R2 MTL 50, MTL 75, MTL 100, MT 60, MT 90 Instruction And Maintenance Manual

...

Rev. 2

7 – 04 – 2016

ENGLISH

Mill Grader

Mod. MT – MTL – MThi - MTLhi

Instructions and maintenance manual

(Translation of the original instructions)

2 2 ENGLISH

Index Pag.

Introduction............................................................................................................................... 3

Machine identification………………………………………………………………………………... 3

Description of the machine and its proper use.…………………………………………………… 4

Technical specifications and dimensions................................................................................. 5

Handling and transportation of the machine………………………………………………………. 5

Accident prevention.................................................................................................................. 6

Components assembly and coupling of the working equipment………………………………... 7

Preparation for use…………………......................................................................................... 8

Working depth adjustment………............................................................................................. 8

Levelling adjustment…............................................................................................................. 8

Machine use…………………………………………………………………………………………... 9

Maintenance............................................................................................................................. 10

Hoes replacement.................................................................................................................... 11

End of work and storage of the machine..................................................................................

12

Scrapping and disposal of the components and packaging …………………………………… 12

Specific references for the hydraulic machines…………………………………………………… 13

Guarantee and Certification..................................................................................................... 17

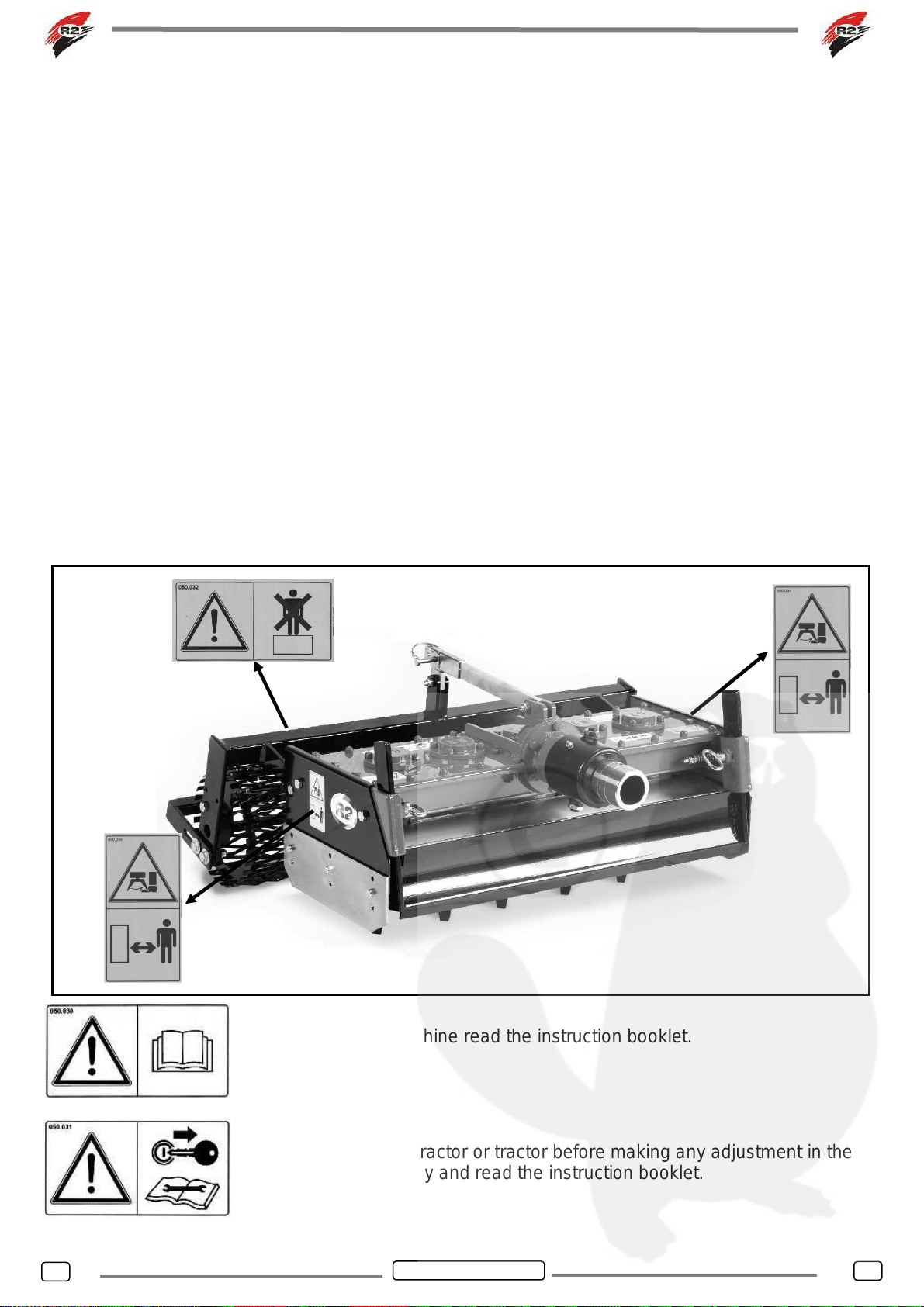

WARNING

Always keep a safe distance when you are in view of the danger symbol placed on the side of the

machine

Never climb on the roller group or on the machine.

Before using the machine read the instruction booklet.

Turn off the walking tractor or tractor before making any adjustment in the

machine , take the key and read the instruction booklet.

3 3 ENGLISH

Introduction

We would start by thanking you for having chosen our product and hope that you will be happy with

your choise.

In order that your MILL GRADER Mod. MT – MTL – MThi - MTLhi can offer the maximum

efficiency for many years, we ask you to pay attention to the instructions for use and maintenance

which you will find in this manual. Observance of these regulations will prevent breakdowns and

accidents for which our company will not accept responsability.

This use and maintenance manual is to be considered an integral part of the machine and therefore

it must always accompany the machine when it is sold, even in the event of its sale to third parties.

If you keep this manual in a safe place and in good condition, you - and whoever must use the

machine - will be able to have a complete, legible reference on hand at all times.

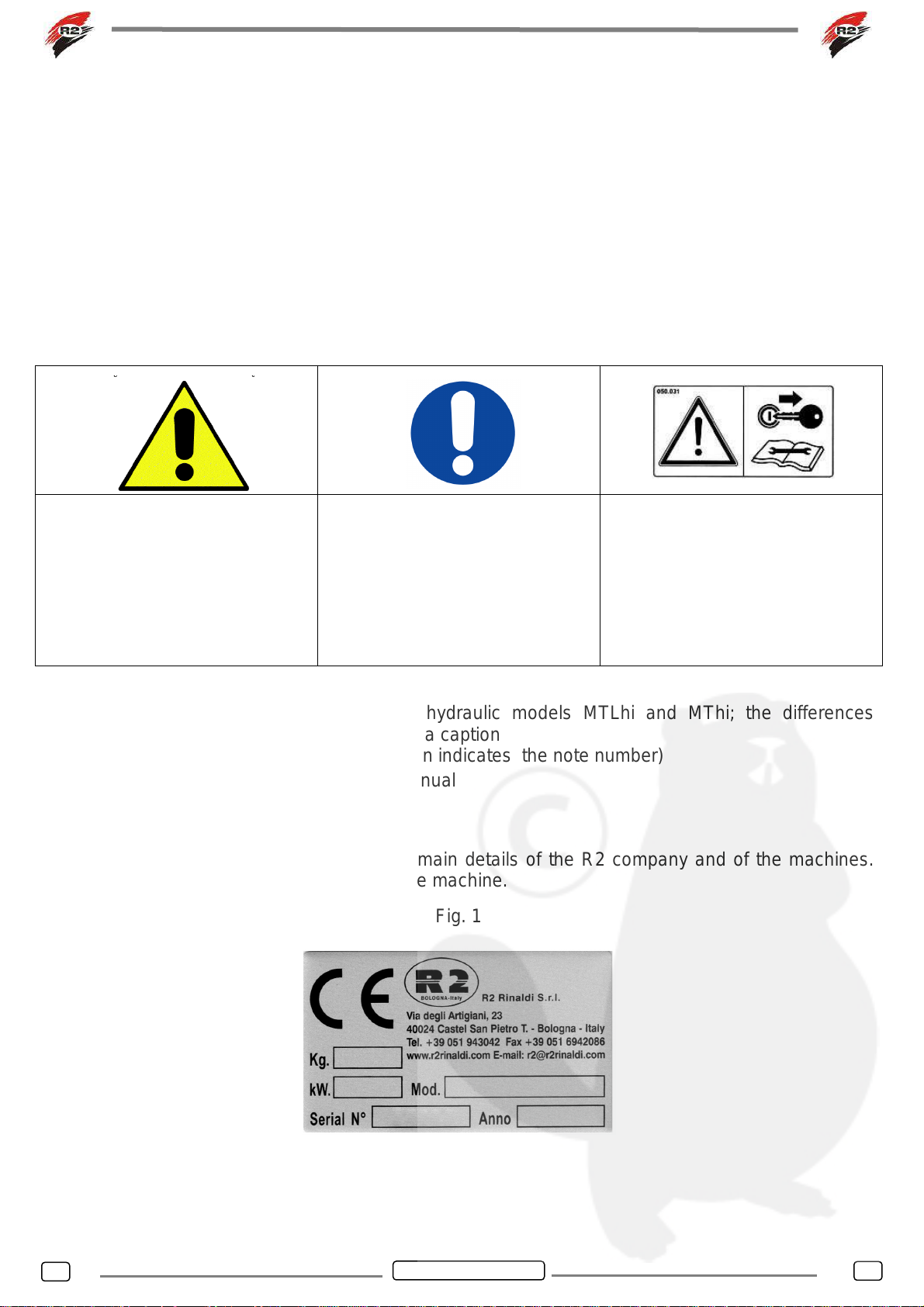

Description of the symbols used in the manual

This symbol will be used in the

manual to indicate actions

( misuse ) elements, behaviours

and situations that could risk

your security and the one of

other people.

The rounded symbols with

white pictograms will be used in

the manual to indicate the

Individual Protective Devices

necessary while using the

machine or while making any

This symbol will be used in this

manual to indicate that the

described operation must be

done with the walking tractor or

tractor turned off and the key

disconnected.

adjustments.

NOTE: This manual concerns the use and maintenance description of the mecchanic mill graders

MT-MTL, which corrisponds largely to the hydraulic models MTLhi and MThi; the differences

between the two models will be indicated with a caption

(*note n mod. hi) (n indicates the note number)

and examined in an specific section of the manual

1 – Machine identification

Each R2 machine has a CE plate with the main details of the R2 company and of the machines.

The plate is positioned on the top center of the machine.

Fig. 1

4 4 ENGLISH

D

B F

A C

E

G

H I

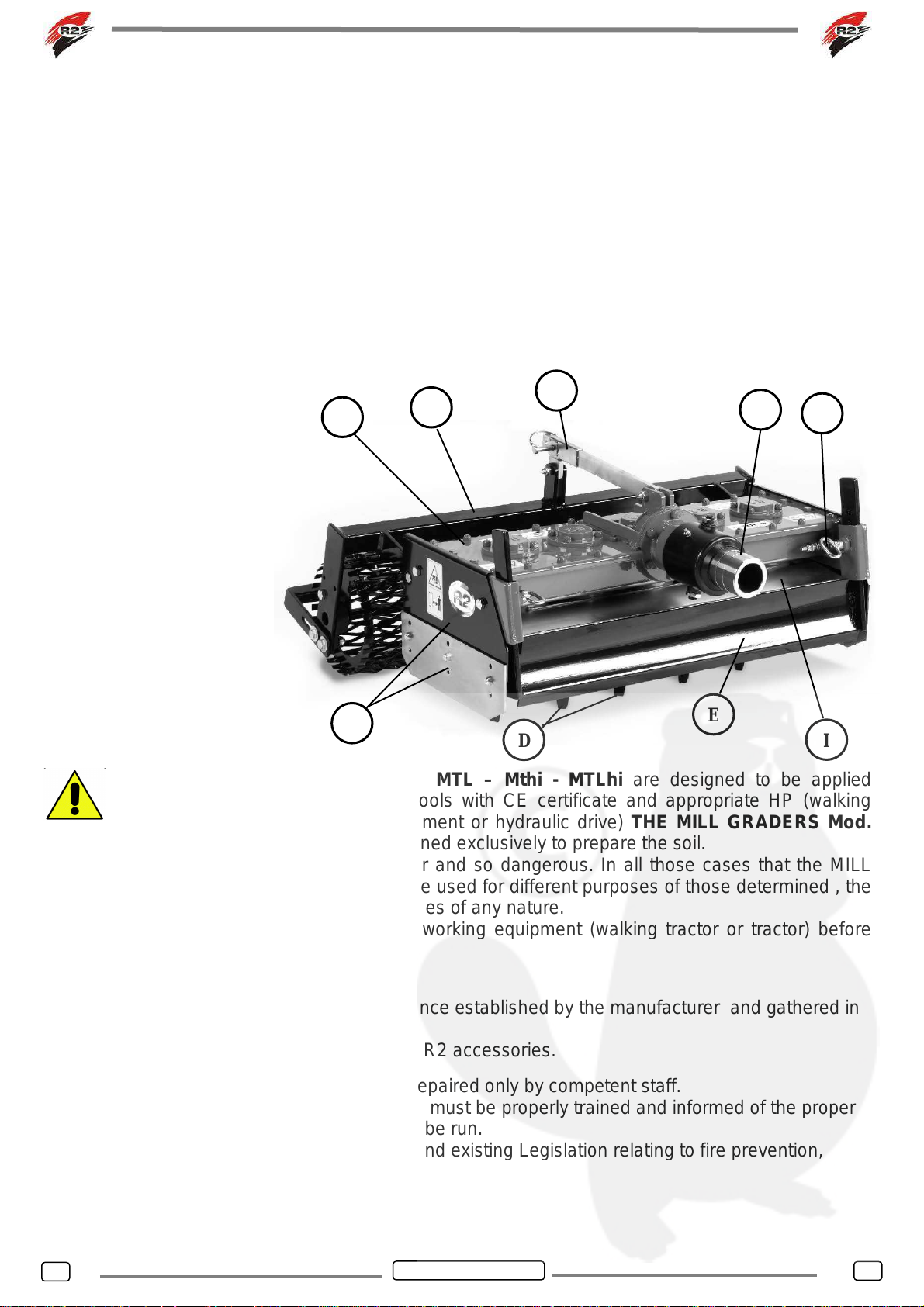

2 -Description of the machine and its proper use.

(*note 1 mod. hi)

The MILL GRADER Mod. MT – MTL – MThi - MTLhi is the only machine that can be applied to all

types of walking tractors or tractors of 12-14-18 HP with flange attachment; it levels, mills and

compresses the soil in a single operation.

As can be seen from the illustration (Fig.2), the MILL GRADER Mod. MT – MTL – MThi – MTLhi is

equipped with an adjustable –height scrapper on the front to shift the earth, a central rotating harrow

to mill the soil and a special grilled roller at the back, which makes it possible to adjust the working

depth of the rotating harrow and to compress the soil.

The MILL GRADER Mod. MT – MTL – MThi - MTLhi is used in the preparation of the soil for fields,

gardens, sporting facilities,vegetables, gardens and for anyone who needs the ground to be

perfectly levelled, also in small spaces.

Fig. 2

A – Main body of

the machine

(harrow)

B –Roller group.

C –Register roller

adjustment

D – Hoes

E – Scraper

F –Screws

adjustment scraper

G –Walking tractor

coupling.

H –Side and side

extension.

I - Protections.

THE MILL GRADERS Mod. MT – MTL – Mthi - MTLhi are designed to be applied

exclusively to professional driven tools with CE certificate and appropriate HP (walking

tractors, tractors with flange atttachment or hydraulic drive) THE MILL GRADERS Mod.

MT – MTL – Mthi - MTLhi are designed exclusively to prepare the soil.

Any other type of use is considered improper and so dangerous. In all those cases that the MILL

GRADERS Mod. MT – MTL – Mthi - MTLhi are used for different purposes of those determined , the

manufacturer disclaims any liabilityf for damages of any nature.

Read always the instruction booklet of the working equipment (walking tractor or tractor) before

fitting and using the R2 machine.

The proper use of the machine implies:

-The respect of the rules of use and maintenance established by the manufacturer and gathered in

this manual.

-the exclusive use of spare parts and original R2 accessories.

The machine must be used, maintained and repaired only by competent staff.

The qualified staff enabled to use the machine must be properly trained and informed of the proper

use of the equipment and the risks that could be run.

The user is required to comply with the rules and existing Legislation relating to fire prevention,

safety at work and traffic in public roads.

5 5 ENGLISH

ecause of the position of

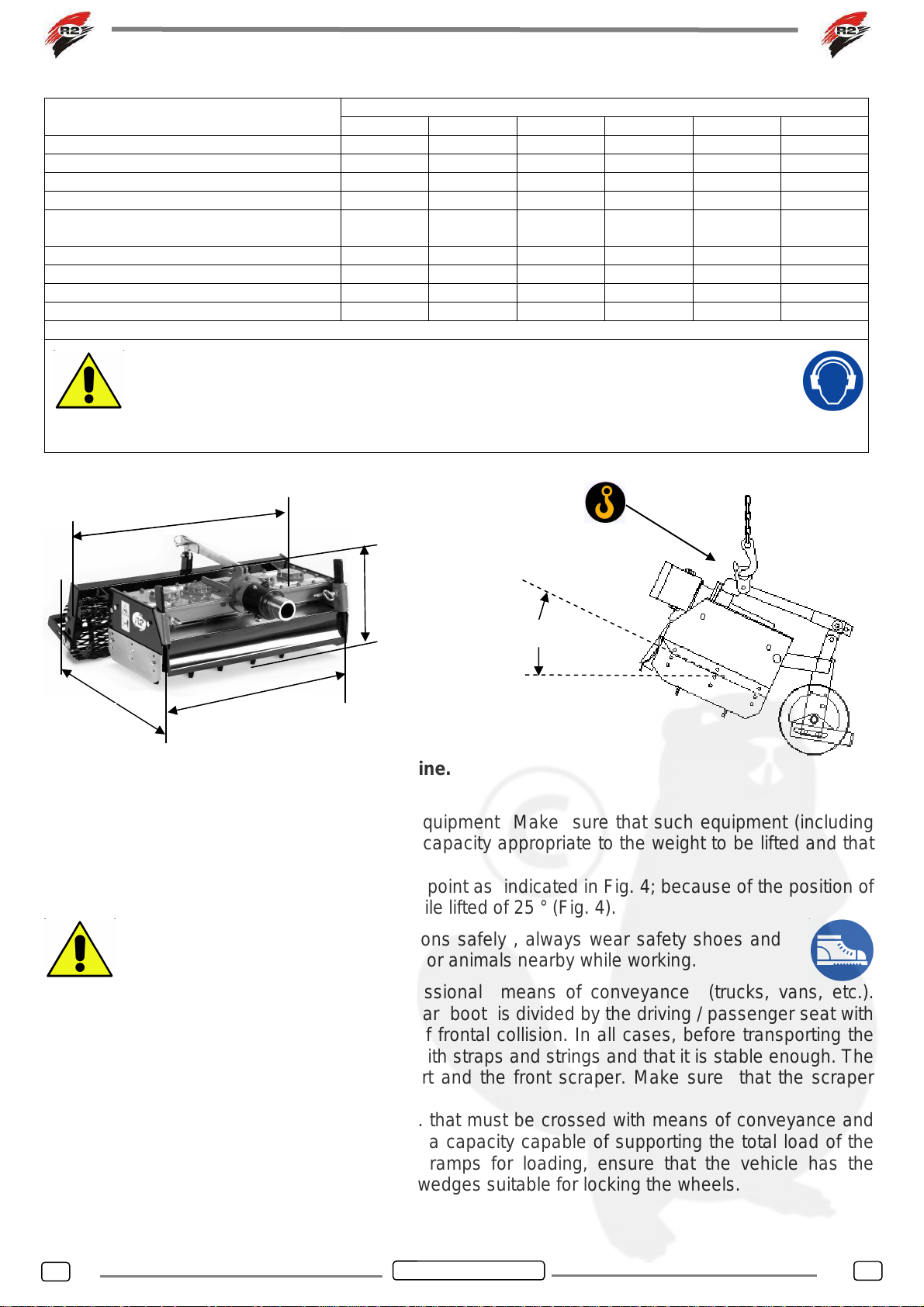

3 – Technical specifications and dimensions

(*note 2 mod. hi)

Model

MTL 50 MTL 75 MTL 100 MT 60 MT 90 MT 125

Milling width (Fig. 3 – Ref. A) 50 cm 75 cm 100 cm 60 cm 90 cm 122 cm

Levelling width (Fig. 3 – Ref. B) 50 cm 75 cm 100 cm 60 cm 90 cm 122 cm

Compactness width (Fig. 3 – Ref. C) 60 cm 85 cm 110 cm 70 cm 100 cm 132 cm

Depth (Fig. 3 – Ref. D) 75 cm 75 cm 75 cm 75 cm 75 cm 75 cm

Maximum height from the ground (Fig. 3

– Ref. E)

Walking tractor/tractor HP 8-10 HP 12-14 HP 14-18 HP 12-14 HP 14-18 HP 16-18 HP

Maximum working depth 14 cm 14 cm 14 cm 14 cm 14 cm 16 cm

Number of hoes 6 10 14 6 10 14

Weight 70 Kg 95 Kg 115 Kg 90 Kg 110 Kg 130 Kg

Lubricant: ROLOIL LITEX - EP/1

Note: Emission of airborne noise. The noise produced by the machine varies according to the soil

features at work. Exposure also depends strictly on the noise produced by the working equipment

(walking tractor or tractor). Considering the data in the literature relating to similar equipment, it can

be considered an approximate value of exposure to the noise (determined by the machine and the

walking tractor or tractor) between 90 dB (A) and 95 dB (A).

Verify the level of exposure to the noise with the proper instruments each time any work is performed. Follow the legislative

references of your country to identify the personal protective necessary equipment.

Fig. 3

C

42 cm 42 cm 42 cm 42 cm 42 cm 42 cm

Fig. 4

E

25°

D

A-B

4 Handling and transportation of the machine.

(*note 3 mod. hi)

- The machine must be handled with lifting equipment Make sure that such equipment (including

the straps and the strings ) have a carrying capacity appropriate to the weight to be lifted and that

they are in good maintenance conditions.

The machine can be anchored in the coupling point as indicated in Fig. 4; b

the center of gravity, the machine will lean while lifted of 25 ° (Fig. 4).

In order to make handling operations safely , always wear safety shoes and

make sure that there are no people or animals nearby while working.

- The machine can be transported by professional means of conveyance (trucks, vans, etc.).

Transportation by car is permitted only if the car boot is divided by the driving / passenger seat with

a barrier that can hold the machine in case of frontal collision. In all cases, before transporting the

machine , make sure that it is well anchored with straps and strings and that it is stable enough. The

anchor points can be the roller group support and the front scraper. Make sure that the scraper

adjustment screws are properly tightened.

Always check that any walkways, ramps, etc. that must be crossed with means of conveyance and

lifting equipment are well anchored and have a capacity capable of supporting the total load of the

vehicle + machine + operator. When using ramps for loading, ensure that the vehicle has the

handbrake on and have been positioned the wedges suitable for locking the wheels.

6 6 ENGLISH

5 – Accident prevention

(*note 4 mod. hi)

Most accidents that happen at work, during the maintenance or the shifting of a machine, are due to

negligence in the observance of the most elementary rules of accident prevention.

It is, therefore, necessary that whoever uses the machine read and respect the rules written below

and the ones on the adhesive stickers of the machine.

1. Verify that on the machine are stuck all the security signs and that they are readable.

2. Before cleaning the machine, making any adjustments or reparations, turn off the walking

tractor or tractor engine. Before each operation put the machine on the floor or on steady

supports.

3. Never approach to the machine moving parts.

4. The MILL GRADER Mod. MT – MTL – MThi - MTLhi has been manufactured for a

specialized use. It must, therefore,always be in perfect working conditions and only R2 spare

parts should be used when making any reparations.

5. Before using the machine , check the tightening of the nuts and screws, in particular those of

the hoes.

6. Keep away all the people or animals before starting to work.

7. Be careful when working alongside roads, pathways or sloping ground.

8. Do not leave the machine working without supervision.

9. While checking or repairing the machine, be sure that nobody can start it up accidentally.

10. Wear tight-fitting clothes that do not cause any footholds in the rotating parts of the machine.

11. Do not climb on the machine at work.

12. Do not interfere with objects on the machine while working.

13. Never use the machine without the back roller or without the protections delivered with the

machine. Never remove the protections.

14. In order to adjust the scraper, always turn off the walking tractor or tractor engine and make

this operation safely

15. In case the machine blocks, before making any reparations, turn off the walking tractor or

tractor engine and remove the key.

16. Always read the instruction booklet of the working equipment (walking tractor or tractor)

before fitting and using the R2 machine.Do not remove or evade the security systems of the

working equipment; before start working, be sure that the security systems of the walking

tractor or tractor work correctly; if not, do not use the machine.

17. Do not carry people , animals or objects on the machine.

18. In case of road traffic respect the regulations in force in your country; put on the machine all

the signals required.

Loading...

Loading...