R2 LANGFORD DC14014, LANGFORD DC14012, LANGFORD DC14013 Fitting Instructions Manual

CLOSE COUPLED PAN & CISTERN

LANDFORD: DC14014 / DC14013 / DC14012

FITTING INSTRUCTIONS

This product must be installed by a qualified fitter or plumber in accordance with and meet the requirements of the Water Supply (Water Fittings) Regulations 1999 and Scottish Byelaws 2004

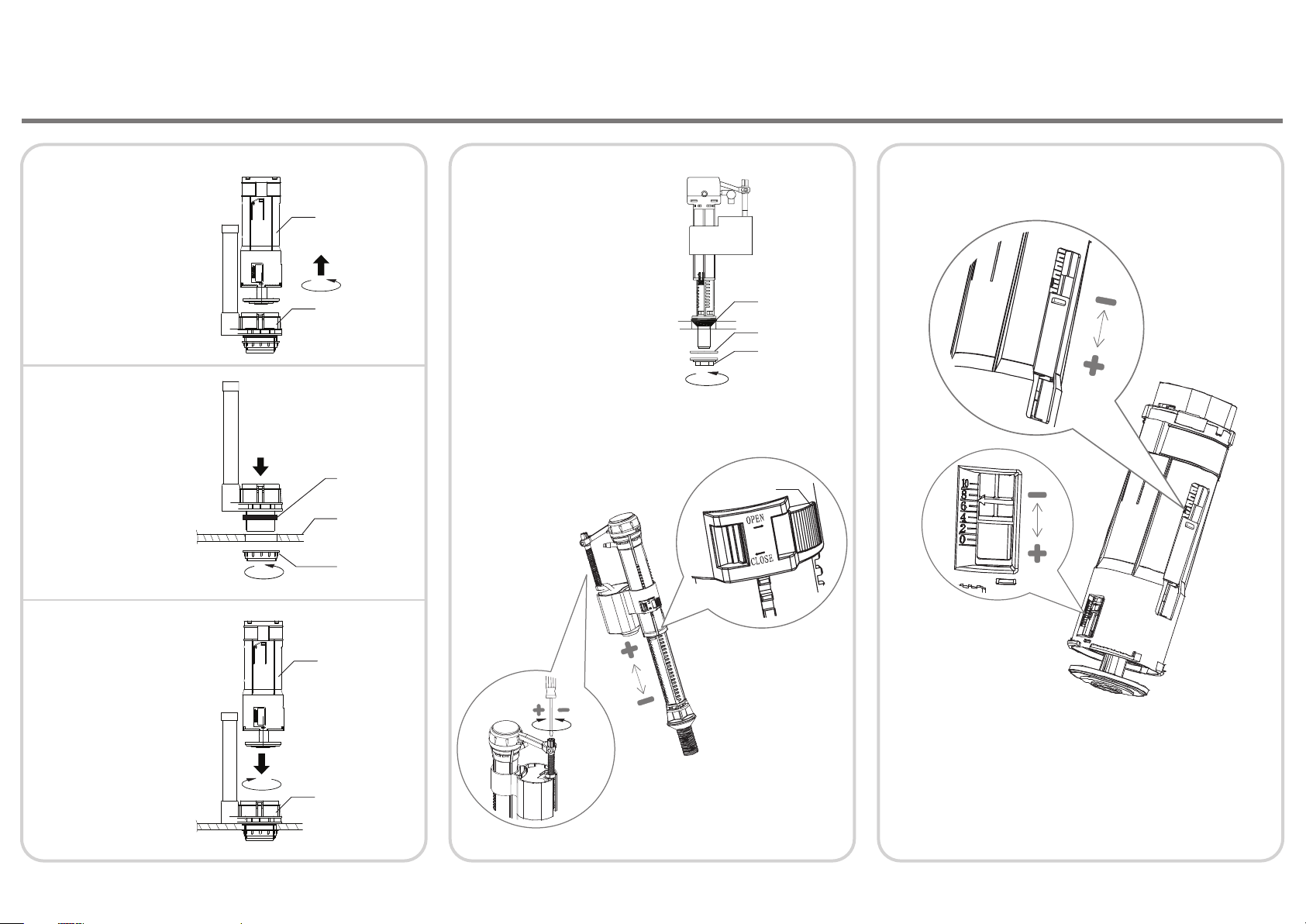

INSTALLATION OF FLUSH VALVE INSTALLATION OF FILL VALVE

Install the fill valve to the tank

body using the rubber seal and

plastic nut. Ensure the float cup

has room to move up and down

freely. The fill valve is pre-set to a

height suitable for the cistern tank

FILL VALVE ADJUSTMENT

The fill valve is factory set but if adjustment is required follow the

instructions below.

Open the stopper to allow the float to

slide up and down. Close stopper once

float is in position.

Turn the flush valve

body anti-clockwise

to part it from the

flush valve seat

Install flush valve seat

and seal as shown

Flush valve body

Flush valve seat

Seal

Cistern tank

Fixing nut

Rubber seal

Washer

Plastic nut

Stopper

FLUSH VALVE ADJUSTMENT

The flush valve is factory set but if adjustment is required see diagram

below.

Reduced flush

adjustment

Flush valve body

Insert flush valve

body into flush valve

seat, turn it

clockwise until you

hear a “click”

Flush valve seat

Brought to you by the Roper Rhodes Group, Brassmill Lane Trading Estate, Bath, BA1 3JF

TEL: 01225 303 900 (R2) | 01225 787 870 (Tavistock)

FINE ADJUSTMENT

Turn screw for fine adjustment of float

height. Anticlockwise to lower float.

Clockwise to heighten float.

Full flush adjustment

IMPORTANT

Flush out all impurities in the cistern prior to installation.

Cistern fittings are suitable for Water pressure: 0.2 - 8 bar

REF: LANGAG0419 | V2.00

CLOSE COUPLED PAN & CISTERN

LANDFORD: DC14014 / DC14013 / DC14012

FITTING INSTRUCTIONS

This product must be installed by a qualified fitter or plumber in accordance with and meet the requirements of the Water Supply (Water Fittings) Regulations 1999 and Scottish Byelaws 2004

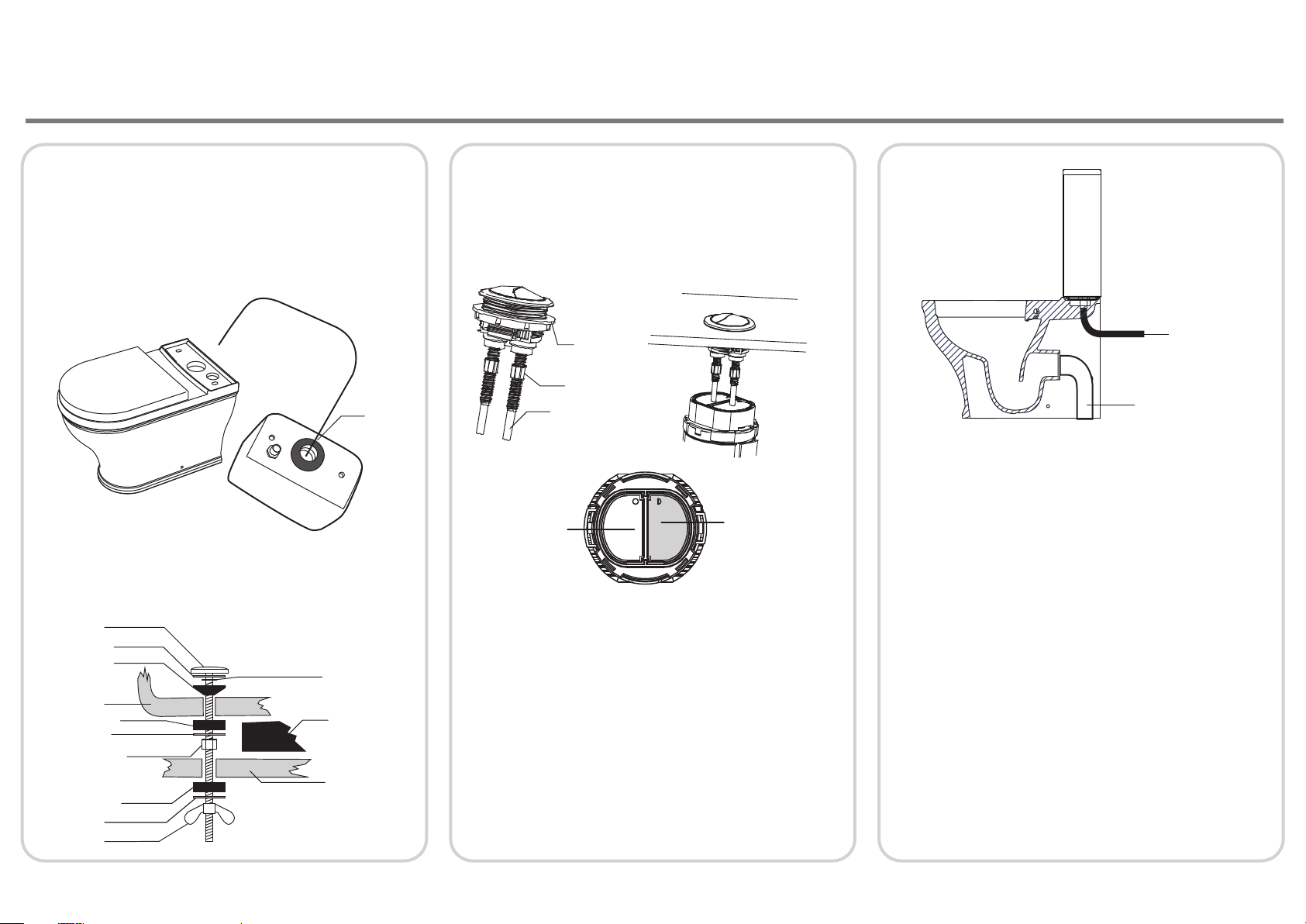

FITTING THE CISTERN TO THE TOILET PAN

With the flush valve and inlet valve fitted and adjusted the cistern

tank can be fitted to the pan.

Fit the gasket around the flush valve outlet on the underside of the

cistern.

When fitting the cistern to the pan take care to ensure the gasket is

properly aligned in the gasket location. Failing to do so could result in

leakage.

Gasket

Insert the cistern fitting bolts arranging the components as shown in

the diagram below.

Firmly tighten the nuts and wing nuts taking care not to overtighten as

this could damage the ceramic.

Fixing bolt

Metal Washer

Rubber Washer

Cistern base

Rubber Washer

Metal Washer

Nut

Rubber Washer

Metal Washer

Wingnut

Small Rubber

Washer

Gasket

Toilet pan

INSTALLING PUSH BUTTON

Fit the push button to the cistern lid using the plastic fixing nut.

Ensure the pins make contact with the flush buttons on the flush

valve. To adjust the length of the rods turn the nut clockwise and

anti-clockwise.

Fixing nut

Nut

Rod

Full Flush

MAKING PLUMBING CONNECTIONS

Connect the soil pipe and ensure it is adequately sealed around the

toilet pan outlet to prevent leakage.

The inlet valve has a threaded connector. It is recommended that this

thread is wrapped in PTFE tape before connecting the water supply.

Do not overtighten the supply to the inlet valve as this could damage

the inlet valve causing leakage.

After connecting the water supply to the inlet valve check that the inlet

valve components do not touch the internal walls of the cistern and

the float can move freely up and down.

Check all connections are secure and a soil pipe is fitted before testing

the flush.

Half Flush

Water supply

connection

Soil pipe

CONNECTION TO WATER SUPPLY

Connect the water supply to the cistern using an approved double

check valve to fluid category 3 in addition to an accessible service

valve.

OPERATION

Press the large button once for a large flush (6 litres factory setting)

Press the small button once for a small flush (4 litres factory setting)

CARE

DO NOT introduce caustic chemical substances (e.g. containing

chlorine compounds or similar). These can damage the valve

components and cause failure.

Brought to you by the Roper Rhodes Group, Brassmill Lane Trading Estate, Bath, BA1 3JF

TEL: 01225 303 900 (R2) | 01225 787 870 (Tavistock)

REF: REF: LANGAG0419 | V2.00

Loading...

Loading...