Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

User Manual

3152

PRECISION PLL SYNTHESIZER

Publication No. 980793

RACAL INSTRUMENTS

Racal Instruments, Inc.

Tel: (800) RACAL-ATE, (800) 722-2528, (949) 859-8999; FAX: (949) 859-7139

4 Goodyear St., Irvine, CA 92618-2002

480 Bath Road, Slough, Berkshire, SL1 6BE, United Kingdom

Tel: +44 (0) 1628 604455; FAX: +44 (0) 1628 662017

18 Avenue Dutartre, 78150 LeChesnay, France

Tel: +33 (1) 3923 2222; FAX: +33 (1) 3923 2225

Strada 2-Palazzo C4, 20090 Milanofiori Assago, Milan, Italy

Tel: +39 (0)2 5750 1796; FAX +39 (0)2 5750 1828

Technologiepark Bergisch Gladbach, Friedrich-Ebert-Strasse, D-51429 Bergisch Gladbach, Germany

Tel.: +49 2204 8442 00; FAX: +49 2204 8442 19

3 Powells Road, Brookvale, NSW 2100, Australia

Tel: +612 9936 7000, FAX: +612 9936 7036

26 Ayer Rajah Crescent, 04-06/07 Ayer Rajah Industrial Estate, Singapore 0513.

Unit 5, 25F., Mega Trade Center, No 1, Mei Wan Road, Tsuen Wan, Hong Kong, PRC

Tel: +852 2405 5500, FAX: +852 2416 4335

Racal Instruments, Ltd.

Racal Systems Electronique S.A.

Racal Systems Elettronica s.r.l.

Racal Elektronik System GmbH.

Racal Australia Pty. Ltd.

Racal Electronics Pte. Ltd.

Tel: +65 7792200, FAX: +65 7785400

Racal Instruments, Ltd.

http://www.racalinstruments.com

Copyright 2000 by Racal Instruments, Inc. Printed in the United States of America. All rights reserved.

This book or parts thereof may not be reproduced in any form without written permission of the publisher.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PUBLICATION DATE: July 25,2000

WARRANTY STATEMENT

All Racal Instruments, Inc. products are designed and manufactured to exacting standards and in full

conformance to Racal’s ISO 9001 procedures.

For the specific terms of your standard warranty, or optional extended warranty or service agreement, contact

your Racal customer service advisor. Please have the following information available to facilitate service.

1. Product serial number

2. Product model number

3. Your company and contact information

You may contact your customer service advisor by:

E-Mail: Helpdesk@racalinstruments.com

Telephone: +1 800 722 3262 (USA)

+44(0) 8706 080134 (UK)

+852 2405 5500 (Hong Kong)

Fax: +1 949 859 7309 (USA)

+44(0) 1628 662017 (UK)

+852 2416 4335 (Hong Kong)

RETURN of PRODUCT

Authorization is required from Racal Instruments before you send us your product for service or calibration. Call

your nearest Racal Instruments support facility. A list is located on the last page of this manual. If you are

unsure where to call, contact Racal Instruments, Inc. Customer Support Department in Irvine, California, USA at

1-800-722-3262 or 1-949-859-8999 or via fax at 1-949-859-7139. We can be reached at:

helpdesk@racalinstruments.com.

PROPRIETARY NOTICE

This document and the technical data herein disclosed, are proprietary to Racal Instruments, and shall not,

without express written permission of Racal Instruments, be used, in whole or in part to solicit quotations from a

competitive source or used for manufacture by anyone other than Racal Instruments. The information herein has

been developed at private expense, and may only be used for operation and maintenance reference purposes or

for purposes of engineering evaluation and incorporation into technical specifications and other documents which

specify procurement of products from Racal Instruments.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FOR YOUR SAFETY

Before undertaking any troubleshooting, maintenance or exploratory procedure, read

carefully the WARNINGS and CAUTION notices.

This equipment contains voltage hazardous to human life and safety, and is capable of

inflicting personal injury.

If this instrument is to be powered from the AC line (mains) through an autotransformer,

ensure the common connector is connected to the neutral (earth pole) of the power supply.

Before operating the unit, ensure the conductor (green wire) is connected to the ground

(earth) conductor of the power outlet. Do not use a two-conductor extension cord or a

three-prong/two-prong adapter. This will defeat the protective feature of the third conductor

in the power cord.

Maintenance and calibration procedures sometimes call for operation of the unit with power

applied and protective covers removed. Read the procedures and heed warnings to avoid

“live” circuit points.

Before operating this instrument:

1. Ensure the instrument is configured to operate on the voltage at the power source. See

Installation Section.

2. Ensure the proper fuse is in place for the power source to operate.

3. Ensure all other devices connected to or in proximity to this instrument are properly

grounded or connected to the protective third-wire earth ground.

If the instrument:

- fails to operate satisfactorily

- shows visible damage

- has been stored under unfavorable conditions

- has sustained stress

Do not operate until performance is checked by qualified personnel.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TABLE OF CONTENTS

g

g

y

gg

g

gg

y

y

y

y

g

g

y

g

g

g

MODEL 3152 PRECISION PLL SYNTHESIZER

Gettin

Started

What’s In this Chapter .............................................. 1-1

Introduction ...................................................... 1-1

Options ......................................................... 1-2

Manual Chan

Considerations .............................................. 1-3

Safet

Supplied Accessories .............................................. 1-4

Specifications .................................................... 1-4

Functional Description .............................................. 1-4

Input and Output Connectors ..................................... 1-4

Operatin

Output T

Output State ................................................... 1-8

Backplane S

Front Panel PLL ................................................ 1-9

Frequenc

Phase Modulation ............................................... 1-9

Filter ......................................................... 1-9

Front Panel Indicators ........................................... 1-9

ramming The Model 3152 ....................................... 1-10

Pro

es.................................................. 1-3

Main Output ............................................... 1-4

SYNC Output .............................................. 1-4

External Clock Input ......................................... 1-4

PM Input .................................................. 1-5

er Input ............................................... 1-5

Tri

Modes ............................................... 1-5

Continuous Mode ........................................... 1-5

ered Mode ............................................ 1-5

Tri

Burst Mode ................................................ 1-6

Gated Mode ............................................... 1-6

pe ................................................... 1-6

Standard Waveforms ........................................ 1-6

Arbitrar

Sequenced Waveforms ...................................... 1-7

Waveforms ........................................ 1-6

nchronization ....................................... 1-9

Counter .............................................. 1-9

Configuring The Instrument

Installation Overview ............................................... 2-1

Unpackin

Safet

Performance Checks ............................................... 2-2

Groundin

Lon

Preparation For Use ............................................... 2-3

ical Address Selection ........................................... 2-3

Lo

Installation .................................................... 2-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

and Initial Inspection ...................................... 2-1

Precautions ................................................ 2-1

Requirements ........................................... 2-2

Term Storage or Repackaging For Shipment ....................... 2-2

i

Using The Instrument

g

g

g

g

ging

g

g

g

g

g

g

g

g

g

g

g

gg

g

g

g

g

g

g

y

y

y

g

g By

g

g

gg

gg

y

y

g

g

y

Overview ........................................................ 3-1

Output Termination ................................................ 3-1

Input/Output Protection ............................................. 3-1

Power On/Reset Defaults ........................................... 3-1

What To Do Now.................................................. 3-2

the APPLy Command ......................................... 3-3

Usin

Output Confi

Selectin

Selectin

Chan

Selectin

Pro

Selectin

Activatin

Enablin

Enablin

the Built-In Standard Waveforms ................................ 3-14

Usin

Selectin

Tri

Gated Mode ................................................... 3-18

Burst Mode .................................................... 3-19

Selectin

Usin

Selectin

Selectin

Usin

Generatin

What Are Arbitrar

Arbitrar

Memor

Loadin

Sequence ....................................................... 3-27

Generatin

What Are Sequenced Waveforms .................................. 3-27

Sequence Commands ........................................... 3-29

Tri

Tri

Backplane Inter-Module S

Front-Panel Phase S

PLL Commands .................................................. 3-33

the Frequency Counter ........................................ 3-34

Usin

the Phase Modulation Input .................................... 3-35

Usin

Amplitude Modulation Commands .................................... 3-35

stem-Related Commands ......................................... 3-36

S

uration Commands ..................................... 3-7

An Output Function Type ................................. 3-7

a Standard Function Shape ............................... 3-8

the Frequency and Sample Clock .......................... 3-8

the Sample Clock Source ................................. 3-9

ramming the Output Amplitude and Offset ........................ 3-9

the Filter Type ......................................... 3-10

the Backplane ECLTRG and TTLTRG ...................... 3-10

ning the Validating Source For TTLTRG ..................... 3-12

Assi

the Main Output ......................................... 3-12

the SYNC Output ....................................... 3-13

ning the Source For the SYNC Output ...................... 3-13

Assi

Selectin

An Operating Mode ........................................ 3-17

ered Mode ................................................ 3-17

the Trigger Source ........................................ 3-19

the Internal Trigger Generator ................................ 3-20

the Soft Trigger ........................................... 3-21

Reversin

Usin

ered Sequence Advance ..................................... 3-30

ered Sequence Advance Commands ........................... 3-31

the SYNC Position .................................. 3-14

the Trigger Slope ....................................... 3-20

the Trigger Level ....................................... 3-21

Arbitrary Waveforms ..................................... 3-21

Waveforms .................................... 3-21

Memory Management .................................... 3-22

Management Commands .................................. 3-22

Arbitrary Waveforms ...................................... 3-23

te Order ........................................ 3-25

Shared Memory....................................... 3-25

Sequenced Waveforms ................................... 3-27

nchronization ................................... 3-33

nchronization ............................... 3-31

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ii

SCPI Command Reference

guag

ying

y

y

y

y

g

y

y

y

gg

y

y

y

g

y

g

g

g

g

g

g

y

g

g

g

y

y

What’s In This Chapter ............................................. 4-1

Introduction To SCPI Lan

Command Format ................................................. 4-2

Command Separator ............................................... 4-2

The MIN and MAX Parameters .................................... 4-3

Quer

SCPI Command Terminator ......................................... 4-3

IEEE-STD-488.2 Common Commands ................................ 4-4

SCPI Parameter T

SCPI Command Summar

Output Confi

Standard Waveform Command Summar

Arbitrar

Modulation Command Summar

Tri

Backplane Inter-Module Phase S

Front-Panel PLL Command Summar

S

IEEE-STD-488.2 Common Commands and Queries ...................... 4-13

The SCPI Status Re

Error Messa

Device-Specific Commands ......................................... 4-22

Parameter Setting......................................... 4-3

Response Format ......................................... 4-3

Quer

pe.............................................. 4-4

Numeric Parameters ............................................ 4-4

Discrete Parameter ............................................. 4-4

Boolean Parameter ............................................. 4-4

Arbitrar

stem-Related Command Summary................................. 4-13

The Status B

Service Request Enable Re

Standard Event Status Re

Standard Event Status Enable Re

Block Parameters ....................................... 4-5

.......................................... 4-5

uration Command Summary.............................. 4-8

Waveform, Sequence, and Shared Memory Command Summary.... 4-11

er Command Summary......................................... 4-12

isters .......................................... 4-15

te Register (STB).................................... 4-18

Readin

Clearin

the Status Byte Register .............................. 4-18

the Status Byte Register .............................. 4-18

es................................................... 4-21

e ...................................... 4-1

.............................. 4-10

..................................... 4-11

nchronization Command Summary........ 4-12

................................. 4-12

ister (SRE) ............................. 4-19

ister (ESR) .............................. 4-19

ister (ESE) ........................ 4-20

Maintenance and Performance Checks

What’s In This Chapter ............................................. 5-1

Disassembl

Special Handlin

Cleanin

Repair and Replacement ........................................... 5-2

Performance Checks ............................................... 5-3

Environmental Conditions ........................................ 5-3

Warm-Up Period ................................................ 5-3

Initial Instrument Settin

Recommended Test Equipment .................................... 5-4

Performance Check Procedures ...................................... 5-4

Frequenc

Amplitude Accurac

DC Offset Characteristics ......................................... 5-5

Squarewave Characteristics ...................................... 5-6

Sine Characteristics ............................................. 5-7

Sine Flatness .................................................. 5-8

Instructions ........................................... 5-1

of Static Sensitive Devices ............................ 5-2

........................................................ 5-2

.......................................... 5-3

Accuracy............................................. 5-4

............................................. 5-5

iii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Tri

g

g

y

y

g

g

g

g

g

g

g

g

g

gg

g

PLL Characteristics ................................................ 5-10

Adjustments ...................................................... 5-11

Environmental Conditions ........................................ 5-11

Warm-up Period ................................................ 5-12

Recommended Test Equipment .................................... 5-12

Adjustment Procedures .......................................... 5-12

Pulse Response Adjustment ...................................... 5-13

Troubleshootin

Recommended Test Equipment .................................... 5-16

Power-Up Tests ................................................ 5-16

Self-Test...................................................... 5-16

Main Board Circuit Checkout ........................................ 5-16

Power Suppl

CPU and VXI ASIC Checkout ..................................... 5-17

Output Amplifier and Amplitude Control Checkout ..................... 5-18

Clock S

Sequence Generator Checkout .................................... 5-20

PLL Checkout.................................................. 5-21

En

En

, Gate and Burst Characteristics ................................ 5-8

Amplitude Adjustment ....................................... 5-13

Offset Adjustment ........................................... 5-14

VCO Adjustment ........................................... 5-14

PLL Adjustment ............................................ 5-15

.................................................. 5-15

Checkout.......................................... 5-16

nthesizer Checkout ...................................... 5-19

ine Board Circuit Checkout ....................................... 5-22

ine Board Checkout .......................................... 5-22

APPENDIX A

Specifications .................................................... A-1

1-1 Segment 1 - Sin(x)/xWaveform ................................ 1-7

1-2 Se

1-3 Se

1-4 Sequenced Waveforms ...................................... 1-8

2-1 Set The Lo

3-1 Definite Len

3-2 12-Bit Waveform Data Format ................................. 3-24

3-3 Sin(x)/x Waveform Loaded Into Se

3-4 Sine Waveform Loaded Into Se

3-5 Pulse Waveform Loaded Into Se

3-6 Sequenced Waveforms - Continuous Advance Mode ............... 3-29

3-7 Sequenced Waveforms - Tri

4-1 SCPI Status Re

FIGURES

ment 2 - Sine Waveform .................................. 1-7

ment 3 - Pulse Waveform ................................. 1-8

ical Address ..................................... 2-4

th Arbitrary Block Data Format ...................... 3-24

ment 1 ....................... 3-27

ment 2 ......................... 3-28

ment 3 ........................ 3-28

ered Advance Mode ................ 3-30

isters ....................................... 4-17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv

TABLES

g

y

y

g

g

g

3-1 Default Conditions After Power On, RESet or *RST ................ 3-2

3-2 Amplitude and Offset Ran

4-1 VXIbus Model 3152 SCPI Commands List Summar

5-1 CPU and VXI Interface Checkout Procedure ...................... 5-17

5-2 Output Amplifier and Amplitude Control Checkout Procedure ........ 5-18

5-3 Clock S

nthesizer Checkout Procedure ......................... 5-19

5-4 Sequence Generator Checkout Procedure ....................... 5-20

5-5 Burst Generator Checks ...................................... 5-21

5-6 PPL Checkout Procedure ..................................... 5-21

5-7a En

5-7b En

5-7c En

ine Board Checkout Procedure - #1 ......................... 5-22

ine Board Checkout Procedure - #2 ......................... 5-23

ine Board Checkout Procedure - #3 ......................... 5-23

es ................................. 3-3

............... 4-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

v

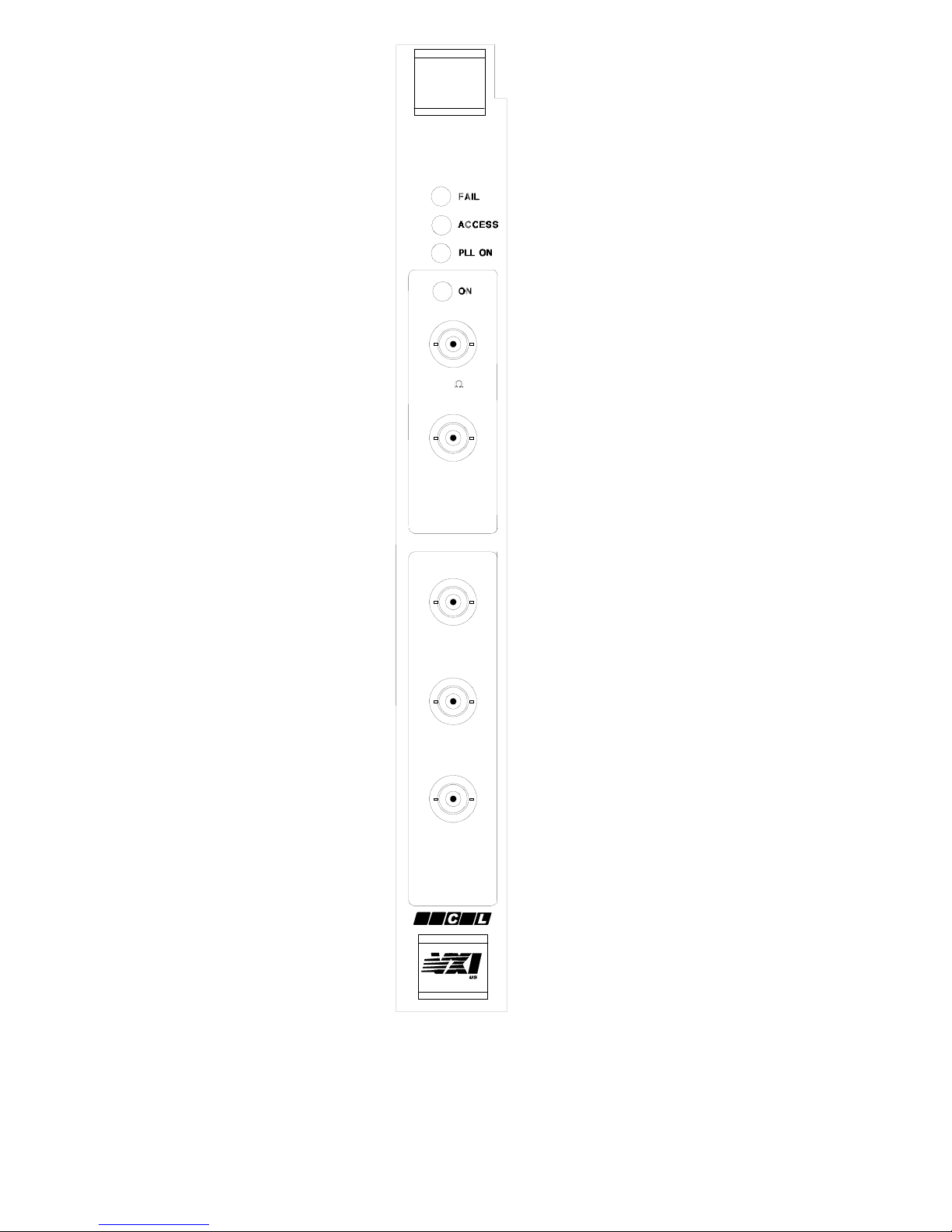

3152

WAVEFORM

SYNTHESIZER

OUTPUT

50

SYNC O UT

TTL

TRIG/P L L IN

30 V MAX

CLOCK IN

ECL

PM IN

30 V M AX

RMS

3152 Front Panel

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

vi

1

Getting Started

What’s In This

Chapter

Introduction

This chapter contains a general description of the VXIbus Model

3152 Waveform Synthesizer and an overall functional description

of the instrument. It lists and describes various options available for

this model. It also describes the Model 3152 front panel connectors

and indicators.

This manual provides a complete description of all features and

options available with the Model 3152; however, some items

described in the following paragraphs may not be installed in your

instrument.

A detailed functional description is given following the general

description of the features, functions, and options available with the

Model 3152.

The Model 3152 is a VXIbus, single slot C-size Synthesized

Waveform Generator. It is a high performance waveform

synthesizer that combines two powerful instruments in one small

package; a function generator and an arbitrary waveform generator.

The instrument provides a variety of standard waveforms to be used

as test stimuli for different electronic devices. The Model 3152 is

also capable of generating arbitrary waveforms with sampling rates

to 100 MHz at 12 bits of vertical resolution.

Despite its small size, the Model 3152 offer many features and

functions such as VXIplug&play compatibility, backplane phase

synchronization, front-panel PLL, counted burst, internal triggergenerator, and more. The instrument generates high quality, high

accuracy waveforms throughout the specified frequency range,

amplitude span, and operating temperature. The Model 3152

generates sine waveforms with a spectral purity that can only be

matched by much more expensive bench type synthesizers.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The Model 3152 generates standard waveforms at frequencies

ranging from 100 µHz to 50 MHz. Frequency may be set with 7

digit resolution. Accuracy and stability of the output frequency

depend on the reference clock. As a default, CLK10 is used as the

reference clock. The typical accuracy and stability of CLK10 is 100

ppm. An optional internal TCXO circuit provides 1 ppm accuracy

and stability. When the optional TCXO is installed, the output

frequency can be programmed with a full seven digits of resolution.

Arbitrary waveforms are generated with clock rates ranging from

100 mHz to 100 MHz. Output amplitude may be programmed within

the range of 20 mV to 32 Vp-p into an open circuit, and 10 mV to

16V into 50S. Amplitude and offsets are programmed with 4 digit

resolution.

Getting Started 1-1

Besides its normal continuous mode, the Model 3152 offers a

variety of interrupted modes. The output waveform may be gated,

triggered, or may generate a counted burst of waveforms. A built-in

trigger generator with a programmable period can replace an

external trigger.

The Model 3152 generates arbitrary waveforms with 12 bits of

resolution. There are nine standard waveforms which are memoryresident. Other waveforms may be generated, either manually or

downloaded from the controller to the instrument using shared

memory or standard data bus transfer. Waveforms may also be

generated using the WaveCAD program.

The Model 3152 waveform synthesizer is a digital instrument.

Besides its standard waveforms, any waveform it generates must

first be loaded into the arbitrary waveform memory. The arbitrary

waveform memory is a bank of 8-bit words. Each word represents

a point on the waveform. Each word has a horizontal address that

can range from 0 to 64536 (optionally 523288) and a vertical

address that can range from -2047 to +2048 (12 bits). Using a high

speed clocking circuit, the digital contents of the arbitrary waveform

memory are extracted and routed to the D/A converter. The D/A

converts the digital data to an analog signal, and the output

amplifier completes the task by amplifying or attenuating the signal

at the output connector.

Options

The Model 3152 is fully programmable using SCPI commands and

syntax. There are two ways to program the Model 3152, the first

being low level programming of each individual parameter. The

second alternative is to use the VXIplug&play soft front panel for

high level programming. The VXIplug&play soft front panel

simulates a mechanical front panel with the necessary push

buttons, displays and dials to operate the Model 3152 as a benchtop instrument. The Model 3152 will not operate without being

programmed. Therefore, it is recommended that the user become

familiar with its basic features, functions and programming concepts

as described in this and the following chapters.

A number of options are offered with the Model 3152. Compare the

option number with the number that is printed on the instrument to

verify which of the options is installed in your instrument. Note that

all Model 3152 options are installed in the factory. Contact your

nearest Racal representative if the number printed on the case does

not reflect the correct version ordered. The list of available Model

3152 options is given below:

1. 407510-001 - Model 3152 - 100MS/s Waveform

Synthesizer, w/64K RAM

2. 407510-002 - Model 3152 - 100MS/s Waveform

Synthesizer, w/256K RAM

3. 407510-011 - Model 3152 - 100MS/s Waveform

Synthesizer, w/512K RAM

4. 407510-021 - Model 3152 - 100MS/s Waveform

Synthesizer, w/64K RAM, 1PPM

Getting Started 1-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5. 407510-012 - Model 3152 - 100MS/s Waveform

Synthesizer, w/256K RAM, 1PPM

6. 407510-002 - Model 3152 - 100MS/s Waveform

Synthesizer, w/512K RAM, 1PPM

7. 407510-012 - Model 3152 - 100MS/s Waveform

Synthesizer, w/ 64K RAM, 100PPM

8. 407510-022 - Model 3152 - 100MS/s Waveform

Synthesizer, w/256K RAM, 100PPM

9. 407510-021 - Model 3152 - 100MS/s Waveform

Synthesizer, w/512K RAM, 100PPM

The 64K RAM option designates the memory size supplied with the

Model 3152. The standard memory size is 64K (65536 words).

With the standard memory size, 64536 point waveforms can be

programmed because 1K is allocated for standard waveforms.

The 256 suffix designates instruments supplied with 256K memory

expansion. With the 256K expansion, 261144 point waveforms can

be programmed.

The 512K RAM option designates instruments supplied with 512K

memory expansion. With the 512K expansion, 523288 point

waveforms can be programmed.

1ppm and 100ppm denote different accuracy and stability grades of

the internal 10 MHz reference clock. Normally, VXIbus modules

receive their clock reference from VXIbus CLK10. There are

applications that require complete separation from VXIbus clocks.

The crystal oscillator (100ppm) and TCXO (1ppm) options, when

installed, provide the required separation.

Manual Changes

Safety

Considerations

WARNING

Technical corrections to this manual (if any) are noted on the pages

themselves, with change dates at the bottom of the page.

The Model 3152 has been manufactured according to international

safety standards. The instrument meets VDE 0411/03.81 and UL

1244 standards for safety of commercial electronic measuring and

test equipment for instruments with an exposed metal chassis that

is directly connected to earth via the chassis power supply cable.

.

Do not remove instrument covers when operating or when

the chassis power cord is connected to the mains.

Any adjustment, maintenance and repair of an opened, powered-on

instrument should be avoided as much as possible, but when

necessary, should be carried out only by a skilled person who is

aware of the hazard involved.

Revised 4/18/00

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Getting Started 1-3

Supplied

Accessories

The Model 3152 is supplied with an Instruction Manual. The manual

includes disks with VXIplug&play soft front panel and drivers along

with WaveCAD for Windows. A Service Manual is available upon

request.

Specifications

Functional

Description

Input and Output

Connectors

Main Output

SYNC Output

Instrument specifications are listed in Appendix A. These

specifications are the performance standards or limits against which

the instrument is tested. Specifications apply under the following

conditions: output terminated into 50S after 30 minutes of warm up

time, and within a temperature range of 20oC to 30oC. Specifications

outside this range are degraded by 0.1% per oC.

A detailed functional description is given in the following

paragraphs. The description is divided into logical groups: input and

output connectors, operating modes, output type, output state,

synchronization, filters and front panel indicators.

The Model 3152 has 5 BNC connectors on its front panel: main

output, SYNC output, phase modulation input, reference clock

output and the trigger input.

The main output connector outputs standard, user, and sequenced

waveforms. Output impedance of this output is 50S, that is, the

cable which is connected to this input should be terminated with a

50S resistance. Output amplitude accuracy is calibrated when

connected to a 50S load. If the output is connected to a different

load resistance, determine the actual amplitude from the resistance

ratio of the internal 50S to the load impedance. The output

amplitude is doubled when the output impedance is above 1 MS.

The SYNC Output generates a single TTL pulse for synchronizing

other instruments (i.e., an oscilloscope) to the output waveform.

The SYNC signal always appears at a fixed point relative to the

waveform. The SYNC output generates a single point pulse for

standard and arbitrary waveforms. The location of the SYNC signal

along the waveform is programmable from point 2 to the last point

on the waveform.

External Clock Input

PM Input

Getting Started 1-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The External Clock Input is available for those applications required

to run the complete system off the same clock. Normally, this input

is disabled. When enabled under program control the clock at this

input replaces the internal clock generator and the output waveform

will begin generating waveforms with clock rates that are present at

the external clock input. Do not confuse the clock frequency with

the frequency of the waveform. The actual frequency of the output

waveform depends on the number of points that are allocated for

the waveform. For example, if the external clock is 10 MHz and the

number of points that were assigned to the active segment is 1000,

the output frequency will be 10 KHz (10 MHz divided by the number

of points). The external clock input accepts fixed level ECL signals

within the range of DC to 100 MHz.

The PM Input accepts signals that phase modulates the main output

frequency. The phase modulation function operates in conjunction

with the PLL function. The PM input is active at all times. Therefore,

unless you intend to use this function, do not connect any cables to

this input during normal operation of the Model 3152.

Trigger Input

The Trigger Input accepts signals that stimulate the Model 3152 to

output waveforms. The trigger input is inactive when the instrument

is in continuous operating mode. When placed in trigger, gated or

burst mode, the trigger input is made active and waits for the right

condition to trigger the instrument. In trigger and burst modes, the

trigger input is edge sensitive, i.e., it senses transitions from high

to low or from low to high to trigger the Model 3152. The direction

of the transition is programmable. In PLL mode, the trigger input is

used as phase reference input.

In gated mode, the trigger input is level sensitive, i.e., the Model

3152 is gated when the level is high and idle when the level is low.

Level sensitivity may be programmed for the trigger input.

Operating Modes

Continuous Mode

Triggered Mode

There are a number of operating modes that the Model 3152 can be

programmed to operate in: continuous mode, triggered mode, gated

mode and burst mode. These operating modes are described

below.

In continuous mode, the selected waveform is output continuously

at the selected frequency, amplitude and offset.

In triggered mode, the Model 3152 circuits are armed to generate

one output waveform. The trigger circuit is sensitive to transitions

at the trigger input. Select between positive or negative transitions

to trigger the instrument. You may also program the trigger level to

the desired threshold level on the external signal. When triggered,

the synthesizer outputs the waveform and remains idle at the last

point of the waveform. The Model 3152 can be armed to receive a

trigger signal from the front panel BNC connector, a VXIbus

backplane TTLTRG<n> or from an internal, programmable trigger

generator.

The trigger signal, whether it comes from the front panel or from

the VXIbus, has to pass through circuitry. These circuits cause a

small delay known as system delay. System delay cannot be

eliminated completely. It is, however, minimized in the Model

3152 to approximately 200ns maximum. System delay is a factor

that must be considered when applying a trigger signal. It defines

how long it will take from a valid trigger edge to the moment that

the output reacts.

Burst Mode

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

While system delay cannot be controlled, the Model 3152 offers a

controllable trigger delay parameter. When utilized, delay from a

trigger signal to output waveform may be programmed from 0

clocks to one million clocks. This delay is additional to the

system delay.

The burst mode is an extension of the triggered mode where the

Model 3152 can be armed to output a counted number of

waveforms following a triggered signal. Like trigger mode, burst

can be triggered from a front panel BNC connector, a VXIbus

backplane TTLTRG<n> or from an internal, programmable trigger

generator.

Getting Started 1-5

Gated Mode

In gated mode, the Model 3152 circuits are armed to generate

output waveforms as long as a gating signal is true. Unlike the

triggered mode, the gated mode is level sensitive. When the gating

signal goes false, the waveform at the output connector is first

completed and the output goes to an idle state. The stop amplitude

level, after a gating signal, is the last point on the waveform.

Output Type

Standard Waveforms

Arbitrary Waveforms

The Model 3152 can output three types of waveforms: standard

waveforms, arbitrary waveforms and sequenced waveforms. The

three types of waveforms are described in the following.

The Model 3152 generates waveforms from a memory that has to

be loaded before the instrument can generate waveforms. There

are 64K points of memory standard, 256K and 512K points

available as an option. 1K points from this memory are allocated for

standard waveforms. Waveforms are loaded into this part of the

memory each time a standard function is selected.

The Model 3152 can be programmed to output nine different

standard waveforms: sine wave, triangular wave, square wave,

pulse, ramp, sinc (sine(x)/x), gaussian pulse, exponential pulse and

DC. There are certain parameters that are associated with each

standard function. These parameters can be programmed to

generate modified standard waveforms.

The arbitrary waveform memory is capable of storing one or more

user waveforms. There are 64536 points (523288 optional) that can

be allocated to one waveform that has this length. If there is no

need to use the complete memory, it can be divided into smaller

segments, variable in size. Load each segment with a different

waveform and program the Model 3152 to output the required

waveform for a specific test. Loading data to arbitrary waveform

memory can be a time-consuming task, especially if the complete

512K is loaded in one shot. The Model 3152 utilizes the VXIbus

shared memory concept that speeds data transfer from and to the

host computer. In this mode, the memory bank is disconnected

from the CPU circuit and its bus is accessible from the VXIbus for

direct memory access by the host computer.

Sequenced Waveforms

Getting Started 1-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The Model 3152 employs a sophisticated circuit that allows dividing

the memory into smaller segments, linking of the segments in userdefined order, and repeating of each linked segment up to one

million times. The sequence circuit is useful for generating long

waveforms with repeated sections. The repeated waveform has to

be programmed once and the repeater will loop on this segment as

many times as selected. When in sequenced mode, there is no loss

of time between linked or looped segments. Figure 1-4 shows an

example of a sequenced waveform. Assume the waveforms in

Figures 1-1 through 1-3 were placed in segments 1 through 3.

Figure 1-1

Segment 1 -

Sin(x)/x

Waveform

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Figure 1-2

Segment 2 -

Sine Waveform

Getting Started 1-7

Figure 1-3

Segment 3 -

Pulse

Waveform

The following sequence was made of segment 2 repeated twice,

segment 1 repeated four times and segment 3 repeated twice.

Figure 1-4 Sequenced Waveforms

Output State

Getting Started 1-8

The main output can be turned on or off. The internal circuit is

disconnected from the output BNC connector by a mechanical switch

under program control (relay). This feature is useful for connecting

the Model 3152 main output, along with other instruments, to an

analog bus. For safety reasons, after power on, the main output is

always off.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Backplane

Synchronization

Multiple Model 3152s may be synchronized and operated together

inside one VXIbus chassis. With one instrument configured as

master and the rest of the instruments configured as slaves, the

instruments are phase-locked to the start phase on the master

module. The slave modules may be configured to have phase offsets

within the range of 0E to 360E. There is no need to install multiple

Model 3152 modules in adjacent slots to be able to phase

synchronize modules.

Front-Panel PLL

Frequency Counter

Phase Modulation

Model 3152 may be phase locked to an external reference and

phase shifted from the start phase of the external reference from 180E to +180E. The reference signal is applied to a front-panel input

BNC. In this way, the same reference can be applied to multiple

modules to generate multi-phase signal patterns. The reference

signal for the PLL function is applied to the TRIG IN. It shares the

same characteristics as the trigger input, programmable trigger level

and programmable slope. When placed in this mode, the model

3152 scans the TRIG IN connector for a valid signal. Once sensed,

the model 3152 measures its frequency and centers its lock-in range

around this frequency. The model 3152 then locks automatically on

the frequency of the external signal. There is no need for manual

initiation or operator intervention for locking the model 3152 to an

external reference. The PLL range is 500 Hz to 10 MHz.

The Model 3152 uses an autoranging counter circuit to measure

frequencies of reference signals at the trigger input. This built-in

counter is made available for you in PLL mode. Thus, you can use

the 3152 as a frequency counter provided that the signal at the

trigger input is valid and the PLL ON LED illuminates. Frequencies

are measured from 500 Hz to 10 MHz. External frequency query

returns four digits with a decimal point and suffix multiplier.

When the Model 3152 is placed in PLL mode, there are two ways to

control the phase offset. The first option is to modify the phase offset

setting using SCPI commands. This method is extremely accurate

while permitting phase offset adjustments with 0.01E increments. The

PM IN provides another option for changing phase offsets. Applying

voltage to this input changes the start phase of the synthesizer

continuously, depending on the voltage level at the phase modulation

input. The applied voltage range is DC to 10 kHz, depending on the

lock frequency and the number of waveform samples.

Filter

Front Panel Indicators

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Three filters are built into the Model 3152, each having a different

cutoff frequency and rise time properties. These filters are available

for use in various applications, depending on the specific

requirement. The 20 MHz Gaussian filter has a gaussian response

which smooths fast transitions and eliminates ringing and

aberrations. The 25 MHz and the 50 MHz filters are elliptical with a

very sharp cutoff frequency. They are useful for removing the

staircase effect from waveforms that are generated with high

frequency clock rates.

There are three LEDs on the front panel. The FAIL LED (Red)

illuminates at power-up until the Model 3152 has passed its self-test.

If the Model 3152 self-test fails, the FAIL LED remains illuminated.

Getting Started 1-9

The FAIL LED may be illuminated during normal operation if the

Model 3152 stops communication.

The ACCESS LED (Amber) illuminates each time a command has

been received by the Model 3152. This light remains on during

shared memory data transfer.

The PLL ON LED is off during normal operation. In PLL mode, the

PLL ON illuminates when a valid signal is available at the trigger

input and lock frequency is available at the main output connector.

When the output state is on, the OUTPUT LED (Green) light

illuminates. It goes off when the output state is changed to off.

Programming The

Model 3152

The Model 3152 has no controls on the front panel. Instrument

functions, parameters, and modes can only be accessed through

VXIbus commands. There are a number of ways to “talk” to the

instrument. They all require that an appropriate software driver be

installed in the Resource Manager (slot 0). The rest is a matter of

practice and knowledge of the language in use. There are other

system considerations like address selection that have to be settled

before programming the instrument. These topics are discussed in

later chapters.

Low level programming of the Model 3152 is done using SCPI

(Standard Commands for Programmable Instruments) language via

VXIbus Word Serial Protocol. Programming aspects are covered in

Chapters 3 and 4.

High level drivers like VXIplug&play and WaveCAD are beyond the

scope of this manual. Contact your Racal representative for more

information about high level drivers for the Model 3152.

Getting Started 1-10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

g

g

g

g

g

g

g

g

y

g

y

y

y

y

g

g

y

y

g

g

ging

y

g

Installation

Overview

Unpacking and Initial

Inspection

Safety Precautions

Confi

This chapter contains information and instructions necessary to

prepare the Model 3152 for operation. Details are provided for initial

inspection,

stora

information.

Unpacking and handling of the synthesizer requires only normal

precautions and procedures applicable to handlin

electronic equipment. The contents of all shippin

be checked for included accessories and certified a

packin

The following safety precautions should be observed before usin

this product and associated computer. Although some instruments

and accessories would normall

volta

present.

This product is intended for use b

shock hazards and are familiar with the safet

to avoid possible injur

before using the product.

Exercise extreme caution when a shock hazard is present. Lethal

volta

The American National Standard Institute (ANSI) states that a shock

hazard exists when volta

or 60 VDC are present.

rounding safety requirements, repacking instructions for

e or shipment, logical address selection and installation

slip to determine that the shipment is complete

es, there are situations where hazardous conditions may be

e may be present on cables, connector jacks, or test fixtures.

uring The Instrument

of sensitive

containers should

ainst the

be used with non-hazardous

qualified personnel who recognize

precautions required

. Read the operating information carefull

e levels greater than 30V RMS, 42.4V peak

WARNING

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

For maximum safety, do not touch the product, test cables, or

other instrument parts while power is applied to the circuit

an

under test. ALWAYS remove power from the entire test s

before connectin

cards from the computer, or making internal changes such as

chan

Do not touch an

common side of the circuit under test or power line (earth)

round. Always keep your hands dry while handling the

instrument.

the module address.

cables or jumpers, installing or removin

object that could provide a current path to the

Configuring The Instrument 2-1

stem

When usin

g

g

y

g

y

y

g

g

g

y

g

g

g

y

ging

y

y

g

g

g

g

g

to the device under test. Safe operation requires that the computer

lid be closed at all times durin

Precautions” instructions that are supplied with your computer.

test fixtures, keep the lid closed while power is applied

operation. Carefully read the “Safet

Performance

Checks

Groundin

Requirements

WARNING

Before performin

test cables.

Maintenance should be performed b

The instrument has been inspected for mechanical and electrical

performance before shipment from the factor

defects and in perfect electrical order. Check the instrument for

dama

the section entitled Unpackin

To insure the safety of operating personnel, the U.S. O.S.H.A.

(Occupational Safet

practice mandate that the instrument panel and enclosure be "earth"

the metal part is connected to earth

Do not make an attempt to float the output from ground as it

ma

e in transit and perform the electrical procedures outlined in

rounded. Although BNC housings are isolated from the front panel,

damage the Model 3152 and your equipment.

any maintenance, disconnect the line cord and all

qualified service personnel

. It is free of physical

and Initial Inspection.

and Health) requirement and good engineerin

round.

Long Term Storage or

Repacka

For

Shipment

If the instrument is to be stored for a long period of time or shipped

immediatel

contact

Instruments Customer Service Department.

1. Repack the instrument usin

2. Be sure the carton is well-sealed with stron

3. Mark the carton with the model and serial number. If it is to

, proceed as directed below. If you have any questions,

our local Racal Instruments Representative or the Racal

the wrappings, packin

material and accessories originally shipped with the unit. If

the ori

materials.

straps.

be shipped, show sendin

of the box.

inal container is not available, purchase replacement

tape or metal

and return address on two sides

Configuring The Instrument 2-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOTE

g

g

g

g

y

g

g

g

y

g

g

y

g

If the instrument is to be shipped to Racal Instruments for

calibration or repair, attach a ta

the owner. Note the problem, symptoms, and service or repair

desired. Record the model and serial number of the instrument.

Show the work authorization order as well as the date and

method of shipment. ALWAYS OBTAIN A RETURN

AUTHORIZATION NUMBER FROM THE FACTORY BEFORE

SHIPPING THE INSTRUMENT TO RACAL INSTRUMENTS.

to the instrument identifyin

Preparation For

Use

Logical Address

Selection

Preparation for use includes removing the Model 3152 from the

container box, selectin

the module in a VXIbus chassis.

The VXIbus Chassis Resource Manager identifies modules in the

stem by the module’s address. VXIbus logical addresses can

s

e from 0 to 255, however, addresses 1 to 254 only are reserved

ran

for VXIbus modules. Lo

Mana

d

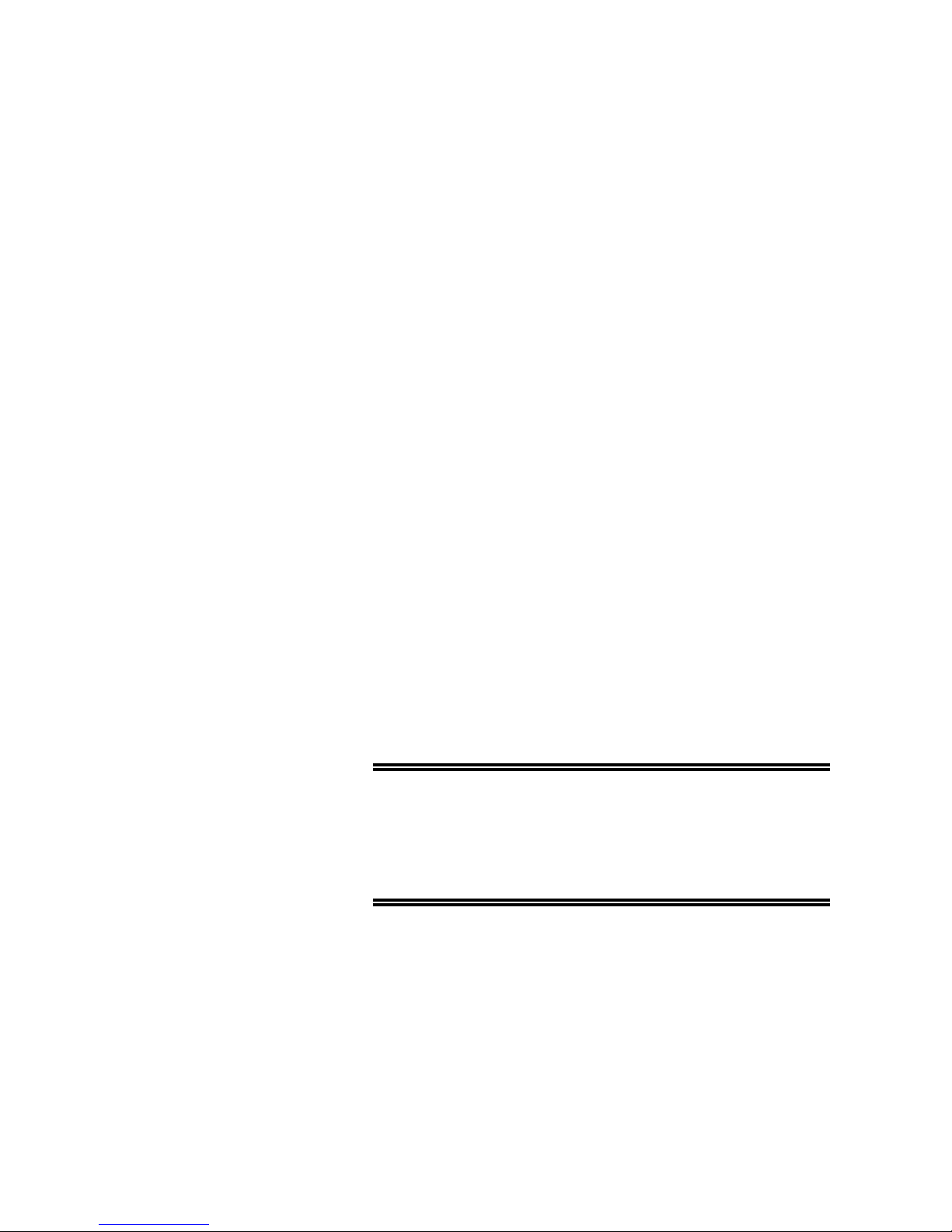

To chan

switch accessible from the top side of the module near the rear end

of the case (switch S1). Fi

address switch. The switches are marked with numbers 1 to 8. The

Model 3152 uses binar

using the active low address switch. A switch is active when its arm

is placed in the ON position.

Racal Instruments ships the Model 3152 with lo

er. Logical address 255 permits the Resource Manager to

namically configure the module logical address.

e the Model 3152’s logical address, use the 8-position DIP

the required logical address and installin

ical address 0 is reserved for the Resource

ure 2-1 shows the location of the logical

0

values (2 to 2 ) to set the logical address

7

ical address 2.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Configuring The Instrument 2-3

LOGICAL ADDRESS SELECT

g

MSB

LSB

0

1

S1

OFF

(LOGIC 0)

ON

(LOGIC 1)

SIDE VIEW

O F SWITCH S1

Configuring The Instrument 2-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ure 2-1 Set The Logical Address

Fi

Installation

g

g

g

y

The instrument can be installed in any slot except slot 0 in a VXIbus

mainframe. When insertin

should be

ently rocked back and forth to seat the connectors into

the backplane receptacle. The ejectors will be at ri

front panel when the instrument is properl

the instrument into the mainframe, it

ht angles to the

seated into the

backplane. Use two captive screws above and below the ejectors to

secure the instrument into the chassis.

After installation, perform an initial checkout and operational

verification.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Configuring The Instrument 2-5

This page was intentionally left blank

Configuring The Instrument 2-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Using The Instrument

Overview

Output

Termination

Input/Output

Protection

Power On/Reset

Defaults

This chapter contains information about how to operate the Model

3152. Unlike bench-type instruments, the Model 3152 must be

programmed to turn on functions, change parameters and configure

various operating modes. The instrument can be programmed using

a set of SCPI commands. A list of SCPI commands that control the

Model 3152 is given in Table 4-1. The following paragraphs

describe the various modes of operation and give examples on how

to program the Model 3152.

During use, output connectors must be properly terminated to

minimize signal reflection or power loss due to an impedance

mismatch. Proper termination is also required for an accurate

amplitude level at the main output connector. Use 50S cables and

terminate the main and SYNC cables with terminating resistors.

Always place the 50S termination at the far end of the cables.

The Model 3152 provides protection for internal circuitry connected

to input and output connectors. Refer to the specifications in

Appendix A to determine the level of protection associated with

each input or output connector.

At Power On or as a result of a software reset, the Model 3152

defaults to the conditions shown in Table 3-1. A complete list of all

parameters and their default values is given in Chapter 4.

Use the following command to place the instrument in its default

state:

RESet;

Using the IEEE-STD-488.2 common command *RST will have the

same result.

Using The Instrument 3-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table 3-1 Default Conditions After Power On, RESet or *RST

Output State: Off Operating Mode: Continuous

Filter State: Off Filter Type: 20 MHz

ECLTRG0-1: Off TTLTRG0-7: Off

Output Trigger Source: BIT SYNC State: Off

Std. Wave Frequency: 1 MHz Arb. Wave Sample Clock: 1 MHz

Amplitude: 5 V Offset: 0 V

Output Mode: Std. Waveforms Standard Waveform: Sine

Inter-module Phase Advance Mode: Auto

Synchronization State: Off SYNC Out Position: Point n-6

SYNC Slate: Off

Trigger Slope: Positive Internal Trigger Period: 100F Sec

Shared Memory State: Off Shared Memory Mode: Read

What To Do Now

When writing low level code to operate the Model 3152, follow the

instructions in this chapter to understand the meaning and response

that each command generates. Examples contained in the following

paragraphs show basic techniques on how to program output

waveforms.

Example 1

The following example programs the Model 3152 to turn on the

main output, generate a square waveform, program the frequency

to 2 MHz, program the amplitude to 5 V and offset to 2.5 V.

/* Reset the Model 3152 to its default condition as listed in Table 3-

1.*/

:RESet;

/* Change the output waveform to square. Note that there is no

need to use the FUNC:MODE command as the default value after

RESet is FIXed.*/

:FUNCtion:SHAPe SQUare;

/* Change the frequency to 2 MHz.*/

:FREQuency 2e6;

Using The Instrument 3-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

/*Change the amplitude to 5 V and the offset to 2.5 V.*/

:VOLTage 5;

:VOLTage: OFFSet 2.5;

There are three offset windows (±8 V, ±800 mV, ±80 mV); the

window selected is a function of the amplitude setting. Table 3.2

shows the maximum offset available within each window.

Table 3-2 Amplitude and Offset Ranges

Amplitude Window Maximum Offset

$1.6 V ±8 V 0 to ±7.19 V

$160 mV ±800 mV 0 to 719 mV

$10 mV ±80 mV 0 to 75 mV

To calculate the maximum offset available for a particular amplitude

setting, use the following inequality:

Using the APPLy

Command

V

_______

amplitude

+ * V

* # 8 V * 800 mV * 80 mV

offset

2

Tip: If the desired amplitude/Offset setting cannot be obtained using

Standard Waveforms, try generating it as an Arbitrary Waveform

using WaveCAD.

/* Turn the main output on.*/

:OUTPut ON;

/*Turn the SYNC output on, if required.*/

:OUTPut:SYNC ON;

If the above commands are executed correctly, a square waveform

will be seen on your oscilloscope.

The APPLy command provides a high level method of programming

the synthesizer. Selection can be made for function, frequency,

amplitude, offset and other parameters which are associated with

the selected function. For example, the following statement outputs

a 2 Vp-p square wave at 1 MHz with a 0 V offset and 10% duty

cycle using APPLy:

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

APPL:SQU 1E6, 2, 0, 10

It is not necessary to enter every parameter with the APPLy

command. If only the frequency and offset need to be changed,

omit the other parameters while keeping the commas. The other

parameters will be set to the power-up default values:

APPL:SQU 10E6,,1

Using The Instrument 3-3

Alternatively, if just the first parameters need to be changed, omit

the commas. The other parameters will be set to the power-up

default values:

APPL:SQU 4e6,2

Queries can also be made on all parameters associated with a

standard function using the APPL: <function_shape>? query. For

example, if the synthesizer was programmed using the above

APPLy:SQU command, query the square wave parameters using

the following query:

APPL:SQU?

The synthesizer returns a string that contains all the parameters

associated with the square function similar to the following string:

“1.000000e+6,2.000,0.000,50"

The command:

APPLy:SINusoid {<frequency>,<amplitude>,<offset>,

<phase>,<power>}

programs the synthesizer to output a sine waveform with frequency,

amplitude, offset, start phase and power parameters. Parameters

are not optional if the above APPLy command is used. Include all

other parameters in the command. The default settings for these

functions are: 1 MHz, 5 Vp-p, 0 V, 0 and 1.

The command:

APPLy:TRIangle {<frequency>,<amplitude>,<offset>,

<phase>,<power>}

programs the synthesizer to output a triangle waveform with

frequency, amplitude, offset, start phase, and power parameters.

The default settings for these functions are: 1 MHz, 5 Vp-p, 0 V, 0

and 1.

The command:

APPLy:SQUare {<frequency>,<amplitude>,<offset>,

<duty_cycle>}

programs the synthesizer to output a square waveform with

frequency, amplitude, offset and duty cycle parameters. The default

settings for these functions are: 1 MHz, 5 Vp-p, 0 V, and 50%.

The command:

APPLy:PULSe{<frequency>,<amplitude>,<offset>,

<delay>,<high_time>,<rise_time>,<fall_time>}

programs the synthesizer to output a pulse waveform with

frequency, amplitude, offset, delay, rise time, high time and fall time

parameters. The default settings for these functions are: 1 MHz, 5

Vp-p, 0 V, 0%, 10%, 10% and 10%.

Using The Instrument 3-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The command:

APPLy:RAMP {<frequency>,<amplitude>,<offset>,

<delay>, <rise_time>,<fall_time>}

programs the synthesizer to output a ramp waveform with

frequency, amplitude, offset, delay, rise time, and fall time

parameters. The default settings for these functions are: 1 MHz, 5

Vp-p, 0 V, 0%, 10% and 10%.

The command:

APPLy:SINC {<frequency>,<amplitude>,<offset>,

<number_cycles>}

programs the synthesizer to output a sine(x)/x waveform with

frequency, amplitude, offset, and number of cycles parameters.

The default settings for these functions are: 1 MHz, 5 Vp-p, 0 V and

10.

The command:

APPLy:EXPonential <frequency>,<amplitude>,<offset>,

<exponent>}

programs the synthesizer to output an exponential waveform with

frequency, amplitude, offset, and exponent parameters. The default

settings for these functions are: 1 MHz, 5 Vp-p, 0 V and -10.

The command:

APPLy:GAUSsian {<frequency>,<amplitude>,<offset>,

<exponent>}

programs the synthesizer to output a gaussian waveform with

frequency, amplitude, offset, and exponent parameters. The default

settings for these functions are: 1 MHz, 5 Vp-p, 0 V and 10.

The command:

APPLy:DC {<percent_amplitude>}

programs the synthesizer to output a DC level. The DC level is set

as a percent of programmed amplitude. The default setting for this

function is 100%.

The command:

APPLy:USER {<segment_number>,<sampling_clock>,

<amplitude>,<offset>}

programs the synthesizer to output an arbitrary waveform. The

specified segment number must be loaded with an arbitrary

waveform before the synthesizer can execute this command

successfully. This command lets you specify segment number,

sampling clock rate, amplitude and offset. The default settings for

these functions are: 1, 1 MHz, 5 Vp-p and 0 V.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Using The Instrument 3-5

The query:

APPLy:<function_shape>?

queries parameters associated with the specified function shape.

Returns a string of values depending on the parameters that are

available for the selected function shape.

The query:

APPLy?

queries parameters associated with the currently selected function

shape and returns a string of values depending on the parameters

available for the selected function shape. For example, if the

synthesizer is programmed to output a ramp waveform, the APPL?

command returns: "1e+6, 5, 0 , 0, 10, 10, 10".

Example 2

The following example programs the Model 3152 using the APPLy

command. This example turns on the main output, generates a

square waveform, programs frequency to 2 MHz, programs

amplitude to 5 V and offset to 2.5 V. It also changes the square

wave duty cycle parameter to 25%.

Output

Configuration

Commands

/* Reset the Model 3152 to its default condition as listed in Table 3-

1.*/

:RESet;

/* Change the output waveform to square, frequency to 2 MHz,

amplitude to 5 V, offset to 2.5 V and duty cycle to 25%. Note that

there is no need to use the FUNC:MODE command because the

default value after RESet is FIXed.*/

:APPLy:SQUare 2e6,5,2.5,25

/* Turn the main output on.*/

:OUTPut ON

/*Turn the SYNC output on, if required. */

:OUTPut:SYNC ON

If the above commands are executed correctly, a square waveform

will be seen on your oscilloscope.

The output configuration commands control the output function,

shape, frequency, amplitude, filter and state. Optional modes are

omitted from these commands.

Using The Instrument 3-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Selecting an Output

Function Type

Use the following command to select the output function type:

FUNCtion:MODE {FIXed | USER | SEQuence}

When "FIXed" is selected, the synthesizer outputs the standard

waveform currently selected by the FUNC:SHAP command. When

"USER" is selected, the synthesizer outputs the arbitrary waveform

currently selected by the TRAC:SEL command. When "SEQuence"

is selected, the synthesizer outputs the sequence that is

programmed using the SEQ:DEF command.

The query:

FUNCtion:MODE?

queries the output function type and returns either FIX, USER or

SEQ.

Selecting a Standard

Function Shape

Changing the

Frequency and

Sample Clock

Use the following command to select a standard output function:

FUNCtion:SHAPe {SINusoid | TRIangle | SQUare |

PULSe| RAMP | SINC | EXPonential | GAUSsian | DC}

The selected waveform is output using the previously selected

frequency, amplitude, offset, and other relevant settings. The

standard waveform will be output only after the FUNC:MODE:FIX

command is selected.

The query:

FUNCtion:SHAPe?

queries the standard function shape and returns either SIN, TRI,

SQU, PULS, RAMP, SINC, EXP, GAUS or DC.

Use the following command to change the frequency for standard

waveforms and sample clock for arbitrary waveforms:

FREQuency {<frequency> | MINimum | MAXimum}

MIN selects the lowest frequency allowed for the currently active

function. MAX selects the highest frequency allowed for the

currently active function. The default frequency setting is 1 MHz for

all functions.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The query:

FREQuency?

queries the frequency setting for the standard function currently

active and returns a value in hertz.

Using The Instrument 3-7

The command:

FREQuency:RASTer {<frequency> | MINimum |

MAXimum}

sets the sample clock frequency for the user and sequenced

functions. MIN selects the lowest frequency allowed for the currently

active segment or sequence. MAX selects the highest frequency

allowed for the currently active segment or sequence. The default

sample clock frequency setting is 1 MHz for all functions.

Note that the output frequency depends on the number of points

specified in the waveform. The output frequency can be computed

using the following formula: Output Frequency = Sample Clock /

Number of points in the active segment.

The query:

FREQuency:RASTer?

queries the sample clock frequency setting for the arbitrary segment

or sequence currently active and returns a value in hertz.

Selecting the Sample

Clock Source

Programming the

Output Amplitude

and Offset

Use the following command to select the source for the sample

clock for the user and sequenced functions:

FREQuency:RASTer:SOURce {EXT | INT | ECLTRG0}

EXT selects an external clock source. The external source is

applied to the front panel CLOCK IN connector. INT selects the

internally synthesized clock synthesizer. ECLTRG0 selects a

sample clock that is available on the backplane. Note that

ECLTRG0 is always the active sample clock source when the Model

3152 is set to operate in phase synchronization mode.

The query:

FREQuency:RASTer:SOURce?

queries the sample clock source setting and returns EXT, INT or

ECLT.

Use the following command to program the peak-to-peak amplitude

for the generated waveform.

VOLTage {<amplitude>|MINimum|MAXimum}

MIN selects the smallest amplitude. MAX selects the largest

amplitude. The default amplitude is 5.00 V (into 50S).

Using The Instrument 3-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The query:

VOLTage?

queries the output amplitude for the currently selected function and

returns a value in volts.

The command:

VOLTage:OFFSet <offset>

sets the offset for the currently active function. The default offset is

0 V.

The query:

VOLTage:OFFSet?

queries the output offset for the currently selected function and

returns a value in volts.

Selecting the Filter

Type

Before selecting the filter type, use the following command to

activate the filter:

OUTPut:FILTer { OFF | ON}

ON enables the filter that has been selected with the

OUTP:FILT:FREQ command. The default filter state setting is OFF.

The query:

OUTPut:FILTer?

queries the output filter state and returns "0" (OFF) or "1" (ON).

The command:

OUTPut:FILTer:FREQuency {<20MHz | 25MHz |

50MHz>}

sets the filter frequency for the currently active function. 20 MHz has

a Gaussian response, and the 25 MHz and the 50 MHz filters have

an Elliptical response. Note that the filters cannot be changed if the

synthesizer is set to output sine waveform from its standard

waveform library. The filters will be activated only after the

OUTP:FILT ON command. The default filter setting is 20 MHz. Note

also that 20 MHz, 25 MHz and 50 MHz designate filter types. These

parameters should be programmed as switches, not as values. The

filter type cannot be programmed using OUTP:FILT:FREQ 25e6 or

OUTP:FILT:FREQ 50e6 Hz.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The query:

OUTPut:FILTer:FREQuency?

queries the currently selected filter setting and returns 20 MHz, 25

MHz or 50 MHz.

Using The Instrument 3-9

Activating the

Backplane ECLTRG

and TTLTRG

The Model 3152 can transmit and receive signals on the VXIbus

ECLTRG and TTLTRG lines.

Use the following command to activate one of two backplane

ECLTRG lines:

OUTPut:ECLTrg<n> { OFF | ON}

<n> designates the activated trigger line; 0 and 1 are available. ON

enables the selected trigger line. The trigger source for this line can

be selected with the TRIG:SOUR command. The default

ECLTrg<n> state is OFF.

The query:

OUTPut:ECLTrg<n>?

queries the ECLTrg<n> state and returns "<n>,0" (OFF) or "<n>,1"

(ON).

Turning on ECLTRG0 causes the module sample clock signal to be

routed onto the VXI backplane. Other Model 3152s may be set up

to receive this sample clock using the command

FREQ:RAST:SOURCE ECLTRG0 (See Selecting the Sample

Clock Source). ECLTRG1 should not be enabled onto the

backplane. Note that ECLTRG0 and ECLTRG1 are both used for

Inter-Module Synchronization.

The TTLTRG lines can be used to transmit and receive trigger

signals between the Model 3152 and other VXIbus modules.

Use the following command to activate one of eight backplane

TTLTRG lines:

OUTPut:TTLTrg<n> { OFF | ON}

<n> designates the activated trigger line and 0 through 7 are

available. ON enables the selected trigger line. The trigger source

for this line can be selected with the TRIG:SOUR command. The

default TTLTrg<n> state setting is OFF.

The query:

OUTPut:TTLTrg<n>?

queries the TTLTRG<n> state and returns "<n>,0" (OFF) or "<n>,1"

(ON).

Using The Instrument 3-10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Assigning the Validating

Source For TTLTRG

The TTLTRG signals, when enabled and placed on the backplane,

can be asserted with signals coming from a number of sources.

Use the following command to assign the signal source for the

active TTLTRG line:

OUTPut:TRIGger:SOURce {BIT | LCOMplete |

INTernal | EXTernal}

BIT Generates a trigger signal at any point in

the waveform. The trigger position within

the waveform can be programmed using

the OUTPUT:SYNC:POS:POIN command.

This command is used to set both the

TRIGger point and the SYNC point.

LCOMplete Generates a trigger signal in SEQuence

mode only once when the selected

segment appears for the first time.

INTernal Generates a trigger signal at intervals set

by the internal trigger generator .

EXTernal Generates a trigger signal every time a

trigger is applied to the front panel TRIG IN

connector.

Enabling the Main

Output

The query:

OUTPut:TRIGger:SOURce?

queries the validating signal source for the backplane TTLTRG<n>

lines and returns BIT, LCOM, INT or EXT.

For safety reasons, the main output default setting is OFF. Disable

or enable the main output using the following command:

OUTPut {OFF | ON}

When the main output state is programmed to ON, the output

connector is connected to the output amplifier through a 50S

resistor. In the OFF position, the output connector is disconnected

from the output amplifier by means of a mechanical relay. Ensure

that voltage is not applied to the main output connector when the

Model 3152 output state is programmed to ON.

The query:

OUTPut?

queries the state of the main output and returns "0" (OFF) or "1"

(ON).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Using The Instrument 3-11