Page 1

SBC BL2600

C-Programmable Single-Board Computer with Ethernet

User’s Manual

019–0142_N

Page 2

SBC BL2600 User’s Manual

©2020 Digi International® Inc.

All rights reserved.

Rabbit, Dynamic C, RabbitCore, RabbitNet, Digi, Digi International, Digi International Company, and the Digi and Rabbit logos are trademarks or registered trademarks of Digi International, Inc. in the United States and other countries worldwide.

All other trademarks are the property of their respective owners.

Information in this document is subject to change without notice and does not represent a commitment on the part of Digi International.

Digi provides this document "as is," without warranty of any kind, expressed or

implied, including, but not limited to, the implied warranties of fitness or merchantability for a particular purpose. Digi may make improvements and/or changes in this

manual or in the product(s) and/or the program(s) described in this manual at any

time.

This product could include technical inaccuracies or typographical errors. Changes

are periodically made to the information herein; these changes may be incorporated in

new editions of the publication.

The latest revision of this manual is available at www.digi.com.

SBC BL2600

Page 3

TABLE OF CONTENTS

Chapter 1. Introduction 1

1.1 BL2600 Description..............................................................................................................................1

1.2 BL2600 Features...................................................................................................................................1

1.2.1 Connector Options ........................................................................................................................3

1.2.2 Memory and Clock Speed Options ...............................................................................................3

1.3 Development and Evaluation Tools......................................................................................................4

1.3.1 Tool Kit .........................................................................................................................................4

1.3.2 Software ........................................................................................................................................5

1.3.3 Additional Tools ...........................................................................................................................5

1.4 CE Compliance .....................................................................................................................................6

1.4.1 Design Guidelines .........................................................................................................................7

1.4.2 Interfacing the BL2600 to Other Devices .....................................................................................7

Chapter 2. Getting Started 9

2.1 Preparing the BL2600 for Development...............................................................................................9

2.2 BL2600 Connections ..........................................................................................................................10

2.2.1 Hardware Reset ...........................................................................................................................11

2.3 Installing Dynamic C ..........................................................................................................................12

2.4 Starting Dynamic C ............................................................................................................................13

2.5 PONG.C..............................................................................................................................................14

2.6 Where Do I Go From Here? ...............................................................................................................14

Chapter 3. Subsystems 15

3.1 BL2600 Pinouts ..................................................................................................................................16

3.1.1 Connector Options ......................................................................................................................18

3.2 Digital I/O ...........................................................................................................................................19

3.2.1 Digital Inputs...............................................................................................................................19

3.2.2 PWM Outputs .............................................................................................................................20

3.2.3 High-Current Digital Outputs .....................................................................................................21

3.2.4 Configurable I/O .........................................................................................................................23

3.3 Serial Communication ........................................................................................................................25

3.3.1 RS-232 ........................................................................................................................................25

3.3.2 RS-485 ........................................................................................................................................25

3.3.3 Programming Port .......................................................................................................................27

3.3.4 Ethernet Port ...............................................................................................................................28

3.4 A/D Converter Inputs..........................................................................................................................29

3.4.1 A/D Converter Calibration..........................................................................................................30

3.5 D/A Converter Outputs.......................................................................................................................31

3.5.1 D/A Converter Calibration..........................................................................................................32

3.6 Analog Reference Voltage Circuit......................................................................................................33

3.7 Serial Programming Cable..................................................................................................................34

3.7.1 Changing Between Program Mode and Run Mode ....................................................................34

3.8 Other Hardware...................................................................................................................................35

3.8.1 Clock Doubler .............................................................................................................................35

3.8.2 Spectrum Spreader ......................................................................................................................35

User’s Manual

Page 4

3.9 Memory .............................................................................................................................................. 36

3.9.1 SRAM......................................................................................................................................... 36

3.9.2 Flash Memory............................................................................................................................. 36

3.9.3 Serial Flash ................................................................................................................................. 36

3.9.4 NAND Flash............................................................................................................................... 37

Chapter 4. Software 39

4.1 Running Dynamic C........................................................................................................................... 39

4.1.1 Upgrading Dynamic C................................................................................................................ 41

4.2 Sample Programs................................................................................................................................ 42

4.2.1 General BL2600 Sample Programs ............................................................................................ 42

4.2.2 Digital I/O................................................................................................................................... 42

4.2.3 Serial Communication................................................................................................................ 43

4.2.4 A/D Converter Inputs ................................................................................................................. 44

4.2.5 D/A Converter Outputs............................................................................................................... 45

4.2.6 Use of BL2600 with SF1000 Serial Flash Card ......................................................................... 46

4.2.7 Use of NAND Flash ................................................................................................................... 46

4.2.8 Real-Time Clock ........................................................................................................................ 47

4.2.9 TCP/IP Sample Programs........................................................................................................... 47

4.3 BL2600 Libraries ............................................................................................................................... 47

4.4 BL2600 Function Calls ...................................................................................................................... 48

4.4.1 Board Initialization..................................................................................................................... 48

4.4.2 Digital I/O................................................................................................................................... 49

4.4.3 Serial Communication................................................................................................................ 57

4.4.4 A/D Converter Inputs ................................................................................................................. 59

4.4.5 D/A Converter Outputs............................................................................................................... 66

4.4.6 SRAM Use.................................................................................................................................. 70

4.4.7 NAND Flash Drivers.................................................................................................................. 70

Chapter 5. Using the TCP/IP Features 71

5.1 TCP/IP Connections........................................................................................................................... 71

5.2 TCP/IP Sample Programs................................................................................................................... 73

5.2.1 How to Set IP Addresses in the Sample Programs..................................................................... 73

5.2.2 How to Set Up your Computer’s IP Address for a Direct Connection ...................................... 74

5.2.3 Run the

5.2.4 Running More Demo Programs With a Direct Connection ....................................................... 76

5.3 Where Do I Go From Here?............................................................................................................... 76

PINGME.C Demo...................................................................................................... 75

Appendix A. Specifications 77

A.1 Electrical and Mechanical Specifications.......................................................................................... 78

A.1.1 Exclusion Zone .......................................................................................................................... 80

A.1.2 Headers ...................................................................................................................................... 81

A.2 Conformal Coating ............................................................................................................................ 82

A.3 Jumper Configurations ...................................................................................................................... 83

A.4 Use of Rabbit 3000 Parallel Ports ..................................................................................................... 85

Appendix B. Power Supply 87

B.1 Power Supplies .................................................................................................................................. 87

B.1.1 Power for Analog Circuits ......................................................................................................... 88

B.2 Batteries and External Battery Connections...................................................................................... 88

B.2.1 Replacing the Backup Battery ................................................................................................... 88

B.3 Power to Peripheral Boards ............................................................................................................... 89

Appendix C.

Demonstration Board 91

SBC BL2600

Page 5

C.1 Connecting Demonstration Board......................................................................................................91

Appendix D. RabbitNet 95

D.1 General RabbitNet Description..........................................................................................................95

D.1.1 RabbitNet Connections ..............................................................................................................95

D.1.2 RabbitNet Peripheral Cards........................................................................................................96

D.2 Physical Implementation....................................................................................................................97

D.2.1 Control and Routing...................................................................................................................97

D.3 Function Calls ....................................................................................................................................98

D.3.1 Status Byte ...............................................................................................................................104

Schematics 105

Index 107

User’s Manual

Page 6

SBC BL2600

Page 7

The BL2600 is a high-performance, C-programmable singleboard computer that offers built-in digital and analog I/O combined with Ethernet connectivity in a compact form factor. The

BL2600 is ideal for both discrete manufacturing and processcontrol applications.

®

A Rabbit

3000 microprocessor operating at up to 44.2 MHz

provides fast data processing with 10/100Base-T Ethernet connectivity. Serial flash options support a full directory file structures to maximize remote access control and programmability.

The I/O can be expanded with RabbitNet peripheral cards.

1.1 BL2600 Description

1. INTRODUCTION

Throughout this manual, the term BL2600 refers to the complete series of BL2600 singleboard computers unless other production models are referred to specifically.

The BL2600 is an advanced single-board computer that incorporates the powerful Rabbit

3000 microprocessor, flash memory, serial flash options, static RAM, digital I/O ports,

A/D converter inputs, D/A converter outputs, RS-232/RS-485 serial ports, and a

10/100Base-T Ethernet port.

1.2 BL2600 Features

• Rabbit® 3000 microprocessor operating at 29.4 MHz or 44.2 MHz.

• Dual-entry IDC through-hole I/O header sockets allow header mounting on either side

of the BL2600 board.

• Industry-standard friction-lock connectors for power-supply wiring harness.

• 512K static RAM and 512K flash memory standard.

• 36 digital I/O: 16 protected digital inputs, 4 high-current digital outputs software-

configurable as sinking or sourcing, and 16 I/O individually software-configurable as

inputs or sinking outputs.

• 12 analog channels: eight 11-bit A/D converter inputs, four 12-bit D/A converter 0–10 V

or ±10 V buffered outputs.

User’s Manual 1

Page 8

• One RJ-45 Ethernet port compliant with IEEE 802.3 standard for 10/100Base-T

Ethernet protocol.

• Up to 5 serial ports:

Three serial ports (2 RS-232 or 1 RS-232 with RTS/CTS, 1 RS-485 or RS-232).

Two RabbitNet™ expansion ports multiplexed from one serial port.

One serial port dedicated to programming/debugging.

• Provision to install optional SF1000 serial flash, other memory options have provision

for removable memory cards.

• Battery-backed real-time clock.

• Watchdog supervisor.

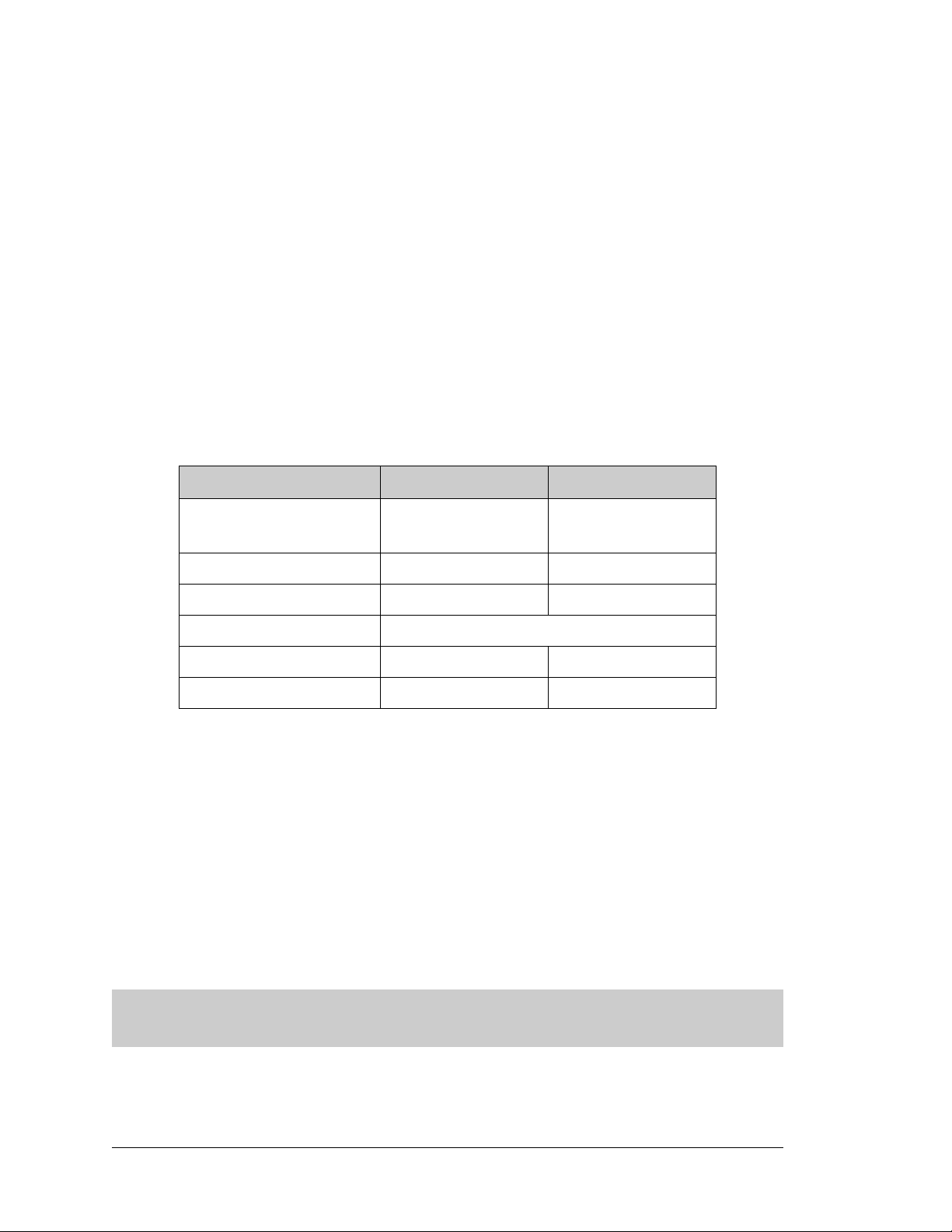

Two BL2600 models are available. Their standard features are summarized in Table 1.

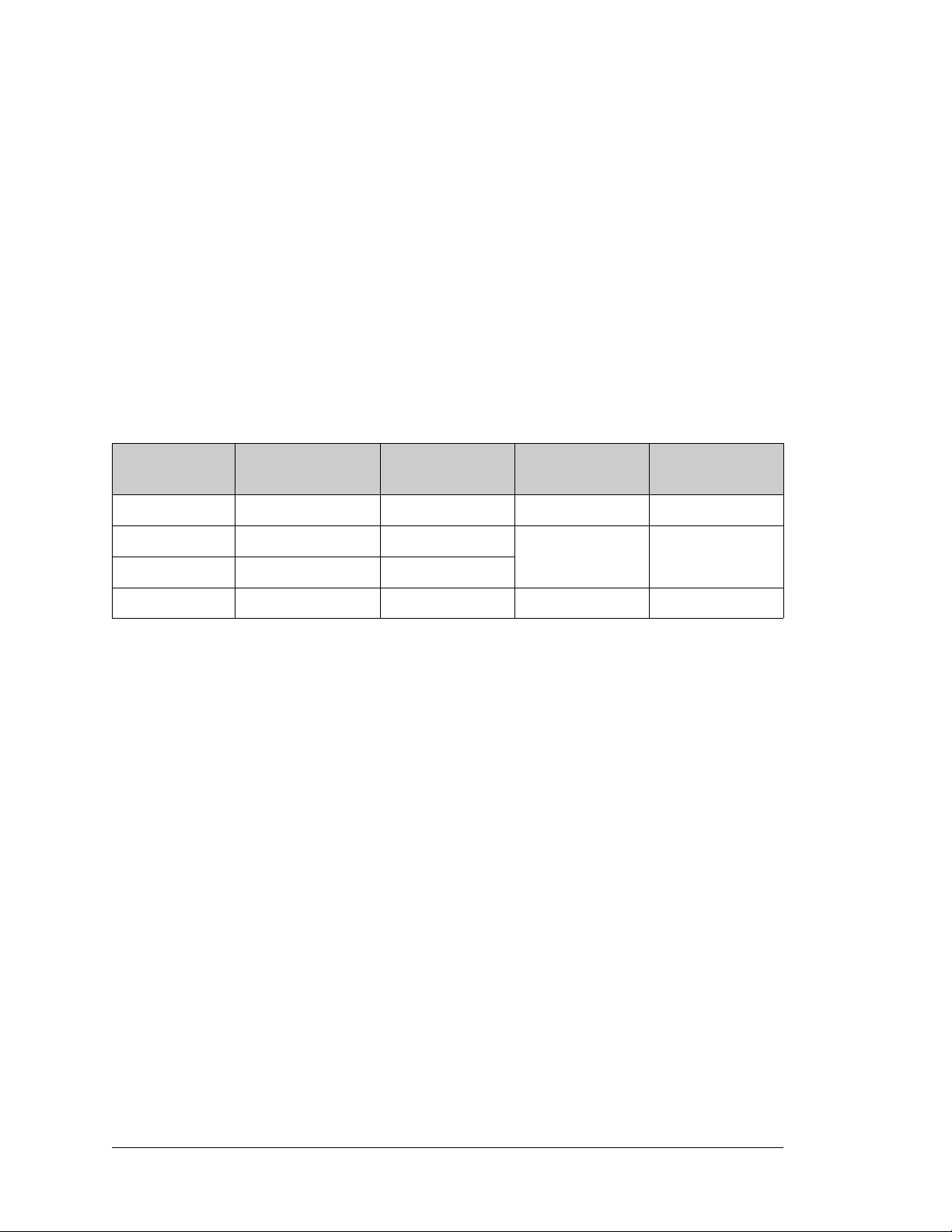

Table 1. BL2600 Models

Feature BL2600 BL2610

®

Microprocessor

Program Execution SRAM 512K —

Rabbit

3000 running at

44.2 MHz

Rabbit® 3000 running at

29.4 MHz

Data SRAM 256K 512K

Flash Memory 512K

Ethernet Port 10/100Base-T, 3 LEDs —

RabbitCore Module Used RCM3200 RCM3100

Additional memory and clock speed options are available, and are described in

Section 1.2.2.

The BL2600 consists of a main board with a RabbitCore module. Refer to the RabbitCore

module manuals, available on the Web s ite, for more information on the RabbitCore modules, including their schematics.

The BL2600 is programmed over a standard PC serial port through a programming cable

supplied with the Tool Kit, and can also be programed through a USB port with an

RS-232/USB converter, or over an Ethernet with the RabbitLink (both available from Rabbit).

Appendix A provides detailed specifications.

Visit the Web si te for up-to-date information about additional add-ons and features as

they become available. The Web site also has the latest revision of this user’s manual.

2 SBC BL2600

Page 9

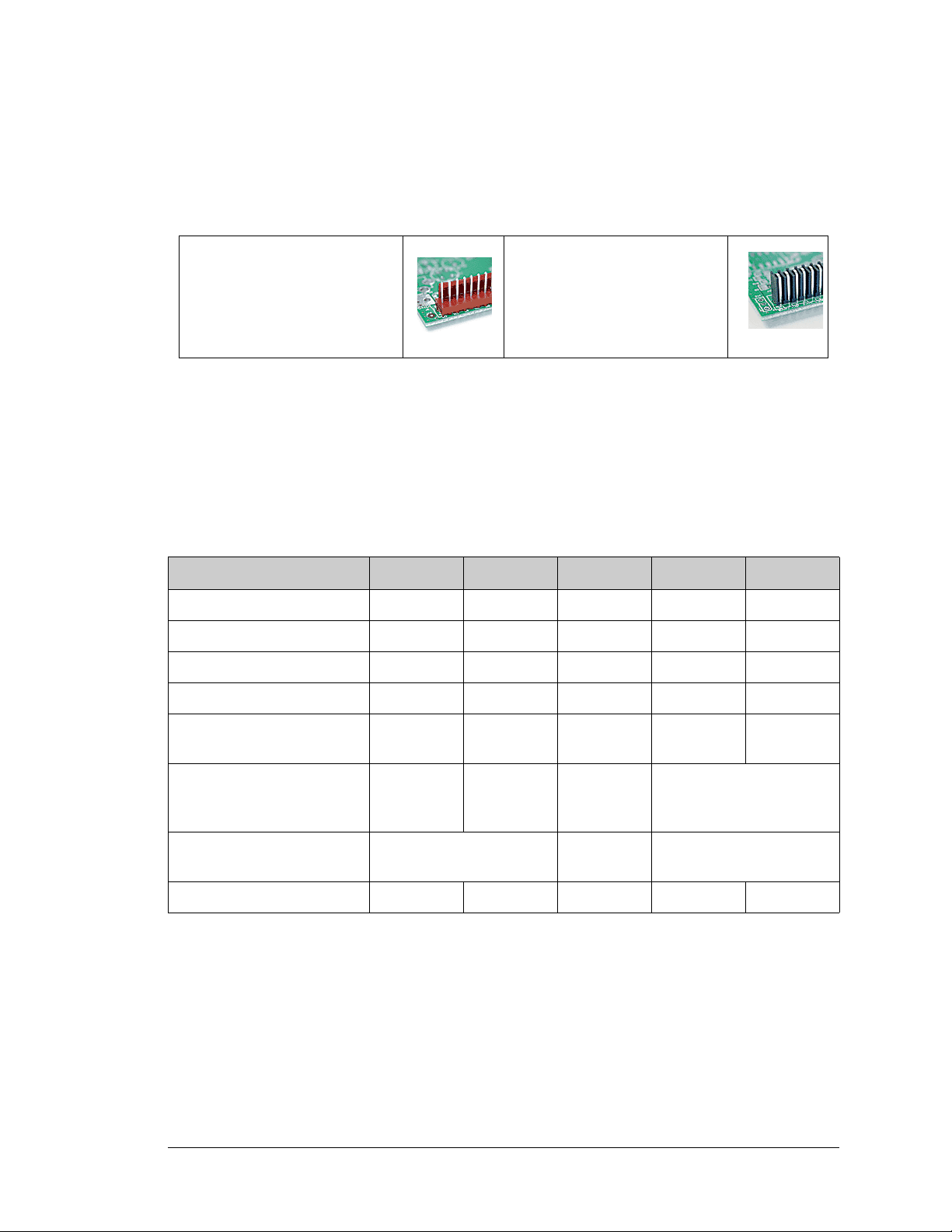

1.2.1 Connector Options

In addition to the standard polarized friction-lock connectors supplied on BL2600 boards,

dual-entry 0.1" IDC sockets can be used to connect to the BL2600 either from the top or

the bottom.

Standard polarized friction-lock

terminals, 0.1" pitch

0.1" IDC sockets can accept

header pins from either top or

bottom

1.2.2 Memory and Clock Speed Options

In addition to the two standard production models of the BL2600, the concept of pairing a

RabbitCore module with the BL2600 “motherboard” allows for additional versions of the

BL2600 to be offered for custom orders involving nominal lead times. These additional

versions and their part numbers are listed below.

Table 2. Additional BL2600 Memory, Clock Speed, and Ethernet Options

Feature 101-0906 101-0907 101-0908 101-1095 101-1096

Clock Speed 29.4 MHz 29.4 MHz 29.4 MHz 44.2 MHz 44.2 MHz

Program Execution SRAM — — — 512K 512K

Data SRAM 512K128K128K512K512K

Flash Memory (program) 512K 256K 256K 512K 512K

NAND Flash Memory

(mass data storage, fixed)

NAND Flash Memory

(mass data storage, removable

memory card)

Ethernet Port

RabbitCore Module Used RCM3000 RCM3010 RCM3110 RCM3365 RCM3375

— — — 16 Mbytes —

up to 128 Mbytes

10/100-compatible

10Base-T interface

— 10/100Base-T

Check the Web si te or contact your Digi sales representative or authorized distributor for

more information.

User’s Manual 3

Page 10

1.3 Development and Evaluation Tools

1.3.1 Tool Kit

A Tool Kit contains the hardware essentials you will need to use your own BL2600 singleboard computer. The items in the Tool Kit and their use are as follows.

• Getting Started instructions.

• Dynamic C CD-ROM, with complete product documentation on disk.

• Programming cable, used to connect your PC serial port to the BL2600.

• Universal AC adapter, 12 V DC, 1 A (includes Canada/Japan/U.S., Australia/N.Z.,

U.K., and European style plugs).

9 to 36 V DC at 12 W

.

• Stand-offs to serve as legs for the BL2600 board during development.

• Demonstration Board with pushbutton switches and LEDs. The Demonstration Board

can be hooked up to the BL2600 to demonstrate the I/O and the TCP/IP capabilities of

the BL2600.

• Wire assembly to connect Demonstration Board to BL2600.

• Connector pins and parts to build your own wire assemblies: 0.1" crimp terminals;

0.156" crimp terminals; 1 × 4, 1 × 10, and 1 × 13 friction-lock connectors.

If you are using another power supply, it must provide

• Rabbit 3000 Processor Easy Reference poster.

• Registration card.

4 SBC BL2600

Page 11

Figure 1. BL2600 Tool Kit

1.3.2 Software

The BL2600 is programmed using version 8.51 or later of Rabbit’s Dynamic C. A compat-

ible version is included on the Tool Kit CD-ROM.

Digi also offers add-on Dynamic C modules for purchase containing the popular µC/OS-II

real-time operating system, as well as PPP, Advanced Encryption Standard (AES), and

other select libraries. In addition to the Web-based technical support included at no extra

charge, a one-year telephone-based technical support module is also available for purchase. Visit our Web site at www.digi.com or contact your Digi sales representative or

authorized distributor for further information.

1.3.3 Additional Tools

Rabbit also has available additional programming tools and parts to help you to make your

own wiring assemblies with the friction-lock connectors.

• An RS-232/USB converter cable (Part No. 540-0070) is available for use with the

programming cable supplied with the Tool Kit. You will need such a converter if your

PC only has a USB port.

• Crimp tool (Part No. 998-0013) to secure wire in crimp terminals.

Visit our Web site at www.digi.com or contact your Digi sales representative or authorized

distributor for further information.

User’s Manual 5

Page 12

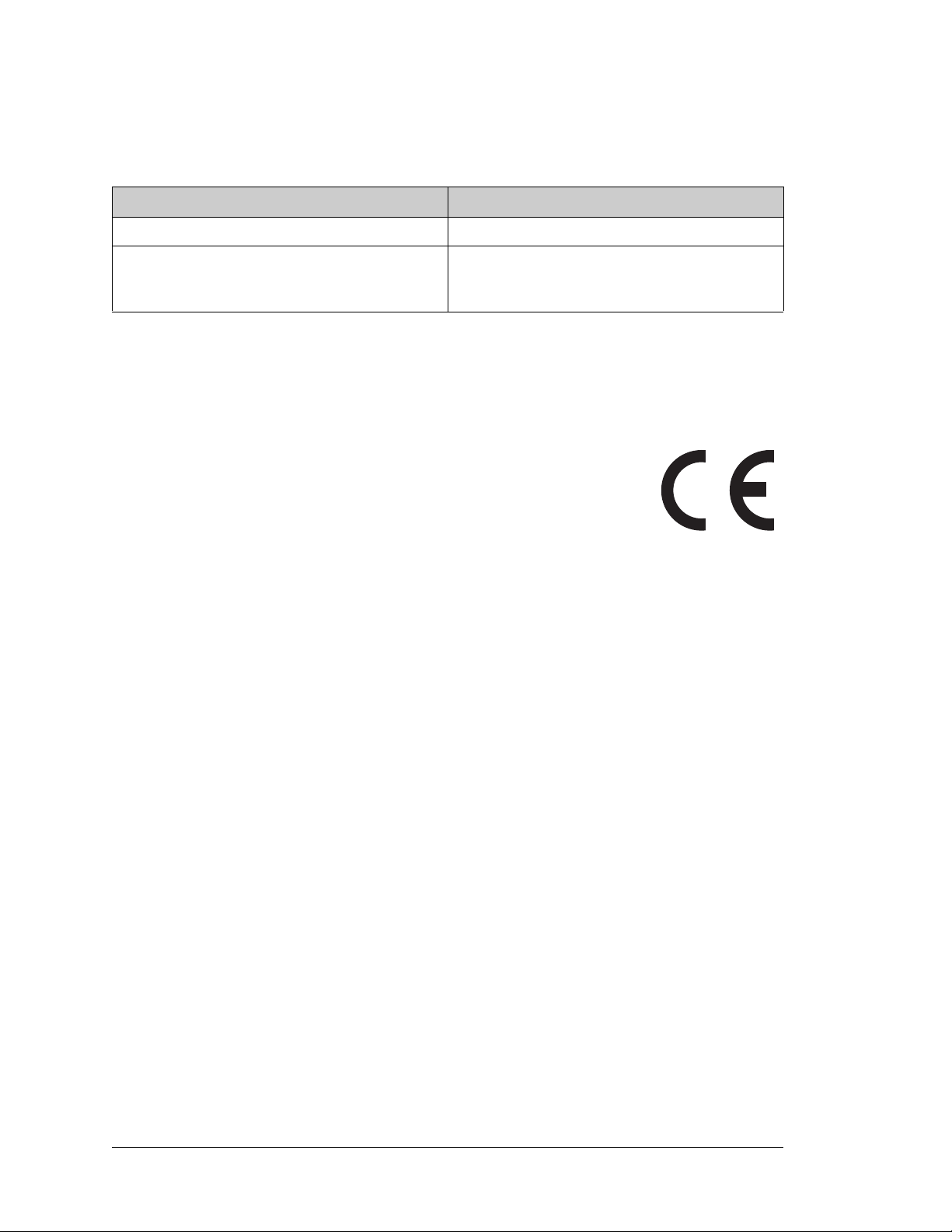

1.4 CE Compliance

Equipment is generally divided into two classes.

CLASS A CLASS B

Digital equipment meant for light industrial use Digital equipment meant for home use

Less restrictive emissions requirement:

less than 40 dB µV/m at 10 m

(40 dB relative to 1 µV/m) or 300 µV/m

More restrictive emissions requirement:

30 dB µV/m at 10 m or 100 µV/m

These limits apply over the range of 30–230 MHz. The limits are 7 dB higher for frequencies above 230 MHz. Although the test range goes to 1 GHz, the emissions from Rabbitbased systems at frequencies above 300 MHz are generally well below background noise

levels.

The BL2600 single-board computer has been tested and was found to

be in conformity with the following applicable immunity and emission

standards. The BL2610 single-board computer is also CE qualified as it

is a sub-version of the BL2600 single-board computer. Boards that are

CE-compliant have the CE mark.

NOTE: Earlier versions of the BL2600 that do not have the CE mark are not CE-compliant.

Immunity

The BL2600 series of single-board computers meets the following EN55024/1998 immunity standards.

• EN61000-4-3 (Radiated Immunity)

• EN61000-4-4 (EFT)

• EN61000-4-6 (Conducted Immunity)

Additional shielding or filtering may be required for a heavy industrial environment.

Emissions

The BL2600 series of single-board computers meets the following emission standards.

• EN55022:1998 Class B

• FCC Part 15 Class B

Your results may vary, depending on your application, so additional shielding or filtering

may be needed to maintain the Class B emission qualification.

6 SBC BL2600

Page 13

1.4.1 Design Guidelines

Note the following requirements for incorporating the BL2600 series of single-board

computers into your application to comply with CE requirements.

General

• The power supply provided with the Tool Kit is for development purposes only. It is the

customer’s responsibility to provide a CE-compliant power supply for the end-product

application.

• When connecting the BL2600 single-board computer to outdoor cables, the customer is

responsible for providing CE-approved surge/lightning protection.

• Rabbit recommends placing digital I/O or analog cables that are 3 m or longer in a

metal conduit to assist in maintaining CE compliance and to conform to good cable

design practices.

• When installing or servicing the BL2600, it is the responsibility of the end-user to use

proper ESD precautions to prevent ESD damage to the BL2600.

Safety

• All inputs and outputs to and from the BL2600 series of single-board computers must

not be connected to voltages exceeding SELV levels (42.4 V AC peak, or 60 V DC).

• The lithium backup battery circuit on the BL2600 single-board computer has been

designed to protect the battery from hazardous conditions such as reverse charging and

excessive current flows. Do not disable the safety features of the design.

1.4.2 Interfacing the BL2600 to Other Devices

Since the BL2600 series of single-board computers is designed to be connected to other

devices, good EMC practices should be followed to ensure compliance. CE compliance is

ultimately the responsibility of the integrator. Additional information, tips, and technical

assistance are available from your authorized Rabbit distributor, and are also available on

our Web site at www.digi.com.

User’s Manual 7

Page 14

8 SBC BL2600

Page 15

2. GETTING STARTED

J15

J16

AIN0

AIN1

AIN2

AIN3

JP6

420 mA

AV0 AV1 AV2 AV3 AI0 AI1 AI2 AI3 AGND

GND HOUT0 +HK1 GND HOUT2 +HK3 GND

+HK0 GND HOUT1 +HK2 GND HOUT3

TXC TXF TXE 485 GND

GND RXC RXF RXE 485+

J17

GND HOUT0 +HK1 GND HOUT2 +HK3 GND

+HK0 GND HOUT1 +HK2 GND HOUT3

TXC TXF TXE 485

AIN1 AIN3 AIN5 AIN7 AGND AV1 AV3 AI1 AI3 AGND

AIN0 AIN2 AIN4 AIN6 AGND AV0 AV2 AI0 AI2 AGND

J11

20

19

R43

JP6

R44

R39

R38

R20

R33

R34

U13

R22

R21

R17

C18

C19

U12

R15

C13

R16

C10

R10

U11

J8

R14 R13 C11

AIN0 AIN1 AIN2 AIN3 AIN4 AIN5 AIN6 AIN7 AGND

C12 R12 R11

U10

BT1

C26

C27

D1

U15

C25

J12

J13

C22

R55

R42

C23

C24

R41

R40

R

35

R36

R37

U14

R26

R28

R30

R19

R29

R32

R31

R56

R57

L1

R27R25

R23R

24

C20

C21

R18

C16

1

2

25

26

RXE

J14

Q19

D3

Q17D2Q18

RXC

D4

Q20

C34

RXF

485+

C35 C36 C37

JP7

485 TERM.

RESISTOR

C30

R58

R59

R60

U18

C32

C33

RCM2

U17

C31

R9

U16

R8

J10

R7

GND/EGND

RP5

RP6

U2

C4

R5

C5

R6

C6

U4

JA

RCM1

RCM3000 ETHERNET CORE MODULE

U3

RP17 RP18

34

33

16

15

1

2

1

2

15

16

33

34

C1

U1

RP3

RP4

GND

+K

DCIN

+5V

JP3,

JP4

AND

JP4

JP1 AND JP2

GND

+K

DCIN

+5V

J4 RABBITNET 1

J6 RABBITNET 0

J7

C14

C17

C15

C78

J9

C9

U9

RP16

C8

U8

R4

R3

RP15

RP14

RP12

RP13

RP11

R1

R2

C7

U6

U7

U5

RP8

RP7

RP9

RP10

C2

Q9

Q10

J5

Q12

Q15Q14 Q16

Q11

Q13

C3

Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8

JP2

JP1

J1

J2

GND DIN28 DIN24 DIN20 DIN16 GND DIO12 DIO08 DIO04 DIO00

DIN30 DIN26 DIN22 DIN18 +K DIO14 DIO10 DIO06 DIO02 GND

DIN31 DIN27 DIN23 DIN19 +K DIO15 DIO11 DIO07 DIO03 GND

GND DIN29 DIN25 DIN21 DIN17 GND DIO13 DIO09 DIO05 DIO01

GND DIO14 DIO12 DIO10 DIO08 DIO06 DIO04 DIO02 DIO00 GND

+K DIO15 DIO13 DIO11 DIO09 DIO07 DIO05 DIO03 DIO01 GND

GND DIN30 DIN28 DIN26 DIN24 GND DIN22 DIN20 DIN18 DIN16

DIN31 DIN29 DIN27 DIN25 +K DIN23 DIN21 DIN19 DIN17 GND

DIO 0007 PULLS

DIO 0815 PULLS

1

2

39

40

SW1

J3

1

2

DCIN DCIN GND GND

R111

R112

RESET

RP2

RP1

JP3

DIN 1619 PULLS

JP4

DIN 2023 PULLS

DIN 2431 PULLS

JP5

R84

C28

1

2

DS1

U1

U6

R28

R38

R41

C5

C3

C9

C8

C12

C17

C23

C30

C18

C29

C35

C33

R29

R37

R39

R40

R42

Y3

C42

R35

R31

R27

R25

DS1

R67

R70

J4

C79

Y4

C83

C86

GND

R75

R74

R71

DS3

DS2

R63 R64

C71

C72

C68

C64

C67

L2

U8

R49

R48

C62

R51

C61

R44

R47

C59

C49

C57

L1

R69

R72

R73

C75

C74

R58

C53

C47

C48

C45

C44

C43

JP5

C31

JP3

JP4

C28

C27

C37

C36

C32

R24

R22

C19

R23

C24

R20

C20

R19

C16

C15

R17

R18

R7

R9

R1

R8

C1

R10

R14

C4

SPD LNK ACT

J3

U5

U4

D1

Q1

C39

RP1

RabbitCore

Module

Chapter 2 explains how to connect the programming cable and

power supply to the BL2600.

2.1 Preparing the BL2600 for Development

Position the BL2600 as shown below in Figure 2. Attach the four standoffs supplied with

the Tool Kit in the holes at the corners as shown.

Figure 2. Attach Standoffs to BL2600 Board

The standoffs facilitate handling the BL2600 during development, and protect the bottom

of the printed circuit board against scratches or short circuits while you are working with

the BL2600.

User’s Manual 9

Page 16

2.2 BL2600 Connections

J15

J16

AIN0

AIN1

AIN2

AIN3

JP6

420 mA

AV0 AV1 AV2 AV3 AI0 AI1 AI2 AI3 AGND

GND HOUT0 +HK1 GND HOUT2 +HK3 GND

+HK0 GND HOUT1 +HK2 GND HOUT3

TXC TXF TXE 485 GND

GND RXC RXF RXE 485+

J17

GND HOUT0 +HK1 GND HOUT2 +HK3 GND

+HK0 GND HOUT1 +HK2 GND HOUT3

TXC TXF TXE 485

AIN1 AIN3 AIN5 AIN7 AGND AV1 AV3 AI1 AI3 AGND

AIN0 AIN2 AIN4 AIN6 AGND AV0 AV2 AI0 AI2 AGND

J11

20

19

R43

JP6

R44

R39

R38

R20

R33

R34

U13

R22

R21

R17

C18

C19

U12

R15

C13

R16

C10

R10

U11

J8

R14 R13 C11

AIN0 AIN1 AIN2 AIN3 AIN4 AIN5 AIN6 AIN7 AGND

C12 R12 R11

U10

BT1

C26

C27

D1

U15

C25

J12

J13

C22

R55

R42

C23

C24

R41

R40

R35

R36

R37

U14

R26

R28

R30

R19

R29

R32

R31

R56

R57

L1

R27R25

R23

R24

C20

C21

R18

C16

1

2

25

26

RXE

J14

Q19

D3

Q17D2Q18

RXC

D4

Q20

C34

RXF

485+

C35 C36 C37

JP7

485 TERM.

RESISTOR

C30

R58

R59

R60

U18

C32

C33

RCM2

U17

C31

R9

U16

R8

J10

R7

GND/EGND

RP5

RP6

U2

C4

R5

C5

R6

C6

U4

JA

RCM1

RCM3000 ETHERNET CORE MODULE

U3

RP17 RP18

34

33

16

15

1

2

1

2

15

16

33

34

C1

U1

RP3

RP4

GND

+K

DCIN

+5V

JP3,

JP4

AND

JP4

JP1 AND JP2

GND

+K

DCIN

+5V

J4 RABBITNET 1

J6 RABBITNET 0

J7

C14

C17

C15

C78

J9

C9

U9

RP16

C8

U8

R4

R3

RP15

RP14

RP12

RP13

RP11

R1

R2

C7

U6

U7

U5

RP8

RP7

RP9

RP10

C2

Q9

Q10

J5

Q12

Q15Q14 Q16

Q11

Q13

C3

Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8

JP2

JP1

J1

J2

GND DIN28 DIN24 DIN20 DIN16 GND DIO12 DIO08 DIO04 DIO00

DIN30 DIN26 DIN22 DIN18 +K DIO14 DIO10 DIO06 DIO02 GND

DIN31 DIN27 DIN23 DIN19 +K DIO15 DIO11 DIO07 DIO03 GND

GND DIN29 DIN25 DIN21 DIN17 GND DIO13 DIO09 DIO05 DIO01

GND DIO14 DIO12 DIO10 DIO08 DIO06 DIO04 DIO02 DIO00 GND

+K DIO15 DIO13 DIO11 DIO09 DIO07 DIO05 DIO03 DIO01 GND

GND DIN30 DIN28 DIN26 DIN24 GND DIN22 DIN20 DIN18 DIN16

DIN31 DIN29 DIN27 DIN25 +K DIN23 DIN21 DIN19 DIN17 GND

DIO 0007 PULLS

DIO 0815 PULLS

1

2

39

40

SW1

J3

1

2

DCIN DCIN GND GND

R111

R112

RESET

RP2

RP1

JP3

DIN 1619 PULLS

JP4

DIN 2023 PULLS

DIN 2431 PULLS

JP5

R84

C28

1

2

DS1

U1

U6

R28

R38

R41

C5

C3

C9

C8

C12

C17

C23

C30

C18

C29

C35

C33

R29

R37

R39

R40

R42

Y3

C42R35

R31

R27

R25

DS1

R67

R70

J4

C79

Y4

C83

C86

GND

R75

R74

R71

DS3

DS2

R63 R64

C71

C72

C68

C64

C67

L2

U8

R49

R48

C62

R51

C61

R44

R47

C59

C49

C57

L1

R69

R72

R73

C75

C74

R58

C53

C47

C48

C45

C44

C43

JP5

C31

JP3

JP4

C28

C27

C37

C36

C32

R24

R22

C19

R23

C24

R20

C20

R19

C16

C15

R17

R18

R7

R9

R1

R8

C1

R10

R14

C4

SPD LNK ACT

J3

U5

U4

D1

Q1

C39

RP1

DIAG

PROG

Colored edge

To

PC COM port

Programming Cable

PROG

J1

Color

shrink wrap

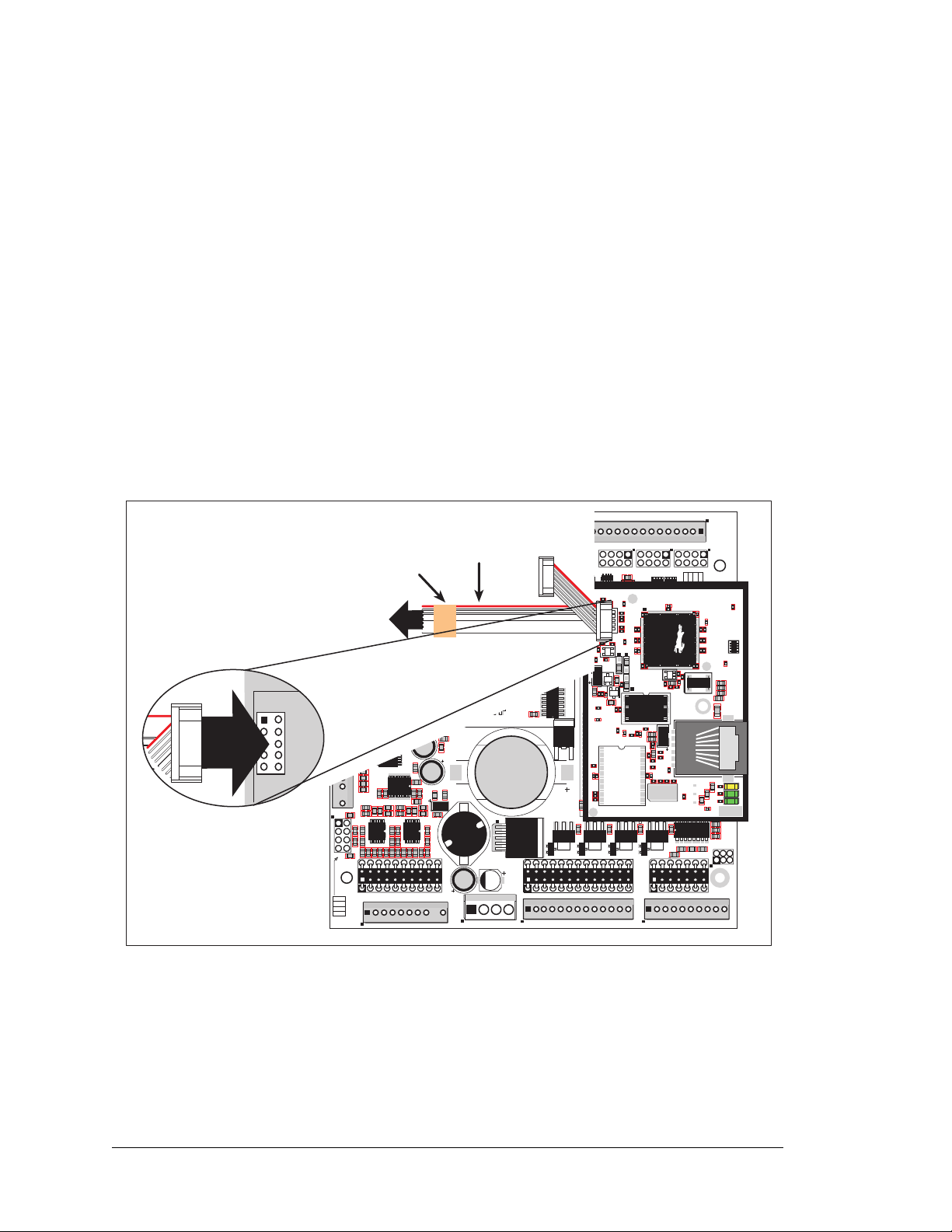

1. Connect the programming cable to download programs from your PC and to program

and debug the BL2600.

NOTE: Use only the programming cable that has a blue shrink wrap around the RS-232

level converter (Part No. 101-0542). If you are using a BL2610, which is based on the

RCM3100, you will need the programming cable that has a red shrink wrap around the

RS-232 level converter (Part No. 101-0513). Other programming cables are not

voltage-compatible or their connector sizes may be different.

Connect the 10-pin PROG connector of the programming cable to header J3 on the

BL2600’s RabbitCore module (the programming header is labeled J1 on special-edition

BL2600s based on the RCM3365/RCM3375). Ensure that the colored edge lines up with

pin 1 as shown. (Do not use the DIAG connector, which is used for monitoring only.) Connect the other end of the programming cable to a COM port on your PC. Make a note of

the port to which you connect the cable, as Dynamic C will need to have this parameter

configured. Note that COM1 on the PC is the default COM port used by Dynamic C.

NOTE: Some PCs now come equipped with a USB port only. It may be possible to use

10 SBC BL2600

an RS-232/USB converter (Part No. 20-151-0178) with the programming cables mentioned above. Note that not all RS-232/USB converters work with Dynamic C.

Figure 3. Programming Cable Connections

Page 17

2. When all other connections have been made, you can connect power to the BL2600.

First, prepare the AC adapter for the country where it will be used by selecting the plug.

The BL2600 Tool Kit presently includes Canada/Japan/U.S., Australia/N.Z., U.K., and

European style plugs. Snap the top of the plug assembly into the slot at the top of the

AC adapter as shown in Figure 4, then press down on the spring-loaded clip below the

plug assembly to allow the plug assembly to click into place.

Connect the AC adapter to header J12 on the BL2600 as shown in Figure 4. You can

use the crimps and the friction-lock connector included in the Tool Kit to connect the

leads from the power supply, then match the friction lock tab on the friction-lock connector to the back of header J12 on the BL2600 as shown. The friction-lock connector

will only fit one way.

Figure 4. Power Supply Connections

3. Apply power.

Plug in the AC adapter. The power LED will light up when the BL2600 is powered up

correctly.

CAUTION: Unplug the AC adapter while you make or otherwise work with the connections

to the headers. This will protect your BL2600 from inadvertent shorts or power spikes.

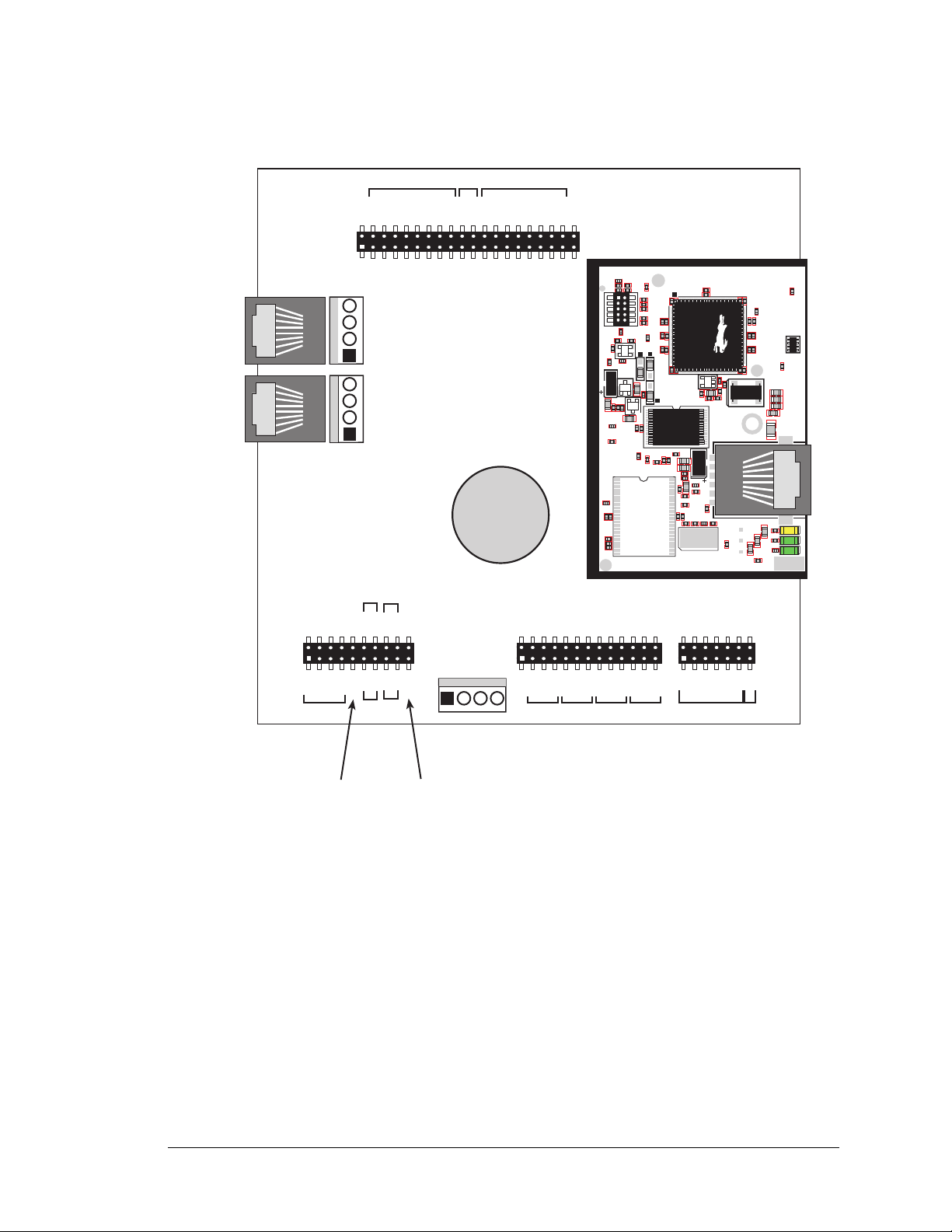

2.2.1 Hardware Reset

A hardware reset is done by unplugging the ACV adapter, then plugging it back in, or by

pressing the RESET button located just above the RabbitCore module.

User’s Manual 11

Page 18

2.3 Installing Dynamic C

If you have not yet installed Dynamic C version 8.51 (or a later version), do so now by

inserting the Dynamic C CD from the BL2600 Tool Kit in your PC’s CD-ROM drive. The

CD will auto-install unless you have disabled auto-install on your PC.

If the CD does not auto-install, click Start > Run from the Windows Start button and

browse for the Dynamic C setup.exe file on your CD drive. Click OK to begin the

installation once you have selected the setup.exe file.

The online documentation is installed along with Dynamic C, and an icon for the documentation menu is placed on the workstation’s desktop. Double-click this icon to reach the

menu. If the icon is missing, create a new desktop icon that points to default.htm in the

docs folder, found in the Dynamic C installation folder.

The latest versions of all documents are always available for free, unregistered download

from our Web sites as well.

The Dynamic C User’s Manual provides detailed instructions for the installation of

Dynamic C and any future upgrades.

NOTE: If you have an earlier version of Dynamic C already installed, the default instal-

lation of the later version will be in a different folder, and a separate icon will appear on

your desktop.

Once your installation is complete, you will have up to three icons on your PC desktop.

One icon is for Dynamic C, one opens the documentation menu, and the third is for the

Rabbit Field Utility, a tool used to download pre-compiled software to a target system.

If you have purchased any of the optional Dynamic C modules, install them after installing

Dynamic C. The modules may be installed in any order. You must install the modules in

the same directory where Dynamic C was installed.

12 SBC BL2600

Page 19

2.4 Starting Dynamic C

Once the BL2600 is connected to your PC and to a power source, start Dynamic C by

double-clicking on the Dynamic C icon on your desktop or in your Start menu.

If you are using a USB port to connect your computer to the BL2600, choose Options >

Project Options

Communications tab. Click OK to save the settings.

If you are using a BL2600 model running at 44.2 MHz, set the compiler to run the application in the fast program execution SRAM by selecting “Code and BIOS in Flash, Run in

RAM” in the “BIOS Memory Setting” on the Compiler tab under the Options > Project

Options

menu. Click OK to save the settings.

Dynamic C defaults to using the serial port on your PC that you specified during installation. If the port setting is correct, Dynamic C should detect the BL2600 and go through a

sequence of steps to cold-boot the BL2600 and to compile the BIOS. (Some versions of

Dynamic C will not do the initial BIOS compile and load until the first time you compile a

program.)

If you receive the message No Rabbit Processor Detected, the programming

cable may be connected to the wrong COM port, a connection may be faulty, or the target

system may not be powered up. First, check both ends of the programming cable to ensure

that it is firmly plugged into the PC and the programming port.

and check “Use USB to Serial Converter” in “Serial Options” on the

If there are no faults with the hardware, select a different COM port within Dynamic C.

On your computer, open Control Panel > System > Hardware > Device Manager >

Ports

and look at the list of available COM ports. In Dynamic C, select Options > Proj-

ect Options

, then select one of these available COM ports on the Communications tab,

then click OK. Press <Ctrl-Y> to force Dynamic C to recompile the BIOS. If Dynamic C still

reports it is unable to locate the target system, repeat the above steps for another available

COM port. You should receive a Bios compiled successfully message once this

step is completed successfully.

If Dynamic C appears to compile the BIOS successfully, but you then receive a communication error message when you compile and load a sample program, it is possible that your

PC cannot handle the higher program-loading baud rate. Try changing the maximum

download rate to a slower baud rate as follows.

• Locate the Serial Options dialog in the Dynamic C Options > Communications

menu. Select a slower Max download baud rate. Click OK to save the settings.

If a program compiles and loads, but then loses target communication before you can

begin debugging, it is possible that your PC cannot handle the default debugging baud

rate. Try lowering the debugging baud rate as follows.

• Locate the Serial Options dialog in the Dynamic C Options > Communications

menu. Choose a lower debug baud rate. Click OK to save the settings.

User’s Manual 13

Page 20

2.5 PONG.C

You are now ready to test your set-up by running a sample program.

Find the file PONG.C, which is in the Dynamic C SAMPLES folder. To run the program,

open it with the File menu (if it is not still open), compile it using the Compile menu, and

then run it by selecting Run in the Run menu. The STDIO window will open and will display a small square bouncing around in a box.

This program shows that the CPU is working. The sample program described in

Section 5.2.3, “Run the PINGME.C Demo,” tests the TCP/IP portion of the board.

2.6 Where Do I Go From Here?

NOTE: If you purchased your BL2600 through a distributor or Rabbit partner, contact

the distributor or partner first for technical support.

If there are any problems at this point:

• Use the Dynamic C Help menu to get further assistance with Dynamic C.

• Check the Rabbit Technical Bulletin Board and forums at www.rabbit.com/support/bb/

and at www.rabbit.com/forums/.

• Use the Technical Support e-mail form at www.rabbit.com/support/questionSubmit.shtml.

If the sample program ran fine, you are now ready to go on to explore other BL2600 features and develop your own applications.

Chapter 3, “Subsystems,” provides a description of the BL2600’s features, Chapter 4,

“Software,” describes the Dynamic C software libraries and introduces some sample programs, and Chapter 5, “Using the TCP/IP Features,” explains the TCP/IP features.

14 SBC BL2600

Page 21

3. SUBSYSTEMS

SRAM

32 kHz

osc

RabbitCore Module

RABBIT

3000

Battery-Backup

Circuit

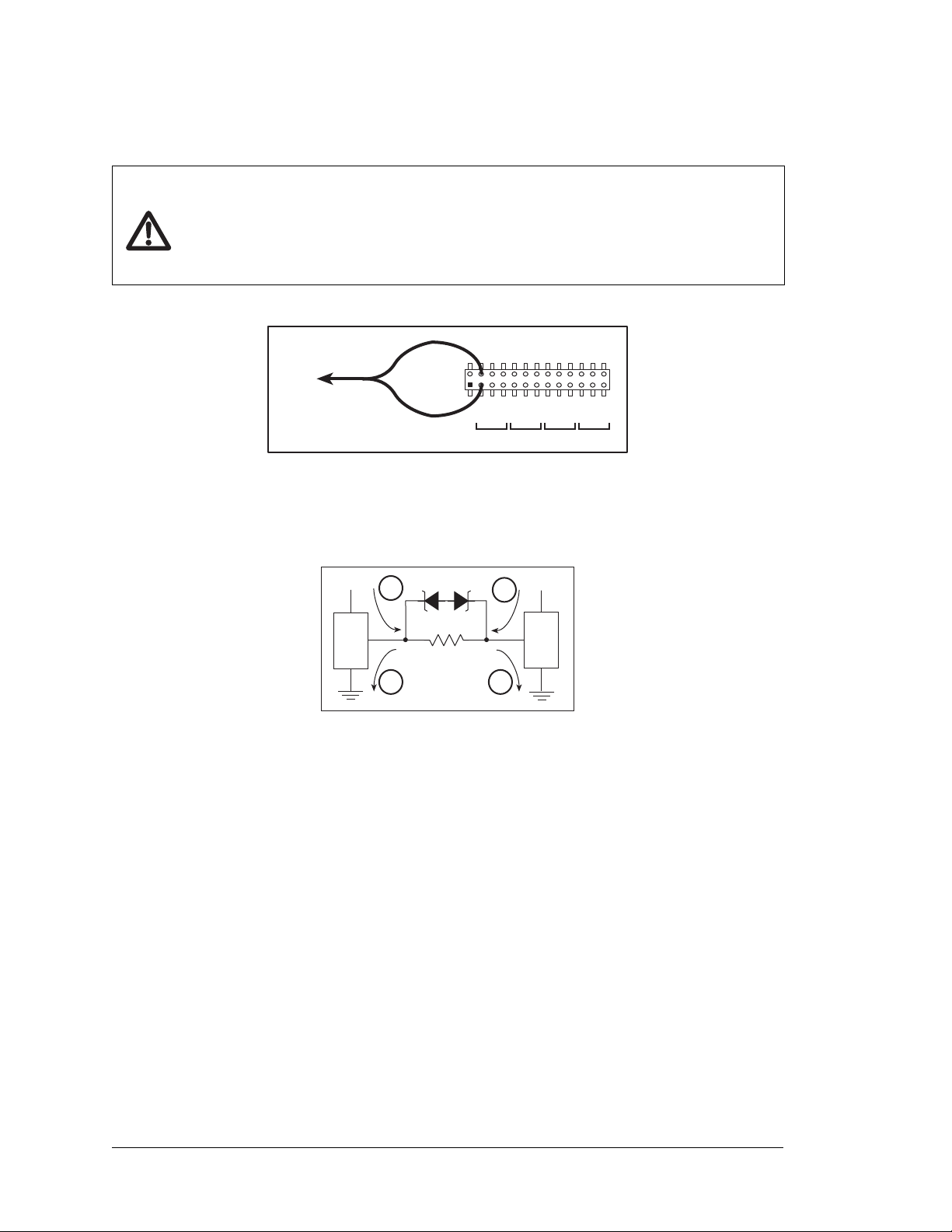

Ethernet

Program

Flash

22.1 MHz

osc

RS-232

RS-485

Data

Register

Data

Register

A/D

Converter

D/A

Converter

High-Current

Outputs

RabbitNet

Digital

Inputs

Configurable

I/O

Data

Register

Optional

Serial or

NAND Flash

Card

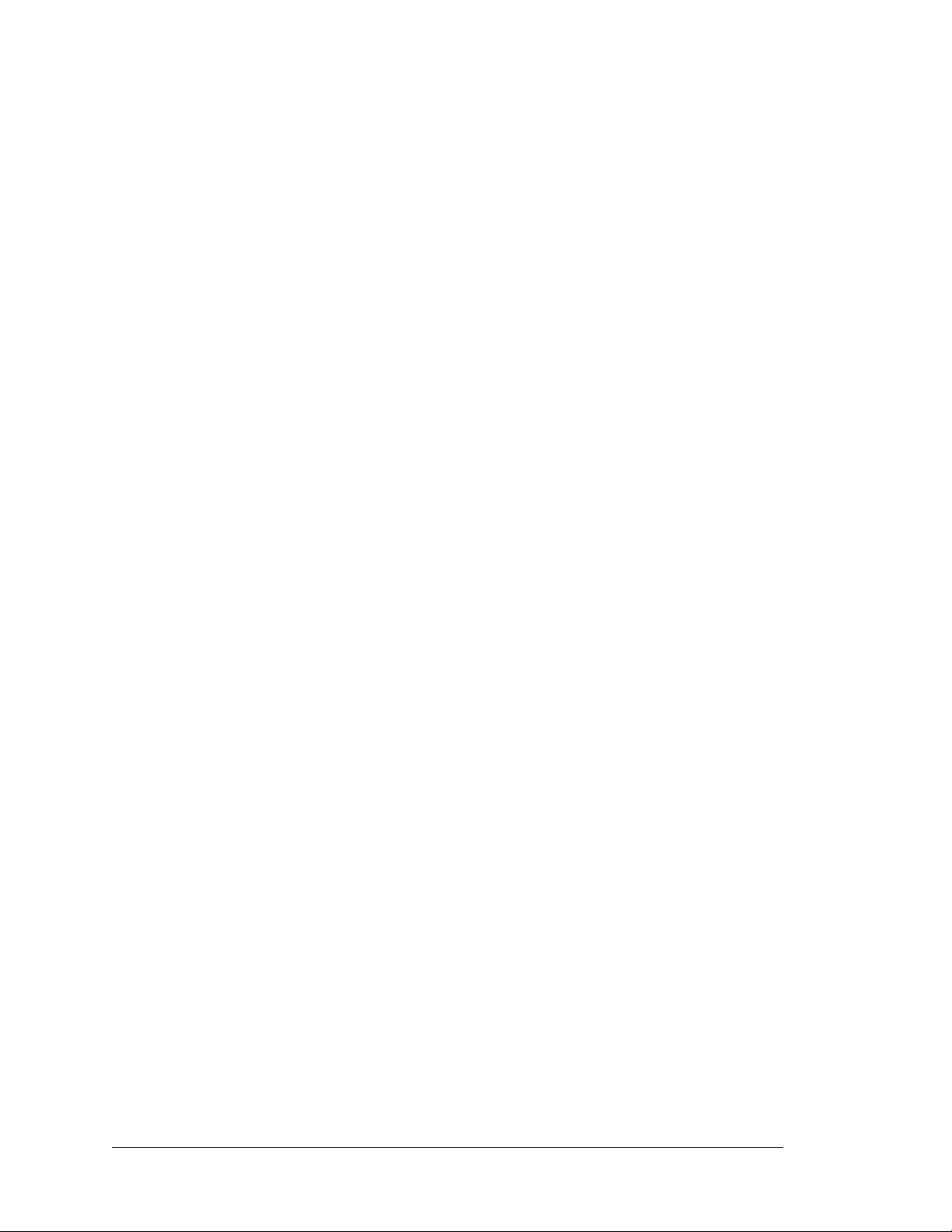

Chapter 3 describes the principal subsystems for the BL2600.

•Digital I/O

•Serial Communication

•A/D Converter Inputs

•D/A Converter Outputs

•Analog Reference Voltage Circuit

•Memory

Figure 5 shows these Rabbit-based subsystems designed into the BL2600.

User’s Manual 15

Figure 5. BL2600 Subsystems

Page 22

3.1 BL2600 Pinouts

J15

DCIN

DCIN

GND

GND

J16

AV0 AV1 AV2 AV3 AI0 AI1 AI2 AI3 AGND

GND HOUT0 +HK1 GND HOUT2 +HK3 GND

+HK0 GND HOUT1 +HK2 GND HOUT3

TXC TXF TXE 485 GND

GND RXC RXF RXE 485+

J17

J12

J5

J1 J2

U1

U6

R28

R38

R41

C5

C3

C9

C8

C12

C17

C23

C30

C18

C29

C35

C33

R29

R37

R39

R40

R42

Y3

C42R35

R31

R27

R25

DS1

R67

R70

J4

C79

Y4

C83

C86

GND

R75

R74

R71

DS3

DS2

R63 R64

C71

C72

C68

C64

C67

L2

U8

R49

R48

C62

R51

C61

R44

R47

C59

C49

C57

L1

R69

R72

R73

C75

C74

R58

C53

C47

C48

C45

C44

C43

JP5

C31

JP3

JP4

C28

C27

C37

C36

C32

R24

R22

C19

R23

C24

R20

C20

R19

C16

C15

R17

R18

R7

R9

R1

R8

C1

R10

R14

C4

SPD LNK ACT

J3

U5

U4

D1

Q1

C39

RP1

J8

High-Current

Digital Outputs

Analog

Ground

Analog

Outputs

Battery

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

AGND

Analog

Inputs

RabbitNet

J6

J4

J7

GND

GND

DIO00

DIO01

DIO02

DIO03

DIO04

DIO05

DIO06

DIO07

DIO08

DIO09

DIO10

DIO11

DIO12

DIO13

DIO14

DIO15

GND

+K

GND

DIN16

DIN17

DIN18

DIN19

DIN20

DIN21

DIN22

DIN23

GND+KDIN24

DIN25

DIN26

DIN27

DIN28

DIN29

DIN30

DIN31

GND

Configurable I/O

Digital Inputs

Digital Inputs

Analog

Ground

Ethernet

AV0

AV1

AV2

AV3

AI0

AI1

AI2

AI3

AGND

Power

Supply

GND

+HK0

HOUT0

GND

+HK1

HOUT1

GND

+HK2

HOUT2

GND

+HK3

HOUT3

GND

VOLTAGE CURRENT

0 1 2 3

GND

TxC

RxC

TxF

RxF

TxE

RxE

485

485+

GND

RS-232

RS-485

+K

+K

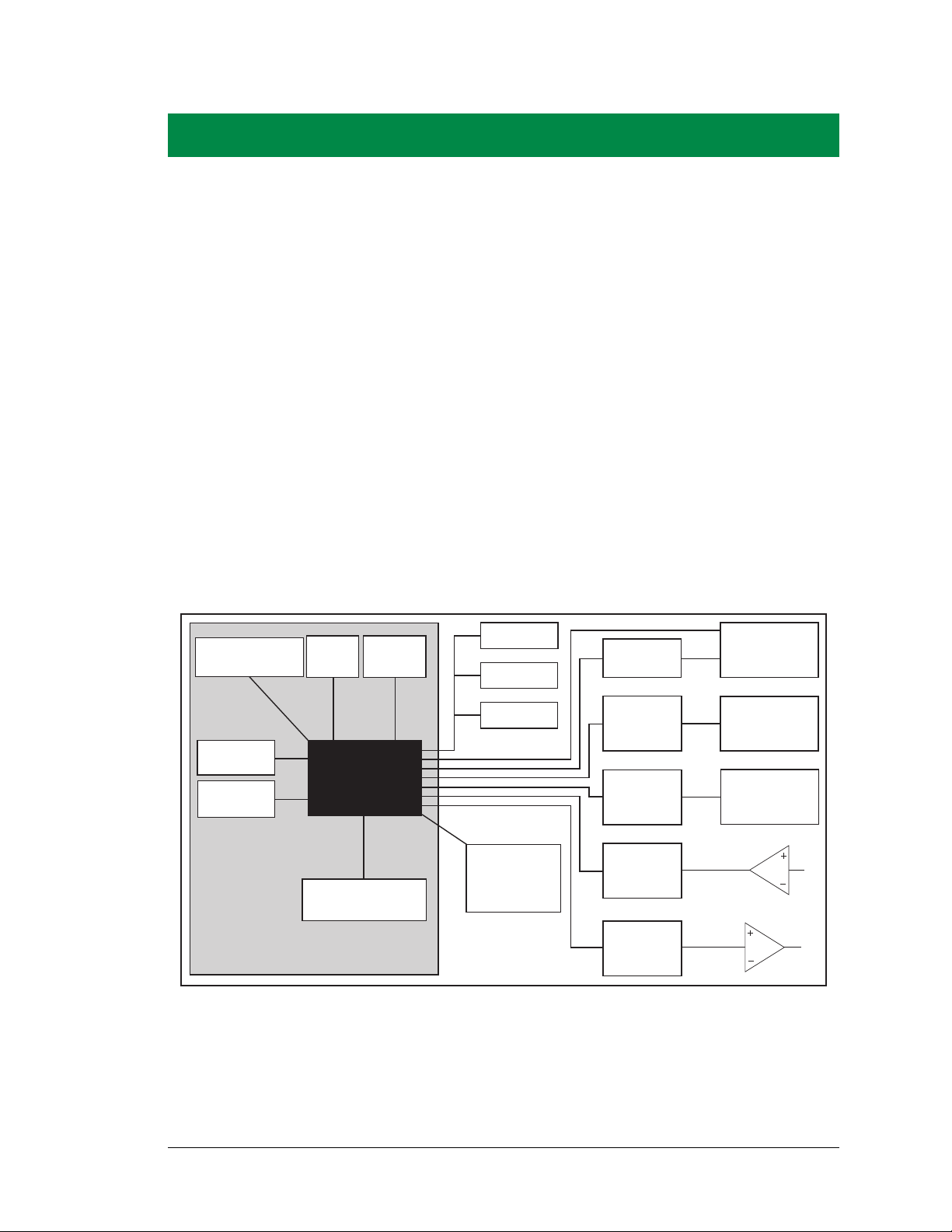

The BL2600 pinouts are shown in Figure 6(a) and Figure 6(b).

Figure 6(a). BL2600 Pinouts (friction-lock connectors)

16 SBC BL2600

Page 23

DCIN

DCIN

GND

GND

J13

J12

J5

J3

J11

J14

U1

U6

R28

R38

R41

C5

C3

C9

C8

C12

C17

C23

C30

C18

C29

C35

C33

R29

R37

R39

R40

R42

Y3

C42R35

R31

R27

R25

DS1

R67

R70

J4

C79

Y4

C83

C86

GND

R75

R74

R71

DS3

DS2

R63 R64

C71

C72

C68

C64

C67

L2

U8

R49

R48

C62

R51

C61

R44

R47

C59

C49

C57

L1

R69

R72

R73

C75

C74

R58

C53

C47

C48

C45

C44

C43

JP5

C31

JP3

JP4

C28

C27

C37

C36

C32

R24

R22

C19

R23

C24

R20

C20

R19

C16

C15

R17

R18

R7

R9

R1

R8

C1

R10

R14

C4

SPD LNK ACT

J3

U5

U4

D1

Q1

C39

RP1

High-Current

Digital Outputs

Analog

Ground

Analog

Outputs

Battery

Analog

Inputs

RabbitNet

J6

J4

J7

GND

DIO01

DIO03

DIO05

DIO07

DIO09

DIO11

DIO13

DIO15

GND+KDIN17

DIN19

DIN21

DIN23

DIN25

DIN27

DIN29

DIN31

GND

Configurable

I/O

Digital Inputs

AIN0

AIN2

AIN4

AIN6

AGND

AV0

AV2

AI0

AI2

AGND

Power

Supply

GND

+HK0

HOUT0

GND

+HK1

HOUT1

GND

+HK2

HOUT2

GND

+HK3

HOUT3

GND

VOLTAGE

CURRENT

0 1 2 3

TxC

GND

TxF

GND

TxE

GND

485

RS-232

RS-485

+K

GND

DIO00

DIO02

DIO04

DIO06

DIO08

DIO10

DIO12

DIO14

GND

+K

DIN16

DIN18

DIN20

DIN22

DIN24

DIN26

DIN28

DIN30

GND

AIN1

AIN3

AIN5

AIN7

AGND

AV1

AV3

AI1

AI3

AGND

RxC

GND

RxF

GND

RxE

GND

485+

Analog

Ground

TOP VIEW

GND

+HK0

HOUT0

GND

+HK1

HOUT1

GND

+HK2

HOUT2

GND

+HK3

HOUT3

GND

VOLTAGE

CURRENT

NOTE: Remember that the pinouts will mirror those shown above when they are viewed

Figure 6(b). BL2600 Pinouts (IDC sockets)

from the other side of the board.

User’s Manual 17

Page 24

3.1.1 Connector Options

Standard BL2600 models are equipped with two 1 × 20 friction-lock connector terminals

(J1 and J2), two polarized 1 × 10 friction-lock connector terminals (J8 and J15) where pin 9

is removed to polarize the connector terminals, one 1 × 13 friction-lock connector terminal

(J16), and one 1 × 10 friction-lock connector terminal (J17); all of these friction-lock connector terminals have a 0.1" pitch.

Two 4-pin 0.156" friction-lock connector terminals at J5 and J7 are installed to supply

power (DCIN and +5 V) to the RabbitNet peripheral expansion boards. The 4-pin 0.156"

friction-lock connector terminal at J12 is for the main power supply connections.

Table 3 lists Molex connector part numbers for the crimp terminals, housings, and polarizing

keys needed to assemble female friction-lock connector assemblies for use with their male

counterparts on the BL2600.

Table 3. Female Friction-Lock Connector Parts

Friction-Lock

Connector

0.1" 1 × 20 J1, J2 TEC 2-770602-0 TEC 770601-1 None

0.1" 1 × 13 J16 Molex 22-01-2137

0.1" 1 × 10 J8, J15, J17 Molex 22-01-2107

0.156" 1 × 4 J5, J7, J12 Molex 09-50-3041 Molex 08-50-0108 Molex 15-04-0219

Used with BL2600

Headers

Housing

Part Number

Crimp Terminals Polarizing Keys

Molex 08-50-0113 Molex 15-04-9209

The RJ-45 jacks at J4 and J6 labeled RabbitNet are serial I/O expansion ports for use with

RabbitNet peripheral expansion boards. The RabbitNet jacks do not support Ethernet connections.

The BL2600 also has 2 × 20, 2 × 13, 2 × 10, and 2 × 7 IDC sockets with a pitch of 0.1" in

addition to the friction-lock connectors. Corresponding headers or ribbon cables may be

plugged into these sockets from either the top or the bottom. A top view of the pinouts for

these sockets is shown in Figure 6(b).

18 SBC BL2600

Page 25

3.2 Digital I/O

27 kW

+K

DCIN

+5 V

Rabbit® 3000

Microprocessor

+3.3 V

DIN16DIN31

DIN20DIN23 27 kW

100 kW

DIN16DIN19

DIN24DIN31

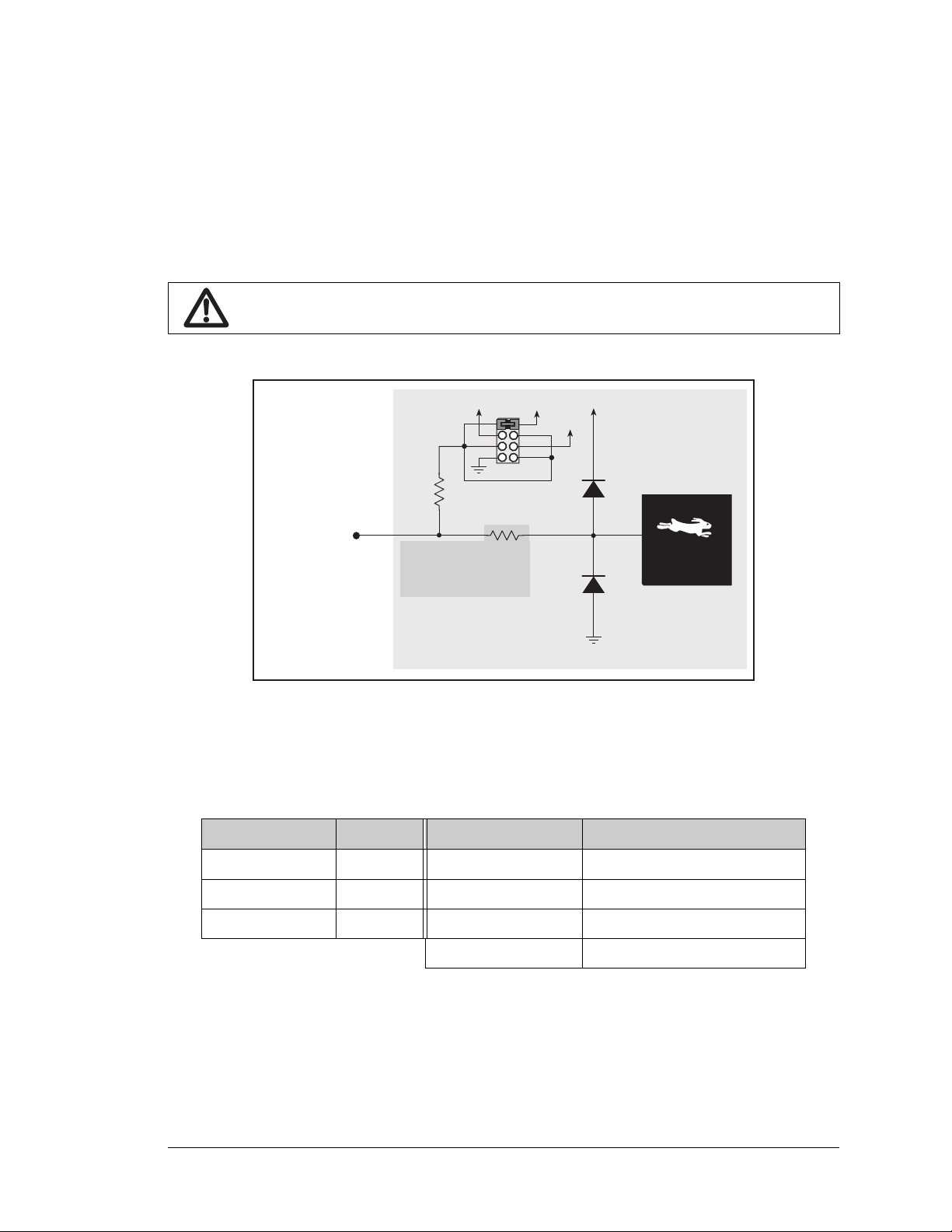

3.2.1 Digital Inputs

The BL2600 has 16 digital inputs, DIN16–DIN31, each of which is protected over a range

of –36 V to +36 V. The inputs are factory-configured to be pulled up to +5 V, but they can

also be pulled up to +K or DCIN, or pulled down to 0 V in banks by changing a jumper as

shown in Figure 7.

CAUTION: Do not simultaneously jumper more than one setting on a particular

jumper header (JP3, JP4, and JP5) when configuring a bank of digital inputs.

Figure 7. BL2600 Digital Inputs DIN16–DIN31 [Pulled Up—Factory Default]

Table 4 lists the banks of digital inputs and summarizes the jumper settings.

Table 4. Banks of BL2600 Digital Inputs

Digital Inputs Header Pins Jumpered Pulled Up/Pulled Down

DIN16–DIN19 JP3 1–2 Inputs pulled up to +5 V

DIN20–DIN23 JP4 3–4 Inputs pulled up to DCIN

DIN24–DIN31 JP5 5–6 Inputs pulled up to +K

7–8 Inputs pulled down to GND

When you use the software digIn function call to read the digital inputs, DIN16–DIN31

are considered to be digital input channels 16–31.

User’s Manual 19

Page 26

The actual switching threshold is approximately

+40 V

+36 V

+3.3 V

40 V

Normal Switching

Levels

Spikes

Digital Input Voltage

Spikes

Spikes

1.40 V. Anything below this value is a logic 0, and

anything above is a logic 1. The digital inputs are

each fully protected over a range of -36 V to +36 V,

and can handle short spikes of ±40 V.

NOTE: If the inputs are pulled up to +K or to

DCIN, the voltage range over which

the digital inputs are protected changes

to +K (or DCIN) – 36 V to +36 V.

Individual DIN16–DIN23 channels may be used

for interrupts, input capture, as quadrature decoders, or as PWM outputs.

Figure 8. BL2600 Digital Input

Protected Range

The use of these channels for interrupts, input capture, and as quadrature decoders is described

in the Rabbit 3000 Microprocessor User’s Manual, and is illustrated through sample programs in the Dynamic C SAMPLES\RABBIT3000 folder. Table 5 lists these alternate uses.

Table 5. Alternate Uses for BL2600 Channels DIN16–DIN23

Channel Interrupt Input Capture

DIN16 ×

DIN17 ×

DIN18 ×

DIN19 ××

DIN20 ××

DIN21 ×××

DIN22 ××

DIN23 ×××

Quadrature

Decoder

PWM Outputs

3.2.2 PWM Outputs

Digital inputs DIN20–DIN23 can be used as PWM output channels by setting the jumper

on header JP4 across pins 7–8 to pull the digital inputs to ground. Once the PWM driver

sets up a given PWM channel, the corresponding digital input channel is no longer available for use as a digital input. The output voltage swing will be 0 to 1.65 V, which is not

suitable for interfacing only to CMOS-level inputs. Since the output impedance is approximately 13 k, the input impedance of the circuit the PWM output is connected to should

be at least 10 times as high.

The sample program PWM.C in the IO subdirectory in SAMPLES\BL2600 shows how to

set up and use the PWM outputs.

20 SBC BL2600

Page 27

3.2.3 High-Current Digital Outputs

+HKx

100 kW

330 W

10 kW

10 kW

27 kW

1 nF

100 kW

1 nF

MMBT4401

B

A

(in sinking

mode)

(in sourcing

mode)

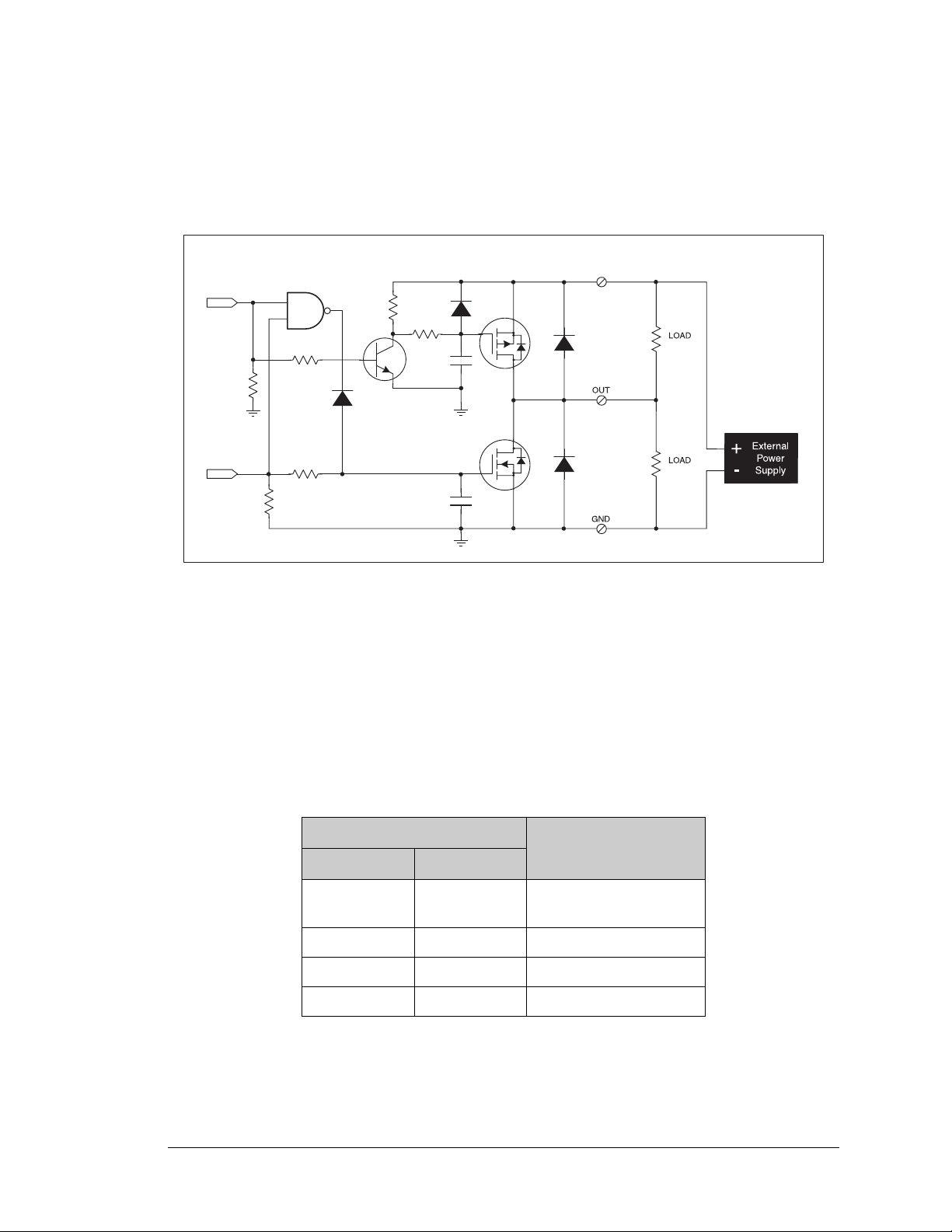

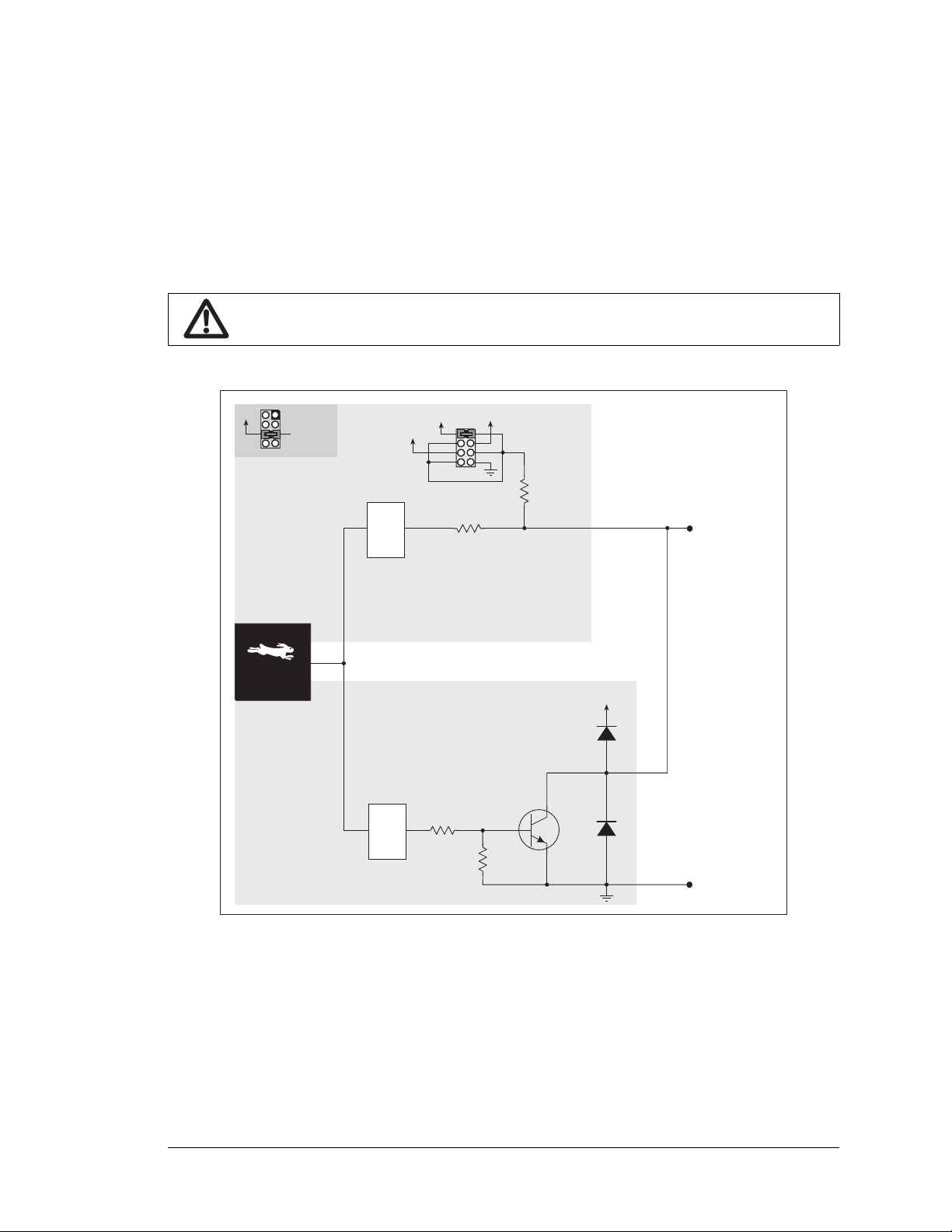

The BL2600 has four high-current digital outputs, HOUT0–HOUT3, which can each sink

or source up to 2 A. Figure 9 shows a wiring diagram for using the digital outputs in either

a sinking or a souring configuration.

Figure 9. BL2600 High-Current Digital Outputs

All the digital outputs sink and source actively. They can be used as high-side drivers, lowside drivers, or as an H-bridge driver. When the BL2600 is first powered up or reset, all

the outputs are disabled, that is, at a high-impedance tristate, until the digHoutConfig

software function call is made. The digHoutConfig call sets the initial state of each

high-current output according to the configuration specified by the user, and enables the

digital outputs to their initial status.

Table 6. BL2600 High-Current Outputs Logic States

U3 Output

A B

High High

High Low Sourcing

Low High Sinking

Low Low High-impedance (tristate)

High-Current Output

Prohibited

(defaults to sourcing)

User’s Manual 21

Page 28

Each high-current output has its own +K supply. When wiring the high-current outputs,

J13

GND

+HK0

HOUT0

GND

+HK1

HOUT1

GND

+HK2

HOUT2

GND

+HK3

HOUT3

GND

0 1 2 3

GND

+HK0

HOUT0

GND

+HK1

HOUT1

GND

+HK2

HOUT2

GND

+HK3

HOUT3

GND

+HK0

+Ka

+Kb

LOAD

A

A

B

B

keep the distance to the power supply as short as possible.

CAUTION: If you are using a BL2600 with the IDC header connectors, beware that

an individual IDC header pin can only handle up to 1 A. Since the same high-current

outputs are available on opposite pairs of IDC header connectors, you can still use the

2 A sinking or sourcing capability of the BL2600 by wiring all your connections,

including the ground, in parallel to the opposite pairs (see Figure 10 for an example).

Figure 10. Example of Wiring HK0 In Parallel on IDC Header

For the H bridge, which is shown in Figure 11, Ka and Kb should be the same.

Figure 11. H Bridge

22 SBC BL2600

Page 29

3.2.4 Configurable I/O

100 kW

27 kW

+K

DCIN

+5 V

SINKING

OUTPUT

27 kW

220 W

DIGITAL

INPUT

DIO00DIO15

Factory

Default

setting

+K

Sinking

Output

setting

+K

Buffer

Latch

Rabbit® 3000

Microprocessor

GND

The BL2600 has 16 configurable I/O that may be configured individually in software as

either digital inputs or as sinking digital outputs. By default, a configurable I/O channel is

a digital input, but may be set as a sinking digital output by using the digOutConfig

function call. The inputs are factory-configured to be pulled up to +5 V, but they can also

be pulled up to +K or DCIN, or pulled down to 0 V in banks by changing a jumper as

shown in Figure 12.

CAUTION: Do not simultaneously jumper more than one setting on a particular

jumper header (JP1 and JP2) when configuring a bank of configurable I/O.

Figure 12. BL2600 Configurable I/O DIO00–DIIO15 [Inputs Pulled Up—Factory Default]

User’s Manual 23

Page 30

When you use the software digIn function call to read the configurable I/O, DIO00–

DIO00DIO15

LOAD

+K

GND

DIO15 are considered to be digital input channels 00–15. Note that the digIn function

call can also read these channels if they are set to be sinking digital outputs.

Table 7 lists the banks of configured digital inputs and summarizes the jumper settings.

Table 7. Banks of BL2600 Configured Digital Inputs

Digital Inputs Header Pins Jumpered Pulled Up/Pulled Down

DIO00–DIO07 JP1 1–2 Inputs pulled up to +5 V

DIO08–DIO15 JP2 3–4 Inputs pulled up to DCIN

5–6 Inputs pulled up to +K

7–8 Inputs pulled down to GND

As for the nonconfigurable digital inputs, the actual switching threshold is approximately

1.40 V. Anything below this value is a logic 0, and anything above is a logic 1. The digital

inputs are each fully protected over a range of -36 V to +36 V, and can handle short spikes

of ±40 V.

NOTE: If the inputs are pulled up to +K or to DCIN, the voltage range over which

the digital inputs are protected changes to +K (or DCIN) – 36 V to +36 V.

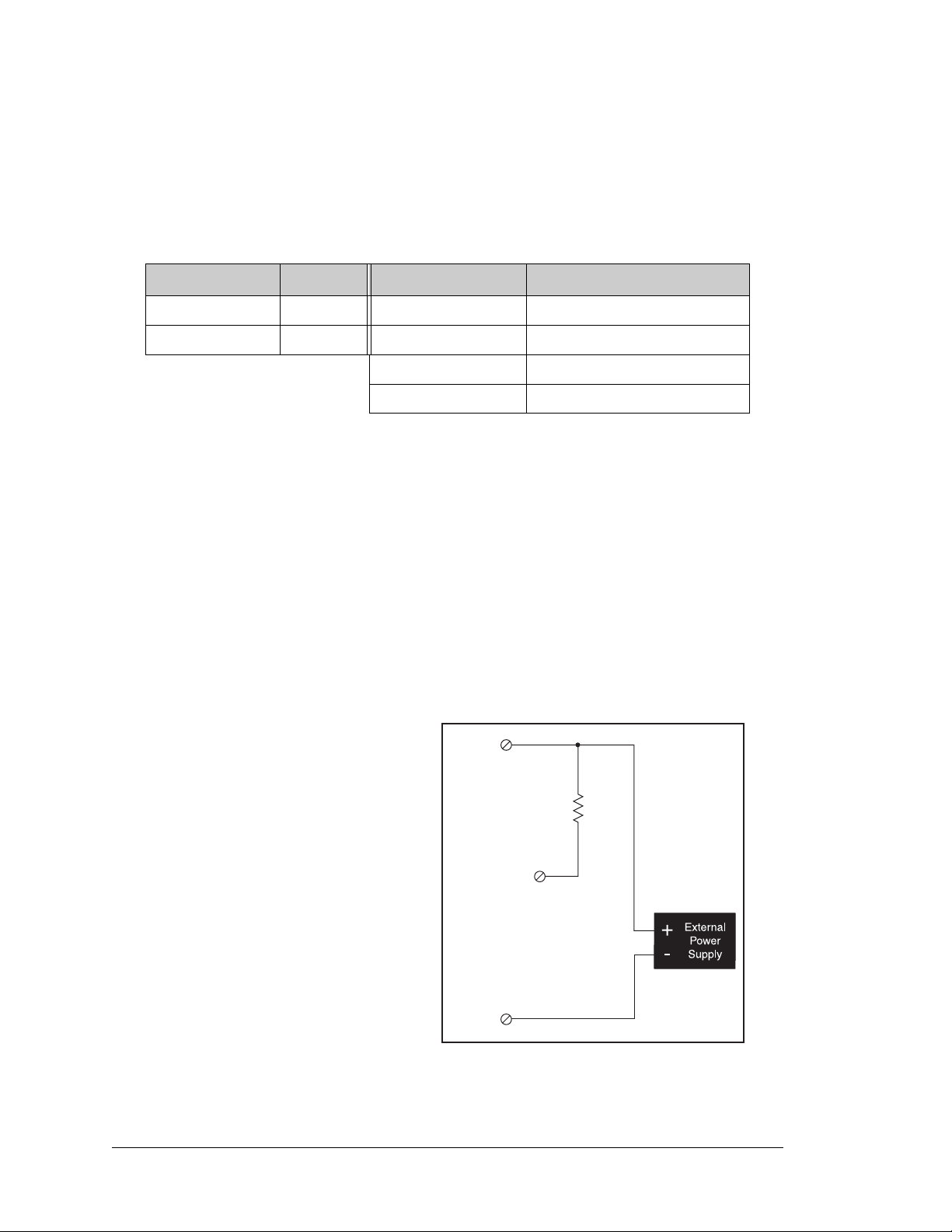

When set as a sinking digital output, a configurable I/O channel can sink up to 200 mA at

up to 40 V. When you use the software digOutConfig function call to set the configurable I/O, DIO00–DIO15 are considered to be digital output channels 00–15. The output

can be set up either as a sinking output or it can be put in a high-impedance tristate.

When a configurable I/O is configured

as a sinking output, be sure to connect

an external voltage source up to 36 V

DC across +K and GND on header

J1/J3, and set the pullup jumper on the

corresponding JP1/JP2 header to +K.

Figure 13. Load and +K Power Supply

Connections for Sinking Digital Output

24 SBC BL2600

Page 31

3.3 Serial Communication

The BL2600 has three serial communication ports, which can be configured as one RS-232

serial channel (with RTS/CTS) and one RS-232 (3-wire) channel or one RS-485 channel, or

as three RS-232 (3-wire) channels, or as two RS-232 (3-wire) channels and one RS-485

channel by using the serMode software function call. Table 8 summarizes the options.

Table 8. Serial Communication Configurations

Serial Port

Mode

0 RS-232, 3-wire RS-232, 3-wire RS-232, 3-wire

1 RS-232, 3-wire RS-485 RS-232, 3-wire

2 RS-232, 5-wire RS-232, 3-wire CTS/RTS

3 RS-232, 5-wire RS-485 CTS/RTS

The BL2600 also has one CMOS serial channel that serves as the programming port.

All four serial ports operate in an asynchronous mode. An asynchronous port can handle 7

or 8 data bits. A 9th bit address scheme, where an additional bit is sent to mark the first

byte of a message, is also supported. Serial Port A, the programming port, can be operated

alternately in the clocked serial mode. In this mode, a clock line synchronously clocks the

data in or out. Either of the two communicating devices can supply the clock. The BL2600

boards typically use all four ports in the asynchronous serial mode. Serial Ports C and F

are used for RS-232 communication, and Serial Port E is used for RS-232 or RS-485 communication. The BL2600 uses a 22.12 MHz resonator, which is doubled to 44.2 MHz. At

this frequency, the BL2600 supports standard asynchronous baud rates up to a maximum

of 5.525 Mbps.

C E F

3.3.1 RS-232

The BL2600 RS-232 serial communication is supported by an RS-232 transceiver. This

transceiver provides the voltage output, slew rate, and input voltage immunity required to

meet the RS-232 serial communication protocol. Basically, the chip translates the Rabbit

3000’s CMOS signals to RS-232 signal levels. Note that the polarity is reversed in an

RS-232 circuit so that a +3.3 V output becomes approximately -10 V and 0 V is output as

+10 V. The RS-232 transceiver also provides the proper line loading for reliable communication.

RS-232 can be used effectively at the BL2600’s maximum baud rate for distances of up to

15 m.

3.3.2 RS-485

The BL2600 can be set for one RS-485 serial channel, which is connected to the Rabbit

3000 Serial Port E through an RS-485 transceiver. The half-duplex communication uses

the Rabbit 3000’s PE3 pin to control the transmit enable on the communication line.

User’s Manual 25

Page 32

The BL2600 can be used in an RS-485 multidrop network. Connect the 485+ to 485+ and

RS-485

RS485+

GND

RS-485

RS485+

GND

RS-485

RS485+

GND

J15

J16

AIN0

AIN1

AIN2

AIN3

JP6

420 mA

AV0 AV1 AV2 AV3 AI0 AI1 AI2 AI3 AGND

GND HOUT0 +HK1 GND HOUT2 +HK3 GND

+HK0 GND HOUT1 +HK2 GND HOUT3

TXC TXF TXE 485 GND

GND RXC RXF RXE 485+

J17

GND HOUT0 +HK1 GND HOUT2 +HK3 GND

+HK0 GND HOUT1 +HK2 GND HOUT3

TXC TXF TXE 485

AIN1 AIN3 AIN5 AIN7 AGND AV1 AV3 AI1 AI3 AGND

AIN0 AIN2 AIN4 AIN6 AGND AV0 AV2 AI0 AI2 AGND

J11

20

19

R43

JP6

R44

R39

R38

R20

R33

R34

U13

R22

R21

R17

C18

C19

U12

R15

C13

R16

C10

R10

U11

J8

R14 R13 C11

AIN0 AIN1 AIN2 AIN3 AIN4 AIN5 AIN6 AIN7 AGND

C12 R12 R11

U10

BT1

C26

C27

D1

U15

C25

J12

J13

C22

R55

R42

C23

C24

R41

R40

R35

R36

R37

U14

R26

R28

R30

R19

R29

R32

R31

R56

R57

L1

R27R25

R23

R24

C20

C21

R18

C16

1

2

25

26

RXE

J14

Q19

D3

Q17D2Q18

RXC

D4

Q20

C34

RXF

485+

C35 C36 C37

JP7

485 TERM.

RESISTOR

C30

R58

R59

R60

U18

C32

C33

RCM2

U17

C31

R9

U16

R8

J10

R7

GND/EGND

RP5

RP6

U2

C4

R5

C5

R6

C6

U4

JA

RCM1

RCM3000 ETHERNET CORE MODULE

U3

RP17 RP18

34

33

16

15

1

2

1

2

15

16

33

34

C1

U1

RP3

RP4

GND

+K

DCIN

+5V

JP3,

JP4

AND

JP4

JP1 AND JP2

GND

+K

DCIN

+5V

J4 RABBITNET 1

J6 RABBITNET 0

J7

C14

C17

C15

C78

J9

C9

U9

RP16

C8

U8

R4

R3

RP15

RP14

RP12

RP13

RP11

R1

R2

C7

U6

U7

U5

RP8

RP7

RP9

RP10

C2

Q9

Q10

J5

Q12

Q15Q14 Q16

Q11

Q13

C3

Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8

JP2

JP1

J1

J2

GND DIN28 DIN24 DIN20 DIN16 GND DIO12 DIO08 DIO04 DIO00

DIN30 DIN26 DIN22 DIN18 +K DIO14 DIO10 DIO06 DIO02 GND

DIN31 DIN27 DIN23 DIN19 +K DIO15 DIO11 DIO07 DIO03 GND

GND DIN29 DIN25 DIN21 DIN17 GND DIO13 DIO09 DIO05 DIO01

GND DIO14 DIO12 DIO10 DIO08 DIO06 DIO04 DIO02 DIO00 GND

+K DIO15 DIO13 DIO11 DIO09 DIO07 DIO05 DIO03 DIO01 GND

GND DIN30 DIN28 DIN26 DIN24 GND DIN22 DIN20 DIN18 DIN16

DIN31 DIN29 DIN27 DIN25 +K DIN23 DIN21 DIN19 DIN17 GND

DIO 0007 PULLS

DIO 0815 PULLS

1

2

39

40

SW1

J3

1

2

DCIN DCIN GND GND

R111

R112

RESET

RP2

RP1

JP3

DIN 1619 PULLS

JP4

DIN 2023 PULLS

DIN 2431 PULLS

JP5

R84

C28

1

2

DS1

U1

U6

R28

R38

R41

C5

C3

C9

C8

C12

C17

C23

C30

C18

C29

C35

C33

R29

R37

R39

R40

R42

Y3

C42R35

R31

R27

R25

DS1

R67

R70

J4

C79

Y4

C83

C86

GND

R75

R74

R71

DS3

DS2

R63 R64

C71

C72

C68

C64

C67

L2

U8

R49

R48

C62

R51

C61

R44

R47

C59

C49

C57

L1

R69

R72

R73

C75

C74

R58

C53

C47

C48

C45

C44

C43

JP5

C31

JP3

JP4

C28

C27

C37

C36

C32

R24

R22

C19

R23

C24

R20

C20

R19

C16

C15

R17

R18

R7

R9

R1

R8

C1

R10

R14

C4

SPD LNK ACT

J3

U5

U4

D1

Q1

C39

RP1

JP7

4

3

2

1

R97

681 W

R98

220 W

R96

681 W

485+

485

6

7

termi-

nation

bias

bias

U17

JP7

2

1

6

5

6

5

Factory

Default

485– to 485– using single twisted-pair wires (nonstranded, tinned) as shown in Figure 14.

Note that a common ground is recommended.

Figure 14. BL2600 Multidrop Network

The BL2600 comes with a 220 termination resistor and two 681 bias resistors installed

and enabled with jumpers across pins 1–2 and 5–6 on header JP7, as shown in Figure 15.

26 SBC BL2600

Figure 15. RS-485 Termination and Bias Resistors

Page 33

For best performance, the bias and termination resistors in a multidrop network should

only be enabled on both end nodes of the network. Disable the termination and bias resistors on any intervening BL2600 units in the network by removing both jumpers from

header JP6.

TIP: Save the jumpers for possible future use by “parking” them across pins 1–3 and 4–6

of header JP7. Pins 3 and 4 are not otherwise connected to the BL2600.

3.3.3 Programming Port

The RabbitCore module on the BL2600 has a 10-pin programming header. The programming port uses the Rabbit 3000’s Serial Port A for communication, and is used for the following operations.

• Programming/debugging

• Cloning

The programming port is used to start the BL2600 in a mode where the BL2600 will

download a program from the port and then execute the program. The programming port

transmits information to and from a PC while a program is being debugged.

The Rabbit 3000 startup-mode pins (SMODE0, SMODE1) are presented to the programming port so that an externally connected device can force the BL2600 to start up in an

external bootstrap mode. The BL2600 can be reset from the programming port via the

/EXT_RSTIN line.

The Rabbit 3000 status pin is also presented to the programming port. The status pin is an

output that can be used to send a general digital signal.

NOTE: Refer to the Rabbit 3000 Microprocessor User’s Manual for more information

related to the bootstrap mode.

User’s Manual 27

Page 34

3.3.4 Ethernet Port

ETHERNET

RJ-45 Plug

1. E_Tx+

2. E_Tx

3. E_Rx+

6. E_Rx

1

8

RJ-45 Jack

Figure 16 shows the pinout for the Ethernet port (J4 on the BL2600 module). Note that

there are two standards for numbering the pins on this connector—the convention used

here, and numbering in reverse to that shown. Regardless of the numbering convention

followed, the pin positions relative to the spring tab position (located at the bottom of the

RJ-45 jack in Figure 16) are always absolute, and the RJ-45 connector will work properly

with off-the-shelf Ethernet cables.

Figure 16. RJ-45 Ethernet Port Pinout

Two LEDs are placed next to the RJ-45 Ethernet jack, one to indicate an Ethernet link

(LNK) and one to indicate Ethernet activity (ACT).

The RJ-45 connector is shielded to minimize EMI effects to/from the Ethernet signals.

28 SBC BL2600

Page 35

3.4 A/D Converter Inputs

ADC

1 MW

1 nF

AIN0

AGND

AIN1

1 nF

Ref. Voltage

from D/A Converter

105 kW

105 kW

The single A/D converter chip used in the BL2600 has a resolution of 12 bits (11 bits for the

value and one bit for the polarity)

Each external input has circuitry that provides scaling and filtering. All 8 external inputs

are scaled and filtered to provide the user with an input impedance of 1 M and a variety

of single-ended unipolar, single-ended bipolar, and differential bipolar ranges as shown in

Table 9.

Figure 17 shows a pair of A/D converter input circuits. The resistors form an approx. 10:1

attenuator, and the capacitors filter noise pulses from the A/D converter inputs.

. The A/D converter chip has a programmable amplifier.

Figure 17. Buffered A/D Converter Inputs

The A/D converter chip can only accept positive voltages. By pairing the analog inputs and

setting the reference voltage from the D/A converter [0 V for single-ended unipolar or differential measurements, V = (voltage range) ÷ 9 for single-ended bipolar measurements],

single-ended unipolar, single-ended bipolar, differential bipolar, or current (4–20 mA on

channels 0–3 only) measurements are possible, and can be configured for each channel or

channel pair with the opmode parameter in the anaInConfig software function call.

Adjacent A/D converter inputs are paired to make bipolar measurements. The default

setup is to measure only voltages for the ranges listed in Table 9.

User’s Manual 29

Page 36

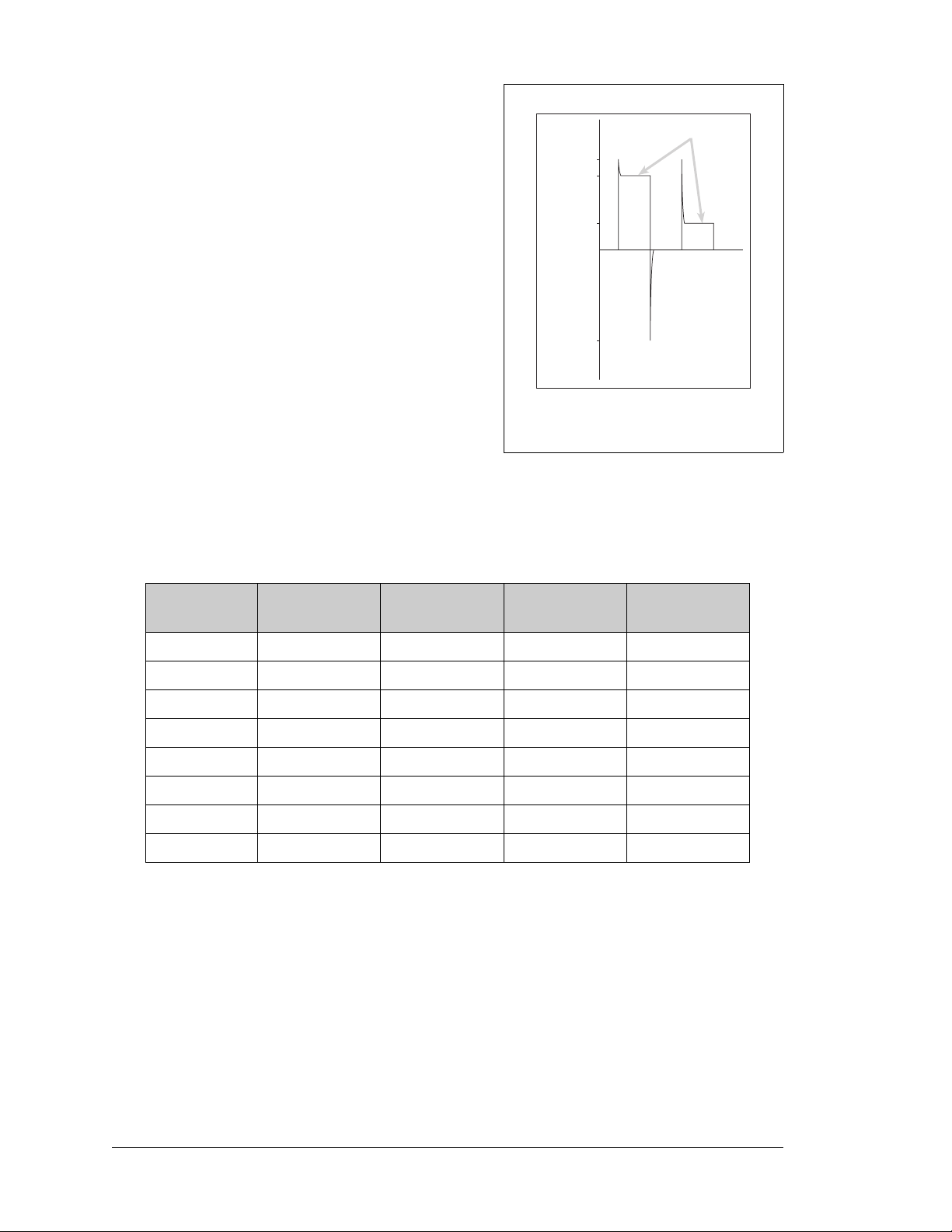

Table 9. A/D Converter Input Voltage Ranges

Amplifier

Gain

1 0–20 V ±10 V ± 20 V 10

2 0–10 V ±5 V ± 10 V 5

4 0–5 V ±2.5 V ± 5 V 2.5

5 0–4 V ±2 V ± 4 V 2.0

*

8

10 0–2 V ±1 V ± 2 V 1.0

16 0–1.25 V ±0.625 V ± 1.25 V 0.625

20 0–1 V ±0.5 V ± 1 V 0.500

* 4–20 mA operation is available with an amplifier gain of 8

Single-Ended

Unipolar

0–2.5 V ±1.25 V ± 2.5 V 1.25

Voltage Ra n g e

Single-Ended

Bipolar

Differential

Bipolar

mV per Tick

When using channels AIN0–AIN3 for current measurements, remember to set the corresponding jumper(s) on header JP6.

The A/D converter inputs are factory-calibrated and the calibration constants are stored in a

separate EEPROM.

3.4.1 A/D Converter Calibration

To get the best results form the A/D converter, it is necessary to calibrate each mode (single-ended, differential, and current) for each of its gains. It is imperative that you calibrate

each of the A/D converter inputs in the same manner as they are to be used in the application. For example, if you will be performing floating differential measurements or differential measurements using a common analog ground, then calibrate the A/D converter in

the corresponding manner. The calibration table in software only holds calibration constants based on mode, channel, and gain. Other factors affecting the calibration must be taken

into account by calibrating using the same mode and gain setup as in the intended use.

Sample programs are provided to illustrate how to read and calibrate the various A/D

inputs for the three operating modes.

Mode Read Calibrate

Single-Ended, unipolar AD_RD_SE_UNIPOLAR.C ADC_CAL_SE_UNIPOLAR.C

Single-Ended, bipolar AD_RD_SE_BIPOLAR.C ADC_CAL_SE_BIPOLAR.C

Differential, bipolar AD_RD_DIFF.C ADC_CAL_DIFF.C

Milli-Amp AD_RD_MA.C ADC_CAL_MA.C

These sample programs are found in the ADC subdirectory in SAMPLES\BL2600. See

Section 4.2.4 for more information on these sample programs and how to use them.

30 SBC BL2600