Page 1

Wildcat (BL2000)

C-Programmable Singl e-Boar d Comp ut er with Et hern et

User’s Manual

019–0094 • 090529–O

Page 2

Wildcat (BL2000)

Digi International Inc.

www.rabbit.com

Wildcat (BL2000) User’s Manual

Part Number 019-0094 • 090529–O • Printed in U. S.A.

©2001–2009 Digi International Inc. • All right s rese rved.

Digi International reserves the right to make changes and

improvements to its products without providing n otice.

T r ade mark s

Rabbit and Dynamic C are registered trademarks of Digi International Inc.

Rabbit 2000 is a trademark of Digi International Inc.

No part of the contents of this manual may be reproduced or transmitted in any form or by any means

without the express written permission of Digi International.

Permission is granted to make one or more copies as long as the copyright page contained therein is

included. These copies of the manuals may not be let or sold for any reason without the express written

permission of Digi International.

The latest revision of this manual is available on the Rabbit Web s ite, www.rabb it.com,

for free, unregistered download.

Page 3

User’s Manual

TABLE OF CONTENTS

Chapter 1. Introduction 1

1.1 BL2000 Description..............................................................................................................................1

1.2 BL2000 Features...................................................................................................................................1

1.2.1 Connector Options........................................................................................................................2

1.3 Development and Evaluation Tools......................................................................................................3

1.3.1 Tool Kit.........................................................................................................................................3

1.3.2 Software........................................................................................................................................4

1.4 CE Compliance.....................................................................................................................................5

1.4.1 Design Guidelines.........................................................................................................................6

1.4.2 Interfacing the BL2000 to Other Devices.....................................................................................6

Chapter 2. Getting Started 7

2.1 BL2000 Connections............................................................................................................................7

2.2 Installing Dynamic C..........................................................................................................................10

2.3 Starting Dynamic C ............................................................................................................................11

2.4 PONG.C..............................................................................................................................................12

2.5 Where Do I Go From Here? ...............................................................................................................12

Chapter 3. Subsystems 13

3.1 BL2000 Pinouts..................................................................................................................................14

3.1.1 Headers and Screw Terminals.....................................................................................................15

3.1.2 Power Supply Pins......................................................................................................................16

3.2 Digital I/O...........................................................................................................................................17

3.2.1 Digital Inputs...............................................................................................................................17

3.2.2 Digital Outputs............................................................................................................................19

3.3 Relay Outputs .....................................................................................................................................21

3.4 Serial Communication ........................................................................................................................22

3.4.1 RS-232 ........................................................................................................................................22

3.4.2 RS-485 ........................................................................................................................................22

3.4.3 Ethernet Port ...............................................................................................................................24

3.4.4 Programming Port.......................................................................................................................25

3.5 A/D Converter Inputs..........................................................................................................................27

3.6 D/A Converter Outputs .......................................................................................................................28

3.7 Memory...............................................................................................................................................30

3.7.1 SRAM .........................................................................................................................................30

3.7.2 Flash Memory.............................................................................................................................30

3.8 Programming Cable............................................................................................................................31

3.8.1 Changing Between Program Mode and Run Mode....................................................................31

3.9 Other Hardware...................................................................................................................................32

3.9.1 External Interrupts.......................................................................................................................32

3.9.2 Clock Doubler.............................................................................................................................32

3.9.3 Spectrum Spreader......................................................................................................................33

Chapter 4. Software 35

4.1 An Overview of Dynamic C...............................................................................................................35

4.1.1 Upgrading Dynamic C................................................................................................................37

Page 4

Wildcat (BL2000)

4.2 Sample Programs................................................................................................................................38

4.2.1 General BL2000 Sample Programs............................................................................................38

4.2.2 Digital I/O...................................................................................................................................38

4.2.3 Serial Communication................................................................................................................39

4.2.4 A/D Converter Inputs.................................................................................................................39

4.2.5 D/A Converter Outputs...............................................................................................................40

4.2.6 Real-Time Clock ........................................................................................................................40

4.2.7 TCP/IP Sample Programs...........................................................................................................40

4.3 BL2000 Libraries...............................................................................................................................41

4.4 BL2000 Function Calls......................................................................................................................42

4.4.1 Board Initialization.....................................................................................................................42

4.4.2 Digital I/O...................................................................................................................................44

4.4.3 Serial Communication................................................................................................................45

4.4.4 Relay and LED Outputs..............................................................................................................46

4.4.5 A/D Converter Inputs.................................................................................................................47

4.4.6 D/A Converter Outputs...............................................................................................................50

Chapter 5. Using the TCP/IP Features 53

5.1 TCP/IP Connections...........................................................................................................................53

5.2 TCP/IP Sample Programs...................................................................................................................55

5.2.1 How to Set IP Addresses in the Sample Programs .....................................................................55

5.2.2 How to Set Up your Computer’s IP Address for a Direct Connection ......................................56

5.3 Run the PINGME.C Sample Program................................................................................................57

5.4 Running More Sample Programs With a Direct Connection.............................................................58

5.5 Where Do I Go From Here?...............................................................................................................58

Appendix A. Specifications 59

A.1 Electrical and Mechanical Specifications..........................................................................................60

A.1.1 Headers......................................................................................................................................63

A.2 Conformal Coating............................................................................................................................64

A.3 Jumper Configurations......................................................................................................................65

A.4 Use of Rabbit 2000 Parallel Ports..................................................................................................... 67

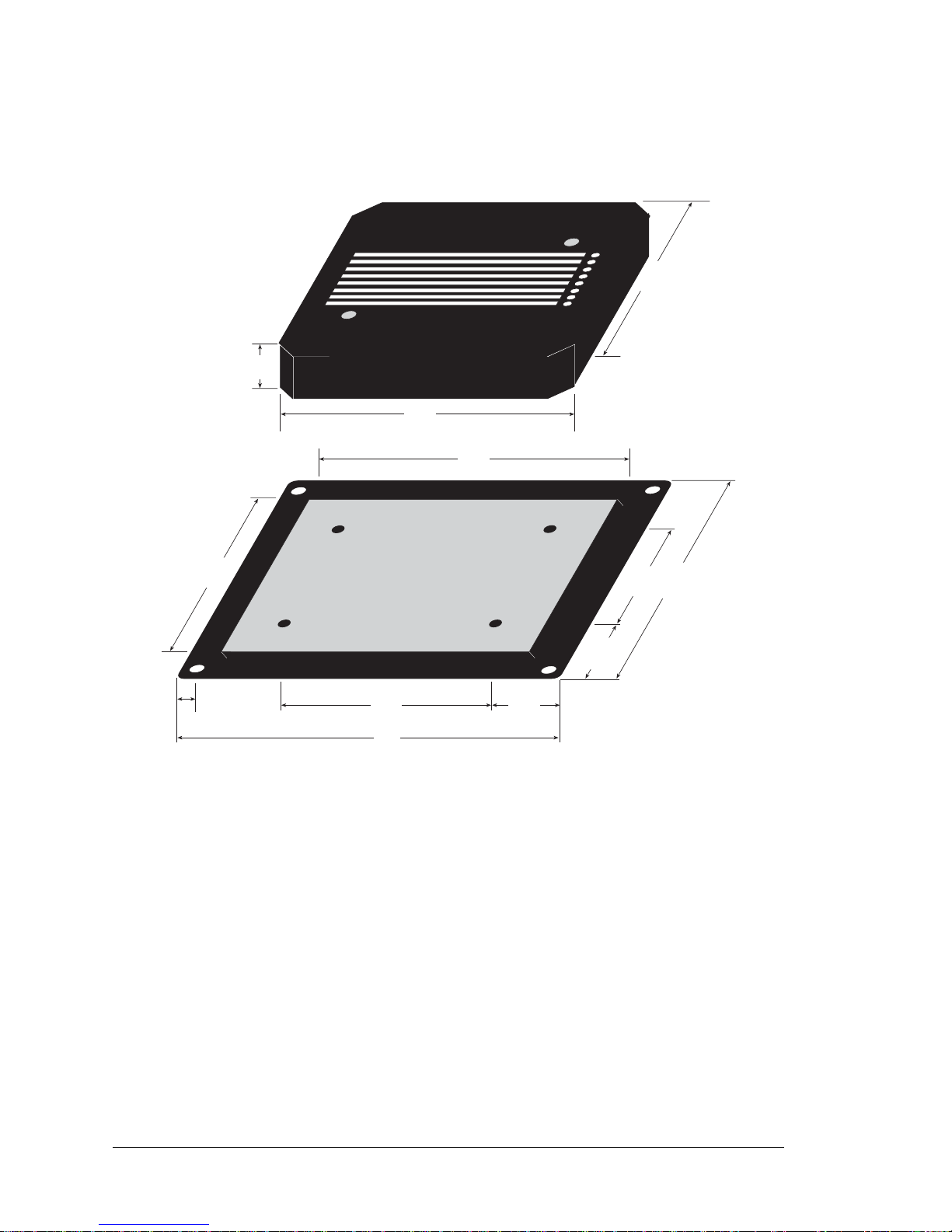

Appendix B. Plastic Enclosure 69

B.1 Assembly...........................................................................................................................................70

B.2 Dimensions........................................................................................................................................72

Appendix C. Power Supply 73

C.1 Power Supplies..................................................................................................................................73

C.1.1 Power for Analog Circuits.........................................................................................................74

C.2 Batteries and External Battery Connections........................................... ...... ...... ...............................74

C.2.1 Replacing the Backup Battery...................................................................................................75

C.2.2 Battery-Backup Circuit..............................................................................................................75

C.2.3 Power to VRAM Switch............................................................................................................76

C.2.4 Reset Generator..........................................................................................................................77

C.3 Chip Select Circuit.............................................................................................................................78

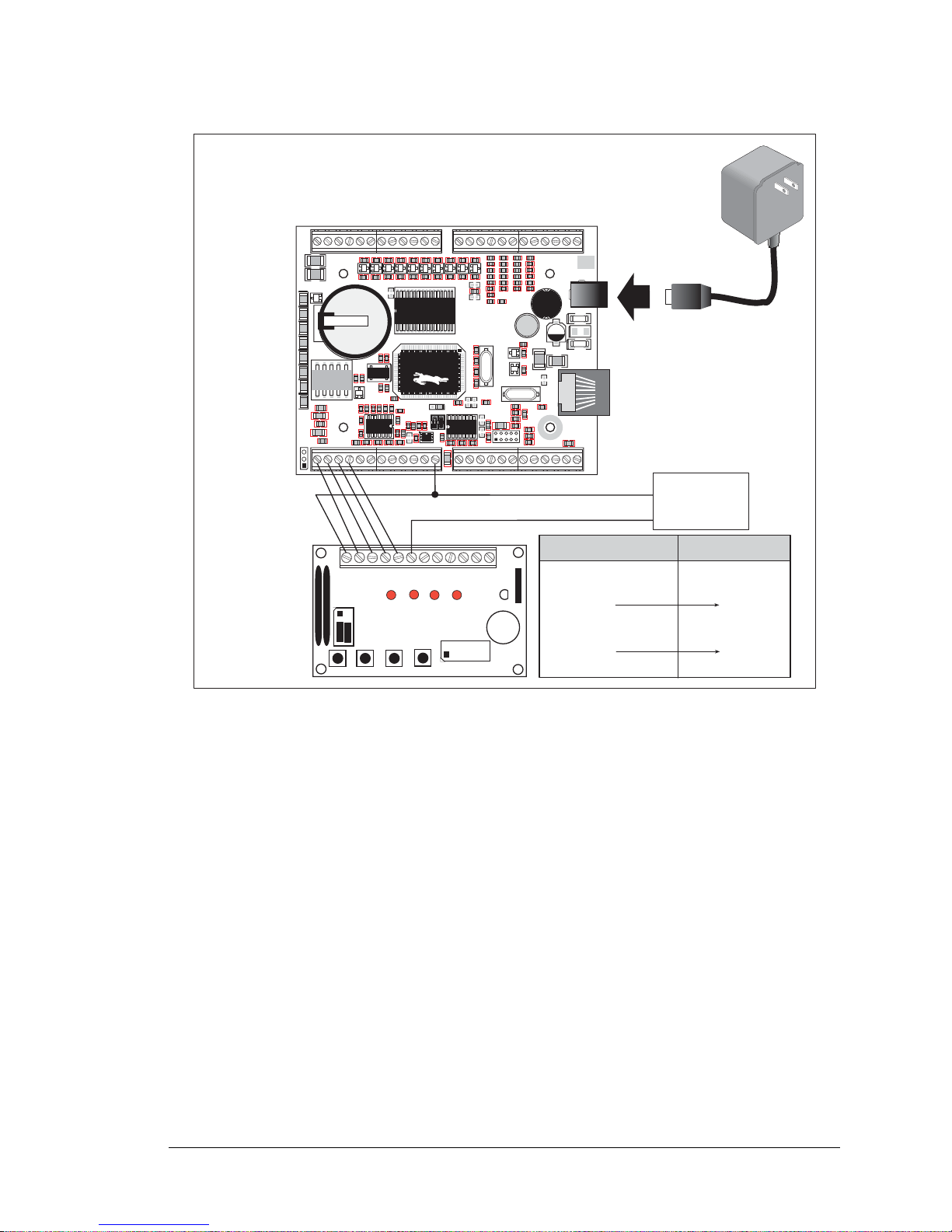

Appendix D. Demonstration Board 81

D.1 Connecting Demonstration Board.....................................................................................................81

Index 85

Schematics 89

Page 5

User’s Manual 1

1. INTRODUCTION

The BL2000 is a high-performance, C-programmable singleboard computer that offers built-in digital and analog I/O combined with Ethernet connectivity in a compact form factor. A

Rabbit

®

2000 microprocessor operating at 22.1 MHz provides

fast data processing. An optional plastic enclosure is available,

and may be wall-mounted or panel-mounted.

1.1 BL2000 Description

The BL2000 is an advanced single-board computer that incorporates the powerful Rabbit

2000 microprocessor, flash memory, static RAM, digital I/O ports, A/D converter inputs,

D/A converter outputs, an SPDT relay output, and a 10Base-T Ethernet port.

1.2 BL2000 Features

• Rabbit® 2000 microprocessor operating at 22.1 MHz.

• 128K static RAM and 256K flash memory.

• Up to 28 digital I/O:

11 protected digital inputs (plus up to 7 dual-purpose unbuffered analog inputs that

may be software-configured for use as digital inputs) and 10 high-current digital

sinking outputs that may be factory-configured as sourcing outputs.

• 11 analog channels: nine 12-bit A/D converter inputs, two 12-bit D/A converter outputs.

• Onboard SPDT relay .

• One RJ-45 Ethernet port compliant with IEEE 802.3 standard for 10Base-T Ethernet

protocol.

• Eight status LEDs.

• 4 serial ports (2 RS-232 or 1 RS-232 with RTS/CTS, 1 RS-485, and 1 CMOS-compati-

ble programming port).

• Real-time clock.

• Watchdog supervisor.

• Voltage regulator.

Page 6

2 Wildcat (BL2000)

• Backup battery.

• Ability to send e-mail and serve Web pages containing embedded data from single-

board computer.

• Remote program downloading and debugging capability via RabbitLink.

• Boards with the CE mark are CE-compliant.

• Optional plastic enclosure (can be wall-mounted or panel-mounted) and LED light

pipes (enclosure and light pipes are included with the Tool Kit, and are also sold separately).

Appendix A provides detailed specifications.

Four models of the BL2000 are available. Their standard features are summarized in

Table 1.

1.2.1 Connector Options

In addition to the standard screw-terminal connectors supplied on BL2000 boards, IDC

headers, bottom-mount connectors, and polarized friction-lock terminals may be factoryinstalled instead. Visit our Web site at www.rabbit.com or contact your Rabbit sales repre-

sentative or authorized distributor for further information.

Table 1. BL2000 Series Features

Model Features

BL2000 Full-featured single-board computer.

BL2010

BL2000 with eleven 10-bit A/D converter inputs (no D/A

converter outputs).

BL2020 BL2000 without Ethernet interface, only 6 LEDs.

BL2030 BL2010 without Ethernet interface, only 6 LEDs.

Standard screw terminals, accept

up to 14 AWG (1.5 mm

2

) wire

“Bottom-mount connector” to

mount BL2000 directly on 0.1"

pitch pins located on motherboard

2 × 17 IDC headers, 0.1" pitch

Polarized friction-lock terminals,

0.1" pitch

Page 7

User’s Manual 3

1.3 Development and Evaluation Tools

1.3.1 Tool Kit

A T ool Kit contains the hardware essentials you will need to use your own BL2000 singleboard computer. The items in the Tool Kit and their use are as follows:

• Getting Started instructions.

• Dynamic C CD-ROM, with complete product documentation on disk.

• Programming cable, used to connect your PC serial port to the BL2000.

• Universal AC adapter, 12 V DC, 1 A (includes Canada/Japan/U.S., Australia/N.Z.,

U.K., and European style plugs).

• Demonstration Board with pushbutton switches and LEDs. The Demonstration Board

can be hooked up to the BL2000 to demonstrate the I/O.

• Wire assembly to connect Demonstration Board to BL2000.

• Plastic enclosure with four screws and eight customer-installable light pipes.

• Screwdriver.

• Rabbit 2000 Processor Easy Reference poster.

• Registration card.

Figure 1. BL2000 Tool Kit

Rabbit and Dynamic C are registered trademarks of Digi International Inc.

Wildcat (BL2000)

The BL2000 provides optional Ethernet connectivity in a low-cost, high-performance single-board

computer rich with the digital I/O, A/D, and D/A designers need for embedded control and monitoring

applications on a compact board. These Getting Started instructions included with the Tool Kit will

help you get your BL2100 up and running so that you can run the sample programs to explore its capabilities and develop your own applications.

Tool Kit Contents

The BL2000 Tool Kit contains the following items:

• Dynamic C CD-ROM, with complete product documentation on disk.

• Programming cable, used to connect your PC serial port to the BL2000.

• Universal AC adapter, 12 V DC, 1 A (includes Canada/Japan/U.S., Australia/N.Z., U.K., and

European style plugs).

• Demonstration Board with pushbutton switches and LEDs. The Demonstration Board can be

hooked up to the BL2000 to demonstrate the I/O.

• Wire assembly to connect Demonstration Board to BL2000.

• Plastic enclosure with four screws and eight customer-installable light pipes.

• Screwdriver.

• Getting Started instructions.

• Rabbit 2000 Processor Easy Reference poster.

• Registration card.

Visit our online Rabbit store at www.rabbit.com/store/ for the latest information on peripherals and

accessories that are available for the BL2000 single-board computers.

Step 1 — Install Dynamic C

®

Before doing any development, you must install Dynamic C. Insert the CD from the Development Kit in

your PC’s CD-ROM drive. If the installation does not auto-start, run the setup.exe program in the root

directory of the Dynamic C CD. Install any Dynamic C modules after you install Dynamic C

.

PROG

DIAG

Programming

Cable

Screwdriver

Plastic Enclosure

Getting Started

Instructions

LED Light Pipes

Demo Board

Demo Board

Wiring Harness

Universal

AC Adapter

with Plugs

·

B

U

Z

Z

E

R

·

L

E

D

4

·

L

E

D

3

·

L

E

D

2

·

L

E

D

1

·

K

·

+

5

V

·

S

W

4

·

S

W

3

·

S

W

2

·

S

W

1

·

G

N

D

BUZZER

H

1

J

1

H2

· ·

1-2

· ·

3-4

· ·

5-6

LED1 LED2 LED3 LED4

SW1 SW2 SW3 SW4

·

·

8

-

7

·

·

6

-

5

·

·

4

3

·

·

2

-

1

DEMO BOARD

Page 8

4 Wildcat (BL2000)

1.3.2 Software

The BL2000 is programmed using version 7.04 or later of Rabbit’s Dynamic C. A compat-

ible version is included on the Tool Kit CD-ROM.

Dynamic C v. 9.60 includes the popular

µC/OS-II real-time operating system, point-to-point protocol (PPP), FAT file system,

RabbitWeb, and other select libraries that were previously sold as individual Dynamic C

modules.

Rabbit also offers for purchase the Rabbit Embedded Security Pack featuring the Secure

Sockets Layer (SSL) and a specific Advanced Encryption Standard (AES) library. In addition to the Web-based technical support included at no extra charge, a one-year telephonebased technical support subscription is also available for purchase. Visit our Web site at

www.rabbit.com for further information and complete documentation, or contact your

Rabbit sales representative or authorized distributor.

Page 9

User’s Manual 5

1.4 CE Compliance

Equipment is generally divided into two classes.

These limits apply over the range of 30–230 MHz. The limits are 7 dB higher for frequencies above 230 MHz. Although the test range goes to 1 GHz, the emissions from Rabbitbased systems at frequencies above 300 MHz are generally well below background noise

levels.

The BL2000 single-board computer has been tested and was found to

be in conformity with the following applicable immunity and emission

standards. The BL2010, BL2020, and BL2030 single-board computers

are also CE qualified as they are sub-versions of the BL2000 singleboard computer. Boards that are CE-compliant have the CE mark.

NOTE: Earlier versions of the BL2000 sold before 2003 that do not have the CE mark

are not CE-compliant.

Immunity

The BL2000 series of single-board computers meets the following EN55024/1998 immunity standards.

• EN61000-4-3 (Radiated Immunity)

• EN61000-4-4 (EFT)

• EN61000-4-6 (Conducted Immunity)

Additional shielding or filtering may be required for a heavy industrial environment.

Emissions

The BL2000 series of single-board computers meets the following emission standards

using the enhanced-EMI PCB, Part# 175-0224 Rev. A, and the 668-0003 Rev. A Rabbit

2000 microprocessor.

• EN55022:1998 Class B

• FCC Part 15 Class B

Your results may vary, depending on your application, so additional shielding or filtering

may be needed to maintain the Class B emission qualification.

CLASS A CLASS B

Digital equipment meant for light industrial use Digital equipment meant for home use

Less restrictive emissions requirement:

less than 40 dB µV/m at 10 m

(40 dB relative to 1 µV/m) or 300 µV/m

More restrictive emissions requirement:

30 dB µV/m at 10 m o r 100 µV/m

Page 10

6 Wildcat (BL2000)

1.4.1 Design Guidelines

Note the following requirements for incorporating the BL2000 series of single-board computers into your application to comply with CE requirements.

General

• The power supply provided with the Tool Kit is for development purposes only. It is the

customer’s responsibility to provide a CE-compliant power supply for the end-product

application.

• When connecting the BL2000 single-board computer to outdoor cables, the customer is

responsible for providing CE-approved surge/lighting protection.

• Rabbit recommends placing digital I/O or analog cables that are 3 m or longer in a

metal conduit to assist in maintaining CE compliance and to conform to good cable

design practices.

• When installing or servicing the BL2000, it is the responsibility of the end-user to use

proper ESD precautions to prevent ESD damage to the BL2000.

Safety

• All inputs and outputs to and from the BL2000 series of single-board computers must

not be connected to voltages exceeding SELV levels (42.4 V AC peak, or 60 V DC).

• The lithium backup battery circuit on the BL2000 single-board computer has been

designed to protect the battery from hazardous conditions such as reverse charging and

excessive current flows. Do not disable the safety features of the design.

1.4.2 Interfacing the BL2000 to Other Devices

Since the BL2000 series of single-board computers is designed to be connected to other

devices, good EMC practices should be followed to ensure compliance. CE compliance is

ultimately the responsibility of the integrator. Additional information, tips, and technical

assistance are available from your authorized Rabbit distributor, and are also available on

our Web site at www.rabbit.com.

Page 11

User’s Manual 7

2. GETTING S TARTED

Chapter 2 explains how to connect the programming cable and

power supply to the BL2000.

2.1 BL2000 Connections

1. Attach the BL2000 to the plastic enclosure base.

Position the BL2000 over the plastic enclosure base as shown below in Figure 2. Attach

the BL2000 to the base at the top left and bottom right positions using the two 4-40 × ¼

screws supplied with the enclosure.

Figure 2. Attach BL2000 to Plastic Enclosure Base

The plastic enclosure base facilitates handling the BL2000 during development, and provides an attractive mounting alternative. Alternatively, you may wish to use standoffs to

protect the components on the other side of the board. The plastic enclosure is offered as a

separate option when individual BL2000 boards are purchased.

NOTE: Appendix B, “Plastic Enclosure,” provides additional information and specifications

for the plastic enclosure.

14

23

L1

D2

J8

POWER IN

J7

T

V

S

1

J10

+

C28

R1

C23

C25

C17

J6

C20

D1

U4

Y3

Q2

C24

R30

R

1

5

1

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

U1

C2

C3

C19

R153

C18

R154

R9

R13

R15

C1

Y2

R

2

7

C

2

2

C

2

7

R

2

8

9

0

1

5

6

5

4

0

U5

R

5

5

R

5

4

R

3

7

R

3

6

R

3

8

R

5

6

C

4

0

C

3

9

C

3

8

R

5

0

R

5

1

R

5

2

R

5

8

R

5

9

R

6

0

C

3

5

C

3

4

C

3

3

C31

+

C29

R33

R31

C

3

6

U6

R32

R34

R35

C

4

1

R

5

3

R

6

1

D5

D4

R41

R42

D3

R40

R

5

7

R

3

9

C45

C44

C43

J2

J1

J4

J3

D6

D7 D8 D9

J9

J11

R43 R44

R45

C49C48

C47

C46

+

+

BT1

D

G

S

Q3

Q5

C32

D10

D11 D12

R46

R47

R48

R49

C51

C52

C50

C8

U2

R5

R

1

1

R

1

0

C75

C

1

1

R17

C4

C13

U3

R8

R18

R2

R3

R

2

3

R22

C

1

4

R152

R7

C78

C77

C76

C79

C5

C

1

5

1432

Y1

C26

Q4

Q1

R

2

5

R

2

4

R29

C21

R

2

6

1

56

1

0

K1

+

C9

R14

C12

R21

C7

J12

D

S

1

D

S

4

D

S

3

D

S

2

Q6

C

3

7

C

4

2

D

S

5

D

S

6

D

S

7

DS8

GND

IN3IN2 IN4 IN5 IN6 IN7 IN8 IN9 IN10 OUT8 OUT9 GND GNDOUT0 OUT1 OUT2 OUT3 OUT4 OUT5 OUT6 OUT7 NC

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1 AGND DAC1 DAC0 ADC8 ADC7 ADC6ADC5 ADC4 ADC3ADC2 ADC1 ADC0+RAW +K

NO

COM

GND

GND

GND

GN D

GND

GND

GND

GNDGNDGNDGND

GN D

GND GND

GND

GND GND

GN D

AGND

AGND

AGND

AGND

AGND

AG ND

P

W

R

L

N

K

A

C

T

O

U

T

0

O

U

T

1

O

U

T

2

O

U

T

3

B

A

D

JP2

Battery

CAUTION

C85

J

P

1

R

1

5

7

Page 12

8 Wildcat (BL2000)

2. Connect the programming cable to download programs from your PC and to debug the

BL2000.

Connect the 10-pin

PROG connector of the programming cable to header J5 on the BL2000.

Ensure that the colored edge lines up with pin 1 as shown. (Do not use the DIAG connector,

which is used for a normal serial connection.) Connect the other end of the programming

cable to a COM port on your PC.

Figure 3. Programming Cable Connections

NOTE: Never disconnect the programming cable by pulling on the ribbon cable. Carefully

pull on the connector to remove it from the header.

NOTE: Some PCs now co me equipped only with a USB port. It m ay be possible to use an

RS-232/USB converter (Part No. 20-151-0178) with the programming cable supplied with

the Tool Kit. Note that not all RS-232/USB converters work with Dynamic C.

R1

C23

C25

C17

J6

C20

U4

Y3

Q2

C24

R30

R151

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

U1

C2

C3

C19

R153

C18

R154

R9

R13

R15

C1

Y2

R27C22

C27

R28

90

15

65

40

U5

J2

J1

J4

J3

C8

U2

R5

R11

R10

C75

C11

R17

C4

C13

U3

R8

R18

R2

R3

R23

R22

C14

R152

R7

C78

C77

C76

C79

C5

C15

1432

Y1

C26

Q4

Q1

R25

R24

R29

C21

R26

1

56

10

K1

+

C9

R14

C12

R21

C7

J12

DS1

DS4

DS3

DS2

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1 AGND DAC1 DAC0 ADC8 ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0+RAW +K

GND GND

GND

GND GND

GN D

AGND

AGND

AGND

AGND

AGND

AG ND

PWRLNKACTOUT 0

JP2

Colored edge

Programming Cable

To

PC COM port

C85

JP1

R157

PROG

J5

DIAG

PROG

Red

shrink wrap

Page 13

User’s Manual 9

3. Connect the power supply.

First, prepare the AC adapter for the country where it will be used by selecting the plug.

The BL2000 Tool Kit presently includes Canada/Japan/U.S., Australia/N.Z., U.K., and

European style plugs. Snap in the top of the plug assembly into the slot at the top of the

AC adapter as shown in Figure 4, then press down on the spring-loaded clip below the

plug assembly to allow the plug assembly to click into place.

Connect the bare ends of the power supply to the +RAW and GND positions on screw-

terminal header J2 as shown in Figure 4.

Figure 4. Power Supply Connection

4. Apply power.

Plug in the AC adapter. If you are using your own power supply , it must provide 9 V to 40 V

DC—voltages outside this range could damage the BL2000.

CAUTION: Unplug the power supply while you make or otherwis e work with t he co nnection s

to the headers. This will prot ect your BL2000 fr om ina dver tent shor ts or power spikes.

NOTE:

The green PWR LED and the red BAD LED on the opposite end of the board

should come on, indicating that the BL2000 is now ready to be used.

NOTE: A hardware RESET is done by unplugging the AC adapter, then plugging it back in,

or by momentarily grounding the board reset input at pin 9 on screw-terminal header J2.

14

23

L1

D2

J8

POWER IN

J7

TVS1

J10

+

C28

R1

C23

C25

C17

J6

C20

D1

U4

Y3

Q2

C24

R30

R151

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

C19

R153

R154

R9

R13

R15

C1

Y2

R27C22

C27

R28

U5

R55

R54

R37

R36

R38

R56

C40

C39

C38R50

R51

R52

R58

R59

R60

C35

C34

C33

C31

+

C29

R33

R31

C36

R32

R34

R35

C41R53

R61

D4

R41

D3

R40

R57

R39

C44

C43

J2

J1

GND

IN3IN2 IN4 IN5 IN6 IN7 IN8 IN9 IN10 OUT8 OUT9 GND

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1+RAW +K

GND

GNDGNDGNDGND

GN D

GND GND

GND

GND GND

GN D

RESET

PIN

Remove slot cover,

insert tab into slot

Snap plug into place

2

1

Assemble

AC Adapter

J2

+

Red

Heat-Shrink

Tubing

Page 14

10 Wildcat (BL2000)

2.2 Installing Dynamic C

If you have not yet installed Dynamic C version 7.04 (or a later version), do so now by

inserting the Dynamic C CD in your PC’s CD-ROM drive. The CD will auto-install unless

you have disabled auto-install on your PC.

If the CD does not auto-install, click Start > Run from the Windows St art button and

browse for the Dynamic C setup.exe file on your CD drive. Click OK to begin the

installation once you have selected the

setup.exe file.

The online documentation is installed along with Dynamic C, and an icon for the documentation menu is placed on the workstation’s desktop. Double-click this icon to reach the

menu. If the icon is missing, create a new desktop icon that points to default.htm in the

docs folder, found in the Dynamic C installation folder.

The latest versions of all documents are always available for free, unregistered download

from our web sites as well.

The Dynamic C User’s Manual provides detailed instructions for the installation of

Dynamic C and any future upgrades.

NOTE: If you have an ea rl ier ve rs ion of Dynamic C alrea dy i ns tal l ed, t he default installat io n

of the later versi on wi ll be in a diff erent folder, and a separate icon will appear o n you r d esktop.

Page 15

User’s Manual 11

2.3 Starting Dynamic C

Once the BL2000 is connected to your PC and to a power source, start Dynamic C by

double-clicking on the Dynamic C icon on your desktop or in your Start menu.

Dynamic C defaults to using the serial port on your PC that you specified during installation. If the port setting is correct, Dynamic C should detect the BL2000 and go through a

sequence of steps to cold-boot the BL2000 and to compile the BIOS. (Some versions of

Dynamic C will not do the init ial BIOS compile and load until the first t ime you compile a

program.)

If you are using a USB port to connect your computer to the BL2000, choose

Options >

Project Options

and select “Use USB to Serial Converter.” Click OK.

If you receive the message

No Rabbit Processor Detected, the programming

cable may be connected to the wrong COM port, a connection may be faulty, or the target

system may not be powered up. First, check both ends of the programming cable to ensure

that it is firmly plugged into the PC and the programming port.

If there are no faults with the hardware, select a different COM port within Dynamic C.

From the Options menu, select Communications. Select another COM port from the list,

then click OK. Press <Ctrl-Y> to force Dynamic C to recompile the BIOS. If Dynamic C

still reports it is unable to locate the target system, repeat the above steps until you locate the

active COM port. You should receive a Bios compiled successfully message

once this step is completed successfully.

If Dynamic C appears to compile the BIOS successfully, but you then receive a communication error message when you compile and load a sample program, it is possible that your

PC cannot handle the higher program-loading baud rate. Try changing the maximum

download rate to a slower baud rate as follows.

• Locate the Serial Options dialog in the Dynamic C Options > Communications

menu. Select a slower Max download baud rate.

If a program compiles and loads, but then loses target communication before you can

begin debugging, it is possible that your PC cannot handle the default debugging baud

rate. Try lowering the debugging baud rate as follows.

• Locate the

Serial Options dialog in the Dynamic C Options > Communications

menu. Choose a lower debug baud rate.

Page 16

12 Wildcat (BL2000)

2.4 PONG.C

You are now ready to test your set-up by running a sample program.

Find the file PONG.C, which is in the Dynamic C SAMPLES folder. To run the program,

open it with the File menu (if it is not still open), compile it using the Compile menu, and

then run it by selecting Run in the Run menu. The STDIO window will open and will display a small square bouncing around in a box.

This program does not test the serial ports, the I/O, or the TCP/IP part of the board, but

does ensure that the board is basically functional. The sample program described in

Section 5.3, “Run the PINGME.C Sample Program,” tests the TCP/IP portion of the

board.

2.5 Where Do I Go From Here?

NOTE: If you purchased your BL2000 through a distributor or Rabbit partner, contact the

distributor or partner first for technical support.

If there are any problems at this point:

• Use the Dynamic C Help menu to get further assistance with Dynamic C.

• Check the Rabbit Technical Bulletin Board and forums at www.rabbit.com/support/bb/

and at www.rabbit.com/forums/.

• Use the Technical Support e-mail form at www.rabbit.com/support/.

If the sample program ran fine, you are now ready to go on to explore other BL2000 fea-

tures and develop your own applications.

Chapter 3, “Subsystems,” provides a description of the BL2000’s features, Chapter 4,

“Software,” describes the Dynamic C software libraries and introduces some sample programs, and Chapter 5, “Using the TCP/IP Features,” explains the TCP/IP features.

Page 17

User’s Manual 13

3. SUBSYSTEMS

Chapter 3 describes the principal subsystems for the BL2000.

• Digital I/O

• Relay Outputs

• Serial Communication

• A/D Converter Inputs

• D/A Converter Outputs

• Memory

• External Interrupts

Figure 5 shows these Rabbit-based subsystems designed into the BL2000.

Figure 5. BL2000 Subsystems

SRAM

Flash

11 MHz

osc

32 kHz

osc

BL2000

RABBIT

2000

RS-232

RS-485

A/D

Converter

Digital

Outputs

Relay

Output

Programming

Port

Digital

Inputs

Ethernet

D/A

Converter

Page 18

14 Wildcat (BL2000)

3.1 BL2000 Pinouts

The BL2000 pinouts are shown in Figure 6(a) and Figure 6(b).

Figure 6(a). BL2000 Pinouts (screw-terminal headers)

Battery

Serial Port Nomenclature

HeaderJ2

TXD1

RXD1

TXD2

RXD2

Rabbit 2000

TxB

RxB

TxC/RTS

RxC/CTS

+RAW

GND

+K

/RESET

IN1

IN0

485

485+

RXD2

TXD2

RXD1

TXD1

J2

12

11

10

9

8

7

6

5

4

3

2

1

J8

AGND

DAC1

DAC0

ADC8

ADC7

ADC6

ADC5

ADC4

ADC3

ADC2

ADC1

ADC0

J4

12

11

10

9

8

7

6

5

4

3

2

1

J8

J12

GND

VBATEXT

GND

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

NO

COM

NC

GND/VCC

J9

1

2

3

4

5

6

7

8

9

10

11

12

J8

1

2

3

4

5

6

7

8

9

10

11

12

J8

IN2

IN3

IN4

IN5

IN6

IN7

IN8

IN9

IN10

OUT8

OUT9

GND

J8

DS8

DS7

DS6

DS5

DS4

DS3

DS2

DS1

BAD OUT3 OUT2 OUT1 OUT0 ACT LNK PWR

J6

J7

Page 19

User’s Manual 15

3.1.1 Headers and Screw Terminals

All BL2000 models are equipped with 1 × 12 screw terminal strips (J2, J4, J8, and J9) and

a 2-pin power jack (J7). The BL2000 and BL2010 also have the RJ-45 Ethernet jack (J6).

There is provision on the circuit board to accommodate one of the following types of

connectors instead of the screw-terminal strips.

• 2 × 17 IDC headers with a pitch of 0.1".

• 1 × 17 friction-lock connectors with a pitch of 0.1".

• 1 × 17 bottom-mount sockets with a pitch of 0.1". The holes for the bottom-mount

sockets are on the “outside” edges of the connector locations

The pinouts for these connectors are shown in Figure 6(b).

Figure 6(b). BL2000 Pinouts (other 0.1" headers)

Battery

Serial Port Nomenclature

HeaderJ2

TXD1

RXD1

TXD2

RXD2

Rabbit 2000

TxB

RxB

TxC/RTS

RxC/CTS

+RAW

GND

GND

+K

/RESET

GND

IN1

IN0

GND

485

485+

GND

RXD2

TXD2

GND

RXD1

TXD1

J1

AGND

DAC1

AGND

DAC0

ADC8

AGND

ADC7

ADC6

AGND

ADC5

ADC4

AGND

ADC3

ADC2

AGND

ADC1

ADC0

J3

J12

GND

VBATEXT

GND

OUT0

OUT1

GND

OUT2

OUT3

GND

OUT4

OUT5

GND

OUT6

OUT7

GND

NO

COM

GND

NC

GND/VCC

J11

IN2

IN3

GND

IN4

IN5

GND

IN6

IN7

GND

IN8

IN9

GND

IN10

OUT8

GND

OUT9

GND

J10

DS8

DS7

DS6

DS5

DS4

DS3

DS2

DS1

BAD OUT3 OUT2 OUT1 OUT0 ACT LNK PWR

J6

J7

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

33

31

29

27

25

23

21

19

17

15

13

11

9

7

5

3

1

33

31

29

27

25

23

21

19

17

15

13

11

9

7

5

3

1

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

Page 20

16 Wildcat (BL2000)

3.1.2 Power Supply Pins

Instead of connecting an AC adapter to the power supply jack, J7, the input power supply

(9 V to 40 V DC) may be connected to pins 12 and 11 on header J2 (see Figure 6(a) or

Figure 6(b)).

Pin 12 on header J9 or J10 is normally GND by factory default, but may be changed to

Vcc by removing resistor R161 and installing resistor R160. See Appendix C, “Power

Supply,” for more information on this configuration and for information on backupbattery options.

Page 21

User’s Manual 17

3.2 Digital I/O

3.2.1 Digital Inputs

The BL2000 has 11 digital inputs, IN0–IN10, each of which is protected over a range of

–36 V to +36 V. The inputs are factory-configured to be pulled up to +5 V, but they can

also be pulled down by moving the surface-mounted jumper at JP6 as shown in Figure 7.

Figure 7(a). BL2000 Digital Inputs [Pulled Up—JP6(1–2) connected]

Figure 7(b). BL2000 Digital Inputs [Pulled Down—JP6(2–3) connected]

JP6

10 nF

22 kW

27 kW

Rabbit 2000

Microprocessor

Factory

Default

Vcc

1

3

GND

JP6

JP6

10 nF

22 kW

27 kW

Rabbit 2000

Microprocessor

Vcc

1

3

GND

+5 V

JP6

Page 22

18 Wildcat (BL2000)

Figure 7(c). Example of Logic Gate Driving BL2000 Digital Input

The actual switching threshold is approximately 2.40 V for channels IN0–IN10. Anything

below this value is a logic 0, and anything above is a logic 1.

The A/D converter inputs can be used as additional digital inputs using the parameters

specified for the digIn software function call. The default threshold for channels IN11–

IN21 is also set to 2.40 V, but may be changed by adding two lines to your program as discussed for the digIn software function call.

The digital inputs are each fully protected over a range of -36 V to +36 V, and can handle

short spikes of ±40 V.

Figure 8. BL2000 Digital Input Protected Range

10 nF

22 kW

27 kW

Rabbit 2000

Microprocessor

Vcc

1

3

JP6

+40 V

+36 V

+3.3 V

40 V

Normal Switching

Levels

Spikes

Digital Input Voltage

Spikes

Spikes

Page 23

User’s Manual 19

3.2.2 Digital Outputs

The BL2000 has 10 digital outputs, OUT0–OUT9, each of which can either sink or source

up to 200 mA, depending on how the outputs are configured. On boards that carry the CE

mark, OUT8 and OUT9 are each capable of sinking up to 750 mA.

Each output can be configured individually as either a sinking or a sourcing output as shown

in Figure 9. The outputs can be pulled as a group to Vcc, +K, or GND through 27 kΩ resistors. Tie the outputs high to either Vcc or +K when using the outputs as sinking outputs (via

0 Ω resistors at R32 or R35 respectively), or tie the outputs to GND via R34 when using the

outputs as sourcing outputs. +K is an externally supplied voltage of up to 40 V DC, and is

used primarily in combination with current sourcing outputs, and must also be connected to

an external supply when an inductive load is connected to a sinking output.

NOTE: Remove the 27 kΩ resistors (R143–R150) from the output circuits if no pull-

up/down is required to avoid leakage between the outputs. These resistors are located

on the bottom side of the BL2000 board above the solder points for screw terminal

header J9.

Vcc

27 kW

Vcc

27 kW

K

SINKING OUTPUTFactory Default

0 W

0 W

SOURCING OUTPUTSpecial Order

K

Page 24

20 Wildcat (BL2000)

Figure 9. BL2000 Digital Outputs

The locations of the output pull-up/pull-down select resistors R32, R34, and R35 are

shown in Figure 10.

Figure 10. Locations of Resistors R32, R34, and R35

All BL2000 models are factory-configured with sinking outputs and pull-up resistors tied

to Vcc via a 0 Ω resistor at R32.

14

23

L1

D2

J8

POWER IN

J7

TVS1

J10

+

C28

C25

D1

Q2

R30

R55

R54

R37

R36

R38

R56

C40

C39

C38R50

R51

R52

R58

R59

R60

C35

C34

C33

C31

+

C29

R33

R31

C36

U6

R32

R34

R35

C41R53

R61

D5

D4

R41

R42

D3

R40

R57

R39

C45

C44

C43

D6

D7 D8 D9

J9

J11

R43 R44

R45

C49C48

C47

C46

+

+

BT1

D

G

S

Q3

Q5

C32

D10

D11 D12

R46

R47

R48

R49

C51

C52

C50

C26

Q4

R29

DS4

Q6

C37

C42

DS5

DS6

DS7

DS8

GND

IN3IN2 IN4 IN5 IN6 IN7 IN8 IN9 IN10 OUT8 OUT9 GND GND/VCCOUT0 OUT1 OUT2 OUT3 OUT4 OUT5 OUT6 OUT7 NCNO

COM

GND

GND

GND

GN D

GND

GND

GND

GNDGNDGNDGND

GN D

OUT 0OUT 1OUT 2OUT 3BAD

SRAM

R32

R34

R35

Battery

Page 25

User’s Manual 21

3.3 Relay Outputs

Figure 11 shows the BL2000 relay contact connections. A diode across the coil provides a

return path for inductive spikes, and snubbers across the relay contacts protect the relay

contacts from inductive spikes.

Figure 11. BL2000 Relay Output Contact Connections

The relay is driven by PA0, which is the same Rabbit 2000 parallel port that drives OUT0

and LED DS4. OUT0 therefore works in parallel with the relay output.

The relay included on the BL2000 has contacts rated for 1 A @ 30 V DC or 300 mA @

120 V AC. When using the BL2000 in a CE-certified application, the voltages handled by

the relay must not exceed SELV levels (42.4 V AC peak, or 60 V DC).

7

8

9

1

10

COM

NO

NC

4

3

2

COM

NO

NC

Vcc

47 W

100 nF

47 W

100 nF

J9

9

10

11

Rabbit 2000

Microprocessor

Page 26

22 Wildcat (BL2000)

3.4 Serial Communication

The BL2000 has one RS-232 serial channel (with RTS/CTS) or two RS-232 (3-wire)

channels, one RS-485 serial channel, and one CMOS serial channel. The RS-232 channel(s) are configured with the serMode software function call. Table 2 summarizes the

options.

All four serial ports operate in an asynchronous mode. An asynchronous port can handle 7

or 8 data bits. A 9th bit address scheme, where an additional bit is sent to mark the first

byte of a message, is also supported. Serial Port A can be operated alternately in the

clocked serial mode. In this mode, a clock line synchronously clocks the data in or out.

Either of the two communicating devices can supply the clock. The BL2000 series boards

typically use all four ports in the asynchronous serial mode. Serial Ports B and C are used

for RS-232 communication, and Serial Port D is used for RS-485 communication. The

BL2000 uses an 11.0592 MHz crystal, which is doubled to 22.1184 MHz. At this frequency, the BL2000 supports standard baud rates up to a maximum of 230,400 bps.

3.4.1 RS-232

The BL2000 RS-232 serial communication is supported by an RS-232 transceiver , U1. U1

provides the voltage output, slew rate, and input voltage immunity required to meet the

RS-232 serial communication protocol. Basically, the chip translates the Rabbit 2000’s

CMOS/TTL signals to RS-232 signal levels. Note that the polarity is reversed in an

RS-232 circuit so that a +5 V output becomes approximately -10 V and 0 V is output as

+10 V. U1 also provides the proper line loading for reliable communication.

RS-232 can be used effectively at this baud rate for distances up to 15 m.

3.4.2 RS-485

The BL2000 has one RS-485 serial channel, which is connected to the Rabbit 2000 Serial

Port D through U8, an RS-485 transceiver.

U8 supports the RS-485 serial communication

protocol. The chip’s slew rate limiters provide for a maximum baud rate of

230,400

bps

,

which allows for a network of up to 300 m (or 1000 ft). The half-duplex communication

uses the Rabbit 2000’s PB6 pin to control the transmit enable on the communication line.

The BL2000 can be used in an RS-485 multidrop network. Connect the 485+ to 485+ and

485– to 485– using single twisted-pair wires (nonstranded, tinned) as shown in Figure 12.

Note that a common ground is recommended.

Table 2. Serial Communication Configurations

Mode

Serial Port

B C D

0 RS-232, 3-wire RS-232, 3-wire RS-485

1 RS-232, 5-wire CTS/RTS RS-485

Page 27

User’s Manual 23

Figure 12. Multidrop BL2000 Network

R1

C17

C20

Y3

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

U1

C2

C3

C19

R153

C18

R154

R9

R13

R15

C1

Y2

U5

J2

J1

J4

J3

C8

U2

R5

R11

R10

C75

C11

R17

C4

C13

U3

R8

R18

R2

R3

R23

R22

C14

R152

R7

C78

C77

C76

C79

C5

C15

Q1

R24

C21

+

C9

R14

C12

R21

C7

J12

DS1

DS2

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1 AGND DAC1 DAC0 ADC8 ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0+RAW +K

GND GND

GND

GND GND

GN D

AGND

AGND

AGND

AGND

AGND

AG ND

PWRLNK

JP2

C85

JP1

R157

R1

C17

C20

Y3

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

U1

C2

C3

C19

R153

C18

R154

R9

R13

R15

C1

Y2

U5

J2

J1

J4

J3

C8

U2

R5

R11

R10

C75

C11

R17

C4

C13

U3

R8

R18

R2

R3

R23

R22

C14

R152

R7

C78

C77

C76

C79

C5

C15

Q1

R24

C21

+

C9

R14

C12

R21

C7

J12

DS1

DS2

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1 AGND DAC1 DAC0 ADC8 ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0+RAW +K

GND GND

GND

GND GND

GN D

AGND

AGND

AGND

AGND

AGND

AG ND

PWRLNK

JP2

C85

JP1

R157

R1

C17

C20

Y3

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

U1

C2

C3

C19

R153

C18

R154

R9

R13

R15

C1

Y2

U5

J2

J1

J4

J3

C8

U2

R5

R11

R10

C75

C11

R17

C4

C13

U3

R8

R18

R2

R3

R23

R22

C14

R152

R7

C78

C77

C76

C79

C5

C15

Q1

R24

C21

+

C9

R14

C12

R21

C7

J12

DS1

DS2

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1 AGND DAC1 DAC0 ADC8 ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0+RAW +K

GND GND

GND

GND GND

GN D

AGND

AGND

AGND

AGND

AGND

AG ND

PWRLNK

JP2

C85

JP1

R157

GN

+K

/RESET

IN1

IN0

485

485+

RX

J2

10

9

8

7

6

5

Ground recommended

Page 28

24 Wildcat (BL2000)

The BL2000 comes with a 220 Ω termination resistor and two 681 Ω bias resistors installed

and enabled with jumpers across pins 1–2 and 3–4 on header JP1, as shown in Figure 13.

Figure 13. RS-485 Termination and Bias Resistors

The bias and termination resistors in a multidrop network should only be enabled on both

end nodes of the network. Disable the termination and bias resistors on the intervening

BL2000 units in the network by removing both jumpers from header JP1.

3.4.3 Ethernet Port

Figure 14 shows the pinout for the Et her net po rt (J6) . Note t hat th ere are tw o stan dar ds for

numbering the pins on this connector—the convention used here, and numbering in reverse

to that shown. Regardless of the numbering convention followed, the pin positions relative

to the spring tab position (located at the bottom of the RJ-45 jack in Figure 14) are always

absolute, and the RJ-45 connector will work pr operly with off-the-shelf Ethernet cables.

Figure 14. RJ-45 Ethernet Port Pinout

RJ-45 pinouts are sometimes numbered opposite to the way shown in Figure 14.

R68

681 W

R70

220 W

R77

681 W

485+

485

6

7

termi-

nation

bias

bias

U8

Factory

Default

U1

C2

C3

J4

J3

C8

U2

R5

R11

R10

C75

C11

C4

U3

R8

R18

R2

R3R7C78

C79

C5

+

C9

R14

C12

C7

J12

RXD1 TXD1 AGND DAC1 DAC0 ADC8 ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0

GND AGND

AGND

AGND

AGND

AGND

AG ND

C85

JP1

R157

JP1

1

2

3

4

JP1

1

2

3

4

ETHERNET

RJ-45 Plug

1. E_Tx+

2. E_Tx

3. E_Rx+

6. E_Rx

1

8

RJ-45 Jack

J6

Page 29

User’s Manual 25

The transformer/connector assembly ground is connected to the BL2000 printed circuit

board digital ground via a 0 Ω resistor “jumper,” R1, as shown in Figure 15.

Figure 15. Isolation Resistor R1

The factory default is for the 0 Ω resistor “jumper” at R1 to be installed. In high-noise

environments, it may be useful to ground the transformer/connector assembly directly

through the chassis ground. This will be especially helpful to minimize ESD and/or EMI

problems. Once you have removed the 0 Ω resistor “jumper,” R1, use a ring lug to attach

the BL2000 to the chassis ground, thereby grounding the transformer/connector assembly.

A convenient position for the ring lug has been provided at the top-left mounting screw

hole near the RJ-45 jack as shown in Figure 16.

Figure 16. Recommended Location for Ring Lug

3.4.4 Programming Port

The BL2000 has a 10-pin programming header labeled J5. The programming port uses the

Rabbit 2000’ s Serial Port A for communication. Dynamic C uses the programming port to

download and debug programs.

The programming port is also used for the following operations.

• Cold-boot the Rabbit 2000 after a reset.

• Remotely download and debug a program over an Ethernet connection using the

RabbitLink EG2110.

• Fast copy designated portions of flash memory from one Rabbit-based board (the

master) to another (the slave) using the Rabbit Cloning Board.

RJ-45 Ethernet Plug

R1

Chassis

Ground

Board

Ground

R1

C23

C17

J6

C20

D1

U4

Y3

Q2

C24

R151

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

C19

R153

R154

R9

R13

R15

C1

Y2

R27C22

C27

R28

U5

J2

J1

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1+RAW +K

GND GND

GND

GND GND

GN D

Remove R1

Add solder lug to

connect ground

wire to chassis

Page 30

26 Wildcat (BL2000)

Alternate Uses of the Serial Programming Port

All three clocked Serial Port A signals are available as

• a synchronous serial port

• an asynchronous serial port, with the clock line usable as a general CMOS input

The serial programming port may also be used as a serial port via the DIAG connector on

the serial programming cable.

In addition to Serial Port A, the Rabbit 2000 startup-mode (SMODE0, SMODE1), status,

and reset pins are available on the serial programming port.

The two startup mode pins determine what happens after a reset—the Rabbit 2000 is

either cold-booted or the program begins executing at address 0x0000. These two

SMODE pins can be used as general inputs once the cold boot is complete.

The status pin is used by Dynamic C to determine whether a Rabbit microprocessor is

present. The status output has three different programmable functions:

1. It can be driven low on the first op code fetch cycle.

2. It can be driven low during an interrupt acknowledge cycle.

3. It can also serve as a general-purpose output.

The /RESET_IN pin is an external input that is used to reset the Rabbit 2000 and the

onboard peripheral circuits on the RabbitCore module. The serial programming port can be

used to force a hard reset on the RabbitCore module by asserting the /RESET_IN signal.

Refer to the Rabbit 2000 Microprocessor User’s Manual for more information.

Page 31

User’s Manual 27

3.5 A/D Converter Inputs

The single 14-channel A/D converter used in the BL2000 has a resolution of 12 bits (models

BL2000 and BL2020) or 10 bits (models BL2010 and BL2030). Eleven of the 14 channels

are available externally, and three are used internally for the reference voltages: 4.096 V

(V

ref

), 2.048 V (V

ref

/2), and Analog Ground. These internal voltages can be used to check

the functioning of the A/D converter.

The A/D converter only measures voltages between 0 V and the applied reference voltage.

Therefore, each external input has circuitry that provides scaling and buffering. The first

four external inputs are scaled and buffered to provide the user with an input impedance of

1 MΩ and a range of -10.24 V to +10.24 V. The remaining five or seven inputs are not

buffered, but are scaled to provide inputs that can range from 0 V to +49 V.

Figure 17 shows the buffered A/D converter inputs.

Figure 17. Buffered A/D Converter Inputs

The op-amp is powered from the +V supply. The 1 MΩ and 200 kΩ resistors set the gain

(scale factor), which is 0.2 in this case. This results in a dynamic input range of 4.096 V ÷

0.2 or 20.48 V. The center point of this range is set by the 1.707 V reference voltage. With

the reference set to 1.707 V, the center point is at 0 V and the input voltage can range from

-10.24 V to +10.24 V. To maintain the best accuracy, the input range should be limited to

-10.0 V to +10.0 V.

The five or seven unbuffered inputs have an impedance of 12 kΩ and a scale factor of

0.0833, which provides for an input voltage range of 0 V to 49.15 V. Accuracy is main-

tained over the specified voltage range from 0 V to 48 V DC.

The analog inputs can also be used as digital inputs when required. In this case a lower

quality 10-bit D/A converter can be used, and the software would assign a 1 or 0 to a voltage based on whether it is above or below a particular threshold. See the

digIn function

description for more information.

100 pF

200 kW

To AD C

1 MW

R

IN

100 pF

ADC0

AGND

+ V

ADC1

Page 32

28 Wildcat (BL2000)

3.6 D/A Converter Outputs

Figure 18 shows the analog voltage reference circuit.

Figure 18. Analog Reference Voltages

This circuit generates the 4.096 V reference voltage, which is used by the A/D converter

and optionally by the two D/A converters. This sets the operating range of the A/D converter and the D/A converters (0–4.096 V). To use the full accuracy of the A/D converter

and the D/A converters, this voltage must be accurate to the same degree.

Under normal operation, the 453 Ω resistor is not installed. The reference zener diode in

combination with the 100 Ω resistor form a shunt regulator. The 4.096 V reference voltage

then feeds the A/D converter, the D/A converters, and the voltage divider composed of the

10 kΩ and the 14 kΩ resistors. The voltage divider generates a second reference voltage of

1.707 V to feed the four op-amps for the buffered A/D converter inputs.

The reference voltage can be ratiometric rather than absolute. This is done by removing

the zener diode and installing the 453 Ω resistor. With this arrangement, the reference

voltages follow changes in the power supply voltages Vcc and V+, which is a filtered version of Vcc. This type of measurement circuit is preferred by some customers whose sensors are powered from the Vcc supply and hence the outputs track Vcc.

A jumper on header JP3 allows the D/A converters to be powered either from the 4.096 V

reference (factory default) or from the analog supply +V. The D/A converters use their

power source also as the reference input, so normally powering the D/A converters from

the more accurate 4.096 V reference is best. However, should a customer desire more

dynamic range (0–5 V rather than 0–4.096 V), the jumper across JP3 can be set to power

the D/A converters from +V. When powered from the +V supply, the outputs of the D/A

converters will always be ratiometric, independent of whether the zener diode is installed.

10 kW

1.707_VREF

14 kW

100 nF

100 nF

100 W

+V

453 W

4.096_VREF

1

3

2

JP3

DAC_PWR

+ V

4.096 V

ref diode

Page 33

User’s Manual 29

Only the BL2000 and the BL2020 models are stuffed with D/A converters. The D/A converters provide only a voltage output. This means that in order to maintain the maximum

accuracy of the D/A converters, only a small amount of current should be drawn from the

D/A converter output (of the order of µA).

With D/A converters installed, the user has the option of using an unbuffered A/D converter input to read the output of a D/A converter or one of the two fixed voltages +V or

Vcc. The standard BL2000 configuration is for A/D converter channels 9 and 10 to monitor D/A converter channels 0 and 1 respectively.

Figure 19 shows the D/A converter outputs with buffer amplifiers, which may be used to

increase the D/A converter output voltage range to 0 V to +10 V.

Figure 19. D/A Converter Outputs

11 kW

10 nF

DAC0

AGND

DAC1

DAC0

ADC

AIN9

1 kW

+

+

Page 34

30 Wildcat (BL2000)

3.7 Memory

Section A.3, “Jumper Configurations,” shows where the 0 Ω surface-mounted “jumpers”

described in this section are found.

3.7.1 SRAM

The BL2000 is designed to accept 128K to 512K of SRAM packaged in an SOIC case.

The standard models come with 128K of SRAM. Table 3 lists the jumper settings for the

jumpers used to set the SRAM size. The “jumpers” are 0 Ω surface-mounted resistors.

3.7.2 Flash Memory

The BL2000 is also designed to accept 128K to 512K of flash memory packaged in a

TSOP case.

The BL2000 comes with one 256K flash memory. Table 3 lists the jumper settings for the

jumpers used to set the SRAM size. The “jumpers” are 0 Ω surface-mounted resistors.

NOTE: Rabbit recommends that any customer applicatio ns sh ould not be constrained by

the sector size of the flash memory since it may be necessary to change the sector size

in the future.

A Flash Memory Bank Select jumper configuration option exists at JP2 with 0 Ω surfacemounted resistors. This option, used in conjunction with some configuration macros,

allows Dynamic C to compile two different co-resident programs for the upper and lower

halves of the 256K flash in such a way that both programs start at logical address 0000.

This is useful for applications that require a resident download manager and a separate

downloaded program. See Technical Note 218, Implementing a Serial Download Man-

ager for a 256K Flash, for details.

Table 3. Memory Jumper Selections

SRAM (JP5) Flash Memory (JP4)

1–2 128K 1–2 128K/256K

2–3 512K 2–3 512K

Page 35

User’s Manual 31

3.8 Programming Cable

The programming cable is used to connect the BL2000’s programming port to a PC serial

COM port. The programming cable converts the RS-232 voltage levels used by the PC

serial port to the TTL voltage levels used by the Rabbit 2000.

When the PROG connector on the programming cable is connected to the BL2000’s

programming header, programs can be downloaded and debugged over the serial interface.

The DIAG connector of the programming cable may be used on the BL2000’s programming

header with the BL2000 operating in the Run Mode. This allows the programming port to

be used as a regular serial port.

3.8.1 Changing Between Program Mode and Run Mode

The BL2000 is automatically in Program Mode when the PROG connector on the programming cable is attached to the BL2000, and is automatically in Run Mode when no

programming cable is attached. When the Rabbit 2000 is reset, the operating mode is

determined by the status of the SMODE pins. When the programming cable’s PROG

connector is attached, the SMODE pins are pulled high, placing the Rabbit 2000 in the

Program Mode. When the programming cable’s PROG connector is not attached, the

SMODE pins are pulled low, causing the Rabbit 2000 to operate in the Run Mode.

Figure 20. BL2000 Program Mode and Run Mode Setup

A program “runs” in either mode, but can only be downloaded and debugged when the

Jackrabbit is in the Program Mode.

Refer to the Rabbit 2000 Microprocessor User’s Manual for more information on the pro-

gramming port and the programming cable.

14

23

L1

D2

J8

POWER IN

J7

TVS1

J10

+

C28

R1

C23

C25

C17

J6

C20

D1

U4

Y3

Q2

C24

R30

R151

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

U1

C2

C3

C19

R153

C18

R154

R9

R13

R15

C1

Y2

R27C22

C27

R28

90

15

65

40

U5

R55

R54

R37

R36

R38

R56

C40

C39

C38R50

R51

R52

R58

R59

R60

C35

C34

C33

C31

+

C29

R33

R31

C36

U6

R32

R34

R35

C41R53

R61

D5

D4

R41

R42

D3

R40

R57

R39

C45

C44

C43

J2

J1

J4

J3

D6

D7 D8 D9

J9

J11

R43 R44

R45

C49C48

C47

C46

+

+

BT1

D

G

S

Q3

Q5

C32

D10

D11 D12

R46

R47

R48

R49

C51

C52

C50

C8

U2

R5

R11

R10

C75

C11

R17

C4

C13

U3

R8

R18

R2

R3

R23

R22

C14

R152

R7

C78

C77

C76

C79

C5

C15

1432

Y1

C26

Q4

Q1

R25

R24

R29

C21

R26

1

56

10

K1

+

C9

R14

C12

R21

C7

J12

DS1

DS4DS3DS2

Q6

C37

C42

DS5

DS6

DS7

DS8

GND

IN3IN2 IN4 IN5 IN6 IN7 IN8 IN9 IN10 OUT8 OUT9 GND GNDOUT0 OUT1 OUT2 OUT3 OUT4 OUT5 OUT6 OUT7 NC

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1 AGNDDAC1 DAC0 ADC8 ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0+RAW +K

NO

COM

GND

GND

GND

GN D

GND

GND

GND

GNDGNDGNDGND

GN D

GND GND

GND

GND GND

GN D

AGND

AGND

AGND

AGND

AGND

AG ND

PWRLNKACTOUT 0OUT 1OUT 2OUT 3BAD

JP2

C85

JP1

R157

Battery

14

23

L1

D2

J8

POWER IN

J7

TVS1

J10

+

C28

R1

C23

C25

C17

J6

C20

D1

U4

Y3

Q2

C24

R30

R151

R4

C16

R20

R6

R12

C10

J5

R19

C80

R16

R130

U1

C2

C3

C19

R153

C18

R154

R9

R13

R15

C1

Y2

R27C22

C27

R28

90

15

65

40

U5

R55

R54

R37

R36

R38

R56

C40

C39

C38R50

R51

R52

R58

R59

R60

C35

C34

C33

C31

+

C29

R33

R31

C36

U6

R32

R34

R35

C41R53

R61

D5

D4

R41

R42

D3

R40

R57

R39

C45

C44

C43

J2

J1

J4

J3

D6

D7 D8 D9

J9

J11

R43 R44

R45

C49C48

C47

C46

+

+

BT1

D

G

S

Q3

Q5

C32

D10

D11 D12

R46

R47

R48

R49

C51

C52

C50

C8

U2

R5

R11

R10

C75

C11

R17

C4

C13

U3

R8

R18

R2

R3

R23

R22

C14

R152

R7

C78

C77

C76

C79

C5

C15

1432

Y1

C26

Q4

Q1

R25

R24

R29

C21

R26

1

56

10

K1

+

C9

R14

C12

R21

C7

J12

DS1

DS4DS3DS2

Q6

C37

C42

DS5

DS6

DS7

DS8

GND

IN3IN2 IN4 IN5 IN6 IN7 IN8 IN9 IN10 OUT8 OUT9 GND GNDOUT0 OUT1 OUT2 OUT3 OUT4 OUT5 OUT6 OUT7 NC

GND RST- IN1 IN0 485- 485+ RXD2 TXD2 RXD1 TXD1 AGNDDAC1 DAC0 ADC8 ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0+RAW +K

NO

COM

GND

GND

GND

GN D

GND

GND

GND

GNDGNDGNDGND

GN D

GND GND

GND

GND GND

GN D

AGND

AGND

AGND

AGND

AGND

AG ND

PWRLNKACTOUT 0OUT 1OUT 2OUT 3BAD

JP2

C85

JP1

R157

Battery

RESET

PIN

Power

Run Mode

Power

Program Mode

RESET BL2000 when changing mode:

Short out RESET pin on header J2 to ground,

OR

Cycle power off/on

after removing or attaching programming cable.

GND

Colored edge

Programming Cable

To

PC COM port

DIAG

PROG

Red

shrink wrap

Page 36

32 Wildcat (BL2000)

3.9 Other Hardware

3.9.1 External Interrupts

BL2000 boards with a Rabbit 2000 microprocessor labeled IQ3T or higher have external

interrupts available on digital inputs IN2 and IN3. Older BL2000 boards (Rabbit 2000

microprocessors labeled IQ2T) have one external interrupt available—see Tech nical Note

TN301, Rabbit 2000 Microprocessor Interrupt Problem, for further information on how

to use this interrupt on the older boards.

3.9.2 Clock Doubler

The BL2000 takes advantage of the Rabbit 2000 microprocessor’s internal clock doubler.

A built-in clock doubler allows half-frequency crystals to be used to reduce radiated emissions. The 22.1 MHz frequency is generated using an 11.0592 MHz crystal. The clock

doubler is disabled automatically in the BIOS for crystals with a frequency above

12.9 MHz.

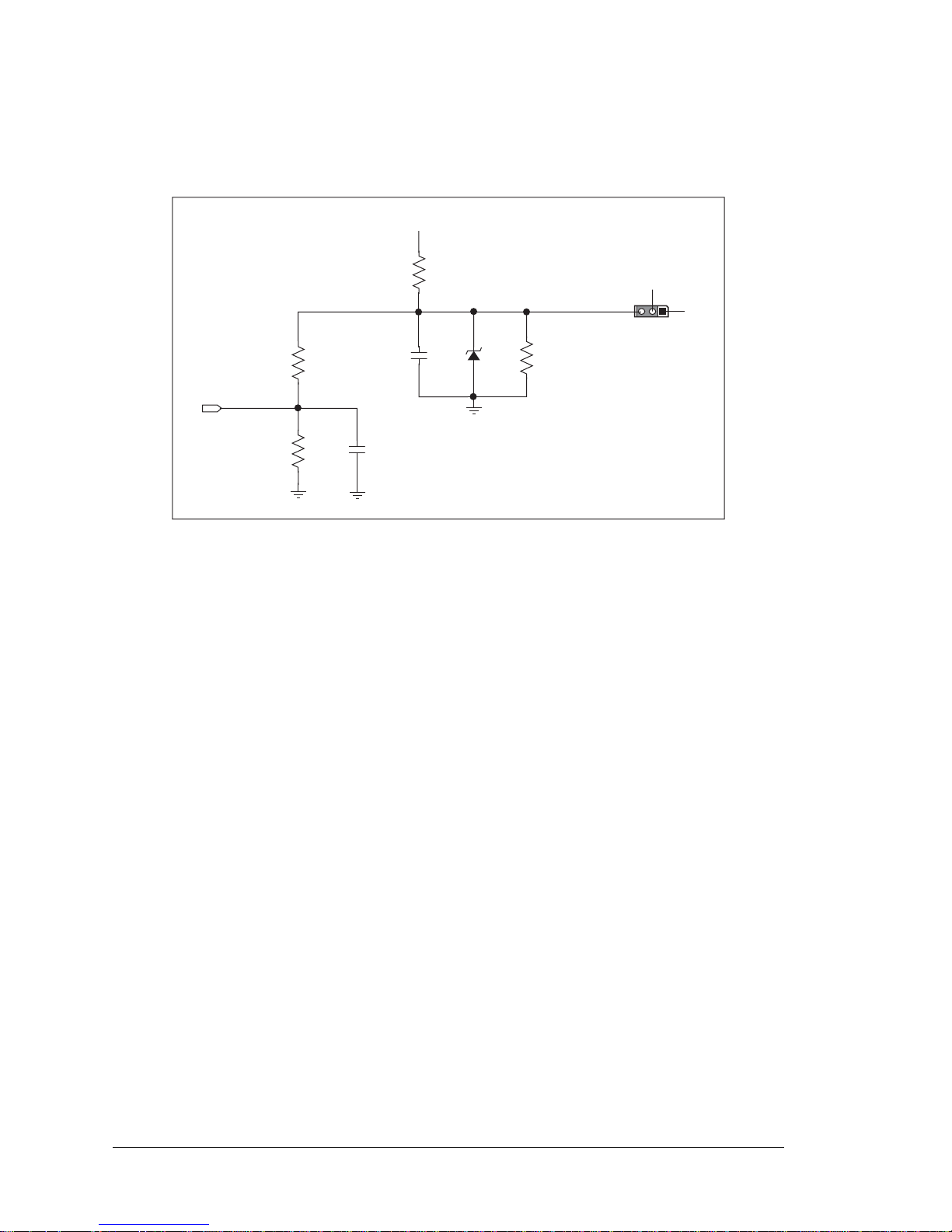

The clock doubler may be disabled if 22.1 MHz clock speeds are not required. Disabling