Page 1

Reliability

and

Performance

you

can

depend

on

Page 2

~r~~m~~~9u

COMPUTERIZED

METERING

§

DEVICE

ffi>~

CONTENTS

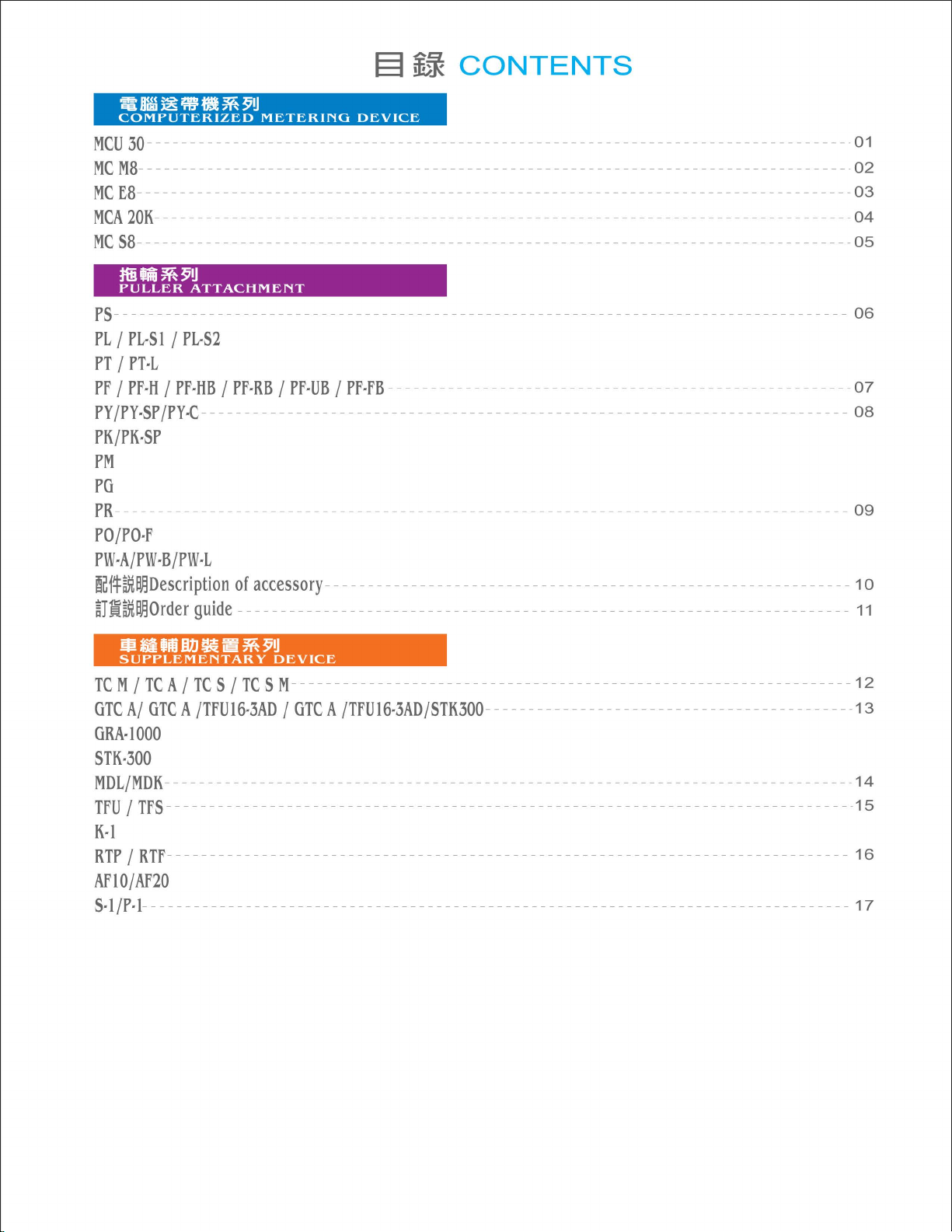

MCU 30---------------------------------------------------------------------------------MCMB

----------------------------------------------------------------------------------

MCEB

----------------------------------------------------------------------------------MCA20K

MCSB

---------------------------------------------------------------------------------

-----------------------------------------------------------------------------------

lf§

!Jii8

~

PULLER

9U

ATTACHMENT

PS------------------------------------------------------------------------------------PL I PL·S

1 I

PL·S2

PT I PT·L

PF I PF·H I PF·HB I PF·RB I PF·UB I PF·FB

-----------------------------------------------------PY/PY·SP/PY·C--------------------------------------------------------------------------PK/PK·SP

PM

PG

PR------------------------------------------------------------------------------------PO/PO·F

PW·A/PW·B/PW·L

~Gi*m~oescription

n~m~order

of

accessory

guide

-----------------------------------------------------------------------

-------------------------------------------------------------

01

02

03

04

05

06

07

08

09

1 o

11

ifi U til

SUPPLEMENTARY

TC

M I

GTC

A/

D1J

TC

A I

GTC A /TFU16·3AD / GTC A /TFU16·3AD/STK300

GRA-1000

STK·300

MDL/MDK

TFU

K·l

RTP I RTF

--------------------------------------------------------------------------------

/TFS

--------------------------------------------------------------------------------

-------------------------------------------------------------------------------

AF10/AF20

S·l

/P ·1--

--------------- ----- ----- ---------- ----- ----- ----- ----- ---------- ----- ----- ---- -

~iii~

TC

S I

TC

9U

DEVICE

S M-----------------------------------------------------------------12

-------------------------------------------

13

14

15

16

17

Page 3

MCU

e Tension

Elastic

can Auto

Beautiful

after

type

Aftaching_Sewing.

cut

thelape

jQint

combmat1on).

~o

J

comP.uterized

~9~ -~~

SERIES

metering

Special

Fast in

..

26

programs, 8 tensions

~

0&1

~

::t.H~

ffiU

C m

*ii

R

"tr

m

~

) +

E3

itl

tJJ

~

&

itHi'¥

9'SJ

JJJ

~~

=

OJ

*ii

~ § ~

~~~~ · wgu~*ii~~~ru!~~e'SlnH~w

WJE3i/J'I~~tJ.Jmvf:fijm~m*ii

CDJit*a208~)

front

device

for

Connecting

of

the Presser Foot

for

Precise Tension. With Auto

available

the

for

each

•

HHiWIJZ~~~~

Circular

for

Sewing.

Covering Sewing

program

{Max. 208

•

m*iict:Jf~~~a_r~r:tl!HBIJ'Sil

•

~26*.§If~~c'l~~

Cutting

During_the

to

Make

and

Sewing

the

tensions

Re-Insert.

Flat and

are

•

@1*.§8~

To

Operation,

available

any

~~

It

MCU

e

aJnm~

MCU

-30

Order

a

guide

-30/TR/RTA/PEGASUS

4 5 6

EX5100

MCU

/D.D.MOTOR

-30/TR/RTA

a

l/

•~ID!i~~:

1

!l.l e Model number

!lt

•~mi!!i2f"'=

e Optional attachments.

TR

<f

etJJm~f~~m~~n~~J&~

.Keeps

em~s~~m~~·M~mm~~-ID!~~£15Jm~·~tJJ~~£15J~~mmRiili~~~m*e5l~:t.J·~m~~u£15J~

e For use when sewing

RTA:

~~Wdsl~n~mu< ~IH<iiR-rrm~

for

computerized tension type metering device.

:

f~*l.Rl&~

Thread Release Device :

tension on the elastic

:

circular

~·-·--

.,~

ri]M~~~1for

after

cutting

to

keep the tension

for

RTA·30

®lf.liB~l9~30mm(3/4""~

l

+EiitltJJm&l.1tm£15lmlili

•

m••~••~~u~•••mw

e Releases the thread

thread cutting.

.

6mm

to

22mm elastic (114"

:

19mm

to

30mm elastic

after

the elastic is

for

easier

1

3116"

(3/4"

to

~

cut

to produce a perfect joint.

RTA

7/8")

")

to 1 3/16")

~~~

·~l;'ll<Jifjt(~Ji)30mm(13/16")

e Maximum elastic

••mm

•w•®~~~•w~•~~mu•

eSuitable

:

ffl~~BJ3

for

thread cutters.

USAGE

'~~i'll'm

Elastic tape ovet1ap

overlock machines

/

/

v

lllll

width

30mm

(1

3/16")

with

vacuum

~

Elastic tape

"'

fli~i'll'

~

Elastictape j

\/'JV\JVVV'V'-v

ffi~OI_j

Fabric

over1ap

I

: /

....!

~

I

:

: Non-tension

/

RTA:

5N:JJ1lf(li'f

Nonnal:

0

nsion

§J

•~m

11

·~l&£t~~~~ru!

e Machine brand and model number. e Please advise

i!UI!!~l.I\Wi~~~~~ID!

motor

the

in case sewing machine is

brand and model No.of Direct Drive

-1-

with

DO

motor.

C3

o o •

·

~ ~

Air

compressor

1!!8

liir.ii

required

Page 4

Me

M8

1it9U

~/J:it

Versatile Tension type computerized metering device

SERIES

(The

~~~H~~F.Jlli~~ml

main

unit

is

separate

C±ml~t~ffiU~;J-~~lD

from

the control box and

display

panel )

MC

~u-

EXAMPLE 1 : ZIG-ZAG

Me

~u-

EXAMPLE 1 : ZIG-ZAG

MBU

=.A~*

M8s

=.A~*

~~

RFEED

111U~

SIDE

FEED

~u=

= WD*ii*

EXAMPLE 2 : COVERSTITCH

.

;

m==§*ii*

EXAMPLE 3 : OVERLOCK

~u=

= WD*ii*

EXAMPLE 2 : COVERSTITCH

~±

:

MC

M8U

[

Remark : MC

MC

m-=.A~*

EXAMPLE 1 : ZIG-ZAG EXAMPLE 2 : COVERSTITCH

>«i

a~$

>«i

PLEASE

~.i'HI3 3 ~

REFER

MBB

C..t.~)

MBU

i!'H5

~

ij,Ej

TO

PRODUCT SPEC.

(upper

loif

oMFEED

~MC

feed)

PER

P.

3

M8S

Ci.!!~~)

and

MC

~Jf.l

MBS

(side

feed)

-2-

are

interchangeable

]

~u=

= WD*ii*

Page 5

Me

Jii9g

EBU

SERIES

~:n:i.t

Tension type computerized metering device

{The

J:~wm • ~f&~H~~F.Jro~~m

c±m~1~ffilJ~81#~

for

upper feed only.

main unit, control box and panel are all together in one

•

~~F~i~)

unit)

MC

-19U-

EXAMPLE 1 : ZIG-ZAG

E8U

:

.A~*

rlii~

RFEED

~JRmqij

Order

guide

MC

M8 U

-/

SY I D.D.MOTOR

1 2 3 4

••~~-=~••~m~••m~~-~

1

e

Model

for

Multi-

Function

MC

MB

MC

MB

bottom.

(The

main

MC

EBU

MC

EBU

(The

main

2

·:B~i'i:

eFeed

U :

L~

U :

Upper

s :

illU~

S :

Side

B:

l'

B :

Bottom

3

~it!=:

e

Accessory

SY

:

~~B$ell;!l<!HB!iiiii91J~tlj~

mt1§3l

SY : Fits

"ffi.

9U:

~'1l[Hii<\~1.Ji:U~II'l'm

SERIES

:Computerized

side

or

rear

feeds.

unit

is

separate

"ffi.

9U:

~

unit.

the

'1l[Hii<\

control

SERIES : Computerized

Type:

Feed

Feed

~

[

Feed

:

on

the

machine

changes.

(optional)

computerized

tension

from

the

L~lill

tension

box

and

ti

:

MC

Remark

MC MSS

•

gtJe.lJ[IJ191J£tljE!!IJJ~W

hand

wheel

tension

c:±m

type

metering

control

box

and

c

:±m.mWf:l"ffiU

type

metering

the

panel

are

MBU

CL~l

: MC MSU

(side

feed)

to

control

the

Wf:l"

device

the

ffiUs

all

1n

W

MC

(upper

are

C

~Ii~f!l=

auto

-19U=

:

~ffimii*

EXAMPLE 2 : COVERSTITCH

type

metering

device.

ffiU~5J

i1lt!!il!

l

for

upper.

display)

i#!il! •

device

one

MBS

section

P'~fll'l~l

for

upper

unit)

feed)

interchangeable

feed

C

illU~

l

:tl:m ]

and

l

only.

-19E:::

EXAMPLE 3 : OVERLOCK

~f-J:mqij

Accessory

descriptions for

E8

lll!lh~Willllill

I

Knee

EIO

I

LED+

I

LED

display

section

LED

1

~wmmm ct~!~f-!:

I

LED

(Note:

:

®mii*

MC

series

C

t~!~Cf-t:

Switch(Standard)

~!IJJ~WC~Ii~cf-t:l~ll'JI

and

manual

shows

changes

Indicator

MC

MBB

l = D¥~Will

:For

section

change(Dptional

the

current

section

switch

.

l

n =

(Standard

bottom

feed

manual

•

llf'l'llllff

and

McMas

Parts)

does

not

o

section

changes.

o

Parts):This

includes a manual

Cf~

l

1'11fit

include

this

tiny

display)

Specifications

...

~~:<E:O'EI:

Mount

If!i!i':2~

Program & Memory

&j:~ti1!!;i'fl'A

Feed

Range/Per

Stitch

:$~~r,r;'

MAX

. Speed

litl'l'l:ffg

S Y Stitch Counter

E8

lf.:.Jlf.Jlf.,~

ElQ

fe~o~l~a~~~~;

LED

~f~t~~;~

E9

rr:.~

i1!!;i'fl'~m;'J!a~

MAX

. Feeding width

~j})j\

Power

4 e

e

,

~~ Manual

Section Change

,;;:

r

~~~~

icat

e

Lamp)

lay

~T~~~

i~ffl~~~rnL~5¥~59;DIIi\WM~M~

Please

advise

the

brand

machine

is

with

[][]

and

motor.

261113

&11113BW

~g~~~~~i~i

CITi!ici3ef!IH

tmil"~cJ'I'

Standard (Note:

include th1s display.

AC

AC 1 00-240V

model

No.of

llirect

!~~~s~~spir~:r~C.:i~~~r~::m~~~di,mum

64mm(2

l00-240VEiilJWJ~

Drive

rg

~~i!ic

Standard

<Mil

Table

<C>Eli!*B

• l!l§ZOBI'lil

0.4-4.0mm

:\

Ui.H1\\U~~

Unlimited

~li'i!ici!f:

Optional

rg

~li'i!ici!f:

Optional

C&!'

'

MCMBB

1'~

MC

MBB

rg

motor

1/2"

Auto Switching

T""l

bottom feed does not

inches)

in

case

i!f:

Parts

sewing

-3-

E9

ll!!I~I.Jillllill

I

Free

E6·1

•

~!llll!!I~I.Jillllill

I

Foot

c

t~!~f!l=

Tape

Switch(Standard

pedal

chain

l

Parts)

(

~Ji~Cf-1:

)

switch

for

free

tape

(optional)

Page 6

MeA

eAuto

Cutting

During

to

Make the

are

available

the

Sewing Operation,

Flat

after

and

~9U

20

SERIES

Re-Insert

and

Beautiful

combination}.

•E:Jmt~tJ.JW&~WEI'SJJJJ~

~~w • mmJ:PJ!~fr!DJ~ffl!HfiJJaP~uE:I!Jti~J~tJ.J~JT~m~mm

~~ . =ij"26*EII~:Eact~

:To

any

It

can Auto

joint.

Elastic

26

Attaching

cut

the

Tape Fast in

programs, 8 tensions

=

o~Uli~§~J~~W~~ . W:1!U~m~~~~~~EI'SJ

•

.

Bj*Eiam

Sewing.

available

Cm:§7DJit*a2oam) o

Special

front

of

for

Connecting

the

Presser Foot

for

each

the

program

for

(Max. 208

m~ws:p:~~

Circular

Covering Sewing

Sewing.

tensions

MCA20K-38

MCA20K-64

•

•

~Jii:~Qij

MCA20K-

•~~~•=•~~~m~~~m~~-~

eModel

Metering Device :

Order

guide

38/TR/TFU/RTA/

2 3 4 5

for

Multi-Function Computerized Elastic

E1.*iimm

FOR

OVERLOCK

MCA

~

PEGASUS

li

38

20K-38/TR/TFU/RTA

~

~'*•~ · ~Jn~il

AVAILABLE

f!IUiUHf.l

FOR

COVERSTITCH

A¥~m

FOR

ZIG-ZAG

EX5100 I D.D.MOTOR

&I

•~m~~(~~l

e Feeding

:

38mm

( 1

width

Max in mm and inches.

Wfflll!lil

~

1/2")

Exclusive

Pre

sser

:=li!i!fflfor

l!!lllffl For

Foot

3

4 thread d'fo

thread

3.5-13mm(1/4")

~

f--'--'-:-:---'---:-'~'--t-c

~

l-8_-2

_6_m_m(:_1-'--)

19-38mm(

FOR

CUSTOM-MADE

rr:~a';

d

Parts

lll"''"

;;::"'c;;"'-'-""

---1~0 t~

ion

:C:::

''"'"'

1112")

""'"'

~~~~Parts ~!"rt•N"!

i8~U

EXAMPLE

~::-N

~

"-t-

~2--

--+--

~~

!""'

:~N~o--

163

-'-'---1

1-64---j

165

64:

64mm ( 2 112")

19:

19mm

§.1

-~!ili!!iC.l~

e Optional Parts

TFU

:

...t.~ru'~~li\1

Upper

Tape

Lit

etDm~f~~m~:nJJiu~•~

eKeeps

•~~s~~m~~·~~m~~~-~~~~m~·Rt!l~~~~~mm•~~•Mm*~~:n·~m~•u~~~

eFor

~

-~-~t~Nlil~~~

e Machine brand and model number. e Please advise the brand and model No.

tension on the elastic

use when sewing

RTA:

;.=-.;

..;...;;.;.

-___,=-.._

•

$~P

Feeder • Please refer

circular

...-

L...o:::..-1!11

.15

after

cutting.

to

keep

----.

RTA-22

~ffllB

for

6mm

RTA-38:

~fflrB~l9~3Bmm(3/4"~1

for

19mm to 38mm elastic

RTA-50:

~ffllB

for

25mm to 50mm elastic

RTA-64:

~ffllBIIJ38~54mm(1

for

38mm to 64mm elastic

to

P.15

the

tension

:

Ill

5~22mm(1

to

22mm elastic

Ill

25~50mm(1" ~2")

TR

•

m••~••~~m••••mw~

e Releases the thread for easier thread

cutting.

after

the elastic is

/4"

~

1

/8")

(1/4"

(3/4"

(1

112"~2

(1

§J

·~ffl

@:lll!!~i.I~~~Nlil~~~

motor

(3/4")

:

fU:,'R&~

Thread Release Device :

to

112")

to

" to

2")

112")

112"

in case sewing machine is

:

cut

to produce a perfect joint.

RTA:

7/8")

1 112")

to 2 1/2")

~==;~

-4-

ffl~ffi:Sfl

with

••mm~

esuitable

thread cutters.

USAGE

f~~llli~~~

Elastic tape overlap

/

/

of

Direct Drive

DO

motor.

38-64mm(

&•m~~•~m~•~~m~

with

Fabric

lJI!t:IGt;.

z

ur)

Optional Parts

overlock machines

/

:

0

a.

m~Jnii~iFm

o o •

Air

compressor

with

vacuum

Nonnal:

Non-tension

required

•

Page 7

Me

S8

elf.HJi'J'

Rt9~

SERIES

ecompact

--~~8~~~&~ffi~~2~~~~"E[~ffl

ecan

•

~i"\l'!!:"E!Ti~~m;;:;r-:~~~'!WM

size. 8 available

be

used

with

any

clutch

sections,

or

position

•

~~:f~fimM~

with

precise

o

motor.

o

tension

control,

are

available.

Me

Me

Sac

SBB

• 57

-57

mo~mm

FOR COVERTITCH

T:~m

FORBOTTOM

FEED

Me

~)

I

SBK

• 57

Me

@.~§l[ffl

FOR OVERLOCK

SBS

•

57

Me

~

1l'!Ui1!Sffl

FOR

SIDE

SBZ-57

FEED

F'o

~if-~

G

•

8JR~ft~

MCS8 C PEGASUS

1

e

MC S8:

~·C:

eK:§~~If.l

z:

e

3

-~~~t~Rij~~~

~m@~I!!J®ii;wH5~Jiij~~~

e Please advise the brand and model No.of Direct Drive

case sewing machine

Order

guide

2

~~mA:JI!Jt57mm

Feeding

Sections are

!lffi~~lf.l

A~~m

e

Coverstitch e S:

e

Overlock

•

Zig-Zag

width

esewing

available

3

up to 57mm(2

is

W562

D.D.MOTOR

4

( 2 1/4" )

e

B:

Machine Brand And Model Number.

with

~F\m:<~H~~fi/f'!q]~~!Jt

1/4")

Up

to

with

Precise Tension Control.

ill!l~

eside

1'~

esottom

DO

motor.

8 Separate

Feeding

Feeding

motor

in

o

-5-

•

-~~

J

~

F

¥

1'i"~JEJ5'i'l.

Bracket mounting location

~m<acrmll

Feed

Range

(mm)/per

i!;e;~Jl[l'

MAX.

Speed

'lt

ilil<

Power

Specifications

Me

ss

~re~

Me

sac

I

i!Jliili

Machine

0.

4-3.8

Tape

I

Head

•

li1tEI~li1ttJ1~3

IS 40mm.

The

AUTO

SWITCHING

MC

586

MAX. Stitch/Per.

stitch

el

MCS8Z

Machine

60001

IMCS8K I

i!Jliili

I "'!& I

Head

Table

, m

Cl'!\WH!l'JifiJ[l'tJ1~40mm

p

(The

MAX.

W1dth

for

AC100-240VEiiitJW~

AC

100-240V

I

MC

S8S

if!

I&

Table

-

5mm/>t)

IS

3.5mm)

Page 8

Mll~9~~~

PULLER

Ps

ATTACHMENT

'Niffi ,

-"t"-~t

,

FOR

SINGlE

~Ht~ffl

OR

TWIN

NEEDlE(REGUlAR)

Ct.il'l~~)

SMAll

ROllER

• :tiHi!Fi' m

eoisengage

e~ffl&fi·~·R~fi~·Elli·®

gJW!fm

eExtremely

curve

materials.

Bi¥

err

cu~

roller

•

<mli'e•l'lo~sJ1Uli$ll

close

and

short

rt

if

not

pulling,

sewing

needed

o

facilitates

on

thin

-"t"-~t , '!Ht~ffl

FOR

PL

PL S 1

SINGlE

•

Ct.i!'i~~)

OR

TWIN

NEEDlE(REGUlAR)

m!i*ii~ffl

FOR

FlAT

BED

COVERSTITCH

•

~ ~

8'9

i~

f'F

~

ewith

·-~~--tt~•···~~~~

ewith

PL

Large

Jf-'12~*li

various

different

•

S2

1".\l

Space

for

Operation

0

optional

kinds

~~m!i*li~ffl

FOR

CYliNDER

of

materials.

rollers

BED

COVERSTITCH

for

-"t"-~t

,

PT

*iil!!$~.i'i!lil'l10'

* PlEASE

~Ht~ffl · l:l'.l!illl~

FOR

SINGlE

OR

TWIN

NEEDlE

ll~~o'ffi~I3J'l

REFER

TO

PRODUCT

SPEC.

Ct.il'l~~)

WITH

UPPER

PER

P.

10 & P.

AND

lOWER ROllERS(REGUlAR)

11

PT

-6-

m~~ · m~~T~~~

•

FOR

lONG

ARM,

L

~Jli'l:B;!ii5!ij)ffi'ffiiRIU.lil~i'@iil'!&I~H'F~r.ll

Please advise the roller lifting height and operation space

(please refer to

AVAilABlE

P1 0).

FOR

CUSTOM-MADE

C

$~~P10)

Page 9

1Ji!m!!I!~9U

FOR

FEEI).()FF-THE-ARM

-m:m'¥3lm ·

PF

For

General Fabric.

PF

~!Wm · ..cilffii~lll!ii.J

H

• For Heavy Duty.

PF-FB/EFV

IZ!litli:*!Rm 8iltll''rttmilffii

Belt

Type

Puller

..Cilffii~ni.J

Top

Driven Roller

Top

~

for

Flat-Seamer

Driven Roller

PF-HB/ECV/AF

~WJ • fo:Jg~WJfflBZ?M:r.\:tffirmi

<~~tt!!ici~3/16"x3/16"H~~..EI)

Belt

type

puller

for

Extra

(Optional

parts

gauge

Heavy

set

3/16" x 3/16")

PF-RB/ECV/AF

-~ffi:jS!fflSZ?M:r.\:tffirmi

BELT

TYPE

PULLER

FOR

REGULAR

PF-UB/EFV/AF

~

WJ • fo:Jg ~ WJ

m~~,£1: 9/

Belt

Type

(Gauge

Set:

ffl

BZ

'l!ll'

Extra

9/64"

:r.\:

/8"xl/8"

Heavy

or

1/8"x1/8"

Machine

64"x9/64"9.li:l

Puller

for

9/64"x

®fflli'l1!!1:

Adaptable

~

llf~~!Wwffll/B"xl/B"iHU£1

Duty

with

gauge

set

1/8" x 1/8"

for

~

FABRIC

~

tffi

rmi

~-~ffl

Duty

Alternative)

u.s.

Model: JUKI

PEGASUS

YAMATO

KANSAI

35800

MS3580

fV2

DT-30

SX6803

)

heavy

duty

i!!iG~~!Jij

~iJ.JrtEJiJ.JtiJN:~~~

Electronic

ECV

EFV

*~i!!$~.i'i!llf'i10'

*

PLEASE

(IUIIG~)

chain

cutter

=

~~~m

Feed-Off-

The-Arm

: ll!lit/\*!Rm

Flat-Seamer

ll~i!!fiffi'limij)'j

REFER

TO

PRODUCT

SPEC.

Description

a

0 0

PER

P.l 0 &

P.11

of

accessory

~7Jrt:J-It~*LiJ.JtiJ7J~~

Pneumatic

GFV-8

GFV-16

(Optional

Guillotine

:

t;JJ7J§M

Cutter

:

t;JJ7J§M

Cutter

(~§BMM)

Width

Max.

(~§16MM)

Width

Max.16mm

parts)

Cutter

8mm

~

iM7.1<£<Wfflm

for

Diving

-7-

::$:~~crr~~jjj'ij~

This

device

can

be

Suit

ordered

A F

*1.

Pneumatic

individually.

iJJ

rt

I!!Jl§IJ:t:~.

presser

a

-~g;g~~rm

o o •

Air

compressor

rt

~ ~

foot

~

required

Page 10

~-~9U~~

PULLER

PY

ATTACHMENT

lri*t , JUtmm

FOR

SINGLE

PULLER WITH

·

..t.l'iJR!i~IU1.J

OR

TWIN

NEEDLE

UPPER

AND

LOWER

MACHINES.

ROLLERS

py:

•

C

mfiMmm

FOR

COVERSTITCH

py:

Sp

•

wHil:te

Ci&;;i;::'!'UDwffl)

FRONT

PULLER

(FOR

SPAGHETTI SEWING)

§Jiimm

PK

FOR

e

;'¥-

:±J

JO\

e

Floating

fllUiJR!iC~!fmffl)

PM

SIDE

OVERLOOK

type

ROLLER

·

..t.""FifRli~lnn

MACHINES. PULLER WITH

(FOR

HEAVY DUTY)

=

'-o--t

UPPER

AND

LOWER

ROLLERS

·

~ffl~liiH!Uf.~~'l@il1Hl;<mll!ll

esuitable

thick

sewing.

for

materials

thin

to

in

extremely

straight

o

P

u

•

~

SP

MW:te

FRONT

PULLER

C5;;1;::'!'UD:Wm)

(FOR

SPAGHETTI SEWING)

§mmm · ,J,ifRliC!W"!fmm)

FOR

PG

OVERLOCK

[

*~l!i$~!\HIHO , ll]::[i!l[aEd

*PLEASE

REFER

WITH SMALL ROLLER(For

4~~~~~tt~~*~~¥~~§~W~~e~§~~..t.

This

puller

is

unable

to

vertical

or

horizontal automatic thread-chain cutter.

i

TO

~ij.Ej

PRODUCT SPEC. PER P.l 0 &

install

onto

thin

material)

overlock

P.11

machine

with

either

]

-8-

~9U?JTm~El'!l¥~g;gre~~

PG

Space

Limitation

·

~ffl~rui

eAvailable

For

PG

Series

'

Models: Example

17MM

19U

JUKI

PEGASUS EX,MX,M

~~gl~t"

SIRUBA

H~Q:lll-"1

CENTER

OF

NEEDLE

(5

o o •

'

.

m~J!H

Air

:

MD

3000,6000

~zv

aooo,6ooo

757H,K

li®

compressor

required

Page 11

PR

§JiUUf.l

FOR

OVERLOCK

·

~"'Il'~~

<lW!Wffll

MACHINES.

PULLER

WITH A REAR

ORIVEN

BELT

-~~~~~~.§~---~~~~-

esuitable

space

for

every

limitation.

machine

without

0

DQ

I '

Pw

=

.II!l~§Jl.i~m

FOR

3 & 4

PULLER

THREAD

WITH

~scrrlltJ~~m~m

FOR

BLINDSTITCH

(Suitable

for

PW-A:

·

..t:~l;!ll'~ [E~§Jl.i~:;r;~m

OVERLOCK

TOP

DRIVEN

<~m~;M7..t<'!Xi'fl*4l

MACHINE

diving-suit

~&:l,!lli~

LONG

BELT

material)

TAPE

MACHINES.

BELTDRIVE

WITH

MOVEABLE

BELT

Not suitable

•

e..t:~m<~i!!!ID.l

esimple

ARM

for

5 Thread

1'~&\'iH~

=6

&.~J1lf2i'fl'f4

top

for

collars,

tough

PW-B

l'i&

installation

drive

different

multi-layer

abrasive

ilky

materials.

:

~H&:I;!Ili~

SHORT

]

.

~m~l§

,

~

~ii!JU'li'E

°

belt.

Suitable

kniting

and

BELT

with

TAPE

el!iii!ffi~ll:l'lt

e®m~~~7'tJ1lf,

DQ

I ' •

ec1ose

esuitable

proximity

needle

improves

materials.

F =

.II!l~EHii~m

FOR

3 & 4

COLLARS

.

~m<WmlilHeifl!!mlli

~!l!li2~tm

of

rear

drive

silky

THREAD

OF A KNIT

PW-L

sewing

and

easy-pucker

<~ll&Hilllwml

OVERLOCK

SHIRT)

WITH

:

~~~~m

LONG

ARM

for

0

o

belt

performance.

llflUiUtJ:I.'C§.i.§~

MACHINES

AN

AIR

and

thin

TYPE

(FOR

SEWING

FOLDER.

THE

('5

o o

!ltJ*Ilm! .

Custom-made

l8-19U

EXAMPLE

*1i~$~.i'i!~l0'

* PLEASE

REFER

~J~~~~

Order

ll~~ffil~ll!'l

TO

PRODUCT

SPEC.

PER

P.l 0 & P.

11

-9-

l8-19U

EXAMPLE

DURKOPP

869

..

a

-~~~iill:um

o o •

Air

compressor

required

Page 12

mmiliiJm~~m&~f~~~~~

Description

~ltr!1H'\'-

solenoid

A.!Jlli$

-

i!!ici!:J:,

Standard

of

Roller

Lifting

Part:

lifting

Height

and

Operation

Space

for

Puller

*L~m~

Pneumatic

-

~lll'i!!ici!:J:'

C.

Optional

Lifting

Part:

a

• o

-~lll'i!!ici

!:J:

E.

Optional

Part:

'

/01¥!-;>i;MoSmm

ll<i'F!'Erollo90nrn

lilting

Height:Bmm

Operation

Space:90mm

-

~lili!!ici!:J:

8

-

Optional

ll!'¥1-il'OMoSmm

IIO>i'F!'Er-11'

lifting

Operation

,

Part:

136mm

Height:Bmm

Space:

136mm

:0

j

=====

=~

==!

~

~•~9Ui!!ia~m~

Description of

mffi~m~~=••w•~ffinm~~~~

accessories

for pullers

!1!1~;>i;Mo15mm

!l<i'F!'Eilll

'98mm

lifting

Height:15mm

Operation

Space:98mm

-

~lili!!ici!:J:

D.

Optional

•

PW -PR -PG

e

The

roller

Part:

lifter

,

~~~~~·mffi~·~~m~

C~~=mMAM~·ey·~~-~~B§fi&~ffi~~--~~-m~•·l

Roller

Lifter

:The

puller

roller

will

lift

at

the

same

time

as

the

foot

This

will

work

on an

auto

foot

lift

(The

puller

comes

complete

with

the

ft~~~~~am~m~·~--~~~Man•~H~

r

~••mffi~~~•~m

[

11

you

do

not

need

the

Roller

Solenoid

( Regular Parts )

lifter.

J

·~~•~m~~

please

Lifter

:

indicate

micro

machine

switches

this

'\..

or

and

all

-

on

your

order

Pneumatic

( Optional Parts )

'\..

lifts

with a manually

the

cables

as

the

cost

Lifter

:

-===

-

PO

:::r:

is

not

included

on

the

required.)

will

==

llfiJ

~!-:i"

for

machine.

lifted

be

reduced.

!li1

~*§

PW.

foot.

PR.

PG. PO.

·

]

101~;>!;Mo45nrn

ll<i'F!'Er-11'

225m

lifting

Height:45mm

Operation

Space:225mm

=P

-

~lll'i!!ici!:J:'

F.

Optional

Part:

!li'¥!-il'OMo45nrn

!li>i'F!'Er-11'

276nrn

lifting

Height:45mm

Operation

Space:276mm

B

~

~ffl~~t~~g{l~IQI~t~li~M~

B Base :

In

case the Reverse Solenoid is at the back

of

Machine.

AK~f:U*El : ~ffl1J~H~~l5!l~~1'5Jl1lll~iBIJ

AK

Relocation Set :

Wft~~m

=

====

If

the foot lift solenoid is located

the back

of

set

the machine a

is required.

i

Pl.

PT.

PT-l

::;o;==;;:;~

~

Pl.

PT.

PT-l

on

AK

relocation

~--~-

PULLER

lll!!i!J8U

Driven

~iJIHilU"'i'i'l

Transmission

ffii'iJfiWl'!'!liit~el!it!

The

Roller

mmfim'i'i'l

Roller

ffisl!l>IJ!'

Puller

ft;l!!;l;il$

Sewing

(

Continuous/Intermittent

'Ill

Wit

:>:<i:lffi!MB*9Ui!!Hll~IJF.I

:>:<i

PULLER

Specification List

Wav

Type

distance

and

Type

length

MAX_

Power

CB•J>J

Between

Needle(MIN.)mm

(Regular}

Cmml

Ci!I!IIUI>MI/ illlW:II>Ul

the

Cmllli~ci'I'J

(mm)

Speed

)

SERIES-PRODUCT

mm

PS

.l::!Mi

Upper Roller

P2510

0.3-6

SPEC.

P-2

28

PL

PL

-B

.l::!Mi

Upper Roller

P-2

50

P5515

0.3-6

4000/6000

PL-Sl

PL-S2

.l::!Mi

Upper Roller

P-2

65

P5550

T5550

/T2560

0.3-6

PT

PT-L

.l::l'!Mi .l::lll!

Upper &

lower

Rollers

P-2 P-2

130

P5550

P2580

0.3-B

PT:40DD/6DOD

PT-l: 3000/4000

PF/PF-H

PF-HB

PF-RB

PF-UB

PF-FB

Upper Roller

PF/PF- H: 60

PF-HB:

PF-RB:

PF-UB: 32

PF-FB: 50

PF:

~~=~BIRBS6Dt5

PF-UB

:21Dl17 P25BOK

PF-FB

PF:

0.3-6

~~=~~:3:~:9_5

PF-FB :0.3 4

3000/4500

AC

py

PY-C

PY-SP

.l::l'!Mi

Upper &

lower

P-2

45

25

P5515

150

P5550K P5535K

0.3-6 0.3-6

100~240V

Rollers

§iBIJtiJJ¥.!!

-10-

PK

PK-SP

.l::l'!Mi

Upper &

lower

Rollers

P-2

200

P2560K

AC

100-240V

JUKI

AK-34

PM

.l::lll!

Upper Roller

--

P4512

0.3-6

35

84

85 88

PG

.l::!Mi

Upper Roller

P-2

P-2 P-2

40

P2811 335DMXLOB

0.

3-6

4000/6000

AUTO

SWITCHING

89

PR

l!t&:'lll'

Rear

40

0.

3-6

a _

• • -Air compressor required

Belt

PO

PO

.l::&:'lll'

Upper Belt

475DMXL10

0.3-6

1'1iE

~

II!

-F

P-2

~ll:

iiiiJ

PW-A

PW-B

PW-L

l'&:'lll'

lower

Belt

P-1

--

PW-A:3520XLD37

~=~,

180xw37

0.3-6

3000/4000

Page 13

tmlii~JJii$lQij

PULLER

!.!1

MODEL

PS

PL

PLSI

PLS2

PT

P'PL

PF

Pf:.H

Pf:.HB

Pf:.RB

Pf:.UB

Pf:.FB

py

P¥SP

P¥C

PK

PK-SP

PM

PG

PR

PO

PO-F

PW-A

PW-B

PW-L

Order Guide

PL P 5515 BROTHER LT2 B842 • 401 D.D.MOTOR

·

~lli'f~5JJE~Il.l'l

e

Puller

Model

Table

~~

ADAPTABLE

~it'

'!!it

Single or

~it'

~it

Single or

OOl~*

Flat Bed Coverstitch

~~«rPM*

Cylinder

~it-

JUt

Single or

~~~~it

long arm Single or

,!;i!~*ffi

Feed-Off-Arm

IZ:9it7\~~*ffi

Feed-Off-the-Arm

~it'

~it

Single or

I'JU:ffi'i:\~it*

Flatbed. Front Puller.

«rPM*

Coverstitch Same

Ei.M*ffi

Overlook

Mffi'i:\Ei.M*®:

Overlock. Front Puller.

Ei.M*ffi

Overlook

Ei.M*ffi

Overlook Diameter 2Bmm Roller.

Ei.M*ffi

Overlook Feeding

Ei.M*ffi

Overlook

Ei.M*ffi

Overlook

'¥-~CITmtJ~~M*ffi

Blind Stitch With Moveable

1 2 3 4 5 6

~

I'!Ht

*

MACHINE

Twin

Needle

Twin

Needle

Bed Coverstitch

Twin

Needle

'

'!!i

t

Twin

Needle

Flatseamer

Twin

Needle Same

ffi

Arm

~l!l!25MM

Diameter 25mm.

Curve and Short Sewing.

~l!l!55MM • l\m-3'-W~H~eilit! 5

Roller

For

~ffl¥@; • ~l!l!55MM • fim-3'-W~iilHei1l!!65MMtJ_..t:.

Roller

For

~ffl¥@;

Special

For

..t:.l'fim~ilrffi:tJ~S!!l

~g;"'~~~u~r~ff!,e~t~~i~l~ower

J.:!,~~~

Same

~l!l!55MM • l\m-3'-W~iilHeili!I60MMtJ_

Roller

J.i!J~!I?ll~ffl

Same

~!l?ll • ~~~Mmm&:mrclffi~

Belt driven

-lil9:i'IJ*-'Iffl&:lli'l'r\.Jffil\m

Belt driven puller for use with regular fabric.

~!l?ll • ~~~Mmm&:mrcm~ . ~m~us3ssoo~ffiX

Belt driven puller extra heavy duty. Suitable for machines similar to

12!Jifi

For

~:<E~~;f&

~:*:fU\il!i~ffl

For

~:<E~~f&

..t:.l'fim~illffi:tl~S!!l

Powerful

For

~:*:fU\il!i~ffl

For

illUfim'!Z~i':E~iilt:IlA

45mm Roller

lj\fimfiml!l!ZBMM

~l't'&:m~~ • ~m~"'~mi'ti*-'~

~l't'..t:.&:m~

Belt driven.

POLO~~ffl

Special

~&:m<ri.l'~

long Belt driven.

~ll.&:l;\'l<J:\.1'~*-'~

Short Belt driven.

~~~ffl

Same

• l\m-3'-W.!UHeilit!im28-

2B-30mm

diameter

general material.

general material.

General Material.

as

as

t I

\*''Ji~ffl

use

as

sewing

as

thin

sewin~

as

55mm. Distance

diameter

55mm. Distance

• lll<ll'fim •

Bracket.

lower

PT

but for long arm machines .

diameter

55mm. Distance

, J}J§g(q)pf

PF

but for heavy materials.

puller for use

'

~ffl~effl!i'IJ*-'1

on

flatseaming machines. Suitable for all

,

J}Jf'jgfq]pT

PT

puller but

•

~:<E~~f&

spaghetti

PT

upper

to

heavy duty material.

spa~hetti

By

Timing Belt.

For

Knit Shirt Collars. With Knee Pneumatic Switch to Act

PW but for use with long arm machines.

straps.

, J}J§gfq]pT

puller but for use

and

lower rollers.

straps.

diameter

·

~ffl~JW!I?lli'ti*-'1

·

~m~s~~~~~-~~&•Mm*-'1

For

use with multi-layer.

• ill<t§Jli

*-'l

·~ffl~;'/l!*?Ri'ti*-'1

For

sewing

,

~ffl~)'ll!*?Ri'tili'-'1

For

sewing

30MM

•

Between

0MMtJ_..t:.

between

between

fiml!l!55MM

•

the

•

•

Side roller beside the

iS§

•

Roller. Diameter

fim

l!l!55MM •

Rollers. Diameter 55mm. More than 130mm Between Needle and Roller.

between

on

heavy or extremely heavy

PY

is fixed to

Fixed to

on

coverstitch machines. Fixed to

l\ml!l!55MM

Upper

l\ml!l!45MM

For

Thin Material.

For

Thin Material.

•

lllHlll*i:i11!m~&'Iti55i11

diving

diving

~ffl~lWi'ti*-'lm~eilit!~~

Needle and Roller.

•

~ffl~-lil9:~ , ~i'ti*-'1

the

roller and the needle is more than

the

roller and the needle is more than

~-3'-W~H~ei1l!!65M

55mm.

fim-3'-W~iilHei1l!!l30MMtJ_..t:.

..t:.

• J.:!,-lil9:i'ti*-'lffl

the

roller and the needle is more than 60mm.

the

table.

the

table.

•

fim-3'-W~iilHei1l!!200MMtJ_..t:.

roller diameter 55mm. Distance between the roller

•

~ffl~$!1?2Ji'IJ*-'I

pressure

abrasive

and silky material.

suits.

suits.

For

Short Thin Material.

•

~ffl~-lil9:~

M

tJ_..t:.

More than 65mm

materials.

types

of fabric.

for Heavy Duty.

llJ

i'!Ji3§

50mm.

, "'i'ti*-'1

•

~ffl~-lil9:~

Between

•

~ffl~~!l?lJ!ijU~~!I?ll

US35BOO.

the

table

•

~ffl~~¥U~$~!2l~~ei1l!!~~

the

Moveable Folder Right or

65mm.

, "'i'ti*-'1

Needle and Roller.

.

and

•

~~eilit!~~

For

general material.

the needle

is

left

more

than 200mm.

Side.

ID

e

!I!

Ali

--3'-t-t~W9'1-lli'

e

Roller

i"t

Code

t-tm

Material

:71-l!l/

Figure

*

PS

*

Not

~ -

:;tj

2.f·1

Material & Figures

'OJi

p

PU

'¥ll3l

Polyurethane

Plain

~

, PG -

PO

ffli'<UlWITil!iiffl

For

PS -PG -PO

~~2H!!!~Wlf.~lli'

e

Adaptable

~ffli~Jlll!!.~~~i59<

e Please

motor

advise

in

case

Sewing

the

sewing

and

Machine

brand

Belt

Driven

Brand

D

~~~lli'

and

machine

mil!lill3l

Steel

Type

model

is

s

and

with

Teeth

PS-PG

Not

Model

No.of

00

For

Direct

motor

~JI!$@[13j

Plastic

T@iffl

PS ' PG

Drive

.

T

Teeth

B

i31$Z!l!!ll!$

Synthetic

Rubber

0

210Ll7nm

-11-

~ e!I!Ali--3'-~Jlffi

'S!.1

e

Roller

Sizes

u;;:J!l!

D

Diameter

J:::

...

Upper

roller

T

...

lower

roller

* PW , PR , PO fflil":'\l!

* Not

For

PW

...

PR

...

•

El

mDtJJ

eAuto

~JJV.szJl

Thread

~

55

45

25

25

25

30

i11

Til!iiffl

PO

Series With Belt Driven

1

1

Jm\

i!!ic1'1=

Trimmer

or

Other

~

ill

:

mm

Unit : mm

Ji:!l!!:

w

Width

15.35,50

HU5

;~~J.

~ ~Jl

10.15

;~~!n~;

CP

60

so

22

Type

*'1iii

5m

Attachment

*lffiM'ffi:9Ui!!lilffi~~

*PULLER

K8 ffl)

(PK

only)

CPT . PY:Wffl

(PT.

CPFI!J ffl)

(Pf

Device

No.

SERIES-PRODUCT SPEC.

PY

only)

only)

)

Page 14

ti(,I1Jj.\:1PJWJ~9~~~

Pneumatic

Tape

Cutter

Series

TC

M-M45

~

~JilimiJ.I

Order

Guide

ewm:oP:;

eTape

M : •

e

EB

:

~mEI!lii!lil

Knee

switch(regular

TCS

L25U

A : e

e

•

W7J~.1tt§1i;5m

L

25

:~~~

M45

~~~~

H50

*

t/J'i'il'ilt:IJ~Ul4@Qlffili'IJJ!q

•~

·m

*

Cutting

only.(Operating

material

~ • 1lEffll§!,\lll!!~w\Wi59iD~M~~~

TC

A-

L25/

1

F I D.D.MOTOR

2 3

4

Gutting Way

imill'Awm

Manual

Cutting

Switch

(!~~!!icfOOl

parts)

(~!!!!!!!icfOOl

76~®\i!!~s:.\ElilltJJ/;\'l'

Auto

Cutting

by

•

Item

1-t'il!l

Item No.

lli!'WIIl

light

Cutter

qo'lj>JIIJ

Cutter

Medium

Ill! 'Will

Heavy (blade

~~~U~~i'IJJ~q~fiff.!J~

Capability

pressure : 5kg/cm

condition

is

based

before

Ell

Left

'

Photo-sensor:Cut

CiJEli!JWI

No.

of

Wl!l'lllll: mm

Tape Width mm

25

45

50

<

Ii'Fli!\11!

on

14oz

ordering.

(

~!':t~

GJ

(blade

GJ

:

<I=J=I!\Iil!lil

manual

before

cutter

5~5)

!l!

55)

55)

!l!

60l

60)

o

of

material

2

)

Please

<~m::l!cilml

switch(optional

,

i~tJJI;\'l'

o

and

finish

lii Wl!l'i!!i7J

* Cutting Capability

2

•

layers

4

•

layers

10

.

for

consider

layers

ff.!J~

your

the

,

5kg/cm')

parts)

~EB~lltli!ilifmi!Js:.\tJJI;\'l'

sewing

F=IIJUiEil~

Control

• iilii!'\

reference

exact

• Please advise the brand and model No.of Direct Drive

material

panel

automatically.

•

~~iilt!$!

El2

:

15-'J=I!\Iil!li.J

Right

manual

<i!!lll~ci'l',

Including

:710

Auto

WI

(~!!!!!!'iciillll

switch

(optional

"",

E'l'l!!li!IJ;ottJJl!l'l

E8

Knee

~

~W5l!

U

rc

E3

by

Start

cut

Sewing

!Ill w m

Photo-sensor

Cutting

tJ]

•

Cutting

Machine

WI.

t/J'i'il'

Cutting

parts

~tJ]

parts)

Switch(Optional

type

e

C e

motor

in case sewing machine

tape

:left

or

Right

manual

Start

& End

cut

@ffimJ::IH'fl¥@;

Bracket

for

Coverstitch

switch)

is

Machine

with

DD

motor.

I J \

H!J

t'Tl

JJ

,.J

•m

*it

.=::~::.

'P

Co

TC

t J C tt

mpac

S-L25

19U

EX.

u er •tJJ

~

::'"~

•Prompt

7J

•Available

q:rc~:J'I~

=ij"

eoperation

~

1~

~

*U

H*

ffi ~ •

Mz

El

jJ]

!&

~

trimming for rest fabric and collecting fabric to waste bag automatically

~

~ ~

Cutting Width

TC

photo

S-L25M

e

CITW!!*li<UJl,f.i'IJJ!q

eAvailable

mark

n;p

P'!.J

EX.

on

cuff

'*'

16Uc'll1

sewing

for

~

• li'!IB"fiiiJ[_tfl!lOSc'Wt

cutting

the

rest

fabric

in

the

meantime

mark

fabric

@~

and

.

•,

IIIlO

make

Cuff

-12-

1i~

~ ~ ~

EI3

<I=J=I!\Iil!lilr.<l"lil

left

manual

e

3i5i!J'%1£~<Ei±I

illiiEDI!l'iii!'

aim

eMoveable

Easy

Installation.

Oi\'l~!'icilml

switch(regular

clamp

fixing

parts)

i'F~

_t

on

table.

a.https://manualmachine.com/

o o •

E8

•

~~!ill

Waste

bag

aull:

Air

filll

compressor required

Page 15

GTC

A

~9U

SERIES

•liT

•Guillotine

!ia

g. A

~tl

7¥,

~

CiJ

El

mJJ

M

~

tJ.J

7J

w.J7J~m!65MM

tape cutter available

(

::f~MJTi§~)

with

Suitable for all Brands and Models.

(Folder is not included)

•

CiJ

~

~

1:i~a

~

m&

»'1f

~

~t

~

Photo-sensor for Auto cutting.

The

Max. Cutting Width 65mm.

·

GTC A /TFU

/STK300

llf!ll&:f3~

Stacker

included

GRA-1000

16-3AD

~~-~ ~~-~

Tape Feeder

r~~l;i:Jflllfttl.l7J

stacker with cutting assembly makes more than

daily production

a

included

,

®~~JL

of

front-opening sewing

GTC A /TFU

Tape Feeder

"iiJt'Ht1!4SI¥

25%

J!

a

increase in

STK

16-3AD

included

• versatile stacker

300

a

~m:iii~&:t<:::H

GTCA

a

0 0

a

m

Application:Stacking

Stacking

STK-300

~ = f'':l~~m*ii~m

1&~~1.@' = EE500::53"~1200::53-~C!J

~

Capacity:2400

Length:From

~ : ~D~~D"114~t • -~Ci\tJIB'i¥)2,400i!:!=

1.16

""'F

~!

Sewing

ended

and

Cutting

50cm

to

pes

per

day

(8hrs)

.®

1<~

H

iJJ

f'F

;.;?.

Stacking & lifting

for

Shirts

120cm

if

14

stitches

~

Procedures:

front-opening

per

2.

~

16

Cloth

be

inch.

clipped

ffl

Application:Stacking

1&~~1.@' = ~hEE500::53"~1200::53-~C!J

Stacking

3 .

.1'R16

Cloth

-13-

~=1&~~~·~7·E~W2m*ii~~~~h

Length:Cioth

be

thrown

for

shirts,

trousers,

pieces

from

50cm

4.~16~1~7+

Cloth

rack

a.m~

o o • Air compressor required

suit

to

be

lifted

I!!

:Sl!:filll

...

etc.

120cm

Page 16

ifi*iltillmeiii~9U

SUPPLEMENTARY DEVICE

2

MDL

31

A~!:!Hfl:Wffl1i:i

• 4

FOR

SPECIFIC

machine

head)

C;§'!;~~J:E1i~mlii.ili...l::.)

ZIG-ZAG

(Base

is

mounted

on

the

MDL

30

• 4

2

ruD*iHI:!m

FOR

COVERSTITCH

c;§'!;~~J:E1i~m:t.&....t:::.)

(Base

is

mounted

on

the

table)

MDK

61

Bl.mmwm1i:i

• 4

FOR

machine

SPECIFIC

c;§'!;~~J:E~mlii.ili....t:::.)

OVERLOCK

head)

(Base

2

.,

1

"M"DaJJim~

1 T I Order Guide

MD

,

1

.....,-

:lf

~

L

31

2 JUKI LZ2280N · 7

1 2 3 4

.J e

~~:r.t*li~~~ffll&TI~

e

Mechanical

for

-~~~~:

e

Feeding

2 :

4 :

Elastic

Width

2"(50mm)

4"(1

OOmm)

Metering

Tape

:

Device

2

:..! e

5 •

2.1

5 6

·£~.!'[:

L .

e

is

mounted

on

the

Sewing

Machine

Type

:

-'JZBt~m

·

Flatbed

Machine

m~~,~il§~j:Siij]Jil&MIII.~ru/

Please

advise

there

is

with

'3Z~~*Y1~~~~~~

Adaptable

Sewing

the

D. D.

k .

Brand

Motor

.

Machine

MDK

"§JJ&~~m

·

Overlock

and

Model

if

and

Model

60

e1~'5m

3

ecode:

•

6

e

2

Bl.mm

• 4

FOR

30 .60

30.60

31.6

31.61

E:JttltJJ*}.R&I31111i~cf!:!=*~'5m

Auto

C;§'!;~~J:E1i~mt&....t:::.)

OVERLOCK

=

¥~~sln)]o:~;f,&_t

Base

1

¥~~stttro:~~_t

Base

Thread

is

mounted

is

mounted

Trimmer

(Base

on

on

or

is

mounted

the

table

the

machine

Other

on

the

head.

Attachment

table)

Device

Number

-14-

Page 17

mMtiii1J~ii~~u

SUPPLEMENTARY

TFU

TFU

16

• 3

16

•8

ffllll!'Z'<\IlJ'Ht=IUs~~

Mechanical Untangling Device ( Regular parts).

-

e

DEVICE

l:~~!B~i!Siml • ~i!SI§ifi!

Upper

Tape

Feeder,

Feed

Width

l:~~~i!Siml • ~i!SI§ifi!

Upper

Tape

Feeder,

Feed

Clil!1~~c!ilD

~~-~2~~-·~···W~-~

u;m;e*~l!lmo

To

untangle

from

the

box.

the

.

twisted

elastic

Tape

Width

·

or

cord

70mm

200mm

70mm

200mm

TFU

1:

~ ~ ~

l.tH*a~~) · ~i!SI§ifi!70mm

Upper

motor

UT

-2

16·3/UT~2

iiSI

ml

(Ill!!~

t1J

~

llf.j

Tape

Feeder

(with

device).

Feed

mEB'J'I:Il§l'!"~i'&llJJJJ:fJ\j\>ll!fli

To

untangle the twisted or gathered elastic

tape by Motor.

With

untangling

70mm

:I

U§&i\~*il!l

TFU

=*§:±ml

Triple

main

at

the

same

16-3/AD

•

CITil"!JB'i~l!Sil-3!15li

device

to

feed

1

""3

time

.

Tapes

TFS

TFS

K 1

•

26

26

t~ll&~l'l=ml

IT

Pattern

lllU~~~i!Siml • ~i!SI§ifi!

• 3

Side

lllU~~~i!Siml • ~i!SI§ifi!

• 8

Side

Cutting

Machine

Tape

Tape

Feeder,

Feeder,

Feed

Feed

Width

Width

70mm

200mm

70mm

200mm

li

il!

-3'-

COLLAR

li

il!

-3'-

COLLAR

W-ffli!!icl!f:

Special

Accessory

l1it t.&

Ne

edle

Plate

~~

Feed

Dog

=I

E!llliill

Presser

Foot

<t:J

.

~

.

1'

113

0

CUFF

-15-

~r------:1

~~

4

Page 18

!B*lliiiWJ-11~9U

SUPPLEMENTARY

DEVICE

RTP

*'-jjj~)Riffii·SR~~

Pneumatic

Roller

Tension

Device

=

\,--,!

jj]1'F

ACTION

li!iffil

CYLINDER

II!

..

PRESS

f

~

ffi

DIAGRAM

t

~

'"

=

0

0

RTF

-5

:+

ll5l:i'E~iRrmi·~~~

Fixed

Roller

Tension

Device

jj]1'F

~

ffi

ACTION

DIAGRAM

~-:!X:iiWI'

FIRST

ACTION

+

.tTl-

'

UP

li!iffil

CYLINDER

~

'"

=

0

0

II!

...

PRESS

1

-16-

i'"ffl

HOLD

=

~

Ess

"

1

~=:!X:illi'F

SECONO

ACTION

'"

0

0

(5.

m~JIH~iFm

o o • Air compressor required

Page 19

M!RII

TRANSMISSON

- ·" I

,,

--

I

lll'!!rl

Model

7\iJts•m

Input Shaft

~iJU.Ii<tlilll

Output Shaft

HliJ

Torquo(kg/cm)

RPM

(leg/em)

<eill>

(MAX.SPEED)

RPM

(MAX.SPEED)

S~l

2000

430

12 15

P~l

3000

225

P~2

3000

450

15

1 2 3 4

1

·

~iiMim!

.l.l e

Transmission

i1!

lA

S·1

15

10

5

0

5

10

15

P 1

• 1 : 1

15

10

5

tt

Continuous

(mm)

IK

1

.

0

1 '

lr.ll~ttWim

Intermittent

Type

W lliHII

Transmission

\1

\ I

I

I

~..J

180

ill

Transmission

I I

I

v

V'

I I

L

I

v

3eo•

ltll..t:"F

II!l

.

NEEDLE

••<legs>

Weight(kgs)

R-rr•

Spec

ifica1ion

12

e

t±:l1:JfJII1iiUW1.i!E!l

2

~

e

Rotation

of

llf~St

A

Clockwi

l9!~ilt

B

Counter

clockwise

Output

se

~~

Shaft

05

~

•

•

··

.

....

I

........

2 2 2

1

]t{((ffilli-"+--r

5

~

~

~

nJ

=

l c

•

~ii~t±:l.A:tJ!alm.m

e

Specification

list

of

lnpui/Output

Shaft

•!l.i:'mm

Unit :mm

.3

·

(gjl~~

~

e

Mounting

5

10

P 2

• 2 : 1

15

10

5

2 '

lllll

~tt·~·

Intermittent

Transmisson

rt•

..t:"FII!l

NEEDLE

.

4 •

:!./ e

w

N

D

5

10

15

o·

360

°

M

Base

~~~Ill!

With

Base

(a:7mm)

M~~llll

Without

Base

7\1:J/t±:l1:Jl11111I111

location

of

JUI

On

Opposite

~'>].

On

Same

-17-

lnpui/Output

Shaft

Side

Side

h-

n-

I!'U!!!

Tvpe

S~l

P~l

P~2

a

* 7

7

7

7 102

30

30

88

88

102

. 30 102

86 182

106 182

106 182

86 182

7

52

b

•!ll'mm

Unit :mm

c

30

18

30

24

54

24

24

24

54

24

24

Page 20

Loading...

Loading...