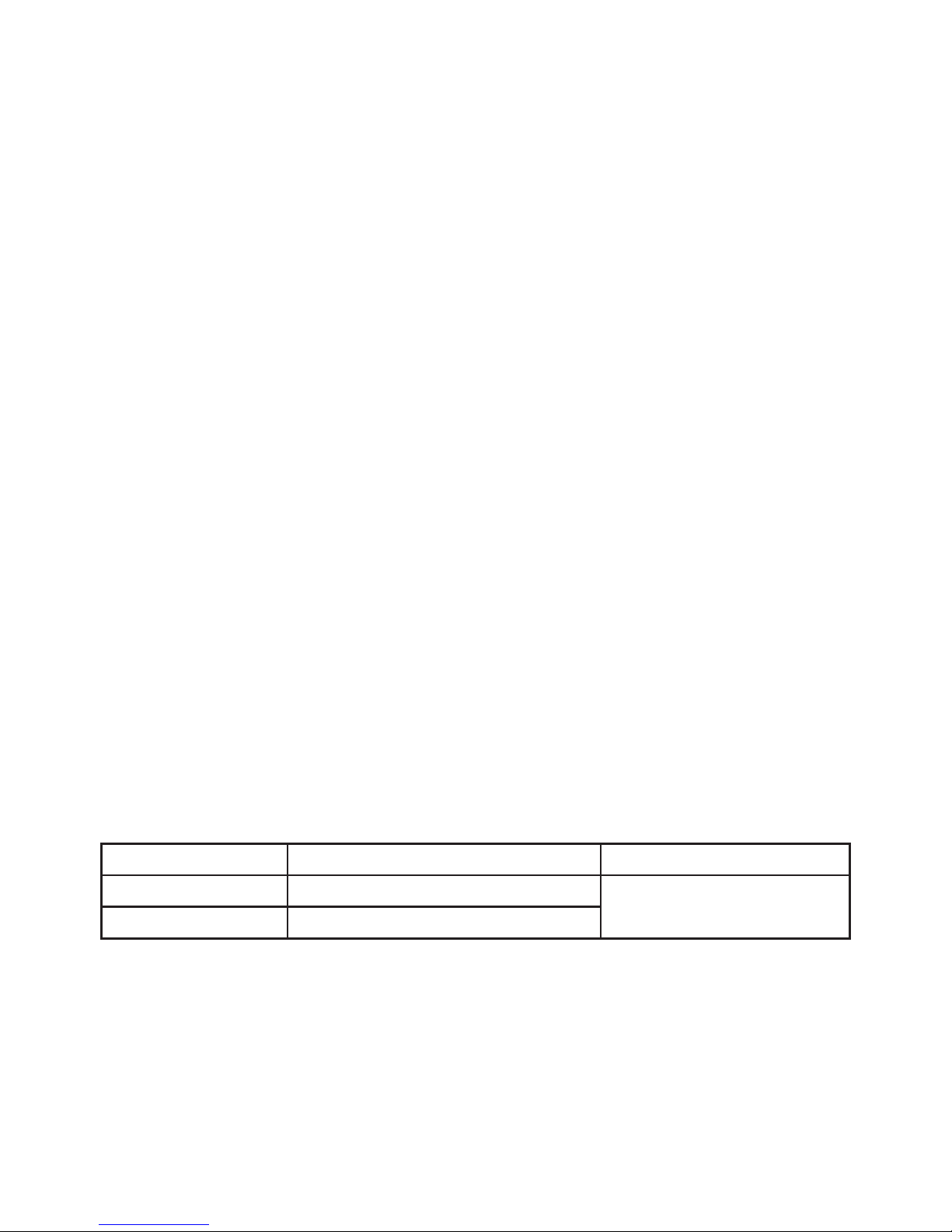

PACK CONTENTS CHECKLIST

1 x Safetherm Tap Control

(Panel Mount)

1 x TMV3 Requirements

Manual

1 x ‘O’ Key

2 x Olives

2 x Compression Nuts

2 x Back Nuts

Tick the appropriate boxes to familiarize yourself with the part names and to

conrm that the parts are included.

Safetherm Panel

1 x 2.5 mm A/F

Hexagon Wrench

1 x 3 mm A/F

Hexagon Wrench

2 x 'O' Seals

1 x Flat Face

Connector Pack

2 x Grub Screws

2 x Inlet

Connector

2 x Concealing

Shroud

~

®

h

@

({)

0

0

0

@

6

Safetherm Basin

1 x Safetherm Tap Control

(Basin Mount)

2 x Olives

2 x Compression Nuts

2 x Back Nuts

1 x ‘O’ Key

1 x 2.5 mm A/F

Hexagon Wrench

1 x 3 mm A/F

Hexagon Wrench

2 x 'O' Seals

2 x Grub Screws

2 x Large Rubber Washer

2 x Deck Mount Ring

2 x Deck Mount Plate

2 x Back Plate

1 x Flat Face

Connector Pack

2 x 'O' Seals

2 x Inlet

Connector

2 x Concealing

Shroud

2 x Extension

Sleeve

2 x Extension

Tube

1 x TMV3 Requirements

Manual

®

@

CS)

@)

({)

®

0

g

0

~ ~

7

SPECIFICATIONS

For Type 3 Valves, the supply conditions specied in the TMV3 Requirements Manual

take precedence over the operating parameters which follow.

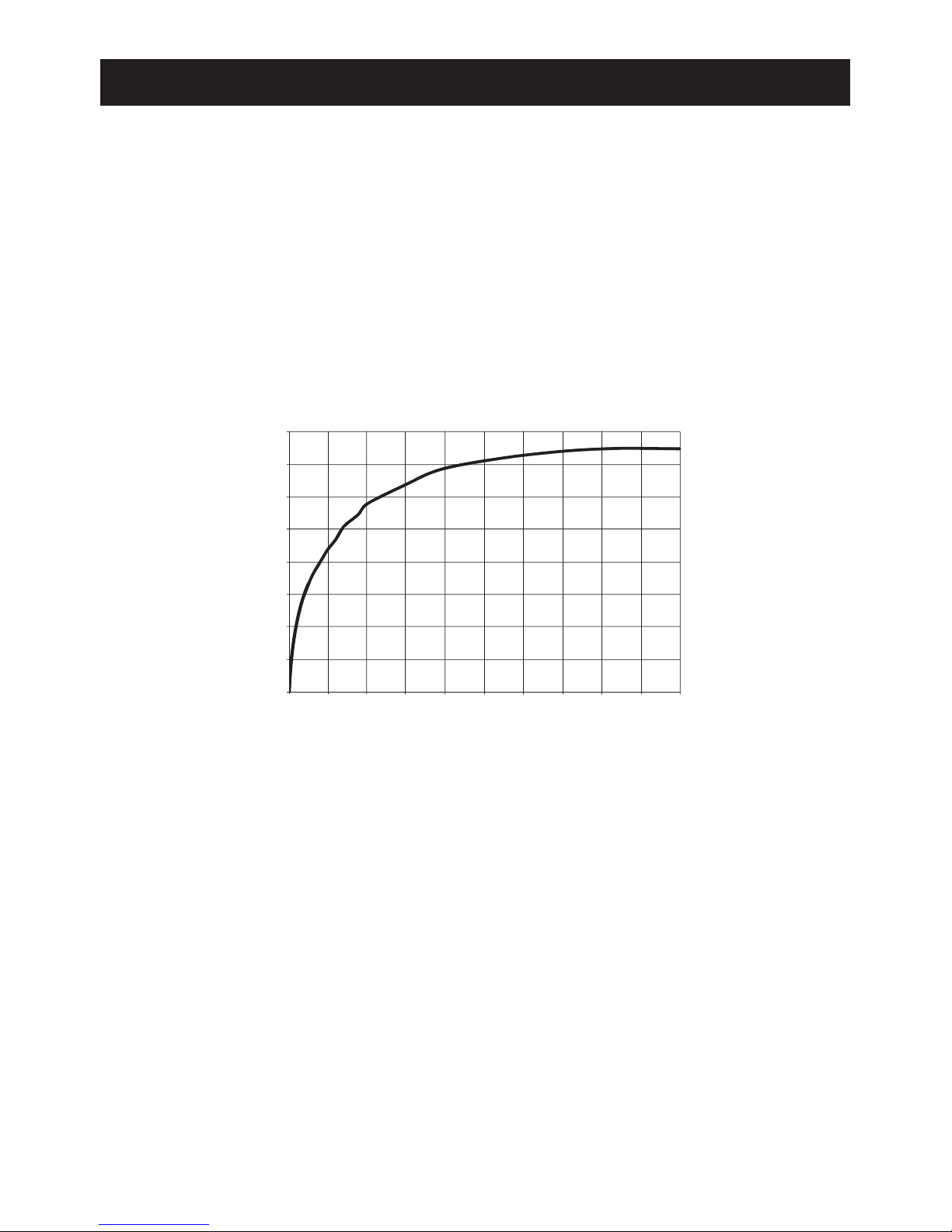

Pressures

• Max Static Pressure: 10 Bar.

• Max Maintained Pressure: 5 Bar.

• Min Maintained Pressure (Gravity System): 0.1 Bar.

(0.1 bar = 1 Metre head from cold tank base to tap outlet).

• For optimum performance supplies should be nominally equal.

Temperatures

• Factory Pre-set (Blend): 41°C.

• Optimum Thermostatic Control Range: 35°C to 43°C (achieved with supplies

of 15°C cold, 65°C hot and nominally equal pressures).

• Recommended Hot Supply: 60°C to 65°C Note! The thermostatic control

can operate at higher temperatures for short periods without damage,

however this could detrimentally affect thermostatic performance. For safety

and performance reasons it is recommended that the maximum hot water

temperature is limited to 65°C.

• Cold Water Range: up to 25°C.

• Minimum Recommended Differential between Hot Supply and Outlet

Temperature: 12°C.

• Please refer to section: ‘Type 3 Valves - Application for Type 3 Valves.

0

1

2

3

4

5

6

7

8

01 23

45

Supply Pressure (bar)

Flow Rate (l/min)

0.5

1.52.5 3.54.5

~

L,-

/~

/

J

I

I

8

Thermostatic Shut-down

• For safety and comfort the thermostat will shut off the thermostatic control

within 2 Seconds if either supply fails (achieved only if the blend temperature

has a minimum differential of 12°C from either supply temperature).

Connections

• Inlets: 15 mm Compression or 1/2" BSP at face.

• Standard connections are: hot - left, cold - right.

• The inlet connectors are xed at 200 mm centres.

Important Points

1. The installation, commissioning and maintenance of this product must be

carried out in accordance with the instructions given in the manual, and must

be conducted by designated, qualied and competent personnel.

2. Installations must comply with all Local/National Water Supply Authority

Regulations/Bye-laws, and Building and Plumbing (UK:BS6700) Regulations.

3. Rada products are precision engineered and should give continued and superior

performance, provided:

a. They are installed, commissioned, operated and maintained in

accordance with these recommendations

b. Periodic attention is given as necessary to maintain the product in

good functional order. Recommended guidelines are given in section:

‘Maintenance’.

4. Warning! Continued use of this product in conditions outside the limits listed

in this section can severely affect the performance and reduce the effective

service life, and can present potential risk to users.

5. Suitable for use with most modulating instantaneous gas water heaters.

For information on other specic applications or suitability, contact Kohler Mira

Ltd or your local agent.

6. Disinfectants and Other Chemicals: In applications where system chemical

disinfection is practised, chlorine can be used (calculated chlorine concentration

of 50 mg/l (ppm) maximum in water, per one hour dwell time, at service interval

frequency). Such procedures must be conducted strictly in accordance with all

relevant Guidelines/Approved Codes of Practice.

9

Note! the use of ammonia or any ammonia type chemicals ( e.g. as found in

some solder uxes) can attack brass material which may lead to premature

failure.

If in any doubt as to the suitability of chemical solutions, contact Kohler Mira

Ltd or your local agent.

Normal Operating Conditions are considered as:

1. Inlet dynamic pressures nominally balanced to within ten percent of each other

during ow.

2. A differential of approximately 50°C between the hot and cold inlet temperatures,

and with differentials of 15 - 35°C between the blend setting and either

supply.

3. Daily usage of 1 - 6 hours.

4. Installation and usage environment not subject to extremes of temperature,

unauthorised tampering or willful abuse.

Loading...

Loading...