Page 1

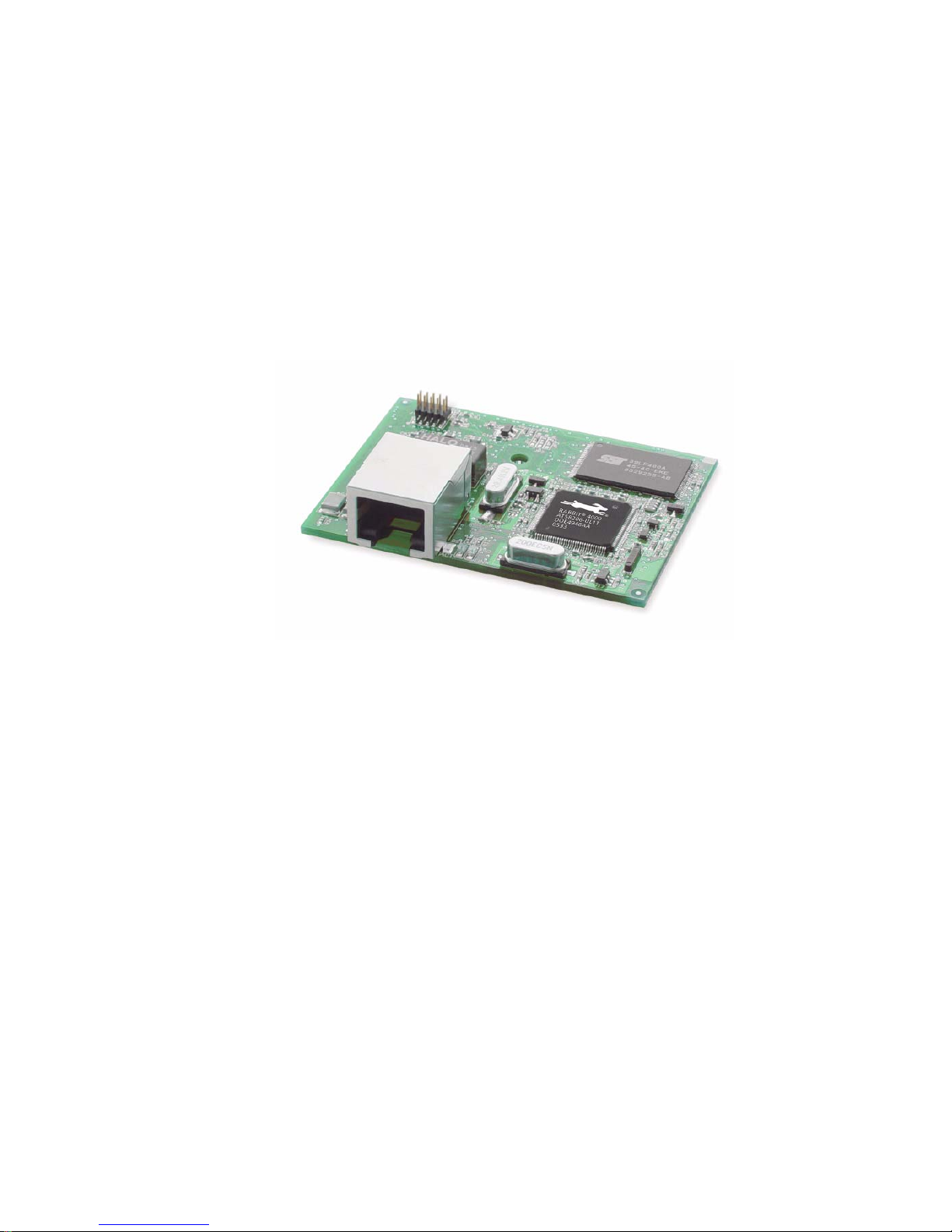

RabbitCore RCM4000

C-Programmable Analog Core Modul e

with Ethernet

User’s Manual

019–0157 • 060501–A

Page 2

RabbitCore RCM4000

Rabbit Semiconductor

2900 Spafford Street

Davis, California 95616-6809

USA

Telephone: (530) 757-8400

Fax: (530) 757-8402

www.rabbi tsemic onduct or.com

RabbitCore RCM4000 User’s Manual

Part Number 019-0157 • 060501–A • Print ed in U.S. A.

©2006 Rabbit Semiconductor • All rights reserv ed.

Rabbit Semiconductor reserves the right to make changes and

improvements to its products without providing not ice.

Trademarks

Rabbit and Dynamic C are registered trademarks of Rabbit Semiconductor.

Rabbit 4000 and RabbitCore are trademarks of Rabbit Semiconduct or.

Page 3

User’s Manual

TABLE OF CONTENTS

Chapter 1. Introduction 1

1.1 RCM4000 Features...............................................................................................................................2

1.2 Advantages of the RCM4000 ...............................................................................................................3

1.3 Development and Evaluation Tools......................................................................................................4

1.3.1 RCM4000 Development Kit.........................................................................................................4

1.3.2 Software........................................................................................................................................5

1.3.3 Online Documentation..................................................................................................................5

Chapter 2. Getting Started 7

2.1 Install Dynamic C.................................................................................................................................7

2.2 Hardware Connections..........................................................................................................................8

2.2.1 Prepare the Prototyping Board for Development..........................................................................8

2.2.2 Attach Module to Prototyping Board............................................................................................9

2.2.3 Connect Programming Cable......................................................................................................10

2.2.4 Connect Power............................................................................................................................11

2.3 Run a Sample Program.......................................................................................................................12

2.3.1 Run a Sample Program ...............................................................................................................12

2.3.2 Troubleshooting..........................................................................................................................12

2.4 Where Do I Go From Here? ...............................................................................................................13

2.4.1 Technical Support.......................................................................................................................13

Chapter 3. Running Sample Programs 15

3.1 Introduction.........................................................................................................................................15

3.2 Sample Programs................................................................................................................................16

3.2.1 Use of NAND Flash (RCM4000 only).......................................................................................18

3.2.2 Serial Communication.................................................................................................................20

3.2.3 A/D Converter Inputs (RCM4000 only).....................................................................................22

3.2.4 Real-Time Clock.........................................................................................................................22

Chapter 4. Hardware Reference 23

4.1 RCM4000 Digital Inputs and Outputs................................................................................................24

4.1.1 Memory I/O Interface.................................................................................................................29

4.1.2 Other Inputs and Outputs............................................................................................................29

4.2 Serial Communication ........................................................................................................................30

4.2.1 Serial Ports..................................................................................................................................30

4.2.2 Ethernet Port ...............................................................................................................................31

4.2.3 Programming Port.......................................................................................................................32

4.3 Programming Cable............................................................................................................................33

4.3.1 Changing Between Program Mode and Run Mode....................................................................33

4.3.2 Standalone Operation of the RCM4000......................................................................................34

4.4 A/D Converter (RCM4000 only)........................................................................................................35

4.4.1 A/D Converter Power Supply.....................................................................................................37

Page 4

RabbitCore RCM4100

4.5 Other Hardware..................................................................................................................................38

4.5.1 Clock Doubler ............................................................................................................................38

4.5.2 Spectrum Spreader......................................................................................................................38

4.6 Memory..............................................................................................................................................39

4.6.1 SRAM.........................................................................................................................................39

4.6.2 Flash EPROM.............................................................................................................................39

4.6.3 NAND Flash...............................................................................................................................39

Chapter 5. Software Reference 41

5.1 More About Dynamic C .....................................................................................................................41

5.2 Dynamic C Function Calls................................................................................................................43

5.2.1 Digital I/O...................................................................................................................................43

5.2.2 Serial Communication Drivers...................................................................................................43

5.2.3 SRAM Use.................................................................................................................................. 43

5.2.4 Prototyping Board Functions......................................................................................................45

5.2.4.1 Board Initialization............................................................................................................ 45

5.2.4.2 Alerts.................................................................................................................................. 46

5.2.5 Analog Inputs (RCM4000 only).................................................................................................47

5.3 Upgrading Dynamic C .......................................................................................................................61

5.3.1 Add-On Modules........................................................................................................................61

Chapter 6. Using the TCP/IP Features 63

6.1 TCP/IP Connections...........................................................................................................................63

6.2 TCP/IP Primer on IP Addresses.........................................................................................................65

6.2.1 IP Addresses Explained..............................................................................................................67

6.2.2 How IP Addresses are Used.......................................................................................................68

6.2.3 Dynamically Assigned Internet Addresses.................................................................................69

6.3 Placing Your Device on the Network ................................................................................................70

6.4 Running TCP/IP Sample Programs....................................................................................................71

6.4.1 How to Set IP Addresses in the Sample Programs.....................................................................72

6.4.2 How to Set Up your Computer for Direct Connect....................................................................73

6.5 Run the PINGME.C Sample Program................................................................................................74

6.6 Running Additional Sample Programs With Direct Connect............................................................74

6.7 Where Do I Go From Here?...............................................................................................................75

Appendix A. RCM4000 Specifications 77

A.1 Electrical and Mechanical Characteristics ........................................................................................78

A.1.1 A/D Converter...........................................................................................................................82

A.1.2 Headers......................................................................................................................................83

A.2 Rabbit 4000 DC Characteristics........................................................................................................84

A.3 I/O Buffer Sourcing and Sinking Limit.............................................................................................85

A.4 Bus Loading ......................................................................................................................................85

A.5 Conformal Coating............................................................................................................................88

A.6 Jumper Configurations......................................................................................................................89

Appendix B. Prototyping Board 91

B.1 Introduction ....................................................................................................................................... 92

B.1.1 Prototyping Board Features.......................................................................................................93

B.2 Mechanical Dimensions and Layout.................................................................................................95

B.3 Power Supply.....................................................................................................................................96

B.4 Using the Prototyping Board.............................................................................................................97

B.4.1 Adding Other Components........................................................................................................99

B.4.2 Measuring Current Draw...........................................................................................................99

B.4.3 Analog Features (RCM4000 only)..........................................................................................100

B.4.3.1 A/D Converter Inputs...................................................................................................... 100

B.4.3.2 Thermistor Input............................................................................................................. 102

B.4.3.3 A/D Converter Calibration.............................................................................................. 102

Page 5

User’s Manual

B.4.4 Serial Communication..............................................................................................................103

B.4.4.1 RS-232............................................................................................................................. 104

B.5 Prototyping Board Jumper Configurations ......................................................................................105

Appendix C. Power Supply 109

C.1 Power Supplies.................................................................................................................................109

C.1.1 Battery-Backup Circuits...........................................................................................................109

C.1.2 Reset Generator........................................................................................................................110

Notice to Users 111

Index 113

Schematics 117

Page 6

RabbitCore RCM4100

Page 7

User’s Manual 1

1. INTRODUCTION

The RCM4000 series of RabbitCore modules is one of the next

generation of core modules that tak e advantage of n ew Rabbit

®

4000 features such as hardware DMA, clock speeds of up to

60 MHz, I/O lines shared with up to five serial ports and four

levels of alternate pin functions that include variable-phase

PWM, auxiliary I/O, quadrature decoder, and input capture.

Coupled with more than 500 new opcode instructions that help

to reduce code size and improve processing speed , this equates

to a core module tha t is fast, efficien t, and the id eal soluti on for

a wide range of embedded applications. The RCM4000 also features an integrated 10 Bas e-T Et hern et po r t.

The Development Kit has the essentials that you need to design

your own microprocessor-based system, and includes a complete Dynamic C softw are development system. Th is Development Kit also contains a Prototyping Board that will al low you

to evaluate the RCM4000 and to prototype circuits that interface

to the RCM4000 module. You will also be able to write and test

software for the RCM4000 modules.

Throughout this manual, the term RCM4000 refers to the complete series of RCM4000

RabbitCore modules unless other production models are referred to specifically.

The RCM4000 has a Rabbit 4000 microprocessor operating at up to 58.98 MHz, static

RAM, flash memory, NAND flash mass-storage option, an 8-channel A/D converter, two

clocks (main oscillator and timekeeping), and the circuitry necessary for reset and management of battery backup of the Rabbit 4000’s internal real-time clock and the static

RAM. One 50-pin header brings out the Rabbit 4000 I/O bus lines, parallel ports, A/D

converter channels, and serial ports.

The RCM4000 receives its +3.3 V power from the customer-supplied motherboard on

which it is mounted. The RCM4000 can interface with all kinds of CMOS-compatible

digital devices through the motherboard.

Page 8

2 RabbitCore RCM4000

1.1 RCM4000 Features

• Small size: 1.84" × 2.42" × 0.77" (47 mm × 61 mm × 20 mm)

• Microprocessor: Rabbit 4000 running

at 58.98 MHz

• Up to 29 general-purpose I/O lines configurable with up to four alternate functions

• 3. 3 V I/O li nes wi th low-p ow er mo des down t o 2 kH z

•

Five CMOS-compatible serial ports — f

our ports are configurable as a clocked serial

ports (SPI), and one port is configurable as an SDLC/HDLC serial port.

• Combinations of up to eight single-ended or four differential 12-bit analog inputs

(RCM4000 only)

• Alternate I/O bus can be configured for 8 data lines and 6 address lines (shared with

parallel I/O lines), I/O read/write

• 512K flash memory, 512K SRAM, with a fixed mass-storage flash-memory option that

may be used with the standardized directory structure supported by the Dynamic C F AT

File System module

• Real-time clock

• Watchdog supervisor

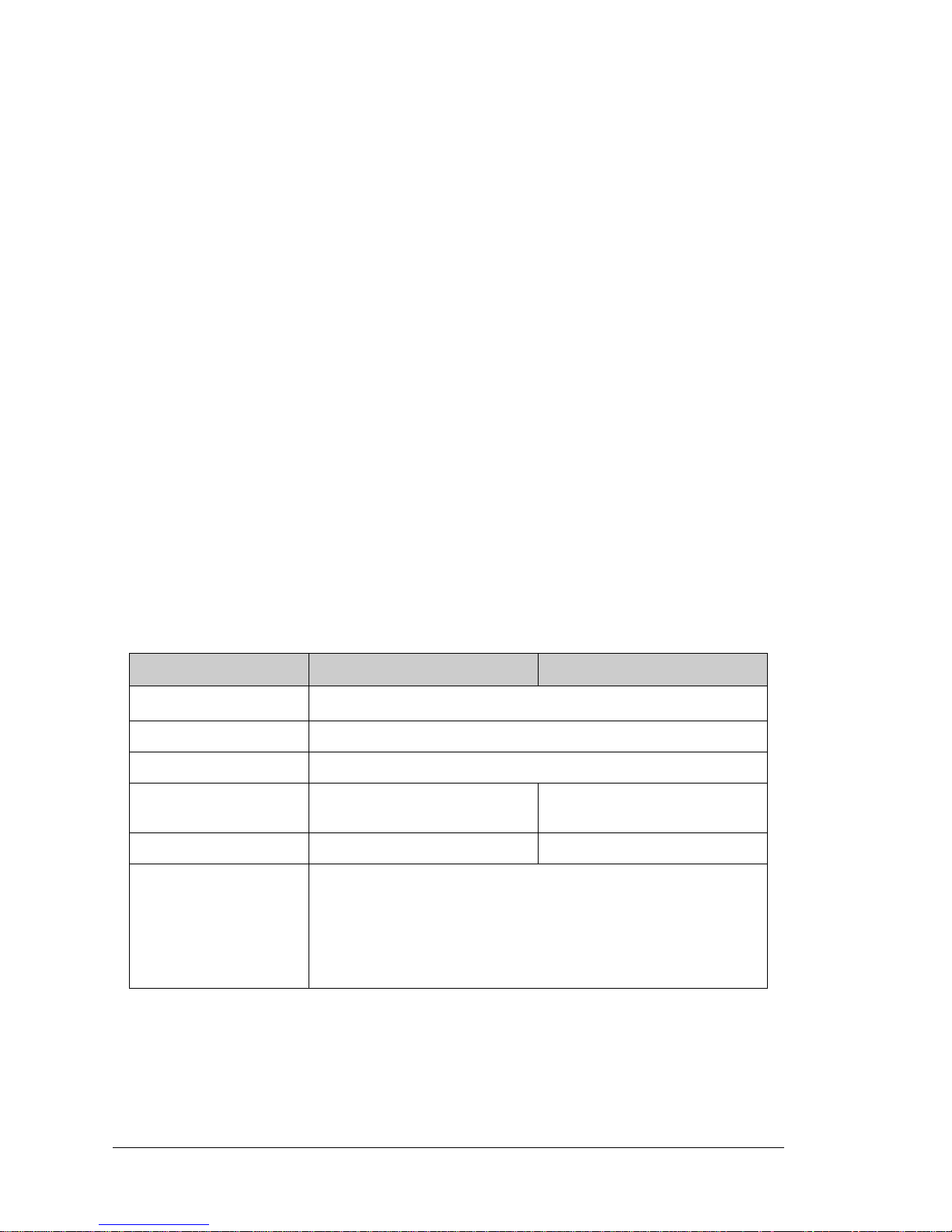

There are two RCM4000 production models. T able 1 summarizes their main features.

The RCM4000 is programmed ov er a stan dard PC seri al port th rough a programmi ng cable

supplied with t he Develo pment K it, and can also be program ed throug h a USB po rt with an

RS-232/USB convert er or over an Ethe rnet with the R abbitLink (both available from Rabbit

Semiconductor ).

Appendix A provides detailed specifications for the RCM4000.

Table 1. RCM4000 Features

Feature RCM4000 RCM4010

Microprocessor

Rabbit® 4000 at 58.98 MHz

SRAM 512K

Flash Memory (program) 512K

Flash Memory

(mass data storage)

32 Mbytes (NAND flash) —

A/D Converter 12 bits —

Serial P orts

5 shared high-speed, CMOS-compatible ports:

5 are configurable as asynchronous serial ports;

4 are configurable as clocked serial ports (SPI);

1 is configurable as an SDLC/HDLC serial port;

1 asynchronous serial port is used during programming

1 asynchronous serial po rt is ded i cated fo r A /D co nver ter (R CM40 00)

Page 9

User’s Manual 3

1.2 Advantages of the RCM4000

• Fast time to market using a fully engineered, “ready-to-run/ready-to-program” microprocessor core.

• Competit ive pr ici ng when c ompar ed with the alternative of purchasing and assembling

individual components.

• Easy C-language program development and debugging

• Rabbit Field Utility to download compiled Dynamic C .bin files, and cloning board

options for rapid production loading of programs.

• Generous memory size allows large programs with tens of thousands of lines of code,

and substantial data storage.

Page 10

4 RabbitCore RCM4000

1.3 Development and Evaluation Tools

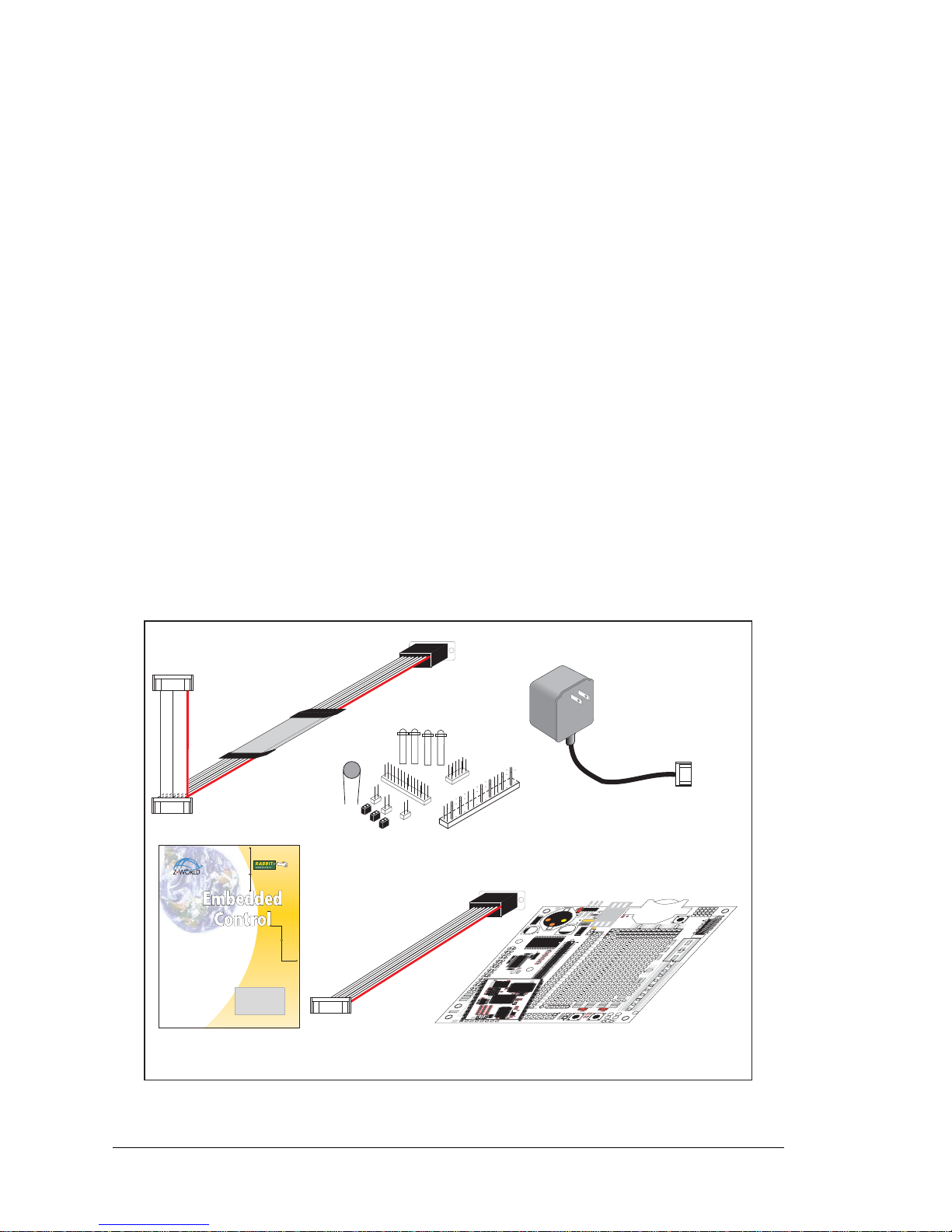

1.3.1 RCM4000 Development Kit

The RCM4000 Development Kit contains the hardware essentials you will need to use

your RCM4000 module. The items in the Development Kit and their use are as follows.

• RCM4010 module.

• Prototyping Board.

• AC adapter, 12 V DC, 1 A. (Included only with Development Kits sold for the North

American market. A header plug leading to bare leads is provided to allow overseas

users to connect their own power supply with a DC output of 8–24 V at 8 W.)

• 10-pin header to DE9 programming cable with integrated level-matching circuitry.

• 10-pin header to DB9 serial cable.

• Dynamic C® CD-ROM, with complete product documentation on disk.

• Getting Started instructions.

• A bag of accessory parts for use on the Prototyping Board.

• Rabbit 4000 Processor Easy Reference poster.

• Registration card.

Figure 1. RCM4000 Development Kit

®

A Digi International® Company.

Rabbit Semiconductor, Rabbit, Z-World, and Dynamic C are

registered trademarks of their respective holders.

RabbitCore RCM4000

Getting Started

Development Kit Contents

The RCM4000 Development Kit contains the following items:

• RCM4000 module.

• Prototyping Board.

• AC adapter, 12 V DC, 1 A. (Included only with Development Kits sold for the North American market. A

header plug leading to bare leads is provided to allow overseas users to connect their own power supply

with a DC output of 8–30 V.)

• 10-pin header to DB9 programming cable with integrated level-matching circuitry.

• 10-pin header to DB9 serial cable.

• Dynamic C

®

CD-ROM, with complete product documen-

tation on disk.

• Getting Started instructions.

• A bag of accessory parts for use on the Prototyping

Board.

• Rabbit 4000 Processor Easy Reference poster.

• Registration card.

Installing Dynamic C

®

Insert the CD from the Development Kit in

your PC’s CD-ROM drive. If the installation

does not auto-start, run the

setup.exe

program in the root directory of the

Dynamic C CD. Install any Dynamic C

modules after you install Dynamic C.

PROG

DIAG

Programming

Cable

Getting Started

Instructions

Prototyping Board

Accessory Parts for

Prototyping Board

Serial

Cable

D

1

R

1

PWR

DS1

GND

J1

U1

C1

GND

C2

J

P

1

C

3

D

2

J

P

2

C

4

+

3

.

3

V

J2

R

2

BT1

1

S1

RESET

R

X

D

T

X

D

T

X

C

R

X

C

G

N

D

J

4

U

X

2

9

RX81

R

X

8

7

C

X

4

1

RX83

RX11

C

X

3

9

UX30

UX10

UX12

UX14

UX16

RX79

C

X

2

9

C

X

1

7

RX67

U

X

4

5

R

X

8

5

GND

GND

GND

1

R24

R22

R21

R23

CX23

RX77

1

R

2

7

R

2

8

JP25

CX25

RX75

RX73

CX27

DS3

S3S2

DS2

J3

UX49

UX4

UX47

+5 V

GND

+3.3 V

RCM1

U

2

/RST_OUT

/IOWR

VBAT

EXT

PA1

PA3

PA5

PA7

PB1

PB3

PB5

PB7

PC1

PC3

PC5

PC7

PE1

PE3

PE5

PE7

PD1

LN1

PD3

LN3

PD5

LN5

PD7

LN7

VREF

GND

/IORD

/RST_IN

PA0

PA2

PA4

PA6

PB0

PB2

PB4

PB6

PC0

PC2

PC4

PC6

PE0

PE2

PE4

PE6

PD0

LN0

PD2

LN2

PD4

LN4

PD6

LN6

CVT

AGND

J

P

2

4

J

P

2

3

C

1

4

C

1

2

C

1

0

C8C7C

9

C

1

1

C

1

3

R10

R8R6R4R3R5R

7

R20

R

1

8

R

1

6

R

1

4

R

1

3

R

1

5

R

1

7

R29

J

P

1

1

J

P

1

5

J

P

1

9

J

P

2

1

J

P

2

2

J

P

2

0

J

P

1

7

J

P

1

3

R19

R9

RX57

RX55

RX97

RX49

U

X

3

3

U

X

3

1

R

X

8

9

UX3

U

X

3

7

U

X

4

2

U

X

4

1

R

X

6

3

R

X

6

5

R

X

6

1

RX59

R

2

6

R25

Q1

C15

C

1

9

C

2

0

U3

C18

C

1

7

JP16

JP6

JP5

JP12

JP4

JP3

JP14

JP8

JP7

JP18

JP9

JP10

C16

L1

C6

C5

A

G

N

D

C

V

T

L

N

6

I

N

L

N

4

I

N

L

N

2

I

N

L

N

0

IN

V

R

E

F

L

N

7

I

N

L

N

5

I

N

L

N

3

I

N

L

N

1

I

N

A

G

N

D

A

G

N

D

R

1

1

R

1

2

R

X

4

7

RX43

AC Adapter

(North American

kits only)

C20

L1

C21

R5

R6

R7

R8

R9

R10

R11

R12

R13

C9

C10

C11

C12

C13

C14

C15

C16

R

P1

JP6

JP5

R20

JP4

C3

U4

TP2

J1

R

38

R2

R1

U1

C8

C1

U2

C5

C4

R3

U3

R37

R21

U5

C17

C18

C52

C56

R23

R22

U6

JP3

R41

C6C7R4

U9

C53

1

40

41

80

Page 11

User’s Manual 5

1.3.2 Software

The RCM4000 is programmed using version 10.03 or later of Dynamic C. A compatible

version is included on the Development Kit CD-ROM.

Rabbit Semiconductor also offers add-on Dynamic C modules containing the popular

µC/OS-II real-time operating system, as well as PPP, Advanced Encryption Standard

(AES), and other select libraries. In addition to the Web-based technical support included

at no extra charge, a one-year telephone-based technical support module is also available

for purchase. Visit our Web site at www.rabbit.com or contact your Rabbit Semiconductor

sales representative or authorized distributor for further information.

1.3.3 Onlin e Documentation

The online documentation is installed along with Dynamic C, and an icon for the documentation menu is placed on the workstation’s desktop. Double-click this icon to reach the

menu. If the icon is missing, use your browser to find and load default.htm in the docs

folder, found in the Dynamic C installation folder.

The latest versions of all documents are always available for free, unregistered download

from our Web sites as well.

Page 12

6 RabbitCore RCM4000

Page 13

User’s Manual 7

2. GETTING S TARTED

This chapter describes the RCM4000 hardware in more detail, and

explains how to set up and use the accompanying Prototyping Board.

NOTE: This chapter (and thi s manual) assume that you have t he RCM4000 Development

Kit. If you purchased an RCM4000 module by itself, you will have to adapt the information in this chapter and elsewhere to your test and development setup.

2.1 Install Dynamic C

To develop and de bug pr ogram s for the RCM400 0 (a nd for a ll o ther Rabbit Se micond ucto r

hardware), you must install and use Dynamic C.

If you have not yet installed Dynamic C version 10.03 (or a later version), do so now by

inserting the Dynamic C CD from the RCM4000 Development Kit in your PC’ s CD-ROM

drive. If autorun is enabled, the CD installation will begin automatically.

If autorun is disabled or the installation does not start, use the Windows Start | Run menu

or Windows Disk Explorer to launch setup.exe from the root folder of the CD-ROM.

The installation program will guide you through the installation process. Most steps of the

process are self-explanatory.

Dynamic C uses a COM (serial ) port to communica te with the tar get deve lopment sy stem.

The installation allows you to choose the COM port that will be used. The default selection is COM1. You may select any available port for Dynamic C’s use. If you are not certain which port is available, select COM1. This selection can be changed later within

Dynamic C.

NOTE: The installation utility does not check the selected COM port in any way. Speci-

fying a port in u se by a not her device (mouse, modem, et c.) may l ea d t o a message such

as

"could not open serial port" when Dynamic C is started.

Once your installation is complete, you will have up to three new icons on your PC desktop. One icon is for Dynamic C, one opens the documentation menu, and the third is for

the Rabbit Field Utility, a tool used to download precompiled software to a target system.

If you have purchased any of the optional Dynamic C modules, install them after installing

Dynamic C. The modules may be installed in any order. You must install the modules in

the same directory where Dynamic C was installed.

Page 14

8 RabbitCore RCM4000

2.2 Hardware Connections

There are three steps to connecting the Prototyping Board for use with Dynamic C and the

sample programs:

1. Prepare the Prototyping Board for Development.

2. Attach the RCM4000 module to the Prototyping Board.

3. Connect the programming cable between the RCM4000 and the PC.

4. Connect the power supply to the Prototyping Board.

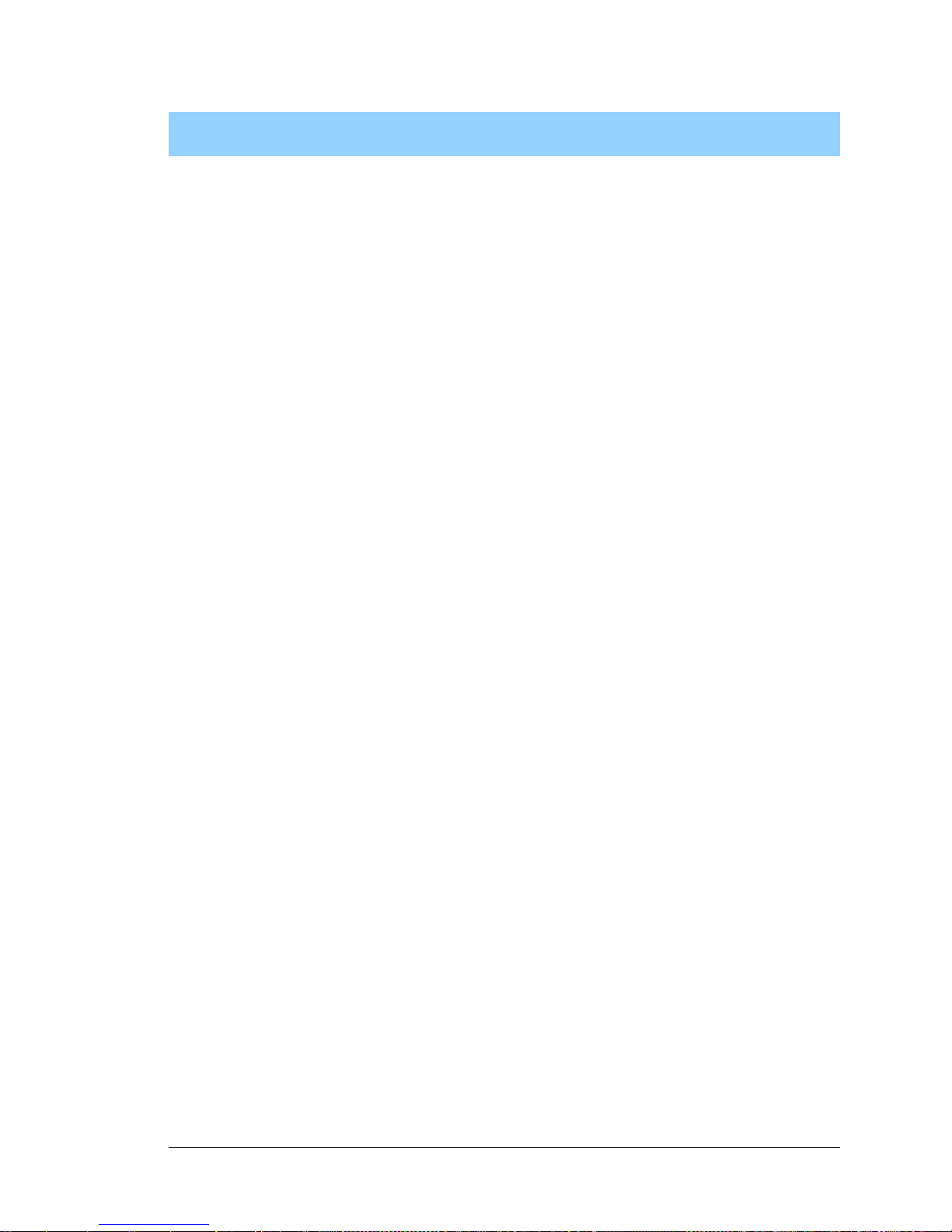

2.2.1 Prepare the Prototyping Board for Development

Snap in four of the plastic standoffs supplied in the bag of accessory parts from the Development Kit in the holes at the corners as shown.

Figure 2. Insert Standoffs

D

1

R

1

PWR

DS1

GND

J1

U1

C1

GND

C2

JP

1

C

3

D

2

JP

2

C

4

+

3.3 V

J2

R

2

BT1

1

S1

RESET

R

XD

TX

D

TX

C

R

XC

G

N

D

J4

UX

29

RX81

R

X

87

C

X41

RX83

RX11

C

X

39

UX30

UX10

UX12

UX14

UX16

RX79

C

X

29

C

X17

RX67

U

X45

RX

85

GND

GND

GND

1

R24

R22

R21

R23

CX23

RX77

1

R27R

28

JP25

CX25

RX75

RX73

CX27

DS3

S3S2

DS2

J3

UX49

UX4

UX47

+5 V

GND

+3.3 V

RCM1

U

2

/RST_OUT

/IOWR

VBAT

EXT

PA1

PA3

PA5

PA7

PB1

PB3

PB5

PB7

PC1

PC3

PC5

PC7

PE1

PE3

PE5

PE7

PD1

LN1

PD3

LN3

PD5

LN5

PD7

LN7

VREF

GND

/IORD

/RST_IN

PA0

PA2

PA4

PA6

PB0

PB2

PB4

PB6

PC0

PC2

PC4

PC6

PE0

PE2

PE4

PE6

PD0

LN0

PD2

LN2

PD4

LN4

PD6

LN6

CVT

AGND

JP24JP

23

C14C12C

10

C8C7C

9

C

11

C

13

R10

R8R6R4R3R5R

7

R20

R18R16R14R13R15R

17

R29

JP11JP15JP19JP21JP22

JP20

JP17

JP

13

R19

R9

RX57

RX55

RX97

RX49

U

X33U

X

31

R

X

89

UX3

U

X

37

U

X

42

U

X

41

R

X

63

R

X

65

R

X

61

RX59

R

26

R25

Q1

C15

C

19

C

20

U3

C18

C

17

JP16

JP6

JP5

JP12

JP4

JP3

JP14

JP8

JP7

JP18

JP9

JP10

C16

L1

C6

C5

AG

N

D

C

V

T

LN

6INLN4INLN2INLN0IN

V

R

E

F

LN

7INLN5INLN3INLN1IN

A

G

N

D

A

G

N

D

R

11

R

12

R

X

47

RX43

Page 15

User’s Manual 9

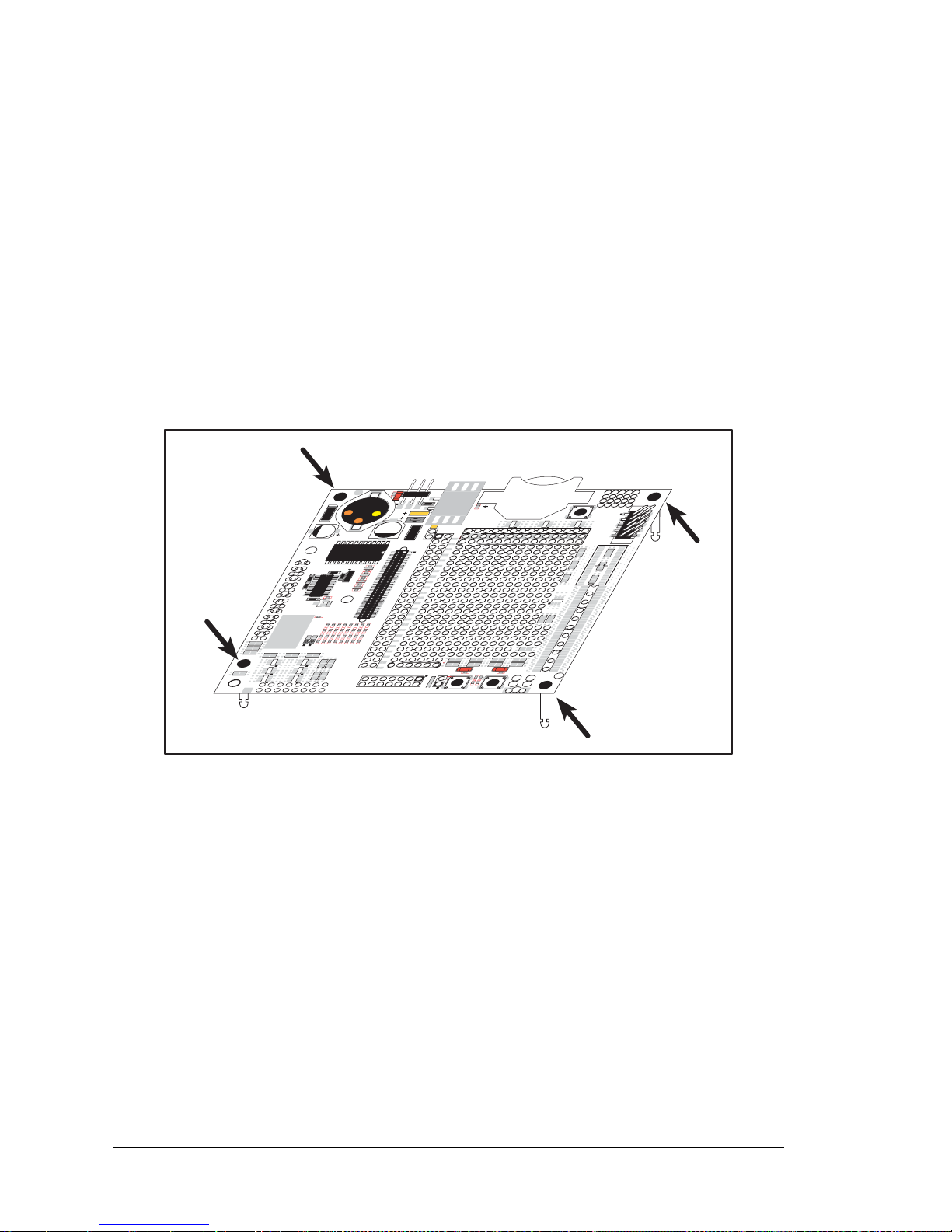

2.2.2 Attach Module to Prototyping Board

Turn the RCM4000 module so that the mounting holes line up with the corresponding

holes on the Prototyping Board. Insert a standoff between the upper mounting hole and the

Prototyping Board as shown, then insert the module’s header J3 on the bottom side into

socket RCM1 on the Prototyping Board.

Figure 3. Install the Module on the Prototyping Board

NOTE: It is important that you line up the pins on header J3 of the module exactly with

socket RCM1 on the Pr ototyp ing Boa rd. The header pins may bec ome bent or da maged

if the pin alignment is offse t, and the module will not work. Permanent electrical damage to the module may also result if a misaligned module is powered up.

Press the module’s pins gently into the Prototyping Board socket—press down in the area

above the header pins—and “snap” the standoff into the mounting holes.

D1

R1

PWR

DS1

GND

J1

U1

C1

GND

C2

JP1

C3

D2

JP2

C4

+3.3 V

J2

R2

BT1

1

S1

RESET

RXD TXD

TXC RXC

GND

J4

UX29

RX81

RX87

CX41

RX83

RX11

CX39

UX30

UX10

UX12

UX14

UX16

RX79

CX29

CX17

RX67

UX45

RX85

GND

GND

GND

1

R24

R22

R21

R23

CX23

RX77

1

R27

R28

JP25

CX25

RX75

RX73

CX27

DS3

S3S2

DS2

J3

UX49

UX4

UX47

+5 V

GND

+3.3 V

RCM1

U2

/RST_OUT

/IOWR

VBAT

EXT

PA1

PA3

PA5

PA7

PB1

PB3

PB5

PB7

PC1

PC3

PC5

PC7

PE1

PE3

PE5

PE7

PD1

LN1

PD3

LN3

PD5

LN5

PD7

LN7

VREF

GND

/IORD

/RST_IN

PA0

PA2

PA4

PA6

PB0

PB2

PB4

PB6

PC0

PC2

PC4

PC6

PE0

PE2

PE4

PE6

PD0

LN0

PD2

LN2

PD4

LN4

PD6

LN6

CVT

AGND

JP24

JP23

C14

C12

C10

C8C7C9

C11

C13

R10

R8R6R4R3R5

R7

R20

R18

R16

R14

R13

R15

R17

R29

JP11

JP15

JP19

JP21

JP22

JP20

JP17

JP13

R19

R9

RX57

RX55

RX97

RX49

UX33UX31

RX89

UX3

UX37 UX42

UX41

RX63

RX65

RX61

RX59

R26

R25

Q1

C15

C19 C20

U3

C18

C17

JP16

JP6

JP5

JP12

JP4

JP3

JP14

JP8

JP7

JP18

JP9

JP10

C16

L1

C6

C5

AGND

CVT

LN6IN

LN4IN

LN2IN

LN0IN

VREF

LN7IN

LN5IN

LN3IN

LN1IN

AGND

AGND

R11

R12

RX47

RX43

R34

C8

C7

C9

C12

C14

L6

L7

C15

C11

L5

L4

R20

J2

C41

R35

DS1

DS2

R37

R36

ACT

LINK

C72

Y3

C71

U17

C66

R46

U18

R47

C53

C54

C52

C51

C50

C49

C47

C48

U7

C42

C43

U6

C34

C35

Y1

U5

R25

C33

R24

C20

Q1

T1

C18

L3

R7

R6

L2

C16

C13

L9

L8

R5

R4

R3

R1

R2

R8

R51

C10

U1

R9

R10

JP1

JP3

JP2

U3

C22

C23

RP2

R43

D1

R27

R28

JP4

R33

R32

R31

Y2

R48

C55

C56

C46

C45

C44

U9

R30

C38

U8

C36

R26

C32

C30

C31

R29

C29

C28

C26

C27

C24

C25

J1

RCM4000/

RCM4010

RCM1

Line up mounting

holes with holes

on Prototyping Board.

Insert standoff

between upper

mounting hole and

Prototyping Board.

Page 16

10 RabbitCore RCM4000

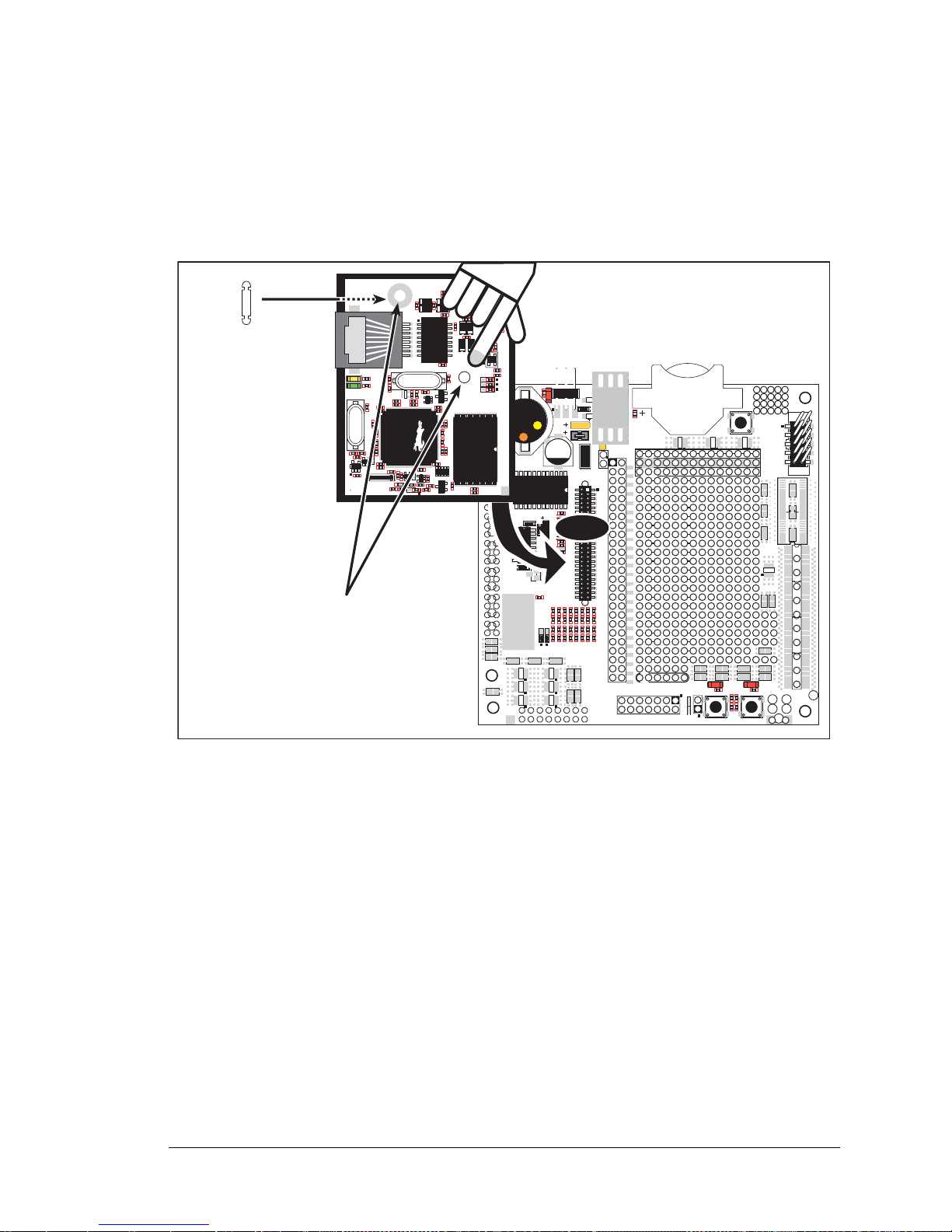

2.2.3 Connect Programming Cable

The programming cable connects the module to the PC running Dynamic C to download

programs and to monitor the module during debugging.

Connect the 10-pin connector of the programming cable labeled PROG to header J1 on

the RCM4000 as shown in Figure 4. Be sure to orient the marked (usually red) edge of the

cable towards pin 1 of the connector. (Do not use the DIAG connector , which is used for a

normal serial connection.)

Figure 4. Connect Programming Cable and Power Supply

NOTE: Be sure to use the pro gramming c able (p art numbe r 10 1-0542) suppli ed with this

Development Kit—the programming cable has blue shrink wrap around the RS-232

converter section located in the middle of the cable. Programming cables with red or

clear shrink wrap from other Z-World or Rabbit Semiconductor kits ar e not designe d to

work with RCM4000 modules.

Connect the other end of the programming cable to a COM port on your PC.

NOTE: Some PCs now come equipped only with a USB port. It may be possible to use

an RS-232/USB converter (Part No. 540-0070) with the programming cable supplied

with the RCM4000 Development Kit. Note that not all RS-232/USB converters work

with Dynamic C.

D1

R1

PWR

DS1

GND

J1

U1

C1

GND

C2

JP1

C3

D2

JP2

C4

+3.3 V

J2

R2

BT1

1

S1

RESET

RXD TXD

TXC RXC

GND

J4

UX29

RX81

RX87

CX41

RX83

RX11

CX39

UX30

UX10

UX12

UX14

UX16

RX79

CX29

CX17

RX67

UX45

RX85

GND

GND

GND

1

R24

R22

R21

R23

CX23

RX77

1

R27

R28

JP25

CX25

RX75

RX73

CX27

DS3

S3S2

DS2

J3

UX49

UX4

UX47

+5 V

GND

+3.3 V

RCM1

U2

/RST_OUT

/IOWR

VBAT

EXT

PA1

PA3

PA5

PA7

PB1

PB3

PB5

PB7

PC1

PC3

PC5

PC7

PE1

PE3

PE5

PE7

PD1

LN1

PD3

LN3

PD5

LN5

PD7

LN7

VREF

GND

/IORD

/RST_IN

PA0

PA2

PA4

PA6

PB0

PB2

PB4

PB6

PC0

PC2

PC4

PC6

PE0

PE2

PE4

PE6

PD0

LN0

PD2

LN2

PD4

LN4

PD6

LN6

CVT

AGND

JP24

JP23

C14

C12

C10

C8C7C9

C11

C13

R10

R8R6R4R3R5

R7

R20

R18

R16

R14

R13

R15

R17

R29

JP11

JP15

JP19

JP21

JP22

JP20

JP17

JP13

R19

R9

RX57

RX55

RX97

RX49

UX33UX31

RX89

UX3

UX37 UX42

UX41

RX63

RX65

RX61

RX59

R26

R25

Q1

C15

C19 C20

U3

C18

C17

JP16

JP6

JP5

JP12

JP4

JP3

JP14

JP8

JP7

JP18

JP9

JP10

C16

L1

C6

C5

AGND

CVT

LN6IN

LN4IN

LN2IN

LN0IN

VREF

LN7IN

LN5IN

LN3IN

LN1IN

AGND

AGND

R11

R12

RX47

RX43

R34

C8

C7

C9

C12

C14

L6

L7

C15

C11

L5

L4

R20

J2

C41

R35

DS1

DS2

R37

R36

ACT

LINK

C72

Y3

C71

U17

C66

R46

U18

R47

C53

C54

C52

C51

C50

C49

C47

C48

U7

C42

C43

U6

C34

C35

Y1

U5

R25

C33

R24

C20

Q1

T1

C18

L3

R7

R6

L2

C16

C13

L9

L8

R5

R4

R3

R1

R2

R8

R51

C10

U1

R9

R10

JP1

JP3

JP2

U3

C22

C23

RP2

R43

D1

R27

R28

JP4

R33

R32

R31

Y2

R48

C55

C56

C46

C45

C44

U9

R30

C38

U8

C36

R26

C32

C30

C31

R29

C29

C28

C26

C27

C24

C25

J1

AC Adapter

RESET

3-pin

power connector

J1

Colored

edge

To

PC COM port

Blue

shrink wrap

PROG

DIAG

Programming

Cable

PROG

J1

Page 17

User’s Manual 11

2.2.4 Connect Power

Once all the other connections have been made, you can connect power to the Prototyping

Board. Connect the AC adapter to 3-pin header J1 on the Prototyping Board as shown in

Figure 4 above. The connector may be attached either way as long as it is not offset to one

side—the center pin of J1 is always connected to the positive terminal, and either edge pin

is ground.

Plug in the AC adapter. The PWR LED on the Prototyping Board next to the power connector at J1 should light up. The RCM4000 and the Prototyping Board are now ready to be

used.

NOTE: A RESET button is provided on the Protot yping Boar d next to t he batter y holder

to allow a hardware reset without disconnecting power.

Other Power-Supplies

Development Kits sold outside North America include a header connector that may be

used to connect your power supply to 3-pin header J1 on the Prototyping Board. The

power supply should deliver 8 V–30 V DC at 8 W.

Page 18

12 RabbitCore RCM4000

2.3 Run a Sample Program

If you already have Dynamic C installed, you are now ready to test your programming

connections by running a sample program. Start Dynamic C by double-clicking on the

Dynamic C icon or by double-clicking on dcrab_XXXX.exe in the Dynamic C root

directory, where XXXX are version-specific characters.

If you are using a USB port to connect your computer to the RCM4000, choose Options >

Project Options

and select “Use USB to Serial Converter” under the Communications

tab. You may have to determine which COM port was assigned to the RS-232/USB

converter.

2.3.1 Run a Sample Program

Find the file PONG.C, which is in the Dynamic C SAMPLES folder. To run the program,

open it with the File menu, comp ile it us ing th e Compile menu, and then run it by selecting

Run in the Run menu. The STDIO window will open on your PC and will display a small

square bouncing around in a box.

2.3.2 Troubleshooting

If Dynamic C appears to compile the BIOS successfully, but you then receive a communication error message when you compile and load a sample program, it is possible that your

PC cannot handle the higher program-loading baud rate. Try changing the maximum

download rate to a slower baud rate as follows.

• Locate the Serial Options dialog in the Dynamic C Options > Project Options >

Communications

menu. Select a slower Max download baud rate.

If a program compiles and loads, but then loses target communication before you can

begin debugging, it is possible that your PC cannot handle the default debugging baud

rate. Try lowering the debugging baud rate as follows.

• Locate the Serial Options dialog in the Dynamic C Options > Project Options >

Communications

menu. Choose a lower debug baud rate.

If you receive the message No Rabbit Processor Detected, the programming

cable may be connected to the wrong COM port, a connection may be faulty, or the target

system may not be powered up. First, check to see that the power LED on the Prototyping

Board is lit and that the jumper across pins 5–6 of header JP10 on the Prototyping B oard is

installed. If the LED is lit, check both ends of the programming cable to ensure that it is

firmly plugged into the PC and the programming port on the Prototyping Board. Ensure

that the module is firmly and correctly installed in its connectors on the Prototyping Board.

If there are no faults with the hardware, select a different COM port within Dynamic C.

From the Options menu, select Project Options, then select Communications. Select

another COM port from the list, then click OK. Press <Ctrl-Y> to force Dynamic C to

recompile the BIOS. If Dynamic C still re ports it is unable to locate the target system, repeat

the above steps until you locate the active COM port.You should receive a message Bios

compiled successfully once this step is completed successfully.

Page 19

User’s Manual 13

2.4 Where Do I Go From Here?

If the sample program ran fine, you are now ready to go on to the sample programs in

Chapter 3 and to develop your own applications. The sample programs

can be easily modi-

fied for your own use. The user's manual also provides complete hardware reference infor-

mation and software function calls for the RCM4000 and the Prototyping Board.

For advanced development topics, refer to the Dynamic C User’s Manual, also in the

online documentation set.

2.4.1 Technical Support

NOTE: If you purchased your RCM4000 through a d ist ri buto r or thr ough a Rabbit Semi-

conductor or Z-World partner, contact t he di stributor or partner first for technical support.

If there are any problems at this point:

• Use the Dynamic C Help menu to get further assistance with Dynamic C.

• Check the Rabbit Semiconductor/Z-World Technical Bulletin Board at

www.rabbit.com/support/bb/.

• Use the Technical Support e-mail form at www.rabbit .com/sup port/ .

Page 20

14 RabbitCore RCM4000

Page 21

User’s Manual 15

3. RUNNING SAMPLE PROGRAMS

To develop and debug programs for the RC M4000 (and for all

other Z-World and Rabbit Semiconductor hardware), you must

install and use Dynamic C. This chapter provides a tour of its

major features with respect to the RCM4000.

3.1 Introduction

To help familiarize you with the RCM4000 modules, Dynamic C includes several sample

programs. Loading, executing and studying these programs will give you a solid hands-on

overview of the RCM4000’s capabilities, as well as a quick start with Dynamic C as an

application development tool.

NOTE:

The sample progr ams assum e that you have at lea st an el ementa ry gr asp of ANS I C.

If you do not, see the introductory pages of the Dynamic C User’s Manual for a sug-

gested reading list.

In order to run the sample programs discussed in this chapter and elsewhere in this manual,

1. Your module must be plugged in to the Prototyping Board as described in Chapter 2,

“Getting Started.”

2. Dynamic C must be installed and running on your PC.

3. The programming cable must connect the programming header on the module to your

PC.

4. Power must be applied to the module through the Prototyping Board.

Refer to Chapter 2, “Getting Started,” if you need further information on these steps.

To run a sample program, open it with the File menu (if it is not still open), then compile

and run it by pressing F9.

Each sample program has comments that describe the purpose and function of the pro-

gram. Follow the instructions at the beginning of the sample program.

More complete information on Dynamic C is provided in the Dynamic C User’s Manual.

Page 22

16 RabbitCore RCM4000

3.2 Sample Programs

Of the many sample programs included with Dynamic C, several are specific to the

RCM4000 modules. These programs will be found in the SAMPLES\RCM4000 folder.

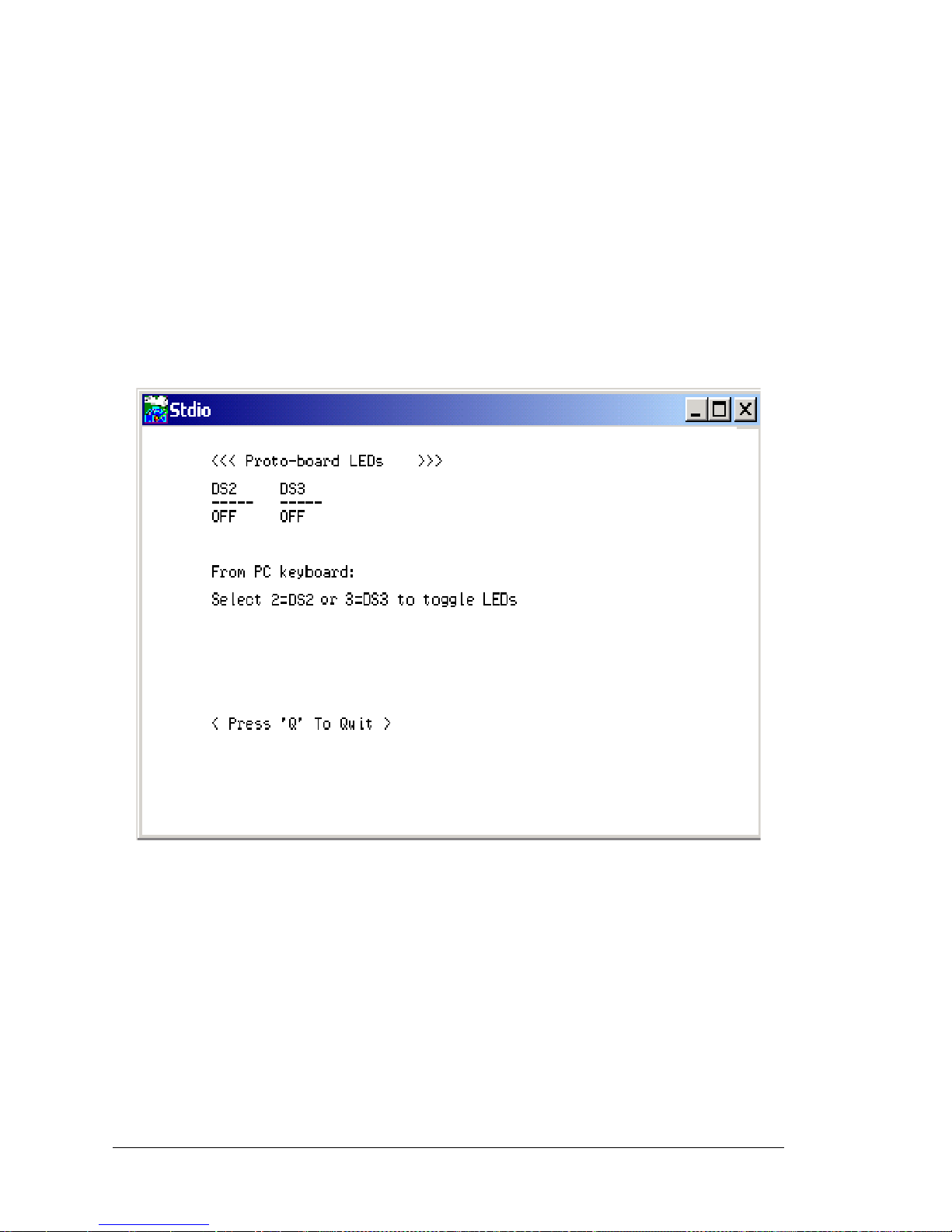

• CONTROLLED.C—Demonstrates use of the digital outputs by having you turn LEDs

DS2 and DS3 on the Prototyping Board on or off from the STDIO window on your PC.

Parallel Port B bit 2 = LED DS2

Parallel Port B bit 3 = LED DS3

Once you compile and run CONTROLLED.C, the following display will appear in the

Dynamic C STDIO window.

Press “2” or “3” on your keyboard to select LED DS2 or DS3 on the Prototyping

Board. Then follow the prompt in the Dynamic C STDIO window to turn the LED ON

or OFF. A logic low will light up the LED you selected.

• FLASHLED1.C—demonstrates the use of assembly language to flash LEDs DS2 and

DS3 on the Prototyping Board at different rates. Once you have compiled and run this

program, LEDs DS2 and DS3 will flash on/off at different rates.

• FLASHLED2.C—demonstrates the use of cofunctions and costatements to flash LEDs

DS2 and DS3 on the Prototyping Board at different rates. Once you have compiled and

run this program, LEDs DS2 and DS3 will flash on/off at different rates.

Page 23

User’s Manual 17

• LOW_POWER.C—demonstrates how to implement a function in RAM to reduce power

consumption by the Rabbit microprocessor . There are four features that lead to the lowest possible power draw by the microprocessor.

1. Run the CPU from the 32 kHz crystal.

2. Turn off the high-frequency crystal oscillator.

3. Run from RAM.

4. Ensure that internal I/O instructions do not use CS0.

Once you are ready to compile and run this sample program, use <Alt-F9> instead of

just F9. This will disable polling, which will allow Dynamic C to continue debugging

once the target starts running off the 32 kHz oscillator.

This sample program will toggle LEDs DS2 and DS3 on the Prototyping Board. You

may use an oscilloscope. DS2 will blink the fastest. After switching to low power , both

LEDs will blink together.

• TAMPERDETECTION.C—demonstrates how to detect an attempt to enter the bootstrap

mode. When an attempt is detected, the battery-backed onchip-encryption RAM on the

Rabbit 4000 is erased. This battery-backed onchip-encryption RAM can be useful to

store data such as an AES encryption key from a remote location.

This sample program shows how to load and read the battery-backed onchip-encryption

RAM and how to enable a visual indicator.

Once this sample is compiled running (you have pressed the F9 key while the sample

program is open), remove the programming cable and press the reset button on the

Prototyping Board to reset the module. LEDs DS2 and DS3 will be flashing on and off.

Now press switch S2 to load the battery-backed RAM with the encryption key. The

LEDs are now on continuously. Notice that the LEDs will stay on even when you press

the reset button on the Prototyping Board.

Reconnect the programming cable briefly and unplug it again. The LEDs will be flashing because the battery-backed onchip-encryption RAM has been erased. Notice that

the LEDs will continue flashing even when you press the reset button on the Prototyping Board.

You may press switch S2 again and repeat the last steps to watch the LEDs.

• TOGGLESWITCH.C—demonstrates the use of costatements to detect switch presses

using the press-and-release method of debouncing. LEDs DS2 and DS3 on the Prototyping Board are turned on and off when you press switches S2 and S3. S2 and S3 are

controlled by PB4 and PB5 respectively.

Once you have loaded and executed these five programs and have an understanding of

how Dynamic C and the RCM4000 modules interact, you can move on and try the other

sample programs, or begin building your own.

Page 24

18 RabbitCore RCM4000

3.2.1 Use of NAND Flash (RCM4000 only)

The following sample programs can be found in the SAMPLES\RCM4000\NANDFlash folder.

• NFLASH_DUMP.c—This program is a utility for dumping the nonerased contents of a

NAND flash chip to the Dynamic C

STDIO window, and the contents may be redi-

rected to a serial port.

When the sample program starts running, it attempts to communicate with the user-

selected NAND flash chip. If this communication is successful and the main page size

is acceptable, the nonerased page contents (non 0xFF) from the NAND flash page are

dumped to the Dynamic C STDIO win.for inspection.

Note that an error message might appear when the first 32 pages (0x20 pages) are

“dumped.” You may ignore the error message.

• NFLASH_INSPECT.c—This program is a utility for inspecting the contents of a

NAND flash chip. When the sample program starts running, it attempts to communicate with the NAND flash chip selected by the user . Once a NAND flash chip is found,

the user can execute various commands to print out the contents of a specified page,

clear (set to zero ) all the bytes in a s pecified pag e, erase (set to FF), or write to specified

pages.

CAUTION: When you run this sample program, enabling the #define

NFLASH_CANERASEBADBLOCKS macro makes it possi ble t o write to bad blocks.

• NFLASH_LOG.c—This program runs a simple Web server and stores a log of hits in

the NAND flash.

This log can be viewed and cleared from a browser by connecting the RJ-45 jack on the

RCM4000 to your PC as described in Section 6.1. The sidebar on the next page

explains how to set up your PC or notebook to view this log.

Page 25

User’s Manual 19

As long as you have not modified the TCPCONFIG 1 macro in the sample program,

enter the following server address in your Web browser to bring up the Web page

served by the sample program.

http://10.10.6.100

Otherwise use the TCP/IP settings you entered in the TCP_CONFIG.LIB library.

This sample program does not exhibit ideal behavior in its method of writing to the

NAND flash. However, the inefficiency attributable to the small amount o f data written

in each append operation is offset somewhat by the expected relative infrequency of

these writes, and by the sample program's method of “walking” through the flash

blocks when appending data as well as when a log is cleared.

• NFLASH_ERASE.c—This program is a utility to erase all the good blocks on a NAND

flash chip. When the program starts running, it attempts to establish communication

with the NAND flash chip selected by the user. If the communication is successful, the

progress in erasing the blocks is displayed in the Dynamic C STDIO window as the

blocks are erased.

Follow these instructions to set up your PC or notebook. Check with your administrator if you are unable to change the settings as described here since you may need

administrator privileges. The instructions are specifically for Windows 2000, but the

interface is similar for other versions of Windows.

TIP: If you are using a PC that is already on a network, you will disconnect the PC

from that network to run these sample programs. Write down the existing settings

before changing them to facilitate restoring them when you are finished with the

sample programs and reconnect your PC to the network.

1. Go to the control panel (Start > Settings > Control Panel), and then double-click

the Network icon.

2. Select the network interface card used for the Ethernet interface you intend to use

(e.g., TCP/IP Xircom Credit Card Network Adapter) and click on the “Properties” button. Depending on which version of Windows your PC is running, you may

have to select the “Local Area Connection” first, and then click on the “Properties”

button to bring up the Ethernet interface dialog. Then “Configure” your interface

card for a “10Base-T Half-Duplex” or an “Auto-Negotiation” connection on the

“Advanced” tab.

NOTE: Your network interface card will likely have a different name.

3. Now select the IP Address tab, and check Specify an IP Address, or select TCP/IP

and click on “Properties” to assign an IP address to your computer (this will disable

“obtain an IP address automatically”):

IP Address : 10.10.6.101

Netmask : 255.255.255.0

Default gateway : 10.10.6.1

4. Click <OK> or <Close> to exit the various dialog boxes.

Page 26

20 RabbitCore RCM4000

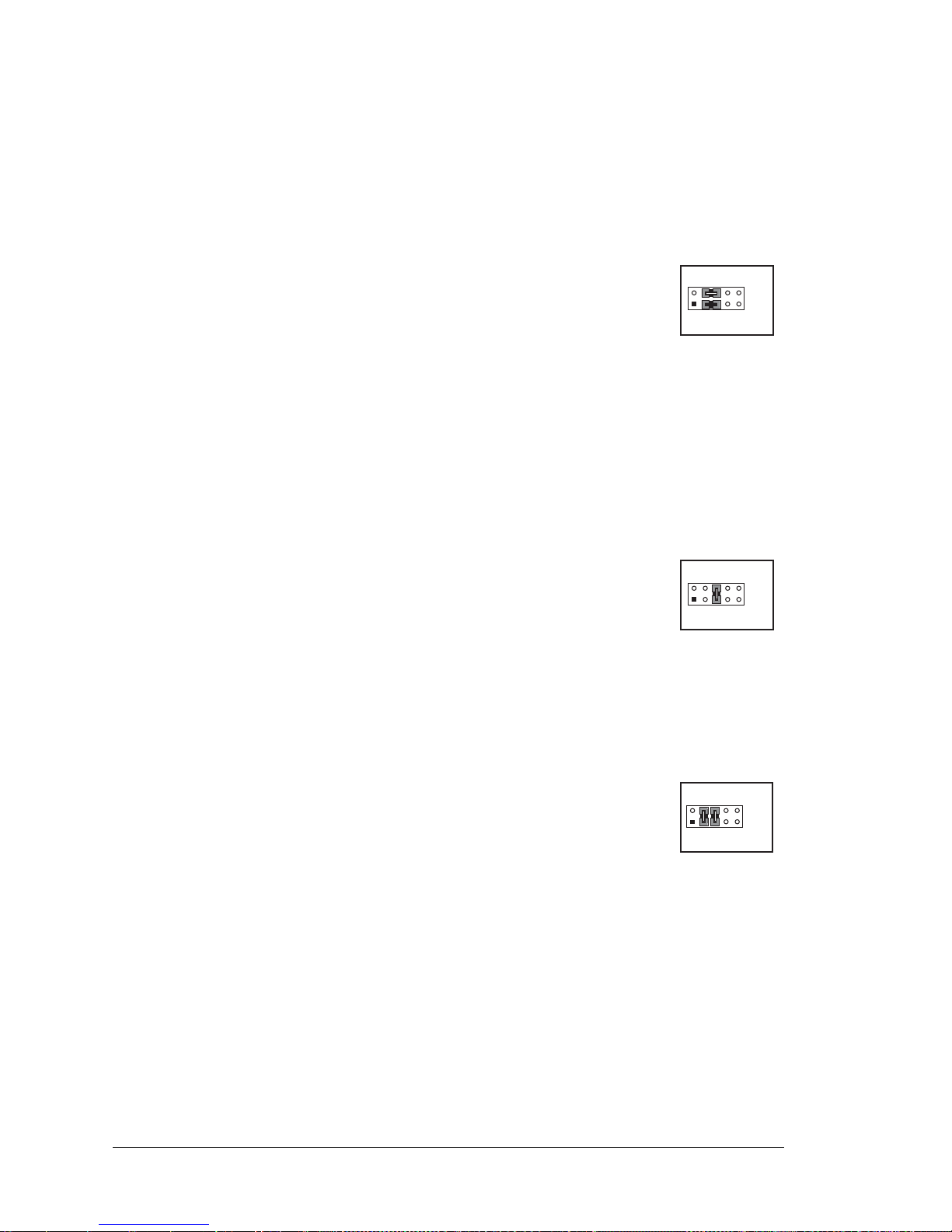

3.2.2 Serial Co mmunication

The following sample programs are found in the SAMPLES\RCM4000\SERIAL folder.

• FLOWCONTROL.C—This program demonstrates how to configure Serial Port D for

CTS/RTS with serial data coming from Serial Port C (TxC) at 115,200 bps. The serial

data received are displayed in the STDIO window.

To set up the Prototyping Board, you will need to tie TxD and RxD

together on the RS-232 header at J4, and you will also tie TxC and

RxC together using the jumpers supplied in the Development Kit as

shown in the diagram.

A repeating triangular pattern should print out in the STDIO window.

The program will periodically switch flow control on or of f to demonstrate the ef fect of

no flow control.

If you have two Prototyping Boards with modules, run this sample program on the

sending board, then disconnect the programming cable and reset the sending board so

that the module is operating in the Run mode. Connect TxC, TxD, and GND on the

sending board to RxC, RxD, and GND on the other board, then, with the programming

cable attached to the other module, run the sample program.

• PARITY.C—This program demonstrates the use of parity modes by

repeatedly sending byte values 0–127 from Serial Port C to Serial Port D.

The program will switch between generating parity or not on Serial

Port C. Serial Port D will always be checking parity, so parity errors

should occur during every other sequence.

To set up the Prototyping Board, you will need to tie TxC and RxD together on the

RS-232 header at J4 using one of the jumpers supplied in the Development Kit as

shown in the diagram.

The Dynamic C STDIO window will display the error sequence.

• SIMPLE3WIRE.C—This program demonstrates basic RS-232 serial

communication. Lower case characters are sent by TxC, and are

received by RxD. The characters are converted to upper case and are

sent out by TxD, are received by RxC, and are displayed in the

Dynamic C STDIO window.

To set up the Prototyping Board, you will need to tie TxD and RxC together on the

RS-232 header at J4, and you will also tie RxD and TxC together using the jumpers

supplied in the Development Kit as shown in the diagram.

J4

RxC TxC

GND

TxD RxD

J4

RxC

RxD GND

TxD

TxC

J4

RxC TxC

GND

TxD RxD

Page 27

User’s Manual 21

• SIMPLE5WIRE.C—This program demonstrates 5-wire RS-232 serial communication

with flow control on Serial Port D and data flow on Serial Port C.

To set up the Prototyping Board, you will need to tie TxD and RxD

together on the RS-232 header at J4, and you will also tie TxC and

RxC together using the jumpers supplied in the Development Kit as

shown in the diagram.

Once you have compiled and run this program, you can test flow control by disconnecting TxD from RxD while the program is running. Characters will no

longer appear in the STDIO window, and will display again once TxD is connected

back to RxD.

If you have two Prototyping Boards with modules, run this sample program on the

sending board, then disconnect the programming cable and reset the sending board so

that the module is operating in the Run mode. Connect TxC, TxD, and GND on the

sending board to RxC, RxD, and GND on the other board, then, with the programming

cable attached to the other module, run the sample program. Once you have compiled

and run this program, you can test flow control by disconnecting TxD from RxD as

before while the program is running.

• SWITCHCHAR.C—This program demonstrates transmitting and then receiving an

ASCII string on Serial Ports C and D. It also displays the serial data received from both

ports in the STDIO window.

To set up the Prototyping Board, you will need to tie TxD and RxC

together on the RS-232 header at J4, and you will also tie RxD and

TxC together using the jumpers supplied in the Development Kit as

shown in the diagram.

Once you have compiled and run this program, press and release

switches S2 and S3 on the Prototyping Board. The data sent between the serial ports

will be displayed in the STDIO window.

J4

RxC TxC

GND

TxD RxD

J4

RxC TxC

GND

TxD RxD

Page 28

22 RabbitCore RCM4000

3.2.3 A/D Converter Inputs (RCM4000 only)

The following sample programs are found in the SAMPLES\RCM4000\ADC folder.

• AD_CAL_CHAN.C—Demonstrates how to recalibrate one single-ended analog input

channel with one gain using two known voltages to generate the calibration constants

for that channel. The constants will be rewritten into the user block data area.

Connect a positive voltage to an analog input channel on the Prototyping Board, and

connect the ground to GND. Use a voltmeter to measure the voltage, and follow the instruc-

tions in the Dynamic C STDIO window. Remember that analog input LN7 on the Prototyping

Board is used with the thermistor and should not be used with this sample program.

NOTE: The above sample program will overwrite any existing calibration constants.

• AD_RDVOLT_ALL.C—Demonstrates how to read all single-ended A/D input channels

using previously defined calibration constants. Coefficients are read from the simulated

EEPROM in the flash memory to compute equivalent voltages, and cannot be run in

RAM.

Compile and run this sample program once you have connected a positive voltage from

0–20 V DC to an analog input (except LN7) on the Prototyping Board, and ground to

GND. Follow the prompts in the Dynamic C STDIO window. Computed raw data and

equivalent voltages will be displayed.

• AD_SAMPLE.C—Demonstrates how to how to use a low level driver on single-ended

inputs. The program will continuously display the voltage (averaged over 10 samples)

that is present on the A/D converter channels (except LN7). Coefficients are read from

the simulated EEPROM in the flash memory to compute equivalent voltages, so the

sample program cannot be run in RAM.

Compile and run this sample program once you have connected a positive voltage from

0–20 V DC to an analog input (except LN7) on the Prototyping Board, and ground to

GND. Follow the prompts in the Dynamic C STDIO window. Computed raw data and

equivalent voltages will be displayed. If you attach a voltmeter between the analog

input and ground, you will be able to observe that the voltage in the Dynamic C STDIO

window tracks the voltage applied to the analog input as you vary it.

• THERMISTOR.C— Demonstrates how to use analog input LN7 to calculate temperature

for display to the STDIO window. This sample program assumes that the thermistor is

the one included in the Development Kit whose values for beta, series resistance, and

resistance at standard temperature are given in the part specification.

Install the thermistor at location JP25 on the Prototyping Board before running this

sample program.

3.2.4 Real-Time Clock

If you plan to use the real-time clock functionality in your application, you will need to set

the real-time clock. Set the real-time clock using the SETRTCKB.C sample program from

the Dynamic C SAMPLES\RTCLOCK folder, using the onscreen prompts. The

RTC_TEST.C sample program in the Dynamic C SAMPLES\RTCLOCK folder provides

additional examples of how to read and set the real-time clock.

Page 29

User’s Manual 23

4. HARDWARE REFERENCE

Chapter 4 describes the hardware components and principal hardware

subsystems of the RCM40 00. Appendix A, “RC M4000 Specific ations,” provides complete physical and electrical specifications.

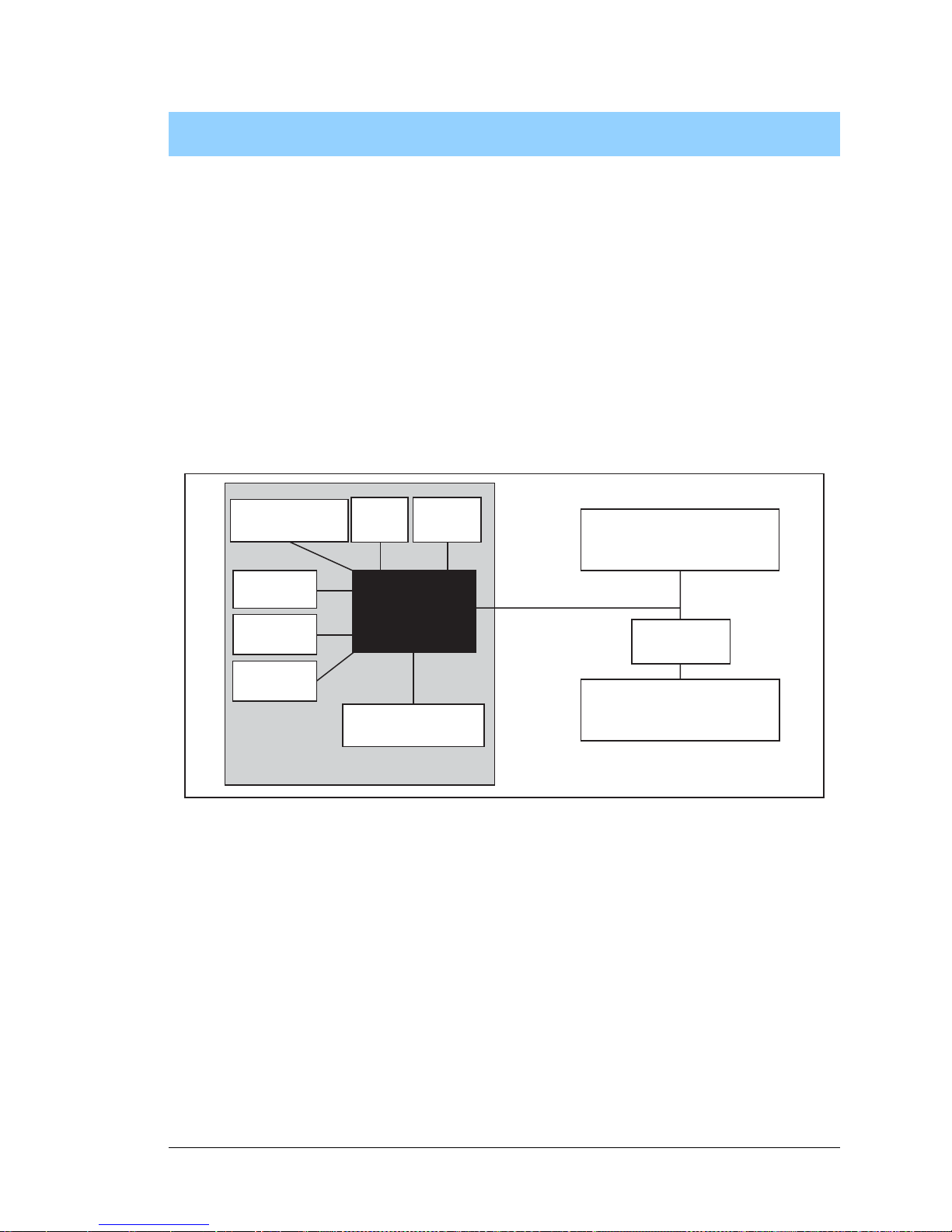

Figure 5 shows the Rabbit-based subsystems designed into the RCM4000.

Figure 5. RCM4000 Subsystems

32 kHz

osc

RabbitCore Module

RABBIT

®

4000

CMOS-level signals

RS-232, RS-485

serial communication

drivers on motherboard

Customer-specific

applications

Level

converter

Ethernet

44.2 MHz

osc

A/D Converter

SRAM

Program

Flash

NAND

Flash

Page 30

24 RabbitCore RCM4000

4.1 RCM4000 Digital Inputs and Outputs

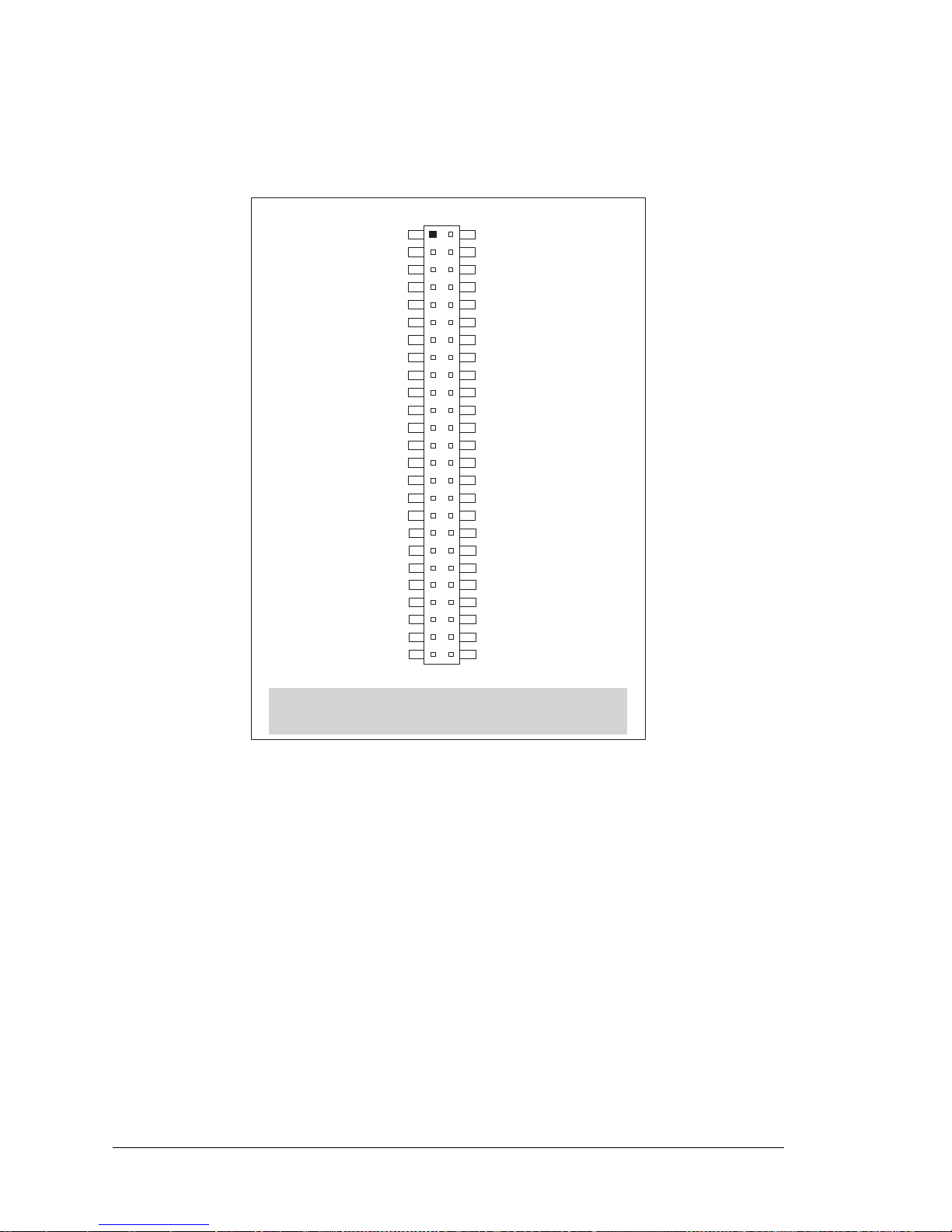

Figure 6 shows the RCM4000 pinouts for header J3.

Figure 6. RCM4000 Pinout

Headers J3 is a standard 2 × 25 IDC header with a nominal 1.27 mm pitch.

Note:

These pinouts are as seen on

the Bottom Side of the module.

+3.3 V_IN

/RESET_OUT

/IOWR

VBAT_EXT

PA1

PA3

PA5

PA7

PB1

PB3

PB5

PB7

PC1

PC3

PC5

PC7

PE1

PE3

PE5/SMODE0

PE7/STATUS

LN1

LN3

LN5

LN7

n.c./VREF

GND

/IORD

/RESET_IN

PA0

PA2

PA4

PA6

PB0

PB2

PB4

PB6

PC0

PC2

PC4

PC6

PE0

PE2

PE4

PE6/SMODE1

LN0

LN2

LN4

LN6

CONVERT

GND

J3

n.c. = not connected

Page 31

User’s Manual 25

Figure 7 shows the use of the Rabbit 3000 m icroprocessor ports in t he RCM4000 mo dules.

Figure 7. Use of Rabbit 4000 Ports

The ports on the Rabbit 4000 microprocessor used in the RCM4000 are configurable, and

so the factory defaults can be reconfigured. Table 2 lists the Rabbit 4000 factory defaults

and the alternate configurations.

R

ABBIT

®

4000

Port A

Port B

Port D

Port E

PA0PA7

PB2PB7

PE0PE7

PD0PD7

/RESET_OUT,

/IOWR,

STATUS

SMODE0

SMODE1

Watchdog

11 Timers

Clock Doubler

Slave Port

Real-Time Clock

RAM

Backup Battery

Support

Flash

Misc. I/O

/RES_IN

/IORD

PC4*

PC5*

Port C

(Serial Ports C & D)

Programming

Port

(Serial Port A)

A/D Converter

(Serial Port B)

PB1, PC6

PC7, /RES

PC0, PC2

PC1, PC3

Serial Ports E & F

PC4 and PC5 are

not available on

RCM4100 module.

*

Page 32

26 RabbitCore RCM4000

Table 2. RCM4000 Pinout Configurations

Pin Pin Name Default Use Alternate Use Notes

1 +3.3 V_IN

2 GND

3 /RES_OUT Reset output Reset inp ut

Reset output from Reset

Generator

4 /IORD Input External read strobe

5 /IOWR Output External write strobe

6 /RESET_IN Input Input to Reset Generator

7 VBAT_EXT Battery input

8–15 PA[0:7] Input/Output

Slave port data bus

(SD7–SD1)

External I/O data bus

(ID7–ID1)

16 PB0 Input/Output

SCLKB

External I/O Address IA6

CLKB (used by RCM4000

A/D converter)

17 PB1 Input/Output

SCLKA

External I/O Address IA7

Programming port CLKA

18 PB2 Input/Output

/SWR

External I/O Address IA0

19 PB3 Input/Output

/SRD

External I/O Address IA1

20 PB4 Input/Output

SA0

External I/O Address IA2

21 PB5 Input/Output

SA1

External I/O Address IA3

22 PB6 Input/Output

/SCS

External I/O Address IA4

23 PB7 Input/Output

/SLAVATN

External I/O Address IA5

Page 33

User’s Manual 27

24 PC0 Input/Output

TXD

I/O Strobe I0

Timer C0

TCLKF

Serial Port D

25 PC1 Input/Output

RXD/TXD

I/O Strobe I1

Timer C1

RCLKF

Input Capture

26 PC2 Input/Output

TXC/TXF

I/O Strobe I2

Timer C2

Serial Port C

27 PC3 Input/Output

RXC/TXC/RXF

I/O Strobe I3

Timer C3

SCLKD

Input Capture

28 PC4 Input/Output

TXB

I/O Strobe I4

PWM0

TCLKE

Serial Port B (used by

RCM4000 A/D converter)

29 PC5 Input/Output

RXB/TXB

I/O Strobe I5

PWM1

RCLKE

Input Capture

30 PC6 Input/Output

TXA/TXE

I/O Strobe I6

PWM2

Programming port

31 PC7 Input/Output

RXA/TXA/RXE

I/O Strobe I7

PWM3

SCLKC

Input Capture

32 PE0 Input/Output

I/O Strobe I0

A20

Timer C0

SCLKD/TCLKF

INT0

QRD1B

Table 2. RCM4000 Pinout Configurations (c ontinued)

Pin Pin Name Default Use Alternate Use Notes

Page 34

28 RabbitCore RCM4000

33 PE1 Input/Output

I/O Strobe I1

A21

Timer C1

RXD/RCLKF

INT1

QRD1A

Input Capture

34 PE2 Input/Output

I/O Strobe I2

A22

Timer C2

TXF/SCLKC

DREQ0

QRD2B

35 PE3 Input/Output

I/O Strobe I3

A23

Timer C3

RXC/RXF/SCLKD

DREQ1

QRD2A

Input Capture

36 PE4 Input/Output

I/O Strobe I4

/A0

INT0

PWM0

TCLKE

37 PE5/SMODE0 Input/Output

I/O Strobe I5

INT1

PWM1

RXB/RCLKE

Input Capture

SMODE0 is the default

configuration

38 PE6/SMODE1 Input/Output

I/O Strobe I6

PWM2

TXE

DREQ0

SMODE1 is the default

configuration

39 PE7/STATUS Input/Output

I/O Strobe I7

PWM3

RXA/RXE/SCLKC

DREQ1

Input Capture

STATUS is the de fault

configuration

Table 2. RCM4000 Pinout Configurations (c ontinued)

Pin Pin Name Default Use Alternate Use Notes

Page 35

User’s Manual 29

4.1.1 Memory I/O Interface

The Rabbit 4000 address lines (A0–A19) and all the data lines (D0–D7) are routed internally to the onboard flash memory and SRAM chips. I/0 write (/IOWR) and I/0 read

(/IORD) are available for interfacing to external devices.

Parallel Port A can also be used as an external I/O data bus to isolate external I/O from the

main data bus. Parallel Port B pins PB2–PB7 can also be used as an auxiliary address bus.

When using the auxiliary I/O bus for any reason, you must add the following line at the

beginning of your program.

#define PORTA_AUX_IO // required to enable auxiliary I/O bus

Selected pins on Parallel Ports D and E as specified in Table 2 may be used for input

capture, quadrature decoder, DMA, and pulse-width modulator purposes.

4.1.2 Other Inputs and Outputs

The status and the two SMODE pins, SMODE0 and SMODE1, can be brought out to

header J3 instead of PE5–PE7 as explained in Appendix A.6.

/RESET_IN is normally associated with the programming port, but may be used as an

external input to reset the Rabbit 4000 microprocessor and the RCM4000 memory.

/RESET_OUT is an output from the reset circuitry that can be used to reset other

peripheral devices.

40–47 LN[0:7] Analog Input

A/D converter

(RCM4000 only)

48 CONVERT Analog Input

49 VREF

Analog reference

voltage

1.15 V/2.048 V/2.500 V

on-chip re f. voltage

(RCM4000 only)

50 GND Ground Analog ground

Table 2. RCM4000 Pinout Configurations (c ontinued)

Pin Pin Name Default Use Alternate Use Notes

Page 36

30 RabbitCore RCM4000

4.2 Serial Communication

The RCM4000 module does not have any serial transceivers directly on the board. However, a serial interface may be incorporated on the board the RCM4000 is mounted on. For

example, the Prototyping Board has an RS-232 transceiver chip.

4.2.1 Serial Ports

There are five serial ports designated as Serial Ports A, B, C, D, and F. All five serial ports

can operate in an asynchronous mode up to the baud rate of the system clock divided by 8.

An asynchronous port can handle 7 or 8 data bits. A 9th bit address scheme, where an

additional bit is sent to mark the first byte of a message, is also supported.

Serial Port A is normally used as a programming port, but may be used either as an asynchronous or as a clocked serial port once application development has been completed and

the RCM4000 is operating in the Run Mode.

Serial Port B is used by the A/D converter, and is not available for other use off the

RCM4000, but is available on the RCM4010.

Serial Ports C and D can also be operated in the clocked serial mode. In this mode, a clock

line synchronously clocks the data in or out. Either of the two communicating devices can

supply the clock.

Serial Ports F can also be configured as an SDLC/HDLC serial port. The IrDA protocol is

also supported in SDLC format by this serial port.

Table 3 summarizes the possible parallel port pins for the serial ports and their clocks.

Table 3. Rabbit 4000 Serial Port and Clock Pins

Serial P ort A

TXA PC6, PC7, PD6

Serial Port D

TXD PC0, PC1

RXA PC7, PD7, PE7 RXD PC1, PD1, PE1

SCLKA PB1 SCLKD PD0, PE0, PE3, PC3

Serial P ort B

TXB PC4, PC5, PD4

Serial Port F

TXF PD6, PE6, PC6

RXB PC5, PD5, PE5 RXF PD3, PE3, PC3

SCLKB PB0 RCLKF PD1, PE1, PC1

Serial P ort C

TXC PC2, PC3 TCLKF PD0, PE0, PC0

RXC PC3, PD3, PE3 TCLKF PD0, PE0, PC0

SCLKC PD2, PE2, PE7, PC7

RCLKF must be selected to be on the same parallel port as TXF.

Page 37

User’s Manual 31

4.2.2 Ethernet Port

Figure 8 shows the pinout for the RJ-45 Ethernet port (J2). Note that some Ethernet connectors are numbered in reverse to the order used here.

Figure 8. RJ-45 Ethernet Port Pinout

Two LEDs are placed next to the RJ-45 Ethernet jack, one to indicate an Ethernet link

(LINK) and one to indicate Ethernet activity (ACT).

The RJ-45 connector is shielded to minimize EMI effects to/from the Ethernet signals.

ETHERNET

RJ-45 Plug

1. E_Tx+

2. E_Tx

3. E_Rx+

6. E_Rx

1

8

RJ-45 Jack

Page 38

32 RabbitCore RCM4000

4.2.3 Programming Port

The RCM4000 is programmed via the 10-pin header labeled J1. The programming port

uses the Rabbit 4000’ s Serial Port A for commun ication. Dynamic C uses the programming

port to download and debug programs.

Serial Port A is also used for the following operations.

• Cold-boot the Rabbit 4000 on the RCM4000 after a reset.

• Remotely download and debug a program over an Ethernet connection using the

RabbitLink EG2110.

• Fast copy designated portions of flash memory from one Rabbit-based board (the

master) to another (the slave) using the Rabbit Cloning Board.

Alternate Uses of the Programming Port

All three clocked Serial Port A signals are available as

• a synchronous serial port

• an asynchronous serial port, with the clock line usable as a general CMOS I/O pin

The programming port may also be used as a serial port via the DIAG connector on the

programming cable.

In addition to Serial Port A, the Rabbit 4000 startup-mode (SMODE0, SMODE1), status,